Page 1

3B SCIENTIFIC

Friction Measuring Apparatus 1009942

Instruction sheet

07/12 DML/ALF

®

PHYSICS

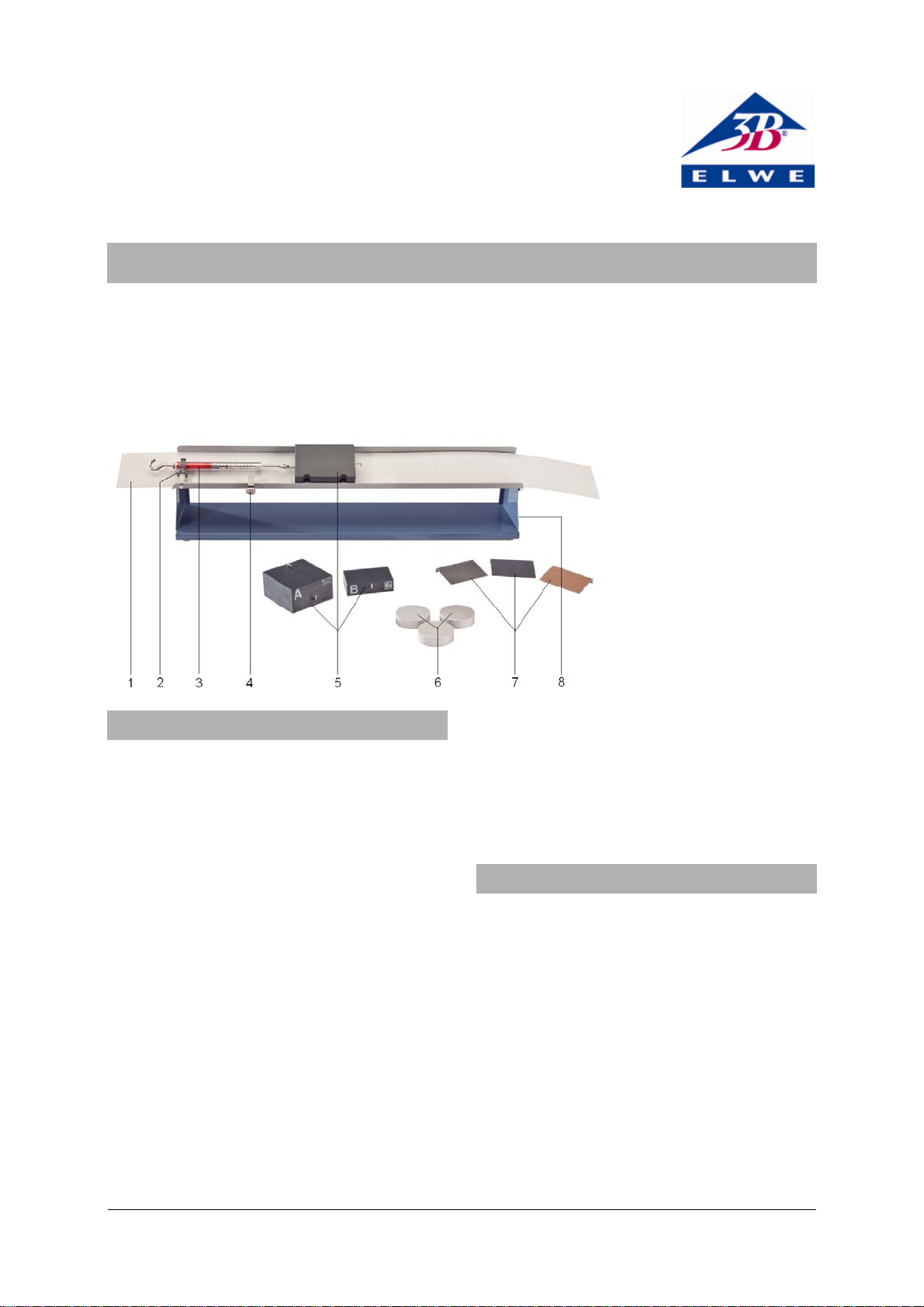

1 Friction surface

2 Clamp for dynamometer

3 Dynamometer

4 Stopper for the friction bod-

ies

5 Friction bodies

6 Additional weights

7 Sliders

8 Protractor

1. Description

The friction measuring apparatus is used to

measure static and rolling friction between different kinds of surfaces.

A friction track in the form of a mounted, rotating

U-shaped structure made of aluminium serves as

the basis for the experiments. Between the friction bodies and the friction plane, there is a long,

inlaid friction surface made of plastic, which can

be pulled at a uniform velocity. At the opposite

end, a dynamometer is horizontally clamped to

the friction track. The dynamometer shows the

frictional forces between the surfaces, resulting

from the movement of the sliding friction surface.

When the friction surface begins to move, the

body resting upon it experiences static friction

and is dragged along with the sliding surface. As

the sliding friction surface continues to be moved

at uniform velocity, the static friction changes to

sliding friction and the friction body remains at a

state of rest relative to the friction plane.

The friction bodies have surfaces of different

areas and degrees of roughness. This makes it

possible to investigate the influence the area of

contact and the nature of the surface has on the

frictional forces.

It is possible to vary the angle of the friction

track, thereby creating an incline to the horizontal plane. In this way, the normal force with

which the friction body acts upon the particular

surface can be made to vary.

2. Scope of delivery

1 Friction plane

1 Friction body A

1 Friction body B

1 Friction body C

1 Sliding friction surface

1 Dynamometer

1 Stopper for the friction bodies

1 Sliders, rubber-coated

1 Sliders, Teflon-coated

1 Sliders, uncoated

3 Additional weights, 100 g

1

Page 2

3. Technical data

4. Set-up

Friction track

U-shaped track: 600 x 80 x 20 mm

Protractor: 0° – 60°

3

Sliding friction surface

Material: PVC, smooth on one

side and coarse on the

other side

Length: 850 mm

Friction body A

Dimensions: 79 x 38 x 73 mm

3

Material: PVC

Surface: Uncoated

Surface area ratio: 2:1

Weight: 325 g approx.

Fastening rings: 2

Friction body B

Dimensions: 73 x 20 x 47 mm

3

Material: PVC

Surface: Coated with velour pa-

per

Weight: 100 g approx.

Additional weights

Design: To fit friction body B

Weight: 100 g

Sliders

Design: To fit friction body B

Material: Aluminium

Surface: Rubber-coated (No. 1),

Teflon-coated (No. 2),

Uncoated (No. 3)

Dimensions: 55 x 55 x 15 mm

3

Friction body C

Dimensions: 75 x 31 x105 mm

3

Surface: Coated with velour pa-

per

Weight: 325 g

Securing rings: 2

Castors: 2, ball-bearings

Dynamometer

Measuring range: 2 N, tension and com-

pression

• Secure the dynamometer by means of the

clamp.

• Attach a stopper for the friction body to the

U-shaped track (the stopper prevents any

sudden recoil of the friction body that might

arise as the sliding friction surface is pushed

back.)

5. Measurements conducted on a horizontal

friction plane

• Align the friction track so that the pointer on

the protractor is in the zero position.

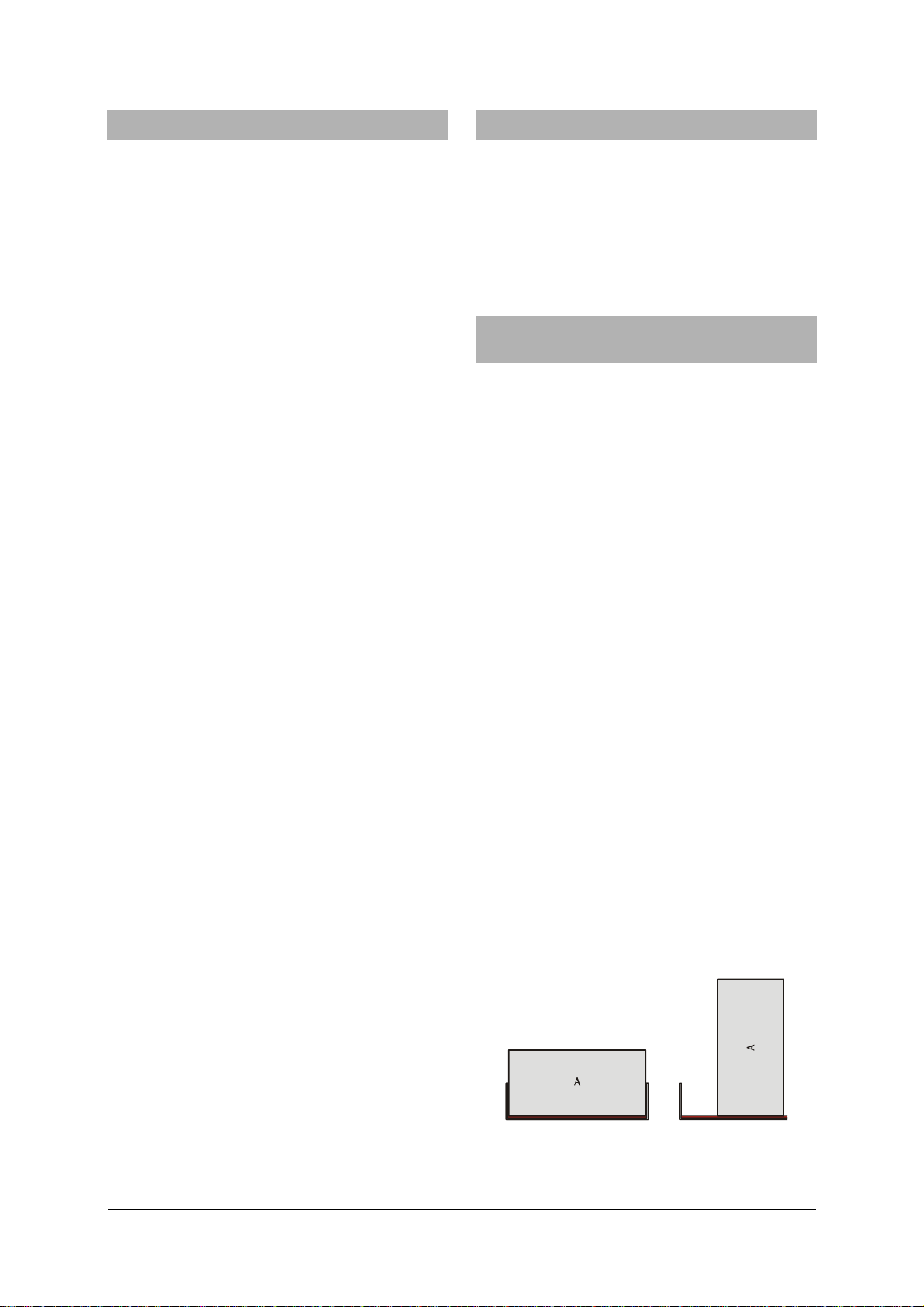

• Insert the sliding friction surface into the

friction track either with its smooth or coarse

facing down. Then place a friction body onto

the sliding friction surface. (See Fig. 1 and

Fig. 2.)

5.1 Static friction

• Pull the sliding friction surface, making sure

it is displaced with a uniform motion.

• Read the maximum value from the dyna-

mometer while the friction body is still being

dragged along with the sliding friction surface.

• Perform this measurement on several occa-

sions and calculate the average.

This value represents a measure of the static

frictional force.

5.2 Sliding friction

• Conduct measurements as described under

5.1. However, take the reading on the dynamometer as soon as the friction body has

stopped moving along with the sliding friction surface.

• Perform this measurement on several occa-

sions and calculate the average.

This value represents a measure of the sliding

frictional force.

Fig. 1: Investigation of static and sliding friction with

friction body A with two different contact areas.

2

Page 3

ϕ

Fig. 2: Investigation of static and sliding friction with

friction body B with different weights (left) and

different materials constituting the contact surface, in that a different surface coating is glued

to the sliders (right)

6. Measurements conducted when the friction plane is at an incline

The friction track can be inclined by an angle

ϕ from the normal. As a result, the normal force

exerted by a weight G changes according to

F

N

⋅= cos

the equation:

• Align the friction surface so that the pointer

GF .

N

of the protractor is set to the desired inclination (0 – 60°).

• Insert the sliding friction surface into the

friction track either with its smooth or coarse

facing down.

• Place friction body C onto the sliding friction

surface so that the castors on the narrow

side face downwards towards the track wall

(see Fig. 3).

6.1 Static friction

• Pull the sliding friction surface, making sure

it is displaced with a uniform motion.

• Read the maximum value from the dyna-

mometer while the friction body is still being

dragged along with the sliding friction surface.

• Perform this measurement on several occa-

sions and calculate the average.

This value represents a measure of the static

frictional force.

6.2 Sliding friction

• Conduct measurements as described under

6.1. However, take the reading on the dynamometer as soon as the friction body has

stopped moving along with the sliding friction surface.

• Perform this measurement on several occa-

sions and calculate the average.

This value represents a measure of the sliding

frictional force.

Fig. 3: Measurements conducted with friction body C

when the friction track is inclined

Elwe Didactic GmbH ▪ Steinfelsstr. 5 ▪ 08248 Klingenthal ▪ Germany ▪ www.elwedidactic.com

3B Scientific GmbH ▪ Rudorffweg 8 ▪ 21031 Hamburg ▪ Germany ▪ www.3bscientific.com

Subject to technical amendments

© Copyright 2012 3B Scientific GmbH

Page 4

Loading...

Loading...