Installing the Boom Mount

ET 350 Monitor (Model ET 350R)

Intended Use

When properly installed using the materials provided,

and according to these instructions, the boom mount is

intended to mount the ET 350 monitor to provide a

means of mechanically supporting the monitor on a

suspension arm.

Warning

Read and understand all safety information

before installing and using this product.

To reduce the risk of fire or electric shock

which could result in personal injury or death:

! Follow all product and accessory installation

instructions.

! Any servicing or other procedures not described in

this document are to be performed only by 3M Touch

Systems service personnel.

! Wiring installation should be done by a journeyman

electrician and must comply with federal and local

electrical codes.

! The complete structural integrity of the monitor on

the suspension arm should be evaluated by a

licensed journeyman electrician.

! The boom mount does not provide a NEMA seal.

! Mounting the ET 350R monitor with the Boom Mount

Kit will make the unit suitable only for Pollution

Degree 2 environments.

! When connecting power with fixed field wiring for the

ET 350L3 monitor and the ET 350R monitor, the

power cable must be double insulated. A clear,

flexible insulator (supplied) must cover the portion of

the cable that is not double insulated when

connecting to a terminal strip connector.

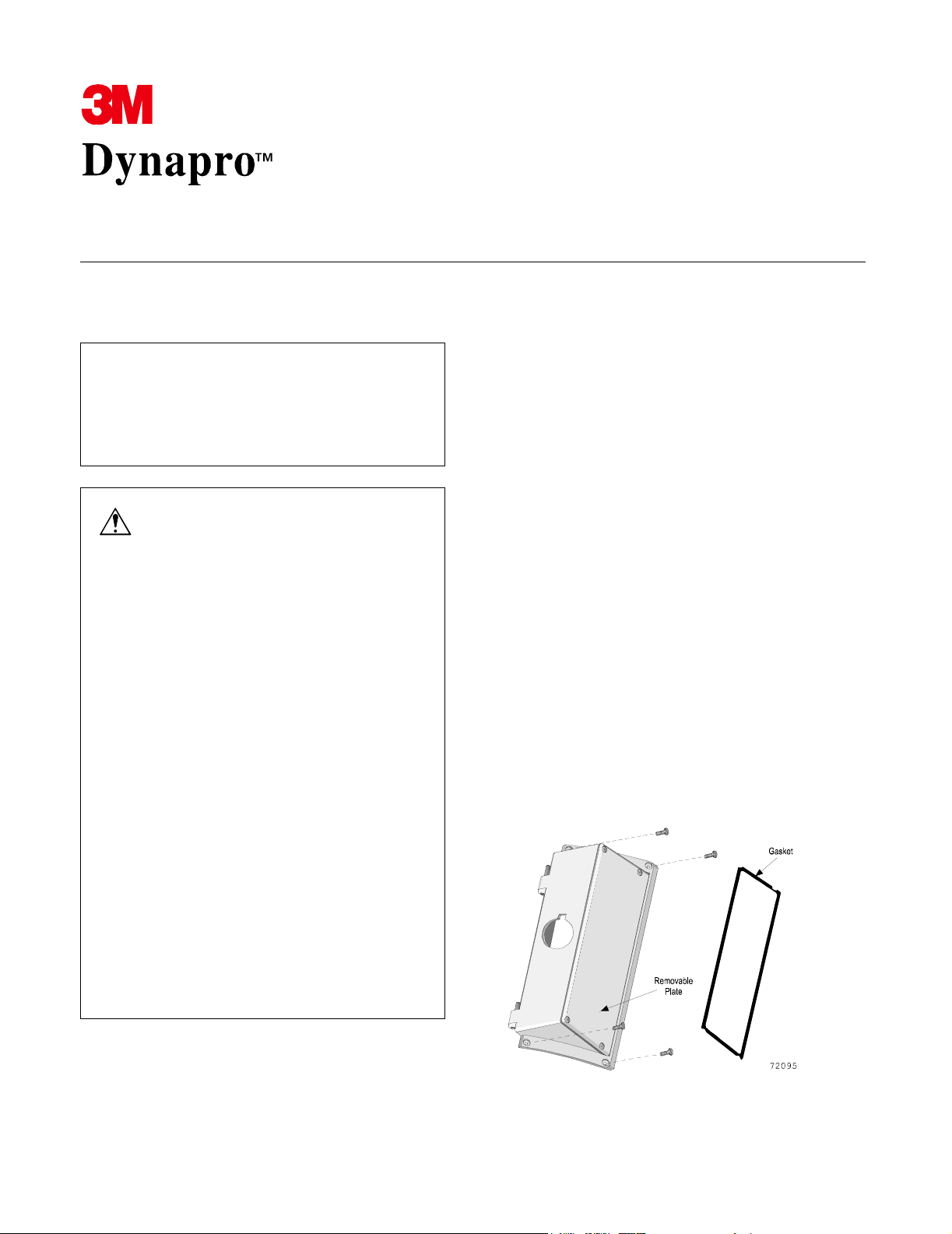

About the boom mount

The Boom Mount Kit consists of a special hatch and

related hardware for boom mounting or post

mounting the ET 350R monitor. The boom mount

may only be used on a monitor that is configured with

fixed field wiring.

The hatch is designed to be fastened to a post, boom,

or suspension arm using the suspension arm coupling

(provided with the kit). This coupling may be used

with a 1.90" (48.3 mm) diameter steel pipe with

0.138" (3.5 mm) nominal wall thickness.

The boom itself may provide a conduit for power and

data cables.

Equipment

Materials provided

The boom mount kit includes:

! 1 hatch with boom mount opening, removable

plate and extended hatch cover (extended hatch

cover not shown in illustration below)

! 1 sealing gasket for hatch

Installing the Boom Mount 3M Dynapro ET 350 Monitor (ET 350R)

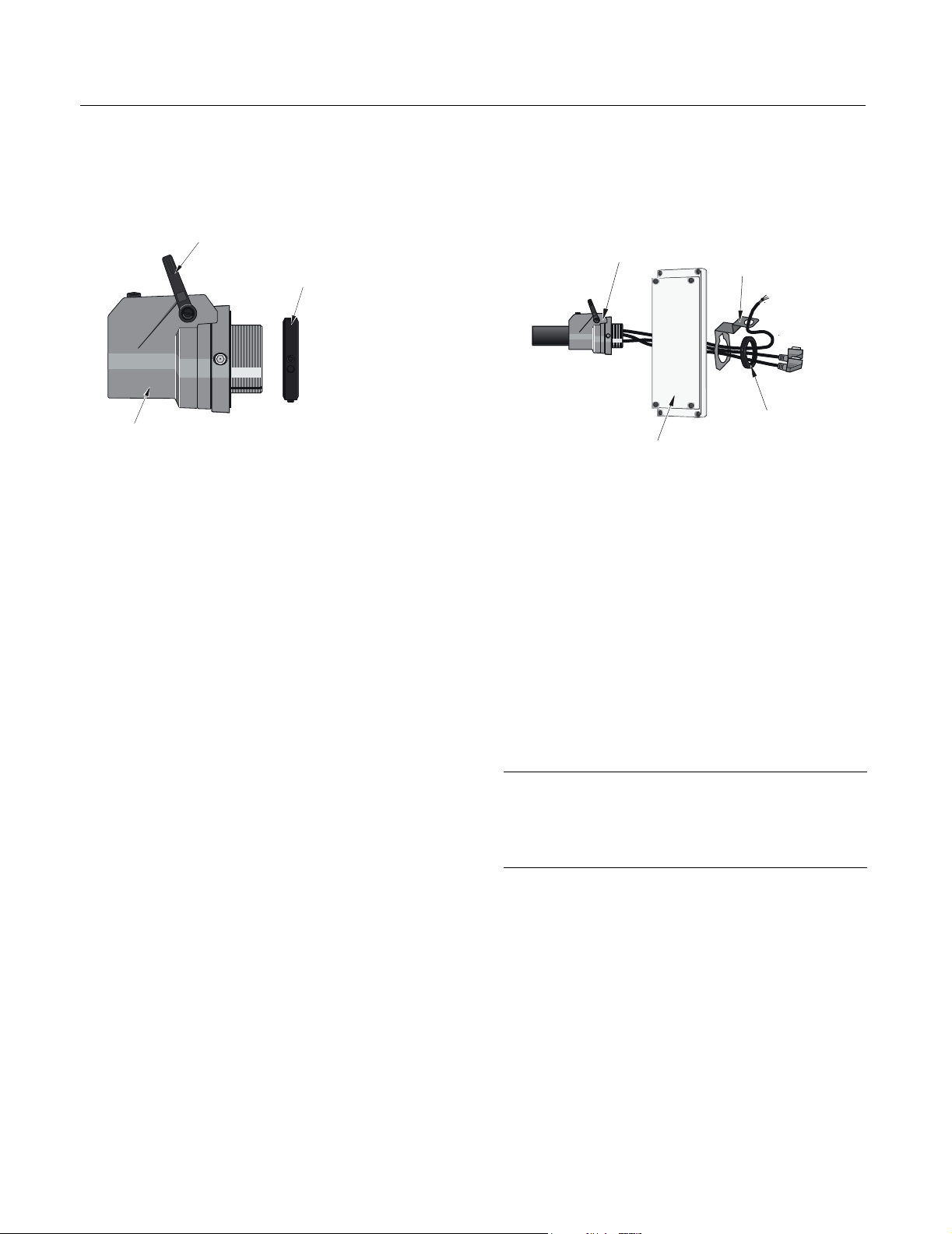

! 1 metal suspension arm coupling with tightening

ring (attached) and locking ring.

Tightening handle

Locking ring

Coupling

! 4 #6-32 x ¼ inch Phillips sealing lock screws

72042

(panhead)

! 1 conduit termination bracket (including #6-32 by

¼ inch grounding screw with captive washer

Tools required

! Phillips No. 2 screwdriver

! 9/32-inch (6 mm) Allen key

! 3/32-inch (2 mm) Allen key

Assembling the components

1. Using a 9/32-inch (6 mm) Allen key, attach the

suspension arm coupling to the boom.

2. Feed the necessary data cables through the boom

so the connectors are accessible at the ET unit’s

end.

3. Feed the cable through the boom mount so the

far end is available for connection to the power

source, and the near end is available for

connection to the power receptacle on the back

of the ET unit.

4. Fit the hatch to the suspension arm coupling,

feeding the cables through the hole in the hatch.

Coupling

Hatch cover

5. Install the conduit termination bracket, if

Conduit

termination

bracket

Locking ring

73147b

required.

6. Screw the locking ring over the threaded end of

the suspension coupling until it is tight against

the coupling and holds the hatch in an upright

position, with the hinge pins pointing upward.

7. Using a 3/32-inch (2 mm) Allen key, tighten the

set screws on the edge of the locking ring to

fasten the locking ring securely in place.

Attaching the gasket

Important

If you ordered your unit with a hatch, this gasket was

fitted at the factory. Proceed to “Mounting the unit‚” on

page 3.

1. Place the monitor face down on a horizontal

work surface (covered with foam pads or other

material to protect the monitor’s bezel and touch

screen), with the access hatch facing you.

2. Before removing the gasket backing, position the

gasket over the recessed edge of the access hatch

opening so that you know which way it fits.

13909 (Rev. 1.1) Page 2

Loading...

Loading...