Page 1

a 3M company

g

®

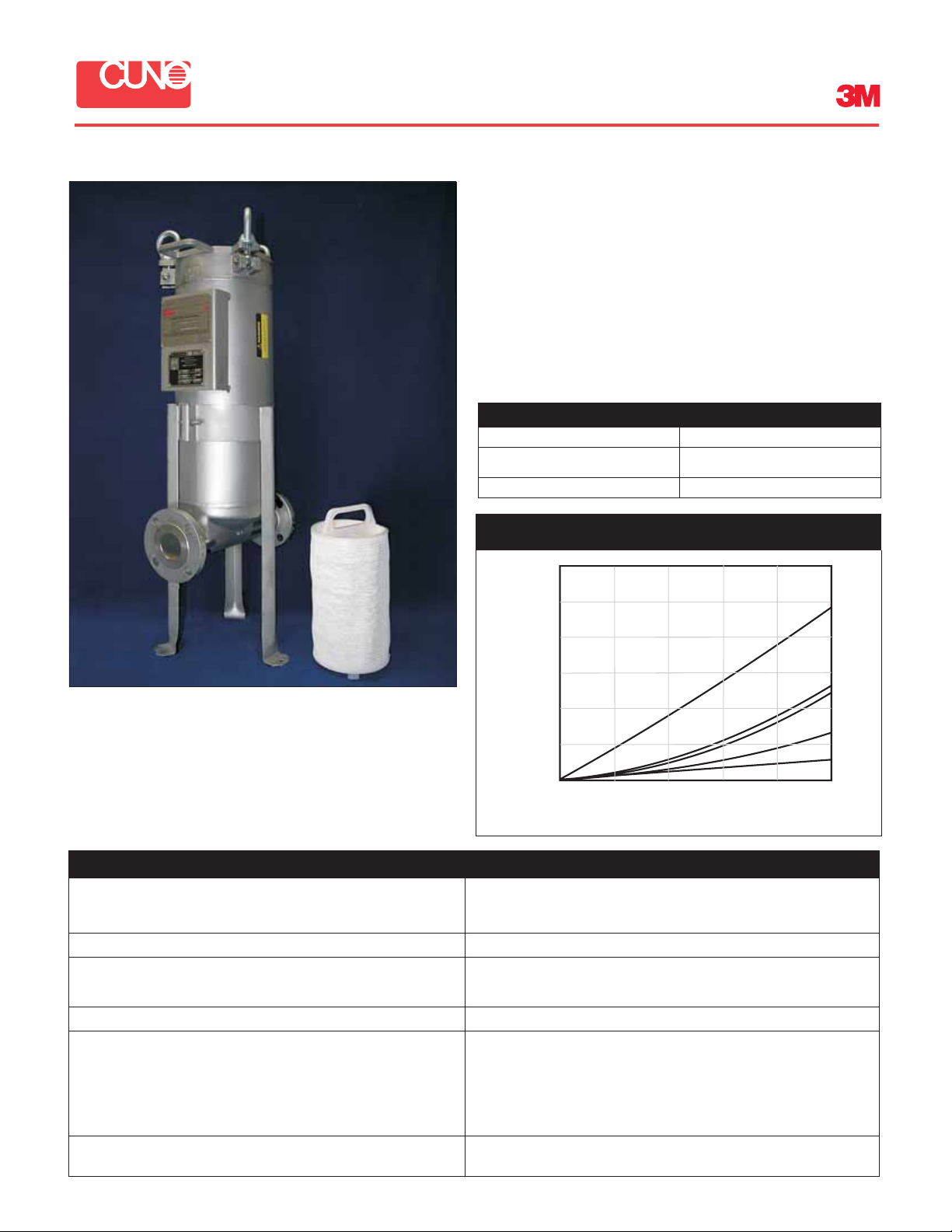

CUNO High Flow Filtration Systems

Features such as an ergonomically designed handle and

a “twist-to-lock” seating mechanism facilitate easy opera

tion and maintenance of the filter system. The system is

particularly suitable for many OEM applications.

Materials Of Construction

Each grade of the CUNO High Flow Filter is manufactured

from meltblown FDA compliant polypropylene microfiber

media, providing high particle removal efficiency with

broad chemical compatibility.

No adhesives, binders, surfactants, or lubricants are used

in the manufacturing process.

Operating Conditions

Maximum Operating Temperature 160°F (71°C)

Maximum Forward Differential

Recommended Changeout Pressure 35 psid @ 68°F (2.4 bar @ 20°C)

Pressure

Typical Housing and Cartridge Flow Rates

50 psid @ 68°F (3.4 bar @ 20°C)

-

The 10” CUNO High Flow System is ideally suited for

applications where convenience and ease of use are

priorities. The system uses 3M Innovation and CUNO’s

extensive filtration experience to enable flow rates up to

85 gpm in a single cartridge. The Compound Radial

Pleat design packs significantly higher usable surface

areas per unit volume than can be achieved with

conventional pleated cartridge filters.

Features Benefits

+

High flow capability of up to 85 gpm per cartridge

+

Compound Radial Pleat design

+

Compact design

+

Absolute rating

+

Easy to Use

+

FDA compliant

+

Reduced filter usage – minimizes product loss, labor,

disposal costs, operator exposure, and downtime for filter

change-out

+

High loading capacity for long life and lower cost filtration

+

Smaller housing minimizes capital expense requirements

+

Reduces system footprint

+

Reproducible effluent quality throughout the filter’s life

+

No special tools or hardware required for filter change-out –

minimizes downtime

+

“Twist-to-lock” seating mechanism provides positive

+

Ergonomically designed handle – facilitates easy

cartridge installation and removal

+

Suitable for wide range of food and beverage

applications

Differential Pressure (psid)

6

5

4

3

2

1

0

0

20

40

Flow (

60

pm)

1 micron

2 micron

Housing Only

5, 10, 15 micron

25, 40, 70 micron

80

100

Page 2

10” Cuno High Flow Housing

The 10” CUNO High Flow Housing is specifically de

signed to deliver all of the system’s benefits in a compact

footprint. The housing is designed, manufactured,

tested, and code stamped in accordance with ASME

Section VIII, Division 1. Vessel construction is 304 stain

less steel with a glass-bead finish.

Housing Specification

Model 1HF10V

Outside Diameter 8 5/8

Number of Filter Elements 1 - 10" Element

Material 304 Stainless Steel

Connection size (inches) 2

Drain Size Inches (NPT) 1/2

Vent or Gauge Size Inches (NPT) 1/4

Approximate Housing Weight (lbs. / kgs) 150 lbs

10” CUNO High Flow ASME Code Housing Ordering Guide

Filter

Elements

1HF10– 10 in. V – Vertical B – 304 SS

Model Size Configuration

Housing

Material

-

-

Gasket Material

GA – Silicone

GB – Fluorocarbon

GC – EPR

GD – Nitrile

CUNO High Flow Housing Dimensions

Dimensions are for overall space requirements only.

For all other uses, request a certified drawing

Head space required

for cartridge removal

27in

(63.5 cm)

42in

(107 cm)

17 ½ in. max

12 ½ in. min

(44.5 cm max.

31.8 cm min.)

13 in.

(33 cm)

High Flow 10 Inch Cartridge Ordering Guide

Filter Designation

HF – High Flow

Important Notice

CUNO MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Since

a variety of factors can affect the use and performance of a CUNO product in a particular application, some of which are uniquely within the user’s knowledge and control, user is responsible for determining

whether or not the CUNO product is fit for a particular purpose and suitable for user’s method of application.

Limitation of Remedies and Liability

If the CUNO product is proved to be defective, THE EXCLUSIVE REMEDY, AT CUNO’S OPTION, SHALL BE TO REFUND THE PURCHASE PRICE OR TO REPAIR OR REPLACE THE DEFECTIVE

PRODUCT. CUNO shall not otherwise be liable for loss or damages, whether direct, indirect, special, incidental or consequential, regardless of the legal theory asserted, including, but not limited to, contract,

negligence, warranty or strict liability.

Seller warrants its equipment against defects in workmanship and material for a period of 12 months

from date of shipment from the factory under normal use and service and otherwise when such equip

ment is used in accordance with instructions furnished by Seller and for purposesdisclosed in writing at

the time of purchase, if any. Any unauthorized alteration or modification of the equipment by Buyer will

void this warranty. Seller's liability under this warranty shall be limited to the replacement or repair,

F.O.B. point of manufacture, of any defective equipment or part which, having been returned to the fac

tory, transportation charges prepaid, has been inspected and determined by the Seller to be defective.

Element Length

(inches)

10 – 10 in. PP - Polypropylene

Material

LIMITED WARRANTY

Absolute Removal Rating

O-Ring

(Microns)

001 – 1 mm

002 – 2 mm

005 – 5 mm

010 – 10 mm

015 – 15 mm

025 – 25 mm

040 – 40 mm

070 – 70 mm

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EITHER EXPRESSED OR IMPLIED,

-

AS TO DESCRIPTION, QUALITY, MERCHANTABILITY, FITNESS FOR ANY PARTICULAR PUR

POSE OR USE, OR ANY OTHER MATTER. Under no circumstances shall Seller be liable to Buyer

or any third party for any loss of profits or other direct or indirect costs, expenses, losses or conse

quential damages arising out of or as a result of any defects in or failure of its products or any part or

-

parts thereof or arising out of or as a result of parts or components incorporated in Seller's equip

ment but not supplied by the Seller.

A – Silicone

B – Fluorocarbon

C – EPR

D – Nitrile

Packaging Options

(per box)

01 - 1 pack

-

-

-

a 3M company

CUNOIncorporated

400 Research Parkway

Meriden, CT 06450, U.S.A.

3M is a trademark of 3M Company. CUNO is a trademark of 3M used under licence. 70020208073

© 2008 3M Company. All Rights Reserved LITHSHFADM2.1110p

Tel: (800) 243-6894

(203) 237-5541

Fax:(203) 630-4530

www.cuno.com

Loading...

Loading...