3M 9262 62-9262-9930-6, 9237 62-9237-9930-8, 9238 62-9238-9930-6, 9284 62-9284-9930-0, 9234 62-9234-9930-5 User Manual

3

3

Sco

tch

-We

ld™

Hot

Me

lt

App

lic

ato

r L

T

Scotch-Weld™Hot Melt Applicator LT

™

Applicateur thermofusible 3M

Aplicador por fusión al calor de Scotch-Weld

OWNER’S MANUAL

MANUEL DE L’UTILISATEUR

MANUAL DEL PROPIETARIO

Scotch-Weld™LT

™

LT de 3M

™

For use with Low Melt Adhesives

Utilisez avec les adhésifs à faible point de fusion

Para uso con adhesivos de baja fusión

Read instructions thoroughly before

operating or performing any

maintenance on 3M™ Scotch-Weld™

Hot Melt Applicator LT. For use with

low melt adhesive only.

Lisez attentivement les instructions

avant d'utiliser ou d'effectuer toute

tâche de maintenance sur

l'applicateur d'adhésif thermo-fusible

LT 3M™ Scotch-Weld™. Utilisez avec

les adhésifs à faible point de fusion.

Lea detalladamente las

instrucciones antes de empezar a

operar o de realizar cualquier

mantenimiento del Aplicador por

fusión al calor de Scotch-Weld™ LT

de 3M. Para uso con adhesivos de

baja fusión.

Kit 9234

62-9234-9930-5

Kit 9262

62-9262-9930-6

Kit 9237

62-9237-9930-8

Kit 9284

62-9284-9930-0

Kit 9238

62-9238-9930-6

3

ENGLISH

General Information

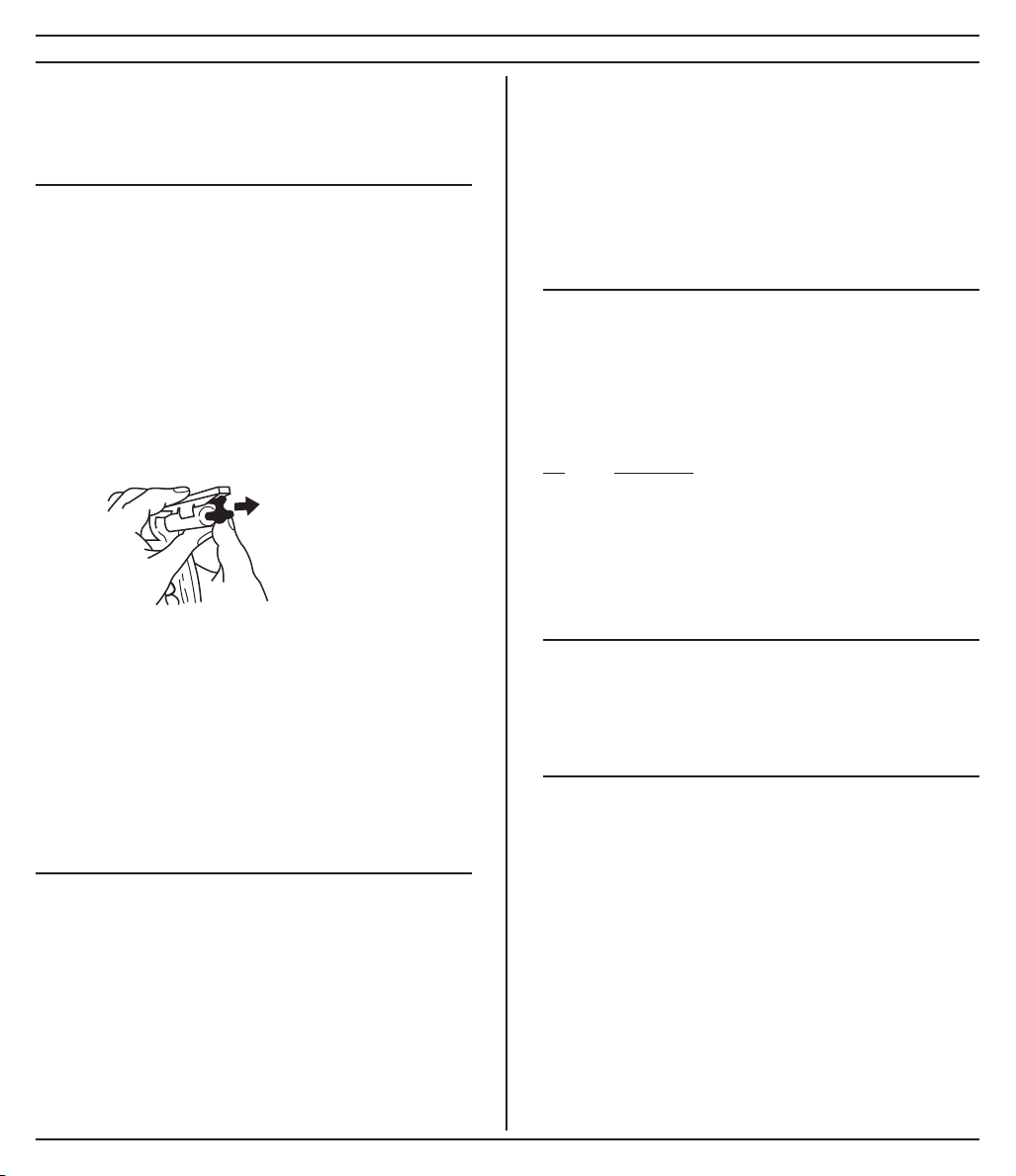

Thumb pressure on the feeder pushes the adhesive stick into

the heat block. The adhesive is melted by the heat block and

pushed out through the tip. A fixed thermostat on the heat

block maintains heat block temperature.

Start-Up and Operation

WARNING: USE ONLY 3M™ SCOTCH-WELD™ HOT MELT

2’’ x 5/8’’ LOW MELT ADHESIVE STICKS. OTHER

ADHESIVES MAY CAUSE BACKMELT AND POSSIBLE

INJURY. DO NOT USE NEAR HIGHLY FLAMMABLE

MATERIALS.

1. Plug the 3M™ Scotch-Weld™ Hot Melt Applicator LT into

a 120 VAC grounded receptacle. Allow 5 to 10 minutes for

heat-up.

2. Pull the feeder back toward the rear of the applicator.

3. Snap a 3M Scotch-Weld Hot Melt Adhesive Stick

(5/8’’ x 2’’) into the holder.

CAUTION: Do not force adhesive. Excessive force

can damage the applicator and cause molten

adhesive to flow out the rear.

4. Gently press the feeder forward and push the adhesive

into the heat block. Melted adhesive will flow from the tip.

WARNING: TIP AND VALVE ARE HOT. KEEP TIP POINTED

AWAY FROM BODY PARTS.

CAUTION: To avoid charring or plugging of the tip,

extrude at least one adhesive stick every three hours that

the applicator is turned on.

Shut-Down

1. Unplug the applicator.

2. Extrude one adhesive stick to cool down the applicator.

Preventive Maintenance

WARNING: TIP AND VALVE ARE HOT. WEAR HEATRESISTANT GLOVES WHEN CLEANING TIP. KEEP TIP

POINTED AWAY FROM BODY PARTS.

To maintain proper operation, follow these steps.

1. Inspect nozzle tip daily. Make sure it is clean and clear of

foreign matter.

2. Keep the adhesive clean and free of airborne

contaminants.

Accessory Tips

The 3M Scotch-Weld Hot Melt Applicator LT comes equipped

with a standard .093’’ tip. Contact your 3M Scotch-Weld Hot

Melt Applicator distributor for additional tips.

Applicator must be at operating temperature. Hold the valve

firmly with a 5/8’’ wrench and remove the tip with a 1/2’’

wrench. Mount the new tip and tighten.

ip Description

T

9725 Mini-extension/0.072’’ opening

9726 “T” tip/RSC carton closing

9727 “L” tip/FOL carton closing

9785 .070” Tapered aluminum extension

9940 .125’’ opening

9913 Two-hole spreader

9916 Three-hole spreader

9921 Standard .093’’ opening

9922 .063’’ Fluted tip

Changing Tips

WARNING: THE TIP AND VALVE ARE HOT. WEAR HEATRESISTANT GLOVES AND POINT TIP AWAY FROM BODY

PARTS.

CAUTION: Do not overtighten. Overtightening damages

threads.

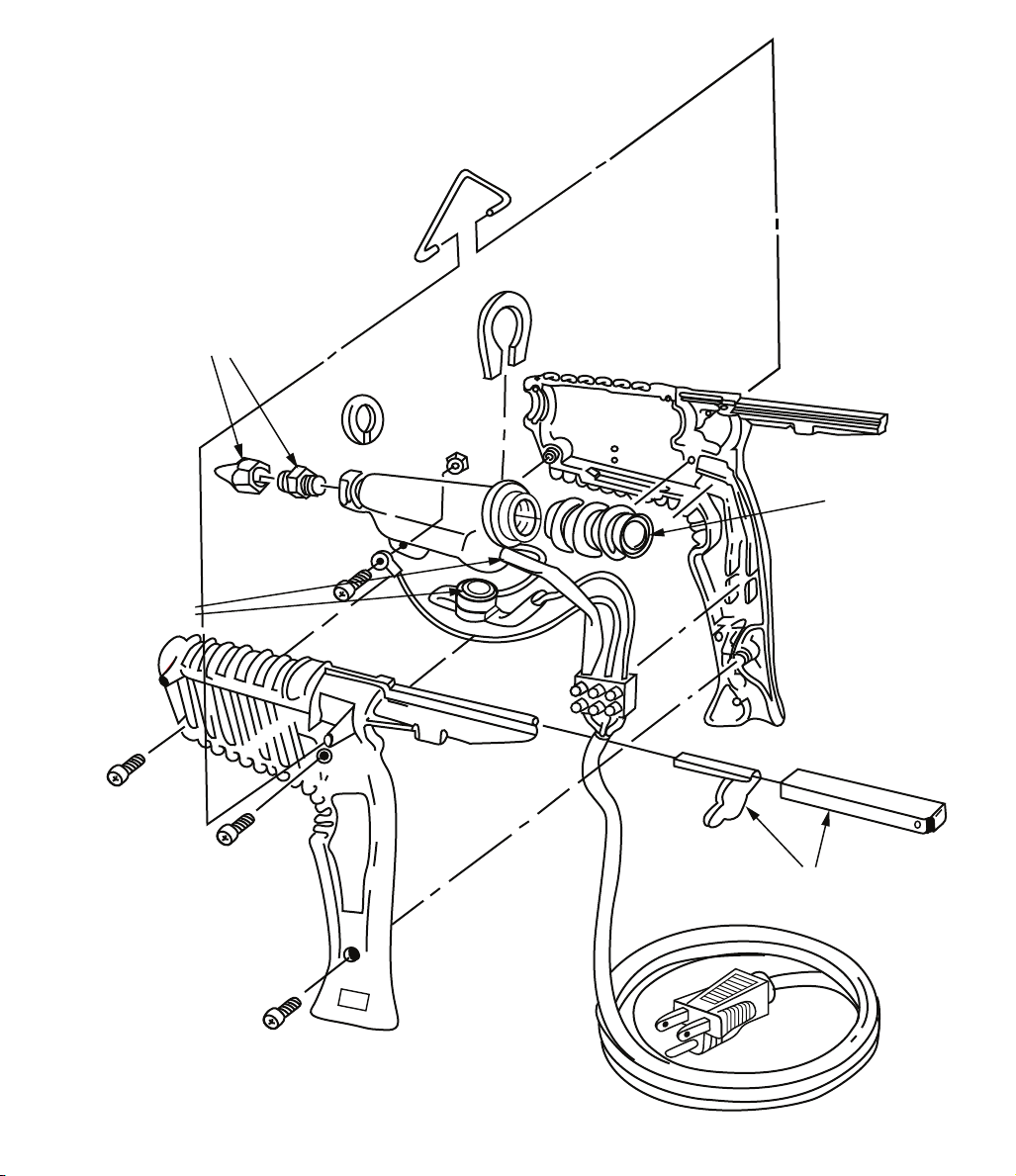

Repair Parts Kit

9234 Valve Assembly Kit 3M Stock # 62-9234-9930-5

a. .093’’ tip

b. Valve Assembly

9237 Sleeve Kit 3M Stock # 62-9237-9930-8

a. Sleeve

b. Brass Flange (4)

9238 Feeder Kit 3M Stock # 62-9238-9930-6

a. Feeder

b. Metal Clip

9284 Power Cord Kit

a. Power Cord (orange)

9262 Heater/Thermostat Kit

a. Heater

b.

Assembly

Thermostat/TCO

3M Stock # 62-9284-9930-0

3M Stock # 62-9262-9930-6

Loading...

Loading...