AEG-Electrolux 2000D-M User Manual

2000 D

Dunstabzugshaube

Fume Extractor Hood

Montage- und Gebrauchsanweisung

Installation and Operating Instructions

ContentsContents

Contents

ContentsContents

IntroductionIntroduction

Introduction

IntroductionIntroduction

Extractor version 28

Filter version 29

Electrical connectionsElectrical connections

Electrical connections

Electrical connectionsElectrical connections

Safety warnings for electrician 30

TT

echnic Detailsechnic Details

T

echnic Details

TT

echnic Detailsechnic Details

InstallationInstallation

Installation

InstallationInstallation

Safety warnings for kitchen unit installer 32

Installation 34

Safety warnings for user 38

VV

iew of the hoodiew of the hood

V

iew of the hood

VV

iew of the hoodiew of the hood

Hood OperationHood Operation

Hood Operation

Hood OperationHood Operation

Setting the fan speed 40

Hood lighting 40

Intensive speed P 41

Fan timer 41

Switching off the fan 42

2828

28

2828

3030

30

3030

3131

31

3131

3232

32

3232

3939

39

3939

3939

39

3939

Maintenance and careMaintenance and care

Maintenance and care

Maintenance and careMaintenance and care

Warnings on the activated carbon filter 43

Display warning on saturation of activated carbon filter 44

Display warning on saturation of metal grease filter 46

Warning 48

Replacing light bulbs 48

CleaningCleaning

Cleaning

CleaningCleaning

Special accessorySpecial accessory

Special accessory

Special accessorySpecial accessory

TT

echnical assistance serviceechnical assistance service

T

echnical assistance service

TT

echnical assistance serviceechnical assistance service

4343

43

4343

4949

49

4949

4949

49

4949

4949

49

4949

27

IntroductionIntroduction

Introduction

IntroductionIntroduction

Extractor versionExtractor version

Extractor version

Extractor versionExtractor version

●The hood is supplied as an extractor unit and can also be

used with a filtering function by fitting activated carbon

filters (special accessory).

● You will need original AEG activated carbon filters for this

function (see Special Accessories).

● The air is forced out through a hose fitted to the

connection flange

● The outlet hose must have a diameter of 150 mm (special

accessory) for the filtering version.

● If the cooking vapour is passed through an outside

wall, you will need an MKZ150 telescopic wall pipe

E-Nr.: 942 118 609 (150 mm Ø) from our range of

special accessories.

28

Filter versionFilter version

Filter version

Filter versionFilter version

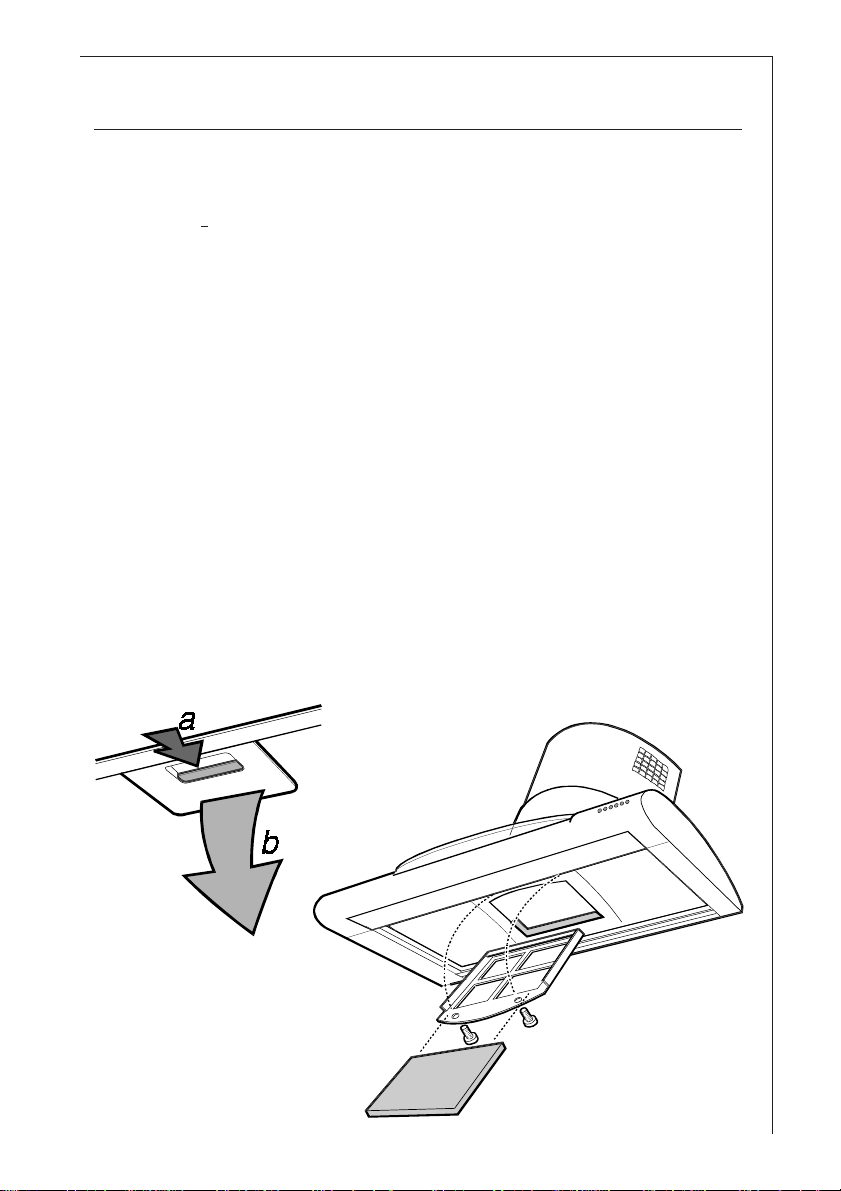

● The air is filtered through an activated carbon filter and

passed back into the kitchen through the top outlet duct

grids. This type of operation is chosen when there is no

outlet connection to the outside or when it is not possible

to install one. You will need to ask your supplier or

technical assistance centre for an activated carbon filter

for this type of operation, stating the hood model for

which it is required.

● You will need an original AEG KF2000 activated carbon

filter for the filtering function. (See Special Accessories).

● Unplug the unit or disconnect it from the power supply

● Remove the metal grease filters.

● Unscrew the two carbon filter frame screws and insert the

active carbon filter in the support.

● Re-close the carbon filter frame using the same screws

● Refit the metal grease filters.

Fig. 1Fig. 1

Fig. 1.

Fig. 1Fig. 1

Fig. 2Fig. 2

Fig. 2.

Fig. 2Fig. 2

Fig. 1Fig. 1

Fig. 1

Fig. 1Fig. 1

Fig. 2Fig. 2

Fig. 2

Fig. 2Fig. 2

29

Electrical connectionsElectrical connections

Electrical connections

Electrical connectionsElectrical connections

Safety warnings for electricianSafety warnings for electrician

Safety warnings for electrician

Safety warnings for electricianSafety warnings for electrician

Check that the power supply voltage shown on the rating

plate corresponds to the mains supply before proceeding

to make any electrical connections. If the unit is supplied

ready-fitted with a plug, it can be connected to any easily

accessible socket installed in compliance with the

regulations in force.

If a fixed connection is required, the hood must be

installed exclusively by an electrician registered with the

local electrical company. The hood should be installed

using an omnipolar switch with contacts that open to at

least 3 mm.

Fused switches can be used for this purpose (with

cartridge fuses that can be extracted from the fuse

holder), as can automatic circuit breakers and contactors

which open to more than 3 mm.

We decline all responsibility for any problems or faults

caused by a failure to observe the above instructions.

30

If the power socket is positioned directly above the

extractor hood or on the chimney cover this will give two

advantages:

1. The socket cannot be seen.

2. The unit can be disconnected whenever required by

simply taking out the plug.

Electrical connectionsElectrical connections

Electrical connections

Electrical connectionsElectrical connections

220-230 V - using fixed power supply line with plug.

(The unit should only be connected up by an authorized

electrician).

TT

echnic Detailsechnic Details

T

echnic Details

TT

echnic Detailsechnic Details

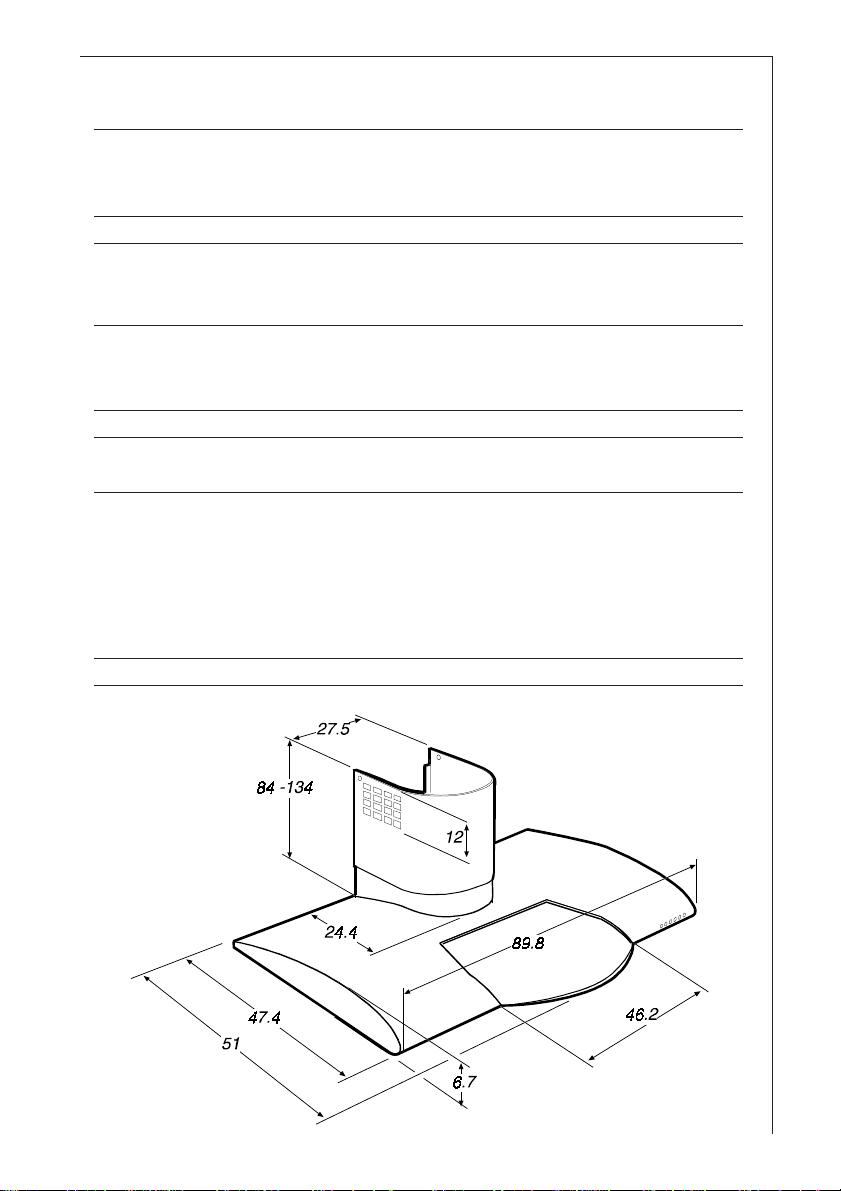

Dimensions:

Height x Width x Depht (in cm) 84-134 x 89,8 x 51

Weight: Net: Gross:

22,3 kg 29 kg

Maximum absorbed power: 240 W

Motor absorption: 1 x 215 W

Lighting: 2 x 9 W

Length of the cable: 120 cm

Fan powers (speed), speed in compliance with DIN 44971

Extractor version: min. max. Int.

199 m

Filter version: min. max. Int.

123 m3/h 265 m3/h 290 m3/h

Exhaust pipe 150 mm Ø

3

/h 414 m3/h 570 m3/h

31

InstallationInstallation

Installation

InstallationInstallation

Safety warnings for kitchen unit installerSafety warnings for kitchen unit installer

Safety warnings for kitchen unit installer

Safety warnings for kitchen unit installerSafety warnings for kitchen unit installer

● When used as an extractor unit, the hood must be fitted

with a 150mm diameter hose.

● If the fumes must be forced out through the wall, you

must obtain a MKZ150 sizable wall exhaust pipe (with

external exhaust and air intake), E-Nr.- 942 118 609 (Ø

150 mm) which is one of our optional parts.

When installing the hood, make sure you respect theWhen installing the hood, make sure you respect the

●

When installing the hood, make sure you respect the

When installing the hood, make sure you respect theWhen installing the hood, make sure you respect the

following minimum distance from the top edge of thefollowing minimum distance from the top edge of the

following minimum distance from the top edge of the

following minimum distance from the top edge of thefollowing minimum distance from the top edge of the

cooking hob/ring surfaces:cooking hob/ring surfaces:

cooking hob/ring surfaces:

cooking hob/ring surfaces:cooking hob/ring surfaces:

electric cookerselectric cookers

electric cookers

electric cookerselectric cookers

gas cookersgas cookers

gas cookers

gas cookersgas cookers

coal and oil cookerscoal and oil cookers

coal and oil cookers

coal and oil cookerscoal and oil cookers

● The air outlet must not be connected to chimney flues or

combustion gas ducts. The air outlet must under no circumstances be connected to ventilation ducts for rooms

in which fuel-burning appliances are installed.

● It is advisable to apply for authorization from the

relevant controlling authority when connecting the outlet

to an unused chimney flue or combustion gas duct.

The air outlet installation must comply with the

regulations laid down by the relevant authorities.

● When the unit is used in its extractor version, a

sufficiently large ventilation hole must be provided, with

dimensions that are approximately the same as the outlet

hole.

● National and regional building regulations impose a

number of restrictions on using hoods and fuel-burning

appliances connected to a chimney, such as coal or oil

room-heaters and gas fires, in the same room.

● The national decree on fuel-burning systems specifies a

maximum depression of 0.04 bar in such rooms.

600 mm600 mm

600 mm

600 mm600 mm

650 mm650 mm

650 mm

650 mm650 mm

700 mm min.700 mm min.

700 mm min.

700 mm min.700 mm min.

32

● Hoods can only be used safely with appliances connected

to a chimney if the room and/or flat (air/environment

combination) is ventilated from outside using a suitable

ventilation hole approximately 500-600 cm2 large to

avoid the possibility of a depression being created during

operation of the hood.

If you have any doubts, contact the relevant controlling

authority or building inspector’s office.

● Since the rule for rooms with fuel burning appliances is

“outlet hole of the same size as the ventilation hole”, a

hole of 500-600 cm2, which is to say a larger hole, could

reduce the performance of the extractor hood.

● If the hood is used in its filtering function, it will operate

simply and safely in the above conditions without the

need for any of the aforementioned measures.

● When the hood is used in its extractor function, the

following rules must be followed to obtain optimal

operation:

— short and straight outlet hose

— keep bends in outlet hose to a minimum

— never install the hoses with an acute angle, they must

always follow a gentle curve only

— keep the hose as large as possible (150 mm Ø).

● Failure to observe these basic rules will drastically reduce

the performance and increase the noise levels of the

extractor hood.

33

Loading...

Loading...