Page 1

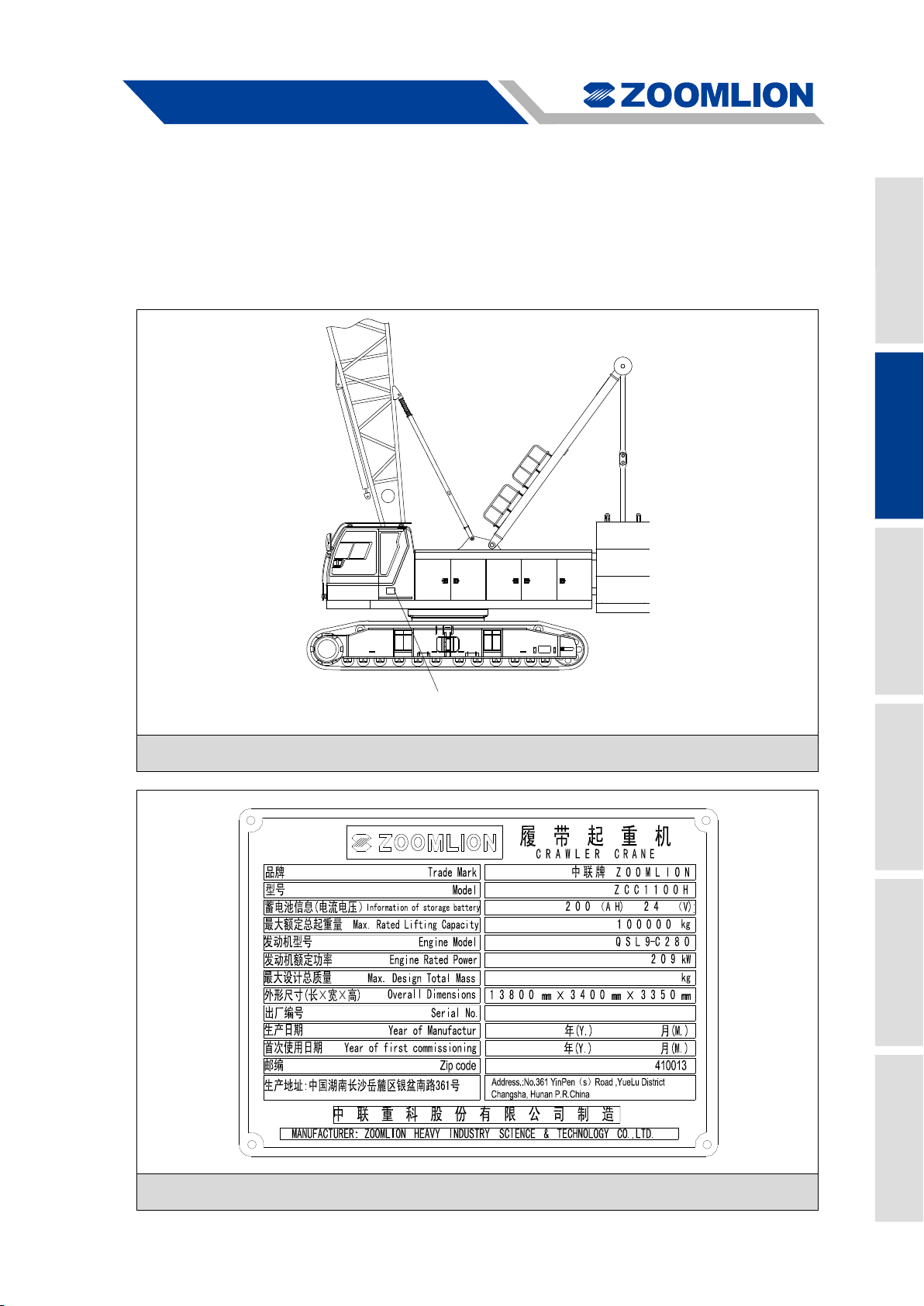

CRAWLER CRANE

Vision creates future

CRAWLER CRANE

Zoomlion Heavy Industry Science and Technology Co., Ltd

OPERATOR’S MANUAL

OPERATOR’S MANUAL

Add: Quantang Industrial Park, No. 1636, 2nd Yuanda Road, Economic and

Technological Development Zone, Changsha, Hunan Province, China.

PC: 410131

www.zoomlion.com

Zoomlion Heavy Industry Science and Technology Co., Ltd.

Page 2

Page 3

Edition 1 5, 2014

ZCC1100H Crawler Crane

Operator’s Manual

Page 4

Page 5

Operator’s Manual for Crawler Crane

Operator’s Manual for Crawler Crane

To Users

Zoomlion appreciates your selection of ZOOMLION crawler crane for your application.

No one should operate the crane unless they read and understand the information in this manual.

This manual contains the instructions and data on the safety and operation of the crawler crane.

Follow the operation procedures to make sure that your machine operates at MAXIMUM

EFFICIENCY. The operator must keep this manual in the cab of the crane.

If there is anything in the manual that is not clear or you do not understand, please contact our

service technician. We (Zoomlion) are NOT responsible for damages from an operator who does not

obey the instructions in the OPERATOR’S MANUAL.

The OPERATOR’S MANUAL is an important part of the crane. If the crane becomes the property of

a different person, make sure that the manual stays in the cab of the crane.

The data (data, specifications, illustrations) in this manual is for cranes in production at the time of

this manuals publication. We reserve the right to make changes to this manual at any time, without

obligation.

The manual has been translated to be best of our knowledge. Zoomlion assumes no liability for

translation errors. The Chinese version of the OPERATOR’S MANUAL is solely applicable for

factual accuracy.

Thank you!

Mobile Crane Branch Company of Zoomlion Heavy Industry Science and Technology Co., Ltd.

Copyright

Under the copyright laws, this manual may not be copied, photocopied, reproduced, translated, or reduced to any electronic

medium or machine readable form, in whole or part, without the prior written consent of Zoomlion Heavy Industry Science

and Technology Co., Ltd.

Copyright © 20XX, Zoomlion Heavy Industry Science and Technology Co., Ltd.

All rights reserved.

I

Page 6

Page 7

Operator’s Manual for Crawler Crane

Operator’s Manual for Crawler Crane

Contents

To Users ........................................................................................................................................ I

Safety Instructio ns ....................................................................................................................... II

Chapter 1 Safety

1.1 Important instructions ................................................................................................... 1-1

1.1.1 Notes ............................................................................................................... 1-1

1.1.2 Alarms and warnings ........................................................................................ 1-1

1.2 Safe ty tips .................................................................................................................... 1-2

1.2.1 Safety precautions ........................................................................................... 1-2

1.2.2 Precautions for operator safety ......................................................................... 1-2

1.3 Environmental safety ................................................................................................... 1-2

1.4 Personnel protective equipment (PPE) ....................................................................... 1-2

1.5 Organizational safety measures ................................................................................... 1-3

1.6 Personnel qual ification, requirem ents and responsibilities ............................................ 1-3

1.7 Safety advi c e regarding specific operation phases ....................................................... 1-4

1.8 Special Hazards ........................................................................................................... 1-4

1.8.1 Electrical power ................................................................................................ 1-4

1.8.2 Gas, dust, steam , sm ok e and noise .................................................................. 1-5

1.8.3 Welding or naked flames .................................................................................. 1-5

1.8.4 Hydrauli c equipm ent......................................................................................... 1-5

Chapter 2 Description of Crane

2.1 Product model ............................................................................................................. 2-1

2.1.1 Product name plate and its position .................................................................. 2-1

2.1.2 Engine type and its manufacturer ..................................................................... 2-2

2.1.3 Int ended use of the crane ................................................................................. 2-2

2.1.4 Classif ic ation of the crane ............................................................................... 2-2

2.2 Terminology ................................................................................................................. 2-5

2.2.1 Crane modes ................................................................................................... 2-5

2.2.2 Descripti on of main components ....................................................................... 2-8

2.3 Product description .................................................................................................... 2-10

2.3.1 Cr

2.3.2 Crawler tr av el gear ......................................................................................... 2-10

2.3.3 Crane superstruct ur e...................................................................................... 2-10

ane working environment ............................................................................ 2-10

III

Page 8

Operator’s Manual for Crawler Crane

2.3.4 Over all dim ensi ons......................................................................................... 2-12

2.4 Techni c al data ............................................................................................................ 2-13

2.4.1 Main technic al parameter ............................................................................... 2-13

2.4.2 Specification of load hook and sel ec tion of rope reeving ................................. 2-15

2.4.3 Performance of wire rope and winch............................................................... 2-15

2.4.4 Lifti ng height .................................................................................................. 2-18

2.4.5 Lifti ng capacit y chart....................................................................................... 2-21

2.4.6 Lifti ng capacit y i n assembly m ode .................................................................. 2-57

Chapter 3 Safety Guideli nes

3.1 Operational planning .................................................................................................... 3-1

3.1.1 Correct use of the cr ane ................................................................................... 3-2

3.1.2 Possible c onsequence s resulting from im pr oper use of the cr ane ..................... 3-2

3.1.3 Responsibi lity of relevant personnel ................................................................. 3-3

3.1.4 Work area ........................................................................................................ 3-4

3.2 Safety technic al notes .................................................................................................. 3-5

3.2.1 Safety instructions for crane operator ............................................................... 3-5

3.2.2 The requir em ent for the crane operator during the whole operat ion .................. 3-5

3.2.3 Safety instructions for the rigger ....................................................................... 3-6

3.2.4 Safety instructions for the signalman ................................................................ 3-7

3.2.5 Safety instructions for crane operating crew ..................................................... 3-7

3.2.6 Electromagnetic influences ............................................................................... 3-8

3.2.7 Safety signs ..................................................................................................... 3-9

3.2.8 The pot ential dangers existing in crane operation ........................................... 3-17

3.2.9 Injuries due to hydraulic energy ...................................................................... 3-18

3.2.10 Scald ........................................................................................................... 3-19

3.2.11 Ri sk of chemic al bur ns.................................................................................. 3-19

3.2.12 Risk of fir e and ex plosi on ............................................................................. 3-20

3.2.13 Risk of poi soni ng and asphyxiation ............................................................... 3-22

3.2.14 Endangering the environment ....................................................................... 3-23

3.3 S

IV

lings ........................................................................................................................ 3-24

3.3.1 Hooks ............................................................................................................ 3-24

3.3.2 Rigging introduction ....................................................................................... 3-24

3.3.3 Sli ngs i ntroduc tion .......................................................................................... 3-25

3.3.4 Sli ng safet y .................................................................................................... 3-25

3.3.5 Sli ng safet y gui de ........................................................................................... 3-26

3.3.6 Taglines ......................................................................................................... 3-26

3.3.7 Load center of grav ity ..................................................................................... 3-27

Page 9

Operator’s Manual for Crawler Crane

Operator’s Manual for Crawler Crane

3.4 Requirements for oper ating site ................................................................................. 3-28

3.4.1 Slopes and trenches....................................................................................... 3-28

3.4.2 Permissibl e gr ound pr essure .......................................................................... 3-29

3.4.3 Travel on level ground or slope wit hout a load ................................................ 3-30

3.4.4 Travel on level ground or slope wit h a load ..................................................... 3-30

3.4.5 The requir em ents for cr awler c r ane with attachments on uphill slopes ............ 3-30

3.5 Operation weather ..................................................................................................... 3-32

3.5.1 Snow and ice ................................................................................................. 3-32

3.5.2 Lightning Strikes ............................................................................................. 3-32

3.6 Electric al safety.......................................................................................................... 3-33

3.6.1 Safety regulations for auxiliary power supply (220V AC) ................................ 3-33

3.7 Underground cabl es................................................................................................... 3-34

3.7.1 In undergr ound working, it is possible to damage: ......................................... 3-34

3.7.2 Safety prec autions and protectiv e measures when operating t he equipment near

underground cables ................................................................................................... 3-34

3.7.3 Notes in c onnec tion with gas pipes ................................................................. 3-35

3.7.4 The consequences of a gas pi pe’s damage .................................................... 3-35

3.7.5 Measures adopted if a gas pipe is damaged and the gas escapes, or a l eak is

suspected.................................................................................................................. 3-36

3.7.6 Measures adopted in the event of a gas fire ................................................... 3-36

3.7.7 Notes in c onnec tion with underground electri c cabl es ..................................... 3-37

3.7.8 The consequences of dam aging an underground cabl e .................................. 3-37

3.7.9 The measures taken when the machine damages an underground cable ....... 3-37

3.8 Checking safety measures ......................................................................................... 3-39

3.8.1 Daily i nspect ion of the crane........................................................................... 3-39

3.8.2 Safety chec ki ng before crane operation .......................................................... 3-39

3.9 Crane operation with a load ....................................................................................... 3-40

3.9.1 Counterweight ................................................................................................ 3-40

3.9.2 Crane operat ion ............................................................................................. 3-41

3.10 Hand signals for controlling crane oper ations ........................................................... 3-53

Chapter 4 Crane operation

4.

1 Operating and cont r ol instr um ents................................................................................ 4-1

4.1.1 Operator’s cab, overvi ew .................................................................................. 4-1

4.1.2 Operating console ............................................................................................ 4-3

4.1.3 Control lever..................................................................................................... 4-4

4.1.4 Left control panel .............................................................................................. 4-7

4.1.5 Right control panel ........................................................................................... 4-8

V

Page 10

Operator’s Manual for Crawler Crane

4.1.6 Control panel on the roof of operator’s cab ....................................................... 4-9

4.2 Instructi on for digital display system ........................................................................... 4-12

4.2.1 Load moment limiter ....................................................................................... 4-12

4.2.2 Electrical system ............................................................................................ 4-13

4.3 Startup of the crane ................................................................................................... 4-19

4.3.1 Adj ustm ent of crane operator ’s seat ............................................................... 4-19

4.3.2 Checks bef or e startup .................................................................................... 4-21

4.3.3 Turn on power supply ..................................................................................... 4-22

4.3.4 Operation of air conditioning in operator ’s cab ................................................ 4-24

4.3.5 Horn............................................................................................................... 4-24

4.3.6 Start of engine ................................................................................................ 4-25

4.4 Safe ty d evice ............................................................................................................. 4-27

4.4.1 Emergency stop button .................................................................................. 4-27

4.4.2 Battery master switch ..................................................................................... 4-28

4.4.3 Flashing light .................................................................................................. 4-29

4.4.4 Load moment limiter ....................................................................................... 4-29

4.4.5 Boom angle indicator ..................................................................................... 4-31

4.4.6 Derricki ng lim iter ............................................................................................ 4-32

4.4.7 Lowering limiter .............................................................................................. 4-33

4.4.8 Hoisting lim iter ............................................................................................... 4-34

4.4.9 Anemometer .................................................................................................. 4-35

4.4.10 Crane i ncli nom eter ....................................................................................... 4-35

4.4.11 Checklist of safety device ............................................................................. 4-36

4.5 Crane operation ......................................................................................................... 4-40

4.5.1 Preparation for operation ................................................................................ 4-40

4.5.2 Inspection during operati on ............................................................................ 4-40

4.5.3 Valid area of control lever ............................................................................... 4-41

4.5.4 Setting of work mode ..................................................................................... 4-42

4.5

.5 Operation of travel gear .................................................................................. 4-42

4.5.6 Operation of crane winches ............................................................................ 4-46

4.5.7 Operation of slewing mechanism .................................................................... 4-51

4.5.8 Auxiliary remote control box ........................................................................... 4-55

4.6 Rope reeving ............................................................................................................. 4-57

4.6.1 Hoisting r ope guidance and reeving ............................................................... 4-57

4.6.2 Derricki ng r ope r eeving .................................................................................. 4-61

4.6.3 Fixation of rope end point ............................................................................... 4-63

VI

Page 11

Operator’s Manual for Crawler Crane

Operator’s Manual for Crawler Crane

Chapter 5 Assembly and Di smantling

5.1 Safety-technical notes .................................................................................................. 5-1

5.1.1 Notes on assembly ........................................................................................... 5-1

5.1.2 Checking safety measures ............................................................................... 5-1

5.1.3 Checking wire rope, load hook, rope pull ey and anchoring r od .......................... 5-3

5.2 Assembly of basic m ac hine .......................................................................................... 5-5

5.2.1 Unloading of basic machine.............................................................................. 5-5

5.2.2 Self-assembly and dismantling of crawler c ar ri er (opt ional) ............................. 5-10

5.2.3 Ext ending and r etracting of crawler carrier ...................................................... 5-16

5.2.4 Assembl y of central c ounterweight ................................................................. 5-22

5.2.5 Self-assembl y and dismantling of counterweight ............................................. 5-26

5.2.6 Fixation of mounting cylinder .......................................................................... 5-32

5.3 Available boom confi gur ations.................................................................................... 5-34

5.4 Boom configur ation .................................................................................................... 5-37

5.4.1 Main boom (S-1) ............................................................................................ 5-37

5.4.2 Main boom wit h fixed jib (SF-1) ...................................................................... 5-50

5.5 Assembly and dismantling of main boom ................................................................... 5-59

5.5.1 Preparations for assembly .............................................................................. 5-59

5.5.2 Assembl y of main boom ................................................................................. 5-59

5.5.3 Elect ri c al c onnec tion to main boom ................................................................ 5-66

5.5.4 Erecting main boom ....................................................................................... 5-68

5.5.5 Lowering and di smantling main boom ............................................................. 5-70

5.6 Assembly and dismantling of main boom with fix ed jib ................................................ 5-71

5.6.1 Preparation for assembly ................................................................................ 5-71

5.6.2 Assembl y of fixed jib....................................................................................... 5-71

5.6.3 Electrical connection to fixed jib ...................................................................... 5-76

5.6.4 Erecting main boom with fixed jib ................................................................... 5-78

5.7 Assembly and dismantling of tip boom ....................................................................... 5-81

5.8 Transport weights and dimensions of m ain c om ponents ............................................. 5-82

ransport means and safet y precautions for transport ................................................ 5-85

5.9 T

5.9.1 Safety prec autions for transport ...................................................................... 5-85

5.9.2 Other requirements ........................................................................................ 5-85

VII

Page 12

Page 13

履带起重机操作手册

第一章 安全操作说明

Operator’s Manual for Crawler Crane

Chapter 1 Safety

Page 14

Page 15

履带起重机操作手册

安

全

操

作

说

明

Operator’s Manual for Crawler Crane

Safety

Operator’s Manual for Crawler Crane

CAUTION

Chapter 1 Safety

1.1 Important instructions

1.1.1 Notes

a) Read this manual and familiarize yourself with any associated documents before operating

this crane.

b) Ensure that a copy of this manual is available to any person installing, using, maintaining

or repairing this equipment. Training should be provided to ensure safe working practices.

c) To avoid the risk of electric shock, always isolate this equipment from the power supply

prior to carrying out any maintenance adjustment or removing any guards or covers.

d) Always follow the procedures outlined in the Operator’s Manual and Maintenance Manual.

e) If in doubt, do not take personal risk.

f) Only trained personnel can be allowed to install, set, operate, maintain, and commission

this equipment.

g) End-user (the owner) should follow the restrictions of using the crane and all the relevant

parameters specified by the manufacturer. If technical parameters can not be obtained

clearly, experienced and qualified engineer should judge the restrictions of using, which

should be recorded in the archive. Do not exceed the rated capacity specified in the

documents associated with the crane.

h) End-user should comply with requirements in 29CRS, OSHA about CC section.

1.1.2 Alarms and warnings

a) As to the persistent danger mentioned in this manual, affix the warning symbols in proper

positions of the crane.

b) Alarm symbols

1) You can be injured if you do not obey the safety instructions as indicated on warning

stickers.

2) Ensure that safety instructions and warnings attached to the crane are always

complete and perfectly legible.

3) Keep warnings and instruction labels clean.

4) Replace unreadable or missing labels with new ones before operating the crane.

Make sure the replacement parts include warning or instruction labels where

necessary.

(1) Follow the warnings and instructions for the sake of personal safety.

(2) For the position of warnings and instruction labels, please see chapter 3 "Safety

Guidelines".

ZCC1100H Crawler Crane 1-1

Page 16

Operator’s Manual for Crawler Crane

Safety

1.2 Safety tips

1.2.1 Safety precautions

a) Do not use this equipment with guards removed or incorrectly fastened.

b) Do not use this equipment with safety devices maladjusted or removed.

1.2.2 Precautions for operator safety

a) Safety component – crane emergency stop button. Ensure all safety components are in

place.

b) Support plates, handrails, tread plates and fixed guards are provided to assist the

personnel to climb on the crane.

1.3 Environmental safety

a) A regular service should be taken on the crane strictly in accordance with maintenance

procedures to ensure that engine emission is close to a minimum value.

b) Consumable materials

1) Diesel spillages must be dealt with immediately.

2) Only use the lubricating oil recommended in the maintenance manual.

3) Local regulations must be observed strictly when disposing of waste.

4) Improper disposal of waste will affect the ecological environment, which is also illegal.

5) Potentially harmful waste used on this crane includes such items as hydraulic oil, fuel,

coolant, filters and batteries, etc.

6) Use leak-proof containers for draining fluids. Do not use food or beverage containers

that may mislead someone into drinking or eating them.

7) Do not pour waste into the ground, into sewer system or into any water source.

8) Ensure that all consumable and replaced parts are disposed of safely and with

minimum environmental impact.

c) Machine disposal. This machine must only be disposed of by a special machine breaker.

1.4 Personnel protective equipment (PPE)

a) Loose or baggy clothing can get caught in running machinery.

b) Where possible when working close to engines or machinery, only do so when they are

stopped. If this is not practical, remember to keep tools, test equipment and other tools

that will enable parts of your body away from the moving parts.

c) For reasons of safety, long hair must be tied back or otherwise secured. Garments must be

close fitting and no jewellery such as rings may be worn.

d) Correctly wear personnel protective equipment.

e) Recommended personnel protective equipment includes:

1-2 ZCC1100H Crawler Crane

Page 17

履带起重机操作手册

安

全

操

作

说

明

Operator’s Manual for Crawler Crane

Safety

Operator’s Manual for Crawler Crane

- Hard hat

- Safety glasses/Goggles

- Hearing protection device

- Close fitting overalls

- Safety boots

- Industrial gloves

- High visibility vest or jacket

1.5 Organizational safety measures

a) The crane must only be operated by a suitably qualified operator who holds a current

license in line with construction site or international legislation.

b) Understand the service procedure before doing work. Keep working area clean and dry.

c) Never lubricate, clean or adjust crane while it is moving (excluding central lubrication).

d) Keep hands, feet and clothing clear of power driven parts or running nip-points.

e) Keep all parts in good condition. Ensure that all parts are properly installed. Fix damage

immediately. Replace worn and broken parts. Remove grease, oil and debris in time.

f) Disconnect battery ground cable and power supply before making adjustments on

electrical systems.

g) Disconnect battery ground cable, switch off the engine and unplug all plugs of controllers

before welding on machine.

h) During maintenance only use the correct tool for the job.

i) Never make any modifications, additions or changes which might affect safety without the

manufacturer’s approval.

j) In the event of safety relevant modifications or changes in the behavior of the machine

during operation, stop the machine, lock it immediately and report the malfunction to the

relevant authority / person.

1.6 Personnel qualification, requirements and responsibilities

a) Any work on and / or with the crane must be executed by trained, reliable and authorized

personnel only.

b) Maintenance work must only be undertaken by suitable qualified engineers with specialist

knowledge of this crane.

c) Work on the hydraulic system must be carried out only by personnel with special

knowledge and experience of hydraulic equipment.

ZCC1100H Crawler Crane 1-3

Page 18

Operator’s Manual for Crawler Crane

Safety

1.7 Safety advice regarding specific operation phases

a) Standard operation

1) Take necessary precautions to ensure that the crane is used in a safe and reliable

state.

2) This crane is a conventional assembly & dismantling machine. Do not apply the crane

for other purpose. Operate the crane only for its designed purpose and only if all

guarding, protective and safety-orientated devices, emergency shut-off equipment,

sound proofing element and exhausts, are in place and fully functional.

3) Ensure that any local barriers erected to stop unauthorized entry to this equipment

are in place.

4) Before starting the engine, ensure it is safe to do so.

b) Malfunction

In the event of any malfunction or operational difficulty, stop the crane immediately.

c) Unguarded areas

1) In-running nip points on moving machinery can cause serious injury or even death.

2) Do not reach into unguarded machinery. Your arm could be pulled in and amputated.

3) Stop the crane before removing any safety devices or guarding devices.

4) Limit access to the machine and its surrounding where barrier guards are

appropriately erected to reduce the risk of potential mechanical hazards, such as

falling lifted loads.

1.8 Special Hazards

1.8.1 Electrical power

a) External considerations and hazards

When working with the crane, maintain a safe distance from the overhead electric lines. If

overhead lines are in the immediate vicinity, a risk assessment must be completed prior to

operating this crane.

If your machine comes into contact with a live wire:

- Vacate the area

- Warn others against approaching and touching the crane.

- Report the incident and have the live wire de-energized.

b) Machine – Electrical

- The electrical equipment of the crane must be inspected at regular intervals. Defects

such as loose connections, scorched or otherwise damaged cables must be rectified

immediately.

- Use only original fuses with the specified current rating.

- Switch off the machine immediately if trouble occurs in the electrical system.

1-4 ZCC1100H Crawler Crane

Page 19

履带起重机操作手册

安

全

操

作

说

明

Operator’s Manual for Crawler Crane

Safety

Operator’s Manual for Crawler Crane

- This crane is wired on a negative earth. Always observe correct polarity.

c) Battery

- Always disconnect battery leads before carrying out any maintenance to the electrical

system.

- Recharge the battery in a well ventilated area.

- The battery contains sulphuric acid, an electrolyte which can cause severe burns and

produce explosive gases. Avoid contact with the skin, eyes or clothing.

- No smoking when maintaining battery.

- Wear appropriate PPE.

1.8.2 Gas, dust, steam, smoke and noise

a) Always operate internal combustion engines out of doors or in a well ventilated area.

b) If a crane is operated for maintenance purposes in an enclosed area, ensure that there is

sufficient ventilation.

c) Observe the rules and regulations at different working sites.

d) Dust found on the crane or produced during work on the crane must not be removed by

blowing with compressed air.

e) Toxic dust / waste must only be handled by authorized persons, dampened, placed in a

sealed container and marked, to ensure safe disposal.

1.8.3 Welding or naked flames

a) Welding, flame cutting and grinding work on the crane must only be carried out if this has

been expressly authorized, as there may be a risk of explosion and fire.

b) No welding that will affect its structural integrity should be undertaken on this crane.

c) Avoid all naked flames in the vicinity of this crane.

d) Only when a fire extinguisher with a specification of no less than 10BC is equipped in the

operator’s cab, can the crane work.

1.8.4 Hydraulic equipment

a) Work on hydraulic system must be carried out by persons having special knowledge and

experience of hydraulic system.

b) Check all lines, hoses and screwed connections regularly for leaks and obvious damage.

Repair damage immediately. Sprayed oil may cause personal injury and fire.

c) Always relieve pressure from the hydraulic system before carrying out any kind of

maintenance or adjustment work.

d) Depressurize all system components and pressure pipes (such as hydraulic system,

compressed air system) to be removed in accordance with the specific instructions for the

unit concerned before carrying out any repair work.

ZCC1100H Crawler Crane 1-5

Page 20

Operator’s Manual for Crawler Crane

Safety

e) Hydraulic lines and compressed air lines must be laid and fitted properly. Ensure that no

connections are interchanged. The fittings, lengths and quality of the hoses must comply

with the technical requirements.

f) Only fit replacement components of a type provided by the manufacturer.

g) Always keep hydraulic elements clean.

h) Hydraulic fluid under pressure can penetrate the skin and cause serious injury.

i) Once the fluid is injected under/into the skin, seek medical help immediately.

1-6 ZCC1100H Crawler Crane

Page 21

履带起重机操作手册

第二章 起重机的描述

Operator’s Manual for Crawler Crane

Chapter 2 Description of Crane

Page 22

Page 23

Operator’s Manual for Crawler Crane

Description of Crane

Operator’s Manual for Crawler Crane

Figure 2-1 Position of product name plate

Figure 2-2 Product name plate

Position of product name plate

Chapter 2 Description of Crane

2.1 Product model

2.1.1 Product name plate and its position

ZCC1100H Crawler Crane 2-1

Page 24

Operator’s Manual for Crawler Crane

Description of Crane

CAUTION

2.1.2 Engine type and its manufacturer

QSL9-C 280, American Cummins (Imported)

2.1.3 Intended use of the crane

This crawler crane is designed for lifting loads!

It is prohibited to transport people with this equipment! In many cases, there have been serious

injuries when people have been transported using this equipment (or even on the hook or on

loads). Under such circumstances, they have no control over the crane movements and are not

protected against bumps or falls. Even the smallest error can cause vital injury! In exceptional

cases, please consult the responsible authorities concerning safety regulations.

It is expressly forbidden to use the crane for jumps with rubber ropes (bungee jumping)! Using

the crane for such jumps represents a misuse of the crane and entails extreme danger for life

and limb!

The crane is designed exclusively for assembly operation, i.e. lifting loads, non-continuous use

of crane. Any other type of use or otherwise use which goes beyond its limits specified, such as

handling of general cargo or grab operation, are not classified as intended use. The

manufacturer shall not be liable for any damage caused. The operator bears full responsibility

for this type of misuse.

The use of two hoisting winches for lifting loads (twin hook operation) is only permitted following

consultation with the crane manufacturer.

The intended use also includes the observation of Operator’s Manual and Maintenance

Manual.

2.1.4 Classification of the crane

2.1.4.1 General

The crane has been constructed using state of the art technology and in accordance with

recognized safety regulations. Nevertheless, its use can lead to hazards for the life and limb of

2-2 ZCC1100H Crawler Crane

the operator and third parties, and/or damage to the machine and other objects.

Use the crane only when it is in full working order and only for its intended use, paying attention

at all times to safety and potential hazards, and in observance of the Operator’s Manual and

Maintenance Manual.

Have any malfunctions which might impair safety rectified immediately.

Page 25

Operator’s Manual for Crawler Crane

Description of Crane

Operator’s Manual for Crawler Crane

No.

Working

mechanism

Operating class

Load collective

class

Crane group

1

Hoisting winch

T3/T5

L2/L3

M4/M6

2

Slewing

mechanism

T2

L2

M2

3

Derricking

mechanism

T2

L2

M2

4

Travel gear

T2

L1

M1

Note:

Among hoisting winches, the group of winch with free-fall function is M6, and group of normal winch is M4.

125.0

p

K

3

maxQ

Qi

T

i

P

P

P

C

C

K

2.1.4.2 Classification of the crane

The crane group of the crane is A1, operating class is U2 and the load collective class is Q1.

All important components of the crane are designed and manufactured for normal assembly

operation. Operating conditions or types of use other than assembly operation require the

permission of the manufacturer and normally lead to a reduction in the lifting capacities.

Otherwise, the life of the crane will reduce. The classification of various mechanisms is shown

in table 2-1.

Table 2-1 Classification of various mechanisms

2.1.4.3 Service life

Classification of the crane is based on a total operating life (service life) of 20 years under the

following conditions:

a) The crane is operated as an assembly crane. The load capacity charts specified for the

crane are for assembly operation only. General cargo handling or grab operation can only

be permitted following express permission from the manufacturer under suitable

conditions.

b) The entire number of the crane’s load cycles

A “load cycle” encompasses processes which begin when a load is lifted and end when the

crane is ready to lift the next load, including the time of crane operation and normal break.

The entire number of the crane’s load cycles with operating class U2 is 32000 – 63000 (for

example: 8 – 20 strokes / day on 200 days / year).

c) The load collective class of the crane

The load spectrum coefficient of the crane with load collective class Q1

the rated load rarely, but the medium-duty load frequently), the calculation of load

spectrum coefficient is expressed as follows:

(lift

ZCC1100H Crawler Crane 2-3

Page 26

Operator’s Manual for Crawler Crane

Description of Crane

Qi

P

maxQ

P

i

C

Qi

P

T

C

CAUTION

Where,

is the i value appearing in the whole service life of the crane.

is the max. load value appearing in the crane’s entire service life.

is the crane’s load cycles corresponding to

load in the crane’s entire service life.

is the entire number of the crane’s load cycles in the crane’s service life.

The examples of load spectrum coefficient are as follows:

10% of crane’s load cycles in the crane’s entire service life is under the maximum load.

40% of crane’s load cycles in the crane’s entire service life is under 40% of the maximum

load.

50% of crane’s load cycles in the crane’s entire service life is under 10% of the maximum

load.

“Load” is to be understood in this connection as the sum total of load, load handling

devices and lifting tackle (e.g.: load + load hook + sling rope).

Under these circumstances, assuming that maintenance work is carried out properly, the

theoretical service life can be more than 20 years. Harder operating conditions lead to a

reduction in the service life.

If the user uses the crane according to other operating class and load collective class, the

corresponding entire number of crane’s load cycles and load spectrum coefficient are

adjusted, which result in a change of crane service life.

Some components (for example, wire rope, pulley and bearing) are not designed for the

entire service life of the crane, but must be replaced after a certain amount of time.

2-4 ZCC1100H Crawler Crane

Page 27

Operator’s Manual for Crawler Crane

Description of Crane

Operator’s Manual for Crawler Crane

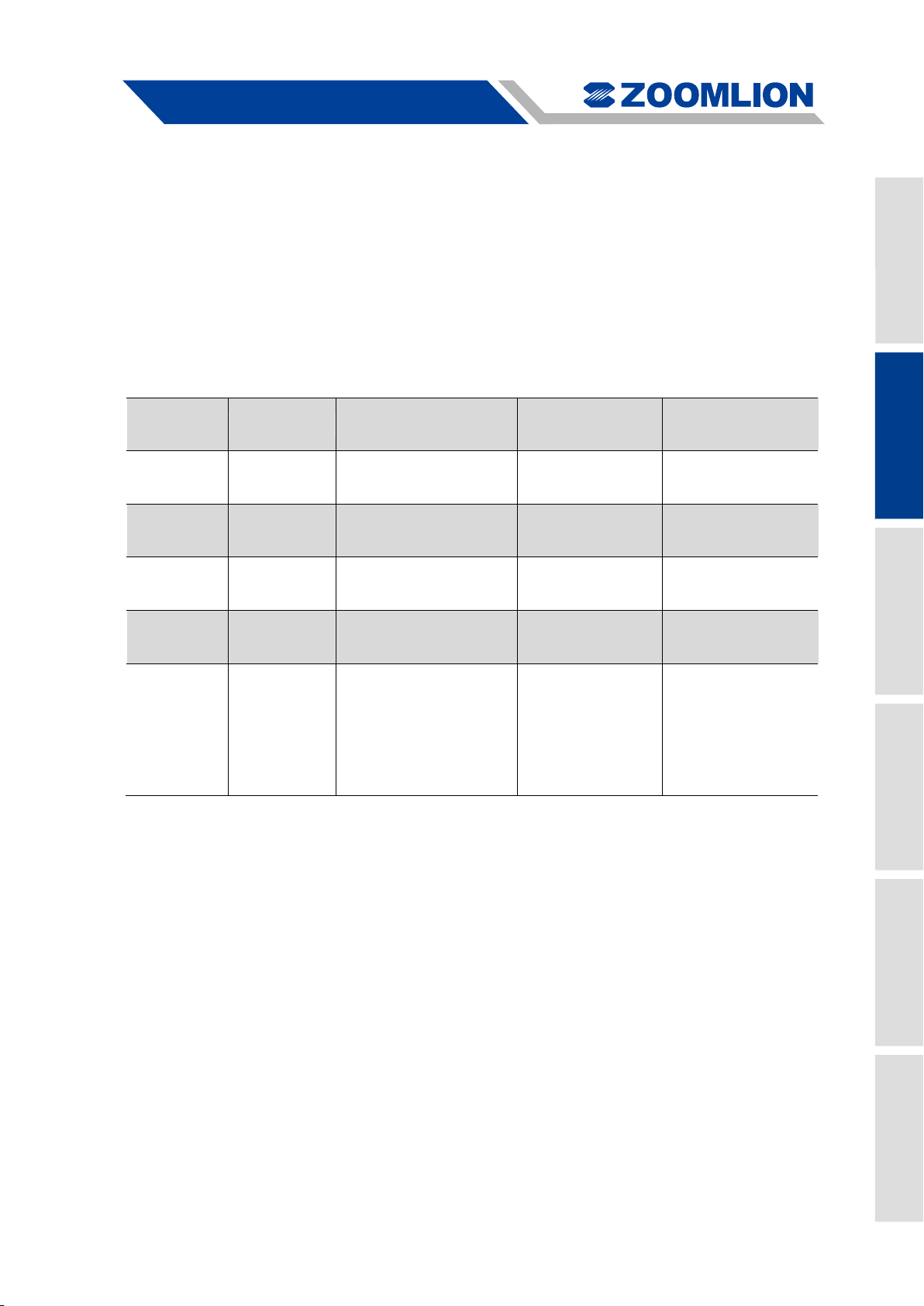

Configuration

no.

Description

Length of main boom

Length of fixed jib

Remarks

S-1

Main boom

42’8”(13m)-219’10”(67m)

No

The load is attached

onto main boom.

S-2

Main boom

with fixed jib

101’9”(31m)-180’5”(55m)

19’8”(6m)-59’(18m)

The load is attached

onto main boom.

S-3

Main boom

with tip boom

42’8”(13m)-200’2”(61m)

No SF-1

Main boom

with fixed jib

101’9”(31m)-180’5”(55m)

19’8”(6m)-59’(18m)

The load is attached

onto fixed jib.

SF-2

Main boom

with fixed jib

101’9”(31m)-180’5”(55m)

19’8”(6m)-59’(18m)

Main boom is

attached with a load

hook. However, the

load is attached onto

fixed jib.

2.2 Terminology

2.2.1 Crane modes

2.2.1.1 Working mode

The boom configurations of ZCC1100H crawler crane in working mode are shown in the table

2-2.

Table 2-2 Boom configurations of ZCC1100H crawler crane in working mode

ZCC1100H Crawler Crane 2-5

Page 28

Operator’s Manual for Crawler Crane

Description of Crane

Figure 2-3 Boom configurations

DANGER

S-1 S-2 S-3 SF-1 SF-2

The boom configurations are shown in the figure 2-3.

It’s prohibited to lift a load by use of two hooks (twin hook operation) without the

permission of the manufacturer under the boom configurations S-2, S-3, SF-2, otherwise,

the crane may topple over.

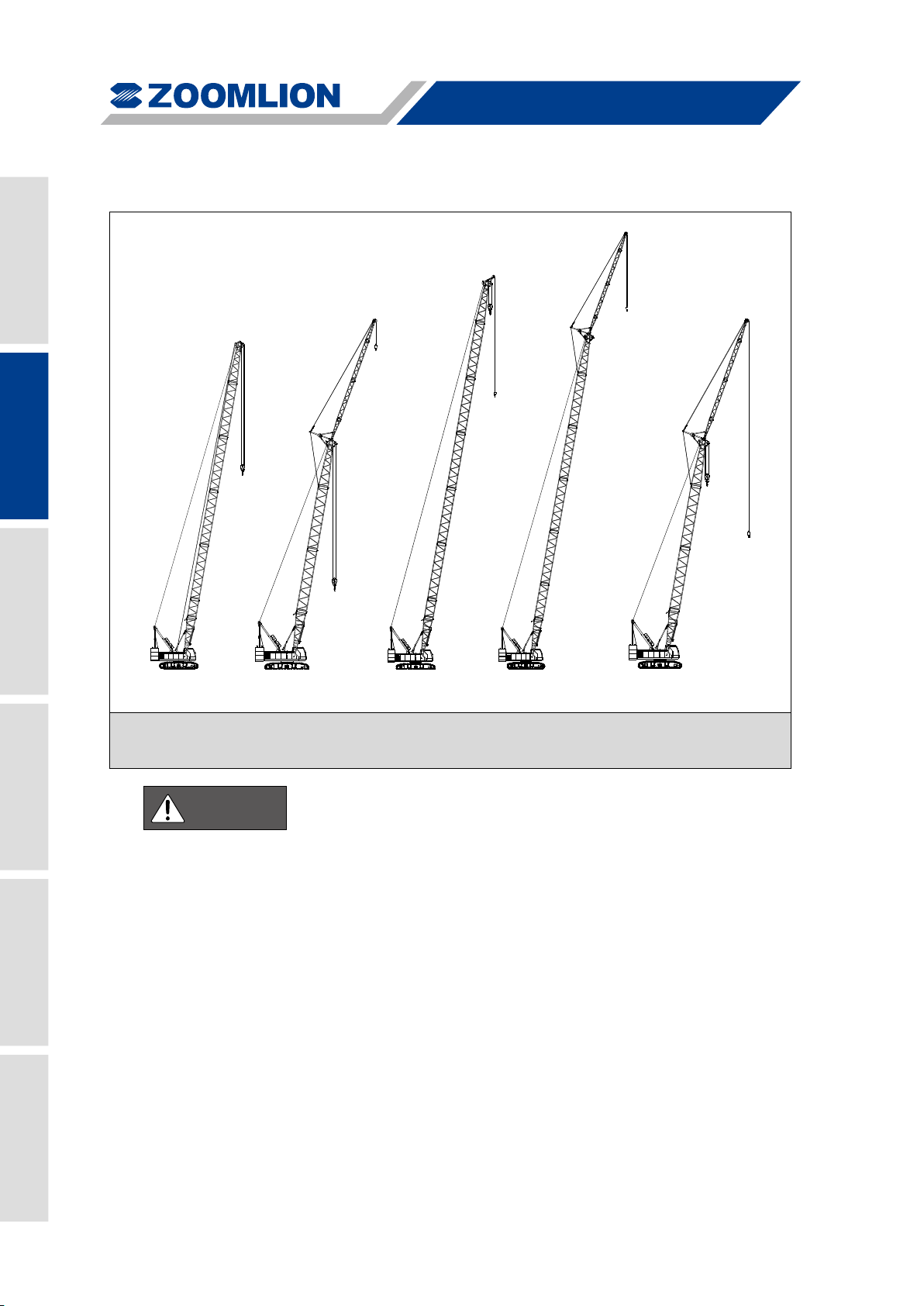

2.2.1.2 Assembly mode

There exists an assembly mode for ZCC1100H crawler crane, which is used for crane

self-assembly and dismantling during crane conversion. During crane self-assembly and

dismantling operation, mounting cylinder is used to lift a load. The maximum lifting capacity of

mounting cylinder is 26460lb (12t). The assembly mode of crane is shown in figure 2-4,

however, when the crane is attached with crawler carriers, the mounting cylinder can also be

used to lift a load. At this time, the assembly mode in load moment limiter is SA.

2-6 ZCC1100H Crawler Crane

Page 29

Operator’s Manual for Crawler Crane

Description of Crane

Operator’s Manual for Crawler Crane

Note: L is the working radius in assembly mode.

Figure 2-4 Assembly mode

CAUTION

L

Whenever using mounting cylinder on the boom to lift the load, be sure to make the

crane in assembly mode.

According to actual requirements, there are five working modes and an assembly mode

available for this crawler crane. For the details, please refer to relevant documents of load

moment limiter.

ZCC1100H Crawler Crane 2-7

Page 30

Operator’s Manual for Crawler Crane

Description of Crane

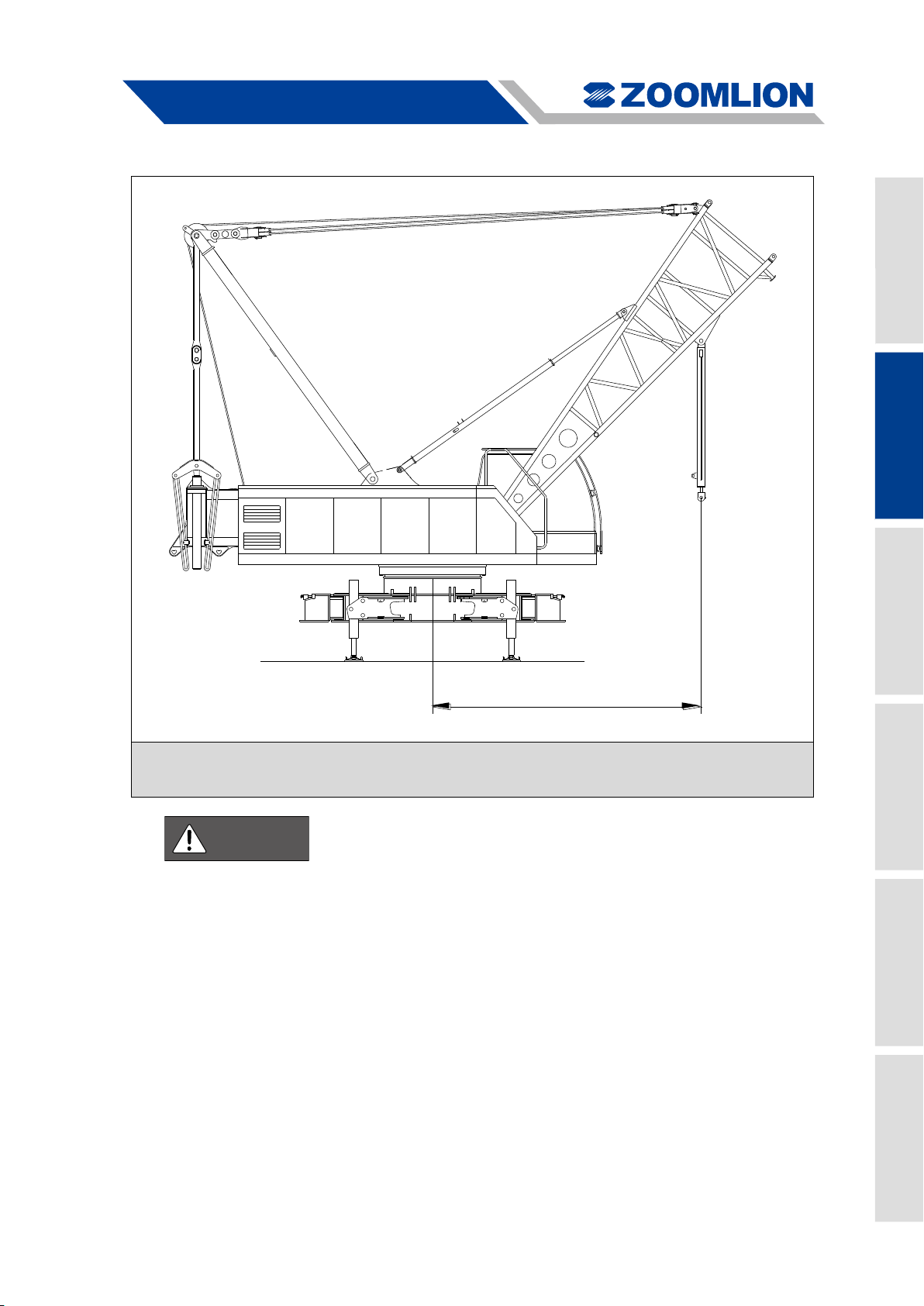

Figure 2-5 Components on slewing table

No.

Names of the components

No

Names of the components

1

Rear counterweight

9

Slewing mechanism

2

Counterweight lifting cylinder

10

Fuel tank

3

Hydraulic oil tank

11

Hoisting winch 1

4

Hoisting winch 2

12

Engine

5

Main valve

13

Hoisting winch 3 (optional)

6

Battery box

14

Derricking winch

7

Tool box

15

Counterweight assembly

8

Operator’s cab

1 3 4 5 6 7 8 9 10

12

13

14 2 15

11

2.2.2 Description of main components

2.2.2.1 Components on superstructure

The positions of components on slewing table are shown in the figure 2-5, and the description

of components is shown in the table 2-3.

2-8 ZCC1100H Crawler Crane

Table 2-3 Description of components on slewing table

Page 31

Operator’s Manual for Crawler Crane

Description of Crane

Operator’s Manual for Crawler Crane

1 2 3 4 5 6 7 8 9 10

11 12 13 14

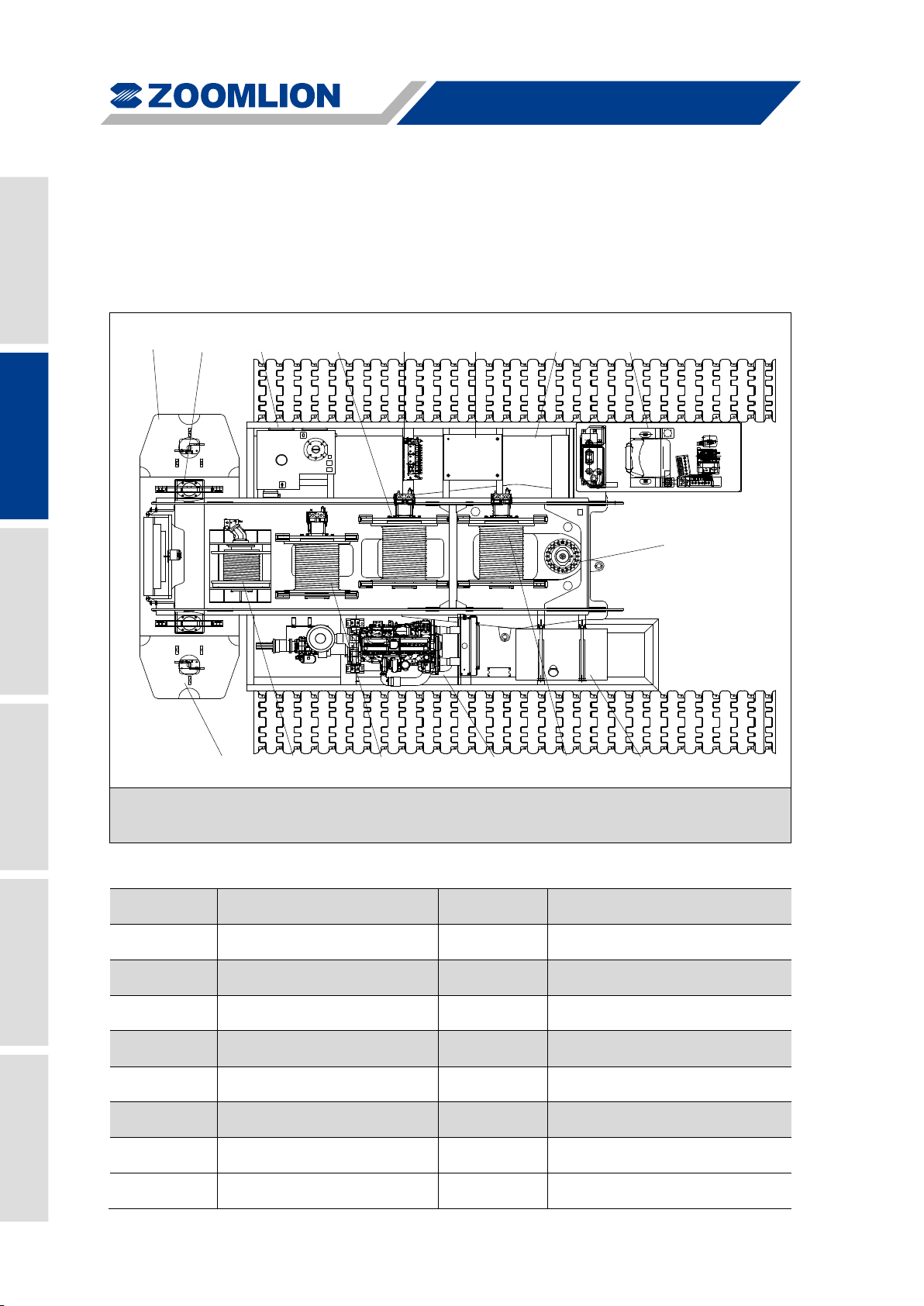

Figure 2-6 Components on undercarriage

No.

Names of the components

No

Names of the components

1

Drive sprocket

8

Vertical support (optional)

2

Crawler carrier

9

Support plate (optional)

3

Track roller

10

Support cylinder (optional)

4

Track carrier roller

11

Central counterweight

5

Track pad

12

Undercarriage central section

6

Driven sprocket

13

Horizontal cylinder

7

Folding bracket

14

Undercarriage control lever

2.2.2.2 Components on undercarriage

The positions of components on undercarriage are shown in the figure 2-6, and the description

of components is shown in the table 2-4.

Table 2-4 Description of components on undercarriage

ZCC1100H Crawler Crane 2-9

Page 32

Operator’s Manual for Crawler Crane

Description of Crane

CAUTION

2.3 Product description

2.3.1 Crane working environment

Working temperature: -20℃-40℃

Allowed air relative humidity: 85% (100% is allowed for a short period of time)

Allowed in-service wind speed: 9.8mps

Allowed out-of-service wind speed: 13.8mps

2.3.2 Crawler travel gear

Travel gear

Adopt flat track pad; crawler width: 2’7” (0.8m); distance between track center: 13’9” (4.2m).

Travel drive

The crawlers are driven independently through hydraulic motor and planetary reducer. Such

traveling moments are available as traveling straight ahead/ backwards, turning on the spot.

Drive performance

Infinitely variable speed from (0-0.78) mph (0-1.25kmph)

2.3.3 Crane superstructure

Slewing table

Self-manufactured and high-rigid welded structure of high-stiffness structural steel; connected

to undercarriage via a single-row roller four-point connecting slewing ring for 360° continuous

rotation.

Crane engine

6-cylinder diesel engine, manufactured by Cummins, type QSL9-C280, rated power 280 HP

(209 KW) at 2100 rpm; maximum torque 1050 Lb·ft (1424 N.m) at 1500 rpm

The rated output power of the engine at a height above sea level 7872’ (2400m) or below

will not be reduced, but it will be reduced if the altitude is higher than 7872’ (2400m). For

details, please consult the local service provider of the engine or technological

department of crawler crane of Zoomlion.

2-10 ZCC1100H Crawler Crane

Page 33

Operator’s Manual for Crawler Crane

Description of Crane

Operator’s Manual for Crawler Crane

Crane drive

The driving force is supplied by diesel engine, and it is transmitted by a coupling to

- A piston variable pump, which provides oil for travel gear and winches;

- A piston variable pump, which provides oil for slewing mechanism;

- A constant-pressure piston variable pump, which provides oil for auxiliary mechanism;

- A gear pump, which provides oil for oil cooler motor;

- A gear pump, which provides oil for control system.

Crane control

CAN bus technology connecting engine, PLC controller and digital display; All motions are

controlled by two 4-way control levers

Crane winches

Both hoisting winches and derricking winch, are hydraulically driven by axial piston variable

displacement pump and planetary gear with spring loaded multi-disc brake

Slewing mechanism

Hydraulically powered by axial piston variable displacement pump and planetary gear with

spring-loaded multi-disc brake;

Infinitely variable speed from 0 to 2.3 rpm

Counterweight

61740 lb (28 t) in total;

The counterweight is attached symmetrically to the rear of the superstructure.

Crane operator’s cab

All-steel construction cab with safety glass;

Fitted with operator’s seat, control and operating instruments

Safety equipment

Angle indicator, load moment limiter, hoisting limiter , support cylinder locking device, safety

valves, derricking limiter and so on

Electrical system

24v DC, negative ground

ZCC1100H Crawler Crane 2-11

Page 34

Operator’s Manual for Crawler Crane

Description of Crane

Unit: ft (mm)

(4700)

(3330)

(3350)

10'11"

R15'5"

(5440)

20'10"

(6340)

17'10"

11'10"

(3600)

4'3"

(1300)

6'5"

(1970)

11"

(6850)

22'5"

(1000)

3'3"

30°~82.5°

42'8"~219'9"

(13000~67000)

16'5"/11'2"

(5000/3400)

(437)

17"

2'7"

(800)

3'7"

(1100)

Figure 2-7 Overall dimensions of the crane

Extended/retracted

Extended/retracted

2.3.4 Overall dimensions

2-12 ZCC1100H Crawler Crane

Page 35

Operator’s Manual for Crawler Crane

Description of Crane

Operator’s Manual for Crawler Crane

Item

Unit

Value

Remarks

Max. lifting capacity/radius

US Tons / ft (t/m)

110/10’6” (100/3.2)

Max. lifting capacity of fixed jib

US Tons (t)

8.8 (8)

Length of main boom

ft (m)

42’8”-219’10” (13-67)

Length of fixed jib

ft (m)

19’8”-59’ (6-18)

Max. length of main boom with

fixed jib

ft (m)

180’5”+59’ (55+18)

Main boom angle

°

30-82.5

Fixed jib angle

°

10, 30

Rope speed

of hoisting

winches 1

and 2/

With free-fall

function

ft/min (m/min)

374 (114)

On the 6th rope

layer

Without free-fall

function

ft/min (m/min)

425 (129)

On the 5th rope

layer

Single rope speed of

derricking winch

ft/min (m/min)

190 (58)

On the 4th rope

layer

Max./rated

single rope

force of

hoisting

winches 1

and 2

With free-fall

function

Lbs (t)

44100/29988 (20/13.6)

On the 1st rope

layer

Without free-fall

function

Lbs (t)

24255/22050 (11/10)

On the 4th rope

layer

Max. single rope force of

derricking winch

Lbs (t)

15656 (7.1)

On the 1st rope

layer

Slewing speed

r/min

0-2.3

Travelling speed (high/low

speed)

mph (km/h)

0.78/0.31 (1.25/0.5)

Gradeability

% (°)

30% (16.7°)

Max. transport weight of basic

machine

Lbs (t)

99887 (45.3)

Deadweight with basic boom

Lbs (t)

189630 (86)

2.4 Technical data

2.4.1 Main technical parameter

Table 2-5 Technical parameter of ZCC1100H crawler crane

ZCC1100H Crawler Crane 2-13

Page 36

Operator’s Manual for Crawler Crane

Description of Crane

Item

Unit

Value

Remarks

Counterweight

Lbs (t)

61740 (28)

Rear

Counterweight

22050 (10)

Central

counterweight

Slewing radius

ft (m)

15’5” (4.7)

Overall dimensions (L×W×H)

(m)

ft (m)

45’3”×11’2”×11’

(13.8×3.4×3.35)

Ground clearance of the

undercarriage

ft (mm)

17” (437)

Engine

Type

Cummins QSL9-280

Rated (max.)

power

HP @ RPM

(Kw @ RPM)

280 @ 2100

(209 @ 2100)

Torque

Lbs·ft @ RPM

(N·m @ RPM)

1050 @ 1500

(1424 @ 1500)

Exhaust emission

According to U.S. EPA

Tier 3

Distance between track center

× crawler contact length ×

crawler width

ft (m)

8’2”×17’10”×2’7”

(2.5×5.44×0.8)

Crawler carrier

retracted

13’9”×17’10”×2’7”

(4.2×5.44×0.8)

Crawler carrier

extended

Note:

(1) The max. single rope force mentioned in above table is not decided by the strength of wire rope. The

rope speed and travelling speed of the crane are calculated on the basis of engine speed of 2100rpm.

(2) Max. transport weight of basic machine in the table refers to the weight of basic machine whose

hoisting winches 1 and 2 have free-fall functions.

2-14 ZCC1100H Crawler Crane

Page 37

Operator’s Manual for Crawler Crane

Description of Crane

Operator’s Manual for Crawler Crane

Specification of load

hook (UST/t)

Number of

pulleys

Maximum rope reeving

Weight of load hook

(lbs/kg)

110/100

5

10

3352/1520

55/50 3 7

2712/1230

33/30 3 7

1720/780

8.8/8

No

1

595/270

CAUTION

Length of

main boom

ft(m)

Reeving

Length of wire

rope needed ft(m)

Length of

main boom

ft(m)

Reeving

Length of wire

rope needed ft(m)

42’8”(13)

10

541’2”(165)

141’2”(43)

3

600’2”(183)

52’6”(16)

10

646’2”(197)

150’11”(46)

3

636’4”(194)

62’4”(19)

9

685’6”(209)

160’10”(49)

3

675’8”(206)

72’3”(22)

8

705’2”(215)

170’8”(52)

3

715’(218)

82’(25)

7

708’6’(216)

180’5”(55)

2

570’8”(174)

91’11”(28)

6

688’9”(210)

190’4”(58)

2

600’2”(183)

101’9”(31)

5

652’8”(199)

200’2”(61)

2

629’9”(192)

111’6”(34)

5

711’9”(217)

210’(64)

2

659’3”(201)

121’5”(37)

4

646’2”(197)

219’10”(67)

2

688’9”(210)

131’3”(40)

4

695’4”(212)

2.4.2 Specification of load hook and selection of rope reeving

There are four types of load hooks available for ZCC1100H crawler crane. In actual operation,

choose appropriate load hook according to the weight of load and the length of boom.

Table 2-6 Hook information

The specification of load hook in above table is not the standard load hook configuration.

It is subject to the contract signed with the customer.

2.4.3 Performance of wire rope and winch

2.4.3.1 Hoisting rope reeving

Under crane operation with main boom, maximum hoisting rope reevings for different boom

lengths are shown in the table 2-7. When crane is working with fixed jib, the hoisting rope

reeving is 1.

Table 2-7 Hoisting rope reeving and wire rope length in main boom configuration

ZCC1100H Crawler Crane 2-15

Page 38

Operator’s Manual for Crawler Crane

Description of Crane

CAUTION

Wire rope of hoisting

winch 1

Wire rope of hoisting

winch 2

Wire rope of derricking

winch

Rope

diameter (mm)

26

26

20

Rope length

ft (m)

721’7”(220)

557’7”(170)

541’2”(165)

Type of rope

35(W)X7-26-S-

left-hand ordinary lay-

1960

35(W)X7-26-S-

left-hand ordinary lay-

1960

6X29Fi+IWR-20-right-hand

lang-lay-1910

Note:

If hoisting winch 3 is mounted, its wire rope type will be the same with that of hoisting winch 2.

Working

layer of

wire

rope

Maximum

single rope

force

kips (t)

Rated single

rope force

kips (t)

Winch speed

with max. load

ft/min (m/min)

Winch speed

without a load

ft/min (m/min)

Permissible

length of wire

ropes on

each layer ft

(m)

1

44.1 (20)

30 (13.6)

82 (25)

255 (78)

126 (38.6)

2

40.3 (18.3)

27.5 (12.5)

88 (27)

278 (85)

138 (42.1)

3

37.2 (16.9)

25.5 (11.6)

95 (29)

301 (92)

149 (45.6)

4

34.6 (15.7)

23.8 (10.8)

98 (30)

324 (99)

160 (49.0)

5

32.4 (14.7)

22.2 (10.1)

104 (32)

347 (106)

172 (52.5)

6

30.4 (13.8)

20.9 (9.5)

111 (34)

373 (114)

183 (55.9)

If the crane is working with hoisting rope reeving less than the value listed in the above

table, single hoisting rope load and rope layers on the drum must be checked to make

sure that they satisfy the rated single rope force in the tables 2-9, 2-10, and 2-12 in

section 2.4.3.3.

2.4.3.2 Parameters of wire rope

Table 2-8 Parameters of wire rope

2.4.3.3 Parameters of winches

The tables 2-9 to 2-12 show the performance parameters of hoisting winch 1, hoisting winch 2,

derricking winch and hoisting winch 3. The maximum single rope force is not determined by the

strength of the wire rope. The speed in the table refers to the wire rope speed.

Table 2-9 Parameters of hoisting winches 1 and 2 with free-fall function

2-16 ZCC1100H Crawler Crane

Page 39

Operator’s Manual for Crawler Crane

Description of Crane

Operator’s Manual for Crawler Crane

Working

layer of

wire

rope

Maximum

single rope

force

kips (t)

Rated single

rope force

kips (t)

Winch speed

with max.

load

ft/min (m/min)

Winch speed

without a load

ft/min (m/min)

Permissible

length of wire

ropes on

each layer

ft (m)

1

31.3 (14.2)

27.3 (12.4)

108 (33)

305 (93)

135 (41)

2

28.4 (12.9)

25.7 (11.7)

114 (35)

334 (102)

148 (45)

3

26.3 (11.9)

23.8 (10.8)

124 (38)

364 (111)

161 (49)

4

24.2 (11)

22 (10)

131 (40)

393 (120)

174 (53)

5

22.4 (10.2)

20.5 (9.3)

141 (43)

423 (129)

187 (57)

Working

layer of

wire rope

Maximum single

rope force

kips (t)

Rated single rope

force

kips (t)

Winch speed with

max. load

ft/min (m/min)

Permissible

length of wire

ropes on each

layer ft (m)

1

15.6 (7.1)

15.6 (7.1)

147 (45)

72 (22)

2

14.3 (6.5)

14.3 (6.5)

160 (49)

79 (24)

3

13.2 (6)

13.2 (6)

173 (53)

85 (26)

4

12.3 (5.6)

12.3 (5.6)

190 (58)

92 (28)

5

11.4 (5.2)

11.4 (5.2)

203 (62)

99 (30)

6

10.8 (4.9)

10.8 (4.9)

216 (66)

105 (32)

Working

layer of

wire rope

Maximum

single rope

force

kips (t)

Rated single

rope force

kips (t)

Winch speed

with max.

load

ft/min (m/min)

Winch speed

without a load

ft/min (m/min)

Permissible

length of wire

ropes on each

layer ft (m)

1

28.4 (12.9)

24.2 (11)

108 (33)

308 (94)

118 (36)

2

26.2 (11.9)

22.2 (10.1)

114 (35)

337 (103)

131 (40)

3

24.2 (11)

20.7 (9.4)

124 (38)

364 (111)

141 (43)

4

22.4 (10.2)

19.1 (8.7)

131 (40)

393 (120)

150 (46)

5

20.9 (9.5)

17.8 (8.1)

141 (43)

419 (128)

164 (50)

WARNING

Table 2-10 Parameters for hoisting winches 1 and 2 without free-fall function

Table 2-11 Parameters of derricking winch

Table 2-12 Parameters of hoisting winch 3 (optional)

If rated single rope force on the corresponding layer is exceeded, the service life of

winch reducer will reduce obviously.

ZCC1100H Crawler Crane 2-17

Page 40

Operator’s Manual for Crawler Crane

Description of Crane

Figure 2-8 Lifting height on main boom

CAUTION

42’8” (13)

52’6” (16)

62’4” (19)

72’3” (22)

82’ (25)

91’11” (28)

101’9” (31)

111’6” (34)

121’5” (37)

131’3” (40)

141’2” (43)

150’11” (46)

160’10” (49)

170’8” (52)

180’5” (55)

190’4” (58)

200’2” (61)

210’ (64)

219’10” (67)

80°

70°

60°

50°

40°

30°

20’

(6.1)

40’

(12.2)

60’

(18.3)

80’

(24.4)

100’

(30.5)

120’

(36.6)

140’

(42.7)

160’

(48.8)

180’

(54.9)

200’

(61)

Working radius ft (m)

Slewing center

40’

(12.2)

60’

(18.3)

80’

(24.4)

100’

(30.5)

120’

(36.6)

140’

(42.7)

160’

(48.8)

180’

(54.9)

200’

(61)

220’

(67.1)

Boom length

Lifting height ft(m)

2.4.4 Lifting height

2.4.4.1 Lifting height on main boom

(1) The X-axis indicates the working radius in ft(m), and the Y-axis indicates the lifting

height in ft(m).

(2) The boom lifting height curve is drawn without considering boom deflection.

2-18 ZCC1100H Crawler Crane

Page 41

Operator’s Manual for Crawler Crane

Description of Crane

Operator’s Manual for Crawler Crane

Figure 2-9 Lifting height on fixed jib (fixed jib angle=10°)

CAUTION

40’

(12.2)

60’

(18.3)

80’

(24.4)

100’

(30.5)

120’

(36.6)

140’

(42.7)

160’

(48.8)

180’

(54.9)

20’

(6.1)

200’

(61)

220’

(67.1)

101’9”+19’8”

(31+6)

101’9”+39’4”

(31+12)

101’9”+59’

(31+18)

180’5”+19’8”

(55+6)

180’5”+39’4”

(55+12)

180’5”+59’

(55+18)

40’

(12.2)

60’

(18.3)

80’

(24.4)

100’

(30.5)

120’

(36.6)

140’

(42.7)

160’

(48.8)

180’

(54.9)

200’

(61)

220’

(67.1)

240’

(73.2)

10°

Boom configuration

Lifting height ft (m)

Working radius ft (m)

Slewing center

2.4.4.2 Lifting height on fixed jib

(1) The X-axis indicates the working radius in ft (m), and the Y-axis indicates the lifting

height in ft (m).

(2) The boom lifting height curve is drawn without considering boom deflection.

ZCC1100H Crawler Crane 2-19

Page 42

Operator’s Manual for Crawler Crane

Description of Crane

Figure 2-10 Lifting height on fixed jib (fixed jib angle=30°)

CAUTION

40’

(12.2)

60’

(18.3)

80’

(24.4)

100’

(30.5)

120’

(36.6)

140’

(42.7)

160’

(48.8)

180’

(54.9)

20’

(6.1)

200’

(61)

220’

(67.1)

101’9”+19’8”

(31+6)

101’9”+39’4”

(31+12)

101’9”+59’

(31+18)

180’5”+19’8”

(55+6)

180’5”+39’4”

(55+12)

180’5”+59’

(55+18)

40’

(12.2)

60’

(18.3)

80’

(24.4)

100’

(30.5)

120’

(36.6)

140’

(42.7)

160’

(48.8)

180’

(54.9)

200’

(61)

220’

(67.1)

240’

(73.2)

30°

Boom configuration

Lifting height ft (m)

Working radius ft (m)

Slewing center

(1) The X-axis indicates the working radius in ft (m), and the Y-axis indicates the lifting

height in ft (m).

(2) The boom lifting height curve is drawn without considering boom deflection.

2-20 ZCC1100H Crawler Crane

Page 43

Operator’s Manual for Crawler Crane

Description of Crane

Operator’s Manual for Crawler Crane

2.4.5 Lifting capacity chart

2.4.5.1 Lifting capacity on main boom

a) The value given in the lifting capacity chart is the permissible maximum lifting capacity,

which is obtained from the calculation when the load is suspended (according to the

standard ASME/ANSI B30.5). The value can not exceed 75% of the overturning lifting

capacity when the crane is on firm and flat ground.

b) The value mentioned in the chart is the lifting capacity when the crane is working with

61740Lbs (28t) rear counterweight and 22050lbs (10t) central counterweight in 360°

range. The crawler carriers of the crane are extended completely.

c) The sign “*/*” in the chart indicates “lifting capacity/radius”.

ZCC1100H Crawler Crane 2-21

Page 44

Operator’s Manual for Crawler Crane

Description of Crane

Radius

ft(m)

Main boom length ft(m)

Radius

ft(m)

42'8"

(13)

52'6"

(16)

62'4"

(19)

72'3"

(22)

82'

(25)

91'11"

(28)

101'9"

(31)

111'6"

(34)

121'5"

(37)

10'6"

(3.2)

220.5

(100)

10'6"

(3.2)

12

(3.7)

193.2

(87.6)

12

(3.7)

13

(4)

179.9

(81.6)

13

(4)

14

(4.3)

171.1

(77.6)

14

(4.3)

15

(4.6)

161.2

(73.1)

159.0

(72.1)

15

(4.6)

16

(4.9)

151.9

(68.9)

151.7

(68.8)

146.0

(66.2)

16

(4.9)

17

(5.2)

142.9

(64.8)

142.4

(64.6)

138.7

(62.9)

17

(5.2)

18

(5.5)

134.9

(61.2)

134.3

(60.9)

131.4

(59.6)

131.4

(59.6)

18

(5.5)

19

(5.8)

127.9

(58)

127.2

(57.7)

126.1

(57.2)

124.1

(56.3)

19

(5.8)

20

(6.1)

120.2

(54.5)

121.1

(54.9)

120.2

(54.5)

119.7

(54.3)

116.2

(52.7)

20

(6.1)

25

(7.6)

89.3

(40.5)

89.1

(40.4)

89.1

(40.4)

88.8

(40.3)

88.8

(40.3)

88.6

(40.2)

88.4

(40.1)

88.2

(40.0)

25

(7.6)

30

(9.1)

69.5

(31.5)

69.2

(31.4)

69.0

(31.3)

68.8

(31.2)

68.8

(31.2)

68.6

(31.1)

68.4

(31.0)

68.1

(30.9)

67.9

(30.8)

30

(9.1)

35

(10.7)

55.8

(25.3)

55.6

(25.2)

55.3

(25.1)

55.3

(25.1)

55.1

(25.0)

54.9

(24.9)

54.7

(24.8)

54.5

(24.7)

54.2

(24.6)

35

(10.7)

40

(12.2)

47.0

(21.3)

46.7

(21.2)

46.7

(21.2)

46.5

(21.1)

46.3

(21.0)

46.1

(20.9)

45.9

(20.8)

45.6

(20.7)

45.4

(20.6)

40

(12.2)

50

(15.2)

35.3

(16)

35.1

(15.9)

35.1

(15.9)

34.6

(15.7)

34.6

(15.7)

34.4

(15.6)

34.2

(15.5)

34.0

(15.4)

50

(15.2)

60

(18.3)

28.9/57

(13.1/17.4)

27.6

(12.5)

27.3

(12.4)

27.1

(12.3)

26.9

(12.2)

26.7

(12.1)

26.5

(12.0)

60

(18.3)

70

(21.3)

24.5/65

(11.1/19.8)

22.5

(10.2)

22.3

(10.1)

22.1

(10.0)

21.8

(9.9)

21.6

(9.8)

70

(21.3)

80

(24.4)

20.1/75

(9.1/22.9)

18.5

(8.4)

18.3

(8.3)

18.1

(8.2)

17.9

(8.1)

80

(24.4)

90

(27.4)

15.7

(7.1)

15.4

(7.0)

15.2

(6.9)

90

(27.4)

100

(30.5)

13.2

(6.0)

13.0

(5.9)

100

(30.5)

110

(33.5)

11.2

(5.1)

110

(33.5)

Table 2-13 Lifting capacity on S-1 boom

Unit: kip (ton)

2-22 ZCC1100H Crawler Crane

Page 45

Operator’s Manual for Crawler Crane

Description of Crane

Operator’s Manual for Crawler Crane

Radius

ft(m)

Main boom length ft(m)

Radius

ft(m)

131'3"

(40)

141'2"

(43)

150'11"

(46)

160'10"

(49)

170'8"

(52)

180'5"

(55)

190'4"

(58)

200'2"

(61)

210'

(64)

219'10"

(67)

30

(9.1)

67.7

(30.7)

67.7

(30.7)

30

(9.1)

35

(10.7)

54.2

(24.6)

53.8

(24.4)

49.6

(22.5)

41.9

(19)

40.1

(18.2)

35

(10.7)

40

(12.2)

45.2

(20.5)

45.0

(20.4)

44.8

(20.3)

40.1

(18.2)

38.4

(17.4)

33.7

(15.3)

31.3

(14.2)

40

(12.2)

50

(15.2)

33.7

(15.3)

33.5

(15.2)

33.3

(15.1)

33.1

(15.0)

32.9

(14.9)

30.2

(13.7)

29.8

(13.5)

27.3

(12.4)

26.2

(11.9)

26.2

(11.9)

50

(15.2)

60

(18.3)

26.2

(11.9)

26.0

(11.8)

25.8

(11.7)

25.6

(11.6)

25.4

(11.5)

25.1

(11.4)

24.9

(11.3)

24.7

(11.2)

24.5

(11.1)

23.6

(10.7)

60

(18.3)

70

(21.3)

21.4

(9.7)

21.2

(9.6)

20.9

(9.5)

20.7

(9.4)

20.5

(9.3)

20.3

(9.2)

20.1

(9.1)

19.9

(9.0)

19.4

(8.8)

19.1

(8.7)

70

(21.3)

80

(24.4)

17.6

(8.0)

17.4

(7.9)

17.2

(7.8)

17.0

(7.7)

16.8

(7.6)

16.5

(7.5)

16.3

(7.4)

15.8

(7.2)

15.7

(7.1)

15.7

(7.1)

80

(24.4)

90

(27.4)

15.0

(6.8)

14.8

(6.7)

14.6

(6.6)

14.3

(6.5)

14.1

(6.4)

13.9

(6.3)

13.7

(6.2)

13.2

(6)

13.0

(5.9)

12.8

(5.8)

90

(27.4)

100

(30.5)

12.8

(5.8)

12.6

(5.7)

12.3

(5.6)

12.1

(5.5)

11.9

(5.4)

11.7

(5.3)

11.5

(5.2)

11.0

(5.0)

10.8

(4.9)

10.6

(4.8)

100

(30.5)

110

(33.5)

11.2

(5.1)

10.8

(4.9)

10.6

(4.8)

10.4

(4.7)

10.1

(4.6)

9.9

(4.5)

9.7

(4.4)

9.3

(4.2)

9.0

(4.1)

8.8

(4.0)

110

(33.5)

120

(36.6)

10.1/115

(4.6/35.1)

9.3

(4.2)

9.0

(4.1)

8.8

(4.0)

8.6

(3.9)

8.3

(3.8)

8.2

(3.7)

7.9

(3.6)

7.7

(3.5)

7.5

(3.4)

120

(36.6)

130

(39.6)

8.6/125

(3.9/38.1)

7.9

(3.6)

7.7

(3.5)

7.5

(3.4)

7.3

(3.3)

7.1

(3.2)

6.6

(3.0)

6.4

(2.9)

6.2

(2.8)

130

(39.6)

140

(42.7)

7.3/135

(3.3/41.1)

6.6

(3.0)

6.4

(2.9)

6.1

(2.8)

5.9

(2.7)

5.7

(2.6)

5.5

(2.5)

5.1

(2.3)

140

(42.7)

150

(45.7)

5.5

(2.5)

5.3

(2.4)

5.1

(2.3)

4.9

(2.2)

4.6

(2.1)

4.2

(1.9)

150

(45.7)

160

(48.8)

4.6

(2.1)

4.4

(2)

4.0

(1.8)

3.7

(1.7)

3.5

(1.6)

160

(48.8)

170

(51.8)

3.7

(1.7)

3.3

(1.5)

3.1

(1.4)

2.9

(1.3)

170

(51.8)

180

(54.9)

2.9/175

(1.3/53.4)

2.4

(1.1)

2.2

(1.0)

180

(54.9)

Table 2-13 Lifting capacity on S-1 boom

Unit: kip (ton)

ZCC1100H Crawler Crane 2-23

Page 46

Operator’s Manual for Crawler Crane

Description of Crane

CAUTION

(1) The values in bold are the lifting capacity determined by the strength of the machine,

while the values that are not in bold are the lifting capacity determined by the

stability of the machine.

(2) Do not lift a load in the area which is not in the lifting capacity range, otherwise the

crane may topple over or be damaged.

(3) The value in the chart is the maximum lifting capacity of the crane, including the

weight of lifting device, hook, wire rope at the end of the hook and so on.

(4) The value in the chart is the lifting capacity of the crane without a tip boom. When

main boom is fitted with tip boom, the lifting capacity must include the weight of

main load hook, wire rope, lifting device as well as the weight of tip boom, auxiliary

hook, and wire rope.

2-24 ZCC1100H Crawler Crane

Page 47

Operator’s Manual for Crawler Crane

Description of Crane

Operator’s Manual for Crawler Crane

Main boom length ft(m) 101’9"(31)

Radius

ft

(m)

Fixed jib length ft(m)

Radius

ft

(m)

19'8"

(6)

39'4"

(12)

59'1"

(18)

Fixed jib angle(°)

10

30

10

30

10

30

30

(9.1)

64.3

(29.1)

64

(29)

63.4

(28.7)

62.7

(28.4)

62.3

(28.2)

61.2

(27.7)

30

(9.1)

35

(10.7)

51

(23.1)

50.7

(23)

49.8

(22.6)

49.4

(22.4)