Page 1

ZTECORPORATION

NO.55,Hi-techRoadSouth,ShenZhen,P .R.China

Postcode:518057

Tel:+86-755-26771900

Fax:+86-755-26770801

URL:http://ensupport.zte.com.cn

E-mail:support@zte.com.cn

ZXSDRR8860

CDMARemoteRadioUnit-8860

InstallationManual

Page 2

LEGALINFORMATION

Copyright©2011ZTECORPORA TION.

Thecontentsofthisdocumentareprotectedbycopyrightlawsandinternationaltreaties.Anyreproductionor

distributionofthisdocumentoranyportionofthisdocument,inanyformbyanymeans,withoutthepriorwritten

consentofZTECORPORATIONisprohibited.Additionally,thecontentsofthisdocumentareprotectedby

contractualcondentialityobligations.

Allcompany,brandandproductnamesaretradeorservicemarks,orregisteredtradeorservicemarks,ofZTE

CORPORATIONoroftheirrespectiveowners.

Thisdocumentisprovided“asis”,andallexpress,implied,orstatutorywarranties,representationsorconditions

aredisclaimed,includingwithoutlimitationanyimpliedwarrantyofmerchantability,tnessforaparticularpurpose,

titleornon-infringement.ZTECORPORATIONanditslicensorsshallnotbeliablefordamagesresultingfromthe

useoforrelianceontheinformationcontainedherein.

ZTECORPORA TIONoritslicensorsmayhavecurrentorpendingintellectualpropertyrightsorapplications

coveringthesubjectmatterofthisdocument.ExceptasexpresslyprovidedinanywrittenlicensebetweenZTE

CORPORATIONanditslicensee,theuserofthisdocumentshallnotacquireanylicensetothesubjectmatter

herein.

ZTECORPORA TIONreservestherighttoupgradeormaketechnicalchangetothisproductwithoutfurthernotice.

UsersmayvisitZTEtechnicalsupportwebsitehttp://ensupport.zte.com.cntoinquirerelatedinformation.

TheultimaterighttointerpretthisproductresidesinZTECORPORATION.

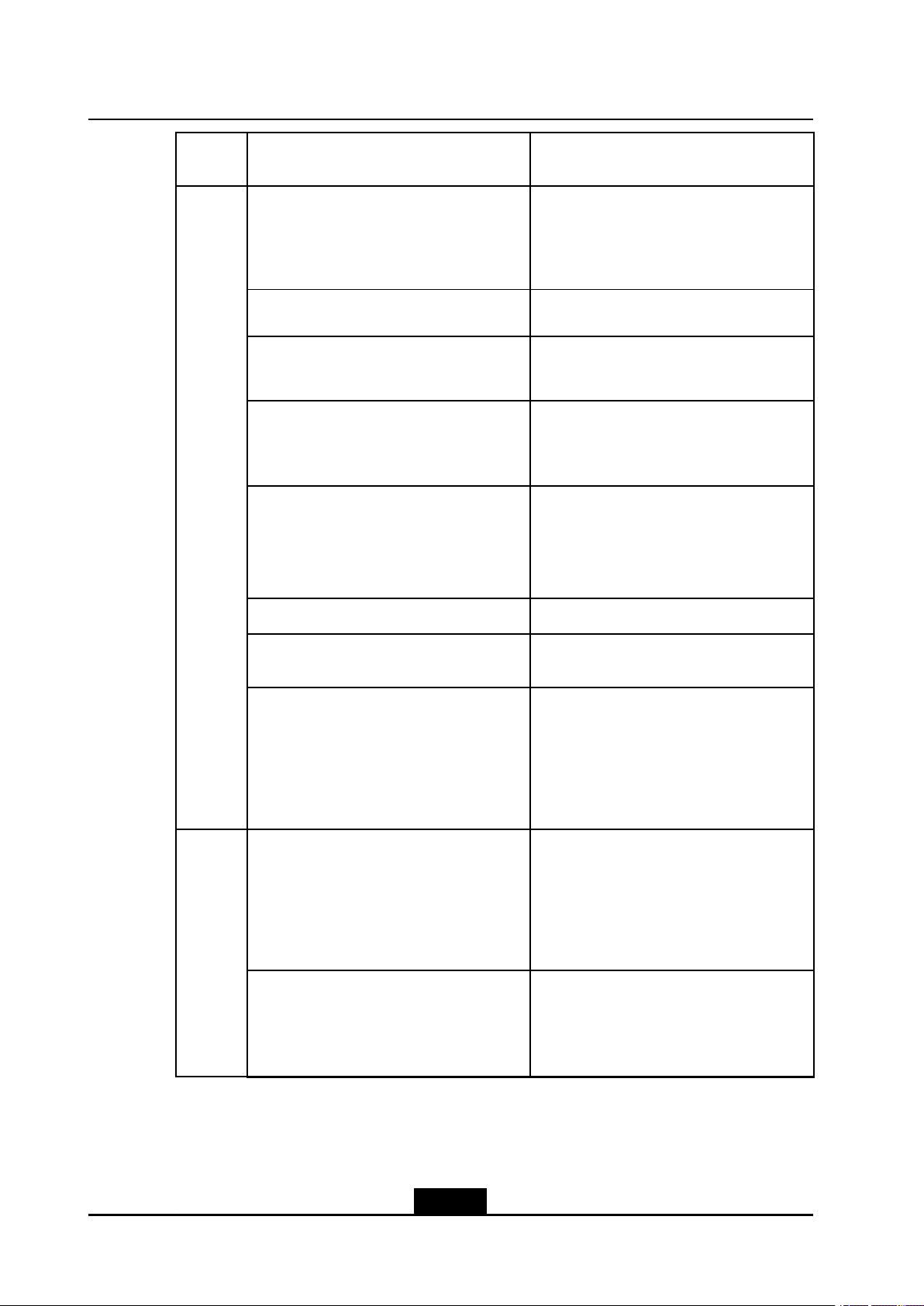

RevisionHistory

RevisionNo.RevisionDateRevisionReason

R1.008/30/2010FirstEdition

R1.112/30/2010ModifyStylesheetDropthecontentofinstallingWaveTrapDrop

thecontentofinstallingSunshield

R1.201/20/2011Waterproofprocessingmustbeperformedonalltheoutdoor

metalconnectorsoftheRRUs.

R1.302/20/2011AddinstallingPIMDCDroptheFloorStand-mountedInstallation

ModeDroptheSimpliedCabinetIntegratedInstallationMode

SerialNumber:SJ-20100722143906-002

PublishingDate:02/20/2011(R1.3)

Page 3

DeclarationofRoHS Compliance

Tominimizetheenvironmentalimpactandtakemoreresponsibilitytotheearthwelive,

thisdocumentshallserveasformaldeclarationthatZXSDRR8860manufacturedby

ZTECORPORATIONareincompliancewiththeDirective2002/95/ECoftheEuropean

Parliament-RoHS(RestrictionofHazardousSubstances)withrespecttothefollowing

substances:

lLead(Pb)

lMercury(Hg)

lCadmium(Cd)

lHexavalentChromium(Cr(VI))

lPolyBrominatedBiphenyls(PBB’s)

lPolyBrominatedDiphenylEthers(PBDE’s)

…

TheZXSDRR8860manufacturedbyZTECORPORA TIONmeettherequirementsofEU2002/95/EC;

however,someassembliesarecustomizedtoclientspecications.Additionofspecialized,

customer-speciedmaterialsorprocesseswhichdonotmeettherequirementsofEU2002/95/EC

maynegateRoHScomplianceoftheassembly.T oguaranteecomplianceoftheassembly,the

needforcompliantproductmustbecommunicatedtoZTECORPORATIONinwrittenform.This

declarationisissuedbasedonourcurrentlevelofknowledge.Sinceconditionsofuseareoutside

ourcontrol,ZTECORPORATIONmakesnowarranties,expressorimplied,andassumesnoliability

inconnectionwiththeuseofthisinformation.

I

Page 4

II

Page 5

FCC&ICSTATEMENT

Thisdevicecomplieswithpart15oftheFCCRules.Operationissubjecttothefollowing

twoconditions:

1.Thisdevicemaynotcauseharmfulinterference.

2.Thisdevicemustacceptanyinterferencereceived,includinginterferencethatmay

causeundesiredoperation.

ThisClass[A]digitalapparatuscomplieswithCanadianICES-003.

Note:

Workingwiththeequipmentwhileinoperation,mayexposethetechniciantoRF

electromagneticeldsthatexceedFCCrulesforhumanexposure.VisittheFCC

websiteatwww.fcc.gov/oet/rfsafetytolearnmoreabouttheeffectsofexposuretoRF

electromagneticelds.

Changesormodicationstothisunitnotexpresslyapprovedbythepartyresponsiblefor

compliancewillvoidtheuser’sauthoritytooperatetheequipment.Anychangetothe

equipmentwillvoidFCCandICgrant.

ThisequipmenthasbeentestedandfoundtocomplywiththelimitsforaClassAdigital

device,pursuanttotheFCCandICRules.Thisequipmentgenerates,usesandcan

radiateradiofrequencyenergyand,ifnotinstalledandusedinaccordancewiththe

instructions,maycauseharmfulinterferencetoradiocommunications.However,thereis

noguaranteethatinterferencewillnotoccurinaparticularinstallation.

I

Page 6

II

Page 7

RFExposureInformationfor PMR

TheproductgeneratesRFelectromagneticenergyduringtransmitmode.

Thisradioisdesignedforandclassiedas“OccupationalUseOnly”,meaningitmust

beusedonlyduringthecourseofemploymentbyindividualsawareofthehazards,and

thewaystominimizesuchhazards.ThisradioisNOTintendedforusebythe“General

Population”inanuncontrolledenvironment.

ThisradiohasbeentestedandcomplieswiththeFCCRFexposurelimitsfor“Occupational

UseOnly”.

Inaddition,theproductcomplieswiththefollowingStandardsandGuidelineswithregard

toRFenergyandelectromagneticenergylevelsandevaluationofsuchlevelsforexposure

tohumans:

1.FCCOETBulletin65Edition97-01SupplementC,EvaluatingCompliancewithFCC

GuidelinesforHumanExposuretoRadioFrequencyElectromagneticFields.

2.tAmericanNationalStandardsInstitute(C95.1-1992),IEEEStandardforSafetyLevels

withRespecttoHumanExposuretoRadioFrequencyElectromagneticFields,3kHz

to300GHz.

3.AmericanNationalStandardsInstitute(C95.3-1992),IEEERecommendedPractice

fortheMeasurementofPotentiallyHazardousElectromagneticFields–RFand

Microwave.

4.Thefollowingaccessoriesareauthorizedforusewiththisproduct.Useofaccessories

otherthanthose(listedintheinstruction)speciedmayresultinRFexposurelevels

exceedingtheFCCrequirementsforwirelessRFexposure.

I

Page 8

II

Page 9

AboutThisManual

Purpose

ZXSDRR8860isanoutdoorremoteRFunit.ComposinganintegratedBTS,ZXSDR

R8860andZXSDRR8860implementwirelesstransmissionwithincoverageareas,control

ofwirelesschannelaswellascommunicationwithBSC.

Thismanualprovidesbasicinstallationguideforengineeringpersonnelwhoperform

ZXSDRR8860hardwareinstallation.Atthesametime,itservesforthereference

materialforthepersonnelresponsibleforoperationandmaintenance.

IntendedAudience

Thisdocumentisintendedforengineersandtechnicianswhoperformoperationactivities

ZXSDRR8860.

lEngineeringtechnicians

lEquipmentinstallationengineers

lEquipmentcommissioningengineers

PrerequisiteSkillandKnowledge

Tousethisdocumenteffectively,usersshouldhaveageneralunderstandingofZXSDR

R8860equipmentanditscomponents.Familiaritywiththefollowingishelpful:

lZXSDRR8860hardwarestructure

lBasicsoftwareknowledge

WhatisinThisManual

Thismanualcontainsthefollowingchapters:

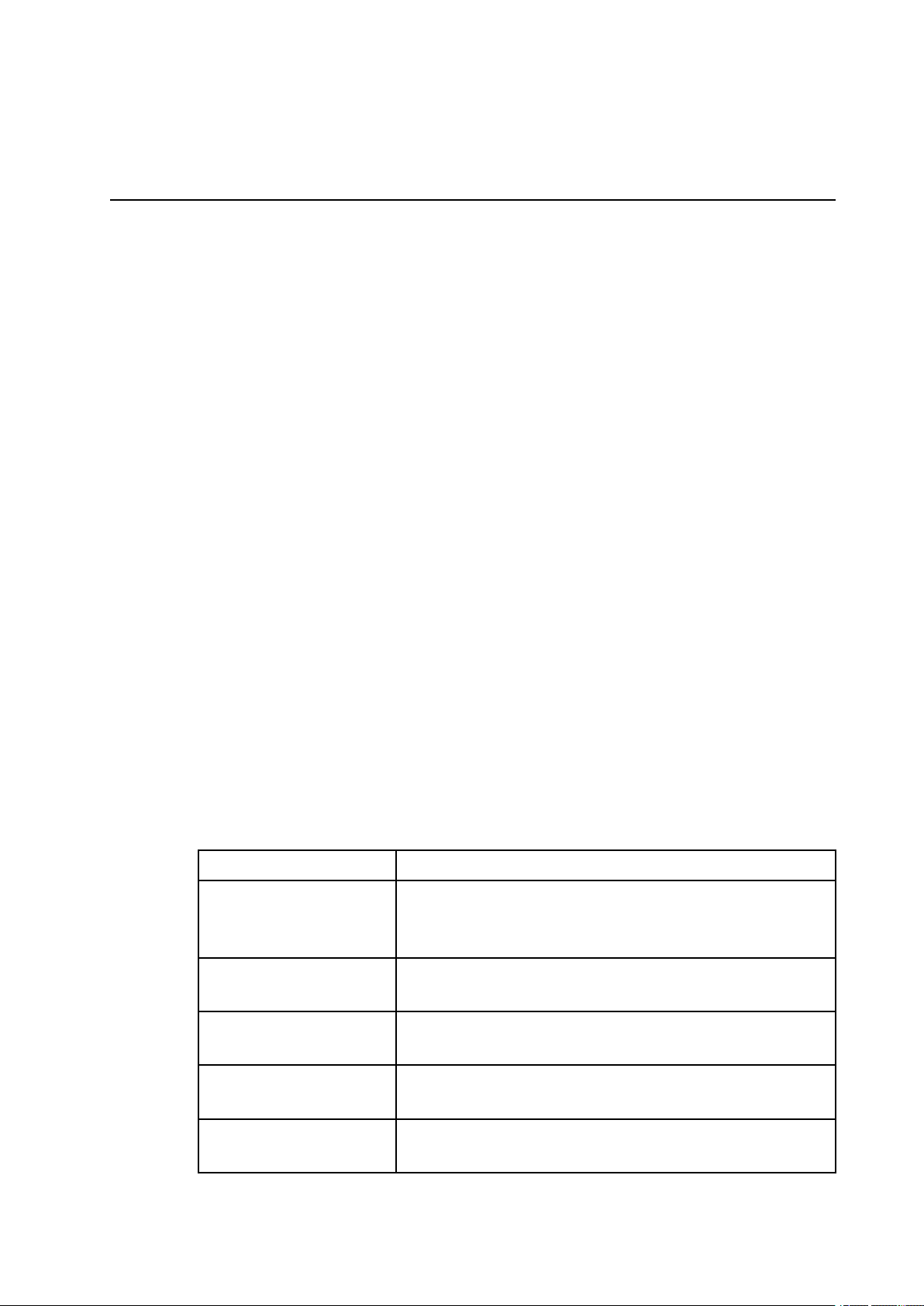

ChapterSummary

Chapter1SafetyDescriptionDescribessafetyprecautionsduringZXSDRR8860installation

oroperationmaintenanceaswellasmeaningsofvarioussafety

symbols.

Chapter2Installation

Overview

Chapter3CabinetInstallationDescribesfourinstallationmodesofZXSDRR8860cabinetand

Chapter4ExternalCable

Installation

DescribestheZXSDRR8860installationowsandinstallation

precautions.

installationsituations.

DescribestheinstallationmethodsofvariousZXSDRR8860external

cables.

Chapter5MainAntenna

FeederSystemInstallation

DescribestheinstallationowsandinstallationmethodsofZXSDR

R8860mainantennafeedersystem.

I

Page 10

ChapterSummary

Chapter6Hardware

InstallationInspection

Chapter7PoweronandoffDescribesthemethodsandprecautionsofZXSDRR8860power

Describestheinspectionmethodsofcabinetandcablesafter

installationcompletion.

onandoff.

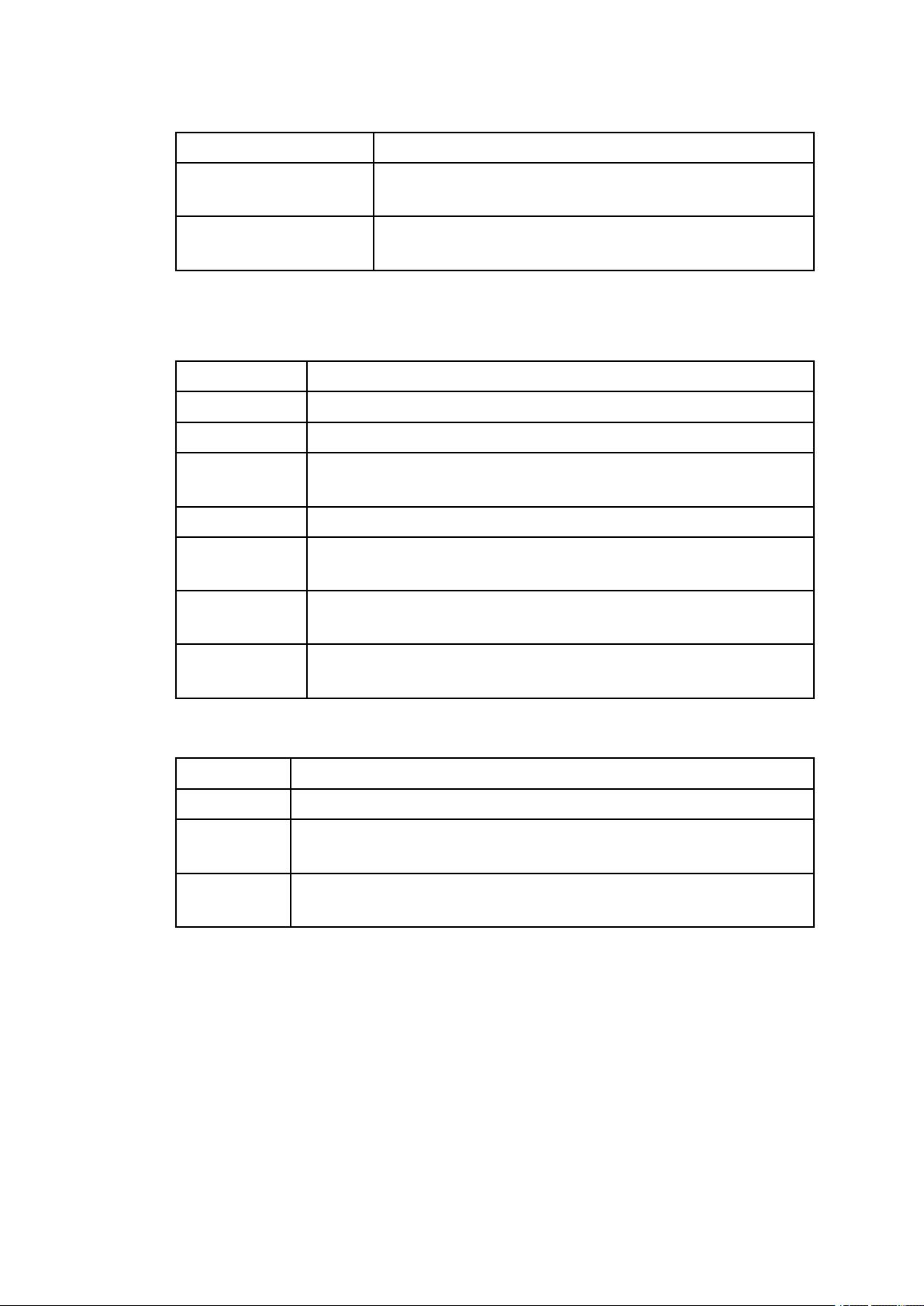

Conventions

ZTEdocumentsemploythefollowingtypographicalconventions.

TypefaceMeaning

ItalicsReferencestootherManualsanddocuments.

“Quotes”Linksonscreens.

BoldMenus,menuoptions,functionnames,inputelds,radiobuttonnames,check

boxes,drop-downlists,dialogboxnames,windownames.

CAPSKeysonthekeyboardandbuttonsonscreensandcompanyname.

Note:Providesadditionalinformationaboutacertaintopic.

Checkpoint:Indicatesthataparticularstepneedstobecheckedbefore

proceedingfurther.

Tip:Indicatesasuggestionorhinttomakethingseasierormoreproductive

forthereader.

Mouseoperationconventionsarelistedasfollows:

TypefaceMeaning

ClickReferstoclickingtheprimarymousebutton(usuallytheleftmousebutton)once.

Double-clickReferstoquicklyclickingtheprimarymousebutton(usuallytheleftmousebutton)

twice.

Right-clickReferstoclickingthesecondarymousebutton(usuallytherightmousebutton)

once.

II

Page 11

Contents

DeclarationofRoHSCompliance.................................................................I

FCC&ICSTA TEMENT...................................................................................I

RFExposureInformationforPMR................................................................I

AboutThisManual.........................................................................................I

Chapter1SafetyDescription....................................................................1-1

1.1SafetySpecicationsGuide................................................................................1-1

1.2SafetySymbols..................................................................................................1-2

1.3SafetyInstructions..............................................................................................1-3

Chapter2InstallationOverview................................................................2-1

2.1ComponentstobeInstalled.................................................................................2-1

2.2InstallationFlow.................................................................................................2-1

2.3InstallationPreparation.......................................................................................2-2

2.3.1EngineeringConditionInspection..............................................................2-2

2.3.2T oolsandInstrumentsPreparation............................................................2-4

2.3.3On-siteDocuments..................................................................................2-9

2.3.4UnpackingAcceptance...........................................................................2-10

Chapter3CabinetInstallation...................................................................3-1

3.1EngineeringIndices............................................................................................3-1

3.2Pole-mountedInstallationMode..........................................................................3-2

3.2.1ComponentsUsedinPole-mountInstallation.............................................3-2

3.2.2InstallingSingleCabinetonPole(Pole–Mount).........................................3-5

3.2.3InstallingTwoZXSDRR8860Pole-mountCabinets....................................3-6

3.2.4InstallingThreeZXSDRR8860CabinetsonPole.......................................3-9

3.3Wall-mountedInstallationMode..........................................................................3-11

3.3.1ComponentsUsedinWall-MountInstallation............................................3-11

3.3.2InstallingCabinetonWall(Wall-Mount)....................................................3-12

Chapter4ExternalCableInstallation.......................................................4-1

4.1ExternalCableLayout........................................................................................4-1

4.2ExternalCableInstallationFlow..........................................................................4-2

4.3Specicationsof1+3+3WaterproofProcessingwithPlasterandTape...................4-4

4.4InstallingPowerCable........................................................................................4-6

4.5InstallingGroundingCable..................................................................................4-7

I

Page 12

4.6InstallingFiberbetweenBBUandRRU................................................................4-9

4.7InstallingFiberbetweenRRUandRRU.............................................................4-10

4.8InstallingEnvironmentMonitoringCable............................................................4-12

4.9InstallingAISGControlCable............................................................................4-13

4.10InstallingFrequencyPointExtensionCable......................................................4-14

4.11InstallingJumper............................................................................................4-15

4.12InstallingPIMDC............................................................................................4-16

4.12.1PIMDCechnicalIndices........................................................................4-16

4.12.2PIMDCAppearance..............................................................................4-17

4.12.3PIMDCInstallationDescription..............................................................4-18

Chapter5MainAntennaFeederSystemInstallation..............................5-1

5.1MainAntennaFeederSystemStructure...............................................................5-1

5.2MainAntennaFeederSystemInstallationPreparation..........................................5-7

5.3MainAntennaFeederSystemInstallationFlow....................................................5-8

5.4AntennaInstallation............................................................................................5-9

5.4.1AntennaInstallationT echnicalSpecications..............................................5-9

5.4.2AntennaInstallationPosition...................................................................5-10

5.4.3InstallingDirectionalAntenna.................................................................5-10

5.4.4InstallingOmniAntenna.........................................................................5-13

5.4.5ConnectingJumperandAntenna............................................................5-14

5.5FeederInstallation............................................................................................5-15

5.5.1FeederCuttingPrinciple.........................................................................5-15

5.5.2InstallingFeederonT opofBuilding.........................................................5-16

5.5.3InstallingFeederonT ower......................................................................5-18

5.5.4FeederLayoutPrinciples........................................................................5-19

5.5.5FixingMainFeeder.................................................................................5-20

5.5.6FeederGroundingPrinciple....................................................................5-20

5.5.7InstallingFeederGroundingClips............................................................5-22

5.5.8ConnectingJumperandFeeder..............................................................5-25

5.6InstallingFeederHermetic-window....................................................................5-25

5.7FeederIndoorIngoing......................................................................................5-27

5.7.1FeederIndoorArrangementPrinciple......................................................5-27

5.7.2LeadingMainFeederintoRoom.............................................................5-28

5.7.3InstallingT op-equipmentJumper.............................................................5-30

5.8PerformingAntennaFeederSystemTest...........................................................5-31

5.9PerformingOutdoor-ConnectorWaterproofProcessing.......................................5-32

5.10PerformingFeederHermetic-windowWaterproofProcessing............................5-36

II

Page 13

5.11ChassisJumperInstallationDescription...........................................................5-39

5.12VSWRT est....................................................................................................5-40

Chapter6HardwareInstallationInspection.............................................6-1

6.1CheckingCabinetInstallation..............................................................................6-1

6.2CheckingCableInstallation.................................................................................6-1

6.2.1CablesInstallationGeneralSpecication...................................................6-1

6.2.2PowerandGroundingCablesInstallationCheck........................................6-3

6.2.3OpticalFiberInstallationCheck.................................................................6-4

6.3CheckingMainAntennaSystemInstallation.........................................................6-4

Chapter7Poweronandoff.......................................................................7-1

7.1PoweronPreparation.........................................................................................7-1

7.2PowerON..........................................................................................................7-1

7.3PowerOFF........................................................................................................7-2

AppendixACabinet-combinedInstallation............................................A-1

A.1ComponentsUsedinCabinet-combiningInstallation............................................A-1

A.2PerformingCabinet-combination.........................................................................A-2

AppendixBCascadingCabinetInstallation...........................................B-1

B.1ComponentsUsedinCascadingInstallation........................................................B-1

B.2PerformingCabinetCascading...........................................................................B-2

AppendixCOAU........................................................................................C-1

C.1OAUAppearanceandInterface..........................................................................C-1

C.2InstallingOAUinPole-mountMode.....................................................................C-2

C.3InstallationOAUinWall-mountMode..................................................................C-9

C.4InstallingOAUCable........................................................................................C-12

AppendixDOLP48-2.................................................................................D-1

D.1OLP48-2T echnicalIndices.................................................................................D-1

D.2OLP48-2AppearanceandInterface....................................................................D-1

D.3OLP48-2InstallationDescription.........................................................................D-3

AppendixEILP48-3....................................................................................E-1

E.1ILP48-3T echnicalIndices...................................................................................E-1

E.2ILP48-3AppearanceandInterface......................................................................E-2

E.3ILP48-3InstallationDescription...........................................................................E-3

AppendixFACLightningArrester...........................................................F-1

F.1ACLightningTechnicalIndices............................................................................F-1

F.2ACLightningAppearanceandInterface...............................................................F-2

F.3ACLightningInstallationDescription....................................................................F-3

III

Page 14

F.4InstallingShieldedGroundingKit........................................................................F-7

AppendixGPDM.......................................................................................G-1

G.1PDMAppearanceandInterface.........................................................................G-1

G.2InstallingPDM..................................................................................................G-1

Figures.............................................................................................................I

Tables.............................................................................................................V

Glossary.......................................................................................................VII

IV

Page 15

Chapter1

SafetyDescription

TableofContents

SafetySpecicationsGuide........................................................................................1-1

SafetySymbols..........................................................................................................1-2

SafetyInstructions......................................................................................................1-3

1.1SafetySpecificationsGuide

Thesesafetyinstructionsmustbeconsideredassupplementaryforlocalsafety

regulations.Theprioritymustbegiventolocalsafetyregulationsifthereisanyconict

betweenthetwo.

Themaintenancepersonnelmusthavetheknowledgeofsafetyoperationsand

maintenancewithrequiredqualicationandtechnicalbackground.

Warning!

Thisdevicecomplieswithpart15oftheFCCRules.Operationissubjecttothefollowing

twoconditions:

lThisdevicemaynotcauseharmfulinterference.

lThisdevicemustacceptanyinterferencereceived,includinginterferencethatmay

causeundesiredoperation.

Changesormodicationsnotexpresslyapprovedbythepartyresponsibleforcompliance

couldvoidtheuser'sauthoritytooperatetheequipment.

TheequipmentisintendedforinstallationinRESTRICTEDACCESSLOCA TIONS.

Alltheoperationandmaintenancepersonnelmustfollowthesafetyprecautionsand

instructionsprovidedbyZTECorporationtoavoidanyaccident.

Note:

ZTECorporationdoesnotbearanyliabilitiesincurredbecauseofviolationofthe

universalsafetyoperationrequirements,orviolationofsafetystandardsfordesigning,

manufacturingandusingtheequipment.

1-1

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 16

ZXSDRR8860InstallationManual

FCCRadiationExposureStatement:

ThisequipmentcomplieswithFCCradiationexposurelimitssetforthforanuncontrolled

environment.Thisequipmentshouldbeinstalledandoperatedwithminimumdistance4m

betweentheradiator&yourbody.

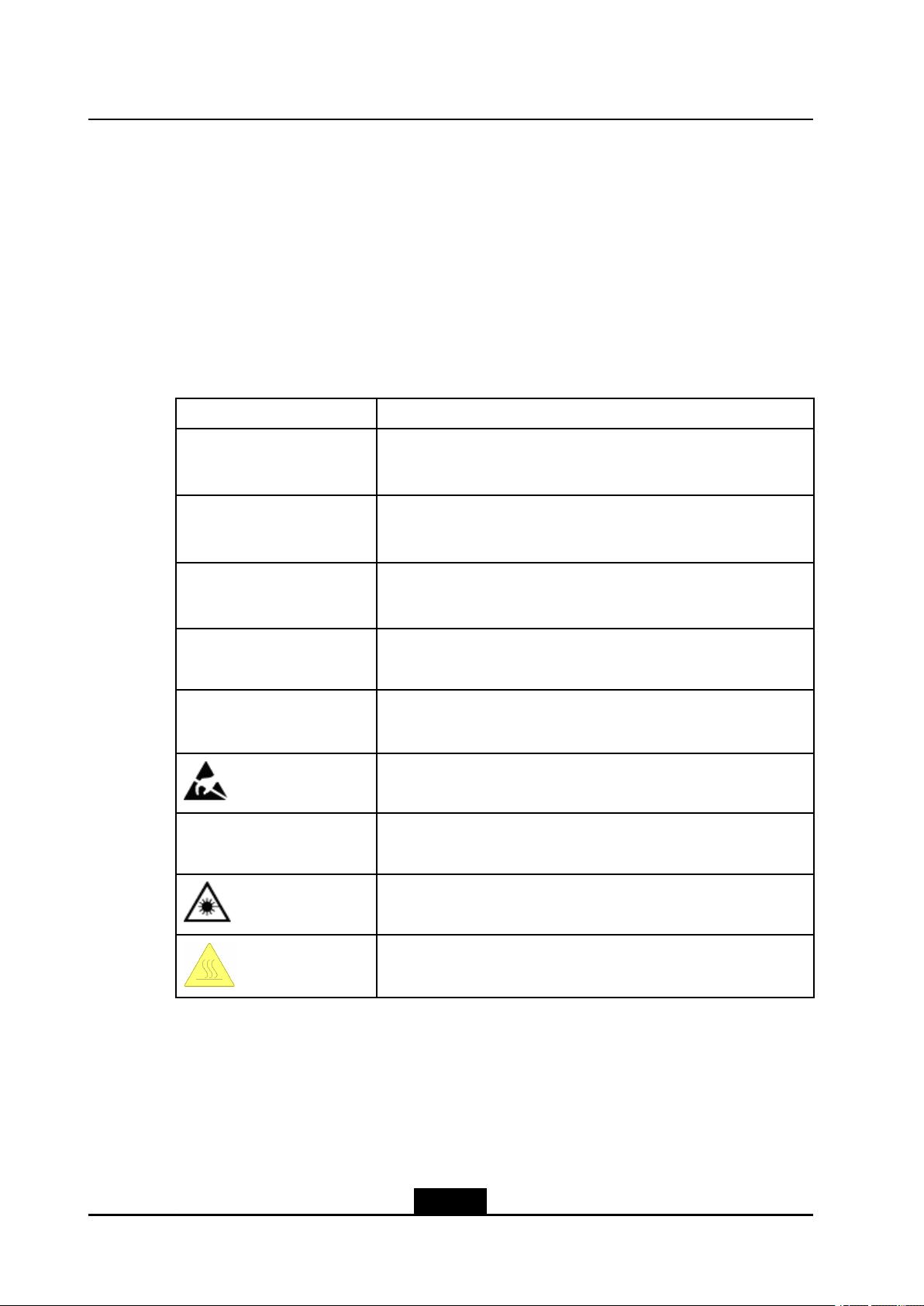

1.2SafetySymbols

Table1-1listssafetysymbols.Theyaretoprompttheuserofthesafetyprecautionstobe

observedduringZXSDRR8860operationandmaintenance.

Table1-1SafetySymbolsDescription

SafetySymbolsMeaning

Nosmoking:Smokingisforbidden

Noammables:Noammablescanbestored.

Notouching:Donottouch.

Universalalertingsymbol:Generalsafetyattentions.

Electricshock:Riskofelectricshock.

Electrostatic:Thedevicemaybesensitivetostaticelectricity .

Microwave:Bewareofstrongelectromagneticeld.

Laser:Bewareofstronglaserbeam.

Scald:Bewareofscald.

Amongstthesesafetysymbols,theuniversalalarmsymbolsareclassiedintothreelevels:

danger,warning,andcaution.Theformatsandmeaningsofthethreelevelsaredescribed

asbelow:

1-2

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 17

Chapter1SafetyDescription

Danger!

Indicatesapotentiallyhazardoussituationwhich,ifnotavoided,willresultindeathor

seriousinjuryofpeople,orequipmentdamagesandbreakdown.

Warning!

Indicatesapotentiallyhazardoussituationwhich,ifnotavoided,couldresultindeathor

seriousinjury.

Caution!

Indicatesapotentiallyhazardoussituationwhich,ifnotavoided,couldresultinserious

injuries,equipmentdamagesorinterruptionofpartservices.

1.3SafetyInstructions

Thissectiondescribesthesafetyinstructionsrelatedtoelectricalsafety,antistatic,heavy

objectsandmodules.

ElectricalSafetyInstructions

Thefollowingaretheelectricalsafetyinstructionsabouttools,highvoltage,powercables,

holesandlightning:

lTools

Usespecialtoolsratherthancommontoolsforhigh-voltageandACoperations.

lHighVoltage

Danger!

Highvoltageishazardous.Directorindirectcontactwithhighvoltageormainsupply

usingawetobjectcouldresultindeath.

àStrictlyfollowlocalsafetyrulestoinstallACpowerdevices.

àInstallationstaffmustbequaliedforperforminghigh-voltageandACoperations.

1-3

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 18

ZXSDRR8860InstallationManual

àDonotwearanywatch,handchain,bracelet,ringoranyotherconductiveobjects

àPreventmoisturefromaccumulatingontheequipmentduringoperationsina

lPowerCable

Neverinstalloruninstallpowercableswhiletheyarelive.Otherwise,thepowercable,

whencontactingaconductor,mayresultinsparksorelectricarccausingareoreven

damagetoeyes.

àMakesureofshuttingoffpowersupplybeforeinstallingordisconnectingapower

àBeforeconnectingthepowercable,makesurethattheconnectingcableandits

duringsuchoperations.

dampenvironment.

Warning!

cable.

labelareappropriatefortheactualinstallationrequirements.

lDrillingHoles

Warning!

Itisnotallowedtodrillchassisholeswithoutpermission.

àUnqualieddrillingcoulddamagewiringandcablesinsidethechassis.

Additionally,metalpiecesinsidethechassiscreatedbythedrillingcouldresult

inashortcircuit.Useinsulationprotectionglovesandrstmovecablesinsidea

chassisawaywhendrillingisnecessaryonachassis.

àProtecteyesduringdrillingasdustoryingdebrismaydamageeyes.

àCleananydebrisintimeafterdrilling.

lLightning

Danger!

Donotperformhigh-voltage,AC,irontowerormastoperationsinathunderstorm.

Thunderstormswouldgiverisetoastrongelectromagneticeldintheatmosphere.

Therefore,theequipmentmustbegroundedandprotectedintimeagainstlightning

strikes.

1-4

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 19

Chapter1SafetyDescription

AntistaticSafetyInstructions

Caution!

Staticelectricityproducedbyhumanbodycandamagestatic-sensitivecomponentson

circuitboard,suchaslarge-scaleintegratedcircuits.

lFrictioncausedbyhumanbodyactivitiesistherootcauseofelectrostaticcharge

accumulation.Staticvoltagecarriedbyahumanbodyinadryenvironmentcanbe

upto30kV,andcanremainthereforalongtime.Anoperatorwithstaticelectricity

maydischargeelectricitythroughacomponentwhenhe/shetouchestheconductor

andcausingdamage.

lWearanantistaticwriststrap(theotherendofwriststrapmustbewellgrounded)

beforetouchingtheequipmentorholdingaplug-inboard,circuitboard,Integrated

Circuit(IC)chiporotherdevices,topreventhumanstaticelectricityfromdamaging

sensitivecomponents.

lTheantistaticwriststrapusedmustbesubjecttoregularcheck.Donotreplacethe

cableofanantistaticwriststrapwithanyothercables.

lDonotcontactstatic-sensitivemoduleswithanyobjectthateasilygeneratesstatic

electricity.Forexample,frictionofpackagebag,transferboxandtransferbeltmade

frominsulationplasticmaycausestaticelectricityoncomponents.Dischargeofstatic

electricitymaydamagecomponentswhentheycontactahumanbodyortheground.

lModulesshouldonlycontactmaterialssuchasanantistaticbag.Keepmodulesin

antistaticbagsduringstorageandtransportation.

lDischargestaticelectricityofthetestdevicebeforeuse,thatis,groundthetestdevice

rst.

lDonotplacethemodulenearastrongDCmagneticeld,suchasthecathode-ray

tubeofamonitor.Keepthemoduleatleast10cmaway.

HoistingHeavyObjects

Warning!

Whenhoistingheavyobjects,ensurethatnobodyisstandingorwalkingunderthehoisted

object.

lEnsurethehoistercanmeethoistingrequirementswhendisassemblingheavy

equipment,ormovingandreplacingequipment.

lTheinstallationpersonnelmustbedulytrainedandqualiedforhoistingoperations.

lHoistingtoolsmustbeinspectedandcompletebeforeservice.

1-5

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 20

ZXSDRR8860InstallationManual

lMakesurethathoistingtoolsarexedrmlyonasufcientlysecuredobjectorwall

beforethehoistingoperation.

lGivebrieforalinstructionsduringhoistingoperationstopreventanymishap.

Unplugging/PluggingaModule

lNeverplugamodulewithexcessiveforce,toensurethatthepinsonthebackplane

donotgetdeformed.

lPlugthemodulerightintotheslotandmakesuremodulecircuitfacesdonotcontact

eachotherlestanyshortcircuitmayoccur.

lKeephandsoffthemodulecircuit,components,connectorsandcabletroughwhen

holdingamodule.

RackMountSafetyInstructions

RackMountInstructions-Thefollowingorsimilarrack-mountinstructionsareincluded

withtheinstallationinstructions:

lElevatedOperatingAmbient-Ifinstalledinaclosedormulti-unitrackassembly,the

operatingambienttemperatureoftherackenvironmentmaybegreaterthanroom

ambient.Therefore,considerationshouldbegiventoinstallingtheequipmentinan

environmentcompatiblewiththemaximumambienttemperature(Tma)speciedby

themanufacturer.

lReducedAirFlow-Installationoftheequipmentinarackshouldbesuchthatthe

amountofairowrequiredforsafeoperationoftheequipmentisnotcompromised.

lMechanicalLoading-Mountingoftheequipmentintherackshouldbesuchthata

hazardousconditionisnotachievedduetounevenmechanicalloading.

lCircuitOverloading-Considerationshouldbegiventotheconnectionofthe

equipmenttothesupplycircuitandtheeffectthatoverloadingofthecircuitsmight

haveonovercurrentprotectionandsupplywiring.Appropriateconsiderationof

equipmentnameplateratingsshouldbeusedwhenaddressingthisconcern.

lReliableEarthing-Reliableearthingofrack-mountedequipmentshouldbe

maintained.Particularattentionshouldbegiventosupplyconnectionsotherthan

directconnectionstothebranchcircuit(e.g.useofpowerstrips).

OtherSafetyInstructions

Note:

Donotperformmaintenanceordebuggingindependently,unlessaqualiedpersonis

present.

lPerformanairtighttestbeforeRRUdelivery ,andprohibitdisassemblingtheRRUon

site.

1-6

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 21

Chapter1SafetyDescription

lReplacinganypartsormakinganychangestotheequipmentmightresultinan

unexpecteddanger.Therefore,besurenottoreplaceanypartsorperformany

changestotheequipmentunlessauthorizedotherwise.

lDuetothatRRUisinhightemperatureduringrunning,theRRUshouldbeinstalled

insomeregionsoutofoperators'reachorstrictlyrestricted.

lContactZTEofceifyouhaveanyquestion,toensureyoursafety .

1-7

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 22

ZXSDRR8860InstallationManual

Thispageintentionallyleftblank.

1-8

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 23

Chapter2

InstallationOverview

TableofContents

ComponentstobeInstalled........................................................................................2-1

InstallationFlow.........................................................................................................2-1

InstallationPreparation...............................................................................................2-2

2.1ComponentstobeInstalled

ForZXSDRR8860,thefollowingcomponentswillbeinstalled:

lZXSDRR8860cabinetandcomponents

Note:

Theinnercablesandfunctionalmodules/boardsinthecabinetarealreadyinstalled

beforeequipmentdelivery.

lSunshield(usedfortheoutdoorZXSDRR8860installation)

lCables

lAntennafeedersystemincludingantenna,jumpersandfeeder

2.2InstallationFlow

TheinstallationowofZXSDRR8860isdemonstratedinFigure2-1.However,itisnot

requiredtostrictlyfollowthestepsshowedinthisow.Theactualinstallationprocedures

dependontherequirementsonsite.

2-1

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 24

ZXSDRR8860InstallationManual

Figure2-1InstallationFlow

2.3InstallationPreparation

2.3.1EngineeringConditionInspection

Beforeinstallingdevices,followtherequirementsofEnvironmentAcceptanceReportand

checkinstallationenvironment.Thefollowingcontentisjustasareference.

InstallationPositionInspection

ZXSDRR8860installationpositionshouldaccordwiththerequirementsofengineering

design,thespeciedrequirementsasfollows:

lAvoiddusty,harmful-gasorexplosive-goodsenvironment;

2-2

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 25

Chapter2InstallationOverview

lAvoidtheplaceswithbigshockorstrongnoise;

lFarawaysubstation;

lFarawaypollutionsource;

lAvoidanindustrialboilerandheatingboiler;

lFarawayhigh-powerwirelessinterferencesource.

TemperatureandHumidityInspection

ZXSDRR8860temperatureandhumidityinworkenvironmentshouldmeetthe

requirements,asshownin

PowerSupplyInspection

TherequirementsofZXSDRR8860powersupplyaredescribedasfollows.

1.DCpowersupply:ZXSDRR8860is–48VDCpowersupplyandthevoltageofpower

supplyis–40VDC~–57VDC.

2.IndirectACpowersupply:adoptanoutdoorACunit(OAU);theOAUcanprovide220V

ACpowersupplyforoneZXSDRB8200C100andoneZXSDRR8860atthesame

time.

LightningInspection

TheZXSDRR8860lightningrequirementsaredescribedasfollows.

lOutdoorInstallation

1.ForDCpowersupply,congureanoutdoorDClightningboxOLP48-2.Ifthe

DCpowerisexportedfromtheequipmentroom,thelengthofpowercableis

morethan10m(lessthan50m)andtheoutputendofindoorDCpowerisnot

conguredwithB-levelorabovelightningdevices,itisrequiredtocongurean

indoorDClightningboxILP48–3intheequipmentroom.

2.ForindirectACpowersupply,itisrequiredtocongureanAClightningbox

(ZXPCScombinedarrester).

lForindoorinstallation,ifthepowercableisdistributedoutdoors,congurethepower

lightningboxaccordingtotheconditionsofoutdoorinstallation.

GroundingInspection

ZXSDRR8860adoptsanassociatedgroundingmode.Thevalueofgroundingresistance

isnotmorethan5ohm.

OtherInspections

1.ThecorollarydevicesorcomponentsshouldaccordwiththerequirementsofZXSDR

R8860engineeringdesigndrawing.

2.ThetransmissiondevicesinterconnectedwithBBUshouldhavebeenprepared.

2-3

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 26

ZXSDRR8860InstallationManual

2.3.2ToolsandInstrumentsPreparation

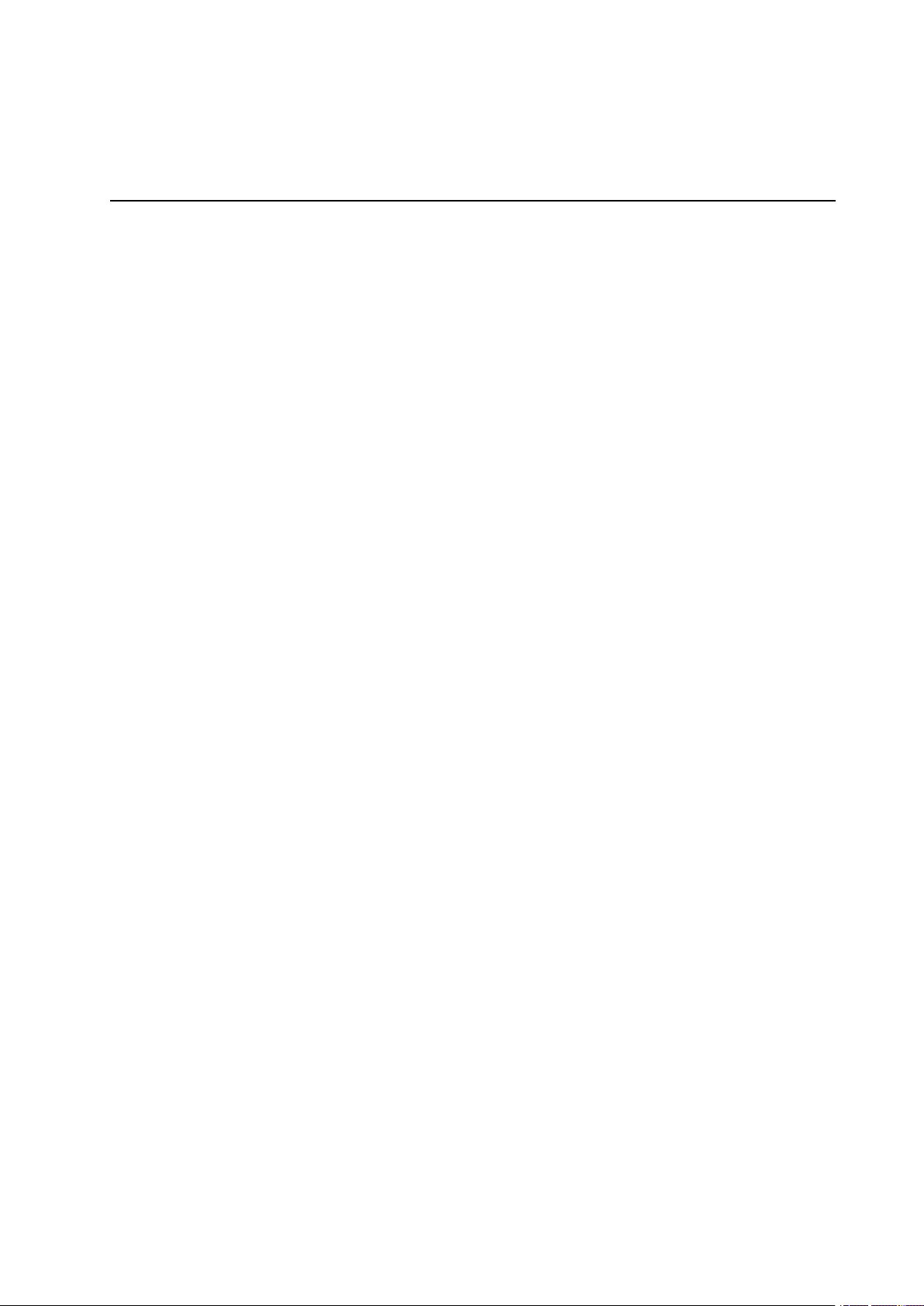

Table2-1showstoolsandmeterslistrequiredduringinstallation.

Table2-1ToolandMeterList

Cate-

gory

Onefeederconnectorknife

One75Ωcoaxialcablestripper

Onemulti-functionalcrimpingpliers

Special-

purpose

tools

Onemultimeter

NameExample

Onestandingwaveratiotester

Oneearthresistancetester

Oneelectricpercussiondrill

Punch-

ingtools

Severalauxiliarypercussiondrillbits

2-4

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 27

Chapter2InstallationOverview

Cate-

gory

Onevacuumcleaner

Powerconnectorboard(providingatleast3

two-phasesocketsand3three-phasesock-

ets,withthecurrentcapacitylargerthan15

A)

Crossscrewdrivers(4”,6”and8”each)

Flatheadscrewdrivers(4”,6”and8”each)

NameExample

Adjustablewrenches(6”,8”,10”and12”

each)

Dual-purposewrenches(17”and19”each)

Onesetofsocketwrenches

General-

purpose

tools

Onepaperknife

5kgnailhammer

One300Wironandone40Wiron

2-5

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 28

ZXSDRR8860InstallationManual

Cate-

gory

Onesetofinner-hexagonwrench

Solderwires

NameExample

One50m(164feet)tapemeasure

One5m(16feet)steeltape

Mea-

sure-

ment

tools

Oneangleinstrument

Onecompass

2-6

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 29

Chapter2InstallationOverview

Cate-

gory

Onelevelbar

Oneplumb

Antistaticwriststrap

slip-proofgloves

Protec-

tiontools

NameExample

Safetyhelmet

Onehacksaw(withseveralsawblades)

Onepairofsharp-nosepliers(8″)

Onepairofdiagonalpliers(8″)

Clamp

tools

Onepairofround-nosepliers(8″)

Onepairofvices(8″)

2-7

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 30

ZXSDRR8860InstallationManual

Cate-

gory

Onesetofneedleles(medium-sized)

Nippers

Onepaintbrush

Onepairofscissors

Onehotairblower

NameExample

Onesolderremovaltool

Onehydrauliccrimper

Onecrowbar

Pulleyset

Auxiliary

tools

Rope

2-8

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 31

Chapter2InstallationOverview

Cate-

gory

Ladder

Spectrumanalyzer(requiredincertainspe-

cialcases)

BTStester

Meters

NameExample

2.3.3On-siteDocuments

Fieldstrengthtester(requiredincertainspe-

cialcases)

ZXSDRR8860installationneedsthefollowingtechnicaldocumentstobeready.

lZXSDRR8860EngineeringExplorationReport

lZXSDRR8860EnvironmentAcceptanceReport

ZXSDRR8860manualkitincludes:

lZXSDRR8860CommissioningandCongurationManual

lZXSDRR8860OperationandMaintenanceManual

lZXSDRR8860TechnicalManual

2-9

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 32

ZXSDRR8860InstallationManual

2.3.4UnpackingAcceptance

2.3.4.1CountingGoods

Context

Therepresentativeofcustomerandtheprojectsupervisormustbepresentonsitewhen

countingreceivedgoods.Ifeitherpartyisnotpresent,transportermustberesponsiblefor

theintactnessofthegoods.

Steps

1.ChecktheDeliveryChecklistofZTECorporation.Checkthetotalnumberofthegoods

andtheintactnessofthepackingboxes.Checkthepackinglisttoseeiftheplaceof

arrivalistheactualinstallationplace.Ifthegoodsareintact,unpackandinspectthem.

Note:

2.3.4.2CrateUnpacking

Itisrecommendedtounpackthegoodsabout30minutesafterreceipt,becausethere

isapossibilityofmoisturecontentduetotemperaturevariations.

2.Theequipmentinspectionlistandunpackingacceptancereportarepresentinthe

rstpackingcarton.Firstly,openrstthepackingcartonandtakeouttheUnpacking

AcceptanceReporttocheckwhetherthegoodsreceivedareinaccordancewiththe

inspectionlist.

3.Duringthecountingandunpackinginspectionprocess,ifanymaterialisfoundshort,

orgoodsdamaged,llintheUnpackingAcceptanceFeedbackTableandcontactZTE

promptly.

–EndofSteps–

Prerequisites

Preparetheappropriatetoolssuchasstraightscrewdriver,pliers,andcrowbar.

Context

Performthefollowingstepstoopenthecrate:

Steps

1.Insertaatheadscrewdriverornailhammerintothemetallatchofthecoverboardof

thecrate,andmovetheatheadscrewdriverornailhammertoloosentheironsheet.

2-10

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 33

Chapter2InstallationOverview

Thenusethecrowbarorpincerstoputthemetallatchinthestraightdirection,as

showninFigure2-2.

Figure2-2PuttingtheMentalLatchinStraightDirection

1.Mentalsheet

2.Coverboard

3.Mentallatch4.Flatheadscrewdriver

ornailhammer

2.Usethetoolstoputallthemetallatchesonthecoverboardofthecrate,andthen

removethecoverboardofthecrate,asshowninFigure2-3.

Figure2-3RemovingCoverBoard

3.Puttheothermetallatchesonthefoursidesofthecrate,removetheboardsandtake

outtheequipmentfromthecrate,asshowninFigure2-4.

2-11

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 34

ZXSDRR8860InstallationManual

Figure2-4RemovingOtherBoards

2.3.4.3CartonUnpacking

–EndofSteps–

Prerequisites

Preparetheappropriatetoolssuchasstraightscrewdriver,diagonalpliers,andpaperknife.

Context

Performthefollowingstepstounpackthecarton:

Steps

1.Usediagonalplierstocutpackingstraps.

2.Useapaperknifetocutadhesivetapealongtheslitsoncartoncover,avoiddamaging

goodsinside.

3.Openthecarton,andremovethefoamboard.

4.Checkthegoodswithinthecarton.

5.Takeouttheantistaticpackingbag.

6.Opentheantistaticpackingbagtotakeouttheelectronicequipmentcomponents,as

showninFigure2-5.

2-12

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 35

Figure2-5TakingOutComponentwithanAntistaticWristStrap

Chapter2InstallationOverview

Note:

lAvoiddamagingtheantistaticbag(Itcanbeusedinthefutureforstorageofspare

parts)duringunpacking.

lWhiletheequipmentismovedtoahotteranddamperplace,waitfor30minutes

beforeunpackingtheequipment.Otherwise,moisturemaycondenseonthe

surfaceoftheequipmentandcausedamage.

lProperlydisposeofrecycledesiccants.

–EndofSteps–

2.3.4.4GoodsAcceptanceandHandover

Context

Performthisprocedureforacceptinggoods,andhandingthemovertooperators.

Steps

1.Acceptance

Basedonthename,categoryandnumbermentionedontheshippinglist,carefully

checkthegoodspiecebypiece.Makesurethatallgoodsmeetthefollowing

conditions:

a.Thereisnobubbly,peeling,nickandlthmarkonthesurfaceofthechassis.

b.Theoilpaintonthechassissurfaceisintact.

c.Allclampingscrewsaretightandintact.

2-13

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 36

ZXSDRR8860InstallationManual

d.Allcomponentsareproperlyinstalledinposition.

e.Theinspectedgoodsareplacedbycategory .

2.Handover

Aftercompletingtheunpackingprocedure,representativeofcustomerandproject

supervisorshouldapproveandsigntheUnpackingforInspectionReport.Bothparties

shouldhaveacopyofUnpackingforInspectionReport.

–EndofSteps–

2-14

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 37

Chapter3

CabinetInstallation

TableofContents

EngineeringIndices....................................................................................................3-1

Pole-mountedInstallationMode.................................................................................3-2

Wall-mountedInstallationMode................................................................................3-11

3.1EngineeringIndices

Table3-1describestheengineeringindicesofZXSDRR8860.

Table3-1ZXSDRR8860EngineeringIndices

OverallDimensionWidthxHeightxDepth:320mmx500mmx172mm

ItemIndices

UpperEnclosureDimensionWidthxHeightxDepth:320mmx370mmx72mm

LowerEnclosureDimensionWidthxHeightxDepth:320mmx500mmx100mm

Weight<22kg

Power-48VDC;-40V~-57V

220VAC:150V~285V/45Hz~65Hz(viaexternal

AC-to-DCconversionlightningbox)

WorkT emperature-40℃to55℃-40℉to131℉

WorkHumidity5%RH~95%RH

PowerConsumptionofNormalWork

Under-48VDCPowerSupply

l1Carrier

àOutputPower:20W/C/S

àPowerConsumption:160W

l2Carrier

àOutputPower:20W/C/S

àPowerConsumption:200W

l3Carrier

àOutputPower:20W/C/S

àPowerConsumption:250W

3-1

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 38

ZXSDRR8860InstallationManual

ThetechnicalindicesoftheindoorDClightningbox,exempliedby

JD40K085C20H2–K1Z,arelistedinTable3-2,whichissubjecttotheactualeld

technicalspecicationsforpracticalapplication.

Table3-2JD40K085C20H2–K1ZDCLightningBoxTechnicalIndices

DimensionsWidthxHeightxDepth:400mmx450mmx100mm(The

NominalWorkingVoltage–48V

InstallationModeIndoorwall-mountinstallation

WorkingT emperature-5℃to70℃

WorkingHumidity≤95%RH

ThetechnicalindicesoftheexternalAC-to-DCconversionlightningbox,exempliedby

GPAD501M54-1A,arelistedinT able3-3,whichissubjecttotheactualeldtechnical

specicationsforpracticalapplication.

ItemIndex

heightoftopcoverboxlockexcluded)

Table3-3GPAD501M54-1AExternalAC-to-DCConversionLightningBoxTechnical

Indices

ItemIndex

DimensionsWidthxHeightxDepth:217mmx288mmx127mm

Weight4.65kg

InputVoltageMin.value:150V

Typicalvalue:220V

Max.value:285V

InputFrequencyMin.value:45Hz

Typicalvalue:50Hz

Max.value:65Hz

InstallationModePole-mountandwall-mountinstallation

WorkingT emperature-40℃+65℃

WorkingHumidity5%95%

3.2Pole-mountedInstallationMode

3.2.1ComponentsUsedinPole-mountInstallation

Themaincomponentsusedinpole-mountinstallationinclude:

lPoleanchorclampcomponents;

lPolexingbracketcomponents.

3-2

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 39

Chapter3CabinetInstallation

Thepoleanchorclampcomponentsareusedforpole-mountinstallationofoneortwo

ZXSDRR8860s.Thepolexingbracketcomponentsareusedforpole-mountinstallation

ofthreeZXSDRR8860s.

Themainpoleanchorclampcomponentsusedinpole-mountinstallationforsingleZXSDR

R8860arelistedinTable3-4

Table3-4MainComponentList1

NameQuantity

Shortanchorclamp2

Longanchorclamp2

Standardspringwasher104

M10×120hexagonheadbolt(fullthread)4

I-typecommonM10hexagonalnut4

Flatwasher104

Standardspringwasher84

M8×40hexagonheadbolt4

Bigwasher84

Themainpoleanchorclampcomponentsusedinpole-mountinstallationfortwoZXSDR

R8860arelistedinT able3-5

Table3-5MainComponentList2

NameQuantity

Longanchorclamp4

Standardspringwasher104

M10×120hexagonheadbolt(fullthread)4

M10×80hexagonheadbolt(fullthread)4

I-typecommonM10hexagonalnut4

Flatwasher104

Standardspringwasher88

M8×40Hexagonheadbolt8

Bigwasher88

Themainpolexingbracketcomponentsusedinpole-mountinstallationforthreeZXSDR

R8860arelistedinTable3-6

3-3

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 40

ZXSDRR8860InstallationManual

Table3-6MainComponentList3

NameQuantity

Polexingbracket4

Standardspringwasher104

M10×120hexagonheadbolt(fullthread)4

I-typecommonM10hexagonalnut4

Flatwasher104

Standardspringwasher812

M8×40hexagonheadbolt12

Bigwasher812

Figure3-1illustratespoleanchorclampcomponents.Figure3-2illustratespolexing

bracketcomponents.

Figure3-1PoleAnchorClampComponents

Figure3-2PoleFixingBracketComponents

3-4

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 41

Chapter3CabinetInstallation

Note:

ThepoleanchorclampcomponentsshowninFigure3-1isadoptedinonepole-mount

installation.Thepoleanchorclampcomponentsusedintwopole-mountinstallationonly

changestwoshortanchorclampsintotwolonganchorclamps,thespeciclistdescribed

inT able3-5

3.2.2InstallingSingleCabinetonPole(Pole–Mount)

Context

ThistopicdescribesthemethodtoxasingleZXSDRR8860cabinetonapole.

Steps

1.Installpoleanchorclampcomponents.

a.Fixanchorclampsontothepole,andaligntheanchorclampholesandscrewthe

boltsabit;

b.Adjustthespacebetweentheclipsbasedonthescrew'spositionofsupporting

panel,andxthesupportingpanelontheclipswithM8boltsandtightenitproperly;

c.ScrewdownM10boltstightly.

Figure3-3illustratestheinstallationofanchorclampcomponents.

Figure3-3Pole-MountInstallation(1)

1.M8×40hexagonhead

bolt

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

2.Standardspring

washer

3-5

3.Bigflatwasher

4.Insulationflange

Page 42

ZXSDRR8860InstallationManual

5.Supportingpanel

6.Insulationboard

7.Longanchorclamp

8.M10×120hexagon

headbolt(fullthread)

9.Pole

10.Flatwasher

11.Standardspring

washer

12.I-typecommonM10

hexagonalnut

13.Shortanchorclamp

2.MounttheZXSDRR8860cabinetonthesupportingpanelandfastenthecabinetwith

fourM6X20hexagonsocketcapscrewsasshowninFigure3-4

Figure3-4Pole-MountInstallation(2)

1.M6Screw2.Retainingboard3.Supportingpanel

–EndofSteps–

3.2.3InstallingTwoZXSDRR8860Pole-mountCabinets

Steps

1.Fixanchorclampsbacktobackontothepole,andaligntheholesandscrewdowna

bitwithbolts.Adjustspacebetweenanchorclampsbasedonthescrews'positionof

supportingpanelasshowninFigure3-5.

3-6

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 43

Figure3-5Pole-mountInstallation(1)

Chapter3CabinetInstallation

1.I-typecommonM10

hexagonalnut

2.Standardspring

washer10

3.Bigflatwasher10

4.Longanchorclamp

5.M10×120hexagon

headbolt(fullthread)

Tip:

DuringtwoZXSDRR8860cabinetinstallation,thesuggestedpolediameteris60to

120mmandtherearetwokindsofboltlengths:

lUsetheboltoflength80mmforpolediameterof60mmto90mm;

lUsetheboltoflength120mmforpolediameterof90mmto120mm.

2.FixtwosupportingpanelsontheanchorclampwithM8boltsandscrewM10bolts

tightly,asshowninFigure3-6.

3-7

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 44

ZXSDRR8860InstallationManual

Figure3-6Pole-mountInstallation(2)

1.M8×40Hexagonhead

bolt

2.Standardspring

washer8

3.Bigflatwasher8

4.Insulationflange

5.Supportingpanel

6.Insulationboard

7.Longanchorclamp

3.MountthetwoZXSDRR8860cabinetsonthesupportingpanelandfastenthecabinet

withfourM6×20hexagonsocketcapscrewsasshowninFigure3-7.

Figure3-7Pole-mountInstallation(3)

–EndofSteps–

3-8

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 45

3.2.4InstallingThreeZXSDRR8860CabinetsonPole

Steps

1.Fixthetwosetsofxingbracketsontothepoleandaligntheholesandscrewitabit

withbolts,asshowninFigure3-8.

Figure3-8Pole-mountInstallation(1)

Chapter3CabinetInstallation

1.FixingBracket

2.M10×120hexagon

headbolt(fullthread)

3.Standardspring

washer10

4.Flatwasher10

5.I-typecommonM10

2.Adjustspacebetweenthexingbracketsbasedonthescrews'positionofinsulation

boardsatthebackofsupportingpanelsasshowninFigure3-9.Fixthreesupporting

panelsonthexingbracketswithM8bolts.ScrewthexingbracketswithM10bolts.

hexagonalnut

3-9

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 46

ZXSDRR8860InstallationManual

Figure3-9Pole-mountInstallation(2)

1.Fixingbracket

2.Insulationboard

3.Supportingpanel

4.Insulationflange

5.Bigflatwasher8

6.Standardspring

washer8

7.M8×40Hexagonhead

bolt

3.MounttheZXSDRR8860cabinetsonthesupportingpanelsandfastenthecabinets

withM6×20hexagonsocketcapscrewsasshowninFigure3-10.

Figure3-10Pole-mountInstallation(3)

3-10

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 47

Tip:

Thesidewithoutxingbracketcanbelocatedalongthewall.

–EndofSteps–

3.3Wall-mountedInstallationMode

3.3.1ComponentsUsedinWall-MountInstallation

Thecomponentsusedinwall-mountinstallationarelistedinT able3-7

Table3-7MainComponents

NameQuantity

Supportingpanel1

Chapter3CabinetInstallation

Drilltemplate1

M8×80expansionbolt4

Bigwasher84

ThesupportingpanelisshowninFigure3-11.Theholemarkingdesigntemplateisshown

inFigure3-12.

Figure3-11SupportingPanel

3-11

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 48

ZXSDRR8860InstallationManual

Note:

Thesupportingpanel,asthecommoncomponentinZXSDRR8860installation,isused

inthewall-mount,pole-mountandgantry-mountinstallationmodes.

Figure3-12HoleMarkingDesignT emplate(Unit:mm)

3.3.2InstallingCabinetonWall(Wall-Mount)

Context

Figure3-13illustratesthespacerequirement(Unit:mm)forwall-mountinstallation.

3-12

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 49

Chapter3CabinetInstallation

Figure3-13SpaceRequirementforWall-mountInstallation(Unit:mm)

Steps

1.Firstlymarktheholepositionsonthewallwithholedesigntemplate.Drillthemarked

pointsabout60mmwithpercussivedrillandinstalltheexpansionbolts.

2.FixthesupportingpanelonthewallwithboltsasshowninFigure3-14

Figure3-14SupportingPanelInstallationonWall

1.M8×80expansionbolt

2.Insulationboard

3.Supportingpanel

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

4.Insulationflange

5.Bigflatwasher8

6.Standardspringmat8

3-13

7.M8nut

Page 50

ZXSDRR8860InstallationManual

l

3.MounttheZXSDRR8860cabinetontothesupportingpanel,andfastenthecabinet

withfourM6X20hexagonsocketcapscrewsasshowninFigure3-15.

Figure3-15MountingCabinet

1.Supportingpanel2.M6safeguardscrew3.Retainingboard

–EndofSteps–

3-14

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 51

Chapter4

ExternalCableInstallation

TableofContents

ExternalCableLayout................................................................................................4-1

ExternalCableInstallationFlow.................................................................................4-2

Specicationsof1+3+3WaterproofProcessingwithPlasterandT ape.......................4-4

InstallingPowerCable................................................................................................4-6

InstallingGroundingCable.........................................................................................4-7

InstallingFiberbetweenBBUandRRU......................................................................4-9

InstallingFiberbetweenRRUandRRU....................................................................4-10

InstallingEnvironmentMonitoringCable...................................................................4-12

InstallingAISGControlCable...................................................................................4-13

InstallingFrequencyPointExtensionCable..............................................................4-14

InstallingJumper......................................................................................................4-15

InstallingPIMDC......................................................................................................4-16

4.1ExternalCableLayout

TheconnectionrelationshipofZXSDRR8860externalcablesisdescribedinTable4-1.

Table4-1ZXSDRR8860ExternalCableConnectionRelationship

NameConnectionRelationshipDescription

PowercableConnectstheZXSDR

GroundingcableConnectsoneZXSDR

R8860powerinterface(DCIN)

tothepowersupplyequipment

interface

R8860groundbolttothe

copperbar

Oneendistheaviationplugand

theotherendisreservedfor

powercablemadeonsite.The

lengthofcableisbasedonthe

engineeringsurvey.

Thegroundingcableismade

upofstrandsofame-retardant

wire.Thecrosssectionalarea

ofZXSDRR8860grounding

cableis10mm

groundingcableisyellowand

green.Copperlugsarecrimped

atbothendsoftheZXSDR

R8860groundingcable.

2

.Thecolorof

4-1

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 52

ZXSDRR8860InstallationManual

NameConnectionRelationshipDescription

OpticalFiberTherearetwotypesofZXSDR

R8860ber:BBUconnection

/ZXSDRR8860cascading.

EnvironmentmonitoringcableConnectstheZXSDR

R8860environmentmonitoring

interfaceMONtotheexternal

monitoringcomponentsorthe

drycontact.

AISGcontrolcableConnectstheZXSDR

R8860debugginginterface

(AISG)tothecontrolinterfaceof

electrical-adjustmentantenna.

Frequencypointextension

cable

InterconnectstheZXSDRR8860

RXin/RXoutinterfaces.

TherearetwotypesofZXSDR

R8860opticalber:oneusedin

BBUconnectionandtheother

usedincascadingbetween

ZXSDRR8860s.

Aendoftheenvironment

monitoringcableisPINdesign.

Bend,with3mlengthintotal,

needsmakingbasedonthe

on-siteengineering.

AISGisusedforcontrolofthe

electrical-adjustmentantenna.

Thefrequencypointextension

cableusuallyadoptsthenished

1/2″jumperwith2mlength.The

jumpercanbeself-madebased

onthereal-timeconditionon

site.

AandBendsofjumperareN

connectors(male).

Antenna,feederandjumperConnectstheZXSDRR8860to

themainfeeder.

4.2ExternalCableInstallationFlow

Figure4-1liststheinstallationowofexternalcable.Thisowcanbeadjustedbasedon

thereal-timecondition.

TheRFjumperusuallyadopts

thenished1/2″jumperwith

2mlength.Thejumpercan

beself-madebasedonthe

real-timeconditiononsite.

TheendofjumperisN

connector(male)andtheother

endisDINconnector(female).

4-2

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 53

Figure4-1ExternalCableInstallationFlow

Chapter4ExternalCableInstallation

4-3

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 54

ZXSDRR8860InstallationManual

4.3Specificationsof1+3+3WaterproofProcessing

withPlasterandTape

Overview

Waterproofprocessingmustbeperformedonalltheoutdoormetalconnectorsofthe

RRUs.Theconnectorsinclude:thegroundingcableconnector,feederconnector,optical

berconnector,powercableconnector,anddrycontactconnectingcableconnector.

In1+3+3plasterandtapewaterproofprocessing,thewaterproongself-adhesive

insulatedtape(plasterforshort)+electricalinsulatedtape(tapeforshort)+UV-stabilized

cablefastenersontwoendsareadopted.Thisis1+3+3waterproofprocessing,namely,

1layeroftape+3layersofplaster+3layersoftape.Figure4-2showstheplasterand

tape.

Figure4-2AppearanceofthePlasterandTape

OperationProcedure

1.Cleantheconnectorsandthepartofthecablesurfacesthatistobesealed.

2.Tosimplifyremovalofthe1+3+3waterproofmaterialasawholeinfuturemaintenance,

wrapalayeroftapewiththestrengthofunwrappingthetapefrombottomtotop,

overlappingeachturn50percent,asshowninFigure4-3.

Figure4-3WrappingaLayerofTape

3.Unwraptheplaster,andpeelthepaperbacking.Then,extendtheplastertooneto

twotimestheoriginalsize,facethestickyside(fromwhichsidethepaperbackingis

removed)totheconnectororcable,andthenapplythreelayersofplaster,frombottom

totop,fromtoptobottom,andfrombottomtotop.Overlapeachturn50percent.Use

yourngerstomoldtheplastersothattheplasterbetweenthreelayersiswellbond,

asshowninFigure4-4.

4-4

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 55

Chapter4ExternalCableInstallation

Figure4-4WrappingThreeLayerofPlaster

4.Withthestrengthofunwrappingthetape,wrapthreelayersoftape,frombottomto

top,fromtoptobottom,andfrombottomtotop,overlappingeachturn50percent.Use

yourngerstomoldthetapesothattheplasterandtapearewellbond,asshownin

Figure4-5.

Figure4-5WrappingaLayerofTape

5.Onthetwoend,tightlybindUV-stabilizedcablefastenerstothetape(underwhich

thereareplasterlayers)topreventremovalofthetape,asshowninFigure4-6.

4-5

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 56

ZXSDRR8860InstallationManual

Figure4-6BindingCableFasteners

Note

1.Wrapthetapewiththestrengthofunwrappingthetape(thatis,thestrengthofnaturally

unwrappingthetape).Thetapeshouldnotbeextended.

2.Extendtheplastertoonetotwotimestheoriginalsizewhilewrapping.

3.Overlapeachturnofthetapeandplasteratleast50percent.

4.Thedirectionsoftheplasterandtapeshouldbethesame.Thedirectionmustbegood

forfasteningthescrew.Thispreventsshrinkoftheextendedplasterfromloosening

theconnector.

5.Onthetwoends,overlaptheplasterandtapeforoneturn(whenchangingthe

wrappingdirection).

6.Afterwrapping,useyourngerstomoldtheplastersothattheplasterbetweenthe

layersiswellbond.

7.Thewrappinglengthofthetapemustbe(about10mm)longerthanthatofplaster,

especiallyonthecableend.Ensurethattheplasterisoverthetapesothatthe1+3+3

waterproofmaterialcanberemovedasawholeinfuturemaintenancewithcables

undamaged.

8.Afterwrapping,cuttheplasterandtapewiththescissorsorknife.Donotbreakthe

plasterortapedirectlywithyourhands.

9.Bindthecablefastenerstothetape(underwhichthereareplasterlayers)toprevent

removalofthetapeorshrinkoftheplasterifthecablefastenersareloosened.

4.4InstallingPowerCable

Context

TheZXSDRR8860cabinetadopts-48VDC/220VACpowersupply.EndAistheaviation

plugandEndBisreservedforself-madepowercableonsite.Thelengthofpowercable

isaccordingtotheengineeringsurvey.

ZXSDRR8860Figure4-7showsthestructureofpowercable.

Figure4-7PowerCablestructure

4-6

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 57

Chapter4ExternalCableInstallation

TheACandDCpowercablesarethesameinappearancebutdifferentincorecolorand

quantity,asdescribedinT able4-2andT able4-3.

Table4-2ColorandSpecicationofDCPowerCable

ColorSpecication

Blue-48V

Black-48VGND

Table4-3ColorandSpecicationofACPowerCable

ColorSpecication

BlueN

BlackorKellyPE

BrownL

Steps

1.ConnectEndAofpowercablewithDC/ACINinterfacelocatedatthebottomof

ZXSDRR8860.

2.StriptheprotectivecoatofEndBandconnectitwiththeDC/ACinputpowersource

accordingtocolorsoftheinsidecorecable.

3.MakewaterproofprotectionofEndB.

4.Attachlabelsatbothendsofthepowercable.

5.Fixthepowercable.

6.Performingoutdoorconnectorwaterproofprocessing,referto4.3Specicationsof

1+3+3WaterproofProcessingwithPlasterandTape.

–EndofSteps–

4.5InstallingGroundingCable

Context

Thegroundingcableismadeupofstrandsofame-retardantwire.Thecrosssectional

areaofZXSDRR8860groundingcableis10mm

andgreen.CopperlugsarecrimpedatbothendsoftheZXSDRR8860groundingcable,

asshowninFigure4-8.

2

.Thecolorofgroundingcableisyellow

4-7

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 58

ZXSDRR8860InstallationManual

Figure4-8GroundingCableStructure

Steps

1.CoverandxacopperlugontheagroundingboltoftheZXSDRR8860cabinet,as

showninFigure4-9.

Figure4-9ZXSDRR8860GroundingBolt

1.Groundingbolt

2.Connecttheothercopperlugtotheearth-networkingcopperbarandxitwithabolt,

asshowninFigure4-10.

4-8

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 59

Chapter4ExternalCableInstallation

Figure4-10Earth-networkCopperBar(Unit:mm)

3.Attachthelabelonthegroundingcable.

4.Measurethegroundingresistanceandmakesureitlessthan5Ω.

5.Performingoutdoorconnectorwaterproofprocessing,referto4.3Specicationsof

1+3+3WaterproofProcessingwithPlasterandTape.

–EndofSteps–

4.6InstallingFiberbetweenBBUandRRU

Prerequisites

TheZXSDRR8860cabinetmustbeinstalledandxedsuccessfully.

Context

Figure4-11showsberconnectionbetweenZXSDRR8860andBBU.

Figure4-11FiberConnectionbetweenZXSDRR8860andBBU

1.OutdoorSealComponent

WhileconnectingaBBUtoZXSDRR8860,makesurethatthebasebandRFberinterface

(LC1/2)oftheZXSDRR8860isconnectedtotheopticalinterfaceconnectoroftheBBU.

Steps

1.Attachlabelsatbothendsoftheber.

4-9

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 60

ZXSDRR8860InstallationManual

2.AdjustthesideofEndAwiththecolormarkandinserttheZXSDRR8860ber

interface,andscrewdownthenuts,asshowninFigure4-12

Figure4-12OpticalFiberInstallation

1.Colormark

3.ConnectEndAofthebertothebasebandRFberinterface(LC1/2)oftheZXSDR

R8860.

4.ConnectEndBoftheber,whichisaDLCconnector,totheBBUopticalconnector.

5.ScrewdowntheoutdoorsealcomponentatEndAforwaterproong.

6.Performingoutdoorconnectorwaterproofprocessing,referto4.3Specicationsof

1+3+3WaterproofProcessingwithPlasterandTape.

–EndofSteps–

4.7InstallingFiberbetweenRRUandRRU

Prerequisites

ThecascadingZXSDRR8860cabinetsmustbeinstalledandxedsuccessfully.

Context

Figure4-13showsberconnectionbetweenZXSDRR8860s.

4-10

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 61

Chapter4ExternalCableInstallation

Figure4-13FiberConnectionbetweenZXSDRR8860s

1.OutdoorSealComponent

WhileinterconnectingtheZXSDRR8860s,makesurethatthetwobasebandRFber

interfaces(LC1/2)oftheZXSDRR8860areconnected.

Steps

1.Attachlabelsatbothendsoftheopticalber.

2.AdjustthesideofEndAwiththecolormarkandinserttheZXSDRR8860ber

interface,andscrewdownthenuts,asshowninFigure4-14.

Figure4-14OpticalFiberInstallation

1.Colormark

3.ConnectEndAoftheopticalbertothebasebandRFberinterface(LC1/2)ofthe

ZXSDRR8860.

4.ConnectEndBoftheopticalbertotheotherbasebandRFberinterface(LC1/2)of

theZXSDRR8860.

5.ScrewdowntheoutdoorsealcomponentatEndAforwaterproong.

4-11

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 62

ZXSDRR8860InstallationManual

6.Performingoutdoorconnectorwaterproofprocessing,referto4.3Specicationsof

1+3+3WaterproofProcessingwithPlasterandTape.

–EndofSteps–

4.8InstallingEnvironmentMonitoringCable

Prerequisites

TheZXSDRR8860cabinetmustbeinstalledandxedsuccessfully.

Context

Theenvironmentmonitoringcableprovidesa485interface,usedforZXSDRR8860

environmentmonitoring.Inaddition,thecablealsoprovidesfourextensionaccessesfor

externaldrycontactmonitoring.

EndAisthe37PINconnector,andEndBismadebyon-siteengineering.Thetotallength

is3m.Figure4-15showstheappearanceofenvironmentmonitoringcable.

Figure4-15EnvironmentMonitoringCable

Theconnector,connectingtheenvironmentmonitoringcabletotheZXSDRR8860,

adopts37–coreaviationjack.TheconnectoraccordswiththeGJB599specication.The

connectorappearanceisasshowninFigure4-16

Figure4-16AviationJackAppearance

Table4-4describestheconnectorpins.

Table4-4CablePinDescription

PinCore-CableColorSignalDescription

15/16Whiteandblue/blueDrycontact4-/+

4-12

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 63

Chapter4ExternalCableInstallation

PinCore-CableColorSignalDescription

17/18Whiteandorange/orangeDrycontact3-/+

19/20Whiteandgreen/greenDrycontact2-/+

21/22Whiteandbrown/brownDrycontact1-/+

23/24Redandblue/blueRS485receive

25/26Redandorange/orangeRS485transmit

Steps

1.ConnectEndAtotheMONinterfacelocatedatthebottomofZXSDRR8860.

2.ConnectEndBwithexternalmonitoringdevicesordrycontacts.

3.AttachthelabelatEndB.

4.Performingoutdoorconnectorwaterproofprocessing,referto4.3Specicationsof

1+3+3WaterproofProcessingwithPlasterandTape.

–EndofSteps–

4.9InstallingAISGControlCable

Context

TheAISGcontrolcableisusedforcontroloftheelectricaladjustmentantenna.

Figure4-17showsthestructureoftheAISGcontrolcable.

Figure4-17AISGControlCableStructure

Table4-5describestheserialNo.meaningofAISGcontrolcable.

Table4-5AISGControlCableDescription

SerialNo.NameMeaning

1TRX_ANT_485_+RS485+

4-13

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 64

ZXSDRR8860InstallationManual

SerialNo.NameMeaning

2TRX_ANT_485_-RS485-

3,4TRX_ANT_28V28V

5,6TRX_ANT_28VGND28VGND

7,8NCNull

Steps

1.ConnectEndAtotheZXSDRR8860debugginginterface(AISG)andscrewdownthe

bolt;

2.ConnectEndBtothecontrolinterfaceofelectricaladjustmentantennaandscrew

downthebolt.

3.Performingoutdoorconnectorwaterproofprocessing,referto4.3Specicationsof

1+3+3WaterproofProcessingwithPlasterandTape.

–EndofSteps–

4.10InstallingFrequencyPointExtensionCable

Prerequisites

ThetwoZXSDRR8860cabinetstobecombinedmustbeinstalledandxedsuccessfully.

Context

Afterthecombinationofcabinets,theZXSDRR8860cansupport8carriersectorsatmost.

ThetwoZXSDRR8860cabinetsareconnectedthroughtheirconnectinginterfacessuchas

RXinandRXoutbytwofrequencypointextensioncables.Figure4-18showsthestructure

ofthefrequencypointcable.EndAandEndBareNconnectors(male).

The2M1/2″jumperisoftenusedforthefrequencypointextensioncable.Itmaybe

preparedonsiteifnecessary.

Figure4-18FrequencyPointExtensionCable

Steps

1.ConnectEndAofthefrequencypointextensioncabletothefrequencypointextension

interfaceRXINofoneZXSDRR8860;

4-14

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 65

4.11InstallingJumper

Chapter4ExternalCableInstallation

2.ConnectEndBtoRXoutoftheotherZXSDRR8860;

3.ConnecttheremainingRXin/RXoutinterfacesofthetwocombinedcabinetswiththe

otherfrequencypointextensioncable.

4.Performingoutdoorconnectorwaterproofprocessing,referto4.3Specicationsof

1+3+3WaterproofProcessingwithPlasterandTape.

–EndofSteps–

Context

OneendofRFjumperconnectswiththemainfeederandtheotherendconnectswiththe

antennafeederinterfaceofZXSDRR8860cabinet.BeforeinstallingtheRFjumper,the

mainfeederisinstalled.

TheRFjumperadoptsthe1/2″jumperwitha2mlength.Thejumpercanalsobeself-made

accordingtotheon-sitecondition.

TheinstallationpositionofRFjumperisasshowninFigure4-19.

Figure4-19RFJumperInstallation

PerformthefollowingstepstoinstalltheRFjumper.

Steps

1.ConnecttheDINconnector(male)ofRFjumperwiththeDINconnector(female)of

mainfeeder.

2.ConnecttheDINconnector(male)ofRFjumperwiththeDINconnector(female)of

ZXSDRR8860cabinet.

3.SealtheconnectorswithwaterproofadhesivetapesandPVCtapes.

4-15

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 66

ZXSDRR8860InstallationManual

4.Performingoutdoorconnectorwaterproofprocessing,referto4.3Specicationsof

1+3+3WaterproofProcessingwithPlasterandTape.

–EndofSteps–

4.12InstallingPIMDC

4.12.1PIMDCechnicalIndices

TheoutdoorDClightningbox(PIMDC)isusedforsurgeprotectionofZXSDRR8860.The

followingdescribesitscharacters:

lBreaksawayfromthepowersupplysystempermanentlytoavoidshortcircuitin

electricnetworkwhenmalfunctionedorfailed.

lAdoptsspecialvoltage-sensitivemoduleswithovercurrentandoverheatprotection,

highsurgecurrentandlowresidualvoltage.

lEquipsremotesignallingalarminterface.(Theremotedrycontactisnormallyclosed

atnormalcondition.Whensomepartsfailedorpoweriscutedoff,theremote

signallingdrycontactturnstobenormallyopenfromnormallyclosed.)

lTheenclosureismadeofaluminumdie-castingmetalanditsprotectiondegree

reachesthedemandofIP55.Itcanbeinstalledoutdoorforlongtermuseandhas

goodameretardance.

EngineeringTechnicalIndices

Table4-6describestheengineeringtechnicalindicesofPIMDC.

Table4-6EngineeringT echnicalIndicesofPIMDC

NominalOperatingV olt-

ageUnDC-48VConnectionTypeInSeries

Max.ContinuousOperat-

ingVoltageUcDC-75VProtectionModel

NominalDischargeCur-

rentIn8/20μs20kAResponseTime≤25ns

LeadAreaClampedby

Max.DischargeCurrent

Imax8/20μs40kA

ProtectionLevelUpIn≤180V

RatedLoadCurrentIL18AOperatingT emperature-40℃+70℃

LoadSideImpactCapacity

8/20μs8kAOperatingHumidity109525oC

thePowerConnecting

Terminal2.5mm

LeadAreaClampedby

DryContactTerminal0.15mm

Differentialand

CommonMode

2

2

10mm

2

2

1.3mm

Die-castingAlu-

Enclosure

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

minumSprayPaintAltitude≤3000m

4-16

Page 67

4.12.2PIMDCAppearance

Chapter4ExternalCableInstallation

DegreeofProtectionIP55Weight1.2kg

PIMDCAppearanceisshowninFigure4-20.

Figure4-20PIMDCAppearance

4-17

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 68

ZXSDRR8860InstallationManual

4.12.3PIMDCInstallationDescription

Inatallation

FastenthePIMDCononesideoftheZXSDRR8860mountingbracketusingtwoscrews,

asshowninFigure4-21.

Figure4-21InstallingPIMDC

ConnectingCables

OpenPIMDCcabinet,ConnectthePIMDCcables,asshowninFigure4-22.

4-18

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 69

Figure4-22PIMDCConnection

Chapter4ExternalCableInstallation

1.Groundcablebetweenthe

PIMDCandtheRRU

2.Inputpowercableofthe

PIMDC

3.Inputpowercableofthe

RRU

4.Drycontactcable

5.GroundcableofthePIMDC

1.ConnectgroundcableofthePIMDC,thegroundcableofthePIMDCisshowninFigure

4-22"5".

2.ConnecttheA-endtothe"InputSide"ofthePIMDCthroughthewaterproofplastic

ring:connectthebluecableto-48Vportandconnecttheblackcableto-48VRTNport

(theinputpowercableofthePIMDCisshowninFigure4-22"2".)

3.Fastenthepowercablewithalatch.Note:Thislatchshouldstaycontactwiththe

shieldedlayerofthepowercable,asshowninFigure4-23.

4-19

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 70

ZXSDRR8860InstallationManual

Figure4-23ConnectPowerInputCable

4.ConnecttheA-endoftheoutputpowercable(asshowninFigure4-22"3".)tothe

devicesideonthePIMDC:connectthebluecableto-48Vportandconnecttheblack

cableto-48VRTNport,asshowninFigure4-24.

5.Connectthewhiteandbluedrycontactcables(asshowninFigure4-22"4".)tothe

"Alarm"ports,asshowninFigure4-24.

Figure4-24ConnectingOutputPowerCableandDryContactCables

4-20

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 71

Chapter4ExternalCableInstallation

6.ConnectgroundcablebetweenthePIMDCandtheRRU(asshowninFigure4-22"1")

toRRU.

7.Performingoutdoorconnectorwaterproofprocessing,referto4.3Specicationsof

1+3+3WaterproofProcessingwithPlasterandT ape.

4-21

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 72

ZXSDRR8860InstallationManual

Thispageintentionallyleftblank.

4-22

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 73

Chapter5

MainAntennaFeederSystem

Installation

TableofContents

MainAntennaFeederSystemStructure.....................................................................5-1

MainAntennaFeederSystemInstallationPreparation...............................................5-7

MainAntennaFeederSystemInstallationFlow..........................................................5-8

AntennaInstallation....................................................................................................5-9

FeederInstallation....................................................................................................5-15

InstallingFeederHermetic-window...........................................................................5-25

FeederIndoorIngoing..............................................................................................5-27

PerformingAntennaFeederSystemTest.................................................................5-31

PerformingOutdoor-ConnectorWaterproofProcessing............................................5-32

PerformingFeederHermetic-windowWaterproofProcessing...................................5-36

ChassisJumperInstallationDescription...................................................................5-39

VSWRTest...............................................................................................................5-40

5.1MainAntennaFeederSystemStructure

ThetypicalcongurationsofZXSDRR8860mainantennafeedersystemdescribedbelow

includes:

lZXSDRR8860conguredwithcommonantenna

lZXSDRR8860conguredwithcommonantennaandAISGdualtoweramplier

lZXSDRR8860conguredwithelectricallytunedantenna(1)

lZXSDRR8860conguredwithelectricallytunedantenna(2)

lZXSDRR8860conguredwithelectricallytunedantenna,AISGdualtoweramplier

ZXSDRR8860conguredwithcommonantenna

Inthisconguration,generallyZXSDRR8860installationpositionisnearantennaand

theyareallinstalledonthebuildingtop.ZXSDRR8860isconnectedtotheantennaby

1/2″feederdirectly,occasionally5/4″or7/8″feederisadopted,asshowninFigure5-1.

5-1

SJ-20100722143906-002|02/20/2011(R1.3)ZTEProprietaryandCondential

Page 74