Page 1

Instructions and Parts List

Important Safety

Information

™

3M-Matic

800ab Type 40800

Adjustable

Case Sealer

with

™

AccuGlide 3

BEFORE INSTALLING

OR OPERATING THIS

EQUIPMENT

Read, understand, and

follow all safety and

operating instructions.

Spare Parts

It is recommended you

Taping Heads

Serial No.

For reference, record machine serial number here.

3M Industrial Adhesives and Tapes

3M Center, Building 220-5E-06

St. Paul, MN 55144-1000

immediately order the

spare parts listed in the

"Spare Parts/Service

Information" section.

These parts are expected

to wear through normal

use, and should be kept

on hand to minimize

production delays.

"3M-Matic"and "AccuGlide" are Trademarks of,

3M St. Paul, MN 55144-1000

Printed in U.S.A.

© 3M 2010 44-0009-2082-5 (B121510-NA)

Page 2

This instruction manual covers safety aspects,

handling and transport, storage, unpacking,

preparation, installation, operation, adjustments, maintenance, troubleshooting, repair

work and servicing plus parts list of the

3M-Matic

TM

800ab-NA Adjustable case sealer.

3M Industrial Adhesives and Tapes

3M Center, Building 220-5E-06

St. Paul, MN 55144-1000

Edition December 2010

Copyright 3M 2010

All rights reserved

The manufacturer reserves the right to change

the product at any time without notice.

800ab-NA

2010 December

Page 3

Replacement Parts and Service Information

To Our Customers:

®

This is the 3M-Matic™/AccuGlide™/Scotch

equipment you ordered. It has been set up and tested in

the factory with Scotch® tapes. If technical assistance or replacement parts are needed, call or fax the

appropriate number listed below.

Included with each machine is an Instructions and Parts List manual.

Technical Assistance / Replacement Parts and Additional Manuals:

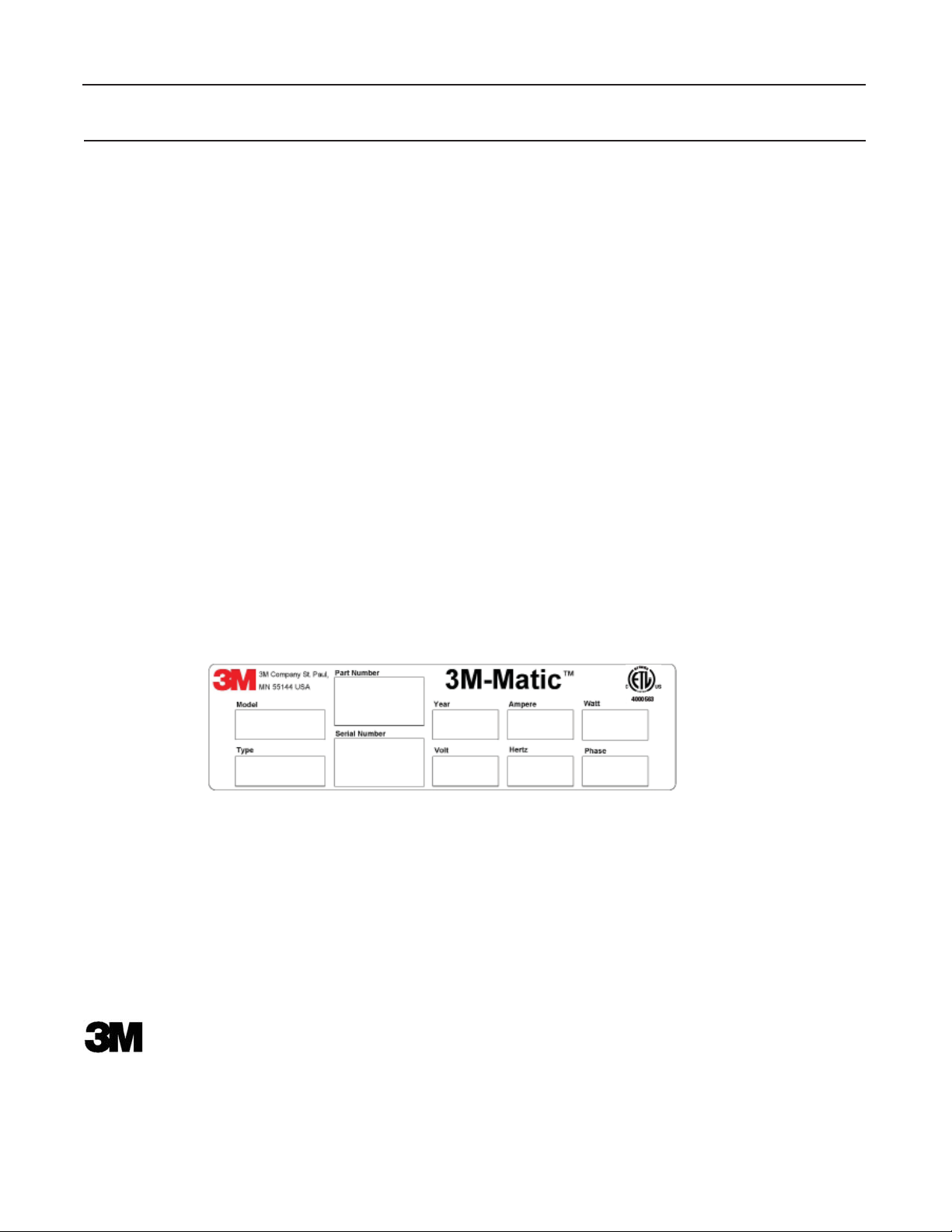

Contact your local service provider. Provide the customer support coordinator with the model/machine

name, machine type, and serial number that are located on the identif cation plate (For example: Model

800ab - Type 40800 - Serial Number 13282).

Identif cation Plate

Minimum billing on parts orders will be $25.00. Replacement part prices available on request.

$10.00 restocking charge per invoice on returned parts

3M Industrial Adhesives and Tapes

3M Center, Building 220-5E-06

St. Paul, MN 55144-1000

3M-Matic™, AccuGlide™ and Scotch™ are Trademarks of

3M St. Paul, MN 55144-1000

Printed in U.S.A.

© 3M 2010 44-0009-1851-4 (H031008-NA)

i

Page 4

THIS PAGE IS BLANK

Page 5

Replacement Parts And Service Information

To Our Customers:

This is the 3M-Matic™/AccuGlide™/Scotch® equipment you ordered. It has been set up

and tested in the factory with Scotch® tapes. If any problems occur when operating this equipment and

you desire a service call or phone consultation, call, write, or fax the appropriate number listed below.

Included with each machine is an Instructions and Parts List manual.

SERVICE, REPLACEMENT PARTS, AND ADDITIONAL MANUALS

AVAILABLE DIRECT FROM:

Order parts by part number, part description, and quantity required. Also, when ordering parts

or additional manuals, include model/machine name, machine type, and serial number that are

located on the identifi cation plate.

3M Industrial Adhesives and Tapes

3M Center, Building 220-5E-06

St. Paul, MN 55144-1000

3M-Matic™, AccuGlide™ and Scotch™ are Trademarks of

3M, St. Paul, MN 55144-1000

Printed in U.S.A.

© 3M 2010 44-0009-1852-2 (F031008-NA)

ii

Page 6

THIS PAGE IS BLANK

Page 7

TABLE OF CONTENTS - MANUAL 1: 800ab Adjustable Case Sealer

(For Taping Head Information - See MANUAL 2: AccuGlide™ 3 Taping Heads - 2 inch)

800ab Adjustable Case Sealer Page

Cover Page

Replacement Parts and Service Information ........................................................................ i - ii

Table of Contents ................................................................................................................. iii - v

Acronyms and Abbreviations ................................................................................................ vi

1. Introduction

1.1 Manufacturing Specifi cations / Description / Intended Use

1.2 How to Read and Use the Manual ............................................................................... 2

1.2.1 Importance of the Manual .................................................................................. 2

1.2.2 Manual Maintenance ......................................................................................... 2

1.2.3 Consulting the Manual ........................................................................................ 2

1.2.4 How to Update the Manual in Case of Modifi cations ........................................... 2

2. General Information

2.1 Identifi cation Data ......................................................................................................... 3

2.2 After-Sale Service ......................................................................................................... 3

2.3 Warranty / Contents ...................................................................................................... 4

3. Safety

3.1 General Safety Information ........................................................................................... 5

3.2 Signal Words Explanation ............................................................................................. 5

3.3 Table of Warnings .......................................................................................................... 6 - 7

3.4 Operator’s Qualifi cations Defi nition .............................................................................. 8

3.5 Number of Operators .................................................................................................... 8

3.6 Safe Use of the Machine Instructions ........................................................................... 8

3.7 Residual Hazards .......................................................................................................... 8

3.8 Prevent Other Hazards - Recommendations and Measures ........................................ 8

3.9 Personal Safety Measures ........................................................................................... 8

3.10 Incorrect / Predictable Actions Not Allowed .................................................................. 8

3.11 Operator's Required Skill Levels .................................................................................. 9

3.12 Component Locations .................................................................................................. 10

3.13 Table of Warnings and Replacement Labels ................................................................ 11

......................................... 1 - 2

4. Technical Specif cations

4.1 Power Requirements .................................................................................................... 12

4.2 Operating Rate

4.3 Operating Conditions .................................................................................................... 12

4.4 Tape .............................................................................................................................. 12

4.5 Tape Width .................................................................................................................... 12

4.6 Tape Roll Diameter ....................................................................................................... 13

4.7 Tape Application Leg Length - Standard .......................................................................13

Tape Application Leg Length - Optional

4.8 Box Board ..................................................................................................................... 13

4.9 Box Weight and Size Capacities ................................................................................... 13

4.10 Machine Noise Levels ................................................................................................... 14

4.11 Machine Dimensions ..................................................................................................... 14

4.12 Set-Up Recommendations ............................................................................................ 14

800ab-NA

............................................................................................................. 12

iii

2010 December

Page 8

THIS PAGE IS BLANK

8

Page 9

TABLE OF CONTENTS (continued)

5. Shipment, Handling, and Storage

5.1 Packed Machine Shipment and Handling ........................................................................... 15

5.2 Overseas Shipment Packaging (Optional) .......................................................................... 15

5.3 Handling and Transportation of Uncrated Machine ............................................................. 15

5.4 Machine Storage ................................................................................................................. 15

6. Unpacking

6.1 Uncrating ............................................................................................................................. 16

6.2 Packaging Materials Disposal ............................................................................................. 16

7. Installation

7.1 Operating Conditions .......................................................................................................... 17

7.2 Space Requirements for Machine Operation and Maintenance ......................................... 17

7.3 Tool Kit Supplied with the Machine ..................................................................................... 17

7.4 Machine Positioning / Machine Set-Up ................................................................................ 17

7.5 Plastic Ties Removal ........................................................................................................... 18

7.6 Assembly Completion .......................................................................................................... 18

7.7 Taping Heads Completion ................................................................................................... 19

7.8 Outboard Tape Roll Holder ................................................................................................. 19

7.9 Preliminary Electric Inspection ............................................................................................ 19

7.10 Main Power Machine Connection and Inspection .............................................................. 19

7.11 Phases Inspection ............................................................................................................... 19

8. Theory of Operation

8.1 Working Cycle Description .................................................................................................. 20

8.2 Running Mode Defi nition ..................................................................................................... 20

8.3.1 Normal Stop Procedure .............................................................................................20

8.3.2 Emergency Stop ....................................................................................................... 20

9. Controls

9.1 Box Width Adjusting Knobs ................................................................................................. 21

9.2 Start / Stop Main Switch........................................................................................................ 21

9.3 Emergency Stop Button (Latching) ...................................................................................... 21

10. Safety devices

10.1 Blade Guards ..................................................................................................................... 22

10.2 Emergency Stop Button ..................................................................................................... 22

10.3 Electric System / Circuit Breaker ......................................................................................... 22

11. Set-Up and Adjustments

11.1 Box Width Adjustment ........................................................................................................ 23

11.2

11.3 Top Flap Compression Roller Adjustment .......................................................................... 23

11.4 Changing the Tape Leg Length .......................................................................................... 23

11.5 Run Boxes to Check Adjustment ........................................................................................ 23

Box Height Adjustment ....................................................................................................... 23

800ab-NA

iv

i

2010 December

Page 10

THIS PAGE IS BLANK

Page 11

TABLE OF CONTENTS (continued)

12. Operation

12.1 Operator’s Correct Working Position .............................................................................. 24

12.2 Starting the Machine ....................................................................................................... 24

12.3 Starting Production ......................................................................................................... 24

12.4 Tape Replacement .......................................................................................................... 24

12.5 Box Size Adjustment ....................................................................................................... 24

12.6 Cleaning ......................................................................................................................... 24

12.7 Table of Adjustments ...................................................................................................... 24

12.8 Safety Devices Inspection .............................................................................................. 24

12.9 Trouble Shooting ............................................................................................................ 25

13. Maintenance

13.1 Safety Measures (see section 3) .................................................................................... 27

13.2 Tools and Spare Parts Supplied with Machine ............................................................... 27

13.3 Maintenance Operations - Recommended Inspections and Frequency .......................... 27

13.4 Inspections to be Performed Before and After Every Maintenance Operation ................ 27

13.5 Safety Features (Inspection Effi ciency) .......................................................................... 27

13.6 Machine Cleaning ........................................................................................................... 27

13.7 Cutter Blade Cleaning .................................................................................................... 27

13.8 Drive Belt Replacement .................................................................................................. 28 - 29

13.9 Drive Pulley Ring ............................................................................................................ 29

13.10 Drive Belt Tension ........................................................................................................... 30

13.11. Special Set-Up Procedures ............................................................................................ 31 - 34

13.11.1 Taping Heads ..................................................................................................... 31

13.11.2 Drive Belt Assembly Height ............................................................................... 32

13.11.3 Chain Removal .................................................................................................. 33

13.12 Maintenance Work Log ................................................................................................... 35

14. Additional Instructions

14.1 Machine Disposal Information ........................................................................................

14.2 Fire emergency ...............................................................................................................

15. Enclosures and Special Information

15.1 Statement of Conformity ................................................................................................. 37

15.2 Hazardous Substances Emission ................................................................................... 37

16. Technical Documentation and Information

16.1 Electric Diagrams ........................................................................................................... 39

16.2 Spare Parts / Ordering / Options and Accessories .......................................................... 40 - 41

Drawings and Parts Lists ....................................................................................................... 43 - End of Manual

TAPING HEAD INFORMATION MANUAL 2: AccuGlide™ 3 Taping Heads - 2 inch (See MANUAL 2 for Table of Contents)

37

37

800ab-NA

v

11

2010 December

Page 12

ABBREVIATIONS AND ACRONYMS

LIST OF ABBREVIATIONS, ACRONYMS

3M-Matic - Trademark of 3M St. Paul, MN 55144- 1000

AccuGlide - Trademark of 3M St. Paul, MN 55144-1000

Scotch - Trademark of 3M St. Paul, MN 55144-1000

Drw. - drawing

Ex. - for example

Fig. - exploded view fi gure no. (spare parts)

Figure - Illustration

Max. - maximum

Min. - minimum

Nr. - number

N/A - not applicable

OFF - machine not operating

ON - machine operating

PLC - Programmable Logic Control

PP - Polypropylene

PTFE - Polytetrafl ourethelene

PU/PU Foam - Polyurethane Foam

PVC - Poly-vinyl chloride

W - Width

H - Height

L - Length

800ab-NA

vi

2010 December

Page 13

1-INTRODUCTION

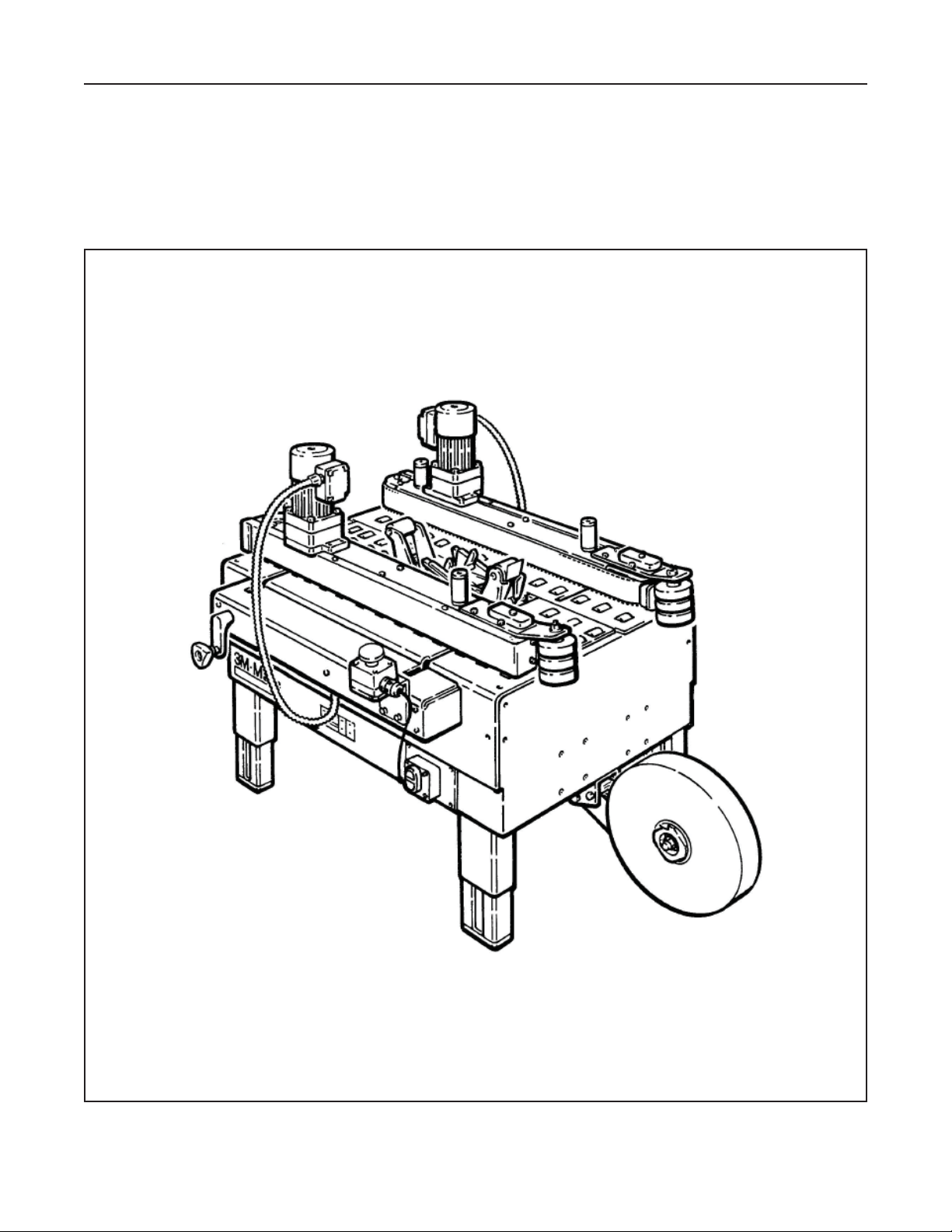

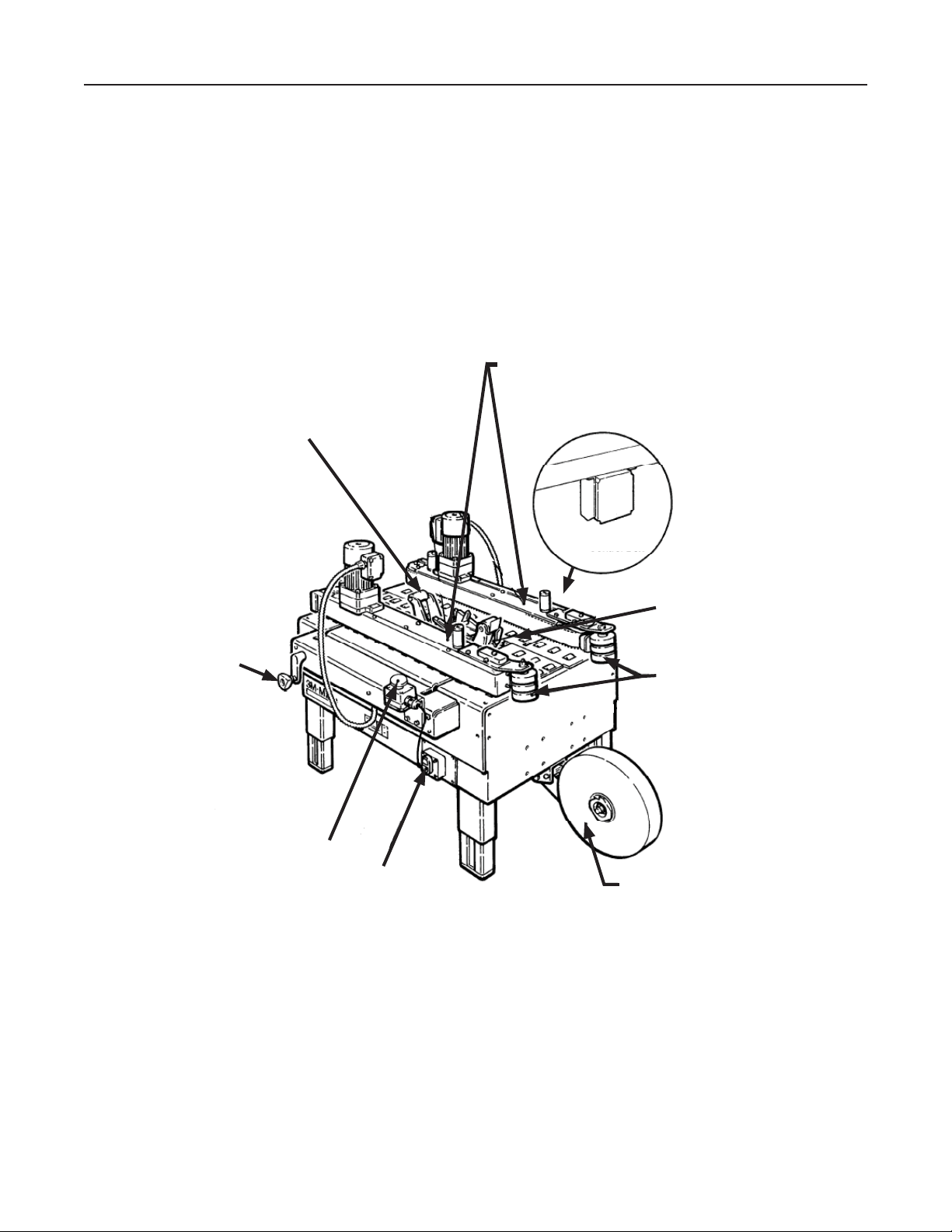

1.1 Manufacturing Specif cations / Description / Intended Use

The 3M-MaticTM 800ab Adjustable Case Sealer with AccuGlideTM 3 Taping Heads is designed to apply a “C” clip

of Scotch® pressure-sensitive fi lm box sealing tape to the bottom center seam of regular slotted containers. The

800ab is manually adjustable to a wide range of box sizes (see "Specifi cations Section – Box Weight and Size

Capacities").

3M-Matic

TM

800ab Adjustable Case Sealer, Type 40800

Note – Shown above is the lower tape supply roll and bracket assembly in the alternate location.

800ab-NA

2010 December

1

Page 14

1-INTRODUCTION (continued)

1.1 Manufacturing Specif cations / Description /

Intended Use (continued)

The 3M-MaticTM case sealing machines have been

designed and manufactured in compliance with the

legal requirements at the date of inception.

1.2 How to Read and Use the Instruction Manual

This instruction manual covers safety aspects,

handling and transport, storage, unpacking, preparation, installation, operation, set-up and adjustments,

technical and manufacturing specifi cations, mainte-

nance, troubleshooting, repair work and servicing,

electric diagrams, warranty information, disposal

(ELV), a defi nition of symbols, plus a parts list of

the 3M-MaticTM 800ab Adjustable case sealer 3M

Industrial Adhesives and Tapes Division 3M Center,

Bldg. 220-5E-06 St. Paul, MN 55144-1000 (USA)

Edition December 2010 Copyright 3M 2010 All rights

reserved. .The manufacturer reserves the right to

change the product at any time without notice Publication © 3M 2010 44-0009-2082-5.

1.2.2 Manual Maintenance

Keep the manual in a clean and dry place near the

machine. Do not remove, tear, or rewrite parts of

the manual for any reason. Use the manual without

damaging it. In case the manual has been lost or

damaged, ask your after sale service for a new copy.

1.2.3 Consulting the Manual

The manual is composed of:

- Pages which identify the document and the machine

- Index of the subjects

- Instructions and notes on the machine

- Enclosures, drawings and diagrams

- Spare parts (last section)

All pages and diagrams are numbered. The spare

parts lists are identifi ed by the fi gure identifi cation

number. All the notes on safety measures or

possible dangers are identifi ed by the symbol:

1.2.1 Importance of the Manual

The manual is an important part of the machine; all

information contained herein is intended to enable

the equipment to be maintained in perfect condition

and operated safely. Ensure that the manual is available to all operators of this equipment and is kept

up to date with all subsequent amendments. Should

the equipment be sold or disposed of, please ensure

that the manual is passed on. Electrical and pneumatic diagrams are included in the manual. Equipment using PLC controls and/or electronic components will include relevant schematics or programs in

the enclosure and in addition, the relevant documentation will be delivered separately.

1.2.4 How to Update the Manual in Case of

Modi f cations to the Machine

Modifi cations to the machine are subject to manu-

facturer’s internal procedures. The user receives a

complete and up-to-date copy of the manual together with the machine. Afterwards the user may

receive pages or parts of the manual which contain

amendments or improvements made after its fi rst

publication. The user must use them to update this

manual.

800ab-NA

2

2010 December

Page 15

2-GENERAL INFORMATION

2.1 Data Identifying Manufacturer and Machine

2.2 Data for Technical Assistance and Service

800ab-NA

3

2010 December

Page 16

2-GENERAL INFORMATION (continued)

2.3 Warranty

Equipment Warranty and Limited Remedy: THE FOLLOWING WARRANTY IS MADE IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTY OF MERCHANTABILITY, THE IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR

PURPOSE AND ANY IMPLIED WARRANTY ARISING OUT OF A COURSE OF DEALING, A CUSTOM OR

USAGE OF TRADE:

3M sells its 3M-Matic™ 800ab Adjustable Case Sealer, Type 40800 with the following warranties:

1. The drive belts and the taping head knives, springs and rollers will be free from all defects for ninety (90

days after delivery.

2. All other taping head parts will be free from all defects for three (3) years after delivery.

3. All other parts will be free from all defects for two (2) years after delivery.

If any part is proved to be defective within its warranty period, then the exclusive remedy and 3M’s and seller’s

sole obligation shall be, at 3M’s option, to repair or replace the part, provided the defective part is returned

immediately to 3M’s factory or an authorized service station designated by 3M. A part will be presumed to have

become defective after its warranty period unless the part is received or 3M is notifi ed of the problem no later than

fi ve (5) calendar days after the warranty period. If 3M is unable to repair or replace the part within a reasonable

time, then 3M at its option, will replace the equipment or refund the purchase price. 3M shall have no obligation

to provide or pay for the labor required to install the repaired or replacement part. 3M shall have no obligation

to repair or replace (1) those parts failing due to operator misuse, carelessness, or due to any accidental cause

other than equipment failure, or (2) parts failing due to non-lubrication, inadequate cleaning, improper operating

environment, improper utilities or operator error.

Limitation of Liability: 3M and seller shall not be liable for direct, indirect, special, incidental or consequential

damages based upon breach of warranty, breach of contract, negligence, strict liability or any other legal theory.

The foregoing Equipment Warranty and Limited Remedy and Limitation of Liability may be changed only by a

written agreement signed by authorized offi cers of 3M and seller.

Contents—800ab Adjustable Case Sealer

(1) 800ab Adjustable Case Sealer, Type 40800

(1) Tool Kit

(1) Instruction Manual

800ab-NA

4

2010 December

Page 17

3-SAFETY

3.1 General Safety Information

Read all the instructions carefully before starting

work with the machine; please pay particular attention to sections marked by the symbol:

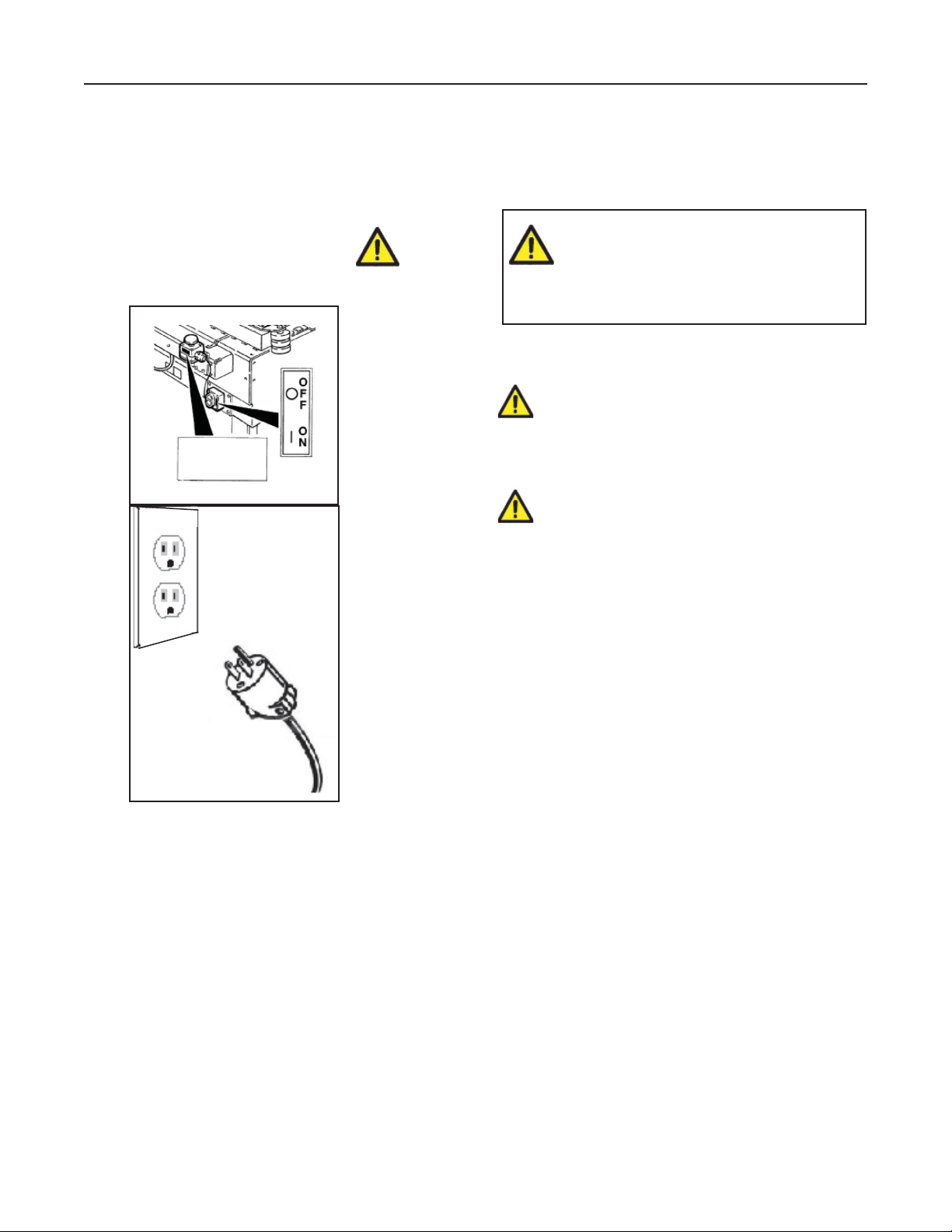

Figure 3-1

E-Stop

Switch

3.2 Explanation of Signal Word and

Possible Consequences

This safety alert symbol identif es

important messages in this manual.

READ AND UNDERSTAND THEM

BEFORE INSTALLING OR

OPERATING THIS EQUIPMENT.

CAUTION:

WARNING:

Indicates a potentially hazardous

situation, which, if not avoided,

may result in minor or moderate

injury and/or property damage.

Indicates a potentially hazardous

situation, which, if not avoided,

could result in death or serious

injury and/or property damage.

The machine is provided with a LATCHING EMERGENCY STOP BUTTON (Figure 3-1); when this

button is pressed, it stops the machine at any point

in the working cycle. Maintain clear access to power

cord while machine is operating. Disconnect plug

from power source before machine maintenance

(Figure 3-1). Also disconnect air if the machine has

a pneumatic system. Keep this manual in a handy

place near the machine. This manual contains information that will help you to maintain the machine in

a good and safe working condition.

800ab-NA

5

2010 December

Page 18

3-SAFETY (continued)

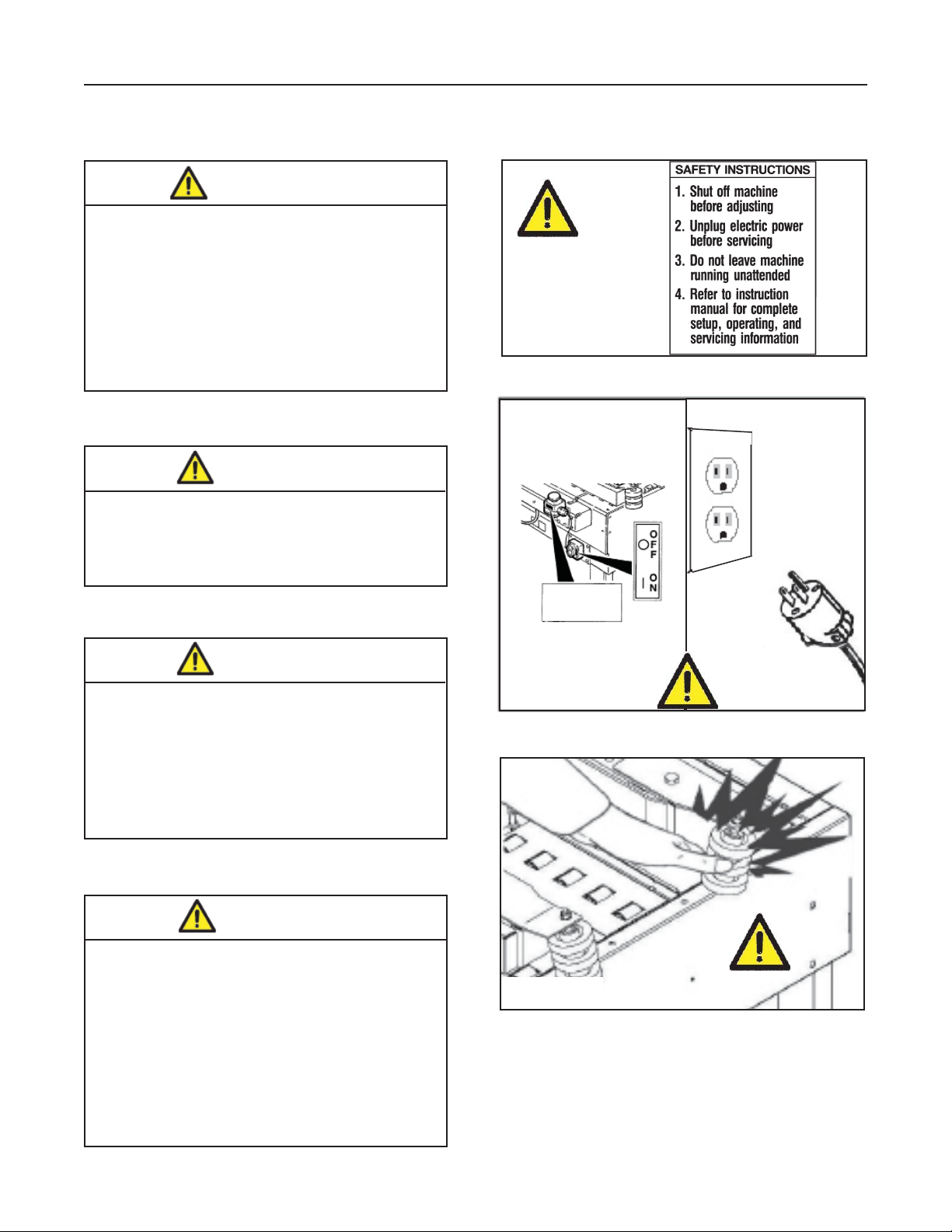

3.3 Table of Warnings

WARNING

• To reduce the risk associated with

mechanical and electrical hazards:

− Read, understand, and follow all safety

and operating instructions before operating

or servicing the case sealer.

− Allow only properly trained and

qualifi ed personnel to operate and service

this equipment.

WARNING

• To reduce the risk associated with

hazardous voltage:

− Position electrical cord away from foot

and vehicle traffi c.

Figure 3-2

E-Stop

Switch

WARNING

• To reduce the risk associated with

pinches, entanglement and

hazardous voltage:

− Turn electrical supply off and

disconnect before performing any

adjustments, maintenance or servicing

the machine or taping heads.

WARNING

• To reduce the risk associated with

pinches and entanglement hazards:

− Do not leave the machine running

while unattended.

− Turn the machine off when not in use.

− Never attempt to work on any part of

the machine, load tape, or remove

jammed boxes from the machine while

the machine is running.

Figure 3-3

Figure 3-4

IMPORTANT! Cavity in the conveyor bed. Never put

your hands inside any part of the machine while it is

working. Serious injury may occur (Figure 3-4).

800ab-NA

6

2010 December

Page 19

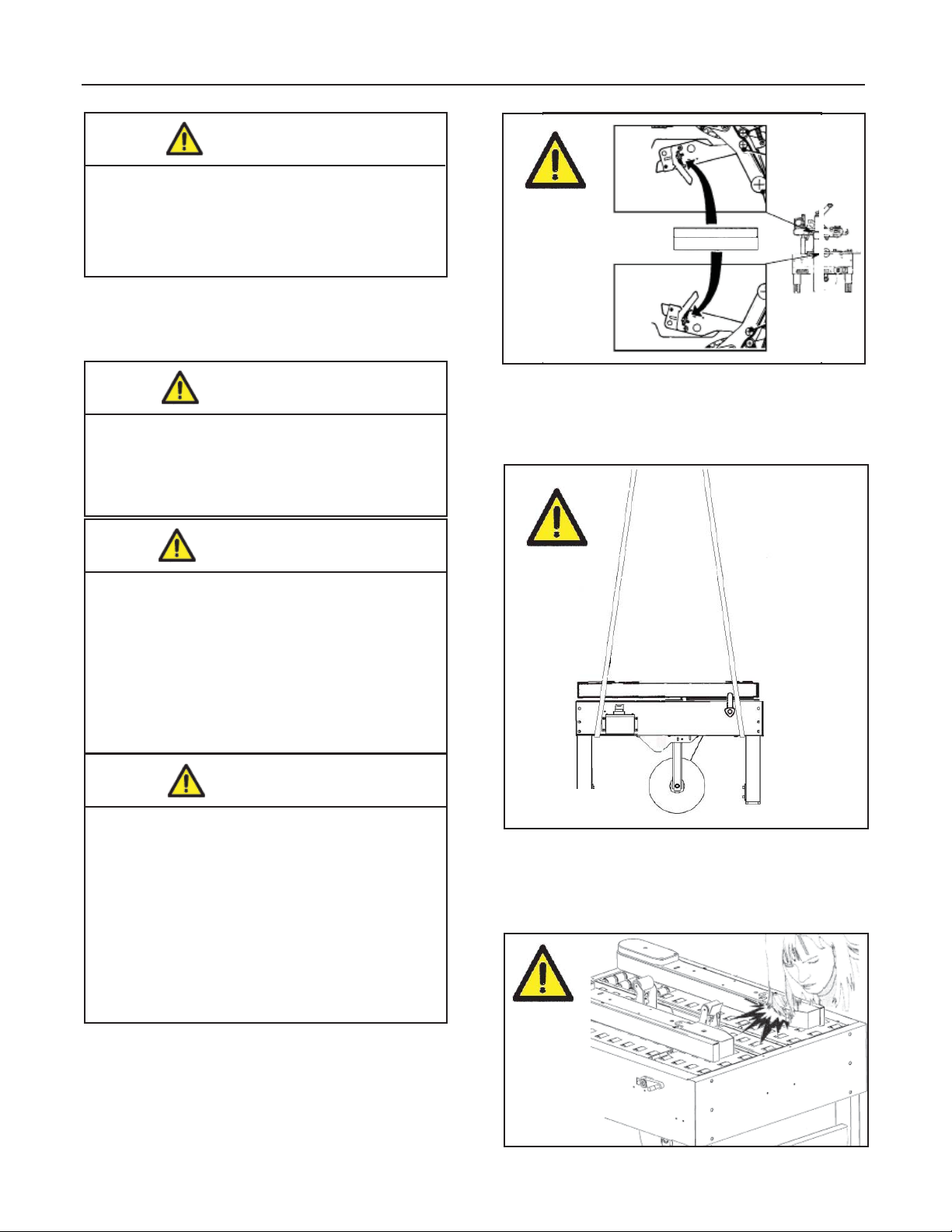

3-SAFETY (continued)

WARNING

• To reduce the risk associated with

sharp blade hazards:

− Keep hands and fi ngers away from

tape cutoff blades under orange blade

guards. The blades are extremely sharp.

IMPORTANT! Tape cutting blade. Never remove

the safety device which covers the blade on the top

and bottom taping units. Blades are extremely sharp.

Any error may cause serious injuries (Figure 3-5).

WARNING

• To reduce the risk associated with

f re and explosion hazards:

− Do not operate this equipment

in potentially fl ammable/explosive

environments.

Figure 3-5

WARNING

Sharp Blade

WARNING

• To reduce the risk associated with

muscle strain:

− Use the appropriate rigging and

material handling equipment when

lifting or repositioning this equipment.

− Use proper body mechanics when

removing or installing taping heads

that are moderately heavy or may be

considered awkward to lift.

CAUTION

• To reduce the risk associated with

pinches hazards:

− Keep hands clear of the upper head

support assembly as boxes are

transported through the machine.

− Keep hands, hair, loose clothing, and

jewelry away from box compression rollers.

− Always feed boxes into the machine by

pushing only from the end of the box.

− Keep hands, hair, loose clothing, jewelry

away from moving belts and taping heads.

Figure 3-6

IMPORTANT! Never keep hands on the box while it

is driven by the belts (Figure 3-6).

IMPORTANT! Drive belts. Never work on the

machine with loose hair or loose garments such as

scarfs, ties or sleeves (Figure 3-7).

800ab-NA

7

Figure 3-7

2010 December

Page 20

3-SAFETY (continued)

3.4 Operator's Qualif cations

- Machine Operator

- Mechanical Maintenance Technician

- Electrical Maintenance Technician

- Manufacturer’s Technician/Specialist

(See Section 3.11)

3.5 Number of Operators

The operations described below have been analyzed

by the manufacturer; the recommended number of

operators for each operation provides the best and

safest work performance.

WARNING

• To reduce the risk associated with

mechanical and electrical hazards:

− Read, understand, and follow all safety

and operating instructions before operating

or servicing the case sealer.

− Allow only properly trained and

qualifi ed personnel to operate and service

this equipment.

3.9 Personal Safety Measures

Note: A smaller or greater number of operators

could be unsafe.

3.6 Instructions for a Safe Use of the Machine /

De f nition of Operator's Qualif cations

Only persons who have the skills described in the

skill levels section should be allowed to work on the

machine. It is the responsibility of the user to appoint

the operators having the appropriate skill level and

the appropriate training for each category of job.

3.7 Residual Hazards

The case sealer 800ab has been designed following the CE 392 directives, and incorporates various

safety protections which should never be removed

or disabled. Notwithstanding the safety precautions

conceived by the designers of the machine, it is

essential that the operator and service personnel

be warned that the following residual hazards exist

which cannot be eliminated.

Safety glasses, safety gloves, safety helmet, safety

shoes, air fi lters, ear muffs - None is required except

when recommended by the user.

3.10 Predictable Actions which are Incorrect and

Not Allowed

- Never try to stop/hold the box while being driven

by the belts. Only use the EMERGENCY

STOP BUTTON.

- Never work without the safety protections.

- Never remove or disable the safety devices.

- Only authorized personnel should be allowed

to carry out the adjustments, repairs or main tenance which require operation with reduced

safety protections. During such operations,

access to the machine must be restricted.

When the work is fi nished, the safety protec-

tions must immediately be reactivated.

- The cleaning and maintenance operations must be

performed after disconnecting the electric power.

- Do not modify the machine or any part of it. The man ufacturer will not be responsible for any modifi cations.

3.8 Recommendations and Measures to Prevent

Other Hazards which Cannot be Eliminated

- The operator must stay on the working position

shown in the Operation Section. He must never

touch the running driving belts or put his hands

inside any cavity.

- The operator must pay attention to the blades

during the tape replacement.

800ab-NA

- Clean the machine using only dry cloths or

light detergents. Do not use solvents, petrols, etc.

- Install the machine following the suggested layouts

and drawings. The manufacturer will not be respon sible for damages caused by improper installation.

2010 December

8

Page 21

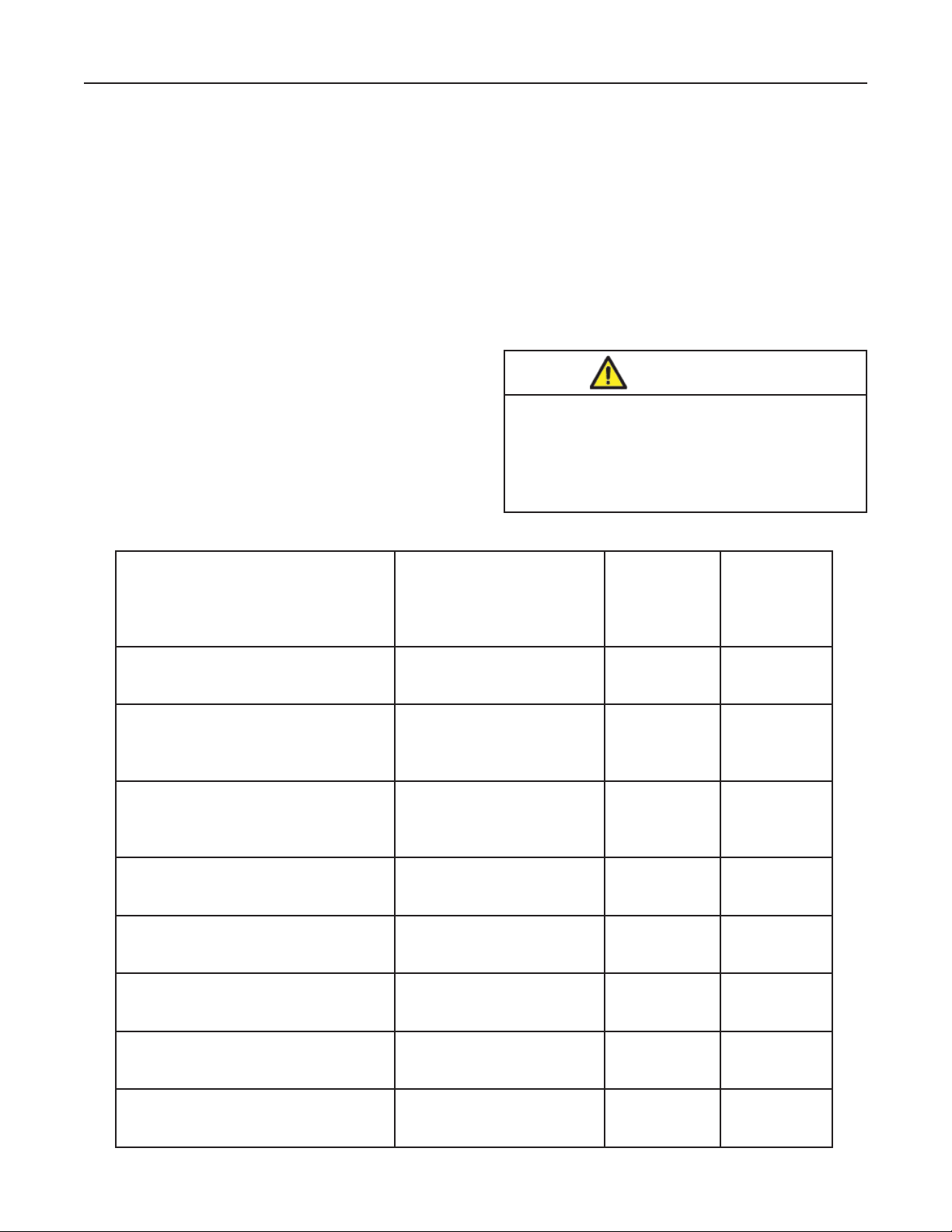

3-SAFETY (continued)

3.11 Operator's Skill Levels Required to Perform

the Main Operations on the Machine

The Table shows the minimum operator's skill for

each machine operation.

Important: The factory manager must ensure that

the operator has been properly trained on all the

machine functions before starting work.

Skill 1: Machine Operator

This operator is trained to use the machine with the

machine controls, to feed cases into the machine,

make adjustments for different case sizes, to change

the tape and to start, stop and restart production.

Skill 2: Mechanical Maintenance Technician

This operator is trained to use the machine as the

MACHINE OPERATOR and in addition is able to:

• Work with the safety protection disconnected

• Check and adjust mechanical parts

• Carry out machine maintenance operations/repairs

He is not allowed to work on live electrical components

Operator's Skill Levels Required to Perform the Main Operations on Machine

Skill 2a: Electrical Maintenance Technician

This operator is trained to use the machine as the

MACHINE OPERATOR and in addition is able to:

• Work with the safety protection disconnected

• Check and adjust mechanical parts

• Carry out machine maintenance operations / repairs / adjustments / repair electrical components

He is allowed to work on live electrical panels,

connector blocks, control equipment, etc.

Skill 3: Specialist from the Manufacturer

Skilled operator sent by the manufacturer or its

agent to perform complex repairs or modifi cations

(on agreement with the customer).

• To reduce the risk associated with

mechanical and electrical hazards:

− Allow only properly trained and

qualifi ed personnel to operate and service

this equipment.

WARNING

Operation Machine Status

Machine installation and setup Running with safety

protections disabled

Adjusting box size

Tape replacement

Blade replacement Electric power

Drive belt replacement Electric power

Ordinary maintenance Electric power

Stopped by pressing the

EMERGENCY STOP

button

Stopped by pressing the

EMERGENCY STOP

button

disconnected

disconnected

disconnected

Required

Operator

Skill

2 and 2a 2

11

11

21

21

21

Number of

Operators

Extraordinary mechanical

maintenance

Extraordinary electrical

maintenance

800ab-NA

Running with safety

protections disabled

Running with safety

protections disabled

9

31

2a 1

2010 December

Page 22

3-SAFETY (continued)

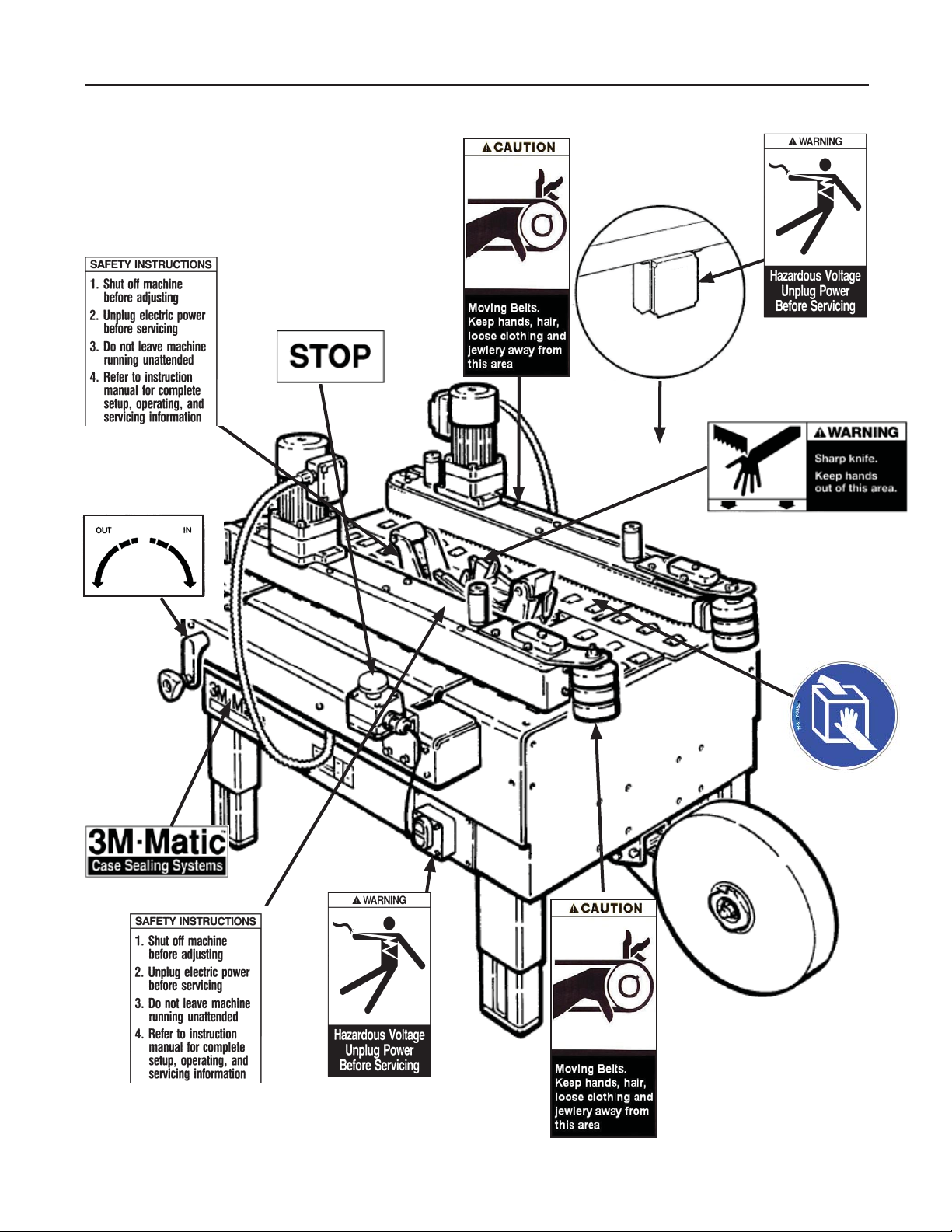

3.12 Component Locations

Refer to Figure 3-8 below to acquaint yourself with the various components and controls of the case sealer.

Also refer to Manual 2 for taping head components.

Adjustable Side

Guides /

Box Drive Belts

Lower Taping Head

Electrical

Control Box

Width

Adjustment

Crank

Emergency

Stop Button

Electrical

On/Off

Switch

Machine Bed

Inclined Rollers

(Alternate)

Lower Tape

Roll Mount

Figure 3-8—800ab Case Sealer Components (Left Front View)

800ab-NA

10

2010 December

Page 23

3-SAFETY (continued)

3.13 Table of Warnings and Replacements Labels (continued)

78-8113-6717-2

78-8070-1366-5

78-8095-1141-9

78-8070-1628-8 (2)

Electrical

Control

Box

78-8070-1329-3

78-8070-1336-8

78-8062-4266-1

78-8070-1329-3

78-8070-1366-5

Figure 3-9 - Replacement Labels / 3M Part Numbers

800ab-NA

11

78-8113-6717-2

78-8137-0886-0

78-8060-8481-6

Leg Height Adjustment Label

(not shown)

78-8070-1339-2

3M Logo

(not shown)

2010 December

Page 24

4-SPECIFICATIONS

1. Power Requirements

Electrical: 120 Volt,60Hz, 3.25 A (220 watts)

The machine is equipped with a 2.4m [8 foot] standard neoprene covered power cord and a grounded plug.

Contact your 3M Representative for power requirements not listed above.

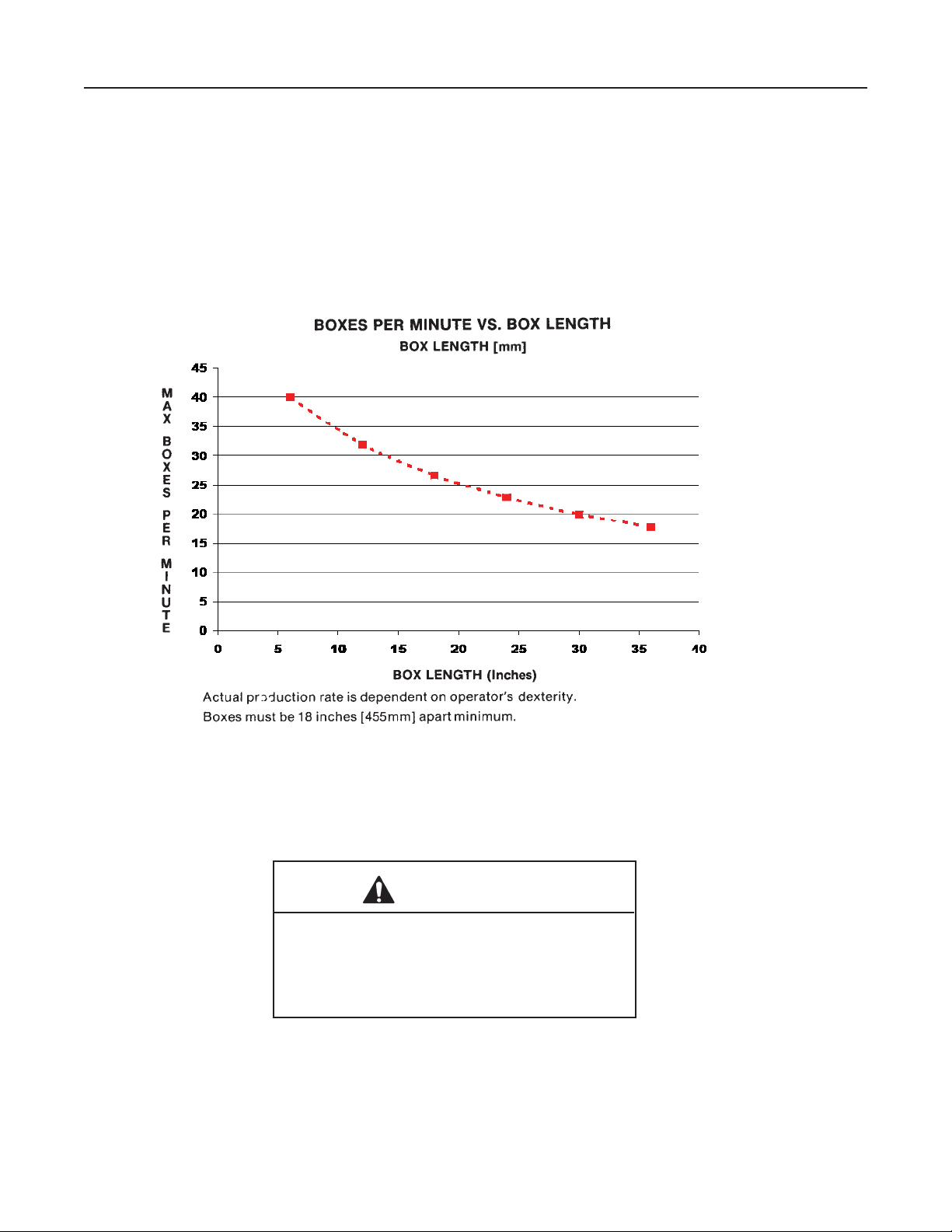

2. Operating Rate

Box drive belt speed is approximately 0.5 m/s [100 feet per minute].

3. Operating Conditions

Use in dry, relatively clean environments at 4.4

Note: Machine should not be washed or subjected to conditions causing moisture condensation on

components.

IMPORTANT SAFEGUARD

o

C to 48.9o C [40o F to 120o F] with clean, dry boxes.

WARNING

IMPORTANT SAFEGUARD

• To reduce the risk associated with f re

and explosion hazards:

− Do not operate this equipment in poten-

tially fl ammable or explosive environments.

4. T ape

®

Scotch

5. T ape Width

36mm [1 1/2 inch] minimum to 48mm [2 inch] maximum

800ab-NA

pressure-sensitive fi lm box sealing tapes.

2010 December

12

Page 25

4-SPECIFICATIONS (continued)

Specif cations

6. Tape Roll Diameter

Up to 405mm [16 inch] maximum on a 76.2mm [3 inch] diameter core.

®

(Accommodates all system roll lengths of Scotch

fi lm tapes.)

7. Tape Application Leg Length – Standard

70mm ± 6mm [2.75 inch ±. 25 inch ]

Tape Application Leg Length – Optional

50mm ± 6mm [2 inch ±. 25 inch]

(See "Removing Taping Heads Procedure – Changing the Tape Leg Length")

8. Box Board

Style – regular slotted containers – RSC

125 to 275 P.S.I. bursting test, single wall or double wall B or C fl ute.

23-44 lbs. per inch of width Edge Crush Test (ECT)

9. Box Weight and Size Capacities

A. Box Weight, fi lled: 5 lbs.–85 lbs. [2.3 kg–38.6 kg]. Contents must support fl aps.

B. Box Size: Minimum Maximum

Length – 150mm [6.0 inch] Unlimited

Width – 115mm [4.5 inch] 545mm [21.5 inch]

Height – 120mm [4.75 inch] Limited by stability of box through Case Sealer

Note: The case sealer can accommodate most boxes within the size range listed above. However, if the box

length (in direction of seal) to box height ratio is 0.6 or less, test run several boxes to ensure proper

machine performance.

DETERMINE THE BOX LIMITATIONS BY COMPLETING THIS FORMULA:

BOX LENGTH IN DIRECTION OF SEAL = SHOULD BE GREATER THAN 0.6

BOX HEIGHT

Any box ratio approaching this limitation should be test run to ensure performance.

800ab-NA

13

2010 December

Page 26

4-SPECIFICATIONS (continued)

L

F FW

Optional

Infeed/Exit

Conveyor

Box Travel

H

A A

10. Machine Dimensions

W L H A* B C F

B

C

Control

Side

Optional Casters

Optional

Infeed/Exit

Conveyor

F

Minimum

mm 825 920 940 460 610 105 620

[Inches] [32-1/2] [36-1/4] [37] [18] [24]* [4-3/16] [24.5]

Maximum

mm 1220 [48] * 890

[Inches] - - - - 1270 [50]** - - [35]* - - - -

* With outer columns relocated to upper position, "H" maximum dimension increases 100 mm [4 inches] and

"B" minimum dimension decreases by 90mm [3-1/2 inches]. (See "Special Set-Up Procedure".)

Weight – approximate 132 kg [290 pounds] crated

approximate 114 kg [250 pounds] uncrated

11. Machine Noise Level: Acoustic pressure measured at a distance of 1m. from machine with

Scotch PVC adhesive tape in operation; 78dB Acoustic radiation pressure at 1.6m. height with

Scotch PVC adhesive tape in operation; 73dB Measurement taken with appropriate instrument:

(Type SPYRI-MICROPHON 11).

12. Set-Up Recommendations:

• Machine must be level.

• Customer supplied infeed and exit conveyors (if used) should provide straight and level box entry and exit.

• Exit conveyors (powered or gravity) must convey sealed boxes away from machine.

800ab-NA

14

2010 December

Page 27

5-SHIPMENT-HANDLING-STORAGE, TRANSPORT

5.1 Shipment and Handling of Packed Machine

- The machine is fi xed on the pallet with four (4) bolts

and can be lifted by using a fork truck.

- The package is suitable to travel by land and by air.

- Optional sea freight package is available.

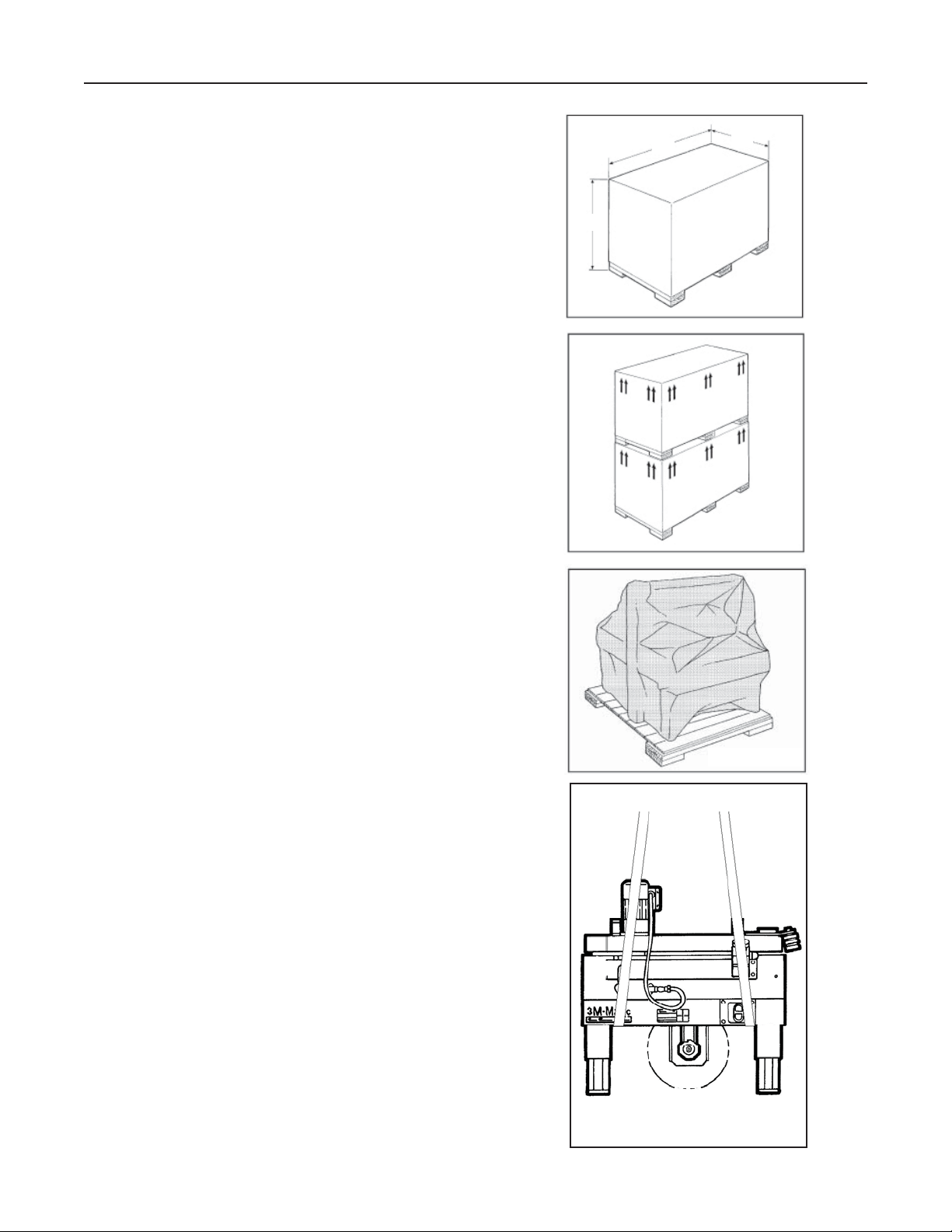

Packaging Overall Dimensions

(Figure 5-1)

W

L

L

H

H

W

See Specifi cations.

During the shipment it is possible to stack a

maximum of 2 machines (Figure 5-2).

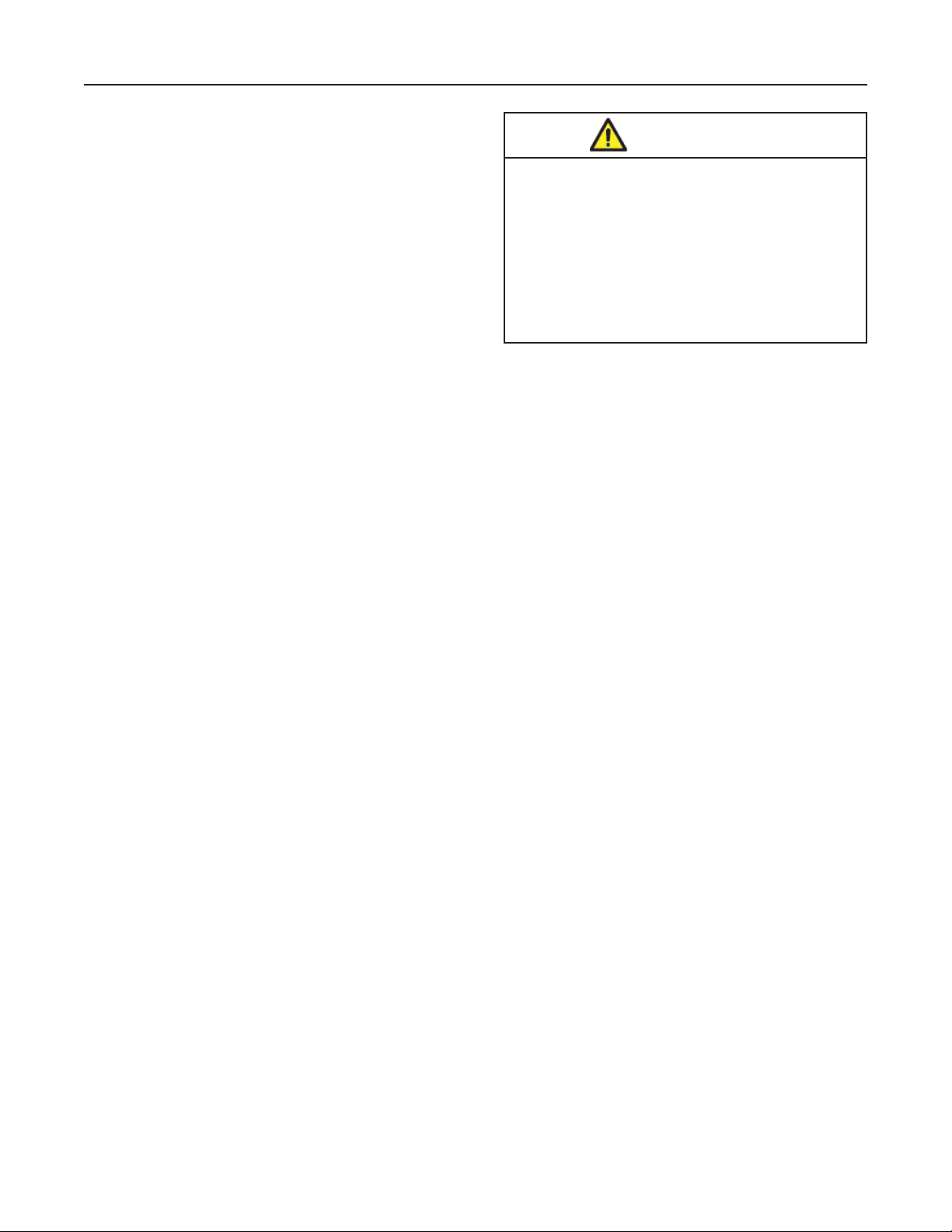

5.2 Packaging for Overseas Shipment

(Optional - Figure 5-3)

The machines shipped by sea freight are covered by

an aluminum/polyester/polythene bag which

contains dehydrating salts.

5.3 Handling and Transportation of Uncrated

Machine

The uncrated machine should not be moved except for

short distances and indoors ONLY. Without the supporting pallet, the machine is exposed to damage and

may cause injuries. To move the machine use belts or

ropes, paying attention to place them in the points indicated using care to not interfere with the lower taping

head (Figure 5-4).

Figure 5-1

Figure 5-2

Figure 5-3

5.4 Storage of the Packed or Unpacked Machine

If the machine is not used for a long period,

please take the following precautions:

- Store the machine in a dry and clean place.

- If the machine is unpacked it is necessary to

protect it from dust.

- Do not stack anything over the machine.

- It is possible to stack a maximum of 2 machines

(if they are in their original packing).

800ab-NA

Figure 5-4

2010 December

15

Page 28

6-UNPACKING

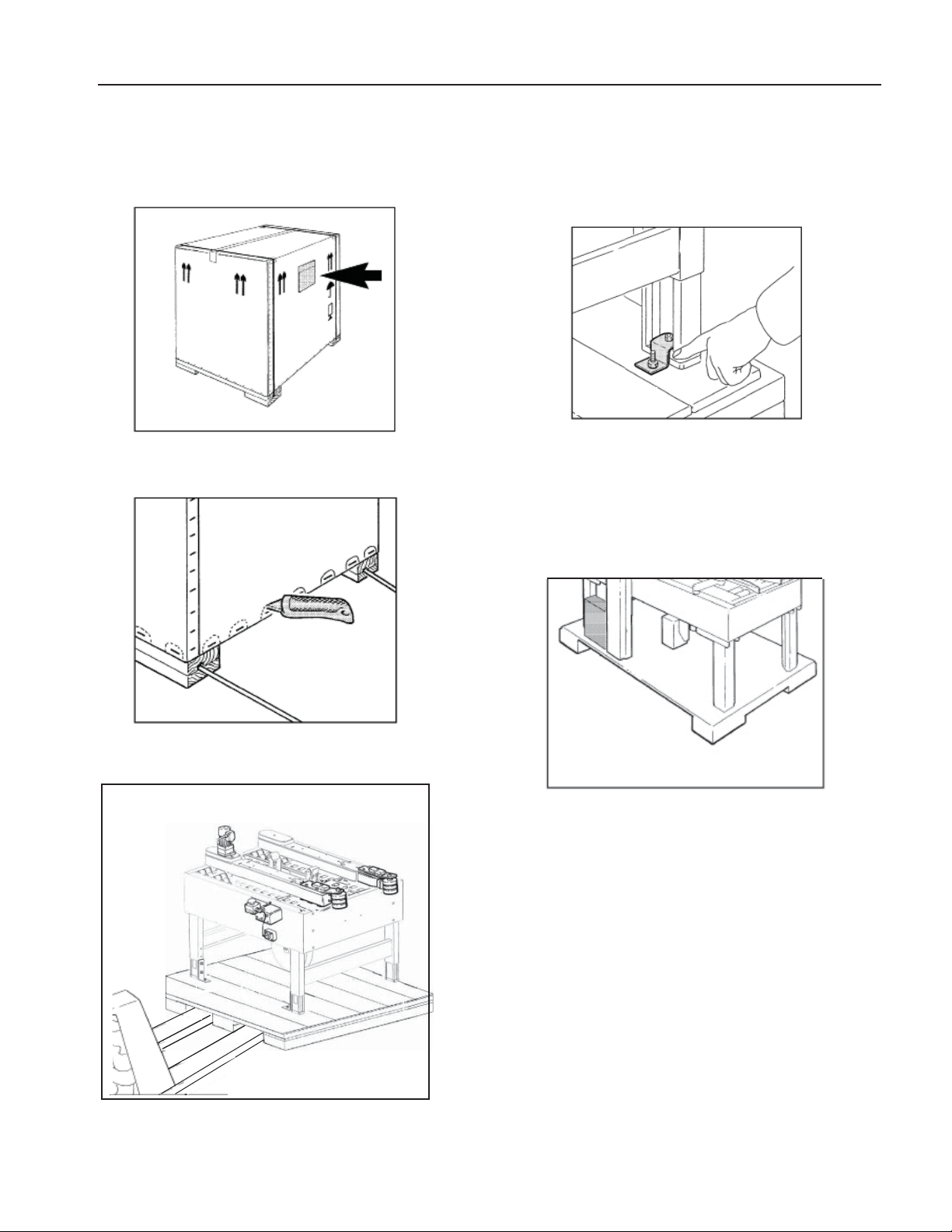

6.1 Uncrating

The envelope attached to the shipping box contains

the uncrating instructions of the machine (Figure 6-1).

Figure 6-1

Cut straps. Cut out staple positions along the bottom

of the shipping box (or remove staples with an

appropriate tool - Figure 6-2).

Removal of Pallet

Loosen and remove nuts and brackets using the

open end spanner supplied in the tool box (Figure 6-4).

Figure 6-4

A cardboard box is located under the machine body.

Retrieve the instruction manual for additional procedures of the set up. The box also contains parts removed for shipping, spare parts and tools (Figure 6-5).

Figure 6-2

After cutting out or removing the staples, lift the

shipping box in order to clear the machine

(two persons required).

Figure 6-3

Transport the machine with a fork-lift truck to the

operating position. Lift the pallet at the point indicated in Figure 6-3 (weight of machine + pallet = See

Specifi caions).

800ab-NA

Figure 6-5

6.2 Disposal of Packaging Materials

The 800ab-NA package is composed of:

- Wooden pallet

- Cardboard shipping box

- Wooden supports

- Metal fi xing brackets

- PU foam protection

- PP plastic straps

- Dehydrating salts in bag

- Special bag of laminated polyester/aluminium/

Polyethylene (sea freight package only)

- Polyethylene protective material

For the disposal of the above materials, please follow

the environmental directives or the law in your country.

16

2010 December

Page 29

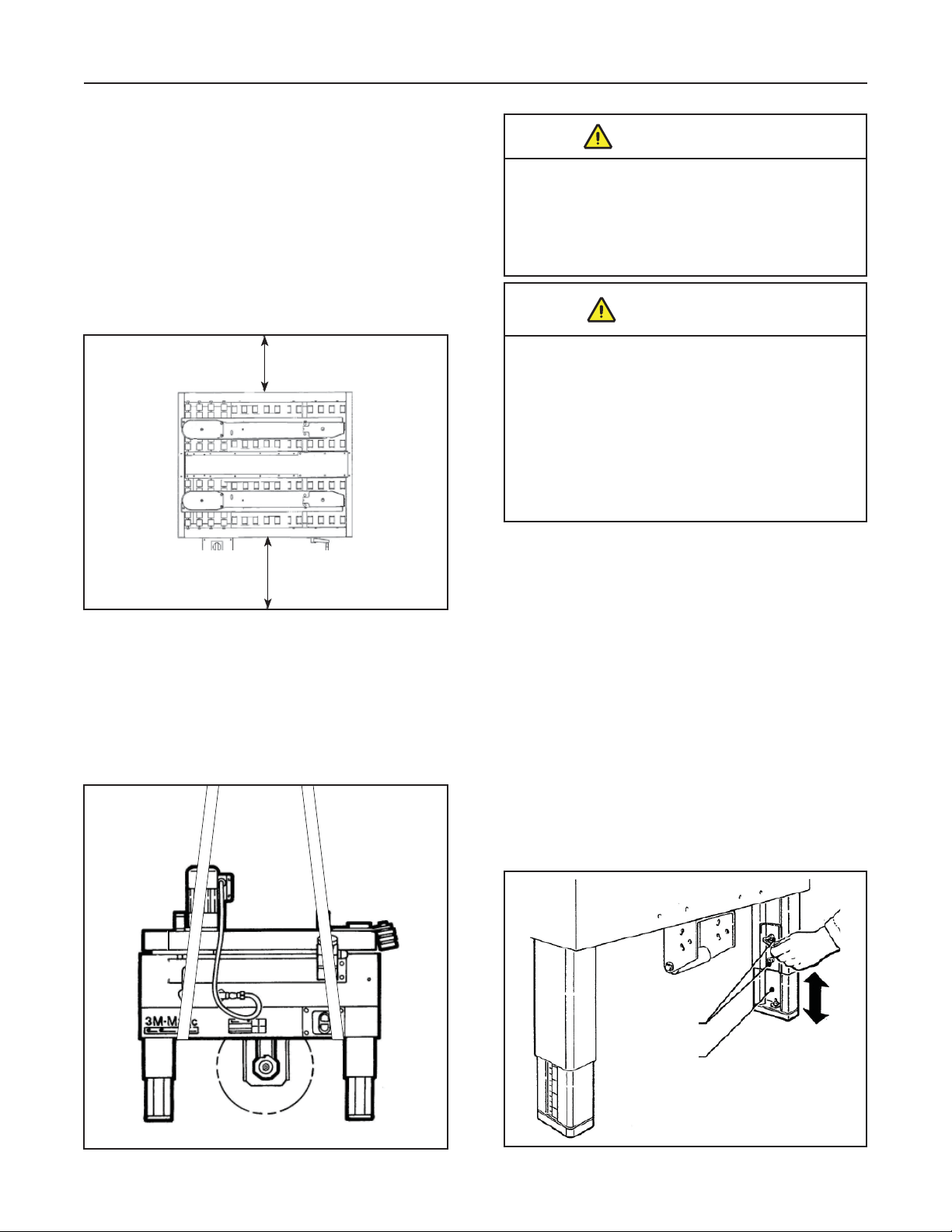

7-INSTALLATION

7.1 Operating Conditions

The machine should operate in a dry and relatively

clean environment (See Specifi cations).

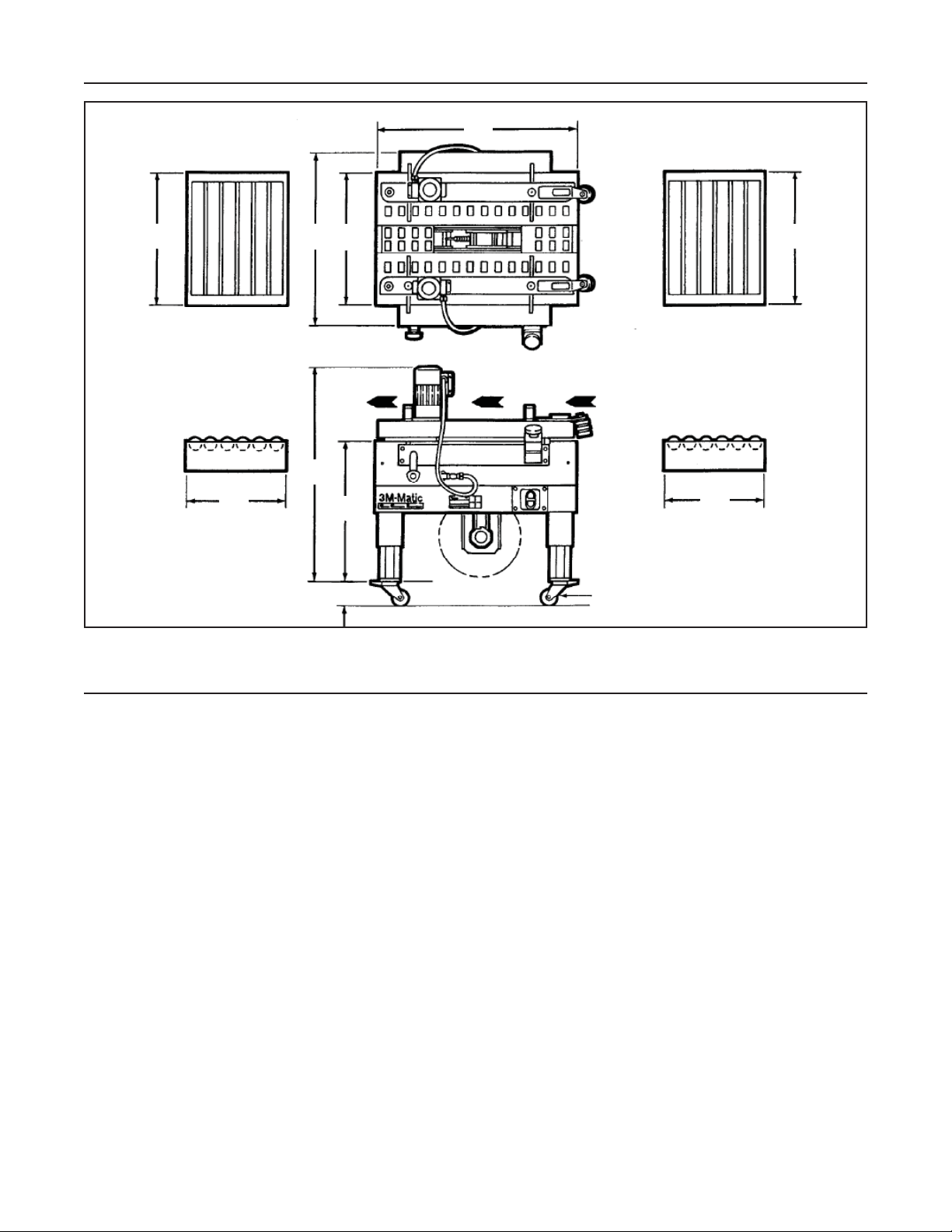

7.2 Space Requirements for Machine Operation

and Maintenance Work

Minimum distance from wall (Figure 7-1):

A = 1000mm.

B = 700mm.

Minimum height = 2700mm.

WARNING

• To reduce the risk associated with

mechanical and electrical hazards:

− Allow only properly trained and

qualifi ed personnel to operate and service

this equipment.

WARNING

• To reduce the risk associated with

muscle strain:

− Use the appropriate rigging and

material handling equipment when

lifting or repositioning this equipment.

− Use proper body mechanics when

removing or installing taping heads

that are moderately heavy or may be

considered awkward to lift.

Figure 7-1

7.3 Tool Kit Supplied with the Machine

A tool kit containing some tools are supplied

with the machine. These tools should be

adequate to set-up the machine, however,

other tools supplied by the customer will be

required for machine maintenance.

Figure 7-2

7.4 Machine Set-Up / Bed Height

Adjust machine bed height. The case sealer is

equipped with four (4) adjustable legs that are

located at the corners of the machine frame. The

legs can be adjusted to obtain different machine bed

heights from 610mm [24 inches] minimum to 890mm

[35 inches] maximum - See Specifi cations.

Refer to Figure 7-3 and set the machine bed height

as follows:

1. Raise and block up the machine frame to allow

adequate leg adjustment.

2. Loosen, but do not remove, two (2) M8 x 16mm

socket head screws in one leg (use M6 hex

wrench). Adjust the leg length for the desired

machine bed height. Retighten the two screws

to secure the leg. Adjust all four (4) legs equally.

M8 x 16mm

Socket Head

Screws

800ab-NA

17

Adjustable

Leg

Figure 7-3

2010 December

Page 30

7-INSTALLATION (continued)

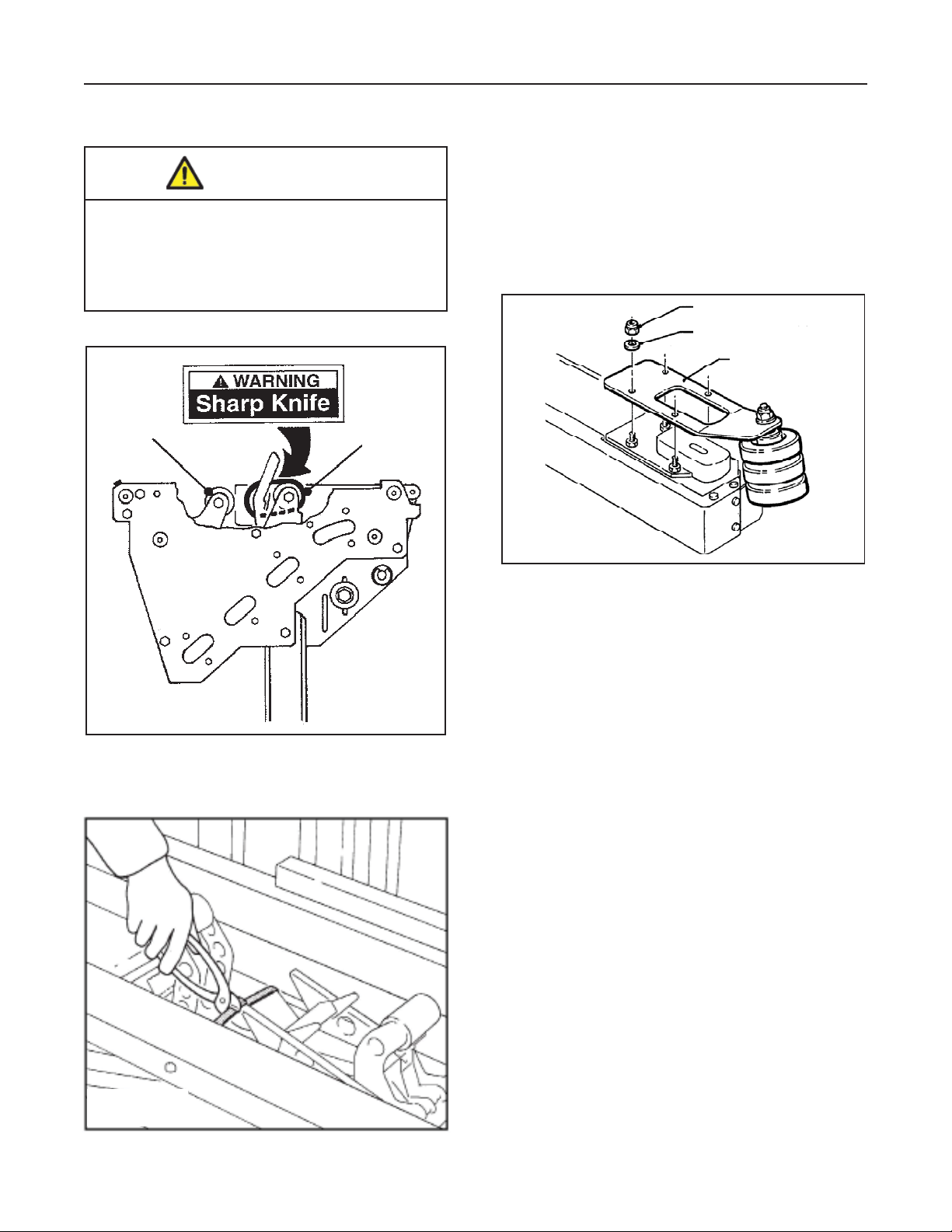

7.5 Removal of Plastic Ties 7.6 Assembly Completion

Install inclined rollers onto infeed end of each drive belt

WARNING

• To reduce the risk associated with

sharp blade hazards:

assembly. Remove M6 lock nuts (4)and M6 plain washers (4) from each drive assembly, position inclined roller

on each drive assembly and fasten with M6 plain

washers and M6 locking nuts (See Figure 7-5)

− Keep hands and fi ngers away from

tape cutoff blades under orange blade

guards. The blades are extremely sharp.

M6 Lock Nut (4)

M6 Plain Washer (4)

Inclined Roller

Assembly

Buff ng

Roller

Cut the plastic ties holding the lower taping head in

position (Figure 7-4).

Cable Tie

Figure 7-5

Figure 7-4

800ab-NA

18

2010 December

Page 31

7-INSTALLATION (continued)

7.7 Completion of Taping Heads

See Manual 2 for Complete Instructions:

1. Place the Upper Taping Head in a convenient

working position

.2. Use Figure 7-6 and tape threading label.

Position the tape supply roll so the adhesive

side of tape is facing the front of the taping head

as it is pulled from the supply roll.

3. Attach the threading needle to the end of the

roll. Guide the threading needle around the wrap

roller (Position 1) then back around the oneway tension roller (Position 2).

4. Continue pulling the threading needle down and

guide it between the two (2) rollers on the apply

arm (Position 3).

5. Pull the threading needle down until the tape

travels between the apply plate and the ears of

the apply arm (Position 4) until it extends past

the applying roller. When properly threaded the

adhesive side of the tape should be facing the

knurled rollers at position 2 and also position 3.

6. Cut away any excess tape and repeat steps for

Lower Taping Head.

Important – Do not cut against the apply roller -

roller damage could occur.

Figure 7-6

Figure 7-7

#2

#3

#4

#1

One Way

Tension

Roller

Tension

Wrap

Roller

Knurled

Roller

Wrap

Roller

Applying

Roller

Threading

Needle

7.8 Outboard Tape Roll Holder

If you intend to use the outboard tape roll holder,

proceed as follows:

1 - Remove the lower taping head from the machine.

2 - Remove the tape drum bracket assembly, stud

spacer, and fasteners from the lower taping head.

3 - Install alternative wrap roller and bracket on the

head in place of tape bracket. Replace lower

head into machine.

4 - Install and secure tape drum bracket assembly

on the entry end of the lower frame (as shown in

Figure 7-7).

7.9 Preliminary Electric Inspection

Before connecting the machine to the mains please

carry out the following operations:

7.9.1 Make sure that the socket is provided with an

earth protection circuit and that both the mains

voltage and the frequency match the specifi -

cations on the name plate.

7.9.2 Check that the connection of the machine

to the mains meets the safety regulations in

your country.

7.9.3 The machine is fi tted with a main switch

and a circuit breaker. The user should check

that the electrical settings of the machine are

compatible with all the components of the

mains system.

7.10 Machine Connection to the Mains

For technical specifi cations: See Section 4 -

Speci f cations

- Push the LATCHING EMERGENCY STOP

BUTTON.

- The main switch is normally OFF.

Connect the power cord supplied with the machine

to a wall socket using a plug which complies with the

safety regulations of your country.

7.11 Inspection of Phases

(For Three-Main Phases Only)

N/A for this machine.

800ab-NA

19

2010 December

Page 32

8-THEORY OF OPERATION

8.1 Description of the Working Cycle

After having closed the top fl aps of the carton, the

operator pushes it under the top infeed end in order

to avoid the opening of the top fl aps. Further push-

ing causes the two bottom side belts to drive the

box through the taping heads which automatically

seal the top and bottom seams. The carton is then

expelled on the exit conveyor.

8.2 Def nition of Running Mode

The case sealer 800ab-NA has only one (automatic)

operating mode with:

- The EMERGENCY STOP BUTTON unlocked

(Figure 8-1)

- The main switch start switch “ON”

(Figure 8-2)

Figure 8-1

8.3.1 Normal Stop Procedure

When the main switch is OFF, the machine stops

immediately at any point of the working cycle. The

same thing happens in case of electrical failure or

when the machine is disconnected from the mains.

8.3.2 Emergency Stop

The LATCHING EMERGENCY STOP BUTTON is

located on the top center of the machine

(Figure 8-1).

Figure 8-2

Belt

Direction

E-Stop

Location

800ab-NA

Figure 8-3

2010 December

20

Page 33

9-CONTROLS

9.1 Box Width Adjusting Knobs

Figure 9-1

9.2 Start/Stop Button

9.3 Latching Emergency Stop Button

Power

Switch

Figure 9-2

21

E-Stop

Switch

Figure 9-3

2010 December800ab-NA

Page 34

10-SAFETY DEVICES OF THE MACHINE

10.1 Blade Guards

Both the top and bottom taping units have a blade

guard. (See Manual 2: AccuGlide™ 3 Taping

Heads - 2 inch).

WARNING

• To reduce the risk associated with

sharp blade hazards:

− Keep hands and fi ngers away from

tape cutoff blades under orange blade

guards. The blades are extremely sharp.

10.2 Emergency Stop Button

The box drive belts are turned on and off with the

electrical switch on the side of the machine frame.

The machine electrical supply can be turned off

by pressing the latching emergency stop switch.

To restart machine, rotate the emergency stop

switch clockwise to release the switch latch.

Restart machine by Pushing the On/Off switch to

the Off (O) position and then to the On (I) position

(Figure 10-1)

.

10.3 Electric System / Circuit Breaker

The electric system is protected by a ground wire

whose continuity has been tested during the fi nal

inspection. The system is also subject to insulation

and dielectric strength tests.

Circuit Breaker

The case sealer is equipped with a circuit breaker

which trips if the motors are overloaded. Located

inside the electrical enclosure on the side of the

machine frame just below the machine bed, the

circuit breaker has been pre-set and requires no

further maintenance.

WARNING

• To reduce the risk associated with

mechanical and electrical hazards:

− Allow only properly trained and

qualifi ed personnel to operate and service

this equipment.

If circuit is overloaded and circuit breaker trips,

unplug machine from electrical power:

WARNING

• To reduce the risk associated with

hazardous voltage:

− Position electrical cord away from foot

and vehicle traffi c.

E-Stop

Switch

Figure 10-1

1. Determine cause of overload and correct.

2. Remove electrical enclosure cover.

3. Press the red "Reset" button and then the

green "Start" button.

4. Replace cover.

5. Plug in machine.

6. Press machine "On" button to resume case

sealing.

Important: The use of an extension cord is not

recommended. However, if one is needed for

temporary use, it must:

• Have a wire size of 1.5mm diameter [AWG 16]

• Have a maximum length of 30.5m [100 ft]

• Be properly grounded.

800ab-NA

22

2010 December

Page 35

11 - SET UP AND ADJUSTMENTS

11.1 Box Width Adjustment

Place a product fi lled box on infeed end of machine

bed with top fl aps folded as shown and manually

move box forward to contact lower taping head

applying roller.

Turn drive belt adjustment crank to position both side

drive belts against sides of box (Figure 11-1).

11.2 Box Height Adjustment

Not Applicable to this machine.

11.3 Adjustment of Top Flap Compression Rollers

Not Applicable to this machine.

11.4 Changing the Tape Leg Length

Taping heads are preset to apply 70mm [2.75 inches]

long tape legs. To change tape leg length to 50mm

[2.0 inches], refer to Instructions below and also to

Manual 2, "Removing Taping Heads Procedure Changing the Tape Leg Length".

11.5 Run Boxes to Check Adjustment

Push electrical switch "On" to start drive belts.

Figure 11-1

IMPORTANT – If drive belts are allowed to slip on

box, excessive belt wear will occur.

Move box forward under upper taping head until it

is taken away by drive belts. If box is hard to move

under head or is crushed, raise head slightly.

If the box movement is jerky or stops under the upper

head, move the side drive belts in slightly to add more

pressure between the box and drive belts.

800ab-NA

23

2010 December

Page 36

12-OPERATION

12.1 Operator's Correct Working Position and

Operational Flow (Figure 12-1).

Figure 12-1

Once the box has been fi lled, close its top fl aps and

push it between the top and bottom drive belts.

Always keep hands in position as shown in

Figure 12-2.

The box will be automatically sealed with adhesive

tape on the top and bottom box seams. Then the

box will be expelled on the exit conveyor.

Figure 12-2

12.3 Starting Production

After having adjusted the machine according to the

box dimensions (height-width), let the machine run

without cartons and check its safety devices. Then

start the working cycle.

12.4 Tape Replacement and Threading

Skill 1 - Operator

See Manual 2: AccuGlide™ 3 High Speed 2 Inch

Taping Heads.

Press the

LATCHING EMERGENCY STOP BUTTON.

WARNING

• To reduce the risk associated with sharp

blade hazards:

− Keep hands and fi ngers away from tape

cutoff blades under orange blade guards.

The blades are extremely sharp.

12.5 Box Size Adjustment

Hand

Position

12.2 Starting the Machine

Important: Before starting the machine, verify that

no tools or other objects are on the conveyor bed.

Push the main switch ON after the EMERGENCY

BUTTON is released.

Repeat all the operations shown in

Section 11 - Set-Up and Adjustments.

12.6 Cleaning

Before carrying out any cleaning or maintenance

operation stop the machine by Pushing the OFF

switch on the main and disconnect the electric power

(Figure 12-3).

12.7 Table of Operation Adjustments Operator Qualif cations

1 Tape loading and threading 1

2 Tape web alignment 1

3 Adjustment of one way tension roller 1

4 Adjustment to box size (H and W) 1

5 Top fl ap compression rollers 1

6 Adjustment of tape applying spring 1

7 Conveyor bed height adjustment 1

8 Special Adjustment-Changing tape leg length 2

9 Special Adjustment-Column re-positioning 2

12.8 Safety Devices Inspection

Figure 12-3

800ab-NA

1 Taping units blade guard

2 Latching emergency stop button

3 STOP (OFF) main switch

2010 December

24

Page 37

12-OPERATION (continued)

12.9 Troubleshooting Guide

Problem

Drive belts do not convey boxes

Drive belts do not turn

Cause

Narrow boxes

Worn drive belts

Top taping head does not apply

enough pressure

Top fl ap compression rollers in too

tight

Taping head applying spring

holder missing

Taping head applying spring set

too high

Worn or missing friction rings

Drive belt tension too low

Correction

Check machine specifi cations.

Boxes are narrower than

recommended, causing slippage

and premature belt wear.

Replace drive belts

Adjust the box height adjustment

with the crank

Readjust compression rollers

Replace spring holder

Reduce spring pressure

Replace friction rings

Adjust belt tension

Drive belt break

Tape not centered on box seam

Electrical disconnect

Motor not turning

Worn belt

Excessive belt tension

Tape drum not centered

Box fl aps not of equal length

Check power and electrical plug

Evaluate problem and correct

Replace belt

Tension to 3.5 kg [7 lbs] per

adjustment section

Reposition tape drum

Check box specifi cations

800ab-NA

2010 December

25

Page 38

THIS PAGE IS BLANK

26

Page 39

13-MAINTENANCE AND REPAIRS

13.1 Safety Measures (see section 3)

Carrying out maintenance and repairs may imply

the necessity to work in dangerous situations.

13.3 Recommended Frequency of Inspection and Maintenance Operations

Operation Frequency Quali f cation Sections

Inspection safety features daily 1 13.4

Cleaning of machine weekly 1 13.5

Cleaning of cutter blade weekly 2 13.6

Oiling of felt pad weekly 2 13.7

Lubrication monthly 2 13.7-13.8

Blade replacement when worn 2 See Manual 2

Drive belt replacement when worn 2 13.10

13.4 Inspections to be Performed Before and

After Every Maintenance Operation

Before every maintenance operation, Push the main

switch OFF and disconnect. During the maintenance

operation, only properly trained and qualifi ed person-

nel must work on the machine. At the end of every

maintenance operation check the safety devices.

13.2 Tools and Spare Parts Supplied with

the Machine

See Spare Parts Order Section.

13.7 Cleaning of Cutter Blade

Qualif cation 2

Should tape adhesive build-up occur, carefully wipe

clean with oily cloth or brush (Figure 13-1). Oil prevents the build-up of tape adhesive.

(See manual 2.)

13.5 Check Eff ciency of Safety Features

1. Blade guard assembly lower taping head

2. Latching Emergency stop button with mechanical

lock (interrupt supply of electrical power)

3. Push the main switch STOP/OFF

13.6 Cleaning of Machine

Qualif cation 1

A weekly cleaning with dry rags or diluted detergents

is necessary. Cardboard boxes produce a signifi cant

quantity of dust and paper chips when processed

or handled in case sealing equipment. If this dust is

allowed to build up on machine components, it can

cause component wear and over-heating of drive

motors. The dust build up is best removed from the

machine with a vacuum cleaner. Depending on the

number of cartons processed, this cleaning should

be done weekly. Excessive build-up that cannot be

removed by vacuuming should be removed with a

damp cloth.

WARNING

• To reduce the risk associated with

mechanical and electrical hazards:

− Read, understand, and follow all safety

and operating instructions before operating

or servicing the case sealer.

− Allow only properly trained and qualifi ed

personnel to operate and service this

equipment.

• To reduce the risk associated with

pinches, entanglement and hazardous

voltage:

− Turn electrical supply off and disconnect

before performing any adjustments,

maintenance or servicing the machine or

taping heads.

800ab-NA

27

2010 December

Page 40

13-MAINTENANCE AND REPAIRS (continued)

WARNING

• To reduce the risk associated with pinch, entanglement and hazardous voltage:

− Turn electrical supply off and disconnect before performing any adjustments, maintenance or

servicing the machine or taping heads

13.8 Drive Belt Replacement

Note – 3M recommends the replacement of drive belts in pairs, especially if belts are unevenly worn.

Replacement - See Steps 1 thru 8

Tension Adjustment - See Steps 3, 7 and 9.

1. Crank the upper taping head to its fully raised position.

2. Remove and retain the three (3) screws (A), three (3) washers (B) and side cover (C). See Figure 13-4.

3. Remove and retain the screw (D), washer (E) and belt tensioner cover (F).

4. Turn belt adjustment screws (G) counterclockwise on both the upper and lower tension assemblies until belt is

loose. See Figure 13-5.

5. Locate the belt lacing (joint) by turning the belt manually. Remove the pin with pliers. Remove and discard

old belt.

WARNING

• To reduce the risk associated with mechanical and electrical hazards:

− Allow only properly trained and qualifi ed personnel to operate and/or service this equipment

A

B

C

D

E

F

Figure 13-4 – Box Drive Belt (Left Side View – Infeed End)

G

28

800ab-NA

G

2010 December

Page 41

13-MAINTENANCE AND REPAIRS (continued)

WARNING

• To reduce the risk associated with pinch, entanglement and hazardous voltage:

− Turn electrical supply off and disconnect before performing any adjustments, maintenance or

servicing the machine or taping heads

G

G

G

Figure 13-5 – Box Drive Assembly, Infeed End

6. Install the new belt around drive rollers and insert new pin. Pin must not extend beyond edge of belt.

7. To set drive belt tension, turn adjustment screws (G) equally on both the upper and lower tension assemblies.

Turn the screws clockwise to increase tension or counterclockwise to decrease tension. See Figure 13-5.

Use a force gauge to pull the belt outward 25mm [1 inch] at mid span, as shown with a moderate pulling force

of 3.5 kg [7 lbs].

8. Reverse procedures in Steps 1-3 (Figure 13-4) to reassemble the drive belt assembly.

Important – Before installing new drive belt, check the belt inside surface for drive direction arrows and install

belt accordingly. If no arrows are shown, the belt may be installed either way.

13.9 Drive Pulley Rings Installation :

Before installing a new belt, check the orange plastic

drive pulley rings for wear. If torn, broken, or worn

smooth, replace the rings (Figure 13-6).

800ab-NA

29

Figure 13-6

2010 December

Page 42

13-MAINTENANCE AND REPAIRS (continued)

Drive Belt

Direction

Infeed EndDischarge End

Box Drive Belt

Figure 13-7 – Box Drive Belt Tension Adjustment, Top View

25mm [2 Inch] Def ection

@ 3.5 kg [7 lbs.] Pull Force at Midspan

WARNING

• To reduce the risk associated with pinch, entanglement and hazardous voltage:

− Turn electrical supply off and disconnect before performing any adjustments, maintenance or

servicing the machine or taping heads

13.10 Drive Belt Tension

Tension adjustment of the drive belts may be required during normal operation. Belt tension must be adequate to

positively move the box through the machine and they should run fully on the surface of the pulleys at each end of

the frame. The idler pulleys on the infeed end are adjusted in or out to provide proper belt tension. Each belt is

adjusted separately.

Belt tension is obtained by tightening the adjustment screw so that a moderate pulling force of 3.5 kg [7 lbs]

applied at the midspan, as shown in Figure 13-7, will defl ect the belt 25mm [1 inch]. This will assure positive

contact between the belt and the drive pulley on the discharge end of the taping head.

To adjust belts, see "Maintenance – Drive Belts", steps 3 and 7.

800ab-NA

30

2010 December

Page 43

13-MAINTENANCE AND REPAIRS (continued)

13.11 Special Set-Up Procedure

• To reduce the risk associated with mechanical and electrical hazards:

− Turn electrical and air supply off and disconnect before performing any adjustments,

maintenance, or servicing the machine or taping heads

13.11.1 Taping Heads

Taping Head Adjustments

WARNING

WARNING

• To reduce the risk associated with sharp blade hazards:

− Keep hands and fi ngers away from tape cutoff blades under orange blade guards. The blades

are extremely sharp

TAPE WEB ALIGNMENT – Manual 2

TAPE DRUM FRICTION BRAKE – Manual 2

APPLYING MECHANISM SPRING – Manual 2

ONE-WAY TENSION ROLLER – Manual 2

TAPE LEG LENGTH

Leading Tape Leg Length Adjustment – Manual 2

Changing Tape Leg Length from 70 to 48mm [2-3/4 to 2 inches] – Manual 2

Note – Changing tape leg to 48mm [2 inches] requires machine adjustment also. See

"Special Set-Up Procedure – Changing Tape Leg Length".

800ab-NA

31

2010 December

Page 44

13-MAINTENANCE AND REPAIRS (continued)

Special Set-Up Procedure (continued)

13.11.2 Drive Belt Assembly Height

WARNING

• To reduce the risk associated with

muscle strain:

− Use proper body mechanics when

removing or installing taping heads that

are moderately heavy or may be

considered awkward to lift

The drive belt assemblies can be raised 48mm

[2 inches] to provide better conveying of tall boxes.

This change increases the minimum box height that

can be taped to 190mm [7-1/4 inches].

A

B

C

D

Disassemble – Figure 13-8

1. It is fi rst necessary to raise the top taping head.

Utilize the height adjustment crank and move

the upper taping head to the fully raised position.

2. Remove and retain the screw (A), cap washer

(B) and spacer (C) from the front and rear arm

assembly pivots.

3. Lift belt drive assembly (D) up off the arm

assembly pivots.

Reassemble – Figure 13-9

4. Reassemble the spacer (C) onto the front and

rear arm assembly pivots.

5. Install the belt drive assembly (D) onto the pivots

and secure with the cap washers (B) and screws

(A).

Note – Both drive belt assemblies must be

installed at the same operating height.

Figure 13-8 – Drive Belt Assembly, Disassembly

A

B

D

C

800ab-NA

Figure 13-9 – Drive Belt Assembly, Reassembly

32

2010 December

Page 45

13-MAINTENANCE AND REPAIRS (continued)

Special Set-Up Procedure (continued)

13.11.3 Chain Removal

WARNING

WARNING

• To reduce the risk associated with

mechanical and electrical hazards:

− Turn electrical and air supply off and

disconnect before performing any

adjustments, maintenance, or servicing the

machine or taping heads

1. Remove M6 x 16 hex hd screw, special washer

and drive belt width adjustment crank -

Figure 13-10.

2. Remove side covers (2) from each side of machine bed - Figure 13-10.

3. Remove chain. If necessary, slip width

adjustment crank on shaft and rotate until chain

master link is in convenient position for removal.

• To reduce the risk associated with

muscle strain:

− Use the appropriate rigging and

material handling equipment when lifting or

repositioning this equipment

− Use proper body mechanics when

removing or installing taping heads that are

moderately heavy or may be considered

awkward to lift

Important – Before removing chain, mark both

front and rear sprockets/chain with chalk "

or paint to be sure sprockets/chain when

re-assembled, will be in same position as

before disassembly. Figure 13-11A and

Figure 13-11B. Do not rotate sprockets

once chain is removed. (This would result

in the right and left drive assemblies not

being parallel.)

Remove chain master link and remove chain.

Figure 13-11C.

M6 X 16

Hex Hd Screw

Washer

Crank

Side Covers

Figure 13-10 – Crank/Chain Guards

C

Master

Link

A

B

Mark Chain

and Sprocket

Mark Chain

and Sprocket

800ab-NA

33

Figure 13-11 – Chain Removal

2010 December

Page 46

THIS PAGE IS BLANK

34

Page 47

13-MAINTENANCE AND REPAIRS (continued)

13.12 List of the Maintenance Operations

Date: Description of Operation

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

________ ________________________________________________________________

800ab-NA

35

2010 December

Page 48

THIS PAGE IS BLANK

36

Page 49

14-ADDITIONAL INSTRUCTIONS 15-ENCLOSURES / SPECIAL INFO.

14.1 Information for Disposal of Machine (ELV)

The machine is composed of the following materials:

- Steel structure

- Nylon rollers

- Drive belts in PVC

- Nylon pulleys

For machine disposal, follow the regulations

published in each country.

14.2 Emergency Procedures

In case of danger/fi re:

Disconnect plug of power cable from power supply.

(Figure 14-1)

IN CASE OF FIRE

Use a fi re extinguisher that is rated for electrical fi res

(Figure 14-2).

Figure 14-1

15.1 Statement of Conformity

Not Applicable.

15.2 Emission of Hazardous Substances

Nothing to report

Figure 14-2

800ab-NA

37

2010 December

Page 50

THIS PAGE IS BLANK

38

Page 51

16-TECHNICAL DIAGRAMS

16.1 Electric Diagram

800ab-NA

39

2010 December

Page 52

16-TECHNICAL DOCUMENTATION AND INFORMATION (continued)

16.2 Spare Parts Order

Replacement Parts Ordering Information and Service

Refer to the fi rst page of this instruction manual "Replacement Parts and Service Information".

Order parts by quoting the following information:

(Refer to the Identifi cation Plate on the Machine)

• MACHINE MODEL

• SERIAL NUMBER

• FIGURE NO.

• POSITION

• 3M PART NO. (11 DIGITS)

• DESCRIPTION

• QUANTITY

Refer to Manual 2 for recommended taping head spare parts.

IMPORTANT!

The machine is constantly revised and improved by our designers. The spare parts catalogue is also periodically

updated. It is very important that all the orders of spare parts make reference to the serial number of the machine

(located on the identifi cation plate on the machine).

The manufacturer reserves the right to modify the machine at any time without notice.

It is suggested that the following spare parts be ordered and kept on hand.

800ab

Qty. 3M-Part Number Description

2 78-8076-5452-6 Belt-Drive W/Hook

Tool Kit

A tool kit, part number 78-8060-8476-6, is available as a stock item. The kit contains the necessary open end and

hex socket wrenches for use with the metric fasteners on the case sealer. The threading tool, part number