Page 1

Page 1 of 1

Cold Shrink

EC-Series End Caps

Data Sheet

__________________________________________________________________________________

Product Description

3M Cold Shrink End Caps environmentally seal and

mechanically protect exposed cable ends using no tools,

mastics or tapes. They are close-ended, tubular rubber

sleeves that are factory expanded and loaded onto a

removable core. When positioned over the end of a

Removal

Once installed, the 3M Cold Shrink End Caps can be

easily removed from the cable. Simply lift the edge of

the end cap, slice the material with a utility knife and the

end cap comes off cleanly, leaving no adhesive residue

or grease.

cable, or other cylindrical object, the core is removed to

provide a reliable seal which protects your cable ends

from environmental damage. They are easily installed

and cleanly removable. Whether in transit from the

manufacturer, stored in the cable yard, or in process in a

Maintenance

3M Cold Shrink EC-Series End Caps are stable under

normal storage conditions. Normal storage and stock

rotation are recommended.

trench, your cable ends are protected from exposure to

moisture, contamination and corrosion. Four different

Properties

end caps are available to accommodate a wide range of

sizes.

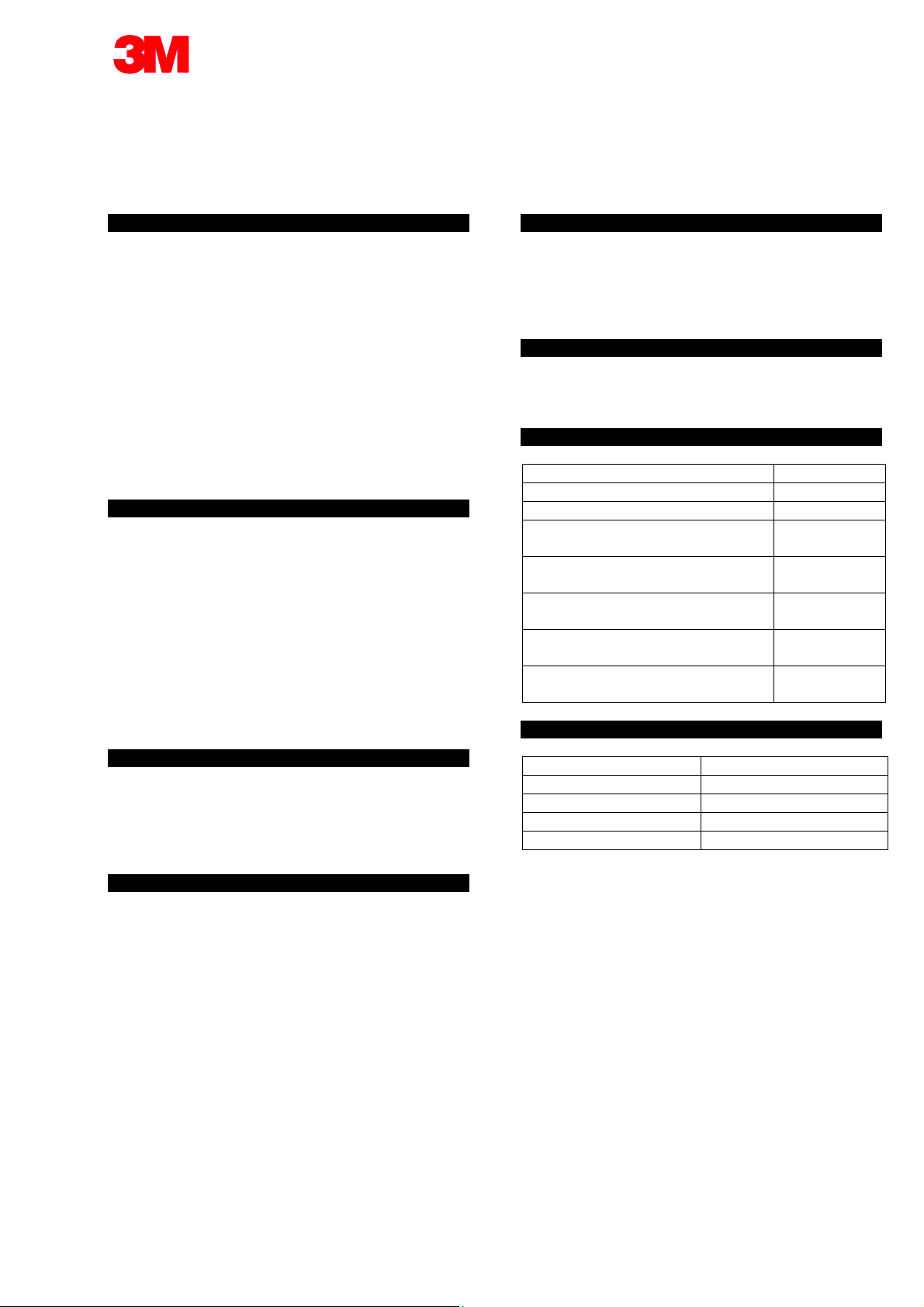

Test Methods Typical Value

Colour Black

Features

Simple and fast installation, no tools required.

Accommodates size ranges from 11.6mm – 84.3mm.

Good abrasion resistance.

Seals tight, retains resiliency and pressure even after

prolonged years of ageing and exposure.

Water-resistant.

No mastic or tape required.

No torches or heat required.

Resists fungus.

Resists acids and alkalis.

Resists ozone.

Easily removed.

No training required for installation.

Applications

The 3M Cold Shrink EC-Series End Caps protect cables,

pipes and other cylindrical objects from exposure to

moisture, contamination, corrosion, ozone, ultra-violet

radiation, physical contact and other environmental

hazards.

Installation

The 3M Cold Shrink EC-Series End caps install quickly

and cleanly without flame or grease. Cold Shrink end

caps are factory expanded on removable innersupporting plastic cores. Once the end cap is positioned

for installation around the end of a cable, the supporting

core is unwound and removed. With the core removed,

the live-memory action of the specially formulated

material shrinks the end cap into position. The constant

radial pressure of the Cold Shrink material ensures a

durable environmental seal. The Cold Shrink material

300% Modulus (ASTM D-412-75) 480 psi

Ultimate Tensile (ASTM D-412-75)

1400 psi

Original

Ultimate Elongation (ASTM D-412-

750%

75) Original

Die C tear (ASTM D-624C-73)

150 pli

Original

Fungus Resistance (ASTM G-21) 28

No Growth

days exposure

Moisture Absorption 7 days @90°C

in H

O

2

1.8% wt. Gain

Selection Chart

Product Number Use Range (mm)

EC-1 11.6 – 20.9

EC-2 15.9 – 30.1

EC-3 26.0 – 49.2

EC-4 45.5 – 84.3

Important Notice

Technical information provided by 3M is based on experience and/or tests

believed to be reliable, but their accuracy is not guaranteed and the results may

not be relevant to every user’s application. For this reason 3M does not accept

responsibility or liability, direct or consequential, arising from reliance upon any

information provided and the user should determine the suitability of the products

for their intended use. Nothing in this statement will be deemed to exclude or

restrict 3M’s liability for death or personal injury arising from its negligence. All

questions of liability relating to 3M products are governed by the seller’s terms of

sale subject where applicable to the prevailing law. If any goods supplied or

processed by or on behalf of 3M prove on inspection to be defective in material

or workmanship, 3M will (at its option) replace the same or refund to the Buyer

the price paid for the goods or services. Except as set our above, all warranties

and conditions, whether express or implied, statutory or otherwise are excluded to

the fullest extent permissible at law. 3M is a trademark of the 3M Company.

Printed in the UK. © 3M United Kingdom PLC, 2001

resists abrasion, fungus, acids or alkalis, and retains its

resiliency for years. Freezing or overheating due to

ambient temperatures encountered during shipping or

storage does not impair the end caps.

__________________________________________________________________________________________

3M UK PLC 3M Ireland 3M UK PLC

Electrical Products Sales Office Sales Office

3M House, PO Box 1 3M House, Adelphi Centre PO Box 393

Bracknell, Berkshire RG12 1JU Dun Laoghaire, Co Dublin, Ireland Bedford MK41 0YE

Telephone: 01344 858616 Telephone: 353 1 280 3555 Telephone: 01234 229462

Fax: 01344 858758 Fax: 353 1 280 3509 Fax: 01234 229433

Loading...

Loading...