Page 1

1

-DIN DIGITAL INDICATOR

8

PRODUCT MANUAL

59039-2

Page 2

PREFACE

This manual comprises two volumes:

Volume I: This supports normal operation of the

Digital Indicator. In normal operation, all actions

taken by the user are to be in front of the panel.

Volume II: This supports the installation, commissioning and

configuring of the

1

-DIN Digital Indicator. It is

8

intended for use only by personnel who are trained,

equipped and authorised to carry out these functions.

1

-DIN

8

CAUTION: REFER TO MANUAL

THE INTERNATIONAL HAZARD SYMBOL IS INSCRIBED ADJACENT TO

THE REAR CONNECTION TERMINALS. IT IS IMPORTANT TO READ THE

MANUAL BEFORE INSTALLING OR COMMISSIONING THE UNIT.

Page 3

59039

1

-DIN Digi tal In di ca tor

8

Prod uct Man ual - Vol ume I

1

-DIN DIGITAL INDICATOR

8

PRODUCT MANUAL

VOLUME I

OPERATING INSTRUCTIONS

In normal operation, the operator must not remove the

Indicator from its housing or have unrestricted access to the

rear terminals, as this would provide potential contact with

hazardous live parts.

Installation and configuration must be undertaken by

technically competent servicing personnel. This is covered in

Volume II of this manual.

SM067- V1 November, 2000 (i)

Page 4

1

-DIN Digi tal In di ca tor 59039

8

Prod uct Man ual - Vol ume I

Con tents

1 IN TRO DUC TION 1-1

2 OP ERA TOR MODE 2-1

3 SET UP MODE 3-1

4 RS485 SE RIAL COM MU NI CA TIONS 4-1

Ap pen di ces

A Al pha beti cal In dex A-1

(ii) November, 2000 SM067- V1

Page 5

59039

1

-DIN Digi tal In di ca tor Sec tion 1

8

Prod uct Man ual - Vol ume I In tro duc tion

SEC TION 1

INTRODUCTION

1

The

-DIN Digital Indicator is an easy-to-operate microprocessor-based instrument,

8

incorporating the latest in surface-mount and CMOS technology. The standard features

include:

Large four- digit LED dis play (or der able as red or green).

*

Dis play for units in di ca tion

*

Uni ver sal sen sor in put - ther mo cou ple, three- wire RTD or DC lin ear

*

(mA, mV or V)

In put range se lected from the front panel.

*

Alarm 1 latch ing or non- latching (user- selectable) re lay out put

*

Alarm hys tere sis

*

Maxi mum Hold, Mini mum Hold and Time Elapsed fea tures.

*

OM067-1 November, 2000 1-1

Page 6

Sec tion 1

In tro duc tion Prod uct Man ual - Vol ume I

90 - 264V AC power sup ply.

*

De signed to com ply with EN50081 Part 2 (Emis sion) and EN50082

*

(Im mu nity) EMC speci fi ca tions.

Front panel seal ing to IP65 (NEMA 4) stan dard.

*

Pro gram ma ble digi tal fil ter.

*

Proc ess Vari able off set fa cil ity

*

Alarm type se lected from front panel.

*

Sen sor Break in di ca tion.

*

and the many optional features include:

1

-DIN Digi tal In di ca tor 59039

8

Alarm 2 and Alarm 3 re lay out puts

*

Re mote re set of latched alarm

*

Re- transmitted Proc ess Vari able out put

*

Trans mit ter power sup ply

*

ASCII and MOD BUS com mu ni ca tions pro to cols

*

RS485 se rial com mu ni ca tions.

*

1-2 November, 2000 OM067-1

Page 7

59039

1

-DIN Digi tal In di ca tor Sec tion 2

8

Prod uct Man ual - Vol ume I Op era tor Mode

SEC TION 2

OPERATOR MODE

2.1 INTRODUCTION

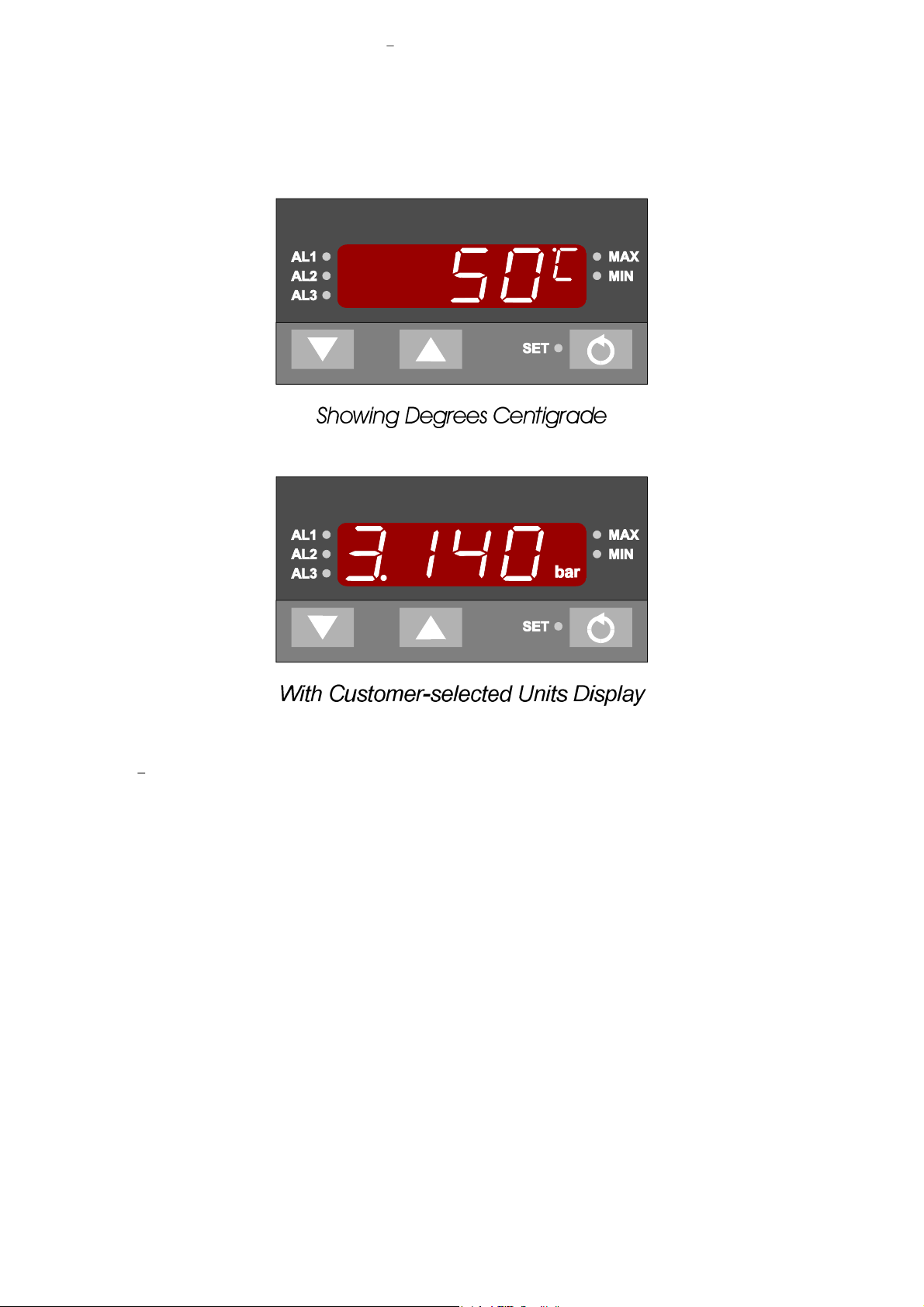

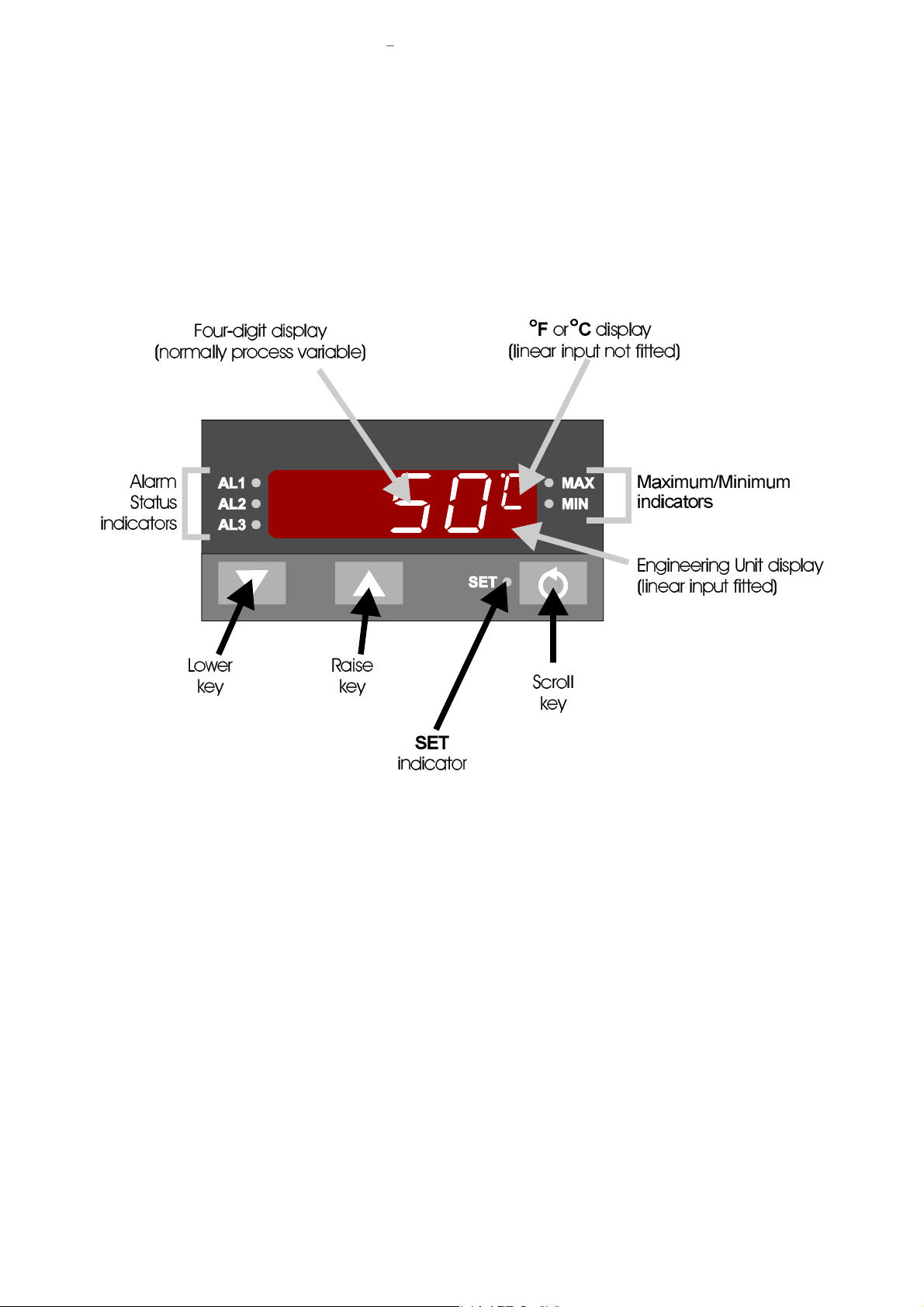

The Operator Mode is the normal mode of the Indicator, once it has been set up and

configured as required. The front panel displays, indicators and keys are shown in

Figure 2-1.

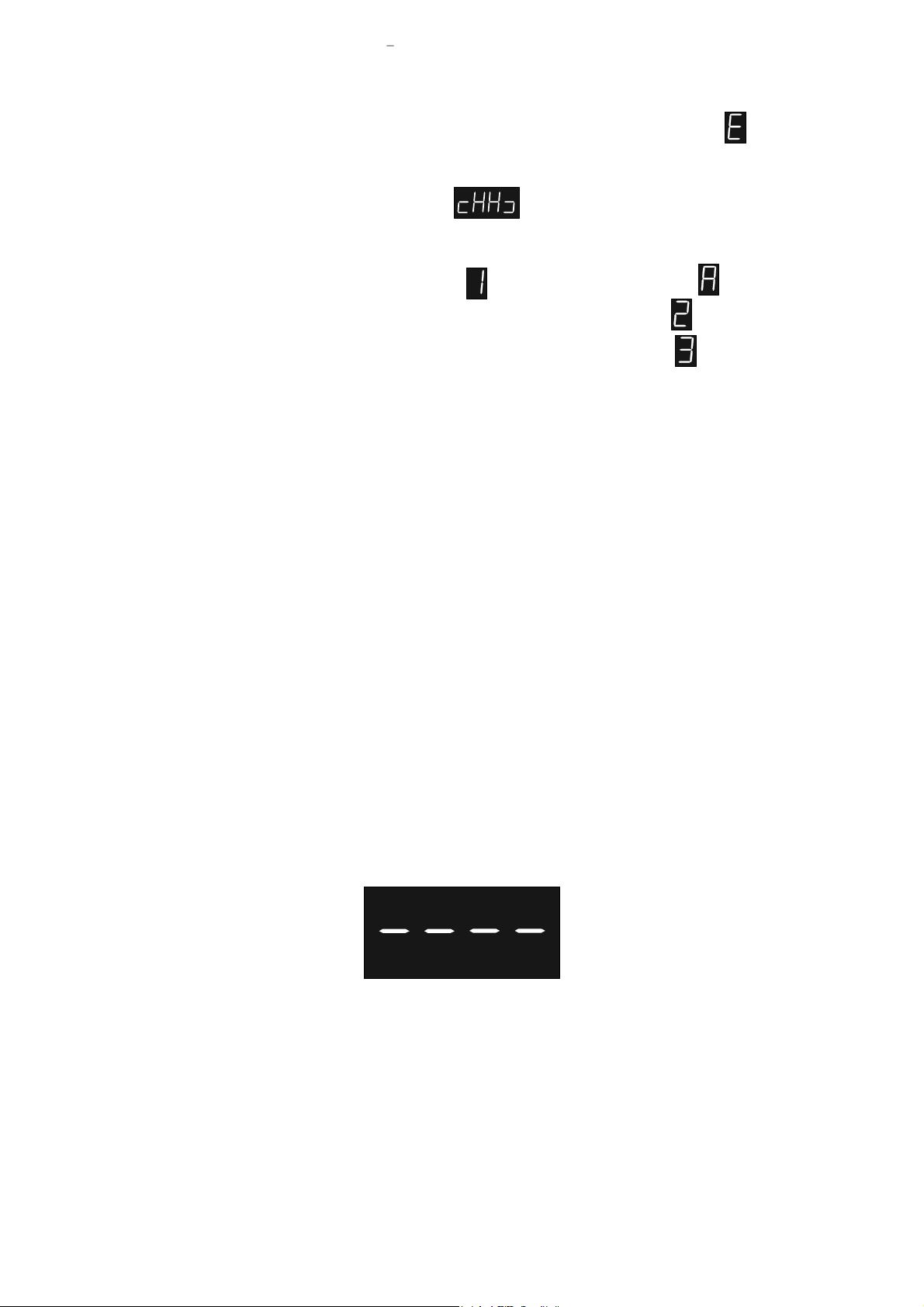

Fig ure 2-1 Front Panel Con trols, Dis plays and In di ca tors

2.2 FOUR-DIGIT DISPLAY

In Operator Mode, this normally displays the process variable value. Using the Scroll

key, the operator may view, in a sequence according to the Operator Mode Display

Strategy parameter in Set Up Mode (see NOTES ON TABLE 3-1):

(i) Cur rent maxi mum value at tained by pro cess vari able (since the maxi mum

value was last re set) - MAX in di ca tor ON when this is dis played. Also saves

the Sen sor Break (see Sub sec tion 2.6) and Over- Range (see Sub sec tion

2.5) con di tions.

(ii) Cur rent mini mum value at tained by pro cess vari able (since the mini mum

value was last re set) - MIN in di ca tor ON when this is dis played. Also saves

the Sen sor Break (see Sub sec tion 2.6) and Under- Range (see Sub sec tion

2.5) con di tions.

OM067-2 November, 2000 2-1

Page 8

Sec tion 2

Op era tor Mode Prod uct Man ual - Vol ume I

1

-DIN Digi tal In di ca tor 59039

8

(iii) Time elapsed in the Alarm 1 ac tive con di tion (units dis play shows ).

The dis play is in the for mat mm.ss [mm = min utes, ss = sec onds] or mmm.s

[mmm = min utes, s = sec onds (tens)]. If elapsed time is greater than 999 min utes 59 sec onds, dis play will show:

NOTE: This does not in clude time when Alarm 1 is latched but alarm con di tion is cleared

(iv) Alarm 1 value (units dis play shows or, if only Alarm 1 pres ent, ).

(v) Alarm 2 value, if fit ted and con fig ured (units dis play shows ).

(vi) Alarm 3 value, if fit ted and con fig ured (units dis play shows ).

(iv) Proc ess vari able value.

Further depressions of the Scroll key will repeat this display sequence.

2.3 ALARM STATUS INDICATORS

The Alarm Status indicators show the current state of the alarm(s):

AL1 - Flashes when Alarm 1 is ac tive (with latch ing alarm, ON when

Alarm 1 is latched but alarm con di tion has cleared)

AL2 - Flashes when Alarm 2 is ac tive

AL3 - Flashes when Alarm 3 is ac tive

For descriptions of the operation of the various types of alarm available, see Section 3.

2.4 RESETTING THE MAXIMUM VALUE/MINIMUM VALUE OR TIME ELAPSED

VALUE

To reset the maximum value, minimum value (to the process variable value at the

instant of resetting) or time elapsed value (to zero):

1. Se lect the dis play of the maxi mum value, mini mum value or time

elapsed value (as ap pro pri ate - see above).

2. De press the Raise key or Lower key for three sec onds.

The resetting of the value is indicated by the four-digit display showing:

for two sec onds be fore re vert ing to the maxi mum value or mini mum value dis play.

2 -2 November, 2000 OM067-2

Page 9

59039

1

-DIN Digi tal In di ca tor Sec tion 2

8

Prod uct Man ual - Vol ume I Op era tor Mode

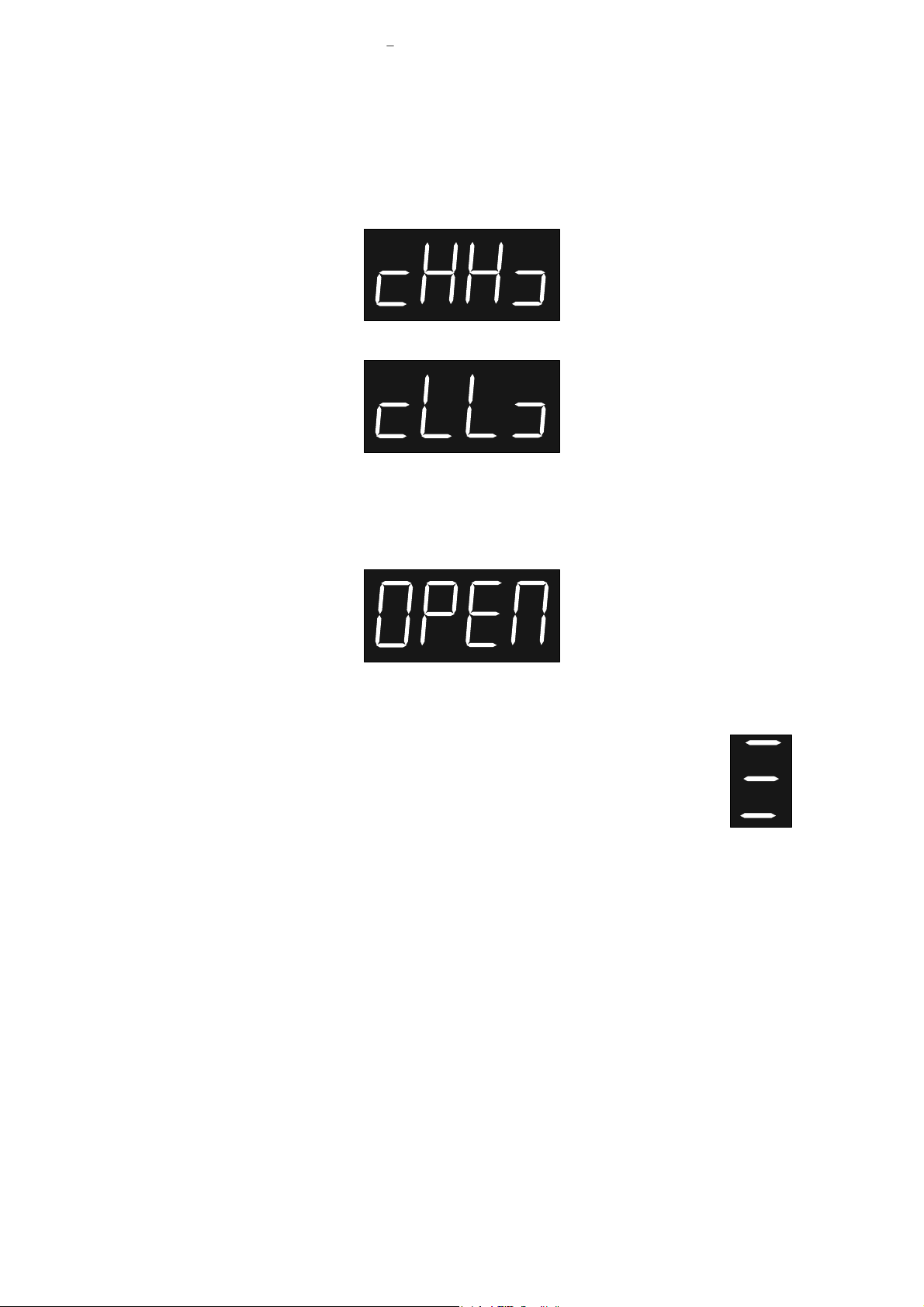

2.5 OVER-RANGE/UNDER-RANGE DISPLAYS

If the process variable attains a value higher than the input scale maximum limit

(over-range) or lower than the input scale minimum limit (under-range), the upper

display will show:

for the over-range condition and:

for the under-range condition.

2.6 SENSOR BREAK INDICATION

If a break is detected in the sensor circuit, the four-digit display will show:

The reaction of the alarms to a detected sensor break is dependent upon the input type.

2.7 COLD JUNCTION COMPENSATION DISABLED

If a thermocouple input is fitted, the Cold Junction Compensation should

be enabled. If it is disabled, whenever the process variable is displayed,

the unit display will be as shown on the right.

2.8 RESETTING THE LATCHED ALARM

If Output 1 is configured to be a latched alarm output, once it becomes active it will

remain active (even if the alarm condition itself is cleared) until reset either from the

front panel or via the Remote Reset hardware option. To reset the latched alarm from

the front panel:

1. En sure that the nor mal Op er at ing Mode dis play (i.e. pro cess vari able)

is shown.

2. Press ei ther the Raise key or the Lower key for at least three sec onds.

The four-digit display will then show:

OM067-2 November, 2000 2-3

Page 10

Sec tion 2

Op era tor Mode Prod uct Man ual - Vol ume I

1

-DIN Digi tal In di ca tor 59039

8

for two seconds, indicating that the latched alarm has been reset. The latched Alarm 1

can be reset only if the original alarm condition has been cleared; this reset has no

effect whilst the alarm condition prevails.

2.9 VIEWING THE HARDWARE DEFINITION CODE

The operator may view the current Hardware Definition Code setting in the four-digit

display by simultaneously depressing the Lower and Scroll keys. A return may be made

to the normal Operator Mode display by simultaneously depressing the Lower and

Scroll keys.

NOTE: An automatic return is made to the normal Operator Mode

display after 30 seconds.

To view the Hardware Option setting, press the Scroll key whilst the Hardware

Definition Code is displayed. To return to the Hardware Definition Code display,

depress the Lower and Scroll keys simultaneously.

2-4 November, 2000 OM067-2

Page 11

59039

1

-DIN Digi tal In di ca tor Sec tion 3

8

Prod uct Man ual - Vol ume I Set Up Mode

SEC TION 3

SET UP MODE

3.1 ENTRY INTO SET UP MODE

To enter Set Up Mode, with the instrument initially in Operator Mode displaying the

process variable value, depress the Raise and Scroll keys simultaneously for three

seconds. The instrument will then enter Set Up Mode and the SET indicator will come

ON, the instrument still displaying the process variable value.

NOTE: If the four-digit display shows:

(i.e. all decimal point positions illuminated), this indicates that one or

more of the critical Configuration Mode parameters - typically input

range - have been altered in value/setting and, as a consequence, all

Set Up Mode parameters have been automatically set to their default

values/settings. To clear this display, simply alter the value/setting of

any Set Up Mode parameter (see below).

The pa rame ters avail able for view/ad just ment in Set Up Mode are sum ma rised in Ta ble

3-1. When Set Up Mode is ac tive, the units dis play (nor mally oF, oC or blank) will show

the single- character leg end for the se lected pa rame ter and the value for that pa rame ter

will be shown in the four- digit dis play. The user may step through the Set Up Mode

pa rame ters by de press ing the Scroll key. The value/set ting may be al tered us ing the

Raise/Lower keys.

OM067-3 November, 2000 3-1

Page 12

Sec tion 3

1

-DIN Digi tal In di ca tor 59039

8

Set Up Mode Prod uct Man ual - Vol ume I

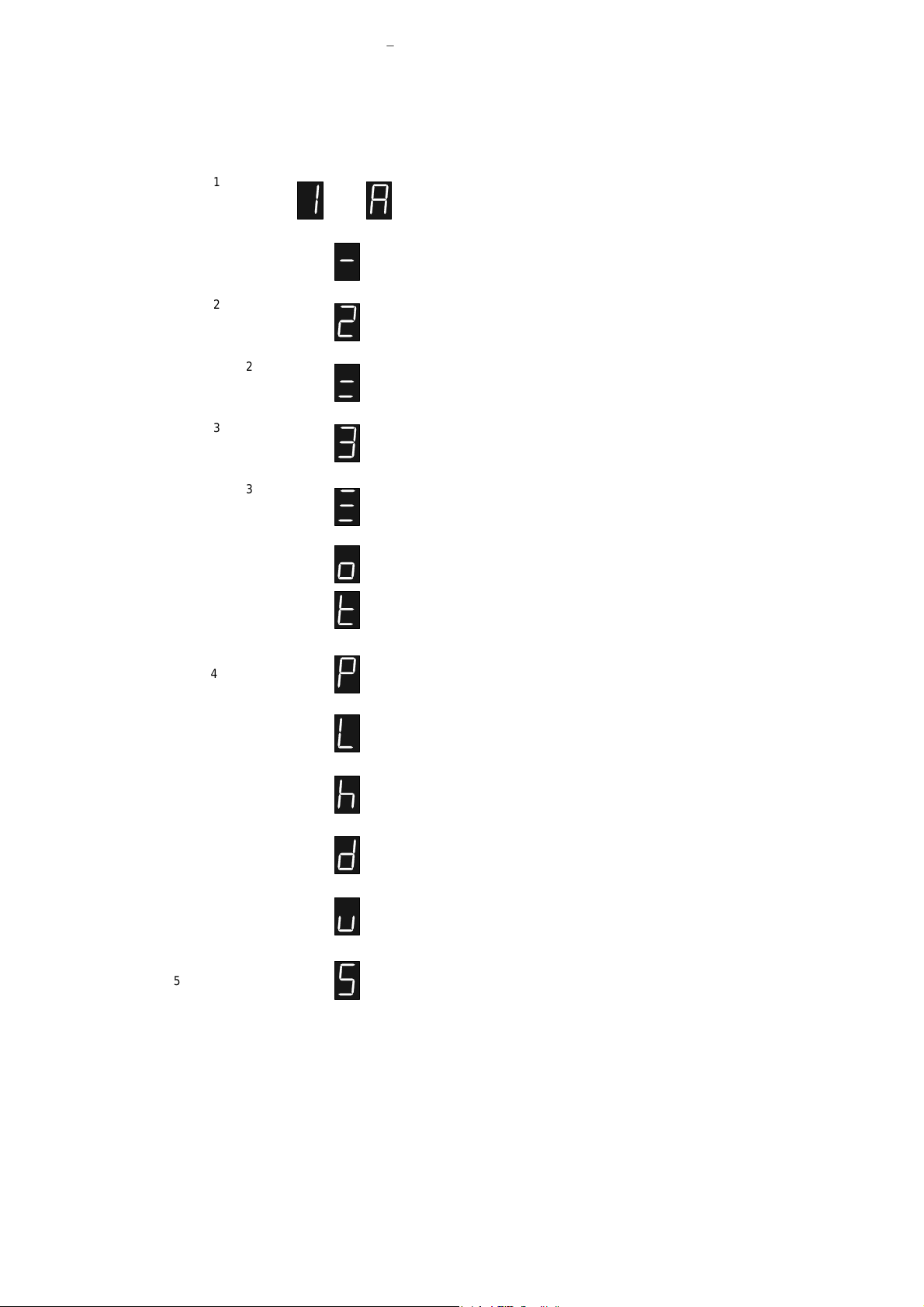

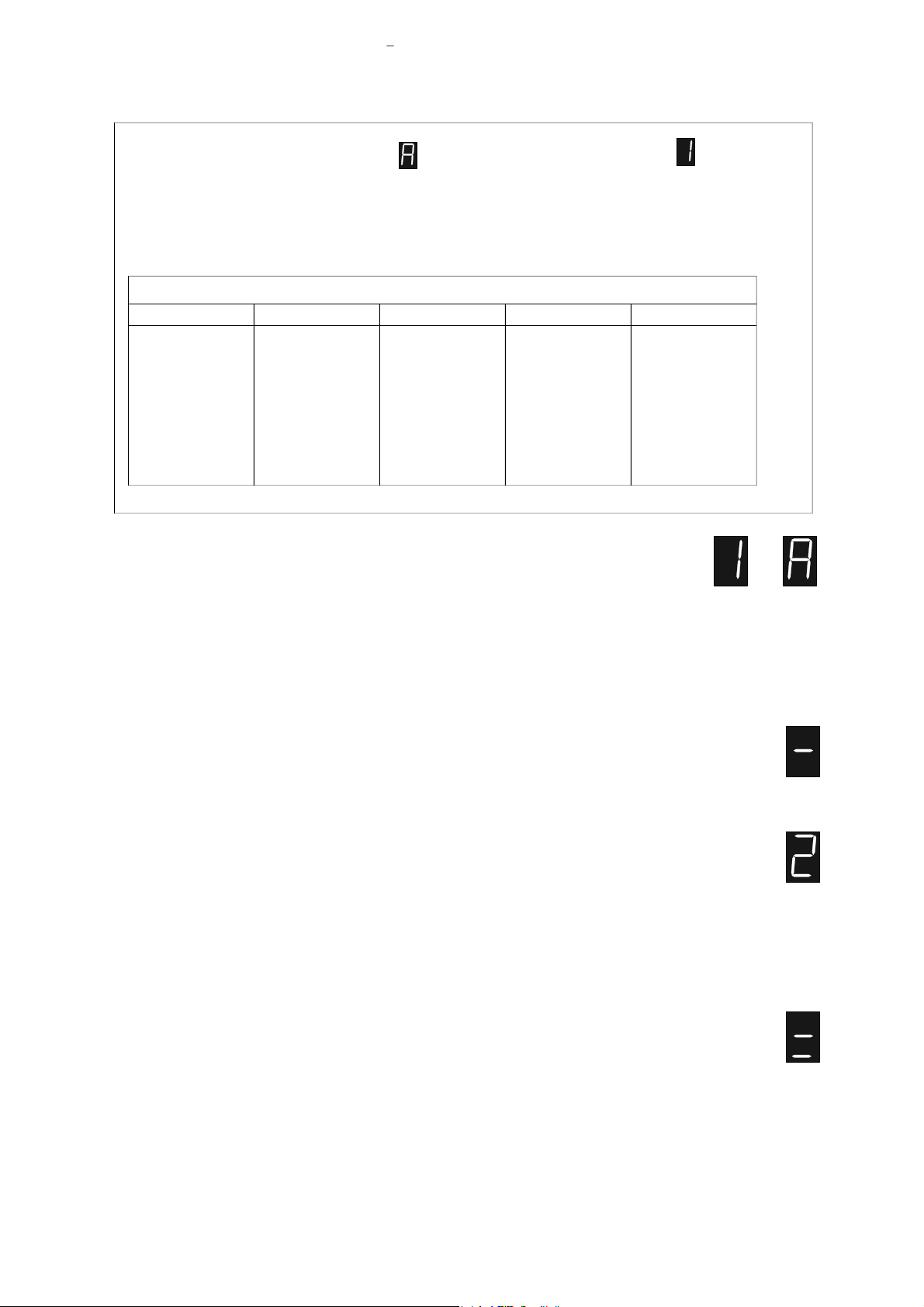

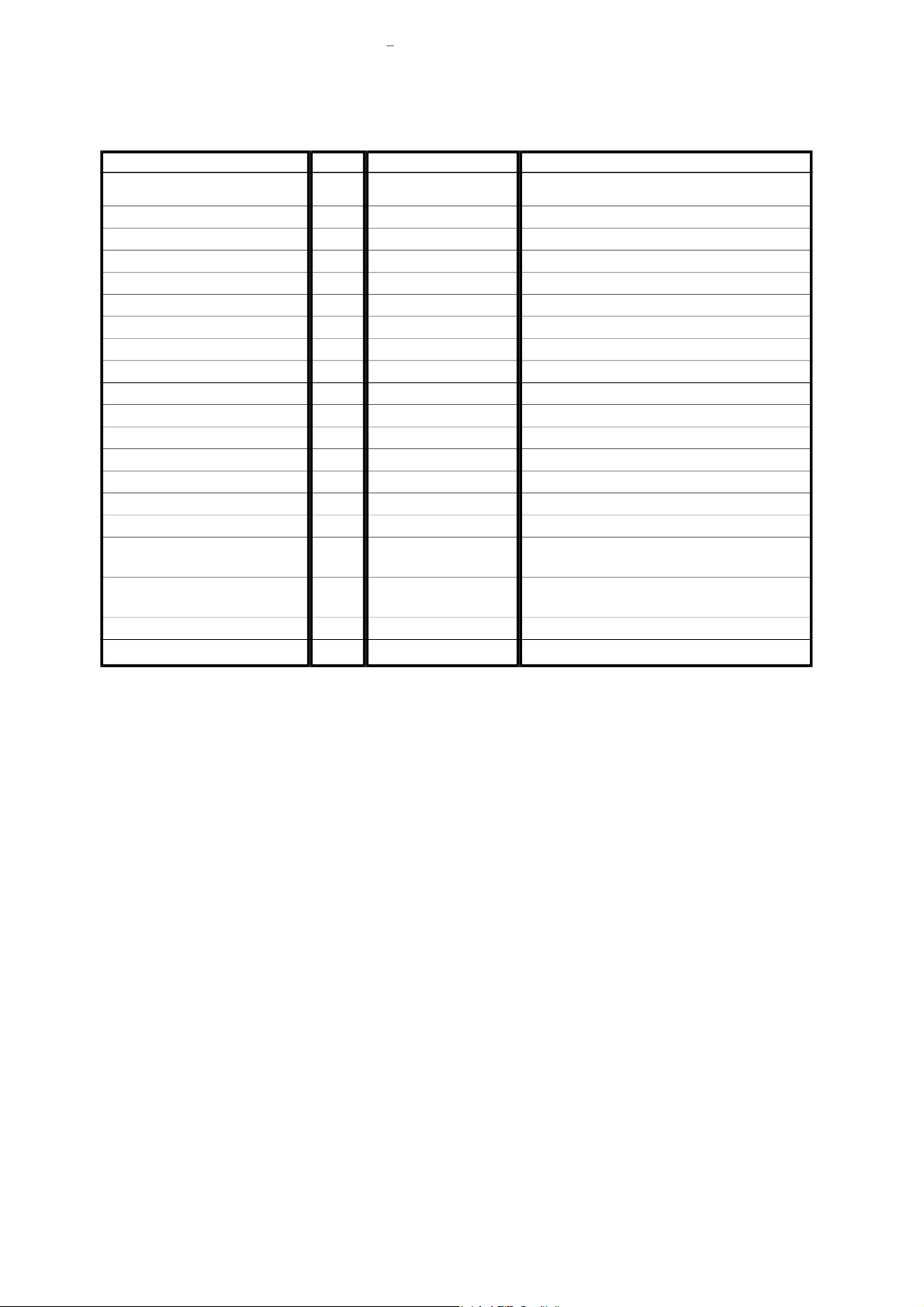

Table 3-1 Set Up Pa rame ters

Parameter

Alarm 1 Value

1

Alarm 1 Hysteresis

Alarm 2 Value

Alarm 2 Hysteresis

Alarm 3 Value

Alarm 3 Hysteresis

2

2

3

3

Process Variable Offset

Digital Filter Time Const.

Legend

or

Adjustment Range

Range Min. to Range Max.

1 LSD to 10% of span expressed

as display units

Range Min. to Range Max.

1 LSD to 10% of span expressed

as display units

Range Min. to Range Max.

1 LSD to 10% of span expressed

as display units

input span of instrument

0.0 secs. (OFF) to 100.0 secs. in

0.5 sec. increments.

Default

Range Max. (Proc. High)

Range Min. (Proc. Low)

1 LSD

Range Max. (Proc. High)

Range Min. (Proc. Low)

1 LSD

Range Max. (Proc. High)

Range Min. (Proc. Low)

1 LSD

0

2.0 secs.

Linear Input Decimal

Point Position

Linear Input Scale

Range Minimum

Linear Input Scale

Range Maximum

4

4

4

Recorder Output Scale

Minimum

Recorder Output Scale

Maximum

Operator Mode Display

Strategy

5

0 (XXXX), 1 (XXX.X), 2 (XX.XX)

or 3 (X.XXX)

–1999 to 9999

–1999 to 9999

–1999 to 9999

–1999 to 9999

0, 1, 2, 3 or 4

1

0000

1000

Range Min.

Range Max.

0

3-2 November, 2000 OM067-3

Page 13

59039

1. The legend for this parameter will be if only Alarm 1 is fitted/configured or if o ther

alarms are fitted/configured.

2. These parameters appear in the display sequence only if Alarm 2 is fitted/configured.

3. These parameters appear in the display sequence only if Alarm 3 is fitted/configured.

4. Only applicable if a DC Linear input is fitted.

5. Defines the parameters displayed in sequence in Operator Mode:

1

-DIN Digi tal In di ca tor Sec tion 3

8

Prod uct Man ual - Vol ume I Set Up Mode

NOTES ON TABLE 3-1

Parameter Setting

0

PV value

Max. PV value

Min. PV value

Elapsed Time

1

PV value

Max. PV value

Min. PV value

2

PV value

Alarm 1 value

Alarm 2 value *

Alarm 3 value *

* If configured/fitted

3

PV value

Max. PV value

Min. PV value

Alarm 1 value

Alarm 2 value *

Alarm 3 value *

4

PV value

Max. PV value

Min. PV value

Elapsed Time

Alarm 1 value

Alarm 2 value *

Alarm 3 value

3.2 ALAR M 1 VALUE or

If Alarm 1 is selected to be a Process High alarm, this defines the process variable

value at or above which Alarm 1 will be active; the default value will be Input Range

Maximum. If Alarm 1 is selected to be a Process Low alarm, this defines the process

variable value at or below which Alarm 1 will be active; the default value will be Input

Range Minimum. Its value may be adjusted between Input Range Maximum and Input

Range Minimum. Alarm operation is illustrated in Figure 3-1.

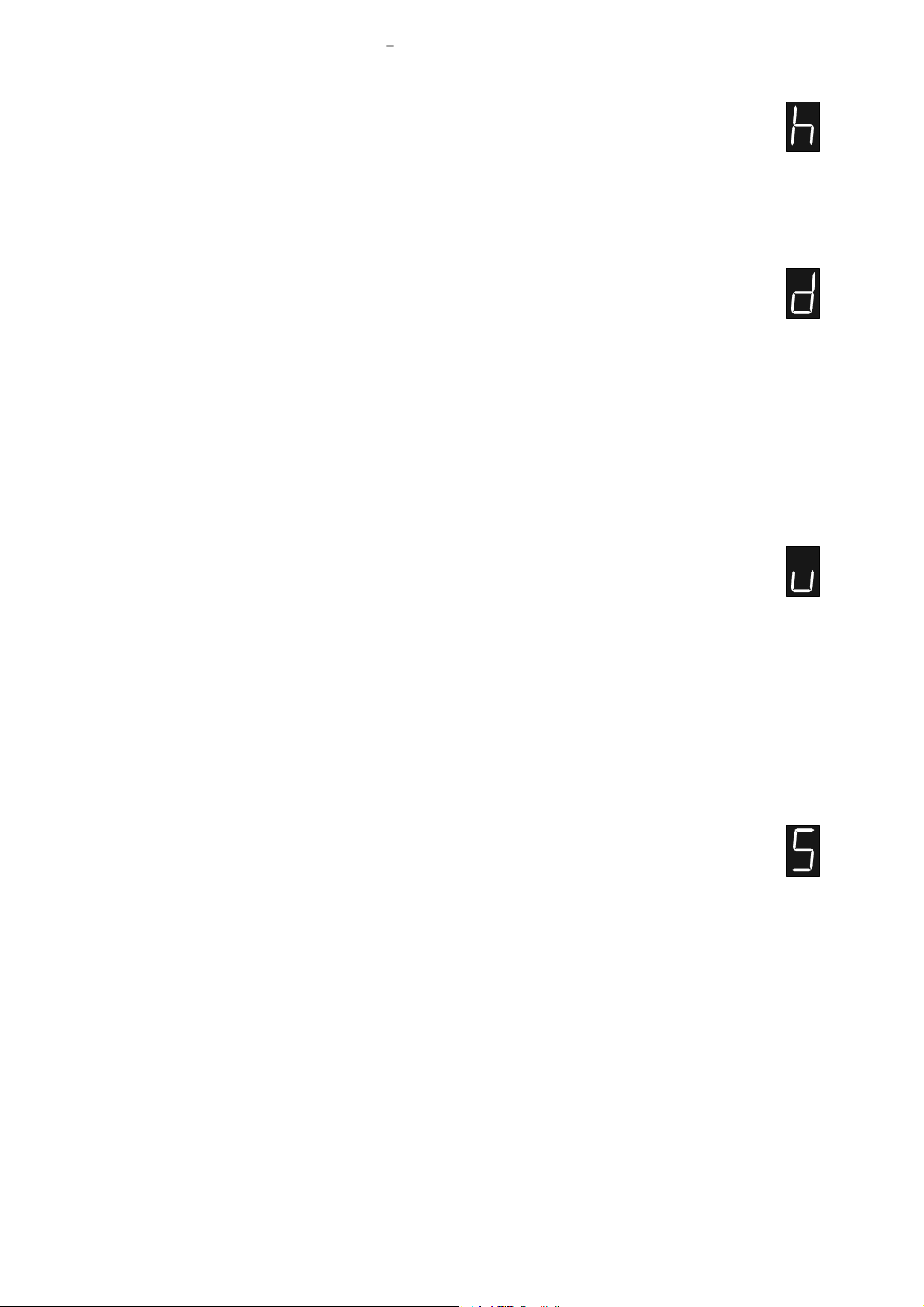

3.3 ALARM 1 HYSTERESIS

This parameter applies a hysteresis band on the “safe” side of the Alarm 1 value. The

effect of the hysteresis value on alarm operation is shown in Figure 3-2.

3.4 ALARM 2 VALUE

If Alarm 2 is selected to be a Process High alarm, this defines the process variable

value at or above which Alarm 2 will be active; the default value will be Input Range

Maximum. If Alarm 2 is selected to be a Process Low alarm, this defines the process

variable value at or below which Alarm 2 will be active; the default value will be Input

Range Minimum. Its value may be adjusted between Input Range Maximum and Input

Range Minimum. Alarm operation is illustrated in Figure 3-1.

3.5 ALARM 2 HYSTERESIS

This parameter applies a hysteresis band on the “safe” side of the Alarm 2 value. The

effect of the hysteresis value on alarm operation is shown in Figure 3-2.

OM067-3 November, 2000 3-3

Page 14

Sec tion 3

Set Up Mode Prod uct Man ual - Vol ume I

1

-DIN Digi tal In di ca tor 59039

8

3.6 ALARM 3 VALUE

If Alarm 3 is selected to be a Process High alarm, this defines the process variable

value at or above which Alarm 3 will be active; the default value will be Input Range

Maximum. If Alarm 3 is selected to be a Process Low alarm, this defines the process

variable value at or below which Alarm 3 will be active; the default value will be Input

Range Minimum. Its value may be adjusted between Input Range Maximum and Input

Range Minimum. Alarm operation is illustrated in Figure 3-1.

3.7 ALARM 3 HYSTERESIS

This parameter applies a hysteresis band on the “safe” side of the Alarm 3 value. The

effect of the hysteresis value on alarm operation is shown in Figure 3-2.

3.8 PROCESS VARIABLE OFFSET

This parameter is used to modify the actual process variable value (measured at the

input terminals) in the following manner:

Offset PV value = Actual PV value + Process Variable Offset value.

The offset process variable value is used for all PV-dependent functions (display,

alarm, recorder output).

CAU TION: This is, in ef fect, a cali bra tion ad just ment. In ju di cious ap pli ca tion

of val ues to this pa rame ter could lead to the dis played pro cess vari able value

bear ing no mean ing ful re la tion ship to the ac tual pro cess vari able value.

There is no front panel in di ca tion when this pa rame ter is in ef fect (i.e.

has been set to a non- zero value).

The default value is 0.

3.9 INPUT FILTER TIME CONSTANT

The input is equipped with a digital filter which is used to filter out any extraneous

impulses on the process variable. This filtered PV is used for all PV-dependent

functions (alarms etc.). The time constant for this filter may be adjusted in the range 0.0

seconds (filter OFF) to 100.0 seconds in 0.5 second increments. The default setting is

2.0 seconds.

CAUTION: If this parameter is set excessively high, the indication

quality may be significantly impaired. The value chosen should be

sufficiently large to attenuate stray noise but no larger.

3.10 LINEAR INPUT SCALE RANGE MINIMUM

This parameter, applicable only if a linear input is fitted, defines the scaled input value

when the process variable input is at its minimum value. It is adjustable between –1999

and 9999 (with decimal point as defined by Linear Input Decimal Point Position). The

default value is 0. This parameter can be set to a value greater than (but not equal to)

Linear Input Scale Range Maximum, in which case the sense of the input is reversed.

3-4 November, 2000 OM067-3

Page 15

59039

1

-DIN Digi tal In di ca tor Sec tion 3

8

Prod uct Man ual - Vol ume I Set Up Mode

3.11 LINEAR INPUT SCALE RANGE MAXIMUM

This parameter, applicable only if a linear input is fitted, defines the scaled input value

when the process variable input is at its maximum value. It is adjustable between –1999

and 9999 (with decimal point as defined by Linear Input Decimal Point Position). The

default value is 1000. This parameter can be set to a value less than (but not equal to)

Linear Input Scale Range Minimum, in which case the sense of the input is reversed.

3.12 RECORDER OUTPUT SCALE MINIMUM

This parameter defines the value of the process variable at which the Recorder Output

reaches its minimum value; for example, for a 0 - 5V Recorder Output, this value

corresponds to 0V. It may be adjusted within the range –1999 to 9999. The decimal

point position for the Recorder Output is always the same as that for the process

variable input range. The default value is Input Range Minimum. This parameter is not

applicable if the Recorder Output option is not fitted.

NOTE: If this parameter is set to a value greater than that for the Recorder Output Scale Maximum (see Subsection 3.13), the relationship between the process variable value and the Recorder Output is reversed.

3.13 RECORDER OUTPUT SCALE MAXIMUM

This parameter defines the value of process variable at which the Recorder Output

reaches its maximum value; for example, for a 0 - 5V Recorder Output, this value

corresponds to 5V. It may be adjusted within the range –1999 to 9999. The decimal

point position for the Recorder Output is always the same as that for the process

variable input range. The default value is Input Range Maximum. This parameter is not

applicable if the Recorder Output option is not fitted.

NOTE: If this parameter is set to a value less than that for the Recorder

Output Scale Minimum (see Subsection 3.12), the relationship

between the process variable/setpoint value and the Recorder Output

is reversed.

3.14 OPERATOR MODE DISPLAY STRATEGY

This defines the sequence of parameter displays available in Operator Mode (see

NOTES ON TABLE 3-1).

3.15 EXIT FROM SET UP MODE

To leave Set Up Mode, select the initial Operator Mode display (process variable value)

then depress the Raise and Scroll keys simultaneously, whereupon the SET indicator

will go OFF and the instrument will return to Operator Mode.

NOTE: An automatic return to Operator mode will be executed if there

is no key activity in Set Up Mode for one minute.

OM067-3 November, 2000 3-5

Page 16

Sec tion 3

Set Up Mode Prod uct Man ual - Vol ume I

1

-DIN Digi tal In di ca tor 59039

8

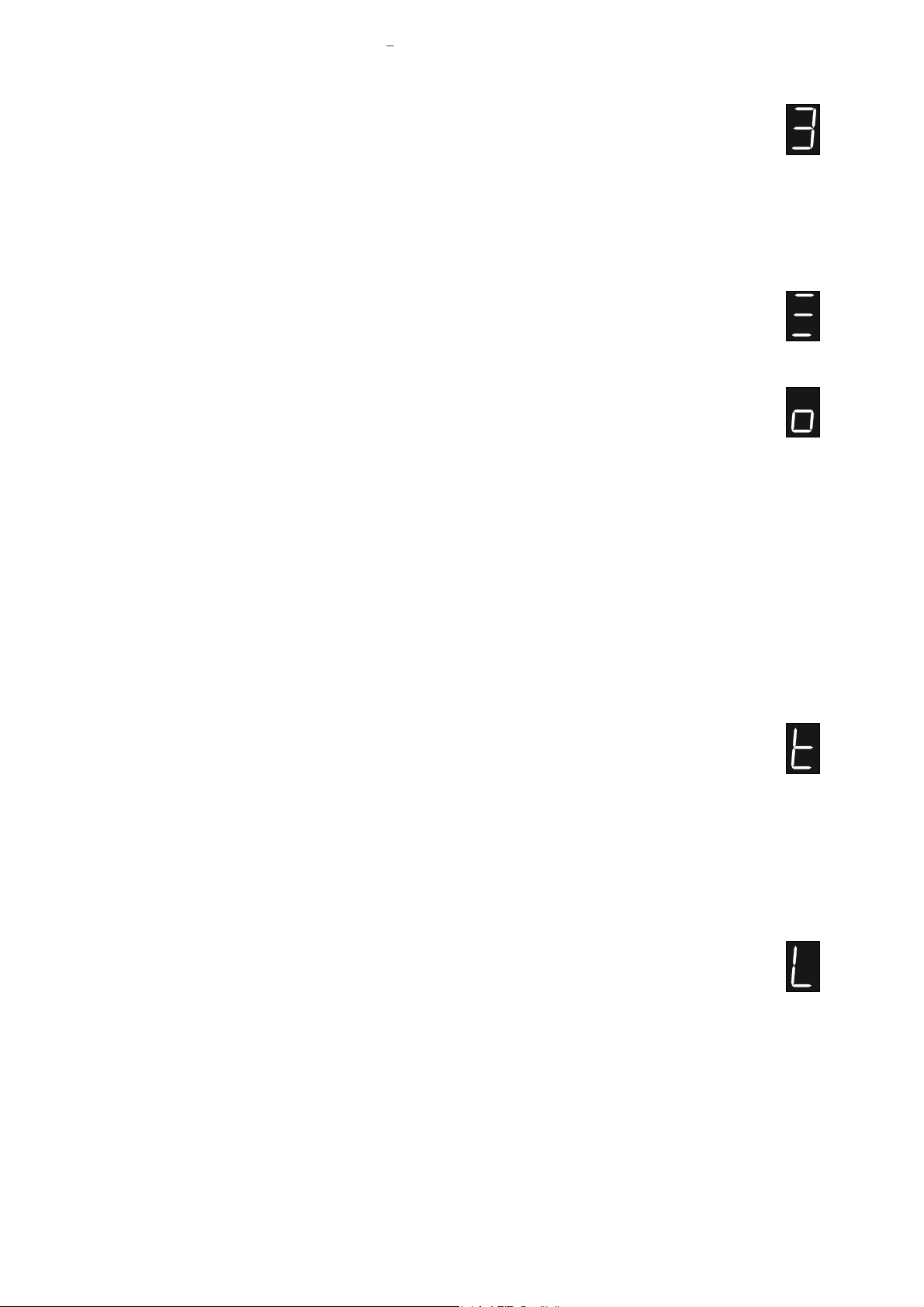

Process High Alarm

direct-acting

Process High Alarm

reverse-acting

Process Low Alarm

direct-acting

Process Low Alarm

reverse-acting

PROCESS

HIGH

ALARM

PROCESS

LOW

ALARM

Figure 3-1 Alarm Op era tion

Alarm Hysteresis

Alarm Inactive

Process Variable

Alarm Hysteresis

Alarm Inactive

Alarm Active

Figure 3-2 Alarm Hys tere sis Op era tion

Alarm Value

Process Variable

Alarm Inactive

Alarm Value

Alarm InactiveAlarm Active

3-6 November, 2000 OM067-3

Page 17

59039

1

-DIN Digi tal In di ca tor Sec tion 4

8

Product Man ual - Vol ume I RS485 Se rial Com mu ni ca tions

SEC TION 4

RS485 SERIAL COMMUNICATIONS

This three-wire RS485-compatible serial communications option is the means by which

communication may occur between the instrument and a master device (e.g. a

computer or terminal).

4.1 PHYSICAL REQUIREMENTS

There are two communications protocols available with this option:

(a) AS CII

(b) MOD BUS

4.1.1 Char ac ter Trans mis sion

Data format is fixed to be seven data bits and one stop bit. The Baud rate may be

selected to be 1200, 2400, 4800 (default) or 9600 Baud. For ASCII protocol, the parity

is even. For MODBUS protocol, the parity is selectable to be even, odd or none.

4.1.2 Line Turn- Round

AS CII Pro to col: The com mu ni ca tions link is op er ated as a multi- drop half

du plex sys tem. When a de vice is trans mit ting, it drives the trans mis sion lines

to the ap pro pri ate lev els; when it is not trans mit ting, its out puts are set to a

high im ped ance in or der that an other de vice can trans mit. It is im por tant that

a trans mit ter re leases the trans mis sion lines be fore an other de vice starts

trans mis sion. This im poses the fol low ing re straints on the mas ter de vice:

(a) The transmitter must release the transmission lines within 6ms of

the end of the last character of a message being transmitted. Note that

delays due to buffers such as those used in universal asynchronous

receivers/transmitters (UARTs) within the master device must be taken

into account.

(b) The transmitter must not start transmission until 6ms has elapsed

since the reception of the last character of a message.

All in stru ments in this range hav ing an RS485 com mu ni ca tions fa cil ity ad here to this stan dard; thus, pro vided that the mas ter de vice con forms simi larly to the stan dard, there should be no line con ten tion prob lems.

MOD BUS Pro to col: The line turn- round tim ings ad here to the in dus try stan dard.

4.2 ASCII PROTOCOL

This protocol assumes half duplex communications. All communication is initiated by

the master device. The master sends a command or query to the addressed slave and

the slave replies with an acknowledgement of the command or the reply to the query.

All messages, in either direction, comprise:

OM067-4 November, 2000 4-1

Page 18

Sec tion 4

RS485 Se rial Com mu ni ca tions Product Man ual - Vol ume I

1

-DIN Digi tal In di ca tor 59039

8

(a) A Start of Message character

(b) One or two address characters (uniquely defining the slave)

(c) A parameter/data character string

(d) An End of Message character

Messages from the master device may be one of four types:

Type 1: L {N} ? ? *

Type 2: L {N} {P} {C} *

Type 3: L {N} {P} # {DATA} *

Type 4: L {N} {P} I *

where all characters are in ASCII code and:

L is the Start of Mes sage char ac ter (Hex 4C)

{N} is the slave ad dress (in the range 1 - 32); ad dresses 1 - 9

may be rep re sented by a sin gle digit (e.g. 7) or in two- digit

form, the first digit be ing zero (e.g. 07).

{P} is a char ac ter which iden ti fies the pa rame ter to be in ter ro -

gated/modi fied - see Ta ble 4-2.

{C} is the com mand (see be low)

# in di cates that {DATA} is to fol low (Hex 23)

{DATA} is a string of nu meri cal data in AS CII code (see Ta ble 4-1)

* is the End of Mes sage char ac ter (Hex 2A)

No space char ac ters are per mit ted in mes sages. Any syn tax er rors in a re ceived

mes sage will cause the slave to is sue no re ply and await the Start of Mes sage

char ac ter.

4-2 November, 2000 OM067-4

Page 19

59039

1

-DIN Digi tal In di ca tor Sec tion 4

8

Product Man ual - Vol ume I RS485 Se rial Com mu ni ca tions

Table 4-1 {DATA} Ele ment - Sign and Deci mal Point Po si tion

Identifier

Character

A

B

C

D

E

F

G

H

J

L

M

N

O

Q

T

Z

[

\

]

m

{DATA} Content

abcd0

abcd1

abcd2

abcd3

abcd5

abcd6

abcd7

abcd8

Sign/Decimal Point Position

+abcd

+abc.d

+ab.cd

+a.bcd

–abcd

–abc.d

–ab.cd

–a.bcd

Table 4-2 Com mands/Pa rame ters and Iden ti fi ers

Parameter/Command

Maximum Process Variable value

Minimum Process Variable value

Alarm 1 value

Alarm 1 Hysteresis value

Alarm 2 value

Alarm 2 Hysteresis value

1

1

Scale Range Maximum

Read Only

Read Only

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write (linear inputs

only) - otherwise Read Only

Scale Range Minimum

Read/Write (linear inputs

only) - otherwise Read Only

Process Variable Offset value

Instrument Status

2

Process Variable value

Alarm 3 value

Alarm 3 Hysteresis

3

3

Scale Range Decimal Point Position

Read/Write

Read Only

Read Only

Read/Write

Read/Write

Read/Write (linear inputs

only) - otherwise Read Only

Time Elapsed

Instrument Commands

4

Recorder Output Scale Maximum

Recorder Output Scale Minimum

Scan Table

6

Input Filter Time Constant value

5

5

Read Only

Write Only

Read/Write

Read/Write

Read Only

Read/Write

Operation

NOTES

1. Applicable only if Alarm 2 is configured.

2. See Subsection 4.3.15.

3. Applicable only if Alarm 3 is configured.

4. See Subsection 4.3.16.

5. Applicable only if Output 2 is configured as a Recorder Output.

6. See Subsection 4.3.17.

OM067-4 November, 2000 4-3

Page 20

Sec tion 4

RS485 Se rial Com mu ni ca tions Product Man ual - Vol ume I

1

-DIN Digi tal In di ca tor 59039

8

4.2.1 Type 1 Mes sage

L {N} ? ? *

This message is used by the master device to determine whether the addressed slave

is active. The reply from the slave instrument, if it is active, is

L {N} ? A *

An inactive instrument will give no reply.

4.2.2 Type 2 Mes sage

L {N} {P} {C} *

This type of message is used by the master device to interrogate or modify a parameter

in the addressed instrument. {P} identifies the parameter (as defined in Table 4-2) and

{C} represents the command to be executed, which may be one of the following:

+ (Hex 2B) - In cre ment the value of the pa rame ter de fined by {P}

– (Hex 2D) - Dec re ment the value of the pa rame ter de fined by {P}

? (Hex 3F) - De ter mine the cur rent value of the pa rame ter de fined by {P}

The reply from the addressed instrument is of the form:

L {N} {P} {DATA} A *

where {DATA} comprises five ASCII-coded digits whose format is shown in Table 4-1.

The data is the value requested in a query message or the new value of the parameter

after modification. If the action requested by the message from the master device would

result in an invalid value for that parameter (either because the requested new value

would be outside the permitted range for that parameter or because the parameter is

not modifiable), the instrument replies with a negative acknowledgement:

L {N} {P} {DATA} N *

The {DATA} string in the negative acknowledgement reply will be indeterminate.

Scan Tables

A parameter identifier character “]” in the message from the master device indicates

that a “Scan Table” operation is required. This provides a facility for interrogating the

values of a group of parameters and status in a single message from the master

device. The reply to such a command would be in the form:

L {N} ] 25 aaaaa bbbbb ccccc ddddd eeeee A *

The digits aaaaa, bbbbb etc. are expressed as shown in Table 4-1. For further

information, refer to Subsection 4.3.17.

4.2.3 Type 3 Mes sage

L {N} {P} # {DATA} *

This message type is used by the master device to set a parameter to the value

specified in {DATA}. The command is not implemented immediately by the slave

instrument; the slave will receive this command and will then wait for a Type 4 message

(see below). Upon receipt of a Type 3 message, if the {DATA} content and the specified

parameter are valid, the slave reply is of the form:

4-4 November, 2000 OM067-4

Page 21

59039

1

-DIN Digi tal In di ca tor Sec tion 4

8

Product Man ual - Vol ume I RS485 Se rial Com mu ni ca tions

L {N} {P} {DATA} I *

(where I = Hex 49) indicating that the instrument is ready to implement the command. If

the parameter specified is invalid or is not modifiable or if the desired value is outside

the permitted range for that parameter, the instrument replies with a negative

acknowledgement in the form:

L {N} {P} {DATA} N *

4.2.4 Type 4 Mes sage

L {N} {P} I *

This type of message is sent by the master device to the addressed slave following a

successful Type 3 message transmission and reply to/from the same slave instrument.

Provided that the {DATA} content and the parameter specified in the preceding Type 3

message are still valid, the slave will then set the parameter to the desired value and

will reply in the form:

L {N} {P} {DATA} A *

where {DATA} is the new value of the parameter. If the new value or parameter

specified is invalid, the slave will reply with a negative acknowledgement in the form:

L {N} {P} {DATA} N *

where {DATA} is indeterminate. If the immediately-preceding message received by the

slave was not a Type 3 message, the Type 4 message is ignored.

4.3 INDIVIDUAL PARAMETERS

The individual parameters and how they may be interrogated/modified are described

below. Unless otherwise stated, the {DATA} element will follow the standard five-digit

format and the decimal point position must be correct for the new value to be accepted

and for modification to occur.

NOTE: The communications identifier character {P} for each

parameter is shown to the right of each subsection heading.

4.3.1 Proc ess Vari able {P} = M

This parameter may be interrogated only, using a Type 2 message. If the process

variable is out of range, the five-digit {DATA} field in the reply will not contain a number,

but will contain <??>0 (over-range) or <??>5 (under-range).

4.3.2 Proc ess Vari able Off set {P} = J

This parameter may be modified/interrogated using a Type 2 message or a Type 3/4

message sequence. It modifies the actual process variable value (as measured at the

instrument’s input terminals) in the following manner:

Modified PV value = Actual PV value + process variable offset value

The modified PV value is limited by Range Maximum and Range Minimum and is used

for display and alarm purposes and for recorder outputs.

OM067-4 November, 2000 4-5

Page 22

Sec tion 4

RS485 Se rial Com mu ni ca tions Product Man ual - Vol ume I

1

-DIN Digi tal In di ca tor 59039

8

NOTE: This parameter value should be selected with care. Any

adjustment to this parameter is, in effect, an adjustment to the

instrument’s calibration. Injudicious application of values to this

parameter could lead to the displayed PV value having no meaningful

relationship to the actual PV value.

4.3.3 Scale Range Maxi mum {P} = G

This parameter (which is adjustable only on DC linear inputs) may be interrogated using

a Type 2 message or may be modified using a Type 3/4 message sequence. The

decimal point position is as for the input range.

4.3.4 Scale Range Mini mum {P} = H

This parameter (which is adjustable only on DC linear inputs) may be interrogated using

a Type 2 message or may be modified using a Type 3/4 message sequence. The

decimal point position is as for the input range.

4.3.5 Scale Range Deci mal Point Po si tion {P} = Q

Adjustable on DC linear inputs only, this parameter may be modified/interrogated using

a Type 2 message or a Type 3/4 message sequence. The value of this parameter

defines the decimal point position, as follows:

Value

0

1

2

3

Decimal Point Position

abcd

abc.d

ab.cd

a.bcd

4.3.6 In put Fil ter Time Con stant

{P} = m

This parameter may be modified/interrogated using a Type 2 message or a Type 3/4

message sequence.

4.3.7 Re corder Out put Scale Maxi mum Value {P} = [

This parameter may be modified/interrogated using a Type 2 message or a Type 3/4

message sequence. It defines the maximum scale value for the Controller’s Recorder

Output and may be adjusted within the range –1999 to 9999. This value corresponds to

the Input Scale Maximum and the decimal point position will always be the same as

that for the input.

NOTE: If this parameter is set to a value less than the Recorder Output

Minimum Value, the sense of the Recorder Output is reversed.

4.3.8 Re corder Out put Scale Mini mum Value {P} = \

This parameter may be modified/interrogated using a Type 2 message or a Type 3/4

message sequence. It defines the minimum scale value for the Controller’s Recorder

Output and may be adjusted within the range –1999 to 9999. This value corresponds to

4-6 November, 2000 OM067-4

Page 23

59039

1

-DIN Digi tal In di ca tor Sec tion 4

8

Product Man ual - Vol ume I RS485 Se rial Com mu ni ca tions

the Input Scale Minimum and the decimal point position will always be the same as that

for the input.

NOTE: If this parameter is set to a value greater than the Recorder

Output Maximum Value, the sense of the Recorder Output is reversed.

4.3.9 Alarm 1 Value {P} = C

This parameter may be modified/interrogated using a Type 2 message or a Type 3/4

message sequence. It defines the level at which Alarm 1 will go active. The decimal

point position is as for the input range.

4.3.10 Alarm 1 Hys tere sis Value {P} = D

This parameter may be modified/interrogated using a Type 2 message or a Type 3/4

message sequence. It defines the hysteresis band applied to the “safe” side of Alarm 1.

The decimal point position is as for the input range.

4.3.11 Alarm 2 Value {P} = E

This parameter may be modified/interrogated using a Type 2 message or a Type 3/4

message sequence. It defines the level at which Alarm 2 will go active. The decimal

point position is as for the input range.

4.3.12 Alarm 2 Hys tere sis Value {P} = F

This parameter may be modified/interrogated using a Type 2 message or a Type 3/4

message sequence. It defines the hysteresis band applied to the “safe” side of Alarm 2.

The decimal point position is as for the input range.

4.3.13 Alarm 3 Value {P} = N

This parameter may be modified/interrogated using a Type 2 message or a Type 3/4

message sequence. It defines the level at which Alarm 3 will go active. The decimal

point position is as for the input range.

4.3.14 Alarm 3 Hys tere sis Value {P} = O

This parameter may be modified/interrogated using a Type 2 message or a Type 3/4

message sequence. It defines the hysteresis band applied to the “safe” side of Alarm 3.

The decimal point position is as for the input range.

4.3.15 In stru ment Status {P} = L

This pa rame ter may be in ter ro gated only, us ing a Type 2 mes sage. The status

in for ma tion is en coded in the four dig its as the deci mal rep re sen ta tion of a bi nary

number. Each bit in the bi nary number has a par ticu lar sig nifi cance:

OM067-4 November, 2000 4-7

Page 24

Sec tion 4

RS485 Se rial Com mu ni ca tions Product Man ual - Vol ume I

1

-DIN Digi tal In di ca tor 59039

8

Bit 5: Alarm 1 Latched

(1 = not latched, 0 = latched)

If non-latching, fixed at 1.

Bit 3: Change Indicator (1 = A parameter other than

Instrument Status or Process Variable has been

changed via the front panel since the last time the

Status Byte was read; 0 = No change has occurred).

000 1

Bit 2: Alarm 3 Status

(0 = Active; 1 = Safe)

Bit 0: Alarm 1 Status

(0 = Active; 1 = Safe)

Bit 1: Alarm 2 Status

(0 = Active; 1 = Safe)

4.3.16 In stru ment Com mands {P} = Z

Only Type 3 or Type 4 messages are allowed with this parameter. In the Type 3

message, the {DATA} field must be one of four five-digit numbers. The reply from the

instrument also contains the {DATA} field with the same content. When the master

device issues the Type 4 message, the instrument responds with the same {DATA} field

content. The commands corresponding to the {DATA} field value are:

00150 = Unlatch Alarm 1 (returns NAK if Alarm 1 is non-latching)

00160 = Reset Process Variable Maximum (to current PV value)

00170 = Reset Process Variable Minimum (to current PV value)

00180 = Reset Time Elapsed (to zero)

4.3.17 Scan Ta ble {P} = ]

The Scan Table operation takes the form of a Type 2 interrogation command which

accesses a set of information (held in the {DATA} element in the response). The

response would be in the form:

L {N} ] 25 aaaaa bbbbb ccccc ddddd eeeee A *

These digits are as described in Table 4-1 and comprise:

aaaaa The cur rent pro cess vari able value

bbbbb The cur rent maxi mum pro cess vari able value

ccccc The cur rent mini mum pro cess vari able value

ddddd The cur rent Time El pased value

eeeee The In stru ment Status (see Sub sec tion 4.3.15).

4.3.18 Er ror Re sponse

The circumstances under which a message from the master device is ignored are:

Par ity er ror de tected

Syn tax er ror de tected

Ti me out elapsed

Re ceipt of a Type 4 mes sage with out a pre ced ing Type 3 com mand mes sage.

Nega tive ac know ledge ments will be re turned if, in spite of the re ceived mes sage be ing

no tion ally cor rect, the in stru ment can not sup ply the re quested in for ma tion or per form

the re quested op era tion. The {DATA} ele ment of a nega tive ac know ledge ment will be

in de ter mi nate.

4 -8 November, 2000 OM067-4

Page 25

59039

1

-DIN Digi tal In di ca tor Sec tion 4

8

Product Man ual - Vol ume I RS485 Se rial Com mu ni ca tions

4.4 MODBUS PROTOCOL

With the RS485 Serial Communication option fitted and configured, communication

between a master device and slave instruments via protocol conforming to the

MODBUS industry standard is available.

NOTE: Support for multi-parameter Write operations is limited to

support of the Multi-word Write Function (Number 16) but this permits

writing of one parameter value only per message.

The parameter numbering system divides the parameters into bits and words, each

group being numbered independently.

4.4.1 Bit Pa rame ters

There are up to 11 bit pa rame ters:

Parameter

Alarm 1 Status

Alarm 2 Status

Alarm 3 Status

Alarm 1 Latched

PV Under-range Flag

PV Over-range Flag

Sensor Break Active

Reset Latched Alarm

Reset PV Maximum

Reset PV Minimum

Reset Time Elapsed

* Always returns 0 if Alarm 1 not configured to be latching.

No.

1

2

3

4

5

6

7

8

9

10

11

Operation

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

Write Only

Write Only

Write Only

Write Only

Notes

1 = Active

1 = Active

1 = Active

1 = Alarm 1 latched *

1 = Active

1 = Active

1 = Active

OM067-4 November, 2000 4-9

Page 26

Sec tion 4

RS485 Se rial Com mu ni ca tions Product Man ual - Vol ume I

1

-DIN Digi tal In di ca tor 59039

8

4.4.2 Word Pa rame ters

Parameter

Process Variable (PV)

PV Maximum

PV Minimum

Time Elapsed

Instrument Status

PV Offset

Alarm 1 value

Alarm 2 value

Alarm 3 value

Alarm 1 Hysteresis

Alarm 2 Hysteresis

Alarm 3 Hysteresis

Filter Time Constant

Decimal Point Position

Scale Range Min.

Scale Range Max.

Recorder Output

Scale Max.

Recorder Output

Scale Min.

Manufacturer ID

Equipment ID

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

121

122

Operation

Read Only *

Read Only *

Read Only *

Read Only *

Read Only

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read Only

Read Only

Notes

Only if Alarm 2 is configured

Only if Alarm 3 is configured

Only if Alarm 2 is configured

Only if Alarm 3 is configured

Read Only for non-linear inputs

Read Only for non-linear inputs

Read Only for non-linear inputs

Only if Recorder Output is

configured

Only if Recorder Output is

configured

= 231 (representing “W1")

number 8010

* When the process variable is over-range or under-range or when a

sensor break condition occurs, the value returned is:

Condition Hex. Signed Unsigned

Over-range F700 –2304 63232

Under-range F600 –2560 62976

Sensor Break condition F800 –2048 63488

The PV Max. parameter will return the Over-range value or Sensor Break

value (as appropriate) if either condition has occurred since the PV Max.

parameter was last reset.

The PV Min. parameter will return the Under-range value or Sensor Break

value (as appropriate) if either condition has occurred since the PV Min.

parameter was last reset.

The Time Elapsed parameter will return the Over-range value if the

time exceeds 1000 minutes.

NOTE: All these parameters return signed values except Time Elapsed

(which is unsigned) and Instrument Status (in which Bits 0 - 6 of the

status byte return Bit Parameters 1 - 7 respectively - see Subsection 4.4.1)

4-10 November, 2000 OM067-4

Page 27

59039

1

-DIN Digi tal In di ca tor Ap pen dix A

8

Prod uct Man ual - Vol ume I Al pha beti cal In dex

Al pha beti cal In dex

A

AL1 Indicator

Function 2-2

AL2 Indicator

Function 2-2

AL3 Indicator

Function 2-2

Alarm Hysteresis

Alarm 1 3-3

Alarm 1 (adjusting - comms.)

4-7

Alarm 2 3-3

Alarm 2 (adjusting - comms.)

4-7

Alarm 3 3-4

Alarm 3 (adjusting - comms.)

4-7

Alarm Status Indicators

Functions 2-2

Alarm Value

Alarm 1 3-3

Alarm 1 (adjusting - comms.)

4-7

Alarm 1 Operator Mode display

2-2

Alarm 2 3-3

Alarm 2 (adjusting - comms.)

4-7

Alarm 2 Operator Mode display

2-2

Alarm 3 (adjusting - comms.)

4-7

Alarm 3 Operator Mode display

2-2

C

Cold Junction Compensation

Disabled, indication of 2-3

Communications

ASCII protocol 4-1

Baud rates 4-1

Data format 4-1

End of Message character

4-2

Line release time maximum

value 4-1

Line turn-round 4-1

Messsage types 4-2

MODBUS bit parameters4-9

MODBUS protocol 4-9

MODBUS word parameters

4-10

Parity (ASCII protocol) 4-1

Parity (MODBUS protocol)

4-1

Scan Tables command 4-4

Start of Message character

4-2

Type 1 message 4-4

Type 2 message 4-4

Type 3 message 4-4

Alarm 3 3-4

OM067-A November, 2000 A-1

Type 4 message 4-5

Page 28

Ap pen dix A

Al pha beti cal In dex Prod uct Man ual - Vol ume I

1

-DIN Digi tal In di ca tor 59039

8

Communications Message Format

4-1

D

Display Strategy (Operator Mode)

3-5

E

Error Responses 4-8

H

Hardware Definition Code

Viewing in Operator Mode

2-4

Hardware Option

Viewing in Operator Mode

2-4

I

Input Filter Time Constant 3-4

Adjusting (comms.) 4-6

Input Over-range Display 2-3

Input Under-range Display 2-3

Scale range maximum (adjusting

- comms.) 4-6

Scale range minimum 3-4

Scale range minimum (adjusting

- comms.) 4-6

P

Process Variable

Interrogating (comms.) 4-5

Operator Mode display 2-1 -

2-2

Process Variable Maximum

Operator Mode display 2-1

Resetting (from front panel)

2-2

Resetting (via comms. link)

4-8

Process Variable Minimum

Operator Mode display 2-1

Resetting (from front panel)

2-2

Instrument Commands 4-8

Instrument Status 4-7

L

Latched Alarm

Resetting (from front panel)

2-3

Resetting (via comms. link)

4-8

Linear Input

Reversing sense of3-4 - 3-5

Scale Range Decimal Point

Position 4-6

Scale range maximum 3-5

Resetting (via comms. link)

4-8

Process Variable Offset 3-4

Adjusting (comms.) 4-5

R

Recorder Output

Reversing sense of3-5 - 4-7

Scale maximum 3-5

Scale Maximum Value (adjusting

- comms.) 4-6

Scale minimum 3-5

Scale Minimum Value (adjusting

- comms.) 4-6

S

A-2 November, 2000 OM067-A

Page 29

59039

Scan Tables Command 4-8

Sensor Break Indication

Operator Mode 2-3

Set Up Mode

Automatic exit from 3-5

Entry into 3-1

Exit from 3-5

Set Up Parameters All At default

Indication of 3-1

T

Time Elapsed

1

-DIN Digi tal In di ca tor Ap pen dix A

8

Prod uct Man ual - Vol ume I Al pha beti cal In dex

Operator Mode display 2-2

Resetting (from front panel)

2-2

Resetting (via comms. link)

4-8

OM067-A November, 2000 A-3

Page 30

Ap pen dix A

1

-DIN Digi tal In di ca tor 59039

8

Al pha beti cal In dex Prod uct Man ual - Vol ume I

A-4 November, 2000 OM067-A

Page 31

59039

1

-DIN Digi tal In di ca tor

8

Prod uct Man ual - Vol ume II

1

-DIN DIGITAL INDICATOR

8

PRODUCT MANUAL

VOLUME II

INSTALLATION AND

CONFIGURATION INSTRUCTIONS

The procedures described in this volume must be

undertaken by technically competent servicing personnel.

SM067- V2 November, 2000 (i)

Page 32

1

-DIN Digi tal In di ca tor 59039

8

Prod uct Man ual - Vol ume II

Con tents

1 IN STAL LA TION 1-1

2 IN TER NAL LINKS AND SWITCHES 2-1

3 CON FIGU RA TION MODE 3-1

Ap pen di ces

A PROD UCT SPECI FI CA TION A-1

B AL PHA BETI CAL IN DEX B-1

(ii) November, 2000 SM067- V2

Page 33

59039

1

-DIN Digi tal In di ca tor Sec tion 1

8

Prod uct Man ual - Vol ume II In stal la tion

SEC TION 1

INSTALLATION

1.1 UNPACKING PROCEDURE

1. Remove the instrument from its packing. The instrument is supplied with a

panel gasket and push-fit fixing strap. Retain the packing for future use,

should it be necessary to transport the instrument to a different site or to

return it to the supplier for repair/testing.

2 . Examine the delivered items for damage or deficiencies. If any is found,

notify the carrier immediately.

1.2 PANEL-MOUNTING

The panel on which the instrument is to be mounted must be rigid and may be up to

6.0mm (0.25 inches) thick. The cut-out required for a single Digital Indicator is as

shown in Figure 1-1.

45mm

+0.5 - 0.0

92mm

+0.5 - 0.0

Figure 1-1 Cut- out Di men sions

The Digital Indicator is 100mm deep (measured from the rear face of the front panel).

The front panel is 48mm high and 96mm wide. When panel-mounted, the front panel

projects 10mm from the mounting panel. The main dimensions of the instrument are

shown in Figure 1-2.

SM067-1 November, 2000 1-1

Page 34

Sec tion 1

In stal la tion Prod uct Man ual - Vol ume II

1

-DIN Digi tal In di ca tor 59039

8

Fig ure 1-2 Main Di men sions

To panel-mount the instrument:

1 . Insert the rear of the housing through the cut-out (from the front of the

mounting panel) and hold the instrument lightly in position against the panel.

Ensure that the panel gasket is not distorted and that the instrument is

positioned squarely against the mounting panel. Apply pressure to the front

panel bezel only.

CAUTION: Do not remove the panel gasket, as this may result in

inadequate clamping of the instrument in the panel.

2 . Slide the fixing strap in place (see Figure 1-3) and push it forward until it is

firmly in contact with the rear face of the mounting panel (the tongues on the

strap should have engaged in matching rachet positions on the housing and

the fixing strap springs should be pushing firmly against the mounting panel

rear face).

Once the in stru ment is in stalled in its mount ing panel, it may be sub se quently re moved

from its hous ing, if nec es sary, as de scribed in Sub sec tion 2.1.

1 -2 November, 2000 SM067-1

Page 35

59039

1

-DIN Digi tal In di ca tor Sec tion 1

8

Prod uct Man ual - Vol ume II In stal la tion

Mounting panel

Front panel

Sealing gasket

Fixing strap

Tongues on fixing strap

engage in ratchet slots

on housing

Housing

TOP VIEW OF INSTRUMENT

Figure 1-3 Panel- Mounting

SM067-1 November, 2000 1-3

Page 36

Sec tion 1

In stal la tion Prod uct Man ual - Vol ume II

1

-DIN Digi tal In di ca tor 59039

8

1.3 CONNECTIONS AND WIRING

The rear terminal connections are illustrated in Figure 1-4.

Output 1 is always a relay output which may be used as Alarm 1 (latching or

non-latching) or the logical OR of Alarms 1 & 2.

Output 2 (option) may be a relay output (Alarm 2, Alarm 3 or logical OR of Alarms

1 & 2, 1 & 3 or 2 & 3) or a DC output (recorder output)

Output 3 (option) may be a relay output (Alarm 2, Alarm 3 or logical OR of Alarms

1 & 2, 1 & 3 or 2 & 3) or a transmitter power supply output

Figure 1-4 Rear Ter mi nal Con nec tions

1-4 November, 2000 SM067-1

Page 37

59039

1

-DIN Digi tal In di ca tor Sec tion 1

8

Prod uct Man ual - Vol ume II In stal la tion

1.3.1 Mains (Line) In put

The instrument will operate on 96 - 264V AC 50/60Hz mains (line) supply. The power

consumption is approximately 4 VA.

CAUTION: This equipment is designed for installation in an enclosure

which provides adequate protection against electric shock. Local

regulations regarding electrical installation should be rigidly observed.

Consideration should be given to prevention of access to the power

terminations by unauthorised personnel. Power should be connected

via a two-pole isolating switch (preferably situated near the equipment)

and a 1A fuse, as shown in Figure 1-5.

Figure 1-5 Mains (Line) Sup ply Con nec tions

If the instrument has relay outputs in which the contacts are to carry

mains (line) voltage, it is recommended that the relay contact mains

(line) supply should be switched and fused in a similar manner but

should be separate from the instrument mains (line) supply.

1.3.2 24V (Nomi nal) AC/DC Sup ply

The supply connections for the 24V AC/DC version are shown in Figure 1-6. Power

should be connected via a two-pole isolating switch and a 315mA slow-blow fuse

(anti-surge Type T).

Figure 1-6 24V AC/DC Sup ply Con nec tions

The nominal 24V supply may be in the following ranges:

24V (nomi nal) AC 50/60Hz - 20 - 50V

24V (nomi nal) DC - 22 - 65V

SM067-1 November, 2000 1-5

Page 38

Sec tion 1

1

-DIN Digi tal In di ca tor 59039

8

In stal la tion Prod uct Man ual - Vol ume II

Table 1-1 Ther mo cou ple Ca ble Col our Codes

1-6 November, 2000 SM067-1

Page 39

1

59039

-DIN Digi tal In di ca tor Sec tion 1

8

Prod uct Man ual - Vol ume II In stal la tion

1.3.3 Ther mo cou ple In put

The correct type of thermocouple extension leadwire/compensating cable must be used

for the entire distance between the instrument and the thermocouple, ensuring that

correct polarity is observed throughout. Joints in the cable should be avoided, if

possible. The CJC facility must be enabled (normal conditions) for this input (see

Subsection 3.10).

NOTE: Do not run thermocouple cables adjacent to power-carrying

conductors. If the wiring is run in a conduit, use a separate conduit for

the thermocouple wiring. If the thermocouple is grounded, this must be

done at one point only. If the thermocouple extension lead is shielded,

the shield must be grounded at one point only.

The colour codes used on thermocouple extension leads are shown in Table 1-1.

1.3.4 RTD In put

The compensating lead should be connected to Terminal 3. For two-wire RTD inputs,

Terminals 2 and 3 should be linked. The extension leads should be of copper and the

resistance of the wires connecting the resistance element should not exceed 5 ohms

per lead (the leads should be of equal length).

1.3.5 Lin ear In put

For linear mA input ranges, connection is made to Terminals 1 and 4 in the polarity

shown in Figure 1-4. For linear mV and V ranges, connection is made to Terminals 2

and 3 in the polarity shown in Figure 1-4. For details of the linear input ranges available,

refer to Appendix A. If it is required to display the engineering units used, refer to

Subsection 2.4.

1.3.6 Re mote Re set (Op tion)

With the Remote Reset option fitted, Terminals 16 and 17 may be connected to an

external switch/relay contacts or to a TTL-compatible logic signal, which is used to reset

the latched Alarm 1. For an external switch/relay contacts, an “open-closed” transition

will reset the latched alarm. For a TTL signal, a “Logic 1 - Logic 0" transition will reset

the latched alarm.

TTL lev els: Logic 1 >2.0V

Logic 0 <0.8V

NOTE: The Remote Reset option and the RS485 Serial

Communications option are mutually exclusive.

See also Subsection 3.3.2 and Appendix A.

1.3.7 Re lay Out put

The contacts are rated at 2A resistive at 120/240V AC.

1.3.8 DC Out put

See Appendix A.

SM067-1 November, 2000 1-7

Page 40

Sec tion 1

In stal la tion Prod uct Man ual - Vol ume II

1

-DIN Digi tal In di ca tor 59039

8

1.3.9 RS485 Se rial Com mu ni ca tions (Op tion)

The connections for the three-wire RS485 serial communications option (if fitted) are on

Terminals 16, 17 and 18, as shown in Figure 1-4. Where several instruments are

connected to one master port, the master port transceiver in the active state should be

capable of driving a load of 12kΩ per instrument; the master port transceiver in the

passive state must have pull-up/pull-down resistors of sufficiently low impedance to

ensure that it remains in the quiescent state whilst supplying up to ±100µA each to the

instrument’s transceivers in the high impedance state.

1 -8 November, 2000 SM067-1

Page 41

59039

1

-DIN Digi tal In di ca tor Sec tion 2

8

Prod uct Man ual - Vol ume II In ter nal Links and Switches

SEC TION 2

INTERNAL LINKS AND SWITCHES

2.1 REMOVING THE INSTRUMENT FROM ITS HOUSING

To withdraw the instrument from its housing, simply grip the side edges of the front

panel (there is a finger grip on each edge) and pull the instrument forwards. This will

release the instrument from its rear connectors in the housing and will give access to

the PCBs. Take note of the orientation of the instrument for subsequent replacement

into the housing.The positions of the PCBs in the instrument are shown in Figure 2-1.

Output 2 Link Jumpers

(DC Output only)

Top edge of

front panel

Power Supply PCB

CPU PCB

RS485 Serial Communications

Option PCB or

Remote Reset Option PCB

Input Link Jumpers

Output 2 Option PCB -

Relay Output (Alarm) or

DC Output (Recorder Output)

Output 3 Option PCB -

Relay Output (Alarm) or

Transmitter Power Supply

REAR VIEW OF UNHOUSED INSTRUMENT

Figure 2-1 PCB Po si tions

SM067-2 November, 2000 2-1

Page 42

Sec tion 2

1

-DIN Digi tal In di ca tor 59039

8

In ter nal Links and Switches Prod uct Man ual - Vol ume II

Figure 2-2 Re mov ing the Out put 2/Out put 3 Op tion PCBs

2 -2 November, 2000 SM067-2

Page 43

59039

1

-DIN Digi tal In di ca tor Sec tion 2

8

Prod uct Man ual - Vol ume II In ter nal Links and Switches

2.2 REMOVING/REPLACING THE OUTPUT 2/OUTPUT 3 OPTION PCBs

With the instrument removed from its housing:

1. Gently push the rear ends of the CPU PCB and Power Supply PCB apart

slightly, until the two tongues on each of the Output 2/Output 3 Option PCBs

become dis-engaged - see Figure 2-2B; The Output 2 Option PCB tongues

engage in holes in the Power Supply PCB and the Output 3 Option PCB

tongues engage in holes on the CPU PCB.

2 . Carefully pull the required Option PCB (Output 2 or Output 3) from its

connector (Output 2 Option PCB is connected to the CPU PCB and Output 3

Option PCB is connected to the Power Supply PCB) - see Figure 2-2C. Note

the orientation of the PCB in preparation for its replacement.

Adjustments may now be made to the link jumpers on the CPU PCB and (if DC output)

the Output 2 PCB. The replacement procedure is a simple reversal of the removal

procedure.

2.3 REMOVING/REPLACING THE RS485 COMMUNICATIONS OPTION PCB OR

REMOTE RESET OPTION PCB

The RS485 Communications Option PCB or Remote Reset Option PCB is mounted on

the inner surface of the Power Supply PCB and can be removed when the instrument is

removed from its housing (see Subsection 2.1) by pulling the Option PCB towards the

rear of the PSU PCB. Figure 2-3 illustrates the removal/replacement procedure. It is not

necessary to remove the Output 2/Output 3 Option PCBs to perform this procedure.

Figure 2-3 Re mov ing/Re plac ing the RS485 Op tion PCB

or Re mote Re set Op tion PCB

SM067-2 November, 2000 2-3

Page 44

Sec tion 2

In ter nal Links and Switches Prod uct Man ual - Vol ume II

1

-DIN Digi tal In di ca tor 59039

8

2.4 INSTALLING THE ENGINEERING UNIT LABEL

The instrument is equipped with a label carrier (see Figure 2-4) to which a self-adhesive

engineering unit label may be attached if required.

Front Panel

(top edge)

Power Supply

PCB

Display PCB

CPU PCB

Label Carrier

Figure 2-4 Lo ca tion of La bel Car rier

If the instrument is configured with a linear input and engineering units are to be

displayed on the front panel, the required unit label (see sheet of peel-off labels at the

rear of this manual) may be installed as follows:

1. Re move the in stru ment from its hous ing (see Sub sec tion 2.1).

2. For the CPU PCB and Power Sup ply PCB si mul ta ne ously, gen tly bend

one re tain ing arm (see Fig ure 2-5A) to free one side of each PCB; swing

the PCBs clear of the front panel and care fully move them away from the

front panel (the CPU PCB will still be con nected to the front panel/Dis play

PCB by a rib bon ca ble - do not stress this rib bon ca ble ).

3. Re move the la bel car rier from its ap er ture in the Dis play PCB (see Fig ure 2-5B).

4. Re move the re quired en gi neer ing unit la bel from the peel- off sheet at

the rear of this man ual and af fix to the front face of the la bel car rier (see

Fig ure 2-5C), us ing the ledge on the front face of the car rier for align ment.

5. Re place the la bel car rier in its ap er ture on the Dis play PCB.

6. Re place the CPU PCB and Power Sup ply PCB in po si tion at the rear of

the front panel.

7. Re place the in stru ment in its hous ing (see Sub sec tion 2.5).

2-4 November, 2000 SM067-2

Page 45

59039

1

-DIN Digi tal In di ca tor Sec tion 2

8

Prod uct Man ual - Vol ume II In ter nal Links and Switches

NOTE: Spare label carriers (Part No. 18633) and engineering label

sheets (Part No. 84107) are available.

TOP VIEW

Attach engineering unit label

to this face (ensuring that the

ledge is at the bottom)

FRONT VIEW

Ledge

Ledge

Figure 2-5 In stall ing the En gi neer ing Unit La bel

SM067-2 November, 2000 2-5

Page 46

Sec tion 2

In ter nal Links and Switches Prod uct Man ual - Vol ume II

1

-DIN Digi tal In di ca tor 59039

8

2.5 REPLACING THE INSTRUMENT IN ITS HOUSING

To replace the instrument, simply align the CPU PCB and Power Supply PCB with their

guides and connectors in the housing and slowly but firmly push the instrument into

position.

CAUTION: Ensure that the instrument is correctly orientated. A stop

will operate if an attempt is made to insert the instrument in the wrong

orientation (e.g. upside-down). This stop must not be over-ridden.

2.6 SELECTION OF INPUT TYPE

The required input type is selected on link jumpers LJ1/LJ2/LJ3 on the CPU PCB (see

Figure 2-6 and Table 2-1).

Figure 2-6 CPU PCB Link Jump ers

Table 2-1 In put Type Se lec tion

Input Type

RTD or DC (mV)

Thermocouple

DC (mA)

DC (V)

2-6 November, 2000 SM067-2

CPU PCB Link Jumper Fitted)

None (Parked)

LJ3

LJ2

LJ1

Page 47

59039

1

-DIN Digi tal In di ca tor Sec tion 2

8

Prod uct Man ual - Vol ume II In ter nal Links and Switches

2.7 OUTPUT 2 TYPE/OUTPUT 3 TYPE

The type of output for Output 2 and Output 3 is determined by the Option PCB fitted in

the appropriate position (see Figure 2-1) and, in the case of the DC Output 2 Option

PCB being fitted, the setting of Link Jumpers LJ8 and LJ9 on that Option PCB (see

Figure 2-7 and Table 2-2). There are three types of option PCB:

1. Re lay Out put Op tion PCB (no link jump ers) - Out put 2 and Ou put 3

2. DC Out put Op tion PCB (link jump ers as in Fig ure 2-7 and Ta ble 2-2) Out put 2 only

3. Trans mit ter Power Sup ply Op tion PCB - Out put 3 only

Figure 2-7 DC Out put 2 Op tion PCB

Table 2-2 DC Out put 2 Type Se lec tion

Output Type

DC (0 - 10V)

DC (0 - 20mA)

DC (0 - 5V

DC (4 - 20mA)

Link Jumpers Fitted

LJ8 (DC Output 2 Option PCB)

LJ9 (DC Output 2 Option PCB)

LJ8 (DC Output 2 Option PCB)

LJ9 (DC Output 2 Option PCB)

SM067-2 November, 2000 2-7

Page 48

Sec tion 3

Con figu ra tion Mode Prod uct Man ual - Vol ume II

1

-DIN Digi tal In di ca tor 59039

8

SEC TION 3

CONFIGURATION MODE

3.1 ENTRY INTO CONFIGURATION MODE

To enter Configuration Mode:

1. Ensure that the instrument is powered-down.

2 . Power-up the instrument and, within ten minutes of power-up, hold down

the Raise and Scroll keys simultaneously for six seconds. If this is done

whilst the instrument is displaying the process variable value, the instrument

will enter/exit Set Up Mode - keep holding the keys down!

NOTE: This need not be the first key action after power-up.

The instrument will then enter Configuration Mode and the SET indicator will flash. The

user will then be presented with the first of a sequence of parameter displays; in each

instance, the parameter will be identified by a single-character legend in the units

display and the setting of that parameter will be shown in the four-digit display. The

user may then step through the parameters using the Scroll key. The setting may be

adjusted using the Raise/Lower keys. As soon as the value/setting is changed, the

four-digit display will flash, indicating that the new value/setting has yet to be confirmed

(this flashing is inhibited during actual adjustment). When the value/setting is as

required, it may be confirmed by:

(a) press ing the Scroll key, where upon the four- digit dis play will show:

(b) press ing the Raise key.

The four-digit display will then show a static (non-flashing) display of the new parameter

setting. Depression of any key other than the Raise key at the SurE? display will cause

the original parameter setting to be retained. The sequence of parameter displays is

shown in Table 3-1.

NOTE: Changes to the value/setting of certain Configuration Mode

parameters (e.g. input range, output use and type) will cause the Set

Up Mode parameters to be automatically set to their default values the

next time Set Up Mode is entered (see also Volume 1, start of Section

3). It is recommended that all Configuration Mode parameters are

finalised before Set Up Mode parameters are adjusted.

3 -1 November, 2000 SM067-3

Page 49

59039

1

-DIN Digi tal In di ca tor Sec tion 3

8

Prod uct Man ual - Vol ume II Con figu ra tion Mode

Table 3-1 Con figu ra tion Mode Pa rame ters

Parameter

Hardware Definition

Code

Hardware Option fitted

Input Range

Alarm 1 Type

Alarm 2 Type

Legend

AL1 ON

AL2 ON

Available Settings

See Subsection 3.2

None fitted

RS485 Communications

Remote Latch Reset

Defined by Input Code (see Subsection 3.4)

Process High Alarm

Process Low Alarm

Not in use

Process High Alarm

Process Low Alarm

Default

2100

1419

Alarm 3 Type

Output 1 Use

AL3 ON

Not in use

Process High Alarm

Process Low Alarm

Alarm 1, non-latching,

direct-acting

Alarm 1, non-latching,

reverse-acting

Alarm 1, latching,

direct-acting

Alarm 1, latching,

reverse-acting

Logical OR of Alarm 1 and

Alarm 2, direct-acting

Logical OR of Alarm 1 and

Alarm 2, reverse-acting

SM067-3 November, 2000 3-2

Page 50

Sec tion 3

1

-DIN Digi tal In di ca tor 59039

8

Con figu ra tion Mode Prod uct Man ual - Vol ume II

Table 3-1 (Cont.) Configuration Mode Parameters

Parameter

Output 2 Use

Legend Available Settings

1

Alarm 2, direct-acting

Alarm 2, reverse-acting

Alarm 3, direct-acting

Alarm 3, reverse-acting

Logical OR of Alarm 1 and

Alarm 2, direct-acting

Logical OR of Alarm 1 and

Alarm 2, reverse-acting

Logical OR of Alarm 1 and

Alarm 3, direct-acting

Logical OR of Alarm 1 and

Alarm 3, reverse-acting

5

5

5

5

5

5

5

5

Default

Output 3 Use

Logical OR of Alarm 2 and

Alarm 3, direct-acting

Logical OR of Alarm 2 and

Alarm 3, reverse-acting

Recorder Output (PV)

2

Alarm 2, direct-acting

Alarm 2, reverse-acting

Alarm 3, direct-acting

Alarm 3, reverse-acting

Logical OR of Alarm 1 and

Alarm 2, direct-acting

Logical OR of Alarm 1 and

Alarm 2, reverse-acting

5

5

6

7

7

7

7

7

7

Logical OR of Alarm 1 and

Alarm 3, direct-acting

7

3-3 November, 2000 SM067-3

Page 51

59039

1

-DIN Digi tal In di ca tor Sec tion 3

8

Prod uct Man ual - Vol ume II Con figu ra tion Mode

Table 3-1 (Cont.) Configuration Mode Parameters

Parameter

Output 3 Use (cont.)

Communications

Baud Rate

Communications

Address

Communications

Protocol

3

3

3

Legend Available Settings

2

1200, 2400, 4800 or 9600 Baud

1 - 32

Logical OR of Alarm 1 and

Alarm 3, reverse-acting

Logical OR of Alarm 2 and

Alarm 3, direct-acting

Logical OR of Alarm 2 and

Alarm 3, reverse-acting

Transmitter Power Supply

ASCII

MODBUS, odd parity

7

7

7

8

Default

4800

1

MODBUS, even parity

MODBUS, no parity

Cold Junction

Compensation

Enable/Disable

4

Enabled

Disabled

NOTES ON TABLE 3-1

1. Only appears in display sequence if Output 2 is fitted/configured in the Hardware

Definition Code (i.e. Digit 3 is non-zero).

2. Only appears in display sequence if Output 3 is fitted/configured in the Hardware

Definition Code (i.e. Digit 4 is non-zero).

3. Only appears in display sequence if the Hardware Option parameter is set to r485.

4. Only appears in display sequence if thermocouple input is fitted/configured

i.e. Digit 1 of Hardware Definition Code is set to 2 (see Subsection 3.2)

5. Only if Output 2 is configured as a relay output

6. Only if Output 2 is configured as a DC linear output

7. Only if Output 3 is configured as a relay output

8. Only if Output 3 is configured as a transmitter power supply output

SM067-3 November, 2000 3-4

Page 52

Sec tion 3

Con figu ra tion Mode Prod uct Man ual - Vol ume II

1

-DIN Digi tal In di ca tor 59039

8

3.2 HARDWARE DEFINITION CODE

This parameter is used to represent the hardware fitted (input type, Output 1 type,

Output 2 type and Output 3 type); this must be compatible with the hardware actually

fitted. Access to the Hardware Definition Code is gained by pressing the Scroll and

Lower keys simultaneously whilst the instrument is in Configuration Mode. The code is

used as follows:

1

Digit 1 - Input Type

Value

1

2

3

4

RTD/Linear DC (mV)

Thermocouple †

Linear DC (mA)

Linear DC (V)

† Default setting

Meaning

Output 1 always

relay output

Digit 4 - Output 3 Type

Value

0

1

8

Digit 3 - Output 2 Type

Value

0

1

3

4

5

7

Transmitter Power Supply

Not fitted †

Meaning

Not fitted †

Relay

DC (0 - 10V)

DC (0 - 20mA)

DC (0 - 5V)

DC (4 - 20mA)

Meaning

Relay

The maximum setting available for this code is 4178. For example, the code for an

instrument with a thermocouple input, relay Output 1, relay Output 2 and relay Output 3

would be 2111.

NOTE: It is essential that this code is changed promptly whenever

there is a change to the instrument’s hardware configuration (change

of input/output type, alarm/recorder output added/removed etc.). The

instrument software depends upon this code to ensure correct

operation.

This code may also be viewed as a Read Only display in Operator Mode (see Volume

1, Subsection 2.9).

3.3 HARDWARE OPTION

There are two hard ware op tions avail able - RS485 Se rial Com mu ni ca tions and Re mote

Latch ing Alarm Re set. These op tions are mu tu ally ex clu sive. Ac cess is gained to the

Hard ware Op tion pa rame ter by press ing the Scroll key whilst the Hard ware Defi ni tion

Code is dis played in Con figu ra tion Mode. The Hard ware Op tion dis play may be viewed

as a Read Only dis play in Op era tor Mode (see Vol ume 1, Sub sec tion 2.9)

3-5 November, 2000 SM067-3

Page 53

1

59039

-DIN Digi tal In di ca tor Sec tion 3

8

Prod uct Man ual - Vol ume II Con figu ra tion Mode

3.3.1 RS485 Se rial Com mu ni ca tions Op tion

For this option, the protocol used is defined by the Communications Protocol

parameter - see Subsection 3.9. Full details of communications operation are given in

Volume 1, Section 4.

3.3.2 Re mote Latch ing Alarm Re set Op tion

This option has the same effect as resetting the latching Alarm 1 (see Output 1 Use

parameter in Table 3-1) from the front panel. The latched Alarm 1 can be reset only if

the original alarm condition has been cleared; this reset has no effect whilst the alarm

condition prevails. See also Appendix A for more details of this option.

3.4 INPUT RANGE

The default setting of this parameter is dependent upon the input hardware fitted, as

indicated by the first (left-most) digit of the Hardware Definition Code (see Subsection

3.2):

Input Hardware Fitted

Thermocouple

RTD/Linear mV)

Linear mA

Linear V

1419 (Type “J”, 0 to 761oC)

7220 (RTD Pt100, 0 to 800oC)

3414 (4 to 20mA)

4446 (0 to 10V)

Default Setting

If the Hardware Definition Code is at its default setting, input code 1419 will be

displayed. The input ranges and codes available are listed in Appendix A.

3.5 ALARM TYPE

The operation of the different alarm types is shown in Volume 1, Figure 3-1.

3.6 LOGICAL COMBINATION OF ALARMS

Output 1, 2 or 3 may be used as a relay output representing a logic OR of two alarms.

EXAMPLE OF LOGICAL COMBINATION OF ALARMS

Logical OR of Alarm 1 with Alarm 2

Alarm Status

Alarm 1

OFF

ON

OFF

ON

Alarm 2

OFF

OFF

ON

ON

Direct-acting

De-energised

Energised

Energised

Energised

Relay State

Reverse-acting

Energised

De-energised

De-energised

De-energised

3.7 COMMUNICATIONS BAUD RATE

This pa rame ter must be set to the same Baud rate as the com mu ni ca tions port on the

mas ter de vice.

SM067-3 November, 2000 3-6

Page 54

Sec tion 3

Con figu ra tion Mode Prod uct Man ual - Vol ume II

1

-DIN Digi tal In di ca tor 59039

8

3.8 COMMUNICATIONS ADDRESS

This is the unique address assigned to the instrument; it is used by the master device to

communicate with the instrument.

3.9 COMMUNICATIONS PROTOCOL

There are two communications protocols available: ASCII (fixed, even parity) and

MODBUS (selectable odd parity, even parity or no parity). Refer to Volume 1, Section 4

for details.

3.10 COLD JUNCTION COMPENSATION

This parameter is applicable only if a thermocouple input is fitted, in which case it must

be enabled in normal use.

NOTE: If a thermocouple input is fitted and the CJC is disabled, in

Operator Mode whenever the process variable is displayed, the unit

display will show: