Page 1

ZOOMLION

Mobile Crane Branch Company

QUY260 Load Moment Indicator

User Manual

Hirschmann Electronics (Shanghai)Co.,Ltd

Apr. 2009

Page 2

User Manual

2009 by Hirschmann Electronics Co.,Ltd.

Copyright

Any reproduction, modification and translation, without official authorization in writing of Hirschmann

Electronics (Shanghai) Co.,Ltd, shall be prohibited. For reproduction of this manual please refer to

Copyright Law.

1st edition on Apr. 2009

Guarantee

The information in this document is subject to change without notice. Hirschmann makes no warranty

of any kind with regard to this material, including, but not limited to the implied warranties of

merchantability and fitness for a particular purpose. Hirschmann shall not be liable for errors contained

herein or for incidental or consequential damages in connection with the furnishing, performance, or

use of this manual.

Hirschmann Electronics(Shanghai)Co.,Ltd

Suite 10K, Huamin Empire Plaza, No.728, West Yan An Road, Shanghai, P.R.China

Tel:021-51082780

Fax:021-52375899

Zipcode:200050

Website:http://www.hirschmann-ac.com

Page 3

User Manual

Index

1.Breif introduction ................................................................................................................................. 2

2.General information ......................................................................................................... .................... 2

3.Warnings ............................................................................................................................................... 2

4.System configuration ............................................................................................................................ 3

4.1Controller ...................................................................................................................................... 3

4.2 Console ......................................................................................................................................... 4

4.3 KMD Force sensor ...................................................................................................................... 4

4.4 Angle sensor ................................................................................................................................. 4

5. System introduction ............................................................................................................................ 5

5.1 OM icon ........................................................................................................................................ 6

5.2 Main interface .............................................................................................................................. 7

5.3 Function key ................................................................................................................................. 8

5.3.1 OM & Reeving setting ........................................................................................................ 9

5.3.2 I/O Port checking ............................................................................................................. 12

5.3.3 System setting ................................................................................................................... 14

5.3.4 CAN-bus checking ............................................................................................................ 16

5.3.5 Angle limitation & Time setting ...................................................................................... 17

6. Trouble shooting ................................................................................................................................ 19

7. System connection ............................................................................................................................. 25

1

Page 4

User Manual

1.Breif introduction

This manual is made for the crawler cranesQUY260 of Zoomlion. Please read the manual carefully

according the collocation of different types.

2.General information

The Hirschmann load moment indicator (LMI) iFLEX5 has been designed to provide the crane

operator with the essential information required to operate the machine within its design parameters.

Using various sensing devices, the Load Moment Indicator monitors various crane function and

provide the operator with a continuous reading of the load capacity. The readings continuously change

as the crane moves and lifts. The LMI provides the operator with information regarding the length and

angle of the boom, tip height, working radius, rated load and total weight of actual lift.

If non-permitted condition is approached, the iFLEX5 Load Moment Indicator will warn the operator

by sounding an audible alarm, lighting a warning light and cutting off those functions that may

aggravate the crane’s condition.

3.Warnings

The LMI is an operational aid that warns a crane operator from approaching conditions of overloading

and over-hoisting which would cause great damage to the equipment and personnel.

The LMI could only prevent overload of the crane boom in lengthwise vertical level but could not

prevent accidents caused by inclined hoisting, wind loading, inclination or foundering of the road and

rail or driving oversteps. So the operators and other people shall not ignore safe management and

operating procedures of the crane because of the existence of the device. It is not, and shall not,

substitute for a good operator’s judgment, great experience or standard operating procedures. The

responsibility for the safe crane operation shall remain with the crane operator who shall ensure that all

warnings and instructions supplied are fully understood and observed.

Prior to operating the crane, the operator must carefully and thoroughly read and understand the

information in this manual to ensure that he knows the operation and limitations of indicator and crane.

Notice:The LMI can only work correctly, if all adjustments have been properly set. For correct

adjustment, the operator has to answer thoroughly and correctly all questions asked during the setup

procedure in accordance with the real rigging state of the crane. To prevent material damage and

serious or even fatal accidents, the correct adjustment of the LMI has to be ensured before starting the

crane operation.

2

Page 5

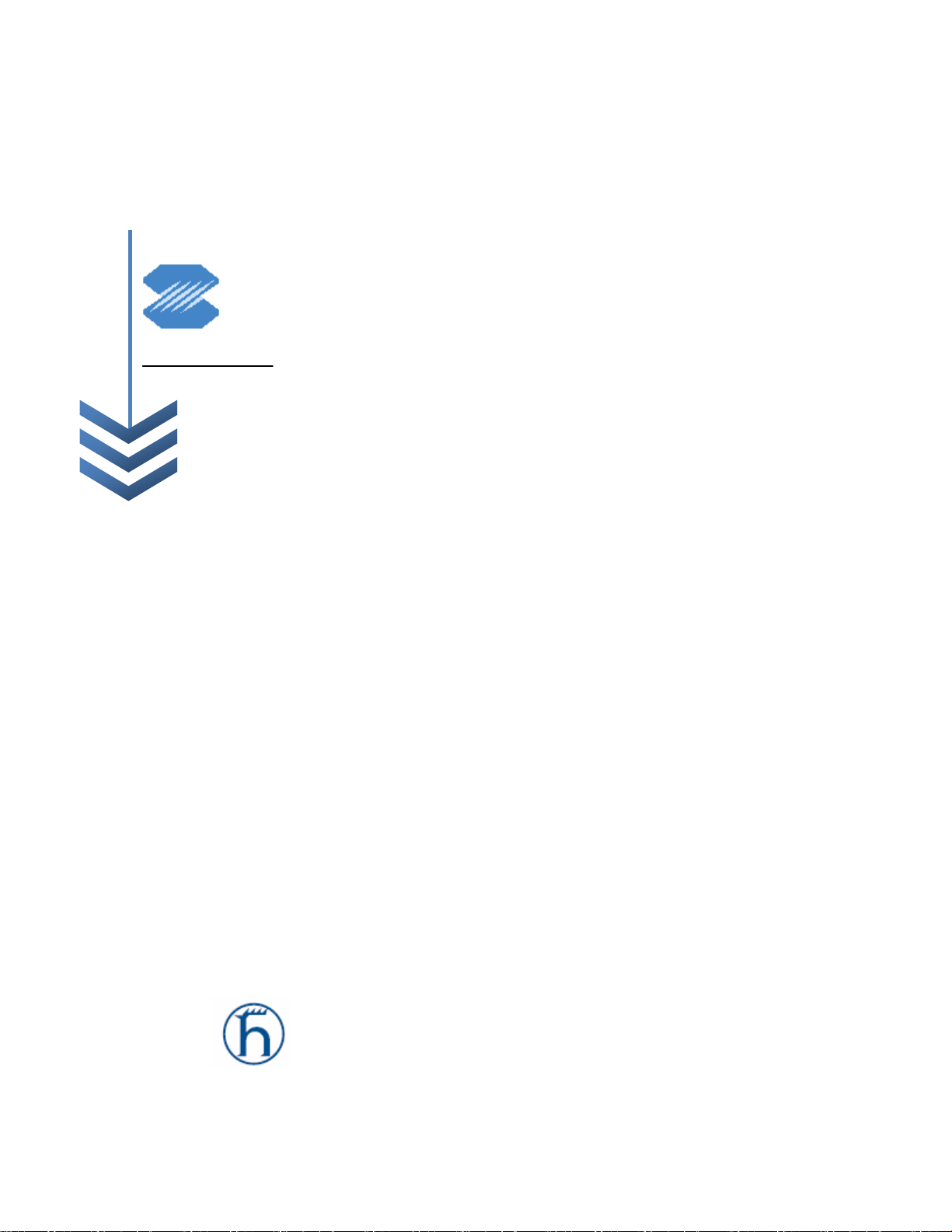

4.System configuration

User Manual

The system is composed of Expert

console, iFLEX5 controller, KMD

force sensor, angle sensor, etc.

When operator sets current OM and

reeving according to the key of the

display, the signal is transmitted to

controller and display by pull sensor.

The display shows the actual weight

and rated weight. The actual weight

and rated weight is compared in the

controller. Once the rated weight is

reached, the controller will indicate

the overloading warning signal and

send warning sound. At this moment,

operator is forbidden to operate to

dangerous direction.

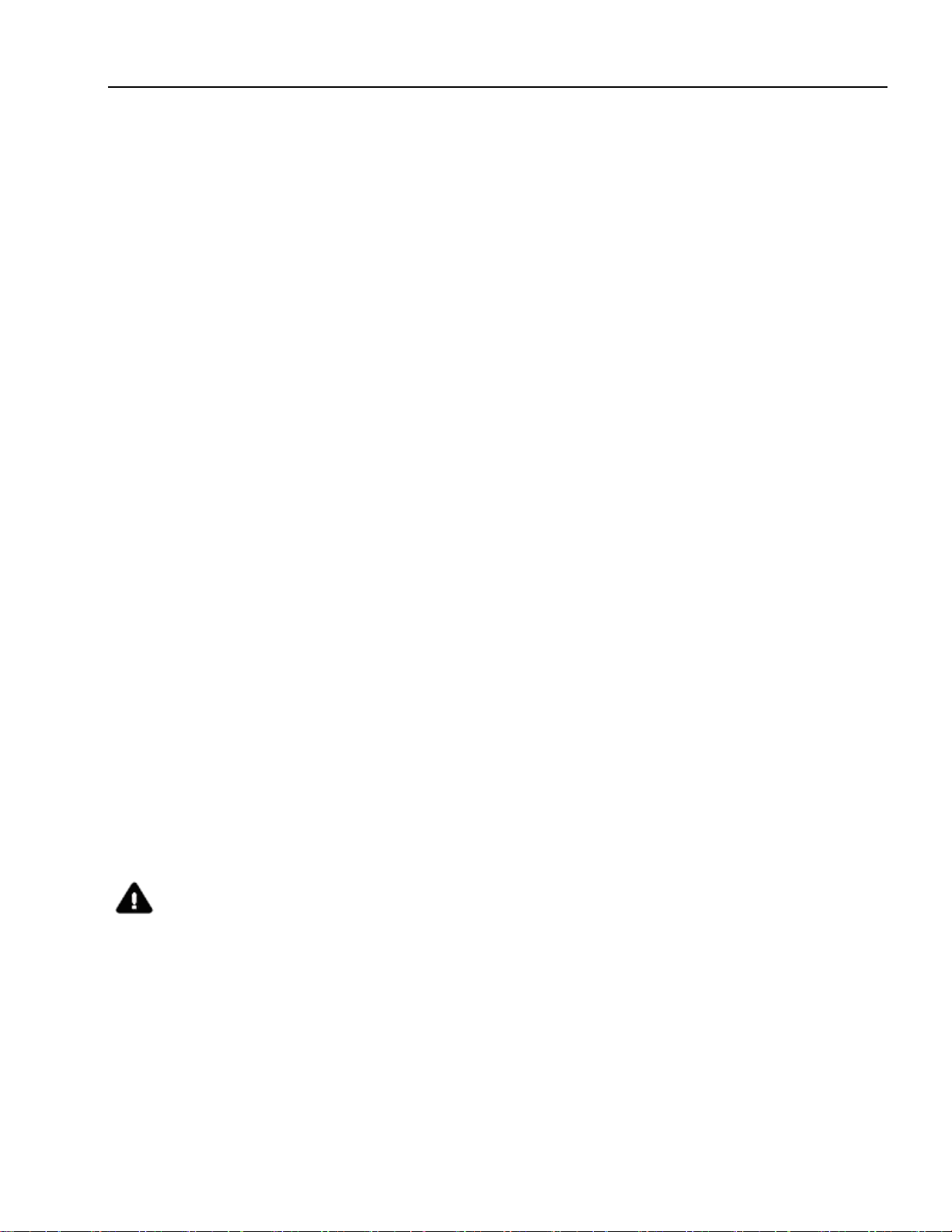

4.1 System configuration

4.1 Controller

Controller: 32 digit industrial control

PLC system and high-powered

processor qualify the requirements of

bad environment for all kinds of

industrial system. IFLEX5 module is

composed of base board or base

board add expansion board.

Customers could choose different

IFLEX5 module according to their

own needs. Each module can be

connected by CANBUS. Due to the

4.2 Controller

building block mode, the IFLEX5 is

not only applicable to medium and

small control systems, but also to big

and complicated control systems.

3

Page 6

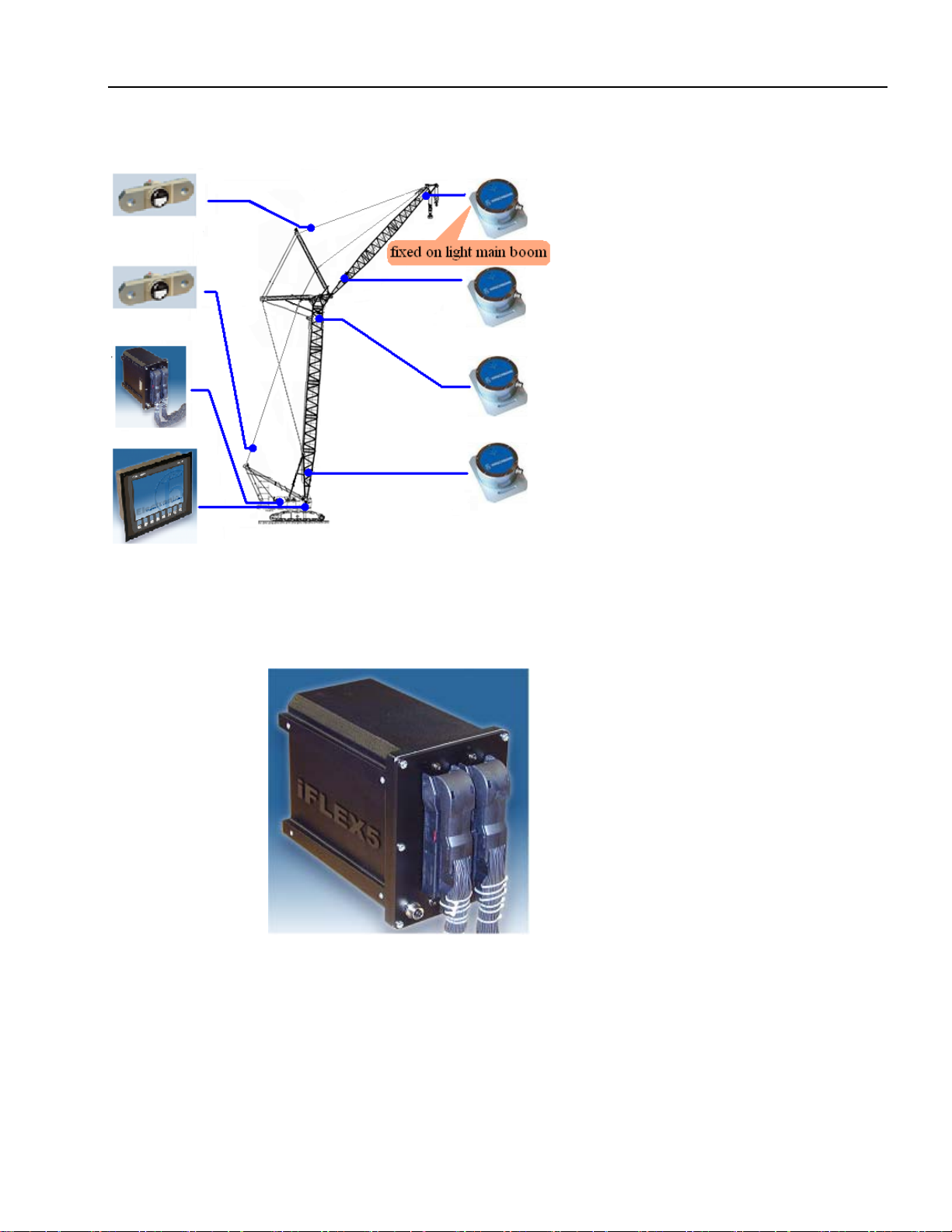

4.2 Console

User Manual

Console: a 640*480 color LCD of industrial

lattice screen graph liquid crystal. It can

display all the operational data that you are

concerned. The combination between the

Graphical display and Genersys software

achieve the on-line program for graph. The

strong graph compiled capability is

incomparable with other Industrial Control

displays.

4.3 Console

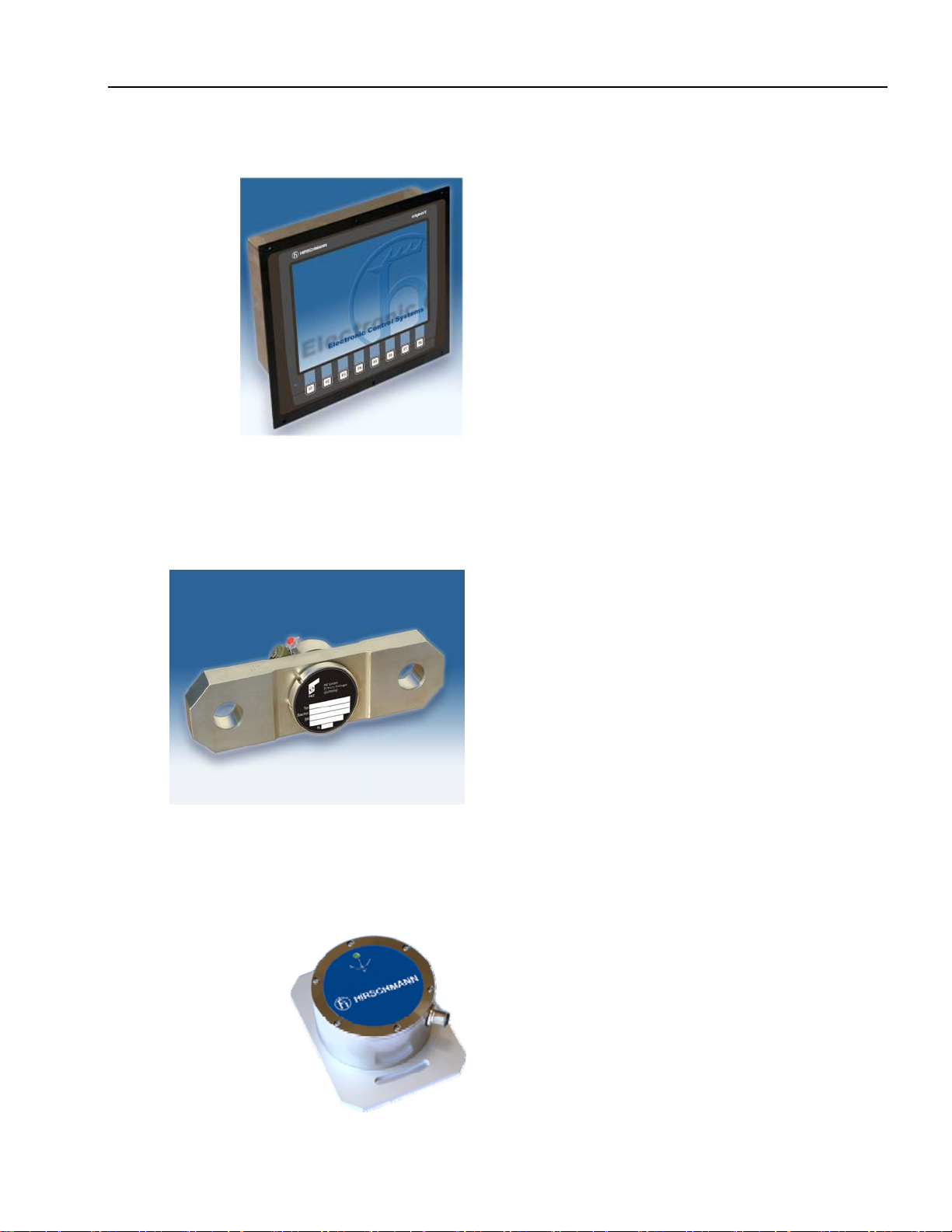

4.3 KMD Force sensor

4.4 KMD force sensor

4.4 Angle sensor

4.5 Angle sensor

The system adopts shock-proof,

anti-electromagnetic interference, and high

precision and low zero drift. As the sensor has

the compensated function of temperature, it

can retain its own quality even with continuous

and high-intensive operation.

Remarks:all the analog sensor for iFLEX5

system must be current type or with CAN-bus.

Voltage sensor have to change to current

sensor.

The WGC angle sensor is for exact measurement

for angle of all kinds of construction machines.

Distinguished by its compact exterior, the sensor

has the feature of simple installation, high

efficiency and accuracy, no hysteresis, high

protective class, long time service life and suited

to extreme ambient condition.

4

Page 7

User Manual

5. System introduction

When the iFLEX5 control system is power on, the console will display QUY260 crawler crane as

below:

5.1 Welcoming interface

After 4~5 seconds, main interface—the LMI interface will present as below:

5.2 LMI main interface

At 5.2, from the top to the bottom is:

Part 1: Operate State column; Part 2:main interface: Part 3: function key column

5

Page 8

User Manual

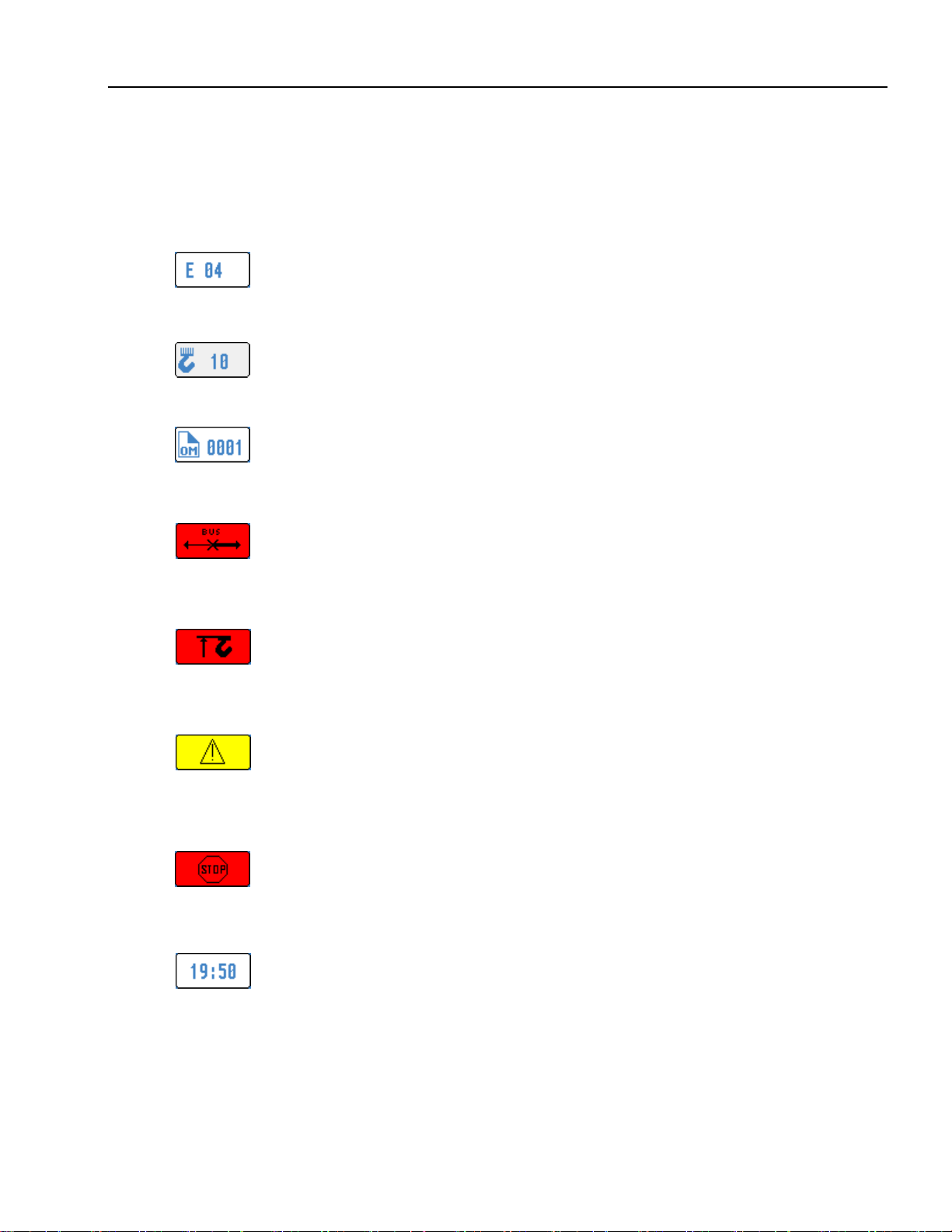

5.1 OM icon

Operators could learn present crane state through the working mode icon on top part of the console.

A.Error code icon

To indicate which part of the LMI is abnormal. Operators then can remove

difficulties accordingly, and the LMI will back to normal condition.

B.Reeving icon

To display present reeving.

C.OM code icon

To display current OM code.

D.CAN-bus mode icon

E.A2B alarming icon

F.Pre-warning icon

G.Stop movement icon

H.Time display icon

To display the CAN communication mode between the console and the

controller. When the light is on, the CAN communication is abnormal.

This means the hook is reaching to the ultimate height, operators shall stop

movement of the hook right away.

This means the moment percentage is over 90%, operators shall be

awared of that.

This means the movement of the crane is very dangerous, operators shall

back to the safe side. Or the LMI is abnormal, the problem shall be solved

immediately.

To display the local time.

6

Page 9

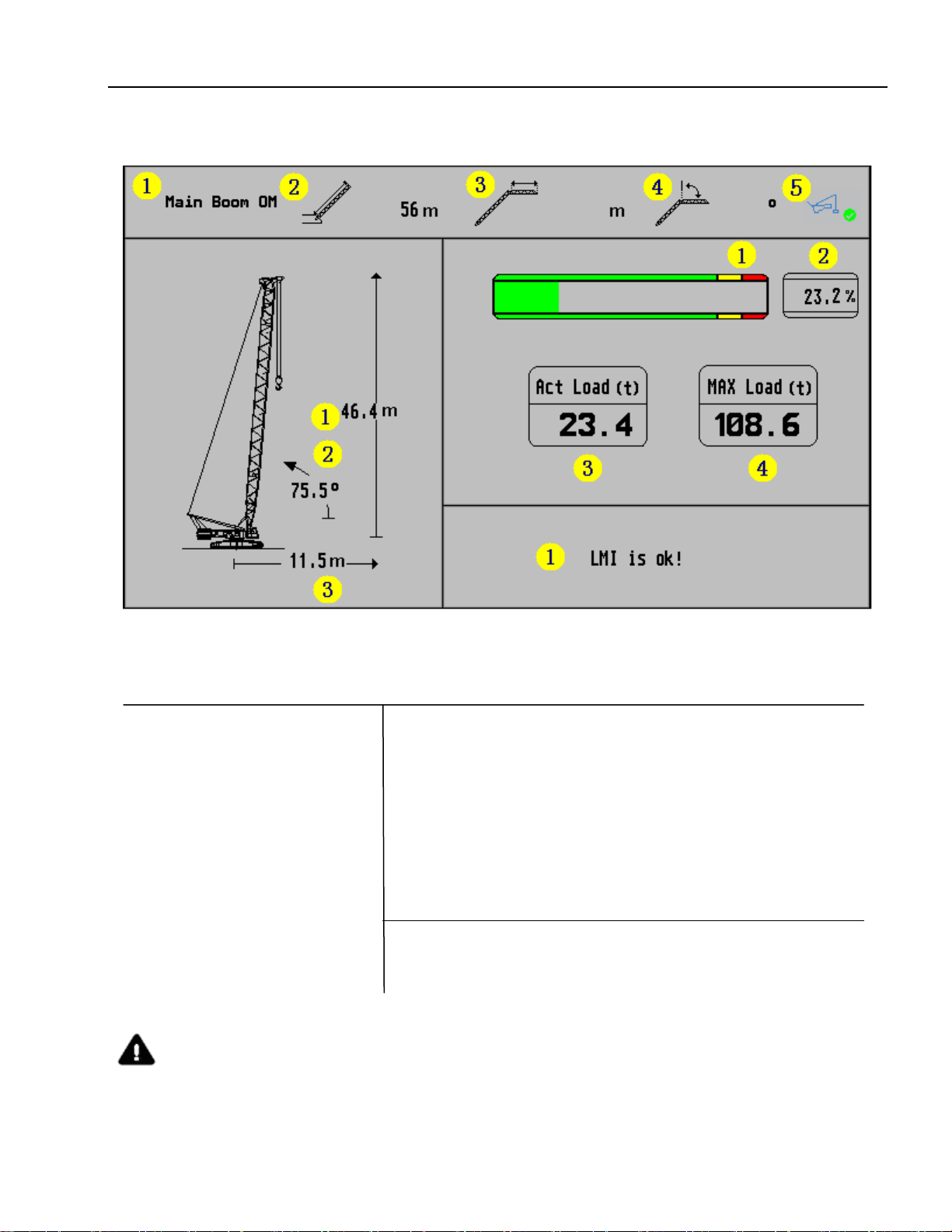

5.2 Main interface

User Manual

5.3 Presenting main interface

①OM introduction ②Main boom length ③jib length ④Installed angle of the fixed jib ⑤Mode display

①operating height

②main boom angle

③operating radius

Still presenting luffing jib

angle at luffing jib OM

①Moment percentage barcode ②Moment percentage value

③Actual load capacity ④Rated load capacity

①LMI Operate State display(presenting normal OM or error

code information and trouble shooting when it is abnormal)

Notice:when operating the crane,operators shall observe changes of the aboved datas at this

interface

7

Page 10

5.3 Function key

At the bottom of the main interface is the function key column, from F1-F8 are as below:

1st interface function key:

User Manual

F1:Main interface shift key, press to enter into 2

F2:OM & Reeving setting key(details refer to 5.3.1);

F3:Data checking,press to check analog input & digit output of iFLEX5 (details

refer to 5.3.2)

F4:System setting key,(details refer to 5.3.3)

F5:CAN-Bus checking,press to check the bus mode between controller and console

(details refer to 5.3.4)

F8:Alarm stop key,press to stop the alarming sound of the system

2nd interface function key:

F1:Main interface shift key, press to enter into 1

nd

interface;

st

interface;

F3:Angle limitation setting key (details refer to 5.3.5)

F4:Time setting key (details refer to 5.3.5)

F8: Alarm stop key,press to stop system alarming

8

Page 11

5.3.1 OM & Reeving setting

Press F2 OM & Reeving setting key at 1st interface to enter into OM & Reeving

setting interface

User Manual

5.4 OM & Reeving setting

F1:OM code checking key

F4:OM code setting key

F6:Reeving setting key

F8:Enter key

9

Page 12

User Manual

Press F1 (continuously press to turn pages) at OM selecting interface to check the

OM code. System will display main OM code separately into 4 pages as follows:

5.5 (a) Main boom OM code

5.5 (b) Main boom runner OM code

10

Page 13

User Manual

5.5 (c) Fixed jib OM code

5.5 (d) Luffing jib OM code

Press F4 at OM selecting interface to set OM:

Press F6 at OM selecting interface to set reeving:

After finish the setting, press F8 backing to OM & Reeving

interface,press F8 once again will come out dialogue

frame of confirmation, press F7 to safe this operation or

press F1 to cancel.

11

Page 14

5.3.2 I/O Port checking

Press F3 at 1st interface to check the I/O port information

User Manual

5.6 Analog input

① Analog channel

② Base board(X1)expanded board(X2)stitch No.

③ Analog description

④ Analog A/D exchange value

⑤ Analog actual measuring value

12

Page 15

User Manual

5.7 Digital value output

① Digital value No.

② Function description

③ Port mode(Blue means output existing)

13

Page 16

5.3.3 System setting

Press F4 at 1st interface to enter into system setting interface

User Manual

5.8 System setting interface

F1:Rigging mode key

F2:Working mode key

F3:Choose main boom angle 65° key(at Luffing jib OM)

F4:Choose main boom angle 75° key(at Luffing jib OM)

F5:Choose main boom angle 85° key(at Luffing jib OM)

F6:Cancel setting key

14

Page 17

User Manual

(1) Selected Rigging/Working Mode:

Operators can press F1 and F2 to select rigging/working mode, the related mode icon will be present

at right column.

(2) Rigging/Working Mode State:

Present working mode of the crane

Rigging mode

Working mode

After rigging mode is selected, the controller will judge whether the mode could shift to rigging mode

according to the present crane OM, if it could, Rigging/Working Mode State will show rigging mode;

if not, Rigging/Working Mode State will show working mode.

(3) LJ OM angle 65°output:

Press F3 will appear that present main boom angle is 65°. If SET icon present at the top of F3 means

F3 key is pressed down and when the main boom angle is 65±1°means one switching value channel put

out. If the F3 key is not pressed, when the main boom angle is 65±1°, no output exist. Output mode is:

LJ OM angle 65°output.

(4) LJ OM angle 75°output:

Press F4 will appear that present main boom angle is 75°. If SET icon present at the top of F4 means

F4 key is pressed down and when the main boom angle is 75±1°means one switching value channel put

out. If the F4 key is not pressed, when the main boom angle is 75±1°, no output exist. Output mode is:

LJ OM angle 75°output.

(5) LJ OM angle 85°output:

Press F5 will appear that present main boom angle is 85°. If SET icon present at the top of F5 means

F5 key is pressed down and when the main boom angle is 85±1°means one switching value channel put

out. If the F5 key is not pressed, when the main boom angle is 85±1°, no output exist. Output mode is:

LJ OM angle 85°output.

(6) Cancel LJ OM MB angle output:

Press F6 , if SET icon present at the top of F6 means F6 key is pressed down. At that time cancel the

setting of 3,4 and 5, the output mode is: Cancel LJ OM MB angle output, and the main boom angle is

approved as 85±1°with one switching value channel put out, the output mode is: LJ OM

angle85°output.

15

Page 18

5.3.4 CAN-bus checking

Press F5 at 1st interface to check CAN-bus mode:

User Manual

CAN-bus mode:

Left column console state

Right column Controller state

State icon and introduction:

Operational mode

Preoperational mode

Lost mode

Stopped mode

Hardware failure

16

Page 19

User Manual

5.3.5 Angle limitation & Time setting

Angle limitation and Time setting is processed at 2nd interface. Press F1 at 1st interface to enter into 2nd

interface:

(1) Angle limitation

Press F3 at 2nd interface to set the limitation of main boom angle and Luffing jib

angle:

① Main boom angle upper limit display

② Main boom angle display

③ Main boom angle lower limit display

④ Main boom angle upper limit setting key

⑤ Main boom angle lower limit setting key

⑥ Main boom setting cancel key

① Luffing jib upper limit display

② Luffing jib angle display

③ Luffing jib lower limit display

④ Luffing jib upper limit setting key

Luffing jib lower limit setting key

⑥ Luffing jib setting cancel key

⑦ Back to main interface

17

Page 20

User Manual

At this interface, operators can set angle limitation of main boom and luffing jib. When the crane boom

approached the limitation, press the related key, it will present SET icon on top of the key which means

the key is already pressed down. At that time, the ultimate angle will be recorded and when the boom

reach to this angle next time, system will alarm.

For example, when the main boom angle is not allowed to exceed 78° due to the operating environment,

lift the main boom to 78° and press angle limitation setting key to set the upper limit. After finish the

setting, when main boom angle exceed 78°, system will alarm operators to stop any dangerous

movement. Press F3 the setting will be canceled.

(2) Time setting

Operators can adjust time when the time displayed is not local time .Press F4 at 2nd interface to set

time:

F4:Turn left key

F5:Turn right key

F6:Value add key

F7:Value reduce key

F8:Confirm and back to main interface key

After finish the related setting, press F8 to confirm and back to main interface.

18

Page 21

User Manual

6. Trouble shooting

In case of any improper operation or LMI malfunction during the crane’s operation it will display some

certain code (error code) for the user’s information. Some errors are caused by illegal operation, some

by people’s cause ad some are caused by other factors.

The following codes can be an aid and help for how to use and maintenance the LMI system:

Notice

If you cannot solve the problem according to the following contents,

please contact us as soon as possible at

Tel:021-51082780 Fax:021-52375899

Error

code

E01

Malfunction Cause Solution

Fallen below the radius

range or angle range

exceeded

Due to the too much hoist up of

the boom which result in lower

than the min. radius or exceed the

max. angle in the capacity chart.

Boom down to a permitted radius

or angle in the load chart.

E02

E04

E05

E06

E07

Exceed the max. radius or

lower than the min. angle.

OM not exist or exceed the

motion of rotary range

Prohibited length range

Fallen below the Minimum

angle range when luffing

down or luffing up

Over load relay checking

Due to the too much hoist down

which result in exceed the max.

radius or lower than he min.

angle.

Improper OM setting or enter into

prohibited slewing area

Choose a main boom length that

is not exist.

The jib luffing down too much

result in the actual angle is lower

than the permitted value in the

capacity chart.

Over load relay act and controller

switching value NO.20 input

channel open

Over load relay not act and

controller switching value NO.20

input channel close

Boom up to a permitted radius or

angle in the load chart.

Properly choose the OM according

to actual operation and slew back

to a permitted range.

Choose a proper main boom

length.

Luffing up the jib to a permitted

radius or angle in the capacity

chart

Check the over load relay and

cable of the controller switching

value NO.20 input channel

Check the over load relay

Check the controller switching

value NO.20 input channel

19

Page 22

User Manual

Error

code

E12

E13

E14

Malfunction Cause Solution

“Main boom right KMD

channel” voltage is lower

than the min. limitation

“Jib right KMD channel”

voltage is lower than the

min. limitation

“Main boom left KMD

channel” voltage is lower

than the min. limitation

Sensor cable defective or plug

water inside

KMD fault Change KMD of main boom

Channel measuring parts broken Change KMD parts

Sensor cable defective or plug

water inside

KMD fault Change KMD of jib

Channel measuring parts broken Change KMD parts

Sensor cable defective or plug

water inside

KMD fault Change KMD of main boom

Channel measuring parts broken Change KMD parts

Change cable or plugs

Change cable or plugs

Change cable or plugs

E14

E15

E16

E17

E18

“Right KMD of luffing jib”

voltage is lower than the

min. limitation.

“Main boom foot angle

sensor channel” voltage is

lower than the min.

limitation。

“Luffing jib foot angle

sensor channel” voltage is

lower than the min.

limitation.

“Left KMD of Luffing jib”

voltage is lower than the

min. limitation.

“Main boom backstop

pressure

voltage is lower than the

min. limitation.

sensor channel”

KMD of luffing jib defective Change KMD of luffing jib

Cable of the checking channel

defective

Sensor cable defective or plug

water inside

KMD fault Change luffing jib KMD

Channel measuring parts broken Change KMD parts

Refer to E15 Refer to E15

Refer to E14 Refer to E14

Refer to E14 Refer to E14

Change cable of the channel

Change cable or plugs

E1B

“Luffing jib top angle sensor

channel” voltage is lower

than the min. limitation.

Refer to E15 Refer to E15

20

Page 23

User Manual

Error

code

E1C

E1D

E1E

E1F

E22

E23

E24

E25

E26

Malfunction Cause Solution

“Top angle sensor of main

boom” voltage is lower than

the min. limitation.

“Super lift mast angle (if

support) channel” voltage is

lower than the min.

limitation.

“KMD channel of luffing

system” voltage is lower

than the min. limitation.

“Super lift mast angle sensor

channel” voltage is lower

than the min. limitation.

“Main boom right KMD

channel” voltage exceed the

limitation.

“Jib right KMD channel”

voltage exceed the

limitation.

“Main boom KMD channel”

voltage exceed the

limitation.

“Main boom foot angle

sensor channel” voltage

exceed the limitation.

“Luffing jib foot angle

sensor channel” voltage

exceed the limitation.

Top angle sensor of main boom

defective.

Cable of the checking channel

defective or unconnected

Refer to E15 Refer to E15

Refer to E14 Refer to E14

Refer to E15 Refer to E15

Refer to E12 Refer to E12

Refer to E14 Refer to E14

Refer to E14 Refer to E14

Refer to E15 Refer to E15

Refer to E15 Refer to E15

Change head angle sensor of main

boom

Connect or change Cable of the

checking channel

E27

E28

E2B

E2C

E2D

“Angle sensor channel of

Luffing jib” voltage exceed

the limitation.

“Main boom Main boom

backstop pressure sensor

channel” voltage exceed the

limitation.

“Luffing jib Top angle

sensor channel” voltage

exceed the limitation.

“Top angle sensor of main

boom” voltage exceed the

limitation.

“Super lift mast angle ( if

support ) channel” voltage

exceed the limitation.

Refer to E14 Refer to E14

Refer to E14 Refer to E14

Refer to E15 Refer to E15

Refer to E15 Refer to E15

Refer to E15 Refer to E15

21

Page 24

User Manual

Error

code

E2E

E2F

E37

E38

E39

E3A

E43

Malfunction Cause Solution

“Luffing jib system force

channel” voltage exceed the

limitation.

“Super lift mast angle sensor

checking channel” voltage

exceed the limitation.

Logical programming fault

System program does not

comply with crane data file

System program does not

comply with performance

table

Crane data file does not

comply with performance

table

RAM fault RAM or controller fault Change controller

Refer to E14 Refer to E14

Refer to E14 Refer to 14

Programming file fault

Flash-EPROM fault Change controller

The LMI system program is

different from crane data file

The LMI system program is

different from performance table

Crane data file is different from

performance table

Update effective software of the

system

Update effective system software

or crane data file

Update effective system program

or performance table

Change data file or performance

table

E51

E52

E56

E57

E60

E61

Crane data file fault

Crane performance file fault

Crane data file fault

Crane serial data file fault

None-identified base file

NO. and programming value

CAN-bus data

communication fault

No readable crane data file Up date crane data file

Flash-EPROM defective Change Flash-EPROM

No readable crane performance

table

Flash-EPROM fault Change Flash-EPROM

No effective data file during

adjustment

Flash-EPROM fault Change controller

No effective data file in the

adjusting data file

Flash-EPROM fault Change controller

No effective data in performance

file

Unprogrammed Base file NO.

Performance table programming

fault

CAN-bus cable between

controller and sensor defective or

unconnected

Controller CAN-bus port fault Change controller

CAN-bus cable short circuit Change Can-bus cable

Update crane performance table

Resume and update effective crane

data file

Update effective data file

Update effective performance file

Program correct base file NO( 1 is

base1, 2 is base 2)

Checking the performance file of

program base file

Check the connecting cable

between controller and sensor

22

Page 25

User Manual

Error

code

E80

E81

E82

E83

E84

E85

Malfunction Cause Solution

Luffing jib system force too

big

Top angle and foot angle of

main boom differ too much

Top angle and foot angle of

Luffing jib differ too much

Main boom force value

exceed limitation of rope

destructive force

Wrong rigging condition.

Wrong setting of range

Exceed the limitation of

destructive force

Top or foot angle sensor of main

boom defective

Top or foot angle sensor cable of

main boom defective

Top or foot angle sensor of

Luffing jib defective

Top or foot angle sensor cable of

Luffing jib defective

Main boom force too big Reduce main boom force

Cable of checking channel

defective

The selected rigging condition is

not contained in the crane data

file.

Setting range of computer is too

small (negative deviation)

Reduce force of luffing system

Change top or foot angle sensor of

main boom

Change top or foot angle sensor

cable of main boom

Change top or foot angle sensor of

Luffing jib

Change top or foot angle sensor

cable of Luffing jib

Change channel cable

Select another rigging condition

Check the programming in the

crane data file.

Check program of crane data file

E88

E89

E94

E98

EAB

EAC

Main boom position

abnormal at Luffing jib OM

Luffing jib angle abnormal

at fixed or Luffing jib OM

No data transfer from

controller to console

LMI watch dog open LMI operated overtime

A2B switch short circuit

A2B switch disconnect

Main boom angle abnormal

cable of main boom angle channel

defective

Luffing jib angle exceed allowed

range when jib luffing

Wrong measurement of Luffing

jib angle

CAN-bus abnormal Re-start the system

System data communication

abnormal

A2B switch short circuit Change A2B switch

A2B switch cable short circuit Change A2B switch cable

A2B switch disconnect Change or connect A2B switch

A2B switch cable disconnect

Main boom angle luff to allowed

range

Change channel cable

Luffing jibto allowed range

Check measurement of Luffing jib

angle

Check CAN-bus cable

Re-start the system

Connect computer ports and

observe wrong information

Change or connect A2B switch

cable

EAD

A2B switch inefficacy

Sensor function fault Change A2B switch

CAN-bus delay Change A2B switch cable

23

Page 26

User Manual

Error

code

EB1

EB2

EB3

Malfunction Cause Solution

No steel wire on hoist Adjust length of steel wire

“Length checking channel

of the hoist steel wire”

voltage is lower than the

min limitation

“Length checking channel

of steel wire on hoist”

voltage exceed the

limitation

“Checking channel of hook

height” voltage exceed the

No measurable sensor exist for

hoisting

Steel wire length no adjust well

Wrong steel wire/hoist parameter

at program data

No counter input defined at

configuration

Counter input fault Change Iflex

Steel wire completely twining

hoist ( only possible at EB2)

Refer to EB1 Refer to EB1

No steel wire between hook and

forward oriented wheel

Install sensor and revise this

function at program data

Adjust steel wire length and

surface

Check parameter of program data

Change I/O configuration

Adjust length of steel wire

Refer to EB1

EDD

EFD

limitation

Battery empty

LMB watch dog overtime

Refer to EB1

Check out low voltage of the two

ports of battery

This function shall be started over

5 min. like writing flash PROM

Setting RTC and change battery

Temporary measurement:press

alarm stop key when

Operation without data loader

After finish programming,

information is not automatically

started

24

Page 27

7. System connection

User Manual

25

Loading...

Loading...