Page 1

Installing the NEMA 4X Hatch

ET 350 Monitor (Models ET 350R and ET 350L3) and ET 3170 Terminal

Intended Use

When properly installed using the materials provided, and

according to these instructions, the NEMA 4X hatch is

intended to provide a NEMA 4X/IP66 seal on all sides for

the 3M Dynapro

TM

ET 350 monitor (specifically, ET 350R

and ET 350L3 monitors) and the ET 3170 terminal. The

ET 350L3 monitor is also UL Listed for use in Pollution

Degree 3 environments.

Product safety information

Read and understand all safety information in this

document before installing and using the NEMA 4X hatch.

WARNING

To reduce the risks associated with electric shock or fire

which, if not avoided, may result in death or serious injury

and/or property damage:

! Follow all product and accessory installation instructions.

! Any servicing or other procedures not described in this

document are to be performed only by 3M Touch Systems

service personnel.

WARNING

To reduce the risks associated with electric shock or fire

which, if not avoided, could result in death or serious injury

and/or property damage.

! Wiring installation should be done by a journeyman electrician

and must comply with federal and local electrical codes.

! Properly install the ET unit with a NEMA 4X gasket that is

undamaged and effective.

! Properly install the ET unit so that it is environmentally sealed to

the NEMA 4X/IP66 standard. Do not use an ET unit that is not

rated for NEMA 4X/IP66 in environments that require such a

seal.

WARNING

To reduce the risks associated with electric shock or fire

which, if not avoided, could result in death or serious injury

and/or property damage.

! Choose fittings and a power cable that provide adequate strain

relief for communications and power cables.

! A cable/fitting combination will have to be found that meets local

electrical requirements and the requirements for a NEMA 4X

seal.

! When connecting power with fixed field wiring, the power cable

must be double insulated. A clear, flexible insulator (supplied)

must cover the portion of the cable that is not double insulated

when connecting to a terminal strip connector.

! When closing the hatch of the ET unit, make sure that it closes

flush and that the hatch screws do not bind when they are

attached. If the hatch is not closed properly, the NEMA 4X seal

may be compromised and the warranty invalidated.

CAUTION

To reduce the risk associated with electric shock or fire that

may result in personal injury or property damage:

! After making an opening for cables, make sure that there are no

metal shavings in the hatch.

! Use round cables that fit the diameter range of the cable fitting,

as shown in Table A, to meet local electrical requirements and

the requirements for a NEMA-4X/IP66 seal.

3M Touch Systems Proprietary Information

1

Page 2

Installing the NEMA 4X Hatch

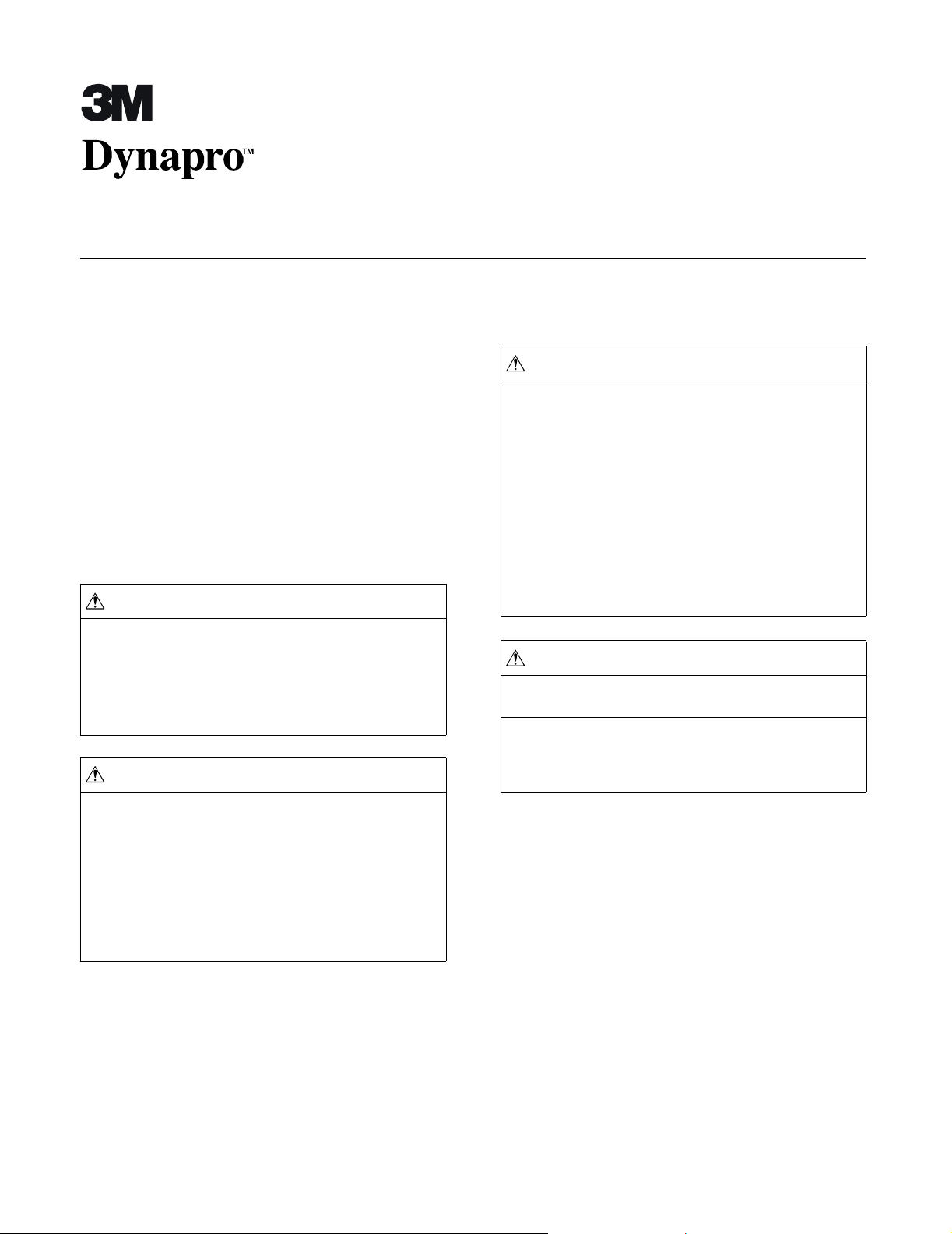

Equipment

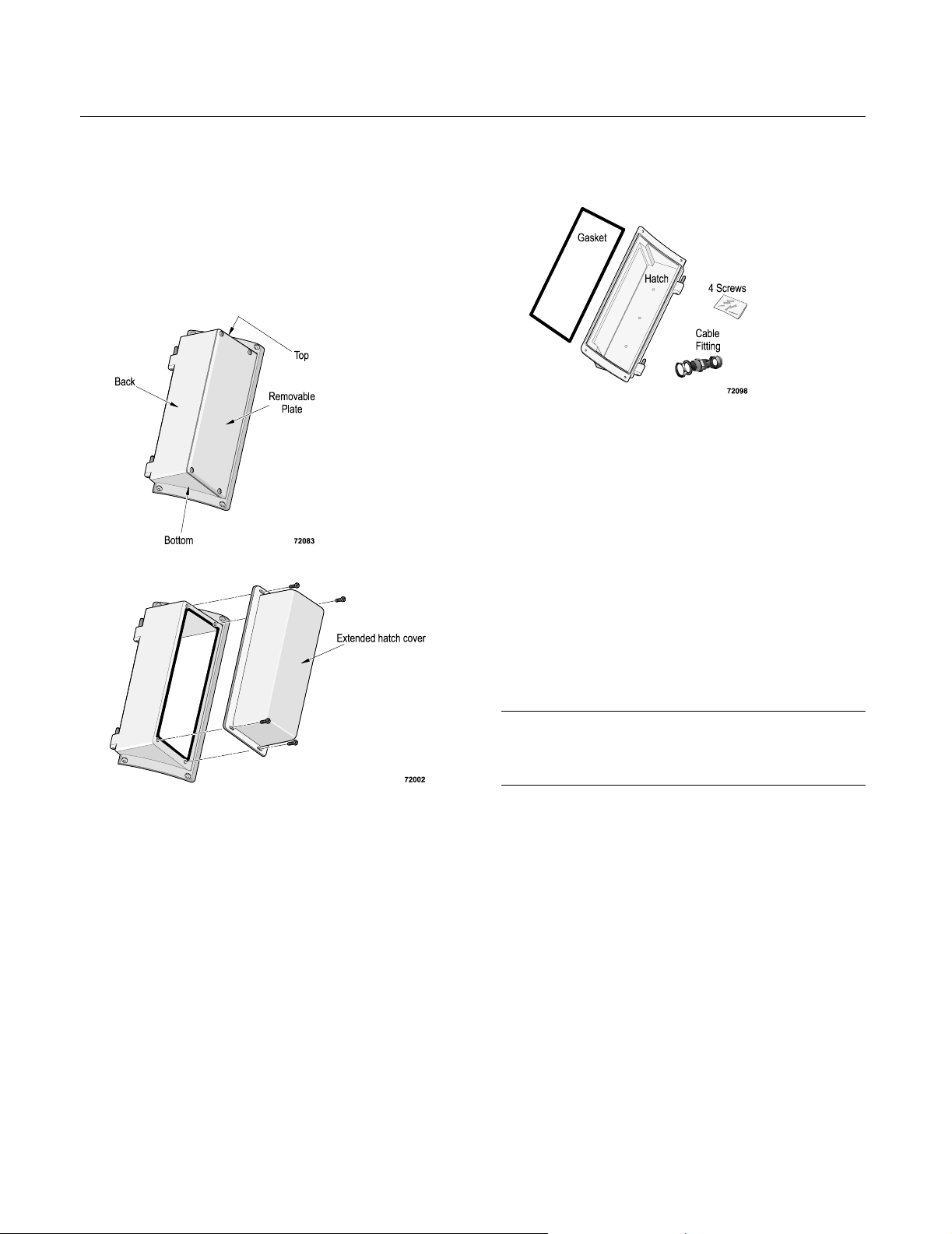

Materials supplied

The following materials are supplied for installing the

NEMA 4X hatch:

! 1 NEMA 4X hatch (with removable plate attached).

! 1 NEMA 4X extended hatch cover

For details about the supplied cable fitting

components, see Table A.

Tools required

To install the NEMA 4X hatch, you will need the

following:

! Horizontal work surface with a padded cover or foam

pads to protect the front bezel and the display of the

unit.

! Flat blade screwdriver with 3/16-inch blade

! No. 1 Phillips torque screwdriver

! 1 19/32" (15 mm) open-end wrench

! 1 15/16" (24 mm) open-end wrench

! 1 gasket

! 4 #6-32 Phillips screws

! Cable fitting components (3 large sizes and 3 small

sizes of each component are provided):

! Locking nut

! O-ring

! Body hex with compression sleeve

! Sealing nut

Attaching the gasket

Important

If you ordered the ET 350L3 monitor, the hatch gasket was

attached at the factory. Proceed to “Preparing the hatch for

cables”.

1. Place the ET unit face down on a horizontal work

surface (covered with foam pads or other material to

protect the unit’s bezel and touch screen), with the

access hatch facing you.

2. Before removing the gasket backing, position the

gasket over the recessed edge of the access hatch

opening so that you know which way it fits.

3M Touch Systems Proprietary Information

2

Page 3

3M Dynapro ET 350 Monitors (Models 350R and 350L3) and ET 3170 Terminal

Note. The gasket is not rectangular. The side of the

gasket that is placed near the back of the ET unit is

shorter than the side that is placed near the front of the

unit.

Back of monitor

Front of monitor

32525_co

3. Start at one corner and peel away just enough of the

backing to expose about 1 inch of adhesive on each

side of the corner.

Important

! The adhesive under the backing is very delicate. To be sure

that you do not remove the adhesive with the backing, use a

razor knife to separate the backing from the adhesive.

! Do not remove the entire backing at once. Start at one corner,

lift and peel back some of the backing only, as described

below.

! Do not stretch the gasket. This can cause the adhesive layer

to come away from the gasket.

4. Place the gasket on the recessed edge of the access

hatch, with the backin g side down. Line i t up w ith t he

edge of the opening in the access hatch, then gently

press the corner with the exposed adhesive into place.

Don’t press it down firmly yet.

5. With the gasket gently adhering at the corner, peel the

backing away from the corner carefully, a little bit at a

time, gently pressing the gasket into place around the

edge of the access hatch as you go along. Don’t press

it down firmly yet.

6. Continue until you have removed all of the backing

and the gasket is lightly tacked into place around the

opening of the access hatch.

7. Make sure that the entire surface of the gasket is in

contact with the recessed edge of the access hatch,

without bumps or ripples.

8. When you are satisfied with the fit, use your fingers to

press the gasket firmly into place all around the

opening of the access hatch.

Preparing the hatch for cables

You can make up to four openings through the back of the

hatch.

Do not make openings in the removable plate, the top or

bottom of the hatch, nor in the extended hatch cover (if you

are using the extended hatch cover).

Important

Be sure that the openings you make are free of burrs and that the

surface around the hole is smooth and free of debris. This will

help ensure that the installed fittings seal properly.

If you want to make your own cables, refer to pin-outs in

the user’s guide for your ET unit.

Connecting cables to the hatch

To ensure safe, certifiable connections and a complete seal

using one of the sealed fittings provided

(Table A), follow the steps in this section.

Table A: Supp lied cable fittings (large and small)

Small fitting Large fitting

Manufacturer Sealcon Sealcon

Part number CD07CA-BK CD13NA-BK

Round cable

diameter range

Clearance hole

(+0.010" / -0.000")

(+0.25 mm / -0.000

mm)

Description Straight Straight

Open-end wrench 19/32"

Torque of locking

nut

Torque of

sealing nut

0.150 - 0.250"

(3.81 - 6.35 mm)

0.490"

(12.5 mm)

(15 mm)

20 inch-pounds 31 inch-pounds

14 inch-pounds 22 inch-pounds

0.250" - 0.450"

(6.35 - 11.43 mm)

0.830"

(21.1 mm)

15/16"

(24 mm)

3M Touch Systems Proprietary Information

3

Page 4

Connecting supplied sealed fittings

1. Make a clearance hole. Clearance holes can be made

anywhere on the back of the hatch, as long as the

hatch can open and close freely on its hinges after the

cables and/or cable fittings are installed.

Note: There are three indentations on the back of the

hatch that may be used as guides when creating holes.

However, these are only guides; if you need four

holes, you will need to decide how best to space them.

For ET 350 monitors only: The number of holes

needed will depend on whether your monitor has a

KVM extender (maximum of four holes) or not (three

holes). Table B shows the clearance holes required in

each case

Installing the NEMA 4X Hatch

Table B: For ET 350 monitors only: Cable clearance

holes required for monitors without and with KVM

extender

Opening for

this cable

Power

Serial

VGA

CAT5

Mouse

Keyboard

ET 350 monitor

without

KVM extender

!!

!

!

ET 350 monitor with

KVM extender

!

!

!

Important

If the diameter of the cable is close to the ranges of both the small

and large fittings shown in T able A, try running the cable through

the smaller fitting before beginning to connect the fittings. If the

cable will go through the small fitting without being forced,

3M Touch Systems recommends using that fitting.

2. The cable fitting comes loosely assembled.

Disassemble the cable fitting into its four

components: locking nut, o-ring, body hex (which

encloses the compression sleeve), and sealing nut.

3. Install the o-ring onto the surface of the body hex and

then insert the body hex (with o-ring attached) into

the clearance hole on the outside of the hatch.

4. On the inside of the hatch, attach the locking nut to

the body hex.

5. Holding the body hex stationary with a wrench, hand-

tighten the locking nut and then use a second wrench

to tighten the locking nut until the cable fitting is held

in place securely (see Table A for suggested torque

values).

6. Slide the sealing nut onto the cable and then, from the

outside of the hatch, feed the cable through the cable

fitting.

7. Gently screw the sealing nut onto the body hex, but do

not tighten it. Leave the sealing nut loose to allow the

cable to move through the fitting.

8. Slide the cable through the body hex and into the

hatch until you are satisfied with the amount of cable

inside and outside of the hatch.

Make sure there is enough slack in the cable to allow

the hatch to fully open and close on its hinges without

straining the cables or connectors.

9. Holding the body hex stationary with a wrench, hand-

tighten the sealing nut and then use a second wrench

to tighten the sealing nut until the wire is held

securely in place (see Table A for suggested torque

values).

3M Touch Systems Proprietary Information

4

Page 5

3M Dynapro ET 350 Monitors (Models 350R and 350L3) and ET 3170 Terminal

10. Using a wrench on the body hex, make sure that the

cable fitting still is tightly screwed into the hatch.

11. Insert the hinge pins of the hatch into the hinges of the

ET unit, close the hatch and make sure that the screw

holes in the edges of the hatch line up with the

threaded holes in the unit’s enclosure.

Important

If you need to examine cables inside the access hatch, take off

the removable plate (or extended hatch cover) from the hatch.

Closing the hatch

To close the hatch, follow these steps:

1. Attach cables to their respective connectors.

2. Close and fasten the hatch by loosely attaching the

four #6-32 Phillips screws.

3. Using a No. 1 Phillips torque screwdriver, gradually

tighten diagonal pairs until all the screws are equally

tight at a torque of 7 inch-pounds. This may require

about three rounds of tightening.

Replacing cables

To replace a cable, disassemble the fitting by following

these steps:

1. Using a wrench to hold the body hex stationary,

loosen the sealing nut with a second wrench.

2. Grip the disconnected cable and pull while turning the

cable in a counter-clockwise direction.

The new cable you install will require a new fitting.

3M Touch Systems Proprietary Information

5

Page 6

Copyright

This manual is © 3M 2002. All rights reserved.

Reproduction of the contents of this copyrighted manual in whole

or in part, by any means, electronic or mechanical, for any

purpose, without written permission of 3M Touch Systems, a

subsidiary of 3M, is prohibited.

Notice

Given the variety of factors that can affect the use and

performance of a 3M Touch Systems Product (the “Product”),

including that solid state equipment has operation characteristics

different from electromechanical equipment, some of which

factors are uniquely within User’s knowledge and control, it is

essential that User evaluate the 3M Touch Systems Product and

software to determine whether it is suitable for User’s particular

purpose and suitable for User’s method of application. 3M Touch

Systems’ statements, engineering/technical information, and

recommendations are provided for User’s convenience, but their

accuracy or completeness is not warranted. 3M Touch Systems

products and software are not specifically designed for use in

medical devices as defined by United States federal law. 3M

Touch Systems products and software should not be used in such

applications without 3M Touch Systems’ express written consent.

User should contact its sales representative if User’s opportunity

involves a medical device application.

Important notice to purchaser

Specifications are subject to change without notice. These 3M

Touch Systems’ Products and software are warranted to meet

their published specifications from the date of shipment and for

the period stated in the specification. 3M Touch Systems makes

no additional warranties, express or implied, including but

not limited to any implied warranties of merchantability or

fitness for a particular purpose.

User is responsible for determining whether the 3M Touch

Systems Products and software are fit for User’s particular

purpose and suitable for its method of production, including

intellectual property liability for User's application. If the Product,

software or software media is proven not to have met 3M Touch

Systems’ warranty, then 3M Touch Systems’ sole obligation and

User’s and Purchaser’s exclusive remedy, will be, at 3M Touch

Systems’ option, to repair or replace that Product quantity or

software media or to refund its purchase price. 3M Touch Systems

has no obligation under 3M Touch Systems’ warranty for any

Product, software or software media that has been modified or

damaged through misuse, accident, neglect, or subsequent

manufacturing operations or assemblies by anyone other than 3M

Touch Systems. 3M Touch Systems shall not be liable in any

action against it in any way related to the Products or

software for any loss or damages, whether non-specified

direct, indirect, special, incidental or consequential (including

downtime, loss of profits or goodwill) regardless of the legal

theory asserted.

Edition

Second edition: October 2002

Document Number: 19504 (Rev. 1.2)

Trademark

3M Dynapro is a trademark of 3M.

3M Touch Systems

3M Optical Systems Division

800 Carleton Court

Annacis Island

New Westminster, BC

Canada V3M 6L3

www.3Mtouch.com

Worldwide Manufacturing Plants

Methuen, Massachusetts

Milwaukee, Wisconsin

Vancouver, BC, Canada

For more information on 3M touch products, visit

3Mtouch.com or call toll-free 1-800-667-0374.

© 3M 2002

19504 (Rev. 1.2)

Loading...

Loading...