Page 1

H3C SecPath U200 Series Unified Threat

Management Products

Installation Manual

Hangzhou H3C Technologies Co., Ltd.

http://www.h3c.com

Manual Version: 5PW101-20090520

Page 2

Copyright © 2009, Hangzhou H3C Technologies Co., Ltd. and its licensors

All Rights Reserved

No part of this manual may be reproduced or transmitted in any form or by any means without prior

written consent of Hangzhou H3C Technologies Co., Ltd.

Trademarks

H3C, , Aolynk, , H3Care,

SecPro, SecPoint, SecEngine, SecPath, Comware, Secware, Storware, NQA, VVG, V

XGbus, N-Bus, TiGem, InnoVision and HUASAN are trademarks of Hangzhou H3C Technologies Co.,

Ltd.

All other trademarks that may be mentioned in this manual are the property of their respective owners.

Notice

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute the warranty of any kind, express or implied.

Technical Support

customer_service@h3c.com

http://www.h3c.com

, TOP G, , IRF, NetPilot, Neocean, NeoVTL,

2

G, VnG, PSPT,

Page 3

About This Manual

Organization

H3C SecPath U200 Series Unified Threat Management Products Installation Manual is organized as

follows:

Chapter Contents

1 Product Overview

2 Interface Modules

3 Preparing for Installation

4 Installing the U200 Series

Device

5 Starting and Configuring

the U200 Series Device

6 Maintaining Software

7 Maintaining Hardware

8 Troubleshooting

Briefly introduces the product specifications, as well as the features

and applications of the H3C SecPath U200 series UTM devices.

Describes the interface cards and interface modules supported by

the H3C SecPath U200 series UTM devices.

Describes the site requirements for installing the H3C SecPath U200

series UTM devices, safety recommendations before and during

installation, and required tools.

Introduces how to install an H3C SecPath U200 series UTM device,

as well as how to connect the power cable, console cable, Ethernet

cable, and interface cable.

Describes how to boot and configure an H3C SecPath U200 serie s

UTM device, including device startup, power-on, and initialization of

system files.

Introduces how to maintain software of the H3C SecPath U200

series UTM devices, including upgrading software and updating

configuration files.

Introduces how to maintain hardware of the H3C SecPath U200

series UTM devices.

Describes some problems you may encounter during installation and

startup of an H3C SecPath U200 series UTM device and how to

solve them.

Appendix Compliance and

Safety Manual

Conventions

The manual uses the following conventions:

Command conventions

Convention Description

Boldface

italic

[ ] Items (keywords or arguments) in square brackets [ ] are optional.

{ x | y | ... }

[ x | y | ... ]

{ x | y | ... } *

This section introduces part of the compliance and safety

precautions that should be followed during the installation and

maintenance of the equipment.

The keywords of a command line are in Boldface.

Command arguments are in italic.

Alternative items are grouped in braces and separated by vertical bars.

One is selected.

Optional alternative items are grouped in square brackets and

separated by vertical bars. One or none is selected.

Alternative items are grouped in braces and separated by vertical bars.

A minimum of one or a maximum of all can be selected.

Page 4

Convention Description

[ x | y | ... ] *

&<1-n>

# A line starting with the # sign is comments.

Optional alternative items are grouped in square brackets and

separated by vertical bars. Many or none can be selected.

The argument(s) before the ampersand (&) sign can be entered 1 to n

times.

GUI conventions

Convention Description

Boldface

>

Window names, button names, field names, and menu items are in

Boldface. For example, the New User window appears; click OK.

Multi-level menus are separated by angle brackets. For example, File >

Create > Folder.

Symbols

Convention Description

Means reader be extremely careful. Improper operation may cause

bodily injury.

Related Documentation

In addition to this manual, each H3C SecPath Series Security Products documentation set includes the

following:

Manual Description

H3C SecPath Series Security

Products User Manual

Obtaining Documentation

You can access the most up-to-date H3C product documentation on the World Wide Web at this URL:

http://www.h3c.com.

The following are the columns from which you can obtain different categories of product docume ntation:

Means reader be careful. Improper operation may cause data loss or

damage to equipment.

Means a complementary description.

Describes the features, operation fundamentals, and configuration

commands of the H3C SecPath series security products, guides

you to make configuration, and provides configuration examples.

[Products & Solutions]: Provides information about products and technologies.

[Technical Support & Document > Technical Documents]: Provides several categories of product

documentation, such as installation, configuration, and maintenance.

[Technical Support & Document > Software Download]: Provides the documentation released with the

software version.

Page 5

Documentation Feedback

You can e-mail your comments about product documentation to info@h3c.com.

We appreciate your comments.

Environmental Protection

This product has been designed to comply with the requirements on environmental protection. For the

proper storage, use and disposal of this product, national laws and regulations must be ob served.

Page 6

Table of Contents

1 Product Overview······································································································································1-1

Introduction ·············································································································································1-1

Features ··········································································································································1-1

Physical Description································································································································1-2

U200-A ············································································································································1-2

U200-M············································································································································1-3

U200-S ············································································································································1-4

Technical Specifications··························································································································1-5

Processor and Storages··················································································································1-5

Dimensions and Weight···················································································································1-5

Fixed Interfaces and Slots···············································································································1-6

Power Input ·····································································································································1-6

Operating Environment Specifications ····························································································1-6

Components············································································································································1-7

Processor and Storages··················································································································1-7

Front Panel LEDs ····························································································································1-7

Fixed Interfaces ·······························································································································1-8

AC Power Input ·····························································································································1-14

Clock··············································································································································1-14

Port Lightning Arrester (Optional)··································································································1-14

Power Lightning Arrester (Optional) ······························································································1-15

Signal Lightning Arrester (Optional) ······························································································1-15

System Software ···························································································································1-16

i

Page 7

1 Product Overview

Introduction

The H3C SecPath U200 Series Unified Threat Management Products are new-generation UTM devices

designed for enterprise users.

The U200 series comprises three models:

z U200-A: Designed for large- and medium-sized enterprise users

z U200-M: Designed for medium-sized enterprise users

z U200-S: Designed for small- and medium-sized enterprise users

In addition to traditional firewall functions, the U200 series protect network security by providing a wide

range of functions including virtual firewall, security zone, intrusion detection and protection, gateway

anti-virus, anti-spam, P2P traffic control, and URL filtering. With the application specification packet filter

(ASPF) technology, a U200 series device can monitor connection setup processes and illegal

operations, and dynamically filter packets based on ACLs. Moreover, the U200 series support multiple

VPN services including IPSec VPN, L2TP VPN, and GRE VPN, and thereby can be used for

constructing a variety of VPN networks. The series deliver abundant routing capabilities and support

RIP and OSPF. Adopting a high-performance multi-core CPU, the U200-A, U200-M and U200-S can

support up to 10, 8, and 7 GE interfaces respectively, delivering high scalability for user investment

protection.

The U200 series are available with AC power supply to ensure high reliability, fully satisfy requirements

for network maintenance, update, and optimization, support detection of chassis internal temperature,

support network management, and provide a Web management interface.

The U200-A provides two MIM expansion slots for future service expansion. Currently, the slots support

the NSQ1GT2UA0 and NSQ1GP4U0 MIM modules.

The U200-M provides one MIM expansion slot and currently supports the same MIM as the U200-A

does.

The U200-S provides a mini expansion slot for future service expansion. Currently, the device supports

the 2-GE and NSQ1WLAN0 interface modules.

Features

The U200 series deliver the following features:

Powerful hardware platform

The U200 series perfectly fit in enterprise networks thanks to the adoption of MIPS64-based CPUs and

integrated high-performance hardware-based VPN accelerators.

Abundant security protection functions

z Security zone management: You can create security zones based on physical interfaces, logical

interfaces, Layer-2 Ethernet interfaces, or combinations of Layer-2 Ethernet interfaces and VLANs.

Interfaces belonging to the same security zone share the same security requirements in security

1-1

Page 8

policy control. With security zones, security administrators can classify interfaces with different

security requirements into different zones. This simplifies policy maintenance and separates

network services and security services.

z Packet filtering: Applies standard or extended ACL rules between security zones to implement

packet filtering based on UDP or TCP port information. You can also implement packet filtering

based on time ranges.

z Application specific packet filter (ASPF): Dynamically determines whether to forward or drop a

packet by checking its application layer protocol information (such as FTP, HTTP, SMTP, RTSP, or

any other application layer protocol carried on TCP/UDP), monitoring the status of

connection-oriented application layer protocols, and maintaining status information for each

connection.

z P2P traffic control: Performs in-depth packet inspection to identify and manipulate P2P traffic. With

various control policies, a U200 series device controls P2P traffic flexibly.

z Virtual firewall: You can create multiple virtual firewalls, each implementing a separate security

policy. These virtual firewalls are isolated from one another and thus can be managed separately.

z Diverse attack prevention functions: Guards against attacks including Land, Smurf, Fraggle,

WinNuke, Ping of Death, Tear Drop, IP Spoofing, IP fragment, fragment, TCP flag invalid, large

ICMP packet, IP Sweep, port scan, and DDoS attacks such as SYN Flood, UDP Flood, and ICMP

Flood.

z Packet filtering: Blocks specified URLs to better utilize network resources.

Powerful VPN functions

z IPSec and GRE

z IKE and PKI

z A built-in hardware-based VPN encryption engine, ensuring high-performance VPN processing

Physical Description

U200-A

Front view

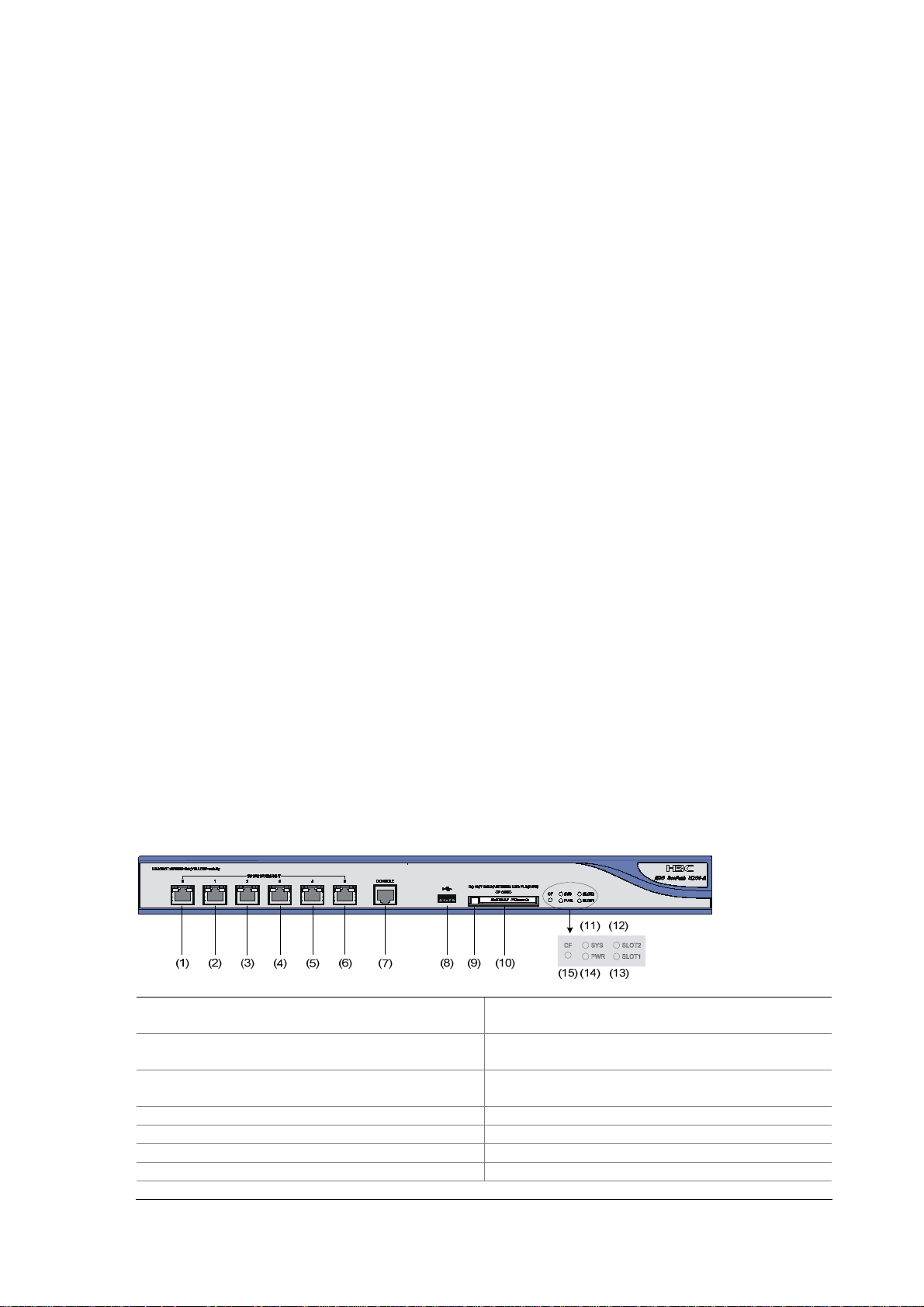

Figure 1-1 U200-A front view

(1) 10/100/1000 Mbps electrical Ethernet

interface 0

(3) 10/100/1000 Mbps electrical Ethernet

interface 2

(5) 10/100/1000 Mbps electrical Ethernet

interface 4

(7) Console port (CONSOLE) (8) USB interface

(9) CF card ejector button (10) CF card slot

(11) System LED (SYS) (12) Slot 2 LED (SLOT2)

(13) Slot 1 LED (SLOT1) (14) Power LED (PWR)

(15) CF card LED (CF)

(2) 10/100/1000 Mbps electrical Ethernet

interface 1

(4) 10/100/1000 Mbps electrical Ethernet

interface 3

(6) 10/100/1000 Mbps electrical Ethernet

interface 5

1-2

Page 9

Rear view

Figure 1-2 U200-A rear view

(1) (2) (3) (4) (5) (6)

(1) Grounding screw and symbol (2) OPEN BOOK symbol

(3) AC power switch (ON/OFF) (4) AC power socket

(5) Slot 1 (with an NSQ1GT2UA0 module

installed)

(6) Slot 2 (with an NSQ1GT2UA0 module

installed)

The open book symbol is used to remind the operator to read the relevant chapters when performing

any of these operations on the U200-A:

z Connecting the ESD-preventive wrist strap

z Installing the device on a workbench or in a rack

z Connecting the PGND cable or the AC power cord

z Connecting the power lightning arrester, signal lightning arrester, or port lightning arrester

z Connecting the console cable, AUX cable, or Ethernet cables

z Opening and closing the chassis cover

z Installing or removing the mini card (available only on the U200-S), MIM module (available only on

the U200-A and U200-M), or CF card

U200-M

Front view

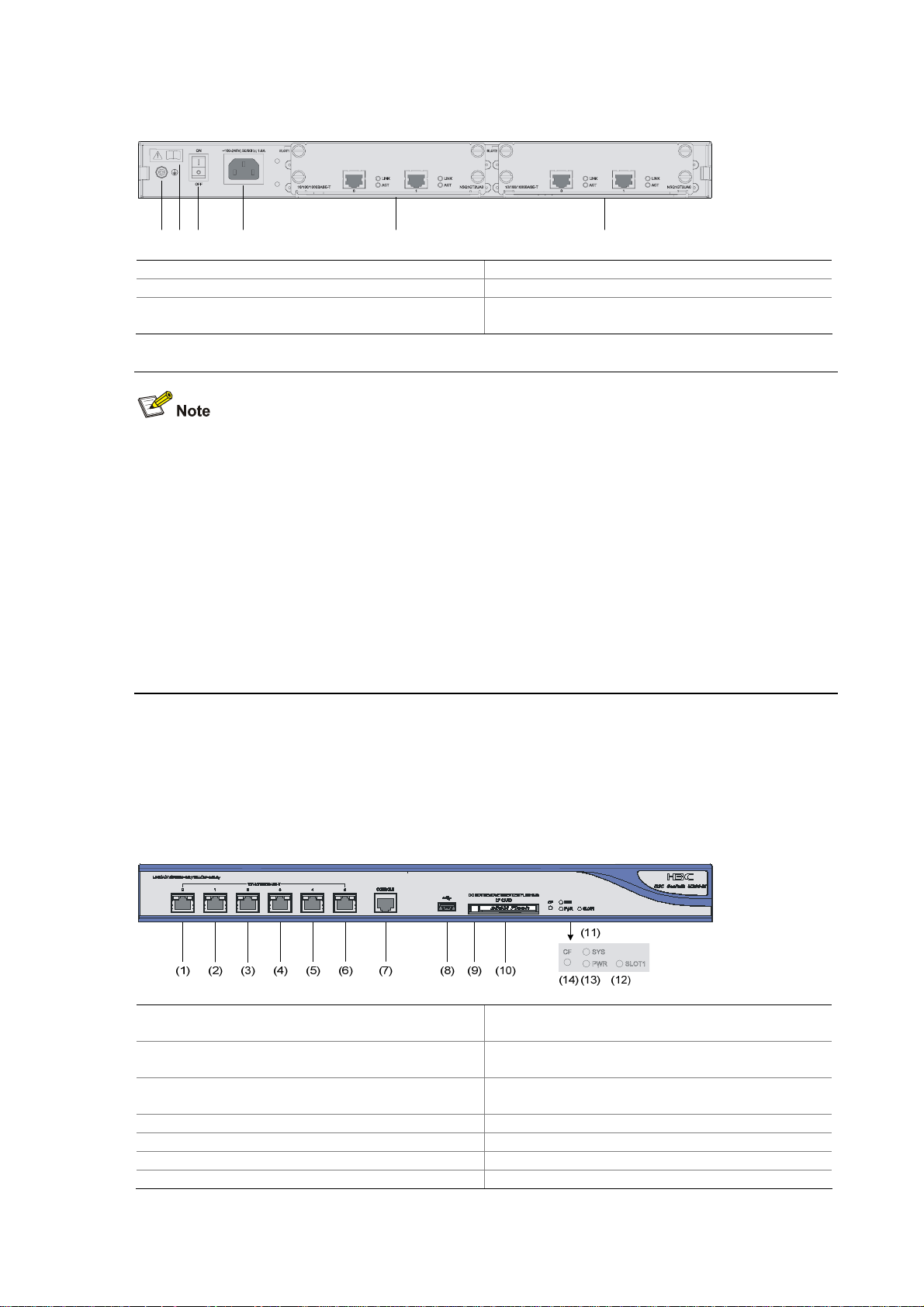

Figure 1-3 U200-M front view

(1) 10/100/1000 Mbps electrical Ethernet

interface 0

(3) 10/100/1000 Mbps electrical Ethernet

interface 2

(5) 10/100/1000 Mbps electrical Ethernet

interface 4

(7) Console port (CONSOLE) (8) USB interface

(9) CF card ejector button (10) CF card slot

(11) System LED (SYS) (12) Slot 1 LED (SLOT1)

(13) Power LED (PWR) (14) CF card LED (CF)

(2) 10/100/1000 Mbps electrical Ethernet

interface 1

(4) 10/100/1000 Mbps electrical Ethernet

interface 3

(6) 10/100/1000 Mbps electrical Ethernet

interface 5

1-3

Page 10

Rear view

Figure 1-4 U200-M rear view

(1) Grounding screw and symbol (2) OPEN BOOK symbol

(3) AC power switch (ON/OFF) (4) AC power socket

(5) Slot 1 (with an NSQ1GT2UA0 module installed)

For detailed description of the OPEN BOOK symbol, refer to the note under Figure 1-2.

U200-S

Front view

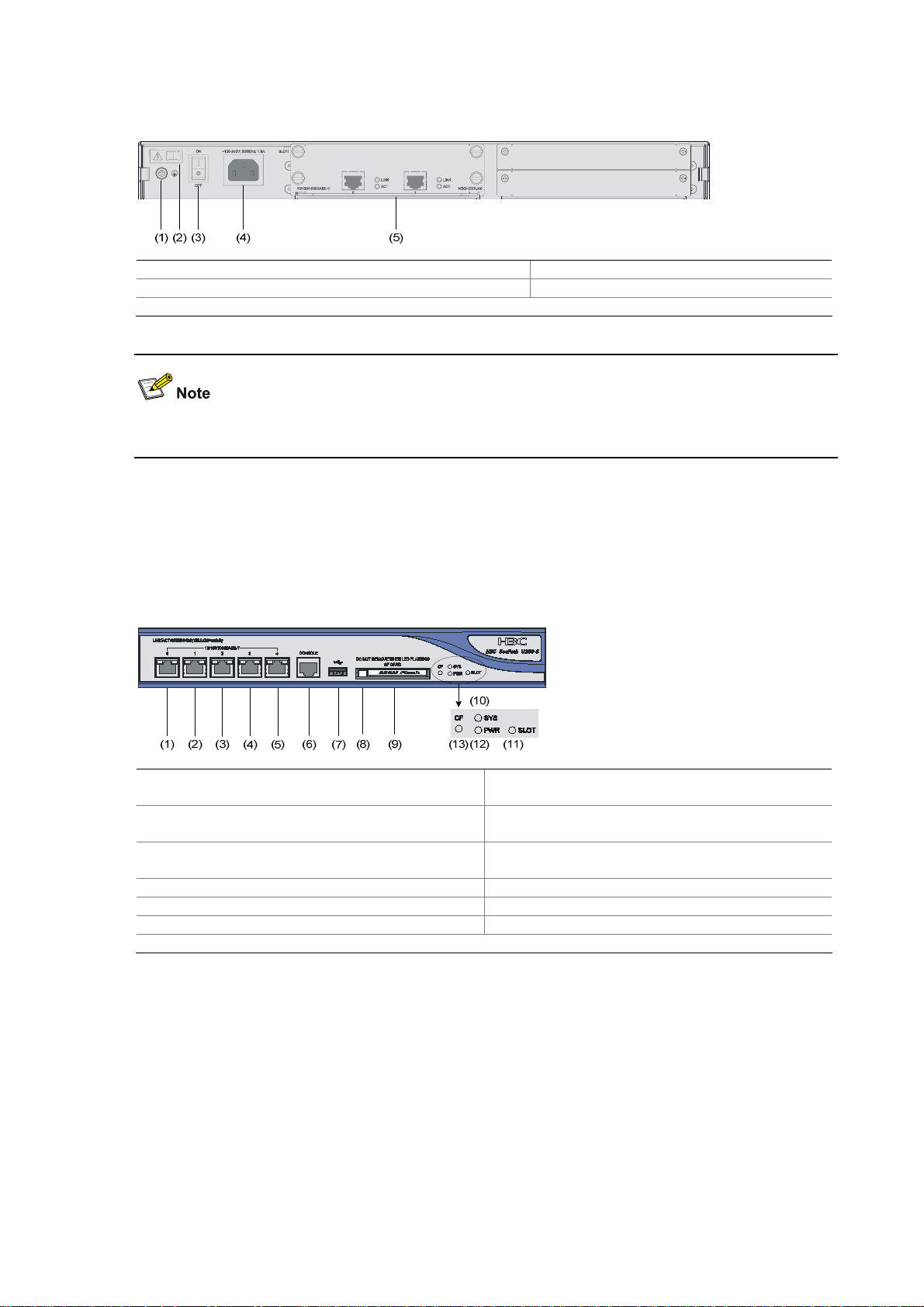

Figure 1-5 U200-S front view

(1) 10/100/1000 Mbps electrical Ethernet

interface 0

(3) 10/100/1000 Mbps electrical Ethernet

interface 2

(5) 10/100/1000 Mbps electrical Ethernet

interface 4

(7) USB interface (8) CF card ejector button

(9) CF card slot (10) System LED (SYS)

(11) Slot LED (SLOT) (12) Power LED (PWR)

(13) CF card LED (CF)

(2) 10/100/1000 Mbps electrical Ethernet

interface 1

(4) 10/100/1000 Mbps electrical Ethernet

interface 3

(6) Console port (CONSOLE)

1-4

Page 11

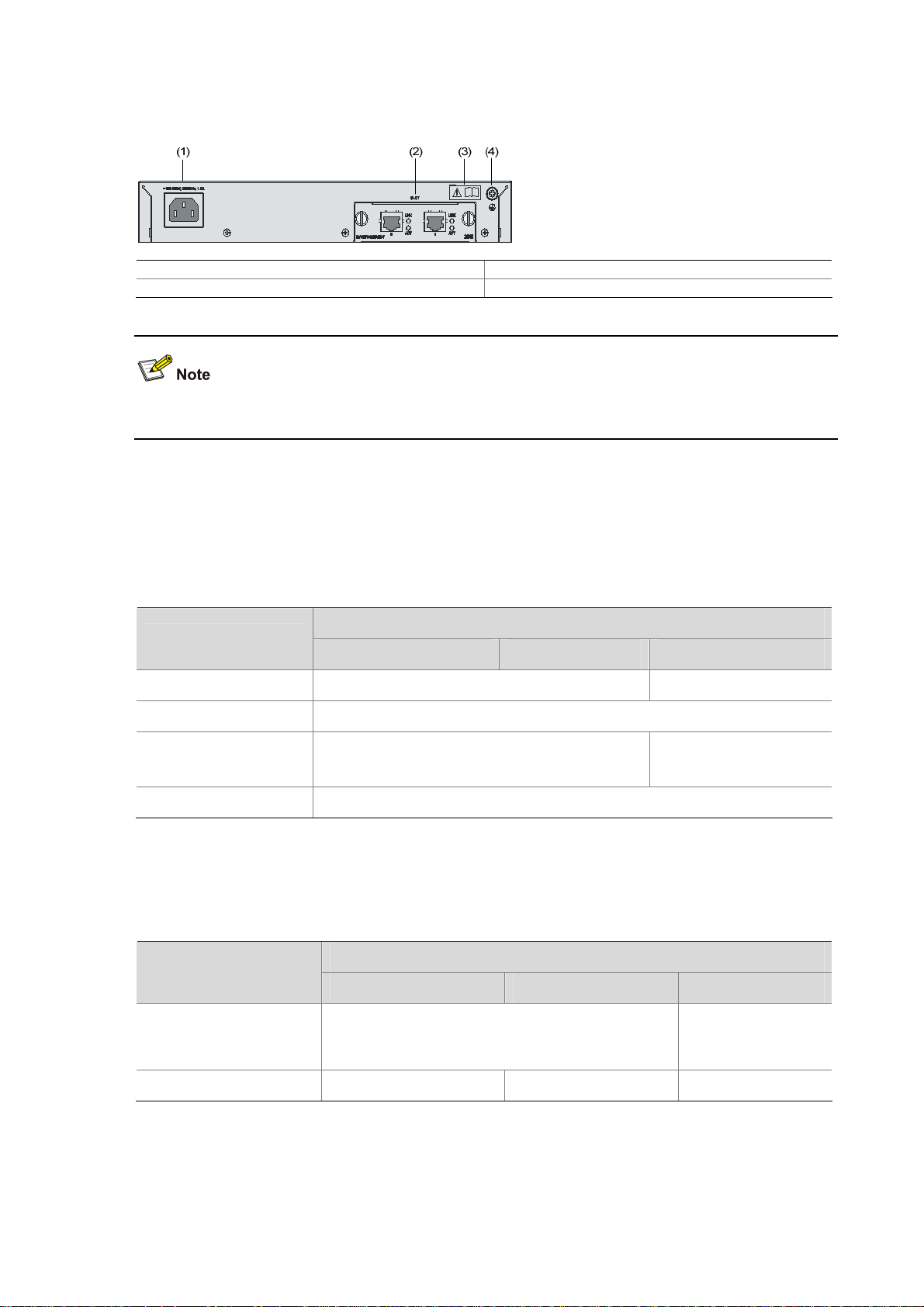

Rear view

Figure 1-6 U200-S rear view

(1) AC power socket (2) Slot (with 2GE)

(3) OPEN BOOK symbol (4) Grounding screw and sign

For detailed description of the open book symbol, refer to the note under Figure 1-2.

Technical Specifications

Processor and Storages

Table 1-1 Processor and storages of the U200 series

Item

Processor RMI XLS208 750 MHz RMI XLS404 800 MHz

Flash 32 MB

DDR2 SDRAM

Memory type and size

External CF card 256 MB, 512 MB, or 1 GB

Dimensions and Weight

Table 1-2 Dimensions and weight of the U200 series

1 GB by default

Description

U200-A U200-M U200-S

DDR2 SDRAM

512 MB by default

Item

U200-A U200-M U200-S

Dimensions (H × W × D),

excluding feet and

mounting brackets

Weight (fully configured) 5.9 kg (13.01 lb) 5.5 kg (12.13 lb) 2.22 kg (4.89 lb)

44.2 × 442 × 400 mm (1.74 × 17.40 × 15.75 in.)

1-5

Description

43.6 × 300 × 260

mm (1.72 × 11.81 ×

10.24 in.)

Page 12

Fixed Interfaces and Slots

Table 1-3 Interface (fixed) and slot specifications

Item

Console port 1 (9600 bps to 115200 bps, 9600 bps by default)

USB

interface

GE

interfaces

CF card slot 1 external CF card slot (256 MB, 512 MB, or 1 GB)

Slots

Power Input

Table 1-4 Input voltage specifications

Description

U200-A U200-M U200-S

1 (host mode, reserved without software support)

6 (GE0 to GE5) 5 (GE0 to GE4)

10/100/1000 Mbps electrical interfaces, MDI/MDIX autosensing

2 MIM expansion slots

Available interface module:

NSQ1GT2UA0 and

NSQ1GP4U0

Item

U200-A U200-M U200-S

1 MIM expansion slot

Available interface module:

NSQ1GT2UA0 and

NSQ1GP4U0

Description

1 Mini expansion slot

Available interface

module: 2GE and

NSQ1WLAN0

Rated voltage range

Maximum input current

Maximum power

100 VAC to 240 VAC; 50 Hz or 60 Hz

1.6 A 0.6 A

100 W 54 W

Operating Environment Specifications

Table 1-5 Operating environment specifications

Item

U200-A U200-M U200-S

Operating temperature 0°C to 45°C (32°F to 113°F)

Operating humidity

(noncondensing)

Operating altitude

10% to 95%

–60 to 3000 m (–196.85 to +9842.52 ft.)

Description

–60 to 2000 m (–196.85

to +6561.68 ft.)

1-6

Page 13

Components

Processor and Storages

Processor

A U200 series device uses a multi-core microprocessor as its data forwarding and service processing

engine.

Flash

A U200 series device uses a 32 MB flash for storing BootWare and APP.

Memory

The memory temporarily stores data for the running system and buffering data to be forwarded. By

default, the U200-A and U200-M are equipped with a 1 GB memory while the U200-S has a 512 MB

memory.

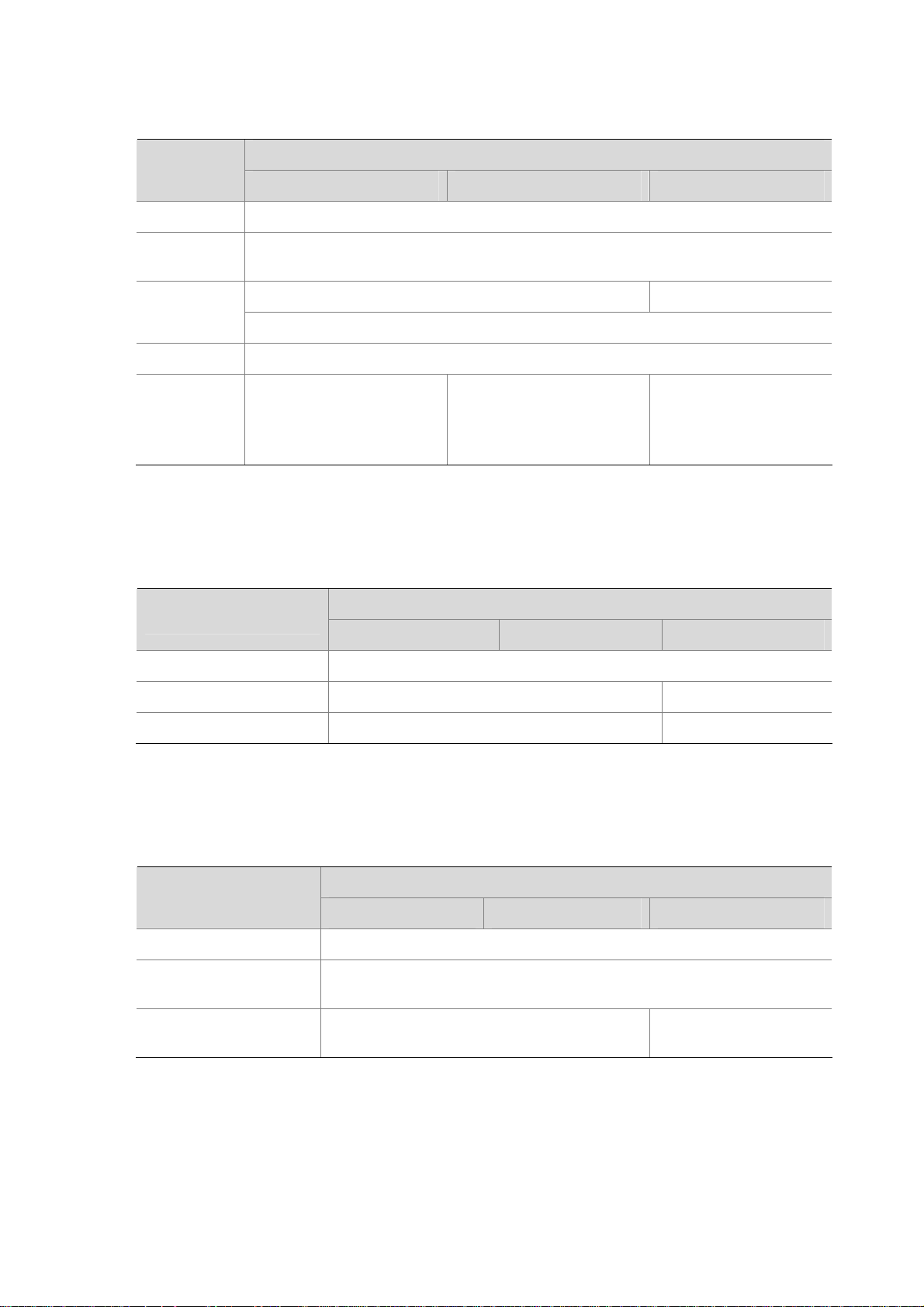

Front Panel LEDs

Figure 1-7 U200-A front panel LEDs

Figure 1-8 U200-M front panel LEDs

Figure 1-9 U200-S front panel LEDs

Table 1-6 Description of the front panel LEDs

LED Status Description

Off

CF (green)

On

Blinking

No CF card is in position or the CF card cannot be

identified.

A CF card is in position and has passed the test. It can

be removed in this state.

The system is accessing the CF card. Do not unplug

the card in this state.

1-7

Page 14

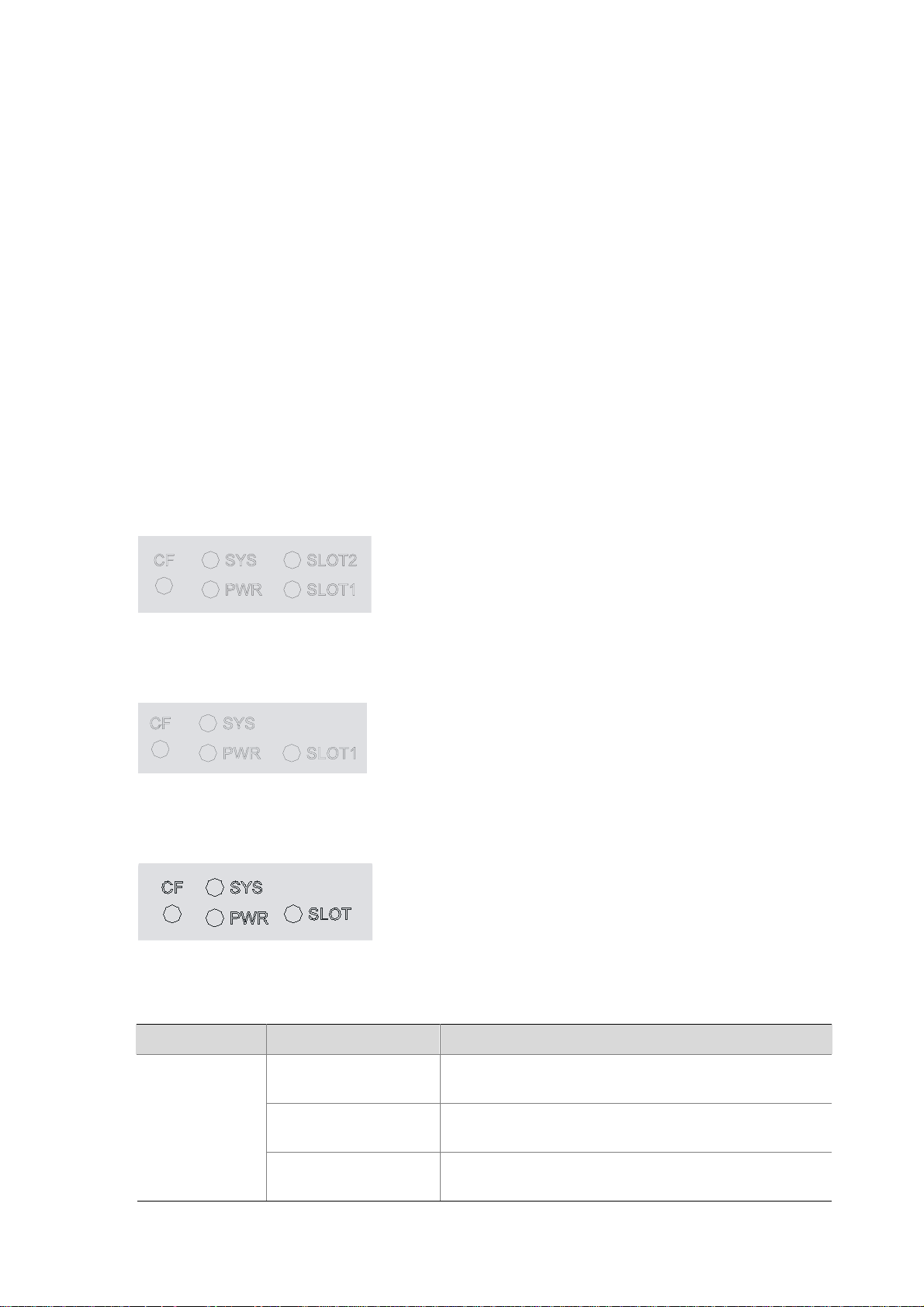

LED Status Description

SYS (green)

PWR (green)

SLOT1/SLOT2/

SLOT (green)

Fixed Interfaces

Table 1-7 Description of the fixed interfaces

Interface Description

Console port 1

Off The system is powered off or faulty.

Slow blinking (at 1 Hz)

The interface module is operating normally as

configured.

Fast blinking (at 8 Hz) Software is being loaded or the system is not working.

Off The power module is not working or faulty.

On The power module is supplying power normally.

Off

On

No interface module is in the slot or the interface

module is faulty.

An interface module is in the slot and operating

normally.

USB interface 1 Host mode, reserved without software support

U200-A 6 10/100/1000 Mbps electrical Ethernet interfaces: GE0 to GE5

GE

interfaces

U200-M 6 10/100/1000 Mbps electrical Ethernet interfaces: GE0 to GE5

U200-S 5 10/100/1000 Mbps electrical Ethernet interfaces: GE0 to GE4

Three CF card options of different memory sizes are available:

CF card slot 1

z 256 MB

z 512 MB

z 1 GB

Console port

1) Introduction

A U200 series device provides an RS232 asynchronous serial console port (Console), which can be

connected to a computer for system debugging, configuration, maintenance, management, and

software loading.

2) Specifications

Table 1-8 Technical specification of the console port

Attribute Description

Connector type

Interface standard

Baud rate

Maximum transmission distance

RJ-45

Asynchronous EIA/TIA-232

9600 bps (default) to 115200 bps

15 m (49.21 ft.)

1-8

Page 15

Attribute Description

Connection to an ASCII terminal

Services

Connection to the serial interface of a local PC to run the

terminal emulation program

Command line interface

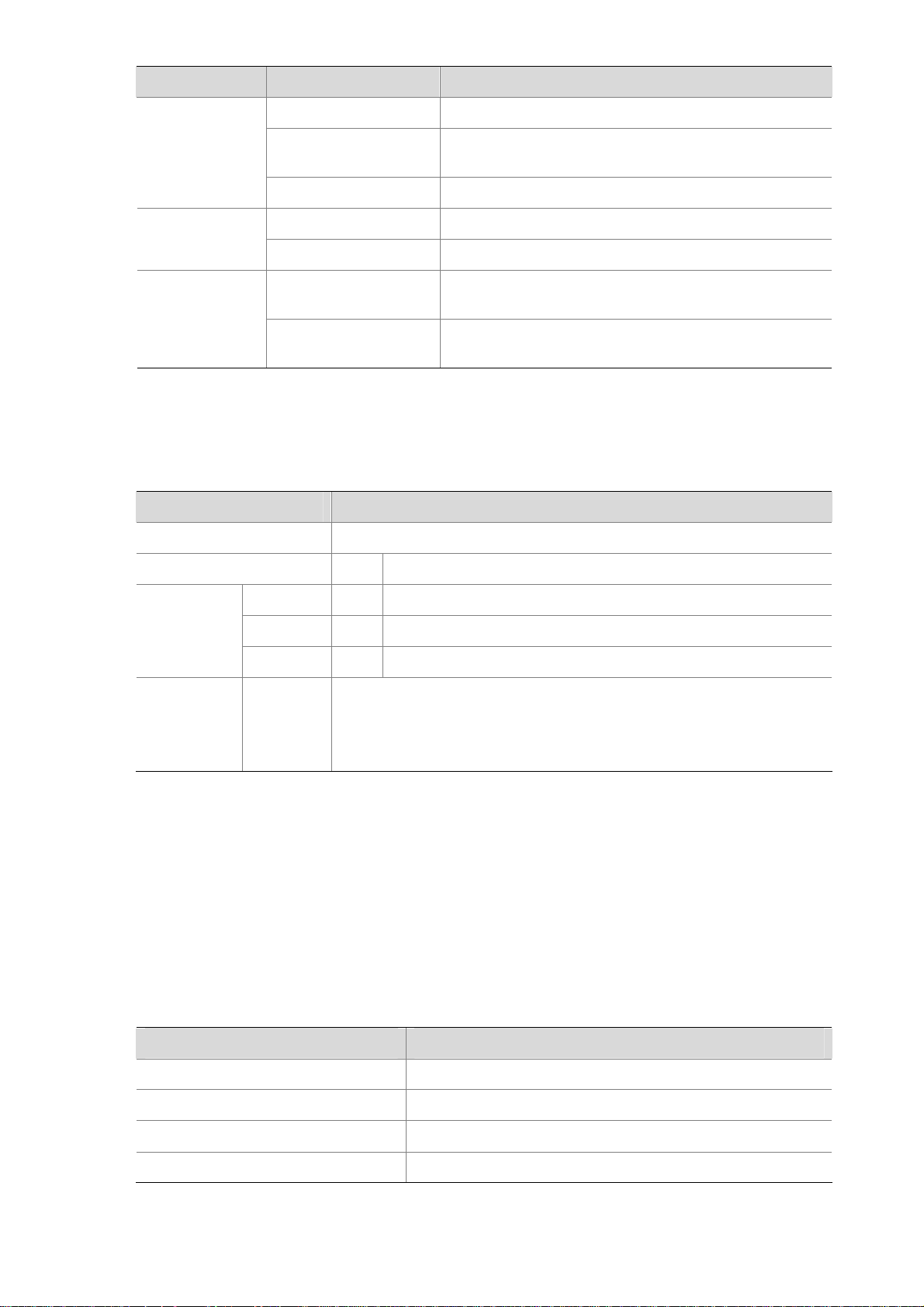

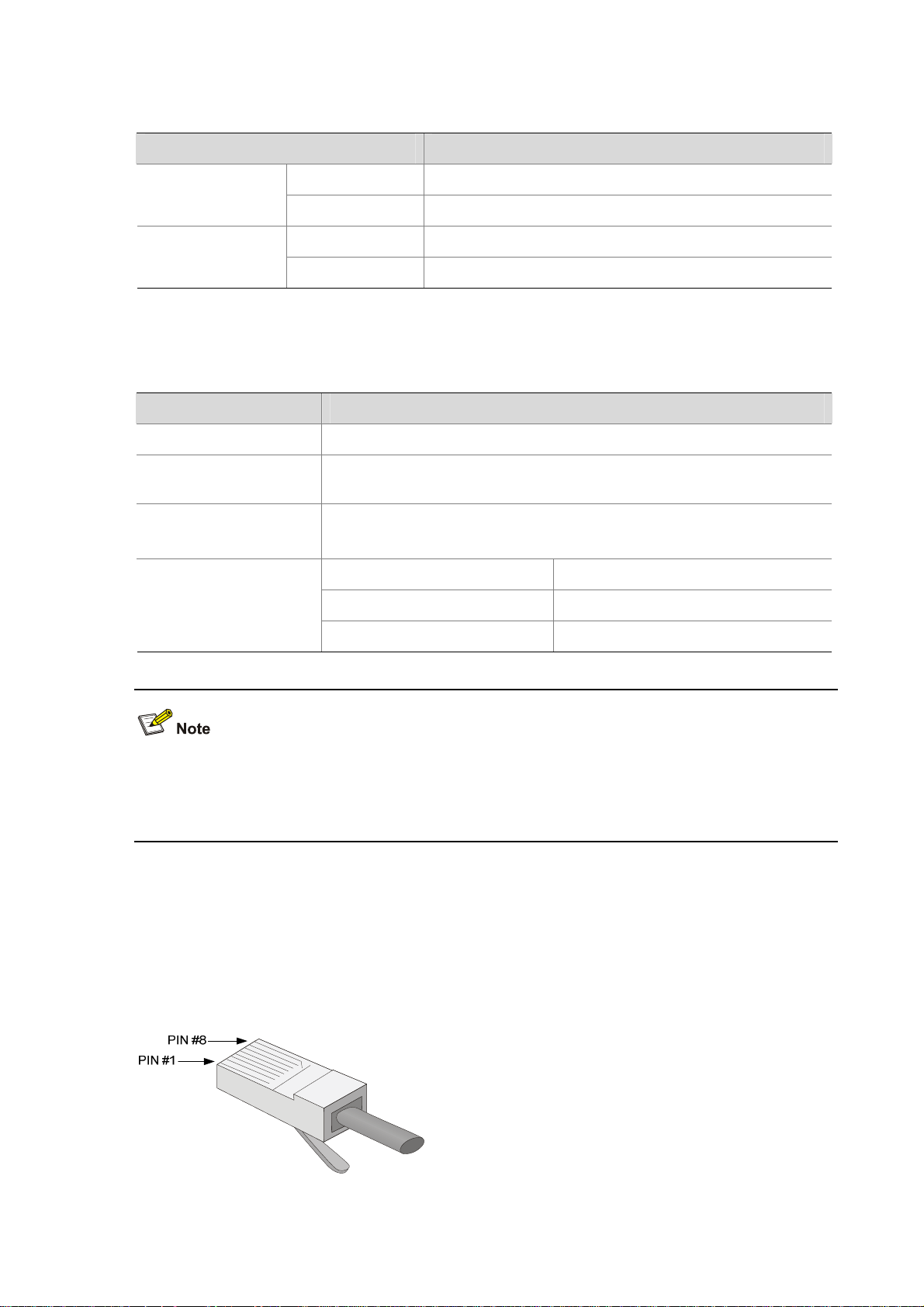

3) Console cable

The console cable is an 8-core shielded cable. The RJ-45 connector at one end of the cable is for the

console port on the UTM device, and the DB-9 female connector at the other end is for the serial port on

a configuration terminal.

Figure 1-10 illustrates the console cable.

Figure 1-10 Console cable

Table 1-9 Console cable pinouts

RJ-45 Signal direction DB9 Signal

1

2

3

4

Æ

Æ

Æ

Å

8 CTS

6 DSR

2 RXD

1 DCD

5 — 5 GND

6

7

8

Å

Å

Å

3 TXD

4 DTR

7 RTS

For how to connect the console cable, refer to the “Connecting the Console Cable” section in Chapter 4

“Installing the U200 Series Device.”

Ethernet interfaces

1) Introduction

A UTM series device provides fixed 10/100/1000Base-T Ethernet interfaces on its front panel, the

number of which depends on the device model. Each fixed Ethernet interface (RJ-45) uses two built-in

1-9

Page 16

LEDs in the upper corners to indicate its status.

Table 1-10 Description of Ethernet interface LEDs

Status Description

LINK

Off No link is present.

On A link is present.

Off No data is being received or transmitted.

ACT

Blinking Data is being received or transmitted.

2) Specifications

Table 1-11 Technical specifications of the Ethernet interfaces

Item Description

Connector type RJ-45

Interface type

Frame format

Rate and negotiation

mode

Autosensing (Ethernet does not support MDI/MDIX autosensing when

working in the forced mode)

Ethernet_II

Ethernet_SNAP

10 Mbps (autosensing)

100 Mbps (autosensing)

1000 Mbps (autosensing)

Half-/full-duplex auto-negotiation

Half-/full-duplex auto-negotiation

Full-duplex auto-negotiation

The media dependent interface (MDI) standard is typically used for the Ethernet interfaces of network

adaptors. The media dependent interface crossover (MDI-X) standard is typically used on hubs or LAN

switches.

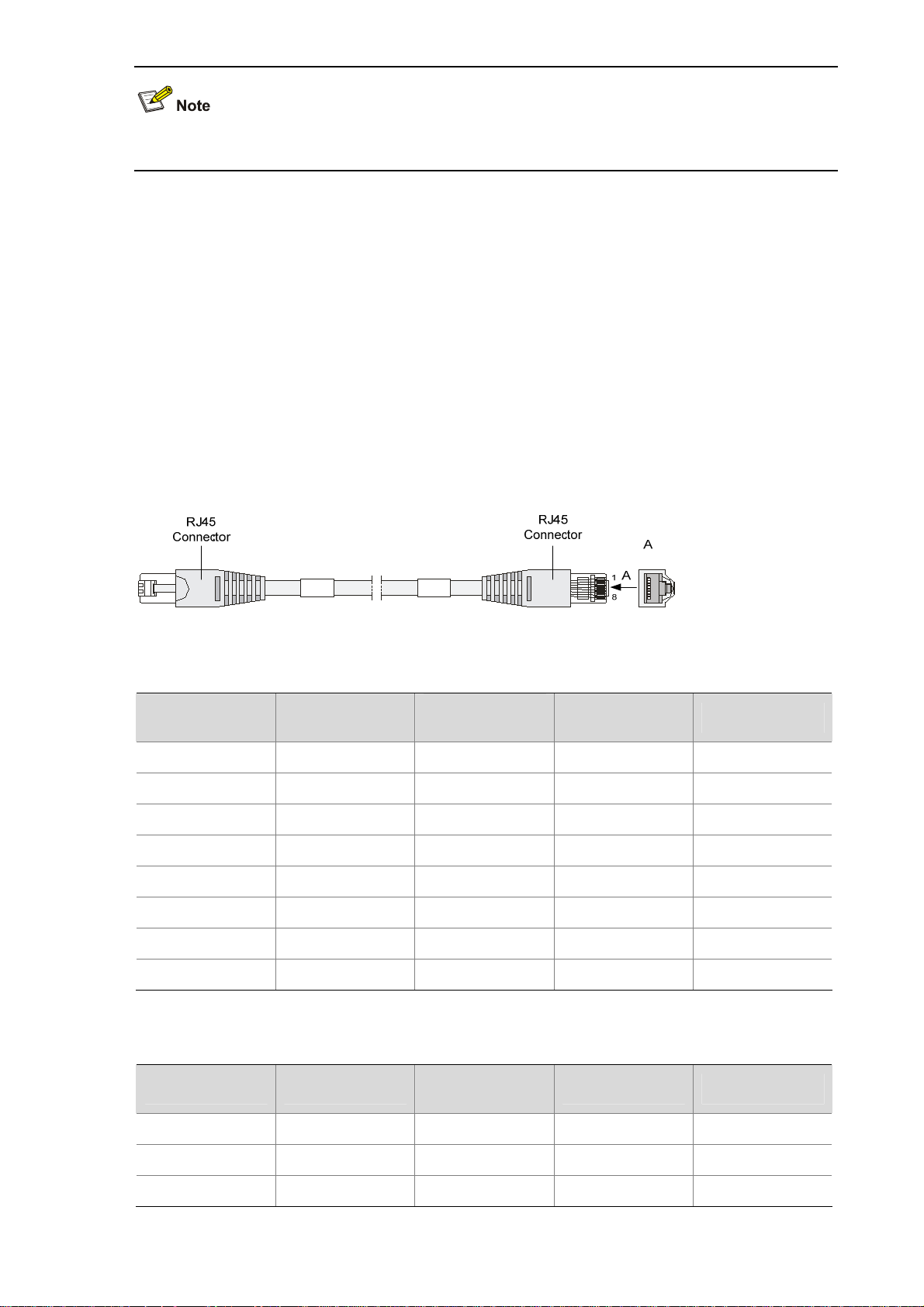

3) RJ-45 connector

The 10/100/1000Base-T Ethernet interfaces of the U200 series use RJ-45 connectors and support

MDI/MDIX autosensing. Category-5 twisted pair cables are used for RJ-45 connectors.

Figure 1-11

shows an RJ-45 connector.

Figure 1-11 RJ-45 connector

1-10

Page 17

When working in the forced mode, Ethernet does not support MDI/MDIX autosensing.

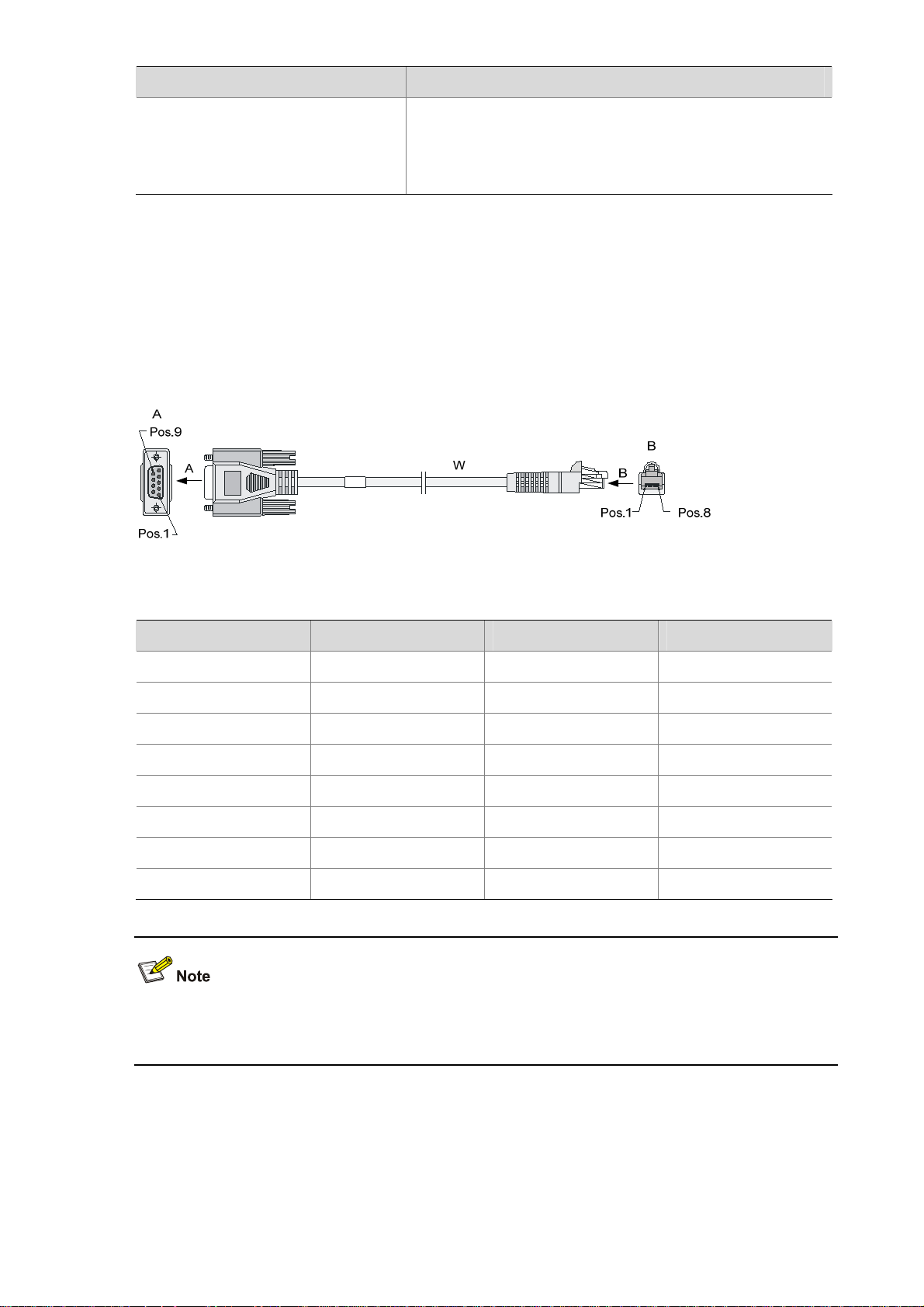

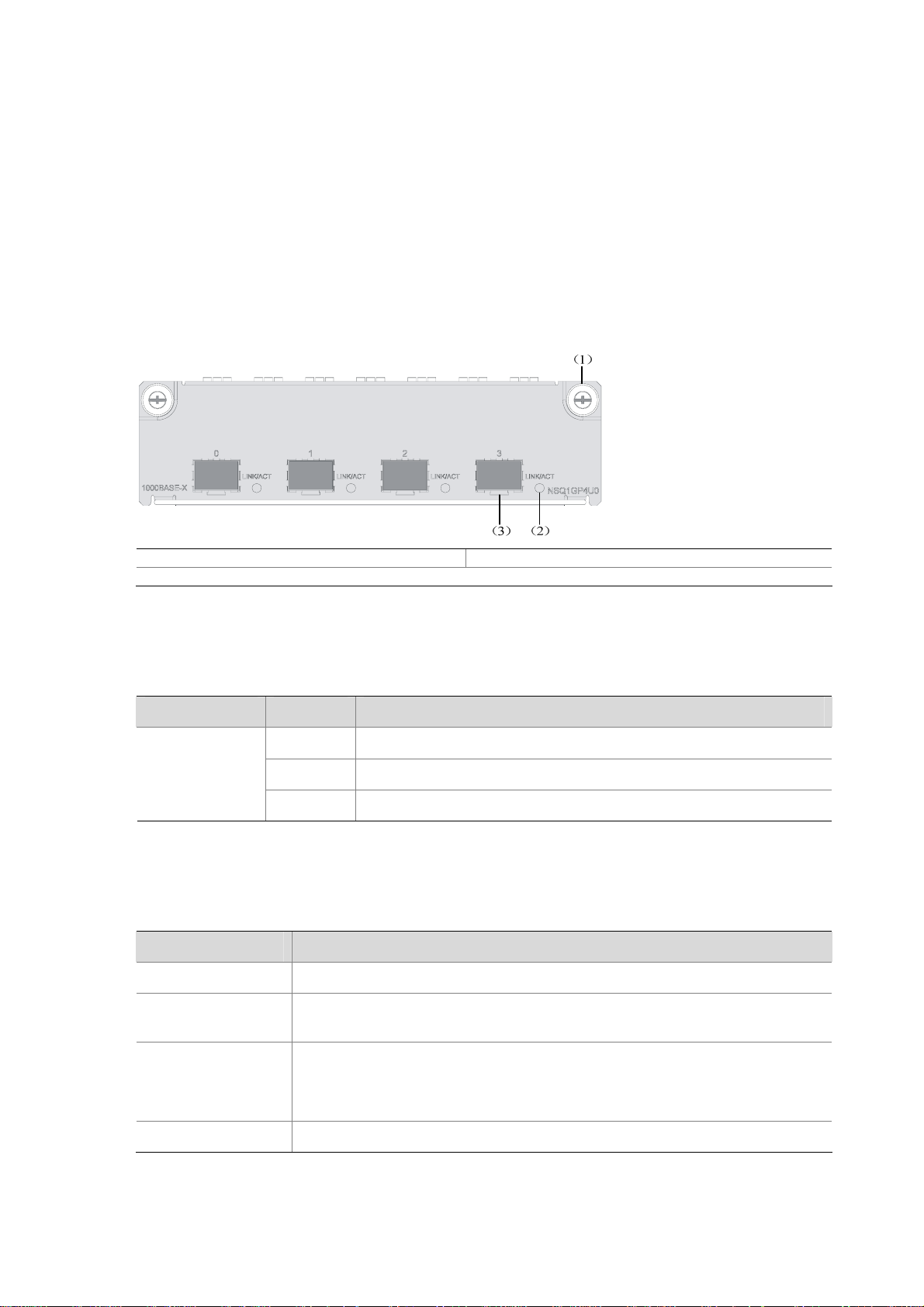

4) Cable connecting electrical Ethernet interfaces

Ethernet electrical interfaces usually use category-5 twisted pair cables. Ethernet cables fall into two

categories:

z Standard cables: Also known as straight-through cables. At both ends of a standard cable, wires

are crimped in the RJ-45 connectors in the same sequence. A straight-through cable is used for

connecting a terminal (for example, a PC or UTM device) to a hub or LAN switch. Straight-through

cables are shipped with the U200 series.

z Crossover cables: At both ends of a crossover cable, wires are crimped in the RJ-45 connectors in

different sequences. A crossover cable is used for connecting two terminals (for example, two PCs

or UTM devices). You can make crossover cables yourself as needed.

Figure 1-12 Ethernet cable

Table 1-12 Straight-through cable connector pinouts

RJ-45 Signal

Category-5

twisted pair

1 TX+ White (Orange)

2 TX- Orange

3 RX+

White (Green)

4 — Blue

5 — White (Blue)

6 RX- Green

7 — White (Brown)

8 — Brown

Table 1-13 Crossover cable connector pinouts

Signal direction RJ-45

Æ

Å

1

2

3

Æ

— 4

— 5

Å

— 7

6

— 8

RJ-45 Signal direction

1 TX+ White (Orange)

2 TX- Orange

3 RX+ White (Green)

Category-5

twisted pair

1-11

Signal direction RJ45

Æ

Æ

Å

3

6

1

Page 18

RJ-45 Signal direction

Category-5

twisted pair

Signal direction RJ45

4 — Blue — 4

5 — White (Blue) — 5

6 RX- Green

Å

2

7 — White (Brown) — 7

8 — Brown — 8

z You can refer to the tables above when trying to identify or preparing the two types of Ethernet

cables.

z When preparing Ethernet cables, follow the color pairings in the tables. Otherwise, communication

quality will be affected even if the two devices at both ends can communicate.

z When preparing Ethernet cables, use shielded cables preferentially for electromagnetic

compatibility.

USB interface

USB interfaces can connect multiple types of devices and provide higher data transfer rates than

common parallel interfaces and serial interfaces.

The U200 series support USB 2.0 to provide important storage and security functions. For example,

with USB interfaces, you can provide large flash memory space for application programs, configuration

files, and VPN certificates for setting up secure VPN connections and, secure distribution of

configuration files.

In addition, USB interfaces provide a backup CF card mechanism to make file backup and restoration

easy and reliable.

Figure 1-13 USB interface

The USB interface provided by a U200 series device is a USB 2.0 type-A interface. Serving as a host, it

can connect an external USB device to expand the device's storage space for storing files and logs and

in addition, facilitate file transfer.

1-12

Page 19

z At present, the USB interface provided on a U200 series device is a reserved module without

software support.

z Use the USB flash drives provided by H3C only, because the U200 series may be incompatible

with other USB flash drives.

z Avoid removing the USB flash drive when its LED is flashing. Doing so may cause the file system

on the drive to get corrupted.

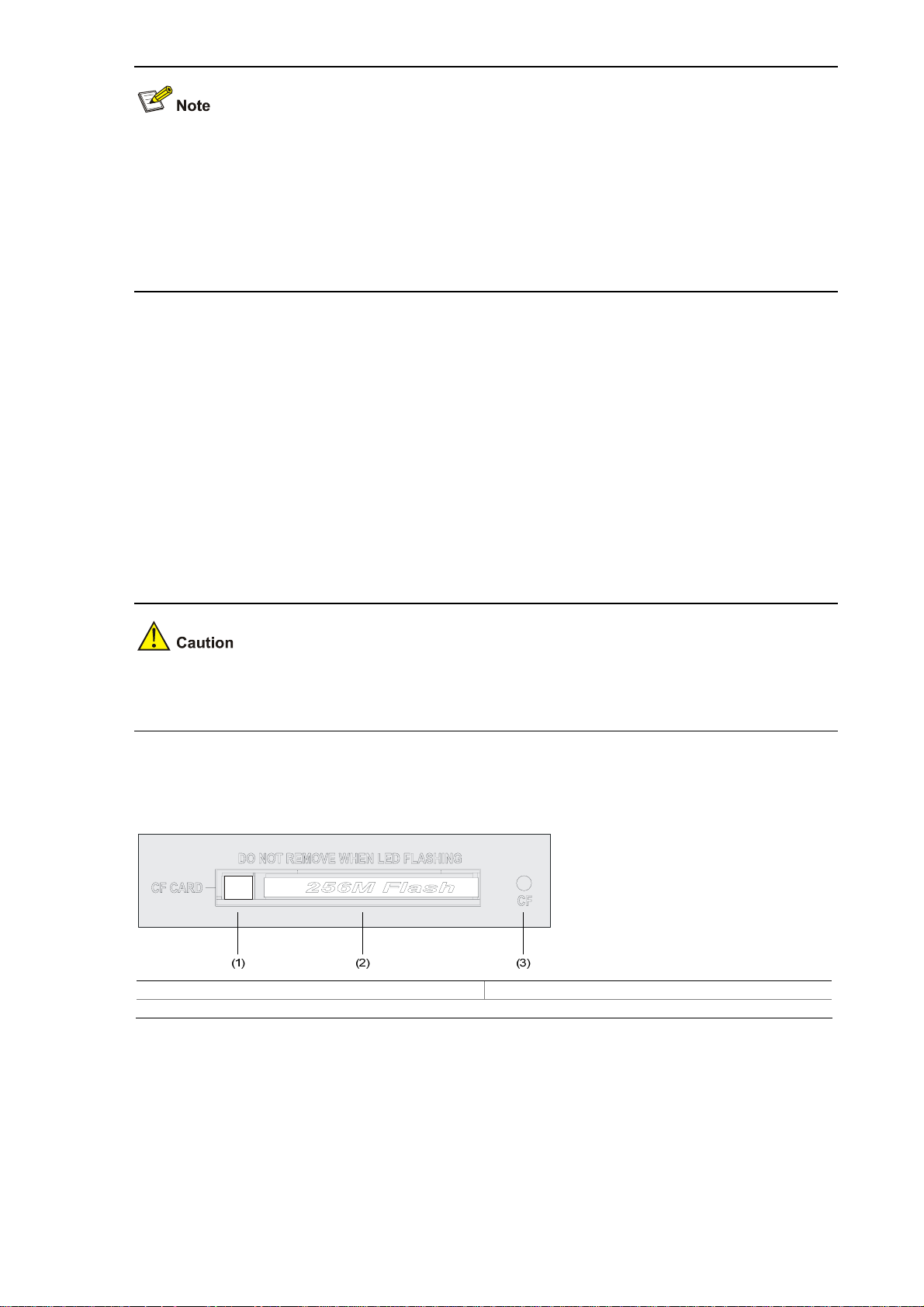

CF card

1) Introduction

A compact flash (CF) card is used for storing logs, host files, and configuration files.

A U200 series device provides an external CF card slot for expanding storage space.

Three CF card options of different memory sizes are available:

z 256 MB

z 512 MB

z 1 GB

Use the CF cards provided by H3C only, because the U200 series may be incompatible with other CF

cards.

2) CF card slot

Figure 1-14 CF card

(1) Ejector button (2) CF card slot

(3) CF card LED (CF)

3) CF card LED

For description of the CF card LED, see

Table 1-6.

1-13

Page 20

The CF card is hot-swappable. When the device is reading from or writing to the CF card or performing

any other file system related operation, the CF card LED blinks. Do not unplug the CF card in this state

because doing so can corrupt the file system in it.

AC Power Input

Table 1-14 lists the AC power specifications for the U200 series.

Table 1-14 AC power specifications

Clock

Item

Description

U200-A U200-M U200-S

Rated voltage range

Maximum input current

Maximum power

100 VAC to 240 VAC; 50 Hz or 60 Hz

1.6 A

100 W 54 W

0.6 A

The U200 series are designed with a clock module for providing system time. You can set the system

time at the command line interface.

The clock module can work despite power failure to ensure that the system time is correct at reboot.

With the device powered off, the clock module can work for at least 10 years.

Note that:

z Never replace the clock module battery when power is present on the device.

z The system time gets lost once the clock module battery is removed. You can set it at the

command line interface.

You can use three commands including clock datetime, ock summer-time one-off (or clock

summer-time repeating), and clock timezone to complete setting the system time. See the

accompanying documentation for how to do that.

Port Lightning Arrester (Optional)

Before connecting an outdoor Ethernet cable to an Ethernet port, install a port lightning arrester to

protect the device against lightning strikes.

The port lightning arresters available for the U200 series feature these:

1-14

Page 21

z For single-port use, maximum discharge current (8/20μs waveform): 5 kA, output voltage

(10/700μs waveform): core-core < 40 V, core-ground < 600 V.

For the installation of the port lightning arrester, refer to the “Installing a Port Lightning Arrester” section

in Chapter 4 “Installing the U200 Series Device.”

Power Lightning Arrester (Optional)

Before connecting an outdoor AC power cable to the device directly, you can connect the AC power

input to a lightning protection busbar to protect the device against lightning strikes. In a heavy lightning

area, you are recommended to install a power lightning arrester.

The lightning arresters available for the U200 series feature these:

z Maximum discharge current of 6500 A, protection for 500 VAC to 220 VAC.

For how to install a power lightning arrester, refer to the “Installing a Power Lightning Arrester

(Optional)” section in Chapter 4 “Installing the U200 Series Device.”

Signal Lightning Arrester (Optional)

Generally, you need to install a signal lightning arrester between a signal cable and the connected

device. This can protect electronic components against surge over-voltage resulting from lightning

strikes or any other interferences, and minimize the impact on the system.

The following are specifications of the three signal lightning arrester options available for the U200

series:

z Maximum discharge current 2.5KA/protection voltage 25V-SMB-75J/SMB-75J-1W-10Mbps.

z Maximum discharge current 2.5KA/protection voltage 25V-BNC-75K/BNC-75K-10MBit/s.

z For U-shape ports, maximum discharge current 3KA/common mode 400 V/differential mode

170V-RJ11

For how to install a signal lightning arrester, refer to the “Installing a Signal Lightning Arrester” section in

Chapter 4 “Installing the U200 Series Device.“

1-15

Page 22

System Software

The U200 series operate on the H3C Comware V5 or i-Ware software platform, integrating a rich set of

security features including virtual firewall, attack prevention, load balancing, and P2P traffic

management. Combining network and security technologies perfectly, the series can be deployed in

various complex network environments to provide strong security protection.

1-16

Page 23

Table of Contents

2 Interface Cards and Interface Modules ···································································································2-1

2GE Module ············································································································································2-1

NSQ1GT2UA0 Module····························································································································2-3

NSQ1GP4U0 Module······························································································································2-4

NSQ1WLAN0 Module ·····························································································································2-6

Arranging Slots and Naming Interfaces ··································································································2-7

Slot Arrangement·····························································································································2-7

Naming Interfaces ···························································································································2-7

Examples·········································································································································2-7

i

Page 24

2 Interface Cards and Interface Modules

z Currently, the U200 series do not support hot-swapping of interface modules.

z With the hot swapping feature, you can remove an interface module after stopping it with the

remove slot number command and then replacing the interface module or plugging in a new

interface module as needed without powering off the device.

z Currently the 2GE and NSQ1GT2UA0 interface modules are not available yet.

2GE Module

Introduction

The 2GE module is a mini high-speed Layer 3 Gigabit Ethernet interface module. The 2GE module

provides two RJ-45 electrical interfaces that support the Layer 3 routing function. Each interface on the

2GE module is available with a link LED and an activity LED for monitoring the link status and data

transmission status. The 2GE module is connected to the processor through a 10-Gbps high-speed bus

and can provide all functions of Layer 3 Ethernet interfaces with high performance.

Front view

Figure 2-1 2GE front view

(1) Captive screw (2) GE interface 0

(3) Link LED (LINK) of GE interface 0 (4) GE interface 1

(5) Link LED (LINK) of GE interface 1

(7) Data transmit/receive activity LED of GE interface 0 (ACT)

(6) Data transmit/receive activity LED of GE interface 1

(ACT)

2-1

Page 25

LEDs

Table 2-1 Description of the LEDs on the front panel of the 2GE module

LED Status Description

LINK

Off No link is present.

On

Off No data is being transmitted or received.

ACT

Blinking Data is being transmitted or received.

Interface specifications

Table 2-2 Interface specifications of 2GE

Item Description

Connector type

Number of interfaces

Interface standards

RJ-45

2

802.3, 802.3u, 802.3ab

Autosensing

Interface type

When working in the forced mode, Ethernet does not support

MDI/MDIX autosensing.

Frame formats

Ethernet_II

Ethernet_SNAP

A link is present.

Maximum transmission

distance

Rate and negotiation mode

100 m (328.08 ft.) over category-5 twisted pairs

10 Mbps (autosensing)

100 Mbps (autosensing)

1000 Mbps (autosensing)

Half-/full-duplex auto-negotiation

Half-/full-duplex auto-negotiation

Full-duplex auto-negotiation

Interface cable

The 2GE module uses a straight-through or crossover Ethernet cable for connection.

Figure 2-2 Ethernet cable

RJ-45

Connector

RJ-45

Connector

A

1

A

8

2-2

Page 26

For how to connect the Ethernet cable, refer to the “Connecting an Ethernet cable for the 2GE module”

section in Chapter 4 “Installing the U200 Series Device.”

NSQ1GT2UA0 Module

Introduction

The NSQ1GT2UA0 module is a MIM high-speed Layer 3 Gigabit Ethernet interface module. The

module provides two RJ-45 electrical interfaces that support the Layer-3 routing function. Each

interface on the NSQ1GT2UA0 module is available with a link LED and an activity LED for monitoring

the link status and data transmission status. The NSQ1GT2UA0 module is connected to the processor

through a PCIE high-speed bus to provide all functions of a Layer-3 Ethernet interface with high

performance.

Front view

Figure 2-3 NSQ1GT2UA0 front view

(1) (2) (5)

(3)

(4)

(6)

(7)

(1) Captive screw (2) GE interface 0

(3) Link LED (LINK) of GE interface 0

(4) Data transmit/receive activity LED (ACT) of GE

interface 0

(5) GE interface 1 (6) Link LED (LINK) of GE interface 1

(7) Data transmit/receive activity LED (ACT) of GE interface 1

LEDs

See Table 2-1.

Interface specifications

See Table 2-2.

Interface cable

See Figure 2-2.

2-3

Page 27

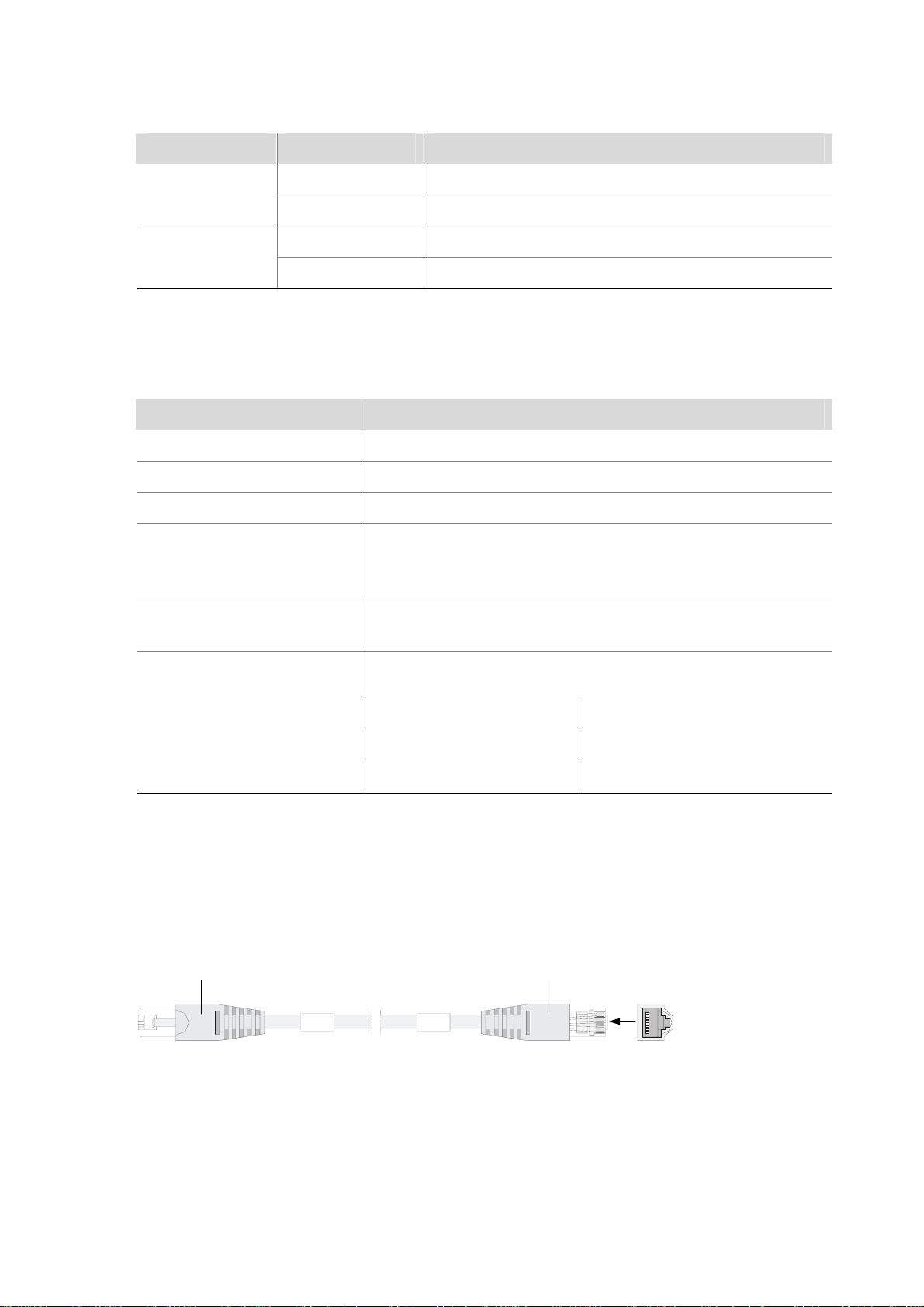

NSQ1GP4U0 Module

Introduction

The NSQ1GP4U0 module is a high-speed Layer 3 Gigabit Ethernet interface module. The module

provides four SFP optical interfaces that support the Layer-3 routing function. Each interface on the

NSQ1GP4U0 module is available with an LED indicating its status. The NSQ1GP4U0 module is

connected to the processor through a PCIE high-speed bus to provide all functions of a Layer-3

Ethernet interface with high performance.

Front view

Figure 2-4 NSQ1GP4U0 front view

(1) Captive screw (2) LINK/ACT LED

(3) SFP interface

LEDs

Table 2-3 Description of LEDs on the front panel of NSQ1GP4U0

LED Status Meaning

Off No link is present on the interface.

LINK/ACT

(Green)

On A 1000 Mbps link is present on the SFP interface.

Blinking The SFP interface is transmitting or receiving data at 1000 Mbps.

Interface specifications

Table 2-4 Interface specifications of NSQ1GP4U0

Item Specification

Connector type SFP/LC

Number of

interfaces

Interface standards

Interface speed 1000 Mbps

4

802.3, 802.3u, and 802.3ab

Ethernet_II

Ethernet_SNAP

2-4

Page 28

Item Specification

Single-mode

ultra-long

haul

Optical

Type

Multi-mode

short haul

Single-mode

medium haul

Long haul

(1310 nm)

Long haul

(1550 nm)

transmit

power

Min. –9.5 dBm –9 dBm –2 dBm –4 dBm –4 dBm

Max. 0 dBm –3 dBm 5 dBm 1 dBm 2 dBm

Receiving

sensitivity

–17 dBm –20 dBm –23 dBm –21 dBm –22 dBm

Central wavelength 850 nm 1310 nm 1310 nm 1550 nm 1550 nm

Max. transmission

distance

Fiber type

0.55 km

(0.34 miles)

62.5/125 μm

multi-mode

10 km (6.21

miles)

9/125 μm

single-mode

40 km (24.86

miles)

9/125 μm

single-mode

40 km (24.86

miles)

9/125 μm

single-mode

70 km (43.50

miles)

9/125 μm

single-mode

Interface cable

z The NSQ1GP4U0 module can work with SFP optical transceivers using optical fibers with LC-type

connectors.

Figure 2-5 and Figure 2-6 show an SFP optical transceiver and an optical fiber with LC-type connectors

respectively.

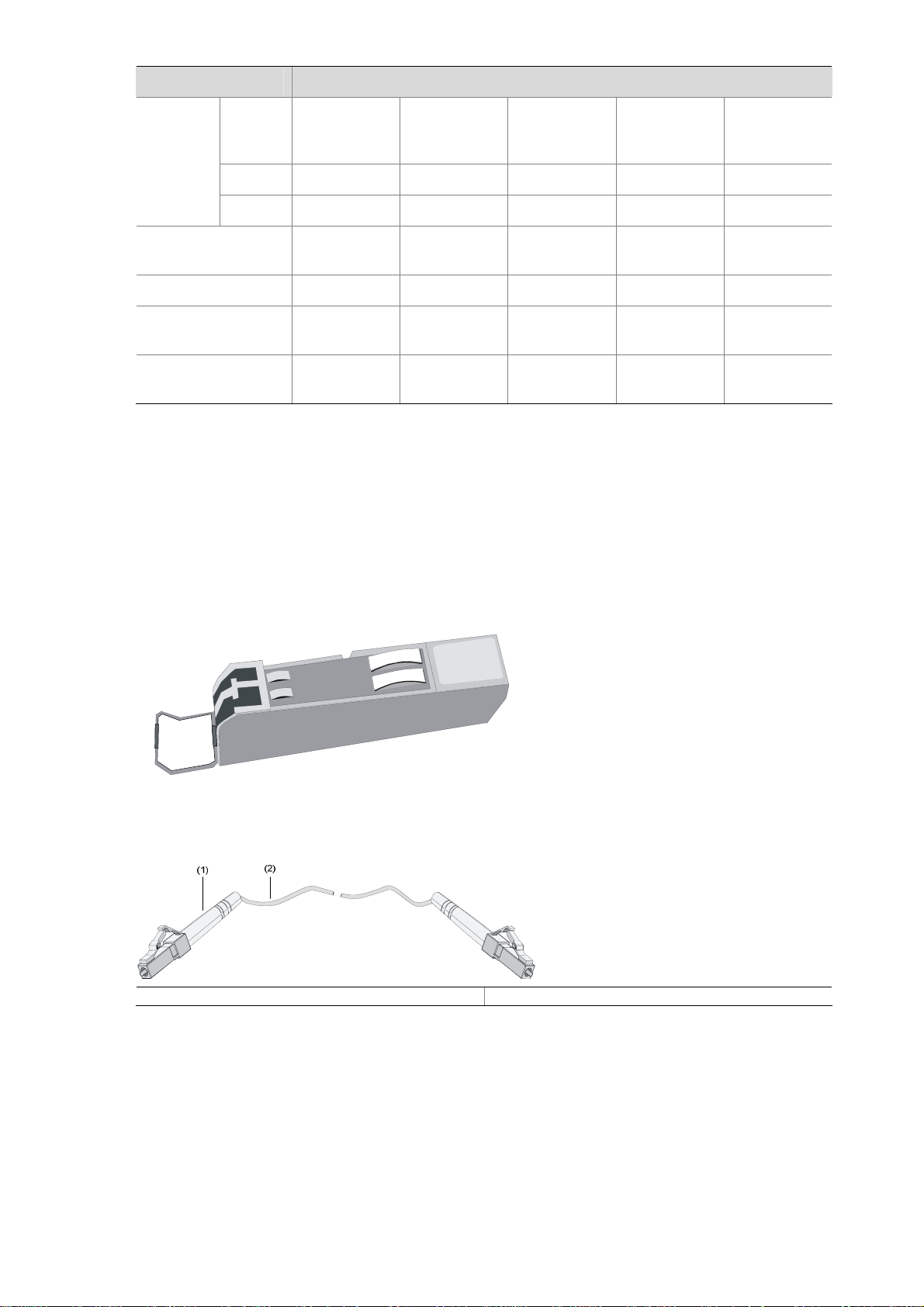

Figure 2-5 SFP optical transceiver

Figure 2-6 Optical fiber with LC connectors

(1) LC-type connector (2) Optical fiber

z The NSQ1GP4U0 module can work with optical-to-electrical SFP modules using straight-through

or crossover Ethernet cables. See

Figure 2-2.

2-5

Page 29

For how to connect the interface cable for the NSQ1GP4U0 module, refer to “Connecting an optical

fiber or Ethernet cable to the NSQ1GP4U0 module" in Chapter 4 “Installing the U200 Series Device.”

NSQ1WLAN0 Module

Introduction

The NSQ1WLAN0 module is an 802.11a/b/g mini WLAN interface module that supports the Layer-3

routing function. The NSQ1WLAN0 module is connected to the processor through a 10-Gbps

high-speed bus to provide all functions of a Layer-3 Ethernet interface with high performance.

Front view

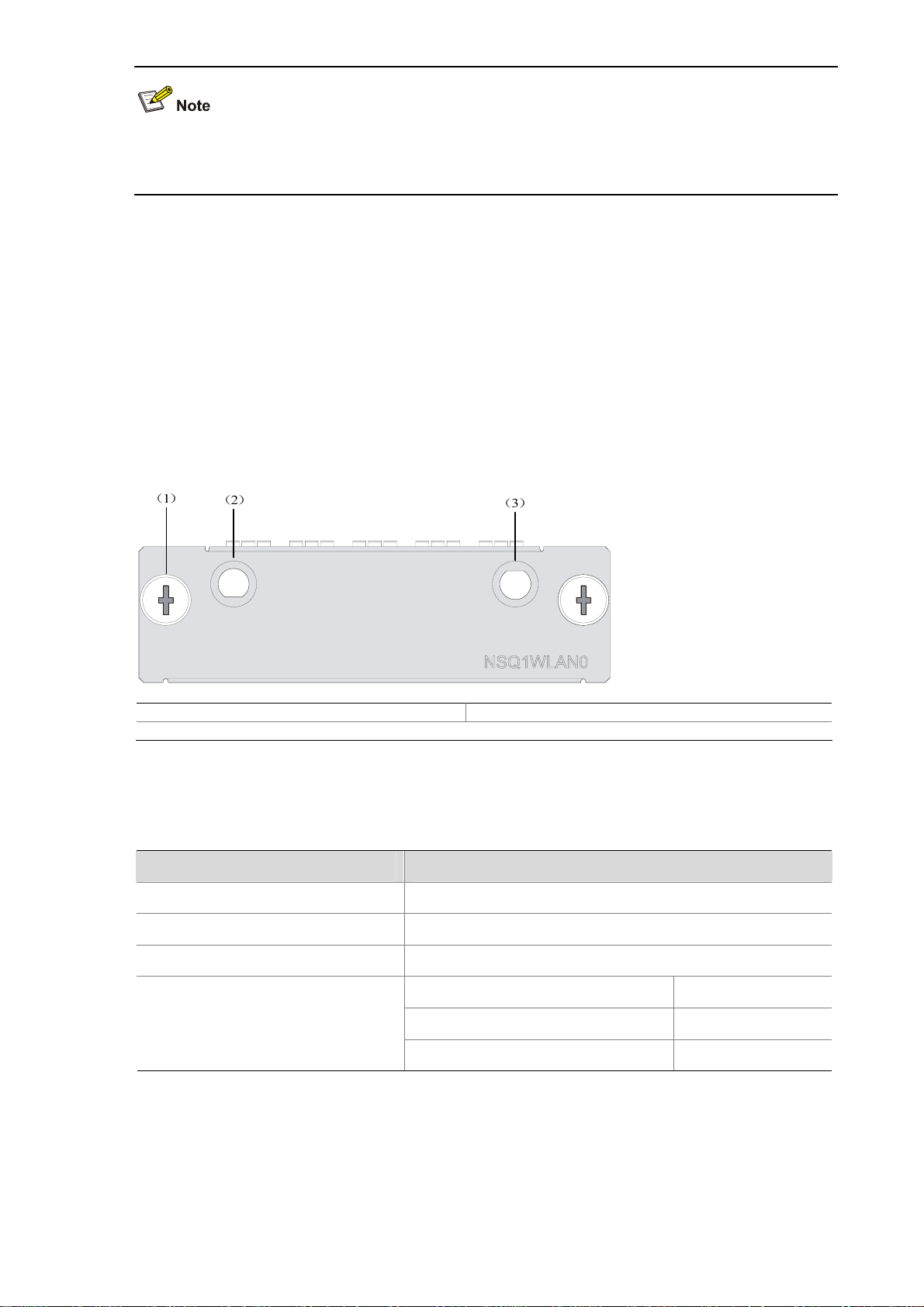

Figure 2-7 NSQ1WLAN0 front view

(1) Captive screw (2) Auxiliary antenna interface

(3) Main antenna interface

Interface specifications

Table 2-5 Interface specifications of NSQ1GP4U0

Item Specification

Interface type Antenna interface (2.4 GHz or 5 GHz)

Number of interfaces 1

Interface standards IEEE 802.11a, IEEE 802.11b, IEEE 802.11g

6, 9, 12, 18, 24, 36, 48, 54 MHz 802.11a

Interface speed and negotiation

mode

1, 2, 5.5, 11 MHz 802.11b

6, 9, 12, 18, 24, 36, 48, 54 MHz 802.11g

Interface cable

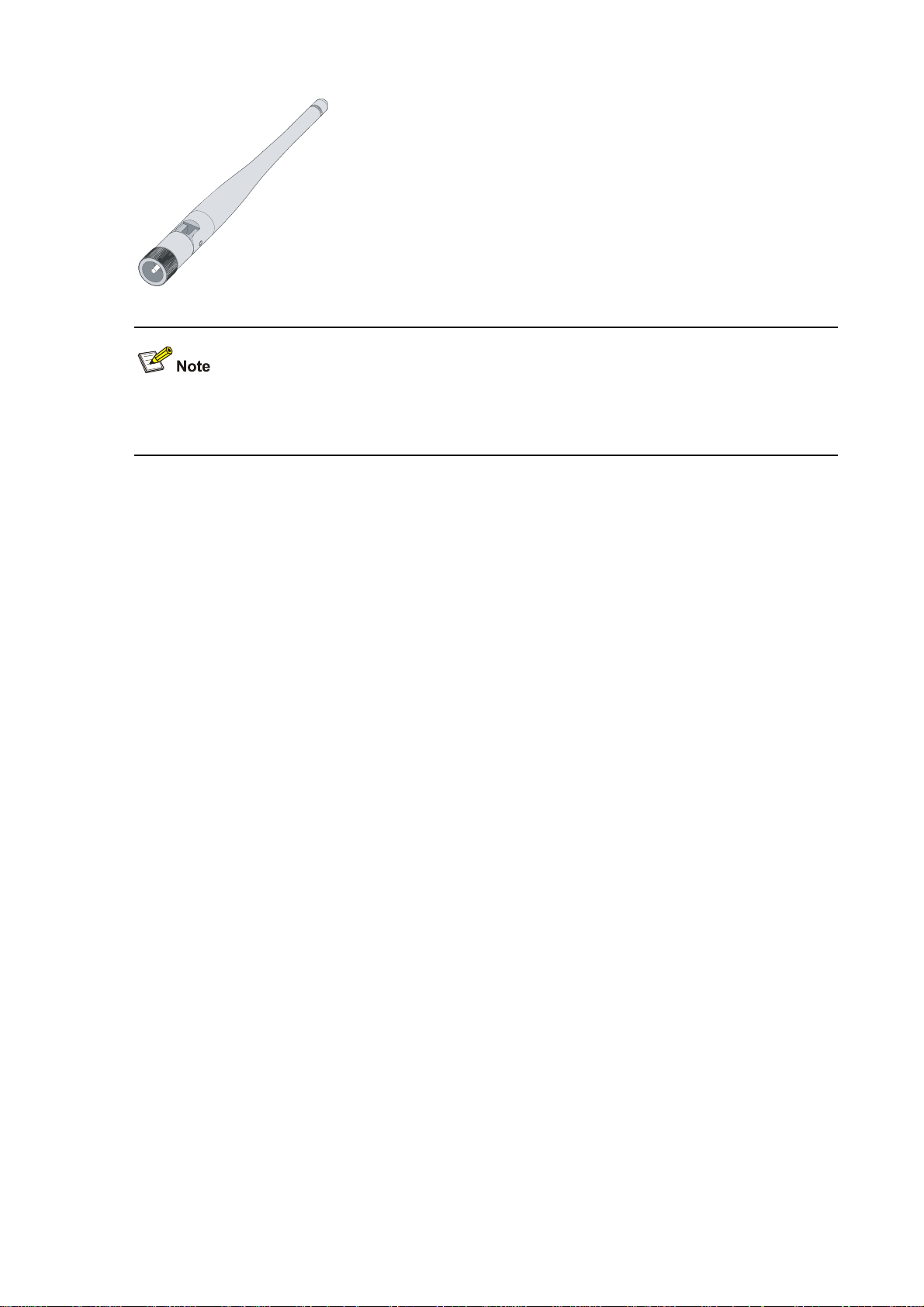

The antenna interface of the NSQ1WLAN0 module supports 2.4 GHz and 5 GHz dual-frequency omni

antennas.

2-6

Page 30

Figure 2-8 Omni antenna for the NSQ1WLAN0 module

For how to connect the antenna for the NSQ1WLAN0 module, refer to “Connecting an antenna for the

NSQ1WLAN0 module” in Chapter 4 “Installing the U200 Series Device.”

Arranging Slots and Naming Interfaces

Slot Arrangement

The U200 series support interfaces such as console, AUX, Gigabit Ethernet, and WLAN interfaces. This

section describes how these interfaces are numbered.

Naming Interfaces

The interfaces on a U200 series device are named following these conventions:

1) An interface is named in the form of interface-type X/Y, where

z interface-type represents the type of the interface, such as GigabitEthernet.

z X represents the number of the slot in which the interface module is inserted.

z Y represents the number of the interface on the interface module.

2) The interfaces on the same interface module uses the same slot number X.

3) The interfaces of the same type on an interface module are numbered starting with 0 for Y from left

to right.

Examples

1) The five fixed GigabitEthernet interfaces on the U200-S are named as follows:

z GigabitEthernet 0/0

z GigabitEthernet 0/1

z GigabitEthernet 0/2

z GigabitEthernet 0/3

z GigabitEthernet 0/4

2) If a 2GE module is installed on the U200-S, the GigabitEthernet interfaces on the 2GE module are

numbered as follows:

z GigabitEthernet 1/0

z GigabitEthernet 1/1

2-7

Page 31

3) If an NSQ1WLAN0 module is installed on the U200-S, the WLAN interface on the module is named

as follows:

z Wlan Radio 1/0

2-8

Page 32

Table of Contents

3 Preparing for Installation ··························································································································3-1

Environment Requirements ····················································································································3-1

Ventilation Requirements ················································································································3-1

Temperature and Humidity Requirements ······················································································3-1

Cleanness Requirements ················································································································3-2

Electrostatic Discharge Prevention ·································································································3-2

Electromagnetic Interference Prevention ························································································3-3

Lightning Protection·························································································································3-4

Workbench Requirements···············································································································3-4

Rack-Mounting Requirements·········································································································3-4

Safety Precautions ··································································································································3-4

Safety Signs ····································································································································3-4

General Safety Recommendations ·································································································3-5

Electricity Safety ······························································································································3-5

Installation Tools, Meters and Devices ···································································································3-5

Installation Accessories Supplied with a U200 Series Device ························································3-5

User supplied tools ··························································································································3-5

Reference ········································································································································3-5

Checklist Before Installation····················································································································3-6

i

Page 33

3 Preparing for Installation

Environment Requirements

The U200 series are designed for indoor use. To ensure normal operation and prolong service life of the

U200 series devices, the installation site must meet the requirements described in this chapter.

Ventilation Requirements

The fans of a U200 series device draw air in through the inlet vents on the left and out through the

exhaust vents on the right. Take the U200-S as an example.

Figure 3-1 Air flow design of the U200 series

Make sure that:

There is at least 10 cm (3.94 in.) of clearance around the air intake and the air exhaust for heat

dissipation of the chassis.

A ventilation system is available at the installation site.

Temperature and Humidity Requirements

The equipment room must maintain proper humidity to prevent poor insulation, electricity creepage and

corrosion accompanying high humidity, and to prevent washer contraction and electrostatic discharge

accompanying low humidity. In dry environments where relative humidity is very low, electrostatic

discharge (ESD) is more likely to happen causing the complementary metal-oxide-semiconductor

(CMOS) circuitry to fail.

A proper temperature condition must also be maintained to prevent premature material aging and

degraded reliability accompanying high temperature conditions.

Table 3-1 lists the temperature and humidity requirements.

Table 3-1 Temperature and humidity requirements in the equipment room

Temperature Relative humidity

0°C to 45°C (32°F to 113°F) 10% to 95% (noncondensing)

3-1

Page 34

Cleanness Requirements

Dust concentration limits

Dust is hazardous to the operating safety of devices. Dust buildup on chassis may result in static

absorption, causing poor contact of metal components or points. When indoor humidity is extremely low,

this is more likely to happen, shortening the useful life of the devices and causing communication

failures.

Table 3-2 lists the dust concentration limits in the equipment room.

Table 3-2 Dust concentration limits in the equipment room

Diameter (μm) 0.5 1 3 5

Concentration

limit (particles/m

3

)

1.4 × 10

7

7 × 105 2.4 × 105 1.3 × 105

Harmful gas concentration limits

Besides, the equipment room should meet the rigorous limits on salt, acid and sulfide to eliminate

corrosion and premature aging of some parts, as shown

Table 3-3 Harmful gas concentration limits

Gas Max (mg/m3)

SO2 0.2

H2S 0.006

NH3 0.05

Cl2 0.01

Electrostatic Discharge Prevention

Table 3-3.

Sources and damages of static electricity

By design, a U200 series device is ESD preventative; but excessive buildup of static electricity can still

damage the card circuitry and even the entire device.

On the communication network connected to a U200 series device, static electricity is primarily

introduced from the outside electrical fields, such as the outdoor high-voltage power cabling and

lightning, and from the inside system, such as the indoor environment, floor materials and the chassis

frame.

Measures against ESD

To protect your device against electrostatic discharge (ESD), follow these guidelines:

Ensure that the device and the floor are well grounded.

Ensure that he equipment room is as dust free as possible.

Maintain adequate humidity and temperature.

Wear an ESD-preventive wrist strap and clothes before touching a circuit board.

Place removed cards (mini interface cards, MIM modules, or CF cards) upward on an antistatic

workbench or into a static shielded bag.

3-2

Page 35

Hold a card, module, or circuit board by its edges when observing or moving it, avoiding direct

contact with the components on it.

Use of an ESD-preventive wrist strap

Follow these steps to wear an ESD-preventive wrist strap:

Step1 Put the ESD-preventive wrist strap around your wrist.

Step2 Tighten the fastener to ensure good skin contact.

Step3 Attach the alligator clip to the ESD-preventive wrist strap.

Step4 Attach the alligator clip to the rack.

Step5 Make sure that the rack is well grounded.

Figure 3-2 Wear an ESD-preventive wrist strap

(1) ESD-preventive wrist strap (2) Fastener

(3) Alligator clip

For the sake of safety, check the resistance of the ESD-preventive wrist strap. The resistance

reading should be in the range of 1 to 10 megohms between human body and the ground.

The U200 series are not delivered with ESD-preventive wrist straps. Make sure that an

ESD-preventive wrist strap is available yourself.

Electromagnetic Interference Prevention

All interference sources, external or internal, adversely affect the device in the way of capacitance

coupling, inductance coupling, electromagnetic radiation, or common impedance (including the

grounding system) coupling. To minimize the impact of interference on the device, follow these

guidelines:

Take effective measures against interference from the power grid.

Separate the protection ground of the device from the grounding device or lightning protection

grounding device of the power supply equipment as far as possible.

3-3

Page 36

Keep the device far away from radio stations, radar, and high-frequency devices working at high

current.

Use electromagnetic shielding when necessary.

Lightning Protection

By design, a U200 series device is lightning protective, but excessive lightning may still damage the

device. To protect the device better, follow these guidelines:

Ensure the PGND cable of the chassis is well grounded.

Ensure the earth point of the power socket is securely connected to the earth ground.

Install a lightning arrester at the input end of the power supply to enhance the lightning protection

capability of the power supply.

To enhance lightning protection, install a special lightning arrester at the input end of outdoor signal

lines to which interface modules of the device are connected.

For how to connect the PGND cable and install a power lightning arrester or signal lightning arrester,

refer to Chapter 4 “Installing the U200 Series Device.”

Workbench Requirements

When installing the device on a workbench, make sure that:

The workbench is sturdy enough to support the weight of the device and installation accessories.

The workbench is well grounded.

Rack-Mounting Requirements

When installing the device in a rack, follow these guidelines:

Install the device in an open rack if possible. If you install the device in a closed cabinet, make sure

that the cabinet has a good ventilation system.

Make sure that the rack is sturdy enough to support the weight of the device and installation

accessories.

Make sure that the size of the rack is appropriate for the device, and that there is enough clearance

around the left and right panels of the device for heat dissipation.

For the sake of heat dissipation and device maintenance, it is recommended that the front and rear

of the rack be at least 0.8 m (31.50 in.) away from walls or other devices, and that the headroom in

the equipment room should be no less than 3 m (9.84 ft.).

Safety Precautions

Safety Signs

When reading this manual, pay attention to the following:

3-4

Page 37

Means the reader be extremely careful. Improper operation may cause device damage

or bodily injury.

Means the reader be careful. Improper operation may cause device malfunction.

General Safety Recommendations

Keep the device and installation tools away from walk area.

Keep the device far away from a moist area and heat sources.

Unplug all external cables before moving the device.

Electricity Safety

Locate the emergency power switch in the equipment room before installation and maintenance so

that you can switch power off quickly in case of an electrical accident. If necessary, unplug the

power cord immediately.

Make sure that the device chassis is correctly grounded.

Do not open or close the chassis cover when power is present.

Do not remove power cables or interface modules when power is present.

Connect the interface cables correctly.

Use an uninterrupted power supply (UPS).

When powering off the device, double check to make sure the device is powered off.

Avoid maintaining the device alone when power is present.

Installation Tools, Meters and Devices

Installation Accessories Supplied with a U200 Series Device

AC power cord

Console cable

PGND cable

Left and right front mounting brackets

User supplied tools

Phillips screwdrivers: P1-100 mm, P2-150 mm, and P3-250 mm

Flat-blade screwdriver: P4-75 mm

Screws of various sizes

Meters and devices, such as hubs, configuration terminal, optional modules or cards, multimeter

Optional cables

ESD-preventive gloves, ESD-preventive wrist straps, antistatic bags or mats

Reference

When installing or maintaining a U200 series device, you can refer to the documentation shipped with

the device or at the H3C documentation center at http://www.h3c.com. The documentation includes

H3C SecPath U200 Series Unified Threat Management Products Installation Manual.

3-5

Page 38

Checklist Before Installation

Before you proceed to install your device, check that all requirements listed in Table 3-4 are met and you

are aware of all listed operation requirements.

Table 3-4 Checklist before installation

Item Requirements

Installation

site

At least 10 cm (3.94 in.) of clearance is reserved around

the inlet vents and exhaust vents for heat dissipation of

Ventilation

the device chassis.

The ventilation system at the installation site is

adequate.

Temperature 0°C to 45°C (32°F to 113°F)

Relative humidity

(noncondensing)

10% to 95%

Cleanness Dust concentration ≤ 3 × 104 particles/m3

The equipment and the floor are well grounded.

The equipment room is as dust free as possible.

Appropriate humidity and temperature are maintained.

Wear an ESD-preventive wrist strap or clothes when

ESD prevention

working with a circuit board.

Place a removed mini interface module, CF card, or

MIM upward on an antistatic workbench or put it away

in an antistatic bag.

Hold a card, module, or circuit board by its edges,

avoiding touching the electronic components on it.

Take effective measures against interference from the

power grid.

Separate the protection ground of the device from the

EMI prevention

grounding device or lightning protection grounding

device as far as possible.

Keep the device far away from radio stations, radar,

and high-frequency devices working at high current.

Use electromagnetic shielding when necessary.

The PGND cable of the chassis is well grounded.

The earth point of the power socket is securely

connected to the earth ground.

Port lightning arresters are installed as necessary.

Lightning protection

(Optional)

A power lightning arrester is installed as necessary.

(Optional)

Signal lightning arresters are installed at the input ends

of external signal cables as necessary. (Optional)

Use of an uninterrupted power supply (UPS) is

recommended.

Electricity safety

Locate the emergency power switch in the equipment

room before installation and maintenance so that you

can switch power off quickly in case of an electrical

accident.

The workbench is sturdy enough to support the weight

Workbench

of the device and installation accessories.

The workbench is well grounded.

3-6

Page 39

Item Requirements

Install the device in an open rack if possible. If you

install the device in a closed cabinet, make sure that the

cabinet has a good ventilation system.

Rack-mounting

requirements

The rack is sturdy enough to support the weight of the

device and installation accessories.

The size of the rack is appropriate for the device.

The front and rear of the rack are at least 0.8 m (31.50

in.) away from walls or other devices.

Safety

precautions

Tools

Reference

The device is far away from moist areas and heat sources.

You have identified the emergency power switch in the equipment room.

Installation accessories supplied with the device are complete and in good

condition.

User-supplied tools are available.

Documentation shipped with the device is complete.

You have access to the online documentation.

3-7

Page 40

Table of Contents

4 Installing the UTM Device·························································································································4-1

Preparations············································································································································4-1

Installation Flowchart ······························································································································4-1

Mounting a U200 Series Device ·············································································································4-1

Mounting a U200 Series Device on a Workbench ··········································································4-1

Rack-Mounting a U200 Series Device ····························································································4-2

Installing Generic Modules······················································································································4-4

PGND Cable Connection ························································································································4-4

Importance of PGND Cable Connection ·························································································4-4

Connecting the PGND Cable ··········································································································4-4

Installing a Port Lightning Arrester (Optional)·························································································4-6

Tools Required ································································································································4-6

Installation Procedure······················································································································4-6

Precautions······································································································································4-7

Installing a Power Lightning Arrester (Lightning Protection Busbar) (Optional) ·····································4-7

Selecting and Installing a Signal Lightning Arrester (Optional)·······························································4-8

Connecting the Power Cable ··················································································································4-9

Power Supply Port and PGND Terminal ·························································································4-9

Connecting the AC Power Cord ····································································································4-10

Connecting Interface Cables·················································································································4-11

Connecting the Console Cable······································································································4-11

Connecting Ethernet Cables ·········································································································4-12

Connecting an Ethernet Cable to the 2GE Module ·······································································4-12

Connecting an Ethernet Cable to the NSQ1GT2UA0 Module ······················································4-13

Connecting an SFP Module in the NSQ1GP4U0 Module ·····························································4-13

Connecting an Antenna for the NSQ1WLAN0 Module ·································································4-14

Verifying Installation······························································································································4-14

i

Page 41

4 Installing the UTM Device

Preparations

Before installing the device, make sure that:

z You have read through Chapter 3 “Preparing for Installation.”

z All the requirements mentioned in Chapter 3 “Preparing for Installation” are satisfied.

Installation Flowchart

Figure 4-1 Installation flowchart

Mounting a U200 Series Device

You can mount a U200 series device on a workbench or in a rack.

Mounting a U200 Series Device on a Workbench

If a 19-inch rack is not available, you can mount a U200 series device on a clean workbench. During

installation, make sure:

4-1

Page 42

z Length and width of the workbench are larger than the distance between the feet of the device. See

Table 4-1 for the dimensions of the U200 series devices.

Table 4-1 Dimensions of the U200 series devices

Item

U200-A U200-M U200-S

Dimensions without

feet or rack-mounting

brackets (H × W × D)

44.2 × 442 × 400 mm (1.74 × 17.40 × 15.75

in.)

Make sure that:

z The workbench is steady and well grounded.

z The workbench is sturdy enough to support the weight of the device and installation accessories.

z There is at least 10 cm (3.94 in.) of clearance around the device for heat dissipation.

z No heavy object is placed on the device for fear of device damage and poor heat dissipation.

Rack-Mounting a U200 Series Device

Installing an N68 rack

A U200 series device can be installed in an H3C N68 rack. For how to install an N68 rack, see N68

Cabinet Installation Guide.

Attaching rack-mounting brackets onto the device

Description

43.6 × 300 × 260 mm (1.72

× 11.81 × 10.24 in.)

The rack-mounting brackets for the U200-S are different from those used for the U200-A and the

U200-M as shown in

Figure 4-2 and Figure 4-3.

Figure 4-2 Rack-mounting brackets for the U200-S

(1) Left front rack-mounting bracket (2) Right front rack-mounting bracket

4-2

Page 43

Figure 4-3 Rack-mounting brackets for the U200-A/U200-M

(1) Left front rack-mounting bracket (2) Right front rack-mounting bracket

Before mounting the device in a rack, attach the rack-mounting brackets securely to the left and right

front sides of the device, the U200-S for example, as shown in

Figure 4-4.

Figure 4-4 Attach front rack-mounting brackets to the U200-S

Mounting the device in a rack

Follow these steps to mount the device in a rack:

Step1 Check that the rack is well grounded and steady.

Step2 Fix the device in the rack horizontally and securely by fastening the mounting brackets onto the front

rack posts with pan-head screws. The size of the pan-head screws should satisfy the installation

requirements (maximally M6) and the surfaces of the screws should be anti-rust treated.

Take the U200-S for example:

4-3

Page 44

Figure 4-5 Mount the device in the rack

Installing Generic Modules

Generic modules include CF card, mini interface cards and MIM modules. For their installation

procedures, see Chapter 7 “Maintaining Hardware.”

PGND Cable Connection

Importance of PGND Cable Connection

Correct connection of the protection ground (PGND) on the device chassis is an essential safeguard

against lightning strikes and EMI. You need to correctly connect the PGND cable when installing or

using the device.

The power input end of a U200 series device is equipped with a noise filter. The neutral ground of the

power input end is directly connected to the chassis and is called PGND (also called the chassis

ground). You need to securely connect the PGND cable to the earth ground to safely lead induced

current and leakage current to the ground and reduce the EMS of the device. The PGND cable can also

protect the device against high lightning voltage induced from external network lines.

Connecting the PGND Cable

The grounding screw of a U200 series device is located on the rear chassis panel and is marked with a

grounding symbol, as shown in

Figure 4-6.

4-4

Page 45

Figure 4-6 Connect the PGND cable

(1) Grounding screw hole (2) OT terminal

(3) Grounding screw (4) PGND cable

(5) Grounding symbol

Follow these steps to connect the PGND cable, taking the U200-S for example:

Step1 Remove the grounding screw from the device chassis.

Step2 Put the supplied OT terminal of the PGND cable on the grounding screw.

Step3 Fasten the grounding screw, which is attached with the OT terminal of the PGND cable, into the

grounding screw hole with a screwdriver.

Step4 Connect the other end of the PGND cable to the ground. If no grounding bar is available, connect the

naked part of the PGND cable to the ground directly. If a grounding bar is available, connect the PGND

cable to the grounding bar as follows:

1) Use a cable stripper to strip off the insulation rubber about 15 mm (0.59 in.) from the PGND cable.

2) Wrap the naked part onto the grounding post of the grounding bar.

3) Fix the PGND cable onto the grounding post with a hex nut.

Figure 4-7 Connect the PGND cable to a grounding bar

(1) Hex nut (2) PGND cable

(3) Naked part of the PGND cable (4) Grounding post

(5) Grounding bar

z The resistance between the device chassis and the ground must be less than 5 ohms.

z Use the PGND cable provided with your U200 series device for effective chassis grounding.

Otherwise, the device may not be effectively grounded and thus be prone to damages.

4-5

Page 46

Installing a Port Lightning Arrester (Optional)

z You need to install lightning arresters only for 10/100 Mbps RJ-45 Ethernet ports.

z The U200 series devices are not shipped with lightning arresters for ports in case of standard

configuration. You can purchase one if needed.

Before connecting an outdoor Ethernet cable to an Ethernet port, install a port lightning arrester to

protect the device against lightning strikes.

The specifications of the port lightning arrester available for the U200 series are as follows:

z Single port

z Maximum discharge current (8/20μs waveform): 5 kA

z Output voltage (10/700μs waveform): core-core < 40 V, core-ground < 600 V

Tools Required

z Phillips or flat-blade screwdriver

z Multimeter

z Diagonal pliers

Installation Procedure

Follow these steps to install a port lightning arrester:

Step1 Use a double-faced adhesive tape to stick the port lightning arrester to the device. The port lightning

arrester should be as close to the grounding screw as possible.

Step2 Cut short the grounding cable of the port lightning arrester according to its distance to the grounding

screw. Then, fix the grounding cable onto the grounding screw of the device.

Step3 Use the multimeter to check the connection between the grounding cable of the port lightning arrester

and the grounding screw of the device.

Step4 Follow the instructions accompanying the lightning arrester to connect the lightning arrester with a

conversion cable. When doing that, connect the external cable to the IN end while the network

conversion cable to the OUT end. Check that the status of the LEDs on the connected interface module

is normal.

Read the instructions carefully before installing a port lightning arrester.

Step5 Bundle the cables with cable ties neatly.

4-6

Page 47

Figure 4-8 Install a port lightning arrester

Indoor Ethernet cables

Outdoor Ethernet cable

UTM device

Port lightning arrester

(stuck on the chassis)

Grounding cable of the

lightning arrester

Rack

Power input

Conversion cable

Grounding screw of the device

Precautions

To ensure the performance of a port lightning arrester, follow these guidelines:

z Correctly connect the IN and OUT ends of the port lightning arrester.

Connect the IN end to the external cable and the OUT end to the Ethernet port of the device.

z Ensure that the port lightning arrester is well grounded.

Make sure that the grounding cable of the port lightning arrester be as short as possible and be well

connected to the grounding screw of the device. You need to check with a multimeter after

connection.

z Install a lightning arrester for every port connected to an outdoor cable.

Installing a Power Lightning Arrester (Lightning Protection Busbar) (Optional)

The U200 series devices are not shipped with lightning arresters for power supplies. You can purchase

one if needed.

Before connecting an outdoor AC power source directly to the device, install a lightning protection

busbar at the AC power input end and then connect the AC power cord to a lightning protection busbar

to protect the device against lightning strikes. You can use cable ties and screws to fasten the lightning

protection busbar on the rack, the workbench, or the wall in the equipment room.

4-7

Page 48

Figure 4-9 Install a power lightning arrester

When connecting a power lightning arrester, follow these guidelines:

1) Make sure that the protection wire (PE) terminal of the power lightning arrester is well grounded

before using it.

2) After the AC power cord of the device is plugged into the multi-purpose socket of the power

lightning arrester (or a socket on a lightning protection busbar), check that the green LED is on and

the red LED is off to make sure that lightning protection can function normally.

3) If the red LED lights, identify the alarm cause and clear the alarm promptly. The red LED may light

because poor connection of the grounding cable or the live and zero wires are connected reversely.

To identify the alarm cause, you can use a multimeter to examine the polarity at the multi-purpose

socket of the power lightning arrester.

z If the live and zero wires are on the left and right respectively (supposing that you are facing the

socket), the PE terminal of the power lightning arrester is not grounded.

z If the live and zero wires are on the right and left respectively (supposing that you are facing the

socket), the polarity of the power socket of the power lightning arrester is reversed. In this case,

open the power socket to correct the polarity. If the red LED is still ON, you can determine that the

PE terminal of the power lightning arrester is not grounded.

Selecting and Installing a Signal Lightning Arrester (Optional)

The U200 series devices are not shipped with lightning arresters for signal components. You can

purchase one if needed.

Generally, before connecting a signal cable to a device, you need to connect the cable with a signal

lightning arrester to protect the device against transient overvoltage resulting from lightning strikes or

other interferences.

4-8

Page 49

Serially connected to a signal cable, a signal lightning arrester must satisfy the requirements of network

performance indexes such as data transmission bandwidth, as well as the lightning protection

performance requirement. Therefore, before installing a signal lightning arrester, you need to consider

such performance indexes of the lightning arrester as lightning protection, bandwidth, transmission loss,

and port type.

Three signal lightning arrester options are available for the U200 series. Their specifications are as

follows:

z Maximum discharge current 2.5KA/protection voltage 25V–SMB-75J/SMB-75J–1W–10Mbps

z Maximum discharge current 2.5KA/protection voltage 25V–BNC-75K/BNC-75K–10Mbps

z Use with U-shape ports, maximum discharge current 3KA/common-mode 400V/differential mode

170V–RJ-11

z The signal lightning arrester should be grounded as near as possible. The grounding resistance

must be less than 4 ohms. The grounding resistance must be less than 1 ohm if there are special

grounding requirements.

z Connect the grounding cable to the special-purpose grounding cable of the signal lightning arrester

and connect it to the earthing network, instead of connecting it to the lightning rod or lightning strip.

Connecting the Power Cable

Power Supply Port and PGND Terminal

A U200 series device only supports AC power input. The AC power socket and power switch are

located on the left of the front panel, as shown in

Figure 4-10 AC power socket of the U200-S

Figure 4-11 AC power socket of the U200-A/U200-M

Figure 4-10 and Figure 4-11.

For the specifications of the AC power socket, see

4-9

Table 4-2.

Page 50

Table 4-2 Technical specifications of the AC power socket

Item

Rated voltage range 100 VAC to 240 VAC, 50 Hz or 60 Hz

Maximum input current 2 A 1.5 A

Maximum power 100 W 54 W

Connecting the AC Power Cord

AC power supply

Rated voltage range: 100 VAC to 240 VAC, 50 Hz or 60 Hz.

AC power socket

z Use a three-terminal, single-phase power connector with a grounding contact