Page 1

HIRSCHMANN

Load Moment Indicator

for Crawler Crane

HC3901

Operator’s Manual

Hirschmann Electronics(Shanghai)Co.,Ltd

Suite 12A, Huamin Empire Plaza, No.726, West Yan An Road, Shanghai, P.R.China

Tel: 021-51082780

Fax: 021-52375899

Zipcode: 200050

Website: http://www.hirschmann.com

Page 2

Copyright

This document contains propriety information which is protected by copyright, and all rights are

reserved. No part of this manual may be photocopied, reproduced or translated to another language

without prior written approval of Hirschmann Electronics (Shanghai) Co., Ltd.

Declaration

All information in this document is subject to change without notice.

Hirschmann makes no warranty of any kind with regard to this material, including, but not limited to,

the implied warranties of merchantability and fitness for a particular purpose.

Hirschmann will not be liable for errors contained herein or for incidental or consequential damages

in connection with reference to, and performance or use of this manual.

Applied Scope

This manual is made for the following crane manufacturer

Zoomlion

This manual can be applied to the following types of crawler cranes manufactured by the partner:

ZCC1100H

Special Notice

Using components of LMI rather than from Hirschmann may cause problems of inaccuracy and

even malfunction of the LMI system. We recommend you use genuine Hirschmann components and

parts during repairing and service. Hirschmann is not liable of any responsibilities in case genuine parts

are not used.

Rev. Date Prepared Checked Modifications

01 2014-08-04 Guo Tao Zhou Fei First issue, English

HC3901for Zoomlion ZCC1100H

Page 3

Table of Contents

1. GENERAL INFORMATION .................................................................................................................... 1

2. IMPORTANT NOTES .............................................................................................................................. 2

3. SYSTEM DESCRIPTION ......................................................................................................................... 3

3.1 HC3901 Controller ............................................................................................................................. 4

3.2 WG Angle Sensor ............................................................................................................................... 5

3.3

Force Sensor........................................................................................................................................ 6

4. OPERATION AND DISPLAY INTERFACE .......................................................................................... 7

4.1 Data display(values are only for example) .................................................................................... 8

4.2 EN13000 ............................................................................................................................................. 8

4.3Weight status bar .................................................................................................................................. 9

4.4 Indicator light ...................................................................................................................................... 9

5. OPERATION METHOD and PROCESS (only for example) ................................................................ 10

5.1 Reeving Setting ................................................................................................................................. 11

5.2 Function Setting ................................................................................................................................ 12

5.3 Error Code Information .................................................................................................................... 15

5.4 Angle Limit Setting ........................................................................................................................... 16

6. SYSTEM FUNCTIONS .......................................................................................................................... 17

6.1 Warning ............................................................................................................................................. 17

6.2 Prohibition ........................................................................................................................................ 17

7 INSPECTION MAINTENANCE AND CONSIDERATIONS ............................................................... 18

7.1 Inspection before Operation ............................................................................................................. 18

7.2 Routine Maintenance ........................................................................................................................ 18

7.3 Routine Consideration ...................................................................................................................... 18

7.4 Buzzer Alarms .................................................................................................................................. 18

7.5 Angle Sensor Adjustment ................................................................................................................. 18

8. TROUBLESHOOTING .......................................................................................................................... 19

Page 4

1. GENERAL INFORMATION

The load moment indicator HC3901 (hereinafter referred to as LMI) is applicable to the telescopic

boom crane, lattice boom crane, all- terrain crane and other types of cranes.

The HC3901 LMI can provide the crane operator with essential information required to operate the

crane within its design parameters. Using different sensors, LMI can provide the crane operator with

information on real time basis regarding boom length, boom angle, working height, working radius, rated

load and actual weight being lifted by the crane

The system operates on the principle of reference/real comparison. The boom angle is measured by

angle sensor that is mounted on the boom. The crane load is measured by force transducers attached to the

boom pendants. The real value, resulting from all the sensors measurement is compared with the

reference data, stored in the controller. If non-permitted conditions are approached, the LMI will warn the

operator by audible alarm, warning light and at the same time, some dangerous movements such as lifting

and luffing down will be stopped with the help of the crane control system.

This manual only gives guide for the LMI operation. Please refer to the Crane Operator’s Manual

provided by the crane manufacturer for detailed operating procedures of the crane.

1

Page 5

Operator’s Manual

2. IMPORTANT NOTES

The LMI and control system is an operational aid that warns a crane operator of approaching

overload conditions and of over-hoist conditions that could cause damage to equipment and personnel.

The device is not, and shall not, be a substitute for good operator judgment, experience and use of

accepted safe machine operating procedures.

The responsibility for safe operation shall remain with the crane operator who shall ensure that all

warnings and instructions supplied are fully understood and observed, Prior to operating the crane ,the

operator must carefully and thoroughly read and understand the information in this manual to ensure

that he knows the operation and limitations of the LMI.

The LMI can only protect overload of the crane in boom vertical range without crane overturn

resulted from non-vertical lifting, ground inclination, derailed wheel etc. Therefore, the operators

should not neglect the crane safety management and operation regulation even if the crane is equipped

with LIM.

The LMI can only work correctly after all adjustments have been properly set. To prevent material

damage and serious or even fatal accidents, operating mode, reeving and limit data have to be properly

set up before operating the crane.

If there is any change in the crane’s configuration data, the LMI needs to be re-calibrated.

Make sure to disconnect the power supply of the LMI from the crane before applying any welding

work on the crane body or booms. The pulse may cause damage to the electrical and electronics parts.

Hirschmann shall not be liable for any damage caused by this.

Make sure to disconnect the power supply of the LMI during thunderstorm weather. Hirschmann

shall not be liable for any damage caused by lightning.

This system can be equipped with an external key-operated switch located in the crane operator's

cab. This key-operated switch overrides control lever function switch-off by the LMI or by the hoist

limit switch system.

This switch may only be used during emergency situations, and even then only by authorized

personnel. Failure to observe these instructions could result in damage to property and severe or even

fatal injuries to personnel.

If the LMI in use fails or is not properly functioning, please do stop the operation of the crane, and

contact the service of Hirschmann or crane manufacturer. Hirschmann does not assume any

responsibility for undesirable consequences resulted from the continued operation!

CAUTION

WARNING

DANGER

2

Page 6

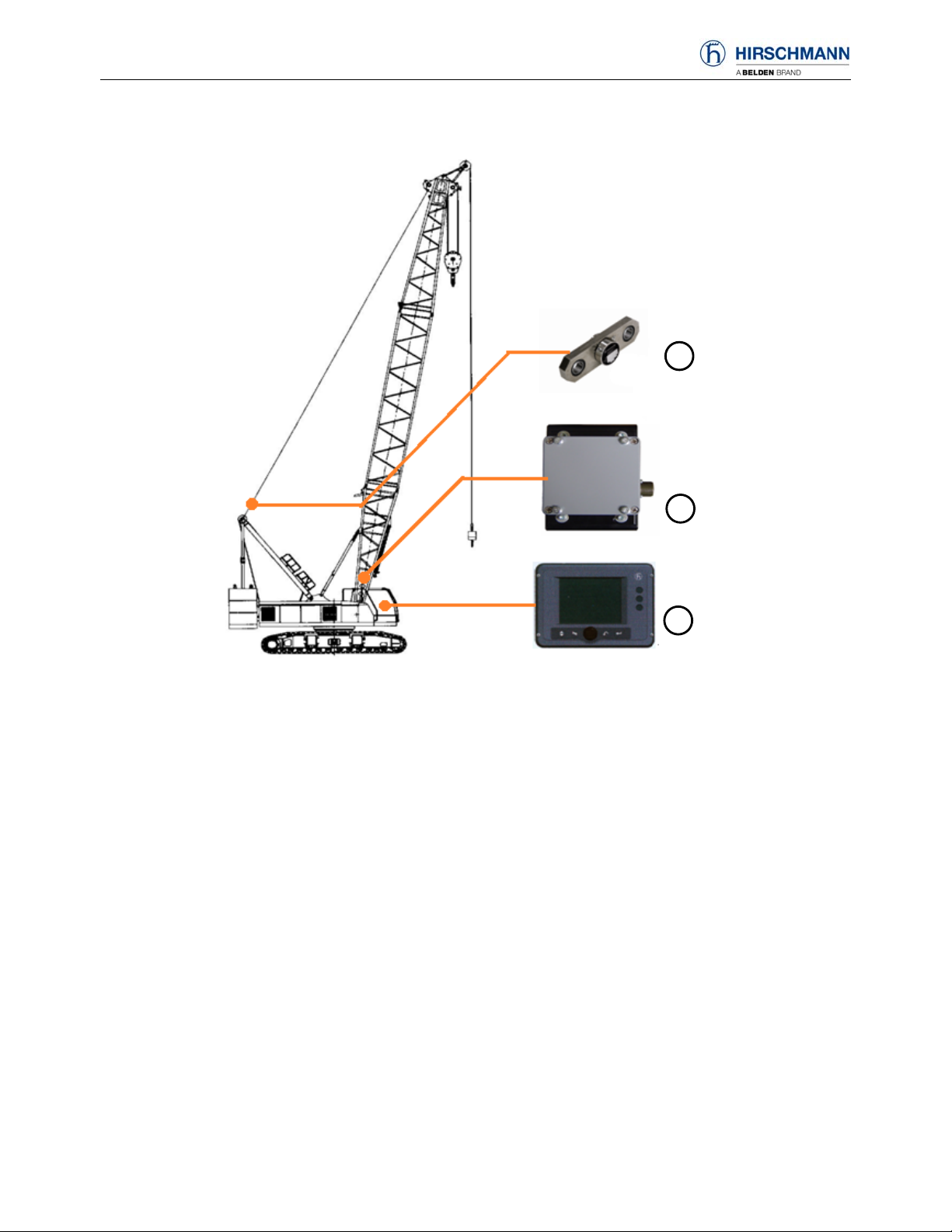

3. SYSTEM DESCRIPTION

3

2

Components of LMI System

Generally, the LMI system consists of

1. HC3901 Controller 1 pc

2. WG103 Angle Sensor 1 pc

3. KMD force Sensor 1 pc

1

3

Page 7

Operator’s Manual

3.1 HC3901 Controller

HC3901 controller uses 16 bit high performance processors and the CANopen communication

technology. It is the safety protector specially designed to meet the required safety standards under the

harsh environment.

Technical data:

Operating temperature: –20°C ~ +70°C.

Operating voltage: 11 ... 36V DC

Operating current: 200mA@24V

Communication interface: 1×CANopen, 1×RS232

Installation: External and horizontal

Display Size: 5.7 inch

Program memory: 2 x 2 MB

Data memory: 2 x 1 MB

Communiacation interface: 1×SAEJ1939,1×CANopen2.0B,2×RS232

Input analog: 6

Input digital: 6

Output digital: 6 (It can be set to PWM output, but it will reduce the no. of output digital.)

Relay output: 1 (max. 5A)

Protection class: IP65

Installation:

When the system is on, it’s forbidden to plug and unplug the cable connecting with the controller.

Before implementing any welding work on the crane body, the operator must take off cables

connecting the controller in order to avoid damage.

This system uses scaffolding installation.

4

Page 8

3.2 WG Angle Sensor

Angle sensor WG accurately measures the boom angle. The high sealed housing keeps the inside

component away from the influence of temperature, humidity etc.

Technical data

Measuring range: 0-90°

Output signal: 4-20mA

Linearity tolerance: <±0.2°

Hysteresis tolerance: <±0.1°

Operating temperature: -25~+70

Storing temperature: -40~+70

Protection class: IP65

Installation

The correct positioning is important for installing angle sensors.

The angle sensors are usually installed along the right side boom, at the inner side of boom base, if

it’s viewed from the boom base to boom tip. (as shown below).

Make sure the horizontal line of sensor is parallel to the horizontal center line of the boom. Adjust the

bolts of the sensor to reduce the angle deviation between actual measured boom angle and displayed

boom angle on the console.

Boom bottom Angle sensor

Horizontal center line

of the boom

Angle Sensor Installation Graph

Angle Senso r Installation Graph

5

Page 9

Operator’s Manual

3.3 Force Sensor

Force sensor KMD is perfectly designed for static and dynamic tensile force measurements.

The sensor stands out for high overload capacity, high fatigue strength, good corrosion resistance

and maintenance-free operation.

Technical data:

Nominal load range: from 1T up to 500T

Charge of measuring body: 200%

Charge of measuring body up to flow limit: 300%

Safe to breaking point: 500%

Linearity: < 0.3% typ.

Hysteresis: < 0.5% typ.

Protection class: IP65

Operating temperature range: -40℃ to +70℃

Installation

KMD force sensor is measuring unit, it should require the conscientious and careful treatment.

Be sure to obtain the fittings and the relative tolerance data suggested by KMD force sensor.

Observe the installation situation to make sure that no elastic parts are used in the force transmission

which might affect the measurements.

The bores in the locking pins must be in alignment.

Make sure force sensor not to bear side force.

KMD Force Sensor Installation Graph

6

Page 10

4. OPERATION AND DISPLAY INTERFACE

1

2

4 33

1.Data display(see 4.1)

2.Indicator light

3.Function keys: from left to right, menu key/buzzer key/back key/confirmation key.(the function keys

have one-to-one relationships with the key symbols on the display.)

4.Rotary button:They can be used to select function items on the display by rotating the button and

confirm the selection by pushing the button.

7

Page 11

Operator’s Manual

4.1 Data display(values are only for example)

2

1

3

4

5

7 8

9

10

11

12

13

21

20

19

1. Height status bar and percentage display

2. Jib angle

3. Jib length

4. Height

5. OM information display

6. Reeving

7. OM code

8. Date and Time

display(year/month/day/hour/minute/second)

9. OM information setting

10. Function setting key symbol

18

17

16 15

14

11. Error code information key symbol

12. Upper and low angle setting

13. Main Hook/ Subhook Switch

14. Wind speed

15. Upper and low angle

16. Rated load weight

17. Actual load weight

18. Boom angle

19. Radius

20. Boom length

21. Error code information

8

Page 12

4.2 EN13000

The yellow icon is force-active warning icon: when the crane is forced to be active, corresponding

warning icon will display on the main interface to remind that the crane is at force-active state now and

LMI will not have corresponding protection function.

LMI override activated

SET-UP mode activated

Main hoist three times protection alarm

Auxiliary hoist three times protection

alarm

SET-UP mode activated alarm

Third hoist three times protection alarm

Derricking in activated

A2B switch on the main hoist alarm

Rope limit override activated

A2B switch on the auxiliary hoist alarm

A2B switch activated

Main Boom luffing angle limit alarm

Slewing limit alarm

9

Page 13

Operator’s Manual

4.3Weight status bar

The weight percentage status bar indicates the relationship between the actual load weight and the

rated load weight during the crane operation and the weight percentage value is subject to the relationship

changes.

Green zone: safe range (weight percentage0-90%)

Yellow zone: pre-warning range (weight percentage 90-100%)

Red zone: over-load warning range (weight percentage exceeding100%)

4.4 Indicator light

Prewarning light

This yellow prewarning light comes up when the load on the machine amounts to more than 90%

of the respective nominal carrying load, which indicates that an overload situation is

immediately pending.

For the operator, this means that the machine work can continue only with the greatest amount of

caution

Overload warning light

This red Overload warning light indicates to the machine operator that an overload condition

has occurred. It lights up when the crane load has reached 100% of maximum load carrying

capacity permitted for the current operating status. The acoustic alarm sounds. The

load-moment-increasing crane movements are switched off at the same time

A2B switch lamp

This red warning light lights up when the heavy bob and spreader of A2B switch meet each

other and are hoisted. In the meanwhile, the buzzer alarms, which indicates the hook block has

arised the height maximum. Combining with the electric system, the crane movements from

hoisting and extending boom to luffing down are stopped. Please check A2B switch before operating the

crane in order to prevent human body and the crane from being injured.

Attention: Since A2B switch signal does not input into LMI system, this A2B switch lamp is used

invalid.

10

Page 14

N

N

5. OPERATION METHOD and PROCESS (only for example)

When controller and console of the system is powered on, the data initialization automatically starts.

This progress cannot be directly observed, but a welcoming display (Logo display) will appear at the

console to present the manufacturer and the initializing status.

The crane drivers shall be very familiar with the operation of LMI system and correctly adjust it

before start to work.

Power on

Self Checking System

Confirm OM

Error or Not?

Is the displayed

OM the same as

the actual one?

Is the showed

Reeve the same

as the actual

Operate the crane to work.

YES

Look up the error code list to solve

O

Choose the same OM by OM

buttons

O

Choose the same Reeving by

Reeving buttons

11

Page 15

Operator’s Manual

5.1 Set OM and Reev

Reeving setting is to set the LMI reeving identical to the actual reeving.Operators shall carefully

adjust the displayed reeving equal to the actual reeving before start to work.

The Reeving must be set equal to the actual reeving, otherwise the LMI may not be able to work properly.

At the main display, select icon by rotary button, press it or confirmation key to enter into

“Set OM and Reev” Display1 as followed:

WARNING

Back to the previous display.

Confirm the select value.

Back to the main display.

In the “Set OM and Reev” Display1, circumgyrate the rotary button, press it or confirmation key to

enter into the “Set OM and Reev” Display2 (Self_assembly OM enter into the main display directly) as

followed:

After selecting OM parameter by pressing and rotating rotary button, press the confirmation key

twice to enter into main interface, then OM setting succeeds. After pressing confirmation key, press turn

back key, which means that setting is cancelled and OM can be reset.

12

Page 16

Two switchable OMs can be selected by default OM option.

5.2 Function Setting

At the main display, select icon by rotate button, press the button or confirmation key to enter

into ”Function Page” as followed:

Back to the previous display.

Confirm the select value.

Back to the main display.

5.2.1 System setting

At the “Function Display”, select “System Set” icon by rotary button, press it or confirmation key to

enter into ”System info” as followed:

Back to the previous display.

Confirm the select value.

Back to the main display.

13

Page 17

Operator’s Manual

Time Setting

Before setting time, the first step is to input the password. If the display shows the wrong time,

please connect with the manufacture first. DO NOT set time yourself.

The setting steps are as followed:

At first, select “Time Set” icon by rotating button at the “Function Display”, press the button or

confirmation key to enter into “Input Password” as the following:

Back to the previous display.

Confirm the select value.

Back to the main display.

At the “Input Password”, the first password “ * ” is showed automatically number “0”. Operator can

select the correct number by rotate button, then press it or confirmation key, the system will transfer to the

second “ * ”.

After inputting four numbers, press the button or confirmation key to enter into “Time Set Display”

as the following:

Back to the previous display.

Confirm the select value.

Back to the main display.

In “Time setting”, when the year number turns blue, select actual year number by rotating button and

press it or confirmation key, the next number will automatically become blue.

After setting all numbers, “Confirm?” will appear on the interface. Press button or confirmation key,

and the “current time” will be modified to the actual time.

14

Page 18

5.2.2 CANbus Status Overview

At the “Function Display”, select “Can Bus” icon by rotary button, press it or confirmation key to

enter into ”CANbus Status Overview Display” as followed:

Back to the previous display.

Confirm the select value.

Back to the main display.

At this display:

If the pane shows green, it means working normally.

If the pane shows yellow, it means preparing.

If the pane shows red, it means error or not-in-use status. At this moment, operators need to check

the system.

5.2.3 I/O Port Inquiry

At the main display, select “port inquiry” icon by rotate button, press the button or confirmation key

to enter into “I/O Port Inquiry Display” as followed:

Back to the previous display.

transfer to Analog Input Port Display

Back to the main display.

This display shows the information of Digital I/O port.The state pane shows green, it means high

level, DIN stands for digital input and DOUT is digital output.

If operators want to inquire analog information, please press menu key which represents icon

and transfer to “Analog Value” as followed:

15

Page 19

Operator’s Manual

Back to the previous display.

Back to the main display.

5.2.4 Load Inquriy

At the “Function Display”, select “Load Chart” icon by rotary button, press it or confirmation button

to enter into the “OM select” display:

Back to the previous display.

Confirm the select value.

Back to the main display.

Select the OM by rotary button, press the confirmation button to enter into the”load chart” display,

as the followed:

Select the BM length by the rotary button, press the confirmation button ,then transfer to the

corresponding load data.

Note: All values in the chart are only for example.

16

Page 20

5.3 Error Code Information

When the system appears malfunction, the error code would appear at the main display.Through the

error code information, crane operators and service engineers can better understand what the error code

stands for, and quickly find out the fault reasons and suggested solutions. (Operators can inquire the error

code by two ways: The error code inquiry in the display and the “troubleshooting” item in the menual.)

At the main display, select icon by rotary button, press the button or confirmation key to

enter into “Fault Help” as followed:

Back to the previous display.

Back to the main display.

Switch to query cause and elimination of different fault by rotarying button.

5.4 Angle Limit Setting

At the main display, select icon by rotary button, press the button or confirmation key to enter

into “Angle Limit Setting” as followed:

Back to the previous display.

Confirm the select value.

Back to the main display.

After the transformer to the maximum(minimum) in the main boom Angle, according to the

confirmed limit Angle value.

17

Page 21

Operator’s Manual

6. SYSTEM FUNCTIONS

6.1 Warning

Under any below conditions, HC3901 LMI system will light up and send out alarm for warning.

The crane is overload

The hook approaching height limitation

System error

6.2 Prohibition

Cooperating with crane electrics system, the LMI system will send alarm warning and any of the

following crane’s movements will be prohibited:

Boom luffing down

Hoisting up

At this moment, only the movements toward safe direction are allowed:

Boom luffing up

Hoisting down

18

Page 22

7 INSPECTION MAINTENANCE AND CONSIDERATIONS

7.1 Inspection before Operation

Check all components of the LMI system to make sure no one damages or breaks off.

Turn the power on and detect whether the display is normal or there is warning, error indication and

so on.

After display works normally, detect whether all the system works normally and whether the main

boom angle, work radius and load display are the same as the actual ones.

7.2 Routine Maintenance

Check the angle transducer as to oil leakage.

Check the insulating layer of all the cables. If the insulating layer or the wire inside damaged, please

replace new one immediately.

Check the cable reel as to sufficient tight or not.

Clean the display regularly to make it clear.

7.3 Routine Consideration

Prevent the central unit (display)、power supply cabin、transducers from severely shake.

Each part of the LMI system including central unit, console, transducers etc had been accurate adjusted

and checked by protection technology before leaving factory. Anyone not be trained professionally is

prohibited from dismantling the housing. Otherwise, the system will probably not work normally because

of humidity and dust getting into the components.

7.4 Buzzer Alarms

The buzzer alarms if the system shows normal without any fault codes after started. At this moment,

exam whether the conjunction between cable and A2B is junction off or short circuit of water-in.

7.5 Angle Sensor Adjustment

Use the angle instrument to measure if the displayed value is the

same when the actual angle is between 0°and 70°. If the

displayed value or radius is not the same with the actual value,

operators should adjust the angle transducer.

Release the three bolts (see the left picture),Slowly turn the

angle transducer till the displayed value accords with the actual

value and then tight the three bolts again.

19

Page 23

Operator’s Manual

8. TROUBLESHOOTING

There are 2 different kinds of errors: system or operation. When an error occurs, this means the system

has a fault. The description and code of errors will appear on the screen.

The following Error Code Table gives a brief description of Error Codes elimination.

The errors showed on the table are part of the possible errors of an LMI system. The Elimination on the

table only gives the operator some basic guidelines of solving the problems. If the errors cannot be

solved by following the instruction in the table, please contact our service team:

Tel: +86-400-887-9936

Fax: +86-516-87793971

Email: infoecs@hirschmann-js.com

Error

Error Cause Elimination

Code

E01

Fallen below radius

range or angle range

exceeded

Fallen below the minimum

radius or gone past the

maximum angle specified in

the respective load chart due

to luffing up the boom too far

E02

Radius range

exceeded or fallen

below angle range

Gone past the maximum

radius or fallen below the

minimum angle specified in

the respective load chart due

to luffing down the boom too

far

E04

Operating mode not

acknowledged or non

permitted slewing

A non existing operating mode

has been selected

zone

E05

Main boom length not

available

A non existing main boom

length has been selected

E06

Radius range

exceeded or fallen

below angle range

with luffing jib

operation

Maximum radius as specified

in the load chart exceeded or

fallen below minimum angle

due to luffing down the luffing

jib too far

E07

Overload relais check

relais = overload active and

CU input 20 = on

relais = no overload and CU

input 20 = off

CAUTION

Luff down the boom to a

radius or angle specified in the

load chart.

Luff up the boom to a radius

or angle specified in the load

chart.

Set the correct operating mode

for the operating state in

question

Set the correct main boom

length for the operating state

in question

Luff the jib to a radius or

angle specified in the load

chart.

check cable to overload relais

and CU input 20

check relais

20

Page 24

Error

Code

E12

E13

E14

E15

E16

E17

Error Cause Elimination

Fallen below lower

limit value in

measuring channel

"force main

boom(MB) right"

Cable between the central unit

and the force transducer

defective or loose. Water

inside the plug of the

transducer

Force transducer defective

Check cable as well as plugs,

replace, if need be

Replace force transducer

Replace sensor unit

Electronic component in the

measuring channel is

defective.

Fallen below lower

limit value in

measuring channel

"force jib right"

Cable between the central unit

and the force transducer

defective or loose. Water

inside the plug of the

transducer

Force transducer defective

Electronic component in the

measuring channel is defective

Check cable as well as plugs,

replace, if need be

Replace force transducer

Replace sensor unit

Fallen below lower

limit value in

measuring channel

"force main boom

left"

Cable between the central unit

and the force transducer

defective or loose. Water

inside the plug of the

transducer

Force transducer defective

Electronic component in the

measuring channel is

defective.

Check cable as well as plugs,

replace, if need be

Replace force transducer

Replace sensor unit

Fallen below lower

limit value in

measuring channel

"angle main boom

foot"

Cable between the central unit

and the angle sensor defective

or loose. Water inside the plug

of the angle sensor

Angle potentiometer defective

Electronic component in the

measuring channel defective.

Check cable as well as plugs,

replace, if need be.

Replace angle sensor

Replace sensor unit

Fallen below lower

limit value in

refer to E15

refer to E15

measuring channel

"angle luffing jib

foot"

Fallen below lower

refer to E14

refer to E14

limit value in

measuring channel

"force luffing jib left"

21

Page 25

Operator’s Manual

Error

Error Cause Elimination

Code

E18

Fallen below lower

limit value in

measuring channel

"MB backstip

pressure"

E19

Fallen below lower

limit value in

measuring channel "

luffing jib backstip

pressure "

E1B

Fallen below lower

limit value in

measuring channel

"angle luffing jib tip"

E1C

Fallen below lower

limit value in

measuring channel

"angle main boom tip"

E1D

Fallen below lower

limit value in

measuring channel

"angle super lift mast"

E22

Upper limit value in

measuring channel

"force main boom

right" has been

exceeded.

E23

Upper limit value in

measuring channel

"force jib right" has

been exceeded.

Cable between the central unit

and the pressure transducer

defective or loose. Water

inside the plug of the

transducer

Force transducer defective

Electronic component in the

measuring channel is

defective.

Cable between the central unit

and the pressure transducer

defective or loose. Water

inside the plug of the

transducer

Force transducer defective

Electronic component in the

measuring channel is

defective.

refer to E15

Cable between the central unit

and the angle sensor defective

or loose. Water inside the plug

of the angle sensor

Angle potentiometer defective

Electronic component in the

measuring channel defective.

Cable between the central unit

and the angle sensor defective

or loose. Water inside the plug

of the angle sensor

Angle potentiometer defective

Electronic component in the

measuring channel defective.

refer to E12

refer to E13

Check cable as well as plugs,

replace, if need be

Replace force transducer

Replace sensor unit

Check cable as well as plugs,

replace, if need be

Replace force transducer

Replace sensor unit

refer to E15

Check cable as well as plugs,

replace, if need be.

Replace angle sensor

Replace sensor unit

Check cable as well as plugs,

replace, if need be.

Replace angle sensor

Replace sensor unit

refer to E12

refer to E13

22

Page 26

Error

Code

E24

E25

E26

E27

E28

E29

E2B

E2C

E2D

Error Cause Elimination

Upper limit value in

measuring channel

refer to E14

refer to E14

"force main boom

left" has been

exceeded.

Upper limit value in

measuring channel

refer to E15

refer to E15

"main boom angle

foot" has been

exceeded.

Upper limit value in

measuring channel

refer to E16

refer to E16

"luffing jib angle

foot" has been

exceeded.

Upper limit value in

measuring channel

refer to E17

refer to E17

"force luffing jib left"

has been exceeded.

Upper limit value in

measuring channel

refer to E18

refer to E18

"MB backstip

pressure " has been

exceeded.

Upper limit value in

measuring channel "

refer to E19

refer to E19

jib backstip pressure "

has been exceeded.

Upper limit value in

measuring channel

refer to E1B

refer to E1B

"jib angle tip" has

been exceeded.

Upper limit value in

measuring channel

refer to E1C

refer to E1C

"main boom angle tip"

has been exceeded.

Upper limit value in

measuring channel

refer to E1D

refer to E1D

"super lift mast angle"

has been exceeded (if

avail.).

23

Page 27

Operator’s Manual

Error

Error Cause Elimination

Code

E37

Error in the logical

program flow

E38

System program and

crane data file do not

match.

E39

System program and

load chart file do not

match

E3A

crane data file and

load chart file do not

match

E43

Error in the

write/read memory,

(RAM)

E51

E52

E56

Error in the crane

data file

Error in load chart

file.

Error in crane data

file.

E57

E60

Error in serial crane

data file.

The number of the

selected File base and

the programmed value

are not identical

E61

Error in the CAN bus

data transfer for all

CAN units

E81

Too large difference

of the boom angles at

tip and base boom (if

avail.)

System program file is

defective

Upload valid system software

Replace central unit

Flash-EPROM defective

The system program in the

LMI does not match to the

programming in the crane data

file

The system program in the

LMI and the programming in

the load chart file do not

match.

Crane type in dat file and load

chart file is different

Write/read memory (RAM) or

central unit defective.

No valid data in the crane

data file.

Flash-EPROM defective

Replace central unit

No valid data in the load chart

file

Flash-EPROM defective

Replace central unit

No valid data in the crane

data file during calibration.

Flash-EPROM defective

Replace central unit

Calibration data file does not

contain valid data.

Flash-EPROM defective

No valid data in the load chart

file

Program the correct base

Base number not programmed

Load chart file wrongly

programmed

Check base programming in

CAN Bus cable between the

central unit and the sensor unit

defective or not connected.

Can bus port in the central unit

defective

Replace the central unit

Replace Can Bus cable

Short circuit in a CAN Bus

cable

The angle as to the horizontal

on the boom head exceeds the

main boom angle by more

Check angle sensor on the

than 5 degrees.

Upload valid system program

file or the valid crane data file

Upload valid system program

file or the valid load chart file

Cange dat file and/or load

chart file

Replace central unit

Upload valid crane data file

Upload valid load chart file

Restore or upload valid crane

data file

Upload calibration data file

Replace central unit

Upload valid load chart file

number (1 for base 1, 2 for

base 2)

the load chart file.

Check the connection between

the central unit and the

sensor units

Check angle sensor on the

boom head.

base boom.

24

Page 28

Error

Code

E82

E83

E84

E85

E88

E89

E94

E98

EAB

EAC

EAD

Error Cause Elimination

Too large difference

of the luffing jib

angles at tip and base

jib.

The angle as to the horizontal

on the jib head exceeds the

luffing jib angle by more than

5 degrees.

Check angle sensor on the jib

head.

Check angle sensor on the jib

base.

Maximum force in the

main boom pendants

exceeded

The force actuating on the

main boom pendants has

exceeded the programmed

Reduce force acting on the

main boom pendants.

value

Wrong rigging

condition.

The selected rigging condition

is not contained in the crane

data file.

Select another rigging

condition

Check the programming in the

crane data file.

Error in the radius

determination

Faulty main boom

position during luffing

jib operation

Faulty positioning of

the jib during

operation with fixed

angle to the main

boom or to a luffing

jib

No data transmits

from central unit to

console

LMI watchdog

activated

The computed radius is too

small (negative deflection)

During luffing jib operation

the main boom is not in the

prescribed angle range

Angle measurement of main

boom defective.

During operation with fixed

jib to the main boom, the jib is

not in the permitted angle

range

Angle measurement of the jib

defective

Can bus defective

The system data transmission

defective

LMI processing time limit

exceeded

Check the programming in the

crane data file.

Luff boom to the permitted

range

Check angle measurement of

the main boom.

Luff the auxiliary jib to the

permitted range

Verify angle measurement of

the auxiliary jib.

Restart system

Check Can bus cable

Reset system

Connect PC terminal and

watch error messages

Short circuit in the

A2B switch circuit

A2B switch circuit

disconnected

No valid A2B switch

status

Short circuit in the A2B

switch

Short circuit in the cable to the

A2B switch

Disconnected cable in the

A2B switch

Disconnected cable to the

A2B switch

Sensor wrong function

CAN bus delay

Replace A2B switch

Replace cable to the A2B

switch

Connect or replace cable in

the A2B switch

Connect or replace cable to

the A2B switch

Replace A2B switch

Replace cable to the A2B

switch

25

Page 29

Operator’s Manual

Error

Error Cause Elimination

Code

EB1

Fallen below lower

limit value in

measuring channel

"rope length on the

winch”

EB2

Upper limit value in

measuring channel "

rope length on the

winch" has been

exceeded.

EB3

Upper limit value in

measuring channel

"hook hight" has been

exceeded.

EDD

Battery empty

EFD

LMB Watchdog extra

time

No rope on the winch

(* only EB1)

calibrate rope length

mount sensor or disable

No sensor for winch

measuring available

rope length not calibrated

calibrate rope length, layer

check parameter in

wrong rope/winch parameters

in data-programming

counter input not deefine in

configuration

change I/O configuration

counter input defective

Rope completely rolled up on

winch (* only EB2)

See EB1

see EB1

No rope length between front

sheave and hook

see EB1

Battery check detected a low

* change battery, after this setup

voltage of the battery

Function needs more than 0,5

Meesage is deactivated

sec to be activated, e.g. write

flash PROM

function in data-programming

data-programming

change Iflex

calibrate rope length

see EB1

of RTC

automatically after processing

26

Loading...

Loading...