3M 8387 User Manual

Splittable Flying Splice Tape 8387

Product Data Sheet

June 2015

Supersedes: NEW

manual application.

splicing.

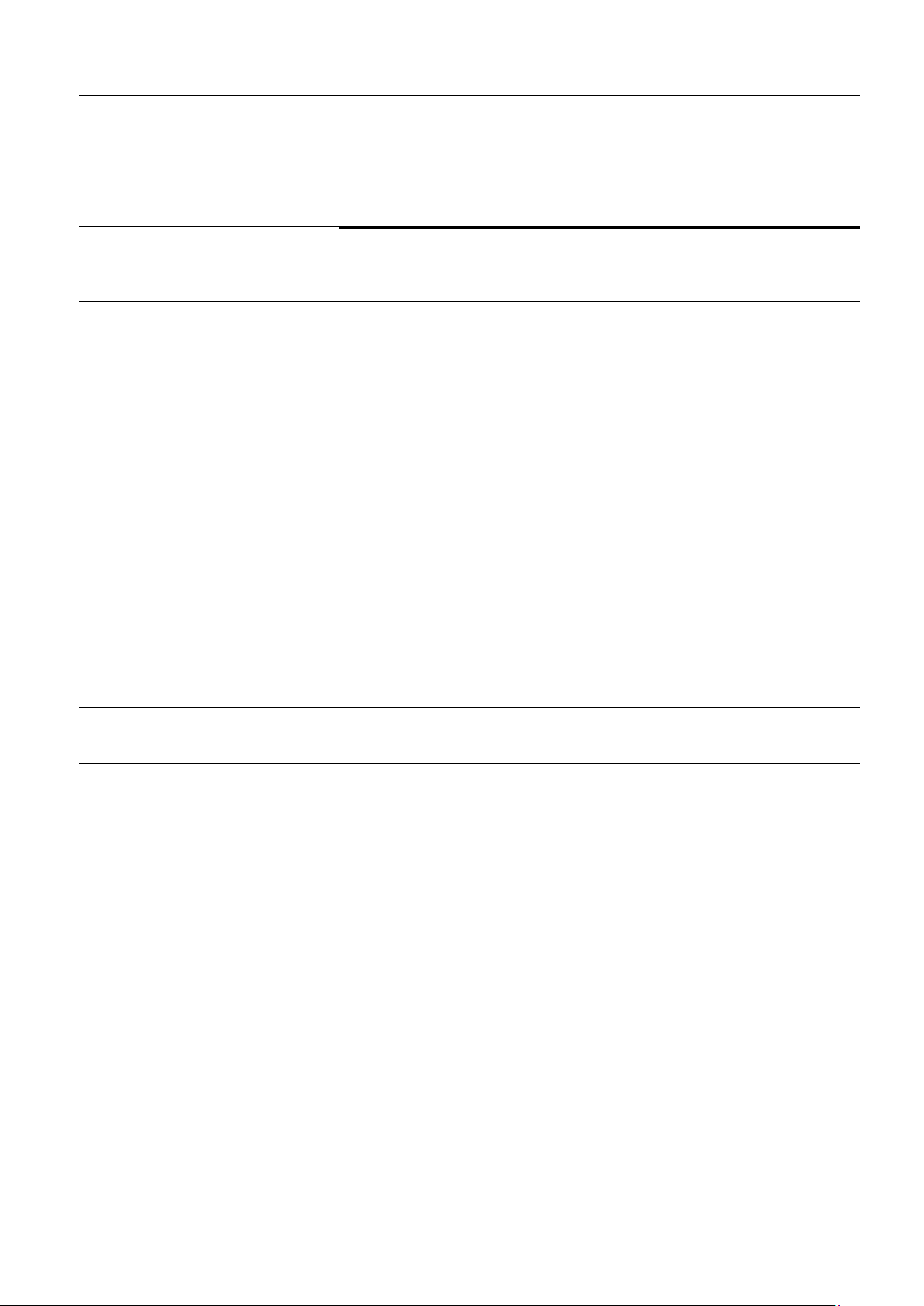

Physical Properties

Adhesive Type

Splicing side

Rubber adhesive

Adhesive Type

Reel side

Acrylic adhesive

Tape Colour

Pink (splicing side)

Black (reel side)

Carrier

Splicing side: Polyester

Reel side: LDPE

Thickness

Total

0.260 mm

Splittable Layer

Fiber-free cleavable layer

Release Liner

Coated easy-release paper

Physical Properties

Repulpability

Construction is not repulpable

Bonding Strength

Designed for high affinity to film

substrates

Product Description

Key Features

A splittable tape construction designed for straight line flying splices,

furnished with aggressive adhesives on both sides for good adhesion

to film substrates, and a coated paper liner with liner score for easy

• designed for film substrates

• designed for straight line flying splices for a wide variety of film

substrates, such as Polyethylene, BOPP, polyester, cast

polypropylene, aluminium foil and paper.

• designed so that no fibers are present after splitting, thereby

preventing contamination of the central impression drum, and

removing the need for costly cleaning to remove fiber residues after

(ASTM D-3652)

Tape

Liner

Before splitting

0.183 mm

0.077 mm

After splitting

Splice side 0.104 mm

Reel side 0.076 mm

Splittable Flying Splice tape 8387

storage without the protective liner.

carton at the conditions specified in “Storage.”

Address correspondence to: 3M

by the terms of the sale subject, where applicable, to the prevailing law.

Values presented have been determined by standard test methods and are average values not to be used for specification

result of our recommendations.

3M is a trademark of the 3M Company.

June 2015

Storage

Shelf Life

For Additional Information

Important Notice

3M™ Splittable Flying Splice Tape 8387 should be stored in the original

carton at 16°C – 27°C and 40 – 60% Relative Humidity.

It is recommended that the protective liner be removed just prior to

splicing, rather than leaving film rolls with prepared splice patterns in

12 months from date of manufacture by 3M when stored in the original

To request additional product information or to arrange for sales

assistance, please call your local sales representative.

All statements, technical information and recommendations contained in

this document are based upon tests or experience that 3M believes are

reliable. However, many factors beyond 3M’s control can affect the use

and performance of a 3M product in a particular application, including the

conditions under which the product is used and the time and

environmental conditions in which the product is expected to perform.

Since these factors are uniquely within the user’s knowledge and control,

it is essential that the user evaluate the 3M product to determine whether

it is fit for a particular purpose and suitable for the user’s method or

application. All questions of liability relating to this product are governed

purposes. Our recommendations on the use of our products are based on tests believed to be reliable but we would ask

that you conduct your own tests to determine their suitability for your applications.

This is because 3M cannot accept any responsibility or liability direct or consequential for loss or damage caused as a

Loading...

Loading...