Page 1

Operation and

Maintenance

Manual

SEBU6251-06

April 1999

Caterpillar Commercial Diesel Engine

Fluids Recommendations

For All Commercial Diesel Engines Except 3600 Series Engines

Page 2

i01097883

Important Safety Information

Most accidents that involve product operation, maintenance and repair are caused by failure to

observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially

hazardous situations before an accident occurs. A person must be alert to potential hazards. This

person should also have the necessary training, skills and tools to perform these functions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have

read and understood the operation, lubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard

warnings are not heeded, bodily injury or death could occur to you or to other persons.

The hazards are identified by the “Safety Alert Symbol” and followed by a “Signal Word” such as

“DANGER”, “WARNING” or “CAUTION”. The Safety Alert “WARNING” label is shown below.

The meaning of this safety alert symbol is as follows:

Attention! Become Alert! Your Safety is Involved.

The message that appears under the warning explains the hazard and can be either written or

pictorially presented.

Operations that may cause product damage are identified by “NOTICE” labels on the product and in

this publication.

Caterpillar cannot anticipate every possible circumstance that might involve a potential hazard. The

warnings in this publication and on the product are, therefore, not all inclusive. If a tool, procedure,

work method or operating technique that is not specifically recommended by Caterpillar is used,

you must satisfy yourself that it is safe for you and for others. You should also ensure that the

product will not be damaged or be made unsafe by the operation, lubrication, maintenance or

repair procedures that you choose.

The information, specifications, and illustrations in this publication are on the basis of information that

was available at the time that the publication was written. The specifications, torques, pressures,

measurements, adjustments, illustrations, and other items can change at any time. These changes can

affect the service that is given to the product. Obtain the complete and most current information before

you start any job. Caterpillar dealers have the most current information available. For a list of the most

current publication form numbers available, see the Service Manual Contents Microfiche, REG1139F.

When replacement parts are required for this

product Caterpillar recommends using Caterpillar replacement parts or parts with equivalent

specifications including, but not limited to, physical dimensions, type, strength and material.

Failure to heed this warning can lead to premature failures, product damage, personal injury or

death.

Page 3

Table of Contents

Foreword ............................................................... 4

Maintenance Section

Lubricant Specifications ........................................ 5

Fuel Specifications ................................................ 17

Cooling System Specifications ............................. 24

Reference Information Section

Reference Materials .............................................. 37

Index Section

Index ..................................................................... 39

3

Table of Contents

Page 4

4

Foreword

Foreword

Literature Information

This manual should be stored in the literature

storage area.

The information contained in this document is the

most current information available for coolants,

fuels, and lubricants. Refer to the Operation and

Maintenance Manual for any special lubrication

requirements for your engine.

Whenever a question arises regarding the engine,

this publication, or the Operation and Maintenance

Manual, please consult any Caterpillar dealer for

the latest available information.

Safety

Refer to the Operation and Maintenance Manual

for your engine for all safety information. Read and

understand the basic safety precautions listed in

the Safety Section. In addition to safety precautions,

this section identifies the text and locations of safety

signs used on the engine.

Read and understand the basic precautions listed

in the Safety Section before operating or performing

lubrication, maintenance and repair on this engine.

Maintenance

Refer to the Operation and Maintenance Manual

for your engine to determine all maintenance

requirements.

Maintenance Intervals

Use the Maintenance Interval Schedule in the

Operation and Maintenance Manual for your

engine to determine servicing intervals. The actual

operating environment of the engine also governs

the maintenance interval schedule. Therefore,

under extremely severe, dusty, wet or freezing cold

operating conditions, more frequent lubrication and

maintenance than is specified in the Maintenance

Interval Schedule may be necessary.

Page 5

Maintenance Section

Lubricant Specifications

5

Maintenance Section

Lubricant Specifications

i01111306

Lubricant Information

SMCS Code: 1000; 1300; 7581

General Information

Because of government regulations regarding

the certification of engine exhaust emissions, the

lubricant recommendations must be followed.

Engine Manufacturers Association

(EMA) Oils

The “Engine Manufacturers Association

Recommended Guideline on Diesel Engine Oil” is

recognized by Caterpillar. For detailed information

about this guideline, see the latest edition of EMA

publication, “EMA LRG-1”.

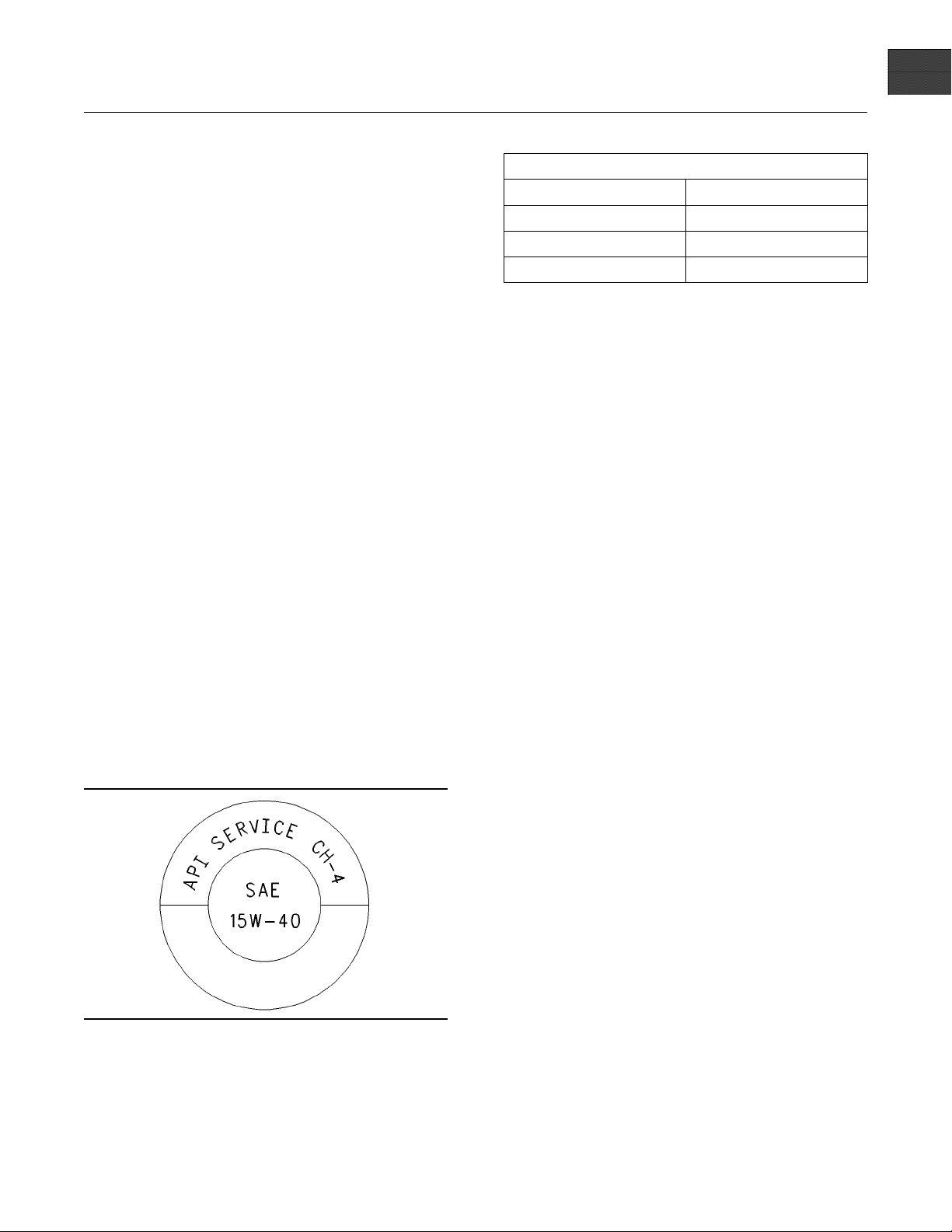

API Oils

The Engine Oil Licensing and Certification System

by the American Petroleum Institute (API) is

recognized by Caterpillar. For detailed information

about this system, see the latest edition of the “API

publication No. 1509”. Engine oils that bear the API

symbol are authorized by API.

Ta bl e 1

API Classifications

Current Obsolete

CF-4, CG-4, CH-4 CE

CF CC, CD

(1)

CF-2

(1)

CD-2 and API CF-2 are classifications for two-cycle diesel

engines. Caterpillar does not sell engines that utilize CD-2 and

API CF-2 oils.

Note: API CF is not the same classification as

API CF-4. API CF oils are only recommended

for Caterpillar 3600 Series Diesel Engines and

Caterpillar engines with precombustion chamber

(PC) fuel systems.

CD-2

(1)

Grease

The classifications of grease are based on the

“ASTM D217” worked penetration characteristics.

These characteristics for grease are given a defined

consistency number.

Terminology

Certain abbreviations follow the nomenclature of

“SAE J754”. Some classifications follow “SAE J183”

abbreviations, and some classifications follow the

“EMA Recommended Guideline on Diesel Engine

Oil”. In addition to Caterpillar definitions, there

are other definitions that will be of assistance in

purchasing lubricants. Recommended oil viscosities

can be found in this publication, “Engine Oil” topic

(Maintenance Section).

Illustration 1

Typical API symbol

Diesel engine oils CC, CD, CD-2, and CE have

not been API authorized classifications since 1

January 1996. Table 1 summarizes the status of the

classifications.

g00546535

i01072547

Engine Oil

SMCS Code: 1348

Caterpillar Diesel Engine Oil

Caterpillar Oils have been developed and tested in

order to provide the full performance and service

life that has been designed and built into Caterpillar

Engines. Caterpillar Oils are currently used to fill

diesel engines at the factory. These oils are offered

by Caterpillar dealers for continued use when the

engine oil is changed. Consult your Caterpillar

dealer for more information on these oils.

Due to significant variations in the quality and in

the performance of commercially available oils,

Caterpillar makes the following recommendations:

Caterpillar Diesel Engine Oil (10W30)

•

Page 6

6

Maintenance Section

Lubricant Specifications

Caterpillar Diesel Engine Oil (15W40)

•

Caterpillar multigrade Diesel Engine Oil is

formulated with the correct amounts of detergents,

dispersants, and alkalinity in order to provide

superior performance in Caterpillar Diesel Engines.

Caterpillar multigrade Diesel Engine Oil is available

in two viscosity grades (10W30 and 15W40).

For direct injection engines, see Table 2 in order

to choose the correct viscosity grade for the

ambient temperature. Multigrade oils provide the

correct viscosity for a broad range of operating

temperatures.

Multigrade oils are effective in maintaining low oil

consumption and low levels of piston deposits.

Caterpillar multigrade Diesel Engine Oil can be

used in other diesel engines and in gasoline

engines. See the engine manufacturer’s guide for

the recommended specifications. Compare the

specifications to the specifications of Caterpillar

multigrade Diesel Engine Oil. The current industry

standards for Caterpillar Diesel Engine Oil are listed

on the product label and on the data sheets for the

product.

Consult your Caterpillar dealer for part numbers

and for available sizes of containers.

Commercial Oils

The performance of commercial diesel engine

oils is based on American Petroleum Institute

(API) classifications. These API classifications are

developed in order to provide commercial lubricants

for a broad range of diesel engines that operate at

various conditions.

If Caterpillar multigrade Diesel Engine Oil is not

used, only use commercial oils that meet the

following classifications:

EMA LRG-1 multigrade oil (preferred oil)

•

API CH-4 multigrade oil (preferred oil)

•

API CG-4 multigrade oil (preferred oil)

•

API CF-4 multigrade oil (acceptable oil)

•

In order to make the proper choice of a commercial

oil, refer to the following explanations:

EMA LRG-1 – The Engine Manufacturers

Association (EMA) has developed lubricant

recommendations as an alternative to the API oil

classification system. LRG-1 is a Recommended

Guideline that defines a level of oil performance

for these types of diesel engines: high speed, four

stroke cycle, heavy-duty, and light duty. LRG-1 oils

may be used in Caterpillar engines when API CH-4,

API CG-4, and API CF-4 oils are recommended.

LRG-1 oils are intended to provide superior

performance in comparison to API CG-4 and API

CF-4.

LRG-1 oils will meet the needs of high performance

Caterpillar diesel engines that are operating in

many applications. The tests and the test limits that

are used to define LRG-1 are similar to the new

API CH-4 classification. Therefore, these oils will

also meet the requirements of the low emissions

diesel engines. LRG-1 oils are designed to control

the harmful effects of soot with improved wear

resistance and improved resistance to oil filter

plugging. These oils will also provide superior piston

deposit control for engines with either two-piece

steel pistons or aluminum pistons.

All LRG-1 oils must complete a full test program

with the base stock and with the viscosity grade of

the finished commercial oil. The use of “API Base

Oil Interchange Guidelines” are not appropriate for

LRG-1 oils. This feature reduces the variation in

performance that can occur when base stocks are

changed in commercial oil formulations.

LRG-1 oils are recommended for use in extended

oil change interval programs that optimize oil life.

These oil change interval programs are based

on oil analysis. LRG-1 oils are recommended

for conditions that demand a premium oil. Your

Caterpillar dealer has the specific guidelines for

optimizing oil change intervals.

API CH-4 – API CH-4 oils were developed in

order to meet the requirements of the new high

performance diesel engines. Also, the oil was

designed to meet the requirements of the low

emissions diesel engines. API CH-4 oils are also

acceptable for use in older diesel engines and in

diesel engines that use high sulfur diesel fuel. API

CH-4 oils may be used in Caterpillar engines that

use API CG-4 and API CF-4 oils. API CH-4 oils will

generally exceed the performance of API CG-4 oils

in the following criteria: deposits on pistons, control

of oil consumption, wear of piston rings, valve train

wear, viscosity control, and corrosion.

Page 7

Maintenance Section

Lubricant Specifications

7

Three new engine tests were developed for the

API CH-4 oil. The first test specifically evaluates

deposits on pistons for engines with the two-piece

steel piston. This test (piston deposit) also measures

the control of oil consumption. A second test is

conducted with moderate oil soot. The second

test measures the following criteria: wear of piston

rings, wear of cylinder liners, and resistance to

corrosion. A third new test measures the following

characteristics with high levels of soot in the oil:

wear of the valve train, resistance of the oil in

plugging the oil filter, and control of sludge.

In addition to the new tests, API CH-4 oils have

tougher limits for viscosity control in applications

that generate high soot. The oils also have improved

oxidation resistance. API CH-4 oils must pass an

additional test (piston deposit) for engines that use

aluminum pistons (single piece). Oil performance is

also established for engines that operate in areas

with high sulfur diesel fuel.

All of these improvements allow the API CH-4 oil

to achieve optimum oil change intervals. API CH-4

oils are recommended for use in extended oil

change intervals. API CH-4 oils are recommended

for conditions that demand a premium oil. Your

Caterpillar dealer has specific guidelines for

optimizing oil change intervals.

Some commercial oils that meet the API

classifications may require reduced oil change

intervals. To determine the oil change interval,

closely monitor the condition of the oil and perform a

wear metal analysis. Caterpillar’sS·O·S oil analysis

program is the preferred method.

NOTICE

Failure to follow these oil recommendations can cause

shortened engine service life due to deposits and/or

excessive wear.

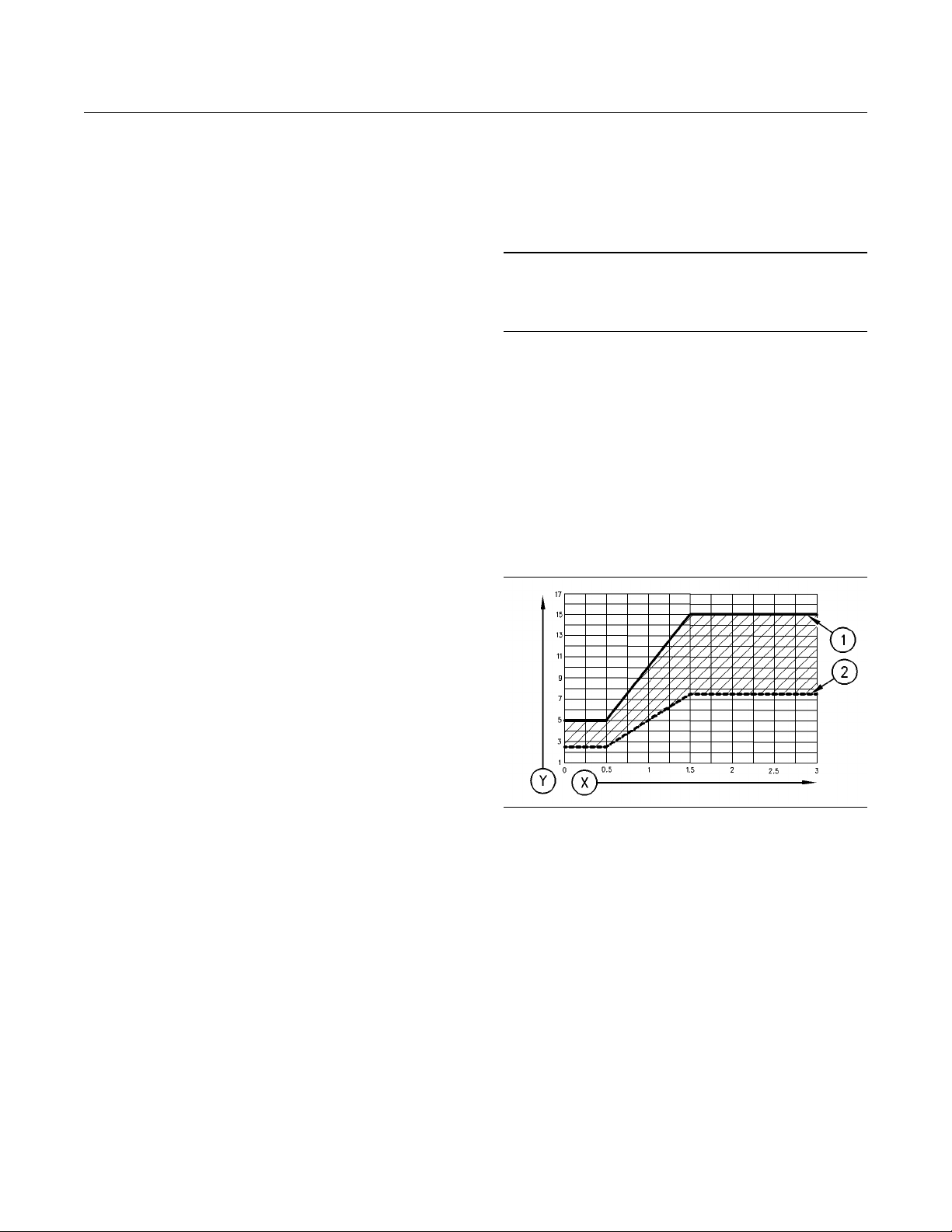

Total Base Number (TBN) and Fuel

Sulfur Levels for Direct Injection

(DI) Diesel Engines

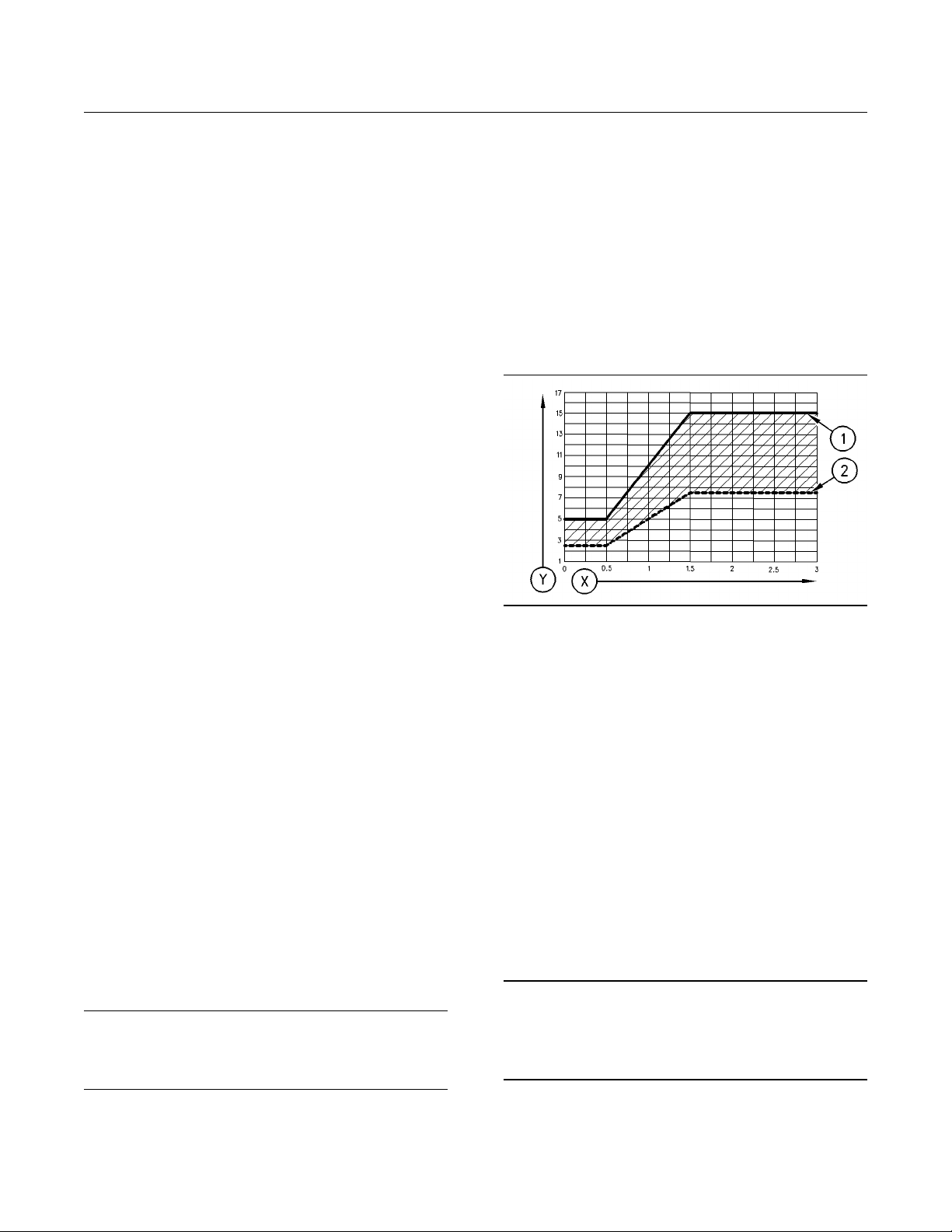

The Total Base Number (TBN) for an oil depends on

the fuel sulfur level. For direct injection engines that

use distillate fuel, the minimum TBN of the new oil

must be 10 times the fuel sulfur level. The TBN is

defined by “ASTM D2896”. The minimum TBN of

the oil is 5 regardless of fuel sulfur level. Illustration

2 demonstrates the TBN.

API CG-4 – API CG-4 oils were developed primarily

for diesel engines that use a 0.05 percent level of

fuel sulfur. However, API CG-4 oils can be used

with higher sulfur fuels. The TBN of the new oil

determines the maximum fuel sulfur level for API

CG-4 and API CF-4 oils. See Illustration 2.

API CG-4 oils are the first oils that are required to

pass industry standard tests for foam control and

viscosity shear loss. API CG-4 oils must also pass

tests that were developed for corrosion, wear and

oxidation.

API CF-4 – These oils service a wide variety of

modern diesel engines. API CF-4 oils provide more

stable oil control and reduced piston deposits in

comparison to API CF and the obsolete CE and CD

classifications of oil. API CF-4 oils provide improved

soot dispersancy in comparison to API CF and

obsolete CD oils. The API CF-4 classification was

developed with a 0.40 percent sulfur diesel fuel.

This represents the type of diesel fuels that are

commonly available worldwide.

Note: Do not use single grade API CF oils or

multigrade API CF oils in Caterpillar Direct Injection

(DI) Commercial Diesel Engines.

Illustration 2

(Y) TBN by “ASTM D2896”

(X) Percentage of fuel sulfur by weight

(1) TBN of new oil

(2) Change the oil when the TBN deteriorates to 50 percent of

the original TBN.

Use the following guidelines for fuel sulfur levels

that exceed 1.5 percent:

Choose an oil with the highest TBN that meets

•

one of these classifications: EMA LRG-1, API

CH-4, API CG-4, and API CF-4.

Reduce the oil change interval. Base the oil

•

change interval on the oil analysis. Ensure that

the oil analysis includes the condition of the oil

and a wear metal analysis.

g00104890

Excessive piston deposits can be produced by an

oil with a high TBN. These deposits can lead to a

loss of control of the oil consumption and to the

polishing of the cylinder bore.

Page 8

8

Maintenance Section

Lubricant Specifications

NOTICE

Operating Direct Injected (DI) diesel engines with fuel

sulfur levels over 1.0 percent may require shortened

oil change intervals in order to help maintain adequate

wear protection.

i01111341

Engine Oil (3116 and 3126

Marine Engines)

SMCS Code: 1348

Lubricant Viscosity Recommendations

for Direct Injection (DI) Diesel Engines

The proper SAE viscosity grade of oil is determined

by the minimum ambient temperature during

cold engine start-up, and the maximum ambient

temperature during engine operation.

Refer to Table 2 (minimum temperature) in order

to determine the required oil viscosity for starting

a cold engine.

Refer to Table 2 (maximum temperature) in order to

select the oil viscosity for engine operation at the

highest ambient temperature that is anticipated.

Generally, use the highest oil viscosity that

is available to meet the requirement for the

temperature at start-up.

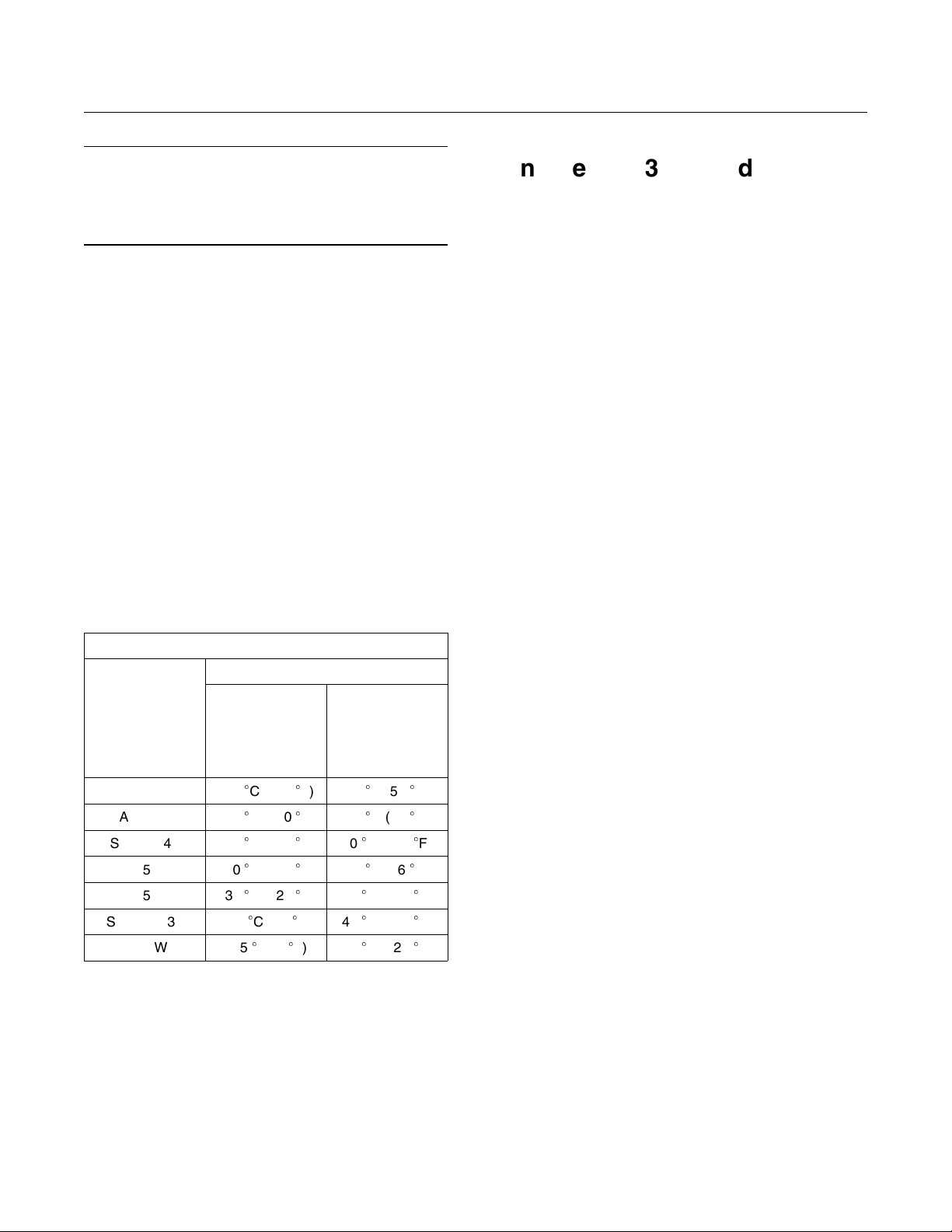

Ta bl e 2

Engine Oil Viscosity

Ambient TemperatureCaterpillar DEO

Multigrade

EMA LRG-1

API CH-4

API CG-4 and

API CF-4

Viscosity Grade

SAE 0W20

SAE 0W30

SAE 0W40

SAE 5W30 −30C(−22F) 30C (86F)

SAE 5W40 −30C(−22F) 40C (104F)

SAE 10W30 −20C(−4F) 40C (104F)

SAE 15W40 −15C(5

Minimum Maximum

−40C(−40

−40

C(−40F)

−40C(−40

F)

F)

F)

10

C (50F)

30

C (86F)

40C (104

50C (122

F)

F)

Recommendations

Caterpillar does not recommend the use of

multigrade oils in the 3116 and 3126 Marine Diesel

Engines with mechanical unit injection.

Multigrade oils use high molecular weight polymers

as viscosity index improvers.

When the crankcase blowby flows through the

turbocharger and the aftercooler, the viscosity

index improvers in the oil vapor can adhere to the

turbocharger compressor and aftercooler core.

The fouling of the turbocharger and aftercooler can

cause reduced air flow, loss of power, and increased

black smoke. The emission of black smoke results

in buildup of soot on the transom of the boat.

Note: Caterpillar recommends the use of single

grade oils with the API CF-4 classification for all

3116 and 3126 Marine Engines unless crankcase

blowby has been routed completely away from the

air cleaner inlet.

Caterpillar Special Application Engine

Oil (SAEO)

Note: Special Application Engine Oil is for use in

Caterpillar 3116 and 3126 Marine Diesel Engines

with mechanical unit injection. This includes all 3116

and 3126 Marine Diesel Engines that begin with the

following serial number prefixes: (S/N: 4KG), (S/N:

1SK), (S/N: 8NM), and (S/N: 6SR).

The factory fill in 3116 and 3126 Marine Engines is

Caterpillar Special Application Engine Oil (SAEO).

The oil that is used for the factory fill has the

following properties:

API CF-4 classification

•

Viscosity of SAE 30

•

For maximum performance in 3116 and 3126 Marine

Diesel Engines with mechanical unit injection,

Caterpillar recommends the following engine oil:

Caterpillar Special Application Engine Oil (SAEO)

•

with a viscosity of SAE 30

Caterpillar Special Application Engine Oil (SAEO)

•

with a viscosity of SAE 40

Page 9

Maintenance Section

Lubricant Specifications

9

Commercial Oils (3116 and 3126

Marine Engines)

The performance of commercial diesel engine

oil is based on American Petroleum Institute

(API) classifications. These API classifications are

developed in order to provide commercial lubricants

for a broad range of diesel engines that operate at

various conditions.

When a Caterpillar Special Application Engine Oil

(SAEO) is not used, use the following commercial

oils:

Single grade oil with a viscosity of SAE 30 or SAE

•

40 with an API CF-4 classification is preferred.

Single grade oil with a viscosity of SAE 30 or

•

SAE 40 with a CF-4 or CG-4 additive package

that does NOT contain viscosity improvers is an

acceptable oil.

For an acceptable commercial single grade oil,

contact your oil supplier or Caterpillar Customer

Service:

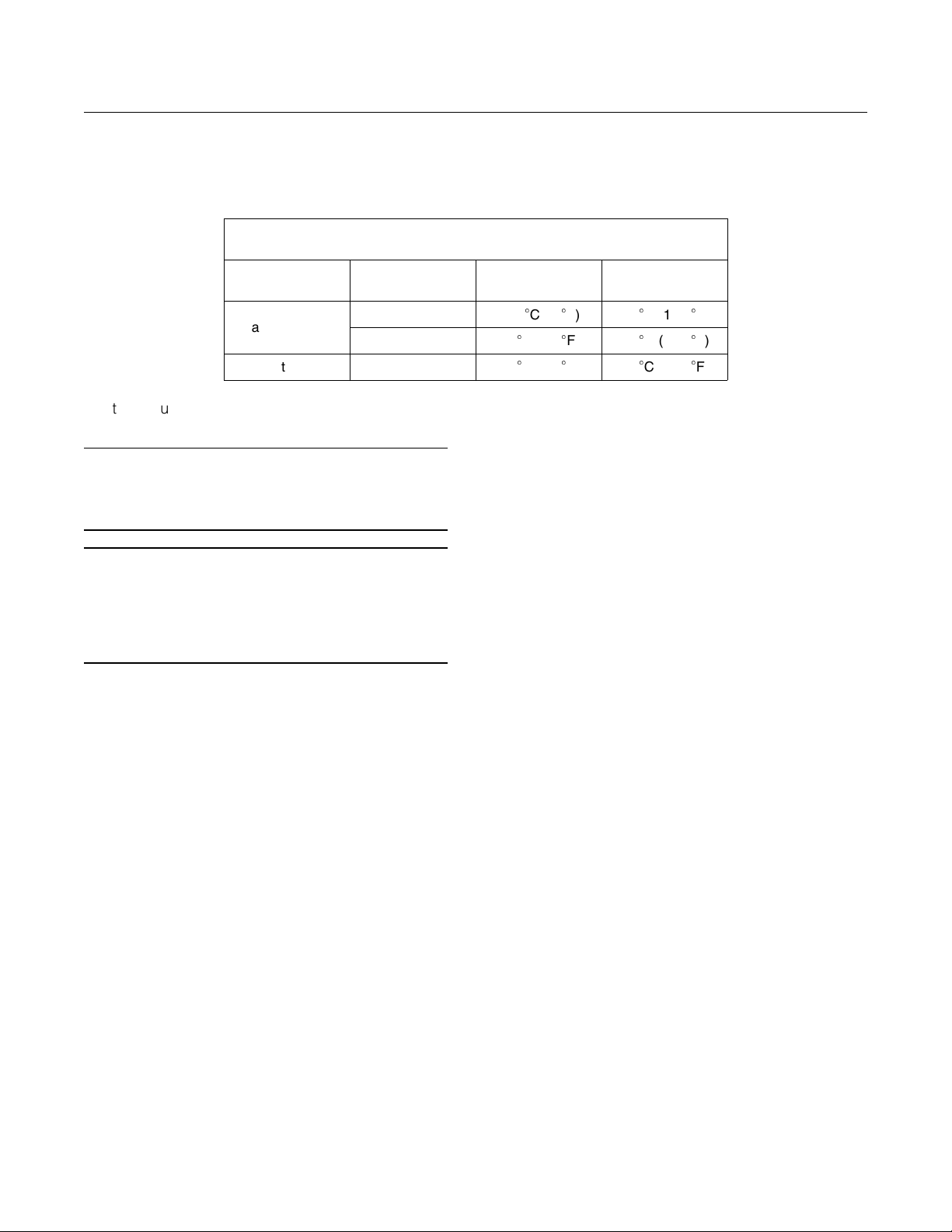

Total Base Number (TBN) and Fuel

Sulfur Levels for Direct Injection

(DI) Diesel Engines (3116 and 3126

Marine Engines)

The Total Base Number (TBN) for an oil depends

on the fuel sulfur level. For direct injection engines

that use distillate fuel, the minimum TBN must be 10

times the fuel sulfur level. The TBN is determined by

the “ASTM D2896” procedure. The minimum TBN

of the oil is 5 regardless of a low fuel sulfur level.

Illustration 3 demonstrates the TBN.

1-800-447-4986

The following explanation of the API CF-4

classification can be used to make the proper

choice when a commercial single grade oil with API

CF-4 classification is chosen.

API CF-4 – These oils service a wide variety of

modern diesel engines. API CF-4 oils provide more

stable oil control and reduced piston deposits in

comparison to API CF and the obsolete CE and CD

classifications of oil. API CF-4 oils provide improved

soot dispersancy in comparison to API CF and

obsolete CD oils. The API CF-4 classification was

developed with a 0.40 percent sulfur diesel fuel.

This represents the type of diesel fuels that are

commonly available worldwide.

Some commercial oils that meet the API CF-4

classifications may require reduced oil change

intervals. To determine the oil change interval,

closely monitor the condition of the oil and perform a

wear metal analysis. Caterpillar’sS·O·S oil analysis

program is the preferred method.

NOTICE

Failure to follow these oil recommendations can cause

shortened engine service life due to deposits and/or

excessive wear.

Illustration 3

(Y) TBN by “ASTM D2896”

(X) Percentage of fuel sulfur by weight

(1) TBN of new oil

(2) Change the used oil when the TBN reaches this level.

Use the following guidelines for fuel sulfur levels

that exceed 1.5 percent:

Choose an oil with the highest TBN within the

•

API CF-4 classification.

Reduce the oil change interval. Base the oil

•

change interval on the oil analysis. Ensure that

the oil analysis includes the condition of the oil

and a wear metal analysis.

Excessive piston deposits can be produced by an

oil with a high TBN. These deposits can lead to a

loss of control of the oil consumption and to the

polishing of the cylinder bore.

NOTICE

Operating Direct Injected (DI) diesel engines with fuel

sulfur levels over 1.0 percent may require shortened

oil change intervals in order to help maintain adequate

wear protection.

g00104890

Page 10

10

Maintenance Section

Lubricant Specifications

Lubricant Viscosity

Recommendations (3116 and

3126 Marine Engines)

The proper SAE viscosity grade of oil is determined

by the minimum ambient temperature during

cold engine start-up, and the maximum ambient

temperature during engine operation.

Refer to Table 3 (minimum temperature) in order

to determine the required oil viscosity for starting

a cold engine.

Refer to Table 3 (maximum temperature) in order to

select the oil viscosity for engine operation at the

highest ambient temperature that is anticipated.

Generally, use the highest oil viscosity that is

allowed for the ambient temperature at start-up.

Ta bl e 3

Engine Oil Viscosity

API CF-4 Oil

Viscosity Grade

SAE 30 0C (32F) 40C (104

SAE 40 5

Ambient Temperature

Minimum Maximum

C (41F)

50

C (122F)

i01123508

F)

Caterpillar multigrade Diesel Engine Oil is available

in two viscosity grades (10W30 and 15W40). For

precombustion chamber engines, see Table 4 in

order to choose the correct viscosity grade for the

ambient temperature. Multigrade oils provide the

correct viscosity for a broad range of operating

temperatures.

Multigrade oils are effective in maintaining low oil

consumption and low levels of piston deposits.

Caterpillar multigrade Diesel Engine Oil can be

used in other diesel engines and in gasoline

engines. See the engine manufacturer’s guide for

the recommended specifications. Compare the

specifications to the specifications of Caterpillar

multigrade Diesel Engine Oil. The current industry

standards for Caterpillar Diesel Engine Oil are listed

on the product label and on the data sheets for the

product.

Consult your Caterpillar dealer for part numbers

and for available sizes of containers.

Commercial Oils

The performance of commercial diesel engine

oils is based on American Petroleum Institute

(API) classifications. These API classifications are

developed in order to provide commercial lubricants

for a broad range of diesel engines that operate at

various conditions.

Engine Oil for Precombustion

Chamber (PC) Diesel Engines

SMCS Code: 1348

Caterpillar Diesel Engine Oil

Caterpillar Oils have been developed and tested in

order to provide the full performance and service

life that has been designed and built into Caterpillar

Engines. Caterpillar Oils are currently used to fill

diesel engines at the factory. These oils are offered

by Caterpillar dealers for continued use when the

engine oil is changed. Consult your Caterpillar

dealer for more information on these oils.

Due to significant variations in the quality and in

the performance of commercially available oils,

Caterpillar makes the following recommendations:

Caterpillar Diesel Engine Oil (10W30)

•

Caterpillar Diesel Engine Oil (15W40)

•

Caterpillar multigrade Diesel Engine Oil is

formulated with the correct amounts of detergents,

dispersants, and alkalinity in order to provide

superior performance in Caterpillar Diesel Engines.

If Caterpillar multigrade Diesel Engine Oil is not

used, only use commercial oils that meet the

following classifications:

EMA LRG-1 multigrade oil (preferred oil)

•

API CH-4 multigrade oil (preferred oil)

•

API CG-4 multigrade oil (preferred oil)

•

API CF-4 multigrade oil (acceptable oil)

•

API CF oil (acceptable oil for PC engines)

•

In order to make the proper choice of a commercial

oil, refer to the following explanations:

Page 11

11

Maintenance Section

Lubricant Specifications

EMA LRG-1 – The Engine Manufacturers

Association (EMA) has developed lubricant

recommendations as an alternative to the API oil

classification system. LRG-1 is a Recommended

Guideline that defines a level of oil performance

for these types of diesel engines: high speed, four

stroke cycle, heavy-duty, and light duty. LRG-1 oils

may be used in Caterpillar engines when API CH-4,

API CG-4, and API CF-4 oils are recommended.

LRG-1 oils are intended to provide superior

performance in comparison to API CG-4 and API

CF-4.

LRG-1 oils will meet the needs of high performance

Caterpillar diesel engines that are operating in

many applications. The tests and the test limits that

are used to define LRG-1 are similar to the new

API CH-4 classification. Therefore, these oils will

also meet the requirements of the low emissions

diesel engines. LRG-1 oils are designed to control

the harmful effects of soot with improved wear

resistance and improved resistance to oil filter

plugging. These oils will also provide superior piston

deposit control for engines with either two-piece

steel pistons or aluminum pistons.

All LRG-1 oils must complete a full test program

with the base stock and with the viscosity grade of

the finished commercial oil. The use of “API Base

Oil Interchange Guidelines” are not appropriate for

LRG-1 oils. This feature reduces the variation in

performance that can occur when base stocks are

changed in commercial oil formulations.

LRG-1 oils are recommended for use in extended

oil change interval programs that optimize oil life.

These oil change interval programs are based

on oil analysis. LRG-1 oils are recommended

for conditions that demand a premium oil. Your

Caterpillar dealer has the specific guidelines for

optimizing oil change intervals.

API CH-4 – API CH-4 oils were developed in

order to meet the requirements of the new high

performance diesel engines. Also, the oil was

designed to meet the requirements of the low

emissions diesel engines. API CH-4 oils are also

acceptable for use in older diesel engines and in

diesel engines that use high sulfur diesel fuel. API

CH-4 oils may be used in Caterpillar engines that

use API CG-4 and API CF-4 oils. API CH-4 oils will

generally exceed the performance of API CG-4 oils

in the following criteria: deposits on pistons, control

of oil consumption, wear of piston rings, valve train

wear, viscosity control, and corrosion.

Three new engine tests were developed for the

API CH-4 oil. The first test specifically evaluates

deposits on pistons for engines with the two-piece

steel piston. This test (piston deposit) also measures

the control of oil consumption. A second test is

conducted with moderate oil soot. The second

test measures the following criteria: wear of piston

rings, wear of cylinder liners, and resistance to

corrosion. A third new test measures the following

characteristics with high levels of soot in the oil:

wear of the valve train, resistance of the oil in

plugging the oil filter, and control of sludge.

In addition to the new tests, API CH-4 oils have

tougher limits for viscosity control in applications

that generate high soot. The oils also have improved

oxidation resistance. API CH-4 oils must pass an

additional test (piston deposit) for engines that use

aluminum pistons (single piece). Oil performance is

also established for engines that operate in areas

with high sulfur diesel fuel.

All of these improvements allow the API CH-4 oil

to achieve optimum oil change intervals. API CH-4

oils are recommended for use in extended oil

change intervals. API CH-4 oils are recommended

for conditions that demand a premium oil. Your

Caterpillar dealer has specific guidelines for

optimizing oil change intervals.

API CG-4 – API CG-4 oils were developed primarily

for diesel engines that use a 0.05 percent level of

fuel sulfur. However, API CG-4 oils can be used

with higher sulfur fuels. The TBN of the new oil

determines the maximum fuel sulfur level for API

CG-4 and API CF-4 oils. See Illustration 4.

API CG-4 oils are the first oils that are required to

pass industry standard tests for foam control and

viscosity shear loss. API CG-4 oils must also pass

tests that were developed for corrosion, wear and

oxidation.

API CF-4 – These oils service a wide variety of

modern diesel engines. API CF-4 oils provide more

stable oil control and reduced piston deposits in

comparison to API CF and the obsolete CE and CD

classifications of oil. API CF-4 oils provide improved

soot dispersancy in comparison to API CF and

obsolete CD oils. The API CF-4 classification was

developed with a 0.40 percent sulfur diesel fuel.

This represents the type of diesel fuels that are

commonly available worldwide.

Some commercial oils that meet the API

classifications may require reduced oil change

intervals. To determine the oil change interval,

closely monitor the condition of the oil and perform a

wear metal analysis. Caterpillar’sS·O·S oil analysis

program is the preferred method.

Page 12

12

Maintenance Section

Lubricant Specifications

NOTICE

Failure to follow these oil recommendations can cause

shortened engine service life due to deposits and/or

excessive wear.

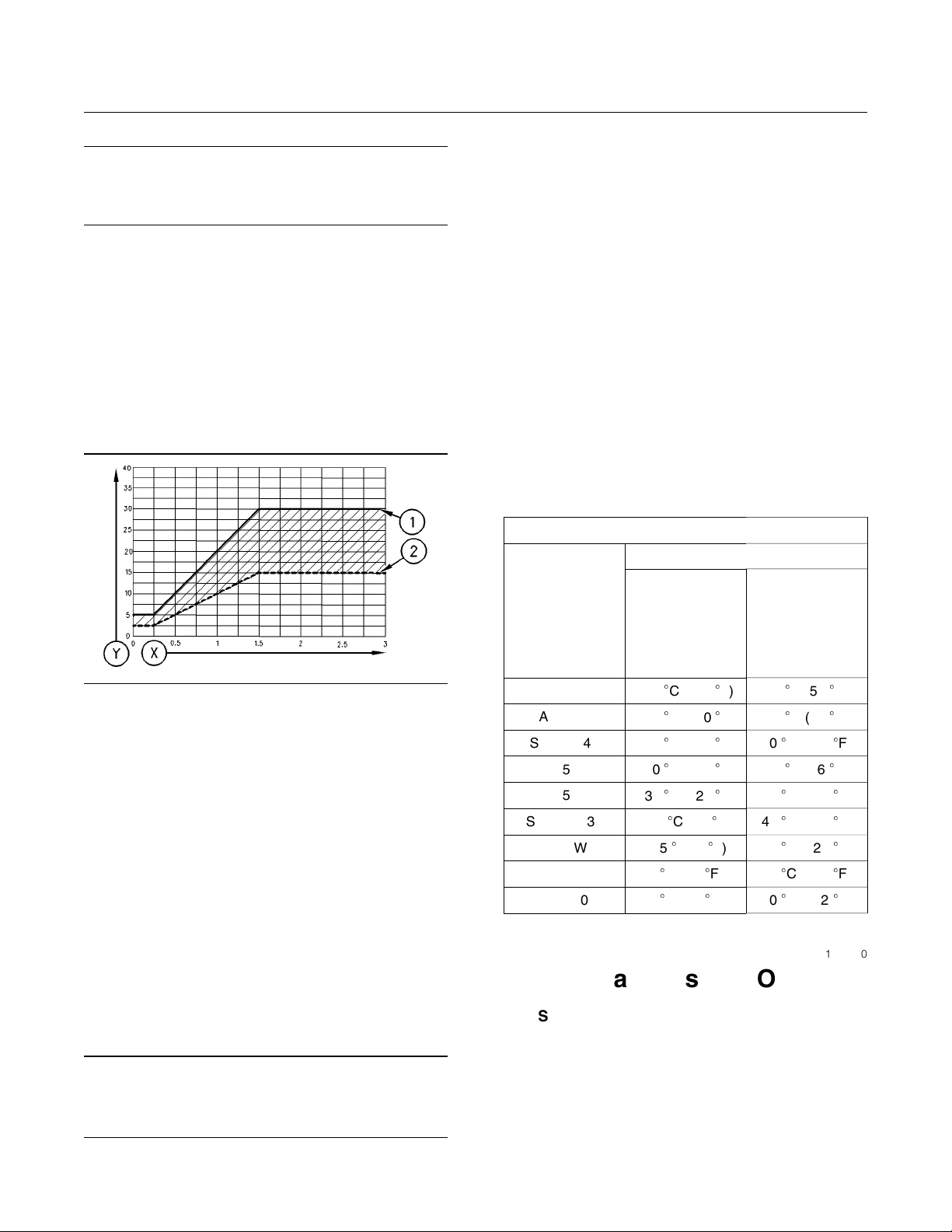

Total Base Number (TBN) and Fuel

Sulfur Levels for Precombustion

Chamber (PC) Diesel Engines

The TBN for a new oil depends on the fuel sulfur

level of the fuel that is used. The minimum TBN of

the oil that is used in PC engines must be 20 times

the fuel sulfur level. The TBN is defined in “ASTM

D2896”. Regardless of fuel sulfur level, the minimum

TBN of new oil is five. Refer to illustration 4.

Lubricant Viscosity Recommendations

for Precombustion Chamber (PC) Diesel

Engines

The proper SAE viscosity grade of oil is determined

by the minimum ambient temperature during

cold engine start-up, and the maximum ambient

temperature during engine operation.

Refer to Table 4 (minimum temperature) in order

to determine the required oil viscosity for starting

a cold engine.

Refer to Table 4 (maximum temperature) in order to

select the oil viscosity for engine operation at the

highest ambient temperature that is anticipated.

Generally, use the highest oil viscosity that

is available to meet the requirement for the

temperature at start-up.

Illustration 4

(Y) The TBN that is shown by “ASTM D2896”

(X) Percentages of fuel sulfur by weight

(1) TBN of new oil

(2) Change the oil when the TBN deteriorates to 50 percent of

the original TBN.

g00274867

Whenever the fuel sulfur exceeds 1.5 percent, do

the following tasks.

Choose an oil with the highest TBN that meets

•

one of these classifications: EMA LRG-1, API CF,

API CF-4, API CG-4, and API CH-4.

Shorten the oil change interval if the oil analysis

•

dictates.

Ta bl e 4

Engine Oil Viscosity

Caterpillar DEO

Multigrade

EMA LRG-1

API CH-4

API CG-4

API CF-4 and

API CF

Viscosity Grade

SAE 0W20 −40C(−40F) 10C (50F)

SAE 0W30

SAE 0W40

SAE 5W30

SAE 5W40

SAE 10W30 −20C(−4F) 40C (104F)

SAE 15W40 −15C(5F) 50C (122F)

SAE 30 0C (32F) 40C (104F)

SAE 40 5C (41F) 50C (122F)

Ambient Temperature

Minimum Maximum

−40C(−40F) 30C (86F)

−40C(−40F) 40C (104F)

−30C(−22F) 30C (86F)

−30C(−22F) 40C (104F)

i01098470

Excessive piston deposits can be produced by an

oil with a high TBN. These deposits can lead to a

loss of control of the oil consumption and to the

polishing of the cylinder bore.

NOTICE

Operating PC engines at fuel sulfur levels over 1.0

percent may require shortened oil change intervals to

maintain adequate wear protection.

Marine Transmission Oil

SMCS Code: 3080; 3300

Caterpillar Transmission/Drive Train Oil (TDTO)

is balanced in order to give maximum frictional

material service life in Caterpillar transmissions.

TDTO exceeds the requirements for the Caterpillar

TO-4 oil specification which includes the frictional

requirements and gear wear requirements. TDTO

is offered in different lubricant viscosity grades

for maximum service life of components at high

ambient temperatures and heavy duty cycles.

Page 13

For maximum transmission service life and

performance, Caterpillar recommends Caterpillar

Transmission/Drive Train Oil (TDTO).

Ta bl e 5

Lubricant Viscosities For Operating Temperatures

Cooling of

Transmission

Raw/Seawater

Jacket Water SAE 50 −5

Oil Viscosities

SAE 30

SAE 50

Caterpillar TDTO

Minimum

Temperature

−15C(5

−5C (23

C (23

13

Maintenance Section

Lubricant Specifications

Maximum

Temperature

F)

F)

F)

80

C (176F)

95C (203

95

C (203

F)

F)

Contact your Caterpillar dealer for part numbers

and for sizes of available containers.

NOTICE

This oil is formulated for transmissions and drive trains

only, and should not be used in engines. Shortened

engine life will result.

NOTICE

Caterpillar Gear Oil (GO) is not the same as

Caterpillar Transmission/Drive Train Oil, and does

not meet Caterpillar’s specifications for TO-4 oil.

Caterpillar GO or commercial gear oils should not be

used in compartments which specify TO-4 oil.

Caterpillar Transmission/Drive

Train Oils

If Caterpillar Transmission/Drive Train Oil is not

used, commercial oils meeting the Caterpillar TO-4

specification must be used in Caterpillar marine

transmissions. Use TO-4 Specification Oils that are

single grade only.

Commercial Marine Transmissions

For marine transmissions which are not

manufactured by Caterpillar, refer to the lubrication

recommendation of the OEM for the marine

transmission or the vessel.

i01111406

Synthetic base oils generally perform better than

conventional oils in the following two areas:

Synthetic base oils have improved flow at low

•

temperatures especially in arctic conditions.

Synthetic base oils have improved oxidation

•

stability especially at high operating temperatures.

Some synthetic base oils have performance

characteristics that enhance the service life of the

oil. However, Caterpillar does not recommend the

automatic extension of oil change intervals for

any type of oil. Oil change intervals for Caterpillar

engines can only be adjusted after an oil analysis

program that contains the following tests: oil

condition and wear metal analysis (Caterpillar’s

S·O·S oil analysis), trend analysis, fuel consumption,

and oil consumption.

i01111412

Re-refined Base Stock Oils

SMCS Code: 1300; 1348; 7581

Re-refined base stock oils are acceptable for

use in Caterpillar engines if these oils meet the

performance requirements that are specified by

Caterpillar. Re-refined base stock oils can be used

exclusively in finished oil or in a combination with

new base stock oils. The US military specifications

and the specifications of other heavy equipment

manufacturers also allow the use of re-refined base

stock oils that meet the same criteria.

Synthetic Base Stock Oils

SMCS Code: 1300; 1348; 7581

Synthetic base oils are acceptable for use

in Caterpillar engines if these oils meet the

performance requirements that are specified for the

engine compartment.

The process that is used to make re-refined base

stock oil should adequately remove all wear metals

that are in the used oil and all additives that are

in the used oil. The process that is used to make

re-refined base stock oil generally involves the

processes of vacuum distillation and hydrotreating

the used oil. Filtering is inadequate for the

production of high quality re-refined base stock oils

from used oil.

Page 14

14

Maintenance Section

Lubricant Specifications

i01123104

Aftermarket Oil Additives

SMCS Code: 1300; 1348; 7581

Caterpillar does not recommend the use of

aftermarket additives in oil. It is not necessary to

use aftermarket additives in order to achieve the

engine’s maximum service life or rated performance.

Fully formulated, finished oils consist of base oils

and of commercial additive packages. These

additive packages are blended into the base oils

at precise percentages in order to help provide

finished oils with performance characteristics that

meet industry standards.

There are no industry standard tests that evaluate

the performance or the compatibility of aftermarket

additives in finished oil. Aftermarket additives may

not be compatible with the finished oil’s additive

package, which could lower the performance of the

finished oil. The aftermarket additive could fail to

mix with the finished oil. This could produce sludge

in the crankcase. Caterpillar discourages the use of

aftermarket additives in finished oils.

To achieve the best performance from a Caterpillar

engine, conform to the following guidelines:

When an engine is started and operated in ambient

temperatures below −30

C(−22

F), use a synthetic

base stock multigrade oil with a 0W viscosity grade

or with a 5W viscosity grade. Use an oil with a pour

point that is lower than −50

C(−58

F).

The number of acceptable lubricants is limited in

cold weather conditions. Caterpillar recommends

the following lubricants for use in cold weather

conditions:

First Choice – use an oil with an EMA LRG-1

Recommended Guideline or use a CH-4 oil that is

API licensed with an SAE 0W20, SAE 0W30, SAE

0W40, SAE 5W30, or SAE 5W40 lubricant viscosity

grade. A CG-4 oil that is API licensed with an SAE

0W20, SAE 0W30, SAE 0W40, SAE 5W30, or SAE

5W40 lubricant viscosity grade may also be used.

A CF-4 oil that is API licensed with an SAE 0W20,

SAE 0W30, SAE 0W40, SAE 5W30, or SAE 5W40

lubricant viscosity grade may also be used.

Second Choice – use an oil that contains the CH-4,

CG-4, or CF-4 additive package although the oil

has not been tested for the requirements of the

API license. The oil must have an SAE 0W20,

SAE 0W30, SAE 0W40, SAE 5W30, or SAE 5W40

lubricant viscosity grade.

Select the proper Caterpillar oil or a commercial

•

oil that meets the “EMA Recommended Guideline

on Diesel Engine Oil” or the recommended API

classification.

See the appropriate “Lubricant Viscosities” table

•

in order to find the correct oil viscosity grade for

your engine.

At the specified interval, service the engine

•

compartment. Use new oil and install a new oil

filter.

Perform maintenance at the intervals that are

•

specified in the Operation and Maintenance

Manual, “Maintenance Interval Schedule”.

i01113213

Cold Weather Lubricants

SMCS Code: 1300; 1348; 7581

When an engine is started and an engine is

operated in ambient temperatures below −20

(−4

F), use multigrade oils that are capable of

flowing in low temperatures.

NOTICE

Shortened engine service life could result if second

choice oils are used.

i01111438

Lubricating Grease

SMCS Code: 1000; 7581

Caterpillar provides greases in order to cover a

variety of applications and extreme temperature

conditions. Consult your Caterpillar dealer for part

numbers and for available sizes of containers.

Note: Some greases may not be used with other

greases. When a commercial grease is used,

ensure that the grease is compatible with the

grease that is currently used in the system. If the

commercial grease is not compatible, the system

must be purged. If any questions arise concerning

the compatibility of a grease, consult the supplier.

C

These oils have lubricant viscosity grades of SAE

0W or SAE 5W.

Page 15

15

Maintenance Section

Lubricant Specifications

Multipurpose Greases

Multipurpose Lithium Complex Grease

(MPGL)

Multipurpose Lithium Complex Grease (MPGL)

is a general purpose lithium complex grease for

medium-duty applications. This product has good

characteristics at high temperatures such as a

dropping point of 260

unleaded extreme pressure additives, antiwear

inhibitors, and corrosion inhibitors that provide extra

protection in the following applications:

Construction

•

Agricultural

•

Automotive

•

MPGL meets the requirements for extended service

intervals of automotive chassis points. MPGL also

meets the requirements for extended service

intervals of wheel bearings with disc brakes in

automobiles, in vans and in light trucks. This

product meets the NLGI certification of “GC-LB”.

MPGL is also available in a NGLI No. 2 grade.

Normal operating temperatures for this product are

−28 to 149

available as a white lithium complex grease.

C(−18 to 300

Multipurpose Lithium Complex Grease

with Molybdenum (MPGM)

Multipurpose Lithium Complex Grease with

Molybdenum (MPGM) is a general purpose

lithium complex grease that is used for light-duty

applications and for medium-duty applications. The

MPGM is available in the following grades: NLGI

No. 2 and NLGI No. 0. The MPGM is strengthened

with a molybdenum disulfide and a polymer for

extra lubrication and protection. MPGM contains

unleaded additives. MPGM also contains antiwear

inhibitors, rust inhibitors, and corrosion inhibitors

that are for protection and lubrication in many

environments. The MPGM is formulated with a base

fluid that has high viscosity.

The MPGM has the following features:

Increased protection against water washout

•

Increased retention

•

Resistance to heavy loads

•

C (500

F). MPGL contains

F). This product is also

This product is recommended for heavily loaded pin

joints and for journal bearings. This product meets

the certification of “GC-LB”. Normal operating

temperatures for this product are −28 to 149

(−18 to 300

temperatures for this product are −18 to 149

(0 to 300

Note: If MPGM is not available, use a multipurpose

type grease which contains three to five percent

molybdenum.

F) for the NLGI No. 0. Normal operating

F) for the NLGI No. 2.

C

C

Special Purpose Grease (SPG)

Bearing Lubrication (SPG)

Bearing Lubricant (SPG) is available in a NLGI

No. 2 grade with a polyurea thickener. This

grease is recommended for high temperature

antifriction bearings in the following applications:

electric starting motors, alternators, fan drives,

and generators. The Bearing Lubricant (SPG) has

an effective operating range of −29 to 177

(−20 to 350

F).

Water and Temperature Resistant Grease

(WTR)

The Water and Temperature Resistant Grease is

designed for use whenever the following conditions

are a concern: water washout, severe corrosion,

and high operating temperatures. The Water and

Temperature Resistant Grease provides extreme

pressure protection, antiwear protection, rust

protection and corrosion protection. The Water and

Temperature Resistant Grease is an environmentally

friendly grease which does not contain the following

materials: antimony, sulfur, barium, zinc, lead, and

phosphorous materials. The Water and Temperature

Resistant Grease has excellent shear stability. Water

and Temperature Resistant Grease can also resist

breakdown in the presence of water. The Water

and Temperature Resistant Grease works well in

the following applications:

Construction

•

Agricultural

•

Automotive

•

Industrial

•

Marine

•

This product meets the NLGI certification of

“GC-LB”. Normal operating temperatures for this

product are −40 to 204

C(−40 to 400F).

C

Page 16

16

Maintenance Section

Lubricant Specifications

Caterpillar Premium Grease (CPG)

Desert Gold (CPG)

Desert Gold is a heavy-duty, premium synthetic

grease that is developed for the most extreme

operating environments. This grease is formulated

with the following characteristics: high viscosity

synthetic base fluid, polymers, molybdenum

disulfide, high viscosity index, and high dropping

point.

Desert Gold will protect equipment against

heavy shock loads. Desert Gold protects against

corrosion in extreme heat, in moist conditions, or

in dusty conditions. This product has excellent

characteristics of adhesion and of stability.

Desert Gold provides longer protection than other

greases. Desert Gold is an environmentally friendly

grease which does not contain the following

materials: antimony, sulfur, barium, zinc, lead,

and phosphorous materials. Normal operating

temperatures are

−6 to 230

Gold can operate at higher temperatures for short

time periods. Desert Gold has additional extreme

pressure protection for highly loaded pin joints.

Arctic Platinum (CPG)

Arctic Platinum is a super-premium extreme

pressure lubricating grease that is developed for

lubrication in temperatures that are below zero to

moderate operating temperatures. Arctic Platinum

is available in grades 000, 00, 0, 1, and 2. These

grades ensure pumpability in central lube systems in

a variety of ambient temperatures from −60 to 18

(−76 to 65

point. Arctic Platinum contains a five percent

concentrate of molybdenum disulfide for protection

against extra heavy loads. Arctic Platinum provides

excellent corrosion protection and rust protection.

Arctic Platinum is an environmentally friendly grease

which does not contain the following materials:

antimony, sulfur, barium, zinc, and phosphorous.

Arctic Platinum is designed for long life lubrication

of the following components: horizontal pivot

bearings, lower link bearings, steering cylinders,

kingbolt bearings, upper hitch link bearings, and

ejector carrier roller bearings. This grease is extra

tacky for retention on excavator carbody bearings.

Arctic Platinum has additional extreme pressure

protection for highly loaded pin joints.

F). Arctic Platinum has a high dropping

C (21 to 450

F). Desert

i01065849

S·O·S Oil Analysis

SMCS Code: 1000; 7542

Caterpillar recommends the use of the S·O·S

oil analysis program in order to monitor the

condition and the maintenance requirements of

the equipment. The S·O·S oil analysis program will

complement the preventive maintenance program.

The S·O·S oil analysis is a diagnostic tool that is

used to determine oil performance and component

wear rates. Contamination can be identified and

measured through the use of the S·O·S oil analysis.

The S·O·S oil analysis includes the following tests:

The Wear Rate Analysis monitors the wear of the

•

engine’s metals. The amount of wear metal and

type of wear metal that is in the oil is analyzed.

The increase in the rate of engine wear metal in

the oil is as important as the quantity of engine

wear metal in the oil. For this reason, regular

sampling at specified intervals is necessary

in order to establish wear rates. Intermittent

sampling does not allow wear rate trend lines

to be established. Engine wear metals in the oil

sample are compared to established Caterpillar

norms in order to determine acceptability.

Tests are conducted in order to detect

•

contamination of the oil by water, glycol or fuel.

The Oil Condition Analysis determines the loss

•

C

of the oil’s lubricating properties. An infrared

analysis is used to compare the properties of

new oil to the properties of the used oil sample.

This analysis allows technicians to determine

the amount of deterioration of the oil during use.

This analysis also allows technicians to verify

the performance of the oil according to the

specification during the entire oil change interval.

The test results of the oil samples will then be used

as a basis for determining the oil change interval

for the engine. The results of the S·O·S oil analysis

may allow the engine to operate longer between oil

changes without the risk of engine damage.

Ta bl e 6

S·O·S Oil Analysis Interval

Compartment

Engine crankcase Every 250 Service Hours

Interval

For more information, see Special Publication,

PEDP7036, “S·O·S Fluid Analysis”. Consult your

Caterpillar dealer for complete information and

assistance about the program.

Page 17

17

Maintenance Section

Fuel Specifications

Fuel Specifications

i01060086

General Fuel Information

SMCS Code: 1250; 1280

Purchase fuel from a reputable supplier.

•

Use fuel that meets the minimum Caterpillar

•

specifications for diesel fuel. The specifications

are included in the table Caterpillar Specifications

for Distillate Fuel. This table is included in the

recommendations for diesel fuel. These fuels

have a minimum lubricity level of 3100 g. This

result is obtained by conducting the Scuffing

Load Wear Test (SBOCLE). If a High Frequency

Reciprocating Rig (HFRR) is used for testing,

the maximum allowable wear scar is .45 mm

(0.018 inch) at 60

allowable wear scar is .38 mm (0.0150 inch) at

25

Keep the fuel storage tank clean of water, debris

•

and sediment.

Drain water and sediment from the fuel storage

•

tank weekly. Drain water and sediment before the

tank is refilled.

C (77

F).

C (140F). The maximum

i01096371

Fuel Information for Diesel

Engines

SMCS Code: 1250; 1280

The two basic types of diesel fuel are No. 2 diesel

fuel and No. 1 diesel fuel. No. 2 diesel fuel is a

heavier diesel fuel than No. 1 diesel fuel. Heavier

fuels can cause problems with fuel filters, fuel

lines, fuel tanks, and fuel storage in cold weather.

Heavier diesel fuels such as No. 2 diesel fuel can

be used in diesel engines that operate in cold

temperatures with a minimum amount of pour point

depressant additive. For more information on fuels

which include blends of No. 1 and No. 2 diesel fuel,

consult your fuel supplier.

When you use No. 2 diesel fuel or other heavier

fuels, some of the fuel’s qualities may interfere

with successful cold weather operation. Additional

information about the characteristics of diesel fuel

is available. This information contains a discussion

on the modification to the characteristics of diesel

fuel. There are several possible methods that can

be used to compensate for the fuel qualities that

may interfere with cold weather operation. These

methods include the use of starting aids, engine

coolant heaters, fuel heaters, and de-icers.

Keep the area around the fuel tank filler neck

•

clean of debris in order to prevent contamination

of the fuel tank.

As required, clean the inside of the engine’s fuel

•

tank.

Drain water and sediment from the engine’s fuel

•

tank daily. Drain the tank at the start of a shift.

After the fuel tank has been filled, allow the fuel

to settle for ten minutes. This will allow the water

and sediment to separate from the fuel. Then,

drain the water and sediment from the tank.

Install water separators.

•

Drain the water from the water separator daily.

•

For some applications, Caterpillar high efficiency

•

fuel filters are required in order to provide

maximum life to the fuel system.

Change fuel filters at the scheduled interval.

•

Never fill the new fuel filter with fuel before

installation. Use the fuel priming pump to remove

air from the system.

Install breather filters on the fuel tanks.

•

Starting Aids

The use of a starting aid is a conventional method

of assistance for cold starts in low temperature

conditions. A variety of starting aids are available

for Caterpillar engines. Follow the recommendations

that are provided by the manufacturer of the starting

aid.

Engine Coolant Heaters

These heaters heat the engine coolant. The heated

coolant flows through the cylinder block. The flow

of heated coolant keeps the engine warm. A warm

engine is easier to start in cold weather. Most

coolant heaters use electrical power. A source of

electricity is necessary for this type of heater. Other

heaters that burn fuel are available as a source of

heat. These heaters may be used in place of the

electrical heaters.

With either type of heater, starting aids and/or fuels

with higher cetane numbers are less important

because the engine is warm. Problems with fuel

cloud point can cause the plugging of fuel filters.

Problems with fuel cloud point cannot be corrected

by engine coolant heaters. This is especially true

for fuel filters that are cooled by air flow during

operation.

Page 18

18

Maintenance Section

Fuel Specifications

Fuel Heaters

The fuel cloud point is related to problems with

fuel filters. The heater heats the fuel above the

cloud point before the fuel enters the fuel filter. This

prevents wax from blocking the filter. Fuel can flow

through pumps and lines at temperatures below the

cloud point. The cloud point is often above the pour

point of a fuel. While the fuel can flow through these

lines, the wax in the fuel can still plug the fuel filter.

In some engine installations, small modifications

can prevent problems that are caused by the cloud

point. One of the following changes can prevent

problems in many conditions: a change in the

location of fuel filters and/or supply lines and the

addition of insulation. In extreme temperatures,

heating of the fuel may be required to prevent the

filters from plugging. There are several types of fuel

heaters that are available. The heaters use either

engine coolant or exhaust gas as a heat source.

These systems may prevent filter waxing problems

without the use of de-icers. These systems may be

ineffective when the fuel contains a large amount

of dirt or of water. Use of a fuel heater can help

eliminate some cold weather problems. A fuel

heater should be installed so that the fuel is heated

before flowing into the fuel filter.

Note: Only use fuel heaters that are controlled

by thermostats or use fuel heaters that are

self-regulated. Do not use fuel heaters in warm

temperatures.

Select a fuel heater that is mechanically simple, yet

adequate for the application. The fuel heater should

also prevent overheating of the fuel. Disconnect the

fuel heater or deactivate the fuel heater in warm

weather. An unacceptable loss of fuel viscosity

and engine power will occur if the fuel supply

temperature is allowed to become too hot.

For additional information on fuel heaters, see your

Caterpillar dealer.

De-Icers

De-icers lower the freezing point of the moisture in

the fuel. De-icers are not generally needed when

fuel heaters are used. If you experience trouble,

consult your fuel supplier for recommendations of

a compatible commercial de-icer.

i01111474

Fuel Recommendations

SMCS Code: 1250; 1280

Diesel engines have the ability to burn a wide

variety of fuels. These fuels are divided into two

general groups. The two groups are called the

preferred fuels and the permissible fuels.

The preferred fuels provide maximum engine

service life and performance. The preferred fuels

are distillate fuels. These fuels are commonly called

diesel fuel, furnace fuel, gas oil, or kerosene.

The permissible fuels are crude oils or blended

fuels. Use of these fuels can result in higher

maintenance costs and in reduced engine service

life.

Diesel fuels that meet the specifications in Table 7

will help to provide maximum engine service life

and performance. In North America, diesel fuel that

is identified as No. 1-D or No. 2-D in “ASTM D975”

generally meet the specifications. Table 7 is for

diesel fuels that are distilled from crude oil. Diesel

fuels from other sources could exhibit detrimental

properties that are not defined or controlled by this

specification.

Ta bl e 7

Caterpillar Specifications for Distillate Diesel Fuel

Specifications

Aromatics 35% maximum “D1319”

Ash 0.02% maximum (weight) “D482”

Carbon Residue

on 10% Bottoms

Cetane Number

Cloud Point

Copper Strip

Corrosion

Distillation

Flash Point legal limit “D93”

Requirements

0.35% maximum (weight) “D524”

40 minimum (DI engines)

35 minimum (PC engines)

The cloud point must

not exceed the lowest

expected ambient

temperature.

No. 3 maximum “D130”

10% at 282C (540F)

maximum

90% at 360C (680F)

maximum

ASTM

Test

“D613”

-

“D86”

(continued)

Page 19

19

Maintenance Section

Fuel Specifications

(Table 7, contd)

Caterpillar Specifications for Distillate Diesel Fuel

Specifications

Requirements

ASTM

Test

30 minimum

“D287”

API Gravity

45 maximum

Pour Point

6

F) minimum

C (10

below ambient

“D97”

temperature

3% maximum “D3605”

(1)

Sulfur

or

“D1552”

Kinematic

Viscosity

Water and

1.4 cSt minimum and 20.0

(2)

cSt maximum at 40

(104

F)

C

0.1% maximum “D1796”

“D445”

Sediment

Water 0.1% maximum “D1744”

Sediment 0.05% maximum (weight) “D473”

Gums and

(3)

Resins

10 mg per 100 mL

maximum

“D381”

3100 g minimum “D6708”

Lubricity

(4)

0.45 mm (0.018 inch)

maximum at 60

C (140

F)

“D6079”

0.38 mm (0.015 inch)

maximum at 25

(1)

Caterpillar fuel systems and engine components can

operate on high sulfur fuels. Fuel sulfur levels affect exhaust

emissions. High sulfur fuels also increase the potential for

corrosion of internal components. Fuel sulfur levels above 1.0

percent may significantly shorten the oil change interval. For

additional information, see this publication, “Engine Oil” topic

(Maintenance Section).

(2)

The values of the fuel viscosity are the values as the fuel

is delivered to the fuel injection pumps. If a fuel with a low

viscosity is used, cooling of the fuel may be required to maintain

a 1.4 cSt viscosity at the fuel injection pump. Fuels with a high

viscosity might require fuel heaters in order to bring down the

viscosity to a 20 cSt viscosity. For additional information, see

Special Publication, SEBD0717, “Diesel Fuel and Your Engine”.

(3)

Follow the test conditions and procedures for gasoline (motor).

(4)

The lubricity of a fuel is a concern with low sulfur fuel. To

determine the lubricity of the fuel, use either the “ASTM D6708

Scuffing Load Wear Test (SBOCLE)” or the “ASTM D6079 High

Frequency Reciprocating Rig (HFRR)” test. If the lubricity of a

fuel does not meet the minimum requirements, consult your

fuel supplier. Do not treat the fuel without consulting the fuel

supplier. Some additives are not compatible. These additives

can cause problems in the fuel system.

C (77

F)

NOTICE

Operating with fuels that do not meet Caterpillar’s recommendations can cause the following effects: starting difficulty, poor combustion, deposits in the fuel injectors, reduced service life of the fuel system, deposits in the combustion chamber, and reduced service life of the engine.

In the USA, 0.05 percent diesel fuels have been

used in all on-highway truck engines since 1

January 1994. This low sulfur diesel fuel was

mandated as a means of directly reducing

particulate emissions from diesel truck engines.

This low sulfur fuel will also be used in Caterpillar

commercial diesel engines when low emissions are

required or when the fuel supply sources provide

this type of fuel. Caterpillar has not seen any

detrimental effects with 0.05 percent sulfur fuel in

Caterpillar diesel engines.

NOTICE

Heavy Fuel Oil (HFO), Residual fuel, or Blended fuel

must NOT be used in Caterpillar diesel engines (except in 3600 Series HFOengines). Severe component

wear and component failures will result if HFO type fuels are used in engines that are configured to use distillate fuel.

In extreme cold ambient conditions, you may

use the distillate fuels that are specified in Table

8. However, the fuel that is selected must meet

the requirements that are specified in Table 7.

These fuels are intended to be used in operating

temperatures that are down to

Ta bl e 8

Distillate Fuels

Specification Grade

“MIL-T-5624R” JP-5

“ASTM D1655” Jet-A-1

“MIL-T-83133D” JP-8

(1)

The fuels that are listed in this Table may not meet the

requirements that are specified in the “Caterpillar Specifications

for Distillate Diesel Fuel” Table. Consult the supplier for the

recommended additives in order to maintain the proper fuel

lubricity.

−54

(1)

C(−65

F).

These fuels are lighter than the No. 2 grades of fuel.

The cetane number of the fuels in Table 8 must be

at least 40. If the viscosity is below 1.4 cSt at 38

(100

F), use the fuel only in temperatures below

C (32F). Do not use any fuels with a viscosity

0

of less than 1.2 cSt at 38

C (100

F). Fuel cooling

C

may be required in order to maintain the minimum

viscosity of 1.4 cSt at the fuel injection pump.

There are many other diesel fuel specifications that

are published by governments and by technological

societies. Usually, those specifications do not

review all the requirements that are addressed

in this specification. To ensure optimum engine

performance, a complete fuel analysis should be

obtained before engine operation. The fuel analysis

should include all of the properties that are listed

in Table 7.

Page 20

20

Maintenance Section

Fuel Specifications

i01111650

Characteristics of Diesel Fuel

SMCS Code: 1250; 1280

The primary characteristics that affect engine

operation and performance in cold temperatures

are the following characteristics: Lubricity, Viscosity,

Cetane Number, Cloud Point, Pour Point, and

Moisture Content.

Refer to Special Publication, SEBD0717, “Diesel

Fuels and Your Engine” for information about the

following fuel properties: ignition quality, gravity

(density), viscosity, cloud point, pour point, and

sulfur content.

Lubricity and Low Sulfur Fuel

Note: The fuel lubricity is important. You should

consider the fuel’s lubricity whenever you operate

the equipment in arctic weather. Also, you should

consider the fuel’s lubricity whenever you use

fuels that are lower in viscosity. There are many

aftermarket additives that are available to treat fuel.

If the fuel’s lubricity is an issue, consult your fuel

supplier for proper recommendations regarding fuel

additives.

In the USA, a 0.05 percent limit on the amount of

fuel sulfur in diesel fuel was mandated in January

of 1994 for on-highway trucks. The removal of

sulfur from diesel fuel helps to reduce particulate

emissions from diesel engines. While limits for

fuel sulfur have not generally been mandated for

off-highway use, some local governments have

regulations that include off-highway use. There

is frequently no difference in the fuel that is

sold for different applications. The same fuel is

often used for both on-highway applications and

off-highway applications. Other areas of the world

are mandating similar limits. Regulations continue to

become more stringent. Lower sulfur limits can be

expected in the future.

The fluid’s lubricity describes the ability of the fluid

to reduce the friction between surfaces that are

under load. This ability reduces the damage that

is caused by friction. Fuel injection systems rely

on the lubricating properties of the fuel. Until fuel

sulfur limits were mandated, the fuel’s lubricity was

generally believed to be a function of fuel viscosity.

The process that is most commonly used to remove

sulfur from fuel is called hydro-treatment. This

process is also the most economical process. Each

source of crude oil contains different amounts

of sulfur. Crude oils with low sulfur require little

hydro-treatment to obtain the 0.05 percent limit.

Crude oils with high sulfur require a more severe

treatment.

The Hydro-treatment removes the fuel’s sulfur as

well as other components. The treatment removes

nitrogen compounds, polar materials, bicyclic

aromatics, polycyclic aromatics, and oxygen

compounds. While the removal of sulfur has shown

no detrimental effects to the engine, the removal of

other compounds have lowered the lubricity of the

fuel. As a result of the lowered lubricity, the fuel is

less tolerant of contamination by water and dirt. The

lower fuel lubricity can be seen as abrasive wear

of fuel system components. Fuels that have a low

lubricity may not provide adequate lubrication to

plungers, to barrels, and to injectors. This problem

may be compounded in areas that require winter

blends of fuel. The lighter winter fuel blend has

the following characteristics: lower viscosity, lower

cloud point, and lower pour point.

All low sulfur fuels do not have a low lubricity. The

fuel’s lubricity may be enhanced with additives.

Many fuel suppliers treat the fuel with these

additives. Do not use a fuel lubricity additive before

you consult the fuel’s supplier. Some aftermarket

additives may not be compatible with the additives

that are already in the fuel. Some additive packages

that are supplied by the aftermarket manufacturer

may not be compatible with the seals that are used

in fuel systems of some diesel engines. Other

additive packages that are supplied by aftermarket

manufacturers cannot provide proper performance

in high temperature conditions. These additives may

leave deposits because of the high temperatures

that exist in the fuel systems of diesel engines.

Maximum life of the fuel system can be achieved by

performing the following tasks: using a reliable fuel

supplier, performing proper maintenance of the fuel

system, and installing Caterpillar high efficiency fuel

filters in the fuel system.

Note: Lighter fuels are frequently used in arctic

temperatures. Lighter fuels may include the following

fuels: Jet A-1, JP-8, JP-5, and kerosene. The fuel

lubricity is not a requirement of the specifications

for these fuels. Do not assume that a fuel meets

the minimum Caterpillar specification. Contact the

fuel supplier for proper recommendations on fuel

lubricity additives.

Viscosity

The viscosity of the fuel is significant because

the fuel serves as a lubricant for fuel system

components. Arctic fuels need to have sufficient

viscosity. The fuel must lubricate the fuel system at

a temperature of 0

kinematic viscosity of the fuel is lower than 1.4 cSt

as supplied to the fuel injection pump or to the unit

injectors, excessive scuffing and seizure can occur.

C (32F) or below freezing. If the

Page 21

21

Maintenance Section

Fuel Specifications

Cetane Number

The cetane number of the fuel has an effect on

the ability of the engine to start. Also, the cetane

number has an effect on the interval of time before

the engine runs smoothly. Generally, an increase

of ten in the cetane number will allow the engine

to be started at a lower temperature. The starting

temperature can be improved approximately

7to8

the cetane number. After the engine reaches the

normal operating temperature, a change in the

cetane from 40 to 50 will have a minimal effect on

engine performance.

Most fuels that have a cetane number above 40 will

permit acceptable engine starts in warmer outside

temperatures. The engine will start satisfactorily with

this fuel when the engine is kept warm. The engine

can be kept warm by using either a heated room

or a coolant heater.

During average starting conditions, direct injection

engines require a minimum cetane number of 40. A

higher cetane value may be required for operation

in high altitudes or for cold weather operation. The

minimum fuel cetane number that is required for the

precombustion engine is 35.

C (12 to 15

Modifying the Cetane Number

The cetane number of a fuel can be changed if

the fuel is mixed with a fuel that has a different

cetane number. Generally, the cetane number of

the mixture will be in direct relation to the ratio of

the fuels that were mixed. Your fuel supplier can

provide the information about the cetane number

of a particular fuel.

Additives can also be used to improve the cetane

number of a fuel. Additives are evaluated through

testing in special engines. However, the fuel

characteristics of additives are not identical to a

natural product. While both fuels may be rated as

having the same cetane number, starting may be

different.

F) for every increase of ten in

Cloud Point