Installing the NEMA 4X hatch

ET 355 Monitor HL

Intended Use

When properly installed according to the instructions,

the NEMA 4X hatch is intended to provide a NEMA

TM

4X/IP66 seal on all sides for the 3M Dynapro

ET 355 Monitor HL (hereafter, ET 355 monitor).

The ET 355 monitor is a component. After the

monitor is installed with the NEMA 4X hatch, the

whole system of which it is a part must be inspected

to confirm seal ratings and compliance with all local

electrical codes.

Product safety information

Opening the unit

DANGER

TO REDUCE THE RISKS ASSOCIATED WITH FIRE AND EXPLOSION

WHICH, IF NOT AVOIDED, WILL RESULT IN DEATH OR SERIOUS INJURY

AND/OR PROPERTY DAMAGE:

! Do not open the monitor while the circuit is live unless the area

is known to be non-hazardous.

! Do not operate the monitor’s OSD switches, DIP switch, KVM

extender remote board, or potentiometer on the KVM extender

remote board unless the area is known to be non-hazardous.

Instructions and procedures

Installing and sealing

WARNING

TO REDUCE THE RISKS ASSOCIATED WITH ELECTRICAL SHOCK, FIRE

AND EXPLOSION WHICH, IF NOT AVOIDED, COULD RESULT IN DEATH

OR SERIOUS INJURY AND/OR PROPERTY DAMAGE, IF THE NEMA 4X

HATCH IS PART OF YOUR APPLICATION:

! Choose Listed (UL) conduit hubs that are rated to NEMA

4X/IP66 standards, are suitable for use in hazardous locations,

and provide adequate strain relief for wiring.

! After making an opening in the NEMA 4X hatch, make sure that

there are no metal shavings in the hatch.

! Properly install the monitor so that it is environmentally sealed

to the NEMA 4X/IP66 standard. Do not use the ET 355 monitor

with mounting options that are not rated for NEMA 4X/IP66 in

environments that require such a seal.

! Properly install the ET 355 monitor with a NEMA 4X gasket that

is clean, undamaged, and effective.

! When closing the hatch of the unit, make sure that it closes flush

and that the hatch screws do not bind when they are attached.

If the hatch is not closed properly, the NEMA 4X seal may be

compromised and the warranty voided.

Power supply, wiring methods

For product safety information about power supply

and wiring methods for the ET 355 monitor, refer to

the Installation Addendum: ET 355 Monitor. The

Installation Addendum ships with the ET 355

monitor.

WARNING

TO REDUCE THE RISKS ASSOCIATED WITH ELECTRICAL SHOCK, FIRE,

OR EXPLOSION WHICH, IF NOT AVOIDED, COULD RESULT IN DEATH OR

SERIOUS INJURY AND/OR PROPERTY DAMAGE:

! Follow all product and accessory installation instructions.

! The procedures described in this document should be performed

only by trained personnel. Failure to perform all operations

correctly could damage the unit and invalidate the warranty.

Read and understand all safety information in this document,

the ET 350 Monitor User’s Installation Guide,

and the Installation Addendum: ET 355 Monitor HL

before installing and using the NEMA 4X hatch.

Installing the NEMA 4X Hatch ET 355 Monitor HL

r

Equipment

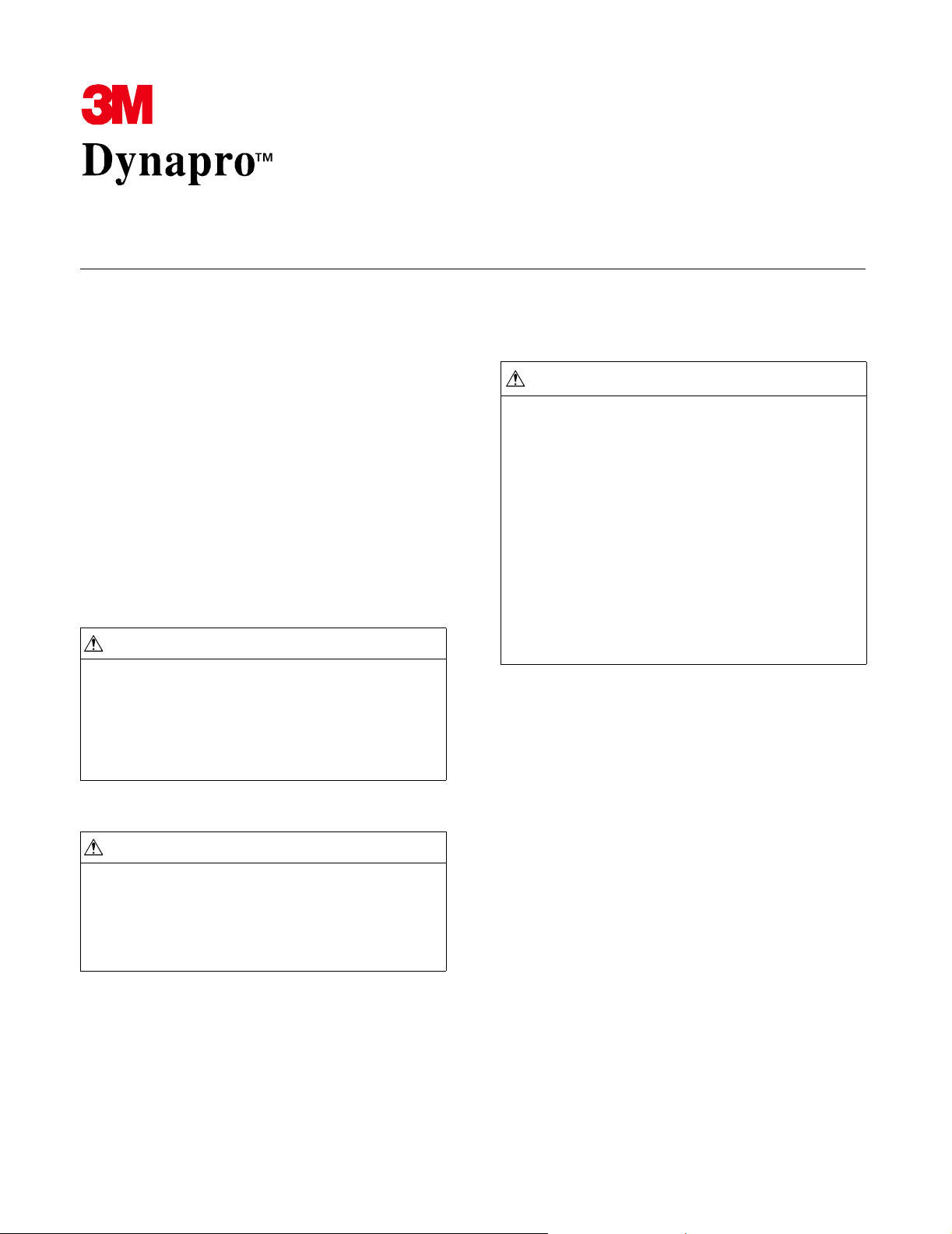

Materials supplied

The following materials are provided for installing

the NEMA 4X hatch on the ET 355 monitor:

! 1 NEMA 4X hatch (with removable plate

attached) and 4 #6-32 Phillips screws

Back

(make all

openings here)

Removable

Plate

4 screws

72083 b

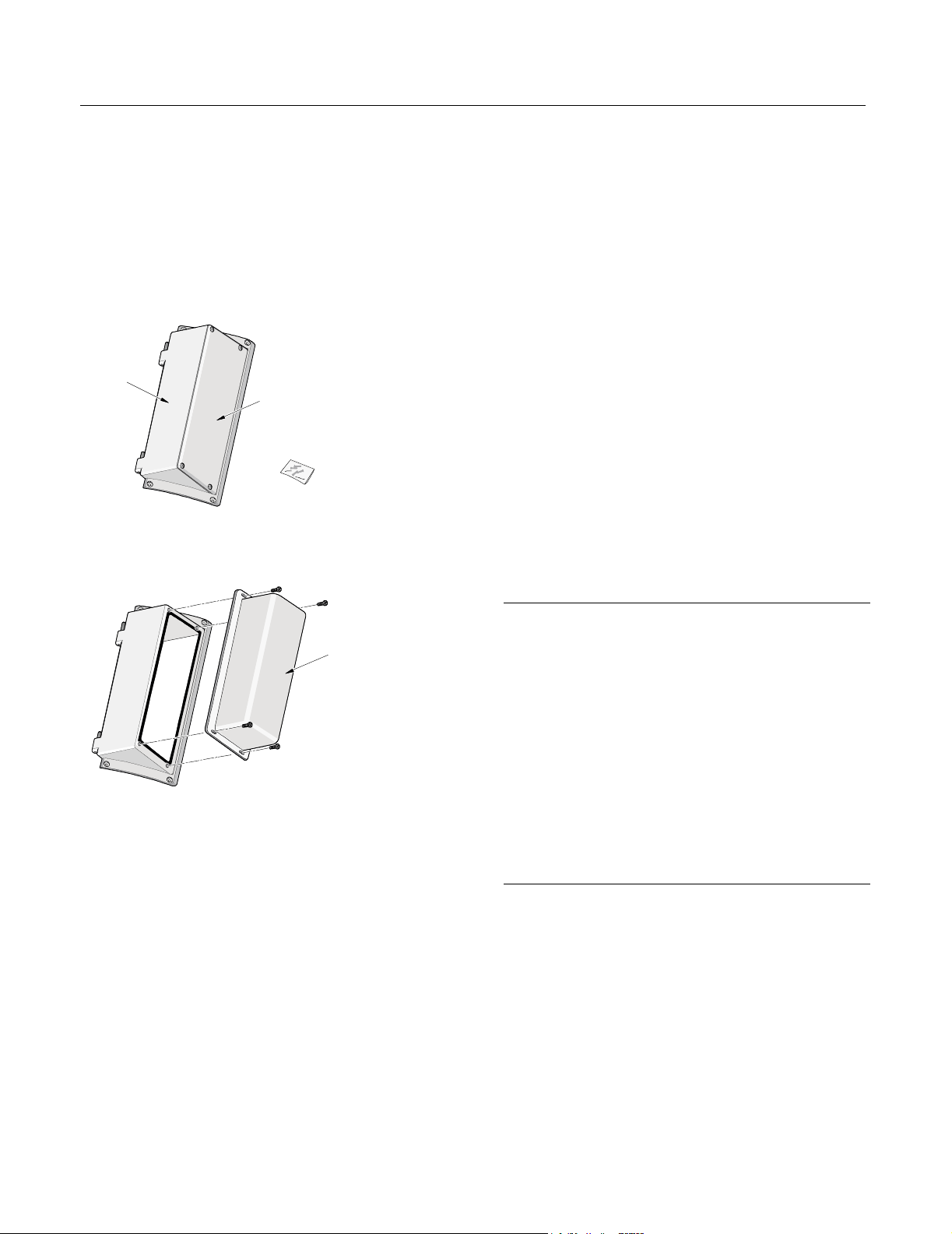

! 1 NEMA 4X extended hatch cover

Extended hatch cove

72002 b

Tools and material required

You will need the following tools and material to

install the NEMA 4X hatch to the ET 355 monitor:

! No. 1 Phillips torque screwdriver

! Sealed Listed (UL) conduit hubs that meet

NEMA 4X/IP66 ratings

! A punch or drill to make openings in the hatch

Steps

To mount a NEMA 4X hatch on the ET 355 monitor,

follow these steps:

1. Decide on the number and locations of hatch

openings required for your application.

2. If the ET 355 monitor is in a hazardous location,

make sure that the location is free of hazardous

gases.

3. Disconnect power and other connections.

4. Make openings in the back of the hatch. If you

need three or fewer openings, you can use as

guides the three indentations on the back of the

hatch. If you need four openings, you will need

to decide how best to space them.

Openings can be made anywhere on the back of

the hatch, as long as the hatch can open and close

freely on its hinges after conduit hubs are

installed.

Important

! Do not make openings in the removable plate, the top, or

the bottom of the hatch, or in the extended hatch cover

(if you are using the extended hatch cover).

! Be sure that any opening you make is free of burrs and

that the surface around the hole is smooth and free of

debris. This will help ensure that the installed fittings seal

properly.

! Be sure that openings do not have sharp edges that

could damage wiring.

! Provide appropriate Listed (UL) conduit hubs that, when

installed according to the manufacturer’s instructions

and the National Electrical Code or local electrical code,

will provide a NEMA 4X/IP66 seal.

5. Attach conduit hubs through the hatch openings

and tighten them to torque settings recommended

by the manufacturer to achieve a NEMA

4X/IP66 rating.

20137 (Rev. 1.0) Page 2

Installing the NEMA 4X Hatch ET 355 Monitor HL

11. Wire all connectors and attach locking devices to

Important

! Flexible conduit allows for greater flexibility during

installation of the NEMA 4X hatch than does rigid

conduit. However, wiring methods must be in

accordance with Class I, Division 2 wiring methods

Article 501-4(b) or the National Electric Code, NFPA 70

for installations in the U.S., or as specified in Section 181J2 of the Canadian Electrical Code for installations

within Canada and in accordance with the authority

having jurisdiction.

! If you use rigid conduit, first attach the monitor to the rigid

conduit and then place the monitor in its final position.

3M Touch Systems recommends that either the monitor

be mounted close to a junction box or that a junction box

be installed close to the monitor.

! The closer the monitor is to a junction box, the easier it

is to make the final connection and mounting of rigid

conduit.

provide strain relief.

12. Close and fasten the hatch by loosely attaching

the four #6-32 Phillips screws. Check to make

sure that the screw holes in the edges of the hatch

line up with the threaded holes in the monitor

enclosure.

Important

If you need to examine wiring inside the hatch, take off the

removable plate (or extended hatch cover) from the hatch.

13. Using a No. 1 Phillips torque screwdriver,

gradually tighten diagonal pairs until all the

screws are equally tight at a torque of 7 inchpounds. This should require about three rounds

of tightening.

6. Install the monitor on its mounting so that it is

rigidly fixed.

7. Temporarily insert the hinge pins of the hatch

and fasten with the #6-32 Phillips screws

provided.

8. Bring the conduit to the hatch, aligning it with

each hub, and attach the conduit to the hub

14. While the monitor is still in a location that is free

of hazardous gases, connect power to the monitor

15. While the monitor is still in a location that is free

of hazardous gases, adjust on-screen display

(OSD) settings as desired. For information on

using OSD controls, refer to the ET 350 Monitor

User’s Installation Guide.

according to the manufacturer’s instructions.

9. Remove the monitor from its mounting.

10. Pull wiring through the conduit, making sure that

there is enough slack in the wiring to allow the

hatch to open and close fully on its hinges

without straining the wiring or connectors.

20137 (Rev. 1.0) Page 3

Installing the NEMA 4X Hatch ET 355 Monitor HL

Contacting 3M Touch Systems

For general information, service, and technical

support for 3M Dynapro products, use the contact

information below:

Area Contact information

USA and

Canada

General Information

Tel 800-667-0374 (toll free)*

Fax 604-521-4629

E-mail etsales@mmm.com

Web site www.3Mtouch.com

Customer Service

Tel 800-667-0374 (toll free)*

Fax 604-521-4629

E-mail

3MTScustomerservice@mmm.com

Technical Support

Tel 800-667-0374 (toll free)*

Fax 604-521-4629

E-mail

3Mdynaprotechsupport@mmm.com

Product registration

Register your 3M Dynapro ET 355 monitor by

mailing the postage-paid Product Registration Card.

It detaches from the Warranty Card that came with

your unit. The Product Registration Card may also be

faxed to 3M Touch Systems (604-521-4629).

Returning products

All returned 3M Dynapro industrial products must be

accompanied by a Service Return Authorization

(SRA) number. For details, contact 3M Touch

Systems customer service.

Outside

USA and

Canada

*Call between 7:30 a.m. and 5:00 p.m., Pacific Time

General Information

Tel 604-521-3962*

Fax 604-521-4629

E-mail etsales@mmm.com

Customer Service

Tel 800-667-0374*

Fax 604-521-4629

E-mail

3MTScustomerservice@mmm.com

Technical Support

Tel 604-521-3962*

Fax 604-521-4629

E-mail

3Mdynaprotechsupport@mmm.com

20137 (Rev. 1.0) Page 4

Copyright

This manual is © 3M 2002. All rights reserved.

Reproduction of the contents of this copyrighted manual in

whole or in part, by any means, electronic or mechanical,

for any purpose, without written permission of 3M Touch

Systems, a subsidiary of 3M, is prohibited.

Notice

Given the variety of factors that can affect the use and

performance of a 3M Touch Systems Product, including

that solid state equipment has operation characteristics

different from electromechanical equipment, some of

which factors are uniquely within User's knowledge and

control, it is essential that User evaluate the 3M Touch

Systems product to determine whether it is suitable for

User’s particular purpose and suitable for User’s method of

application. 3M Touch Systems’ statements,

engineering/technical information, and recommendations

are provided for User’s convenience, but their accuracy or

completeness is not warranted. 3M Touch Systems

products are not specifically designed for use in medical

devices as defined by United States federal law. 3M Touch

Systems products should not be used in such applications

without 3M Touch Systems’ express written consent. User

should contact its sales representative if User’s opportunity

involves a medical device application.

Important notice to purchaser

Specifications are subject to change without notice. 3M

Touch Systems’ Products are warranted to meet their

published specifications from the date of shipment and for

the period stated in the specifications. 3M Touch Systems

makes no additional warranties, express or implied,

including but not limited to any implied warranties of

merchantability or fitness for a particular purpose.

User is responsible for determining whether the 3M Touch

Systems Products are fit for User’s particular purpose and

suitable for its method of production, including intellectual

property liability for User's application. If a Product is

proven not to have met 3M Touch Systems’ warranty, then

3M Touch Systems’ sole obligation and User’s and

Purchaser’s exclusive remedy, will be, at 3M Touch

Systems’ option, to repair or replace that Product quantity

or to refund its purchase price. 3M Touch Systems has no

obligation under 3M Touch Systems’ warranty for any

Product that has been modified or damaged through

misuse, accident, neglect, or subsequent manufacturing

operations or assemblies by anyone other than 3M Touch

Systems. 3M Touch Systems shall not be liable in any

action against it in any way related to the Products for

any loss or damages, whether non-specified direct,

indirect, special, incidental or consequential (including

downtime, loss of profits or goodwill) regardless of the

legal theory asserted.

(11/01)

Edition

First edition: May 2002

Document Number: 20137 (Rev. 1.0)

Trademark

3M Dynapro is a trademark of 3M.

3M Touch Systems

3M Optical Systems Division

800 Carleton Court

Annacis Island

New Westminster, BC

Canada V3M 6L3

www.3Mtouch.com

Worldwide Manufacturing Plants

Austin, Texas

Methuen, Massachusetts

Milwaukee, Wisconsin

Vancouver, BC, Canada

Abingdon, UK

For more information on 3M touch products, visit

3Mtouch.com or call toll-free 1-800-667-0374.

© 3M 2002

20137 (Rev. 1.0)

Loading...

Loading...