Page 1

3M Occupational Health & Environmental Safety Division

3M™ The Edge Personal Noise Dosimeter

MODELS eg3 and eg4

The Edge

models eg4 and eg3

User Manual

Page 2

i Table of Contents

Chapter 1: Introduction ................................................................... 1

Dosimetry ........................................................................................ 1

Noise dosimeter ............................................................................................ 2

Range of sound ............................................................................................. 3

What do the standards say? ........................................................................... 3

Applications of the Edge ................................................................................ 4

Noise assessment steps ................................................................................. 5

The Edge Models ........................................................................................... 6

Virtual dosimeters 6

Getting started ................................................................................ 7

Checking the equipment ................................................................. 7

Turning on ....................................................................................... 8

LED indicator................................................................................................. 8

Navigating 9

Turning off ....................................................................................... 9

Display and keypad ....................................................................... 10

Diagram .......................................................................................................10

3MTMDetection Mangement Software (DMS) ................................. 11

Loading .......................................................................................................11

Docking station functionality ........................................................ 11

Docking station components .........................................................................12

EdgeDock1 or EdgeDock5 .............................................................................12

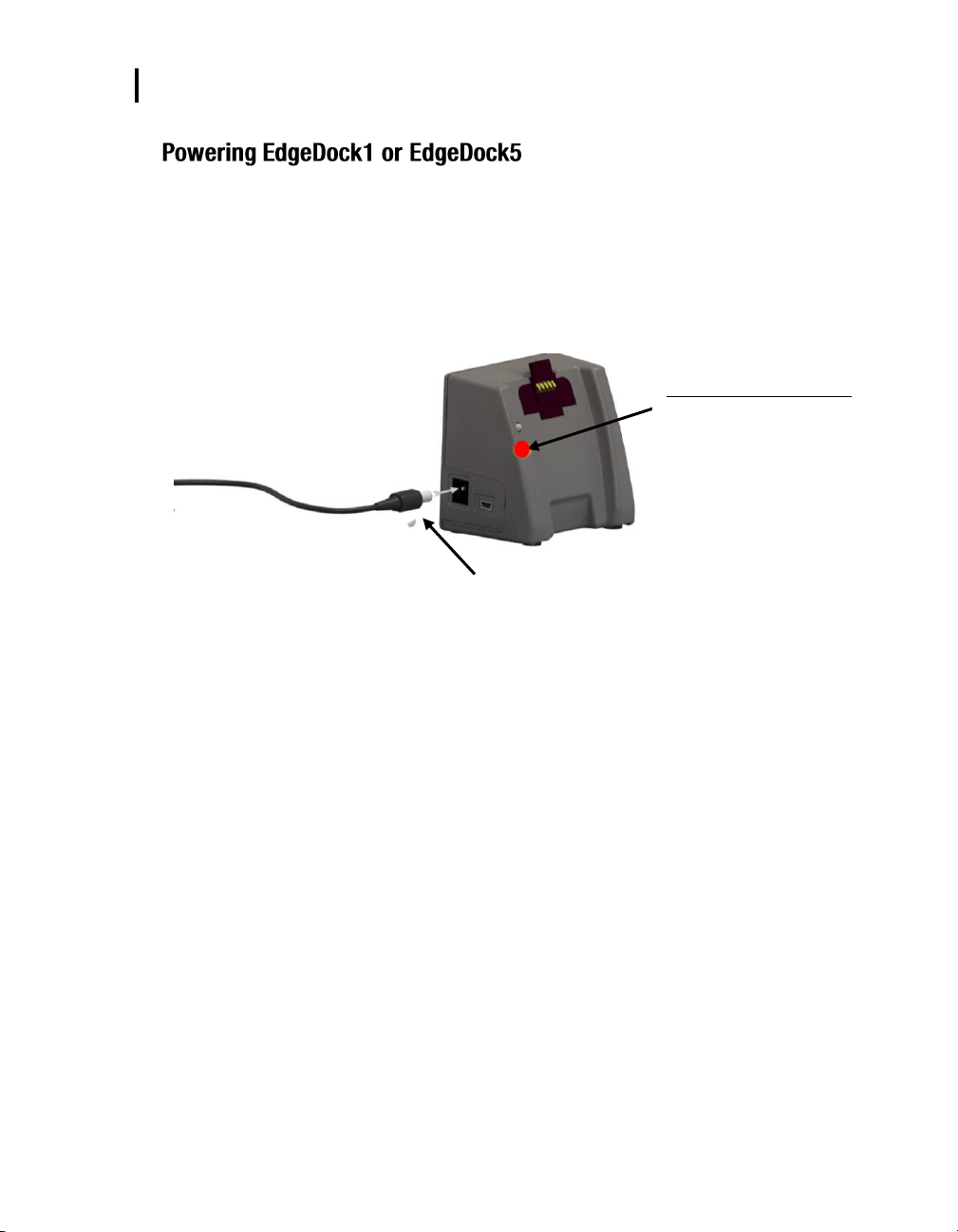

Powering EdgeDock1 or EdgeDock5...............................................................13

Charging your dosimeter ...............................................................................14

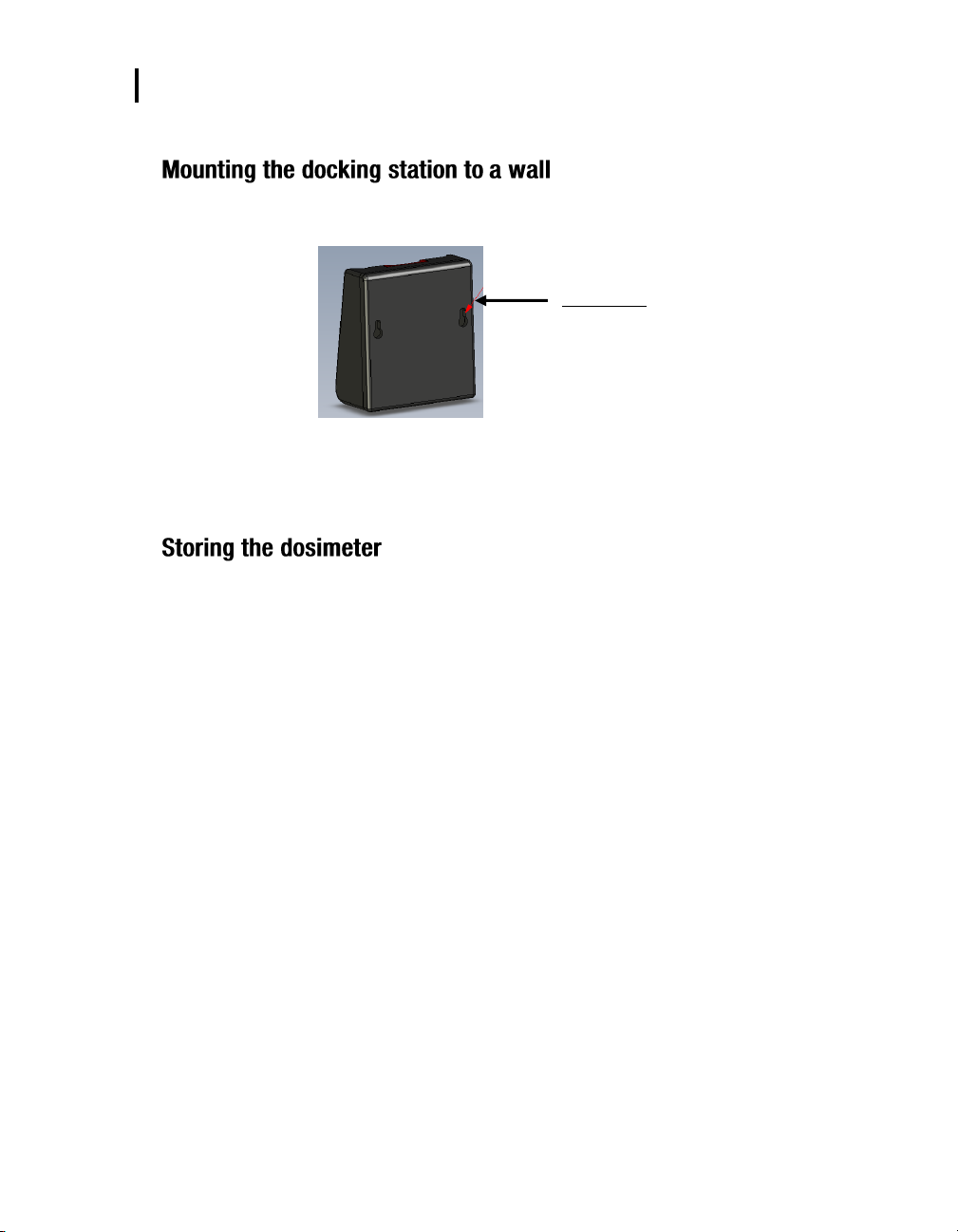

Mounting the docking station to a wall ...........................................................15

Storing the dosimeter ...................................................................................15

053-644, Rev E Page i eg4 & eg3

Page 3

Table of Contents

ii

Chapter 3: Setting-up the Edge via DMS ...................................... 16

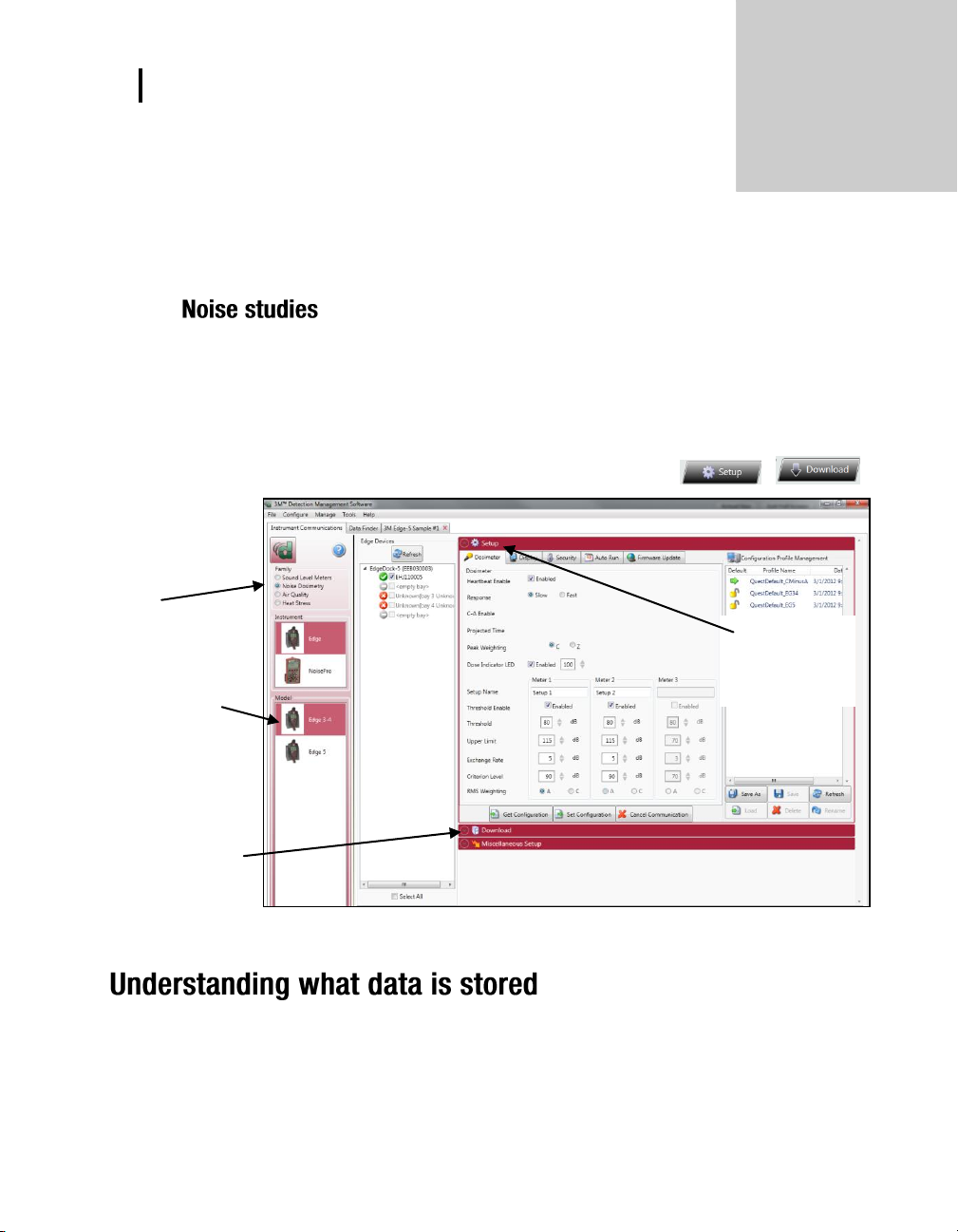

Noise studies ................................................................................. 16

Understanding what data is stored .............................................. 16

Summary data ..............................................................................................17

Time history 17

Views on the Edge ......................................................................... 18

Definitions of data log values and views .........................................................19

Docking .......................................................................................... 22

Communicating & downloading data ..............................................................22

Figure 3-4: Communicating - connecting a docked Edge to a pc .................................. 22

Customizing set-up parameters in DMS ........................................ 23

Dosimeter setting .........................................................................................24

Edge dosimeter settings 25

Display setting .............................................................................................26

Security setting ............................................................................................27

Auto Run setting ..........................................................................................28

Firmware update ..........................................................................................29

Saving and sending/setting configurations .....................................................30

Running and operating your dosimeter ......................................... 31

Overview of running a study ......................................................... 31

Positioning the Edge on your shirt .................................................................32

Windscreen and maintenance ........................................................................32

Checking battery power ................................................................................33

Calibrating ...................................................................................................34

Resetting the dosimeter ................................................................................35

Setting contrast on dosimeter .......................................................................36

Running studies ............................................................................. 37

053-644, Rev E Page ii eg4 & eg3

Page 4

Table of Contents

iii

Starting a run ...............................................................................................37

Stopping a study............................................................................ 38

Indicators/Icons on the display ......................................................................38

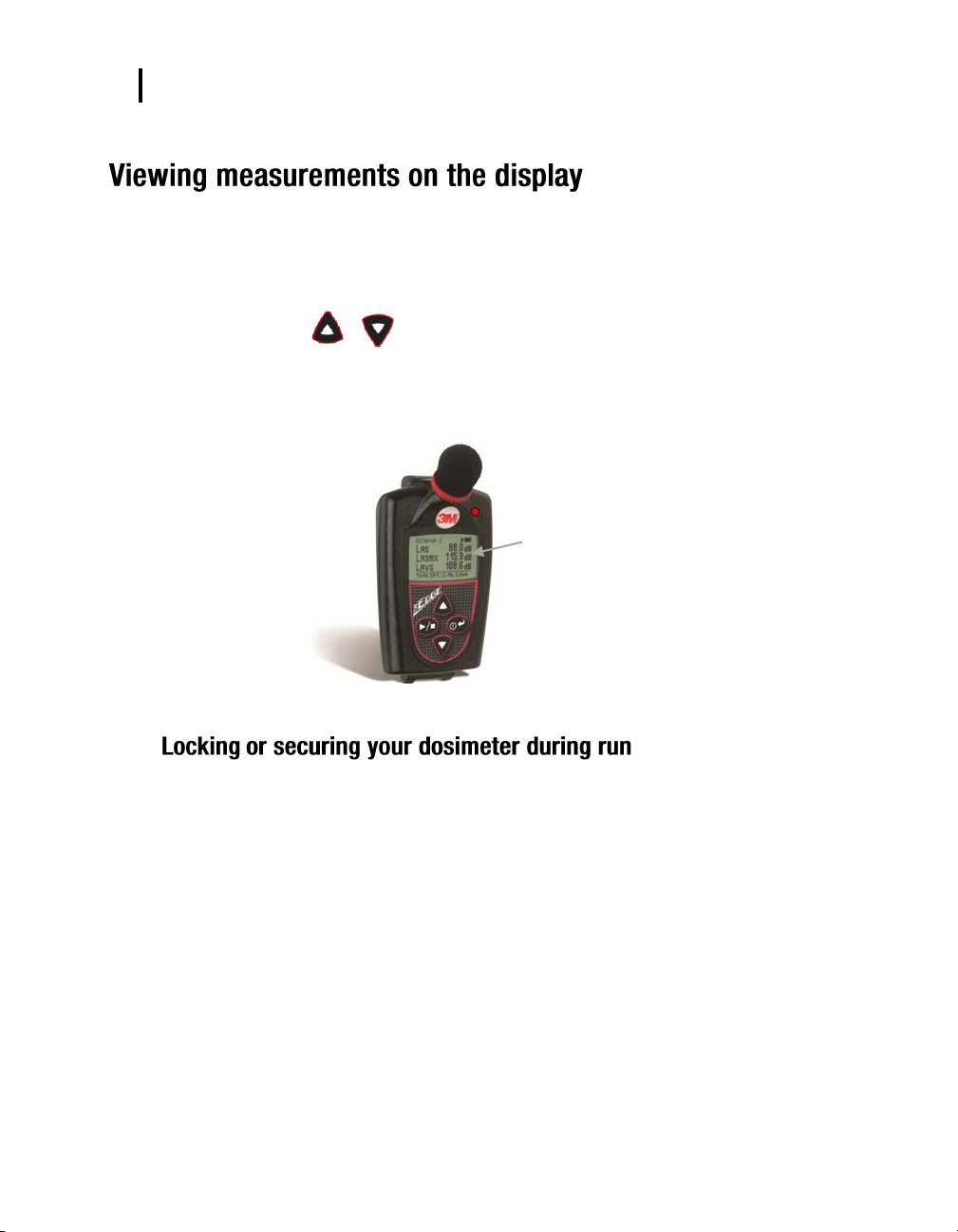

Viewing measurements on the display ......................................... 39

Locking or securing your dosimeter during run ...............................................39

Locking or Securing ......................................................................................40

Unlocking .....................................................................................................40

Downloading data ........................................................................................41

Viewing data and data finder page ................................................................43

Report View .................................................................................................44

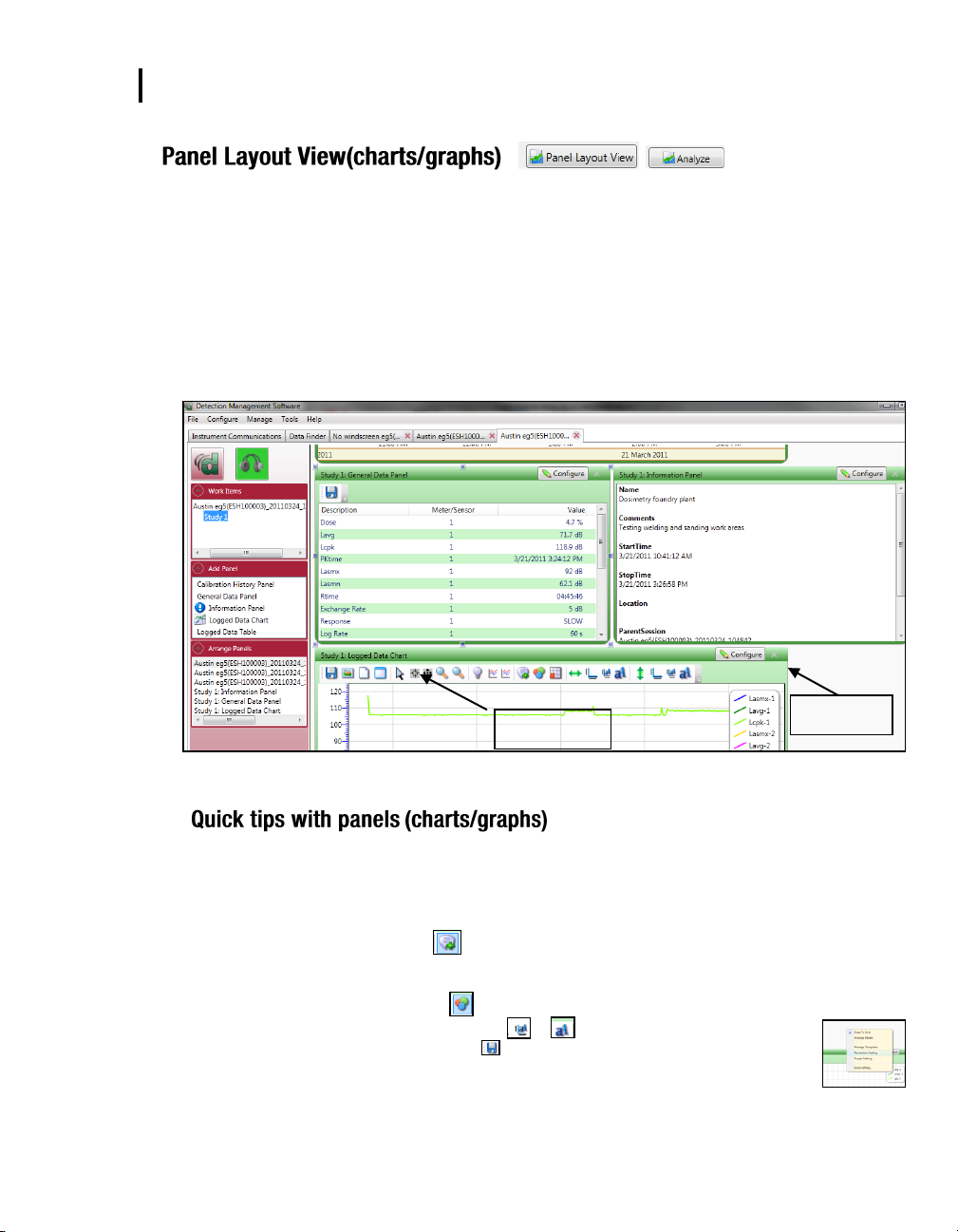

Panel Layout View(charts/graphs) .................................................................45

Quick tips with panels (charts/graphs) 45

Technical Support ......................................................................... 46

LED indicator: disable/enable .......................................................................46

Replacing microphone and windscreen ........................................ 47

Attaching/Detaching .....................................................................................47

Hard Hat Attachment Kit .............................................................. 48

Appendix A: SPECIFICATIONS ..................................................... 49

Standards ...................................................................................... 49

Mechanical characteristics .......................................................... 49

Electrical characteristics ............................................................. 50

Battery ........................................................................................................50

Environmental effects ................................................................... 50

Temperature ................................................................................................50

User Interface ............................................................................... 50

Display ........................................................................................................50

Keypad ........................................................................................................50

053-644, Rev E Page iii eg4 & eg3

Page 5

Table of Contents

iv

EdgeDock1 and EdgeDock5 .......................................................... 51

Physical attributes of EdgeDock1 and EdgeDock5 ...........................................51

Measurements ............................................................................... 52

Types ..........................................................................................................52

Measurement parameters .............................................................................52

Communications ...........................................................................................53

Special functions ..........................................................................................53

Edge Block Diagram ...................................................................... 54

Edge Block Diagram (continued) .................................................. 55

3M Quest Service .......................................................................... 56

Contacting 3M Quest Technologies ................................................................56

International customers ................................................................................56

Warranty ........................................................................................ 56

Appendix B: Glossary of Terms .................................................... 57

INDEX………………………………………………………………………………….85

053-644, Rev E Page iv eg4 & eg3

Page 6

List of Figures

v

Figure 1-1: The Edge and dosimetry .................................................................................................. 1

Figure 1-2: Illustration of how the dosimeter operates and processes .................................................. 2

Figure 1-3: Parameter setup screen for eg4 ....................................................................................... 6

Figure 2-1: Identifying your equipment .............................................................................................. 7

Figure 2-2: Powered on with measurement view displayed .................................................................. 8

Figure 2-3: Edge Keypad .................................................................................................................. 10

Figure 2-4: EdgeDock1 .................................................................................................................... 11

Figure 2-5: Attaching the charger adapter with the plug adapter ........................................................ 12

Figure 2-6: Attaching charger adapter to EdgeDock1 and EdgeDock5 ................................................. 13

Figure 3-1: Edge setup and retrieve data buttons in DMS ................................................................... 16

Figure 3-2: Sample summary data from DMS reporting ...................................................................... 17

Figure 3-3: Sample time history data (or logged data) chart ............................................................... 17

Figure 3-4: Communicating - connecting a docked Edge to a pc ......................................................... 22

Figure 3-5: New Hardware wizard for Edge Dock ............................................................................... 23

Figure 3-6: Dosimeter screen ........................................................................................................... 24

Figure 3-7: Edge display screen ........................................................................................................ 26

Figure 3-8: Edge security setting ...................................................................................................... 27

Figure 3-9: Edge auto run screen ..................................................................................................... 28

Figure 3-10: Edge firmware update screen .......................................................................................... 29

Figure 3-11: Saving and sending Edge setups ..................................................................................... 30

Figure 4-1: Quick help list for running a study ................................................................................... 31

Figure 4-2: Positioning/Attaching the Edge ........................................................................................ 32

Figure 4-3: Battery indicators ........................................................................................................... 33

Figure 4-4: Calibrating ..................................................................................................................... 34

Figure 4-5: Splash screen ................................................................................................................. 35

Figure 4-6: Resetting the Edge from the keypad ................................................................................ 35

Figure 4-7: Changing the contrast from the keypad ........................................................................... 36

Figure 4-8: Display screen while running ........................................................................................... 37

Figure 4-9: Measurement view on the Edge ...................................................................................... 39

Figure 4-10: Locking/Securing run ...................................................................................................... 40

Figure 5-1: Communicating between your pc and the Edge ................................................................ 41

Figure 5-2: DMS start screen ............................................................................................................ 42

Figure 5-3: Downloading with the Edge models eg3/eg4 .................................................................... 42

Figure 5-4: Recent downloaded data ................................................................................................ 43

Figure 5-5: Data Finder page with the downloaded data .................................................................... 43

Figure 6-1: Microphone and windscreen assembly ............................................................................. 47

List of Tables

Table 2-1: LED indicators explained .................................................................................................. 9

Table 2-2: EdgeDock1 and EdgeDock5 components .......................................................................... 12

Table 3-1: Dosimeter views and definitions ...................................................................................... 19

Table 3-2: Dosimeter measurement descriptors/variants ................................................................... 21

Table 4-1: Indicators (i.e., run, stop, battery, and OL) ...................................................................... 38

053-644, Rev E Page v eg4 & eg3

Page 7

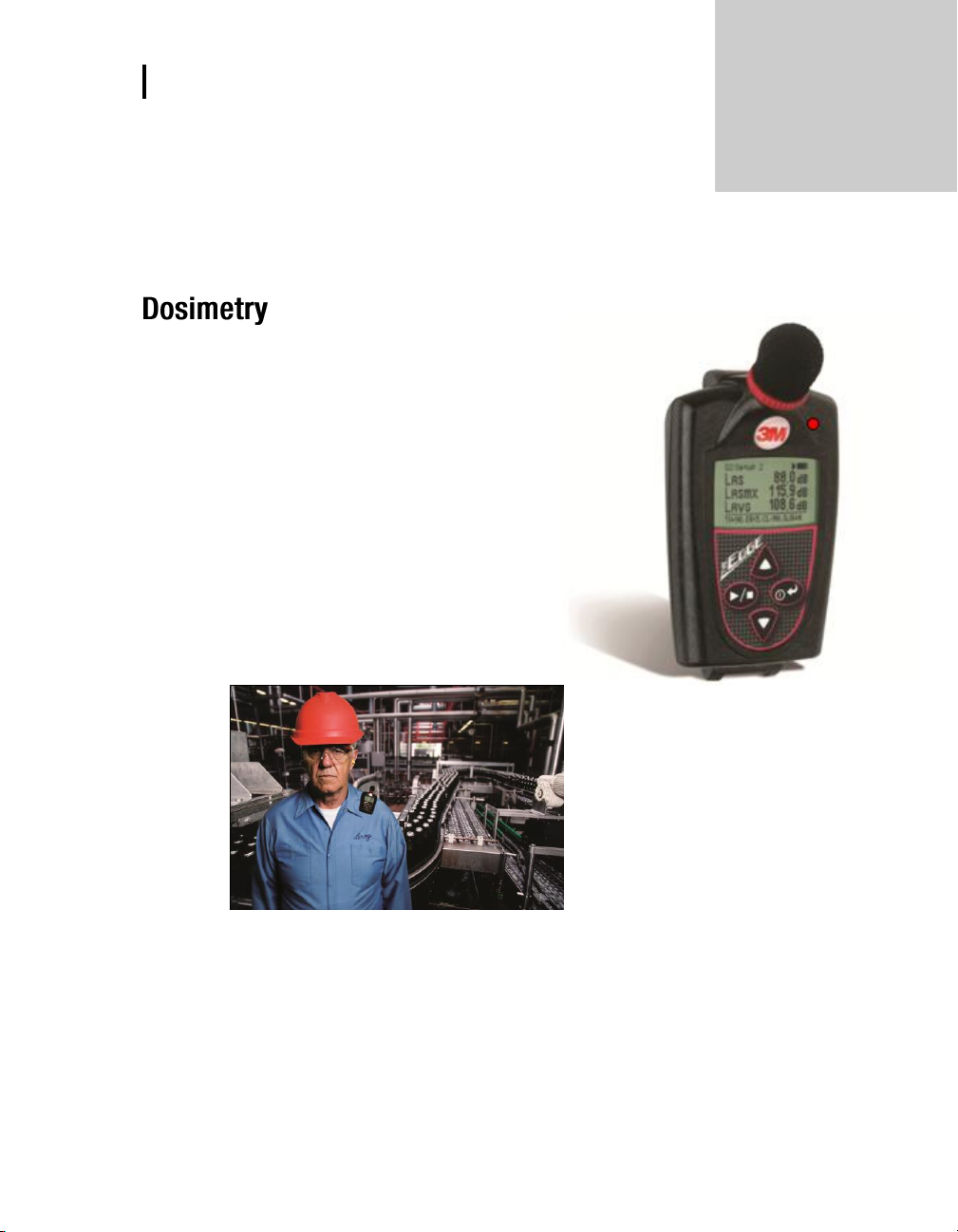

1 Dosimetry

CHAPTER

1

Chapter 1: Introduction

Measuring noise in the workplace is an

important element of hearing conservation

programs and noise reduction programs. With a

noise dosimeter, you can assess and determine

a worker’s daily exposure to noise levels. This

information can be used to ensure compliance

with regulatory bodies or to ensure if hearing

conservation programs are needed.

To get you started quickly with the Edge, the

first chapter is dedicated to introducing basic

noise dosimetry terms and information. The

subsequent chapters will guide you through

setting up the dosimeter, running studies, and

assessing your results with easy to follow steps

and illustrations.

Figure 1-1: The Edge and dosimetry

053-644, Rev E Page 1 eg4 & eg3

Page 8

Dosimetry

2

Mic &

Preamp

Range control

(70-140dB)

Apply filters

(A or C weighting)

Measurement

results on the Edge

Fast/Slow

Response

File storage

system

Calculator

Clock

QSPII – Manage setup and

create graphs, charts and reports

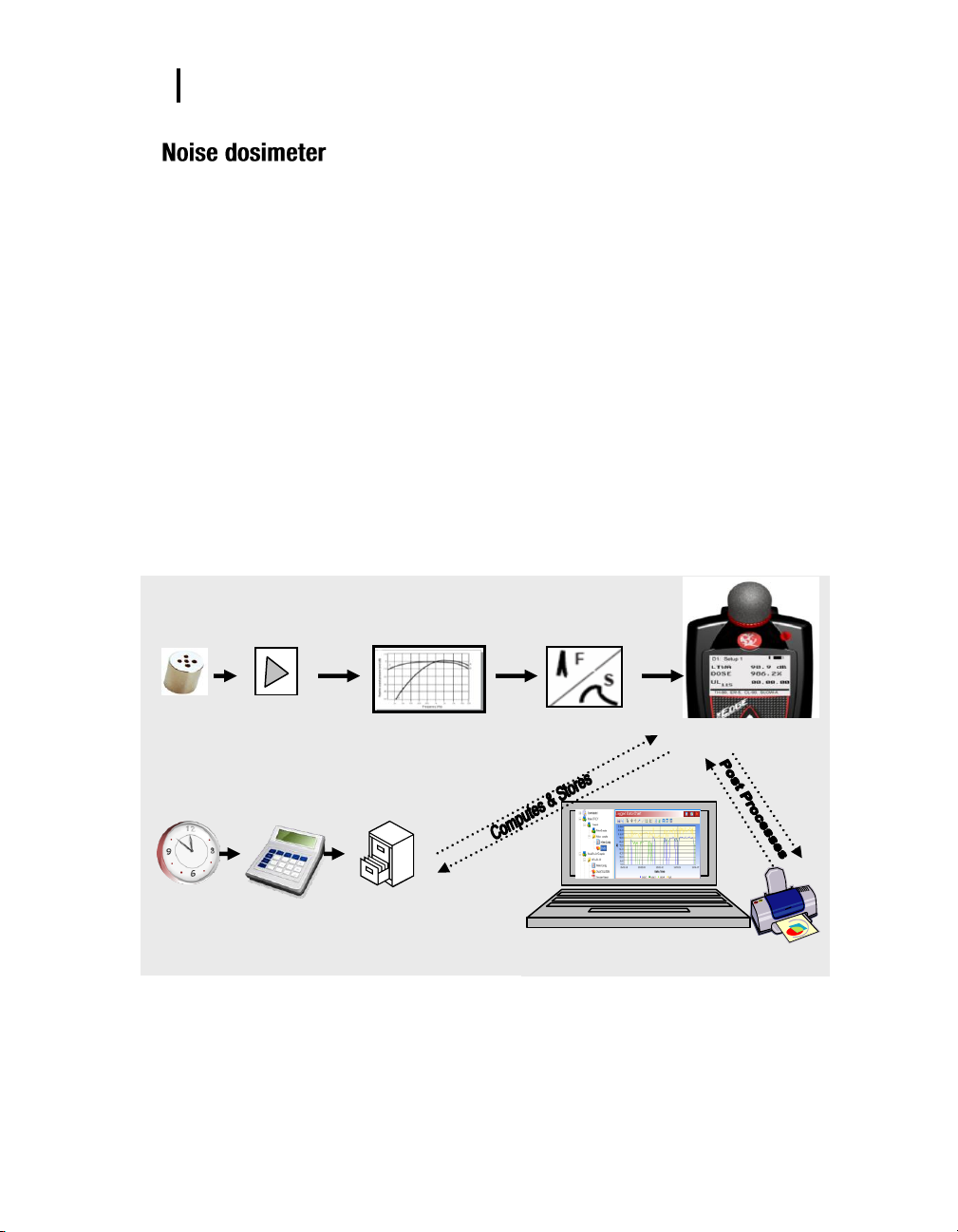

Noise dosimeter

What is a noise dosimeter and how does it compute measurements?

Essentially, a noise dosimeter is composed of the following: a microphone with a

preamplifier, a weighted network, fast or slow response time, an internal clock, calculator,

and memory to store logged data.

The illustration below is a diagram of a basic noise dosimeter. The microphone will, when

exposed to a sound pressure, generate an electrical signal. The signal will be increased by

a preamplifier, and then is regulated to an applicable level by the range control (dB range).

The signal then goes through a filter set or weighting system. The next circuit is the

response circuit, which controls the dampening of the readout. The response choices are

typically Slow or Fast. Finally, the results will display on the dosimeter screen.

For computation and storage, the clock tracks the sampling time. Dosimeters record how

long sound levels exceeded a set upper limit. The calculator computes an L-avg, a dose, a

TWA, and other data. The memory stores all times, calculations, and measurements.

For post-processing, QSP-II is used to view and analyze your measurement results with the

option to view and/or print reports.

053-644, Rev E Page 2 eg4 & eg3

Figure 1-2: Illustration of how the dosimeter operates and processes

Page 9

Dosimetry

3

Range of sound

Sound pressure is measured in decibels, or tenths of a Bel. Sound pressure level is

indicated as dB SPL. Since the human ear can detect sounds with an extensive range of

amplitude, a decibel scale is used to simplify the measurement results. For example, the

ratio between the threshold of hearing and threshold of pain in the human ear if measured

in true energy is 10,000,000 times! The same range using the dB scale is 0 - 140 dB

referenced to 20 µPa (Micropascals).

The quietest sound that humans can hear has an amplitude of approximately 0 dB.

Prolonged exposure to sound pressure levels exceeding 85 dB can cause permanent

damage to the ear. Sound levels in excess of 130 dB are more than the human ear can

safely withstand and can result in serious pain and permanent damage.

Many organizations have studied and analyzed the effects of high sound exposure on

hearing. As a result, standards were developed to regulate personal noise exposure. In the

United States, the Occupational Safety and Health Administration (OSHA), the Mine and

Safety and Health Administration (MSHA), and the American Conference of Governmental

Industrial Hygienists (ACGIH) have all created regulations and limitations on total

permissible noise exposure. International standards are specified by the health and safety

regulations such as the European Union (EU) Directive 2003/10/EC. Additionally, the

International Electrotechnical Commission (IEC) IEC-61252 has specific guidelines and

regulations to monitor noise in the workplace.

To access these copyrighted standards, please refer to the following:

OSHA - http://www.osha.gov

MSHA- http://www.msha.gov

NIOSH - http://www.cdc.gov/niosh/topics/noise

ACGIH - http://www.acgih.org/

IEC - http://www.iec.ch

053-644, Rev E Page 3 eg4 & eg3

Page 10

Dosimetry

4

Time history: manufacturing

Peak Measurement: 121.20 dB

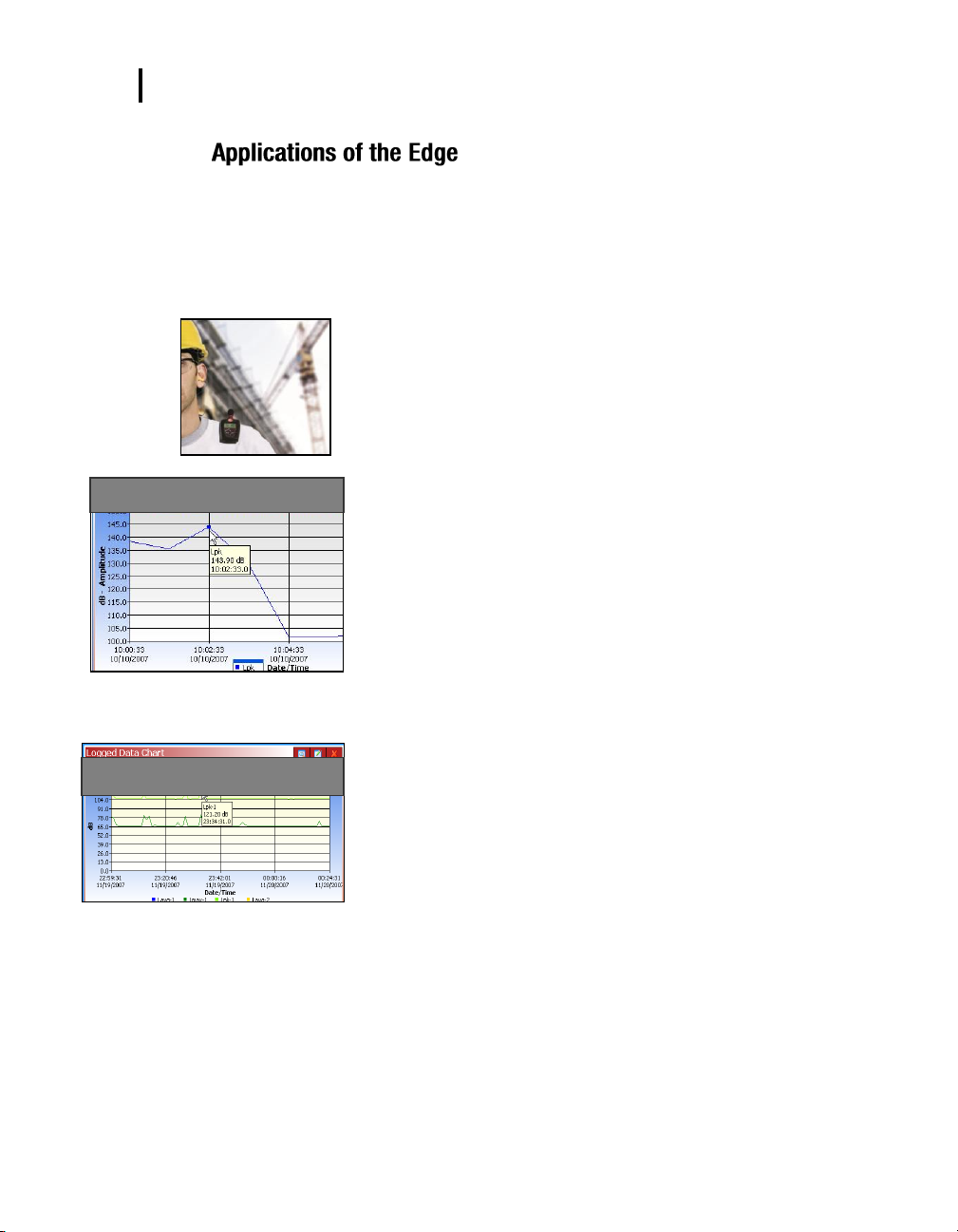

Applications of the Edge

The Edge has a cable-free, mounted microphone that converts sound pressure into an

electrical signal. This signal is conditioned, monitored, and integrated over time in order to

provide a host of automatically calculated values that can be used in occupational and

environmental noise assessments. Programmable parameters permit the Edge to serve

many applications. The Edge can be used in the following applications:

As a personal noise dosimeter - Used to measure a worker's

daily exposure to noise levels. This information can be used to

ensure compliance with OSHA, MSHA, ACGIH, IEC, or your own

customized parameter settings to determine if your workers are

over-exposed to noise.

As a time-history monitor- Used to provide a worker's minute-by-

minute noise exposure levels. This data can help you identify major

contributors to the average daily noise exposure.

As a survey monitor

1. Throughout a plant/facility – used to oversee noise levels

throughout an entire facility. You can identify machines and

equipment which produce harmful noise levels.

2. Specific areas in a plant/facility- used to identify key areas

as “noisy” and implement noise control options. Employees

may be exposed to unacceptable noise levels.

As a peak dosimeter- Used to detect the highest level of

instantaneous sound pressure.

053-644, Rev E Page 4 eg4 & eg3

Page 11

Dosimetry

5

1. Perform a task-based work flow analysis of unacceptable “noisy” areas and list

regulations/codes you will follow.

Observe facility/areas and jot down areas of concern

Check with standards and noise ordinance regulations in your region/city.

See Chapter 1 for basic information on dosimetry and standards

3. Running your studies.

Calibrate dosimeter

Attach the dosimeter

Run, observe, and stop your studies

Understand display indicators

See Chapter 4 “Running and operating the Edge”

4. View your results via QSP-II.

Working with Charts and Graphs

Organizing and saving your studies

See Chapter 5 to view measurements with QuestSuite Professional II

5. Develop corrective actions.

Engineering: redesign tools, implement changes in workstation

Administrative: job sharing/rotations, redefinition of job functions, reduce duration

operating tool/equipment, and/or implement medical surveillance

2. Setting-up your dosimeter parameters for your noise studies.

Customize measurement setup (i.e., criterion level, threshold, weighting,

exchange rate, etc.)

See chapter 2 for getting started with your dosimeter

See Chapter 3 for customizing your set-up parameters

See Chapter 6 for Noise study scenarios

Noise assessment steps

053-644, Rev E Page 5 eg4 & eg3

Page 12

Dosimetry

6

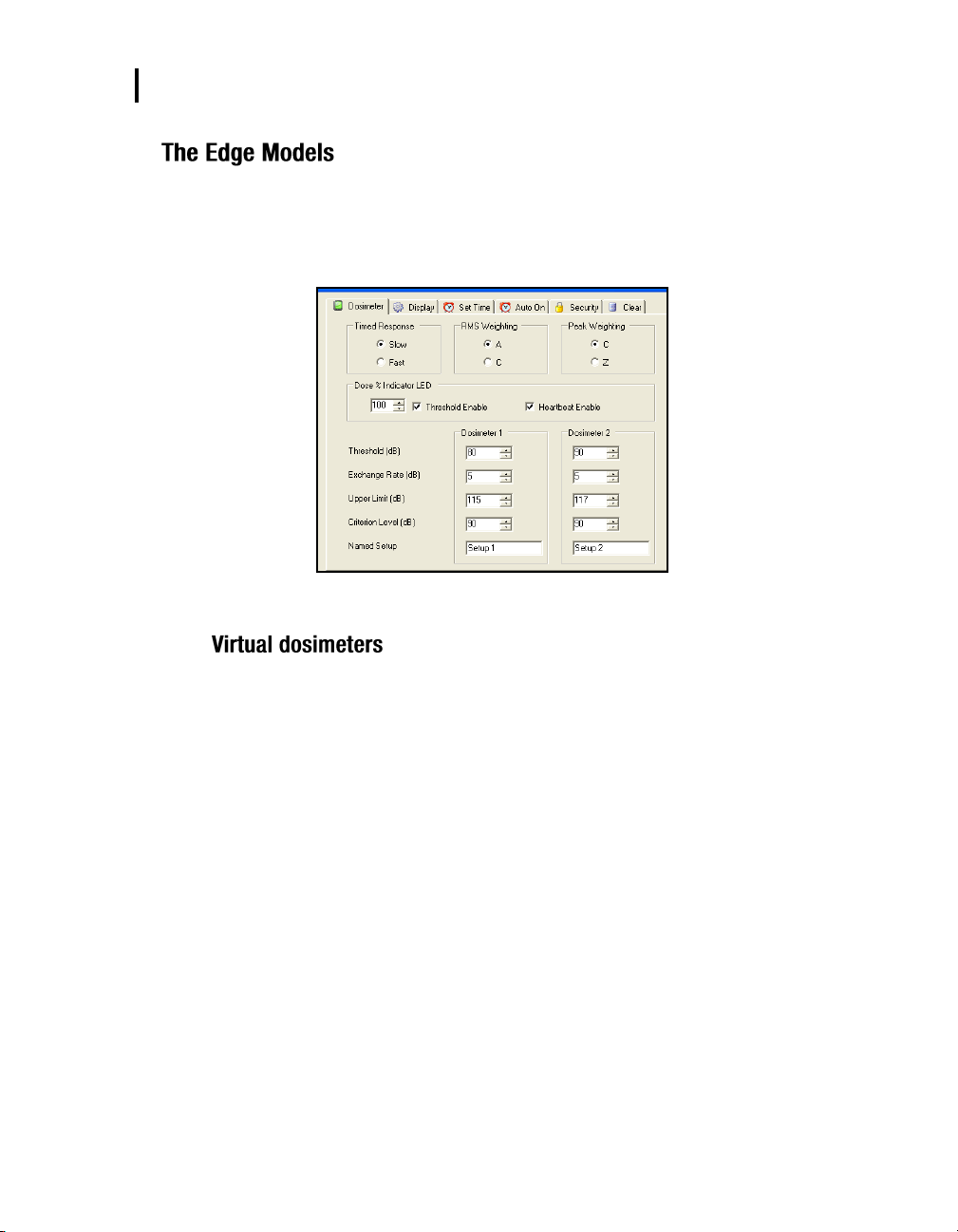

The Edge Models

Quest Technologies offers two Edge models. The “eg4” model features two virtual

dosimeters with data logging. Once the parameters are set and saved in the dosimeter, you

can monitor two different dosimeters by a single press of the Enter button. This will toggle

you between the two dosimeters. The “eg3” model is equipped with one dosimeter setting

and will not data log.

Figure 1-3: Parameter setup screen for eg4

You can monitor and log noise studies by enabling two different parameter settings in one

dosimeter, also referred to as “virtual dosimeters”. For instance, you may want to set one

dosimeter to log using the OSHA HC (Occupational Safety and Health Administration -

Hearing Conversation) parameters and also monitor noise with the OSHA PEL

(Occupational Safety and Health Administration – Permissible Exposure Level) settings.

A few scenarios of virtual dosimeters include:

Industrial noise control

Hearing conservation compliance

Work site assessments

Personal noise verification

Military applications

Regulatory compliance (i.e., OSHA, MSHA, IEC, ACGIH)

053-644, Rev E Page 6 eg4 & eg3

Page 13

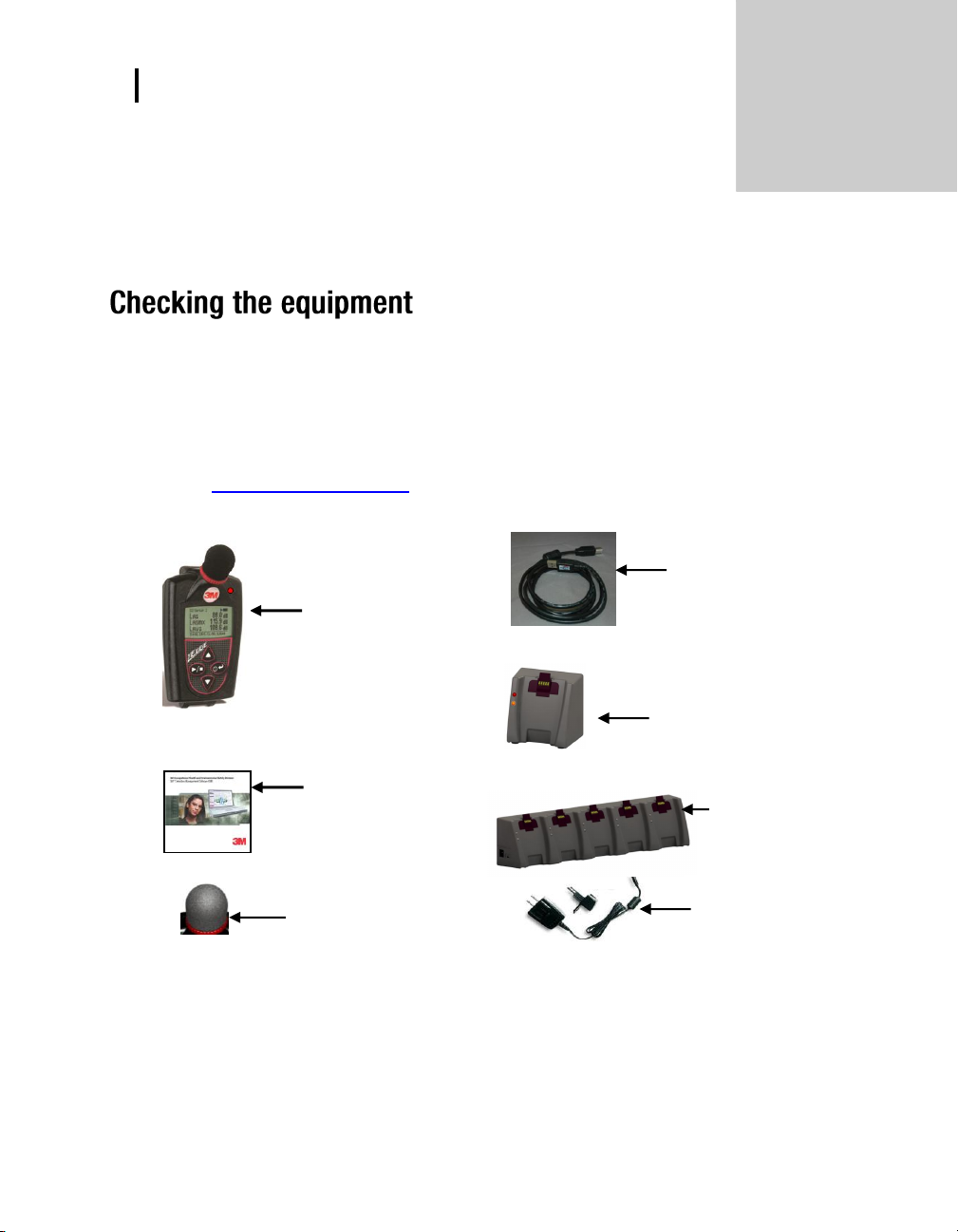

Checking the equipment

7

CHAPTER

2

Edge models eg4/eg3

microphone and

windscreen attached

mounting clasps

attached

USB cable- connects

EdgeDock to the PC

EdgeDock1

**Universal charger

adapter (Power supply

cord for the docking

station)

Extra windscreen for

microphone

EdgeDock5

DMS software

Optional feature

The Edge Models

Getting started

This chapter is designed to guide you through basic information you will need to begin

logging your studies.

If your instrument was sent to you in a storage case, you will want to remove all the

packaging and acquaint yourself with the following equipment so you can quickly get started

with your noise studies.

NOTE: Depending on the accessories you selected, the dosimeter may have the following

components. For the docking stations, you will either have an EdgeDock1 or an

EdgeDock5. (For more information on parts/accessories, please refer to

www.questtechnologies.com.)

Figure 2-1: Identifying your equipment

053-644, Rev E Page 7 eg4 & eg3

Page 14

Turning on

8

View

Displays measurement values, battery

information, and calibration information

LED Indicator

Battery indicator icon

If icon is fully shaded, this indicates full

battery power (approx.50+ hours)

LED indicator

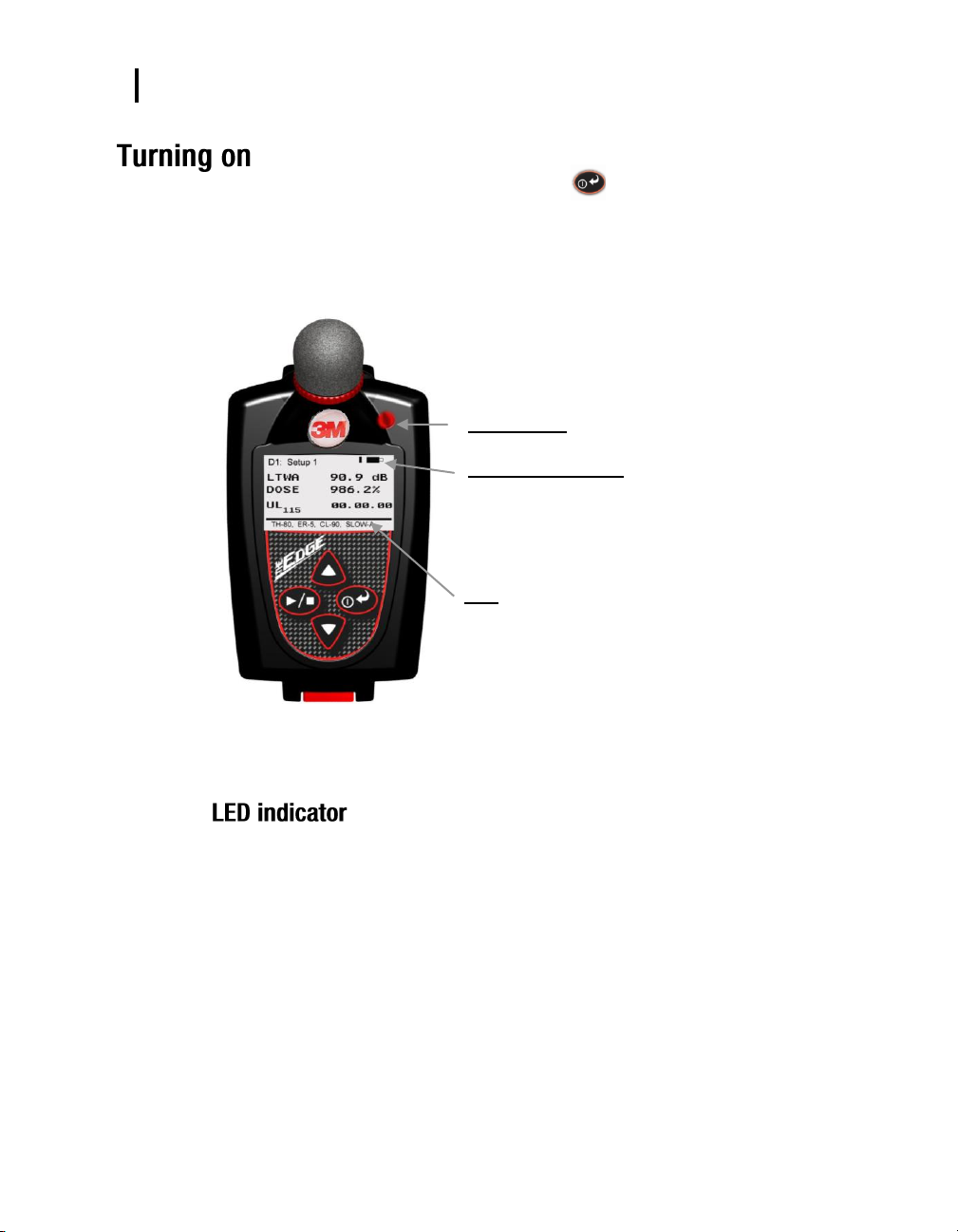

1. To turn on the Edge, press the on/off and enter button.

The Edge splash screen (see Figure 2-3 for an example, page 10) will appear

indicating the model (i.e. “eg4” or “eg3”) and firmware version. The screen will be in the

measurement view.

Figure 2-2: Powered on with measurement view displayed

There is a three-color LED indicator on the Edge, located to the right of the 3M logo which

includes Red, Amber, and Green.

053-644, Rev E Page 8 eg4 & eg3

Page 15

Turning off

9

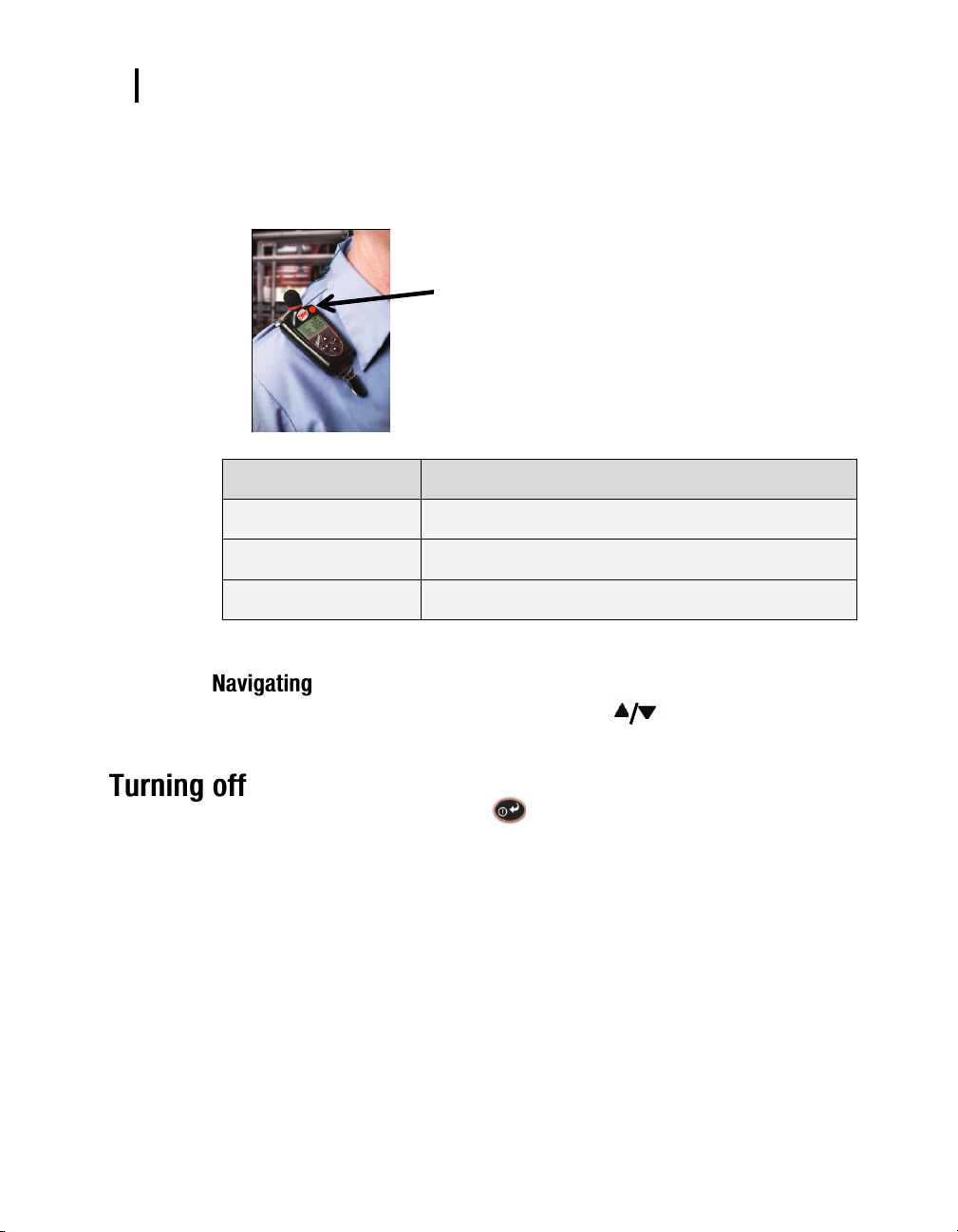

The EDGE LED

indicator

Explanation

Red

A flashing red LED indicates the dose has exceeded the alarm

level.

Amber

A flashing amber LED indicates the dosimeter is stopped and

has not exceeded the dose alarm level.

Green

A flashing green LED indicates the dosimeter is running and has

not exceeded the dose alarm level.

LED indicator

LED indicator

NOTE: The LED indicator can be disabled via DMS (see section, “Dose indicator LED”

page 25).

Table 2-1 identifies when and why the LED indicator color will appear.

Table 2-1: LED indicators explained

Once the dosimeter is “Powered-On”, press the up/down arrows to navigate

through the measurement values and battery run time.

1. Press and hold the on/off and enter button.

“3, 2, and 1” countdown will appear as the dosimeter is powered off.

NOTE: To halt the power off mode, simply let go of the on/off enter button.

053-644, Rev E Page 9 eg4 & eg3

Page 16

Display and keypad

10

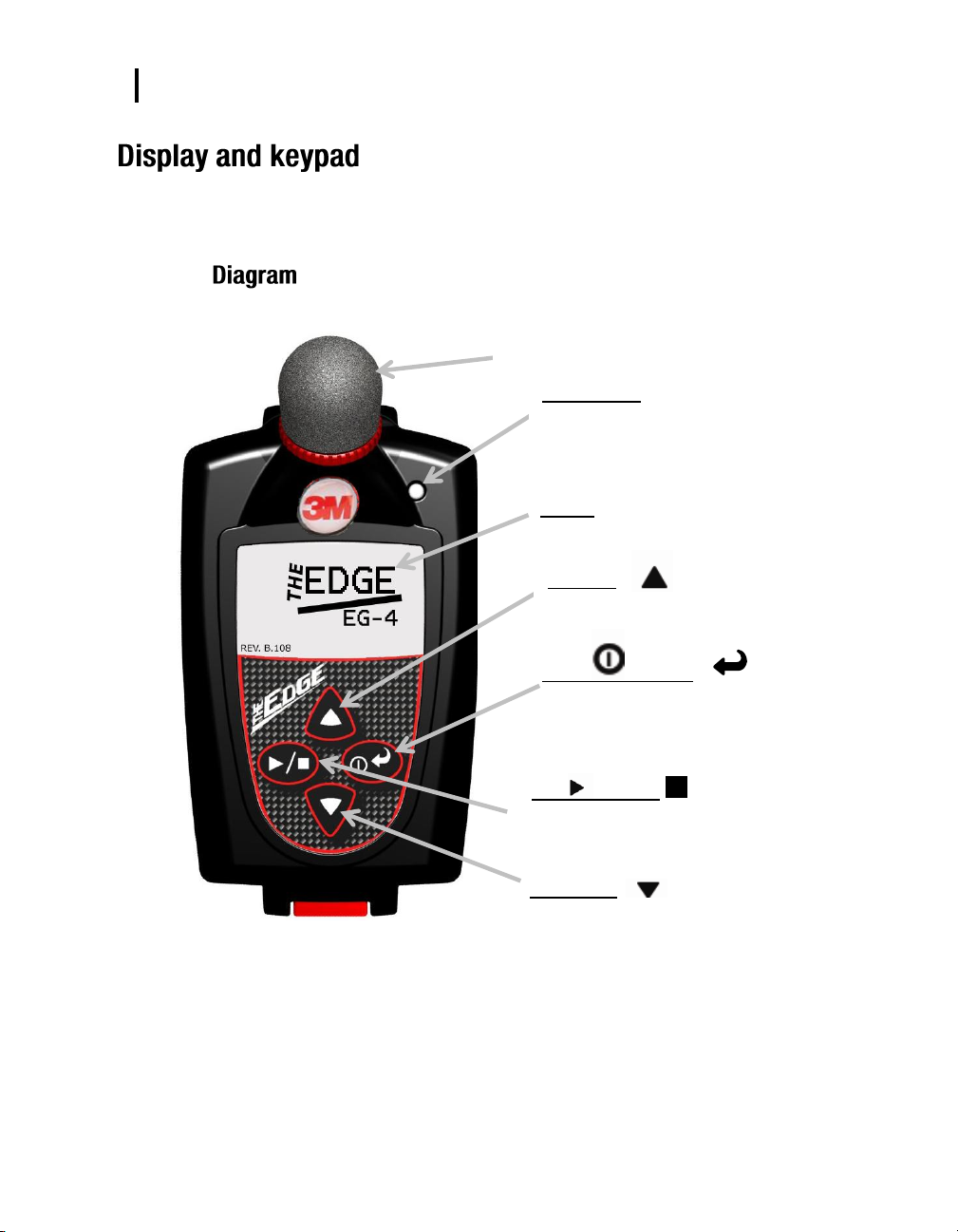

Display (Splash screen shown)

View data and various indicators

Up Arrow

Used to scroll through

display/screen views

On/Off and Enter

Used to power On/Off the meter.

Used to switch between (toggle)

dosimeter one and dosimeter two

measurements and settings.

Down arrow

Used to scroll through

display/screen views

Run and Stop

Used to activate meter when running or

logging measurements.

Used to Stop your noise study.

LED indicator

Red – indicates dose exceeded the alarm level

Amber – dosimeter stopped

Green – dosimeter measuring

Windscreen and microphone

Diagram

The keypad is used to run and stop your studies, view your measurement values, and

power on and off the dosimeter.

The following diagram explains the features on the display and keypad.

Figure 2-3: Edge Keypad

053-644, Rev E Page 10 eg4 & eg3

Page 17

3MTMDetection Mangement Software (DMS)

11

Charging Indicator

Power Indicator

Charge contacts

Power connector

USB connector

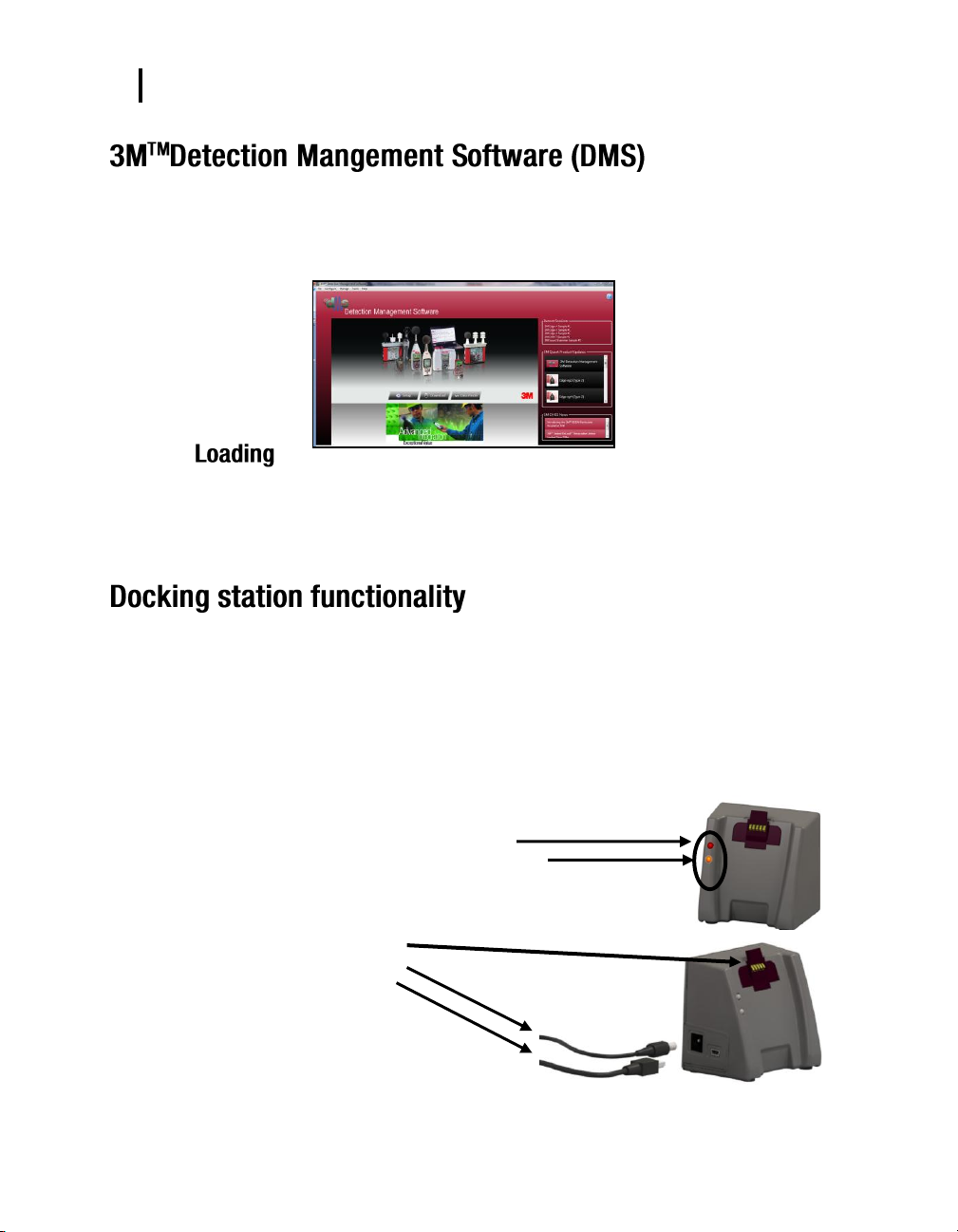

Loading

3MTM Detection Management Software (DMS) is a software application designed by 3M

Quest that runs under the Windows operating system. You can use DMS for a variety of

functions related to the Edge dosimeter and with many other 3M Quest instruments. DMS

has the ability to customize your set-up parameters, display data, manipulate data, and

create reports.

To load DMS, follow the screen prompts.

It will automatically load the drivers for the EdgeDock1 and/or EdgeDock5. If loading from

the 3M detection Internet site, please follow the directions online located:

www.3m.com/detection or www.quest-technologies.com.

Depending on the kit you purchased, you may have an EdgeDock1 and/or an EdgeDock5.

Both are designed similarly with the same LED indicators. The main difference with the

EdgeDock5 is that it has five bays for docking, charging, and/or managing the dosimeters.

If desired, the EdgeDock5 will charge all docked instruments at one time.

The docking station serves a dual-purpose role:

1. It is used to charge the battery on the dosimeter(s).

2. It is used to communicate between the software (DMS) and the dosimeter (i.e.,

import, export settings and measurement files).

Figure 2-4: EdgeDock1

053-644, Rev E Page 11 eg4 & eg3

Page 18

Docking station functionality

12

Docking station

Explanation

Charging indicator

Identifies if the dosimeter is “charging” or “fully charged”. A red blinking LED

indicates the dosimeter is charging. A solid green LED equates to a fully

charged dosimeter. (Note the charging indicator is the first, or top, LED

indicator.)

Power indicator

A red LED indicates the docking station is powered on.

Power connector

Attach the power connector cable to the docking station in order to charge

the dosimeter(s).

USB connector

Attach the USB connector to communicate with the dosimeter(s).

Charge Contacts

Placing the dosimeter (s) onto the charge contacts allows charging and

communication.

B. Slide plug adapter into the crevices of base

A. Charger adapter

Docking station components

The table below explains the EdgeDock1 or EdgeDock5 LED indicators, power connector, USB

connector, and contact pins.

Table 2-2: EdgeDock1 and EdgeDock5 components

The EdgeDock1 and EdgeDock5 are powered by a 12-volt charger adapter.

Figure 2-5 illustrates the assembly of the charger adapter and the plug adapter. It slides into

place by guiding it down the back cavity (opening) of the power supply.

NOTE: the example is a typical adapter which may be different than the one you are using.

Mechanically, it will function similarly.

Figure 2-5: Attaching the charger adapter with the plug adapter

053-644, Rev E Page 12 eg4 & eg3

Page 19

Docking station functionality

13

EdgeDock1 LED indicator

Amber indicates “ON”.

Charger adapter cord

Powering EdgeDock1 or EdgeDock5

Powering EdgeDock1 or EdgeDock5

1. Assemble the charger adapter and plug adapter as illustrated in Figure 2-5. (It will be the

same process for an EdgeDock5.)

2. Plug the charger adapter directly into the wall (electrical wall plate).

3. Plug the opposite end into the power connector (or jack) of the EdgeDock1.

NOTE: a light, solid red light will appear indicating power to the charger.

Figure 2-6: Attaching charger adapter to EdgeDock1 and EdgeDock5

053-644, Rev E Page 13 eg4 & eg3

Page 20

Docking station functionality

14

Open cavity & contacts

Slides into “Hook” of

EdgeDock. The

contacts will align to

each other.

Docking station LED

Hook

Contacts

Backside of Edge

EdgeDock1

Dosimeter LED dock

1

2

3

Docked

Charging your dosimeter

The number of hours you have used your dosimeter from your last charge will impact your total

charge time. For example, if the battery clock indicator (see “Checking the battery power” for

more information) displays 20 hours remaining on the battery and you wish to charge the battery,

the approximate charging time is 2 hours.

To charge a fully discharged battery, allow approximately 4 to 4.5 hours of charge time.

How to charge

1. Plug in the power adapter to the EdgeDock. (See Figure 2-6, page 13.)

When powered on, the EdgeDock bottom LED indicator will appear solid amber.

2. Slide the Edge (1) downward onto the Hook of the EdgeDock. (See Figure 2-7 below).

NOTE: When the dosimeter is docked, the top LED indicator on the base will be

illuminated. A red flashing LED indicates it is charging. A green solid LED indicates a

fully charged battery.

053-644, Rev E Page 14 eg4 & eg3

Figure 2-7: Docking the Edge with a single and 5-bay docks

Page 21

Docking station functionality

15

Screw slots

Used to mount to a wall

Mounting the docking station to a wall

The docking station is equipped with two single screw slots in case you wish to mount the docking

station to the wall. The figure below displays the backside of the single bay dock.

Figure 2-8: Backside of EdgeDock1

To preserve the life of the battery, it is suggested that the dosimeter is turned off when you are

storing the dosimeter.

Additionally, if the dosimeter is docked and stored on the docking station when it is powered off, it

will still draw a small amount of battery power from the dosimeter. Thus, it is recommended to

store the dosimeter(s) separately from the docking station.

053-644, Rev E Page 15 eg4 & eg3

Page 22

Understanding what data is stored

16

CHAPTER

3

Family:

Noise Dosimeters

Edge model

Setup:

Select to

access the

acoustic family

Download panel

Noise studies

Chapter 3:Setting-up the Edge via DMS

The eg4 model comes equipped with two customizable user setups. The eg3 model has

one customizable user setup. You have the option to customize the parameters for

threshold values, exchange rate values, an upper limit value, and a criterion level.

This chapter explains data storage, the pre-set views on the dosimeter, and how to

customize the parameters and display of your Edge via DMS. It concludes with an

explanation of downloading data from the dosimeter to the software.

Figure 3-1: Edge setup and retrieve data buttons in DMS

When you are running noise dosimetry studies, there are two types of data stored on the

dosimeter which include the summary data and time history (or Logged) data.

053-644, Rev E Page 16 eg4 & eg3

Page 23

Understanding what data is stored

17

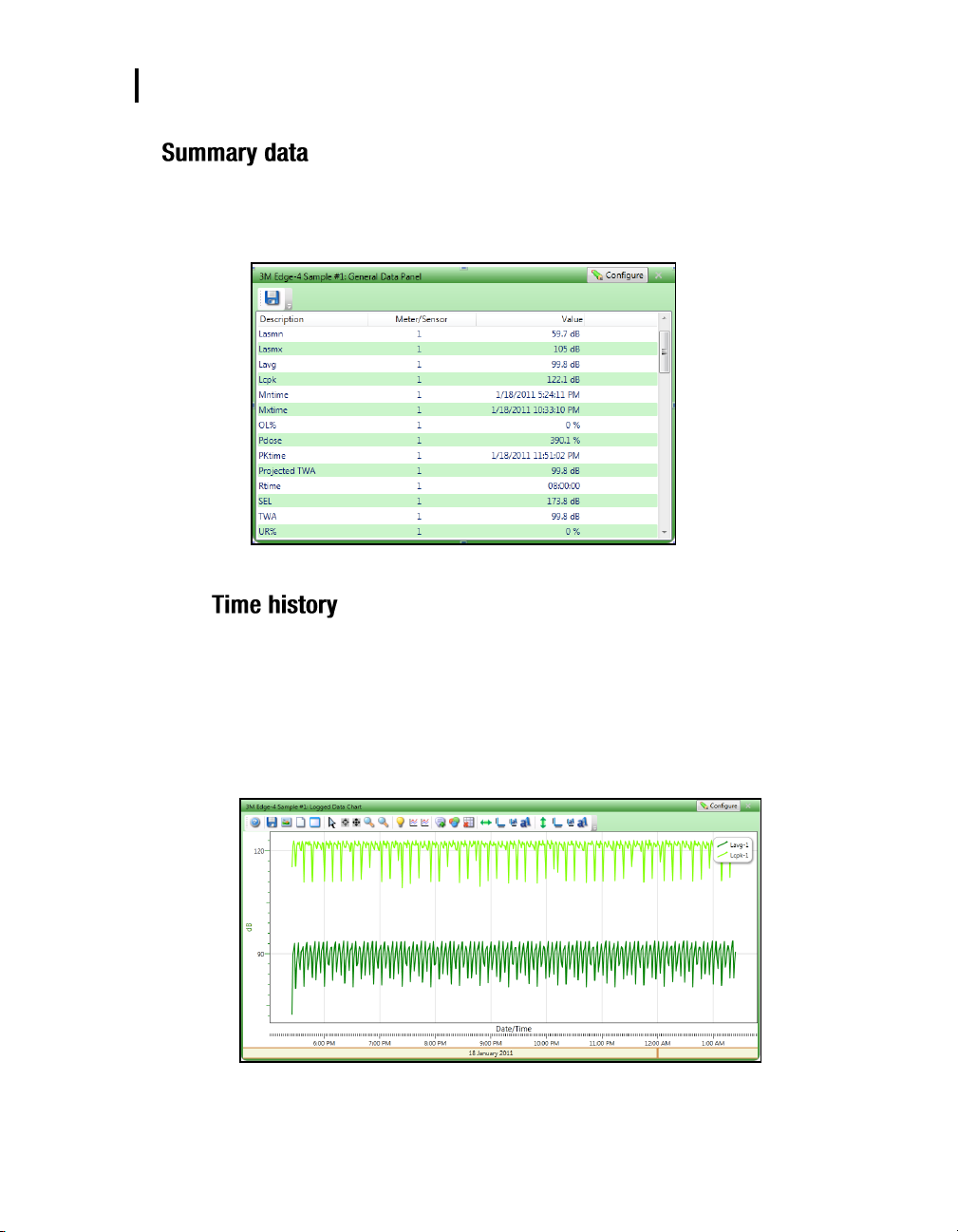

Summary data

Summary data represents values that occurred over the entire run of the study. For an

average value, such as Lavg, it represents the average decibel value over the entire run

time. Peak and Max values are the highest measurements that occurred throughout the run

time.

Figure 3-2: Sample summary data from DMS reporting

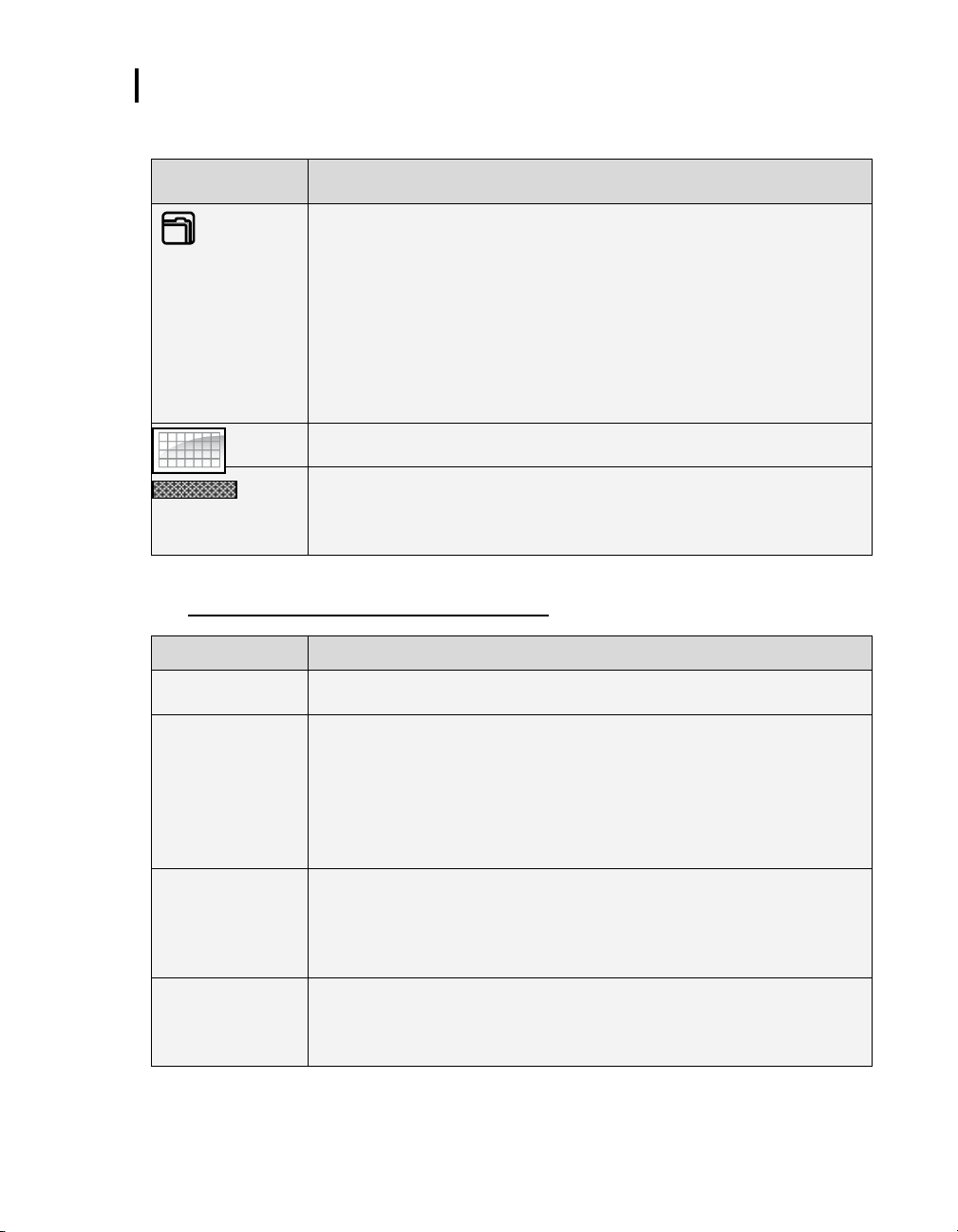

Time history data is also referred as “logged data” which plots measurement values in

minute by minute intervals.

Time History data represents values that occurred over the most recent time period, which

is the logging interval. For example, if the log interval is 1 minute, then the Peak value is

the highest Peak value for that 1 minute, and the Lavg value is the average dB value for

that 1 minute.

Figure 3-3: Sample time history data (or logged data) chart

053-644, Rev E Page 17 eg4 & eg3

Page 24

Views on the Edge

18

Edge:

customize

what appears

on the display

Measurements/parameters

which appear on the Edge

Logging

eg4 model only logs at one minute intervals and includes the following measurements:

Meter 1 logs Lavg/Leq, Lcpk, and Lasmx

Meter 2 logs Lavg/Leq

If the dosimeter runs for one hour, then it will log 60 Lavg/Leq results, and 60 Lasmax/Lcpk

levels. In DMS, you can customize the logged data chart results by checking Lavg/Leq,

Lcpk, and/or Lasmax measurement values when using the button.

The Edge is a user-friendly and customizable dosimeter. In DMS, you may select the

appropriate measurement values or views to appear or not appear on the display of your

dosimeter using the Display Setup configuration as displayed below. Table 3-1 briefly

identifies the displayed data values and views with a brief definition. (See the glossary for

additional information of these terms.)

Note: The measurements/parameters are viewable in charts and graphs in DMS when

downloaded.

053-644, Rev E Page 18 eg4 & eg3

Page 25

Views on the Edge

19

Views on the

EDGE

Explanation

LAS

Sound pressure level - is the basic measure of noise loudness,

expressed in decibels. (In DMS this is noted as “SPL”)

L

ASMX

Maximum sound level- is the highest sound level recorded during a

measurement interval with a particular response setting (Slow or Fast) and

weighting (A or C). LMax is the highest value that is included in LAvg or

dose calculations.

Under OSHA regulations, unprotected workers may not be exposed to

maximum sound levels greater than 115 dB, measured with a Slow

response rate.

L

CPK

Peak Level - is the highest instantaneous sound pressure level recorded

during a measurement interval. Unlike the maximum level, the peak is

detected independently of dosimeter settings for response rate or

weighting.

Under OSHA regulations, unprotected workers may not be exposed to

peak sound levels greater than 140 dB.

L

ASMN

Minimum sound level - The lowest sampled sound level during the

measurement interval allowing for the unit’s Response Time setting (Fast

or Slow).

L

AVG

Average sound level - (in dB) computed for a chosen time duration,

based on a 4, 5, or 6 dB exchange rate. L

AVG

with a 3 dB exchange rate is

referred to as LEQ (equivalent sound level). All sound levels at or above

the threshold level are averaged into the calculations relating to noise

exposure. L

AVG

is typically calculated with no threshold, with a threshold of

80 dB or with a threshold of 90 dB.

Definitions of data log values and views

To set up the Edge and work with noise-level data, you will want to have a good

understanding of the terms listed in Table 3-1.

NOTE: The following table is based on A-weighted, slow measurements. Thus, if you

choose A or C-weighted with Fast or Slow response the measurement values will change

on the display (i.e., you selected sound pressure level with C-weighting with Fast response,

it will display as LCF.) For further details, please see “Dosimeter measurement

descriptors/variants” in Table 3-2.

Table 3-1: Dosimeter views and definitions

053-644, Rev E Page 19 eg4 & eg3

Page 26

Views on the Edge

20

Views on the

Edge

Explanation

L

TWA

Time-weighted average - is the sound level (in dB) that is accumulated for any time period but

with its average level computed over an 8-hour period. TWA is usually measured with A-weighting,

Slow response, and a 5 dB exchange rate.

calculations relating to noise exposure. TWA is calculated with no cutoff, with cutoff 1 (typically 80

dB), or with cutoff 2 (typically 90 dB).

If the time period is less than 8 hours, the TWA will be less than the Lavg/Leq.

If the time period is more than 8 hours, the TWA will be more than the

Lavg/Leq.

LAE

Sound Exposure Level (SEL) – The sound exposure level averages the

sampled sound over a one second period. Assuming the sampled run time to

be greater than one second, SEL is the equivalent one-second noise that

would be equal in energy to the noise that was sampled. SEL is typically

measured using a 3 dB exchange rate without a threshold. (LAE is not used by

OSHA.)

Dose

Dose - Related to the Criterion Level, a dose reading of 100% is the maximum

allowable exposure to accumulated noise. For OSHA, 100% dose occurs for

an average sound level of 90 dB over an 8 hour period (or any equivalent

exposure). (Please see Glossary of Terms for more details, page 59).

UL

Upper Limit - is the amount of time that the sound level exceeds a preset

level (the Upper Limit).

Response Level

(Fast, Slow)

Typically, noise is not constant. Using a response of Slow or Fast simply

flattens the noise fluctuation and makes the sound level easier to work with.

Slow: 1 second (1,000 milliseconds, or msec)

Fast: 0.125 second (125 milliseconds)

RT

Run Time - The overall time of your noise study.

Weighting

(A, C)

A and C weighting are types of frequency filters that cover the frequency range of human hearing

(20Hz to 20 kHz).

“A” weighting: The “A” weighted filter attempts to make the dosimeter respond closer to

the way the human ear hears. It attenuates the frequencies below several hundred hertz as

well as the high frequencies above six thousand hertz. “A” weighted measurements are

often reported as dBA.

“C” weighting: provides a fairly flat frequency response with only slight attenuation of the

very high and very low frequencies. “C” weighting is intended to represent how the ear

perceives sound at high decibel levels and is often used as a “flat” response when LINEAR

is not available. “C” weighted measurements are often reported as dBC.

Definitions of data log values and views

Table 3-1: Dosimeter parameters and definitions (continued

053-644, Rev E Page 20 eg4 & eg3

Page 27

Views on the Edge

21

Views on the

Edge

Explanation

Memory storage symbol –

eg4: The eg4 model displays the total memory storage

remaining in hours and minutes. For example, if it displays the

memory symbol 181:50 this represents 181 hours and 50

minutes of memory storage remaining on the dosimeter.

eg3: The eg3 model displays the memory by indicating the

remaining number of studies it will store into memory. For

example, if the eg3 displays “50” this indicates you can store 50

studies on the dosimeter. (Note: the difference is because the

eg3 model does not data log.)

Calendar symbol– The calendar symbol and calendar field

displays the day-month-year

Battery power clock symbol – The battery power clock

symbol identifies the number of hours and minutes of battery

time remaining on the dosimeter.

Descriptors

Variants

Lmax variants

Sound pressure level - is the basic measure of noise loudness, expressed

in decibels. (In DMS this is noted as “SPL”)

L

ASMX

Maximum sound level- is the highest sound level recorded during a

measurement interval with a particular response setting (Slow or Fast) and

weighting (A or C). LMax is the highest value that is included in LAvg or

dose calculations.

Under OSHA regulations, unprotected workers may not be exposed to

maximum sound levels greater than 115 dB, measured with a Slow

response rate.

L

CPK

Peak Level - is the highest instantaneous sound pressure level recorded

during a measurement interval. Unlike the maximum level, the peak is

detected independently of dosimeter settings for response rate or weighting.

Under OSHA regulations, unprotected workers may not be exposed to peak

sound levels greater than 140 dB.

L

ASMN

Minimum sound level - The lowest sampled sound level during the

measurement interval allowing for the unit’s Response Time setting (Fast or

Slow).

Definitions of data log values and views

Table 3-1: Dosimeter parameters and definitions (continued)

Edge Measurement descriptors/variants

The following is an explanation of the Edge descriptors and equivalents for Lmax, Lmin, & Lpk.

053-644, Rev E Page 21 eg4 & eg3

Table 3-2: Dosimeter measurement descriptors/variants

Page 28

Docking

22

A

B

C

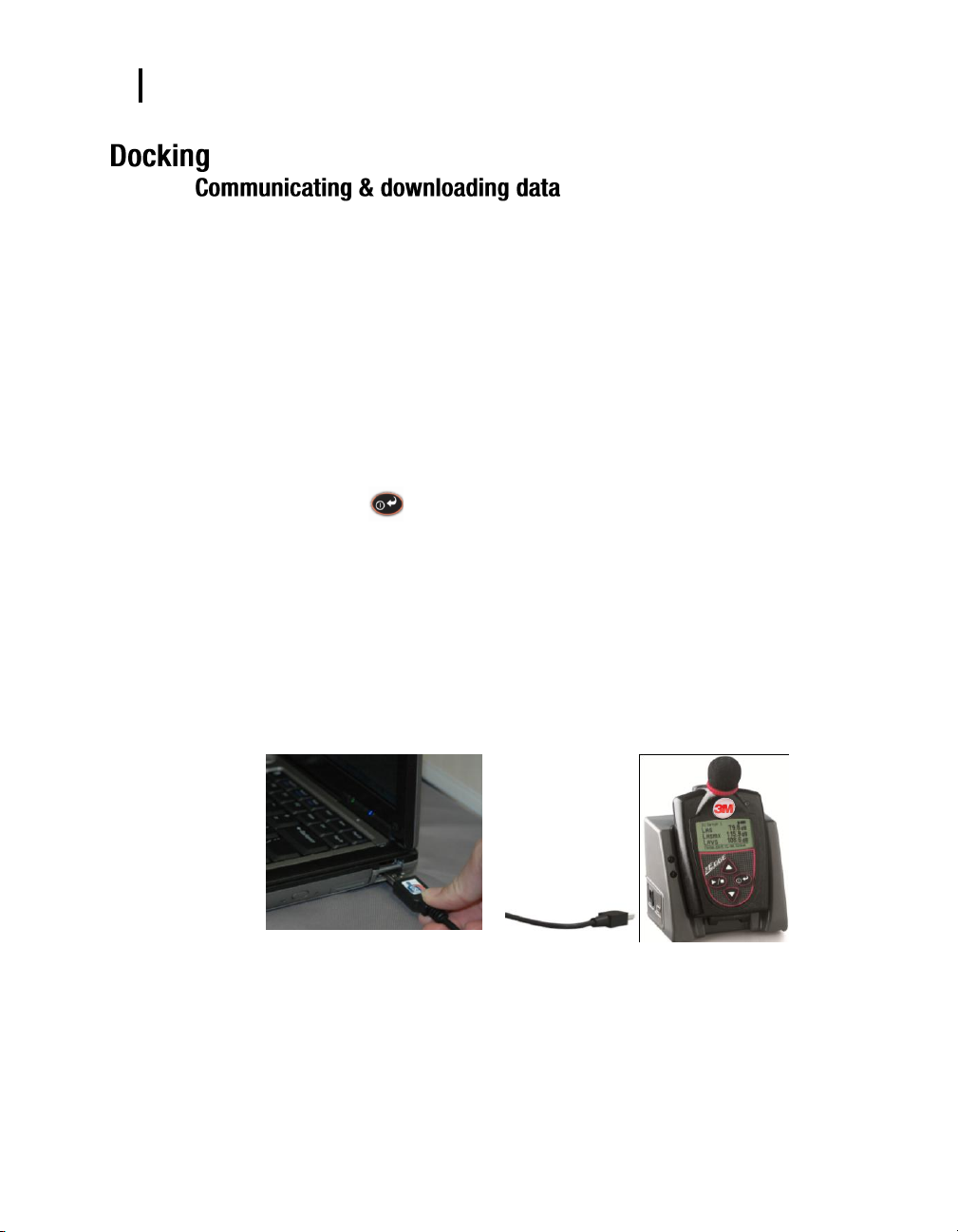

Communicating & downloading data

By using your docking station, USB cable, software, and your dosimeter, you can quickly

communicate between the software and the dosimeter. There are two methods for

communicating which are:

Send setup data: Enables you to configure your set-up parameters in 3M

Management Software and download these parameters to the Edge.

Retrieve data: you have the capability to retrieve the data from the dosimeter into

DMS in order to view and analyze your studies in DMS’ charts, graphs, and reporting

functionality.

How to connect your dosimeter to the computer

1. Dock the dosimeter on the EdgeDock1 (or 5) and turn on the dosimeter by

pressing the button.

2. Plug the USB cable into the computer. (See “A” in Figure 3-4).

3. Plug the opposite end into the docking station (See “B” and “C”).

NOTE: The docking station will be powered through the computer; thus, it is not

required to attach the charger adapter. If you wish to charge the dosimeter, plug in the

charger adapter. (Please see Charging for more information.)

Figure 3-4: Communicating - connecting a docked Edge to a pc

TM

Detection

053-644, Rev E Page 22 eg4 & eg3

Page 29

Docking Customizing set-up parameters in DMS

23

Example of EdgeDock-5

with Edge 4 selected in the

first bay.

Communicating & downloading data

4. For first time use of a docking station, Welcome to the found new hardware

wizard will appear (see Figure 2-8). Select No and press Next through the

remaining wizard. At the end of the wizard, press Finish.

This will install the hardware components associated with your EdgeDock1 and/or

EdgeDock5.

NOTE: If you have more than one EdgeDock1 or EdgeDock5, this wizard will

appear for each new dock which is connected to your pc.

Figure 3-5: New Hardware wizard for Edge Dock

053-644, Rev E Page 23 eg4 & eg3

Customizing and saving set-ups are performed via DMS. The following sections discuss each

of the setup screens and explain how to save and send the parameters to the dosimeter(s).

NOTE: The following DMS settings apply to the eg4 model. If you are also using other models

such as the eg3/eg4 and have them docked in a 5-bay charger, they will appear in the “Edge

Bay Charger” tree section. If you are also using other models (eg5) and have them docked in

a 5-bay charger, they will appear in the “Edge Bay Charger” tree section with a icon. To

select Edge 5 models, first select the Model (on the left-hand panel) and then click the refresh

button. The instruments are selected by clicking in the checkbox(es).

Page 30

Customizing set-up parameters in DMS

24

Dosimeter settings

explained in the

Edge dosimeter

settings (below).

1

Dosimeter setting

The Edge general settings are used to setup the instrument with basic parameters. The eg4 model

features two virtual dosimeters in one with two customized, user-defined settings. Please refer to

the Edge dosimeter settings table below for an explanation of setup details.

1. Click on the Dosimeter tab from the Edge’s Instrument Configuration panel (see 1). To change

the dosimeter settings, follow one (or all) of the selection options below.

Click on the checkbox to enable the dosimeter (LED) heartbeat, Dose indicator LED,

and/or the Meter 1/Meter 2 Threshold settings.

Click in the circular button to select the response time (fast or slow), peak weighting (C or

Z), and/or RMS Weighting (A or C).

To set the numeric fields either type in a value or use the arrows to enter appropriate

values for the Meter1/Meter 2 settings (threshold, upper limit, exchange rate, criterion level,

and RMS weighting).

2. When Meter 1 and Meter 2 settings are “enabled”, this will log (for eg4 model only) two different

setups simultaneously. Typically, users will set the meter 1 and meter 2 with different regulatory

or local standards (such as EU directive and OSHA).

3. To set the dosimeter settings, save and send to the Edge (for more details see “Saving and

sending configurations”).

Figure 3-6: Dosimeter screen

053-644, Rev E Page 24 eg4 & eg3

Page 31

Customizing set-up parameters in DMS

25

Dosimeter settings for the Edge

Name Field

*Note: refer to Glossary for more detailed information.

Heartbeat enable

When enabled (or checked), the LED will flash green while running

and flash amber when stopped.

Response

Either Slow Time Response or Fast Time Response is applied to

the measurements. (Typically Slow time response is used in the

US market while Fast is used in the EU communities.)

C-A enable

When enabled (or checked), C minus A will be calculated.

Projected Time

A selectable time parameter via the up/down arrows or type in a

value. The projected time value is used to make projected dose

calculation for the dose measurement.

Peak Weighting

Select either A, C or Z for the peak frequency weighting.

Dose indicator LED

When enabled (or checked), the LED will flash red when the dose

value exceeds the designated entered value.

Setup name

(Optional field) A setup name may be entered into the Meter 1

and/or Meter 2 fields. When set, it appears on the top of Edge’s

display (example setup names: OHSHA, MSHA, EU directive).

Threshold enable

When the checkbox is selected and a value is entered for meter 1

and/or meter 2, the threshold is used to calculate Lavg, TWA, and

Dose measurements.

Upper Limit

Select a UL dB level by the up/down arrows or by typing in a value.

(Note: The upper limit (UL) is a measurement setting in which the

user selects a specific decibel level. The UL value records the

amount of time that the Sound level is at or greater than the

entered level.)

RMS Weighting

Select either A or C RMS Weighting. (Note: The RMS (root mean

square) are the results from the Edge with the response time and

weighting settings taken into account.)

Criterion Level

Select a Criterion level via the up/down arrow or by typing in a

value. (Note: Criterion level is the average SPL that will result in

100% dose over the criterion time and is typically set by a

regulatory agency such as OSHA, EU directive.)

Exchange Rate

Enter in (or select with up/down arrows) 3, 4, or 5 dB. ER refers to

how sound energy is averaged over time. (OSHA uses a 5 dB

doubling rate while most of the world uses 3 dB.)

Dosimeter setting

Table 1-2: Dosimeter fields explained for the Edge

053-644, Rev E Page 25 eg4 & eg3

Page 32

Customizing set-up parameters in DMS

26

1 2 3 4 4

Display setting

The display screen is used to customize the parameters which will appear on your Edge. It is organized

by two columns, the “Display position” and the “Item to Display” and includes a “Set selected Items”

selection/drop down box. The display position indicates the order of the parameter (or item) which will

appear on the display, while the “Item to display” designates the measurement or parameter. The

example/figure below displays the SPL, Max, Min, Lavg, TWA, Dose, UL, RT, and battery time remaining

parameters to appear on the display. (Note: There are up to 18 selectable parameters. Off indicates no

item will appear.)

1. Click on the Display tab from the Edge’s Instrument Configuration panel (see 1). To customize the

display, click on either the Display position (see 1) or the Item to Display field (see 2). The field will

be shaded in blue when selected.

2. Click on the drop down box of the Set Selected Item field (see 3) and select a parameter (see 4).

3. Repeat these steps as needed to select each position.

NOTE: “OFF” indicates that no item/parameter is selected.

4. To set the display features, save and send to the Edge (for more details see “saving and sending

configurations”.)

Figure 3-7: Edge display screen

053-644, Rev E Page 26 eg4 & eg3

Page 33

Customizing set-up parameters in DMS

27

1 2 3

Security setting

The security setting is a type of “locking” feature (or secure run feature) that enables you to password

protect the instrument to prevent users from inadvertently terminating a study. Initially, this feature is set

through the software and turned on once in run mode by pressing run/stop key three consecutive times.

(To unlock, press run/stop key three consecutive times and then press power key.) To set this feature,

please follow the steps below.

1. Click on the Security tab from the Edge’s Instrument Configuration panel (see 1). To enable, click on

the Enabled check box. (Ensure the specific Edge is selected and communicating to the software.

See “Communicating and downloading” for more information.)

2. Next, select either Not Displayed (see 2) or Displayed (see 3) for the measurement visibility.

Note: if measurement visibility is set to “not displayed” then a padlock icon appears on the Edge

display. If displayed is selected, the measurements appear with a small padlock in the header

section of the display indicating the instrument cannot be stopped during a run while in secure run

mode.

3. Click the button to set the security setting (for more details, see “Saving and sending

configurations”.)

Figure 3-8: Edge security setting

053-644, Rev E Page 27 eg4 & eg3

Page 34

Customizing set-up parameters in DMS

28

2 3 4

1

Auto Run setting

With the Edge auto run setting, you may program up to two auto start and auto stop configurations when

start date and duration parameters are enabled. This may be useful if you wish to pre-set the

instruments to run and stop for a specific time period, such as a week long study. See steps below to

enable.

1. Click on the Auto Run tab from the Edge’s Instrument Configuration panel (see 1) and click in the

Enable auto run mode checkbox (see 2).

2. To program Date 1, click in the Enabled checkbox and select a Start Date (by using the calendar

icon or type in a date). Select the Duration, by either typing in the time (designated in hours,

minutes, and seconds) or using the up/down arrows (see 3). (Repeat this step to setup a second

Auto run mode, except select Date 2. See 4.)

3. Click the button to set the auto run setting (for more details, see “Saving and sending

configurations”.)

Figure 3-9: Edge auto run screen

053-644, Rev E Page 28 eg4 & eg3

Page 35

Customizing set-up parameters in DMS

29

1 2 3

Firmware update

Edge firmware updates are performed in DMS when the instruments are docked, communicating, and

the update key is selected. Please follow the steps below prior to updating your Edge(s). Note: this

feature enables you to update all of your docked Edges (when powered on and not in run mode).

1. Click on the Firmware tab from the Instrument Configuration panel (see 1) and ensure to dock the

Edge (or Edges) . Please read steps under “Firmware Update” prior to updating (see 2).

Press button to refresh the docked instruments (if necessary).

2. Press the button and please wait until the software states that it is Done. (Example of the

message, See 3).

Figure 3-10: Edge firmware update screen

053-644, Rev E Page 29 eg4 & eg3

Page 36

Customizing set-up parameters in DMS

30

2 3 1

Saving and sending/setting configurations

With the Edge, there are saved setup profiles used to quickly access and apply to The Edge(s). Below

explains how to save configuration settings in DMS and how to send/set to the instrument. Note: if you

wish to only send the setup, please skip to step 3. Please refer to this section as you setup your

instrument.

1. To save the Edge configuration in the software, click on a name in the Configuration Profile

Management panel (See 1). Note: The name will be shaded a light gray when selected.

To create a new profile name, click and type in a profile name. Click Save. (It will save

under the configuration profile management panel).

2. Click on the button (see 2) and type in a Name. Click Ok.

Note: This saves the configuration file in the software.

Or click button and rename the setting by typing in a name. Click Ok.

3. To send to the instrument, select the (see 3).

Figure 3-11: Saving and sending Edge setups

053-644, Rev E Page 30 eg4 & eg3

Page 37

Overview of running a study

31

CHAPTER

4

Quick Help List: typical dosimetry session

1. Turn the dosimeter on and check your battery power.

2. Reset the dosimeter.

3. This will clear out all of the data history before your study begins to ensure you have

sufficient memory space on the Edge.

4. Set-up your study parameters via DMS.

5. Calibrate the dosimeter.

6. Attach the dosimeter for your personal noise study.

7. Press the Run/Stop button to start the study.

8. When you are ready to end your study, press the Run/Stop button to stop the study.

9. Review your results either on the meter or download to DMS for further analysis

(graphs/charts, saving and printing).

Running and operating your dosimeter

The focus of this chapter is to discuss the procedures for running and operating the Edge and

includes positioning, calibrating, and viewing the Edge measurements.

The list below is a brief overview of the steps for running a study.

Figure 4-1: Quick help list for running a study

053-644, Rev E Page 31 eg4 & eg3

Page 38

Overview of running a study

32

Positioning

Positioning the Edge on your shirt

Depending on what accessories you ordered with the Edge, you may have either clips on the top

and bottom of the dosimeter or some other type of mounting device. (Please refer to Appendix

A, “Contacting 3M Quest”, page 59).

How to attach the dosimeter

1. Clip the dosimeter on your shirt and ensure the microphone is positioned as high on your

shoulder as possible and away from your neck.

a. If the noise seems to come from one direction, place it on the shoulder and near the

noise source.

b. During monitoring, keep clothing from coming into contact with the windscreen to avoid

contaminating your results.

Figure 4-2: Positioning/Attaching the Edge

Before measuring, ensure the windscreen is free from any accumulated dirt. If you ordered a kit

(as explained in Chapter 2), there are replacement windscreens in the carrying case for your

convenience. Please refer to Figure 6-1, on page 50 for details on replacing the windscreen.

053-644, Rev E Page 32 eg4 & eg3

Page 39

Overview of running a study

33

Battery indicator icon

When fully shaded, this

indicates full battery life.

Battery time remaining

Checking battery power

Typically, the life of the battery is approximately 60+ hours (see Appendix A for specific

specifications). The dosimeter can be charged at any time by using your EdgeDock.

There are two battery identifiers on the dosimeter which are the battery indicator icon and the

battery power clock (see Figure 4-3).

Checking battery power

1. The battery indicator icon (located at the top right of your screen) gives an approximation of

battery life and is always present.

If the battery indicator is half shaded, this illustrates you have approximately 30 hours of

battery life remaining.

If lobat appears, less than 8 hours of run time is available.

2. Additionally, there is a battery time remaining measurement which identifies the number of

hours and minutes remaining on the dosimeter.

3. To view, press the up/down arrows . This will navigate your through the views of the

dosimeter.

NOTE: The battery time remaining measurement can be disabled from the view of the

meter. See Chapter 3 for explanation on changing the display.

Figure 4-3: Battery indicators

053-644, Rev E Page 33 eg4 & eg3

Page 40

Overview of running a study

34

“CAL” flashes

Calibrating

3M Quest Technologies recommends to calibrate your dosimeter before you run your study(ies)

and after your study(ies) to ensure highly accurate measurement results. The steps below

address how to calibrate for either a pre or post calibration.

Calibrating the dosimeter

1. Remove the windscreen from the dosimeter by unscrewing it. (See Figure 6-1 for an

illustration, page 50.)

2. Ensure the Edge is turned on and in the stop mode. (See “Turning on” page 8, and “Turning

Off” page 9).

3. Slide the Edge into the mouth of the calibrator.

NOTE: ensure the adapter ring is inserted into the mouth of the calibrator before you slide the

Edge into the cavity.

4. Turn on the calibrator and ensure parameters are set to 114 dB and 1000 Hz. (See calibration

manual for operation details.)

Figure 4-4: Calibrating

5. “CAL” will flash on the display when detected.

6. Press the on/off enter button to trigger the calibration display.

7. To match the values on the calibration display, press repeatedly the up or down arrow in

order to select the exact output on the calibrator (i.e., 114 dB).

8. When you have selected the appropriate dB level, press the on/off enter button.

A shaded bar will appear loading your calibration information. Then a summary calibration

screen will appear indicating the db level with date and time displayed.

9. To return to the measurement view screen, press the on/off enter .

10. To end the calibration steps, turn off the calibrator. Detach the dosimeter from the calibrator.

053-644, Rev E Page 34 eg4 & eg3

Page 41

Overview of running a study

35

Edge Splash screen

Arrows and enter key

Indicates the valid keys

are selected

Checkmark icon

Is the selection to

exit the setup menu

Reset icon

Resetting the dosimeter

The Edge can be reset through the dosimeter keypad or via QSP-II. The steps below outline how

to reset your dosimeter.

Reset

1. Ensure the meter is Off.

2. Turn the meter on by pressing the on/off enter button.

3. When the splash screen appears, press and hold the run/stop and on/off enter

buttons until the splash disappears.

Figure 4-5: Splash screen

4. The Setup menu appears on the Edge. Press the up or down arrow to select the reset icon

(symbol).

NOTE: Setup menu is used to reset the dosimeter, change the contrast, and return to the

main view.

Figure 4-6: Resetting the Edge from the keypad

5. Press and hold the on/off enter button.

A 3, 2, 1 countdown will appear, and then a shaded bar will appear indicating the dosimeter is

being reset.

6. Press the down arrow until the checkmark icon is selected (denoted by the arrows). Then,

press the on/off enter button to return to the measurement view screen.

053-644, Rev E Page 35 eg4 & eg3

Page 42

Overview of running a study

36

Checkmark icon

Is the selection to

exit the setup menu

Contrast icon

Arrows and enter key

Indicates the valid keys

are selected

Setting contrast on dosimeter

Contrast

1. Ensure the meter is Off.

2. Turn the meter on by pressing the on/off/enter button.

3. When the splash screen appears, press and hold the run/stop and on/off enter

buttons. (See figure 4-5 for splash screen).

4. The Setup menu appears on the Edge. Repeatedly press the arrow key until the Contrast

symbol is selected.

NOTE: Setup menu is used to reset the dosimeter, change the contrast, and return to the

main view.

Figure 4-7: Changing the contrast from the keypad

5. Next press the on/off enter button.

6. A number will appear on your display (i.e., 50). Press the up or down arrow to increase or

decrease the contrast of the Edge.

7. Press on/off enter button to accept the new contrast value.

8. To return to the measurement view screen, press the down arrow and press the

on/off/enter button.

053-644, Rev E Page 36 eg4 & eg3

Page 43

Running studies

37

Run indicator

Appears when running

Battery indicator

Flashing green LED

indicates running

Measurements

Use up/down arrow

to move through

values.

Views are

customizable via

QSP-II setup

Starting a run

With a couple pushes on the keypad buttons, you will be running and viewing your study (ies).

Following your study (ies), you can load the data/files into QSP-II to manipulate, analyze, save,

and create reports (See Chapter 5 for viewing your logged data in QSP-II).

How to run a noise study

1. If your dosimeter is turned off, press the on/off enter button to power on.

2. Press and hold the run/stop button.

3. When running, the following will appear:

A 3, 2, 1 countdown will appear.

A run indicator will appear on the top-right side.

The LED indicator will flash green (unless you disabled this in DMS.)

Figure 4-8: Display screen while running

053-644, Rev E Page 37 eg4 & eg3

Page 44

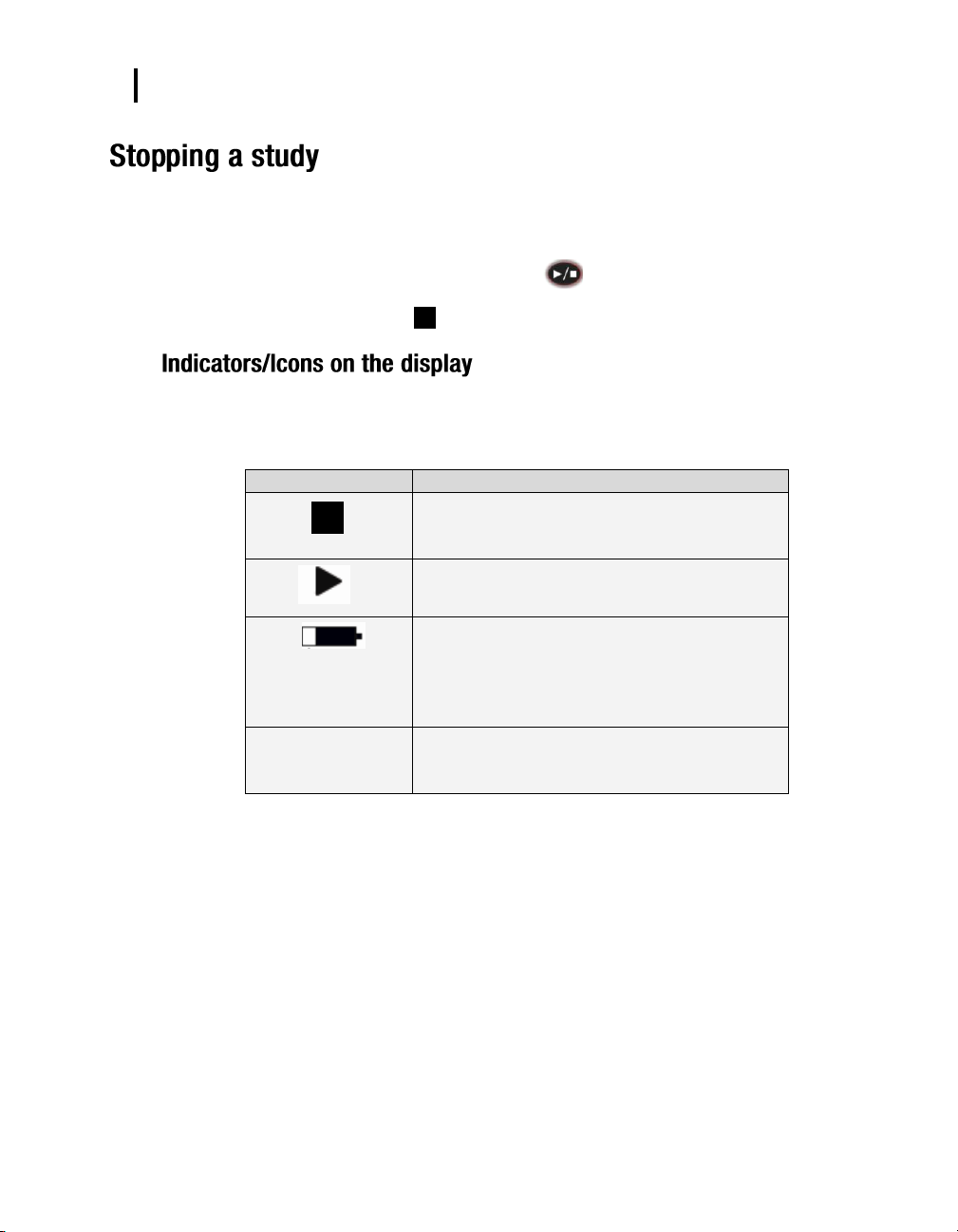

Stopping a study

38

Indicator Icon

Explanation

Stop – indicates the dosimeter is currently in

the stop status (opposed to run).

Run - indicates the dosimeter is currently

logging a study.

Battery charge status – When completely

shaded in black, this indicates full battery

power. If half shaded, this represents ½ battery

power

OL

Overload –will appear whenever the input

signal exceeds the range of the dosimeter.

Indicators/Icons on the display

While the dosimeter is running, you can end the study by pressing and holding the stop button.

How to stop a noise study

1. While running, press and hold the run/stop button.

a. A 3, 2, 1 countdown will appear.

b. The stop indicator will be shown in the display.

The Edge is equipped to notify you of operational/status updates. These indicators (or alert

notices) are located on the top right-hand side of the screen. Table 4-1 explains the function of

each indicator.

053-644, Rev E Page 38 eg4 & eg3

Table 4-1: Indicators (i.e., run, stop, battery, and OL)

Page 45

Viewing measurements on the display

39

Measurement views

on the Edge

Locking or securing your dosimeter during run

The up/down arrows on the keypad of the dosimeter enable you to move through the

various measurements. For specific information on the views of the Edge, please see

“Views on the Edge”, page 18).

Viewing measurements

1. Press the or arrows. This will move you through the views on the display.

NOTE: If you enabled only one measurement to appear on the display, when you

press the up/down arrows it will not show any other measurement values. (To enable

additional measurement settings, see the “Edge Display Screen”.)

Figure 4-9: Measurement view on the Edge

053-644, Rev E Page 39 eg4 & eg3

As explained previously under DMS set-up parameters, the security or lock feature is

designed to lock the meter during run to ensure the study will not be stopped unless the

lock feature is disabled. (Setting this feature is programmed via DMS. Please see “Security

Setting”, page 27 for more details.)

Page 46

Viewing measurements on the display

40

Padlock icon

Secure all

Key indicator

Indicates dosimeter is

locked while running.

Locking or Securing

How to lock or secure

1. Turn the dosimeter on and press the run/stop button to begin logging your study.

2. To enable the lock, press run/stop button three consecutive times within one

second intervals.

The Lock screen will appear.

Figure 4-10: Locking/Securing run

NOTE: If lock/secure run does not activate, please check that locking is set-up on your

dosimeter. Please see “How to set-up secure/lock”, page 30 for further details.

How to unlock

1. To unlock, press run/stop button 3 consecutive times, within one second

intervals, and then press the on/off enter button.

a. If the padlock icon and the key indicator were on the screen, these will vanish and

the measurement view will appear along with the run indicator.

b. If you enabled the lock feature (with the key indicator showing and the

measurement view showing), then the key indicator will disappear.

2. To stop your study, press the on/off enter button and the 3, 2, 1 will display as it

ends the study.

a. To download and view your results in DMS, please see Chapter 5.

053-644, Rev E Page 40 eg4 & eg3

Page 47

Viewing measurements on the display

41

CHAPTER

5

Downloading data

The focus of this chapter is to discuss how to view your studies with the 3MTM Detection

Management Software (DMS). The first section explains how to retrieve your studies from the

dosimeter, and the subsequent sections will then walk you through viewing, organizing, and

customizing your stud.

NOTE: You have the option of ten different languages in DMS including: Chinese (Simplified),

English, French, German, Italian, Korean, Portuguese, Japanese, Russian, and Spanish.

Loading your studies entails communicating, downloading the sessions/studies (files) and viewing

the files in the data finder page, charts and graphs, and/or report views.

Downloading

1. Ensure DMS is downloaded.

Follow the install directions on the CD or visit the website.

2. Dock the dosimeter (s) and connect it to your pc using the USB cable.

Figure 5-1: Communicating between your pc and the Edge

3. Power on the Edge by pressing the button. (Note: the Edge will only download and

communicate when stopped, as indicated by icon on the top of the screen.)

053-644, Rev E Page 41 eg4 & eg3

Page 48

Viewing measurements on the display

42

Download

Noise

Dosimetry

Download button

Optional: click to view files

(sessions/studies) after

download

Edge 3-4

EdgeDock-5 example

Click in the Edge checkboxes to

download specific dosimeters

Edge

1 2 3

4

Downloading data

4. In DMS’ start screen, choose .

Figure 5-2: DMS start screen

5. Select Noise Dosimetry (see 1), Edge (see 2), and Edge 3-4 (see 3) from the family panel.

6. Select the docked Edge (s) to download by clicking in the checkboxes by the EdgeDock-5

section(see 4).

7. Click button.

In the status field, it will state download is successful.

Then, a clear the memory prompt will appear. Click yes to clear the memory or click no if you

Figure 5-3: Downloading with the Edge models eg3/eg4

wish to save the data on the dosimeter.

053-644, Rev E Page 42 eg4 & eg3

Page 49

Viewing measurements on the display

43

Selected

Edge data

Analyze button

1

Quick Report button

Data headings (optional: drag, drop

and/or expand columns to view data)

2

Example of

data file in

recent view

Viewing data and data finder page

8. The sessions (files) will load and post to the Data Finder page under Family: Noise Dosimetry

heading.

Quick tip: click on the button and the data files will post directly under the specific

family. Click on the file and select either to view in charts and graphs.

Figure 5-4: Recent downloaded data

After the data is downloaded, it is stored and viewable in the data finder. With a quick double-click,

the information is viewable in customizable graphs and/or charts.

Selecting and viewing data

1. In the Data Find page (see 1), select the Noise Dosimetry data (see 2) by clicking on either the

session/study (Note: you may need to expand to see the study data.)

Once selected, it will appear with a blue shading.

2. Optional: To reorganize the data displayed in the data finder columns, click drag and drop the

titles of the columns in different positions. To shrink/expand the columns, click and drag the

black column divider(s). (Note: these methods are similar to positioning/expanding in Excel.)

3. To view in Graphs and Tables, click on or buttons.

Figure 5-5: Data Finder page with the downloaded data

053-644, Rev E Page 43 eg4 & eg3

Page 50

Viewing measurements on the display

44

Edge, logged data

chart displayed in

DMS report (scroll

through to view the

online report if

applicable).

Report View

The button provides a quick link to view/print the Edge data. To customize the data,

refer to the next session, panel view page.

Click to print the report.

Figure 5-6: Example of Edge Report in DMS

053-644, Rev E Page 44 eg4 & eg3

Page 51

Viewing measurements on the display

45

1

2

3 4 4

4

Configure

Active cursor

Panel Layout View(charts/graphs)

When you are in the data finder page (see above), select either the Analyze button or double-click on a

session/study to view the data in charts and graphs as displayed in Figure 5-7. The measurements and

parameters will be displayed in charts and graphs which may be customized for analysis and/or reporting

purposes.

1. In the panel layout view page, it is divided into Work Items (see 1), Add panel (see 2), Arrange Panels (see

3) and data panels (see 4).

Work items (1) – select either the session or study (in order to view appropriate measurement/parameter data).

Add panel (2) – double-click on a chart/table type and it will appear as a panel on your screen.

Arrange panels (3) – displays the order of the sessions/studies displayed in the panel section of your screen.

Data Panels (4) – used to view your measurement and/or parameters from your study. Note: use the menu bar icons

and/or configure icon to customize parameters.

Figure 5-7: Panel layout view (viewing the data in charts and graphs)

To stretch the graph, click on one the corner’s edge of a chart or table and drag the mouse. The graph will expand and

widened (depending on how you drag your mouse).

To move the graph, click drag and drop to the appropriate panel position.

To change ranges, when clicking on either the x-axis or y-axis, click and drag the mouse until the appropriate range is

selected. (Note: it will span the numbers up or down depending on how you drag the mouse.)

To add labels, click on the add labels icon. Right-click and select edit text to add note/label on the chart. Type in

text and press the Enter key (on your keyboard). To move the label, left-click and hold to drag to appropriate location

on graph.

To customize chart colors, click on the icon and using the properties box, select different colors as needed.

To customize x or y axis font type, click on these or icons.

To export data to .xls file, click on the export icon.

To save a layout, right-click outside the tables/graphs area as displayed below. Click Remember Setting.

053-644, Rev E Page 45 eg4 & eg3

Page 52

46 Technical Support

CHAPTER

6

Alarm Enable

LED indicator: disable/enable

Technical Support

Some users may prefer to turn off the LED indicator.

To disable this feature, open QSP-II and select the Setup button. On the

dosimeter tab, under Dose% indicator LED uncheck the following:

Alarm enable: Will disable the flashing red LED when the threshold entered

exceeds the designated value during run mode. (If checked, red LED will flash.)