Page 1

3M

™

Water Filtration Products

Installation and Operation Instructions for

High Flow Series

Dual Flow Manifold System DF260-CL-CC

Installer: Please leave this manual with owner/operator.

Owner/Operator: Please retain for operation and future instructions.

Page 2

NOTES

Page 3

SAFETY INFORMATION

SAFETY INFORMATION

EXPLANATION OF SIGNAL WORD CONSEQUENCES

WARN ING

CAUT ION

CAU TIO N

WARN ING

Read, understand, and follow all safety information contained in these instructions prior to installation

and use of the 3M™ Water Filtration Products Dual Flow Manifold System DF260-CL-CC. Retain these

instructions for future reference.

Intended use:

The

Dual Flow Manifold System

equipment and has not been evaluated for other uses. The system is installed indoors, and must be installed by a qualifi ed

professional installer according to these installation instructions.

EXPLANATION OF SIGNAL WORD CONSEQUENCES

DF260-CL-CC is intended for use in fi ltering potable water for foodservice

WARNING

CAUTION

CAUTION

To reduce the risk associated with the ingestion of contaminants:

• Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

Systems certifi ed for cyst reduction may be used on disinfected water that may contain fi lterable cysts. EPA Establishment #070595-CT-001

To reduce the risk associated with choking:

• Do not allow children under 3 years of age to have access to small parts during the installation of this product.

To reduce the risk associated with hazardous voltage due to an installer drilling through existing electric or water pipes in the area of installation:

• Do not install near electric wiring or piping which may be in path of a drilling tool when selecting the position to mount the system bracket.

To reduce the risk of physical injury:

• Depressurize system as shown in manual prior to cartridge removal.

To reduce the risk associated with back strain:

• Follow safe lifting procedures.

Indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury and/or property damage.

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury and/or property damage.

Indicates a potentially hazardous situation, which, if not avoided,

may result in property damage.

WARNING

1

Page 4

IMP ORTA NT N OTES

CAUTION

CAUT ION

To reduce the risk associated with property damage due to water leakage:

• Read and follow Use Instructions before installation and use of this system.

• Installation and use MUST comply with all state and local plumbing codes.

• Before starting installation, shut off main water supply and drain pipes.

• Protect from freezing, remove fi lter cartridge when temperatures are expected to drop below 40 °F (4.4 °C).

• Do not install systems in areas where ambient temperatures may go above 110 °F (43.3 °C).

• Do not install on hot water supply lines. The maximum operating water temperature of this system is 100 °F (37.8 °C).

• Do not install if water pressure exceeds 125 psi (862 kPa). If your water pressure exceeds 80 psi (552 kPa), you must install a pressure

limiting valve. Contact a plumbing professional if you are uncertain how to check your water pressure.

• Do not install where water hammer conditions may occur. If water hammer conditions exist you must install a water hammer arrester. Contact

a plumbing professional if you are uncertain how to check for this condition.

• Any non-metallic fi ttings used in the installations must be of adequate rating for the line pressure.

• Where a backfl ow prevention device is installed on a water system, a device for controlling pressure due to thermal expansion must be installed.

• Do not use a torch or other high temperature sources near system, cartridges, plastic fi ttings or plastic plumbing.

• On plastic fi ttings, never use pipe sealant or pipe dope. Use PTFE thread tape only, pipe dope properties may deteriorate plastic.

• Take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may occur if over tightening occurs.

• Do not install in direct sunlight or outdoors.

• Do not install near water pipes which will be in path of a drilling tool when selecting the position to mount the bracket.

• Mount system in such a position as to prevent it from being struck by other items used in the area of installation.

• Ensure that the location and fasteners will support the weight of the system when installed and full of water.

• Ensure all tubing and fi ttings are secure and free of leaks.

• Do not install unit if collet is missing. Contact your sales representative if collets are missing from any fi ttings.

• The disposable fi lter cartridge(s) MUST be replaced every 12 months, at the rated capacity, or sooner if a noticeable drop in pressure occurs.

IMPORTANT NOTES

• Failure to follow instructions will void warranty.

• Allow a minimum of 3" (7.6 cm) clear space under fi lter to facilitate cartridge change.

• Install with the inlet and outlet ports as labeled. Make sure not to reverse connections.

• Some local codes may require the use of a licensed plumber or certifi ed installer when disrupting a potable water line.

2

Page 5

Table of Contents

Safety Information ...........................................................................1

Dual Flow (DF) Manifold Systems and Cartridges ............................3

Inlet and Outlet Connections ............................................................3

Product Dimensions ........................................................................3

How to Use “Push-in” Connections .................................................4

How to Use “Inlet/Outlet” Fitting Retention Clips .............................4

Equipment Installation ..................................................................... 5

Cartridge Change-out Procedure ..................................................... 6

Troubleshooting ...............................................................................7

Replacement Parts Listing ...............................................................7

Limited Warranty .............................................................................8

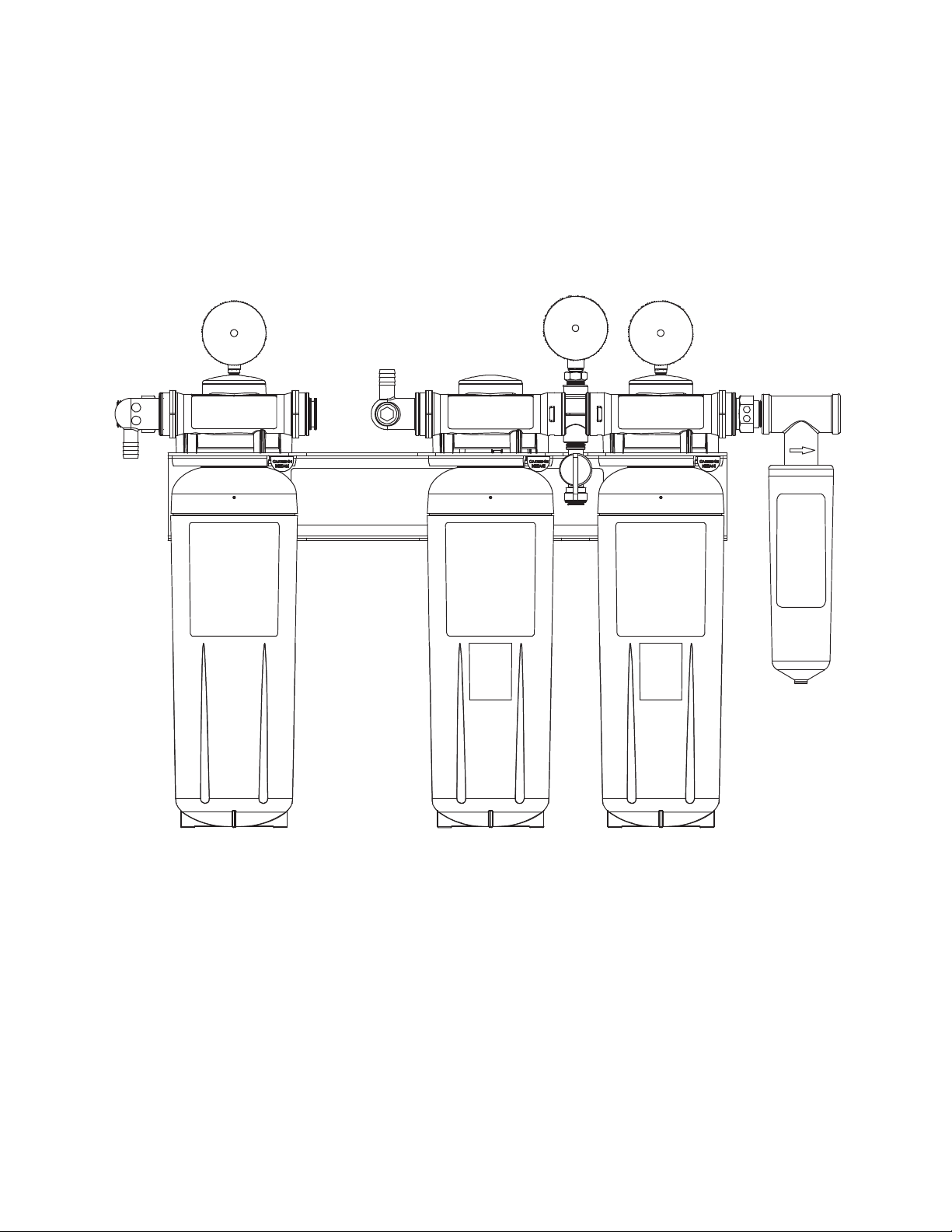

Dual Flow (DF) Manifold System and Cartridges

The DF260-CL-CC Dual Flow (DF) System helps to provide consistent high quality water for multiple applications. The inlet water for the ice machine

enters the manifold on the left rear side, and the inlet water for the beverage and coffee enters the manifold on the right rear side. Each water

stream (ice, beverage, coffee) has a separate outlet connection fi tting.

The left single cartridge (yellow label) is model HF60-S-SR5. It is critical that this cartridge be installed in the left most manifold head which

also has a yellow 3M label. The cartridge is keyed such that it will not fi t properly if installed in either of the other manifold heads. The media in

this cartridge is a pleated nylon membrane with a time released scale inhibitor. It fi lters the water going to the ice machine. The water for the ice

machine exits the manifold on the left side front connection (labeled “Outlet Ice”).

The two cartridges to the right of the ice cartridge (blue label) are model HF60-CL. These cartridges are plumbed in parallel and fi lter the water

going to post mix cold beverage and coffee. The HF60-CL cartridges will not fi t into the left most (ice) head. The water for cold beverage exits the

manifold on the middle front connection (labeled “Outlet Beverage”). Water for coffee exits the manifold on the right side front connection (labeled

“Outlet Coffee”).

Inlet and Outlet Connections

The water inlets are on the rear left and right sides, and the water outlets are on the front right, middle, and left sides. All inlets and outlets are

identifi ed with their corresponding labels. The water inlets fi tting size is ¾” NPT male, the ice and beverage outlet fi tting size is ½” barb, and the

coffee outlet fi tting size is ¾” NPT female. Built-in check valves (non-return) are incorporated into all three outlets.

Product Dimensions

25 9/16"

[64.9 cm]

TOP VIEW

18 3/4"

47.6 cm

OUTLET

TO ICE

OUTLET

TO BEVERAGE

REQUIRED TO REMOVE CARTRIDGE

3" MINIMUM DISTANCE

Figure 1

3

Page 6

How To Use “Push-In” Fittings (Collet)

CAUT ION

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Do not install unit if collet is missing. Contact your sales representative if collets are missing from any fi ttings.

This product is outfi tted with user friendly “push-in” connectors. Proper use of the connectors is shown in Figure 2. It is most important that the

tubing selected for use with these connectors be of high quality, exact size and roundness, and with no surface nicks or scratches. If it is necessary

to cut the tubing, use a plastic tubing cutter or sharp razor knife. Make a clean square cut. Should a leak occur at a “push-in” connector, the cause

is usually due to the tubing. To fi x tubing, relieve the pressure within the tube. Release the end of the tubing with the leak from its

“push-in” connector. Cut off at least 1/4” (0.6 cm) from the end. Reattach the tubing to its “push-in” connector. Confi rm connection is leak free.

To Attach Tubing To Release Tubing

11

Push tubing straight as far as it will go.

22

Tubing is secured in. Push in grey collet to release tubing. Pull tubing straight out.

Figure 2

How to Use the Inlet/Outlet Fitting Retention Clips

This product is outfi tted with inlet/outlet fi ttings. The fi ttings can be attached or removed from the system without tools. Retention clips are semicircular in shape with three internal tabs, bottom, center and top. Tab interlaces with windows in the manifold head near each connection port. Clip

is fl exible and easily assembled following these instruction and illustrations.

1. Insert fi tting into manifold.

2. With fi tting inserted into manifold port, snap clip into place beginning at the bottom slot.

3. Push center tab into center slot.

4. Finally push top tab into top slot.

Step 1

Step 2 Step 3

Figure 3

4

Step 4

Page 7

Equipment Installation

CAUT ION

IMP ORTA NT N OTES

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Read, understand, and follow all safety information contained on pages 1-2 prior to installation and use of this product.

IMPORTANT NOTES

• Failure to follow instructions will void warranty.

• Allow a minimum of 3” (7.6 cm) clear space under fi lter to facilitate cartridge change.

• Install with the inlet and outlet ports as labeled. Make sure not to reverse connections.

DF manifold systems may be used with metal or non-metallic piping systems.

1. Shut off incoming cold water supply.

2. Select the installation location. Allow a minimum of 3 in (7.6 cm) of space below the cartridge for change-outs.

3. Select fasteners (not included) and tools appropriate for the installation location (wall, support structure mounted to wall studs, concrete,

etc.)

4. Mount the manifold/fi lter system to a wall or using the mounting holes provided on the back plate of the metal bracket.

• It is recommended to fi rst draw a level line on the mounting surface at the height of the fasteners.

• Mark the location of the fasteners using the bracket as a template or by measuring the distance between the mounting holes.

• Install the fasteners and allow 1/4”-3/8” (6-10 mm) of each fastener to protrude from the surface.

• Install the manifold onto the fasteners.

• Tighten the fasteners.

5. Install ¾” NPT male inlet fi ttings for the ice water inlet and the beverage/coffee water inlet (left and right rear respectively). Install a ½”

Barb fi tting for the ice water outlet, a ½” Barb fi tting for the beverage water outlet, and a ¾” NPT female fi tting for the coffee water

outlet (left, middle and right front respectively). The inlet Connection Kit (CCP# 125830) includes the ½” Barb fi ttings and the two inlet

ball valves. The three system outlets include the fi ttings only. The instructions for the retention clips are on page 4. (PTFE tape is not

included).

6. Remove the sanitary cap from the HF60-S-SR5 cartridge (cartridge with yellow label) and apply a light coat of water or food-grade

lubricant to the o-rings.

7. Align the tabs on the HF60-S-SR5 cartridge with the slots in the retaining plate of the head on the left hand manifold head (NOTE: Head

has yellow 3M label adhered to it). Insert the cartridge into the head and turn the cartridge to the right until a click sound is heard; the click

indicates that the cartridge is properly engaged.

8. Repeat Steps 6 & 7 for the HF60-CL beverage cartridges into the two heads on the right side of the manifold. NOTE: The HF60-CL

cartridges need to be installed into the heads with the blue 3M labels adhered to them.

Equipment Start-up Procedure

1. Turn on incoming water to system.

2. Pressurize system by opening inlet valves for both the ice and cold beverage/coffee water inlets.

3. Check for leaks.

4. Use vent valve to remove trapped air.

5. Flush system in accordance with the cartridge Performance Data Sheet.

5

Page 8

Cartridge Change-out Procedure

CAUTION

To reduce the risk associated with property damage due to water leakage:

• The disposable fi lter cartridge MUST be replaced every 12 months or sooner at the rated capacity or if a noticeable reduction in fl ow rate occurs.

IMPORTANT NOTE:

The ice cartridge (Model HF60-S-SR5) has a yellow label and will only fi t into the head on the left side of the manifold (head has a yellow 3M label).

The Beverage cartridges (Model HF60-CL) will only fi t into the heads on the right side of the manifold (heads have a blue 3M label).

DF260-CL-CC System Shut-Off procedure:

Cartridges will need to be changed at least every 12 months or when low pressure is indicated on the manifold’s pressure gauge, whichever

occurs fi rst. Depending on local water quality, you may need to change the cartridges prior to the recommended change-out. The loss of fl ow to

carbonators or improper fi ll at the ice maker are also indicators that the cartridges will need to be replaced.

1. Shut-off ice, beverage, and coffee water inlet valves (2 total).

2. Shut-off ice, beverage, and coffee water outlet valves (3 total).

3. Replace HF60-S-SR5 (yellow label), HF60-CL (blue label), and HF8-S cartridges in the sequence shown below. Then complete DF260-CLCC System Pre-Start-Up procedure as shown below before starting system back up.

HF60-S-SR5 Cartridge (yellow label) Replacement:

1. Relieve pressure in the ice line by opening and closing the ice outlet fl ush valve.

2. Push and hold yellow tab to release cartridge locking mechanism while simultaneously rotating cartridge to the left.

3. Using both hands and holding the cartridge from the bottom, rotate the cartridge a quarter turn to the left and gently pull down. NOTE: A

small amount of water will drain from manifold as cartridge is removed.

4. Remove sanitary cap from new cartridge. Install with a quarter turn to the right until cartridge comes to a complete stop. NOTE: Cartridges

are keyed to fi t in proper location only.

HF60-CL Cartridge (blue label) Replacement:

1. Relieve pressure to beverage/coffee line by opening and closing the fl ush valve in between the HF60-CL cartridges.

2. Push and hold yellow tab to release cartridge locking mechanism while simultaneously rotating cartridge to the left.

3. Using both hands and holding the cartridge from the bottom, rotate the cartridge a quarter turn to the left and gently pull down. NOTE: A

small amount of water will drain from manifold as cartridge is removed.

4. Remove sanitary cap from new cartridge. Install with a quarter turn to the right until cartridge come to a complete stop. NOTE: Cartridges

are keyed to fi t in proper location only.

5. Repeat steps 2-4 for second HF60-CL cartridge

HF8-S Cartridge Replacement:

1. Open downstream valve to relieve pressure.

2. Unscrew cartridge by turning clockwise. NOTE: A small amount of water will drain when HF8-S cartridge is removed.

3. Lubricate o-ring of new cartridge with water.

4. Install by turning new HF8-S cartridge toward the right until it come to a complete stop. Do not over tighten. (never use tools to tighten

cartridge)

6

Page 9

DF260-CL-CC System Pre-Start-Up procedure:

1. Turn ice water inlet valve ON.

2. Remove trap air in the ice line by opening and closing the ice outlet fl ush valve.

3. Turn ice water outlet valve ON.

4. Turn beverage/coffee water inlet valve ON.

5. Remove trap air in the beverage line by opening and closing the beverage outlet fl ush valve.

6. Turn beverage water outlet valve ON.

7. Turn coffee water outlet valve ON

8. Slowly turn the beverage/coffee inlet water valve ON and check for leaks.

9. Slowly turn the ice inlet water valve ON and check for leaks.

10. Flush per the cartridge Performance Data Sheet and check for leaks. System is now ready for use.

Troubleshooting

No water fl ow through system

Not enough water to the

downsteam application(s)

Short fi lter life Temporarily dirty water

Inlet valve closed

Cartridges clogged

Low incoming water pressure

Cartridges clogged

Check shut-off valve position

Replace cartridges

Check source

Replace cartridges

Change cartridges or install an

additional upstream prefi lter

7

Page 10

Replacement Parts Listing

Item Part no. Description Qty* Function

1 6228408 DF2xx -CL-CC 1 Assembly, complete

2 60-2333700 Vent Valve 1 Release trapped air

3a 5617103 HF60-S-SR5 Cartridge 1 Water for ice

3b 5625901 HF60-CL Cartridge 1 Water for beverage

3c 55821-06 HF8-S Cartridge 1 Water for coffee

4a 8500552 Inlet Pressure Gauge 1 Monitor inlet water pressure

4b 8500553 Outlet Pressure Gauge 1 Monitor outlet water pressure

5 50-91401 Fitting Retention Clip & O-Ring (not shown) 1 Retain & seal inlet/outlet fi ttings

6 6236101 Optional install kit (not shown) 1 N/A

7 622506 Inlet fi tting kit 1 Inlet fi tting

8a 6225012 Outlet fi tting kit (Ice & Beverage) 1 Ice & Beverage Outlet fi tting

8b 6225009 Outlet fi tting kit (Coffee) 1 Coffee Outlet fi tting

*Per part number, not per system or assembly.

Outlet Fitting Kit

8 8

Inlet Fitting Kit

7

Outlet To Coffee

8

8

8

TOP VIEW

3a 3b 3b

FRONT VIEW

ISOMETRIC VIEW

Figure 4

8

Page 11

Limited Warranty

3M Purifi cation Inc. warrants this Product (excluding disposable fi lter cartridges(s) or membranes(s)) will be free from defects in material and

manufacture for fi ve (5) years from the date of purchase. The disposable fi lter cartridge or membrane is warranted from defects in material and

manufacture for a period of one (1) year from the date of purchase. This warranty does not cover failures resulting from abuse, misuse, alteration

or damage not caused by 3M Purifi cation Inc. or failure to follow installation and use instructions. No warranty is given as to the service life of

any fi lter cartridge or membrane as it will vary with local water conditions and water consumption. 3M PURIFICATION INC. MAKES NO OTHER

WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OR CONDITION OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR ANY IMPLIED WARRANTY OR CONDITION ARISING OUT OF A COURSE

OF DEALING, CUSTOMER OR USAGE OF TRADE. If the Product fails to satisfy this Limited Warranty during the warranty period, 3M Purifi cation

Inc. will replace the Product or refund your Product purchase price. This warranty does not cover labor. The remedy stated in this paragraph is

Customer’s sole remedy and 3M Purifi cation Inc.’s exclusive obligation.

This warranty gives you specifi c legal rights, and you may have other rights which may vary from state to state, or country to country. For any

warranty questions, please call (866) 990-9785 or mail your request to: Warranty Claims, 3M Purifi cation Inc., 400 Research Parkway, Meriden,

CT 06450. Proof of purchase (original sales receipt) must accompany the warranty claim, along with a complete description of the Product, model

number and alleged defect.

Limitation of Liability.

3M Purifi cation Inc. will not be liable for any loss or damage arising from this 3M Purifi cation Inc. product, whether direct, indirect, special,

incidental, or consequential, regardless of the legal theory asserted, including warranty, contract, negligence or strict liability. Some states and

countries do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

9

Page 12

Important Notice

The information described in this literature is accurate to the best of our knowledge. A variety of factors, however, can affect the performance of the Product(s) in a particular

application, some of which are uniquely within your knowledge and control. INFORMATION IS SUPPLIED UPON THE CONDITION THAT THE PERSONS RECEIVING THE SAME

WILL MAKE THEIR OWN DETERMINATION AS TO ITS SUITABILITY FOR THEIR USE. IN NO EVENT WILL 3M PURIFICATION INC. BE RESPONSIBLE FOR DAMAGES OF ANY

NATURE WHATSOEVER RESULTING FROM THE USE OF OR RELIANCE UPON INFORMATION.

It is your responsibility to determine if additional testing or information is required and if this product is fi t for a particular purpose and suitable in your specifi c application.

3M Purifi cation Inc.

400 Research Parkway

Meriden, CT 06450, U.S.A.

Tel (866) 990-9785

(203) 237-5541

Fax (203) 238-8977

www.cunofoodservice.com

www.3Mpurifi cation.com

3M is a trademark of 3M Company.

© 2011 3M Company. All rights reserved.

Please recycle. Printed in U.S.A.

INSTR4382 0411

Loading...

Loading...