Page 1

3M™ Aura™ Particulate Respirators

9300+Gen3 Series

Technical Data Sheet

Product description

The 3M™ Aura™ Particulate Respirators 9300+Gen3

Series meet the requirements of European Standard

EN149:2001+A1:2009, filtering facepiece respirators for

useagainst particles. They provide effective respiratory

protection for use in industries where workers will be exposed

to solid (dust) particles and/or non-volatile liquid particles.

Applications

These respirators are suitable for use in concentrations

ofsolid (dust) particles and/or non-volatile liquid particles

upto the following limits:

Product

Maximum

Product

9310+Gen3

9312+Gen3

9320+Gen3

9322+Gen3

9330+Gen3

9332+Gen3

EN 149:2001+A1:2009

classification

FFP1 NR D 4

FFP2 NR D 12

FFP3 NR D 50

Workplace

Exposure

Limit (WEL)

Filter penetration

The filter penetration, initial and after 120mg of loading with

both 120mg of NaCl* and Paraffin Oil, shall not exceed the

following limits:

EN 149:2001+A1:2009

classification

FFP1 NR D 20%

FFP2 NR D 6%

FFP3 NR D 1%

*Loading of NaCl may be stopped if filter penetration during loading is observed

to decrease.

Maximum

Filter

Penetration

Total inward leakage

Ten subjects perform five test exercises whilst wearing the

respirator. The total inward leakage inside of the respirator

due to face seal leakage, filter penetration and valve leakage

is measured for each subject exercise. The subject mean total

inward leakage for 8 out of 10 subjects shall not exceed the

following limits:

EN 149:2001+A1:2009

classification

Maximum

Total Inward

Leakage

*Many countries apply Assigned Protection Factors (APFs) which reduce the

maximum concentrations of particles inwhich these products can be used.

Seenational regulations and EN 529:2005.

Respiratory protection is only effective if it is correctly

selected, fitted and wornthroughout the time when the

wearer is exposed to hazards.

Standards

Products are classified by filtering efficiency and maximum

total inward leakage performance (FFP1, FFP2 and FFP3),

alsoby usability and clogging resistance.

Performance tests in this standard include filter penetration;

extended exposure (loading) test; flammability; breathing

resistance and total inward leakage. Reusable products are

also subjected to cleaning, storage and mandatory clogging

resistance tests (clogging is optional for non-reusable

products). A full copy of EN 149:2001+A1:2009 can

bepurchased from your national standards body.

FFP1 22%

FFP2 8%

FFP3 2%

1

Page 2

3M™ Personal Safety Division | 3M™ Aura™ Particulate Respirators 9300+Gen3 Series

Breathing resistance

The breathing resistance of the respirator is tested during

inhalation and exhalation. Thebreathing resistance of the

respirators shall not exceed the following limits:

EN 149:2001

+A1:2009

classification

FFP1 0.6 mbar 2.1 mbar 3.0 mbar

FFP2 0.7 mbar 2.4 mbar 3.0 mbar

FFP3 1.0 mbar 3.0 mbar 3.0 mbar

Maximum Breathing Resistance

Inhalation

at 30l/min

Inhalation

at 95l/min

at 160l/min

Exhalation

Clogging

For single shift use respirators (NR), the clogging test

isoptional. For re-usable respirators (R) this test is mandatory.

The respirators are loaded with very high amount of Dolomite

dust which will tend to clog the filter. After loading with the

required amount of dust, the breathing resistance of the

respirators shall not exceed the following limits:

EN 149:2001

+A1:2009

classification

FFP1

FFP2

FFP3

Maximum Breathing Resistance

Inhalation

at 95l/min

4.0 mbar

(valvedrespirator)

3.0 mbar

(unvalvedrespirator)

5.0 mbar

(valvedrespirator)

4.0 mbar

(unvalvedrespirator)

7.0 mbar

(valvedrespirator)

5.0 mbar

(unvalvedrespirator)

Exhalation

at 160l/min

3.0 mbar

(valvedrespirator)

3.0 mbar

(valvedrespirator)

3.0 mbar

(valvedrespirator)

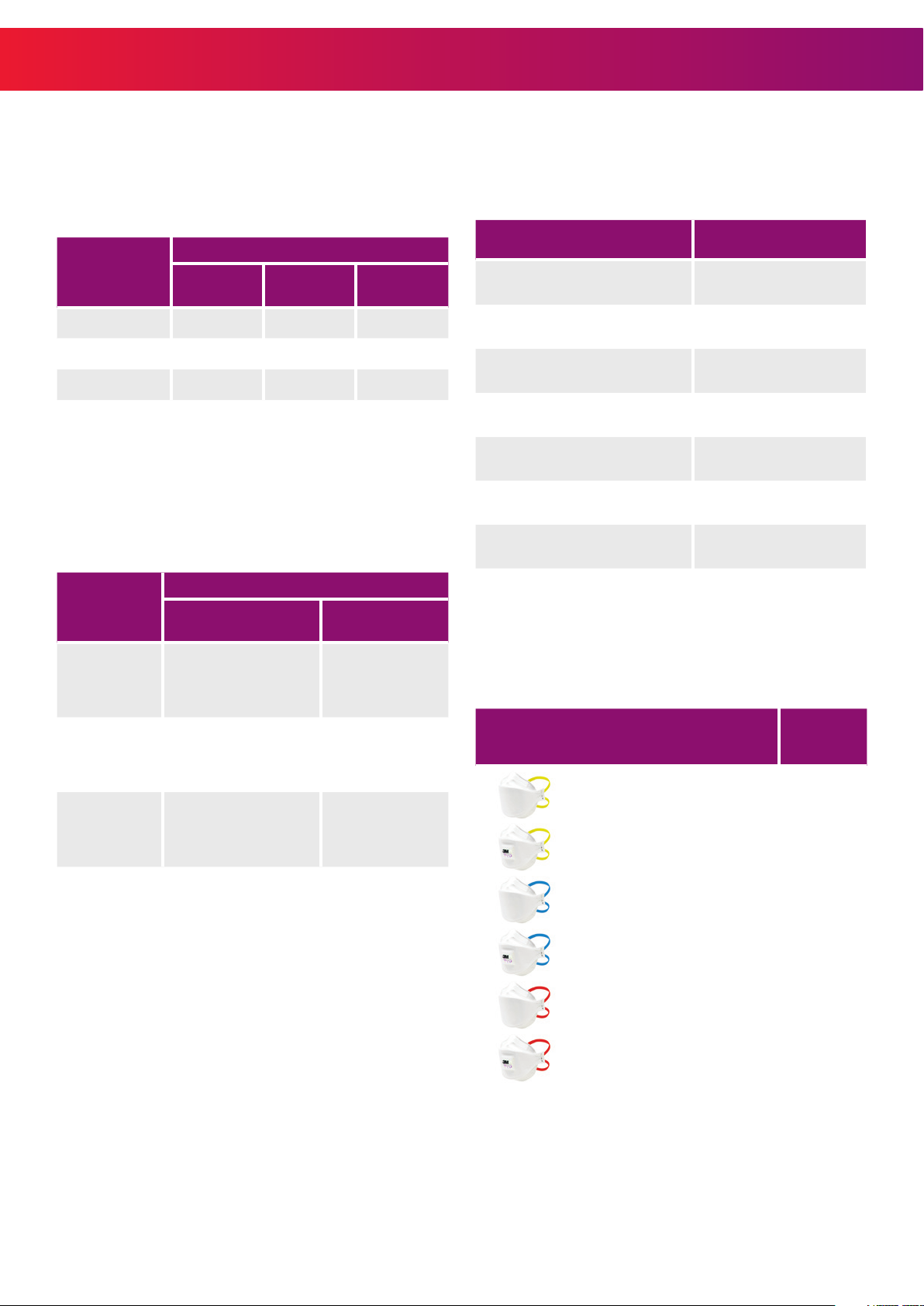

Components and materials

The following materials are used in the production of the

3M™Aura™ Particulate Respirators 9300+Gen3 Series:

Component Material

Straps (yellow for FFP1, blue

forFFP2 and red for FFP3)

Staples Steel

Nose foam Polyurethane

Nose clip Aluminum

Filter Polypropylene

Tabs Polypropylene

3M™ Comfort Cool Flow™ Valve

Individual wrapper Polypropylene

These products do not contain components made from

natural rubber latex.

Polyisoprene /

Polyester

Polypropylene /

Polyisoprene

Typical weight

Product

3M™ Aura™ Particulate

Respirator 9310+Gen3

3M™ Aura™ Particulate

Respirator 9312+Gen3

Typical

Weight

11g

15g

Flammability

Tested respirators are mounted on a metallic head which

rotates with a linear speed of 60mm/s. The respirators are

passed within 20mm of the tip of an 800°C (±50°C) propane

burner flame. The respirator shall not burn orcontinue to burn

within 5 seconds of removal from the flame.

3M™ Aura™ Particulate

Respirator 9320+Gen3

3M™ Aura™ Particulate

Respirator 9322+Gen3

3M™ Aura™ Particulate

Respirator 9330+Gen3

3M™ Aura™ Particulate

Respirator 9332+Gen3

11g

15g

11g

15g

2

Page 3

3M™ Personal Safety Division | 3M™ Aura™ Particulate Respirators 9300+Gen3 Series

Storage and transportation

3M™ Aura™ Particulate Respirators 9300+Gen3 Series have

ashelf life of 5 years from date of manufacture. End of shelf

life is marked on the product packaging and upon the product.

Before initial use, always check that the product is within the

stated shelf life (use by date).

Product should be stored in clean, dry conditions within the

temperature range: – 20°C to + 25°C with a maximum relative

humidity of <80%. When storing or transporting the respirator,

remove bend in noseclip, align top and bottom panels together

before pushing the top panel flat. Store respirator inoriginal

packaging provided.

Warnings and use limitations

Always be sure that the complete product is:

Ŕ Suitable for the application;

Ŕ Fitted correctly;

Ŕ Worn during all periods of exposure;

Ŕ Replaced when necessary.

Proper selection, training, use and appropriate maintenance

are essential in order for the product to help protect the

wearer from certain airborne contaminants. Failure to follow

all instructions on the use of these respiratory protection

products and/or failure to properly wear the complete

product during all periods of exposure may adversely affect

the wearer’s health, lead to severe or life threatening illness

orpermanent disability.

For suitability and proper use follow local regulations,

refer toall information supplied or contact a safety

professional/3M representative.

Before use, the wearer must be trained in use of the complete

product in accordance with applicable Health and Safety

standards/guidance.

These products do not contain components made from

natural rubber latex.

These products do not protect against gases/vapours.

Do not use in atmospheres containing less than 19.5% oxygen.

(3M definition. Individual countries may apply their own limits

on oxygen deficiency. Seek advice if in doubt).

Do not use for respiratory protection against atmospheric

contaminants/concentrations which are unknown

orimmediately dangerous to life and health (IDLH).

Do not use with beards or other facial hair that may inhibit

contact between the face and the product thus preventing

agood seal.

Leave the contaminated area immediately if:

Ŕ Breathing becomes difficult.

Ŕ Dizziness or other distress occurs.

Discard and replace the respirator if it becomes damaged,

breathing resistance becomes excessive or at the end

oftheshift.

Do not clean, alter, modify or repair this device.

In case of intended use in explosive atmospheres, contact 3M.

Before initial use, always check that the product is within the

stated shelf life (use by date).

Fitting instructions

See Figure 1.

Before fitting device, ensure hands are clean.

All respirator components should be inspected for damage

prior to each use.

1. With reverse side up and using tabs, separate top

andbottom panels.

2. Pull chin and nose panel tabs until the noseclip bends

sothat the respirator forms a cup shape. Ensure both

panels are fully unfolded.

3. Whilst still holding the tabs, hold the respirator with

openside towards face and bring respirator to face.

4a. VALVED respirator – With one hand, hold the sides

ofthevalve to hold respirator position on face.

4b. UNVALVED respirator – Cup respirator in one hand

withopen side towards face.

5. With other hand, take each strap in turn and pull each

strap over your head.

6. Locate the upper strap across the crown of the head

and the lower strap below the ears. Straps must not

betwisted. Adjust top and bottom panels, using tabs,

foracomfortable fit. Ensure that panels are not folded

andthat tabs are folded flat.

7. Using both hands, mould noseclip to the shape of the

noseto ensure a close fit and good seal. Pinching the

noseclip using only one hand may result in less effective

respirator performance.

8. The seal of the respirator on the face should

befit-checked before entering the workplace.

Figure 1

3

Page 4

3M™ Personal Safety Division | 3M™ Aura™ Particulate Respirators 9300+Gen3 Series

Fit check

1. Cover the front of the respirator with both hands

beingcareful not to disturb the fit of the respirator.

2a. UNVALVED respirator – EXHALE sharply.

2b. VALVED respirator – INHALE sharply.

3. If air leaks around the nose, re-adjust the noseclip

toeliminate leakage. Repeat the above fit check.

4. If air leaks at the respirator edges, work the straps

backalong the sides of the head to eliminate leakage.

Repeat the above fit check.

If you CANNOT achieve a proper fit DO NOT enter

thehazardous area. See your supervisor.

Users should be fit tested in accordance with

nationalrequirements.

For information regarding fit testing procedures,

pleasecontact 3M.

Disposal

Contaminated products should be disposed as hazardous

waste in accordance with national regulations.

Marking

NR = Non reusable

D = Meets the clogging requirements

End of Shelf Life. Date format: YYYY/MM/DD

Temperature Range

Maximum Relative Humidity

Name and address of Legal Manufacturer

Dispose of in accordance with local regulations

Approvals

These products are CE Marked to the requirements

ofCommunity Directive 89/686/EEC or European Regulation

(EU) 2016/425. The applicable legislation can be determined

by reviewing the Certificate and Declaration of Conformity

athttp://www.3M.com/Respiratory/certs

These products are type approved and audited annually

byBSI, Kitemark Court, Davy Avenue, Knowlhill, Milton

Keynes MK5 8PP, UK, Notified Body No. 0086.

Made in UK, in an ISO 9001:2008, ISO 14001:2004

andOHSAS 18001:2007 certified plant.

Important notice

The use of the 3M product described within this document assumes that the user has previous experience of this type of product and

that it will be used by a competent professional. Before any use of this product it is recommended to complete some trials tovalidate

theperformance of the product within its expected application.

All information and specification details contained within this document are inherent to this specific 3M product and would not be applied

toother products or environment. Any action or usage of this product made in violation of this document is at the risk of the user.

Compliance to the information and specification relative to the 3M product contained within this document does not exempt the user from

compliance with additional guidelines (safety rules, procedures).

Compliance to operational requirements especially in respect to the environment and usage of tools with this product must be observed.

The3M group (which cannot verify or control those elements) would not be held responsible for the consequences of any violation of these

rules which remain external to its decision and control.

Warranty conditions for 3M products are determined with the sales contract documents and with the mandatory and applicable clause,

excluding any other warranty or compensation.

Personal Safety Division

3M United Kingdom plc

3M Centre

Cain Road, Bracknell

Berkshire RG12 8HT

t: 0870 60 800 60

www.3M.eu/PPEsafety

Please recycle. Printed in the UK.

3Misatrademark of the 3M company. Used

under licence by 3M subsidiaries and affiliates.

© 3M 2017. All rights reserved. J379204

Loading...

Loading...