Page 1

Replacing backlights

ET 3255 Computer HL (Hazardous Locations)

Intended Use

When properly installed using the materials provided, and

according to these instructions, this Backlight

Replacement Kit is intended to allow backlights for the

ET 3255 Computer HL to be replaced.

Warning

Read and understand all safety information in the

ET 3200 Series Computer User’s Guide and in this

document before installing and using the ET 3255

computer.

If there appears to be a conflict between information in the

ET 3200 Series Computer User’s Guide and this

document, this document takes precedence.

Warning

TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK WHICH

COULD RESULT IN SERIOUS PERSONAL INJURY OR DEATH:

! This repair should be performed only by trained

personnel. Failure to perform all operations correctly

could damage the unit and invalidate the warranty.

! To ensure compliance with electrical codes and safe

operation of the computer, removal and re-installation of

the computer should be performed by a licensed

journeyman electrician who is familiar with local codes.

! Any servicing or other procedures not described in this

document are to be performed only by 3M Touch

Systems personnel.

Warning

TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK WHICH

COULD RESULT IN SERIOUS PERSONAL INJURY OR DEATH:

! If the computer is in a hazardous location, it should be

removed to a non-hazardous location in a facility

suitable for repairing electronics. Before disconnecting

power and other connections and removing the unit from

its mounting, make sure that the area is free of

hazardous gases.

! Before removing the computer from its mounting,

disconnect power to the unit.

! When replacing the backlights, use the ones included

with these instructions in the Backlight Replacement Kit.

! Properly install the computer ensuring that all NEMA 4X

gaskets are clean, undamaged, and effective.

! When closing the hatch of the computer, make sure that

it closes flush and that the hatch screws do not bind

when they are attached. If the hatch is not closed

properly, the NEMA 4X seal may be compromised and

the warranty voided.

! Take care not to pinch backlight inverter wires when

reassembling and reinstalling the display plan or when

closing the computer

! Do not pull on or repeatedly bend lead wires. The wires

could break, causing backlight failure.

! Do not solder backlight leads. A thermal shock may

cause the glass part to crack and the backlight to fail.

! Do not substitute, lengthen, or cut the CCFL lead wires

on the backlights. Due to the high voltage applied at the

ends of the wires, the leads are made of high voltageresistant material.

Warning

TO REDUCE THE RISK OF FIRE OR EXPLOSION WHICH COULD

RESULT IN SERIOUS PERSONAL INJURY OR DEATH, do not use

cleaners that are flammable or combustible.

Page 2

Replacing backlights ET 3255 Computer HL (Hazardous Locations)

Equipment

Caution

TO REDUCE THE RISK OF MINOR OR MODERATE INJURY FROM

CONTACT WITH CLEANING SOLUTIONS OR FLUIDS THROUGH

MEANS SUCH AS INJESTION AND SKIN CONTACT:

! Do not touch the inner surface of a damaged backlight

with bare skin. If bare skin does come in contact with the

inner surface of a backlight, immediately wash with soap

and water. There is a small amount of mercury inside

the backlights.

! Before using a cleaner, refer to the cleaner

manufacturer’s material safety data sheet and follow all

instructions and recommendations.

Caution

TO REDUCE THE RISK OF ENVIRONMENTAL CONTAMINATION

WHICH MAY RESULT IN MINOR OR MODERATE INJURY OR

CAUSE PROPERTY DAMAGE:

! Old backlights must be disposed of in accordance with

local municipal and governmental ordinances, laws, and

regulations.

! Protect backlights from strong shock or other forces that

could cause them to break. A broken backlight has the

potential for injury and should be handled with care.

! Do not look directly at a lit backlight at close proximity

and do not work for many hours exposing your eyes to

direct output from backlights. Disregarding this caution

could result in eye injury.

Caution

TO REDUCE THE RISK OF FIRE OR SMOKE, do not let paper,

cloth, or other flammable materials come in contact with

a backlight.

Materials supplied in the kit

The backlight replacement kit contains:

! 1 upper backlight

! 1 lower backlight

! 1 5/32-inch (4 mm) Allen key

! 1 grounding wrist strap

Materials and tools required

! 5/32-inch (4 mm) Allen key (supplied) or

1/4-inch flat-blade screwdriver to open the

computer

! 5/16-inch torque hex nut driver

! No. 1 Phillips torque screwdriver

! Security screwdriver, if the enclosure is secured

with security screws. A security screwdriver

option is available from 3M Touch Systems or

from your local hardware retailer.

! Cleaner and cloths designed for cleaning coated

optical glass that are neither flammable nor

combustible.

! 1 grounding strap (for assistant)

Personnel and facilities required

To complete this procedure you will need:

! Two people (each wearing a grounding strap).

! A clean, ESD-protected environment with a work

surface covered with foam pads or other suitable

material to protect the touch screen and bezel.

20008 (Rev.1.0) Page 2

Page 3

Replacing backlights ET 3255 Computer HL (Hazardous Locations)

Replacing the backlights: Steps

The Backlight Replacement kit for the ET 3255

Computer HL contains two backlights: one for the top

of the display and one for the bottom. The top and

bottom backlights are not interchangeable. 3M Touch

Systems recommends replacing both backlights at the

same time.

1. Put on a grounding strap, connect to ground, and

touch a grounded object to discharge any builtup static.

Important

To prevent damage from electrostatic discharge (ESD),

wear a grounding wrist strap when working with electronic

components inside the enclosure. Follow the instructions

that come with the wrist strap.

Warning

TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK WHICH

COULD RESULT IN SERIOUS PERSONAL INJURY OR DEATH, if

the computer is in a hazardous location, it should be

removed to a non-hazardous location that is suitable for

repairing electronics. Before disconnecting power and

other connections and removing the unit from its

mounting, make sure that the area is free of hazardous

gases.

5. To protect the touch screen and bezel, place the

unit in an ESD-protected environment and on a

work surface covered with ESD-dissipative foam

pads or other ESD-dissipative material.

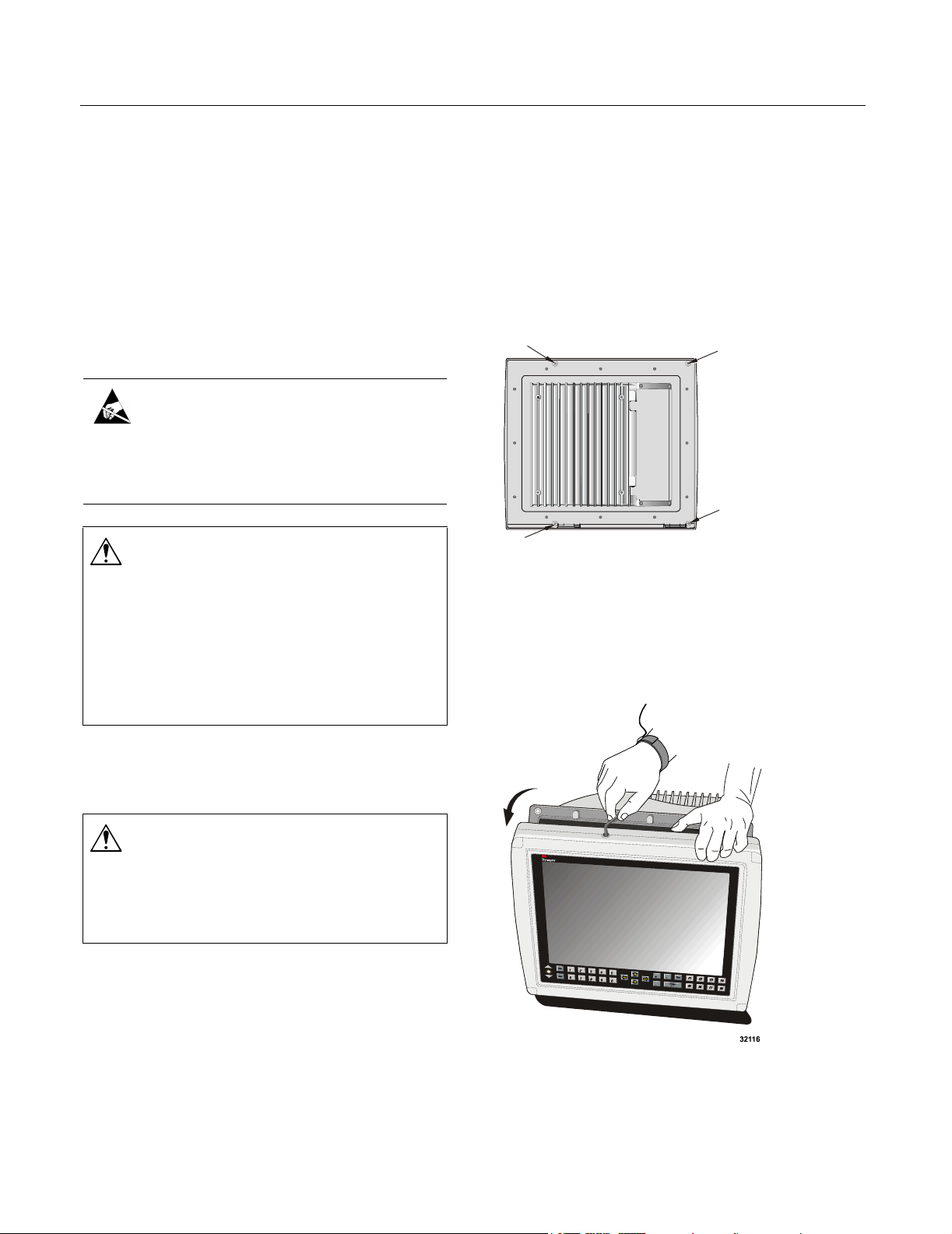

6. See if there are security screws at the four

corners of the back of the bezel and, if there are,

remove them with a security screwdriver (for

information on getting a security screwdriver,

see “Materials and tools required”).

Security

Screws (4)

Figure 1: Locations of security screws (security

screws are not attached to all units)

7. To unlock the bezel assembly, find the latch

screw on the top of the enclosure and use the

Allen key or a flat-blade screwdriver to turn the

latch screw ¼ turn counter-clockwise, or until

you feel the enclosure open (Figure 2).

2. Make sure the area is free of hazardous gases and

then disconnect the power supply to the unit.

Warning

TO REDUCE THE RISK OF ELECTRIC SHOCK WHICH COULD

RESULT IN SERIOUS PERSONAL INJURY OR DEATH, before

removing the computer from its mounting, disconnect

power to the unit.

3. Disconnect all communication cables from the

unit.

4. Remove the unit from its mounting and, if the

computer is in a hazardous location, move it to a

non-hazardous location.

20008 (Rev.1.0) Page 3

Figure 2: Opening the computer enclosure

Page 4

Replacing backlights ET 3255 Computer HL (Hazardous Locations)

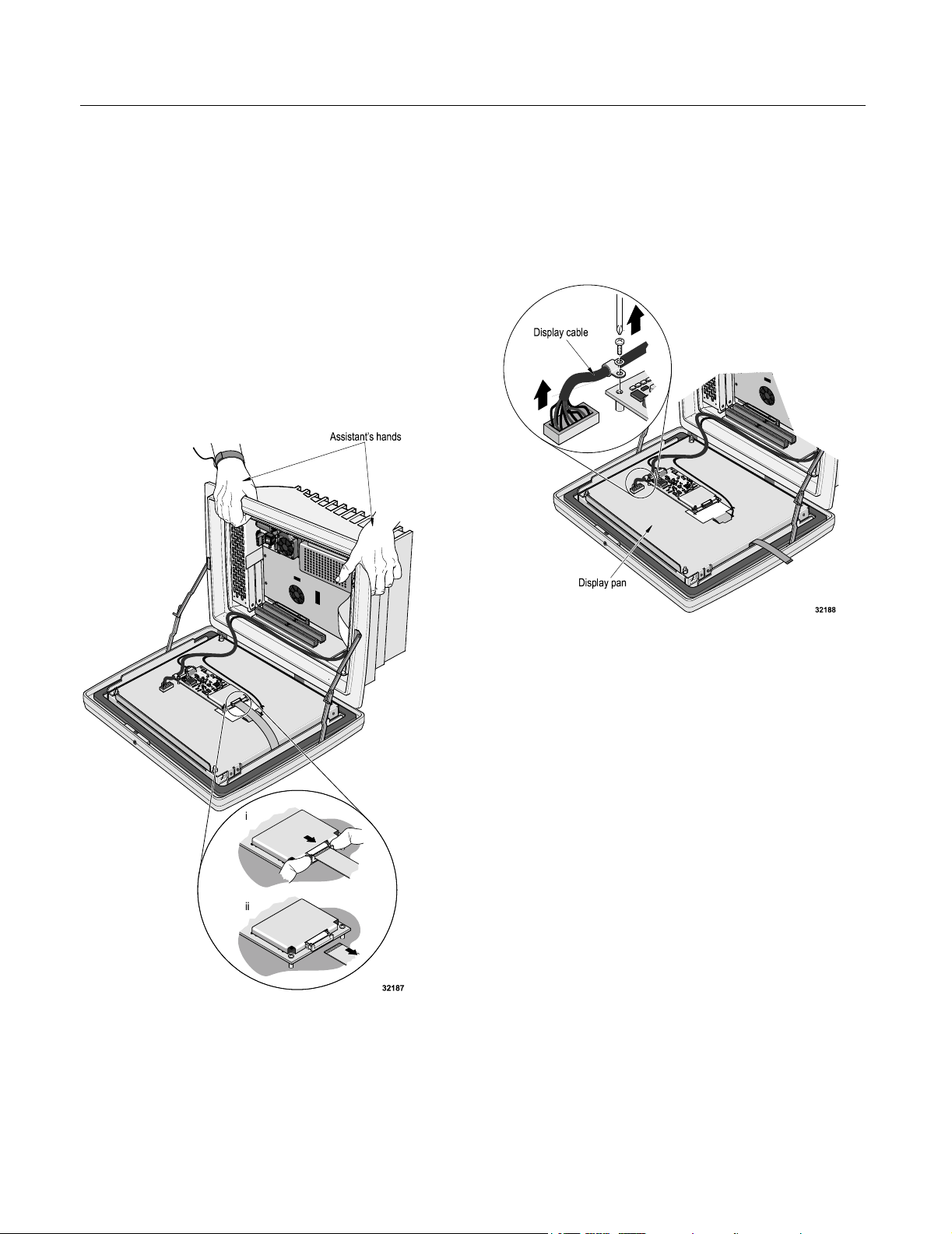

8. Place the computer face down on the work bench

and open the main enclosure as far as it will go.

9. Have another person assist you by supporting the

enclosure in the open position so that it does not

tip over. Make sure that your assistant is also

wearing a grounding strap.

10. Carefully disconnect the touch screen tail

(Figure 3):

i. Using two fingers, gently pull the connector

tab towards you until it stops.

ii. Carefully pull the touch screen tail from the

connector.

11. Using a No.1 Phillips screwdriver, remove the

screw and washer from the clamp that holds the

display cable to the touch screen controller

(Figure 4).

12. Carefully disconnect the display cable connector

from the socket on the back of the display pan.

Figure 3: Disconnecting the touch screen tail

Figure 4: Disconnecting the display cable connector

13. Loosen the four nuts that secure the display pan,

and remove them. Notice that the two nuts on the

hinge side of the pan do not have washers. The

nuts on the opposite side have flat washers

(Figure 5).

20008 (Rev.1.0) Page 4

Page 5

Replacing backlights ET 3255 Computer HL (Hazardous Locations)

Figure 5: Removing the display pan nuts

14. Carefully slide the display pan away from the

threaded studs and lift it to a vertical position,

taking care not to damage the cable that connects

it to the computer (Figure 6):

i. Lift the hinge side of the display pan up from

the threaded studs.

ii. Slide the display pan away from the other

two threaded studs.

Figure 6: Sliding the display pan out and lifting it.

Important

When you lift the display pan, you expose the display and

the interior side of the glass touch screen.

The surface of the display and the glass surface of the

touch screen mark easily. Do not touch or scratch these

surfaces while replacing the backlights. If you do touch

them and leave stains or fingerprints, clean them before

you close the enclosure. See Step 25 on page 8.

iii. Lift the display pan to a vertical position and

have your assistant support both the display

and the main enclosure.

15. Unscrew the display from the display pan, using

a No. 1 Phillips screwdriver, as follows

(Figure 7):

i. First, remove the two screws on the right

side of the display.

ii. Then remove the four screws on the left side

of the display.

20008 (Rev.1.0) Page 5

Page 6

Replacing backlights ET 3255 Computer HL (Hazardous Locations)

Figure 7: Unscrewing the display from the display pan

16. Carefully lift the display from the display pan,

taking care not to damage the backlight

connector wires that still connect it to the display

pan.

17. Under the display, you will see wires running

from the backlights to the backlight inverter on

the display pan. Disconnect the backlight

connectors from the backlight inverter

(Figure 8 and Figure 9).

Important

Pay attention to the orientation of the connectors as you

remove them so that later you can reinsert them correctly.

Figure 8: Disconnecting the backlight connectors

Figure 9: Backlight connector fully connected and

disconnected

18. Remove the display from the display pan and set

the display on a clean, protected work surface

with the display side down.

20008 (Rev.1.0) Page 6

Page 7

Replacing backlights ET 3255 Computer HL (Hazardous Locations)

19. On the display, you will see wires that are

attached to each of the backlights. Each backlight

is inserted into a white plastic retaining channel.

The backlights are held in place with small, darkcolored Phillips-head retaining screws.

To remove a backlight:

i. Remove the screw using a No. 1 Phillips

screwdriver (Figure 10).

ii. Using your fingers, gently pull out the

Important

! When handling a backlight, avoid touching the bulb

with bare fingers. Oil from fingers will leave a deposit

on the glass that will decrease the life span of the bulb.

! Before inserting the new backlights, note that there is

an upper backlight (labelled

(labelled

backlight. Make sure you insert the correct backlight

into each retaining channel.

“Low”). The label is on the underside of the

“Up”), and a lower one

backlight (Figure 11).

Notice that the glass tube inside the backlight

is facing the edge of the display, and that

there is only one way for the backlight to fit

in the retaining channel.

iii. Remove the other backlight.

Figure 10: Removing the screw that holds the

backlight (upper backlight, in this illustration)

.

20. Insert the new backlights into the retaining

channels, sliding them in until the holes for the

backlight retaining screws line up. Note that the

backlights are not interchangeable. The backlight

labelled “Up” is the top backlight; the one

labelled “Low” is the bottom backlight.

The label is located on the side of the backlight

that faces down as you slide it into the retaining

channel (Figure 11).

21. Attach the backlights to the display frame with

the small Phillips-head retaining screws that

were removed in Step 19. Hand tighten the

screws.

Important

Do not overtighten the screws, or you will strip the

threads in the plastic backlight.

22. Re-position the display on the display pan and

re-attach the backlight wire connectors to the

backlight inverter on the display pan (Figure 9 on

page 6 and Figure 12).

Important

There is only one way to insert the backlight connector.

Do not force the connector if it does not fit.

Backlight label

"UP" or "LOW"

(underneath

backlight)

Figure 11: Removing the backlight (upper backlight in

this illustration)

20008 (Rev.1.0) Page 7

Page 8

Replacing backlights ET 3255 Computer HL (Hazardous Locations)

24. Attach the display frame to the display pan (see

Figure 7 on page 6):

i. First attach the four screws on the left side of

the display.

ii. Then attach the two screws on the right side

of the display.

iii. Tighten the screws to a torque of 5 inch-

pounds.

25. The back of the MicroTouch

Imaging

TM

(NFI) touch screen (the surface that

TM

Near Field

faces the inside of the computer) may have a

special anti-reflective coating that can be

damaged by commercial glass cleaners and

cloths. To clean this surface, use a noncombustible, non-flammable cleaner designed

for cleaning coated glass.

26. Lower the display pan to its original position and

secure it with the nuts that were removed in

Step 13. Make sure you use the washers with the

threaded studs on the side of the display pan

farther from the hinges (see Figure 5 on page 5).

Figure 12: Connecting the new backlights

Tighten the nuts to a torque of 10 inch-pounds.

23. Bend the backlight wires so that they are out of

the way and will not be pinched when you

reassemble and reinstall the display pan and

close the computer.

27. Reconnect the display cable to the connector on

the back of the display pan (see Figure 4 on

page 4).

28. Using a Phillips-head screwdriver, re-attach the

cable and cable clamp to the controller to a

Warning

torque of 5 inch-pounds (refer to Figure 4 on

page 4).

To reduce the risk of fire or electric shock which could

result in serious personal injury or death, take care not to

pinch backlight inverter wires when reassembling and

reinstalling the display plan or when closing the computer.

20008 (Rev.1.0) Page 8

Page 9

Replacing backlights ET 3255 Computer HL (Hazardous Locations)

29. Reconnect the touch screen tail to the controller

(Figure 13):

i. Use two fingers to carefully pull the

connector tab towards you until it stops.

ii. Gently insert the touch screen tail into the

connector.

iii. Press the connector tab back into place.

30. Check the connectors to make sure they are

properly seated and that cables are not damaged.

31. Close the bezel assembly and lock it by inserting

the Allen key (or a flat-blade screwdriver) in the

latch screw on the top of the enclosure, making

sure that the latch screw engages the housing pin.

Turn the latch screw ¼ turn clockwise or until it

stops. If the bezel assembly was secured with

security screws, re-install them now.

Warning

When closing the hatch of the computer, make sure that

it closes flush and that the hatch screws do not bind when

they are attached. If the hatch is not closed properly, the

NEMA 4X seal may be compromised and the warranty

voided.

32. If the front surface of the touch screen needs

cleaning, use a non-combustible, non-flammable

cleaner that will not corrode glass.

33. Power up the computer, check that the LCD

display is operating and, if so, disconnect power

again.

Figure 13: Reconnecting the touch screen tail

34. Before returning the computer to its hazardous

location, make sure that the hazardous location is

free of hazardous gases.

35. Return the computer to its hazardous location

and re-install it in its mounting device.

36. Connect power to the computer and check again

that the LCD display is operating.

Troubleshooting

If the display does not function properly:

1. Remove the computer to a non-hazardous

location.

2. Open the computer and make sure that all the

connectors are properly seated and that no wires

or cables were damaged during re-assembly of

the computer.

3. If the display still does not function properly,

contact 3M Touch Systems technical support

(see “Contacting 3M Touch Systems”).

20008 (Rev.1.0) Page 9

Page 10

Replacing backlights ET 3255 Computer HL (Hazardous Locations)

Contacting 3M Touch Systems

For general information, service, and technical

support for 3M Dynapro products, use the contact

information below:

Area Type of

service

USA

and

Canada

Outside

USA

and

Canada

General

information

Customer

service

Technical

support

General

information

Contact information

Tel 800-667-0374 (toll free)*

Fax 604-521-4629

E-mail etsales@mmm.com

Web site www.3Mtouch.com

Tel 800-667-0374 (toll free)*

Fax 604-521-4629

E-mail

3MTScustomerservice@mmm

.com

Tel 800-667-0374 (toll free)*

Fax 604-521-4629

E-mail

3Mdynaprotechsupport@mmm

.com

Tel 604-521-3962*

Fax 604-521-4629

E-mail etsales@mmm.com

Customer

service

Technical

support

*Call between 7:30 a.m. and 5:00 p.m., Pacific Time

20008 (Rev.1.0) Page 10

Tel 800-667-0374*

Fax 604-521-4629

E-mail

3MTScustomerservice@mmm

.com

Tel 604-521-3962*

Fax 604-521-4629

E-mail

3Mdynaprotechsupport@mmm

.com

Page 11

Replacing backlights ET 3255 Computer HL (Hazardous Locations)

Copyright

This manual is © 3M 2002. All rights reserved.

Reproduction of the contents of this copyrighted manual in

whole or in part, by any means, electronic or mechanical,

for any purpose, without written permission of 3M Touch

Systems, a subsidiary of 3M, is prohibited.

Notice

Given the variety of factors that can affect the use and

performance of a 3M Touch Systems Product, including

that solid state equipment has operation characteristics

different from electromechanical equipment, some of

which factors are uniquely within User's knowledge and

control, it is essential that User evaluate the 3M Touch

Systems product to determine whether it is suitable for

User’s particular purpose and suitable for User’s method of

application. 3M Touch Systems’ statements,

engineering/technical information, and recommendations

are provided for User’s convenience, but their accuracy or

completeness is not warranted. 3M Touch Systems

products are not specifically designed for use in medical

devices as defined by United States federal law. 3M Touch

Systems products should not be used in such applications

without 3M Touch Systems’ express written consent. User

should contact its sales representative if User’s opportunity

involves a medical device application.

Important notice to purchaser

Specifications are subject to change without notice. 3M

Touch Systems’ Products are warranted to meet their

published specifications from the date of shipment and for

the period stated in the specification. 3M Touch Systems

makes no additional warranties, express or implied,

including but not limited to any implied warranties of

merchantability or fitness for a particular purpose.

User is responsible for determining whether the 3M Touch

Systems Products are fit for User’s particular purpose and

suitable for its method of production, including intellectual

property liability for User's application. If a Product is

proven not to have met 3M Touch Systems’ warranty, then

3M Touch Systems’ sole obligation and User’s and

Purchaser’s exclusive remedy, will be, at 3M Touch

Systems’ option, to repair or replace that Product quantity

or to refund its purchase price. 3M Touch Systems has no

obligation under 3M Touch Systems’ warranty for any

Product that has been modified or damaged through

misuse, accident, neglect, or subsequent manufacturing

operations or assemblies by anyone other than 3M Touch

Systems. 3M Touch Systems shall not be liable in any

action against it in any way related to the Products for

any loss or damages, whether non-specified direct,

indirect, special, incidental or consequential (including

downtime, loss of profits or goodwill) regardless of the

legal theory asserted.

(11/01)

Edition

First edition: March 2002

Document Number: 20008 (Rev. 1.0)

Trademark

3M Dynapro, MicroTouch, and Near Field Imaging are

trademarks of 3M.

20008 (Rev.1.0) Page 11

Page 12

3M Touch Systems

3M Optical Systems Division

800 Carleton Court

Annacis Island

New Westminster, BC

Canada V3M 6L3

www.3Mtouch.com

Worldwide Manufacturing Plants

Austin, Texas

Methuen, Massachusetts

Milwaukee, Wisconsin

Vancouver, BC, Canada

Abingdon, UK

For more information on 3M touch products, visit

3Mtouch.com or call toll-free 1-800-667-0374.

© 3M 2002

20008 (Rev. 1.0)

Loading...

Loading...