Page 1

a 3M company

®

®

DuoFLO Filter Systems

Filter Cartridge Benefits...

...Filter Bag Economy

Easily retrofits standard

bag filter housings

Provides up to 4 times or

more life than conventional

bag filters

Eliminates filter media rupture,

contaminant by-pass and

unloading

Simplifies filter installation,

removal,and disposal

Reduces hold-up volume by

up to 67% or more

Page 2

The CUNO DuoFLO filter system is an advanced proven alternative to the use of standard bag filters. Developed

using CUNO's extensive depth filtration experience, the DuoFLO filter features a true graded-porosity media

structure and a 62 % increase in filter surface area. Compared to conventional felt filter bags, DuoFLO filters

provide:

up to 4 times or more the service life

+

superior contaminant removal efficiency

+

enhanced flow per filter element

+

reduced loses associated with frequent filter change-outs (production

+

downtime, disposal, and labor costs)

The DuoFLO filter will easily retrofit most existing bag filter housings. To

take advantage of the DuoFLO system in applications where bag filter

housings are currently in use, simply remove the existing bag support

basket, replace it with a DuoFLO support basket, and insert the DuoFLO

filter. For new installations, CUNO offers a full line of DuoFLO filter

housings (page 5).

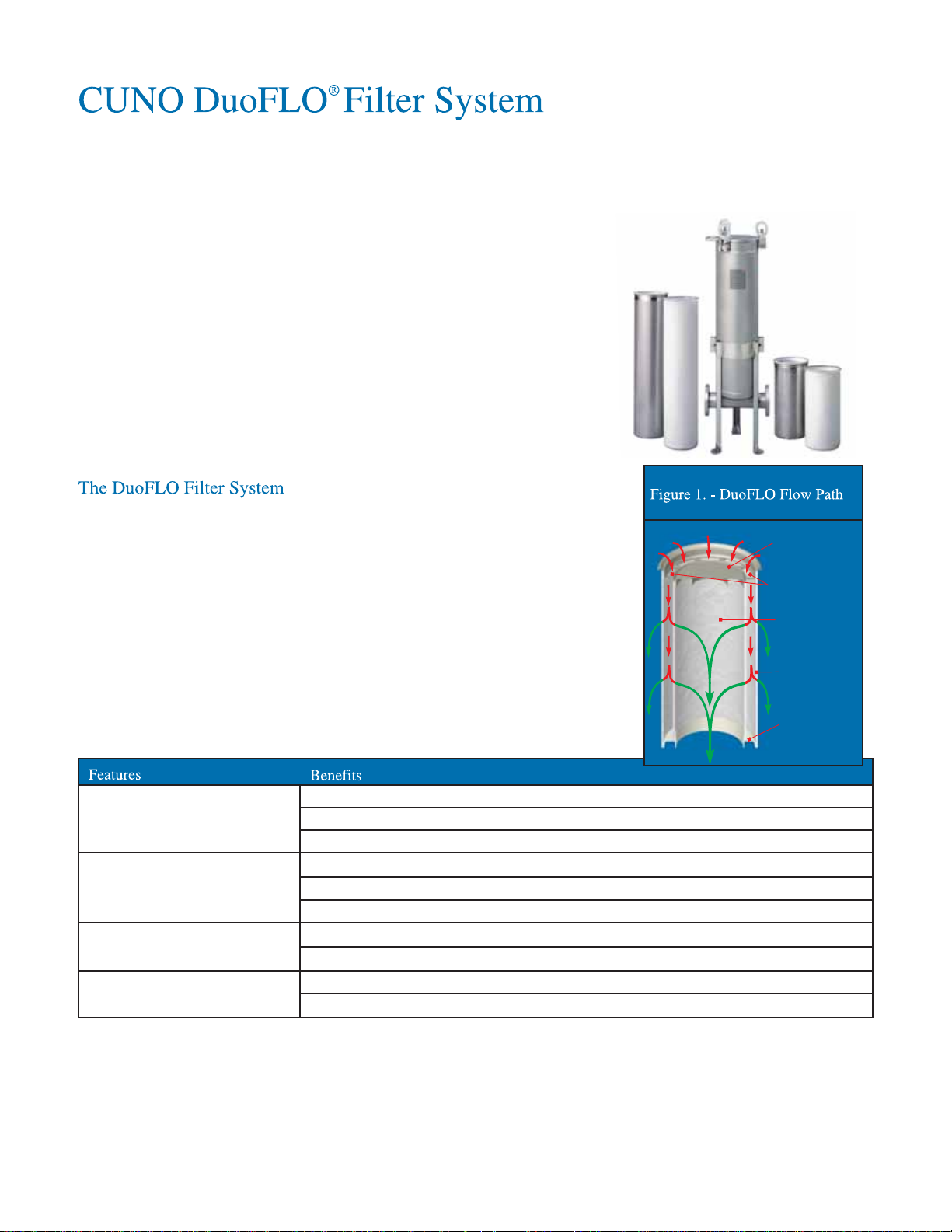

The DuoFLO element is comprised of two cylinders bonded to a top plate and a

lower seal plate. As shown in Figure 1, the fluid enters the top of the filter

through flow channels located in the DuoFLO filter top plate. The fluid flows

between the inner and outer media cylinders, and then passes through the media

and support basket into the clean chamber of the filter housing.

Top P lat e

Flow Channels

The DuoFLO design incorporates an innovative new geometry of both filter

element and restrainer basket which provides 100% 3 dimensional support of

the DuoFLO media. This eliminates the potential for filter element rupture and

the resulting gross contamination of the downstream effluent with previously

Inner Media

Cylinder

Outer Media

Cylinder

removed particles. The design of the DuoFLO element also reduces filter

element hold-up fluid volume by 67% compared to conventional bags,

minimizing worker exposure to process fluids.

+

Filter design combining a

graded-porosity media with 62%

greater filter surface area

+

Hold-up volume reduced by

67% compared to conventional

bag filters.

+

100%, downstream support of

the filter element

+

Superior flow characteristics

+

Longer Service Life – up to 4 times or more that of conventional felt filter bags

+

Reduced Filter Usage - minimizes product loss, labor, disposal costs, and operator exposure

+

Increased productivity - less down time for filter change-out

+

Reduced product loss & related disposal costs

+

Used element retains less fluid, making it lighter weight for easier removal

+

Eliminates displacement balloons and associated spillage during change-out

+

Eliminates filter rupture, contaminant bypass and unloading

+

Allows operation to higher differential pressures before filter change-out

+

Maximizes utilization of filter surface area and maintains low operating pressure drop

+

Reduces flow per unit area (flux) for improved effluent quality

Lower Seal

Plate

CUNO utilizes state-of-the-art technology to produce the DuoFLO filter element optimizing both performance and

filtrate quality to ensure customer satisfaction. DuoFLO filter elements are sized to replace conventional # 1and # 2

bag filters and are available in both polypropylene and polyester materials (including 21 CFR listed materials) with

nominal ratings from 1 to 200 micron.

1

Page 3

The DuoFLO filter design provides an increase in filter

surface area of 62% when compared to commonly used

#1 and #2 bag filters. This additional surface area

provides the following benefits

Lower flux (flow rate per unit area): Since filter

+

life is inversely proportional to flux, reducing the

flux by 50% can achieve up to a three-fold

increase in filter life. Additionally, lower flux

improves the retention efficiency of the element.

Lower initial pressure drop: This increases the

+

time before the recommended change-out

pressure is reached

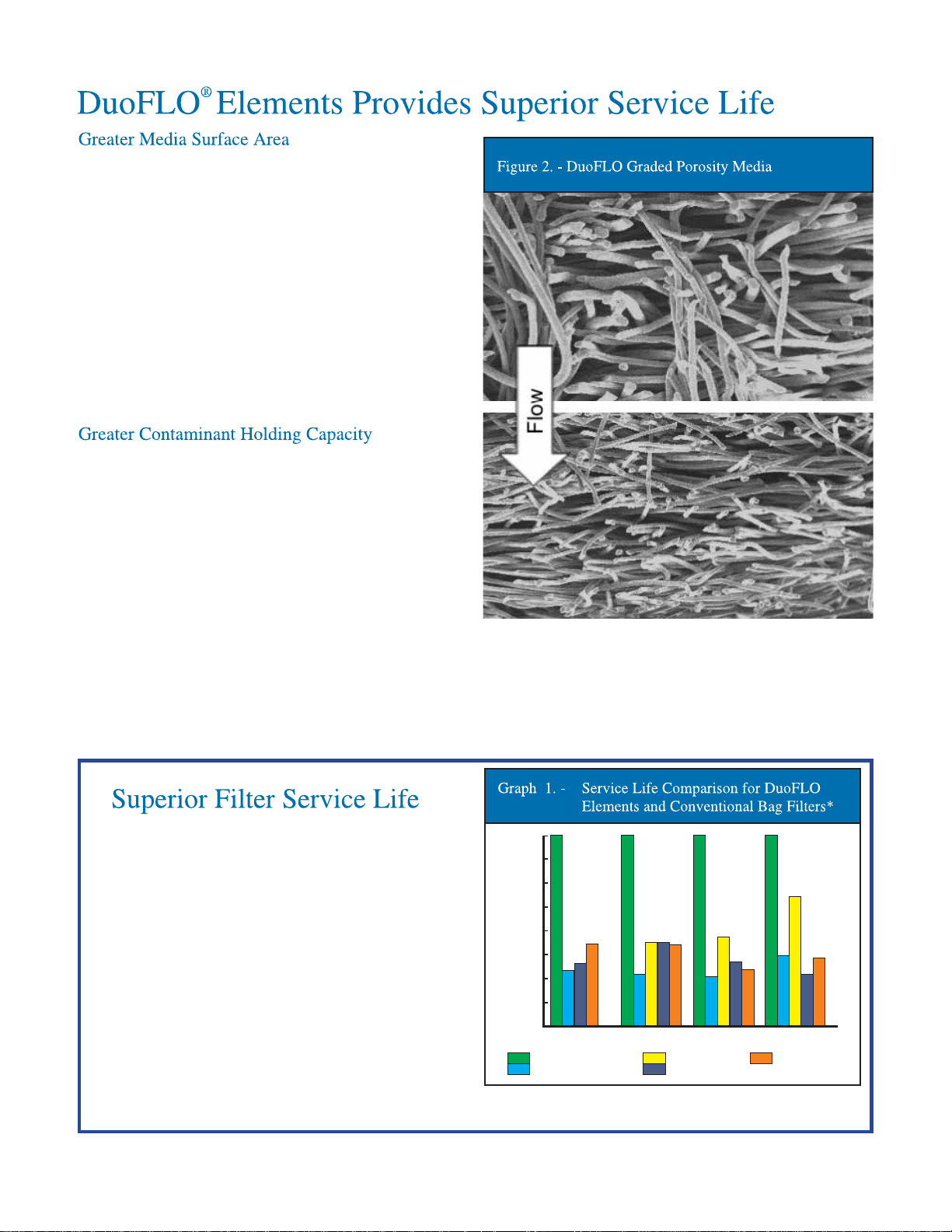

DuoFLO filters are offered in a graded porosity filter

media where two media layers of different porosities are

combined. The result is superior contaminant holding

capacity. The added capacity is achieved by removing

the larger contaminants in the first layer and the finer

contaminants in the tighter, downstream layer (see

Figure 2). The configurations of each nominally rated

filter media have been optimized to achieve the longest

service life. Media Migration is eliminated by thermally

bonding the exterior surface of the downstream media

layer.

Extensive testing, supported by field results,

has demonstrated the superior life advantage

achieved by DuoFLO elements while obtaining

superior efficiencies. As shown in Graph 1,

DuoFLO elements provide for up to 4 times the

throughput compared to equivalently rated

conventional bag filters (the life of the filters

were measured to the same terminal differential

pressure).

100

75

50

25

Throughput (Percent)

0

1 micron 5 micron 10 micron 25 micron

CUNO DuoFLO Elements

Competitor F

* Polypropylene media

22

Competitor FEX

Competitor H

Competitor HEX

Page 4

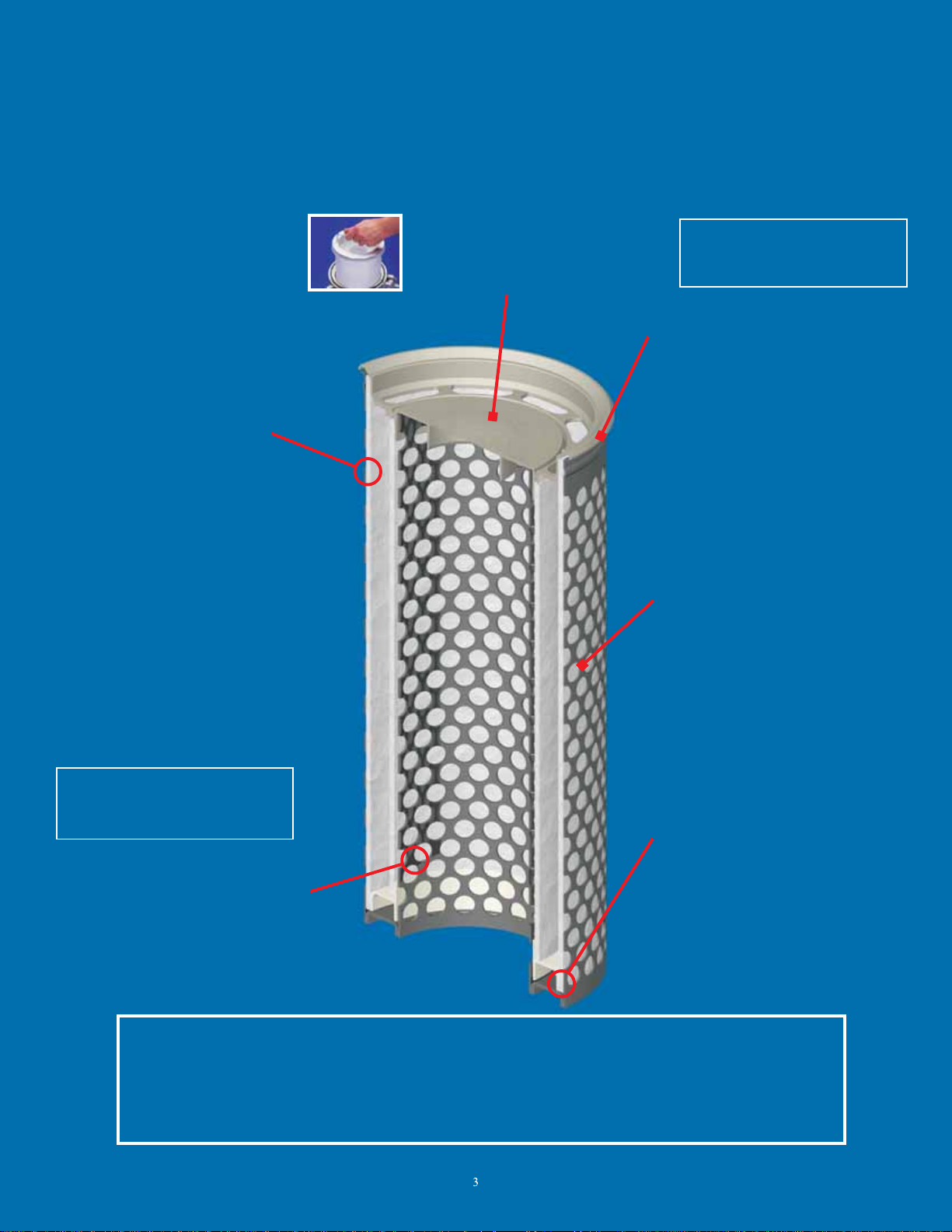

®

DuoFLO Filter Elements

Simple Filter Removal - Simply

insert the CUNO removal tool

into the top plate and lift the

filter from the housing.

Easy Filter Installation -.The

DuoFLO filter element is a rigid

cylinder that easily slides into

the support basket

Graded Porosity Media DuoFLO media consists of

2 layers. The first layer or

upstream zone is “open” to

remove the larger contaminant

while the downstream zone is

“tighter” to remove the smaller

contaminant. This design

provides greater contaminant

holding capacity and longer life

than conventional single layer

media.

Reduced Hold-Up Volume A 67% reduction in hold-up

volume significantly decreases

lost product and disposal costs.

Superior Sealing Collar Constructed from molded

polypropylene or polyester

with an advanced sealing

lip that provides a dynamic

spring-like seal, the DuoFLO

design eliminates

contaminant bypass.

Size Hold-Up Volume (gallons)

#2 DuoFLO 1.4

#2 Standard bag

Support Basket - Full Support

of the filter element ensures

filter integrity even under the

most demanding conditions by

eliminating the potential for

media stretching which can

open the pore structure and

allow larger particles to pass.

4.3

Increased Surface Area -The

unique design provides 62%

more area than typical bag filters

for longer life and fewer filter

change-outs.

Size Filter Area (ft )

#2 DuoFLO 6.7

#2 Standard Bags 4.1

Singed Media Surface - Many

filter bags release fibers that end

up in the filtered product. The

DuoFLO filter media is thermally

treated to eliminate loose fibers.

2

The unique DuoFLO element design - 62% greater area and a unique

graded-porosity media structure - provides a service life advantage of up to

4 times greater than conventional filter bags. Other features

media treatment, thermal seaming, ultrasonic bonding

ensure that the

DuoFLO filter is unsurpassed in quality and performance.

Thermal Side Seam - Using

advanced thermal sealing

processes, the DuoFLO seam

eliminates the problem of

contaminants passing through

large needle holes.

Integral Media to Plate Seal an integral seal between the

plastic components and the

filter media is ensured by using

state-of-the-art ultrasonic welding

techniques.

(sealing collar

of plastic parts to media)

Page 5

Each grade of DuoFLO filter is manufactured from high

)

(

performance fibers selected based on extensive media

performance testing. No adhesives, binders, or silicone

are used in the manufacturing process. The DuoFLO

filter element is available in all-polypropylene,

all-polyester, or polyester media with polypropylene

lower seal and top plate construction.

DuoFLO elements are available in sizes and ratings to

replace standard #1 and #2 filter bags as follows:

Nominal Removal Ratings (microns) 1, 5, 10, 25, 50, 100, and 200*

Filter Diameter (inches/cm) 7 / 17.8

Filter Length (inches/cm) 14.3 / 36.3 27.8 / 70.6

Media Area (ft

Hold Up Volume per Filter

(Gallons/Liters)

* available in polyester only

Maximum Operating

Temperature (°F / °C) *

Maximum Recommended

Flow Rate (gpm / lpm)

Maximum Forward

Differential Pressure

Recommended Change-out

Differential Pressure

CFR Compliant All component materials of the DuoFLO "PP"

* Maximum temperature ratings are dependent on the fluid being filtered -

2/m2

) 3.4 / 0.32 6.7 / 0.62

0.7 / 2.6 1.4 / 6.2

180 / 82 300 / 149

75

/ 284 150 / 568 75 / 284

35 psid @ 68°F (2.4 bar @ 20°C)

20 psid (1.4 bar)

polypropylene element and "FE" polyesterare

listed for food contact per 21 CFR 177.1520.

see Chemical Compatibility Table.

150 / 568

DuoFLO filter elements are compatible with wide range

of chemicals and process conditions. The thermal and

chemical resistance data presented is for guidance only.

Factors such as duration, degree of concentration of a

substance in a fluid and temperature should also be

considered. Thermal and chemical resistance should

also be considered when choosing all materials exposed

to fluids. CUNO strongly recommends that

compatibility be tested prior to use.

Biological Agents Excellent Excellent

Mineral Acids Excellent Good

Organic Acids Excellent Excellent

Alkalies Excellent Poor

Oxidizing Agents Fair Fair

Organic Solvents Fair Good

Water (< 150°F) Excellent Fair

Flow vs. differential pressure for a DuoFLO #2 size

element and support basket in water is depicted in

Graph 2. A typical filter system is often sized for an

initial differential pressure of 0.5 to 1 psi (0.04 to 0.07

bar). A lower flow rate per element typically extends

the life of the filter system.

0.08

0.06

0.04

0.02

0

150

Differential Pressure (psid

1.2

1.0

0.8

0.6

0.4

0.2

1&5micron

10 & 25 micron

50, 100, & 200 micron

0

25

0

50

75

Flow (gpm)

100

125

bar)

Differential Pressure

*#2 Size Element and Support Basket Pressure Drop Only, housing pressure losses are

not included.

4

0

100

200

300

Flow (lpm)

400

500

Page 6

CUNO DuoFLO filter housings are designed and manufactured to economically meet

demanding applications. The housings are available for #1 and #2 size DuoFLO filters

and are constructed from 304 or 316L stainless steel. DuoFLO ASME code housings

are designed, fabricated, and "U" stamped in accordance with ASME Section VIII,

Division 1 for 150 psi @ 300°F*. For those applications not requiring AMSE code

housings, an economical "DFN" version is available. A variety of inlet/outlet

connection styles are available (see specification table below). In addition, custom

designs are available on request.

The DuoFLO filter housing allows the user to realize all of the benefits of the

DuoFLO filter element. A positive element sealing mechanism eliminates bypass of

unfiltered fluid into the effluent stream. Since the DuoFLO filter element has more

surface area and better flow characteristics, larger conventional bag housings can be

eliminated in favor of smaller DuoFLO housings - reducing up-front capital

expenditures and installation costs. In addition, the true “in-line” configuration of

the inlet and outlet connections allow for installation without the additional piping

and elbows required by conventional filter bag housings.

The flow configuration of the DuoFLO housing eliminates the “dirty chamber” that is common in bag filter

housings, thus eliminating the potential for cross contamination of dirty fluid into the clean effluent during filter

element change-out. DuoFLO housings incorporate a design that results in environmental, health, and safety

benefitse by allowing used DuoFLO filter element removal without the spillage of, or contact by the operator with,

the process fluid.

+ Positive element sealing

mechanism

+ No dirty fluid chamber

+

Inline piping configuration

+

Excellent flow characteristics

#1

304 or 316L

#2 150 / 568 100 lb/45.4 kg 12 lb/5.4 kg

#1 304 or 316L

#2 150 / 568 56 lb/25 kg 12 lb/5.4 kg

S.S.

S.S.

2” ANSI or DIN Flange

2” NPT or 2" BSPTr

2" NPT 75 / 284 150 PSI @ 250°F

+ Ensures no bypass of unfiltered fluid into the

effluent stream.

+

Eliminates unfiltered fluid from contaminating the clean

effluent side of the housing during filter change-out

+

Reduces operator contact with the fluid

+

Significantly reduces installation time and costs

+

Ease of piping for series or parallel installation

+

Reduces capital investment since fewer filter elements

are required for a given flow rate

75 / 284

✦ Dependent upon the material of the gasket installed.

150 PSI @300°F

(10.4 bar @ 149°C)

(10.4 bar @ 121°C)

80 lb/36.3 kg 8 lb/3.6 kg

44 lb/20 kg 8 lb/3.6 kg

4 lb/ 1.8 kg

5

Page 7

®

DuoFLO ASME Code Filter Housings

Minimized Dirty Fluid Chamber - the DuoFLO filter element

extends to the top of the housing cover to significantly reduce the

dirty fluid volume compared to conventional bag filter systems

¼” NPT Connection- for easy

vent valve or pressure gauge

3 Eye Nuts - eliminate the

need for special tools and

allows for quick and easy

filter element installation

and removal

Light weight cover - remains

attached to the housing and

pivots open to allow easy

access for filter change-out.

Can be rotated for ideal pivot

orientation.

304 or 316L Construction -

provides compatibility with

a wide range of fluids. Shot

blast exterior finish improves

appearance and allows for

easy cleaning

installation

O-Ring Housing Seal - to

provide a positive seal between

the housing and the cover when

the system is in use

Double O-Ring Element Seal Seals the DuoFLO filter element

to the top of the stand pipe (inlet)

ensuring no by-pass

Support Basket - Full Support

of the filter element ensures

filter integrity even under the

most demanding conditions.

Eliminates media stretching

which can open the media

pores and allow larger

particles to pass.

ASME Code - meets local

and state design requirements

for pressure vessels

Inlet Stand Pipe - directs

fluid to the top of the filter

housing and inlet channels

of the DuoFLO filter element

Available Connections -

include 2” ANSI flange (shown),

2” NPT, 2” DIN flange, or

2” BSPTr to satisfy most common

piping requirements

Dished Bottom - drains the

clean liquid to the housing outlet

for better product recovery and

cleaner system operation

Optional Legs (shown below) -

Adjustable legs can accommodate an inlet/outlet centerline

height adjustment of up to

11 inches

In-line Bottom Inlet & Outlet - provides easy

and cost effective installation by reducing the

complexity of the piping scheme. Both the inlet

and outlet piping have ½” NPT connections for

drains, sample ports, or pressure gauge

installation.

Page 8

Flange Thread Max. Min. Bolt Circle

anc

es

1DF1 35/89 20/51

13/33.2 11 ½/29.2 15/38.1 4/10.2 10 ½ / 26.7

1DF2 63/160 34/87

Inches cm Inches cm Inches cm Inches cm

1DFN1 29 1/2 74.9 40 101.6 12 30.5

5 12.7

1DFN2 43 3/4 111.1 68 1/4 173 12 30.5

The inline bottom inlet and outlet connections offer tremendous flexibility in manifolding the housings for series or

parallel filtration. This concept allows for enhanced adaptability in achieving both short and long term flow and

process requirements. Manifold piping systems (with and without valves) are available for installing DuoFLO

housings in duplex, triplex, and quadplex configurations. Consult factory for more details.

Space Required to remove

element and support basket

Space Required to remove

element and support basket

B

A

CUNO

DuoFLO

C

E

5/16” diameter

hor hol

B

A

INLET

D

D

OUTLET

C

7

Page 9

DuoFLO®Filter System Accessories

The following accessories are available for use with the DuoFLO filter system:

DuoFLO Element

Installation Tool

DuoFLO Element

Removal Tool

Coatings

Industrial

Chemical

Petrochemicals

Food & Beverage

Pharmaceutical

Electronics

Water Treatment

Element Insertion Tool (Part # 60300-31): Constructed from 316

stainless steel, this tool facilitates insertion of DuoFLO elements into

DuoFLO Element

Hold Down Spring

the support basket. The tool is designed with curved ends to ensure no

damage is done when inserted into the element.

Element Removal Tool (Part # 74132-31): Constructed from 316

stainless steel, this tool facilitates removal of DuoFLO elements from

the support basket. The tool is designed with an easy-to grip handle

and locking tabs for proper support of element.

Element Hold Down Spring (Part # 64254-31): Constructed from

DuoFLO Magnet

316 stainless steel, this spring assembly ensures the DuoFLO element is

properly seated in side entry housings to prevent fluid bypass.

Magnet Assembly (Part # 60376-01): Constructed using 12,000 gauss

strength magnets inserted into a 304 / 304 L Stainless steel tube, this

magnet assembly provides for improved capture of metallic fines from

fluid streams. This assembly is designed for easy insertion and

removal and is fully supported when inserted into a DuoFLO element.

DuoFLO®Filter Applications

Electrodeposition Paper Coatings Printing Ink

Trade Paint

Can Coatings Automotive Paint Coil Coatings

Dispersions Architectural Paint

Parts Washing Ground Water Lubricants

Pulp & Paper Waste Water Machine Tool Coolants

Cooling Water Hydraulic Fluids Transformer Oil

Acids Fuels Silicones

Chemicals Catalyst Recovery Aerosol Products

Process Water Resins Mineral Oil

Alcohols Alkalines Waxes

Glycols Esters Solvents

Fuel Additives Distillation Fuels

Glycols Enhanced Oil Recovery Injection Fluids

Lube Oils Amines

Vegetable Oil Fruit Juice Liquid Sugar

Syrups Beer Bottled Water

Edible Oils Honey Gelatin

Soft Drinks High Fructose Corn Syrup Ready to Drink Tea

Wine Vinegar Sports Drinks

Spirits

Catalyst Recovery Solvents Water Systems

Vitamin Extracts Active Pharmaceutical Ingredients Opthalmics

Bulk Pharmaceutical Chemicals Carbon Removal Lotions

OTC Solutions

Etching Baths CD’s / DVD’s Solvents

Process Water / RO Prefiltration Photochemicals Printed Circuit Manufacturing

Cooling Water Well Water Waste Water

Process Water Ground Water RO Prefiltration

Adhesives Resins

8

Page 10

CUNO offers a complete line of DuoFLO 316 stainless steel support baskets (many available in

316 L S.S.) for use in existing bag filter housings or in the DuoFLO filter housing. The

DuoFLO element utilizes a basket for proper element support. The DuoFLO filter

basket has two concentric stainless steel cylinders to support both the inner and

outer filter element sleeves. This design ensures media integrity and consistent

effluent quality. DuoFLO baskets include the optimum combination of strength

and open area to provide proper media support, excellent flow characteristics, and

minimal pressure drop.

The DuoFLO filter support basket ordering guide (below) cross references the

competitive filter bag housing manufacturer and model to the correct DuoFLO

support basket needed to upgrade to the DuoFLO filter element.

***

# # ) )

Filtrek BMB 1 - 17 Side #2 N/A N/A 60382-35 N/A

FSI FS - 85 & Up 1 - 24 Side #2 N/A N/A 60382-38**** N/A

FSI FSP - 40 1 Side #1 N/A N/A 60382-32**** N/A

FSI FSP - 85 & Up 1 - 24 Side #2 N/A N/A 60382-31**** 60382-39

Filtration Systems 112 1 Over the top #1 60343-31 N/A 60382-32 N/A

Filtration Systems 122 1 Over the top #2 60343-31 N/A 60382-31 60382-39

GAF/AFFCO RB(1,2 or 4) 1 - 4 Over the top #1 60339-31xx* N/A 60382-32 N/A

GAF/AFFCO RB(1,2 or 4) L 1 - 4 Over the top #2 60339-31xx* N/A 60382-31 60382-39

GAF/AFFCO RB1 SE 1 Side #1 N/A 60334-3x442** 60382-34 N/A

GAF/AFFCO RB1 L-SE 1 Side #2 N/A 60334-3x442** 60382-33 N/A

GAF/AFFCO RB(2 - 12)C2L 2 - 12 Side #2 N/A 60334-3x442** 60382-33 N/A

Hayward POLYLINE FLT 4202 1 Side #2 60362-31 N/A 60382-31 60382-39

Hayward TOPLINE TBF 0101 1 Over the top #1 N/A N/A 60382-32 N/A

Hayward TOPLINE TBF 0102 1 Over the top #2 N/A N/A 60382-31 60382-39

Hayward MAXILINE MBF 3 - 24 Side #2 N/A N/A 60382-31 60382-39

Hayward MAXILINESEMB 3 - 24 Side #2 N/A N/A 60382-31 60382-39

Krystil Klear M88302 (OEM) 1 Side #2 60346-31 N/A 60382-31 60382-39

Krystil Klear L8815 1 Side #1 N/A N/A 60382-32 N/A

Krystil Klear L8830 1 Side #2 N/A N/A 60382-31 60382-39

Parker SB1 or 4 1 or 4 Side #1 60340-31xx* N/A 60382-32 N/A

Parker SB1 or 4 1 or 4 Side #2 60340-31xx* N/A 60382-31 60382-39

Rosedale 8 - 15 1 Side #1 N/A N/A 60382-36 N/A

Rosedale D8 - 15 (Duplex) 2 Side #1 N/A N/A 60382-36 N/A

Rosedale 8 - 30 1 Side #2 N/A N/A 60382-35 N/A

Rosedale D8 - 30 (Duplex) 2 Side #2 N/A N/A 60382-35 N/A

Rosedale 16 - 48 2 - 23 Side #2 N/A N/A 60382-37 N/A

Strainrite U F1-180 1 - 12 Side #2 N/A N/A 60382-31 60382-39

Gasket GAF/AFFCO Parker Gasket Part Number

Nitrile 60339-31GA 60340-31GA Nitrile 60334-36442

EPR 60339-31GB 60340-31GB EPR 60334-37442

Viton 60339-31GC 60340-31GC Viton 60334-38442

TEV 60339-31GD 60340-31GD TEV 60334-39442

*** Hold down Spring (Part # 64254-31) required for all side entry one bag housings

**** Seal Ring & FSI installation tool (Part # 74132-31) required

9

Page 11

DuoFLO®Filter Element Ordering Guide

Filter

Designation

DFG - DuoFLO

Graded-Porosity

Nominal Removal

Rating (Microns)

001 - 1µm PP - Polypro/Polypro 1 - 14.3 nominal C - Open (DuoFLO

005 - 5µm EE - Polyester/Polyester 2 - 27.8 nominal

010 - 10µm EP - Polyester/Polypro R - Closed (Standard Bag

025 - 25µm FE - Polyester/Polyester**

050 - 50µm

100 - 100µm

200* - 200µm

* Available in single layer polyester material (Code EE) only ** 21CFR Materials, available in 1, 5, and 10 µm only

(Media/Plastic Components)

Material

Element

Length

(inches)

DuoFLO AMSE Code Filter Housing Ordering Guide

Number

Around

1 = 1 Around DF

DuoFLO Size

1 = #1 Size B = 304 SS 1 = 2" ANSI Flange L = Legs* GA = Nitrile**

2 = # 2 Size C = 316L SS 2 = 2" NPT N = No legs GB = EPR

Housing

Material

Connection Type

3 = 2" DIN Flange GC = Viton

4 = 2" BSPTr

Support

Legs

Connection Style

Housings

Housings)

Gasket

Material

* Housing Legs (when ordered separately) 98848-01 ** Limits housing operating temperature to 250°F (121°C)

DuoFLO DFN Filter Housing Ordering Guide

Number

Around

1 = 1 Around DFN

DuoFLO Size

1 = #1 Size B = 304 SS

2 = #2 Size C = 316L SS GB - EPR

Housing

Material

Connection Type

DuoFLO Filter Accessories

DuoFLO Element

Installation Tool

Part # 60300-31

DuoFLO Magnet

Part # 60376-01

DuoFLO Element Removal Tool

Part # 74132-31

2 = 2" NPT

Support

Legs

C - Mounting

Clips

Gasket

Materials

GA - Nitrile

GC - Viton

DuoFLO Element Hold

Down Spring

Part # 64254-31

10

Page 12

]

]

]

]

]

CUNO MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. Since a variety of factors can affect the use and performance of a CUNO product in a particular application, some of which are uniquely within the user’s knowledge and control, user is responsible

for determining whether or not the CUNO product is fit for a particular purpose and suitable for user’s method of application

.

If the CUNO product is proved to be defective, THE EXCLUSIVE REMEDY, AT CUNO’S OPTION, SHALL BE TO REFUND THE PURCHASE PRICE OR TO REPAIR OR REPLACE THE

DEFECTIVE PRODUCT. CUNO shall not otherwise be liable for loss or damages, whether direct, indirect, special, incidental or consequential, regardless of the legal theory asserted, including, but not limited

to, contract, negligence, warranty or strict liability.

WARRANTY

Seller warrants its equipment against defects in workmanship and material for a period of 12 months from date of shipment from the factory under normal use and service and

otherwise when such equipment is used in accordance with instructions furnished by Seller and for purposes disclosed in writing at the time of purchase, if any. Any

unauthorized alteration or modification of the equipment by Buyer will void this warranty. Seller's liability under this warranty shall be limited to the replacement or repair,

F.O.B. point of manufacture, of any defective equipment or part which, having been returned to the factory, transportation charges prepaid, has been inspected and determined by

the Seller to be defective. THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EITHER EXPRESSED OR IMPLIED, AS TO DESCRIPTION, QUALITY,

MERCHANTABILITY, FITNESS FOR ANY PARTICULAR PURPOSE OR USE, OR ANY OTHER MATTER. Under no circumstances shall Seller be liable to Buyer or any

third party for any loss of profits or other direct or indirect costs, expenses, losses or consequential damages arising out of or as a result of any defects in or failure of its products

or any part or parts thereof or arising out of or as a result of parts or components incorporated in Seller's equipment but not supplied by the Seller.

a 3M company

CUNOIncorporated

400 Research Parkway

Meriden, CT 06450, U.S.A.

Tel:(800) 243-6894

(203) 237-5541

Fax:(203) 630-4530

www.cuno.com

CUNO and DuoFLO are trademarks of 3M Company used under license.

© 2007 3M Company. All Rights Reserved LITCDUOF1.1110p

Loading...

Loading...