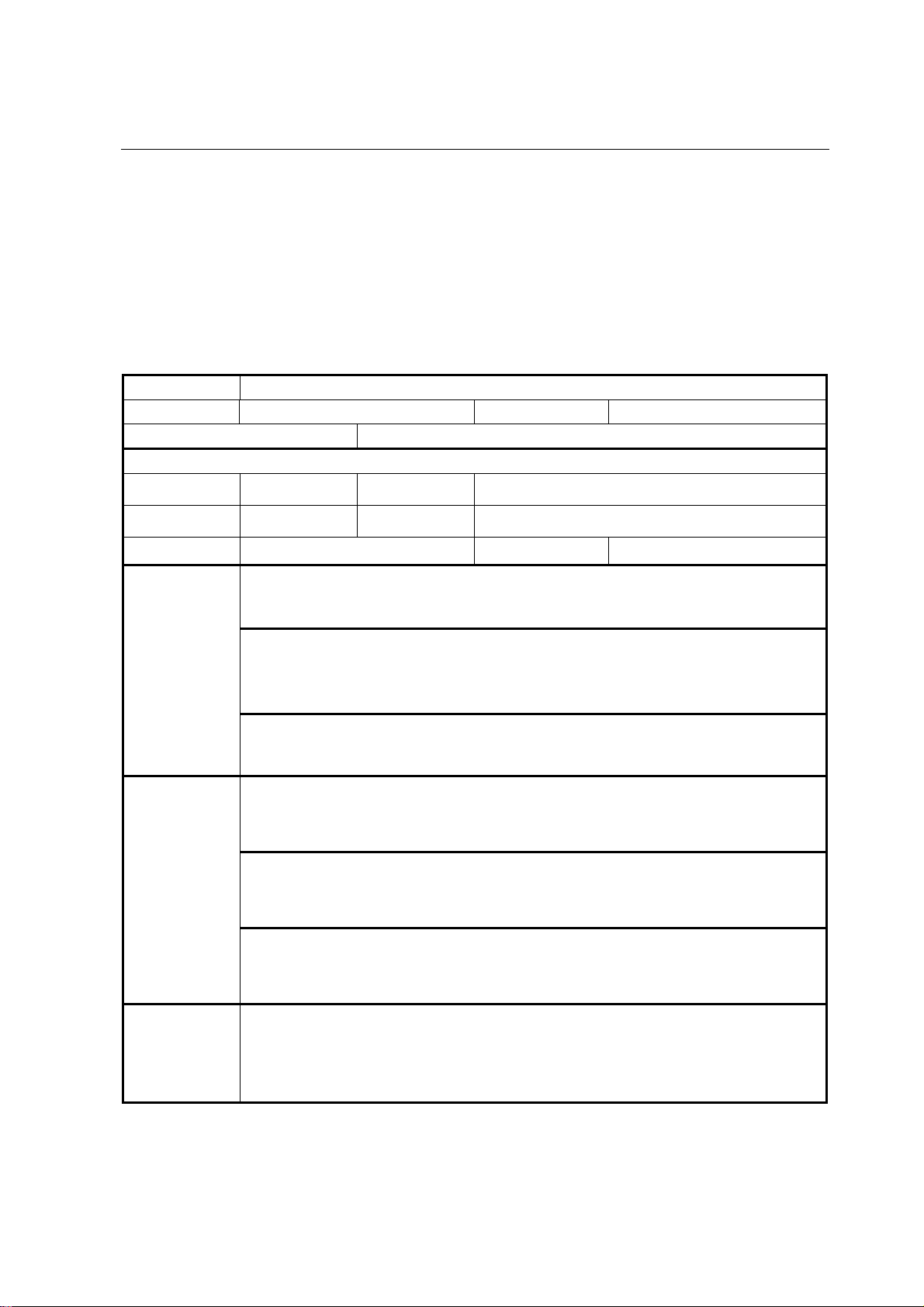

Page 1

ZXCBTS (V5.4)

CDMA Micro Base Transceiver Station

& RF Remote Station

Installation Manual

ZTE CORPORATION

Page 2

ZXCBTS (V5.4) CDMA Micro Base Transceiver Station/RF Remote

Station

Installation Manual

Manual Version 20050422-R1.1

Product Version V5.4

Copyright © 2004 ZTE Corporation

All rights reserved.

No part of this documentation may be excerpted, reproduced, translated, annotated or

duplicated, in any form or by any means without the prior written permission of ZTE

Corporation.

* * * *

ZTE CORPORATION

ZTE Plaza, Keji Road South, Hi-Tech Industrial Park, Nanshan District, Shenzhen, P.R.China

Website: http://www.zte.com.cn

Postcode: 518057

Customer Support Center: (+86755) 26771900 800-9830-9830

Fax: (+86755) 26770801

Email: support@zte.com.cn

* * * *

S.N.: sjzl20030272

Page 3

FAX:+86-755-26770160

Suggestions and Feedback

To improve the quality of ZTE product documentation and offer better services to our customers, we hope

you can give us your suggestions and comments on our documentation and fax this form to

rd

+86-755-26770160; or mail to “Marketing center 3

Park, Nanshan District, Shenzhen, P. R. China”. Our postcode is 518057.

Document name ZXCBTS (V5.4) CDMA Micro Base Transceiver Station/RF Remote Stations Installation Manual

Product version V5.4 Document version 20050422-R1.1

Equipment installation time

Your information

floor ZTE Plaza, Keji Road South, Hi-Tech Industrial

Name

Postcode

Telephone

Your evaluation

of this

documentation

Your suggestions

for improvement

of this

documentation

Presentation: How is information presented? (Introductions, procedures, illustrations, others)

F Good F Fair F Average F Poor F Bad

Accessibility: Can you find the information you want? (Table of contents, Index, headings,

numbering, others)

F Good F Fair F Average F Poor F Bad

Intelligibility: Can you understand it when you find it? (Language, vocabulary, readability, others)

F Good F Fair F Average F Poor F Bad

Presentation:

Accessibility:

Intelligibility:

Company

Company address

E-mail

Your other

suggestions on

ZTE product

documentation

Page 4

Page 5

Preface

About This Manual

This manual presents the hardware installation procedures of ZXCBTS micro base

transceiver stations (BTSs)/remote stations.

It is one of ZTE manual series for CDMA cellular mobile communications system. It

aims to providing guidance to the engineering personnel who install ZTE CDMA

micro-BTS/remote stations, as well as offering reference for the equipment

maintenance personnel.

Correct hardware installation is the basis for reliable and normal running of the base

transceiver stations, thus enjoying importance in engineering construction. To facilitate

the installation, this manual is written following the sequence of actual hardware

installation. First, it briefs the structure of the ZXCBTS products, which is helpful for

the installation personnel to get familiar with the equipment. Next, it describes the

equipment installation procedures in detail. Finally, it presents how to check the

equipment after the installation.

How to Use This Manual

1. Overview

Introduces the basic structure, basic installation procedures and points for

attention during installation of the micro-BTS/remote stations.

2. Preparations

Introduces the preparations for the installation, including listing needed tools

and checking the installation environment.

3. Open-box Inspection

Introduces the procedures and cautions for opening boxes and inspecting the

equipment.

4. Installation of Cabinet

Details the fixation and installation of the cabinet of the equipment.

5. Installation of Power Supply System

Page 6

Details the installation of the power supply system of the equipment.

6. Installation of Grounding System

Details the installation of the grounding system of the equipment.

7. Connection of Cables

Details the check of internal cable connections between various modules, as well

as type selection and connection of external cables.

8. Installation of Primary Antenna Feeder System

Details the installation of the antenna feeder system of the equipment, including

the procedures of assembling feeder cable connectors, installing antenna, laying

feeder cables, installing feeder cable window and grounding equipment.

9. Installation of GPS antenna feeder system

Details the installation of GPS antenna feeder system for the equipment,

Conventions

including the procedures of assembling feeder cable connectors and installing

antenna.

10. Installation of Internal Modules

Details the installation of internal modules.

11. Hardware Installation Check

Presents how to check the hardware installation.

12. Power-on and Power-off

Presents the procedures of powering on/off the equipment.

13. Appendix

Presents the equipment performance specifications, meaning of various

indicators and connection of cables.

1. Notational Convention

Angular brackets “< >” identify names of keys and buttons, and the information

typed by an operator from a terminal. Square brackets “[ ]” indicate a

man-machine interface, menu item, data list or field name. The symbol “→”

Page 7

separates a multi-level menu, for example, [File→New→Folder] indicates the

[Folder] menu item under the [New] submenu of the menu [File].

2. Keyboard Operation Convention

Format Description

<Key>

<Key1+Key2> Press Key 1 and Key 2 at the same time.

<key1, Key2> Press Key1 first. Then release Key 1 and press Key 2.

Indicate a key or button name, for example, <Enter>, <Tab>,

<Backspace>, and <a>.

3. Mouse Operation Convention

Format Description

Click

Double-click

Right-click

Drag Refers to pressing and holding a mouse button and move the mouse

Refers to clicking the primary mouse button (usually the left mouse

button) once

Refers to quickly clicking the primary mouse button (usually the left

mouse button) twice

Refers to clicking the secondary mouse button (usually the right mouse

button) once.

4. Danger, Warning, Caution and Note Statements

Note, Caution, War ni ng , Danger statements are

used throughout this manual to emphasize important and critical information.

You must read these statements to help ensure safety and to prevent product

damage.

Statement: The actual product may differ from what is described in this

manual due to frequent update of ZTE products and fast development of

technologies. Please contact the local ZTE office for the latest updating

information of the product.

Page 8

FCC & IC STATEMENT

Before using this CDMA Micro Base Transceiver Station & RF Remote Station, read this important RF

energy awareness and control information and operational instructions to ensure compliance with the FCC

and IC RF exposure guidelines.

NOTICE: Working with the equipment while in operation, may expose the technician to RF

electromagnetic fields that exceed FCC rules for human exposure. Visit the FCC website at

www.fcc.gov/oet/rfsafety

Changes or modifications to this unit not expressly approved by the party responsible for compliance will

void the user’s authority to operate the equipment. Any change to the equipment will void FCC and IC

grant.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to the FCC and IC Rules. This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation.

For OUTDOOR use, a PNALE Antenna with a maximum gain of 17dBi is authorized for use with this unit.

Outside antennas must be positioned to observe minimum separation of 2M (6.56 feet.) for 800MHz unit

and 1.5M (4.92 feet.) for 1900MHz unit from all users and bystanders. For the protection of personnel

working in the vicinity of outside (uplink) antennas, the following guidelines for minimum distances

between the human body and the antenna must be observed.

to learn more about the effects of exposure to RF electromagnetic fields.

The installation of an OUTDOOR antenna must be such that, under normal conditions, all personnel cannot

come within 2M (6.56 feet) for 800MHz unit and 1.5M (4.92 feet) for 1900MHz unit from the outside

antenna. Exceeding this minimum separation will ensure that the worker or bystander does not receive

RF-exposure beyond the Maximum Permissible Exposure according to section 1.1310 i.e. limits for

Controlled Exposure.

Page 9

Contents

1 Overview..................................................................................................................................................1-1

1.1 Introduction to Micro-BTS ............................................................................................................1-1

1.2 Installation Overview.....................................................................................................................1-4

1.3 Installation Flow ............................................................................................................................1-5

1.4 Points for Attention ........................................................................................................................1-7

2 Preparations ............................................................................................................................................2-1

2.1 Installation Environment Check..................................................................................................... 2-1

2.1.1 Checking Equipment Building Conditions..........................................................................2-1

2.1.2 Checking Indoor Environment............................................................................................2-1

2.1.3 Checking Power Supply System .........................................................................................2-2

2.1.4 Checking Grounding System ..............................................................................................2-2

2.1.5 Checking Relative Devices .................................................................................................2-2

2.2 Tools and Instruments ....................................................................................................................2-2

2.3 Technical Documents ..................................................................................................................... 2-3

3 Open-box Inspection...............................................................................................................................3-1

3.1 Checking Packing List and Goods ................................................................................................. 3-1

3.2 Packaging.......................................................................................................................................3-2

3.3 Open-box Procedures.....................................................................................................................3-2

4 Installation of Cabinet............................................................................................................................4-1

4.1 Installation Flow ............................................................................................................................4-1

4.2 Installation Modes.......................................................................................................................... 4-2

4.2.1 Installing Cabinet on Pole ................................................................................................... 4-2

4.2.2 Installing Cabinet on Wall................................................................................................... 4-6

-i-

Page 10

5 Installation of Power Supply System ....................................................................................................5-1

5.1 Introduction to Power Cables ........................................................................................................ 5-1

5.1.1 -48V DC Power Cable ........................................................................................................ 5-1

5.1.2 120V AC Power Cable........................................................................................................ 5-2

5.2 Connection of Power Cables ......................................................................................................... 5-2

5.3 Assembling Power Cable Connector ............................................................................................. 5-3

5.3.1 Assembling -48V DC Power Cable Connector................................................................... 5-3

5.3.2 Assembling 120V AC Power Cable Connector .................................................................. 5-5

6 Installation of Grounding System .........................................................................................................6-1

6.1 Introduction to the Grounding System........................................................................................... 6-1

6.2 Installing Grounding System ......................................................................................................... 6-2

6.2.1 Installing Outdoor Grounding Copper Busbar.................................................................... 6-2

6.2.2 Installing the Grounding System of Micro-BTS................................................................. 6-3

6.2.3 Installing Feeder Cable Grounding Kit............................................................................... 6-4

7 Connection of Cables..............................................................................................................................7-1

7.1 Checking Internal Cable Connections ........................................................................................... 7-1

7.1.1 Type and Configuration of Internal Cables......................................................................... 7-1

7.1.2 Connection of Internal Cables ............................................................................................ 7-3

7.2 Connecting External Cables .......................................................................................................... 7-3

7.2.1 Connecting Optical Fiber.................................................................................................... 7-3

7.2.2 Connecting Multi-carrier Interconnection RF Cables......................................................... 7-7

7.2.3 Waterproof Processing of Joints ......................................................................................... 7-8

7.2.4 Connection of Trunk Cables ............................................................................................... 7-9

8 Installation of Primary Antenna Feeder System.................................................................................. 8-1

8.1 Preparations ................................................................................................................................... 8-1

8.1.1 Installation Personnel.......................................................................................................... 8-1

-ii-

Page 11

8.1.2 Installation Environment.....................................................................................................8-2

8.1.3 Security Measures ............................................................................................................... 8-2

8.1.4 Installation Tools.................................................................................................................8-2

8.2 Composition and Installation Requirements of Antenna Feeder System ....................................... 8-3

8.2.1 Composition........................................................................................................................8-3

8.2.2 Technical Parameters........................................................................................................... 8-5

8.3 Installation Flow ............................................................................................................................8-5

8.4 Installation of Antenna ...................................................................................................................8-6

8.4.1 Determining Installation Location ......................................................................................8-6

8.4.2 Installing Accessories of Directional Antenna ....................................................................8-7

8.4.3 Transporting and Raising Antenna......................................................................................8-8

8.4.4 Installing and Adjusting Directional Antenna.....................................................................8-9

8.4.5 Installing and Adjusting Omni Antenna............................................................................8-10

8.4.6 Connecting Jumper Cable with Antenna and Sealing Their Joint.....................................8-10

8.5 Installation of Feeder Cable Window........................................................................................... 8-11

8.6 Connection of Feeder Cable......................................................................................................... 8-12

8.6.1 Determining Route for Feeder Cable ................................................................................ 8-13

8.6.2 Assembling Connectors of Primary Feeder Cable ............................................................8-13

8.6.3 Cutting Feeder Cable.........................................................................................................8-16

8.6.4 Raising Primary Feeder Cable...........................................................................................8-17

8.6.5 Laying and Fastening Primary Feeder Cable .................................................................... 8-18

8.6.6 Connecting Jumper Cable with Feeder Cable and Sealing Their Joint ............................. 8-20

8.6.7 Leading Primary Feeder Cable into Equipment Room .....................................................8-21

8.6.8 Connecting Indoor Jumper Cable......................................................................................8-23

8.7 Grounding System of Micro-BTS................................................................................................8-23

8.8 Test of Antenna Feeder System....................................................................................................8-26

-iii-

Page 12

8.9 Waterproof Processing of Connectors.......................................................................................... 8-26

9 Installation of GPS Antenna Feeder System ........................................................................................ 9-1

9.1 Preparations ................................................................................................................................... 9-1

9.1.1 Installation Personnel.......................................................................................................... 9-1

9.1.2 Installation Environment..................................................................................................... 9-1

9.1.3 Security Measures............................................................................................................... 9-2

9.1.4 Installation Tools................................................................................................................. 9-2

9.2 Composition of GPS Antenna Feeder System ............................................................................... 9-3

9.3 Installation Procedures................................................................................................................... 9-3

9.4 Test of Antenna Feeder System...................................................................................................... 9-5

10 Installation of Internal Modules........................................................................................................10-1

10.1 Overview ................................................................................................................................... 10-1

10.1.1 Logical Positions of Equipment Modules....................................................................... 10-1

10.1.2 Layout of Internal Modules ............................................................................................ 10-2

10.1.3 Functions of the Modules ............................................................................................... 10-4

10.2 Module Installation Flow........................................................................................................... 10-7

10.3 Installation and Replacement of Modules.................................................................................. 10-8

10.3.1 Installation Sequence...................................................................................................... 10-8

10.3.2 Table of Cable Connections............................................................................................ 10-8

10.3.3 Fastening and Bundling of Internal Cables..................................................................... 10-9

10.3.4 Installation of OIM ....................................................................................................... 10-11

10.3.5 Installation of LFM....................................................................................................... 10-12

10.4 Points for Attention.................................................................................................................. 10-12

11 Hardware Installation Check..............................................................................................................11-1

11.1 Checking Components in the Cabinet........................................................................................ 11-1

11.2 Checking the Cabinet................................................................................................................. 11-1

-iv-

Page 13

11.3 Checking Cables.........................................................................................................................11-2

11.4 Checking Power Cables and Grounding Cables.........................................................................11-2

11.5 Checking T1 Cables ................................................................................................................... 11-4

11.6 Checking Indoor 1/2” Jumper Cables ........................................................................................11-4

11.7 Checking Primary Feeder Cables and GPS Feeder Cables ........................................................ 11-5

11.8 Checking Water-blocking Curve for Feeder Cable Window and Primary Feeder Cables.......... 11-6

11.9 Checking Hangers ...................................................................................................................... 11-6

11.10 Checking Outdoor 1/2” Jumper Cables.................................................................................... 11-7

11.11 Checking Antenna .................................................................................................................... 11-7

11.12 Checking Standing Wave Ratio of Feeder Cables.................................................................... 11-9

11.13 Checking Indoor and Outdoor Environment ............................................................................ 11-9

12 Power-on and Power-off.....................................................................................................................12-1

12.1 Checking Components in the Cabinet before Power-on ............................................................ 12-1

12.2 Checking External Cables before Power-on ..............................................................................12-2

12.3 Powering on/off the Cabinet ...................................................................................................... 12-2

13 Installing the Integrated Micro-BTS.................................................................................................13-1

13.1 Introduction to the Solution of Micro-BTS Integration .............................................................13-1

13.1.1 Implementation of the Micro-BTS Integration ...............................................................13-1

13.1.2 Micro-BTS Integration Solution .....................................................................................13-2

13.1.3 Module Layout of the Integrated Micro-BTS and RF Remote Station ...........................13-4

13.1.4 Networking Modes of the Integrated SDH......................................................................13-7

13.2 Installing the Built-in SDH of Micro-BTS.................................................................................13-7

13.2.1 Position and Internal Connection of the Built-in SDH in the Micro-BTS ......................13-7

13.2.2 Connecting the External Optical Fibers and Cables During Installation.........................13-8

13.3 Installing the Integrated UPS of Micro-BTS/RF Remote Station............................................13-10

13.3.1 Introduction to ZXUPS L010........................................................................................ 13-10

-v-

Page 14

13.3.2 Precautions for UPS Installation................................................................................... 13-11

13.3.3 Structural Feature and Installation Mode of UPS ......................................................... 13-12

13.3.4 Installing the Engineering Cables of L010UPS............................................................ 13-13

13.3.5 Installing UPS............................................................................................................... 13-14

13.4 Installing the Ancillary Combinational Power Supply of Micro-BTS/RF Remote Station ..... 13-15

13.4.1 Installing the Outdoor Power Box ................................................................................ 13-15

13.4.2 Installing the Outdoor Battery Box............................................................................... 13-17

13.4.3 Cable Connection for Outdoor Power Box................................................................... 13-17

Appendix A Packaging, Storage and Transportation ............................................................................ A-1

A.1 Packaging..................................................................................................................................... A-1

A.2 Storage ......................................................................................................................................... A-1

A.3 Transportation.............................................................................................................................. A-2

Appendix B Table of Cable Connections.................................................................................................B-1

B.1 Cable Connections in M800T Single-carrier Micro-BTS .............................................................B-1

B.2 Cable Connections in M800T Double-carrier Micro-BTS............................................................B-2

B.3 Cable Connections in R800T Single-carrier Remote Stations ......................................................B-3

B.4 Cable Connections in R800T Double-carrier Remote Stations.....................................................B-5

B.5 Cable Connections in M190T Single-carrier Micro-BTS .............................................................B-6

B.6 Cable Connections in M190T Double-carrier Micro-BTS............................................................B-7

B.7 Cable Connections in R190T Single-carrier Remote Stations ......................................................B-8

B.8 Cable Connections in R190T Double-carrier Remote Stations.....................................................B-9

B.9 Cable Connections in M802T Single-carrier Micro-BTS ...........................................................B-10

B.10 Cable Connections in M802T Double-carrier Micro-BTS........................................................B-12

B.11 Cable Connections in R802 Single-carrier RF Remote Stations...............................................B-13

B.12 Cable Connections in R802T Double-carrier Remote Stations.................................................B-14

B.13 Cable Connections in M191T Single-carrier Micro-BTS .........................................................B-15

-vi-

Page 15

B.14 Cable Connections in M191T Double-carrier Micro-BTS....................................................... B-16

B.15 Cable Connections in R191T Single-carrier Remote Stations.................................................. B-18

B.16 Cable Connections in R191T Double-carrier Remote Stations ................................................ B-19

B.17 Cable Connections in M192T Single-carrier Micro-BTS......................................................... B-20

B.18 Cable Connections in M192T Double-carrier Micro-BTS....................................................... B-21

B.19 Cable Connections in R192T Single-carrier Remote Stations.................................................. B-22

B.20 Cable Connections in R192T Double-carrier Remote Stations ................................................ B-23

Appendix C Equipment Parameters .......................................................................................................C-1

C.1 Dimension .................................................................................................................................... C-1

C.2 Power Consumption ..................................................................................................................... C-1

Appendix D Indicators..............................................................................................................................D-1

D.1 BDM Indicators............................................................................................................................ D-1

D.2 Indicators on Front Panel of MGPS ............................................................................................. D-1

D.3 Indicators of LFM, RFM and OIM ..............................................................................................D-2

Appendix E Abbreviations .......................................................................................................................E-1

-vii-

Page 16

Page 17

A List of Figures

Fig. 1.1-1 Structure of ZXCBTS M800T Micro-BTS....................................................................... 1-2

Fig. 1.1-2 Structure of Remote Stations ............................................................................................ 1-3

Fig. 1.1-3 Connection between Remote Station and Macro-BTS.....................................................1-3

Fig. 1.1-4 Connection between Remote Station and Macro-BTS.....................................................1-4

Fig. 1.2-1 Schematic Diagram of the Hardware Installation of Micro-BTS/Remote Station ...........1-5

Fig. 1.3-1 Hardware Installation Flow Diagram ............................................................................... 1-6

Fig. 3.2-1 Packing Box for ZXCBTS Cabinet .................................................................................. 3-2

Fig. 3.3-1 Schematic Diagram for Opening a Box............................................................................3-3

Fig. 4.1-1 Flow of Installing the Cabinet .......................................................................................... 4-2

Fig. 4.2-1 Schematic Diagram of Fastening the Cabinet onto the Pole (step 1) ...............................4-3

Fig. 4.2-2 Schematic Diagram of Fastening the Cabinet onto the Pole (step 2) ...............................4-4

Fig. 4.2-3 Schematic Diagram of Fastening the Cabinet onto the Pole (step 3) ...............................4-4

Fig. 4.2-4 Schematic Diagram of the Cabinet Fastened onto the Pole..............................................4-5

Fig. 4.2-5 Schematic Diagram of Installing the Support onto the Wall ............................................4-6

Fig. 4.2-6 Schematic Diagram of Installing the Cabinet onto the Wall............................................. 4-7

Fig. 5.1-1 Four-pin Connector and Four-core Power Cable.............................................................5-1

Fig. 5.2-1 Connection of Power Cables and Grounding Cables at the Bottom of a Cabinet............5-3

Fig. 5.3-1 Assembling a Power Cable Connector (step 1)................................................................5-3

Fig. 5.3-2 Assembling a Power Cable Connector (step 2)................................................................5-4

Fig. 5.3-3 Assembling a Power Cable Connector (step 4)................................................................5-4

Fig. 5.3-4 Assembling a Power Cable Connector (step 5)................................................................5-5

Fig. 5.3-5 Assembling a Power Cable Connector (step 6)................................................................5-5

Fig. 6.1-1 Schematic Diagram of Grounding Connections...............................................................6-2

-i-

Page 18

Fig. 6.2-1 Appearance of a Grounding Copper Busbar .................................................................... 6-3

Fig. 6.2-2 Connection of Power Cable and PGND Cable at the Bottom of a Cabinet...................... 6-4

Fig. 6.2-3 Structure of a Grounding Kit............................................................................................ 6-5

Fig. 6.2-4 Schematic Diagram of Wrapping Waterproof Adhesive Tape Around the Grounding Cable

............................................................................................................................................................. 6-6

Fig. 7.2-1 Structure of Optical Fiber (1)........................................................................................... 7-3

Fig. 7.2-2 Structure of Optical Fiber (2)........................................................................................... 7-4

Fig. 7.2-3 Structure of Optical Fiber (3)........................................................................................... 7-5

Fig. 7.2-4 Structure of Optical Fiber (4)........................................................................................... 7-5

Fig. 7.2-5 Schematic Diagram of Connecting Optical Fiber ............................................................ 7-6

Fig. 7.2-6 Connection of Interconnection RF Cables ....................................................................... 7-8

Fig. 7.2-7 Connection of T1 Cables.................................................................................................. 7-9

Fig. 8.2-1 Typical Structure of the Antenna Feeder System ............................................................. 8-4

Fig. 8.3-1 Antenna Installation Flow................................................................................................ 8-6

Fig. 8.4-1 Installation of the KATHREIN Antenna .......................................................................... 8-7

Fig. 8.4-2 Schematic Diagram of Raising the Antenna to the Tower Top ........................................ 8-8

Fig. 8.4-3 Schematic Diagram of Adjusting the Pitch Angle of the Antenna ................................. 8-10

Fig. 8.5-1 Structure of a Feeder Cable Window ............................................................................. 8-12

Fig. 8.6-1 Structure of the Feeder Cable of a Micro-BTS/Remote Station..................................... 8-13

Fig. 8.6-2 Cutter for Assembling 7/8” Feeder Cable Connectors................................................... 8-14

Fig. 8.6-3 Schematic Diagram of Cutting the Feeder Cable with the Cutter.................................. 8-14

Fig. 8.6-4 Schematic Diagram of Correct Cutting Size.................................................................. 8-14

Fig. 8.6-5 Schematic Diagram of Expanding the External Copper Conductor............................... 8-15

Fig. 8.6-6 Schematic Diagram of Connecting the Front Part with the Back Part of the Connector8-15

Fig. 8.6-7 Schematic Diagram of Fastening the Front Part with the Back Part of the Connector .. 8-16

Fig. 8.6-8 Schematic Diagram of Pulling the Feeder Cable Up the Tower..................................... 8-18

Fig. 8.6-9 Appearance of a Hanger................................................................................................. 8-19

-ii-

Page 19

Fig. 8.6-10 Schematic Diagram of Wrapping Waterproof Adhesive Tape (1)................................. 8-20

Fig. 8.6-11 Schematic Diagram of Wrapping Waterproof Adhesive Tape (2)................................. 8-21

Fig. 8.6-12 Schematic Diagram of Wrapping Waterproof Adhesive Tape (3)................................. 8-21

Fig. 8.6-13 Leading the Feeder Cable into the Equipment Room - Mode 1 ...................................8-22

Fig. 8.6-14 Leading the Feeder Cable into the Equipment Room - Mode 2 ...................................8-22

Fig. 8.7-1 Structure of a Grounding Kit..........................................................................................8-24

Fig. 8.7-2 Schematic Diagram of Wrapping Waterproof Adhesive Tape Around the Grounding Cable

...........................................................................................................................................................8-25

Fig. 9.2-1 Composition of the GPS Antenna Feeder System............................................................9-3

Fig. 9.3-1 Schematic Diagram of Length of Cable Sheath to be Stripped ........................................9-4

Fig. 9.3-2 Schematic Diagram of Soldering the Core Wire with the Pin ..........................................9-4

Fig. 9.3-3 Structure of N-J7A............................................................................................................9-4

Fig. 10.1-1 Modules and Boards in M800T/M801T/M802T/M190T/M191T/M192T Micro-BTS10-1

Fig. 10.1-2 Modules and Boards in R800T/R801T/R802T/R190T/R191T/R192T ........................10-2

Fig. 10.1-3 Layout of Modules in a ZXCBTS Micro-BTS.............................................................10-3

Fig. 10.1-4 Layout of Modules in a ZXCBTS Remote Station....................................................... 10-4

Fig. 10.2-1 Module Installation Flow Diagram............................................................................... 10-7

Fig. 10.3-1 Schematic Diagram of Bundling Internal Cables (1)....................................................10-9

Fig. 10.3-2 Schematic Diagram of Bundling Internal Cables (2)..................................................10-10

Fig. 10.3-3 Schematic Diagram of Bundling Internal Cables (3)..................................................10-10

Fig. 10.3-4 Corresponding Relations between OIM Expansion Slots in BDM and Sectors......... 10-11

Fig. 10.3-5 Schematic Diagram of Inserting the OIM into the BDM ...........................................10-12

Fig. 12.1-1 Setting of S1 ................................................................................................................. 12-1

Fig. 13.1-1 Solution (I) of Micro-BTS Integration ............................................................................13-3

Fig. 13.1-2 Solution (II) of Micro-BTS Integration...........................................................................13-4

Fig. 13.1-3 Layout of Modules in the ZXCBTS micro-BTS .............................................................13-5

Fig. 13.2-1 Cable Layout of the Built-in SDH in the CDMA Micro-BTS.........................................13-8

-iii-

Page 20

Fig. 13.2-3 Connection of the Optical Fiber.................................................................................... 13-10

Fig. 13.3-1 Appearance of the ZXUPS L010 Series........................................................................ 13-11

Fig. 13.3-2 Inner Structure of the ZXUPS L010 Series................................................................... 13-11

Fig. 13.3-4 Layout of the Monitoring Cables of the CDMA Micro-BTS 485/Dry Contact ............ 13-14

Fig. 13.4-6 Output Connecting Terminal of the Dry Contact .......................................................... 13-19

Fig. C.1-1 Appearance of a ZXCBTS Cabinet .................................................................................C-1

Fig. D.1-1 Indicators of the BDM.................................................................................................... D-1

Fig. D.3-1 Location of Indicators on the OIM Panel ...................................................................... D-4

-iv-

Page 21

A List of Tables

Table 1.1-1 List of ZXCBTS Micro-BTS/Remote Stations (800MHz) ............................................1-1

Table 1.1-2 List of ZXCBTS Micro-BTS/Remote Stations (1900MHz) .......................................... 1-1

Table 2.2-1 Tools and Instruments Needed for the Installation.........................................................2-2

Table 5.1-1 Corresponding Relationship between Core Wires and Binding Posts............................5-2

Table 5.1-2 Corresponding Relationship between Core Wires and Binding Posts............................5-2

Table 5.3-1 Corresponding Relationship between Core Wires and Binding Posts........................... 5-6

Table 7.1-1 List of Types and Configurations of Internal Cables......................................................7-1

Table 13.2-1 Cable Connection of the Built-in SDH inside the CDMA Micro-BTS.........................13-7

Table 13.3-1 From-to-list of the CDMA Micro-BTS 485/dry contact supplementary cables..........13-13

Table B.1-1 Cable Connections in M800T Single-carrier Micro-BTS ............................................ B-1

Table B.2-1 Cable Connections in M800T Double-carrier Micro-BTS........................................... B-2

Table B.3-1 Cable Connections in R800T Single-carrier Remote Stations...................................... B-3

Table B.4-1 Cable Connections in R800T Double-carrier Remote Stations.................................... B-5

Table B.5-1 Cable Connections in M190T Single-carrier Micro-BTS ............................................ B-6

Table B.6-1 Cable Connections in M190T Double-carrier Micro-BTS........................................... B-7

Table B.7-1 Cable Connections in R190T Single-carrier Remote Stations...................................... B-8

Table B.8-1 Cable Connections in R190T Double-carrier Remote Stations.................................... B-9

Table B.9-1 Cable Connections in M802T Single-carrier Micro-BTS .......................................... B-10

Table B.10-1 Cable Connections in M802T Double-carrier Micro-BTS ....................................... B-12

Table B.11-1 Cable Connections in R802T Single-carrier Remote Stations.................................. B-13

Table B.12-1 Cable Connections in R802T Double-carrier RF Remote Stations .......................... B-14

Table B.13-1 Cable Connections in M191T Single-carrier Micro-BTS......................................... B-15

Table B.14-1 Cable Connections in M191T Double-carrier Micro-BTS ....................................... B-16

-i-

Page 22

Table B.15-1 Cable Connections in R191T Single-carrier Remote Stations..................................B-18

Table B.16-1 Cable Connections in R191T Double-carrier Remote Stations.................................B-19

Table B.17-1 Cable Connections in M192T Single-carrier Micro-BTS.........................................B-20

Table B.18-1 Cable Connections in M192T Double-carrier Micro-BTS........................................B-21

Table B.19-1 Cable Connections in R192T Single-carrier Remote Stations..................................B-22

Table B.20-1 Cable Connections in R192T Double-carrier Remote Stations.................................B-23

Table C.2-1 Power Consumption of Several Types of Micro-BTS and Remote Stations.................C-2

Table C.2-2 Power Consumption of Several Types of Micro-BTS and Remote Stations.................C-2

Table C.2-3 Power Consumption of Several Types of Micro-BTS and Remote Stations.................C-3

Table D.2-1 Indicators on the Front Panel of MGPS ....................................................................... D-1

Table D.3-1 Indicators of the LFM.................................................................................................. D-2

Table D.3-2 Indicators of the RFM.................................................................................................. D-3

Table D.3-3 Indicators on the OIM Panel........................................................................................D-4

-ii-

Page 23

1 Overview

Summary

1.1 Introduction to Micro-BTS

Listing the components to be installed.

Describing the installation flow.

Presenting points for attention during the installation

With the development of various new technologies, Base Transceiver Station (BTS) is

oriented to be small and intelligent, with low power consumption, low cost and high

reliability. In large or medium-sized cities, common micro-BTS cannot meet the

demand of some busy-traffic areas due to the block of high buildings. In addition, it is a

waste for micro-BTS to be installed in some remote areas with less traffic. Moreover,

micro-BTS have high requirements on the equipment room environment. To avoid the

above problems, ZTE has developed ZXCBTS products.

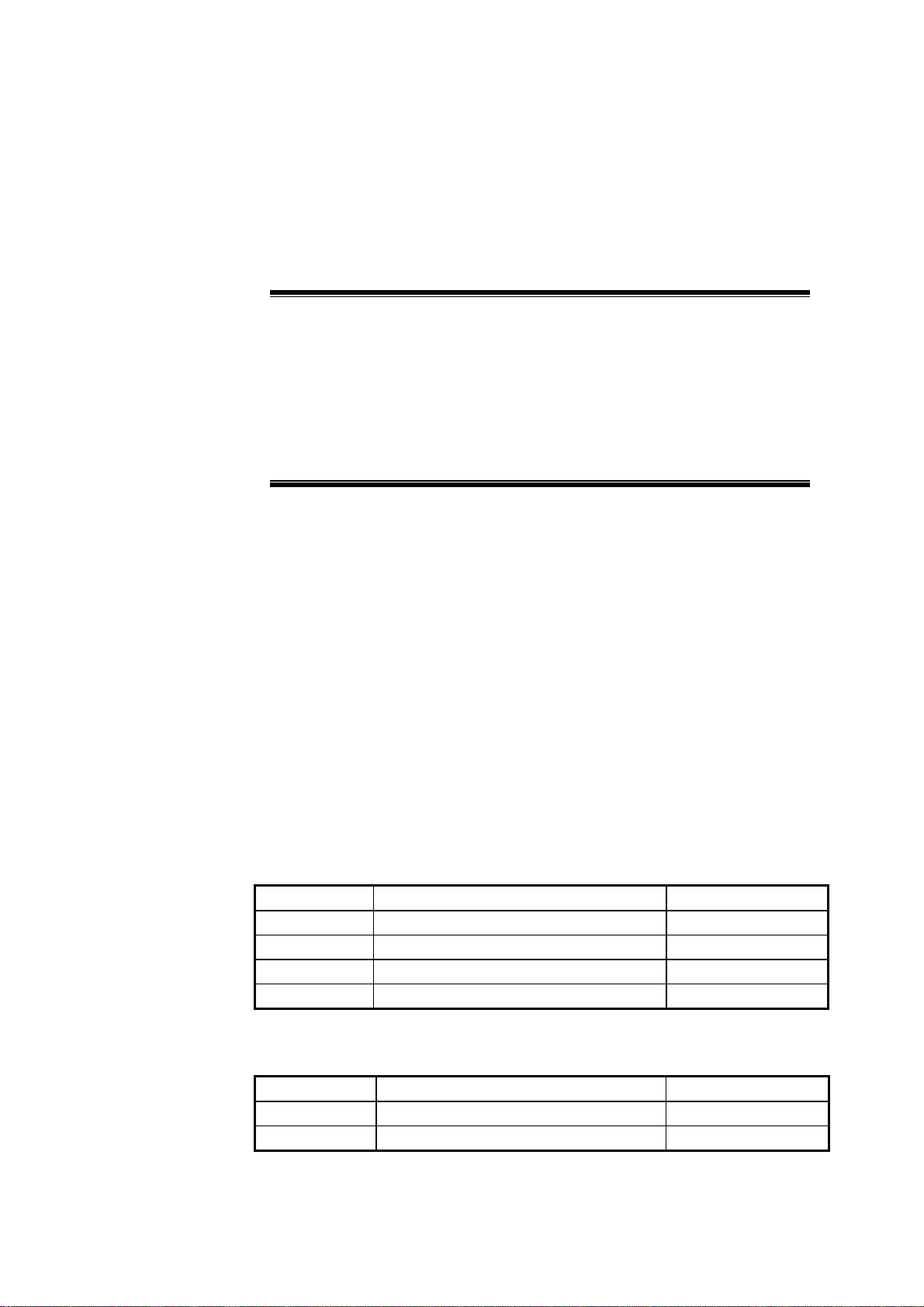

ZXCBTS products are classified based on different frequency bands and transmitter

powers. This manual serves for the installation of the following models:

Table 1.1-1 List of ZXCBTS Micro-BTS/Remote Stations (800MHz)

Model Name Rated Transmission Power

ZXCBTS M800T CDMA micro-BTS (800MHz) 10W

ZXCBTS M802T CDMA micro-BTS (800MHz) 20W

ZXCBTS R800T CDMA remote station (800MHz) 10W

ZXCBTS R802T CDMA remote station (800MHz) 20W

Table 1.1-2 List of ZXCBTS Micro-BTS/Remote Stations (1900MHz)

Model Name Rated Transmission Power

ZXCBTS M190T CDMA micro-BTS (1900MHz) 5W

ZXCBTS M191T CDMA micro-BTS (1900MHz) 10W

1-1

Page 24

ZXCBTS (V5.4) CDMA Micro Base Transceiver Station & Remote Station Installation Manual

Model Name Rated Transmission Power

ZXCBTS M192T CDMA micro-BTS (1900MHz) 20W

ZXCBTS R190T CDMA remote station (1900MHz) 5W

ZXCBTS R191T CDMA remote station (1900MHz) 10W

ZXCBTS R192T CDMA remote station (1900MHz) 20W

ZXCBTS products include micro-BTS and remote stations, working in the frequency

bands of 800MHz and 1.9GHz.

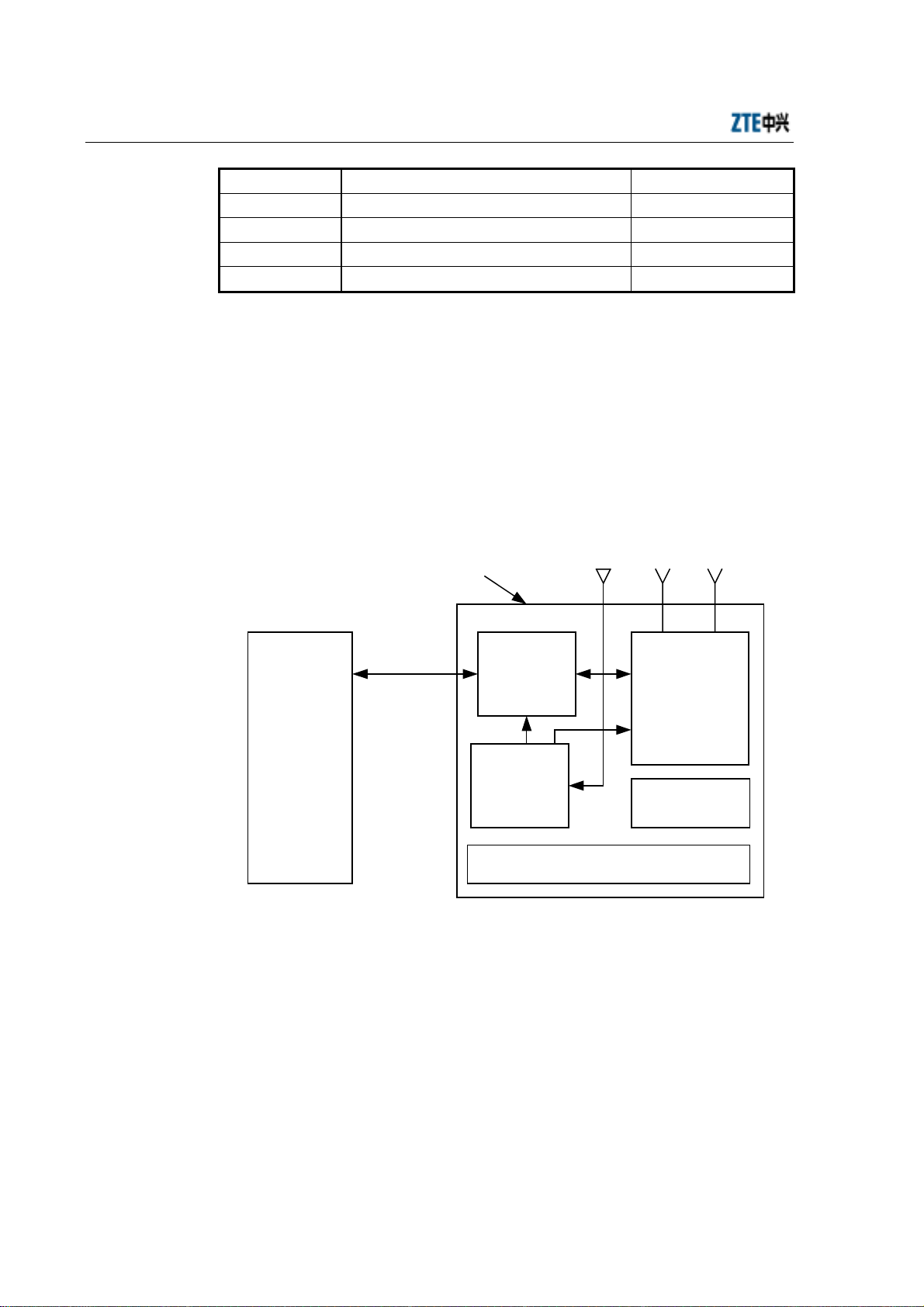

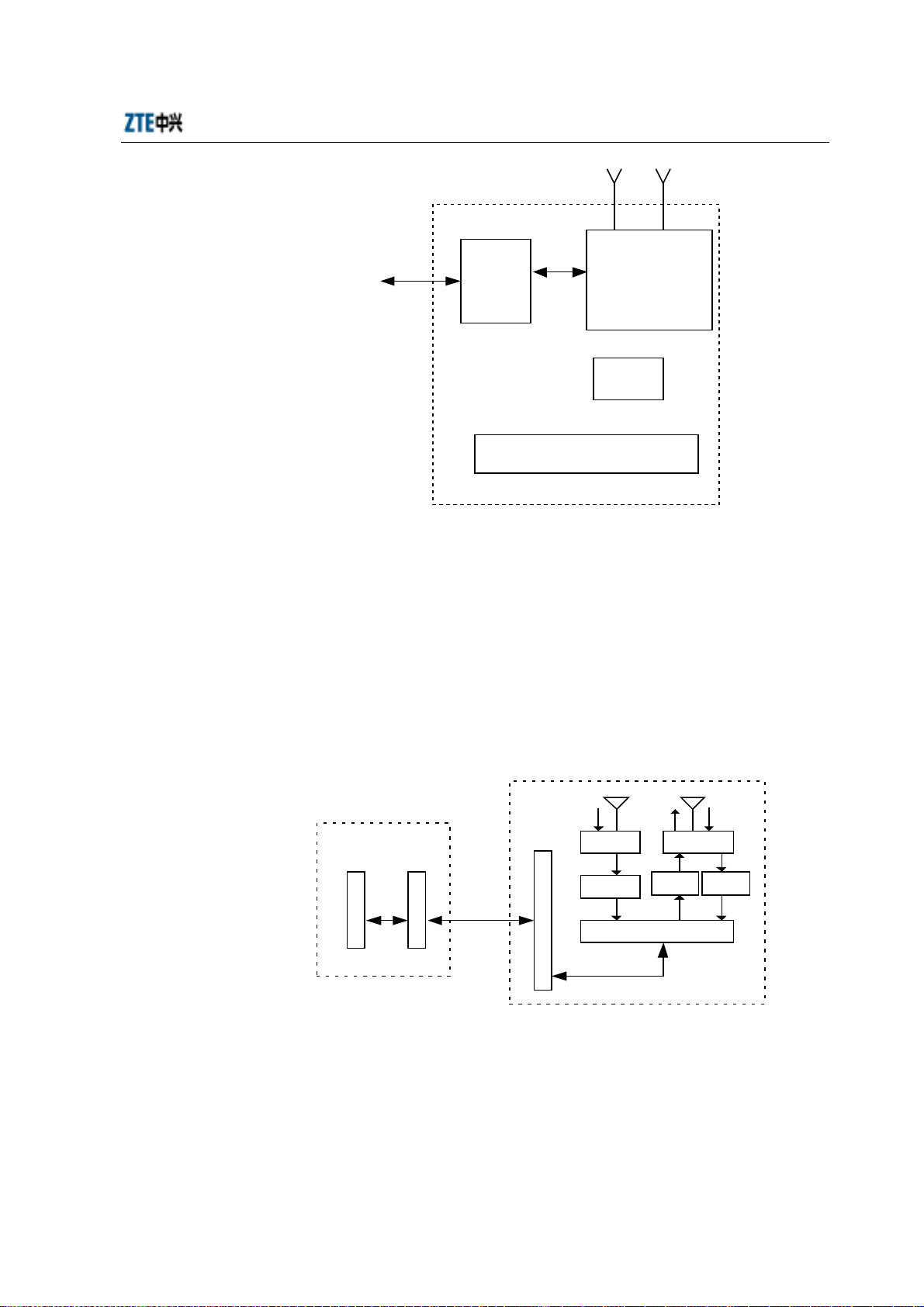

Micro-BTS system consists of Baseband Digital Subsystem (BDS), Timing &

Frequency Subsystem (TFS), power supply subsystem, lightning protection subsystem

and Radio Frequency Subsystem (RFS). The structure of

M800T/M802T//M190T/M191T/M192T micro-BTS is illustrated in the following

figure.

GPS antenna RF antenna

Micro-BTS

T1 (4)

BSC, macro-/

micro-BTS

Fig. 1.1-1 Structure of ZXCBTS M800T Micro-BTS

BDS

subsystem

(BDM)

TFS

subsystem

(GPSTM)

GPS, RF antenna feeder and power lightning

arrester

RFS subsystem

(MTRX, MPA,

MLNA, MDUP

and MDIV)

Power supply

Remote stations are similar to micro-BTS in structure, but different in replacing

Baseband Digital Module (BDM) with Remote Fiber Module (RFM) and removing

GPS Timing Module (GPSTM), for the clock signals of remote stations are

demodulated from the signals sent through optical fiber. The structure of remote

stations is illustrated in the following figure.

1-2

Page 25

Chapter 1 Overview

RF antenna

Optical

fiber

Fig. 1.1-2 Structure of Remote Stations

RFM

RF antenna feeder and power

lightning arrester

RFS (MTRX,

MDUP and MDIV)

Power

supply

Remote stations should cooperate with the macro-/micro-BTS to achieve the BTS

functions, so you need to configure Local Fiber Module (LFM) on micro-BTS or

Optical Interface Module (OIM) on micro-BTS for interworking with the remote

stations.

If the LFM is configured in a macro-BTS, the connection between the remote station

and the macro-BTS is illustrated in the following figure.

RX RXTX

DIV DUP

Macro-BTS

R

F

I

M

Fig. 1.1-3 Connection between Remote Station and Macro-BTS

L

F

M

Optical fiber

R

F

M

RX

MLNA

RX RX

Remote station

TX

MPA

TX

MTRX

RX

MLNA

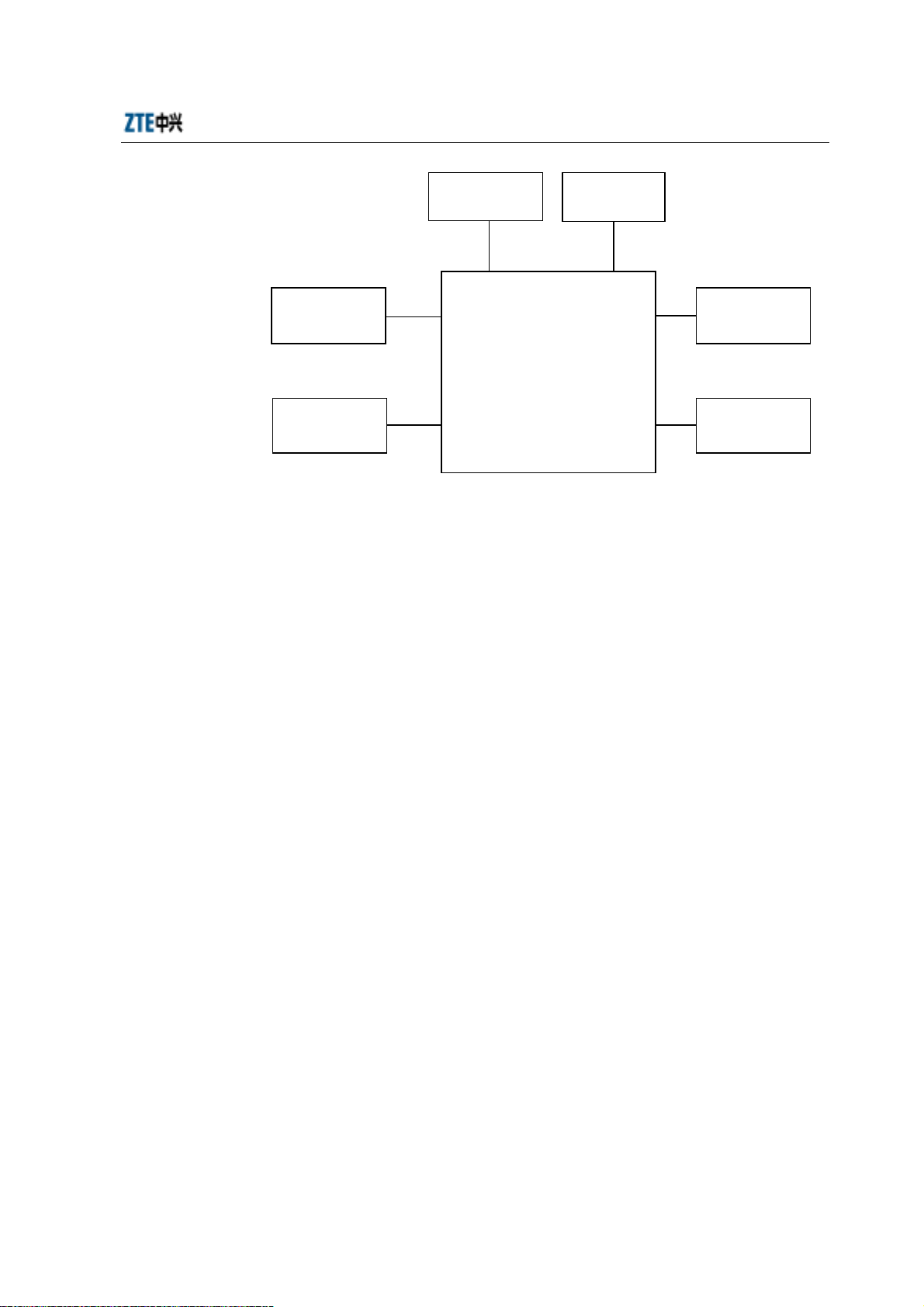

If the OIM is configured in a micro-BTS, the connection between the remote station

and the micro-BTS is illustrated in the following figure.

1-3

Page 26

ZXCBTS (V5.4) CDMA Micro Base Transceiver Station & Remote Station Installation Manual

RX RXTX

DIV DUP

RX

B

D

M

Micro-BTS

Fig. 1.1-4 Connection between Remote Station and Macro-BTS

O

I

M

Optical fiber

R

F

M

MLNA

RX RX

Remote station

MPA

TX

MTRX

RXTX

MLNA

1.2 Installation Overview

The hardware installation of micro-BTS/remote stations can be divided into the

following aspects:

1. Installing shelf and boards, connecting internal cables and setting DIP switches

2. Installing the power supply system

3. Installing the grounding system

4. Locating and installing the antenna, jumper cable and feeder cable, and testing

the antenna feeder system

5. Installing GPS and its feeder cables

6. Connecting trunk cables and assembling their connectors

7. Installing the alarm system for reporting abnormal temperature and humidity

See Fig. 1.2-1.

1-4

Page 27

Chapter 1 Overview

Install the power

supply system

Install the

grounding system

Fig. 1.2-1 Schematic Diagram of the Hardware Installation of Micro-BTS/Remote Station

1.3 Installation Flow

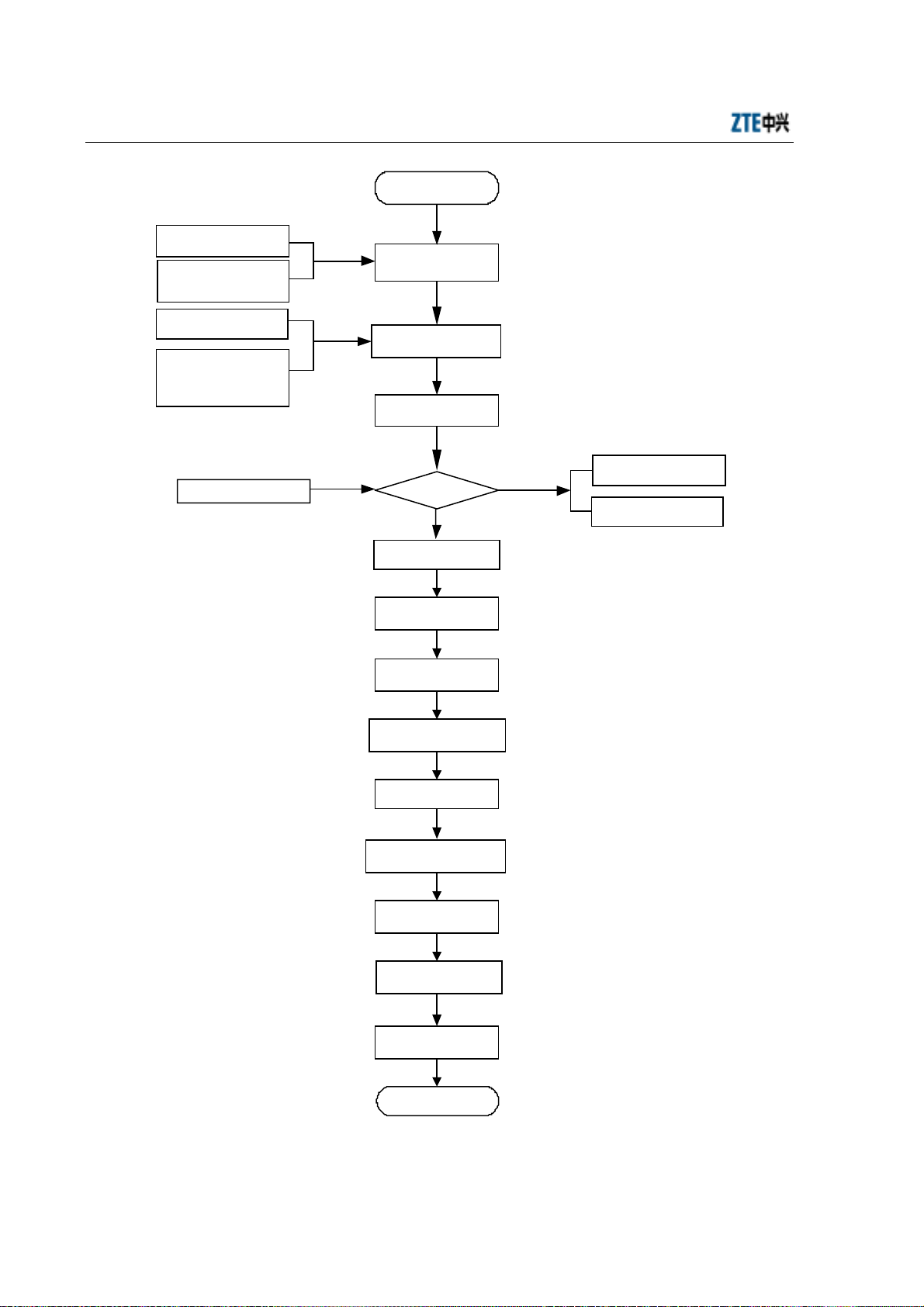

Install the equipment following the specified procedures strictly:

Install the GPS

Install the

antenna system

Install the ZXCBTS cabinet

Install the shelf

Check internal

cables

Set the DIP

switches

Connect trunk

cables

Install the

sunshade cover

1. Install the support;

2. Locate the cabinet on the support;

3. Secure the cabinet;

4. Install the sunshade cover (necessary for outdoor installation);

5. Connect power cables and grounding cables of the cabinet;

6. Connect T1 cables of the cabinet;

7. Install the primary antenna feeder system to connect with the RF cables;

8. Install the GPS;

9. Install and test the boards and modules, and set the DIP switches;

10. Check the installation.

See Fig. 1.3-1.

1-5

Page 28

ZXCBTS (V5.4) CDMA Micro Base Transceiver Station & Remote Station Installation Manual

Start

Engineering Survey

Report

BTS Engineering

Design and

Construction Drawing

Environment

Acceptance Report

Cabling rack Power

supply system

Grounding system

Other accessories

Preparation for

engineering

installation

Check construction

conditions

Open-box inspection

Packing list

Goods are

correct

Yes

Install the shelf

Install the power

supply system

Install the

grounding system

Check cable connections

in the shelf

Connect trunk cables

Check the primary

antenna feeder system

No

Goods Error Feedback

List

Goods Replacement

Feedback List

Install the GPS

Set DIP switches

Hardware installation

check

End

Fig. 1.3-1 Hardware Installation Flow Diagram

1-6

Page 29

Chapter 1 Overview

1.4 Points for Attention

Pay attention to the following points during the installation: The installation personnel

should be trained to obtain the qualification entitled by ZTE and read this manual

before the installation.

1. Do not operate on the cabinet or any module when the power is on.

2. Observe the relative requirements strictly when installing the BTS.

3. Do not install the antenna feeder system in thunder weather.

4. Before the thunder storm season of each year comes, check whether the

lightning arrester is in good condition and is well contacted. If it is damaged,

replace it immediately.

5. When the installation of the cabinet completes, lock the door immediately. If the

door need be opened in case of maintenance, contact the professional personnel

for help.

1-7

Page 30

Page 31

2 Preparations

Summary

Describing the installation environment check.

Listing the installation tools.

Listing the technical documents needed for

installation.

2.1 Installation Environment Check

The items to check:

2.1.1 Checking Equipment Building Conditions

Check if the layout, height, bearing capability, shock-proof ability, doors and windows,

walls and troughs of the equipment building meet the requirements.

2.1.2 Checking Indoor Environment

Check the temperature, humidity, air pressure, ventilation condition, antistatic

protection measures, anti-interference measures, dustproof measures, rodent-resistant

measures, fire-protection facility, lighting condition, water supply and drainage system

of the equipment room.

To the highest priority, the equipment should be installed on the cool and dry walls

indoors with good ventilation; the fire-protection facility should be equipped; there

should be no caustic gas or smog in the room and no leakage on the roof; the

electromagnetic interference strength should be no more than 140dBµV/m

(0.01MHz~110000MHz). Or the equipment can be installed on the shady walls

outdoors with good ventilation and rain blocks. To the least priority, the equipment can

be installed on common walls, towers or high poles. The operating temperature range

of the equipment is between -40°C and +55°C, and the relative humidity range is

between 5% and 100%.

2-1

Page 32

ZXCBTS (V5.4) CDMA Micro Base Transceiver Station & Remote Station Installation Manual

2.1.3 Checking Power Supply System

Check the power supply ability and quality. A group of independent and stable

85V~138V (nominal 120V) AC power should be supplied to the equipment. It is

prohibited to share the power supply with other high-power telecom equipment or the

usually powered-down equipment.

2.1.4 Checking Grounding System

The standard grounding system should be equipped and the resistance should be less

than 5 ohm.

2.1.5 Checking Relative Devices

Check if the other devices relative to the normal operation of the equipment are in good

condition, such as interface device, transmission device, Digital Distribution Frame

(DDF) and Optical Distribution Frame (ODF).

2.2 Tools and Instruments

Prepare the tools and instruments needed for the installation in advance as listed in

Table 2.2-1.

Table 2.2-1 Tools and Instruments Needed for the Installation

Type Name

Special tools

Drilling tools

General tools

One cutter for assembling feeder cable connectors

One 75-ohm coaxial cable stripper

75-ohm coaxial crimping plier

One multi-functional crimping plier

One multimeter

One SiteMaster standing wave ratio tester

One earth resistance tester

One percussive drill

Several drill bits

One cleaner

One power connector board (with at least three two-pin and three-pin

sockets respectively; the current capacity is more than 15 amp.)

Three cross screw-drivers (4”, 6” and 8”)

Three straight screw-drivers (4”, 6” and 8”)

Four adjustable wrenches (6”, 8”, 10” and 12”)

2-2

Page 33

Chapter 2 Preparations

Type Name

Two spanners (17” and 19”)

One hexagon spanner

One socket wrench

One 5kg nail hammer

One 300W electric iron and one 40W electric iron

One coil of solder wires

One 50m tape measure

One 5m steel tape measure

One 400mm horizontal ruler

Measurement tools

Protection tools

Locksmith tools

Assistant tools

One inclinometer

One compass

One multimeter

Ruler

One plumb

Antistatic wrist strap

Safety helmet, slip-proof gloves

One hacksaw, several saw blades

One sharp nose plier (8”)

One diagonal plier (8”)

One slip joint plier (8”)

One vice (8”)

A set of files (middle)

One tweezers

One paint brush

One scissors

One dryer

One solder removal tool

One hydraulic pressure pliers

One crowbar

Pulley group

Rope

Ladder

Forklift

2.3 Technical Documents

Prepare the following technical documents:

1. Engineering Survey Report, BTS Engineering Design and Construction Drawing,

Environment Acceptance Report

2-3

Page 34

ZXCBTS (V5.4) CDMA Micro Base Transceiver Station & Remote Station Installation Manual

Engineering Survey Report should be filled by the technical engineers of the

equipment provider during site survey. If they can not carry out the survey in

time, you should survey the site, fill in the report and then send it to the

equipment provider. This report is used for the preparation of construction

materials.

BTS Engineering Design and Construction Drawing should be prepared by the

design unit you entrusted, and a copy should be provided to the equipment

provider before the delivery.

Environment Acceptance Report is used by the technical engineers of the

equipment provider to check the construction environment during site survey. If

any inconformity is found, you are required to solve the problem. Before the

construction, the second check will be implemented.

2. ZXCBTS(V5.4)CDMA Micro Base Transceiver Stations/RF Remote Stations

Installation Manual, ZXCBTS(V5.4)CDMA Micro Base Transceiver Stations/RF

Remote Stations Technical Manual, ZXCBTS(V5.4)CDMA Micro Base

Transceiver Stations/RF Remote Stations Hardware Manual,

ZXCBTS(V5.4)CDMA Micro Base Transceiver Stations/RF Remote Stations

Maintenance Manual

3. Installation Acceptance Report, Test Acceptance Report

Installation Acceptance Report and Test Acceptance Report should be offered to

you by the equipment provider during delivery. Installation Acceptance Report

is filled after the BTS installation completes. Test Acceptance Report is filled

during the BTS commissioning.

2-4

Page 35

3 Open-box Inspection

Summary

Describing the inspection procedures.

Describing the open-box procedures.

3.1 Checking Packing List and Goods

Caution

Because ZXCBTS equipment is expensive, ensure that it is packed well and the

flags for avoiding water and vibrations are marked. Load and unload the

equipment gently, and avoided damage from sunshine and rain.

1. Check the “ZTE delivery sheet”.

2. Open-box inspection should be done by the engineering supervisor and your

representative. First, check if the total quantity of the goods is correct according

to the packing list, if the packing boxes are in good condition, and if the delivery

location is the right installation site.

3. Next, open the boxes and the engineering supervisor should check the goods

based on the packing list. Open-box Inspection Report is put in the packing box

numbered 1#. Open the 1# box and take out the Open-box Inspection Report to

check if the total quantity of the goods is consistent with the checklist, and then

archive the report.

4. During the inspection, if loss of goods, lack of goods, error delivery or any

damage is found, find out the cause and feedback to the ZTE headquarter for

handling.

5. The goods are packed in either cartons or wooden boxes. You need to open them

on site using different tools.

3-1

Page 36

ZXCBTS (V5.4) CDMA Micro Base Transceiver Station & Remote Station Installation Manual

3.2 Packaging

Note

The cabinets of micro-BTS and remote stations are the same in structure, so is

the packaging method.

Put the support and other accessories of the ZXCBTS cabinet into the wooden box.

In the wooden box, the cabinet is packed with foam boards, a bubble bag and a plastic

bag. After opening the box, you need not uplift it but directly take the equipment out.

When carrying the box, be cautious to prevent the cabinet from being damaged.

The packing box for the ZXCBTS cabinet is shown in Fig. 3.2-1.

Goods:

CDMA micro -BT S

ZTE CORPORATION

ZTE Plaza, Keji Road South, Hi-Tech Industrial

Park, Nanshan District, Shenzhe n, P.R.Chi na

Postcode: 518057

Tel: (+86755) 6790000

Customer Support Cente r: 8008301118

Net Weight: (Kg)

Volume: 81x52x40 (cm)

Qty. :

Packing List:

Fig. 3.2-1 Packing Box for ZXCBTS Cabinet

3.3 Open-box Procedures

Follow the steps below to open the box:

1. Open the cover board.

2. Remove the foam boards.

3. Take the micro-BTS out directly.

See Fig. 3.3-1.

3-2

Page 37

Chapter 3 Open-box Inspection

Accessories

Micro-BTS

)

g

K

(

C

D

M

A

m

i

c

r

o

-

B

T

S

Z

T

Z

T

E

C

O

R

P

O

R

A

T

I

O

E

P

l

a

z

a

,

K

P

e

j

a

i

r

k

R

,

o

a

N

P

o

s

t

c

o

N

d

T

e

l

:

(

+

8

6

C

u

s

t

o

m

e

r

d

a

e

7

ns

S

o

h

u

a

t

n

h

,

D

H

i

s

t

i

-

r

T

i

c

e

t

c

,

h

S

:

5

1

8

0

5

7

5

5

)

6

7

9

0

0

00

S

u

p

p

o

r

t

C

e

n

t

e

r

h

I

n

e

d

n

u

z

:

8

0

0

8

s

he

t

r

i

n

a

,

l

P

.

R

.

C

h

i

n

a

3

01

1

1

8

s

d

o

o

G

W

t

e

N

u

l

o

V

y

t

Q

c

a

P

:

:

t

h

g

i

e

x

1

8

:

e

m

:

.

s

i

L

g

n

i

k

)

m

c

(

0

4

x

2

5

:

t

Fig. 3.3-1 Schematic Diagram for Opening a Box

3-3

Page 38

Page 39

4 Installation of Cabinet

Summary

Describing the procedures to install the

micro-BTS/remote station cabinet

Describing the possible installation modes

4.1 Installation Flow

Note

The cabinets of ZXCBTS micro-BTS/remote stations are the same in structure,

so is the installation method.

The cabinet can be installed in two modes: on pole or on wall. The installation flow is

shown in Fig. 4.1-1.

4-1

Page 40

ZXCBTS (V5.4) CDMA Micro Base Transceiver Station & Remote Station Installation Manual

Installation on pole

Install t he sup p ort

Outdoors

Install the sunshade cover

Install t he cabinet

Ins tallation check

End

Installation on wall

Ins tall the support

Indoors

4.2 Installation Modes

Note

The cabinets of ZXCBTS micro-BTS/remote stations are the same in structure,

so is the installation method.

As shown in Fig. 4.1-1, the cabinet can be installed either on pole or on wall based on

the actual environment.

4.2.1 Installing Cabinet on Pole

1. Disassemble the support from the cabinet.

2. Secure the support onto the pole with fixing plates and 260mm-long bolts. The

diameter of the pole should be between 60mm and 90mm. 75mm is

recommended. See Fig. 4.2-1.

If the equipment is to be installed outdoors, face the front side southward and

Fig. 4.1-1 Flow of Installing the Cabinet

the back side northward (This rule is applicable to the case that the equipment is

4-2

Page 41

Chapter 4 Installation of Cabinet

installed in the Northern Hemisphere. If it is installed in the Southern

Hemisphere, the opposite rule should be applied).

3. Install the sunshade cover onto the support with four M4 bolts. See Fig. 4.2-4.

4. Hold the cabinet to hang it onto the support, then push it into the shelf. See Fig.

4.2-2.

5. Align the bolt holes on the support with those on the cabinet, and then screw

down four M8 hexagon bolts. See Fig. 4.2-3.

6. On the cabinet base there are hangers for rope. If necessary, use the rope to hang

the cabinet onto the pole.

See Fig. 4.2-1 for the schematic diagram of cabinet fastened on pole.

Bolt

Flat washer

Support

M12 nut,

spring washer,

flat washer

Pole

Fixing plate

Fig. 4.2-1 Schematic Diagram of Fastening the Cabinet onto the Pole (step 1)

4-3

Page 42

ZXCBTS (V5.4) CDMA Micro Base Transceiver Station & Remote Station Installation Manual

Fig. 4.2-2 Schematic Diagram of Fastening the Cabinet onto the Pole (step 2)

Fig. 4.2-3 Schematic Diagram of Fastening the Cabinet onto the Pole (step 3)

4-4

Page 43

Chapter 4 Installation of Cabinet

Fig. 4.2-4 Schematic Diagram of the Cabinet Fastened onto the Pole

Caution

For your safety, be sure to wear the safety belt when working at heights and

the safety helmet when working at grounds. It is prohibited to work in

thunder storm weather.

4-5

Page 44

ZXCBTS (V5.4) CDMA Micro Base Transceiver Station & Remote Station Installation Manual

4.2.2 Installing Cabinet on Wall

1. Disassemble the support from the cabinet.

2. Mark four points on the wall based on the four holes on the support, and then

drill four holes with a percussive drill (using M12 drill bit). Secure the support

onto the wall with four M10 expansion bolts. See Fig. 4.2-5.

3. Hold the cabinet to hang it onto the support, and then push it into the shelf.

4. Align the bolt holes on the support with those on the cabinet, and then screw

down four M8 hexagon bolts.

5. Install the sunshade cover if the equipment is to be installed outdoors.

See Fig. 4.2-6 for the schematic diagram of installing cabinet on wall.

Wall

Support

Exp ansion bolt

Hexagon n ut

Washer

Fig. 4.2-5 Schematic Diagram of Installing the Support onto the Wall

4-6

Page 45

Chapter 4 Installation of Cabinet

Fig. 4.2-6 Schematic Diagram of Installing the Cabinet onto the Wall

Note

The modules and cables in micro-BTS (including ultra-wide coverage

micro-BTS) and remote stations have been installed, connected and tested

before delivery. Before commissioning, you only need to check if they are loose

due to conveyance. Refer to Chapter 7 for the connection of cables between

cabinets.

According to the configuration requirement, you might need to add optical

fiber modules or CSM5000 expansion modules in the expansion slots of the

corresponding BDM board.

If any fault occurs, the maintenance personnel can refer to this manual for

simple maintenance.

4-7

Page 46

Page 47

5 Installation of Power Supply System

Summary

Describing the methods for installing the power

supply system..

Describing the procedures to install the power

supply system..

5.1 Introduction to Power Cables

The micro-BTS/remote stations are supplied by 120V AC power or -48V DC power.

AC micro-BTS are supplied by 120V AC power, and DC micro-BTS are supplied by

-48V DC power.

5.1.1 -48V DC Power Cable

The ZTE -48V DC ZXCBTS equipment is equipped with a piece of 10m-long cable,

which can meet the installation requirement in most cases. If you need to assemble the

cable on site in special cases, follow the instructions in this section. The DC power

cable connector is a four-pin connector, and the power cable adopts four-core cable, as

shown in Fig. 5.1-1. The corresponding relationship between the core wires and the

binding posts are listed in Table 5.1-1.

Fig. 5.1-1 Four-pin Connector and Four-core Power Cable

5-1

Page 48

ZXCBTS (V5.4) CDMA Micro Base Transceiver Station & Remote Station Installation Manual

Table 5.1-1 Corresponding Relationship between Core Wires and Binding Posts

Binding Post No. Color of Core Wire Power Polarity

1 Blue -48V

2 Red -48V

3 Black -48VGND

4 Olivine -48VGND

5.1.2 120V AC Power Cable

The ZTE 120V AC ZXCBTS equipment is equipped with a piece of 10m-long cable,

which can meet the installation requirement in most cases. If you need to assemble the

cable connector on site in special cases, follow the instructions in this section. The AC

power cable connector is a three-pin connector, and the power cable adopts three-core

cable. Refer to Table 5.1-2 for the corresponding relationship between the core wires

and the binding posts.

Table 5.1-2 Corresponding Relationship between Core Wires and Binding Posts

Binding Post No. Color of Core Wire Power Polarity

1 Yellow and green PE

2 Brown L

3 Blue N

5.2 Connection of Power Cables

120V AC power supply and -48V DC power supply are used for the micro-BTS and

remote stations. A waterproof connector is used to connect the power to the POWER

terminal at the bottom of a cabinet, as shown in Fig. 5.2-1.

1. Select a suitable type of power cable.

If the cabinet is installed outdoors, outdoor shielded power cables should be

used for power supply, which can withstand the influences of ultraviolet lights,

rains and temperature changes. If common three-core AC power cables are used

in special cases, PVC pipes should be added for protection.

If the cabinet is installed indoors, common three-core power cables can be used

for power supply.

5-2

Page 49

Chapter 5 Installation of Power Supply System

a

r

R

m

2. Power cables should be laid in order. If they are laid in parallel with T1 signal

cables, an interval of 200mm is required between them.

3. Upon bundling of power cables, the space between two cable ties should be less

than 0.5m to prevent friction with the tower upon swing of cables and avoid

damage of power cable sheath.

The power cable with

round connector fo

connecting the POWE

terminal at the botto

of the cabinet

PGND terminal

of the cabinet

Fig. 5.2-1 Connection of Power Cables and Grounding Cables at the Bottom of a Cabinet

5.3 Assembling Power Cable Connector

5.3.1 Assembling -48V DC Power Cable Connector

Step 1: Put the connector components 1, 2, 3, 4 and 5 onto the cable, as shown in Fig.

5.3-1.

4

5

3

2

1

Fig. 5.3-1 Assembling a Power Cable Connector (step 1)

5-3

Page 50

ZXCBTS (V5.4) CDMA Micro Base Transceiver Station & Remote Station Installation Manual

Step 2: Strip the 17mm-long sheath off the four-core cable at the end to be welded. If

the sheath of more than 17mm is stripped, the component 3 cannot press the cable tight;

if less than 17mm, inconvenience might be caused for installation. See Fig. 5.3-2.

4

3

2

1

5

Fig. 5.3-2 Assembling a Power Cable Connector (step 2)

Step 3: Strip the 5mm-long insulation layer off the four core wires respectively, twist

up the copper core wires and brush a slice layer of soldering tin on them, and then put a

10~15mm-long heat-shrink tube onto each core wire.

Step 4: Joint the core wires respectively with the binding posts of the component 6 by

welding them, push the heat-shrink tubes to the proper position and then make them

shrink, as shown in Fig. 5.3-3. Refer to Table 5.1-1 for the corresponding relationship

between the core wires and the binding posts.

4

3

2

1

6

5

Fig. 5.3-3 Assembling a Power Cable Connector (step 4)

5-4

Page 51

Chapter 5 Installation of Power Supply System

Step 5: Screw to connect the component 5 with the component 6, as shown in Fig.

5.3-4.

4

3

2

1

6

5

Fig. 5.3-4 Assembling a Power Cable Connector (step 5)

Step 6: Push the components 2, 3 and 4 into the component 5, and then screw down the

component 1 onto the component 5. Be sure to screw the component 1 but not 5. See

Fig. 5.3-5.

1

6

5

Fig. 5.3-5 Assembling a Power Cable Connector (step 6)

5.3.2 Assembling 120V AC Power Cable Connector

The steps for assembling an AC power cable connector are the same as that for

assembling a DC power cable connector. The only difference is that the three-pin

connector and three-core power cable are used for AC power cables. Refer to the

preceding contents for the procedures and Table 5.3-1 for the corresponding

relationship between the core wires and the binding posts.

5-5

Page 52

ZXCBTS (V5.4) CDMA Micro Base Transceiver Station & Remote Station Installation Manual

Table 5.3-1 Corresponding Relationship between Core Wires and Binding Posts

Binding Post No. Color of Core Wire Power Polarity

1 Yellow and green PE

2 Brown L

3 Blue N

5-6

Page 53

6 Installation of Grounding System

Summary

Describing the method for installing the grounding

system

6.1 Introduction to the Grounding System

This section details the procedures to install the grounding system, including grounding

copper busbar and feeder cable grounding kit.

Grounding aims to protecting both the human being and the equipment against

lightning shock and electromagnetic interference.

The grounding system is composed of indoor groundings, outdoor groundings and

underground grounding net.

The grounding system of a ultra-wide coverage micro-BTS includes protection