Page 1

a 3M company

®

CUNO High Flow Filtration Systems

+

+

+

+

Page 2

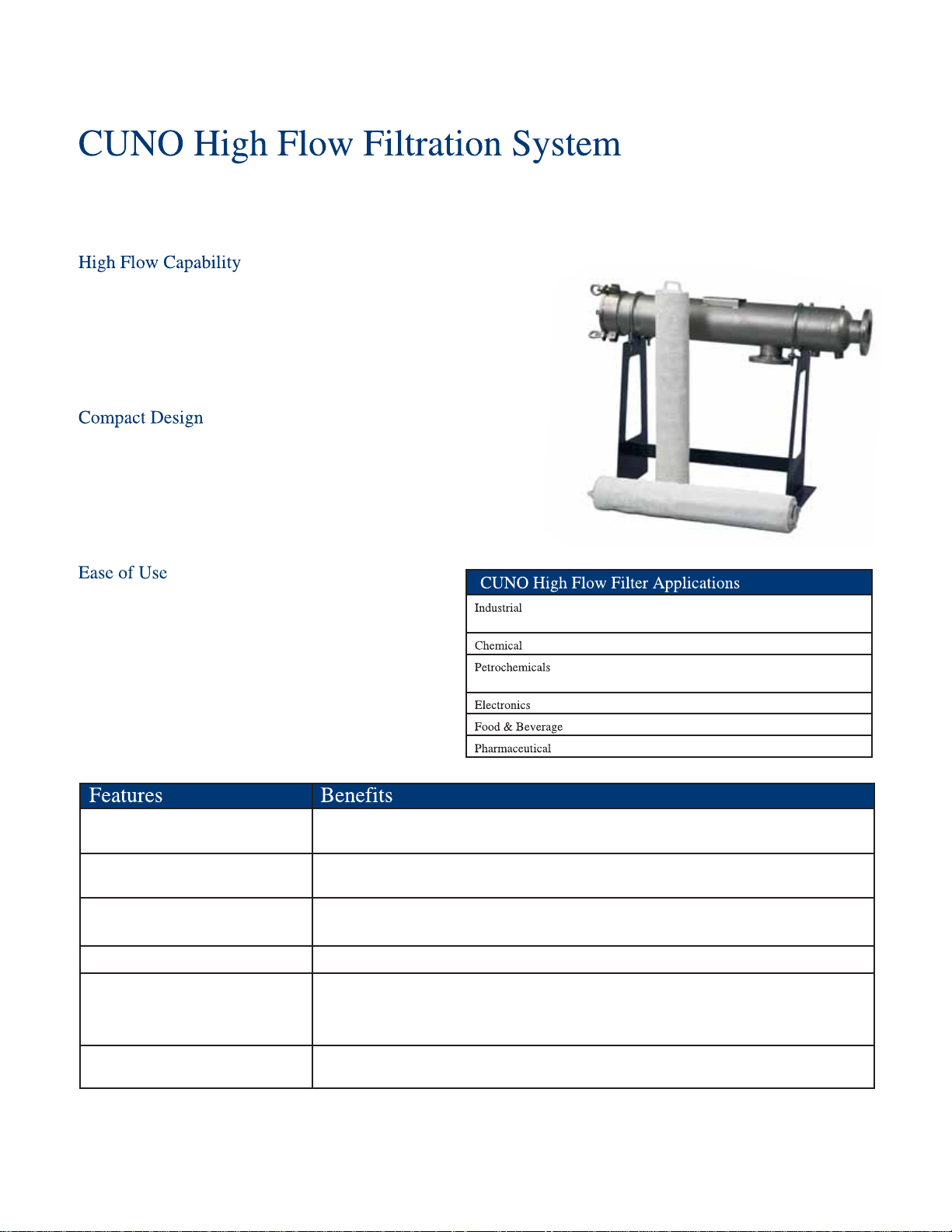

The CUNO High Flow Filtration System is an advanced design that uses 3M Innovation and CUNO’s extensive

filtration experience to deliver a high flow filter in a compact housing design. When compared to conventional

cartridge systems, this system provides the following advantages:

The construction of CUNO High Flow Filters permits flow rates of

up to 500 gpm in a single cartridge. The result? Fewer filter

elements to accommodate your flow requirements. In fact, the

CUNO High Flow Filtration System requires as few as one-tenth

the number of elements as competitive 2.5” pleated cartridges (see

Figure 1).

Using fewer elements combined with an outside-to-in flow path

enables a reduction in the size of housing required for your

application. The CUNO High Flow Housing takes up as little as

one-half the size of competitive housings for a given flow rate.

The result is lower capital investment costs and a compact

footprint that saves valuable plant space (see Figure 1).

The CUNO High Flow Filtration System is designed

with ease-of-use in mind. From a user-friendly,

ergonomically designed handle that makes cartridge

installation and removal easier without the use of

special tools or other hardware, to a "twist-to-lock"

cartridge seating mechanism that provides a positive

seal, the CUNO High Flow System facilitates easy

operation and maintenance of your filter system.

+

+

High flow capability of up to

500 gpm per cartridge

+

Compound Radial Pleat

design

+

Compact design

+

Absolute rating

+

Easy to Use

+

FDA compliant

Reduced Filter Usage – minimizes product loss, labor, disposal costs, operator exposure,

and downtime for filter change-out

+

High loading capacity for long life and lower cost filtration

+

Smaller housing minimizes capital expense requirements

+

Reduces system footprint

+

Reproducible effluent quality throughout the filter’s life

+

No special tools or hardware required for filter change-out – minimizes downtime

+

"Twist to lock" seating mechanism provides positive seal

+

Ergonomically designed handle – facilitates easy cartridge installation and removal

+

Compatible in applications requiring direct food contact in food and beverage processing

per 21 CFR.

- Municipal Water, RO Prefiltration, Reclaimed Water, Coolants,

Nozzle Protection, Boiler Condensate

- Quench Water, Aqueous Salt Solutions, Final Products

- Waterflooding, Produced Water, Enhanced Oil Recovery,

Completion Fluids, Amine Sweetening, Final Products

- RO Prefiltration, Process Water

- Process Water

- Process Water

2

Page 3

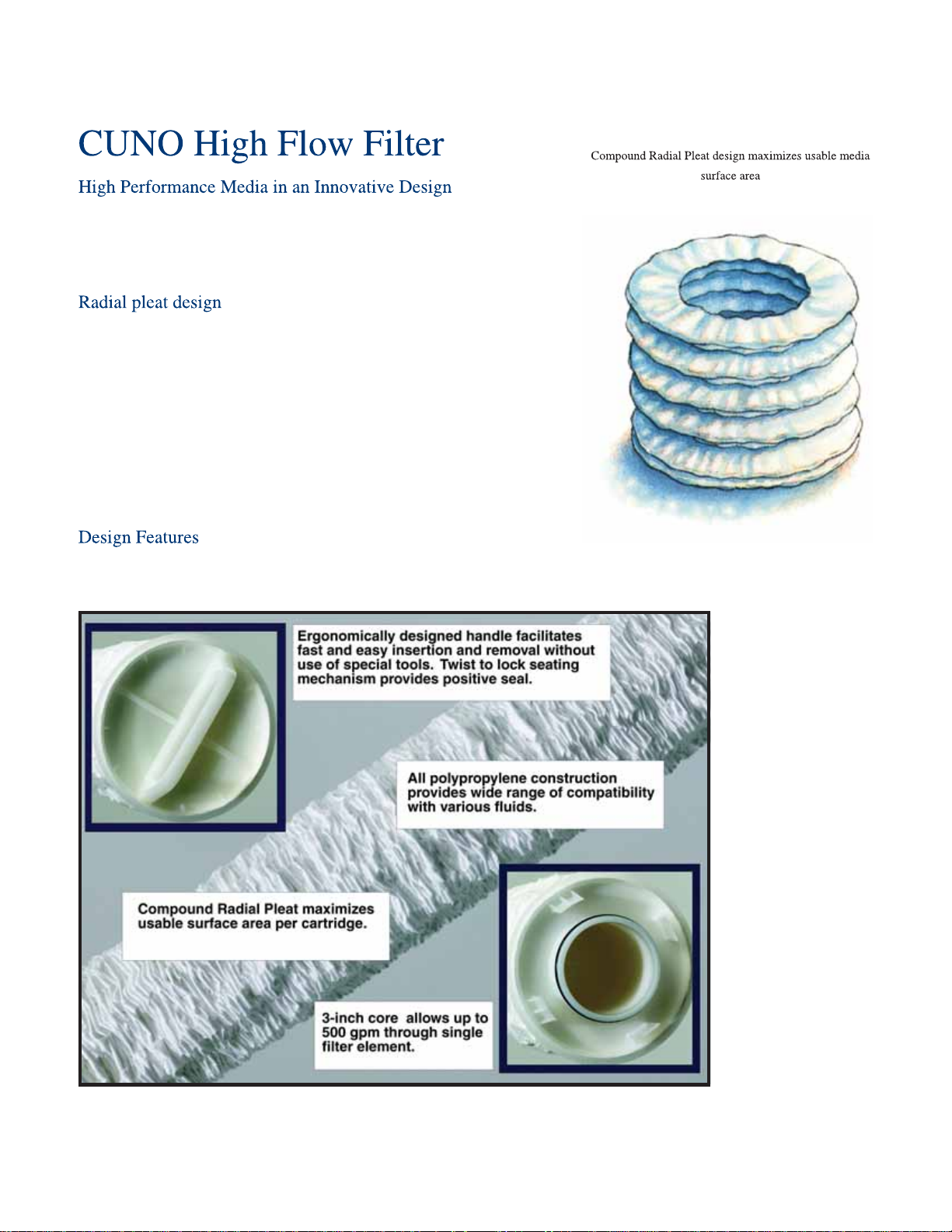

CUNO High Flow Filters are designed using state-of-the-art

technology, optimizing both performance and effluent quality to ensure

customer satisfaction. The elements use a pleat design that results in a

high usable filtering surface area per filter.

3M Innovation is at the heart of the CUNO High Flow Filter. A

compound radial pleat design maximizes the usable surface area per

filter. Blown microfiber forms the basis of the filter media, which is

made to tightly controlled fiber diameter specifications to produce a

media with absolute rated particle retention characteristics. Our

manufacturing process embosses the media to produce a more uniform

pleat pattern, which, in turn, allows greater utilization of the media by

evenly distributing the fluid throughout the entire filter structure. This

results in consistent particle retention in a compact, space-saving

design.

The CUNO High Flow Filter contains several features to combine high

performance with easy operation.

+ A large diameter

core allows up to

500 gpm through a

single filter

element.

+

An ergonomically

designed handle

has been designed

to facilitate fast

and easy insertion

and removal

without the use of

special tools.

Cartridges are

simply inserted

over a built-in

guide tube.

+

The seating

mechanism uses a

“twist to lock”

design to provide a

positive seal.

3

Page 4

Consider the following benefits of the CUNO High Flow System over competitive 2.5” cartridges in a 350 gpm

(1325 lpm) and a 2000 gpm (7571 lpm) system*:

The CUNO High Flow

+

350 GPM System (1325 LPM)

CUNO High

Flow System

Competitive

2.5”Pleated

Cartridges

Competitive

2.5”Depth

Cartridges

System requires 90% fewer

cartridges as competitive

2.5" cartridge systems for a

given flow rate.

CUNO High Flow

+

Housings are 33% to 50%

1 Cartridge

in a

8.6”Diameter

Housing

18 Cartridges

in a

14”Diameter

Housing

24 Cartridges

in a

16”Diameter

Housing

smaller than competitively

sized housings for a given

flow rate.

CUNO High

Flow System

7 Cartridges

in a

24”Diameter

Housing

50

40

2000 GPM System (7571 LPM)

Competitive

2.5”Pleated

Cartridges

Competitive

2.5”Depth

Cartridges

Fewer filters and a

+

user-friendly housing

design means faster

change-outs than

competitively sized

systems.

* Comparison assumes fluid viscosity

of 1 cp

85 Cartridges

in a

30”Diameter

Housing

350 GPM System (1325 LPM) 2000 GPM System (7571 LPM)

120 Cartridges

in a

36”Diameter

Housing

5

4

30

20

Minutes

10

0

CUNO High Flow

System

Competitive

2.5”Pleated

System

Competitive

2.5”Depth

System

3

Hours

2

1

0

CUNO High Flow

System

Competitive

2.5”Pleated

System

Competitive

2.5”Depth

System

4

Page 5

- Each grade of the CUNO High Flow Filter is manufactured from meltblown FDA compliant

polypropylene microfiber media, providing high particle removal efficiency with broad chemical compatibility. No

adhesives, binders, or silicone are used in the manufacturing process. The raw materials composing these filters are

FDA compliant according to CFR Title 21. All support layers and hardware are constructed with polypropylene.

- O-rings are available in a variety of materials to suit your applications, including the standard nitrile,

Ethylene Propylene Rubber (EPR), silicone, and fluorocarbon.

60”Cartridge Flow* Rate (gpm)

150

100

225

150

375

300

70, 40, & 25 µm

250

200

450

1µm

5µm

10 µm

15 µm

300

525

2µm

350

Removal Ratings (microns) 1, 2, 5, 10, 15, 25, 40, and 70

Flow vs. Differential Pressure See Figure 3

Filter Diameter (inches/cm) 6.5 / 16.5

Filter Length (inches/cm) 40 / 101.6 60 / 152.4

Maximum Operating Temperature (ºF / ºC) 160 / 71

Maximum Recommended Flow Rate in

water @ 70°F (gpm / lpm)

Maximum Forward Differential Pressure

Recommended Change-out

Differential Pressure

Regulatory Status - All component materials of the CUNO High Flow

polypropylene element are listed for food contact per 21 CFR.

350 / 1325 500 / 1893

50 psid @ 68°F

(3.4 bar @ 20

°C)

35 psid @ 68°F

(2.4 bar @ 20

°C)

3.0

2.5

2.0

1.5

1.0

Differential Pressure (psid)

0.5

0

0

75

0

50

40”Cartridge Flow Rate (gpm)

Chemical Temperature Chemical Temperature Chemical Temperature

Acetic Acid 20% 160°F (71°C) Hydrogen Peroxide 100°F (38°C) Sodium Carbonate 160°F (71°C)

Alkanolamines 140°F (60°C) Methyl Ethyl Ketone 70°F (21°C) Sodium Hydroxide 70% 160°F (71°C)

Ammonium Hydroxide 10% 160°F (71°C) Mineral Oil 70°F (21°C) Sulfuric Acid 20% 160°F (71°C)

Bleach 5.5% 120°F (49°C) Nitric Acid 20% 120°F (49°C) Sulfuric Acid 70% 160°F (71°C)

Ethylene Glycol 160°F (71°C) Potassium Hydroxide 140°F (60°C) Urea 160°F (71°C)

The thermal and chemical resistance data presented in this brochure is for guidance only. Factors such as duration of exposure, fluid

concentration, and temperature should also be considered. Thermal and chemical resistance should also be considered when choosing all

materials exposed to fluids.

* estimated

5

Page 6

The CUNO High Flow Housings are specifically designed to deliver all of the system’s

benefits in a compact footprint. Housings are available in standard designs, as

well as customizable configurations to suit your specific needs. All

standard CUNO High Flow Housings are designed, manufactured,

tested, and code stamped in accordance with ASME

Section VIII, Division 1. Stainless steel housing

external surfaces are glass-bead blasted for a

consistent, easy care finish, while carbon steel units

are painted.

The CUNO High Flow Housing is available in a variety

of sizes to accommodate from 1 to 7 filter elements in both

40-inch and 60-inch lengths. Larger housings are available

upon request. Housings are also available in horizontal or

vertical configurations, depending on your needs. Choose the

horizontal option to maximize ease of operation, or the

vertical to minimize the system’s footprint.

ASME Code design

+

Robust cartridge center-post design eliminates bulky support plates

+

providing easy access to housing internals

Hinged cover for easy element

+

change-outs

+

Handles liquid at pressures and temperatures of up to 150 psig and 250 ºF

+

Manufactured from 304 or 316L stainless steel for excellent corrosion

protection (carbon steel option available in multi-element housing)

+

Available for 40” and 60”

element lengths

+

Upstream and downstream gauge ports and drains

+

Corrosion allowance for carbon steel housing – consult factory

+

Choice of inlet/outlet flange size

User-friendly cover lifting device for

+

easy element change-outs

+

Available for 40” element lengths

10.0

9.0

8.0

7.0

6.0

5.0

4.0

3.0

2.0

Differential Pressure (psid)

1.0

3HF40

3HF60

1HF40 & 60

0

0

1000

2000

Flow Rate (gpm)

5HF40

3000

5HF60

7HF40

7HF60

4000

1HF 8 5/8 / 21.9 316L SS 4” 4” 350 / 1325 500 / 1893

3HF 16

5HF 20 / 50.8 8” 10” 1550 / 5867** 2450 / 9274** 975 / 442 825 / 374 1150 / 522

7HF 24 / 61 10” 12” 2450 / 9274 3500 / 13249 1350 / 612 1250 / 567 1550 / 703

Larger housings available, consult factory

* Pressure drop across cartridge not included (see Figure 3). ** Maximum flow rate based on nozzle size.

/ 40.6

Carbon

steel, 304,

or 316L SS

6” 8” 875 / 3312** 1500 / 5678 625 / 284 575 / 261 750 / 340

6

150 psig @ 250ºF

(10 bar@121 ºC)

340 / 154 305 / 138 375 / 170

Page 7

Outside

Diameter

8 5/8

16

20

24

8 5/8

16

20

24

Outside

Diameter (cm)

21.9

40.6

50.8

61

21.9

40.6

50.8

61

* Sloped for drainage 1° to 3°

7 1/2 12 1/2 26 1/2 78 5/16 120 28 3/8 5 1/2

12 1/2 161/2 34 9/16 993/8 132 37 1/8 20 5/8

14 1/2 201/2 42 5/8 113 140 45 23 5/8

16 1/2 223/4 48 11/16 126 150 55 26

*

35 7 1/2 12 1/2 64 1/4 108 24 1/2 12

35 9/16 7 1/2 12 1/2 84 1/2 150 24 1/2 12

40 12 1/2 16 1/2 73 1/8 115 30 21

40 12 1/2 18 1/2 97 1/4 156 30 21

40 15/16 14 1/2 20 1/2 81 3/4 120 36 1/2 25

40 15/16 14 1/2 21 1/4 103 3/4 160 36 1/2 25

47 1/32 161/2 22 3/4 87 124 40 30

47 7/16 161/2 24 5/8 108 11/16 165 40 30

19 31.7 66 198.9 317.5 72 13.9

31.75 42.06 87.78 252.41 322.58 94.29 52.38

36.67 52.22 108.26 287.02 351.79 114.3 60

41.91 60.96 136.36 320.04 381 139.7 66.04

86.3 18.8 32.3 163.1 276.8 62.2 30.4

100.4 18.8 48.2 198.1 363.2 62.2 30.4

101.6 31.5 42.38 185.73 292.1 76.2 53.3

101.6 31.1 47.30 247.01 406.4 73.6 53.3

103.9 36.8 52.7 207.6 317.5 92.7 63.5

103.9 36.8 54.6 263.5 419.1 92.7 63.5

119.4 40.7 58.8 220.9 330.2 101.6 76.2

120.4 41.7 63.2 276 381 101.6 76.2

G

F

B

E

D

A

C

A

B

C

SideView

E

D

TopView

G

F

7

Page 8

– High Flow

– 40 in.

– 60 in.

- Polypropylene

– 40 in. – Horizontal – Carbon Steel * – Silicone

– 60 in.** – Vertical ** – 304 SS* – Fluorocarbon

* Not available for single element (1-around) housing

** 60 inch vessel not available in vertical configuration

– 1 mm

– 2 mm

– 5 mm

– 10 mm

– 15 mm

– 25 mm

– 40 mm

– 70 mm

– Silicone

– Fluorocarbon

- 1 pack

– EPR

– Nitrile

– 316L SS – EPR

– Nitrile

CUNO MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. Since a variety of factors can affect the use and performance of a CUNO product in a particular application, some of which are

uniquely within the user’s knowledge and control, user is responsible for determining whether or not the CUNO product is fit for a particular purpose and suitable for user’s method

of application.

If the CUNO product is proved to be defective, THE EXCLUSIVE REMEDY, AT CUNO’S OPTION, SHALL BE TO REFUND THE PURCHASE PRICE OR TO REPAIR OR

REPLACE THE DEFECTIVE PRODUCT. CUNO shall not otherwise be liable for loss or damages, whether direct, indirect, special, incidental or consequential, regardless of the

legal theory asserted, including, but not limited to, contract, negligence, warranty or strict liability.

WARRANTY

Seller warrants its equipment against defects in workmanship and material for a period of 12

months from date of shipment from the factory under normal use and service and otherwise

when such equipment is used in accordance with instructions furnished by Seller and for

purposes disclosed in writing at the time of purchase, if any. Any unauthorized alteration or

modification of the equipment by Buyer will void this warranty. Seller's liability under this

warranty shall be limited to the replacement or repair, F.O.B. point of manufacture, of any

defective equipment or part which, having been returned to the factory, transportation charges

prepaid, has been inspected and determined by the Seller to be defective. THIS WARRANTY

IS IN LIEU OF ANY OTHER WARRANTY, EITHER EXPRESSED OR IMPLIED,

AS TO DESCRIPTION, QUALITY, MERCHANTABILITY, FITNESS FOR ANY

PARTICULAR PURPOSE OR USE, OR ANY OTHER MATTER. Under no

circumstances shall Seller be liable to Buyer or any third party for any loss of profits or

other direct or indirect costs, expenses, losses or consequential damages arising out of

or as a result of any defects in or failure of its products or any part or parts thereof or

arising out of or as a result of parts or components incorporated in Seller's equipment

but not supplied by the Seller.

a 3M company

CUNOIncorporated

400 Research Parkway

Meriden, CT 06450, U.S.A.

Tel:(800) 243-6894

(203) 237-5541

Fax:(203) 630-4530

www.cuno.com

CUNO is a registered Trademark of 3M used under licence

© 2007 3M Company. All Rights Reserved LITCHF1.1110p

Loading...

Loading...