Page 1

ZXC10 CBTS

CDMA2000 Compact Base Transceiver

Station

Installation Manual

ZTE CORPORATION

ZTE Plaza, Keji Road South,

Hi-Tech Industrial Park,

Nanshan District, Shenzhen,

P. R. China

518057

Tel: (86) 755 26771900 800-9830-9830

Fax: (86) 755 26772236

URL: http://support.zte.com.cn

E-mail: doc@zte.com.cn

Page 2

LEGAL INFORMATION

Copyright © 2005 ZTE CORPORATION.

The contents of this document are protected by copyright laws and international treaties. Any reproduction or distribution of

this document or any portion of this document, in any form by any means, without the prior written consent of ZTE

CORPORATION is prohibited. Additionally, the contents of this document are protected by contractual confidentiality

obligations.

All company, brand and product names are trade or service marks, or registered trade or service marks, of ZTE

CORPORATION or of their respective owners.

This document is provided “as is”, and all express, implied, or statutory warranties, representations or conditions are

disclaimed, including without limitation any implied warranty of merchantability, fitness for a particular purpose, title or non-

infringement. ZTE CORPORATION and its licensors shall not be liable for damages resulting from the use of or reliance on

the information contained herein.

ZTE CORPORATION or its licensors may have current or pending intellectual property rights or applications covering the

subject matter of this document. Except as expressly provided in any written license between ZTE CORPORATION and its

licensee, the user of this document shall not acquire any license to the subject matter herein.

The contents of this document and all policies of ZTE CORPORATION, including without limitation policies related to support

or training are subject to change without notice.

Revision History

Date Revision No. Serial No. Description

04/04/2006 R1.0

sjzl20060563

CDMA2000 Compact Base Transceiver Station - English

Contents

Page 3

ZTE CORPORATION

Values Your Comments & Suggestions!

Your opinion is of great value and will help us improve the quality of our

product documentation and offer better services to our customers.

Please fax to: (86) 755-26772236; or mail to Publications R&D

Department, ZTE CORPORATION, ZTE Plaza, A Wing, Keji Road South,

Hi-Tech Industrial Park, Shenzhen, P. R. China 518057.

Thank you for your cooperation!

Document

Name

Product

Version

Equipment Installation Date

Your evaluation

of this

documentation

Your

suggestions for

improvement

of this

documentation

ZXC10 CBTS CDMA2000 Compact Base Transceiver Station Installation Manual

Presentation:

(Introductions, Procedures, Illustrations, Completeness, Level of Detail, Organization,

Appearance)

Good Fair Average Poor Bad N/A

Accessibility:

(Contents, Index, Headings, Numbering, Glossary)

Good Fair Average Poor Bad N/A

Intelligibility:

(Language, Vocabulary, Readability & Clarity, Technical Accuracy, Content)

Good Fair Average Poor Bad N/A

Please check the suggestions which you feel can improve this documentation:

Improve the overview/introduction Make it more concise/brief

Improve the Contents

Improve the organization

Include more figures

Add more/better quick reference aids Add more detail

Other suggestions

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

# Please feel free to write any comments on an attached sheet.

Document

Revision Number

Add more step-by-step procedures/tutorials

Add more troubleshooting information

Make it less technical Add more examples

Improve the index

If you wish to be contacted regarding your comments, please complete the following:

Name Company

Postcode Address

Telephone E-mail

Page 4

This page is intentionally blank.

Page 5

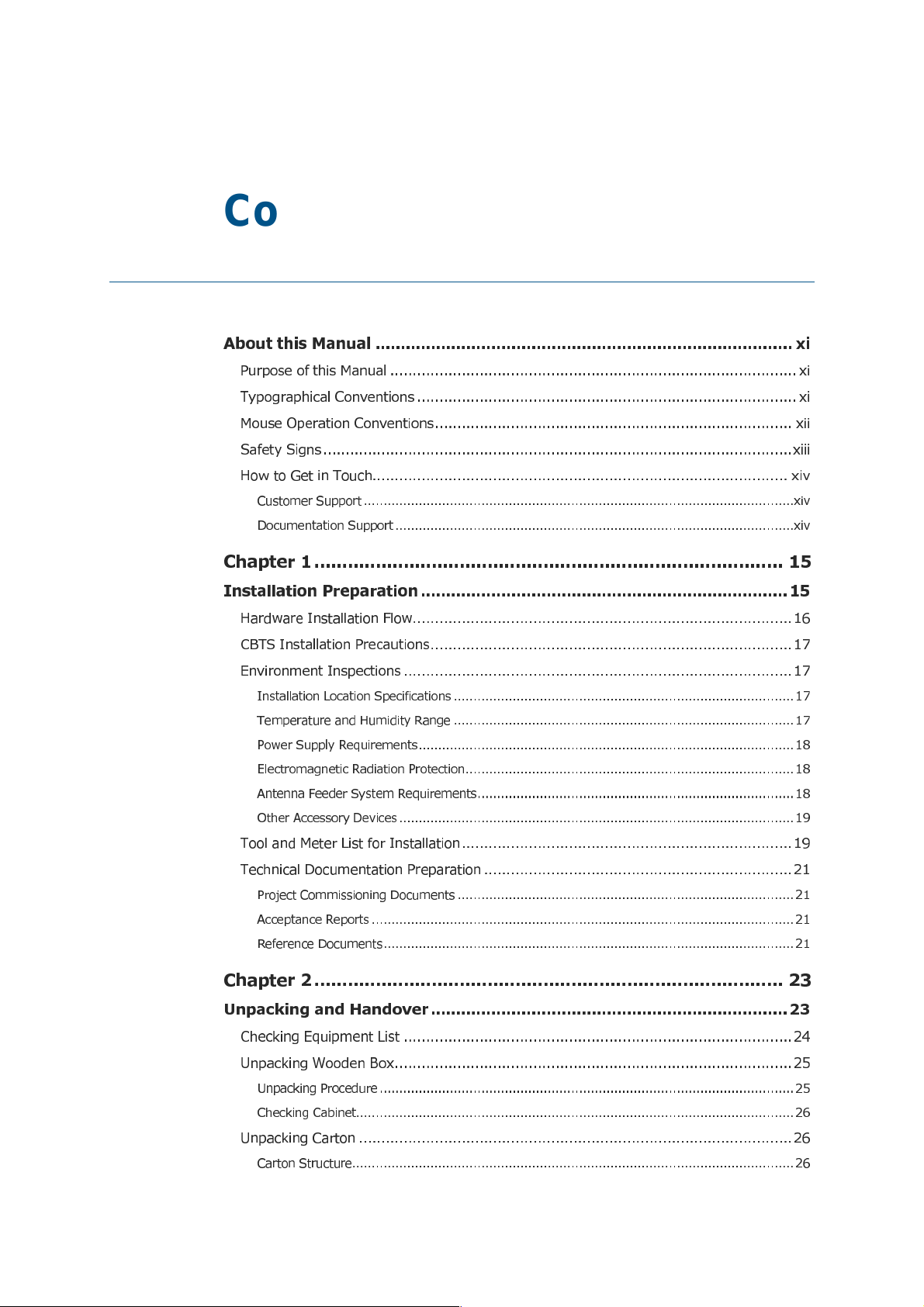

Contents

About this Manual ...................................................................................xi

Purpose of this Manual ........................................................................................... xi

Typographical Conventions.....................................................................................xi

Mouse Operation Conventions................................................................................ xii

Safety Signs.........................................................................................................xiii

How to Get in Touch............................................................................................. xiv

Customer Support..............................................................................................................xiv

Documentation Support......................................................................................................xiv

Chapter 1.................................................................................... 15

Installation Preparation.........................................................................15

Hardware Installation Flow.....................................................................................16

CBTS Installation Precautions.................................................................................17

Environment Inspections.......................................................................................17

Installation Location Specifications .......................................................................................17

Temperature and Humidity Range.......................................................................................17

Power Supply Requirements................................................................................................18

Electromagnetic Radiation Protection....................................................................................18

Antenna Feeder System Requirements.................................................................................18

Other Accessory Devices.....................................................................................................19

Tool and Meter List for Installation..........................................................................19

Technical Documentation Preparation.....................................................................21

Project Commissioning Documents ......................................................................................21

Acceptance Reports............................................................................................................21

Reference Documents.........................................................................................................21

Chapter 2.................................................................................... 23

Unpacking and Handover.......................................................................23

Checking Equipment List .......................................................................................24

Unpacking Wooden Box.........................................................................................25

Unpacking Procedure..........................................................................................................25

Checking Cabinet................................................................................................................26

Unpacking Carton.................................................................................................26

Carton Structure.................................................................................................................26

Page 6

Unpacking Procedure..........................................................................................................26

Unpacking Precautions........................................................................................................27

Checking Boards.................................................................................................................27

Acceptance and Handover .....................................................................................27

Chapter 3.................................................................................... 29

Cabinet Installation................................................................................29

Cabinet Structure..................................................................................................30

Cabinet Installation Precautions..............................................................................31

Installation Location Specification...........................................................................31

Cabinet Installation Modes.....................................................................................32

Direct Installation Mode.........................................................................................33

Direct Installation Mode Flow...............................................................................................33

Direct Installation Mode Procedure.......................................................................................34

Adjustable Base Installation Mode ..........................................................................39

Adjustable Base Structure...................................................................................................40

Adjustable Base Installation Mode Flow ................................................................................41

Adjustable Base Installation Procedure.................................................................................42

Cabinet Accessories Installation...........................................................................................48

Cabling Runway .................................................................................................................48

CBTS Cabinet Interfaces........................................................................................49

Power Interface..................................................................................................................50

Feeder Cable Interface........................................................................................................50

E1/T1 Interfaces.................................................................................................................51

FE Interfaces......................................................................................................................51

Room Monitoring Interface..................................................................................................52

Order Wire Phone Interface.................................................................................................52

Power Monitoring Interface..................................................................................................53

External BDS Interface........................................................................................................53

External Monitoring Interface...............................................................................................54

GPS Interface.....................................................................................................................54

Chapter 4.................................................................................... 55

Cable Installation...................................................................................55

Power and Grounding Cables.................................................................................56

Power Cable Types.............................................................................................................56

Power Cable Preparation.....................................................................................................56

Power and Grounding Cable Connections..............................................................................57

Cable Installation Requirements...........................................................................................58

Trunk Cable Installation.........................................................................................60

T1 Cable Installation...........................................................................................................60

E1 Cable Installation...........................................................................................................61

Page 7

Trunk Cable Processing.......................................................................................................64

Trunk Cable Conversion ......................................................................................................66

E1/T1 Cable Installation Requirements.................................................................................68

Feeder cable installation......................................................................................................69

Chapter 5.................................................................................... 71

Monitoring System Installation..............................................................71

Smog Sensor Installation.......................................................................................72

Installation Procedure.........................................................................................................72

Terminal Connections .........................................................................................................73

Temperature and Humidity Sensor Installation........................................................73

Installation Procedure.........................................................................................................73

Terminal Connections .........................................................................................................75

Installation Precautions.......................................................................................................75

Infrared Sensor Installation....................................................................................75

External Monitoring Cable Installation.....................................................................77

Chapter 6.................................................................................... 79

Main Antenna Feeder System Installation.............................................79

Main Antenna System Installation ..........................................................................80

Antenna Installation Preparation..........................................................................................80

Antenna Installation Precautions..........................................................................................80

Main Antenna Feeder System Structure................................................................................80

Antenna Installation Technical Parameters............................................................................82

Antenna Installation Flow Chart...........................................................................................83

Selecting Installation Position...............................................................................................83

Moving and Hoisting Antenna ..............................................................................................83

Uni-Directional Antenna Installation.....................................................................................85

Omni-Directional Antenna Installation ..................................................................................87

Main Feeder Installation.........................................................................................88

Feeder Window Installation.................................................................................................89

Feeder Connector Preparation..............................................................................................90

Feeder Cutting ...................................................................................................................93

Jumper Installation.............................................................................................................93

Waterproofing Joints...........................................................................................................94

Feeder Grounding Clip Installation........................................................................................95

Routing Feeders.................................................................................................................96

Hoisting Feeders to Tower...................................................................................................97

CBTS Grounding System.....................................................................................................99

Grounding Principles.........................................................................................................100

Grounding Copper Busbar Installation................................................................................100

Lightning Arrester Installation............................................................................................101

Page 8

Routing Feeders into Equipment Room...............................................................................102

Chapter 7.................................................................................. 105

GPS Antenna Feeder System Installation............................................105

GPS Antenna Feeder System Structure.................................................................106

Installation Position and Requirements..................................................................107

Installation Requirements..................................................................................................108

Lightning Protection Requirements.....................................................................................109

NJ-9 Connector Preparation .................................................................................109

NJ-9 Connector ................................................................................................................109

Connector Preparation Procedure....................................................................................... 110

GPS Connector Installation check.......................................................................................115

Chapter 8.................................................................................. 117

Board Installation.................................................................................117

Installation Flow Chart.........................................................................................118

Installation Procedure and Precautions..................................................................119

CTSB Board Slot...............................................................................................................119

RFS Board Installation.......................................................................................................120

BDS Board Installation......................................................................................................121

Installation Precautions.....................................................................................................122

Chapter 9.................................................................................. 123

Hardware Installation Check ...............................................................123

Cabinet Installation Check...................................................................................124

Cabling Rack Installation Check............................................................................124

Cable Installation Check ......................................................................................125

Power and Grounding Cables.............................................................................................125

Trunk and RF Cables.........................................................................................................126

Board and Sensor Installation Check.....................................................................126

Antenna and GPS Feeder System Installation Check ..............................................127

1/2” Indoor Jumper..........................................................................................................127

Lightning arrester.............................................................................................................127

Main GPS Feeder..............................................................................................................127

Feeder Window and Waterproof Curve ...............................................................................128

Three – Way Feeder Clamp...............................................................................................128

1/2” Outdoor Jumper........................................................................................................129

Antenna...........................................................................................................................129

Feeder SWR.....................................................................................................................130

Environment Check.............................................................................................130

Chapter 10................................................................................ 131

Power On and Off Mechanism..............................................................131

Page 9

Power Supply Inspection .....................................................................................132

Power-on Procedure............................................................................................133

First Time Power-on..........................................................................................................133

Normal Power-on.............................................................................................................133

Power-off Procedure............................................................................................133

Appendix A ............................................................................... 135

Packing, Storage and Transportation ..................................................135

Packaging ..........................................................................................................136

Cabinet packing................................................................................................................136

Cabinet Packing Procedure................................................................................................137

Board Packing..................................................................................................................139

Board packing procedure...................................................................................................139

Base Packing....................................................................................................................144

Engineering Materials Packing............................................................................................144

Transportation....................................................................................................144

Storage..............................................................................................................145

Appendix B ............................................................................... 147

SiteMaster Usage..................................................................................147

Frequency Range Selection..................................................................................148

SiteMaster Check................................................................................................148

Feeder Input Parameters.....................................................................................148

Tester Installation...............................................................................................149

Measuring SWR ..................................................................................................149

Measuring DTF ...................................................................................................150

Appendix C ............................................................................... 151

Cabinet Working Modes .......................................................................151

Appendix D............................................................................... 153

Monitoring Cables Definition................................................................153

Acronyms.................................................................................. 157

Figures...................................................................................... 159

Tables....................................................................................... 163

Index ........................................................................................ 165

Page 10

This page is intentionally blank.

Page 11

About this Manual

Purpose of this Manual

This manual describes ZXC10 Compact Base Transceiver Station

hardware installation.

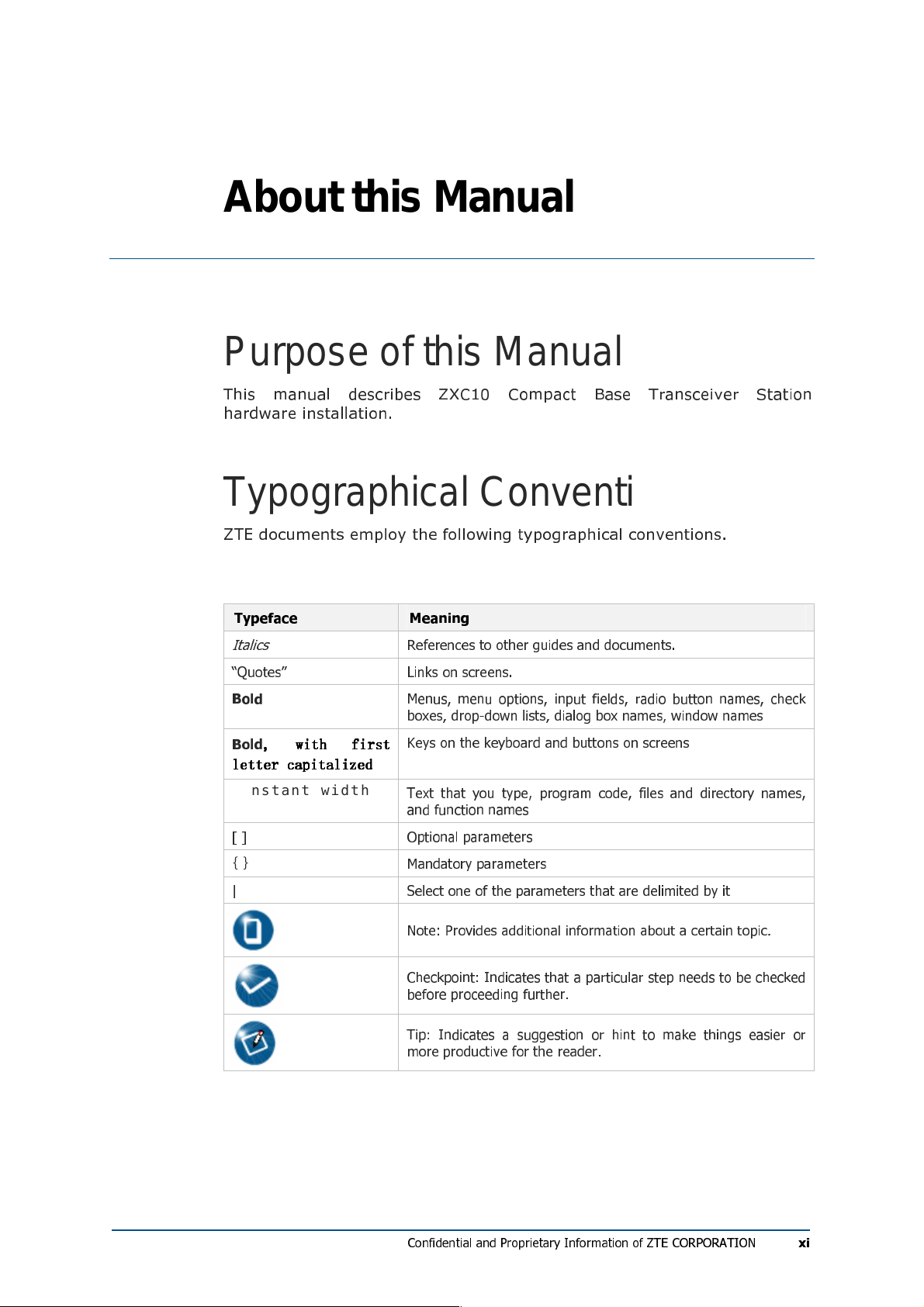

Typographical Conventions

ZTE documents employ the following typographical conventions.

TAB LE 1 - T YP OGR AP HI CAL CO NVE N TIO N S

Typeface Meaning

Italics

“Quotes” Links on screens.

Bold

Bold

, with first

, with first

, with first , with first

letter capitalized

letter capitalized

letter capitalizedletter capitalized

Constan t widt h

[ ] Optional parameters

{ }

| Select one of the parameters that are delimited by it

References to other guides and documents.

Menus, menu options, input fields, radio button names, check

boxes, drop-down lists, dialog box names, window names

Keys on the keyboard and buttons on screens

Text that you type, program code, files and directory names,

and function names

Mandatory parameters

Note: Provides additional information about a certain topic.

Checkpoint: Indicates that a particular step needs to be checked

before proceeding further.

Tip: Indicates a suggestion or hint to make things easier or

more productive for the reader.

Confidential and Proprietary Information of ZTE CORPORATION

xi

Page 12

ZXC10 CBTS I2 Installation Manual

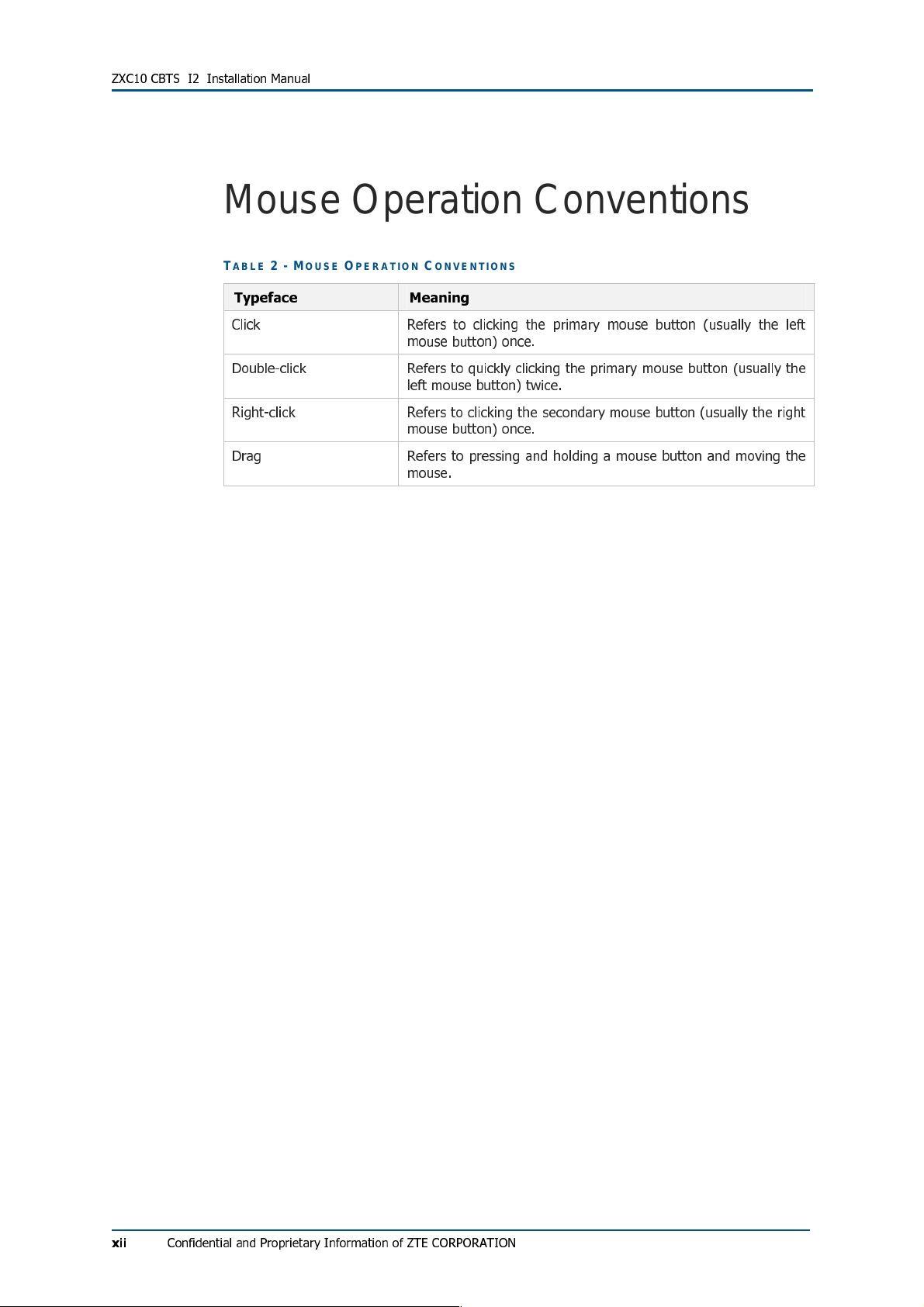

Mouse Operation Conventions

TAB LE 2 - M OUSE O PE RAT I ON CON VEN TI ON S

Typeface Meaning

Click Refers to clicking the primary mouse button (usually the left

Double-click Refers to quickly clicking the primary mouse button (usually the

Right-click Refers to clicking the secondary mouse button (usually the right

Drag Refers to pressing and holding a mouse button and moving the

mouse button) once.

left mouse button) twice.

mouse button) once.

mouse.

xii

Confidential and Proprietary Information of ZTE CORPORATION

Page 13

About this Manual

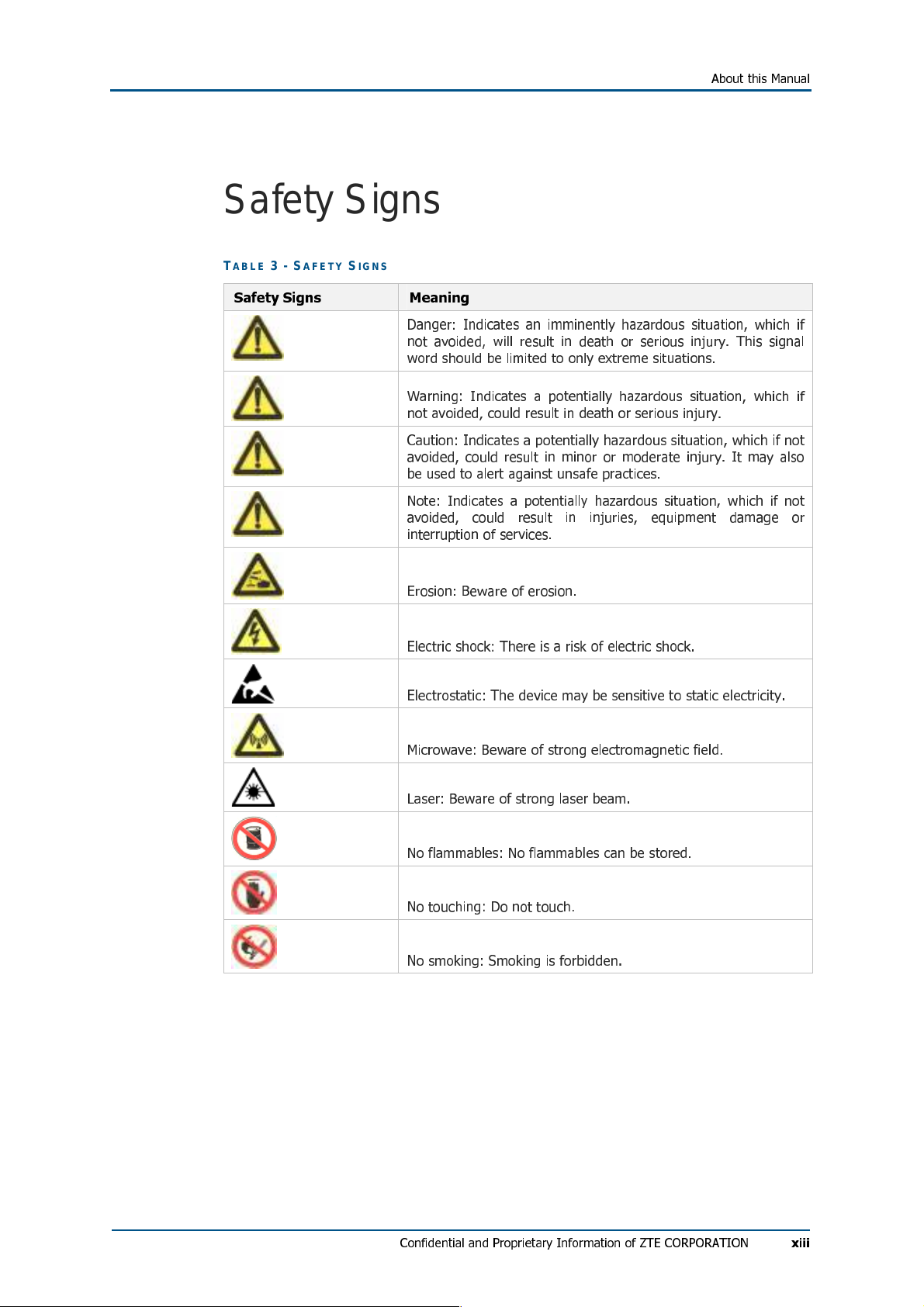

Safety Signs

TAB LE 3 - S AF ETY SIGN S

Safety Signs Meaning

Danger: Indicates an imminently hazardous situation, which if

not avoided, will result in death or serious injury. This signal

word should be limited to only extreme situations.

Warning: Indicates a potentially hazardous situation, which if

not avoided, could result in death or serious injury.

Caution: Indicates a potentially hazardous situation, which if not

avoided, could result in minor or moderate injury. It may also

be used to alert against unsafe practices.

Note: Indicates a potentially hazardous situation, which if not

avoided, could result in injuries, equipment damage or

interruption of services.

Erosion: Beware of erosion.

Electric shock: There is a risk of electric shock.

Electrostatic: The device may be sensitive to static electricity.

Microwave: Beware of strong electromagnetic field.

Laser: Beware of strong laser beam.

No flammables: No flammables can be stored.

No touching: Do not touch.

No smoking: Smoking is forbidden.

Confidential and Proprietary Information of ZTE CORPORATION

xiii

Page 14

ZXC10 CBTS I2 Installation Manual

How to Get in Touch

The following section provides information on how to obtain support for

the documentation and the software.

Customer Support

If you have problems, questions, comments, or suggestions regarding

your product, contact us by e-mail at support@zte.com.cn. You can also

call our customer support center at (86) 755 26771900 and (86) 800-

9830-9830.

Documentation Support

ZTE welcomes your comments and suggestions on the quality and

usefulness of this document. For further questions, comments, or

suggestions on the documentation, you can contact us by e-mail at

doc@zte.com.cn; or you can fax your comments and suggestions to (86)

755 26772236. You can also explore our website at

http://support.zte.com.cn, which contains various interesting subjects like

documentation, knowledge base, forum and service request.

FCC STATEMENT

Before using this CDMA ZXC10 CBTS I28A and CBTS I219, read this

important RF energy awareness and control information and operational

instructions to ensure compliance with the FCC RF exposure guidelines.

NOTICE: Working with the equipment while in operation, may expose the

technician to RF electromagnetic fields that exceed FCC rules for human

exposure. Visit the FCC website at www.fcc.gov/oet/rfsafety to learn more

about the effects of exposure to RF electromagnetic fields.

Changes or modifications to this unit not expressly approved by the party

responsible for compliance will void the user’s authority to operate the

equipment. Any change to the equipment will void FCC grant.

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to the FCC Rules. This equipment

generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that

xiv

interference will not occur in a particular installation.

Confidential and Proprietary Information of ZTE CORPORATION

Page 15

Cha p t e r 1

Installation Preparation

This chapter describes:

Hardware installation flow

CBTS installation precautions

Environment inspections

Installation location specifications

Temperature and humidity requirements

Power supply requirements

Electromagnetic radiation protection

Antenna feeder system requirements

Other accessory devices

Tool and meter list for installation

Technical documentation preparation

Project commissioning documents

Acceptance reports

Reference documents

Confidential and Proprietary Information of ZTE CORPORATION

15

Page 16

ZXC10 CBTS I2 Installation Manual

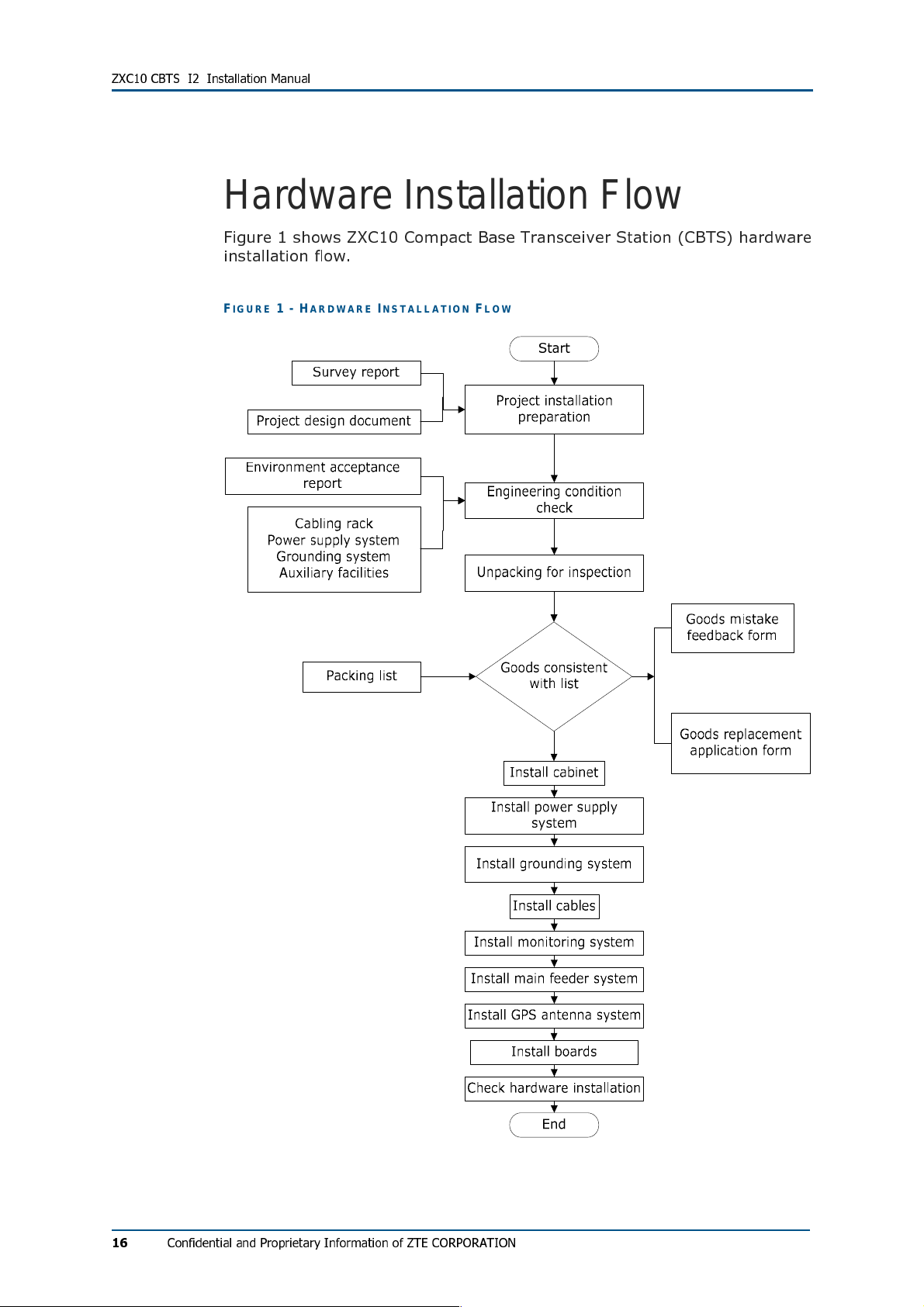

Hardware Installation Flow

Figure 1 shows ZXC10 Compact Base Transceiver Station (CBTS) hardware

installation flow.

FIG UR E 1 - HARD WARE I NS TAL L ATI O N FL OW

16

Confidential and Proprietary Information of ZTE CORPORATION

Page 17

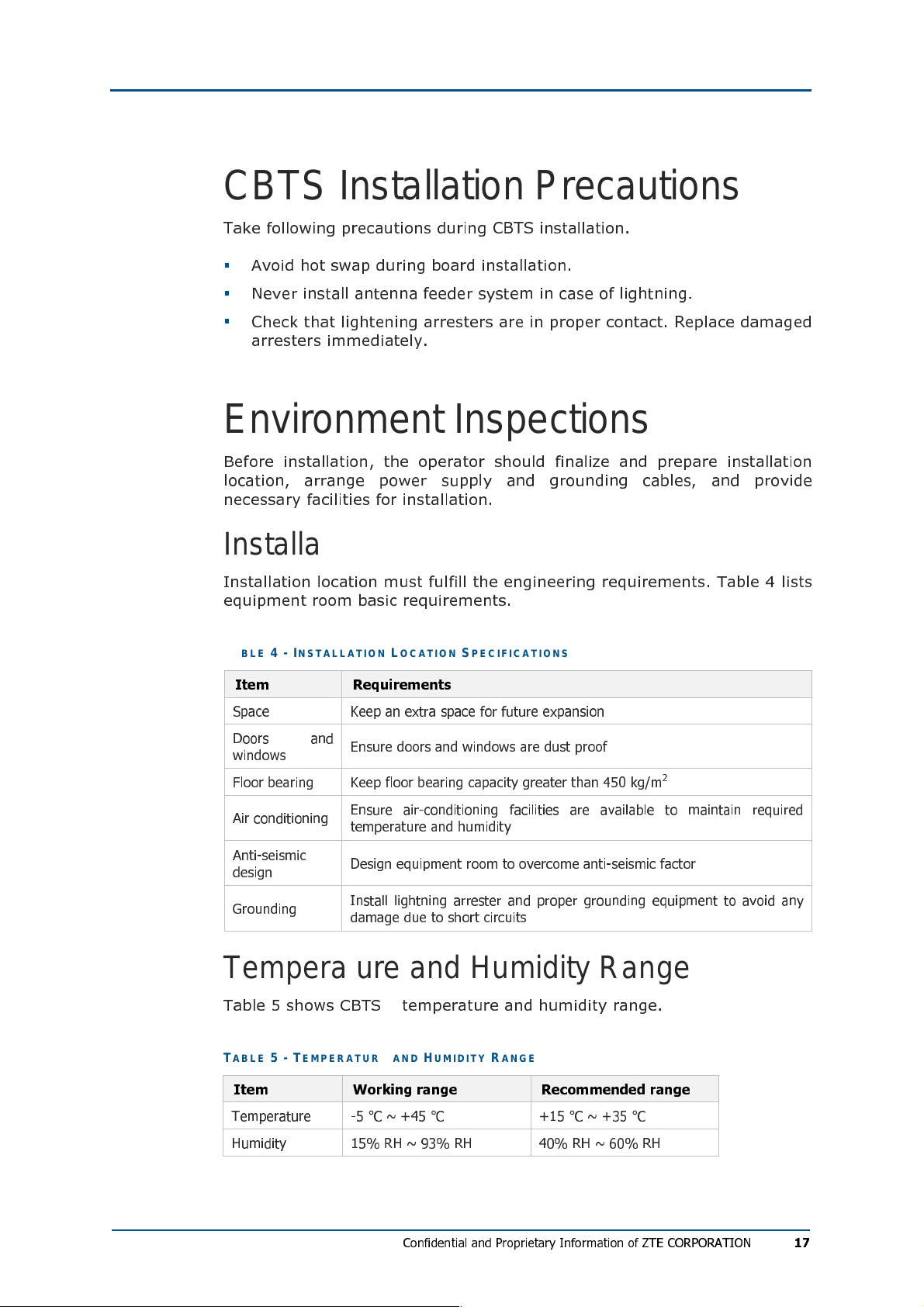

CBTS Installation Precautions

Take following precautions during CBTS installation.

Avoid hot swap during board installation.

Never install antenna feeder system in case of lightning.

Check that lightening arresters are in proper contact. Replace damaged

arresters immediately.

Environment Inspections

Before installation, the operator should finalize and prepare installation

location, arrange power supply and grounding cables, and provide

necessary facilities for installation.

Installation Location Specifications

Installation location must fulfill the engineering requirements. Table 4 lists

equipment room basic requirements.

TAB LE 4 - INST AL L ATI O N LO CATI ON SPE CIFI CATI ON S

Item Requirements

Space Keep an extra space for future expansion

Doors and

windows

Floor bearing Keep floor bearing capacity greater than 450 kg/m

Air conditioning

Anti-seismic

design

Grounding

Ensure doors and windows are dust proof

2

Ensure air-conditioning facilities are available to maintain required

temperature and humidity

Design equipment room to overcome anti-seismic factor

Install lightning arrester and proper grounding equipment to avoid any

damage due to short circuits

Temperature and Humidity Range

Table 5 shows CBTS temperature and humidity range.

TAB LE 5 - TEM PER AT U RE AN D HU MI DI TY R ANG E

Item Working range Recommended range

Temperature -5 °C ~ +45 °C +15 °C ~ +35 °C

Humidity 15% RH ~ 93% RH 40% RH ~ 60% RH

Confidential and Proprietary Information of ZTE CORPORATION

17

Page 18

ZXC10 CBTS I2 Installation Manual

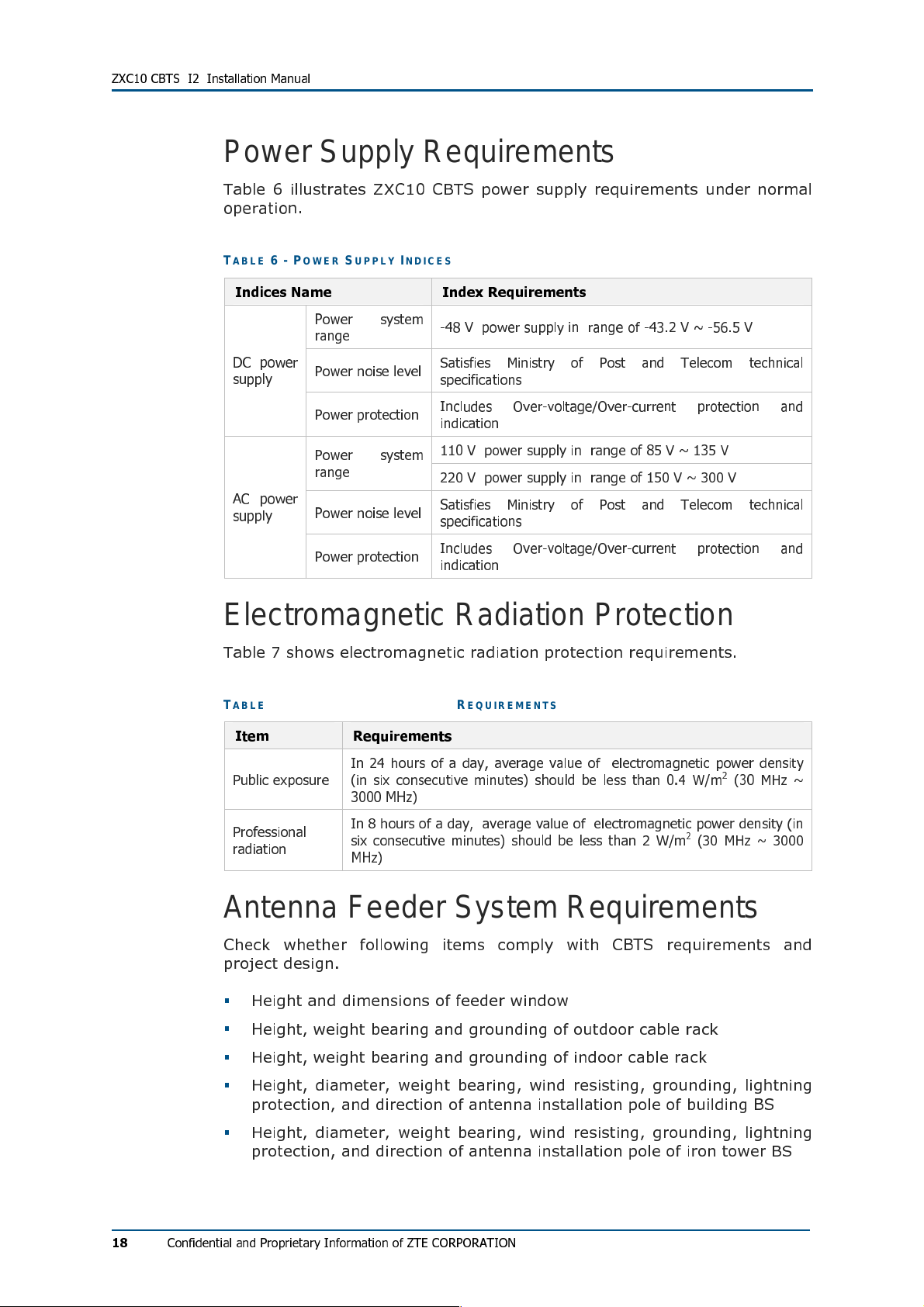

Power Supply Requirements

Table 6 illustrates ZXC10 CBTS power supply requirements under normal

operation.

TAB LE 6 - POWE R SUPP L Y INDI CE S

Indices Name Index Requirements

DC power

supply

AC power

supply

Power system

range

Power noise level

Power protection

Power system

range

Power noise level

Power protection

-48 V power supply in range of -43.2 V ~ -56.5 V

Satisfies Ministry of Post and Telecom technical

specifications

Includes Over-voltage/Over-current protection and

indication

110 V power supply in range of 85 V ~ 135 V

220 V power supply in range of 150 V ~ 300 V

Satisfies Ministry of Post and Telecom technical

specifications

Includes Over-voltage/Over-current protection and

indication

Electromagnetic Radiation Protection

Table 7 shows electromagnetic radiation protection requirements.

TAB LE 7 - R AD IAT I ON P RO TEC TI ON R EQU I REM E NTS

Item Requirements

In 24 hours of a day, average value of electromagnetic power density

Public exposure

(in six consecutive minutes) should be less than 0.4 W/m2 (30 MHz ~

3000 MHz)

18

Professional

radiation

In 8 hours of a day, average value of electromagnetic power density (in

six consecutive minutes) should be less than 2 W/m2 (30 MHz ~ 3000

MHz)

Antenna Feeder System Requirements

Check whether following items comply with CBTS requirements and

project design.

Height and dimensions of feeder window

Height, weight bearing and grounding of outdoor cable rack

Height, weight bearing and grounding of indoor cable rack

Height, diameter, weight bearing, wind resisting, grounding, lightning

protection, and direction of antenna installation pole of building BS

Height, diameter, weight bearing, wind resisting, grounding, lightning

protection, and direction of antenna installation pole of iron tower BS

Confidential and Proprietary Information of ZTE CORPORATION

Page 19

Other Accessory Devices

According to requirements in the contract, check whether following items

are available:

Cables for external power supply and cabinet

E1 cable connecting CBTS and BSC

Fire extinguisher

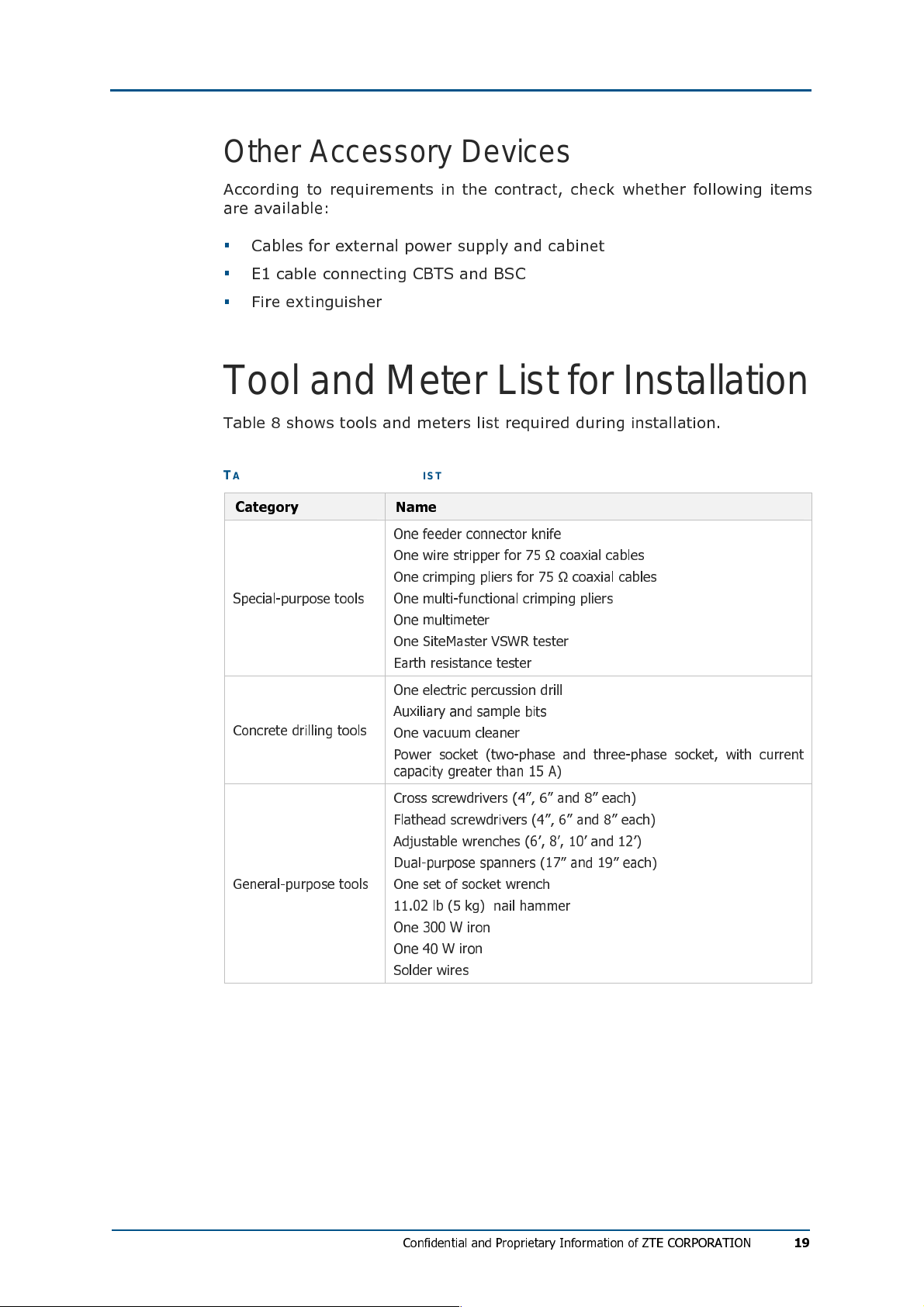

Tool and Meter List for Installation

Table 8 shows tools and meters list required during installation.

TAB LE 8 - TOO L AN D MET ER LIS T

Category Name

Special-purpose tools

Concrete drilling tools

General-purpose tools

One feeder connector knife

One wire stripper for 75 Ω coaxial cables

One crimping pliers for 75 Ω coaxial cables

One multi-functional crimping pliers

One multimeter

One SiteMaster VSWR tester

Earth resistance tester

One electric percussion drill

Auxiliary and sample bits

One vacuum cleaner

Power socket (two-phase and three-phase socket, with current

capacity greater than 15 A)

Cross screwdrivers (4”, 6” and 8” each)

Flathead screwdrivers (4”, 6” and 8” each)

Adjustable wrenches (6’, 8’, 10’ and 12’)

Dual-purpose spanners (17” and 19” each)

One set of socket wrench

11.02 lb (5 kg) nail hammer

One 300 W iron

One 40 W iron

Solder wires

Confidential and Proprietary Information of ZTE CORPORATION

19

Page 20

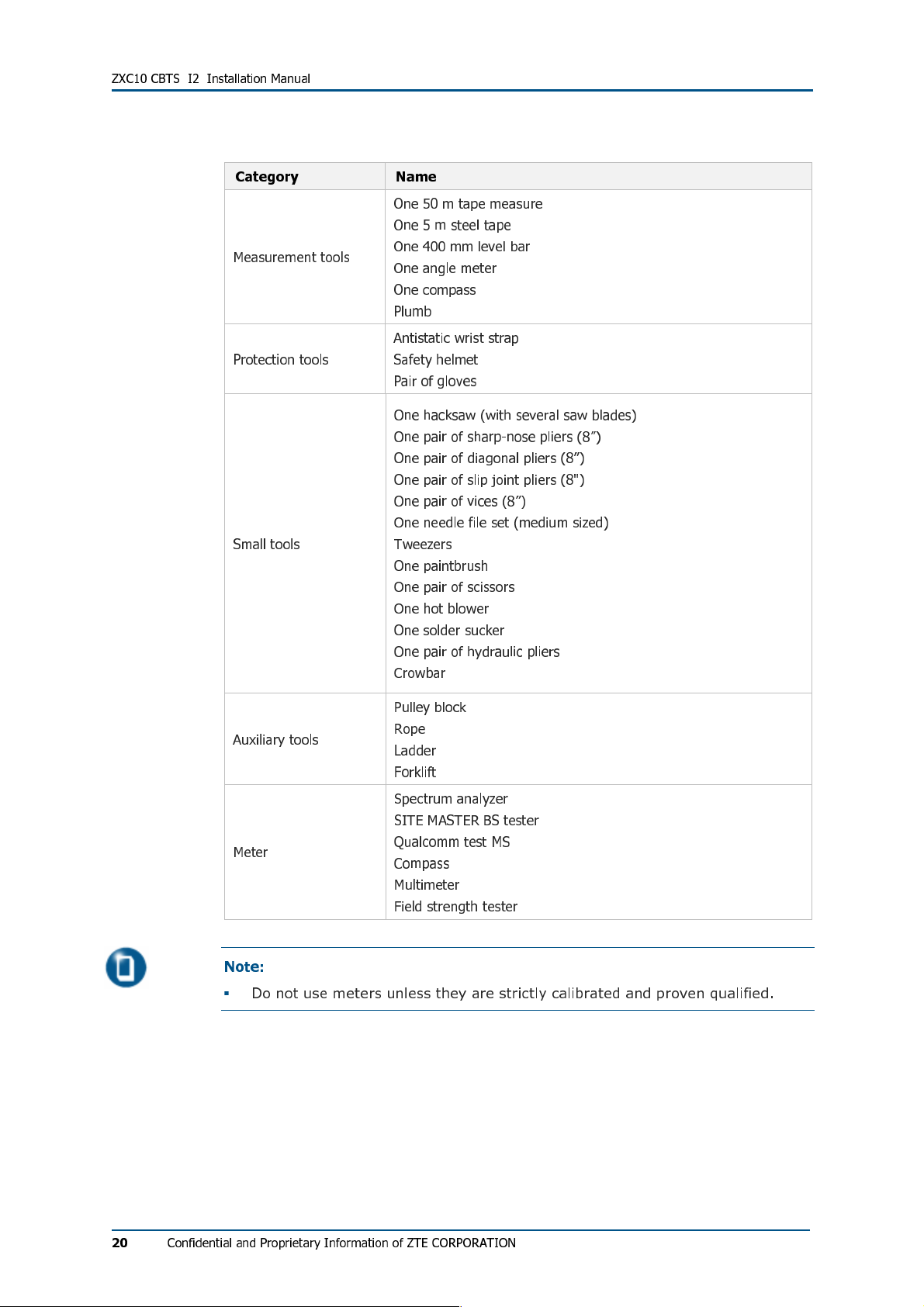

ZXC10 CBTS I2 Installation Manual

Category Name

Measurement tools

Protection tools

Small tools

One 50 m tape measure

One 5 m steel tape

One 400 mm level bar

One angle meter

One compass

Plumb

Antistatic wrist strap

Safety helmet

Pair of gloves

One hacksaw (with several saw blades)

One pair of sharp-nose pliers (8”)

One pair of diagonal pliers (8”)

One pair of slip joint pliers (8")

One pair of vices (8”)

One needle file set (medium sized)

Tweezers

One paintbrush

One pair of scissors

One hot blower

One solder sucker

One pair of hydraulic pliers

Crowbar

Pulley block

Auxiliary tools

Rope

Ladder

Forklift

Spectrum analyzer

SITE MASTER BS tester

Meter

Qualcomm test MS

Compass

Multimeter

Field strength tester

Note:

Do not use meters unless they are strictly calibrated and proven qualified.

20

Confidential and Proprietary Information of ZTE CORPORATION

Page 21

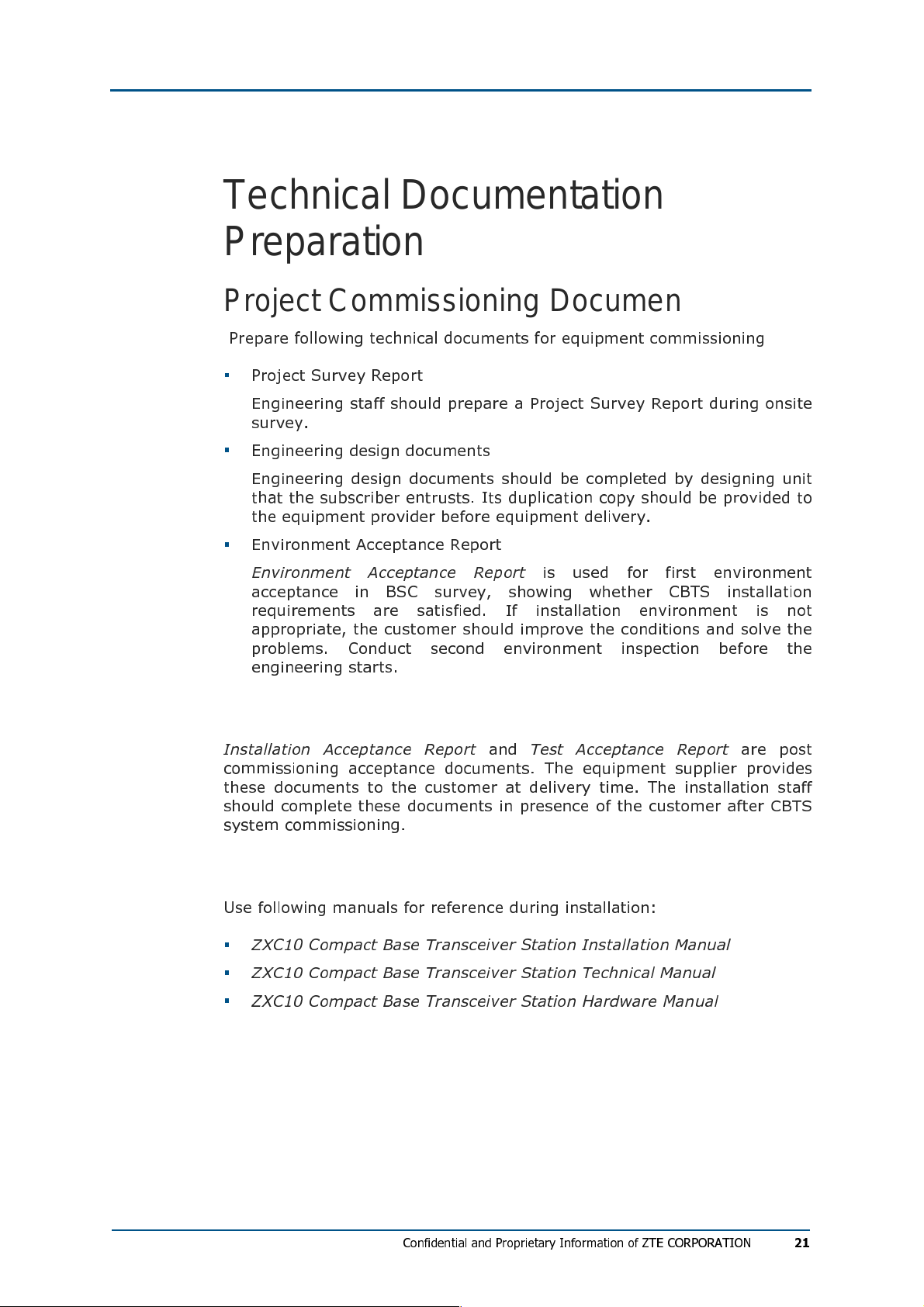

Technical Documentation

Preparation

Project Commissioning Documents

Prepare following technical documents for equipment commissioning

Project Survey Report

Engineering staff should prepare a Project Survey Report during onsite

survey.

Engineering design documents

Engineering design documents should be completed by designing unit

that the subscriber entrusts. Its duplication copy should be provided to

the equipment provider before equipment delivery.

Environment Acceptance Report

Environment Acceptance Report

acceptance in BSC survey, showing whether CBTS installation

requirements are satisfied. If installation environment is not

appropriate, the customer should improve the conditions and solve the

problems. Conduct second environment inspection before the

engineering starts.

is used for first environment

Acceptance Reports

Installation Acceptance Report

commissioning acceptance documents. The equipment supplier provides

these documents to the customer at delivery time. The installation staff

should complete these documents in presence of the customer after CBTS

system commissioning.

and

Test Acceptance Report

are post

Reference Documents

Use following manuals for reference during installation:

ZXC10 Compact Base Transceiver Station Installation Manual

ZXC10 Compact Base Transceiver Station Technical Manual

ZXC10 Compact Base Transceiver Station Hardware Manual

Confidential and Proprietary Information of ZTE CORPORATION

21

Page 22

ZXC10 CBTS I2 Installation Manual

This page is intentionally blank.

22

Confidential and Proprietary Information of ZTE CORPORATION

Page 23

Cha p t e r 2

Unpacking and Handover

This chapter describes:

Checking equipment list

Unpacking wooden case

Unpacking procedure

Checking cabinet

Unpacking carton

Carton structure

Unpacking procedure

Unpacking precautions

Checking boards

Acceptance and handover

Confidential and Proprietary Information of ZTE CORPORATION

23

Page 24

ZXC10 CBTS I2 Installation Manual

Checking Equipment List

Count goods during unpacking and note following points:

Check

Check total number of goods, intactness of packing boxes, and check

whether arrival place is actual installation place against packing list

number attached to packing boxes.

If goods are intact, start to unpack and inspect them.

Contact ZTE headquarters, if any item is damaged or missing during

unpacking inspection process.

Use appropriate tools to open cartons to avoid any equipment damage.

Note

Handle CBTS equipment with care and protect it from direct sunlight and rain.

Count goods against attached list and keep a record.

Delivery Checklist

:

of ZTE CORPORATION.

24

Confidential and Proprietary Information of ZTE CORPORATION

Page 25

Unpacking Wooden Box

Unpacking Procedure

Take following steps to unpack a wooden box:

1. Arrange appropriate tools such as nail hammer, pliers, straight

screwdriver and crowbar.

2. Insert a flat-tip screwdriver into slit between case and front cover

board to make it loose. Then insert a crowbar to unclench cover board.

3. Erect wooden case. Make sure that supports are at the bottom and pull

cabinet out from case gently.

4. Remove packing adhesive cabinet tape.

Note:

Handle CBTS cabinet with care during movement to avoid damage.

Confidential and Proprietary Information of ZTE CORPORATION

25

Page 26

ZXC10 CBTS I2 Installation Manual

Checking Cabinet

Check cabinet according to p

There are no dents, bulges, scratches, peels, blithers, blisters or

smudges on outer surface of cabinets.

Busbars, fans and installation positions on cabinets are free from

damage or distortion.

Cabinet slots for plug-in frames are intact. Guide rails of plug-in slots

are not damaged.

Installation slot labels are intact.

Fastening screws are not loosen, disconnected, or mistakenly placed.

Accessories and fittings needed for cabinet installation are complete.

acking list and

ensure following:

Unpacking Carton

Carton Structure

Figure 2 shows carton box structure.

FIG UR E 2 - CART ON BOX

ZXC10 CBTS I2

Unpacking Procedure

Take following steps to unpack a carton:

1. Use diagonal pliers to cut packing straps.

26

2. Use a paper knife to cut adhesive tape along slits on carton covers.

Confidential and Proprietary Information of ZTE CORPORATION

Page 27

Unpacking Precautions

Take following precautions to unpack carton:

Take anti-static measures to avoid equipment damage.

To avoid damage to goods, do not cut too deep.

Wait for 30 minutes before unpacking equipment, when equipment is

moved from a colder and drier place to a hotter and damper place.

Properly recycle desiccants.

Checking Boards

Check quality, quantity, type, cracks and model of all boards inside carton

against packing list provided by ZTE office.

Acceptance and Handover

Upon completion of unpacking, representative of customer and project

supervisor should sign

acceptance. Each party should have a copy of

Report.

Unpacking for Inspection Report

Unpacking for Inspection

to acknowledge

Confidential and Proprietary Information of ZTE CORPORATION

27

Page 28

ZXC10 CBTS I2 Installation Manual

This page is intentionally blank.

28

Confidential and Proprietary Information of ZTE CORPORATION

Page 29

Cha p t e r 3

Cabinet Installation

This chapter describes:

Cabinet structure

Cabinet installation precautions

Installation location specification

Cabinet installation modes

Direct installation

Direct installation mode flow

Direct installation mode procedure

Adjustable base installation

Adjustable base structure

Adjustable base installation mode flow

Adjustable base installation procedure

Cabinet accessories installation

Cabling runway

CBTS cabinet interfaces

Power interface

Feeder cable interface

E1 and T1 cable interface

FE cable interface

Room monitoring interface

Order wire phone interface

Power monitoring interface

External BDS interface

External monitoring interface

GPS cable interface

Confidential and Proprietary Information of ZTE CORPORATION

29

Page 30

ZXC10 CBTS I2 Installation Manual

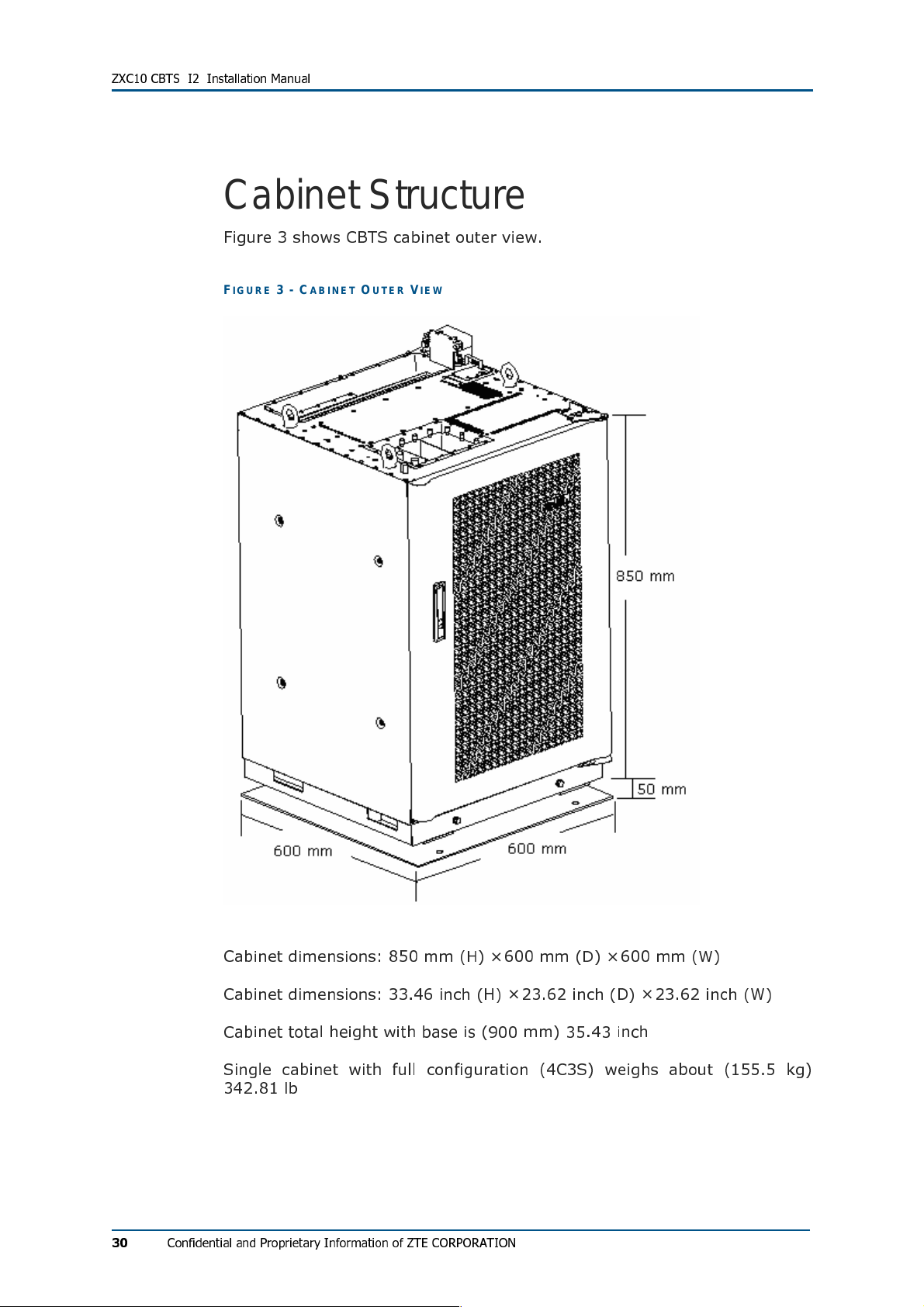

Cabinet Structure

Figure 3 shows CBTS cabinet outer view.

FIG UR E 3 - CABI NE T OU TE R VI EW

30

Cabinet dimensions: 850 mm (H) × 600 mm (D) × 600 mm (W)

Cabinet dimensions: 33.46 inch (H) × 23.62 inch (D) × 23.62 inch (W)

Cabinet total height with base is (900 mm) 35.43 inch

Single cabinet with full configuration (4C3S) weighs about (155.5 kg)

342.81 lb

Confidential and Proprietary Information of ZTE CORPORATION

Page 31

Cabinet Installation Precautions

Install cabinet according to engineering design specifications.

Vertical and horizontal errors should be less than 0.1181 inch (0.3 m)

and 0.196 inch (0.5 m) respectively.

Screw all nuts and bolts tightly.

Handle equipment carefully.

Installation Location Specification

Below figure illustrates installation equipment room specifications:

From top view distance between walls and cabinet must be more than

1.96 inch (600 mm) indicated by letter C.

When cabinet is installed with other equipment distance between

cabinets must be installed as close as possible, indicated by letter A

and B. When cabinet is installed beside walls distance between cabinet

and wall must be more than (100 mm) 3.93 inch indicated by letter A

and B.

Minimum distance between cabinet top and roof must be more than

19.68 inch (500 mm). Minimum distance between front cabinet and

wall or other cabinet must be more than 31.49 inch (800 mm).

Figure 4 shows CBTS cabinet installation location specification.

FIG UR E 4 - INS T AL LAT I ON L OCA T ION SP ECIF IC ATI O N

Confidential and Proprietary Information of ZTE CORPORATION

31

Page 32

ZXC10 CBTS I2 Installation Manual

Cabinet Installation Modes

ZXC10 CBTS cabinet installation modes:

Direct installation mode

Follow direct installation mode when equipment room is without

antistatic floor.

Adjustable base installation mode

Follow adjustable base installation mode when equipment room has

antistatic floor.

32

Confidential and Proprietary Information of ZTE CORPORATION

Page 33

Direct Installation Mode

This section describes CBTS cabinet direct installation mode installation

procedure.

Direct Installation Mode Flow

Figure 5 illustrates direct installation mode flow chart.

FIG UR E 5 - DI REC T I NST AL LA TI ON M ODE FLOW CHA R T

Start

Holes marking and positioning

Drilling holes

Installing expansion bolts

Fixing cabinet base

Insulation test

Yes

No

Fixing cabinet

End

Confidential and Proprietary Information of ZTE CORPORATION

33

Page 34

ZXC10 CBTS I2 Installation Manual

Direct Installation Mode Procedure

Take following steps for direct base installation mode:

1. Hole Marking and Positioning

Use lineation model to determine position of cabinet base and draw

lines according to provided template. If template is not available

determine holes position according to engineering design drawings.

Figure 6 illustrates this process.

FIG UR E 6 - HO LES PO SIT I ON I N DI RE CT INS TAL L ATI O N MO DE (UN ITS MM)

2. Drilling holes

For M12 expansion bolt, use φ 10 drilling bit to drill 3.149 inch (80 mm)

deep hole. Use vacuum cleaner to clean dust meanwhile.

3. Installing expansion bolts

Put tubes in drilled holes and hammer them and insert expansion bolts.

Fix bolt with nut and remove nut for cabinet installation. Figure 7

illustrates this process.

FIG UR E 7 - EXP AN SI ON BOL TS INS TALL AT ION

34

Confidential and Proprietary Information of ZTE CORPORATION

Page 35

4. Fixing cabinet base

Take following steps to fix cabinet base:

i. Move cabinet to installation position. Figure 8 illustrates to install

all items one by one on foundation.

FIG UR E 8 - CABI NE T BAS E FI XI NG

1. Hexagonal nut 2. Frame

3. Insulation board 4. Level adjusting washer

5. Hexagonal nut 6. Plain washer

7. Spring washer 8. Insulating washer

ii. Adjust base level with adjusting washer.

iii. Tight expansion bolts screw with wrench.

Figure 9 shows cabinet base installation final view.

FIG UR E 9 - CABI NE T BAS E IN STAL LATI ON

Confidential and Proprietary Information of ZTE CORPORATION

35

Page 36

ZXC10 CBTS I2 Installation Manual

5. Insulation test

Use multimeter to measure resistance between expansion bolts and

cabinet. Open circuit indicates proper insulation. If result is otherwise,

check insulation again and repeat the test.

6. Cabinet fixing

Take following steps to fix cabinet:

Take out front side screws and washer from cabinet base to fix

cabinet. Figure 10 illustrates this process.

FIG UR E 10 - U NIN S TAL L ING SC RE WS AN D WASH ER S

1. Screw

Place cabinet on cabinet base from front side. Figure 11 illustrates

this process.

FIG UR E 11 - P LACI NG CA B INE T ON B ASE

36

Confidential and Proprietary Information of ZTE CORPORATION

Page 37

Push cabinet gently and slide on rails until it adjusts at cabinet base

ends. Figure 12 illustrates this process.

FIG UR E 12 - ADJ US TIN G CAB IN ET O N BAS E

Use screws and washers to fix cabinet with base. Figure 13

illustrates this process.

FIG UR E 13 - FIXI N G CAB I NET AN D BA SE

Confidential and Proprietary Information of ZTE CORPORATION

37

Page 38

ZXC10 CBTS I2 Installation Manual

Figure 14 shows CBTS direct installation mode final view.

FIG UR E 14 - D IRE C T IN STAL LATI ON M ODE FI NAL VIEW

38

Confidential and Proprietary Information of ZTE CORPORATION

Page 39

Adjustable Base Installation Mode

This section describes adjustable base installation mode. Use two types of

cabinet bases: fixed and adjustable. Figure 15 shows position of antistatic

floor, adjustable base and cemented floor.

FIG UR E 15 - ADJ US TAB L E BA S E INS TALL AT ION MODE

1. Antistatic floor 2. Adjustable base

3. Cemented floor

Slide cabinet onto cabinet base and fix adjustable base with cabinet base

using expansion bolts. To open door easily, keep distance between

antistatic floor and door in range of 0.39 inch (10 mm) ~ 1.57 inch (40

mm). Adjust base according to antistatic floor height in 0.98 inch (25 mm)

steps each time.

Confidential and Proprietary Information of ZTE CORPORATION

39

Page 40

ZXC10 CBTS I2 Installation Manual

Adjustable Base Structure

There are three adjustable base types: A, B and C. This section describes

type A. Use hexagonal nut to adjust base height according to conditions.

Figure 16 shows adjustable base structure.

FIG UR E 16 - ADJ US TAB L E BA S E

1. Upper frame 2. Upper leg

3. Lower leg 4. Lower frame

5. Hexagonal nut 6. Adjusting washer 1

7. Adjusting washer 2

Table 9 illustrates selection of adjustable base type according to antistatic

floor height.

TAB LE 9 - ADJ US TABL E BASE SELEC TI ON

Model Antistatic floor height

A 4.52 inch ~ 5.90 inch (115 mm ~ 150 mm)

B 6.49 inch ~ 9.84 inch (165 mm ~ 250 mm)

C 9.84 inch ~ 16.14 inch (250 mm ~ 410 mm)

40

Confidential and Proprietary Information of ZTE CORPORATION

Page 41

Adjustable Base Installation Mode Flow

Figure 17 shows adjustable base installation mode flow chart.

FIG UR E 17 - ADJ US TAB L E BA S E INS TALL AT ION MODE FLOW CH ART

Start

Cabinet positioning

Adjustable base positioning

Drilling holes

Installing expansion bolts

Fixing adjustable base

Fixing cabinet base

No

Insulation test

Yes

Fixing cabinet

End

Confidential and Proprietary Information of ZTE CORPORATION

41

Page 42

ZXC10 CBTS I2 Installation Manual

Adjustable Base Installation Procedure

Take following steps for adjustable base installation mode:

1. Cabinet positioning

Determine cabinet location according to specific engineering design

drawing.

2. Adjustable base positioning

Use lineation model to determine position of cabinet base and draw

lines according to provided template. If template is not available

determine holes position according to engineering design drawings.

Figure 18 illustrates this process.

FIG UR E 18 - H OLE S P OSI TI ON I N AD JUST AB LE B AS E INS TA LL ATIO N MO DE (UN IT S M M )

3. Drilling holes

For M12 expansion bolt, use φ14 drilling bit to drill 3.14 inch (80 mm)

deep hole. Use vacuum cleaner to clean dust meanwhile.

4. Installing expansion bolt

Put tubes in drilled holes and hammer them and insert expansion bolts.

Fix bolt with nut and remove nut for cabinet installation. Figure 19

illustrates this process.

FIG UR E 19 - E XPAN SI ON B OLT S INS TALL AT ION

42

Confidential and Proprietary Information of ZTE CORPORATION

Page 43

5. Fixing adjustable base

Take following steps to fix adjustable base:

i. Clean cabinet base and cemented floor, fix lower adjustable base

on floor with corresponding expansion bolts. Use plain and spring

washers with expansion bolts. Fix adjustable base on floor with

screw caps. Ensure that torque should be at least 45 Nm. Figure 20

shows lower adjustable base and cemented floor contact.

FIG UR E 20 - LOWE R ADJ US TAB L E BA SE AN D CE M ENTE D FLOO R

1. Adjustable base lower part 2. Screw cap

3. Spring Washer 4. Plain washer

Use washers to level floor when required. Figure 21 shows two types of

washer 0.039 inch and 0.078 inch (1 mm and 2 mm).

FIG UR E 21 - W ASH E RS SPE CIFI CATI ON S

1. 1 mm washer 2. 2 mm washer

Confidential and Proprietary Information of ZTE CORPORATION

43

Page 44

ZXC10 CBTS I2 Installation Manual

ii. Determine base upper part height according to antistatic floor

height. Fix upper and lower parts of base with bolts. Figure 22

illustrates this process.

FIG UR E 22 - B ASE UP PER PART INS TALL AT ION

1. Base upper part 2. Plain washer

3. Spring washer 4. Hexagonal bolt

Figure 23 shows adjustable base and floor after installation.

FIG UR E 23 - ADJ US TAB L E BA S E A N D FL OOR INS TA L LAT I ON F INA L V IEW

44

Confidential and Proprietary Information of ZTE CORPORATION

Page 45

6. Fixing cabinet base

Take following steps to fix cabinet:

i. Put insulating board on adjustable base and align all holes. Figure

24 illustrates to assemble cabinet base, spring washer and plain

washer.

FIG UR E 24 - FIXI N G CAB I NET BASE

1. Hexagonal nut 2. Plain washer

3. Insulating washer 4. Frame

5. Insulating board 6. Adjusting washer

Confidential and Proprietary Information of ZTE CORPORATION

45

Page 46

ZXC10 CBTS I2 Installation Manual

ii. Ensure cabinet base is at level and measure it by level ruler. Use

adjusting washer when required to level base.

iii. Use wrench to fix adjustable base and cabinet tightly. Figure 25

shows adjustable base installation final view.

FIG UR E 25 - ADJ US TAB L E BA S E I NS TALL AT ION FI NAL VIE W

7. Insulation Test

Use multimeter to measure resistance between expansion bolts and

cabinet. Open circuit indicates proper insulation. If result is otherwise,

check insulation again and repeat the test.

8. Cabinet fixing

Cabinet fixing is same as in direct installation mode.

46

Confidential and Proprietary Information of ZTE CORPORATION

Page 47

Figure 26 shows adjustable base installation mode final view.

FIG UR E 26 - ADJ US TAB L E BA S E INS TALL AT ION MODE FINAL V IE W

Confidential and Proprietary Information of ZTE CORPORATION

47

Page 48

ZXC10 CBTS I2 Installation Manual

Cabinet Accessories Installation

This section describes cabinet accessories installation.

Cabling Runway

Install cabling runway at cabinet top with four M4 X 10 bolts. Figure 27

shows cabling runway installation. Install converter on cabling runway with

four M3 X 12 bolts.

FIG UR E 27 - C ABL I NG RUN WAY

48

1. M3 X 12 bolt 2. Converter

3. Cabling tray/pipe 4. M4 x 10 bolt

Confidential and Proprietary Information of ZTE CORPORATION

Page 49

CBTS Cabinet Interfaces

This section describes CBTS cabinet interfaces. Figure 28 illustrates

various CBTS cabinet interfaces.

FIG UR E 28 - C BTS CA BI NET INT E RF ACE S

1. Power interface 2. BSC_E1_G0 interface

3. BSC_E1_G1 interface 4. FE interface group

5. ROOM_MON interface 6. O_PH interface

7. Power monitoring interface 8. EXT_BDS interface

9. EXT_MON interface 10. GPS interface

11. Feeder cable interface

Confidential and Proprietary Information of ZTE CORPORATION

49

Page 50

ZXC10 CBTS I2 Installation Manual

Power Interface

Power interface lies in upper right side in Figure 28. Power interface

consists of: PGND, -48 V GND and -48 V interfaces. Figure 29 shows

power interfaces.

FIG UR E 29 - P OWER I NTE RF AC ES

Feeder Cable Interface

Feeder cable interface lies in left lower side in Figure 30. CBTS has six

feeder cable interfaces. Figure 30 shows feeder cable interfaces.

FIG UR E 30 - FEED E R CA BL E IN TE RFA C E

50

Confidential and Proprietary Information of ZTE CORPORATION

Page 51

E1/T1 Interfaces

CBTS has a group of E1/T1 interfaces in a row. E1 interfaces are DB 44

connectors which lie in rightmost in Figure 28 marked as BSC.E1_G0 and

BSC.E1_G1. Figure 31 shows E1 interfaces.

FIG UR E 31 - C BTS E1 INTER FACE S

FE Interfaces

Figure 32 shows CBTS FE interfaces. There are eight FE interfaces laying

left to E1 interfaces in Figure 28 forming two rows.

Upper row consists of M_TEST, S_TEST, BSC_FE and R_TEST interfaces.

These interfaces are only used for testing low level messages and have

nothing to do in actual operation of CBTS. Use BSC_FE interface to

connect CBTS to BSC, when IP trunk is used to connect CBTS and BSC.

FIG UR E 32 - C BTS FE I NTER FACE S

Lower row consists of S_FE1, M_FE1, S_FE0 and M_FE0 interfaces. Use

these interfaces to connect multiple cabinets. Use M_FE1 and M_FE0 for

media and S_FE1 and S_FE0 for signal stream respectively.

Confidential and Proprietary Information of ZTE CORPORATION

51

Page 52

ZXC10 CBTS I2 Installation Manual

Room Monitoring Interface

Room monitoring interface (ROOM_MON) is DB44 connector laying left to

FE interfaces in Figure 28. Figure 33 shows room monitoring interface.

ROOM_MON interface is used to connect external monitoring cable.

FIG UR E 33 - C BTS RO OM M ONI TO RI NG INTER FACE

Order Wire Phone Interface

Order wire phone interface (O_PH) is RJ11 connecter laying left to

ROM_MON in Figure 28. O_PH interface is used to connect order phone

wire. Figure 34 shows CBTS O_PH interface.

FIG UR E 34 - C BTS OR DWER WI R E PHON E IN TER F ACE

52

Confidential and Proprietary Information of ZTE CORPORATION

Page 53

Power Monitoring Interface

Power monitoring interfaces are DB9 connectors laying left to O_PH

interface in Figure 28. Figure 35 shows power monitoring interfaces.

FIG UR E 35 - P OWER M ONI TO RI NG INT ERF AC ES

There are two power monitoring interfaces in CBTS cabinet: EXT_COM and

PWSB. Use PWSB power interface for connecting monitoring cables in ZTE

equipment only. For equipment other than ZTE use EXT_COM interface to

connect power monitoring cables.

External BDS Interface

External BDS (EXT_BDS) interface is a DB78 connector laying left to power

monitoring interfaces. Use external BDS interface to connect cabinets side

by side in baseband extension mode. Connect EXT_BDS interface of

Master and Slave cabinet. EXT_BDS interface transmits baseband

information. Figure 36 shows CBTS external BDS interface.

FIG UR E 36 - C BTS EX TE RNA L BDS IN TER F AC E

Connect adjacent master and slave ports using FE cables in BDS extend

mode.

Confidential and Proprietary Information of ZTE CORPORATION

53

Page 54

ZXC10 CBTS I2 Installation Manual

External Monitoring Interface

External monitoring (EXT_MON) interface is a DB44 connector laying left

to external BDS interface. Figure 37 shows CBTS external monitoring

interface.

FIG UR E 37 - C BTS EX TE RNA L MO NI TOR I NG INTER FACE

Connect master and slave CBTS cabinet side by side using EXT_MON

interface. It transmits environmental information from slave to master BTS.

GPS Interface

GPS interface lies in left lower side. Use GPS interface to connect GPS

antenna.

54

Confidential and Proprietary Information of ZTE CORPORATION

Page 55

Cha p t e r 4

Cable Installation

This chapter describes cable installation:

Power and grounding cables

Power cable types

Power cable preparation

Power and grounding cable connections

Cable installation requirements

Trunk cable installation

E1 cable installation

Trunk cable processing

Trunk cable conversion

E1 cable installation requirements

Feeder cable installation

Confidential and Proprietary Information of ZTE CORPORATION

55

Page 56

ZXC10 CBTS I2 Installation Manual

Power and Grounding Cables

Power Cable Types

There are three CBTS power cables, their specifications are as follows:

Blue cable with cross section area of 25 mm2 (for -48 V power supply).

Black cable with cross section area of 25 mm2 (for -48V working

ground).

Yellowish green cable with cross section area of 35 mm2 (for protection

ground).

Power Cable Preparation

Take following steps to prepare power cables:

1. Cutting

According to design drawing, cut cable with cutter.

2. Stripping

Take power cable length 0.787 inch (20 mm) ~ 0.11 inch (30 mm)

longer than effective crimping area of wiring terminal. Strip the sheath

with a cable stripper.

3. Crimping

Select a proper wiring terminal and crimp it with a pair of crimping

pliers. Figure 38 shows tightly crimped wiring terminal.

FIG UR E 38 - C RIM P ING PL IER S

1. Clamping tool

56

4. Wrapping

After crimping, wrap up joint with insulation tapes. Use two layers of

insulation tapes one layer overlapping other. Use same color of

insulation tapes used for power cable.

5. Labeling

Label power cables 0.19 inch (5 mm) away from wiring terminals on

both ends.

Confidential and Proprietary Information of ZTE CORPORATION

Page 57

another end

another end to

Power and Grounding Cable Connections

Figure 39 shows CBTS power and grounding cable connections top view.

FIG UR E 39 - C BTS PO WE R A ND GRO UND I NG C AB LE CO NN EC TIO N

Table 10 describes CBTS power and ground cables connection methods.

TAB LE 10 - PO WER AN D GR OUND IN G CAB LE C ONNE CTIO N

Cable Connection methods

----

48 V power

supply cable

----

48 V GND

cable

PE protection

grounding

cable

Connect one end to CBTS -48 V input terminal and

-

48 V rectifier output terminal

Connect one end to CBTS -48 V GND terminal and

-

48V rectifier GND output terminal

Connect one end to CBTS protection grounding terminal and

another end to indoor grounding bar.

Use 6 mm2 yellow/green shorted line as short-circuiting cable

between -48 V GND and PE terminals

Confidential and Proprietary Information of ZTE CORPORATION

57

Page 58

ZXC10 CBTS I2 Installation Manual

Caution:

Ensure that power and grounding cables are according to engineering

specifications and standards.

Take all measures to guarantee staff and equipment safety.

Cable Installation Requirements

Ensure following requirements during power and grounding cables

installation:

Install power supply and grounding cables separately.

Ensure that distance between cable bundles is at least 7.87 inch (200

mm).

Cut cable ties flat after making cable bundles.

Measure cable lengths before installation. Avoid cable connections or

welding.

Figure 40 illustrates this process.

FIG UR E 40 - P OWER S UPP L Y A N D GR OUND IN G CA BL ES

Ensure less contact resistance between cable and busbar by using plain

and spring washers while fixing the lugs.

Avoid overlapping lugs while connecting two or more cables at same

connection stud. In case if overlapping is unavoidable place bigger lug

under smaller one and bend upper lug at 450 or 900 angles.

58

Confidential and Proprietary Information of ZTE CORPORATION

Page 59

Figure 41 illustrates this process.

FIG UR E 41 - P OWER S UPP L Y CA BL E CO NNE C TIO N S

1. Copper busbar 2. Plain washer

3. Nut 4. Bolt

5. Cable 6. Spring washer

Confidential and Proprietary Information of ZTE CORPORATION

59

Page 60

ZXC10 CBTS I2 Installation Manual

Trunk Cable Installation

There are two types of trunk cables: E1 and T1 cables.

T1 Cable Installation

100Ω T1 cable structure

Figure 42 shows 32-core 100Ω T1 cable structure.

FIG UR E 42 - 1 00

ΩΩΩΩ

T1 CA BL E STR UC TU RE

100ΩT1 cable connection

Connect 100Ω T1 cable End A (left end in Figure 32) to BSC E1

interface of conversion board at CBTS top. Connect T1 cable End B

(right end in Figure 32) to DDF.

Table 11 describes 100 Ω T1 cable internal connections in detail.

TAB LE 11 - 10 0

ΩΩΩΩ

IN TE RNA L C ABL E CON NECT IONS

Wire color Wire color Wire number

Wire A Wire B

Wire number

Wire A Wire B

1 White Blue 9 Black Blue

Signal

definition

2 White Orange 10 Black Orange

Signal

definition

3 White Green 11 Black Green

Signal

definition

4 White Brown 12 Black Brown

60

Confidential and Proprietary Information of ZTE CORPORATION

RX0- RX0+

TX0-

RX1- RX1+

TX0+

RX4- RX4+

TX4-

RX5- RX5+

TX4+

Page 61

Wire color Wire color Wire number

Wire A Wire B

Wire number

Wire A Wire B

Signal

definition

5 Red Blue 13 Yellow Blue

Signal

definition

6 Red Orange 14 Yellow Orange

Signal

definition

7 Red Green 15 Yellow Green

Signal

definition

8 Red Brown 16 Yellow Brown

Signal

definition

TX1-

RX2- RX2+

TX2-

RX3- RX3+

TX3-

TX1+

TX0+

TX3+

TX5-

RX6- RX6+

TX6-

RX7- RX7+

TX7-

TX5+

TX6+

TX7+

Note:

For trunk cable details, see ZXC10 CBTS

Hardware Manual

.

This section describes processing and conversion of trunk cables taking a

75 Ohm E1 cable.

E1 Cable Installation

75 Ω E1 cable structure

75 Ω E1 cable contains 8 E1 signals and uses two 8-core coaxial cables.

Outer diameter of a single core cable is less than 0.08 inch (2 mm).

Figure 43 shows E1 cable structure.

FIG UR E 43 - 7 5

ΩΩΩΩ

E1 C AB LE S TR UCT U RE

Confidential and Proprietary Information of ZTE CORPORATION

61

Page 62

ZXC10 CBTS I2 Installation Manual

75 Ω E1 cable connection

Connect 75 Ω E1 cable End A (left end in Figure 43) to BSC E1 socket

of conversion board at CBTS top. Connect E1 cable End B (right end in

Figure 43) to corresponding E1 interface of conversion board on feeder

shelf.

Table 12 describes 75 Ω E1 cable internal connections in detail.

TAB LE 12 - 75

Signal

ΩΩΩΩ

E1 C AB LE IN TE RN AL CONNE CTIO NS

IN0 OUT0 IN1 OUT1

definition

End A pin

22 23 24 25 1 2 3 4

number

Cable number 1-1-internal

1-1-external

Signal

IN2 OUT2 IN3 OUT3

definition

End A pin

5 6 7 8 9 10 11 12

number

Cable number 1-5-internal

1-5-external

Signal

IN4 OUT4 IN5 OUT5

definition

End A pin

13 14 43 44 39 40 41 42

number

Cable number 2-1-internal

2-1-external

Signal

IN6 OUT6 IN7 OUT7

definition

1-2-internal

1-2-external

1-6-internal

1-6-external

2-2-internal

2-2-external

1-3-internal

1-3-external

1-7-internal

1-7-external

2-3-internal

2-3-external

1-4-internal

1-4-external

1-8-internal

1-8-external

2-4-internal

2-4-external

62

End A pin

35 36 37 38 31 32 33 34

number

Cable number 2-5-internal

2-5-external

2-6-internal

2-6-external

Note:

’1-1-internal and 1-1-external’ stands for internal and external conductors of

the 1st core in 8 core cable respectively.

Confidential and Proprietary Information of ZTE CORPORATION

2-7-internal

2-7-external

2-8-internal

2-8-external

Page 63

ellow red 1

rey red 1

reen red 2

ellow red 2

120Ω E1 cable structure

Figure 44 shows 32-core 120Ω E1 cable structure.

FIG UR E 44 - 1 20

ΩΩΩΩ

E1 CABL E STRU CT URE

120ΩE1 cable connection

Connect 120Ω E1 cable End A (left end in Figure 44) to BSC E1 socket

of conversion board at CBTS top. Connect E1 cable End B (right end in

Figure 44) to DDF.

Table 13 describes 120Ω E1 cable internal connection details.

TAB LE 13 - 12 0

Signal

definition

ΩΩΩΩ

E1 C AB LE INTER NAL CO NNEC TI ONS

IN0 OUT0 IN1 OUT1

RX0- RX0+ TX0- TX0+ RX1- RX1+ TX1- TX1+

End A pin

number

Cable color

Signal

definition

End A pin

number

Cable color

Signal

definition

End A pin

number

Cable color

22 23 24 25 1 2 3 4

Blue red 1

Blue black 1

Pink red 1

Pink black 1

Green red 1

Green black 1

Y

Yellow black 1

IN2 OUT2 IN3 OUT3

RX2- RX2+ TX2- TX2+ RX3- RX3+ TX3- TX3+

5 6 7 8 9 10 11 12

G

Grey black 1

Blue red 2

Blue black 2

Pink red 2

Pink black 2

G

Green black 2

IN4 OUT4 IN5 OUT5

RX4- RX4+ TX4- TX4+ RX5- RX5+ TX5- TX5+

13 14 43 44 39 40 41 42

Y

Yellow black 2

Grey red 2

Grey black 2

Blue red 3

Blue black 3

Pink red 3

Pink black 3

Confidential and Proprietary Information of ZTE CORPORATION

63

Page 64

reen red 3

ellow red 3

rey red 3

lue red 4

ZXC10 CBTS I2 Installation Manual

Signal

definition

IN6 OUT6 IN7 OUT7

RX6- RX6+ TX6- TX6+ RX7- RX7+ TX7- TX7+

End A pin

number

Cable color

Note:

’Blue red 1’ stands for there is one red label on blue cable.

’Pink red 2’ stands for there are two red labels on pink cable.

35 36 37 38 31 32 33 34

G

Green black 3

Y

Yellow black 3

G

Grey black 3

Trunk Cable Processing

Make CC4Y-J32 connector for E1 cable.

Figure 45 shows procedure to make CBTS side connector.

FIG UR E 45 - C C4 Y-J32 CO AXI AL C AB LE CON NEC TO R AS SEM B LY

B

Blue black 4

64

Take following steps to make CC4Y-J32 connector.

i. Slip parts 1 and 2 around cable, peel cable end, tin the core wire,

and open shielding layer.

ii. Connect core wire by soldering and screw part 2 to part 3.

iii. Place crimping tube and crimp the connector.

Confidential and Proprietary Information of ZTE CORPORATION

Page 65

Make coaxial connector on DDF side.

Figure 46 shows coaxial cable connector on DDF side.

FIG UR E 46 - C OAX I AL C AB LE O N DDF SI DE

Y-shape connector

with a testing end

Cable connector

Cable connector Socket

Socket

Figure 47 illustrates coaxial connector assembly on DDF side.

FIG UR E 47 - C OAX I AL CON NEC T OR AS S EMB L Y O N DDF SIDE

1. Connector sheath 2. Heat shrink tube

3. Crimping tube 4. Crimping plier

Confidential and Proprietary Information of ZTE CORPORATION

65

Page 66

ZXC10 CBTS I2 Installation Manual

Take following steps to make coaxial connector on DDF side.

i. Strip cable covering about 0.55 inch (14 mm).

ii. Slip cable connector sheath, heat-shrink tube and crimping tube in

sequence. Open shielding net with a net opening sleeve or by hand.

Strip internal insulation layer to expose 0.11 inch (2.5 mm) of

internal conductor.

iii. Insert core into plug. Insert core wire into soldering pin at back of

inner conductor and solder it. Trim shielding mesh with 0.23 inch (6

mm) crimping tube.

iv. Push crimping tube and shielding net into connector tail.

v. Use crimp pliers to crimp the crimping tube into a regular

hexahedron. Crimp twice in different angles.

vi. Slip the heat shrink tube onto crimped tube; heat it with an air

blower to make it shrink, and screw the tail cover.

Trunk cable test

Solder, connectors internal conductors at both ends and coaxial

cables inner conductors leaving no dry joint. Ensure not to short

internal and external conductors.

Trunk Cable Conversion

Implement conversion from 75 Ohm to 120 Ohm trunk cable according to

specifications provided by ZTE. One converter serves as one E1 cable. 75

Ohm trunk cable uses BNC connectors and 120 Ohm trunk cable uses

8P8C Ethernet cable sockets.

Impedance converter

Figure 48 shows impedance converter structure.

FIG UR E 48 - I MPE D ANCE CO N VE RTE R

66

Confidential and Proprietary Information of ZTE CORPORATION

Page 67

Wiring relationship for impedance converter

Figure 49 shows impedance converter wiring relationship.

Take following steps to establish impedance converter wiring

relationship.

i. To receive a balanced signal, connect pin 1 and pin 2. Use

converting chip to convert balanced signal into unbalanced signal

and get output from coaxial TX end.

ii. Convert unbalanced signal into balanced signal at RX end using

converting chip and feed it to RJ-45 socket.

iii. Connect shielding layer at RX end to Pin 6 of RJ-45 socket through

jumper JP2.

iv. Directly connect shielding layer of TX end to shielding layer of RJ-

45 or connect it to Pin 3 of RJ-45 through jumper JP1.

FIG UR E 49 - I MPE D ANCE CO N VE RTE R WI RI NG REL ATIO NSHI P

Table 14 describes specific wiring relationship.