Page 1

Switch 8800

Installation Guide

Version 3.0

3C17500 14-slot Starter Kit

3C17501 10-slot Starter Kit

3C17502 7-slot Starter Kit

and associated modules

http://www.3com.com/

Part No. 10014384

Document Number: DUA1750-0AA01

Published December 2004

Page 2

3Com Corporation

350 Campus Drive

Marlborough, MA

01752-3064

Copyright © 2004, 3Com Corporation. All rights reserved. No part of this documentation may be reproduced

in any form or by any means or used to make any derivative work (such as translation, transformation, or

adaptation) without written permission from 3Com Corporation.

3Com Corporation reserves the right to revise this documentation and to make changes in content from time

to time without obligation on the part of 3Com Corporation to provide notification of such revision or change.

3Com Corporation provides this documentation without warranty, term, or condition of any kind, either

implied or expressed, including, but not limited to, the implied warranties, terms or conditions of

merchantability, satisfactory quality, and fitness for a particular purpose. 3Com may make improvements or

changes in the product(s) and/or the program(s) described in this documentation at any time.

If there is any software on removable media described in this documentation, it is furnished under a license

agreement included with the product as a separate document, in the hard copy documentation, or on the

removable media in a directory file named LICENSE.TXT or !LICENSE.TXT. If you are unable to locate a copy,

please contact 3Com and a copy will be provided to you.

UNITED STATES GOVERNMENT LEGEND

If you are a United States government agency, then this documentation and the software described herein

are provided to you subject to the following:

All technical data and computer software are commercial in nature and developed solely at private expense.

Software is delivered as “Commercial Computer Software” as defined in DFARS 252.227-7014 (June 1995)

or

as a “commercial item” as defined in FAR 2.101(a) and as such is provided with only such rights as are

provided in 3Com’s standard commercial license for the Software. Technical data is provided with limited

rights only as provided in DFAR 252.227-7015 (Nov

1995) or FAR 52.227-14 (June 1987), whichever is

applicable. You agree not to remove or deface any portion of any legend provided on any licensed program

or documentation contained in, or delivered to you in conjunction with, this User Guide.

Unless otherwise indicated, 3Com registered trademarks are registered in the United States and may or may

not be registered in other countries.

3Com and the 3Com logo are registered trademarks of 3Com Corporation.

Intel and Pentium are registered trademarks of Intel Corporation. Microsoft, MS-DOS, Windows, and

Windows NT are registered trademarks of Microsoft

Corporation. UNIX is a registered trademark in the

United States and other countries, licensed exclusively through X/Open Company, Ltd.

IEEE and 802 are registered trademarks of the Institute of Electrical and Electronics Engineers, Inc.

All other company and product names may be trademarks of the respective companies with which they are

associated.

ENVIRONMENTAL STATEMENT

It is the policy of 3Com Corporation to be environmentally-friendly in all operations. To uphold our policy,

we are committed to:

Establishing environmental performance standards that comply with national legislation and regulations.

Conserving energy, materials and natural resources in all operations.

Reducing the waste generated by all operations. Ensuring that all waste conforms to recognized

environmental standards. Maximizing the recyclable and reusable content of all products.

Ensuring that all products can be recycled, reused and disposed of safely.

Ensuring that all products are labelled according to recognized environmental standards.

Improving our environmental record on a continual basis.

End of Life Statement

3Com processes allow for the recovery, reclamation and safe disposal of all end-of-life electronic components.

Regulated Materials Statement

3Com products do not contain any hazardous or ozone-depleting material.

Environmental Statement about the Documentation

The documentation for this product is printed on paper that comes from sustainable, managed forests; it is

fully biodegradable and recyclable, and is completely chlorine-free. The varnish is environmentally-friendly,

and the inks are vegetable-based with a low heavy-metal content.

Page 3

ABOUT THIS GUIDE

This guide describes the 3Com® Switch 8800 and how to install hardware,

configure and boot software, and maintain software and hardware. This guide

also provides troubleshooting and support information for your switch.

This guide is intended for Qualified Service personnel who are responsible for

configuring, using, and managing the switches. It assumes a working knowledge

of local area network (LAN) operations and familiarity with communication

protocols that are used to interconnect LANs.

Always download the Release Notes for your product from the 3Com World Wide

Web site and check for the latest updates to software and product

documentation:

http://www.3com.com

Conventions Ta bl e 1 lists icon conventions that are used throughout this guide.

Ta bl e 1 Notice Icons

Icon Notice Type Description

Information note Information that describes important features or

Caution Information that alerts you to potential loss of data

Warning Information that alerts you to potential personal

Ta bl e 2 lists text conventions that are used throughout this guide.

Ta bl e 2 Text Conventions

Convention Description

Screen displays This typeface represents information as it appears on the

Keyboard key names If you must press two or more keys simultaneously, the key

The words “enter” and “type” When you see the word “enter” in this guide, you must type

instructions.

or potential damage to an application, system, or

device.

injury.

screen.

names are linked with a plus sign (+), for example:

Press Ctrl+Alt+Del

something, and then press Return or Enter. Do not press

Return or Enter when an instruction simply says “type.”

Page 4

4 ABOUT THIS GUIDE

Table 2 Text Conventions

Convention Description

Words in italics Italics are used to:

Emphasize a point.

Denote a new term at the place where it is defined in the

text.

Identify menu names, menu commands, and software

button names.

Examples:

From the Help menu, select Contents.

Click OK.

Words in bold Boldface type is used to highlight command names. For

example, “Use the display user-interface command

to...”

Related Documentation

The following manuals offer additional information necessary for managing your

Switch 8800:

■ Switch 8800 Command Reference Guide — Provides detailed descriptions of

command line interface (CLI) commands, that you require to manage your

Switch 8800.

■ Switch 8800 Configuration Guide— Describes how to configure your Switch

8800 using the supported protocols and CLI commands.

■ Switch 8800 Release Notes — Contains the latest information about your

product. If information in this guide differs from information in the release

notes, use the information in the Release Notes.

These documents are available in Adobe Acrobat Reader Portable Document

Format (PDF) on the CD-ROM that accompanies your router or on the 3Com

World Wide Web site:

http://www.3com.com/

Page 5

SWITCH 8800 COMPONENTS

1

The chapter describes the following Switch 8800 components:

■ Switch Chassis

■ Switch Backplane

■ Fabric Module

■ I/O Modules

■ Power Supply

■ Fan Assembly

■ Switch 8800 Specifications

■ Switch 8800 Software Features

Switch Chassis There are three Switch 8800 Models, the 7-Slot, 10-Slot, and the 14-Slot. Ta bl e 3

lists the hardware features of each model.

Ta bl e 3 Hardware Features of the Switch 8800 Models

7-Slot Chassis 10-Slot Chassis 14-Slot Chassis

Fabric slots 2 2 2

I/O module slots 5 8 12

Fan slot 1 1 2

AC power supply slots 2 2 2

In each starter kit, one Fabric module is installed in the upper Fabric slot and one

AC power supply is installed in the left power slot.

Switch Backplane The Switch 8800 backplane is part of the integrated chassis and delivers

high-speed data transfer between the Fabric and I/O modules. The backplane

bandwidth capacity is 1,440 Tbps.

The backplane supports the following functions:

■ Interconnection of signals between modules

■ Communication channels

■ Hot swapping for modules

■ Auto-recognition of slots

■ Distribution of power and management of the power supply for the system

Page 6

6 CHAPTER 1: SWITCH 8800 COMPONENTS

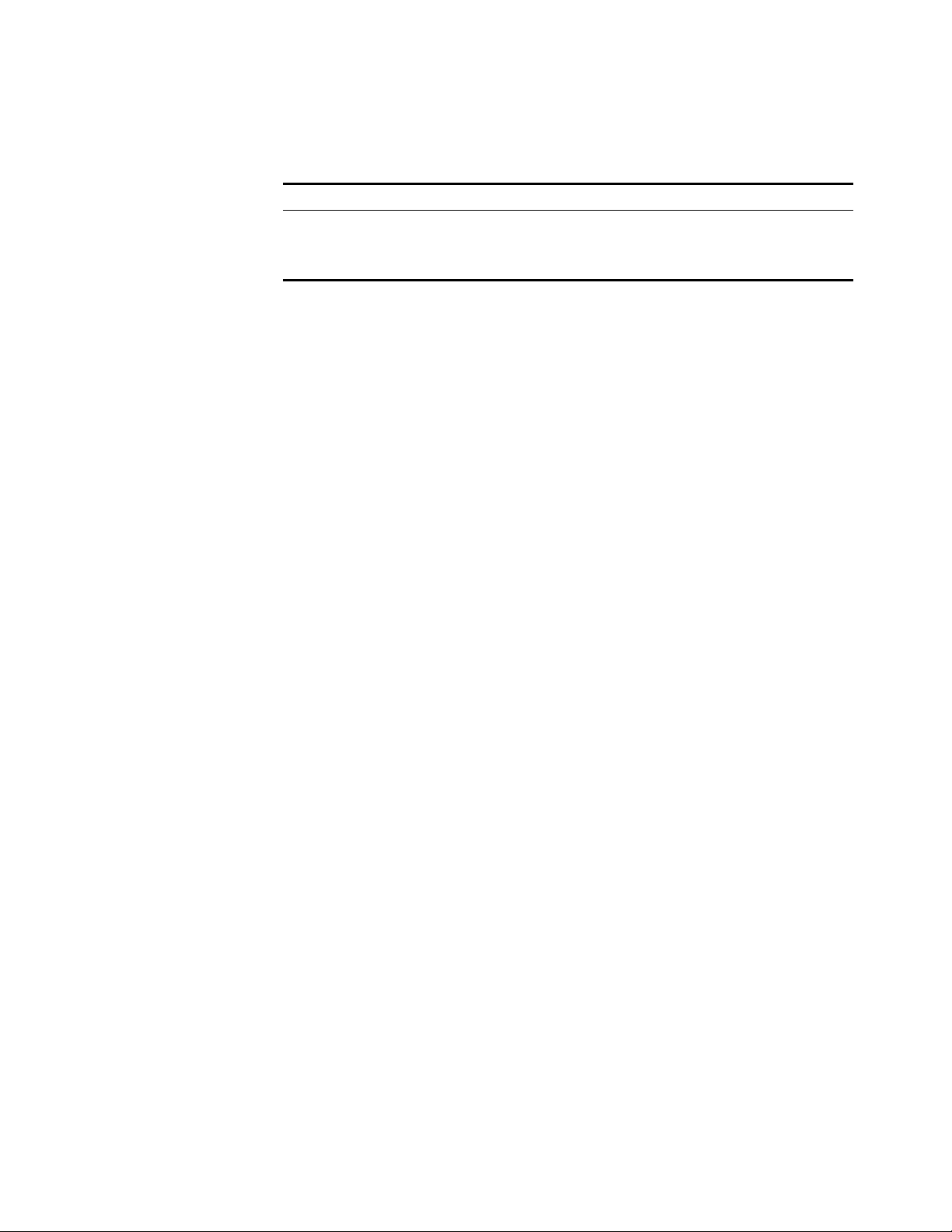

Fabric Module The Fabric module (3C17508) is the core of Switch 8800 system. It has the

following functions:

■ Connects the I/O modules through a crossbar

■ Manages and calculates routing table updates

■ Performs software upgrade and system reset functions

■ Monitors system power and the fan assembly

■ Provides timing

Figure 1 illustrates the front panel of the Fabric.

Figure 1 Switch 8800 Fabric

1

23456

7

1 Compact Flash port 7 I/O module LEDs

2 Management 10BASE-T/100BASE-TX port 8 SFS LED

3 RS232/485 port 9 RUN LED

4 Console port 10 ALM LED

5 AUX (modem) port 11 ACT LED

6 Reset button

Ta bl e 4 lists Fabric specifications.

Ta bl e 4 Fabric Specifications

Item Specification

Bandwidth 360 Gbps

CPU MPC755 133 Mhz

BootROM 512 KB

SDRAM 512 KB

Flash 16 MB

Dimensions (L x W) 366.7 mm x 340 mm (14.5 x 13.5 in)

External ports One console port for local configuration management

One AUX port for remote dial-up configuration management

One 10BASE-T/100BASE-TX port for upgrade and network management

One RS232/485 port for connecting an external PoE power rack

One hot-swap Compact Flash port

Maximum power

consumption

70 W

8

91011

Reset Button The reset button resets the entire system.

Fixed Ports The Switch 8800 Fabric module provides the following fixed ports:

■ Compact Flash (CF) Port

■ Management 10Base-T/100Base-TX port

Page 7

Fabric Module 7

■ RS232/RS485 port

■ Console Port

■ AUX (Modem) Port

Compact Flash (CF) Port

The Fabric module provides a CF port to accommodate a standard CF card, where

you can save logging information, host version information, alarming and other

diagnostic information. You can also use the CF port to upgrade software online.

Management 10Base-T/100Base-TX port

The management 10Base-T/100Base-TX port is connected to a computer using an

RJ-45 connector. You can use this port for system application downloading and

debugging. The management 10Base-T/100Base-TX port can also be connected to

devices such as a network management workstation to manage the system

remotely.

Ta bl e 5 lists specifications for the management 10Base-T/100Base-TX

port.

Ta bl e 5 Management 10Base-T/100Base-TX Port Specifications

Specification Description

Port connector RJ-45

Number of ports 1

Port speed 10 Mbps, half duple/full duplex

100 Mbps, half duplex/full duplex

Maximum transmission

segment over the selected

medium

Services System software upgrade and network management

100 m (328 ft) over the category-5 twisted pair cable

(crossover cable is required.)

See “RJ-45 Connector” on page 56 for an illustration of the RJ-45 connector.

Ta bl e 6 describes the LEDs of the management 10Base-T/100Base-TX port.

Ta bl e 6 Management 10Base-T/100Base-TX Port LEDs

LED Description

LINK Off — The line is not connected.

ACTIVE Green — No data is being transmitted.

Green — The line is connected.

Green flashing — Data is being transmitted.

RS232/RS485 port

The RS232/RS485 port uses an RJ-45 connector to connect to an external power

rack and monitor its status.

Ta bl e 7 RS232/RS485 Port Specifications

Specification Description

Connector RJ-45

Number of ports 1 RS 232 or RS485 port depending on the type of cable.

Functionality Reserved for monitoring and communication with an

Ta bl e 7 lists specifications for the RS232/485 port.

external subsystem

Page 8

8 CHAPTER 1: SWITCH 8800 COMPONENTS

Console Port

The console port is connected to the configuration terminal using an RJ-45

connector. You can use the console port for system debugging, configuration,

maintenance, management, and loading application files.

The console port can also be connected to a modem for functions such as remote

system debugging, configuration, maintenance, and management. You can

configure the baud rate on the console port.

Ta bl e 8 lists console port specifications.

Ta bl e 8 Console Port Specifications

Specification Description

Port connector RJ-45

Port standard Asynchronous EIA/TIA-232

Baud rate 9600 bps (by default)

Transmission distance 15 m (45 ft)

Services Connects with character terminal

Connects with local or remote PC serial port and runs terminal

emulation on a PC (a pair of modems are required for a

remote connection)

AUX (Modem) Port

The AUX port uses an RJ-45 connector and serves as a backup port for the console

port to connect a background terminal or a modem for remote system debugging,

configuration, maintenance, and management.

Ta bl e 9 lists AUX port

specifications.

Ta bl e 9 AUX Port Specifications

Specification Description

Connector RJ-45

Standard Asynchronous EIA/TIA-232

Functionality Connects a serial port of a PC (through a Modem pair for a

remote PC) and runs terminal emulation on the PC.

Module LEDs The module LEDs show the status of the I/O modules, as described in Ta bl e 10.

Ta bl e 10 I/O Module LEDs

LED Status description

RUN Green or off — The module failed or has not been inserted.

Green flashing, slow — The module is working normally.

Green flashing, fast — The module is booting or is not

registered successfully.

ALM Off — The module is working normally or has not been

inserted.

Red or red flashing — The module failed or is not working

normally.

Page 9

I/O Modules 9

Fabric Status LEDs The Fabric status LEDs show the status of the Fabric module, as described in

Ta bl e 11.

Ta bl e 11 Fabric Status LEDs

LED Status description

SFS ( not available) ON — The switching Fabric unit is active.

OFF— The switching Fabric unit is standby.

RUN Green or off — The Fabric failed or has not been inserted.

Green blinking — The Fabric is working normally.

ALM Red — The Fabric has alarms.

OFF — The Fabric has no alarms.

ACT Green — The Fabric is in active mode.

OFF — The Fabric is in standby mode.

I/O Modules The Switch 8800 provides slots for five to twelve I/O modules, in addition to the

Fabric slots. The following I/O modules are supported:

■ 1-Port 10GBASE-X (XENPAK) Module

■ 2-Port 10GBASE-X (XFP) Module

1-Port 10GBASE-X (XENPAK) Module

■ 12-Port 1000BASE-X (SFP) Module

■ 24-Port 1000BASE-X (SFP) Module

■ 24-Port 10/100/1000BASE-T (RJ45) Module

Consider the following when selecting I/O modules:

■ You can configure several I/O modules of the same type

■ All I/O module slots are the same and any combination of I/O modules can be

inserted

■ You must select I/O module port cables that are compatible with each installed

I/O module

The 1-port 10GBASE-X (XENPAK) module provides a single 10 Gbps XENPAK port.

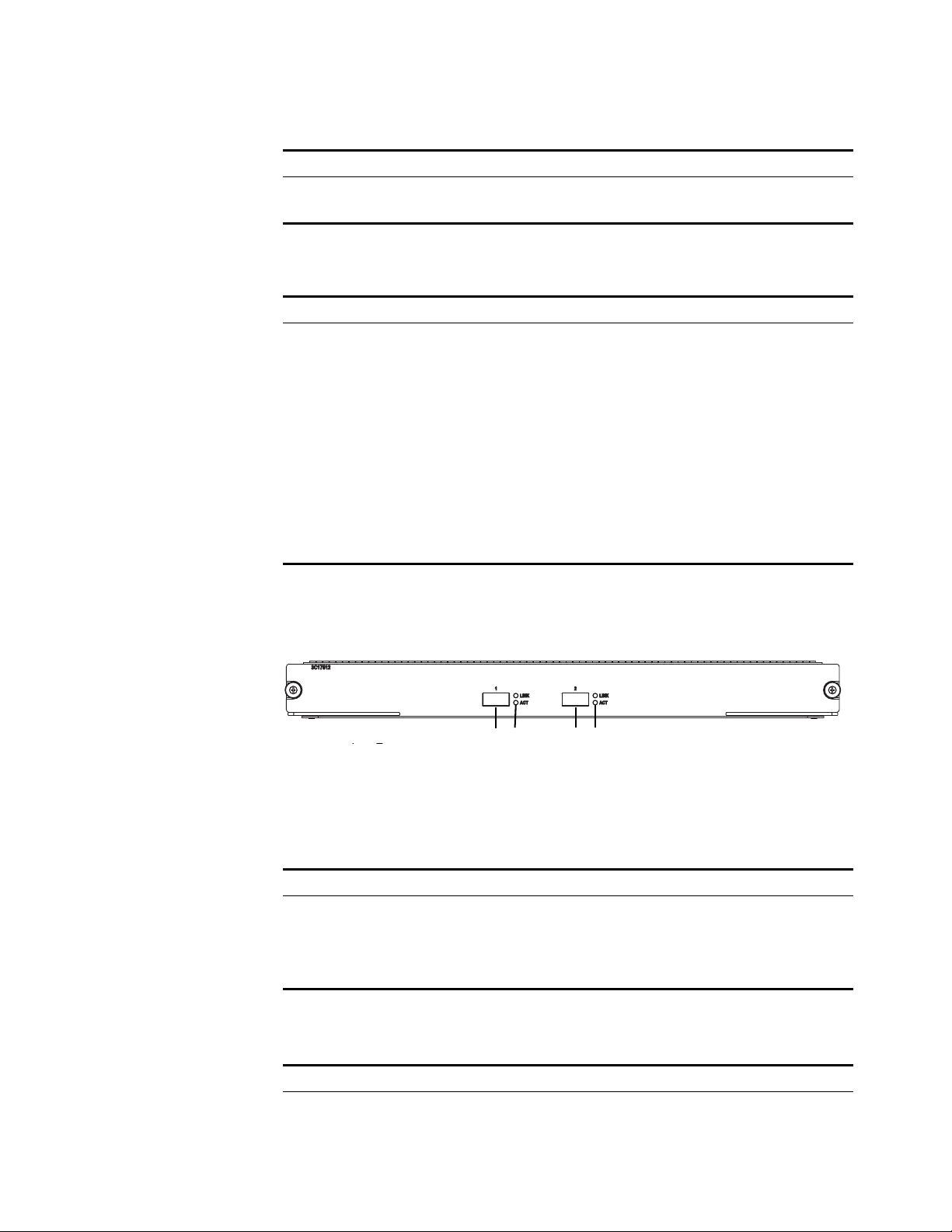

Figure 2 illustrates the front panel of the 1-port 10GBASE-X (XENPAK) module.

Figure 2 Front Panel of the 1-Port 10GBASE-X (XENPAK) Module

12

1 XENPAK port

2 XENPAK port LEDs

Ta bl e 12 describes the 1-port 10GBASE-X (XENPAK) module LEDs.

Ta bl e 12 1-Port 10GBASE-X (XENPAK) Module LEDs

LED Description

LINK Off — The port is not operating

On — The port is operating

Page 10

10 CHAPTER 1: SWITCH 8800 COMPONENTS

Table 12 1-Port 10GBASE-X (XENPAK) Module LEDs (continued)

LED Description

ACT Off — No data is being sent or received

Ta bl e 13 lists specifications of the 1-port 10GBASE-X (XENPAK) module.

Ta bl e 13 Specifications for the 1-Port 10GBASE-X (XENPAK) Module

Specification Description

CPU MPC8245

BootROM 512 KB

SDRAM 128 MB

Dimensions (L x W) 366.7 x 340 mm (14.5 x 13.4 in)

Power consumption 60 W

Connector SC

Number of ports 1

Transmission rate 10 Gbps

Transceiver, cable and

maximum transmission

distance

Orange flashing — Data is being sent or received

3CXENPAK92, 1310 nm, single mode optical fiber, 10 km (6 mi)

3CXENPAK96, 1310 nm, single mode optical fiber, 40 km (25 mi)

2-Port 10GBASE-X (XFP)

Module

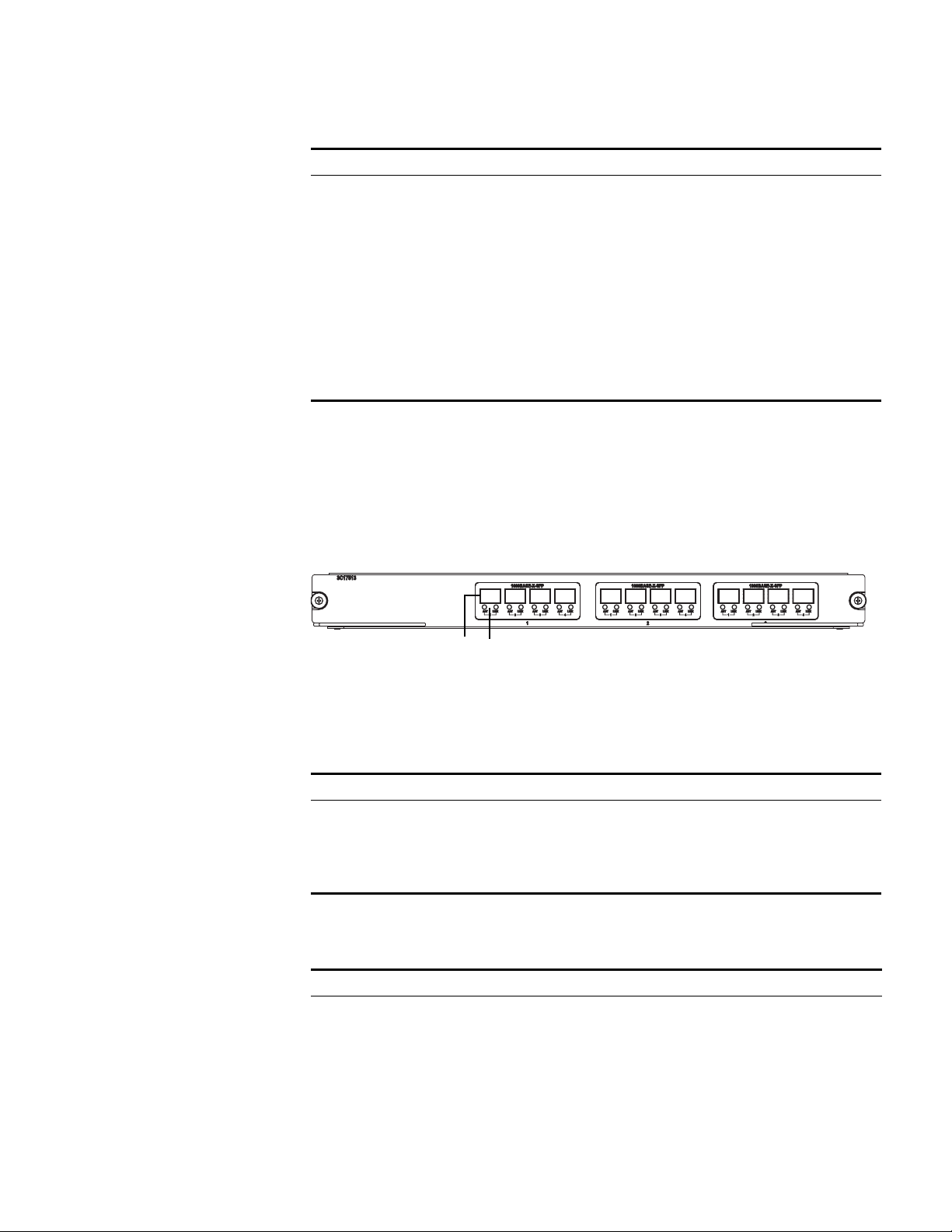

The 2-Port 10GBASE-X (XFP) module provides two 10 Gbps XFP ports.

Figure 3 Front Panel of the 2-Port 10GBASE-X (XFP) Module

12

1 XFP ports

2 XFP LEDs

1

2

Ta bl e 14 describes the 2-Port 10GBASE-X (XFP) module LEDs.

Ta bl e 14 2-Port 10GBASE-X (XFP) Module LED

LED Description

LINK Off — The port is not operating

On — The port is operating

ACT Off — No data is being sent or received

Orange flashing — Data is being sent or received

Ta bl e 15 lists the specifications of the 2-Port 10GBASE-X (XFP) module.

Ta bl e 15 Specifications for the 2-Port 10GBASE-X (XFP) Module

Specification Description

CPU MPC8245

BootROM 512 KB

Page 11

I/O Modules 11

Table 15 Specifications for the 2-Port 10GBASE-X (XFP) Module (continued)

Specification Description

SDRAM 128 MB

Dimensions (L x W) 366.7 x 340 mm (14.5 x 13.4 in)

Maximum power

consumption

Number of ports 2

Connector XFP LC

Port transmission speed 10 Gbps

Transceiver, cable, and

maximum transmission

distance

87 W

3CXFP92, 1310 nm 9/125 µm single mode optical fiber, 10 km (6

mi)

3CXFP96, 1550 nm, 9/125 µm single mode optical fiber, 40 km

(25 mi)

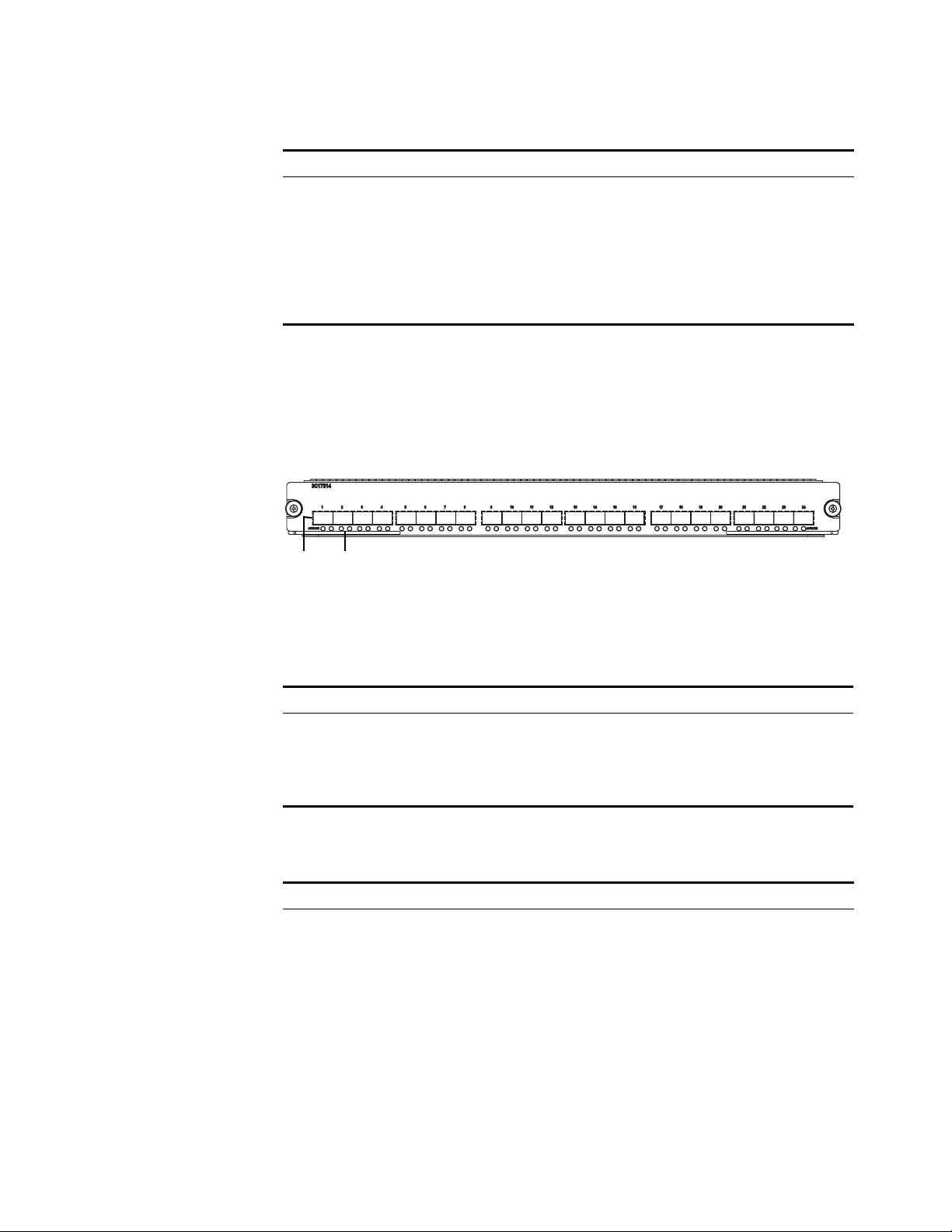

12-Port 1000BASE-X

(SFP) Module

The 12-Port 1000BASE-X (SFP) module provides 12 1000BASE-X full duplex ports

and uses SFP cable.

Each port on the 12-Port 1000BASE-X (SFP) module has 2 LEDs, as shown in

Figure 4.

Figure 4 Front Panel of the 12-Port 1000BASE-X (SFP) Module

1

2

1 SFP ports

2 SFP port LEDs

Ta bl e 16 describes the LEDs on the 12-Port 1000BASE-X (SFP) module.

Ta bl e 16 12-Port 1000BASE-X (SFP) Module LEDs

LED Description

LINK Off — The port is not operating

On — The port is operating

ACT Off — No data is being transmitted

Orange flashing — Data is being transmitted

Specifications of the 12-Port 1000BASE-X (SFP) module are described in Ta bl e 17.

Ta bl e 17 Specifications for the 12-Port 1000BASE-X (SFP) Module

Specification Description

CPU MPC8245

BootROM 512 KB

SDRAM 128 MB

Dimensions (L x W) 366.7 x 340 mm (14.5 x 13.4 in)

Maximum power

consumption

Connector SFP/LC

60 W

Page 12

12 CHAPTER 1: SWITCH 8800 COMPONENTS

Table 17 Specifications for the 12-Port 1000BASE-X (SFP) Module (continued)

Specification Description

Number of ports 12

Port transmission

speed

Transceiver, cable,

and maximum

transmission distance

1000 Mbps

3CSFP91, 850 nm, 50/125 µm multi-mode optical fiber, 550 m (1804

ft)

3CSFP92, 1310 nm, 9/125 µm single mode optical fiber, 10 km (6 mi)

3CSFP93, RJ-45, category 5 100 m (300 ft)

3CSFP97, 1550 nm, 9/125 µm single mode optical fiber, 70 km (43 mi)

24-Port 1000BASE-X

(SFP) Module

The 24-port 1000BASE-X (SFP) module provides 24 1000BASE-X full duplex ports

and uses SFP cable.

Figure 5 illustrates the front panel of the 24-port 1000BASE-X (SFP) module.

Figure 5 Front Panel of the 24-Port 1000BASE-X (SFP) Module

12

1 SFP ports

2 SFP port LEDs

Ta bl e 18 describes the 24-port 1000BASE-X (SFP) module LEDs.

Ta bl e 18 24-Port 1000BASE-X (SFP) Module LEDs

LED Description

LINK Off — The port is not operating

On — The port is operating

ACT Off — No data is being transmitted

Orange flashing — Data is being transmitted

Ta bl e 19 lists specifications of the 24-port 1000BASE-X (SFP) module.

Ta bl e 19 Specifications for the 24-Port 1000BASE-X (SFP) Module

Specification Description

CPU MPC8245

BootROM 512 KB

SDRAM 128 MB

Dimensions (L x W) 366.7 x 340 mm (14.5 x 13.4 in)

Power consumption 100 W

Connector SFP

Number of ports 24

Transmission rate 1000 Mbps full duplex

Page 13

I/O Modules 13

Table 19 Specifications for the 24-Port 1000BASE-X (SFP) Module (continued)

Specification Description

Transceiver, cable,

and maximum

transmission

distance

3CSFP91, 850 nm, 50/125 µm multi-mode optical fiber, 550 m (1804 ft)

3CSFP92, 1310 nm, 9/125 µm single mode optical fiber, 10 km (6 mi)

3CSFP93, RJ-45, category 5, 100 m (300 ft)

3CSFP97, 1550 nm, 9/125 µm single mode optical fiber, 70 km (43 mi)

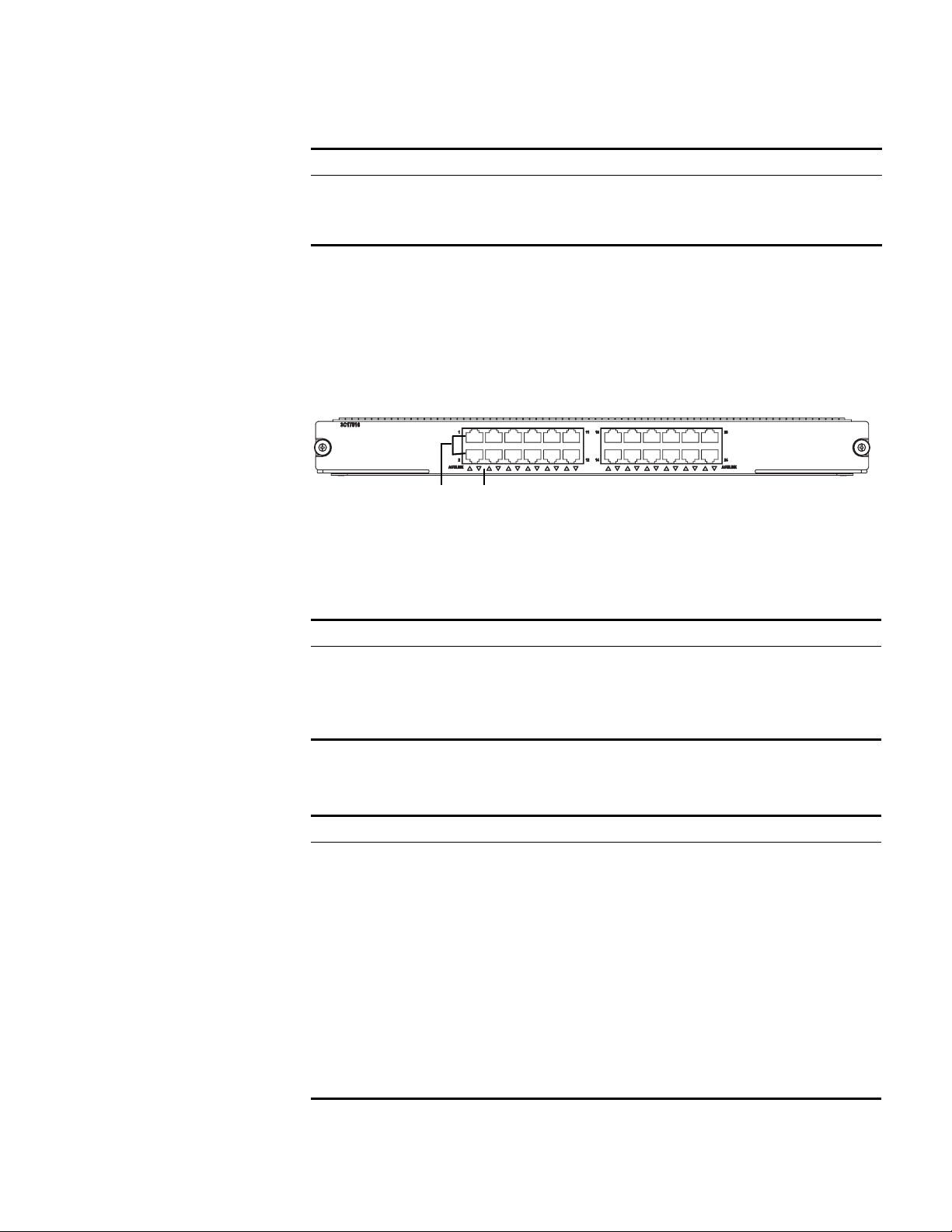

24-Port

10/100/1000BASE-T

(RJ45) Module

The 24-Port 10/100/1000BASE-T (RJ45) module provides 24 10/100/1000BASE-T

(RJ45) auto-sensing Ethernet ports.

Figure 6 illustrates the front panel of the 24-port 10/100/1000BASE-T (RJ45)

module.

Figure 6 Front Panel of the 24-Port 10/100/1000BASE-T (RJ45) Module

12

1 Ethernet ports

2 Ethernet port LEDs

Ta bl e 20 describes the 24-port 10/100/1000BASE-T (RJ45) module LEDs.

Ta bl e 20 24-Port 10/100/1000BASE-T (RJ45) Module LEDs

LED Description

LINK Off — The port is not operating

On — The port is operating

ACT Off — No data is being transmitted

Orange flashing — Data is being transmitted

Ta bl e 21 lists specifications of the 24-port 10/100/1000BASE-T (RJ45) module.

Ta bl e 21 Specifications for the 24-Port 10/100/1000BASE-T (RJ45) Module

Specification Description

CPU MPC8245

BootROM 512 KB

SDRAM 128 MB

Dimensions (L x W) 366.7 x 340 mm (14.5 x 13.4 in)

Power consumption 85 W

Connector RJ-45

Number of ports 24

Transmission rate 10 Mbps half/full duplex

100 Mbps half/full duplex

1000 Mbps full duplex

Cable and maximum

transmission distance

Category-5 twisted pair

100 m (328 ft)

Page 14

14 CHAPTER 1: SWITCH 8800 COMPONENTS

Power Supply The Switch 8800 power supplies are installed at the bottom of the chassis, in the

front. Only one AC power supply is required for each Switch 8800 chassis,

although 2 power supply slots are provided to implement 1+1 redundancy.

The 7-slot chassis uses a 1200 W auto-ranging power supply (3C17506).

The 10- and 14-slot chassis use a 2000 W auto-ranging power supply (3C17507).

When this power supply is used at 110 V, it delivers 1200 W of power, when used

at 220 V, it delivers 2000 W of power.

Do not combine 1200 W and 2000 W power supplies in the same chassis. If you

have two power supplies in your Switch 8800 chassis, they must be of the same

type.

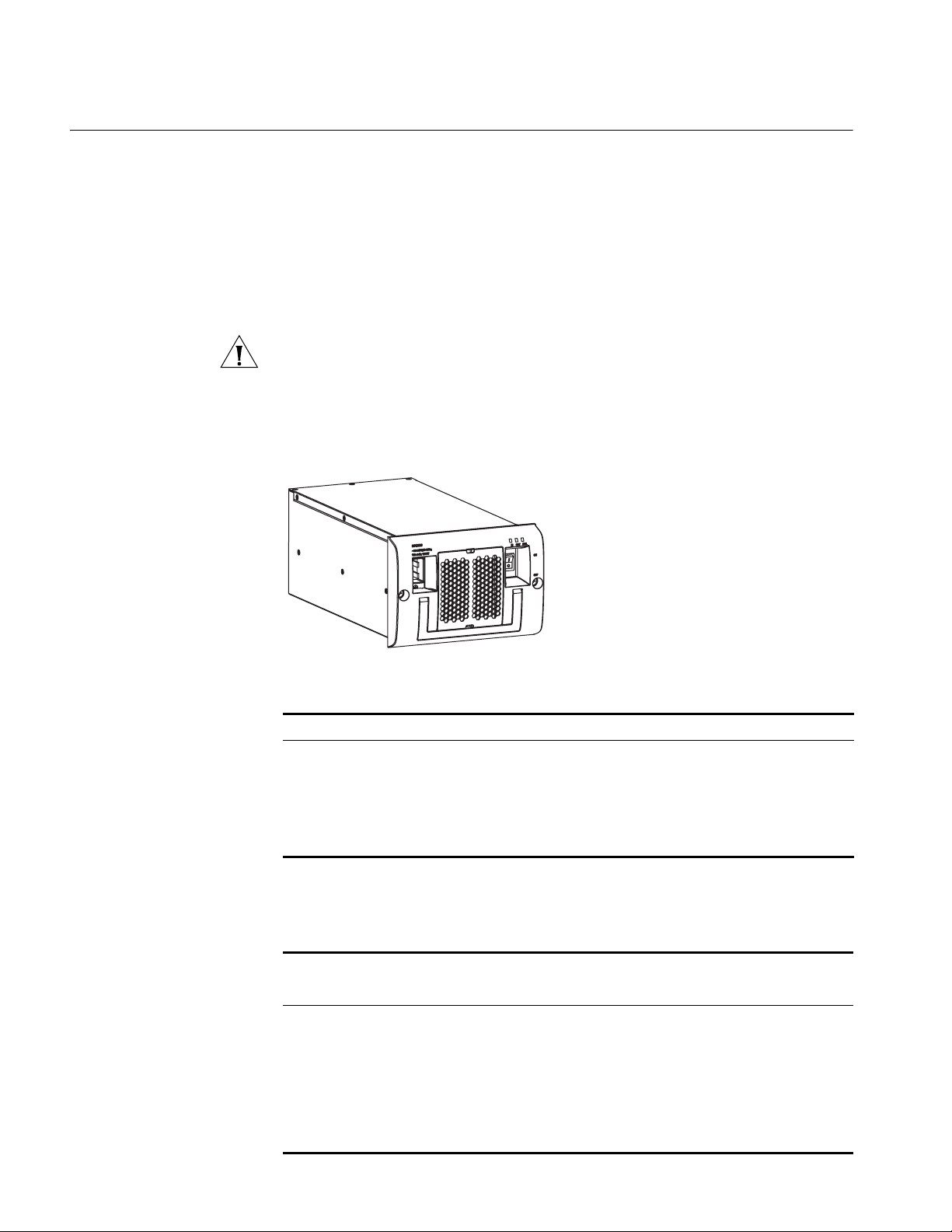

Figure 7 illustrates the 1200 W power supply for the Switch 8800.

Figure 7 Switch 8800 Power Supply

Ta bl e 22 describes the power supply LEDs.

Ta bl e 22 Power Supply LED Status

LED Description

INPUT ON — The power switch in the ON position and power input is normal.

OFF — No power is being supplied.

OUTPUT ON — Power output is normal.

OFF — Power output is not normal.

FAIL ON — The power supply is not operating normally.

OFF — The power supply is operating normally.

Ta bl e 23 describes the specifications of the power supply for the Switch 8800

chassis.

Ta bl e 23 Specifications for the Switch 8800 Power Supply

Specification

Description

Input 100 to 240 V, 50 to 60 Hz

Maximum tolerance 90 to 264 VAC, 47 to 63 Hz

Maximum input

current

Maximum output 1200 W 1200 W (90 to 160 V)

Lightning protection Lightning protection must be provided for all chassis.

7-slot Chassis 10-slot Chassis 14-slot Chassis

14 A

2000 W (160 to 264 V)

Page 15

Fan Assembly 15

Power Cords In North America, power cords for both 110 V and 220 V power input are shipped

with the Switch 8800 chassis. The power cord required depends on the power

output demands of the system.

Ta bl e 24 lists the power cord type that is required for each power supply.

Ta bl e 24 Switch 8800 Power Cords

Power Cord

7-slot chassis 10-slot chassis 14-slot chassis

110 V 1200 W 1200 W 1200 W

220 V 2000 W 2000 W

Power Supply

The North American 220 V power cord that is provided has a NEMA 6-20P

20A/250VAC style plug. The 220 VAC wall outlet needed for this plug is a NEMA

6-20R 20A/250V style outlet.

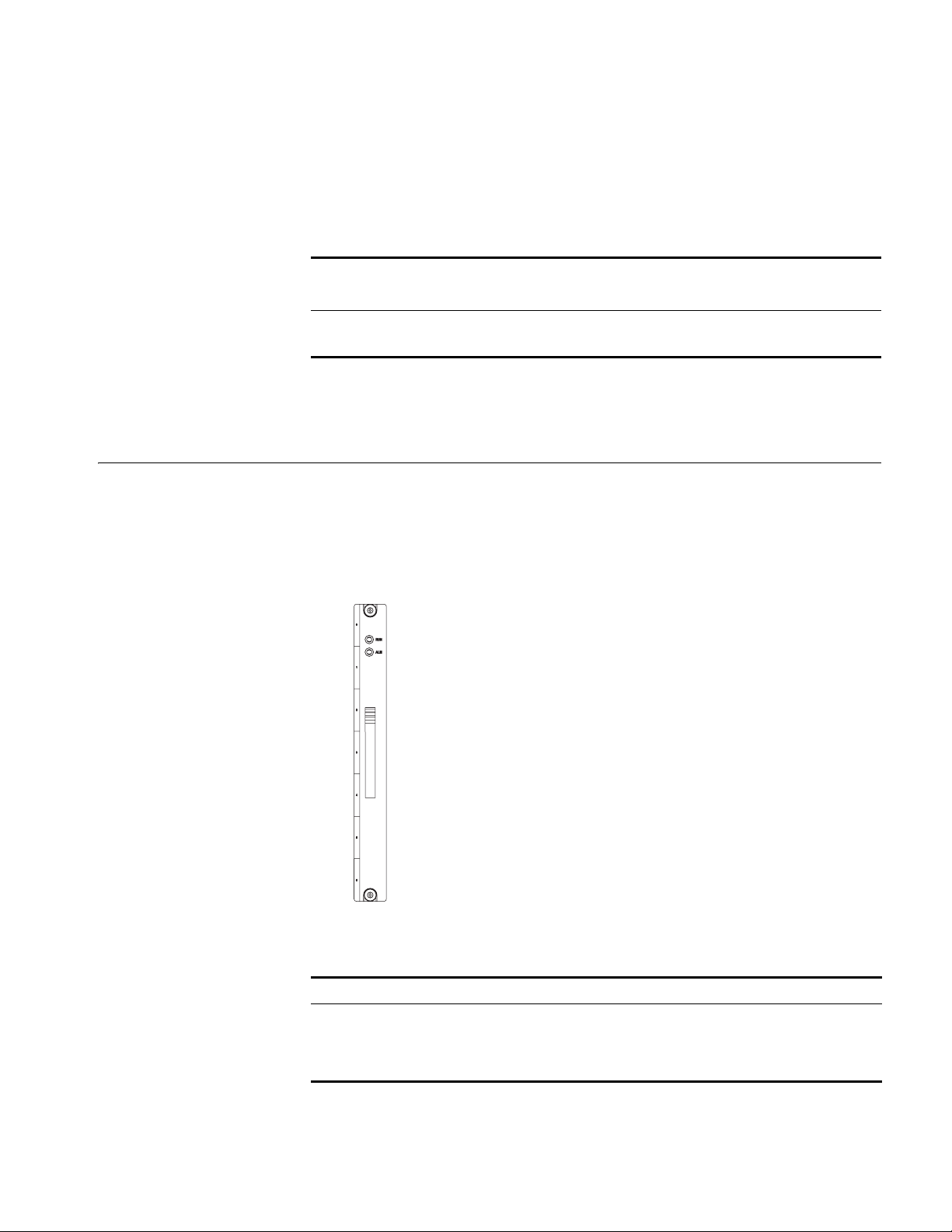

Fan Assembly The fan assembly consists of four to six individual fans and is located on the right

side of the chassis. They operate on -48 V DC current. Each starter kit includes the

appropriate fan assembly.

the 7-slot chassis.

Figure 8 Fan Assembly for the 7-Slot Chassis

Figure 8 illustrates the faceplate of the fan assembly for

Ta bl e 25 describes the Status LEDs on the faceplate of the fan assembly.

Ta bl e 25 Fan Assembly Status LEDs

LED Description

RUN OFF— The fan assembly is not operating normally

ON — The fan assembly is operating normally

ALM OFF — The fan assembly is operating normally

ON — The fan assembly is not operating normally

Page 16

16 CHAPTER 1: SWITCH 8800 COMPONENTS

Ta bl e 26 lists fan assembly specifications.

Ta bl e 26 Switch 8800 Fan Assembly

Specification 7-Slot Chassis 10-Slot Chassis 14-Slot Chassis

Fan assembly needed 1 (3C17503) 1 (3C17504) 2 (3C17503)

Number of fans 4 6 8

Power input 25 W 35 W 50 W

The fans are directly connected to the backplane through connectors. Fan

operation fault signals are collected and transmitted to the system alarm board

through the backplane.

Page 17

Switch 8800 Specifications 17

Switch 8800 Specifications

Ta bl e 27 provides detailed information about features of the Switch 8800.

Ta bl e 27 Specifications for the Switch 8800 System

Item 7-Slot Chassis 10-Slot Chassis 14-Slot Chassis

Dimensions

(H x W x D)

Weight (with all

components)

Fabric slots 2 2 2

I/O Module options 1-Port 10GBASE-X (XENPAK) Module

System switching 300 Gbps 480 Gbps 720 Gbps

Packet processing 178 Mpps 285 Mpps 428 Mpps

Input voltage 90 V to 264 V, 47 to 63 Hz

Max power

consumption

(all components

installed)

Environment

temperature

and

humidity

486 x 436 x 450 mm

(19.1 x 17.2 x 17.7 in)

65 Kg (143 lbs) 80 Kg (176 lbs) 120 Kg (265 lbs)

2-Port 10GBASE-X (XFP) Module

12-Port 1000BASE-X (SFP) Module

24-Port 1000BASE-X (SFP) Module

24-Port 10/100/1000BASE-T (RJ45) Module

665 W 975 W 1390 W

0 to 40 0 C (32 to 104 0 F) and 5% to 85%

619 x 436 x 450 mm

(24.4 x 17.2 x 17.7 in)

753 x 436 x 450 mm

(29.6 x 17.2 x 17.7 in)

Switch 8800 Software Features

Ta bl e 28 describes the software features of the Switch 8800.

Ta bl e 28 Switch 8800 Software Features

Service Support

Wire speed Layer 2

switching

Port auto-negotiation Speed and duplex operation modes.

Switching mode Store and Forward mode

MAC address table Address self-learning

STP/RSTP Implements IEEE 802.1D/802.1w Standard

Traffic control IEEE 802.3x traffic control (full duplex)

Link aggregation 31 groups of 8 ports

VLAN 4K VLANs, implements IEEE 802.1Q standard

Broadcast storm

suppression

Network protocol TCP/IP stack

Switching capacity of 720 Gbps

Packet forwarding rate at 428 Mpps

Wire speed forwarding (with forwarding delay less than 10µs) for

I/O module ports

Implements IEEE 802.1D standard and supporting port lock.

Address table: up to 64 K MAC addresses on each system, 12 K

MAC addresses on each module.

Back-pressure Based Flow Control (half-duplex)

Port-based VLAN

GARP and GVRP

Routing between VLANs

Supported

ARP

DHCP Relay

Page 18

18 CHAPTER 1: SWITCH 8800 COMPONENTS

Table 28 Switch 8800 Software Features (continued)

Service Support

IP address table Up to 128 K IP address forwarding entries

IP routing Static routing

Multicast GMRP

AAA and Security Access user authentication implements IEEE 802.1x

Reliability VRRP

QoS Traffic classification

Load and upgrade system

software

* In the advanced version of the software.

RIP Version 1 and 2

OSPF Version 2

BGP-4*

*

IS-IS

IGMP

PIM-DM

PIM-SM

Local authentication and RADIUS authentication

User hierarchical management and password protection

ACL, L2/L3/L4 information filtration (including frame filtration

based on port and source/destination MAC address, packet

filtration based on source/destination IP address and type of the

upper layer protocol)

Plain text and MD5 text authentication for OSPF and RIP Version 2.

DES56 Encryption for SNMP v3

*

Bandwidth management based on port, MAC address, IP address,

TCP/UDP port number, ToS/Diffserv value and CAR. The granularity

of bandwidth management is 64 Kbps.

Priority-based on VLAN port, IEEE 801.1P and ToS/Diffserv.

Support traffic classification to set CoS

8 egress queues for each port

Queue dispatching algorithm FIFO and PQ.

Xmodem protocol

Telnet

FTP and TFTP

Page 19

2

INSTALLING THE SWITCH 8800

The following sections describe how to prepare and install the components of the

Switch 8800:

■ Preparing to Install

■ General Site Requirements

■ Installation Checklist

■ Installing the Chassis

■ Installing the Cabling Rack

■ Installing a Module

■ Connecting the Ground Wire

■ Connecting and Configuring Power

■ Installing the Fan Assembly

■ Installing Cables

■ Connecting Module Cables

■ Post-installation Checklist

WARNING: Only trained and qualified personnel should install and maintain

3Com products.

Preparing to Install This section provides guidelines for preparing your site and switch for installation.

General Safety

Recommendations

Before installing your switch, note the following safety recommendations:

■ Switch off the power supply before connecting the cables.

■ Keep the switch away from heat sources.

■ Do not keep the switch in a damp place, and prevent liquid from getting into

the switch.

■ Ensure that the neutral point of the power is grounded properly, to avoid

personal injury.

■ Ensure that the power is off before plugging or unplugging the modules and

cables of the switch.

■ Before moving the chassis, disconnect all the power cords and external cables.

■ To avoid damage to the switch, connect all the cables correctly. Never connect

telephone cables (including the ISDN lines) to the console or AUX port.

■ During the installation, wear an antistatic wrist strap and antistatic gloves. See

“Static Electricity” on page 21 for additional information on preventing static.

Page 20

20 CHAPTER 2: INSTALLING THE SWITCH 8800

WARNING: Follow local safety regulations when performing any operation with

the Switch 8800. Follow the related safety information and special safety

instructions provided by 3Com. 3Com bears no responsibility for accidents that

occur due to violations of safe operation requirements.

Electrical Safety To maintain electrical safety, note the following recommendations:

■ Look carefully for possible hazards in your work area, such as ungrounded

power extension cables, missing safety grounds, and moist floors.

■ Locate the emergency power-off switch in the room where you are working.

Shut the power off at once in the event of an accident.

■ Unplug all the power cords and external cables before moving the chassis.

■ Never assume that power is disconnected from a circuit. Always check.

Moving the Switch Use caution when moving the Switch 8800. Note the following recommendations

when moving the switch:

■ Do not move the switch alone. Work with another person.

■ Move the switch slowly. Never move suddenly or twist your body.

Laser Safety Some I/O modules on the Switch 8800 have optical ports. Make sure that an

General Site Requirements

■ Always disconnect all external cables (including power cord) before lifting or

moving the chassis.

■ Do not hold the power handles when carrying the switch.

■ Do not put fingers into the vent of the chassis when carrying the switch.

■ Since the power handles and vent have not been designed to bear the weight

of the entire chassis, using them to carry the switch may damage the switch or

even injure personnel.

optical connector is connected to the optical ports, or a dust proof cover is fitted,

as invisible laser radiation can be emitted from the port.

WARNING: Never look at the transmit LED/laser through a magnifying device

while it is powered on. Never look directly at the fiber TX port and fiber cable ends

when they are powered on.

The environment of the installation site influences the performance and lifetime of

the switch. The installation site for your switch should meet the requirements

described in the following sections.

Temperature and Humidity

To ensure normal operation and to prolong the operational lifetime of the switch,

the temperature and humidity of the equipment room must be within controlled

limits. The requirements for the temperature and humidity of the switch

installation site are listed in

Ta bl e 29.

Ta bl e 29 Temperature and Humidity Requirements

Temperature Relative humidity (noncondensing)

00 to 400C (320 to 1040F) 10% to 90%

Page 21

Installation Checklist 21

Static Electricity

To prevent damage caused by the static electricity, ensure that:

■ The equipment is grounded

■ The equipment room is dust-proof

■ Adequate temperature and humidity conditions are maintained.

■ The operator wears an antistatic wrist strap while handling the module.

■ The module is placed upward on the antistatic workbench, or put into an

antistatic bag.

■ Avoid direct contact with the elements of the circuit board.

Electromagnetic Discharge

To prevent damage by electromagnetic discharge, do the following:

■ Take effective measures against electrical interference for the power supply

system.

■ Separate the working ground of the switch from the grounding device of the

power equipment, or lightning conductor.

■ Adopt electromagnetic shielding if necessary.

Lightning Damage

To minimize the risk of lightning damage do the following:

■ Install a lightning arrester on the input end of a telephone cable, or other

external line.

■ Ensure that the PGND wire of the chassis is well grounded

■ Ensure that the neutral point of the socket of AC power supply is well

grounded

■ Install a lightning arrester at the input end of the power supply

Installation Space For better heat dissipation and equipment maintenance, 3Com recommends that

you keep the front and back of the switch more than 1 meter (3 feet) away from

the walls or other devices. The sides of the switch should be at least 0.8 meters

(2.5 ft) away from the walls. If the optional rack is installed, the clear height of the

room should be more than 3 meters (10 ft).

Installation Checklist When you open the packing case of the switch, check the contents against the

your order contract. Contact your Service representative if you find any

discrepancies.

To install the Switch 8800, you will need:

■ To ol s

■ Phillips screwdriver

■ Flat-head screwdriver

■ Antistatic wrist strap

■ Cables

■ Console cable

Page 22

22 CHAPTER 2: INSTALLING THE SWITCH 8800

■ AUX cable

■ Power cord and chassis ground wire

■ Interface cables for the selected interface modules

■ Equipment

■ The switch

■ Ethernet 100BASE-T Hub or LAN switch

■ Channel service unit/data service unit (CSU/DSU) or other data

communications equipment (DCE) equipment (such as a modem)

■ Configuration terminal, such as a PC

■ Additional equipment for the selected interface modules

Installing the Chassis You can install the Switch 8800 in a standard, 19-inch rack or on a workbench.

Installing in a Standard

Rack

Installing on a

Workbench

Installing the Cabling Rack

When you are ready to install the Switch 8800 in the rack:

1 Carry the switch to the front of the rack. At least two people are required to move

the switch.

2 Put the switch on the tray or the guides and push it into the rack.

3 Fix the switch in the rack with the combination screw and floating nuts that are

shipped with the switch.

To install the switch on a workbench, take the following precautions:

■ Ensure that the workbench is smooth and stable.

■ Leave a heat-dissipation clearance in the front and back of the switch of more

than 1 m (3 ft) and at least 0.8 meters (2.5 ft) away from the walls on the sides.

■ Do not put heavy objects on the switch.

To install the cabling rack:

1 Attach the rack brace to the left side of the chassis (opposite the fan frame).

2 Insert the wiring channel into the brace and fasten the screws.

Installing a Module To install a module:

1 Wear an antistatic wrist strap.

2 Remove the blank plate from the chassis slot and save it for future use.

3 Hold the ejector levers of the module with both hands and push them outward.

4 Align the module with the guides in the chassis and slide it gently into the slot.

5 Push the module until the captive thumb screw on its handle bar touches the hole

in the chassis.

Page 23

Connecting the Ground Wire 23

6 Push the ejector levers inward and push the handle bar pin into the positioning

hole in the chassis.

7 Fasten the module’s captive mounting screws into the holes in the chassis with a

screwdriver.

Connecting the Ground Wire

Connecting and Configuring Power

Connecting AC Power

Cords

To connect the ground wire:

1 Wear an antistatic wrist strap.

2 Remove the screw from the grounding hole in the switch chassis.

3 Set the ground wire connector around the grounding screw.

4 Fasten the grounding screw in the hole on the chassis.

5 Connect the other end of the ground wire to the grounding bar of the switch.

If you install the switch in a rack, 3Com recommends that the ground wire of the

switch be connected to the grounding bar of the rack.

WARNING: The resistance between switch chassis and the ground should be less

than 1 ohm.

The Switch 8800 power supply has one power cord. Use the procedures in the

following sections to connect and configure power to your Switch 8800.

To connect the AC power cord:

1 Power off all the related parts of the switch before connecting the AC power cord

2 Plug the power cord into the socket in the switch and attach the retention clip to

the power cord plug.

3 Plug the other end of the cord into a socket strip with surge protector. Connect

the strip to the power source in the room.

Figure 9 illustrates the power cord connection for the Switch 8800.

Page 24

24 CHAPTER 2: INSTALLING THE SWITCH 8800

Figure 9 Power Cord Connection

12

1 Retention clip

2 AC power socket

3 Input LED

4 Output LED

5 Failure LED

34 5

WARNING: For surge protection, the power should be channelled through an

external protection device into the Switch 8800.

Installing the Fan Assembly

The Switch 8800 is delivered with the fan assembly already installed. If you need

to replace a fan assembly, you can use the following procedure while the switch is

running.

1 Wear an antistatic wrist strap.

2 Remove the fan frame from the pack.

3 Hold the ejector levers on the fan frame with both hands and push them outward.

4 Align the fan with the guides in the chassis and slide it gently into the slot.

5 Push the fan until its positioning pin touches the hole in the chassis.

6 Push the ejector levers inward.

7 Push the handle bar pin into the hole in the chassis.

WARNING: To avoid injury, do not touch any naked wire, terminal, or any other

part of the product labelled Dangerous Voltage. Always wear the antistatic wrist

strap when installing the fan.

Installing Cables This section describes how to connect console and AUX cables to the Switch

8800.

Connecting the Console

Cable

The console cable is an 8-core shielded cable. One end of the cable has a crimped

RJ-45 connector, which is plugged into the console port of the switch. The other

end has both a DB-9-hole connector and a DB-25-hole connector for connection

to a 9-hole or 25-hole serial port at the configuration terminal.

Page 25

Installing Cables 25

See “Console Cable” on page 55 for cable illustration and pinout details.

To connect a terminal or PC to the Switch 8800 using the console cable:

1 Plug the DB-9 or DB-25 female plug of the console cable to the serial port of the

PC or the terminal where the switch is to be configured.

2 Connect the RJ-45 connector of the console cable to the console port of the

switch.

Connecting the AUX

Cable

Connecting Module

Cables

An AUX cable is used to connect the Switch 8800 to a modem in a remote dial-up

configuration.

The AUX cable is an 8-core shielded cable. One end of the cable is an RS-232

RJ-45 connector, which is used to plug into the switch at the AUX port. The other

end has both a DB-9-pin connector and a DB-25 pin for connection to a 9-hole or

25-hole serial port on the virtual modem.

See “AUX Cable” on page 55 for cable illustration and pinout details.

To connect the AUX cable:

1 Plug the RJ-45 end of the AUX cable into the switch AUX port.

2 Connect the DB-25 or DB-9 end of the AUX cable to the serial port of the virtual

modem.

This section describes how to connect electrical and optical cables.

Connecting Electrical Port Cables

The 24-port 10/100/1000BASE-T module require a RJ-45 connector and

category-5 twisted pair cable. See

“RJ-45 Connector” on page 56 for an

illustration of the RJ-45 connector and MDI/MDI-X pinout details.

Use the following steps to connect the port:

1 Plug one end of the straight-through cable into the Ethernet RJ-45 port of the

switch.

2 Plug the other end of the straight-through cable into the RJ-45 port of the hub or

LAN Switch.

Ports on 24-port 10/100/1000BASE-T modules support MDI/MDI-X auto-sensing.

Connecting Optical Fiber Cables

The following modules require fiber optic cables and the SC or LC fiber connector:

■ 1-port 10GBASE-X (XENPAK) module

■ 2-port 10GBASE-X (XFP) module

■ 12-port 1000BASE-X (SFP) module

■ 24-port 1000BASE-X (SFP) module

See “Optical Fiber Cable Connectors” on page 57 for an illustration of the LC fiber

optic cable connector.

Page 26

26 CHAPTER 2: INSTALLING THE SWITCH 8800

Single-mode optical fiber cable is used for external connections of the single-mode

optical port. Multi-mode optical fiber cable is used for external connections of the

multi-mode optical port.

WARNING: When a connector is not inserted in the optical port or when its

dustproof cover is open, invisible radiation can escape from the optical port. Do

not stare into the optical port directly. Cover the optical port if there is no

connector plugged in.

To attach the LC fiber connector:

1 Plug one end of the LC fiber connector into the optical port in the module.

2 Connect the other end of the connector to the corresponding device.

Installing Cabling This section describes how to install and bind cables for your Switch 8800.

Bench-Mounted Switch If you have installed your chassis on a bench, all interface cables run on the left

side of the chassis in the cabling channel, and the chassis power cords run by the

rear chassis panel.

Rack-Mounted Switch If you have installed your switch in a 19-inch standard rack, the cables are bound

on the cable binding rack at the left side of the chassis and arranged to run on the

cable rack or under a raised floor. Collect all the transit data signal cable

connectors and locate them on the floor of the chassis. Power cords run out of the

rear left of the chassis and on a cable rack or under a raised floor.

Cable Binding Keep the following precautions in mind as you bind cables:

■ Do not allow cables to twist or bend as you bind them.

■ The cable body cannot be bent at an angle that is more than twice its diameter.

The cable running out of a connector cannot be bent more than five times its

diameter.

■ Different types of cables (power cord, signal cable, and ground wire) should

not be bound together in a rack. Although different types of cable may cross

over each other, they must not be bound together where they cross. For

parallel cabling, the space between a power cord and a signal cable should be

no less than 30 mm (1.25 in).

■ The cable binding rack and cable channel inside and outside a rack should be

smooth.

■ The hole through which a cable runs through should be smooth or have a

rubber grommet.

■ Use plastic cabling ties to bind the cables.

■ Bind cables before bending them. Ensure that no tie binds the bent part of any

cables to prevent the core of the cable from breaking.

■ Do not tie power cables to the guides of any mobile components.

■ For the cable terminals fixed with screws, the screws or nuts should be

fastened securely.

■ Do not use tapping screws to fasten the cabling terminals.

Page 27

Post-installation Checklist 27

Follow the parameters defined in Tab le 30 for binding cables with ties.

Ta bl e 30 Cable Binding Parameters

Cable Bundle Diameter Space Between Bundles

10 mm (0.5in) 80 – 150 mm (3.5 – 6 in)

10 – 30 mm (.5 – 1.2 in) 150 – 200 mm (6 – 8 in)

30 mm (1.2 in) 200 – 300 mm (8 – 12 in)

Post-installation Checklist

After you install your Switch 8800, use the checklist in Ta bl e 31 to verify that your

switch operates correctly.

WARNING: Confirm that you have turned off the power before checking your

installation. Improper connections can injure people or damage components of

the switch.

Ta bl e 31 Installation Checklist

Item Normal Abnormal (Remarks)

Antistatic wrist strap

Console cable

Ground wire

Power cord

Fabric

I/O module

Fan frame

Power supply

Page 28

28 CHAPTER 2: INSTALLING THE SWITCH 8800

Page 29

3

CONFIGURING THE SWITCH 8800

The following sections of this chapter describe how to configure and boot the

Switch 8800:

■ Configuring the Switch 8800 and a Local Terminal

■ Setting Terminal Parameters

■ Booting the Switch 8800

Configuring the Switch 8800 and a Local Terminal

Setting Terminal Parameters

Configure the local terminal and Switch 8800, using Figure 10 as a reference. The

terminal (a PC in this example) is connected to the switch console port using a

console cable.

Figure 10 Connecting the Switch 8800 to a PC

Switch

Console cable

1 Plug the DB-9 or DB-25 female plug of the console cable into the serial port of the

PC or the terminal where the switch will be configured.

2 Connect the RJ-45 connector of the console cable to the console port of the

switch.

To set terminal parameters and open a HyperTerminal session:

1 Start the PC and select Start > Programs > Accessories > Communications >

HyperTerminal.

The Connection Description dialog box displays, as shown in Figure 11.

Page 30

30 CHAPTER 3: CONFIGURING THE SWITCH 8800

Figure 11 Connection Description Dialog Box

2 Enter the name of the new connection in the Name field and click OK. The dialog

box, shown in

Figure 12 displays. Select the serial port to be used from the

Connect using dropdown menu.

Figure 12 Properties Dialog Box

3 After selecting a serial port, click OK. The port shown in Figure 13 displays and you

can set serial port parameters. Set the following parameters:

■ Baud rate = 9600

■ Databit = 8

■ Parity check = none

■ Stopbit = 1

■ Flow control = none

Page 31

Figure 13 COM1 Properties Dialog Box

Setting Terminal Parameters 31

4 Click OK. The HyperTerminal dialogue box displays, as shown in Figure 14.

Figure 14 HyperTerminal Window

5 Select Properties.

6 In the Properties dialog box, select the Settings tab, shown in Figure 15.

7 Select VT100 in the Emulation dropdown menu.

8 Click OK.

Page 32

32 CHAPTER 3: CONFIGURING THE SWITCH 8800

Figure 15 Settings Tab

Booting the Switch 8800

Before powering on the Switch 8800, verify that:

■ The Fabric and all I/O modules have been properly installed.

■ Power cords have been properly connected.

■ The voltage of power supply can meet the requirements on the switch.

■ The console cable has been connected properly.

■ The PC or terminal for configuration has been started.

■ The terminal parameters have been set.

Page 33

Booting the Switch 8800 33

Powering up and

Booting

Turn on the power for the Switch 8800 and run the BootROM program. The

terminal displays the following information:

Starting...

*************************************************

* *

* Switch 8800 Bootrom, Version 113 *

* *

*************************************************

Copyright(C) 2000-2004 by 3COM Corporation, Inc.

Creation date: Jul 5 2004, 10:43:58

CPU type : MPC755

CPU L2 Cache : 1024KB

CPU Clock Speed : 400MHz

BUS Clock Speed : 100MHz

Memory Size : 512MB

Flash file system init....done

Board self testing...........................

The board is steady

SlotNo of this board is 4

The MCX is existent

BootRom main system CRC check is OK

82559 register testing is OK

EPLD1 testing is OK

EPLD2 testing is OK

16c2552 register testing is OK

Please check LEDs......................LED testing finished

The switch's Mac address is 0040.9c30.b2d4

Press Ctrl+B to enter Boot Menu... 5

To enter Boot Mode (see Chapter 6), press Ctrl+B during the 5 seconds that “Press

Ctrl+B to enter Boot Menu...5” is displayed. To perform decompression

immediately, press ESC while this message is displayed. If you do nothing, the

system enters the following auto-booting port within 5 seconds:

Auto-booting...

Booting from Flash...

Decompress

Image...............................................................

....................................................................

.....OK!

Starting at 0x10000...

User interface con0 is available.

The display of these messages indicates the completion of the switch

auto-booting. Press Enter and the terminal screen displays:

<3Com>

Now you can begin the configuration for the Switch 8800.

Page 34

34 CHAPTER 3: CONFIGURING THE SWITCH 8800

Page 35

MAINTAINING SOFTWARE

4

This chapter covers the following topics:

■ Upgrading Software

■ Lost Passwords

■ Using the BOOT Menu

■ Managing Software Backup

Upgrading Software The following sections describe how to upgrade software on your Switch 8800:

■ Upgrading Software Using FTP

■ Upgrading Software Using The BOOT Menu

■ Upgrading Software Using Xmodem

■ Upgrading Software Using TFTP

Upgrading Software

Using FTP

Always save the configuration file before upgrading applications.

Use the following procedure to upgrade software with FTP:

1 Log in to the system with super-user privileges.

2 From the SW8800 command line, transfer the file from the FTP server to the

system, using the

ftp command.

3 Specify the file to boot the system from, using the boot command.

4 Reboot the system, using the reboot command.

The following example illustrates this procedure:

<SW8800>su

Password:

Now user privilege is 3 level, and just commands which level is

equal to or less than this level can be used.

Privilege note: 0-VISIT, 1-MONITOR, 2-SYSTEM, 3-MANAGE

<SW8800>ftp 192.168.25.210

Trying ...

Press CTRL+K to abort

Connected.

220 3COM FTP server (SunOS 5.6) ready.

User(none): gmiller

331 Password required for gmiller.

Password: xxxxxxx

230 User gmiller logged in.

[ftp]bin

Page 36

36 CHAPTER 4: MAINTAINING SOFTWARE

200 Type set to I.

[ftp]get 88003.app

200 PORT command successful.

150 Binary data connection for 88003.app (192.168.25.210,1117)

(6725435 bytes).

226 Binary Transfer complete.

FTP: 6725435 byte(s) received in 96.753 second(s) 25.00K

byte(s)/sec.

[ftp] quit

221 Goodbye.

<SW8800>boot boot-loader 88003.app

The specified file will be booted next time!

<SW8800>reboot

This command will reboot the system. Continue? [Y/N] y

For more detailed descriptions of the setup and procedures for upgrading

software, see the remaining sections in this chapter.

Upgrading Software

Using The BOOT Menu

To perform this operation, you must have a network connection between the

Ethernet port on the Switch 8800 Fabric module and the FTP/TFTP server. In

addition, you should verify that the file you want to use for the upgrade procedure

is on the FTP/TFTP server in the appropriate directory.

There are several procedures you must perform to complete this operation. They

are described in the following sections:

1 Boot the System

2 Modify the Ethernet Interface Boot Parameters

3 Download an Application to Flash Memory

4 Boot from Flash

Boot the System

After powering on the Switch 8800, the BootROM program runs automatically.

The terminal displays the following information:

Starting......

*************************************************

* *

* Switch 8800 Bootrom, Version 113 *

* *

*************************************************

Copyright(C) 2000-2004 by 3COM Corporation, Inc.

Creation date: Jul 5 2004, 10:43:58

CPU type : MPC755

CPU L2 Cache : 1024KB

CPU Clock Speed : 400MHz

BUS Clock Speed : 100MHz

Memory Size : 512MB

Page 37

Upgrading Software 37

Flash file system init....done

Board self testing...........................

The board is steady

SlotNo of this board is 4

The MCX is existent

BootRom main system CRC check is OK

82559 register testing is OK

EPLD1 testing is OK

EPLD2 testing is OK

16c2552 register testing is OK

Please check LEDs......................LED testing finished

The switch's Mac address is 0040.9c30.b2d4

Press Ctrl+B to enter Boot Menu...

To access the BOOT Menu, press Ctrl+B during the five seconds that “Press Ctrl-B

to enter Boot Menu...” displays. After five seconds, the system begins program

decompression. If you want to access the BOOT Menu after this, you must reboot

the switch.

1 Press Ctrl+B. The system displays:

Initialize flash file system. Please wait!

Password :

CAUTION: While using the switch, keep in mind the modified BOOTROM

password.

2 Enter the BootROM password. After entering the correct password (no password

is set for the switch by default), the system displays the Main Menu:

MAIN MENU

1. Boot with default mode

2. Boot from Flash

3. Boot from CF card

4. Enter serial submenu

5. Enter ethernet submenu

6. Modify Flash description area

7. Modify bootrom password

0. Reboot

Enter your choice(0-7):

Page 38

38 CHAPTER 4: MAINTAINING SOFTWARE

Modify the Ethernet Interface Boot Parameters

Before you can download a file to Flash, you must configure the Ethernet interface

boot parameters.

1 Select option 5 from the Main Menu. The Ethernet Submenu displays:

ETHERNET SUBMENU

1. Download file to SDRAM through ethernet interface and boot

2. Download file to Flash through ethernet interface

3. Modify ethernet interface boot parameter

0. Return to main menu

Be sure to select 3 to modify boot parameter before downloading!

Enter your choice(0-3): 3

2 Select option 3 from the Ethernet Submenu. The following information displays:

Note: Two protocols for download, tftp & ftp.

You can modify the flags following the menu.

tftp--0x80, ftp--0x0.

'.' = clear field; '-' = go to previous field; ^D = quit

boot device : fei0

processor number : 0

host name : 8512

file name : 88002.app 88003.app

inet on ethernet (e) : 192.168.25.210

inet on backplane (b): 192.168.25.158

host inet (h) : 192.168.25.2

gateway inet (g) :

user (u) : 1234

ftp password (pw) (blank = use rsh): 1234

flags (f) : 0x80

target name (tn) :

startup script (s) :

other (o) :

3 Modify this information as follows:

■ file name — Enter the name of the file you want to download.

■ inet on ethernet (e) — Enter the IP address of the Ethernet port on the

Fabric.

■ inet on backplane (b) — Enter the IP address of the backplane.

■ host inet (h) — Enter the IP address of the FTP or TFTP server.

4 TFTP is the default download protocol. If you want to perform the download

operation with FTP, make the following additional changes:

■ user (u) — Enter your FTP user name.

■ ftp password (pw) — Enter your FTP password.

■ flags (f) — Enter 0x0.

5 Press Enter. The following message and the Ethernet Submenu display:

Write flash...done!

ETHERNET SUBMENU

Page 39

Upgrading Software 39

1. Download file to SDRAM through ethernet interface and boot

2. Download file to Flash through ethernet interface

3. Modify ethernet interface boot parameter

0. Return to main menu

Enter your choice(0-3): 2

Download an Application to Flash Memory

To download an application to flash memory:

1 Select option 2 on the Ethernet Submenu. The following text displays:

Attached TCP/IP interface to fei0.

Attaching network interface lo0... done.

boot device : fei

unit number : 0

processor number : 0

host name : 8512

file name : 88003-04.app

inet on ethernet (e) : 192.168.25.210:ffffff00

inet on backplane (b): 192.168.25.158

host inet (h) : 192.168.25.2

user (u) : 1234

ftp password (pw) : 1234

flags (f) : 0x80

Prepare for loading...................................OK

Loading...............done

Free flash Space : 9657344 bytes

Writing

Flash...............................................................

....................................................................

....................................................................

....................................................................

....................................................................

....................................................................

...........Done

2 The Ethernet Submenu displays:

ETHERNET SUBMENU

1. Download file to SDRAM through ethernet interface and boot

2. Download file to Flash through ethernet interface

3. Modify ethernet interface boot parameter

0. Return to main menu

Enter your choice(0-3):0

3 Select 0 to return to the Main Menu.

Page 40

40 CHAPTER 4: MAINTAINING SOFTWARE

Boot from Flash

To boot the system from Flash using the downloaded file, do the following:

1 Select option 2 from the Main Menu. The following information displays:

Booting from Flash

Be sure the BaudRate is 9600bps!

Decompress

Image...............................................................

....................................................................

...........OK!

Starting at 0x10000...

Upgrading Software

Using Xmodem

The Xmodem protocol transmits files through serial ports and supports both

128-byte and 1K-byte packets. Xmodem also supports two types of check; normal

checksum and CRC. When there is a packet error, retransmission is supported,

normally 10 times.

The Xmodem protocol completes transmission by receiving and sending programs.

The receiving program first sends the negotiating characters to negotiate the

check means. After passing the negotiation, the sending program begins to send

the packet.

The receiving program checks the packet according to the negotiated means after

receiving a complete packet. The acknowledgement characters are sent after

passing the check and then the sending program continues to send the next

packet. If the check fails, negative characters are sent and the sending program

sends the packet again.

1 Boot the system and press Ctrl/B to access the Main Menu:

MAIN MENU

1. Boot with default mode

2. Boot from Flash

3. Boot from CF card

4. Enter serial submenu

5. Enter ethernet submenu

6. Modify Flash description area

7. Modify bootrom password

0. Reboot

Enter your choice(0-7):4

2 Select option 4 and press Enter. The Serial Submenu displays:

SERIAL SUBMENU

1. Download file to SDRAM through serial interface and boot

2. Download file to Flash through serial interface

3. Modify serial interface boot parameter

0. Return to main menu

Page 41

Upgrading Software 41

Enter your choice(0-3): 3

3 Select option 3. The select download baudrate menu displays:

1: 9600(default)

2: 19200

3: 38400

4: 57600

5: 115200

please select an appropriate baudrate:

Enter your choice(1-5): 5

4 Select the appropriate download speed. For example, enter 5 to select a download

speed of 115200 bps.

5 Press Enter. The terminal displays the following information:

BaudRate is 115200 bps. Please change the terminal's speed to 115200

bps

6 After you change the baud rate for the serial port on the Switch 8800, you must

change the baud rate at the configuration terminal so that the two baud rates are

the same. When the baud rates are the same, the Serial Submenu displays:

SERIAL SUBMENU

1. Download file to SDRAM through serial interface and boot

2. Download file to Flash through serial interface

3. Modify serial interface boot parameter

0. Return to main menu

Enter your choice(0-3): 2

7 Select option 2 and press Enter to start downloading. The terminal displays the

following information:

Please Select File .

XMODEM downloading ...CCC

8 Select Transfer\Send File from the terminal window.

9 Click Browse in the Send file dialog box, shown in Figure 16 and select the

application you want to download.

Figure 16 Send File dialog box

Page 42

42 CHAPTER 4: MAINTAINING SOFTWARE

10 Change the protocol name for the download to Xmodem.

11 Click Send. The dialog box shown in Figure 17 displays.

Figure 17 Xmodem File Send Dialog Box

12 After the download is complete, the Serial Submenu is displayed:

Loading ...CCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCC done!

SERIAL SUBMENU

1. Download file to SDRAM through serial interface and boot

2. Download file to Flash through serial interface

3. Modify serial interface boot parameter

0. Return to main menu

Enter your choice(0-3): 0

13 Select option 0 to return to the Main Menu:

MAIN MENU

1. Boot with default mode

2. Boot from Flash

3. Boot from CF card

4. Enter serial submenu

5. Enter ethernet submenu

6. Modify Flash description area

7. Modify bootrom password

0. Reboot

Enter your choice(0-7): 2

14 From the Main Menu, select option 2. The following message displays:

Booting from Flash

Be sure the BaudRate is 9600bps!

Decompress

Image...............................................................

....................................................................

.....OK!

Starting at 0x10000...

Page 43

Lost Passwords 43

Upgrading Software

Using TFTP

TFTP (Trivial File Transfer Protocol) is a simple file transfer protocol that is used

without complex interaction between clients and servers.

The client initiates a TFTP transmission. To download files, the client sends a read

request packet to the TFTP server, receives the packet from the server, and sends

the acknowledgement to the server. To upload files, the client sends a write

request packet to the TFTP server, sends the data packet to the server, and receives

the acknowledgement from the server.

The Switch 8800 provides the functions of the TFTP client.

A TFTP Server program is shipped on the CDROM with the Switch 8800.

Before you upgrade:

■ Verify that there is a connection between the TFTP server and the Switch 8800

(use the

■ Verify that the TFTP server is set up according to the manufacturer's instructions

ping command.)

and that it is enabled and pointing to the correct directory.

To upgrade using TFTP:

1 Verify that you are logged in with super-user privileges.

2 From the Switch 8800 command line (in user view), TFTP the image file from the

TFTP server to the Switch 8800 using the following command:

tftp <TFTP Server IP Address> get <Source File/image>< Dest

File-Optional>

3 Set the boot parameters to specify the file to boot the system from, using the

following command:

boot boot-loader filename

4 Reboot the system.

The following example illustrates this procedure:

<SW8800>tftp 192.168.25.210 get 88003.app

Transfer file in binary mode.

Now begin to download file from remote tftp server, please wait...

/

TFTP: 5690749 bytes received in 376 second(s).

File downloaded successfully.

<SW8800>boot boot-loader 88003.app

The specified file will be booted next time!

<SW8800>reboot

This command will reboot the system. Continue? [Y/N] y

Lost Passwords If the BootROM password of the switch is lost, contact your local support center,

listed in

Appendix B.

Page 44

44 CHAPTER 4: MAINTAINING SOFTWARE

Using the BOOT Menu After you power on the Switch 8800, the BootROM program runs automatically.

The terminal displays the following information:

Starting...

*************************************************

* *

* Switch 8800 Bootrom, Version 113 *

* *

*************************************************

Copyright(C) 2000-2004 by 3COM Corporation, Inc.

Creation date: Jul 5 2004, 10:43:58

CPU type : MPC755

CPU L2 Cache : 1024KB

CPU Clock Speed : 400MHz

BUS Clock Speed : 100MHz

Memory Size : 512MB

Flash file system init....done

Board self testing...........................

The board is steady

SlotNo of this board is 4

The MCX is existent

BootRom main system CRC check is OK

82559 register testing is OK

EPLD1 testing is OK

EPLD2 testing is OK

16c2552 register testing is OK

Please check LEDs......................LED testing finished

The switch's Mac address is 0040.9c30.b2d4

Press Ctrl+B to enter Boot Menu...

The contents displayed on the terminal can vary with different versions of Boot

ROM.

If you press Ctrl+B immediately, the system displays the Boot Menu. If you do not

press Ctrl+B, the system initiates the program decompression process. At this time

if you want to access the BOOT Menu, you must reboot the switch.

1 Press Ctrl+B. The system displays:

Initialize flash file system. Please wait!

Password :

Page 45

Managing Software Backup 45

2 Enter the BootROM password. After entering the correct password (no password

is set for the switch by default), the system will access the Main Menu:

MAIN MENU

1. Boot with default mode

2. Boot from Flash

3. Boot from CF card

4. Enter serial submenu

5. Enter ethernet submenu

6. Modify Flash description area

7. Modify bootrom password

0. Reboot

Enter your choice(0-7):

CAUTION: While using the switch, please keep in mind the modified BOOTROM

password.

Managing Software Backup

The Switch 8800 uses the application and configuration files it finds on the Flash

of the Fabric from which it booted the previous time. To back up these files, you

can copy them from Flash to compact Flash. However, there are some important

things to know before you copy files to compact Flash:

■ If the Switch 8800 has two Fabrics installed, and you execute a save

command, it synchronizes the configuration file on the Flash on both Fabrics so

that both Fabrics can use the same configuration information.

■ The Switch 8800 does not synchronize versions of the application file between

Fabrics. Therefore, you must manually download the application file to one

Fabric, then copy the application file between Flashes to insure that both

Fabrics can boot from the same file.

■ To insure that both Fabrics boot the same way, you must configure boot

parameters with the same values on each Fabric.

■ The system does not synchronize files between compact Flash cards or

between compact Flash and Flash.

■ For compact Flash to serve as a reliable file backup, you must take care that

files are copied to compact Flash after every modification or download.

Otherwise, you could have multiple versions of a file on your system.

To verify the names and contents of the Flash and compact Flash on your system,

you can use the

<SW8800>dir ?

/all List all files

STRING<1-136> [drive][path][file name]

cf: Device name

flash: Device name

slot5#cf: Device name

slot5#flash: Device name

<cr>

dir commands, as shown in the following examples:

The entries cf and flash refer to the compact Flash and Flash on the Fabric from

which the system last booted. If more than one Fabric is intalled on the Switch

Page 46

46 CHAPTER 4: MAINTAINING SOFTWARE

8800, the entries slotn#cf and slotn#flash refer to the compact Flash and Flash

on the system’s other Fabric .

<SW8800>dir flash:

Directory of flash:/

0 -rw- 8884 Dec 06 2004 14:33:45 sw8800.cfg

1 drw- - Feb 10 2003 11:13:07 hafile

2 -rw- 4 Dec 06 2004 14:36:04 snmpboots

3 -rw- 6326532 Nov 24 2004 14:18:35 88003-06.app

4 -rw- 6725435 Dec 06 2004 15:16:26 88003-04.app

15621 KB total (2809 KB free)

<SW8800>dir cf:

Directory of cf:/

0 -rw- 6534193 Feb 10 2003 11:35:10 88003-01.app

1 drw- - Mar 16 2003 12:16:00 logfile

250352 KB total (234680 KB free)

Copying Files to

Compact Flash

Use the copy command in the format copy source/filename

destination/filename

to copy a file from a Flash to a compact Flash on the

same Fabric or on the other Fabric, as shown in the following example:

<SW8800>copy flash:/88003-04.app cf:/88003-04.app

Copy flash:/88003-04.app to cf:/88003-04.app?[Y/N]:y

100% complete

Copy file flash:/88003-04.app to cf:/88003-04.app...Done.

<SW8800>copy flash:/sw8800.cfg slot#5cf:/sw8800.cfg

Copy flash:/sw8800.cfg to slot#5cf:/sw8800.cfg?[Y/N]:y

100% complete

Copy file flash:/sw8800.cfg to slot#5cf:/sw8800.cfg...Done.

Page 47

5

MAINTAINING HARDWARE

This chapter covers the following topics:

■ Replacing a Power Supply

■ Replacing I/O Modules

■ Replacing the Fan Assembly

The procedures in this chapter should be performed by trained service personnel

only.

Replacing a Power Supply

To replace a power supply, you need:

■ An antistatic wrist strap

■ A screwdriver

WARNING: When installing or replacing the power supply when the power is on,

do not touch any naked wire, terminal, or any other part of the product labeled

Dangerous Voltage. Always wear the antistatic wrist strap when replacing the

supply.

Use the following steps to replace a power supply:

1 Turn off power to the power supply you are replacing.

2 Pull up on the retention clip that holds the power cord connector and unplug the

power cord.

3 Loosen the captive screws on both sides of the power supply.

4 Support the power supply with one hand and gently pull the handle with the

other hand until it slides out of the slot.

5 If you are not going to install another power supply in this slot, install a blanking

plate on the chassis for dust-proofing and heat dissipation.

6 Remove the new power supply from the package and verify that the correct input

mode is selected.

7 Support the power supply, right side up, in one hand and hold the handle with

another hand. Align the supply with the guides in the chassis and slide the power

supply into the slot.

CAUTION: As you are inserting the power supply, if the pin terminal springs up,

the pin cannot be seated into the hole and the system will sound an alarm. If the

power supply has not been inserted properly, you should slide it out and insert it

again to avoid breaking or cracking the power terminals.

8 Fasten the captive screws.

Page 48

48 CHAPTER 5: MAINTAINING HARDWARE

CAUTION: If the captive screws cannot be fastened, the power supply may not

have been properly seated. Remove and replace the supply.

9 Insert the power cord connector into the power socket on the power supply and

lower the retention clip.

Cleaning the Power

Supply Filter

Over time, the filter on the power supply accumulates dust, which interferes with

the heat dissipation of the chassis. It is important to periodically clean the filter as

described below:

1 Remove the gauze filter by gently pulling it from the front of the power supply.

2 Take the filter to a fresh water supply and clean it.

3 Leave the filter to dry. Do not use heat to dry the filter as this may cause it to

distort.

4 When the filter is completely dry, gently push it back into the front of the power

supply.

CAUTION: Do not clean the filter while it is in position at the front of the power

supply. Attempts to do so could result in damage to the equipment or severe