Page 1

Instruction Manual

3

718 Static Sensor

Safety Information

Intended Use

The 3M™ 718 Static Sensor is a portable,

handheld instrument designed for measuring

voltages associated with electrostatic charge.

Its intended use is for measuring the amount

of voltage, in a range from 0-20 kilovolts,

associated with an electrostatic charge

buildup on a surface. Any deviation from

this intended use could impair the

instrument’s effectiveness and possibly lead

to an unsafe operating condition.

The 3M™ 718A Air Ionizer Test Kit is a

set of accessories for use in conjunction

with the 3M 718 Static Sensor. Their

intended use is for verifying the operation of

air ionizers by measuring the neutralization

time for a static charge placed on a

stationary metal plate. Any deviation

from this intended use could impair the

instrument’s effectiveness and possibly lead

to an unsafe operating condition.

Caution Statements

• The 718 Static Sensor and 718A Charger

use DC 9V power supplied by a 9V

alkaline battery. Usage of any other

power source may cause damage to the

instruments.

• The 718 Static Sensor and 718A Air

Ionizer Test Kit have no user-serviceable

parts. Do not disassemble the products for

any reason. UNAUTHORIZED SERVICE WILL VOID THE WARRANTY.

• The 718 and 718A are NOT designed for usage in hazardous environments where the

possibility of explosion or fire exists.

Read and understand all safety information before installing and operating

this equipment.

Page 2

Page 3

1.0 Description

The 3M™ 718 Static Sensor is a portable

handheld instrument used for locating and

measuring electrostatic charges. It can be

used to locate ESD trouble-areas, and is a

valuable tool for the ESD-control

engineer. Used in conjunction with the

3M™ 718A Air Ionizer Test Kit (available

separately), it can be used for verification

and auditing of air ionizers.

The 718 Static Sensor is battery-powered

and has several measurement features:

Range: measurements can be taken in a 02 kV or 0-20 kV range.

Automatic Zero: pushbutton feature

allows easy adjustment to zero. No screws

or dials to turn.

HOLD function: allows the User to

"freeze" a displayed measurement, for

later evaluation.

Automatic shutoff: conserves battery

power by shutting off the instrument after

20 minutes of inactivity.

2.0 Power Requirements and

Battery Installation

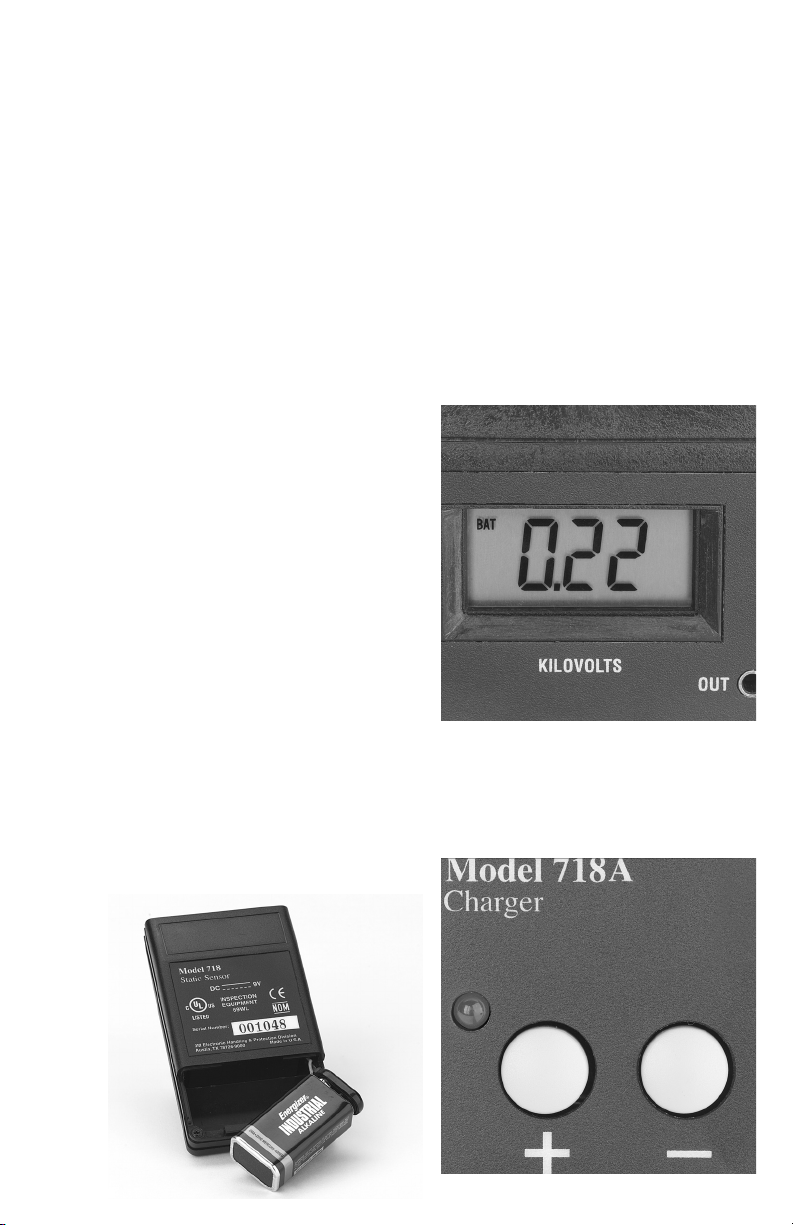

2.1 Both the 718 and 718A Charger us

DC 9V power supplied by a 9V

alkaline battery.

2.2 To install the battery on either unit:

2.2.1 Remove the battery cover, located in

the lower back of the unit. To do

this, press down on the cover and

slide it downward.

2.2.2 Pull the battery connector out of the

housing, and align the male/female

ends of the connector with the

proper terminals on the battery.

2.2.3 Connect the two, and place the

connected battery into the housing

by inserting the connector end first,

then following up with the other end

of the battery.

2.2.4 Replace the cover.

2.3 The 718 Static Sensor has a Low

Battery indicator. Once the battery is

depleted to approximately 6.5 volts,

the instrument will show BAT in the

display. At this time, the 718 will not

produce accurate results and the

battery should be replaced. A fresh

alkaline battery should last greater

than 50 hours, when the instrument is

in continuous usage.

2.4 The 718A Charger also has a low-

battery indicator. This is an LED

located at the left-hand side of the

unit. When the battery voltage drops

below operating level, the LED will

light up. At this time, the user should

Page 4

replace the battery. Usage of the

3M™ 718A Charger under lowbattery conditions would lead

to insufficient voltage levels

being generated.

3.0 Operation of the 718 Static

Sensor

Supplemental notes:

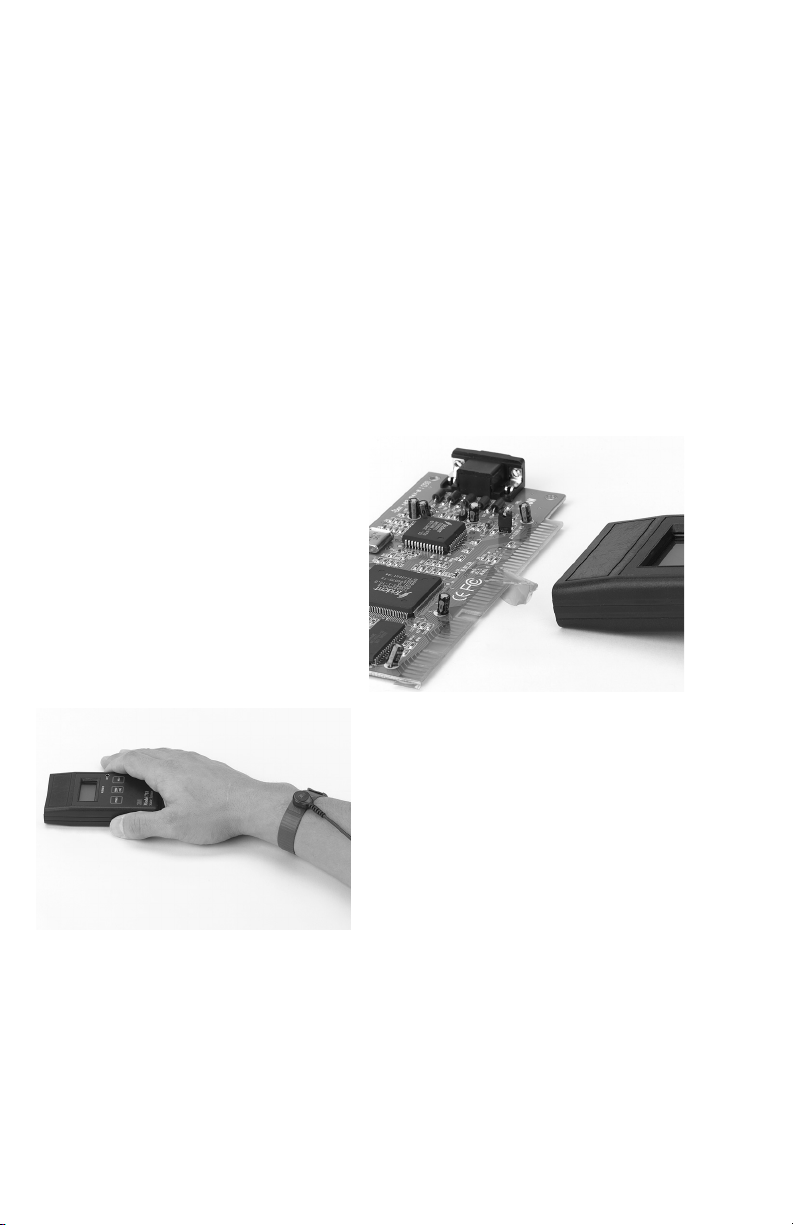

For accurate measurements during usage,

it is recommended that the outside housing

of the 3M™ 718 Static Sensor be

connected to an electrical ground. This

can be accomplished by having the user

holding the instrument connected to

ground through either a static control wrist

strap, or while wearing static control

footwear. The enclosure of the 718 is

made of conductive plastic and is,

therefore, electrically connected to

whomever is holding the instrument. In

addition, ground for the instrument can be

provided through the Voltage Monitor

Output on the front of the case.

The 718 Static Sensor is a precision

electronic instrument. Improper use or

rough treatment can damage the unit, and

render it incapable of providing accurate

measurements.

3.1 Turning the unit ON and OFF: To

turn on the 718 Static Sensor,

momentarily press down on the

membrane switch labeled POWER.

Determining that the power is on can

be verified by seeing that the liquidcrystal display (LCD) is on, and that

the red light-emitting diodes in the

front of the sensor are lit. To shut off

the 718 Static Sensor, momentarily

press down on the membrane switch

labeled POWER. Determining that

the power is off can be verified by

seeing that the liquid-crystal display

(LCD) is off.

3.2 Making Electrostatic Voltage

Measurements: hold the instrument 1inch (2.54 cm) away from the object

being measured. The display will

update with the voltage measurement

in kilovolts. If the measured voltage

is greater than the measurement range

of the instrument, a –1. will be

displayed. At this time, switch to

a greater range. If over-ranging

occurs even with the 20 kV range

activated, the static charge on the

object cannot be measured with the

718 Static Sensor.

3.3 Measurement Range: all measurements

are in kilovolts (kV) as stated on the

front label of the unit. The 718 has

two measurement ranges: 0-2 kV and

0-20 kV. The unit’s current

measurement range mode can be

verified by checking the display.

Three digits following the decimal

point indicate that the unit is in 0-2 kV

range. Two digits following the

decimal point indicate that the sensor

is in 0-20 kV range. To change

between measurement ranges, press

the RANGE/HOLD button once,

momentarily.

3.4 HOLD Function: in the event that the

user wishes to freeze the current

measurement, the HOLD function of

the 718 Static Sensor may be used.

Simply press the HOLD switch

momentarily and the currently

displayed voltage will be frozen.

Page 5

A HOLD notice will also be

displayed to alert the user that the

instrument is currently in HOLD

status. To unfreeze the display and

return to floating measurement,

momentarily press the HOLD switch

once again. Please note that during

HOLD condition the distanceindicating LED’s are turned off.

3.5 Zero adjustment: the 3M™ 718 Static

Sensor has a zero adjustment

function, which sets a zero reference

point for all subsequent

measurements. This zero reference

can be set by pointing the instrument

at a known zero-voltage surface, and

holding down the RANGE/ZERO

button for longer than 3 seconds.

After 3 seconds, the display will flash

and adjust to zero. Repeat this step

for both the 2 kV and the 20 kV

ranges. The zero adjustment should

be performed every time the unit is

turned on.

3.6 Measurement Accuracy:

3.6.1 Distance Indicator: the 718 Static

Sensor is factory calibrated to give

accurate measurements when it is

placed one inch (2.54 cm) away

from the object to be measured. To

assist the user in gauging this

distance, two light-emitting diodes

(LED’s) are present on the front face

of the instrument. These LED’s

emit two red, bullseye targets on the

surface of the object being measured.

As the instrument gets closer to the

one inch measurement distance, the

bullseyes begin to converge. When

they converge and become one, the

instrument is approximately one

inch away, and the measurement can

be made.

For more accurate measurements,

it is recommended that the user

manually measure the distance

between the front housing of the

instrument and the object

being measured.

3.6.2 Accuracy and Size of Object to be

Measured: the minimum surface

area on an electrostatically charged

object which can be accurately

measured is a 5 square inch

(32.3 cm

2

) area.

3.6.3 Measurements from Greater than

One Inch (2.54 cm) Away: in the

event that a one inch separation

between object-to-be measured and

the 718 cannot be achieved, it is

possible to get approximate

readings. This can be accomplished

by holding the instrument at

multiples of one inch (two inches,

three inches, etc.) away from the

object. The measurement reading is

then adjusted according to the

following equation:

Measurement distance (in inches) x

displayed voltage (in kilovolts) =

approximate voltage in kilovolts

Page 6

3.7 Continuous Output: an output jack is

provided on the front of the 3M™

718 Static Sensor. This output can

be used to feed a continuous signal

into a data storage device for

continuous monitoring of measured

voltages. Please use a 3/32 inch (2.5

mm) mono-phone plug to connect

into the output jack. The output is

designed to drive a digital voltmeter

with an input impedance of greater

than 50 kΩ. The output signal is

dependent on the measurement range

currently selected. For the low (2

kV) range, the output signal is 1/1000

of the measured electrostatic voltage.

For the high (20 kV) range, the

output signal is 1/10,000 of the

measured voltage.

3.8 Automatic Shut-Off: the 718 Static

Sensor will automatically shut-off 20

minutes after the last switch activity.

This is done in order to conserve

battery power. In the event that the

user needs to have the unit stay ON

continuously, when turning the unit

on depress the POWER AND

RANGE switches simultaneously.

This deactivates the Automatic ShutOff feature. The BAT indicator will

then flash three times to indicate that

the automatic shut-off features has

been disabled. The Automatic ShutOff feature will reset itself the next

time the instrument is turned on.

4.0 Operation and Use of the

718A Air Ionizer Test Kit

It is recommended that the user be familiar

with ionizer test standards ANSI/ESD S3.1

and draft standard ESD DSP3.3 if the

3M™ 718A Air Ionizer Test Kit is used to

perform verification testing on ionizer

performance.

4.1 Assembly: slide the charge plate over

the 718 Static sensor until it stops.

The charge plate slides onto the lower

groove, on the sides of the 718.

4.2 Charging the plate: holding the 718

Static Sensor (with charge plate

attached) in one hand, use the other

hand to touch the probe of the 718A

Charger to the charge plate. Press

either the

+ button (for a positive

voltage) or the

– button (for a negative

voltage), then remove the probe from

the charge plate. Be sure to keep the

button pressed while removing the

probe from the charge plate. The

display on the 3M™ 718 Static Sensor

will indicate a positive or negative

charging voltage (1.1kV minimum).

If a voltage of less than ±1.1kV is

displayed, check to see if the low

battery indicator on the 718A Charger

is illuminated. If illuminated, replace

the battery in the charger. If the unit

continues to supply an incorrect

voltage to the charge plate, please

contact 3M for additional instructions.

Page 7

4.3 Testing ionizer discharge time: after

charging the plate, hold the 718

approximately one foot (30.5 cm)

away from the ionizer. Monitor the

display to see how quickly the 1.1 kV

charge is dissipated to 0.1 kV. The

speed at which this occurs (the

discharge time) indicates how well

the ionizer is operating. Please refer

to the specific ionizer’s operating

manual or consult with the ionizer

manufacturer to determine what this

discharge time should be. Repeat this

procedure for both a positively and a

negatively charged plate.

4.4 Testing ionizer offset balance: zero

the charge plate by touching it with a

grounded object. This can either be

the finger of a grounded person or

some other item which is connected

to electrical ground. In either case,

zeroing the charge plate should make

the display on the 718 read zero.

Hold the 718 approximately one foot

(30.5 cm) in front of the ionizer.

Monitor the display. The value

displayed is the offset balance of the

ionizer, which is the difference

between the number of positive and

negative ions being emitted. Please

refer to the specific ionizer’s

operating manual or consult with the

ionizer manufacturer to determine

what this offset balance should be.

5.0 Service/Calibration

5.1 Service and Repair: in the event that

you believe the 718 Static Sensor or

the 3M™ 718A Air Ionizer Test Kit

is in need of repair, please contact

your local 3M representative for

troubleshooting help, and, as needed,

repair information. There are no

user-serviceable parts on either

product.

5.2 Calibration: the 718 and 718A

products are supplied by the factory

pre-calibrated. 3M does not specify a

minimum calibration cycle for the

718 or 718A products. The user,

usually according to internal Quality

procedures, determines calibration

cycles. 3M does offer calibration

services on these instruments. Please

contact your local 3M representative

for information on this service. In the

event that the user wishes to perform

a self-calibration, the following steps

should be followed for the 718 Static

Sensor (user-calibration not possible

on the 718A Air Ionizer Test kit).

5.3 Equipment Needed:

Test fixture

High-Voltage Power Supply,

capable of supplying voltages up

to 10,000 V

Voltmeter, with > 50 kΩ input

impedance, capable of measuring

voltages down to the µV range.

Cable with a 3/32 inch (2.5mm)

mono plug and secondary connector

to interface with voltmeter

Page 8

5.4 Test fixture:

Metal plate of at least 5 square

inches area (38.7 cm

2

) area.

Metal stand capable of supporting

718, and holding it one inch (2.54

cm) away from the metal plate,

centered.

Connectors on the plate with which

it can interface with the high voltage

power supply.

Connections on the metal stand with

which it can be connected to

electrical ground.

5.5 Procedure:

5.5.1 Place the 3M™ 718 Static Sensor on

the metal stand. Verify that it is

exactly one inch (2.54 cm) away from

the metal plate, and that its position is

centered relative to the plate.

5.5.2 Connect the stand to ground.

5.5.3 Turn on the 718 Static Sensor and

set it to the 2 kV range.

5.5.4 Ground the plate. Zero the display.

5.5.5 Remove the ground from the plate,

and connect it to the high voltage

power supply. Apply a 1 kV charge

to the plate.

5.5.6 The instrument should now be

reading 1.000. If it is not, remove

the battery door and use a

screwdriver to turn the small screw

located inside the battery

compartment. Use a small

screwdriver to turn the small screw,

located on the front right side of the

instrument. This screw should

adjust the reading on the display.

Once the display has been adjusted

to read 1.000, the low range of the

718 is now calibrated.

5.5.7 Repeat procedures 5.5.2 - 5.5.6 for

the 20 kV range of the meter, using

a test voltage of 5,000 volts.

Page 9

6.0 Physical Characteristics (All values typical)

(at 1 inch (2.54 cm) distance from sensor to target)

3M™ 718 Static Sensor

Dimensions 0.85" (H) x 2.4" (W) x 4.15" (L)

2.2 cm (H) x 6.1 cm (W) x 10.5 cm (L)

Weight 4.5 oz. (128 g) with battery

Operating Conditions 41º F - 95º F (5º C - 35º C)

up to 80% RH, non-condensing

Indoor use only

For use at altitudes below 42, 300 ft. (2000 m)

Pollution Degree II

Class III

Enclosure Conductive Polycarbonate

Power Requirements One 9-volt alkaline battery

Measurement Ranges 0 – 2 kV

0 – 20 kV

Voltage Display 3 1/2 digit liquid crystal display

Display Resolution 1 V/inch (0.39 V/cm) @ low range

10 V/inch (3.9 V/cm) @ high range

+/- 10 counts

Display Update Rate 3 Hz

Voltage Output Jack 3/32 in. (2.5 mm) monophone

Tip: signal

Sleeve: ground

Voltage Output 1/1000 of measured voltage @ low range

1/10,000 of measured voltage @ high range

Automatic Shut-off 20 minutes after last switch activity

Operating Time for Battery Greater than 50 hours, with new battery, @ 21º C

Continuous usage

Distance Indicator LED targets. Aligned targets indicate 1 in.

(2.54 cm) measurement distance

Measurement Accuracy within 5% of measured voltage

Measurement Stability ± 10 counts

Certifications UL, C-UL, CE, CB-scheme, NOM

3M™ 718A Air Ionizer Test Kit

Charge Plate Assembly Per ESD Association Draft Standard D3.3

Charge Plate Bracket Dimensions 1" (H) x 3.1" (W) x 4.25" (L)

Charge Plate Area 3.25" (W) x 1.25" (L)

Charge Plate Assembly Weight 2.5 oz (70 g)

Charger Dimensions 0.85" (H) x 2.4" (W) x 5.0" (L)

Charger Weight 6 oz. (170 g) with battery

Charger Power Requirements One 9 volt alkaline battery

Charger Output 1.1kV minimum for positive or negative voltage

(using 718 with charge plate)

Certifications UL, C-UL, CE, CB-scheme, NOM

Aluminum bracket

Bare stainless steel plate

PTFE spacers isolate plate from bracket

2.5 cm (H) x 7.9 cm (W) x 10.8 cm (L)

8.3 cm (W) x 3.2 cm (L)

2.2 cm (H) x 6.1 cm (W) x 12.7 cm (L)

Page 10

7.0 Parts Listing

3M™ 718 Static Sensor

1 ea. 718 Static Sensor

1 ea. 718/718A Operator’s Manual

1 ea. Certificate of Conformance

3M™ 718A Air Ionizer Test Kit

1 ea. 718A Charge Plate Assembly

1 ea. 718A Charger

1 ea. 718/718A Operator’s Manual

1 ea. Certificate of Conformance

8.0 Contact Information:

Customer and Technical Service

Within the U.S. : Customer service and

technical support can be obtained by

calling the 3M Electronic Handling &

Protection Division

Customer Service: (800) 328-1368

Technical Support: (512) 984-3200

Outside of the U.S.: For customer service

and technical support, please contact your

local representative of the 3M Electronic

Handling & Protection Division.

Page 11

Page 12

Electronic and Interconnect Solutions Division

6801 River Place Blvd.

Austin, TX 78726-9000

www.3m.com/eisd

3

Important Notice:

All statements, technical information,

and recommendations related to 3M’s

products are based on information

believed to be reliable, but the accuracy

or completeness is not guaranteed. Before

using this product, you must evaluate it and

determine if it is suitable for your intended

application.You assume all risks and

liability associated with such use. Any

statements related to the product which is

not contained in 3M’s current publications,

or any contrary statements contained on

your purchase order shall have no force

or effect unless expressly agreed upon,

in writing, by an authorized officer of 3M.

Warranty; Limited Remedy; Limited

Liability.

This product will be free from defects

in material and manufacture for a period

of one year from the time of purchase.

3M MAKES NO OTHER WARRANTIES

INCLUDING, BUT NOT LIMITED TO,

ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE.

If this product is defective within the

warranty period stated above, your

exclusive remedy shall be, at 3M’s option,

to replace or repair the 3M product or

refund the purchase price of the 3M

product. Except where prohibited by

law, 3M will not be liable for any indirect,

special, incidental or consequential loss

or damage arising from this 3M product,

regardless of the legal theory asserted.

Litho in USA

© 3M 2002

34-7051-6227-8

Recycled paper

40% pre-consumer waste paper

10% post-consumer waste paper

Loading...

Loading...