Page 1

MAINTENANCE MANUAL FOR

ROUGH TERRAIN CRANE

Address:Quantang Indust=rial Park, 2nd Yuanda Road,

Changsha Economic and Technological Development

Zone, Hunan Province, China

Postcode: 410131

Website: www.zoomlion.com

Page 2

MAINTENANCE

MANUAL

Edition 1

Dec 2013

Page 3

Dec 2013

Page 4

(Thank you letter)

Owners, Users and Operators:

Zoomlion Cranes appreciates your selection of the ZOOMLION Rough Terrain Crane for your

application.

No one should do the maintenance/service tasks to the crane unless they read and know the

data in this manual and the other technical documents supplied with the crane.

The Maintenance and Service Manual provides periodic inspections, maintenance and service

procedures that are necessary to make sure the performance, safety and reliability are at the

highest level. They can also increase the service life of the crane.

When you follow the instructions in this manual, your crane can operate at MAXIMUM

EFFICIENCY.

To look after your rights & interests and safety, you must obey all safety data in the

Maintenance and Service Manual. Only approved personnel can disassemble and adjust

hydraulic system components during maintenance. When a hydraulic component malfunctions

or is damaged, tell the local repair facility.

You do not have to keep the Maintenance & Service Manual in the cab of the crane. The

Maintenance & Service Manual must be with the crane if it is sold.

If there is something in the manual that you do not understand, speak with us. We (Zoomlion

Cranes) are NOT responsible for damages from an operator or service technician who does not

obey the instructions in the Maintenance and Service Manual.

THANK YOU!

Mobile Crane Branch Company of ZOOMLION Heavy Industry Science and Technology Co.,

Ltd

Copyright

Under the copyright laws, this manual cannot be copied, photocopied, reproduced, translated, or reduced to any electronic medium

or machine readable form, in whole or part, without the prior written consent of Zoomlion Heavy Industry Science and Technology

Co., Ltd.

Copyright © 20XX, Zoomlion Heavy Industry Science and Technology Co., Ltd.

All rights reserved. Printed in the United States

Edition 2 Page i

Dec/2013

Page 5

Edition 2 Page ii

Dec/2013

Page 6

Contents

(Thank you letter) ......................................................................................................................... i

Contents .................................................................................................................................... iii

About This Manual ...................................................................................................................... v

Safety ....................................................................................................................................... vii

Introduction ............................................................................................................................ 1

1.1 INTRODUCTION ....................................................................................................... 1

1.2 OPERATOR OBSERVATION .................................................................................... 1

1.3 WIRE-ROPE INSPECTION RECORD ....................................................................... 3

1.4 ENGINE MAINTENANCE .......................................................................................... 4

1.5 ENGINE RADIATOR MAINTENANCE ....................................................................... 7

1.6 TRANSMISSION MAINTENANCE ............................................................................ 8

1.7 AXLE MAINTENANCE CHECK ............................................................................... 10

1.8 TIRE MAINTENANCE CHECK ................................................................................ 11

1.9 BRAKE SYSTEM MAINTENANCE .......................................................................... 14

1.10 AIR SYSTEM MAINTENANCE ................................................................................ 15

1.11 BATTERY MAINTENANCE ..................................................................................... 15

1.12 FUEL, COOLANT AND TORQUE CONVERTER HYDRAULIC TRANSMISSION

OIL .......................................................................................................................... 16

1.13 LUBRICATION ........................................................................................................ 17

1.14 HYDRAULIC OIL ..................................................................................................... 24

1.15 GEAR OIL ............................................................................................................... 28

1.16 LUBRICATING GREASE......................................................................................... 30

1.17 LUBRICATING POINTS .......................................................................................... 31

1.18 ADJUST, CLEAN AND REPLACE THE PARTS ...................................................... 33

1.19 BATTERY MAINTENANCE AND SERVICE ............................................................ 50

1.20 BATTERY MAINTENANCE – WINTER ................................................................... 51

1.21 OPERATION IN WINTER ........................................................................................ 52

1.22 OPERATION IN SUMMER ...................................................................................... 53

Troubleshooting .......................................................................................................................... 1

Edition 2 Page iii

Dec/2013

Page 7

2.1 ELECTRICAL SYSTEM ............................................................................................. 1

2.2 HYDRAULIC SYSTEM ............................................................................................ 12

2.3 EXTEND / RETRACT SYSTEM............................................................................... 13

2.4 DERRICKING MECHANISM ................................................................................... 14

2.5 SWING MECHANISM ............................................................................................. 15

2.6 HOIST MECHANISM ............................................................................................... 16

2.7 OUTRIGGERS ........................................................................................................ 17

2.8 TRANSMISSION ..................................................................................................... 18

2.9 BRAKE SYSTEM .................................................................................................... 21

2.10 STEERING SYSTEM .............................................................................................. 22

2.11 FRONT / REAR AXLES ........................................................................................... 25

2.12 DRIVE SHAFT ......................................................................................................... 27

2.13 TIRES...................................................................................................................... 28

2.14 ENGINE ERROR CODE.......................................................................................... 30

2.15 TRANSMISSION ERROR CODE ........................................................................... 40

Inspection ................................................................................................................................. 84

3.1 PRE-START INSPECTION ..................................................................................... 84

3.2 NEW CRANE SPECIAL BREAK-IN REQUIREMENTS ........................................... 88

3.3 PERIODIC INSPECTIONS AND SERVICE ............................................................. 88

3.4 PERIODIC CRANE INSPECTIONS ......................................................................... 96

3.5 INSPECTIONS AND MAINTENANCES DURING BREAK-IN PERIOD .................. 103

3.6 FILTER ELEMENTS LISTS ................................................................................... 104

3.7 FLUID VOLUME REQUIREMENTS ...................................................................... 106

Edition 2 Page iv

Dec/2013

Page 8

About This Manual

General

The data (data, specifications, illustrations) in this manual is for cranes in production at the time of this

manuals publication. We reserve the right to make changes to this manual at any time, without obligation.

This manual is for maintaining and servicing the RT Crane in the field. Follow the operation and

maintenance procedures to make sure that your machine operates at MAXIMUM EFFICIENCY. Use the

CRANE PERIODIC INSPECTION CHECKLIST. Keep a maintenance log to monitor all maintenance

work on the machine.

An example of a Maintenance Log and Crane Periodic Inspection Checklist is at the end of this section.

Again, we at ZOOMLION appreciate your selection of our crane. User safety is most important. To

complete on-site tasks safely, operators and service technicians must be responsible. Obey the

instructions that follow:

• Comply - with Occupational Safety and Health Administration (OSHA), Federal,

State and Local Regulations.

• Read, Understand and Follow - the instructions in this and other manuals and

documents that come with the crane.

• Use Good, Safe Work Practices - in a common sense way.

• Only have trained operators and service technicians - directed by informed

and knowledgeable job-site supervisors.

• Do not use this crane - before the portable fire extinguisher, installed in the cab,

agrees with local fire protection rules.

Edition 2 Page v

Dec /2013

Page 9

OSHA prohibits the alteration or modification of this crane without written

manufacturer’s approval. Use only the factory approved parts to service or repair

the crane.

If you make modifications/additions which affect the safe operation of the

equipment to the crane before you use it, the crane owner must make sure that the

modifications/additions agree with OSHA 1926:1412.

Speak with us if special data is necessary for the maintenance or operation of your RT Crane. Send your

machine model and a serial number to make sure that you receive the correct data.

If there is anything in this manual that is not clear or which you think is necessary, write to the address

that follows:

Rough Terrain Crane R & D Institute

Zoomlion Mobile Crane Branch Company

Quantang Industrial Park, 2nd Yuanda Road,

Economic and Technological Development Zone,

Changsha, Hunan Province, China, 410131

You can also speak to us by telephone at 0086-84671997 (international), 0731-84671997 (in China).

Thank You!

Edition 2 Page vi

Dec /2013

Page 10

Safety

The safety symbol, used on the Danger, Warning and Caution labels, tells personnel of possible death,

injury, or property damage. Obey all safety data that follows this symbol to prevent dangerous conditions.

HAZARD CLASSIFICATION

Hazard classification is a system to show different classes of possible injury levels. A safety symbol and

a signal word show how dangerous the level of possible injury can be.

A signal word without a safety symbol refers to property damage, protection devices, or important data.

You will find this system used in this manual and on signs on the crane to help find and prevent

dangerous situations.

HAZARD INDICATORS

DANGER, WARNING, CAUTION and NOTE labels are on signs and decals and as you read this manual

to show important instructions. In this manual, DANGER, WARNING and CAUTION labels are before the

paragraph or item to which they apply. NOTEs follow the paragraph or item they apply to. The labels are

as follows:

Refers to a dangerous situation which, if you do not prevent, will cause death or injury.

Refers to a possible dangerous situation which, if you do not prevent, could cause death or injury.

Refers to a possible dangerous situation which, if you do not prevent, may cause light or moderate injury.

Refers to a tip or hint in the instructions.

INTENDED USE

Edition 2 Page vii

Dec /2013

Page 11

Scope

The owner of this crane must know federal, state and local rules. When your equipment is in operation, the

area must be safe for employees and non-employees. Do not cause damage to other equipment or local

structures while you operate this crane. Rules change by location and this manual does not give that data.

ZOOMLION makes manuals for different construction and industrial equipment. It is policy to include

applicable national consensus, industry standards and safety data with the manuals. Use this data to give

applicable training to personnel who are to operate, do the maintenance and supervise the equipment

correctly and safely.

We make equipment for heavy-duty labor. Do periodic inspections regularly because the equipment wears

during operation. This prevents accidents, decreases downtime and helps equipment work satisfactorily. The

goal of these inspections is to find worn, cracked, damaged parts and loose or missing fasteners before they

cause a problem.

Correct training and inspection procedures are necessary to prevent injury to persons, property damage and

high maintenance costs.

Read and understand the data that comes with this crane. Help is available from the distributors of your

ZOOMLION crane and from the ZOOMLION manufacturing facility.

This manual contains the instructions and data on the operation, maintenance, lubrication and adjustments of

the Rough Terrain Crane. Do not operate or service the crane before you understand the data in this manual.

Edition 2 Page viii

Dec /2013

Page 12

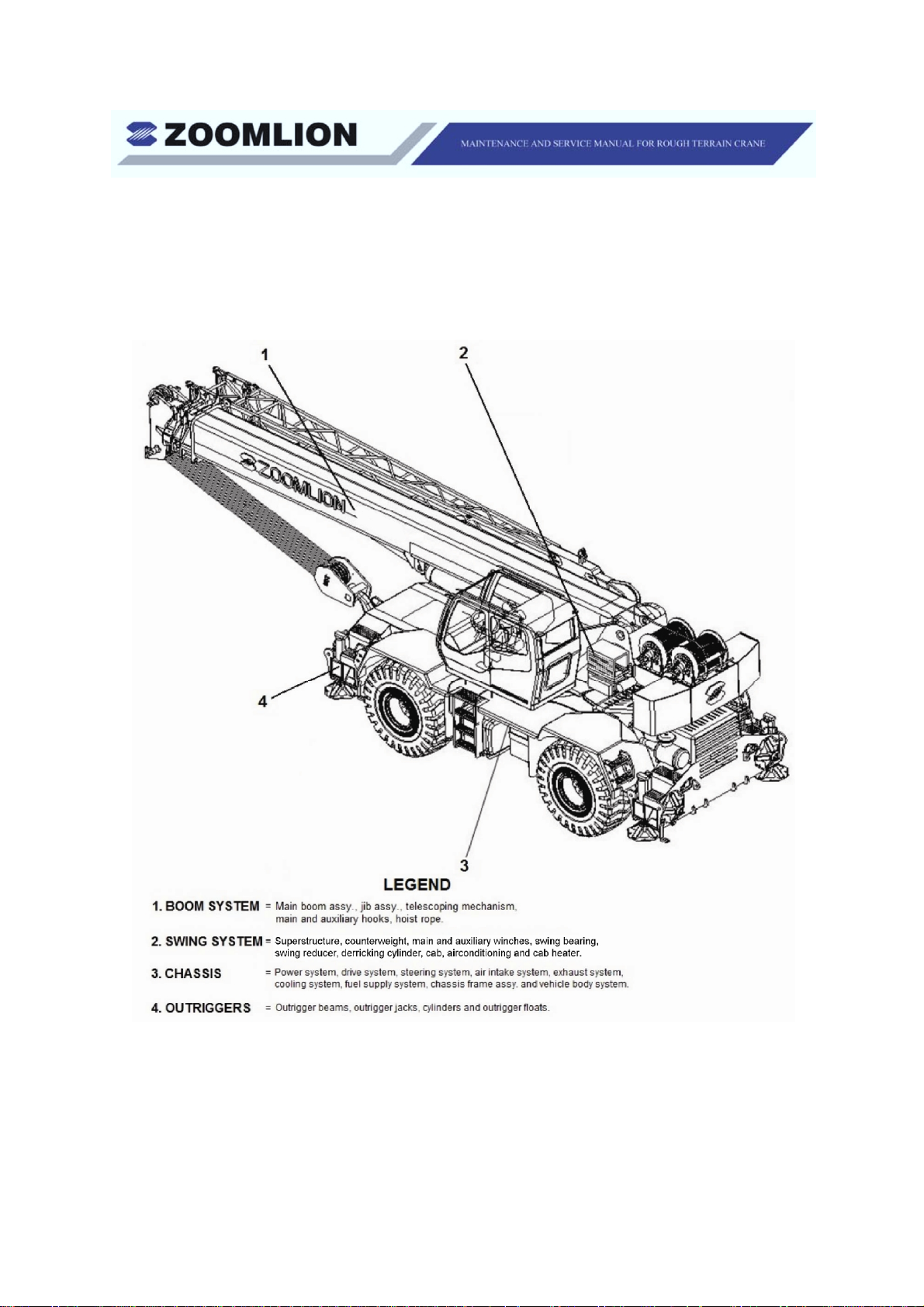

Nomenclature

To help you understand the contents of this manual, refer to the figure below. Each numbered term can

represent several components of the same main part.

Edition 2 Page ix

Dec /2013

Page 13

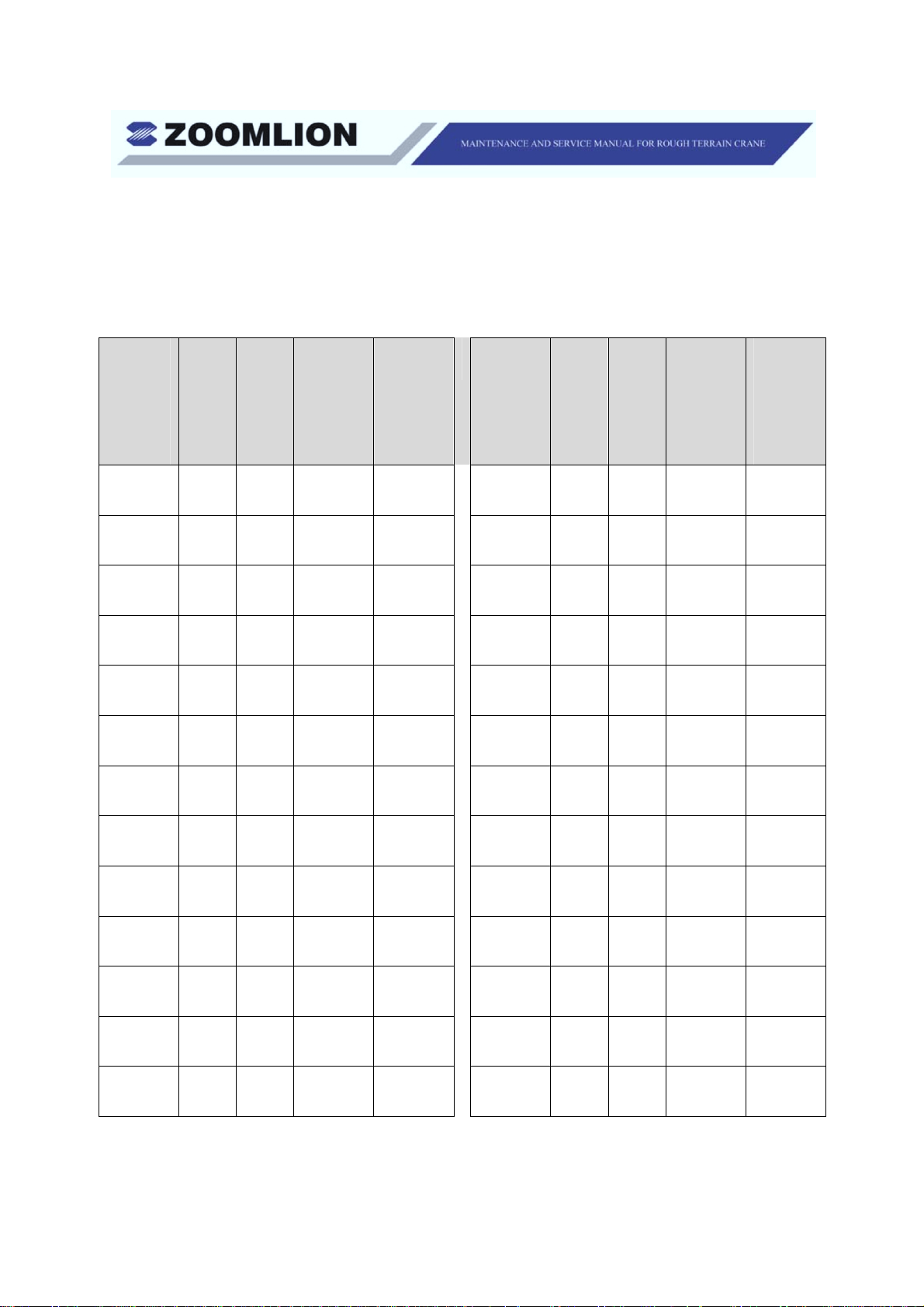

CRANE PERIODIC INSPECTION CHECKLIST

This inspection checklist provides supplementary data to facilitate the correct operation and maintenance

of the crane.

Component

Inspected

Interval

Function

Adjusting

Condition

Maintenance

Condition

Component

Inspected

Inspection

Code Function

Adjusting

Condition

Maintenance

Condition

Edition 2 Page x

Dec /2013

Page 14

MAINTENANCE LOG

Item

Adjusting Condition

Date

Edition 2 Page xi

Dec /2013

Page 15

Edition 2 Page xii

Dec /2013

Page 16

MAINTENANCE AND SERVICE MANUAL FOR ROUGH TERRAIN CRANE

Chapter 1 Maintenance and Service

Page 17

Page 18

1.1 INTRODUCTION

A set of preventive maintenance tasks is necessary to extend the serviceable life of

the crane. The tasks can help to maximize efficient service and decrease the time

the crane is at the repair facility. This section has checks and procedures which you

are to do on daily, weekly, monthly and semi-annual intervals. These intervals are

specified in conditions of calendar and hours of operation.

The checks for long intervals include all the checks that you do in the shorter

intervals. Thus, the weekly check includes all items in the daily check. The monthly

check includes the weekly and the daily checks. The semi-annual check includes the

quarterly, monthly, weekly and daily checks.

The chart makes it possible for you to record the preventive maintenance tasks that

you complete. It also supplies you with a tool to find the problem areas and to

examine the value of the maintenance tasks. The items in each check interval on the

chart are assembled by their applicable headings and explained in this chapter.

This maintenance schedule is a procedure to make sure that basic preventive

maintenance tasks are completed in the usual conditions that you operate. The

conditions which increase wear, loads or strain on the crane, usually make it

necessary to decrease the interval time. Before you change the maintenance

schedule, examine your operation and the maintenance records of the crane. Think

about all the factors involved and make a new schedule that is sufficient to align the

usual maintenance tasks.

Introduction

As a part of each preventive maintenance check, refer to the Engine Manufacturer’s

Manual for engine maintenance tasks. When you do the servicing of the engine, use

the data in the engine manual if this chapter has data that is different.

1.2 OPERATOR OBSERVATION

A. Do a visual inspection for:

(1) Unusual conditions

(2) Hydraulic system leaks or damage.

B. Examine the area around the engine for:

(1) Belts (tension and wear)

(2) Coolant level

(3) Engine oil level

(4) Hydraulic transmission oil level

Edition 2 Chapter 1 Page 1-1

Dec /2013 Maintenance

Page 19

(5) Air cleaner vacuum actuated indicator

(6) Air inlet

(7) Silencer and exhaust device.

C. Examine the condition of each battery.

D. Examine the boom for:

(1) Sheave (wear or damage)

(2) The function of the anti-two block system

(3) Wire-rope on the winches (wear and breaks)

(4) Wear of the cylinder pin.

E. Tires, axles and drivelines (wear or damage).

F. Examine the cab for:

(1) Gauge and indicator functions

(2) Function of the switches and joysticks

(3) Clear windows

(4) Safety device in position

(5) Each light operates

(6) Cleanliness: free from dirt, mud and waste material.

Edition 2 Chapter 1 Page 1-2

Dec /2013 Maintenance

Page 20

WIRE

-

ROPE INSPECTION RECORD

________________________________

________________________________

_________

1.3 WIRE-ROPE INSPECTION RECORD

(See pages 1-37 and 1-38)

Place of inspection ________________________ Date _______________

DESCRIPTION OF CRANE

Make _____________________________ Model _________ Serial No. ___________

Type and Arrangement of Attachments ___________________________________________

Date of Last Rope Inspection __________________________________________________

Hours and Time of Service Since Last Inspection ___________________________________

RESULT OF INSPECTION

Rope Inspected Type and Size Conditions noted Recommendations

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

___________________ Inspector:

Edition 2 Chapter 1 Page 1-3

Dec /2013 Maintenance

Page 21

1.4 ENGINE MAINTENANCE

For Cummins engine maintenance, refer to the EngineManufacturer’s Manual.

Engine productivity, longevity and low-cost performance depend on a regular

program of periodic maintenance. The materials presented here are listed in

accordance with the EngineManufacturer’s Manual. Consideration may dictate a

revision in scheduling for the periodic checks.

A good periodic preventive maintenance program can increase the productivity,

longevity and low-cost performance of the engine. The data, in this section of the

manual, is from the data in the EngineManufacturer’s Manual. You can change the

interval or schedule of the preventive maintenance program because of the area and

the types of operations you do.

A. Daily Inspections:

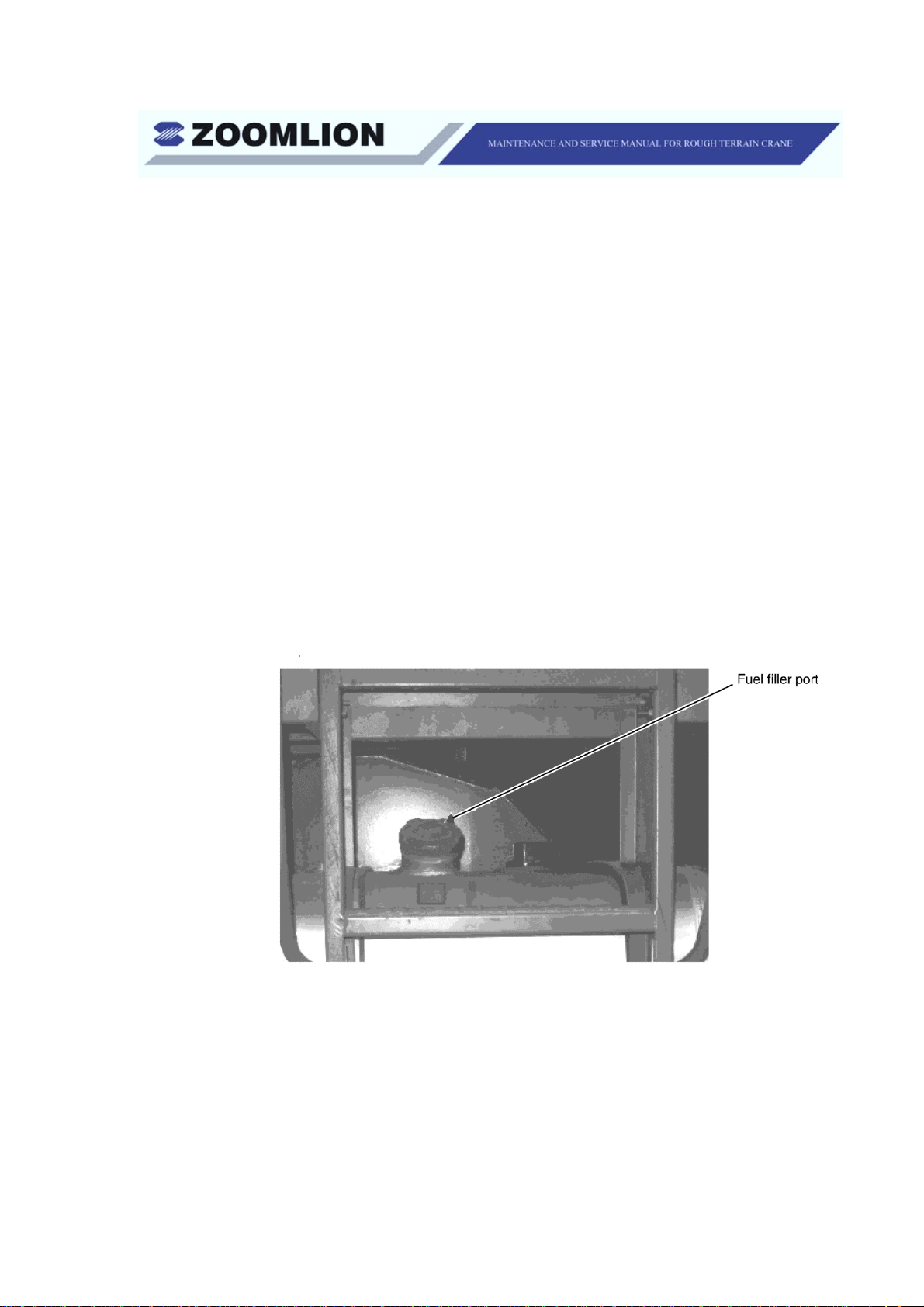

(1) Fuel Level

(a) You can find the fuel tank on the left side of the crane (Figure 1-1). If

you keep the tank full of fuel, in cold weather, you can decrease the

quantity of condensation.

Figure 1-1 Fuel Tank Cap

(b) Use a good grade of diesel fuel. The tank capacity is 79 gal. (300 l).

Edition 2 Chapter 1 Page 1-4

Dec /2013 Maintenance

Page 22

(2) Engine Oil Level

(a) You can measure the level of oil in the engine by a dipstick. The

dipstick is on the right side of the engine (aft end of the crane). The

engine must be OFF and sit for a short time before you can

measure the oil level. Wait for 15 minutes, after you stop the engine,

to measure the level. Adjust the level of oil to the full mark.

(b) Do not overfill!

Do not operate the crane if the level of engine oil is too low or too high.

(3) Water Separator

(a) The fuel line contains a water separator. It removes the

condensation and contamination from the fuel before it goes into the

engine. You must examine the water separator before you operate

the crane to drain the condensation and contamination.

(b) Do not let the water separator fill more than 1/2 full.

(4) Air Filter

(a) Examine the air filter and its connections for leaks, dents and

damage (See Figure 1-2).

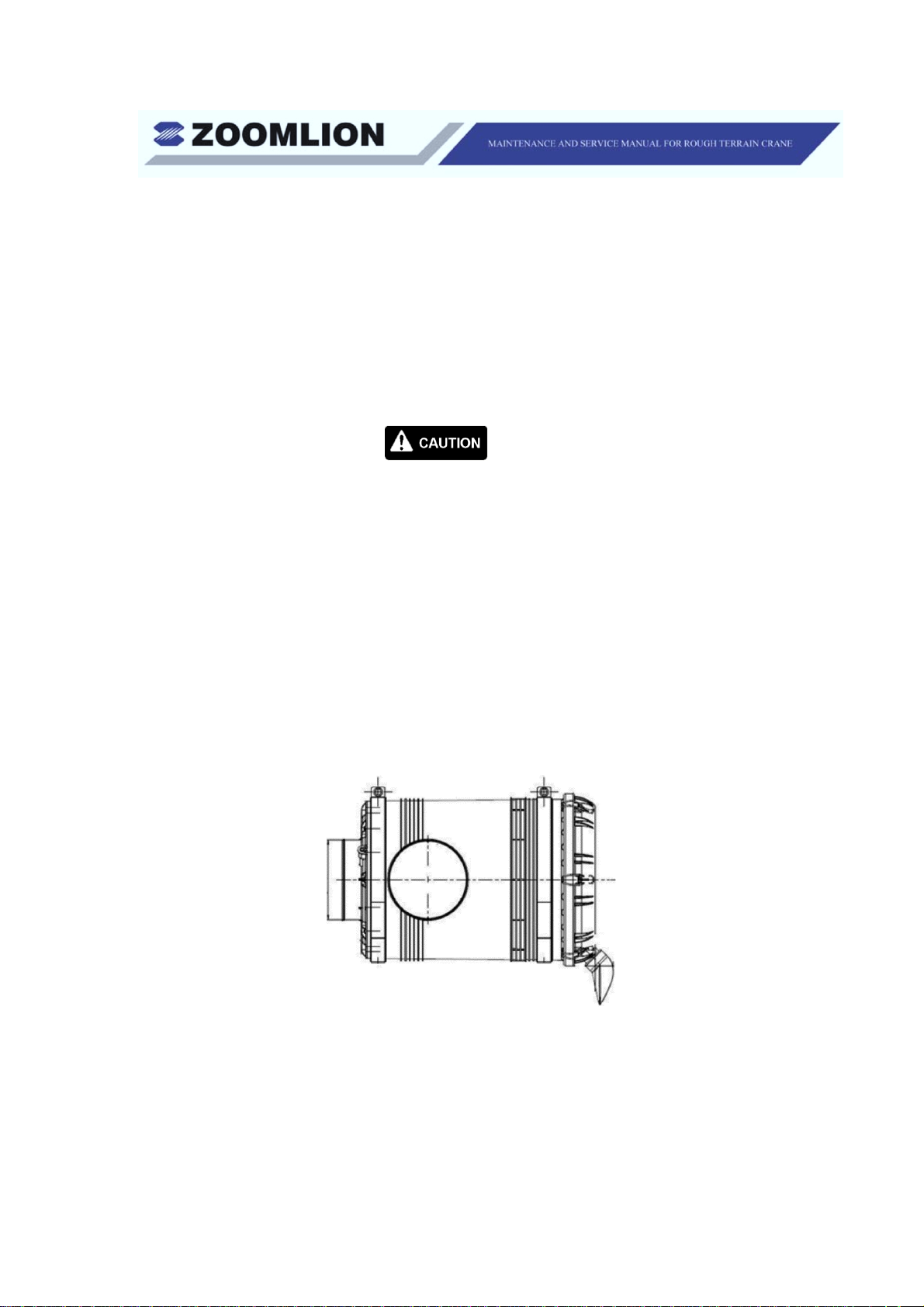

Figure 1-2 Air Filter

Edition 2 Chapter 1 Page 1-5

Dec /2013 Maintenance

Page 23

Figure 1-3 Indicator

(b) A vacuum actuated indicator (See Figure 1-3) is attached on the

side of the air filter assembly. Its gives you an indication of restricted

airflow through the air filter. The quantity of airflow shows on the

indicator at three different levels. When the light is in the green area,

the air filter is good. If the light is in the yellow area, you need to

clean or replace the filter cartridge. If the light is in red area, do not

operate the engine. Replace or clean the filter cartridge. Examine

the intake screen and cartridge area.Make sure that they are clean.

When you use a degreasing agent to clean the engine, make sure that

you put a protective material around the vacuum actuated indicator

(filter minder). The polycarbonate base of the engine degreasing

solvents can damage or destroy the indicator.

(c) Reset the air cleaner indicator each time after the filter element is

replaced to assure proper function.

(d) After you do the servicing on the air filter assembly, reset the

indicator.

(5) Engine Belts

(a) Examine the engine belts for condition and correct adjustment.

Refer to the Engine Manufacturer’s Manual for the belt tension and

the correct procedure to make the belts tight.

Edition 2 Chapter 1 Page 1-6

Dec /2013 Maintenance

Page 24

B. Quarterly Inspection

(1) Fuel Tank

(a) Drain the collected water and sediment from the fuel tank.

• Remove the drain plug and let the tank drain.

• Stop the flow when the fuel is clear of water and sediment.

(b) If the tank has a large quantity of sediment, do the task that follows:

• Fully drain the tank.

• Flush the tank with kerosene until you remove all the sediment.

• Fully drain the kerosene and refuel the tank.

C. Semi-Annually Inspection

(1) Crankcase Breather

To do servicing on the crankcase breather, follow the procedure in the

Engine Manufacturer’s Manual.

1.5 ENGINE RADIATOR MAINTENANCE

A. Daily / 8 Hours:

(1) Coolant Level

(a) Insert the engine radiator coolant level and add coolant to adjust the

level. You can see the level of coolant in the sight gauge near the

top of the radiator tank. A solution of 50% ethylene glycol by volume

is the recommended year-round coolant mixture. If necessary, refill

the corrosion inhibitor. Refer to the engine manual or the servicing

facility to pick the correct coolant and corrosion inhibitor.

(b) If you operate in an area that does not freeze, use a solution of

clean water with a corrosion inhibitor. This gives you the best

performance.

Edition 2 Chapter 1 Page 1-7

Dec /2013 Maintenance

Page 25

B. Monthly / 160 Hours:

(1) Radiator Exterior

Clean the radiator fins and through-core cooling passages. Use

compressed air and water in the opposite direction of usual air flow to

push the unwanted material out of the radiator core.

C. Quarterly:

(1) Corrosion Inhibitor

Adjust the cooling system corrosion inhibitor to the correct level after 500

hours of operation.

Do not use a chromate based corrosion inhibitor when the coolant in

the system contains ethylene glycol. Only use non-chromate based

inhibitors. The chromate base inhibitorreacts with ethylene glycol to

make hydroxide. This you know as Green Slime. The slime decreases

the heat movement rate and can cause the engine to be too hot.

D. Semi-Annually:

(1) Cooling System

Clean the cooling systemat 1000 hours or semi-annually whichevercomes

first. Use a radiator cleaning compound and follow the instructions on the

container. Flush the system with clean water and fill it with an ethylene

glycol solution of 50% by volume.

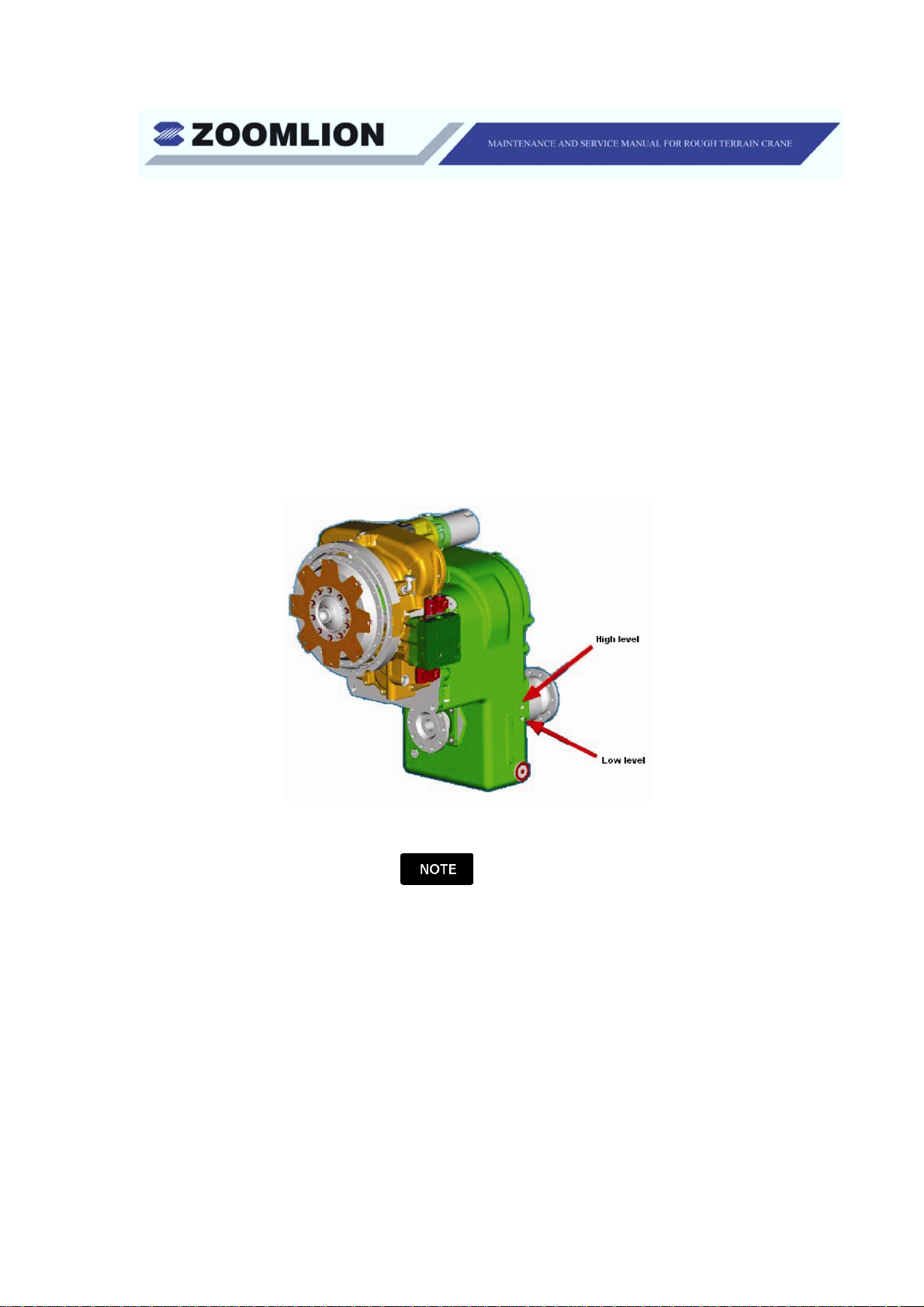

1.6 TRANSMISSION MAINTENANCE

A. Daily Maintenance Check

(1) Before you move the crane, make sure that the level of oil in the

transmission is correct.

(2) Start the engine and let it idle at 1000 to 1500 rpm until the transmission

increases to a temperature of 180° F to 200° F (82.2° C to 93.3° C).

When the engine is at the correct temperature, slowly move the shift lever

through all the gear positions. This moves oil to all parts of the system.

Set the shift lever to the neutral position and set the engine speed at idle

rpm.

Edition 2 Chapter 1 Page 1-8

Dec /2013 Maintenance

Page 26

B. Service the Transmission After Overhaul

When you service the crane for the first time after vehicle installation and / or

after repair, fill the unit as follows:

(1) Fill the transmission with recommended lubricant.

(2) Start the engine and set the speed at idle to let oil fill the torque converter

and lines. Stop the engine after 3 minutes.

(3) Adjust the level of transmission oil as follows:

(a) Find and remove the oil level plugs on the lower part of the

transmission case on the right side of the crane.

Figure 1-4 Low and High Level Plugs

There are two taper pipe thread oil level holes. One is the low level plug

and the other one is the full level plug.

(b) Add the transmission oil until it flows out of the low level plug hole.

(c) Start the engine at idle speed to let the oil flow through the torque

converter, oil cooler and lines. Check the oil level. Add transmission

oil until it flows out of the low level plug. Install the low level plug.

(d) Let the oil temperature increase to between 180° F and 200° F (82.2°

C and 93.3° C). Add oil until it flows out of the full level plug. Install

the full level plug.

Edition 2 Chapter 1 Page 1-9

Dec /2013 Maintenance

Page 27

(e) Always do the transmission oil level checks with the speed of the

engine at idle. The transmission must be in the neutral position and

the transmission temperature between 180° F and 200° F (82.2° C

and 93.3° C).

(4) Do not put too much fluid in the transmission!

C. Lubricant and Filter Change Interval

(1) Refer to Section 1.13 for the lubrication schedule.

(2) Use the Dana-Clark Filter.

(3) Change the hydraulic transmission oil and filter after the first 50 hours of

transmission operation. After the first transmission oil and filter change,

the change interval is 500 hours or 3 months of operation. Change the

lubricant at the 1000 hours or 6 months of operation point.

When you operate in cold weather areas or at the initial startup, the

transmission oil is cold and thick. This can cause the oil to intermittently

bypass the filter.

1.7 AXLE MAINTENANCE CHECK

A. Monthly

(1) Examine the wheel end oil level as follows:

(a) Move each wheel until the planet gear cover is at the position in

Figure 1-5. The arrow on the planet gear cover points horizontally

when the cover is at the correct position. Make sure that the oil is at

the correct level.

Figure 1-5 Wheel End

Edition 2 Chapter 1 Page 1-10

Dec /2013 Maintenance

Page 28

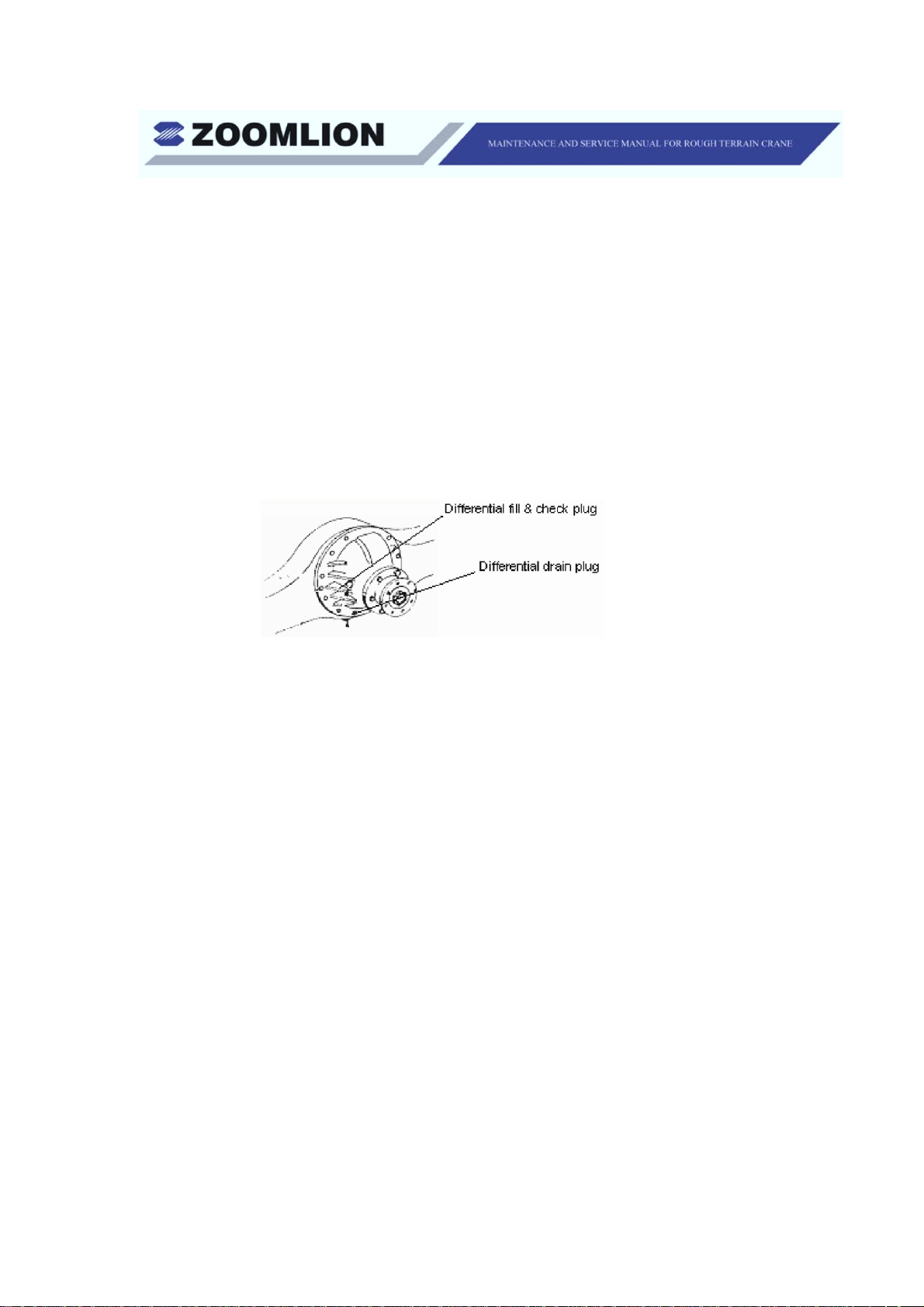

(b) Check the differential oil level by removing the filler and check plug

indicated in Figure 1-6. Add oil as necessary to bring the oil level to

the bottom of the hole.

(2) Do a check of the level of differential oil as follows:

(a) Remove the fill plug.

(b) Make sure that you can see oil at the bottom of the plug hole.

(c) If necessary, add oil until it comes out of the fill plug hole.

(d) Install the fill plug.

Figure 1-6 Differential Plugs

B. Annually

(1) Remove and replace the oil in the differential as follows:

(a) Remove the fill plug and the check plug to drain the oil. Refer to

Figure 1-6.

(b) Make sure that you can see oil at the bottom of the plug hole.

(c) If necessary, add oil until it comes out of the fill plug hole.

(d) Install the fill plug.

1.8 TIRE MAINTENANCE CHECK

A. Weekly

(1) Examine the tires and rims for the items that follow:

(a) Damage

(b) Cuts and bruises

(c) Cracks

Edition 2 Chapter 1 Page 1-11

Dec /2013 Maintenance

Page 29

(d) Punctures

(e) Abrasion.

(2) If necessary, make sure that you repair these items.

(3) Replace or repair the wheels if they are bent, contain a crack or are loose.

(4) Make sure that the wheel nuts are correctly tightened.

B. Tire Pressures

(1) Always keep the correct tire pressure in all the tires.

(2) Friction makes heat that increases the pressure in the tires when you

move the crane. Movement at high speeds also increases the pressures

in the tires. Do not deflate the tires if these conditions occur. Decrease

your speed or stop until the pressure decreases.

(3) Always use an accurate tire pressure gauge. You must measure the tire

pressure when the tires are cool. Do a check of the pressures at regular

intervals.

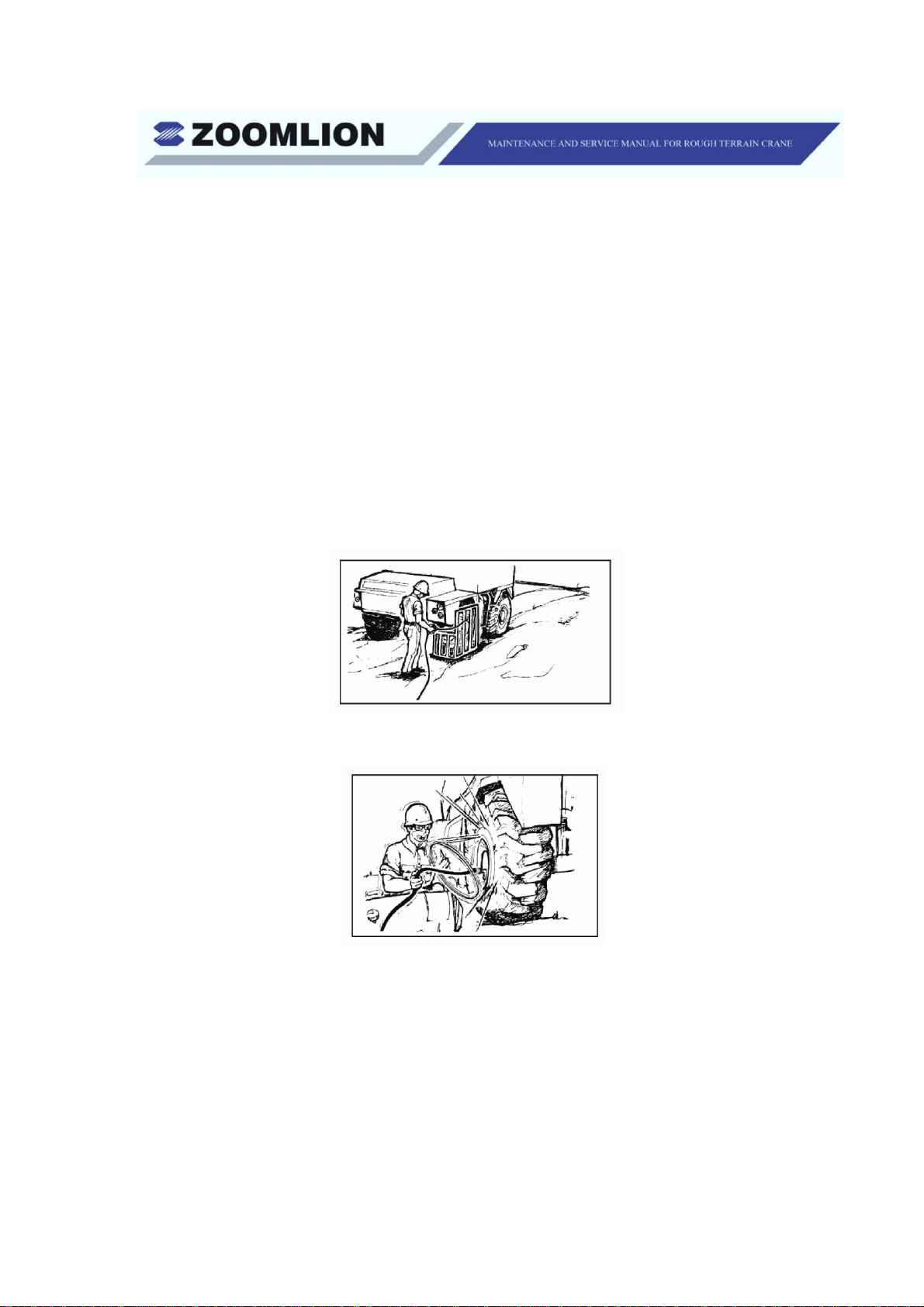

Because of the explosive nature (high temperature and high pressure)

of the tire and rim it is dangerous to change a tire if you are not trained.

Death or personal injury can occur while you touch or do the

maintenance work on these tires. You must follow special procedures

and use special tools to safely change the tires. If it is possible, let your

repair company do this work. If you must change a tire, follow the step

by step instructions in a Tire Repair Manual. If you must add air

because of low pressure, do not be adjacent to the tire tread. Use a long

extension hose to be behind the tire tread. Always use a tire cage or

equivalent protection when you add air.

(4) Do not deflate air from a hot tire. The pressure lowers but the

temperature increases when the tire continues to move. This increase in

temperature causes the tire to malfunction.

Edition 2 Chapter 1 Page 1-12

Dec /2013 Maintenance

Page 30

(5) Under Inflation

The tires that do not have a sufficient quantity of pressure in them cause

them to wipe and scuff over the road. Strain on the tire increases the

chance to bruise.

(6) Correct Inflation

When the tires have the correct pressure in them, they do not wear too

quickly.

(7) Over Inflation

When the tires have too much pressure in them, they do not touch the

surface of the ground correctly. When this occurs, the tires touch the

ground on the crown of the tires and quickly wear in the middle.

Figure 1-7 Correct Way

Figure 1-8 Wrong Way

Edition 2 Chapter 1 Page 1-13

Dec /2013 Maintenance

Page 31

C. Tire Change Safety Precautions

When you must make the repair on a wheel (demount and mount the rim and

tire), follow these precautions:

DO:

(1) Follow the procedures (assemble and disassemble) that you find in the

tire change safety guidelines or other instruction manual.

(2) Before you start to disassemble the wheel, fully deflate the tire.

(3) Replace the parts with damage, cracks, signs of wear and corrosion.

(4) Before you inflate the tire, make sure that you examine the removable

ring. It must be seated correctly.

(5) Examine the side ring and make sure that it is not too loose. This is an

indication of parts that do not match correctly.

(6) Do not inflate the tire until the safety cage is in position.

(7) After you inflate the tire, make sure that the rim ring clearance is between

0.06 in. to 0.25 in. (1.6 mm to 6.3 mm).

(8) After you complete the repair, examine the wheel nuts and rim clamps for

wear, corrosion, proper centering and the correct torque.

DO NOT:

(1) Mix the parts. This is a dangerous condition. Make sure that the side ring

and lock ring agree with the identification marks on the base.

(2) Lift a load or move a load that is above the capacity of the crane.

(3) Inflate a tire if it is fully flat or near flat. You must first disassemble and

examine the tire and rim assembly.

(4) Use a tire and rim configuration that is not approved by the Tire & Rim

Association (TRA).

1.9 BRAKE SYSTEM MAINTENANCE

A. Brake Pedal

(1) Routine Maintenance

(a) Usually the brake pedal is a maintenance free part.

(b) Make sure that the brake pedal moves freely before you move the

crane.

Edition 2 Chapter 1 Page 1-14

Dec /2013 Maintenance

Page 32

(c) Examine the brake pedal annually and replace the parts that show

wear or damage.

If you push the service brake pedal and the distance to stop is more than

usual, the system can have a malfunction. When the service brake indicator

illuminates, the pressure in the system can be low. In that condition, do the

necessary steps to correct the condition or send the crane to the repair facility.

Do not move the crane if the indicator stays illuminated.

B. Park Brake

(1) Routine Maintenance

Usually the park pedal is a maintenance free part.

1.10 AIR SYSTEM MAINTENANCE

When the air system does not supply the usual quantity of air, look at the items that

follow to correct the condition:

• Defective components

• System leak

• Blocked lines

• Moisture and sediment in the system.

A good preventive maintenance program is a necessary part of the air system

operation. Refer to the maintenance schedule in this manual. You can change the

interval between checks if the conditions and weather are hard on the equipment.

1.11 BATTERY MAINTENANCE

A. Examine the batteries and the area around the batteries as follows:

(1) Make sure that the terminal connections are tight.

(2) Remove dirt and corrosion from the wires and terminals.

(3) Clean the battery area with soda water or pure water. When the terminals

dry, apply Vaseline to them.

Edition 2 Chapter 1 Page 1-15

Dec /2013 Maintenance

Page 33

Figure 1-9 Battery

1.12 FUEL, COOLANT AND TORQUE CONVERTER HYDRAULIC TRANSMISSION OIL

A. Fuel Selection

(1) Always use the correct light diesel fuel and engine oil. Make your

selection on the lowest ambient temperature where you are to do the

work.

(2) Refer to the Operator’s Manual for the fuel sulfur content standards.

(3) Refer to the Service and Maintenance Manual for the Engine when it is

necessary to put oil into the engine.

Do not use fuel which is mixed with lubricant or other chemicals.

Make sure that the fuel you use in the crane has the correct thickness.

Make your selection on the lowest temperature you operate in.

Make sure that the fuel tank is full. Condensation, rust and sediment

can freeze and cause a blockage in the flow of fuel. The engine cannot

start if the fuel does not flow or flows too slowly.

B. Coolant Selection

We recommend that you use ethylene glycol coolant. It is all-season, allpurpose and continues to cool for long intervals of time. You can use other

types of antifreeze if it continues to cool for long intervals of time and has:

• High boiling point

• Low freezing point

• Correct PH-value.

Edition 2 Chapter 1 Page 1-16

Dec /2013 Maintenance

Page 34

C. Torque Converter Hydraulic Transmission Oil Selection

For torque converter hydraulic transmission oil selection and change

interval, refer to the Operating Instructions for the Torque Converter.

1.13 LUBRICATION

You can increase the service life of the crane if you obey the preventive maintenance

schedule and use the correct lubricants. When you decrease the effects of friction on

the parts that move, you can prevent unusual malfunctions. Refer to Figure 1-10.

A. Chassis Lubrication

Make sure that you obey the lubrication types and intervals in Table 1-1.

Lubrication method: grease or inject with grease pump.

Figure 1-10 Crane Chassis Lubrication Points

Edition 2 Chapter 1 Page 1-17

Dec /2013 Maintenance

Page 35

Number of

3106 miles

6213 miles

Change the

Steering knuckle

Tie-rod ball pin of

Intermediate

Sliding fork for

6213 miles

31065 miles

Change the

Sliding fork for

3106 miles

Inject with

ZL-2 lithium

3106 miles

6213 miles

Change the

3106 miles

6213 miles

Change the

Change the

Sliding fork for

3106 miles

Inject with

ZL-2 lithium

3106 miles

(5000 km)

6213 miles

Change the

Table 1-1 Lubrication

Ser.

No.

1

2

3

4

5

6 Transmission 1

7

Description

Central reducer

for front axle

of front and rear

axles

front and rear

axles

bearing for drive

lines

intermediate drive

lines

rear drive lines

Lubricating

Point

1

4

4

1

2

1

Lubricating

Intervals

(5000 km)

(10000 km)

3106 miles

(5000 km)

3106 miles

(5000 km)

932 miles

(1500 km)

3106 miles

(5000 km)

(10000 km)

(50000 km)

(5000 km)

Lubricating

Method

Add grease

grease

Inject with

grease pump

Inject with

grease pump

Inject with

grease pump

Inject with

grease pump

Add grease

grease

grease pump

Lubricating

Grease Type

GL-5 80W/90

ZL-2 lithium

base grease

ZL-2 lithium

base grease

ZL-2 lithium

base grease

ZL-2 lithium

base grease

Great Wall # 8

hydraulic

transmission oil

base grease

Wheel ends for

8

rear axle

Central reducer

9

for rear axle

Engine oil

10

underpan

11

front drive lines

Wheel ends for

12

front axle

2

1

1

1

2

(5000 km)

(10000 km)

(5000 km)

(10000 km)

250 hours Add grease

500 hours

(5000 km)

(10000 km)

Add grease

grease

Add grease

grease

grease

grease pump

Add grease

grease

GL-5 80W/90

GL-5 80W/90

10W/40 CH-4

engine oil

base grease

GL-5 80W/90

Edition 2 Chapter 1 Page 1-18

Dec /2013 Maintenance

Page 36

The engine oil add or change interval (in your preventive maintenance

schedule) cannot be more than the interval you find in the diesel engine

maintenance specifications in the Engine Manufacturer’s Manual.

When you add or change grease, you must clean the grease off and

around the plug (grease nipple) and check for leaks.

B. Monthly Lubrication

(1) Do a check of the level of oil in the transmission.

(a) You can find the transmission oil change interval in Section 1.6. If

you do work in harsh conditions, you can decrease the interval

between oil changes.

(b) The oil changes can become more frequent if the crane operates in

rough conditions.

(2) Do a check of the gear oil level in the front and rear axles. Refer to Figure

1-11.

Figure 1-11 Front and Rear Axles

Edition 2 Chapter 1 Page 1-19

Dec /2013 Maintenance

Page 37

When you change the gear oil, only drain the remaining gear oil while it

is warm.

(3) The first time you replace the middle and rear axle gear oil (after the

break-in period) of a new crane:

(a) Drain the gear oil and add engine oil to the axle to the correct level.

(b) Lift the axles off the ground (support with jack stands). Start the

engine and set the transmission in gear.

(c) Allow the wheels to turn for five minutes and then drain the oil.

(d) Add new gear oil to the correct level.

(4) Add grease to the main reducer and wheel ends until the grease comes

out of the oil filler.

(5) Add grease to the oil cup.

When you add or change grease, you must clean the grease off and

around the plug (grease nipple) and check for leaks.

(6) Add grease to the drive lines. Refer to Figure 1-12.

Figure 1-12 Drive Line Lubrication Points

Edition 2 Chapter 1 Page 1-20

Dec /2013 Maintenance

Page 38

(7) Lubricate the rear suspension. Refer to Figure 1-13.

Figure 1-13 Rear Suspension Points

(8) Lubricate the steering system. Refer to Figure 1-14.

Figure 1-14 Steering System Lubrication Points

C. Lubrication – 500 Hours

(1) Change engine oil.

(a) On a warm engine, remove the oil pan drain plug and drain the oil

from the engine and oil filter assembly.

(b) Replace the oil filter.

Always replace the oil filter when you replace the engine oil.

Edition 2 Chapter 1 Page 1-21

Dec /2013 Maintenance

Page 39

(c) Install the oil pan drain plug and add oil to the engine through the oil

filler port. Refer to Figure 1-15.

The weather in the area that you operate the crane determines what type of

oil to use in the engine. The oil viscosity decreases in areas of heat and

increases in areas of cold. As a result, incorrect engine oil can cause the

crane to be hard to start in a cold area. Use Table 1-2 to make a selection of

the correct type of oil for the engine.

(d) Install the oil filler cap.

(e) Operate the engine, without a load, for approximately three minutes.

Examine the area below the engine for leaks.

(f) Stop the engine and let it stand for 30 minutes. Measure the level of

oil with the dipstick. Add oil until it increases to the full mark on the

dipstick. Do not add too much oil in the engine.

Figure 1-15 Oil Fill Port

Table 1-2 Engine Oil Viscosity

Ambient Temperature Oil Viscosity

Above 104° F (40° C) 20W/40

104° F to 14° F (40° C to -10° C) 10W/40

Below 14° F (-10° C) 5W/30or 10W/30

Edition 2 Chapter 1 Page 1-22

Dec /2013 Maintenance

Page 40

• The service life of the engine decreases when you operate the engine at high

speeds or the operating load is high for long intervals.

• When the crane is new, change the engine oil after the engine operates

between 30-50 hours.

(2) Change gear oil in the transmission.

(a) When the transmission is warm, remove the drain plug.

(b) Clean the drain plug and install it onto the transmission.

(c) Add gear oil to the transmission.

When the crane is new, change the transmission gear oil after the crane

travels the first 1242-3106 miles (2000-5000 km).

D. Lubrication Every 3 Months

Do a check of the level of gear oil in the front and rear axles as follows:

(1) Remove the fill plug.

(2) Make sure that you can see oil at the bottom of the plug hole.

(3) If necessary, add oil until it comes out of the fill plug hole.

(4) Install the fill plug.

E. Lubrication Every 6 Months

Remove and replace the oil in the front and rear axles as follows:

Only do this procedure when the oil is warm.

(1) Remove the drain and fill plugs to drain the oil.

(2) Install the drain plug.

(3) Add oil (specified on the lubrication chart) until it comes out of the fill plug

hole.

(4) Replace the fill plug.

Edition 2 Chapter 1 Page 1-23

Dec /2013 Maintenance

Page 41

When the crane is new, change the gear oil after the crane operates the first

250 hours.

1.14 HYDRAULIC OIL

When the crane comes out of the factory, the hydraulic tank is topped up with

hydraulic oil.

The controls on the crane are hydraulically operated.

The most important item for the usual operation of the crane is the quality

viscosity of the hydraulic oil used in the crane. Also important is how

clean you keep the oil.

A lack of knowledge of (ignorance to) the hydraulic oil replacement

schedule can cause different components to malfunction and greatly

decrease the service life of the crane.

Zoomlion cannot be legally responsible for the damage you cause when

you do not obey the data in this manual with reference to: oil and oil filter

change.

Figure 1-16 Filtering – Changing Intervals

A. Changing Steps

(1) Remove and replace the hydraulic oil in the hydraulic tank as follows:

(a) Remove the drain plug at the bottom of the tank.

(b) Remove the master oil return pipe.

(c) Carefully clean the oil tank and filter with a chemical cleaning agent

(solid particle pollution grade ≤ 18/15).

(d) After the tank is dry, clean the tank with new hydraulic oil (solid

particle pollution grade ≤ 18/15).

(e) Drain the oil used to clean the tank.

(f) Fill the tank with new hydraulic oil.

Edition 2 Chapter 1 Page 1-24

Dec /2013 Maintenance

Page 42

≥ 40 µ

30

(g) Screw down the plug fitted on the brake disc to drain the hydraulic

oil in brake return lines every 6 months.

(2) Flush the expired (initial) oil out of the system as follows:

The function of this procedure is to remove all the initial oil out of the system.

(a) Start the engine and operate it at a low speed.

(b) Start the hydraulic system pump.

(c) Operate all the hydraulically controlled functions.

• Make sure that you fully move the items through the full travel

of operation.

• Make sure that you add new oil into the tank as the expired oil

flows out.

• Do not let the initial oil go back into to the oil tank.

• Do not stop the system pump until the new oil flows out of the

master oil return pipe.

(3) Connect master oil return pipe to the oil tank. Move all the hydraulically

controlled functions through the full travel and monitor the level of oil in

the tank. If necessary, add oil.

(4) You must monitor (interval set by management) the quality of the oil.

Change the oil when the number of particles is greater than the number in

the chart.

Change the oil when:

Particle Size Number of particles / ounce (milliliter)

≥ 10 µ 3000

≥ 20 µ 300

≥ 30 µ 100

≥ 50 µ 10

≥ 100 µ 1

Edition 2 Chapter 1 Page 1-25

Dec /2013 Maintenance

Page 43

Change the oil when the oil is found to be contaminated. Do not wait for the

scheduled service.

Always use the correct oil for the temperature the crane operates in.

You cannot mix oil of different brands (specifications) or types.

You must change the oil every 24 months.

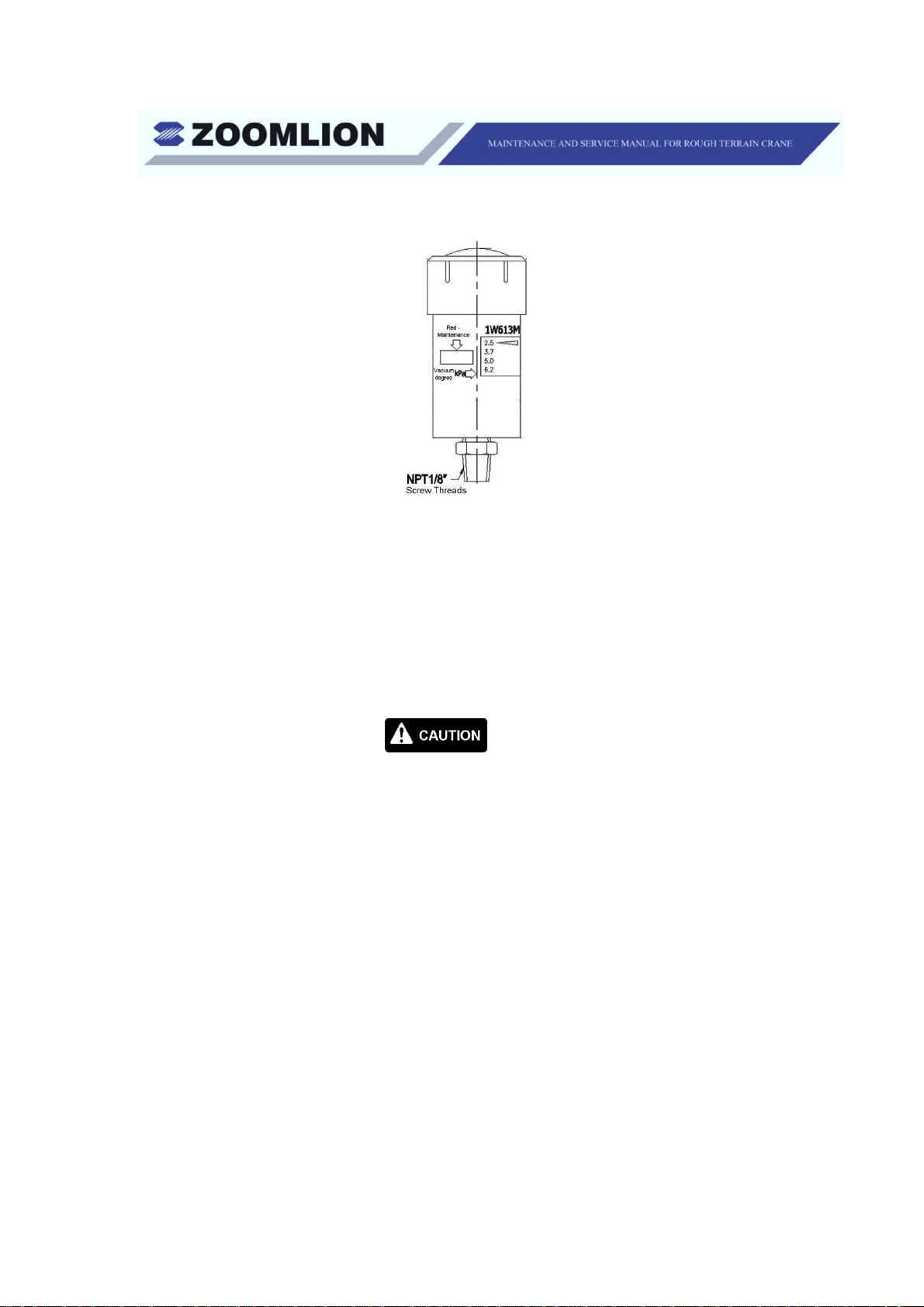

Figure 1-17 Liquid Level Gauge

B. Hydraulic Oil Temperature

(1) Examine the hydraulic oil temperature through the liquid level gauge.

(2) When the crane is in operation, the oil temperature cannot be more than

176° F (80° C).

C. Hydraulic Oil Level

(1) When the crane travels between locations, monitor the level of hydraulic

oil through the liquid level gauge.

Retract cylinders when you do an oil level check.

(2) If the oil level is below the low mark, add oil to the tank until the oil level is

between the low and full marks.

D. Hydraulic Oil Performance and Type

The selection of the type of oil you use in the crane must align with the data

found in Table 1-3.

Edition 2 Chapter 1 Page 1-26

Dec /2013 Maintenance

Page 44

Table 1-3 Hydraulic Oil Performance and Type

Ambient

Item

Reference standard GB11118.1-94 GB11118.1-94

Type L-HM L-HV L-HS

Viscosity grade 68 32 22 10

Min. flash point

(split) ° F (° C)

Kinematic viscosity at

104° F in²/s

(40° C mm²/s)

Max. temperature

when kinematic

viscosity at

59 in²/s ° F

(1500 mm²/s ° C)

Min. viscosity index 95 130 130

Max. pour point (° C)

Temperature

Above 104° F

(40° C)

356 (180) 320 (160) 284 (140) 198 (92)

61.2-74.8 28.8-35.2 19.8-24.2

-0.4 (-18) -22 (-30) -58 (-50)

15.8 (-9) -27 (-33) -49 (-45)

Ambient

Temperature

-4° F - 104° F

(-20° C - 40° C)

Ambient

Temperature-

22° F - -4° F

(-30° C - -20° C)

GB11118.1-94 SH 0358-95

Ambient

Temperature

Below -22° F

(-30° C)

Aviation

hydraulic oil

More than 10

at 50° C

Edition 2 Chapter 1 Page 1-27

Dec /2013 Maintenance

Page 45

1.15 GEAR OIL

Organic acid fat, phosphoric acid

A. Always use the correct gear oil (type and viscosity) in the crane.

B. When the crane comes out of the factory, the gear oil level is full. You must use

the data from Table 1-4 when you choose the type of oil for the crane.

Table 1-4 Gear Oil Performance

Kinematic viscosity at

212° F (100 °C)

mm²/s

56.3 (13.5) ~<24.0

Minimum flash

point (split)

° F (° C)

329 (165)

Ingredients

fat, silicic acid fat, fluorin oil, silicon

oil, polyphenylene oxide +

addictive

Figure 1-18 Changing Intervals

When there is contamination in the gear oil, change the oil immediately.

Monitor the oil level regularly and add oil if it is below the low mark.

You cannot mix oil of different brands (specifications) or types.

Always use the correct oil based on the temperature the crane operates in.

If you use the incorrect oil (type or viscosity) in the reducer mechanism,

you can damage it.

Edition 2 Chapter 1 Page 1-28

Dec /2013 Maintenance

Page 46

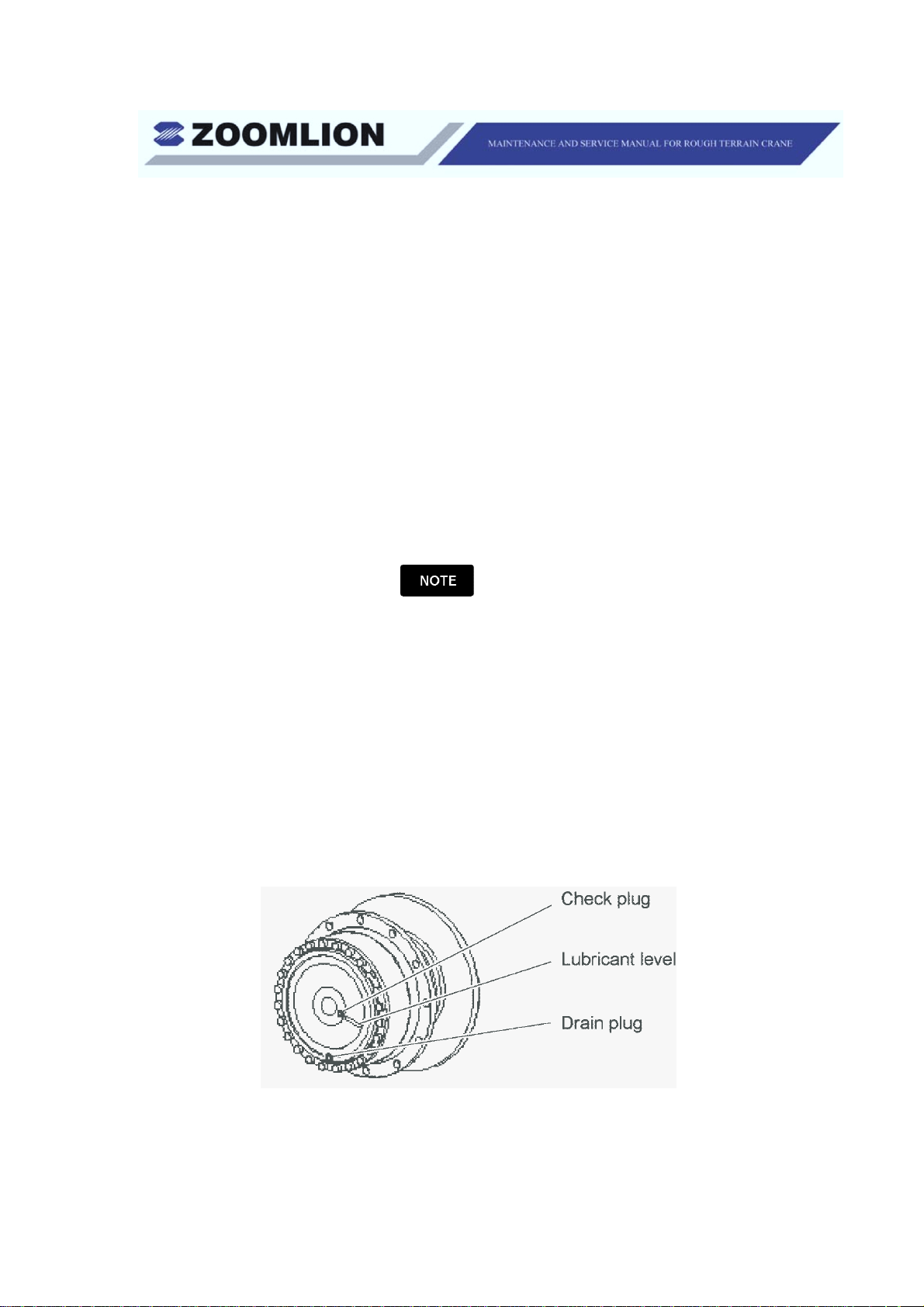

C. Oil Change Parts

(1) Winch Reducer

Figure 1-19 Fill, Check and Drain Ports

Fill the gear oil to the top.

(2) Swing Reducer

(a) Fill oil after removing the plug of oil fill aperture.

Figure 1-20 Swing Reducer Fill and Drain Ports

Fill the gear oil to the top.

Edition 2 Chapter 1 Page 1-29

Dec /2013 Maintenance

Page 47

1.16 LUBRICATING GREASE

Smooth inunctum

with the color from

Equal

inunctum

with the color from

When you lubricate the crane, use only ZL-2 or ZG-3 types of grease. There are two

procedures to lubricate the crane:

• Use a grease pump to put (inject) lubricant through a grease fitting (nipple).

• Apply the grease directly to the part by hand.

Figure 1-21 Grease Pump

Table 1-5 Types of Grease

Type of

Grease

ZL-2

ZG-3

Appearance

light yellow to brown.

light yellow to dark brown.

Parameters

Drop point

°F (°C)

347 (175) 1 ——

194 (90) 1 2.5

Cone

penetration

(in)

Maximum

moisture

(%)

Edition 2 Chapter 1 Page 1-30

Dec /2013 Maintenance

Page 48

1.17 LUBRICATING POINTS

Lubricant

A. You can use Table 1-6 and Figure 1-22.

Table 1-6 Lubrication Intervals and Points

No.

Upper pulley block (shaft) on

1

main boom

2 Slider pads of main boom 10 Days

Lower pulley block (shaft) on

3

main boom

Sliding surfaces of the main

4

boom

Upper articulated-point shaft

5

of derricking cylinder

Pulley block (shaft) on main /

6

auxiliary hook

7 Drive lines of oil pump Daily

Lower articulated-point shaft

8

of derricking cylinder

9 Outrigger slider pads 10 Days

Description Intervals Method

10 Days Grease ZL-2

10 Days

10 Days Grease ZL-2

Monthly

10 Days

Monthly

Grease or inject

with grease pump

Inject with grease

pump

Inject with grease

pump

Inject with grease

pump

Inject with grease

pump

Inject with grease

pump

Grease or inject

with grease

Type

ZL-2

ZL-2

ZL-2

ZG-3

ZL-2

ZL-2

ZL-2

10 Main / auxiliary winch Semi-annual Directly pour

11 Main boom main shaft Daily

12 Swing reducer Semi-annual Directly pour

13 Wire-rope 10 Days Grease ZG-3

14 Pulley block (shaft) on jib 10 Days

Grease or inject

with grease pump

Inject with grease

pump

90# industrial

gear oil

ZL-2

90# industrial

gear oil

ZL-2

Edition 2 Chapter 1 Page 1-31

Dec /2013 Maintenance

Page 49

Figure 1-22 Crane Lubrication Points

Edition 2 Chapter 1 Page 1-32

Dec /2013 Maintenance

Page 50

Semi

-

Before you put lubricant (grease) on a part by hand, clean the part then add

the lubricant.

Clean and lubricate all the sliding surface areas (bare metal, includes cylinder

pistons), not in the table, at a regular interval.

You cannot mix grease of different brands (specifications) or types.

When you inject lubricant (grease) with a grease pump, continue the

procedure until you see old grease come out of the joints.

1.18 ADJUST, CLEAN AND REPLACE THE PARTS

A. Adjustments

Table 1-7 Adjustments

Item Monthly Quarterly

Adjust the adjusting bolt under the brake

pedal to make sure that the free stroke

varies from 0.4 to 0.86 in. (10 to 22 mm).

Adjust the limit screw on the steering

knuckle of front axles to ensure that the limit

screws on steering axles reach their limit

position at the same time.

Adjust engine fan, air compressor and

generator belts to between 0.4 to 0.6 in. (10

to 15 mm).

•

Annual

Yearly

•

•

Figure 1-23 Adjustments

Edition 2 Chapter 1 Page 1-33

Dec /2013 Maintenance

Page 51

B. Clean the Chassis

Semi

-

(1) Intervals

Table 1-8 Intervals

Item Daily Monthly Quarterly

Drain brake system. Pull the draw

ring of manual water drain valve

downwards to drain water.

Clean the fuel filter.

Clean the water tank.

Clean the air cleaner filter

element with compressed air from

the inside.

Clean the air cleaner filter

element.

C. Clean the Diesel Fuel Filter

(1) Clean the diesel fuel filter as follows:

(a) Put a container below the fuel filter drain plug.

(b) Loosen the air relief cock and remove the drain plug to drain fuel

and unwanted material from the filter bowl.

(c) Remove the long central treaded bolt and washer from the fuel filter

assembly. Remove the parts that follow:

•

Annual

Yearly

•

•

•

•

• Fuel filter bowl

• Spring

• Spring seat

• Filter element

• Washer.

(d) Clean the parts from step (c) but do not clean the filter element.

Edition 2 Chapter 1 Page 1-34

Dec /2013 Maintenance

Page 52

Do not wash the filter element!

(e) Examine the filter element. If it is dirty or full of contamination,

discard it. If this is a 1000 hours inspection, discard the element.

If you install a new filter element, replace the washer and O-ring.

(f) Assemble the fuel filter in sequence as follows (See Figure 1-24):

• Long central treaded bolt

• Washer (new)

• Fuel filter bowl

• Spring

• Spring seat

• Filter element (new)

• O-ring (new).

(g) Remove the air with manual oil pump.

(h) Examine the filter assembly for leaks.

Figure 1-24 Fuel Filter and Water Separator

Edition 2 Chapter 1 Page 1-35

Dec /2013 Maintenance

Page 53

D. Clean the Cooling System

Operate the engine until it increases to the usual temperature of 185° F (85° C).

If the water temperature is too low, the thermostat cannot open and the coolant

cannot flow through the radiator. Clean the cooling system as follows:

(1) Loosen the radiator drain cock to fully drain the engine coolant. Operate

the engine at idle speed (as you remove the engine coolant) for five

seconds.

(2) Close the radiator drain cock and remove the radiator cap. Fill the

radiator with a fluid to clean the engine coolant system and tap water.

Install the radiator cap.

(3) Operate the engine until it increases to the usual temperature 185° F

(85° C). Set the heater control to full heat and the blower to ON.

(4) Operate the engine for 30 minutes at idle speed with no load.

(5) Stop the engine and drain the coolant system.

(6) Add tap water and operate the engine to flow through the system, then

stop the engine and drain the coolant system. Do this step again 2 or 3

times.

(7) Add the correct quantity of antirust, antifreeze and tap water to fill the

system.

(8) Operate the engine until it increases to the usual temperature 185° F

(85° C). Remove the air from the system.

(9) Stop the engine and make sure that the level of fluid in the system is at

the correct level. If necessary, add tap water to fill the system.

E. Clean the Air Cleaner

Clean the air cleaner as follows:

(1) Remove the clamp from the air cleaner and remove the rear end cover.

(2) Remove the filter element.

(3) Clean the contaminations from the inner side of the air cleaner and cover.

Make sure that the air filter element is free of contamination. If necessary,

replace the element.

(4) Install the element and cover. Tighten the clamp.

Edition 2 Chapter 1 Page 1-36

Dec /2013 Maintenance

Page 54

Every

Every 2

Every 4

F. Chassis Parts – Replacement Intervals

Table 1-9 Replacement Intervals

Item

Diaphragm and rubber parts of pressure

regulating valve of air dryer

Air cleaner filter element

Shims and rubber parts of service brake valve

Hose connecting the air compressor and

pressure regulating valve

Shim and rubber parts of the relay valve

Shims and rubber parts of quick release valve

Shims and rubber parts of park brake valve

Shims and rubber parts of tee clack

Air cleaner filter element

Diesel fuel hose inside the engine hood

Diesel fuel hose outside the engine hood

1 year

•

•

•

•

•

•

•

•

•

years

•

years

•

G. Wire-RopeMaintenance

When the wire-rope is on the crane for a long interval, it can become

weak and can cause a dangerous condition.

(1) Wire-Rope Inspection

Replace the wire-rope if you find one of the items that follow:

• Steel wire breaks: six on one rope layer or three on one rope strand.

Edition 2 Chapter 1 Page 1-37

Dec /2013 Maintenance

Page 55

• Torsion resistant wire-rope breaks: two steel wires of rope diameter in

less than 0.2 in. (6 mm) or four steel wires of rope diameter in less than

1.2 in. (30 mm).

• A break in the wire-rope on the external rope layer at the core position

(causes rope core to extrude or in circle).

• The thickness (diameter) of one wire-rope on the external layer is less

than 2/3 of its usual thickness (diameter).

• Wire-rope that is not usual: distortion, flattened or broke wire nests etc.

• Wire-rope with an area of damage because of too much heat.

• If the wire-rope has an area that you think is not as thick as it must be,

you must replace the rope. Use the data that follows to examine the rope:

Inches Millimeters

Rope Thickness D Maximum Loss Rope Thickness D Maximum Loss

≤ 0.3 0.02 ≤ 8 0.4

0.4 to 0.5 0.03 9.5 to 13 0.8

0.6 to 0.7 0.05 14.5 to 19 1.2

0.9 to 1.1 0.06 22 to 29 1.6

1.3 to 1.5 0.09 32 to 38 2.4

• Wire strand breaks: two out of the rope connection or one at the rope

connection.

(2) Wire-Rope Replacement

(a) Make the crane level on a hard surface.

(b) Fully retract the boom.

(c) Lower the main hook and set it on the ground.

Figure 1-25 Hook on the Ground

Edition 2 Chapter 1 Page 1-38

Dec /2013 Maintenance

Page 56

Operate carefully to avoid the rope from disordering on the drum.

(d) Remove the press nipple from the boom (top section) or the main

hook.

1 Tools necessary: Wrench.

2 Set the parts to the side until they are necessary.

Figure 1-26 Main Hook and Nipple

(e) Remove the wire-rope from the press nipple.

1 Tools necessary: Steel rod (punch), hammer and wrench.

2 Set the parts to the side until they are necessary.

Figure 1-27 Wire-Rope Nipple

(f) Manually pull all the wire-rope from the drum.

Edition 2 Chapter 1 Page 1-39

Dec /2013 Maintenance

Page 57

Figure 1-28 Pull Wire-Rope

The 3rd wrap warning alarm comes ON when only 3 hoist rope wraps are

left on the main winch. Push the bypass key switch until the wire-rope

stops.

(g) Remove the wire-rope from the main winch drum.

1 Tools necessary: Steel rod (punch) and hammer.

2 You must be careful when you remove the chock.

Figure 1-29 Wire-Rope Off the Drum

(h) Reeve the new wire-rope through the boom sheave.

1 Tools necessary: Thin steel wire or ethylene plastic strap.

Figure 1-30 The End of the New Wire-Rope

Edition 2 Chapter 1 Page 1-40

Dec /2013 Maintenance

Page 58

Put thin steel wire or ethylene plastic strap on the end of the wire-rope.

(i) Install the new wire-rope onto the main winch drum with the chock.

1 Tools necessary: Hammer.

Figure 1-31 New Wire-Rope on the Drum

• Make sure that the chock is in the correct position before you make the

wire-rope tight.

• Make sure that the end of the wire-rope does not go fully through the

drum. The wire-rope must extend more than the surface of the drum.

(j) Spool-up the wire-rope.

1 Tools necessary: Thin steel wire or ethylene plastic strap.

Figure 1-32 Monitor the Rope (Must Lay Flat and Evenly)

Edition 2 Chapter 1 Page 1-41

Dec /2013 Maintenance

Page 59

Do not spool-up the wire-rope too quickly. Make sure that the rope

collects on the drum correctly.

(k) Reeve the wire-rope through the top boom head sheave and hook

pulley block in the related line parts.

Make sure that you attach the wire-rope in the correct sequence.

Figure 1-33 Wire-Rope Wrap Sequence

(l) Install the becket and wedge onto the wire-rope.

1 Tools necessary: Wrench and hammer.

Figure 1-34 Becket and Wedge

Make sure that the tapered (beveled) end of the becket is in the same

direction as the end of the wire-rope.

Edition 2 Chapter 1 Page 1-42

Dec /2013 Maintenance

Page 60

(m) Install the becket to the end of the boom or to the main hook.

1 Tools necessary: Wrench.

Figure 1-35 Becket Attachment

(n) Derrick the boom and fully extend the boom. Reel-off the wire-rope

from the main winch until the 3rd wrap alarm sounds.

Figure 1-36 Boom Extended and Elevated

Do not let the main hook hit the ground or move too quickly to prevent

rope damage or an accident.

(o) Attach a load to the main hook and spool-up the wire-rope. The load

must not be more than 30% of the maximum lift capacity for each

wire strand. For example:

1 Weight of the load: W = 0.3 x NP

2 Line parts: N

3 Max. permissible lift capacity per strand: P

Edition 2 Chapter 1 Page 1-43

Dec /2013 Maintenance

Page 61

Figure 1-37 Spool-Up Wire-Rope

Do not lift more than the lift capacity of the wire-rope.

(p) Remove the load from the main hook.

H. Hook Inspection

(1) Do an inspection on the hook. Replace the hook if you find one of the

items in the next step.

Do not weld the hooks to repair the disfigurements.

(a) A crack and crevasse on the surface of the hook.

(b) The split degree of the hook cannot be more than 10% of the usual

distance.

(c) An abrasion of the dangerous sectional plane cannot be more than

10% of the usual thickness.

(d) The wear extent of the sectional plane in point where wire-rope

suspended exceeds 10% of original height.

(e) The torsion and deformation of hook exceeds 10°.

(f) There is plastic deformation in dangerous sectional plane such as

the tail of hook, the screw threaded part and hook web.

Edition 2 Chapter 1 Page 1-44

Dec /2013 Maintenance

Page 62

I. Replace the Return-Line Filter Element

The hydraulic tank (reservoir) has a return-line filter on the input connection

(return-line). The filter stops contamination of the hydraulic fluid, such as

particles of metal and rubber. Make sure that you are careful when you add

fluid to the system.

The filter element in the filter stops the particles that are more than 1 um in

dimension. It can decrease the number of magnetized and non-magnetized

particles. The filter increases the quality of the hydraulic fluid which increases

the service life of all the components in the system.

The texture of the filter is a non-woven chemical fabric which can stop the flow

of contamination and let a large quantity of fluid go through. The usual system

pressure does not decrease. Its filter precision is calibrated by the absolute

filter precision. Its filter ratio and efficiency align with the requirements of ISO.

To replace the filter, the top cover is the only part you must remove.

When the system is open (top cover off), the contamination that is caught by

the filter cannot go into the system because of the internal fluid openings.

Figure 1-38 Filter Change Interval

Do not replace the filter element if the hydraulic system is pressurized.

J. Filter Replacement

(1) Remove the four bolts and top cover.

Figure 1-39 Top Cover

Edition 2 Chapter 1 Page 1-45

Dec /2013 Maintenance

Page 63

(2) Remove the spring and the permanent magnetunit.

Figure 1-40 Disassemble

(3) Remove and replace the filter element.

Figure 1-41 Filter Element

(4) Install thepermanent magnetunit and spring.

Figure 1-42 Assemble

Edition 2 Chapter 1 Page 1-46

Dec /2013 Maintenance

Page 64

(5) Install the top cover with the four bolts.

Figure 1-43 Top Cover Assembly

K. Boom Extend / Retract

(1) Troubleshoot

Problem: The top boom section does not fully retract.

Cause: The boom extend / retract rope is not at the correct length.

Correction: Adjust the rope.

(2) Adjust the retract rope top section of the boom as follows:

(a) Remove the access panel on top boom section to get access to the

nut at the head of the boom retraction rope.

(b) Loosen the lock nut, then turn the adjustment nut to tighten the

extend rope. Make sure that the rope is not loose. Do not make the

rope too tight.

Tools necessary: Socket wrench.

Edition 2 Chapter 1 Page 1-47

Dec /2013 Maintenance

Page 65

locking nut

Adjusting nut

top section

Figure 1-44 Adjust and Lock nuts

(3) Adjust the retract rope on the boom section 2 as follows:

Use the same procedure that you used to adjust the top section retract

rope. The adjustment nut is on the side of the boom head.

• Make sure that the crane is on a hard surface.

• The boom extend rope is not adjustable.

• Do not make the adjustment nut too tight. Make sure that the

lock nut is tight after you adjust the wire-rope.

L. Swing Bearing Bolts – Inspection and Torque

It is important to do an inspection on the swing bearing bolts. The interval of the

inspection is set to make sure that the crane operates in a safe manner.

Make sure that the bolts are tight with the specified torque.

After the break-in period, examine the bolts semi-annually or after 1000 hours.

Edition 2 Chapter 1 Page 1-48

Dec /2013 Maintenance

Page 66

Torque sequence:

When you do a check of the torque on the bolts, follow the sequence in Figure

1-45.

(1) Tighten the bolts on the inner ring (chassis frame).

(2) Tighten the bolts on the outer ring (superstructure).

Figure 1-45 Torque Sequence

Edition 2 Chapter 1 Page 1-49

Dec /2013 Maintenance

Page 67

1.19 BATTERY MAINTENANCE AND SERVICE

The batteries in the crane align with national standard GB/T 5008.1 - 2005. If the

electrical system is free of malfunctions, keep the batteries fully charged. If the

batteries do not charge or cannot hold voltage, examine the generator and voltage

regulator for malfunction.

Do an inspection of the batteries and the battery storage area as follows:

A. When the batteries are fully charged, make sure that the acid level is between

0.4 and 0.6 in (10 and 15 mm) above the top edge of the battery plates.

B. Examine the battery cell caps as follows:

• The caps are tight and air vents are not blocked.

• The batteries and the storage area are dry.

C. Usual charge refers to the charge of battery after use. When you measure the

level of charge on a battery, the voltage on a usual charged battery is 1.2 - 1.5

times that of a discharged one. When you find a battery that is too low,

measure the voltage level of each cell. If you find a cell that has less than 1.75

volts, stop the check and charge the battery.

D. Charge a usual charged battery as follows:

(1) Make sure that the charger power is OFF and put the charger power plug

into the power socket. If the charger has a voltage selector switch, set it

to the correct voltage of the battery/batteries you charge. When you

charge two batteries (batteries in series) at the same time, set the voltage

selector switch to 24 V.

(2) Connect the positive (+) and negative (-) clips to the battery terminals.

Adjust the time to charge interval by the charger operating manual. Do

not do a rapid charge on the batteries.

(3) Set the charger power switch to ON and adjust the current selector

(below 20 A). When the battery electrolyte temperature increases to 113°

F (45° C), immediately stop charge.

(4) The battery charge can continue for approximately 5 - 10 hours. When

the battery/batteries are fully charged, use a voltmeter to measure the

voltage. The voltage in the battery must be > 15 volts or electric eye is in

good condition.

(5) Set the current rotary switch and the charger power switch to OFF.

(6) Disconnect the positive (+) and negative (-) clips from the battery

terminals.

(7) Remove the charger power plug.

Edition 2 Chapter 1 Page 1-50

Dec /2013 Maintenance

Page 68

E. Do an equalizing charge procedure if one of the items that follows occurs:

• Monthly, when the crane operates in usual conditions.

• When the battery charge interval is too long or unusually high loss of power

in the battery.

• The battery voltage is too low or it fails to charge.

• If you find a battery cell with a voltage level of < 1 volt or three cells that are

< 1.5 volts.

(1) Equalizing charge procedure:

(a) When the battery has a usual charge do not move it for one hour.

(b) Charge the battery (at 10 amp setting) until the battery electrolyte

starts to bubble. Do not move it for one hour.

(c) Do step 2 again until the electrolyte starts to bubble. Make sure that

the level of electrolyte and the voltage are at the correct level.

F. If you do not operate the crane for a long time, remove the battery from the

crane and charge it. Do a usual charge two times each month. Do a full

discharge and charge four times each year.

G. Examine the batteries and the area around the batteries as follows:

• Make sure that the terminal connections are tight.

• Remove dirt and corrosion from the wires and terminals.

1.20 BATTERY MAINTENANCE – WINTER

When you operate the crane in cold conditions, you use more electricity more than in

other season. Battery maintenance before winter is very important for the battery and

crane operation.

A. Make sure that the acid level is between 0.4 and 0.6 in (10 and 15 mm) above

the top edge of the battery plates. If necessary, add distilled water.

B. Adjust the electrolyte ratio (acid to distilled water) determined by the area and

time of year.

C. Make sure that you install the fluid air plugs correctly. The vent holes must be

clean, dry and have no blockage.

D. Make sure that the battery terminals are clean (corrosion free), dry and

connected correctly and tight. Add a small quantity of Vaseline to prevent

corrosion.

Edition 2 Chapter 1 Page 1-51

Dec /2013 Maintenance

Page 69

E. If you do not operate the crane for a long time, remove the battery from the

crane and make sure that it is charged at all times.

F. Before you start the engine, make sure that all items that use battery power are

in the OFF position.

G. If the engine does not start after 15 seconds, do not continue to apply power to

the starter. Wait for 2 minutes before you start the engine again.

H. When a battery is bad, replace it. Make sure that the new battery has the same

power capacity.

When the temperature is lower than 22°F (-30° C), make sure that you

protect the battery to prevent loss of heat.

1.21 OPERATION IN WINTER

When you operate the crane in the winter, the fluids in the crane become thick. Make

sure that all the fluids are the correct type for the area time of year. Good

maintenance and correct operations are very important for safety operation and can

prevent many crane malfunctions.

Make sure that you prepare the crane correctly when you operate the crane in cold

area. Decrease the speed of the crane when you move. If it is necessary, stop the

crane at a flat, dry and sunny area.

A. Chassis Maintenance

(1) The engine oil must be the correct grade to operate in cold weather.

When the temperature decreases, the viscosity of the oil decreases. If it

is too low, the oil cannot move to all the inner parts of the engine. You

can cause damage to the engine.

• Do not mix the engine oil of different brand and different type.

• Make sure that you always use the correct oil type and grade of oil. Multi-

grade oils let the engine to operate in a wide range of temperatures.

(2) Add / change the coolant. Clean the engine cooling system and add the

coolant. You can get the best system performance (all-seasons and allpurpose) when you use a long-acting coolant.

Edition 2 Chapter 1 Page 1-52

Dec /2013 Maintenance

Page 70

If you find that the coolant is bad, make sure that you follow the

procedure(Clean the Cooling System).

(3) Always use the correct type of diesel fuel. For more data on the correct

fuel to use, refer to the Engine Manufacturer’sManual. The fuel must be

winterized when the crane operates in a cold area. Change the diesel fuel