Page 1

3

LC Hot Melt

Fiber Optic Connectors

Installation

March 2005

78-8135-4385-3-A

Page 2

Contents

1.0 Safety and Helpful Hints ................................................................................................................3

Hot Melt Oven Safety Information ................................................................................................3

2.0 3M™ LC Expansion 6650-LC Kit Contents ...................................................................................4

3.0 3M™ LC Connectors ......................................................................................................................5

4.0 Setup ............... 6

5.0 900 micron Cable Connector Preparation ......................................................................................8

6.0 1.6 – 2.0 mm Jacketed Cable Connector Preparation ....................................................................8

7.0 3.0 mm Jacketed Cable Connector Preparation .............................................................................8

8.0 Strip Guide ..... 9

9.0 Stripping Procedure for 900 micron Fiber .....................................................................................9

10.0 Stripping Procedure for 1.6 – 2.0 mm Jacketed Fiber ....................................................................9

11.0 Stripping Procedure for 3 mm Jacketed Fiber ..............................................................................11

12.0 Connector Mounting ....................................................................................................................12

13.0 Boot Placement for 900 micron Fiber ..........................................................................................14

14.0 Crimping and Boot Placement for 1.6 – 2.0 mm Jacketed Fiber .................................................14

15.0 Crimping and Boot Placement for 3 mm Jacketed Fiber .............................................................16

16.0 Scribing ........ 17

17.0 Multimode Polish .........................................................................................................................18

18.0 Singlemode Polish to –40db .........................................................................................................21

19.0 Singlemode Polish to –55db .........................................................................................................23

20.0 Finishing ....... 24

21.0 Installing Duplex Yokes ................................................................................................................24

22.0 3M™ Expansion Kit 6650-LC and Replacement Part Numbers ...................................................26

2 78-8135-4385-3-A

Page 3

1.0 Safety and Helpful Hints

Use reagent-grade isopropyl alcohol that is 99% pure to clean the fibers and other components. When

terminating connectors on any cable containing grease, ensure that all grease is wiped away and the buffer,

coating and fiber are thoroughly cleaned with isopropyl alcohol.

Isopropyl alcohol is not shipped with the 3M™ Field Termination Kits; however, a bottle for the alcohol is

included.

Note: Carefully follow safety, health and environmental information given on the container label or the Material

Safety Data Sheet for the isopropyl alcohol.

CAUTION

Do not touch any part of the heating block of the Hot Melt oven during operation.

It is very HOT.

WARNING

• Safety glasses should be worn when working around optical fibers.

• Do not view fiber ends if they are illuminated with a laser.

• Keep oven clear from flammable material.

• Disconnect power supply when cleaning.

Hot Melt Oven Safety Information

This Hot Melt Connector Oven is intended for melting Hot Melt adhesive in Hot Melt Connectors. It has

been designed and tested for use only with the 3M™ Fiber Optic Connectors System. Other uses of this

product may lead to poor performance or an unsafe condition.

WARNING

1. Power cord must be grounded and plugged into a grounded outlet.

2. Eye hazard. Do not view fiber ends if they are laser illuminated as eye

damage may result. Illuminate fiber ends with white light only.

3. Wear safety glasses.

4. No serviceable parts - return unit to the manufacturer for servicing.

5. For indoor use only.

6. To avoid possible environmental contamination, dispose of the unit in

accordance with applicable governmental regulations.

7. Avoid touching hot surfaces.

Explanation of symbols:

Warning - Refer to accompanying documents.

Caution - Risk of electric shock. Refer all servicing to manufacturer.

This is the EU symbol for equipment that is covered under the Waste from Electrical and

Electronic Equipment (WEEE) directive per CENELEC Specification 50419, and it indicates that

certain products should not be discarded in the trash, but rather should be recycled. This applies

to all electronic pluggable and battery powered products.

78-8135-4385-3-A 3

Page 4

2.0 3M™ LC Expansion 6650-LC Kit Contents

A

A

A

A

H

A. LC Hot Melt Connector Holder (4)

C

B

D

B

1

E

G

F

I

B. LC Polishing Jig Assembly with Weight

B1 Spare Polishing Jig

C. LC Crimp Tool

D. LC Adapter for View Scope

E. Heat Shrink Fixture

F. Cleaning Pins (3)

G. Laminated Strip Template

H. Polishing Pads 4.5" × 5.5"

I. Lapping Film

a. 9 micron silicon carbide 5" diameter (Slate Gray)

b. One Step 2 micron AO 5" diameter (Blue/Green)

c. 0.5 micron diamond 4.5" × 5.5" (Pale Gray)

d. 0.02 micron Final Polish SiO2 4.5" × 5.5" (Frosted White)

To complete the termination of the 3M™ Hot Melt LC Connector, both the 3M™ Universal Hot Melt Kit

6365/6361 and the 6650-LC Expansion Kits are required.

Visually inspect all components. If any component is missing or appears damaged, do not install.

Call customer service at 1-800-426-8688 for a replacement product.

4 78-8135-4385-3-A

Page 5

3.0 3M™ LC Connectors

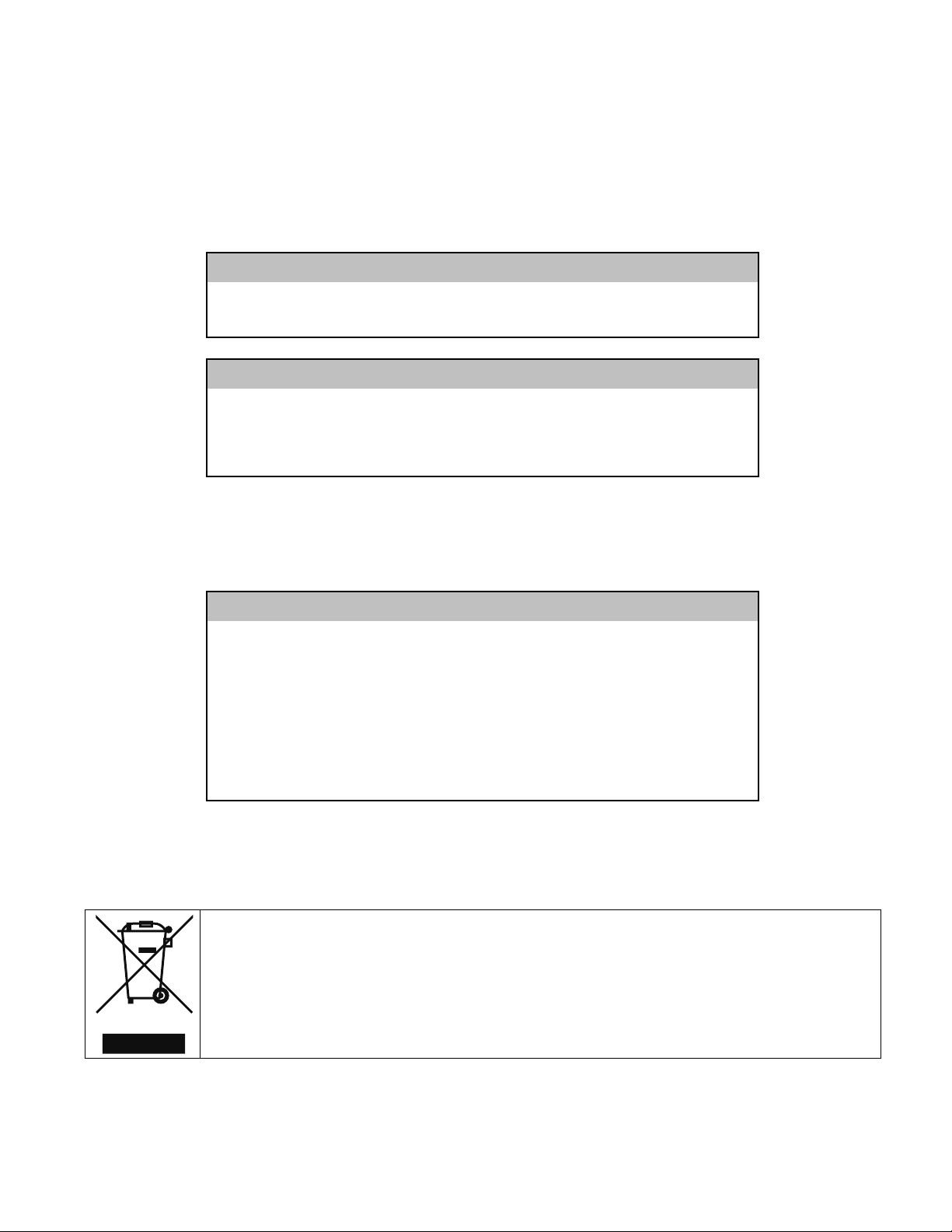

3.1 The Behind The Wall (BTW) LC is used for simplex

900 micron applications. The connector contains (A)

dust cap, (B) connector, and (C) strain relief boot.

Note: The BTW LC multimode connector has a beige

extender cap at the rear of the connector. The singlemode

connector has a blue extender cap at the rear of the

connector.

3.1 The duplex 900 micron LC contains (A) dust cap,

(B) connector, (C) duplex clip, and (D) strain

relief boot.

Note: Do not confuse the multimode or singlemode

duplex connectors as they both have black outer housings.

Multimode connectors are packaged with beige duplex

yokes and singlemode connectors are packaged with

blue yokes.

A B C

3.2 1.6–2.0 mm LC connector contains a (A) dust cap,

(B) connector, (C) heat shrink crimp sleeve, and

(D) strain relief boot.

A B C D

A B C D

78-8135-4385-3-A 5

Page 6

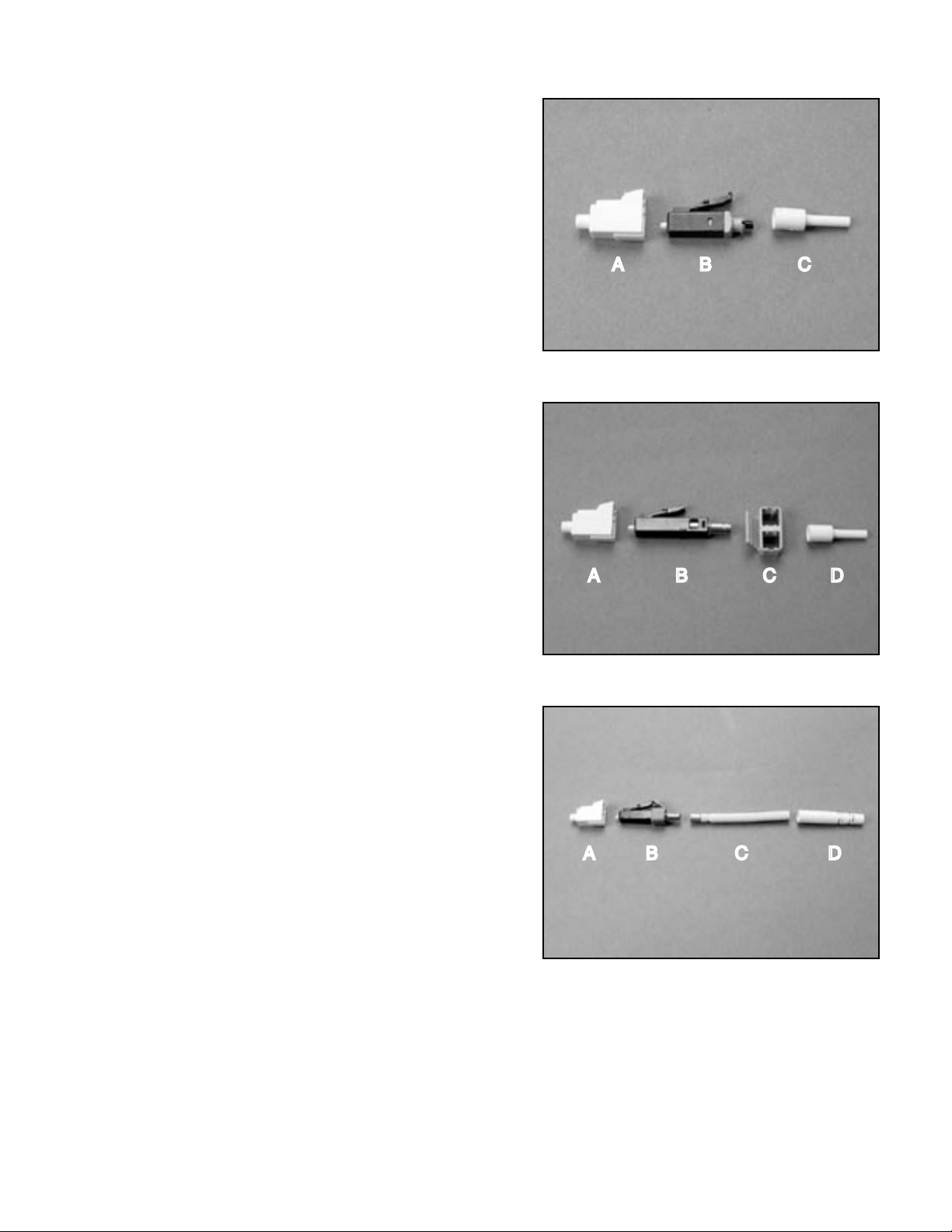

3.3 The 3.0 mm LC connector contains (A) dust cap,

(B) connector, (C) metal strength sheath, (D) metal

crimp sleeve, (E) strain relief boot.

Note: Multimode simplex yokes are beige and singlemode

yokes are blue.

4.0 Setup

4.1 Plug in the 120V or 230V power cord. Turn on the

3M™ Hot Melt Oven. The oven requires 6 minutes to

warm up (red exposed on switch indicates power on).

A B C D E

4.2 Open the connector package and remove components.

4.3 Attach hot melt holder handle to the load adapter with

the slot aligned to the front.

6 78-8135-4385-3-A

Page 7

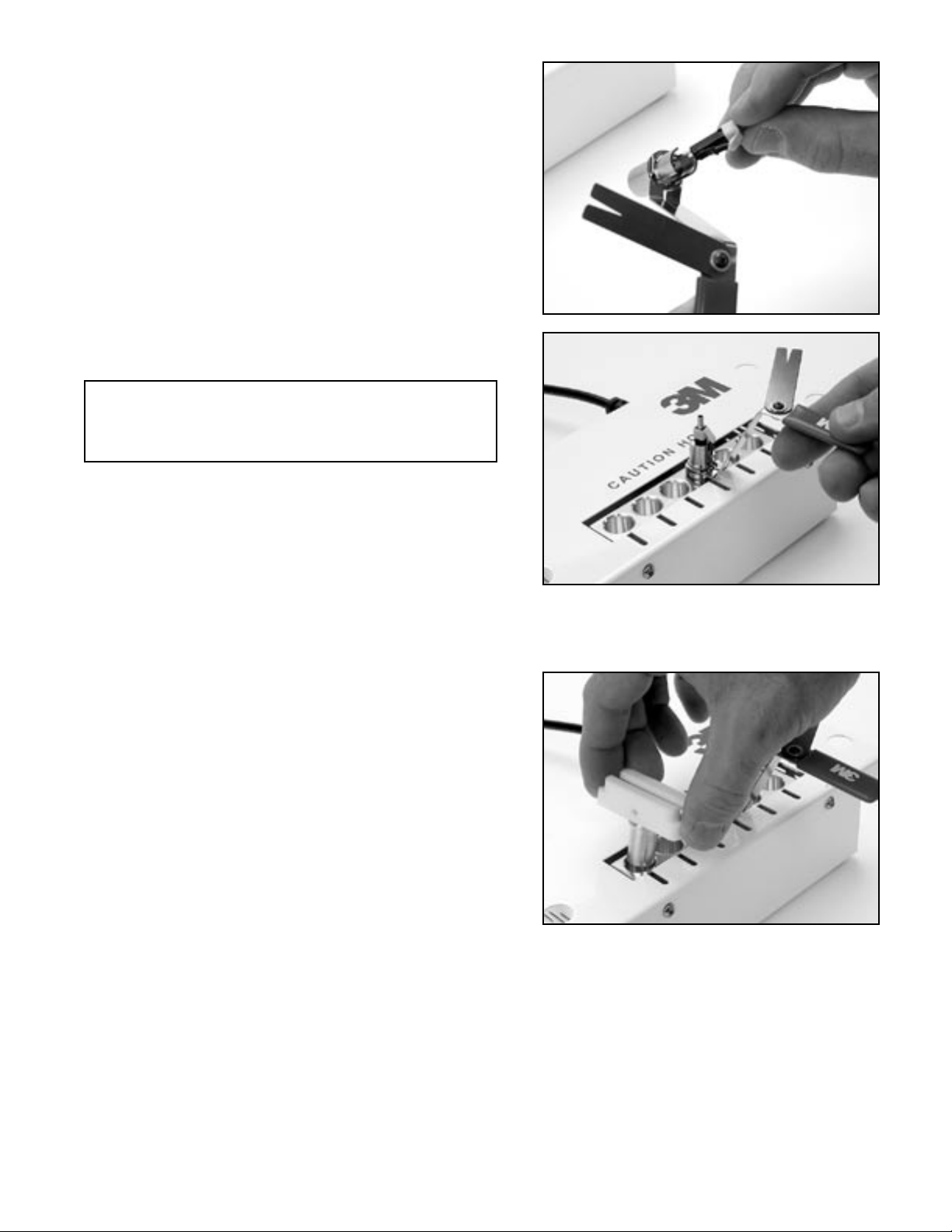

4.4 Insert the connector into the hot melt connector

holder.

4.5 Place the load adapter, with slot aligned with handle,

into an available port in the oven.

IMPORTANT: Do not place connector in a hot load

adapter. This may cause adhesive to flow to the

outside of the ferrule. Load adapter should be at room

temperature when connector is inserted.

4.6 The 3M™ LC Hot Melt Connector should be in the

oven for at least 75 seconds. The connector should not

be in the oven longer than 5 minutes.

4.7 Place the heat shrink fixture in an available port in the

oven.

Note: This step is only necessary for use with the

1.6–2.0 mm jacketed LC hot melt connector.

78-8135-4385-3-A 7

Page 8

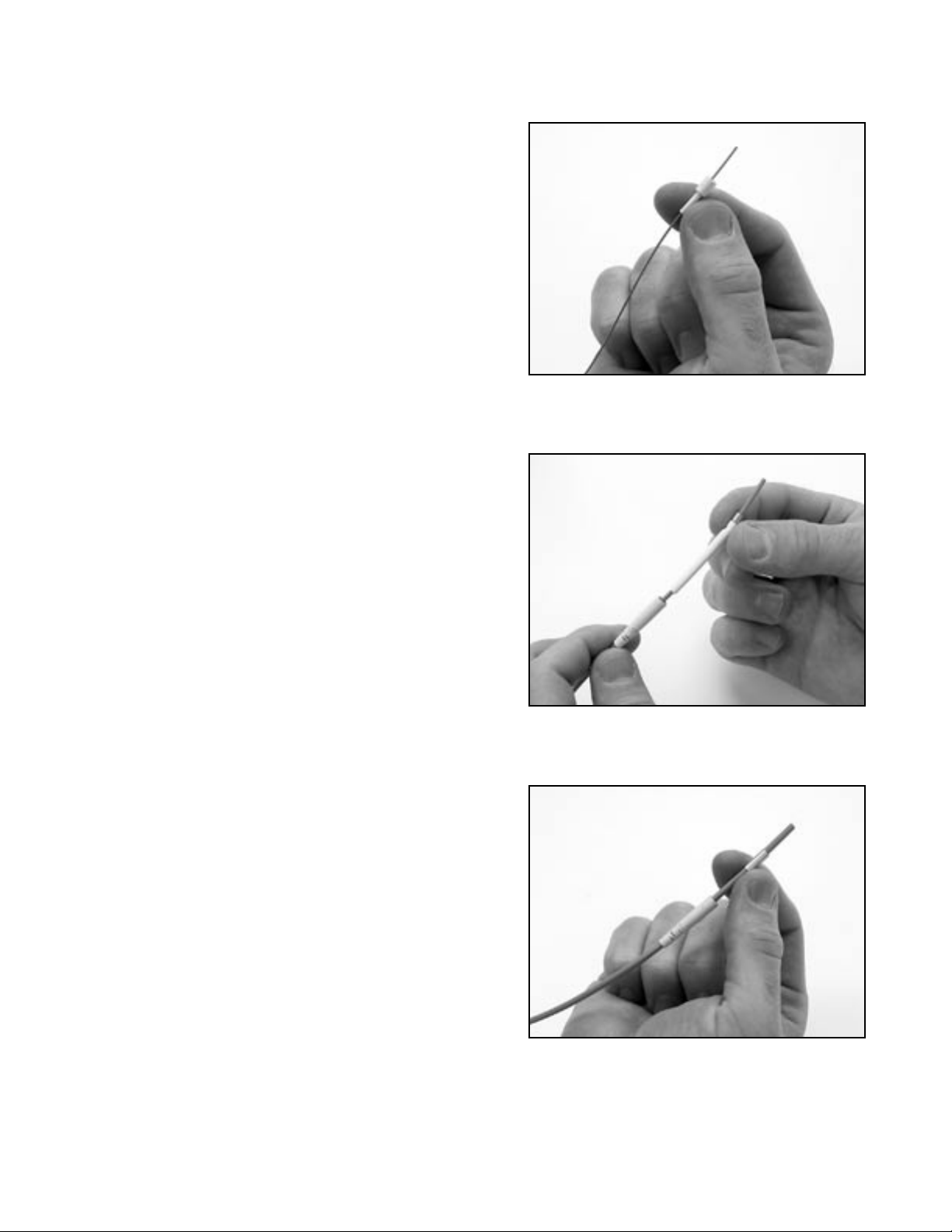

5.0 900 micron Cable Connector

Preparation

5.1 Place strain relief boot on cable as shown.

6.0 1.6 – 2.0 mm Jacketed Cable Connector

Preparation

6.1 Place the strain relief boot first and then the heat

shrink crimp sleeve on the cable as shown.

7.0 3.0 mm Jacketed Cable Connector

Preparation

7.1 Place the strain relief boot first and then the metal

crimp sleeve on the cable as shown.

8 78-8135-4385-3-A

Page 9

8.0 Strip Guide

9.0 Stripping Procedure for 900 micron

Fiber

9.1 Place the cable on the strip template. Mark buffer

at 11 mm. Using the 3M™ Stripping Tool 6365-ST,

remove the buffer in small increments until 11 mm of

buffer has been removed.

9.2 Using a lint-free cloth moistened with isopropyl

alcohol, clean the bare fiber to remove any oils or

acrylate coating debris.

9.3 Check the final strip length and adjust if necessary.

10.0 Stripping Procedure for 1.6 – 2.0 mm

Jacketed Fiber

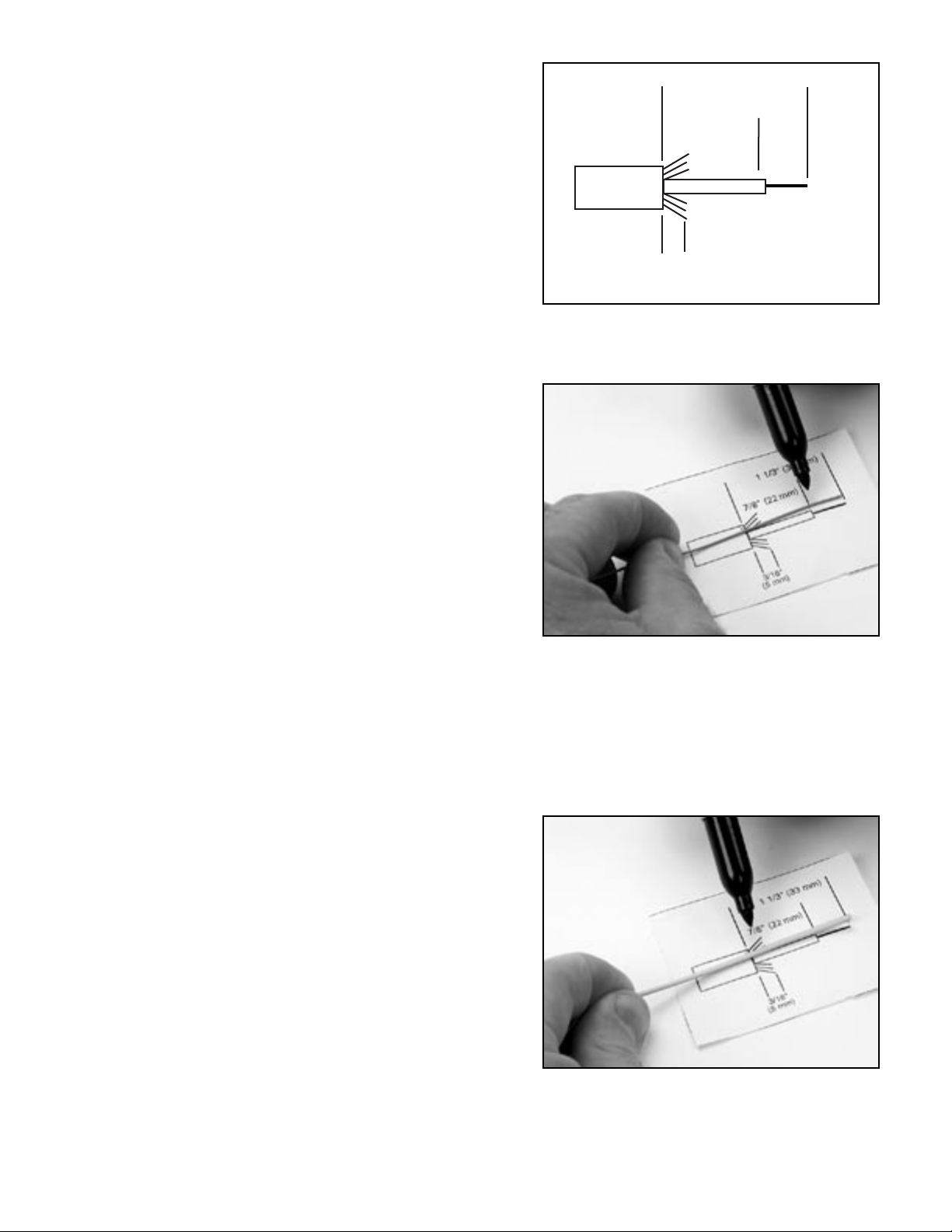

10.1 Place the jacketed fiber on the strip template and use

a fiber marking pen to mark the location of the jacket

cut. Using the 3M™ Stripping Tool 6365-ST, remove

33 mm (1 1/3") of jacket off cable.

78-8135-4385-3-A 9

Page 10

10.2 Snip the aramid yarn to 5-6 mm (approx. 3/16").

10.3 Flare aramid yarn evenly around buffer.

10.4 Using the 3M™ Stripping Tool 6365-ST, remove the

buffer in small increments until 21–22 mm (approx.

7/8") of buffer is left.

10.5 Using a lint-free cloth moistened with isopropyl

alcohol, clean the bare fiber to remove any oils or

acrylate coating debris.

10.6 Check the final strip lengths and adjust if necessary

10 78-8135-4385-3-A

Page 11

11.0 Stripping Procedure for 3 mm

Jacketed Fiber

11.1 Place the jacketed fiber on the strip template and use

a fiber marking pen to mark the location of the jacket

cut. Using the 3M™ Stripping Tool 6365-ST, remove

33 mm (1 1/3") of jacket off cable.

11.2 Holding the aramid yarn firmly away from the buffer

tube, insert the metal strength sheath over the buffer

tube and push down until fully inserted into the jacket.

Top of sheath should be even with the upper edge of

jacket

11.3 Snip the aramid yarn to 5-6 mm (approximately

3/16").

11.4 Flare aramid yarn evenly around buffer tube.

78-8135-4385-3-A 11

Page 12

11.5 Using the 3M™ Stripping Tool 6365-ST, remove the

buffer in small increments until 21–22 mm (approx.

7/8") of buffer is left.

11.6 Using a lint-free cloth moistened with isopropyl

alcohol, clean the bare fiber to remove any oils or

acrylate coating debris.

11.7 Check the final strip lengths and adjust if necessary.

12.0 Connector Mounting

12.1 While connector is still in oven, mount fiber into

connector inserting until buffer stops inside the

connector. Be sure to insert fiber within the guide tube

at the rear of the connector.

Note: Removing the connector holder from the oven prior

to fiber insertion will cause adhesive to thicken rapidly,

greatly limiting the time to insert the fiber.

Cable jackets should be approximately 1mm from the rear

of crimp area when buffer is correctly located.

IMPORTANT: Do not lift the connector while in the load

adapter during the heating process. This will prevent

adhesive from bonding to the load adapter. If adhesive

does adhere itself to the inside of the load adapter, use

the cleaning pin to remove adhesive prior to inserting

next connector. Use alcohol with the pin, if needed.

Note: To ease fiber insertion, make sure fiber is kept very

straight when mounting. If resistance is felt when within

1/8” of buffer, you are stubbing and should back out a short

distance and re-enter making sure that the fiber is kept

straight at all times.

12 78-8135-4385-3-A

Page 13

12.2 Maintaining fiber position in connector, push the

jacketed fiber into the cable v-slot feature on the load

adapter until secure.

12.3 Attempt to line up the holder arm to keep cable as

straight as possible.

12.4 Remove the load adapter from the oven by grasping

the cool-touch handle.

CAUTION

Do not touch the metal portion of the load adapter or

connector, as it will be hot!

12.5 Rest the load adapter in one of the available cooling

ports located on both sides of the oven. Let cool for a

minimum of 3 minutes.

78-8135-4385-3-A 13

Page 14

13.0 Boot Placement for 900 micron Fiber

13.1 Remove connector from the load adapter and slide the

boot over connector until fully seated.

IMPORTANT: Remove connector gently so that you

don’t break the fiber. If connector sticks to the sides of

the load adapter when trying to remove, re-heat the

connector slightly until connector can be removed from

the load adapter. Use the cleaning pin furnished in the

kit to scrape the adhesive out of the load adapter hole

before proceeding with next connector.

14.0 Crimping and Boot Placement for

1.6 – 2.0 mm Jacketed Fiber

14.1 Slide crimp/shrink tube down and over aramid yarn.

14.2 Remove the connector from the load adapter.

14 78-8135-4385-3-A

Page 15

14.3 Using the die labeled “A” with the 3M lettering facing

to the left, crimp the metal portion of the sleeve once.

Note: Crimp sleeve must be bottomed against connector

prior to crimping. The 3M lettered side of the crimp die

should be touching the rear of the connector.

14.4 Place the crimp/shrink tube in the shrink fixture

assembly and heat for 8 to 10 seconds. Tube should

shrink snug around the jacket. Rotate, if needed, to

complete shrink.

14.5 Slide boot over crimp/shrink tube.

Note: Jacketed boots appear the same in the photos but the

boots for all 3 types of connectors are different sizes and

can not be interchanged.

78-8135-4385-3-A 15

Page 16

15.0 Crimping and Boot Placement for 3 mm

Jacketed Fiber

15.1 Remove connector from load adapter

15.2 Slide metal crimp sleeve down and over aramid yarn.

It should rest over the metal strength sheath as shown.

15.3 Using the LC die labeled “A” with the 3M lettering

facing left, crimp the left half of the the crimp ring

once making sure that the 3M lettered side of the die

is flush with the connector prior to crimping.

Note: The crimp ring must be flush against the connector

prior to crimping. The 3M-lettered side of the crimp die

should be touching the rear of the connector.

15.4 Using the LC die labeled “B” line up the non-lettered

side of the die with the rear of the crimp die and crimp

the right half of the crimp ring.

The completed 3 mm crimp shold look like this:

Hex

16 78-8135-4385-3-A

Page 17

15.5 Slide boot over crimp until boot is flush against the

connector.

Note: Jacketed boots appear the same in the photos but the

boots for all 3 types of connectors are different sizes and

cannot be interchanged.

16.0 Scribing

16.1 Position the scribe blade so the flat side of the blade

is resting on the bead of adhesive and the blade is

perpendicular to the fiber.

16.2 Score the fiber by gently sliding the blade across the

fiber just above the bead of adhesive. Scoring means

that you are making a small scratch on the outside of

the fiber.

IMPORTANT: The fiber should not break during this

step.

16.3 Pull the fiber straight away from the connector. Pull

along the axis of the fiber, not to one side or the other.

If the fiber does not pull away, score the fiber again.

16.4 Dispose of the scrap fiber in the designated container.

78-8135-4385-3-A 17

Page 18

17.0 Multimode Polish

17.1 Perform an air polish by holding the 9 micron lapping

film firmly in one hand and gently moving the film in

a circular motion for approximately 10 strokes or until

approximately one half of the bead height is removed.

Note: You can polish approximately 20 connectors with

each piece of 9 micron lapping film.

17.2 Using a lint-free cloth and isopropyl alcohol clean the

connector after the air polish to remove all debris left

by the 9 micron lapping film.

17.3 Clean the round polishing pad found in the 3M™

Universal Hot Melt Kit 6365/6361 with a lint-free

cloth moistened with isopropyl alcohol.

17.4 Place several drops of alcohol onto the round

polishing pad.

17.5 Before alcohol evaporates, place a sheet of the pale

green 2 micron lapping film, shiny side down on the

pad. The alcohol creates suction on the lapping film

and helps hold it in place.

17.6 Clean the lapping film with a lint-free cloth moistened

with isopropyl alcohol.

Note : The 2 micron lapping film can be used for up to 4

connectors.

18 78-8135-4385-3-A

Page 19

17.7 Clean the flat side of the polishing jig with a lint-free

cloth moistened with isopropyl alcohol.

17.8 Place the polishing jig assembly on the lapping film.

17.9 Place the ferrule in the polishing jig aligning the latch

side of the connector with the slot until it stops.

Note: The ferrule must be able to slide freely inside the hole

in the polishing jig. If not, the ferrule may have adhesive

on it which needs to be cleaned off with alcohol and a lintfree cloth.

17.10 Insert the polishing weight into the adapter/jig

assembly covering the connector.

Note: The weight should pop up slightly (1/16") when

holding the jig flat against the lapping film, indicating that

the ferrule can move freely.

78-8135-4385-3-A 19

Page 20

17.11 Polish 10 figure-eight strokes or until bead of adhesive

is no longer visible.

Note: Do not hold polishing jig assembly by the weight

when polishing. Hold only by the textured polishing

adapter.

Note: Because bead is 3 to 4 times smaller than classic hot

melt connectors you will not feel the bead of adhesive being

removed as you polish.

IMPORTANT: Make sure that polishing jig stays flat on

lapping film at all times

17.12 After bead of adhesive is no longer visible, polish an

additional 5 strokes.

17.13 Remove the connector from the polishing jig assembly

and clean the connector endface with a lint-free cloth

moistened with isopropyl alcohol.

17.14 Inspect the connector endface with the 200X

Westover™ Scientific fiber view scope. Use the thumb

toggle switch to activate the light onto the fiber end

face. There are two light settings—coaxial and oblique

angle lighting.

20 78-8135-4385-3-A

Page 21

17.15 Good Polish (Coaxial light)

17.16 Good Polish (Oblique light)

17.17 Bad Polish – Cut or scratch going through center of

core. In this picture half of fiber is missing.

18.0 Singlemode Polish to –40db

18.1 Complete steps17.0 through 17.13 of the multimode

polish before proceeding further with the singlemode

polish.

Note: You may also use steps 18.0 – 18.11 to obtain a

cleaner cosmetic multimode polish.

18.2 Clean the gray rectangular polishing pad with a lintfree cloth moistened with isopropyl alcohol.

IMPORTANT: Do not use the black 4.5" x 5.5" pads for

the singlemode LC polish. Use only the pale gray pads

provided in the 3M

78-8135-4385-3-A 21

™

LC Hot Melt Expansion kit.

Page 22

18.3 Place several drops of alcohol on to the rectangular

rubber pad.

18.4 Before the alcohol evaporates, place a sheet of the

0.5 micron pale gray diamond lapping film on the

polishing pad, shiny side down.

18.5 Clean the lapping film with a lint-free cloth moistened

with isopropyl alcohol.

Note: The 0.5 micron diamond lapping film can be used for

up to 10 connectors.

18.6 Place several drops of distilled water on to the

diamond lapping film.

18.7 Insert the connector into the polishing jig assembly.

18.8 Clean the flat side of the polishing jig with a lint-free

cloth moistened with isopropyl alcohol.

18.9 Place the polishing jig assembly on the wet diamond

lapping film. Perform 3 to 4 figure eights.

18.10 Leaving the polishing jig assembly positioned on

the lapping film, rotate 180 degrees. Perform 3 to 4

additional figure eights.

22 78-8135-4385-3-A

Page 23

19.0 Singlemode Polish to –55db

Note: Complete steps 17.0 through 17.13 of the multimode

polish and 18.0 through 18.11 of the singlemode polish

before proceeding further.

19.1 Place several drops of alcohol on to the second gray

rectangular rubber pad.

19.2 Before the alcohol evaporates, place a sheet of the

white frosted final lapping film on the polishing pad,

shiny side down.

19.3 Clean the lapping film with a lint-free cloth moistened

with distilled water.

IMPORTANT: Do not clean the white frosted lapping

film with alcohol. Use only distilled water.

Note: The frosted final lapping film can be used for up to 5

connectors.

19.4 Place several drops of distilled water onto the frosted

lapping film.

19.5 Clean the flat side of the polishing jig with a lint-free

cloth moistened with isopropyl alcohol.

19.6 Place the polishing jig assembly on the wet frosted

lapping film. Perform 4 figure eights on the wet

frosted lapping film.

78-8135-4385-3-A 23

Page 24

19.8 Leaving polishing jig assembly positioned on the

lapping film rotate 180 degrees. Perform 4 additional

figure eights.

19.9 Once polishing is complete , refer to steps 17.14

through 17.17 on inspecting the connector with the

200X fiber view scope before proceeding to final step.

20.0 Finishing

20.1 If connector is not to be immediately put into service,

install the protective dust cap.

21.0 Installing Duplex Yokes

21.1 Duplex yokes may be mounted after connector has

been terminated.

21.2 With the anti-snag clip facing connector press cable

into slot on the duplex yoke and then slide the yoke up

and over the boot.

24 78-8135-4385-3-A

Page 25

21.3 Taper on the boot will cause the yoke to spread

allowing the correct placement at the rear of the

connector.

21.4 Pinch the top and bottom of the yoke closed and press

together the outer edges of the yoke, snapping firmly

into connector.

21.5 A design improvement includes a live hinge on the

bottom of the duplex yoke (currently available in

multimode). The new duplex yokes will be installed

in the same manner as the current yoke, however, the

live hinge allows the yoke to be re-opened without

damage.

78-8135-4385-3-A 25

Page 26

22.0 3M™ Expansion Kit 6650-LC and Replacement Part Numbers

6650-LC LC Expansion Kit (complete) ............................................................................80-6113-1353-9

6650-LH LC Hot Melt Connector Holder (4 ea.) ..............................................................80-6113-1348-9

6650-JW LC Polishing Jig Assembly with Weight (includes 2 pucks) .............................80-6113-1354-7

6650-LT LC Crimp Tool ...................................................................................................80-6113-1356-2

6650-VS LC Adapter for View Scope ...............................................................................80-6113-1357-0

6650-HS LC Heat Shrink Fixture ......................................................................................80-6113-1358-8

6650-HC LC Holder Cleaning Pins (3 ea.) ........................................................................80-6113-1359-6

6650-LP LC Polishing Pad 4.5 X 5.5” (2 ea.) ...................................................................80-6113-1471-9

6650-LS LC Lapping Film Singlemode Consumable Kit (polishes 400 SM connectors) ........80-6113-1472-7

6650-LM LC Lapping Film Multimode Consumable Kit (polishes 400 MM connectors) ........80-6113-1473-5

6650-LJ LC Polishing Jigs (2 ea. pucks) ..........................................................................80-6113-1355-4

26 78-8135-4385-3-A

Page 27

78-8135-4385-3-A 27

Page 28

3M is a trademark of 3M Company.

Important Notice

All statements, technical information, and recommendations related to 3M’s products are based on information believed to be reliable, but the

accuracy or completeness is not guaranteed. Before using this product, you must evaluate it and determine if it is suitable for your intended

application. You assume all risks and liability associated with such use. Any statements related to the product which are not contained in

3M’s current publications, or any contrary statements contained on your purchase order shall have no force or effect unless expressly agreed

upon, in writing, by an authorized officer of 3M.

Warranty; Limited Remedy; Limited Liability.

This product will be free from defects in material and manufacture for a period of one (1) year from the time of purchase. 3M MAKES NO

OTHER WARRANTIES INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. If this product is defective within the warranty period stated above, your exclusive remedy shall be, at 3M’s option,

to replace or repair the 3M product or refund the purchase price of the 3M product. Except where prohibited by law, 3M will not be liable

for any indirect, special, incidental or consequential loss or damage arising from this 3M product, regardless of the legal theory

asserted.

Communication Markets Division

3M Telecommunications

6801 River Place Blvd.

Austin, TX 78726-9000

800.426.8688

Fax 800.626.0329

www.3MTelecommunications.com

Recycled paper

40% Pre-consumer waste paper

10% Post-consumer waste paper

Litho in USA

© 3M 2005 78-8135-4385-3-A

Loading...

Loading...