Page 1

Wired Intercom System

Performance Series

Models 2470 and 2475

Installation Instructions

Page 2

FCC Information

This device complies with part 15 of the FCC rules. Operation is subject to the

following conditions:

• This device must not cause harmful interference.

• This device must accept any interference received including interference that may cause

undesired operation.

Changes or modifications not expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment.

3M (IPC) 2002. All rights reserved.

Call (800) 328-0033

Page 3

Performance Series

Revision Record

Date Revision Reason For Change

2/02/02 01 Preliminary manual released

4/08/02 02 Preliminary second draft

4/11/02 03 Preliminary third draft

4/15/02 A Manual Released

4/19/04 B Revisions made

Front Matter

i

Page 4

Front Matter

System Components.................................................................................... 1

I/O Card and Noise Reduction Module Installation ................................ 2

I/O Card Installation ................................................................................................ 2

3M Model A125, Noise Reduction Module, Installation (Optional).................... 3

Component Placement................................................................................ 4

Communications Controller..................................................................................... 4

Power Supply........................................................................................................... 4

Call Stations............................................................................................................. 5

Station Selectors ...................................................................................................... 5

Wiring the System....................................................................................... 6

Configuration Worksheets....................................................................................... 7

Wiring Call Stations ................................................................................................ 7

Wiring Station Selectors.......................................................................................... 7

Wiring Communications Controller ........................................................................ 8

Performance Series

Table of Contents

Initializing the System ................................................................................ 9

System Mode Selection: .......................................................................................... 9

Initialization instructions for Pump Mode (factory default).................................... 10

Initialization Instructions for Island Mode .............................................................. 10

Programming the System ........................................................................... 11

Programming State .................................................................................................. 11

Error Message.......................................................................................................... 12

Parameter Selection ................................................................................................. 12

Keypad Function Definitions (for Text entry) (Programming State) ...................... 15

Adjusting the System .................................................................................. 17

Inbound Audio Volume Level................................................................................. 17

VOX (Voice Operated Transmission) Sensitivity Level ......................................... 17

Outbound Talk Volume Level................................................................................. 17

Outbound Music/Messaging Volume Level (Only for systems that use

Music/Messaging) ...................................................................................... 18

Testing the Functions............................................................................................... 18

Configuration Worksheets ......................................................................... 19

ii

Page 5

Performance Series

System Components

System Components

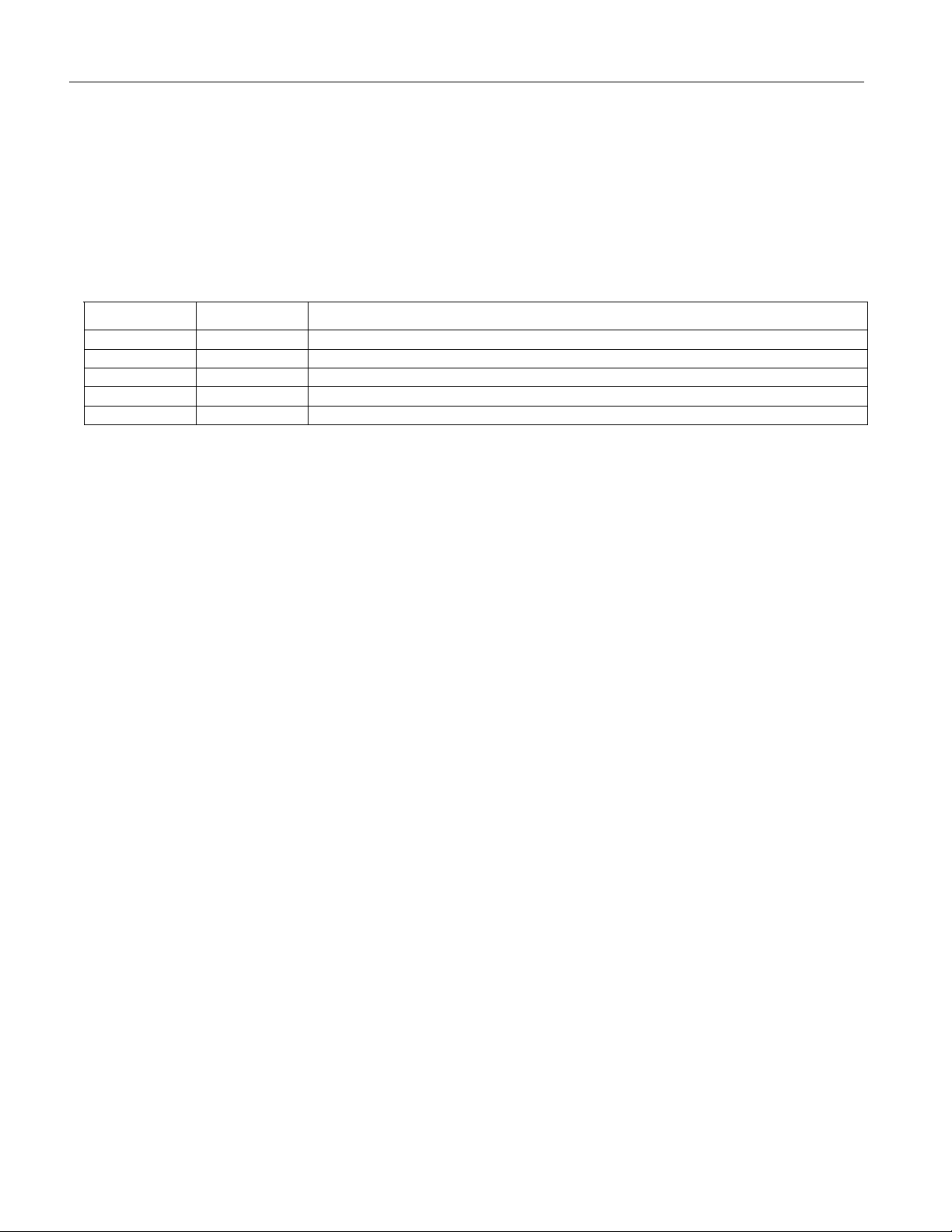

The Performance Series Intercom System consists of:

• A minimum of one Model 2475 Station Selector

• One Model 2470 Communications Controller

• A maximum of 24 Call Stations

The system provides two-way audio communication between the Station Selector and the 24 call stations. The

system also provides communications between station selectors. It is a single channel, half-duplex, wired system.

Figure 1 shows the components.

Figure 1. D-2400 Intercom System Components

Material Required (Not Supplied)

• Assortment of screws, anchors, and cable clamps.

• Sufficient twisted pair sets of audio cable to connect other components such as Station Selector, Call Stations,

etc. See Figure 1.

!

Important

The wires for the speaker connection must be twisted pairs and shielded for proper operation.

1

Page 6

I/O Board and Noise Reduction Module

Installation

I/O Card and Noise Reduction Module Installation

Performance Series

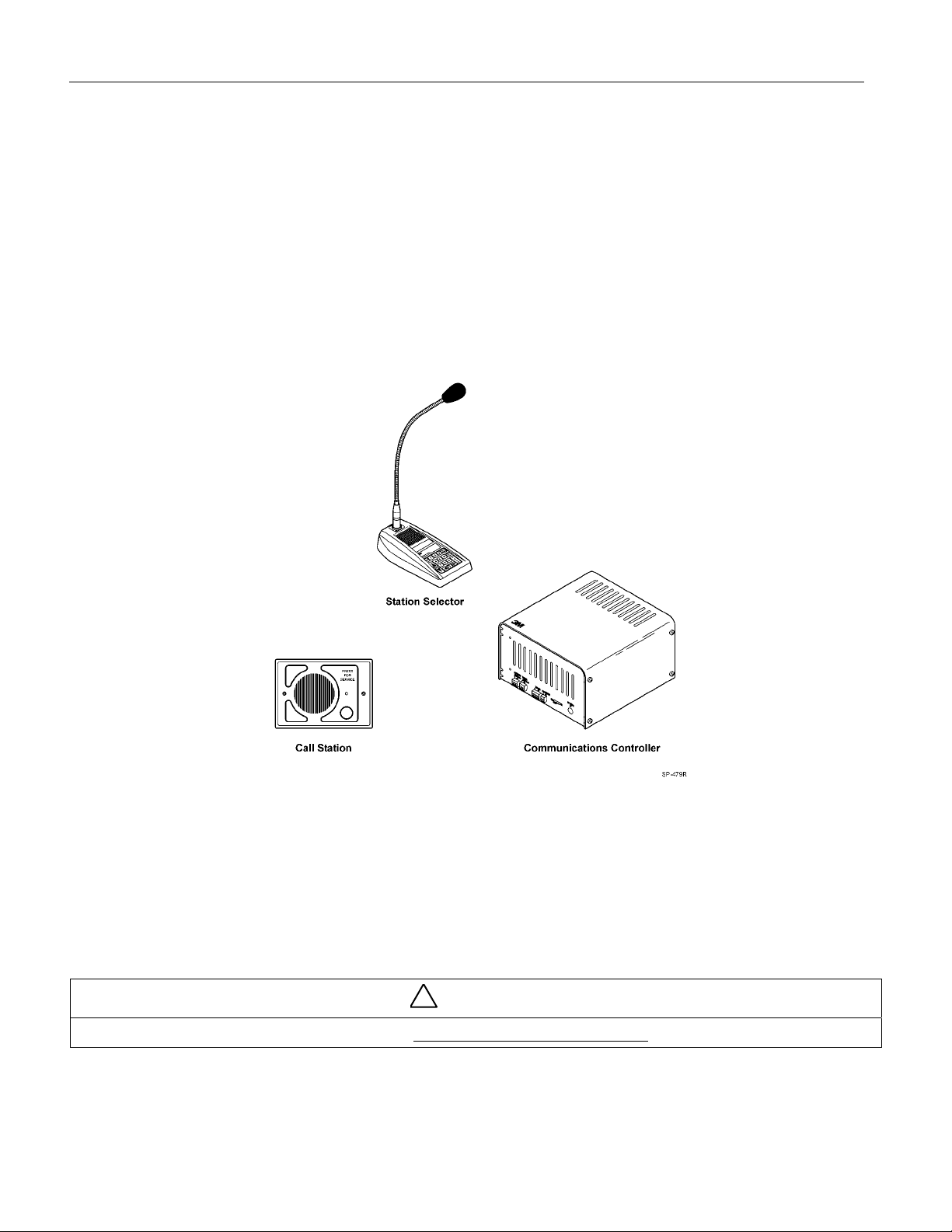

I/O Card Installation

Figure 2. I/O Card Installation

Be sure the system is powered off!

1. Remove 4 screws on each side of the Communications

Controller cover.

2. Remove cover.

Note: Insert I/O cards beginning from connector J5. Add

additional I/O cards sequentially (J6, J7, etc.).

3. Remove slot cover and mounting screw. Refer to Figure 2.

4. Remove all terminal blocks from edge of I/O card.

5. Insert I/O card into I/O connector by pressing gently into

place.

6. Use slot cover mounting screw to secure I/O card to

chassis.

7. Insert terminal blocks into I/O card station ports.

8. Repeat until all I/O cards are installed.

9. Replace cover and 8 screws.

!

Important

A larger power supply must be used if more than four (4).

I/O cards are installed. Use D2470-20 power supply Part

Number 78-8117-4153-3 when more than four (4) I/O cards

are installed.

After the larger power supply is installed, Remove the

following Warning label:

Do not add any I/O cards to these slots

unless power supply output rating exceeds 4

Amps. See installation instructions for

WARNING

details.

Note

If adding additional I/O cards after initial installation, you must re-

program parameter 03, “max stations.”

2

Page 7

Performance Series

I/O Card and Noise Reduction Module

Installation

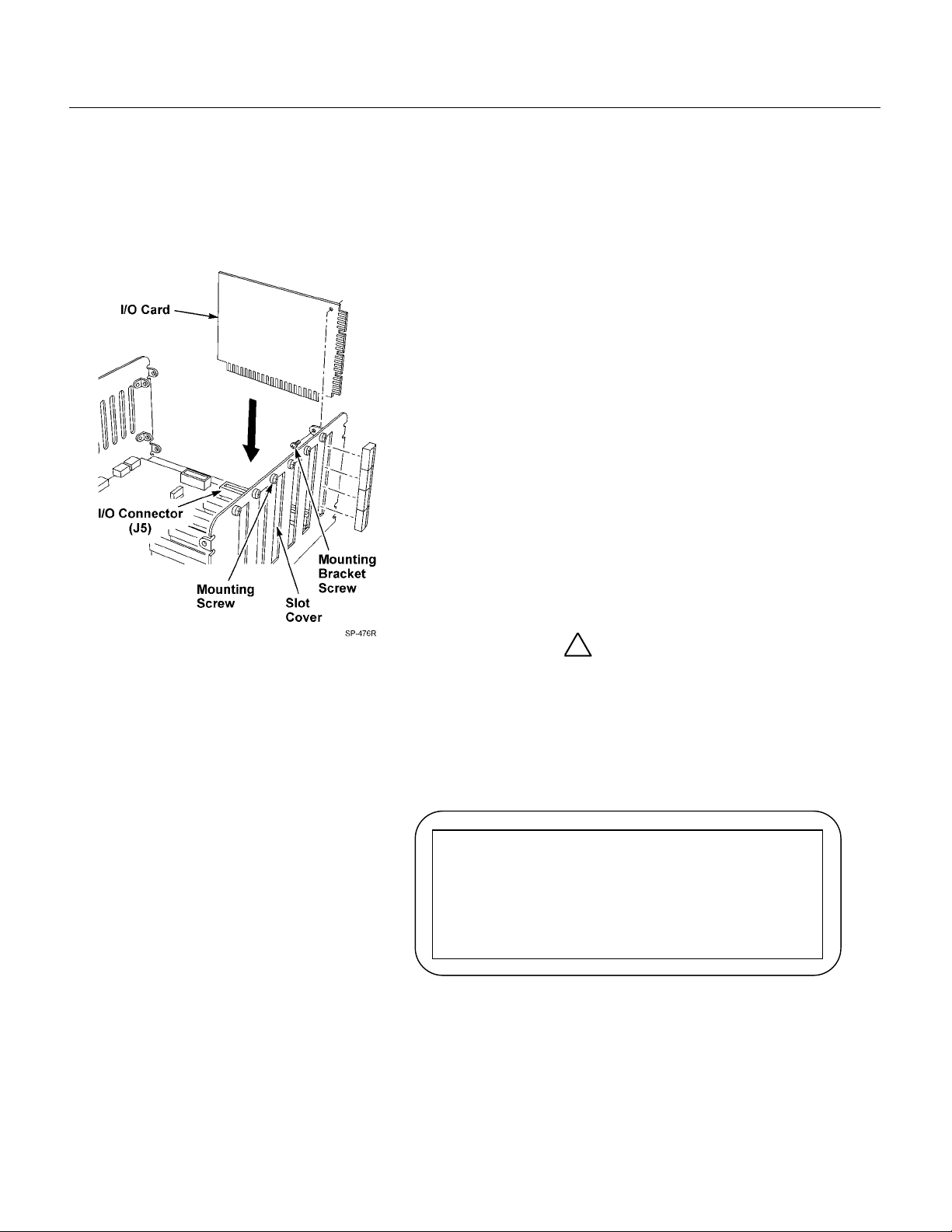

3M Model A125, Noise Reduction

Module, Installation (Optional)

Figure 3. Noise Reduction Module

Installation

Be sure the system is powered off!. Refer to Figure 3.

The optional 3M™ A125 Noise Reduction board (3M part

number 78-9236-6453-2) improves the inbound intelligibility

of an intercom system by reducing environmental background

noise from vehicles, airplanes, noisy intersections, wind, etc.

1. On the A125 circuit board, set the jumpers and

switches as follows:

• Set JMP1 and JMP2 to position A.

• Set SW1 number 1 ON

• Set SW1 number 2 ON

• Set SW1 number 3 as desired:

-- With SW1 number 3 OFF, the A125 is set for

restaurant noise reduction.

-- With SW1 number 3 ON, the A125 is set for

truck stop noise , which provides more noise

reduction with slightly more voice degradation.

• Set SW1 number 4 as desired:

-- With SW2 number 4 ON, the higher-end

frequencies are increased by 3 dB. This should

be set to the customer’s preference.

• SW1 numbers 5 and 6 are not used.

2. Remove 4 screws on each side of Communications

Controller cover.

3. Remove cover.

4. Plug Noise Reduction Module ribbon cable into

Connector J12.

5. Use upper and lower mounting brackets to secure

Noise Reduction Module to Communications

Controller chassis as shown in Figure 3.

6. On the Model 2470 circuit board, Set JMP1 to open.

LED1 (adjacent to JMP1) blinks when noise reduction

module is active.

7. Replace cover and 8 screws.

3

Page 8

Component Placement

Component Placement

This section describes placement of the Performance Series Intercom System components:

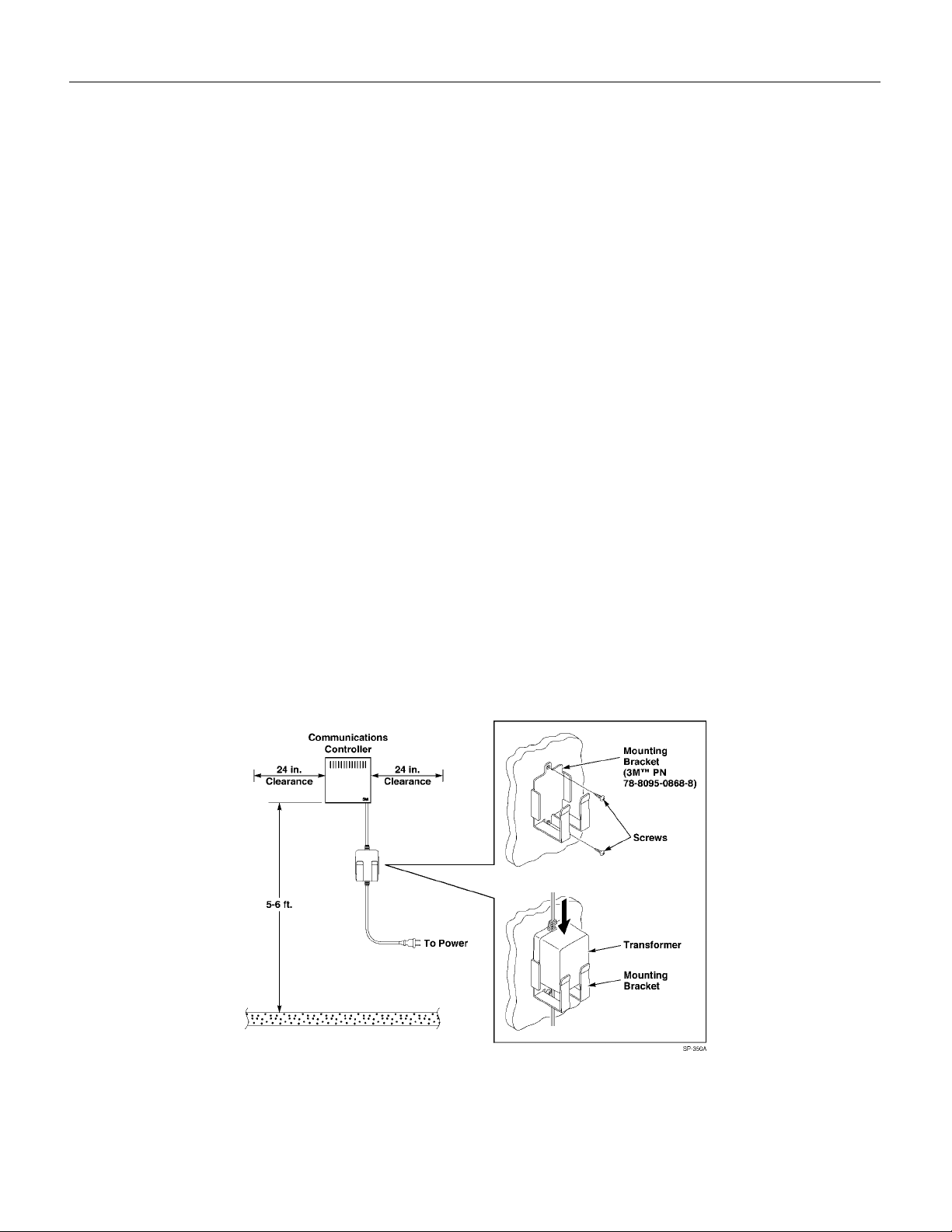

Communications Controller

For proper system operation, locate the Communications Controller:

1. Near the conduit termination of the Call Station wiring.

2. Near the power source.

3. At least 10 feet away from electrical noise sources such as the following:

- large electrical motors (such as air conditioners, freezers, and coolers)

- any electrical components that arc (i.e., relays)

- ballasts (for light fixtures)

4. In a secure room away from traffic.

5. Approximately 5 feet above the floor.

6. Where it is accessible from the top, bottom, and both sides.

Performance Series

7. In a dry and heated (between 50° and 100° Fahrenheit) location.

See Figure 4.

Power Supply

Locate the power supply as follows:

1. Install the power supply mounting bracket in a preferred location, as shown in Figure 4.

2. Insert the power supply transformer into the mounting bracket, as shown in Figure 4.

Figure 4. Suggested Communications Controller Placement

4

Page 9

Performance Series

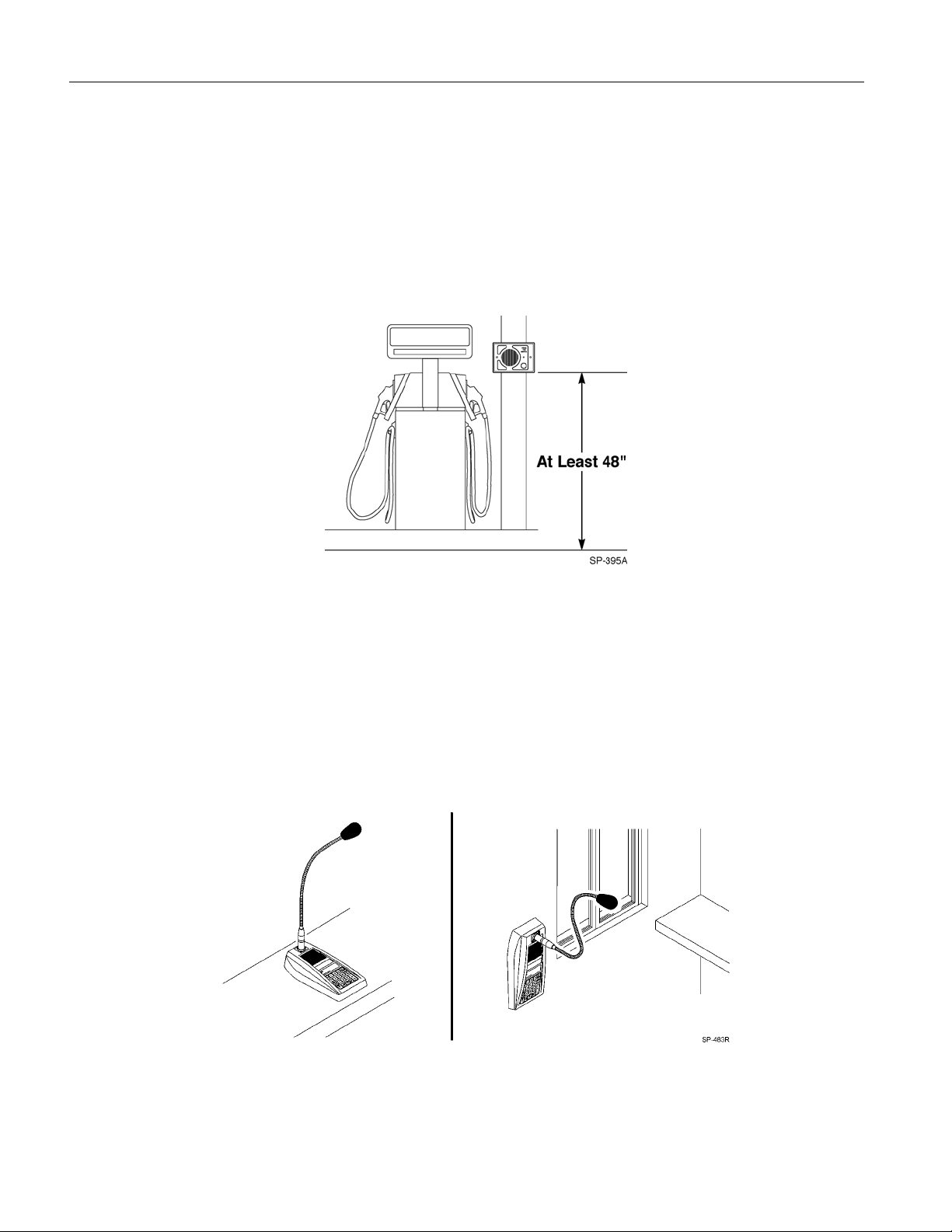

Call Stations

For proper system operation, install the Call Stations in locations:

1. Chosen for ease of use.

2. At least 48 inches above the pavement.

Note

Local codes may dictate placement of call stations.

Component Placement

Figure 5. Suggested Call Station Placement

Station Selectors

For proper system operation, locate the Station Selectors:

1. At locations chosen for maximum efficiency.

2. On counters, mounted on pedestals, or mounted on walls.

3. In dry and heated areas.

Figure 6. Suggested Station Selector Station Placement

5

Page 10

Wiring the System

Performance Series

Wiring the System

Depending on distance, use twisted pair, 14-22 AWG audio cables when wiring the Wired Intercom System,

components. Figure 7 shows an overview of the cable types and number of conductors required for each unit.

Table 1 shows wire gauge required for different distances between components. We recommend installing a

separate power supply transformer (3M part number 78-8095-0910-8), for each Station Selector located over 100

feet from the Communications Controller,

The RS 485 cable carries DC power for the Station Selectors, requiring a larger gauge wire.

Note:

Figure 7. Cable and Connection Requirements

RS 485 Cable (only)

Distance Between

Components

22 Up to 62 feet

20 63-99 feet

18 100-157 feet

16 158-249 feet

14 250-396 feet

Wire Gauge

22 Up to-309 feet

20 310-493 feet

18 494-783 feet

16 784-1245 feet

14 1246-1980 feet

All Audio Wiring

Distance Between

Components

Wire Gauge

Table 1. Wire Size Requirements

6

Page 11

Performance Series

Wiring The System

Configuration Worksheets

Use Configuration Worksheets 1 through 3 (located at the end of this document) to plan and record your system

configuration. You can record the system wire locations, wire color scheme, and program settings on the

worksheets. Store the worksheets inside the cover of the Communications Controller.

Wiring Call Stations

Call Station wiring consists of the following for a one-button, four-wire system:

• 2 Speaker wires.

• Speaker shield wire (used as Common for buttons).

• Call switch.

• LED wire. (if Call Station contains LED)

Configuration Worksheet 1 shows how to connect the Call Stations to the proper Communications Controller ports.

Wiring Station Selectors

!

Important

The D-2400 System is powered by one power supply that provides power for the Communications Controller

and a maximum of three Station Selectors. A separate power supply (3M part number 78-8095-0910-8) must

be plugged into each Station Selector that exceeds the three Station Selector limit. We recommend installing

a separate power supply if the cable length from the Station Selector to the Communications Controller

exceeds 100 feet.

Wiring Station Selectors involves connecting a minimum of 7 wires: 3 audio wires and 4 power and

communications wires.

Figure 8. Connecting Optional Accessories to Station Selector

Refer to Configuration Worksheets 2 and 3 to determine the specific wires and connections to be made.

7

Page 12

Initializing the System

Wiring Communications Controller

Performance Series

Figure 9. Connecting P3 to Communications Controller

Refer to Configuration Worksheets 2 and 3 to determine the specific wires and connections to be made.

8

Page 13

Performance Series

Initializing the System

Initializing the System

System Mode Selection:

Before starting the system Initialization process, you must determine the mode of operation. Check the number of

speakers at each Multiple Product Dispenser (MPD). Typically, each active side of the MPD is identified as a

separate pump:

Number of Speakers

at MPD

1 Island Mode

2 Pump Mode

Table 2. Determining Mode of Operation

Mode of Operation to Use

Figure 10. Pump Mode and Island Mode

9

Page 14

Initializing the System

1. Initialization will erase all memorized parameters and restore factory default values.

2. If Pump Mode (factory default) is desired, initialization is not required.

3. If software is upgraded, the system must be re-initialized.

!

Important

Performance Series

Initialization instructions

for Pump Mode (factory

default)

Init PUMP Mode

‘TALK’ = Yes

1:PUMP MODE

Initialization

Instructions for Island

Mode

Init ISLAND Mode

‘TALK’ = Yes

Pump mode assigns each Call Station to a single number (1 through 24).

Pump mode is used when there are 2 speakers per M.P.D., and each speaker

serves one side of the dispenser.

Procedure 1: Press and hold the ALL CALL key while applying power to the

Selector.

OR

Procedure 2: Reset or remove power from the Station Selector using one of

the following methods:

a. Unplug the RS485 cable.

b. Press and hold the STD BY key while entering the numeric code 911.

Island mode assigns each Call Station to two consecutive numbers (1&2,,

3&4, …….). Island mode is used where a single speaker serves both sides of a

dispenser.

Procedure 1: Press and hold the HOLD key while applying power to any

Selector.

OR

Procedure 2: Reset or remove power from any Station in one of the

following ways.

a. Unplug the RS485 cable.

b. Press and hold the STD BY key while entering the numeric code 911.

Resetting the Station To reset only the station selector:

Selector 1. Press and hold the STD BY key.

(Reset) 2. Enter the numeric code: 911.

Resetting the System To reset only the entire system:

(Reset) 1. Press and hold the STD BY key.

2. Enter the numeric code: 8642.

DEFINITIONS

1) Power On Reset

2) Reset: Restarting the micro controller firmware. Commonly referred to as the “Warm Boot.”

2) Re-Initialize

mode of operation

3) Programming Mode

:

: Turning off power, and then turning it back on. Commonly referred to as a “Cold Boot”.

: Over writes the EEPROM memory with factory default values. This process also selects “Pump” or “Island”

: change the EEPROM memory from factory default values to user preferences

10

Page 15

Performance Series

Programming the System

If you have not selected the mode of operation (Pump or Island) do so now! See System

Mode Selection.

!

Important

Programming the System

Programming State

1

4

7

Figure 11. D-2400 Keypad

2

5

89

MENU

0

To program the Performance Series Intercom System, it is

necessary to put the system in the programming state. From this

state, the entire system is configured and all memorized parameters

are adjusted.

To enter the programming state, simultaneously:

Press and hold the STD BY key.

Enter the numeric code: 97531.

The display shows:

3

6

T

A

L

K

SP-389C

The Parameter #, Parameter Name/Value, and Parameter Value

fields are as shown below.

Parameter

Parameter # Name/Value

← Parameter Value

The “_ “ indicates cursor position. To move the cursor from one

field to another, use the Left Arrow and Right Arrow keys.

01:Selector ID #

{01}

↓ ↓

01:Selector ID #

{01}

All Station Selectors ship from the factory with a default ID number of 15. It is important to

connect and power up each new Station Selector, ONE STATION SELECTOR AT A TIME,

when installing a new system. Doing this allows you to change the ID number to a lower

value (start at 1) and avoid the erratic behavior caused by multiple Station Selectors sharing

the same ID number.

To input data at the cursor position, do one of the following:

• Use the Up Arrow and Down Arrow keys to scroll to desired

value.

• Use the 1, 2, 3, 4, 5, 6, 7, 8, 9, 0/Menu keys.

The STD BY key clears a field to a default value (space for text or

the default value).

The HOLD key shifts case for text data.

The ALL CALL key exits from the programming state and enters

the Off Line mode.

!

Important

11

Page 16

Programming the System

Error Message

The system will display one error message: No Communication.

Performance Series

! E R R O R !

NO COMMUNICATION

Parameter Selection

01:Selector ID #

{01}

02:Controller

{D2400 1-Chnl}

03:Max Stations

{24}

04:Silence Calls

{Off}

05:Alert Volume

{08}

06:Alert Type

{Chime}

This message occurs when there is no communications between the Station

Selector and Communications Controller. To correct this:

• Be sure Communications Controller is powered on.

• Be sure pins 2 and 3 of J3 on the Communications Controller are

connected to pins 2 and 3 of J8 (RS-485 connector) on the Station

Selector. Polarity must be correct!

• Call 3M Technical Service to confirm software compatibility between

station selector and communication controller.

Memorized parameters are given below. These parameters are stored in the

EEPROM. The 16-character by 2-row LCD displays the parameters.

A number (1 to 15 inclusive). Default = 15. This number must be unique

relative to all other Station Selector ID numbers used in the system.

Displays the model of the Communications Controller connected to the Station

Selector. If no Communications Controller is connected {Undefined} will be

displayed.

A number (1 to 24 inclusive). Total number of Call Stations in the system.

Default = What the Communications Controller senses. Stations are numbered

starting with 1 up to this value. This value should be adjusted to equal the

number of speakers connected to the Communications Controller, preventing

an operator from accessing an unwired Call Station. If installing or removing

additional I/O cards after the initial installation, you must re-program

parameter03for each station selector connected to the system.

A value (On, Off). Default = Off.

Off = normal operation.

On = Station Selector will only respond to page requests from other Station

Selectors. It will not respond to Call Station requests. This is useful for a

Station Selector placed in a manager’s office. The manager will not hear Call

Station alerts. He will hear only page requests from employee’s Station

Selectors.

A number (1 to 15 inclusive). Default = 08. Adjusts the volume of the Station

Selector alert tone (Chime or Beep). A value of 15 is the loudest setting.

Beep or Chime. Default = Chime.

12

Page 17

Performance Series

07:VOX Enable

{Off}

08:VOX Sensitive

{15}

09:Talk Vol{10}

S=01 PUMP # 01

10:Music Volume

{08}

11:Priority{Off}

S=xy: User Name

12:Auto Standby

{On)

13:Standby Mode

{Silence}

14:Selector Name

S=xy: User Name

15:Station Name

S=xy: User Name

Programming the System

A value (On, Off). Default = Off. Enables the VOX (Voice Operated

Transmission) feature.

A number (1 to 15 inclusive). Default = 15 (most sensitive). Adjust this value

to accommodate the ambient noise level at the Station Selector location. Use a

lower value for a higher noise environment.

A number (1 to 15 inclusive). Default = 08. The outbound voice volume is

adjusted for all Call Stations simultaneously. Each Call Station can be

individually selected. An assistant can be sent out to each Call Station. When

the Talk key is momentarily pressed, it remains in the Talk state until pressed

again, and then it remains in the Listen state. This allows the installer to

communicate with the assistant over the intercom in setting the proper volume

level.

This value must be adjusted after adjusting Talk volume!

A number (0 to 15 inclusive). Default = 08. With a value of {00} music will

be muted.

A value (Off, 1 to 24 inclusive). Default = Off. The Call Station selected here

has top propriety call in over all other Call Station requests.

A value (On or Off). Default = On. Enables the 90-second station connection

time out. If the Talk key is not pressed within 90 seconds, the Station Selector

returns to the Standby mode.

A value (Silence or All Listen). Default = Silence. “Silence” selects no

inbound volume during Standby mode. “All Listen” allows all Call Stations to

be monitored during Standby mode.

Assignment of Station Selector names (Station Selector numbers 71 through

85 correspond to Station Selector ID numbers 1 through 15) where xy

indicates Station Selector number. Default = SELECTOR xy where xy =

Station Selector number (see “Keypad Function Definitions for Text Entry”).

Assignment of Call Station names (01 through Max Stations) where xy

indicates station number. Default = PUMP number xy where xy = station

number (see “Keypad Function Definitions for Text Entry”).

13

Page 18

Programming the System

16:Music {On }

S=xy: User Name

17: All Call {On }

S=xy: User Name

18:Registry {On }

S=xy: User Name

A value (On, Off) for each Call Station. Default = On. Off will mute music at

selected Call Station(s). This parameter is used to disable music at any Call

Station. This parameter is used to disable music or messages at any Call

Station.

A value (On, Off) for each Call Station. Default = On. Off will disable All

Call broadcasts at selected Call Station(s). This parameter could be useful for

disabling All Call broadcasts at a car wash or manager’s office Call Station.

A value (On, Off) for each Call Station or Station Selector. Default = On. Off

disables this Station Selector from connecting to specific Call Stations or

Station Selectors. This could be useful for making specific Call Stations and

Station Selectors inaccessible from this Station Selector, for privacy purposes.

This Station Selector will still be able to receive calls from other Call Stations

and Station Selectors.

19:Sync All Data

‘ T A L K’ = Yes

Are You Sure ?

‘T A L K’ = Yes

20:Software Rev

Se=a.bc Con=x.yz

Command to synchronize all Station Selectors with the data from the Station

Selector that issued the command. All data is synchronized with the exception

of Selector ID #, Silence Calls, and Registry.

This confirmation message follows the above. Station Selectors must be On

Line to be synchronized.

Read from Station Selector & Communications Controller. Station Selector

and Communications Controller software revision numbers.

Performance Series

14

Page 19

Performance Series

Programming the System

Keypad Function

Definitions (for Text

entry) (Programming

State)

1

4

3

2

56

89

7

MENU

0

Figure 12. D-2400 Key-

pad

T

A

L

K

SP-389C

Key functions are defined below.

Key Function

HOLD (Shift) Shifts between upper and lower case for text data.

UP ARROW Increments data by 1. Fields wrap around.

DOWN ARROW Decrements data by 1. Fields wrap around.

1 Enters the digit 1 for numeric entry.

Enters the following for text entry:

Unshifted A B C 1 (

Shifted a b c 1 )

2 Enters the digit 2 for numeric entry.

Enters the following for text entry:

Unshifted

Shifted d e f 2 ]

D E F 2 [

3 Enters the digit 3 for numeric entry.

Enters the following for text entry:

4 Enters the digit 4 for numeric entry.

Unshifted G H I 3 {

Shifted g h i 3 }

Enters the following for text entry:

5 Enters the digit 5 for numeric entry.

Unshifted J K L 4

Shifted j k l 4

←

→

Enters the following for text entry:

Unshifted M N O 5 :

Shifted m n o 5 ;

15

Page 20

Programming the System

Performance Series

6 Enters the digit 6 for numeric entry.

7 Enters the digit 7 for numeric entry.

8 Enters the digit 8 for numeric entry.

9 Enters the digit 9 for numeric entry.

Key Function

Enters the following for text entry:

Enters the following for text entry:

Enters the following for text entry:

Enters the following for text entry:

Unshifted P Q R 6 _

Shifted p q r 6 |

Unshifted S T U 7 .

Shifted s t u 7 !

Unshifted V W X 8 &

Shifted v w x 8 @

Unshifted Y Z # 9 ’

Shifted y z , 9 “

0/MENU Enters the digit 0 for numeric entry.

Enters the following for text entry:

LEFT ARROW Jump left to next data field.

RIGHT ARROW Jump right to next data field.

ALL CALL Exits the programming state and enters Off Line mode.

STD BY Clear the data field to its default value (space for text or

the default value).

TALK Enter key where appropriate.

Unshifted + * = 0 <

Shifted - / ∧ 0 >

16

Page 21

Performance Series

Adjusting the System

Adjusting the System

Inbound Audio Volume Level

To set the inbound audio volume level:

1. Ask an attendant to stand at a Call Station and push the incoming call button for your Station Selector.

2. Answer the call by pressing the TALK button.

3. As the attendant talks, adjust the up/down arrows on the Station Selector keypad to reach a desirable level.

VOX (Voice Operated Transmission) Sensitivity Level

!

Important

The VOX adjustments are necessary only if VOX is enabled for your system.

The VOX sensitivity level determines the maximum distance from the microphone that the speaker can activate

communication.

!

Important

The suggested average activation distance from the microphone to the attendant is 2 to 6

inches.

To set the VOX sensitivity level:

1. Follow the directions under the section Programming the System to put the Station Selector in programming

mode.

2. Locate the VOX Enable parameter and be sure it is set to ON.

3. Locate the VOX Sensitive parameter and press the right-arrow key to edit the value.

4. Use the up/down arrow keys to adjust sensitivity:

• The up arrow key increases the sensitivity (lengthens the distance from the microphone to the attendant).

Fifteen is most sensitive.

• The down arrow key decreases sensitivity. One is least sensitive.

5. Press the ALL CALL key to exit Programming

Outbound Talk Volume Level

To set the outbound Talk volume level:

1. Follow the directions under the section Programming the System to put the Station Selector in programming

mode

2. Locate the Talk Vol parameter and follow instructions in that section.

17

Page 22

Adjusting the System

Performance Series

Outbound Music/Messaging Volume Level (Only for systems that use Music/Messaging)

To set the outbound Music/Messaging volume level:

1. Follow the directions under the section Programming the System to put the Station Selector in programming

mode

2. Locate the Music Volume parameter and follow the instructions in that section.

Testing the Functions

Perform the following tests after installing the Performance Series D-2400 Intercom System:

1. Checking TALK/LISTEN switching.

a. Ask an attendant to go to Call Station 1 and press the call button.

b. Establish a connection with the CALL STATION (press TALK on the Station Selector or Remote

Microphone).

c. Talk and listen to the attendant to determine that the TALK and LISTEN modes are functioning

satisfactorily.

d. Repeat Steps a through c for all CALL STATIONS.

2. Checking ALL CALL.

a. Ask an attendant to go to a Call Station.

b. Activate ALL CALL (press and hold ALL CALL on the Station Selector or Remote Microphone).

c. Broadcast an announcement from the Station Selector.

d. Ask the attendant to verify that the message is broadcast from all Call Stations, which have not been

disabled.

18

Page 23

Performance Series

Configuration Worksheets

Configuration Worksheets

19

Page 24

Configuration Worksheets

Performance Series

20

Page 25

Performance Series

Configuration Worksheets

21

Page 26

Page 27

Commercial Care Division

Food Service Business

3M Center

St. Paul, MN 55144-1000

Printed in U.S.A.

© 3M 2004 April

78-6912-0739-9 Rev B

Loading...

Loading...