Page 1

Genova

ZGE-E30AS

ZGE-E36AS

ZGE-E30AS290

ZGE-E36AS290

www.zephyronline.com

Model number:

Serial Number:

Use, Care, and Installation Guide

JUL11.0301 © Zephyr Corporation

Page 2

www.zephyronline.com

Page 3

SAFETY NOTICE ................................................................. 2-3

LIST OF MATERIALS ....................................................... 4

INSTALLATION

Ducting Calculation Sheet

....................................... 5

Mounting Height & Clearance

Ducting Options

Hood Specifi cations

Preparing the Cabinet

Installing the Hood

Ductless Recirculation

........................................................... 7

................................................... 8

............................................... 9

...................................................... 10 - 12

.............................................. 13

FEATURES & CONTROLS

Touch Controls

Remote Control (Optional)

.............................................................. 14-15

....................................... 16

MAINTENANCE

Hood and Filter Cleaning

Lights

................................................................................ 18

Wiring Diagram

TROUBLESHOOTING

............................................................ 19

................................................................ 20

......................................... 17

LIST OF PARTS AND ACCESSORIES

................................ 6

Table of Contents

.............................. 21

1

Page 4

READ AND SAVE THESE INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT USE THIS FAN WITH ANY SOLID-STATE CONTROL DEVICE.

WARNING

TO REDUCE THE RISK OF FIRE ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

a. Use this unit only in the manner intended by the manufacturer, if you have questions, contact the manufacturer.

b. Before servicing or cleaning unit, switch power off at service panel and lock panel to prevent power from being switched on accidentally.

When the service disconnecting means cannot be locked, securely fasten a prominent warning device, such as a tag, to the service

panel.

CAUTION

For general ventilating use only. Do not use to exhaust hazardous or explosive materials and vapors. Take care when using cleaning

agents or detergents. Suitable for use in household cooking area.

WARNING

TO REDUCE THE RISK OF RANGE TOP GREASE FIRE:

a. Never leave surface units unattended at high settings. Boilovers cause smoking and greasy spillovers that may ignite. Heat oils slowly

on low or medium settings.

b. Always turn hood ON when cooking at high heat or when fl aming food

Important Safety Notice

c. Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or fi lter.

d. Use proper pan size. Always use cookware appropriate for the size of the surface element.

e. Keep fan, fi lters and grease laden surfaces clean.

f. Use high setting on hood only when necessary.

g. Don’t leave hood unattended when cooking.

h. Always use cookware and utensils appropriate for the type of and amount of food being prepared.

www.zephyronline.com

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A RANGE TOP FIRE, OBSERVE THE FOLLOWING:

a. SMOTHER FLAMES with a close-fi tting lid, cookie sheet, or metal tray, then turn off the burner. BE CAREFUL TO PREVENT BURNS.

If the fl ames do not go out immediately, EVACUATE AND CALL THE FIRE DEPARTMENT.

b. NEVER PICK UP A FLAMING PAN – You may be burned.

c. DO NOT USE WATER, including wet dishcloths or towels – a violent steam explosion will result.

d. Use an extinguisher ONLY if:

1. You know you have a Class ABC extinguisher, and you already know how to operate it.

2. The fi re is small and contained in the area where it started.

3. The fi re department is being called.

4. You can fi ght the fi re with your back to an exit

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

a. Installation work and electrical wiring must be done by qualifi ed person(s) in accordance with all applicable codes and standards.

Including fi re-rated construction.

b. Suffi cient air is needed for power combustion and exhausting of gases through the fl ue (chimney) of fuel burning equipment to prevent

back-drafting. Follow the heating equipment manufacturer’s guideline and safety standards such as those published by the National

Fire Protection Association (NFPA) and the American Society for Heating, Refrigeration and Air Conditioning Engineers (ASHRAE) and

the local code authorities.

c. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

d. Ducted fans must always vent to the outdoors.

e. NEVER place a switch where it can be reached from a tub or shower.

f. Make sure the power is off before installing, wiring or maintenancing.

2

Page 5

WARNING

TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCTWORK.

CAUTION

To reduce risk of fi re and to properly exhaust air outside - Do not vent exhaust air into spaces within walls, ceilings,

attics, crawl spaces or garages. Hood not intended for installation over an outdoor grill.

OPERATION

Always leave safety grilles and fi lters in place. Without these components, operating blowers could catch onto hair, fi ngers

and loose clothing.

The manufacturer declines all responsibility in the event of failure to observe the instructions given here for installation,

maintenance and suitable use of the product. The manufacturer further declines all responsibility for injury due to

negligence and the warranty of the unit automatically expires due to improper maintenance.

*NOTE: Please check www.zephyronline.com for revisions before doing any custom work.

ELECTRICAL REQUIREMENTS

Important:

Observe all governing codes and ordinances.

It is the customer’s responsibility:

- To contact a qualifi ed electrical installer.

- To assure that the electrical installation is adequate and in conformance with National Electrical Code, ANSI/NFPA 70

latest edition* or CSA standards C22.1-94, Canadian Electrical Code, Part 1 and C22.2 No.0-M91 - latest edition** and

all local codes and ordinances.

If codes permit and a separate ground wire is used, it is recommended that a qualifi ed electrician determine that the

ground path is adequate.

Do not ground to a gas pipe.

Check with a qualifi ed electrician if you are not sure the range hood is properly grounded.

Do not have a fuse in the neutral or ground circuit.

*National Fire Protection Association Batterymarch Park, Quincy, Massachusetts 02269

** CSA International 8501 East Pleasant Valley Road, Cleveland, Ohio 44131-5575

This appliance requires a 120V 60Hz electrical supply and connected to an individual properly grounded branch circuit

protected by a 15 or 20 ampere circuit breaker or time delay fuse. Wiring must be 2 wire with ground. Please also refer to

Electrical Diagram on product.

A cable locking connector (not supplied) might also be required by local codes. Check with local requirements, purchase

and install appropriate connector if necessary.

ZGE-E30AS, ZGE-E36AS - 370 Watts, 3.1 Amps

ZGE-E30AS290, ZGE-E36AS290 - 167 Watts, 1.4 Amps

Important Safety Notice

3

Page 6

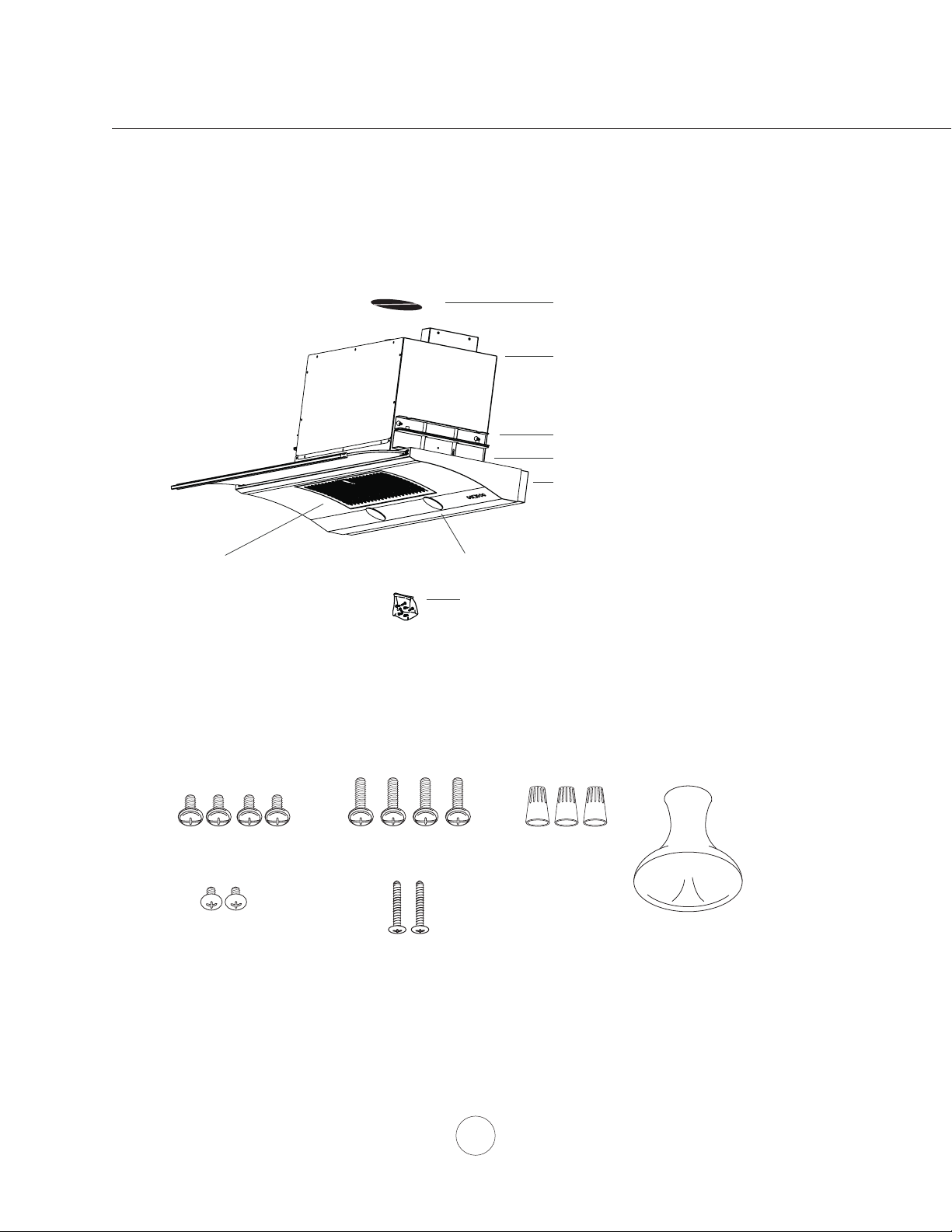

MODELS: ZGE-E30AS, ZGE-E30AS290, ZGE-E36AS, ZGE-E36AS290

PARTS SUPPLIED

List of Materials

www.zephyronline.com

(1) 6” round damper (pre-installed)

(1) hood body with sliding glass

(2) upper installation brackets

(2) lower installation brackets

(1) filler panel (pre-installed)

(1) decorative mesh filter

HARDWARE PACKAGE CONTENTS

(4) 3/16 x 3/8”

(2) M4 x 8 (2) M4 x 1”

PARTS NOT SUPPLIED

- Ducting, conduit and all installation tools

- Cable connector (if required by local codes)

- Recirculating kit accessory - ZRC-00GE

- Remote control accessory - 14000005

(4) 3/16 x 1”

(2) halogen lights, GU-10 50W

(1) hardware package

(3) Wire Nuts

(1) Suction Cup

4

Page 7

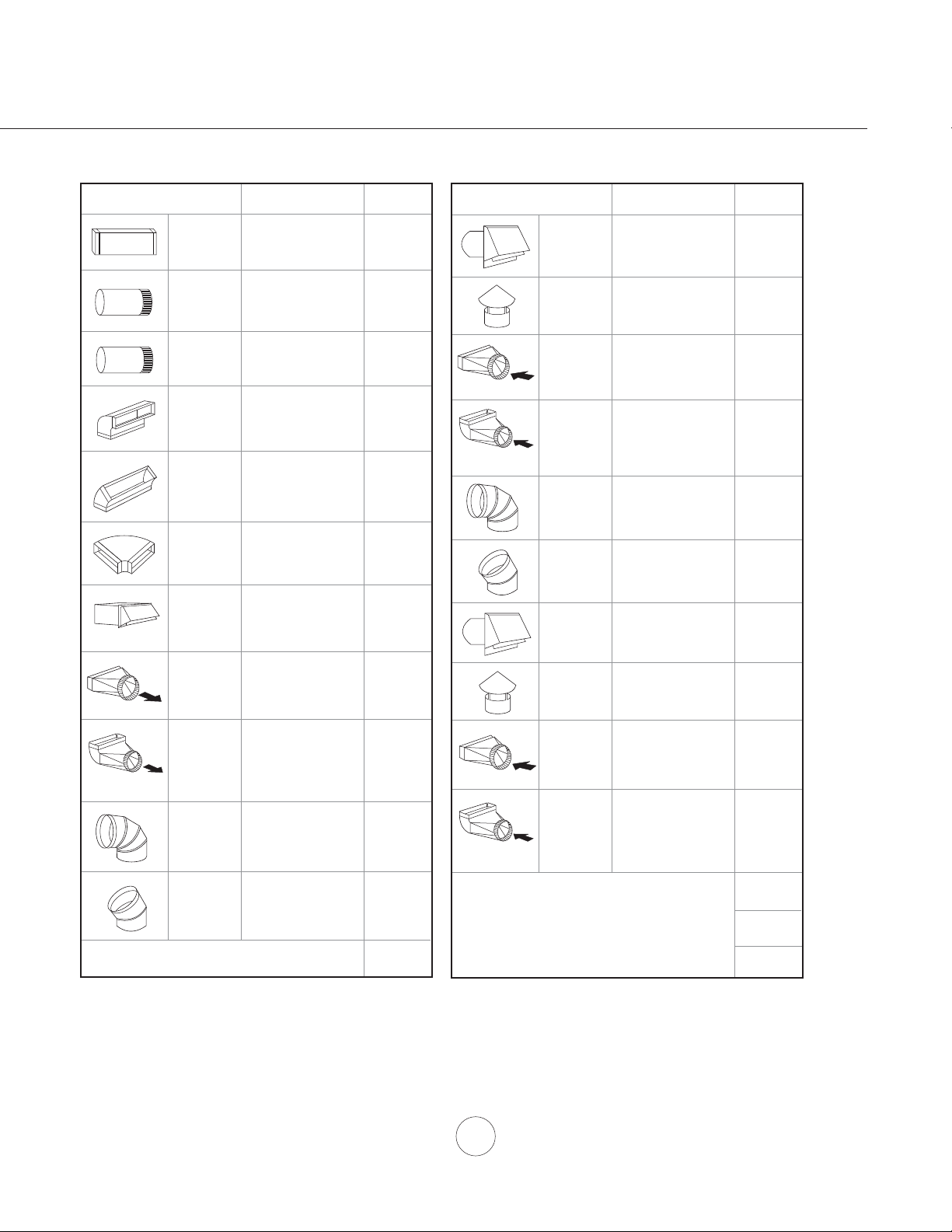

Duct pieces

3- 1/ 4” x 10”

Rect.,

straight

Equivalent number

length x used =

1 Ft. x ( ) =

To t a l

Ft.

Duct pieces

6”- 8” Round

wall cap

with damper

Equivalent number

length x used =

30 Ft. x ( ) =

To t a l

Ft.

7” Round,

straight

8” Round,

straight

3- 1/ 4” x 10”

0

Rect. 90

elbow

3- 1/ 4” x 10”

0

Rect. 45

elbow

3- 1/ 4” x 10”

0

Rect. 90

flat elbow

3- 1/ 4” x 10”

Rect.

wall cap

with damper

3- 1/ 4” x 10”

Rect. to

6” round

transition

3- 1/ 4” x 10”

Rect. to

6” round

transition

0

elbow

90

6” Round,

0

elbow

90

1 Ft. x ( ) =

1 Ft. x ( ) =

15 Ft. x ( ) =

9 Ft. x ( ) =

24 Ft. x ( ) =

30 Ft. x ( ) =

5 Ft. x ( ) =

20 Ft. x ( ) =

15 Ft. x ( ) =

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

6”- 8” Round,

roof cap

6” round to

3- 1/ 4” x 10”

rect.

transition

6” round to

3- 1/ 4” x 10”

rect.

transition

0

elbow

90

7” or 8”

Round,

0

90

elbow

7” or 8”

Round,

0

45

elbow

7” or 8”

Round

wall cap

with damper

7” or 8”

Round,

roof cap

7” round to

3 1/ 4” x 10”

rect.

transition

7” round to

3- 1/ 4” x 10”

rect.

transition

0

elbow

90

30 Ft. x ( ) =

1 Ft. x ( ) =

16 Ft. x ( ) =

15 Ft. x ( ) =

9 Ft. x ( ) =

30 Ft. x ( ) =

30 Ft. x ( ) =

8 Ft. x ( ) =

23 Ft. x ( ) =

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Installation – Ducting Calculation Sheet

Ft.

6” Round,

0

elbow

45

9 Ft. x ( ) =

Subtotal column 1 =

Maximum Duct Length: For satisfactory air movement,

the total duct length of a 3 1/ 4” x 10” rectangular 6” or 7”

diameter round duct should not exceed 100 equivalent feet.

Ft.

Ft.

Subtotal column 2 =

Subtotal column 1 =

Total ductwork =

Ft.

Ft.

Ft.

5

Page 8

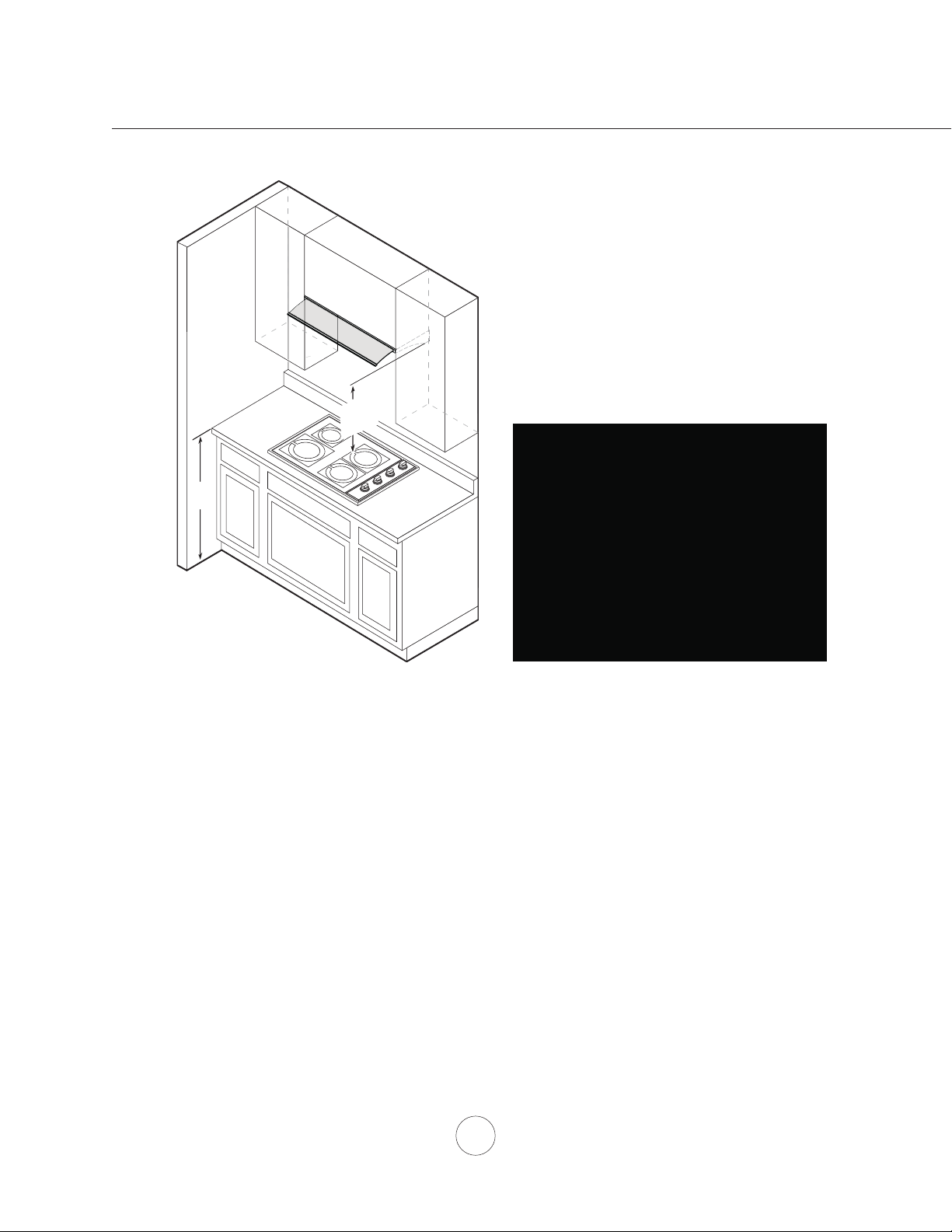

24” min.

32” max.

36”

Installation – Installing the Hood

www.zephyronline.com

Mounting height from top of cooking surface to

bottom of hood should be no less than 24” and no

more than 32”.

It is important to install the hood at the proper

mounting height. Hoods mounted too low could

result in heat damage and fi re hazard while hoods

mounted too high will be hard to reach and will

lose performance and effi ciency.

If available, also refer to range manufacturer’s

height clearance requirements and recommended

hood mounting height above range. Always check

your local codes for any differences.

DAMAGE-SHIPMENT / INSTALLATION:

• Please fully inspect unit for damage before

installation.

• If the unit is damaged in shipment, return the

unit to the store in which it was bought for

repair or replacement.

• If the unit is damaged by the customer, repair

or replacement is the responsibility of the

customer.

• If the unit is damaged by the installer (if other

than the customer), repair of replacement must

be made by arrangement between customer

and installer.

DUCTING

A minimum of 6” round ducting must be used to

maintain maximum air fl ow effi ciency.

Always use rigid type metal ducts only. Flexible

ducts could restrict air fl ow by up to 50%.

Use calculation worksheet to compute total duct

work.

ALWAYS, when possible, reduce the number of

transitions and turns. If a long duct run is required,

increase duct size from 6” to 7” or 8”.

If turns or transitions are required: Install as far

away from opening and as far apart, between 2,

as possible.

6

Page 9

WARNING FIRE HAZARD

NEVER exhaust air or terminate duct work into spaces between walls, crawl spaces, ceiling, attics or garages.

All exhaust must be ducted to the outside, unless using the recirculating option.

Use single wall rigid Metal ductwork only.

Fasten all connections with sheet metal screws and tape all joints w/ certifi ed Silver Tape or Duct Tape.

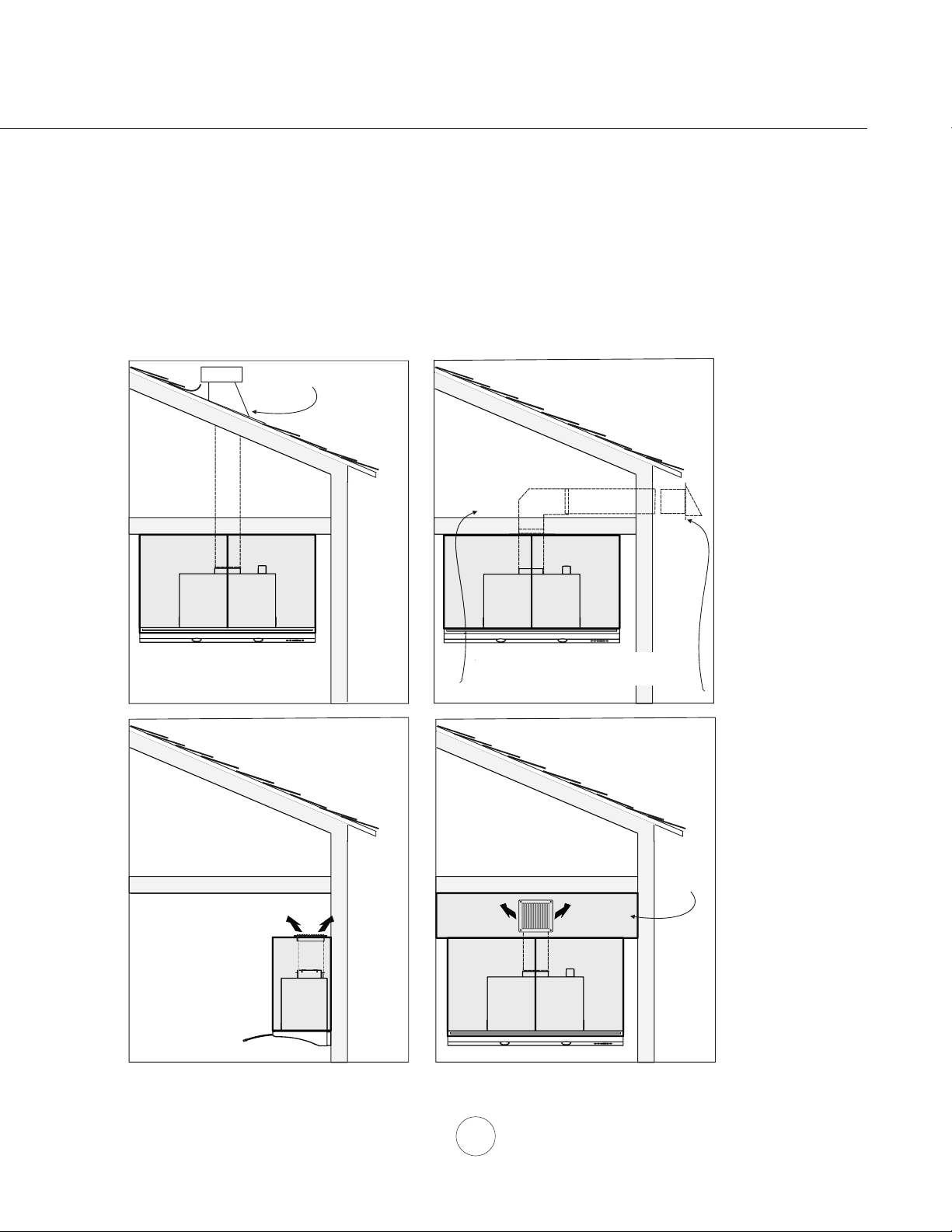

Ducting Options Example

roof pitch w/

flashing & cap

Installation – Ducting Options

ductless

recirculating

side wall cap

w/ gravity damper

soffit or crawl space

ductless

recirculating

soffit

7

Page 10

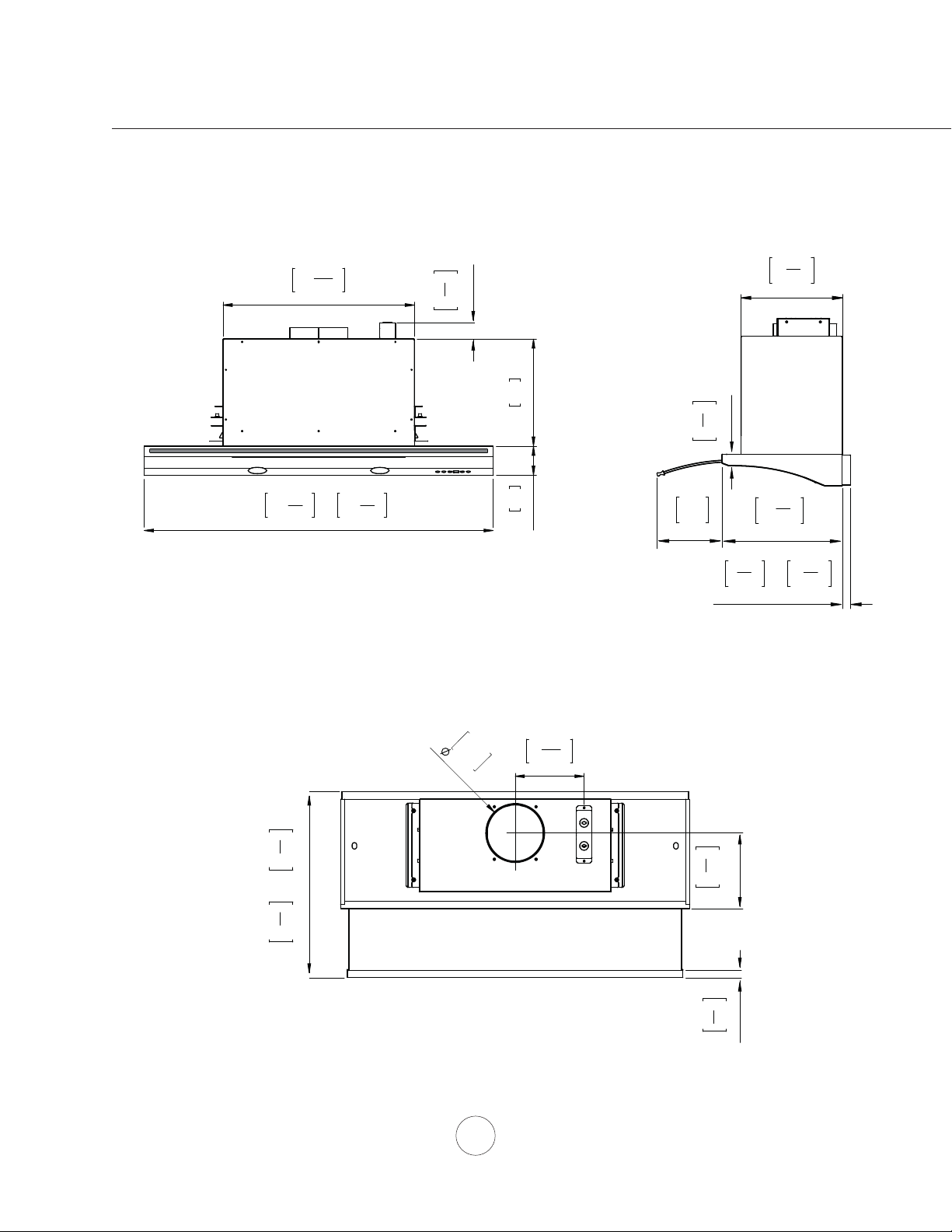

www.zephyronline.com

front of hood

11

"

19

16

500mm

15

29

16

760mm

35

"

912mm

side of hood

1

"

9

"

5

8

1

41mm

11"

280mm

7

"

8

3"

76mm

"

1

8

1

28mm

"

6

153mm

1

4

6mm

242mm

11

286mm

to

"

2

1

4

35mm

"

3

"

1

8

Installation – Hood Specifi cations

top of hood

6

153mm

"

"

5

8

18

473mm

to

"

1

2

17

445mm

blower outlet

1

7

16

180mm

"

junction box

"

3

4

7

197mm

"

5

8

16mm

8

Page 11

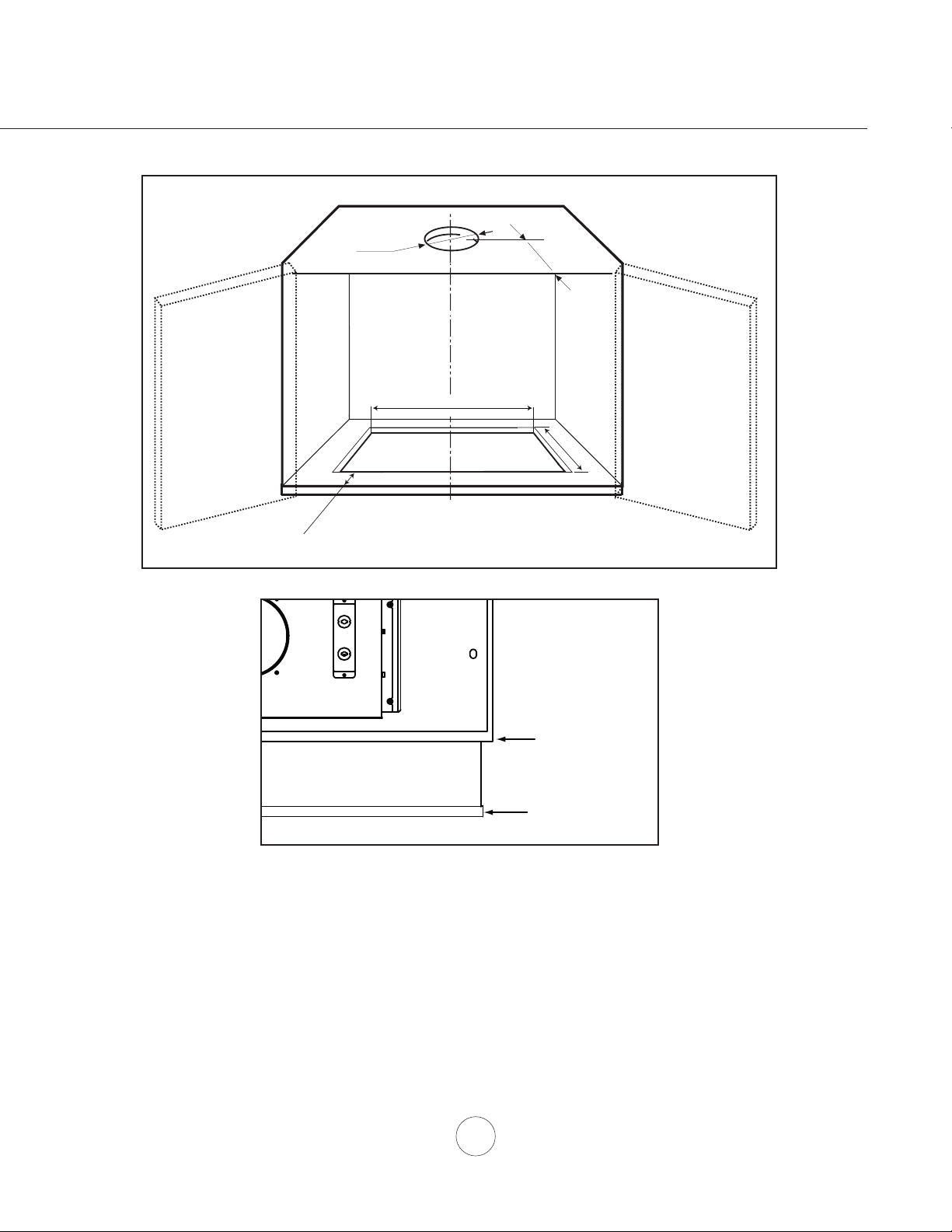

9/16”

-

7”

19-

C/L

Fig.1

7/8”

7

9-

3/4

7/8”

”

Installation – Preparing the Cabinet

front edge

glass handle

Fig.2

1. Determine and mark center line on wall and cabinet bottom with a pencil.

2. If the cabinet bottom is recessed, wood blocking must be installed to ensure proper

alignment of the hood with the cabinet bottom. Wood blocking should be fl ush

within cabinet bottom.

3. Follow the dimensions in Fig.1 and cut-out the bottom of your cabinet to create an opening

for the hood to fi t through. If you have a frameless cabinet begin the 1-9/16” measurement

(referenced in Fig.1) from front of the cabinet door. This way the front edge of the hood will

be fl ush with the cabinet doors when closed, see Fig.2.

9

Page 12

www.zephyronline.com

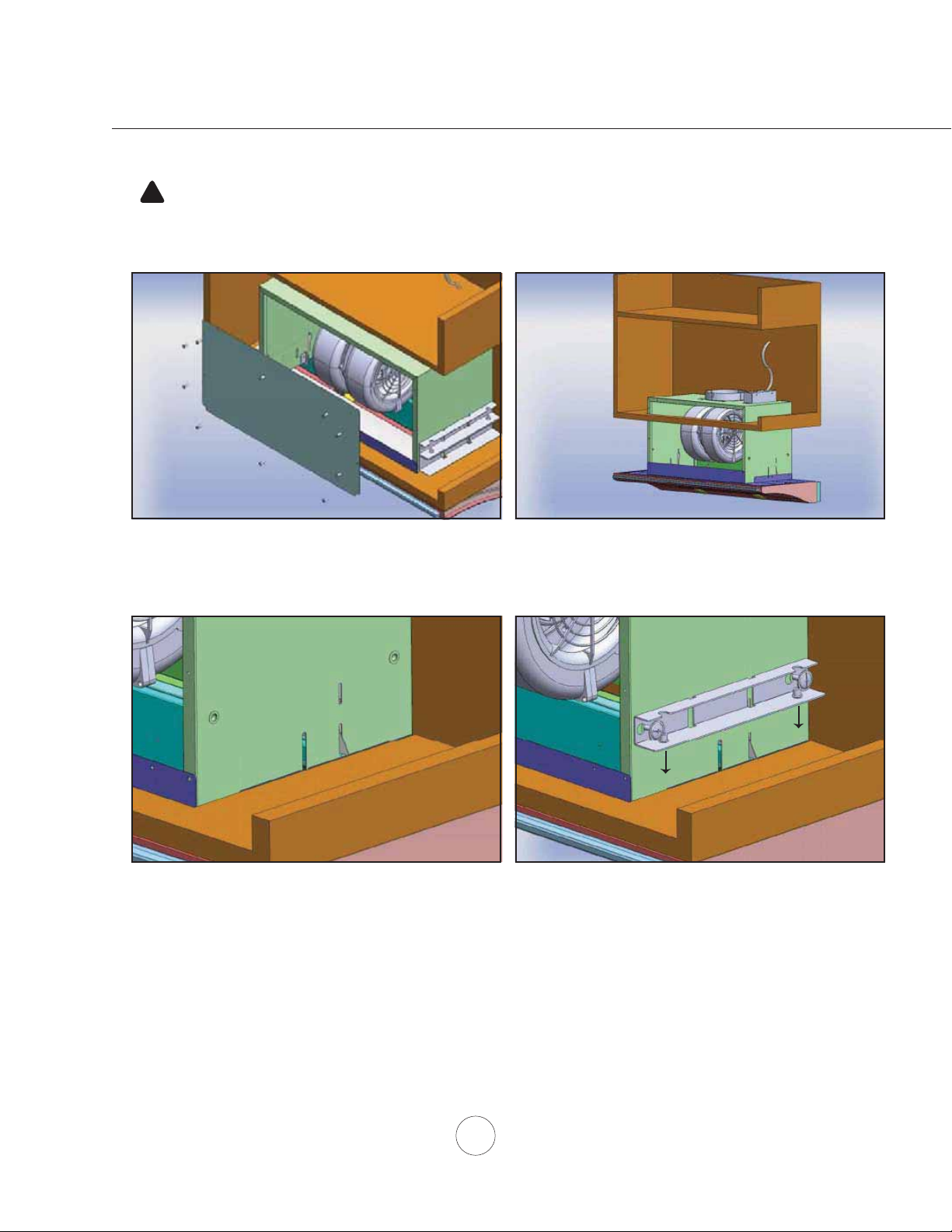

WARNING: Electrical wiring must be done by a qualified person(s) in

!

accordance with all applicable codes and standards. This range hood must be

properly grounded. Turn off electrical power at service entrance before wiring.

1) Prepare electrical wiring and ducting in cabinet. Location of junction box and blower outlet can be found on page 8.

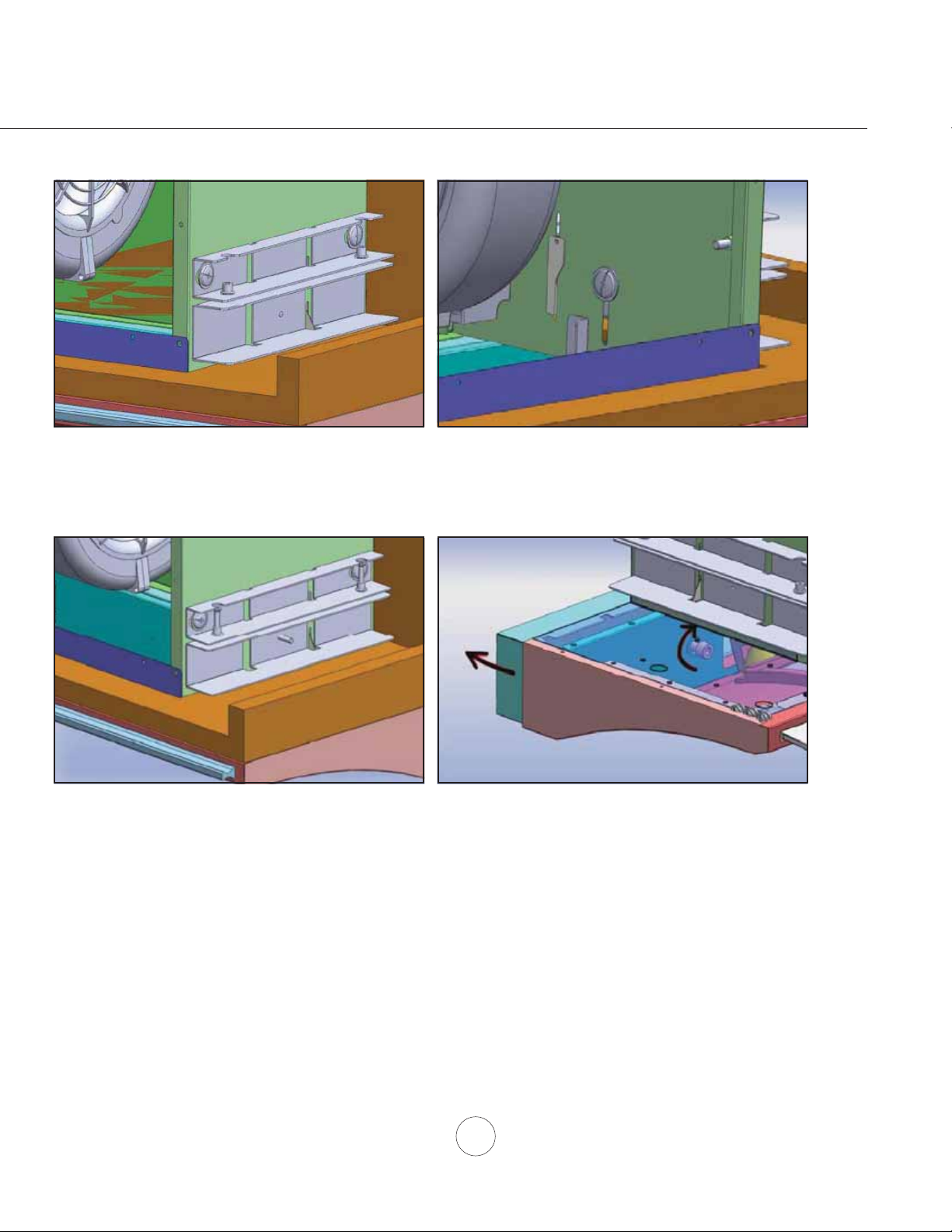

Fig.3 Fig.4

2) Unscrew the (10) screws from front panel and place

the panel aside, Fig.3. You will now have access to the

interrior of the range hood.

3) Open cabinet doors. Lift range hood and slide it through

the opening located in the bottom of the cabinet, Fig.4.

Make sure opening matches the dimensions on page 9,

Fig.1.

Installation – Installing the Hood

Fig.5 Fig.6

4) There are spring clips located on the left and right sides

of the hood body which will temporarily hold the hood in

place, Fig.5.

2

1

5) Secure upper brackets to left and right sides of hood

body by using (2) 3/16 x 3/8” screws for each bracket.

Fig.6. Make sure the (2) captive nut screw holes on

the bracket are facing downward. Note: Due to limited

workspace in 30” cabinets you will need to use a right

angle or 2” long Philips head screwdriver.

10

Page 13

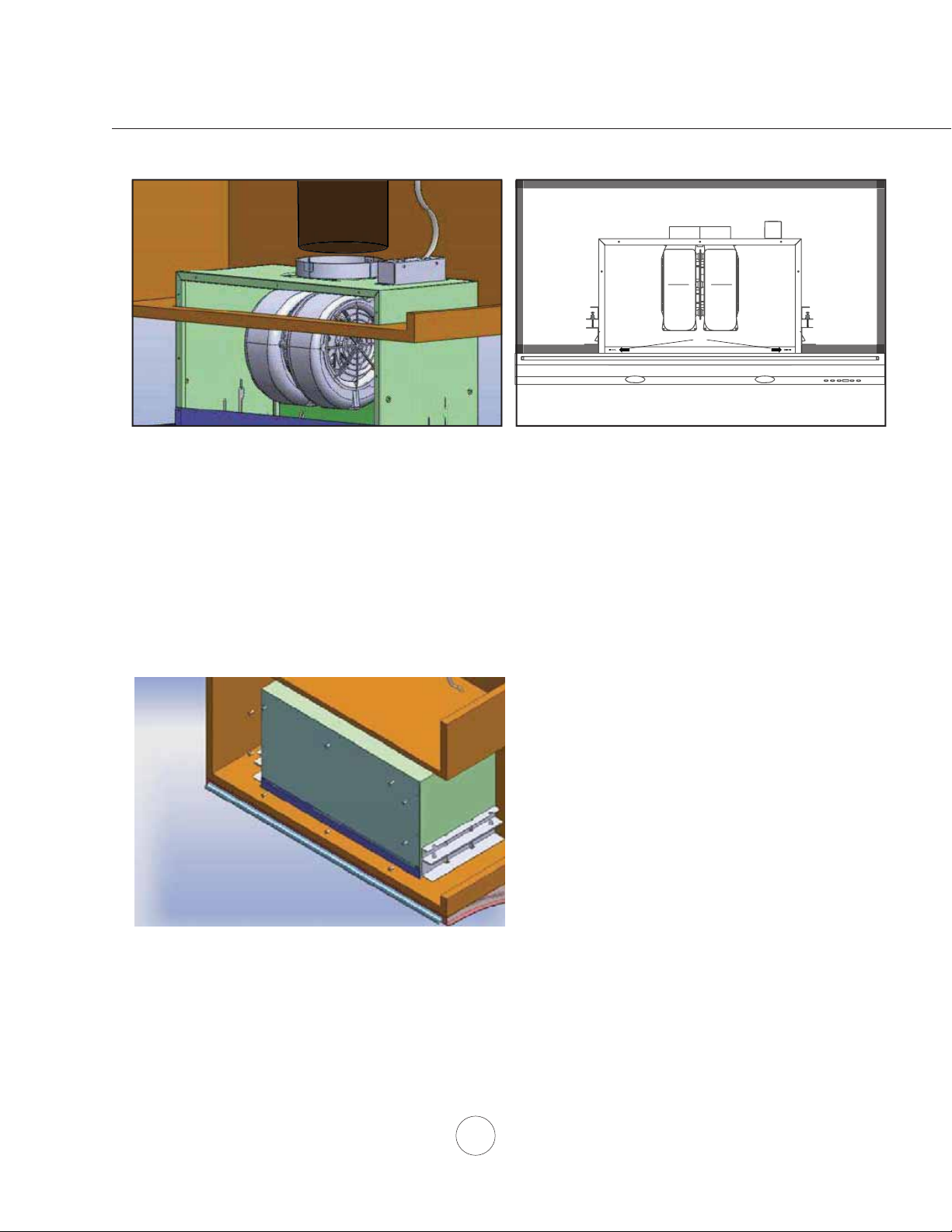

Fig.7 Fig.8

6) Place lower installation brackets under upper installation

brackets located on left and right sides of hood body,

Fig.7. Note: The wider portion of the lower installation

bracket should be at the bottom.

2

1

1

7) From inside the hood, secure (1) M4x8 screw into

each lower installation bracket. The position of this

screw is adjustable to accomodate various cabinet

bottom thicknesses, Fig.8. Do not fully tighten screw yet.

Installation – Installing the Hood

Fig.9 Fig.10

8) Install (2) 3/16x1” screws into the captive nuts of each

upper installation bracket. Tighten screws to adjust the

height of range hood until there is no gap between the

cabinet bottom and front edge of hood, Fig.9. After hood

is positioned, fully tighten the lower installation bracket

screw from step 7, Fig.8-1.

B

A

9) A fi ller panel is included to accomodate multiple cabinet

depths. Inside the hood are (2) thumb screws located

on the left and right sides at the back of the hood,

Fig.10A. Turn each thumb screw clockwise to push

the fi ller panel towards the wall, Fig.10B. Tighten thumb

screws until fi ller panel meets the wall and is secured in

place. See hood specifi cations on page 8 for supported

cabinet depths.

11

Page 14

Fig.11 Fig.12A

10) Place 6” round ducting over blower collar and secure

with aluminum duct tape. If using hood in ductless

recirculating mode turn to page 13.

Install electrical wiring. Note: A cable lock (not

included) may be required by local codes. Check

with local requirements and codes, purchase and install

appropriate connector if necessary.

www.zephyronline.com

A

11) Secure (2) 1” wood screws (A) into the screw holes on

the left and right sides of the fi lter opening. This will secure

the hood body to the cabinet base and prevent the hood

from shifting after installation.

Make sure no packing material is inside hood. Power

Installation – Installing the Hood

up hood check for leaks around duct tape and verify all

functions.

Fig.12B

12) Place front panel back on hood body and secure in

place by using the (10) screws previously removed from

step 2.

12

Page 15

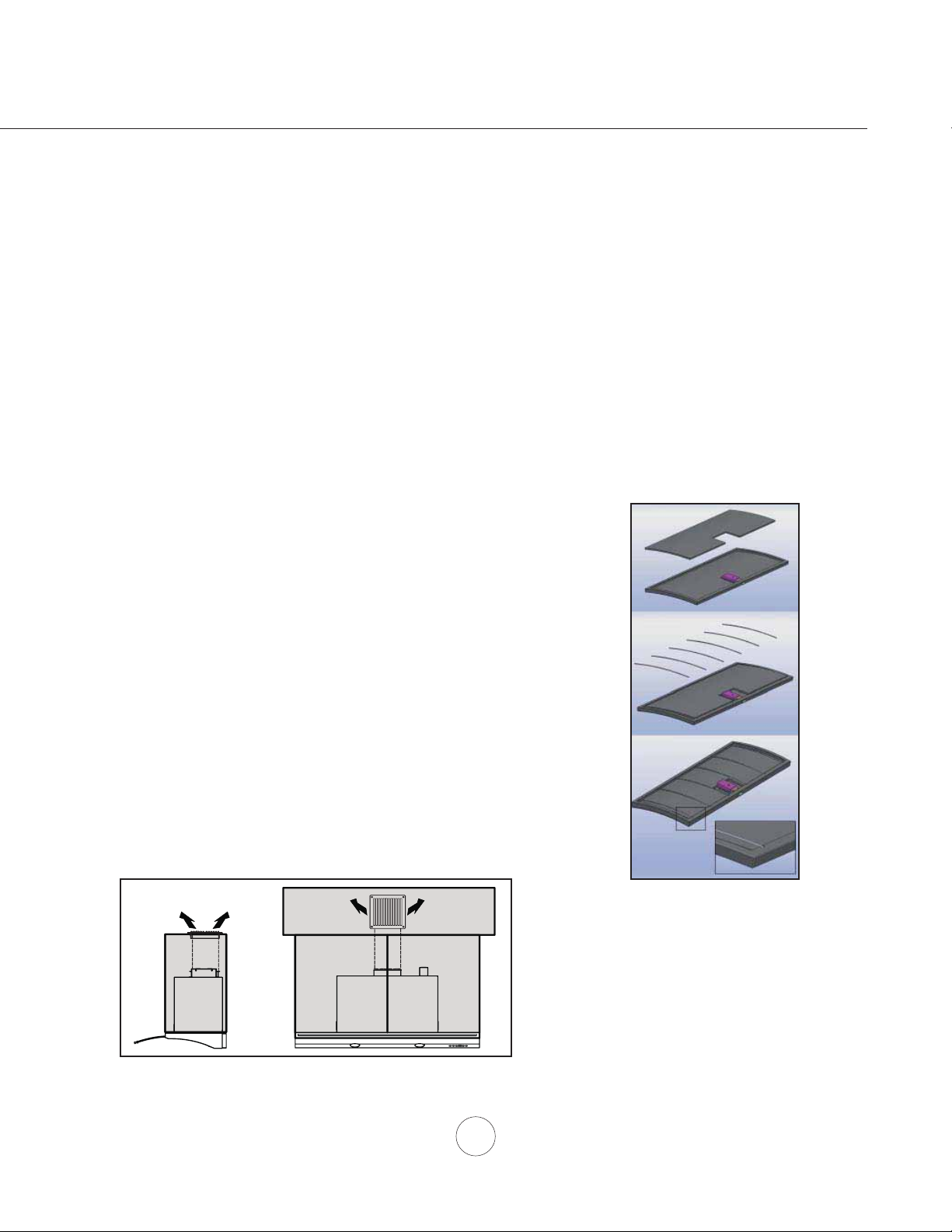

Ductless recirculation is intended for applications where an exhaust duct work is not possible to be installed.

When converted, the hood functions as a recirculating hood rather than an exhaust hood. Fumes and exhaust

from cooking are drawn and fi ltered by an optional charcoal fi lter. The air is then purifi ed and recirculated back

within the home.

We recommend to ALWAYS exhaust air outside of the home by employing existing or installing new duct

work, if possible. The hood is most effective and effi cient as an exhaust hood. Only when the exhaust option

is not possible should you recourse to converting the hood into a recirculating hood.

When converted to be a recirculating hood, a charcoal fi lter is required on top of the decorative mesh fi lter.

Order according to its part number below. The decorative mesh fi lter is intended to capture residue from

cooking and the optional charcoal fi lter helps to purify fumes exhausted from cooking for recirculation.

RECIRCULATING KIT (REQUIRED IF NOT DUCTED OUTSIDE THE HOME)

Kit includes charcoal fi lter, brackets and return air vent.

Hood Model Part No. Filters in Pkg.

ZGE (all models) ZRC-00GE 1

1. Purchase recirculating kit per the part number above.

2. Remove decorative mesh fi lter from hood and place charcoal fi lter on top of

mesh fi lter. Secure charcoal fi lter to mesh fi lter by using the supplied wire

brackets as shown in Fig.13.

3. Reinstall decorative mesh fi lter.

4. In order to recirculate the air properly, a return air vent must be installed to

allow recycled air to be returned to the kitchen, Fig. 14. Ducting must be run

from the blower to the return air vent. The return air vent can be positioned

on top of the cabinet or in a soffi t/ceiling.

5. Enable Charcoal Filter Change indicator on control panel. See page 15.

6. Charcoal fi lter must be replaced after every 120 hours of use or approximately

every 3 to 4 months based on an average daily use of 1 hour of cooking time)

The microprocessor in the controls, when set, will elapse and count usage

time and indicate when charcoal fi lter replacement is required every 120 hrs.

Installation – Ductless Recirculation

Charcoal Filter Replacement

Hood Model Part No. Qty to Order

ZGE (all models Z0F-C0GE 1

Fig.14

Fig.13

13

Page 16

www.zephyronline.com

Blower On/Off

NOTE: Blower and lights will automatically shut off when the glass is closed. The hood

also has a built in memory function that will automatically turn the blower and

lights on at the last setting when the glass is pulled open.

Blower will not operate while the glass is closed but the lights will still function.

1

Blower On/Off

By pressing , the blower is switched On and Off. When switched On, the blower will

operate at the last setting before it was switched Off. When switched Off the entire hood

powers Off, including the lights.

2

Speed Selection

The 3 speed levels are selected by pressing to decrease and to increase speed

level. The display indicates speed level selected. Pressing when the hood is Off will

also switch the blower On.

Display (speed level, delay of

Speed Selection

5 Min Delay Off

f, filter clean/replace)

Lights Normal/Dim/Off

Delay Off

3

Features & Controls – Touch Controls

Delay Off is used for programmed shut down of blower and lights 5 minutes after the function

is activated. Press once and a dot will appear in the lower right side of the Display

indicating the function is on. The hood will change to Speed 1 and shut down after 5 minutes.

Lights Normal/Dim/Off

4

Switch lights on to Normal by pressing once, again to Dim and again to switch Off.

Display

5

Displays blower speed level, delay off status, mesh filter clean and charcoal filter replace notification.

The decorative mesh filter is required to be cleaned frequently and as recommended in

order to maintain blower efficiency. If improperly maintained, residue from cooking will

sift through filter and cause damage to hood blower and other sensitive components by

possibly clogging duct work and creating a fire hazard.

14

Page 17

Decorative Mesh Filter Clean Reminder (metal mesh filter)

F

F

F

F

F

C

C

C

C

C

C

C

Whether your hood is installed as an exhaust or purifying unit, a decorative mesh filter is fitted by the factory. This

mesh filter is intended to filter out residue from cooking. It need not be replaced on a regular basis but is required to

be kept clean. After every 30 hours of use the Filter Clean Reminder function in the microprocessor will automatically remind you by a flashing when the mesh filter needs to be cleaned. The filter can be cleaned by hand

with non-abrasive soap or in a dishwasher. A heavily soiled filter should also be soaked in grease cutting

detergent prior to cleaning.

Decorative Mesh Filter Clean Indicator

When flashes on display, the mesh filter installed is

required to be cleaned. This will occur after every 30

hours of use.

Re-setting Function

Reset the filter clean reminder timer when filter is cleaned

and re-installed. With hood off, press and hold for

approximately 5 seconds until on display disappears

. . The filter clean reminder function is now reset

and a new 30 hours elapse cycle is initiated.

Clean Filters

display < F > flashes

To Re set

hold 5 sec. display from < F > to < >

Charcoal Filter Replace Reminder (charcoal filter, if installed)

When your hood is installed as a recirculating unit it must be fitted with a charcoal filter to purify exhaust and fumes

from cooking and then recirculate the air within the home. This charcoal filter must be replaced after every 120 hours

of use. The charcoal filter should never be cleaned or placed in a dish washer.

The charcoal filter replace reminder function in the microprocessor needs to be switched on. When switched on, the

microprocessor will elapse and count usage time. When charcoal filter replacement is needed a flashing will

appear on the display.

Setting the Charcoal Filter Replace Reminder

With hood off, hold for approximately 5 seconds.

The display will change from (exhaust mode) to

(recirculating mode). This indicates that the elapse

timer function is switched on and charcoal filter is being

used.

Set Mode

hold 5 sec. display from < - > to < C >

Charcoal Filter Replace Indicator

When the display starts flashing, the charcoal filter

needs to be replaced. Purchase replacement charcoal

filters from Zephyr.

Re-setting Function

After charcoal filter is replaced, with hood off, press and

hold for apprimately 5 seconds until on the

display disappears . The filter change reminder is

now re-set and a new 120 hour elapse cycle is initiated.

15

Set Mode

Change FIlter

display < C > flashes

To Re set

hold 5 sec. display from < C > to < >

Features & Controls – Filter Clean and Replace Reminder

Page 18

www.zephyronline.com

FCC Caution: To assure continued compliance, any changes or modifi cations not expressly approved by the party

responsible for compliance could void the user’s authority to operate this equipment. This device complies with Part

15 of the FCC Rules. Operation is subject to the following two conditions. (1) This device may not cause harmful

interference, and (2) This device must accept any interference received, including interference that may cause

undesired operation.

Remote control is sold as an optional accessory. Purchase Zephyr part number: 14000005

This remote control may operate in humid environments, but not when placed on a wet surface.

SYNCHRONIZATION: To create a unique link between your range hood and remote control please follow the below steps:

1. With range hood off, press and hold the “lights” button on the range hood until the letter “F” shows on the display screen.

2. Press the “lights” button on the remote, the lights on the hood will turn on. The synchronization is complete.

REMOTE CONTROL FEATURES:

The RF remote control is equipped with a magnet for easy storage. The remote may be placed on any magnetic surface such

as a refrigerator or the Zephyr remote holder. Maximum remote control communication distance from power pack is 15 feet.

Blower On/

Speed Selection

5 Min Delay Off

1

3

Blower On/

2

Power Off

4

Lights On/Dim/Off

1

Blower On/Speed Selection

By pressing , the blower is switched On. Press again to cycle through all

three blower speeds.

2

Blowers On/Hood Off

By pressing , the blowers will power on at the last speed setting. Press

again and the entire hood will power off, including lights.

Delay Off

3

By pressing , the blower and lights will enter Delay Off mode. A dot will

appear in the lower right corner of the power pack display indicating the

function is on. The blower will change to speed 1 and shut down after 5

minutes.

Lights On/Dim/Off

4

Switch lights On by pressing once, again to dim and again to switch Off.

REMOTE CONTROL MAINTENANCE:

Clean the remote control using non abrasive detergents

Follow instructions below for replacing battery.

Features & Controls – Remote Control (Optional)

+

A

-

Using a small fl at head screwdriver, raise the cover of the battery door (A)

in order to access the battery compartment.

Remove the battery and replace with Type A23 12V.

Negative end of battery should face the spring inside the remote.

Replace battery door and recycle old battery.

16

Page 19

SURFACE MAINTENANCE:

Periodically clean with hot soapy water and clean cotton cloth. Do not use corrosive or abrasive detergent

steel wool or scouring pads which will scratch and damage surface.

For heavier soil use liquid degreaser.

After cleaning it is recommended that you use non-abrasive stainless steel polish/cleaners to polish and buff

out the stainless luster and grain. Always scrub lightly with clean cotton cloth and with the grain.

Do not use any product containing chlorine bleach. Do not use “orange” cleaners.

Decorative Mesh Filters

The mesh fi lter installed by the factory is intended to fi lter out residue and grease from cooking. It need not

be replaced on a regular basis but is required to be kept clean.

Filter should be cleaned after every 30 hours of use or once a month.

Remove and clean by hand or in dishwasher on low heat. Spray degreasing detergent and leave to soak if

heavily soiled.

Dry fi lter and re-install before using hood.

Replacing Mesh Filter

Should fi lter wear out due to age and

prolonged use, replace with the following part

number:

Hood Model: Part No. Qty. to Order.

All ZGE Models 50200036 1

Replace any damaged fi lter that has punctured

or broken mesh or damaged frame.

To remove decorative mesh fi lter:

1. Pull down on handle.

2. Tilt fi lter down and remove from hood.

Maintenance – Hood and Filter Cleaning

1

2

17

Page 20

Maintenance – Lights

www.zephyronline.com

REPLACING LIGHT BULBS

CAUTION: Light bulb becomes extremely hot when turned on.

DO NOT touch bulb until switched off and cooled. Touching hot bulbs could cause serious burns.

Make sure all power is turned off and bulbs are not hot.

Remove by turning bulb counter-clockwise. Note: Bulb does not unscrew; it turns 60 degrees,

stops and falls out.

If bulbs are diffi cult to turn due to prolonged use, fi rmly attach a glass suction cup approximately the diameter of

the bulb or use a rubber/latex glove to grip the bulb and turn counter clockwise.

Replacement bulbs are available at specialty lighting stores. Purchase type (MR16) GU-10 50W halogen.

For Zephyr part numbers please turn to page 21 of the manual.

18

Page 21

370W

270W

Maintenance – Wiring Diagram

19

Page 22

TROUBLESHOOTING PROCEDURES FOR GENOVA

Issue Cause What to do

After installation,

the unit doesn’t

work.

Troubleshooting

Light works,

but motor is not

turning.

The unit is

vibrating.

The motor is

working, but the

lights are not.

The hood is

not venting out

properly.

Metal fi lter is

vibrating.

RF Remote

control does not

work

1. The power source is not turned ON. 1. Make sure the circuit breaker and the unit’s

2. The power line and the cable locking connector

is not connecting properly.

3. The switch board and control board wirings are

disconnected.

4. The wires on control board are loose. 4. Make sure the wires on the control board are

5. The switch board or control board is defective. 5. Change the switch board or control board.

1. The blower is defective, possible seized. 1. Change the blower.

2. The thermally protected system detects if the

motor is too hot to operate and shuts the motor

down.

3. Damaged capacitor. 3. Change the capacitor.

4. The blower wire is not connected. 4. Make sure the blower wire is plugged into the

1. The blower is not secure in place. 1. Tighten the blower screws in place.

2. Damaged blower wheel. 2. Change the blower.

3. The hood is not secured in place. 3. Check the installation of the hood.

1. Defective halogen bulb. 1. Change the halogen bulb.

2. The light bulb is loose. 2. Tighten the light bulb.

3. The wires on the control board are loose. 3. Make sure the wires on control board are

1. The hood might be hanging too high from the

cook top.

2. Wind from opened windows or opened doors in

the surrounding area is affecting the ventilation

of the hood.

3. Blockage in the duct opening or duct work. 3. Remove all the blocking from the duct work or

4. The direction of duct opening is against the wind. 4. Adjust the duct opening direction.

5. Using the wrong size of ducting. 5. Change the ducting to correct size.

1. Mesh fi lter is loose. 1. Change the mesh fi lter.

2. Handle spring clip does not work properly 2. Adjust the handle until the spring clip works

1. Battery is dead 1. Replace battery with type A23 12v

2. Poor communication with the hood 2. Remote control must be within 15 ft of hood

3. RF remote lost communication with hood 3. Reset hood and remote by switching power

www.zephyronline.com

power is ON.

2. Check the power connection with the unit is

connected properly.

3. Make sure the wirings between the switch

board and control board are connected

properly.

connected properly.

2. The motor will function properly after the

thermally protected system cool down.

molex connector.

connected properly.

1. Adjust the distance between the cook top and

the bottom of the hood within 24” and 32”

range.

2. Close all the windows and doors to eliminate

the outside wind fl ow.

duct opening.

off at the circuit breaker for 5 minutes. Place

remote on counter top near hood and switch

the circuit breaker back on.

20

Page 23

DESCRIPTION PART#

Replacement Parts

Light Bulb GU10 50W (each) Z0B0020

Decorative Mesh Filter 50200036

Optional Accessories

Recirculating Kit ZRC-00GE

Replacement Charcoal Filter (each) Z0F-C0GE

RF Remote Control 14000005

To order parts, visit us online at http://store.zephyronline.com or call us at 1.888.880.8368

List of Parts and Accessories

21

Page 24

STAPLE YOUR RECEIPT HERE

Proof of the original purchase

date is needed to obtain

Limited Warranty

TO OBTAIN SERVICE UNDER WARRANTY OR FOR ANY SERVICE RELATED QUESTIONS, please call:

service under warranty

1-888-880-8368

Zephyr Corporation (referred to herein as “we” or “us”) warrants to the original consumer purchaser (referred to herein

as “you” or “your”) of Zephyr products (the “Products”) that such Products will be free from defects in materials or workmanship as follows:

Three Year Limited Warranty for Parts: For three years from the date of your original purchase of the Products, we

will provide, free of charge, Products or parts to replace those that failed due to manufacturing defects. We may choose,

in our sole discretion, to repair or replace parts before we elect to replace the Products.

One Year Limited Warranty for Labor: For one year from the date of your original purchase of the Products, we will

provide, free of charge, the labor cost associated with repairing the Products or parts to replace those that failed due to

manufacturing defects. After the first year from the date of your original purchase, you are responsible for all labor costs

associated with this warranty.

Warranty Exclusions: This warranty covers only repair or replacement, at our option, of defective Products or parts

and does not cover any other costs related to the Products including but not limited to: (a) normal maintenance and

service required for the Products and consumable parts such as light bulbs, metal and carbon filters and fuses; (b) any

Products or parts which have been subject to freight damage, misuse, negligence, accident, faulty installation or installation contrary to recommended installation instructions, improper maintenance or repair (other than by us); (c) commercial use of the Products or use otherwise inconsistent with its intended purpose; (d) natural wear of the finish of the Products or wear caused by improper maintenance, use of corrosive and abrasive cleaning products, pads, and oven cleaner

products; (e) chips, dents or cracks caused by abuse or misuse of the Products; (f) service trips to your home to teach

you how to use the Products; or (g) damage to the Products caused by accident, fire, floods or act of God. If you are

outside our service area, additional charges may apply for shipping costs for warranty repair at our designated service

locations and for the travel cost to have a service technician come to your home to repair, remove or reinstall the Products. After the first year from the date of your original purchase, you are also responsible for all labor costs associated

with this warranty.

Limitations of Warranty. OUR OBLIGATION TO REPAIR OR REPLACE, AT OUR OPTION, SHALL BE YOUR SOLE

AND EXCLUSIVE REMEDY UNDER THIS WARRANTY. WE SHALL NOT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH THE USE OR PERFORMANCE OF

THE PRODUCTS. THE EXPRESS WARRANTIES IN THE PRECEDING SECTION ARE EXCLUSIVE AND IN LIEU OF

ALL OTHER EXPRESS WARRANTIES. WE HEREBY DISCLAIM AND EXCLUDE ALL OTHER EXPRESS WARRANTIES FOR THE PRODUCTS, AND DISCLAIM AND EXCLUDE ALL WARRANTIES IMPLIED BY LAW, INCLUDING

THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Some states or provinces do not

allow limitations on the duration of an implied warranty or the exclusion or limitation of incidental or consequential damages, so the above limitations or exclusions may not apply to you. To the extent that applicable law prohibits the exclusion of implied warranties, the duration of any applicable implied warranty is limited to the same two-year period

described above. Any oral or written description of the Products is for the sole purpose of identifying the Products and

shall not be construed as an express warranty. Prior to using, implementing or permitting use of the Products, you shall

determine the suitability of the Products for the intended use, and you shall assume all risk and liability whatsoever in

connection with such determination. We reserve the right to use functionally equivalent refurbished or reconditioned

parts or Products as warranty replacements or as part of warranty service. This warranty is not transferable from the

original purchaser and applies in the United States and Canada.

To Obtain Service Under Limited Warranty: To qualify for warranty service, you must: (a) notify us at the address or

telephone number stated below within 60 days of the discovery of the defect; (b) give the model number and part identification number and serial number; and (c) describe the nature of any defect in the Product or part. At the time of the

request for warranty service, you must present evidence of your proof of purchase and proof of the original purchase

date. If we determine that the warranty exclusions listed above apply or if you fail to provide the necessary documentation to obtain service, you will be responsible for all shipping, travel, labor and other costs related to the services.

Please check our website for any revisions, www.zephyronline.com.

Zephyr Corporation Service Department, 2277 Harbor Bay Parkway, Alameda, CA 94502 1-888-880-8368

MAR11.0201

Page 25

Genova

ZGE-E30AS

ZGE-E36AS

ZGE-E30AS290

ZGE-E36AS290

www.zephyronline.com

Guide d’utilisation, d’entretien et d’installation

Numéro de modèle :

Numéro de série :

JUL11.0301 © Zephyr Corporation

Page 26

www.zephyronline.com

Page 27

MISE EN GARDE DE SÉCURITÉ .......................... 2-3

LISTE DU MATÉRIEL ....................................................... 4

INSTALLATION

Feuille de calcul pour le conduit

Espace libre et hauteur de montage

Options d’installation pour le conduit

Spécifi cations de la hotte

Préparation de l’armoire

........................................... 9

........................... 5

................... 6

.................. 7

......................................... 8

Installation de la hotte.................................... 10-12

Reprise d’air sans conduit

....................................... 13

COMMANDES

Commandes à effl eurement

.................................. 14-16

Commande à distance (optionnel) .................. 17

ENTRETIEN

Nettoyage des fi ltres et de la hotte

Ampoules

....................................................................... 19

...................... 18

Schéma de câblage....................................... 20

DÉPANNAGE

................................................................................. 21

LISTES DES ACCESSOIRES ET DES PIÈCES

Table des matières

............ 22

1

Page 28

LISEZ ET CONSERVEZ CES INSTRUCTIONS

www.zephyronline.com

AVERTISSEMENT

POUR RÉDUIRE LES RISQUES D’INCENDIE OU DE DÉCHARGE ÉLECTRIQUE, N’UTILISEZ PAS CET APPAREIL AVEC UN TABLEAU

DE COMMANDE À SEMI-CONDUCTEURS.

AVERTISSEMENT

POUR RÉDUIRE LES RISQUES D’INCENDIE, DE DÉCHARGE ÉLECTRIQUE OU DE BLESSURE, RESPECTEZ CES CONSIGNES :

a. N’utilisez cet appareil que de la manière prévue par le fabricant. Si vous avez des questions, communiquez avec le fabricant.

b. Avant de procéder au nettoyage ou à l’entretien de l’appareil, éteignez l’alimentation du panneau électrique et bloquez le dispositif de

déconnexion pour éviter que l’alimentation électrique ne soit accidentellement rallumée. Si le dispositif de sectionnement d’électricité ne peut

être bloqué, attachez un avertissement (comme une étiquette) bien en vue sur le tableau électrique.

ATTENTION

Pour ventilation générale seulement. N’utilisez pas cet appareil pour évacuer des vapeurs et des matériaux explosifs ou dangereux. Prenez garde

lors de l’utilisation d’agents nettoyants ou de détergents. Ne devrait être utilisé que dans la cuisine de votre maison.

AVERTISSEMENT

POUR RÉDUIRE LES RISQUES DE FEU DE GRAISSE SUR LA SURFACE DE CUISSON :

a. Ne laissez jamais l’appareil sans surveillance lors de son utilisation à haute température. Les débordements par bouillonnement causent de la

fumée et des déversements de graisse qui peuvent prendre feu. Faites chauffer l’huile à des températures basses ou moyennes.

b. Allumez toujours la hotte lorsque vous cuisinez à haute température ou que vous faites fl amber des aliments.

c. Nettoyez fréquemment les ventilateurs de la hotte. La graisse ne devrait jamais s’accumuler dans les ventilateurs ou les fi ltres.

d. Utilisez des poêlons aux dimensions adéquates. Utilisez toujours une batterie de cuisine correspondant aux dimensions de l’élément.

Mise en garde de sécurité

e. Assurez-vous que le ventilateur, les fi ltres et les surfaces où la graisse pourrait s’accumuler sont toujours propres.

f. Utilisez le réglage haut de la hotte seulement lorsque nécessaire.

g. Ne laissez pas la hotte sans surveillance lorsque vous cuisinez.

h. Utilisez toujours une batterie de cuisine et des ustensiles convenant au type et à la quantité de nourriture que vous préparez.

AVERTISSEMENT

POUR RÉDUIRE LES RISQUES DE BLESSURE LORS D’UN INCENDIE SUR LA SURFACE DE CUISSON :

a. ÉTOUFFEZ LES FLAMMES avec un couvercle, une plaque à biscuits ou un plateau de métal et éteignez ensuite le brûleur. PRENEZ GARDE

AUX RISQUES DE BRÛLURE. Si les fl ammes ne disparaissent pas, ÉVACUEZ LES LIEUX ET APPELEZ LE SERVICE D’INCENDIE.

b. NE PRENEZ JAMAIS UN POÊLON EN FEU – Vous pourriez vous brûler.

c. N’UTILISEZ PAS D’EAU, ou un linge à vaisselle mouillé – une violente explosion de vapeur s’ensuivra.

d. Utilisez un extincteur SEULEMENT si :

1. Vous savez que vous possédez un extincteur de classe ABC et vous savez vous en servir.

2. Le feu est faible et ne s’est pas répandu depuis son point d’origine.

3. Vous avez appelé le service d’incendie.

4. Vous pouvez sortir facilement de l’endroit où vous combattez le feu.

AVERTISSEMENT

POUR RÉDUIRE LES RISQUES D’INCENDIE, DE DÉCHARGE ÉLECTRIQUE OU DE BLESSURE, SUIVEZ LES CONSIGNES SUIVANTES :

a. Les travaux d’installation et de câblage électrique doivent être faits par une personne qualifi ée selon les stipulations de tous les normes et

standards en vigueur, dont les normes des constructions ayant une cote de résistance au feu.

b. Pour prévenir les contre-explosions, une certaine quantité d’air est nécessaire pour la combustion et l’évacuation des gaz par le carneau

(cheminée) de l’appareil de combustion. Respectez les directives du fabricant d’outillage de chauffage et les normes de sécurité comme celles

publiées par la NFPA (Association nationale des services d’incendie), par la Société américaine des ingénieurs en chauffage, réfrigération et

climatisation (ASHRAE) et par les normes des autorités locales.

c. Lorsque vous coupez ou percez un mur ou un plafond, assurez-vous de ne pas endommager le câblage électrique ou toute autre installation

technique dissimulée.

d. Les ventilateurs canalisés doivent toujours évacuer l’air à l’extérieur.

e. N’installez JAMAIS un interrupteur à une distance atteignable depuis un bain ou une douche.

f. Assurez-vous que l’alimentation électrique est éteinte avant de procéder à l’installation, au câblage ou à l’entretien de l’appareil

.

2

Page 29

ATTENTION

POUR RÉDUIRE LES RISQUES D’INCENDIE, N’UTILISEZ QUE DES CONDUITS D’AÉRATION EN MÉTAL.

ATTENTION

Pour réduire les risques d’incendie et pour évacuer l’air convenablement, assurez-vous de canaliser l’air à l’extérieur de

la maison. N’installez pas l’échappement du conduit dans les espaces entre les murs, le plafond, le grenier, les vides

sanitaires ou le garage.

FONCTIONNEMENT

Laissez toujours les grilles de sûreté et les fi ltres en place. Sans ces éléments, les ventilateurs en marche pourraient

accrocher des cheveux, des doigts ou des vêtements amples.

Le fabricant se dégage de toute responsabilité dans les cas de non-respect des instructions transmises dans le présent

manuel pour l’installation, l’entretien et l’utilisation adéquate du produit. Le fabricant se dégage également de toute

responsabilité pour des blessures qui résulteraient de la négligence lors de l’utilisation. De plus, la garantie prend fi n

automatiquement lors de l’entretien inapproprié de l’appareil.

*NOTE : Veuillez communiquer avec nous ou visitez le www.zephyronline.com pour obtenir des révisions avant

de procéder à des travaux sur commande.

EXIGENCES ÉLECTRIQUES

Important :

Respectez tous les codes et règlements en vigueur.

Il est de la responsabilité du client de :

- Communiquer avec un installateur-électricien qualifi é.

- S’assurer que l’installation électrique est adéquate et qu’elle respecte le Code national de l’électricité, la plus récente

édition* du ANSI/NFPA 70 ou des normes du CSA C22.1-94, le Code canadien de l’électricité, section 1, la plus récente

édition** du code C22.2 No.0-M91 ainsi que tous les codes et réglements en vigueur.

Si les codes permettent l’utilisation d’un fi l de garde isolé et que vous en utilisez un, il est recommandé qu’un électricien

qualifi é détermine si le cheminement du fi l est adéquat.

N’effectuez pas la mise à la terre à un tuyau de gaz.

Demandez à un électricien qualifi é si vous n’êtes pas certain que la hotte a été mise à la terre adéquatement.

N’introduisez aucun fusible dans le circuit neutre ou de mise à la terre.

*National Fire Protection Association Batterymarch Park, Quincy, Massachusetts 02269

** CSA International 8501 East Pleasant Valley Road, Cleveland, Ohio 44131-5575

Cet appareil requiert une alimentation électrique de 120V 60Hz. Il doit être connecté à un circuit terminal individuel

dûment mis à la terre, protégé par un disjoncteur de circuit ou un fusible temporisé de 15 ou 20 ampères. Le câblage doit

compter 2 fi ls avec mise à la terre. Veuillez vous référer au Diagramme électrique étiqueté sur l’appareil.

Un raccord de câble (non inclus) pourrait également être exigé par les normes et réglementations locales. Informez-vous

des exigences et des normes locales. Achetez et installez le connecteur approprié si nécessaire.

ZGE-E30AS, ZGE-E36AS - 370 Watts, 3,1 Ampères

ZGE-E30AS290, ZGE-E36AS290 - 167 Watts, 1,4 Ampères

Mise en garde de sécurité

3

Page 30

Liste du matériel

www.zephyronline.com

(2) M4 x 1”

4

Page 31

Pièces de conduit

3-1/ 4” x 10”

rect., droit

Longueur x

Nombre utilisé

1 pi x ( ) =

To ta l

Pièces de conduit

pi

6”

embout mural

circ./registre

Longueur x

Nombre utilisé

30 pi x ( ) =

To ta l

pi

6” circ., droit

7” circ., droit

3-1/ 4” x 10”

rect.,

coude à 90º

3-1/ 4” x 10”

rect.,

coude à 45º

3-1/ 4” x 10”

rect.,

coude plat

à 90º

3-1/ 4” x 10”

embout mural

rect./registre

3-1/ 4” x 10”

rect. à circ.

de 6"

1 pi x ( ) =

1 pi x ( ) =

15 pi x ( ) =

9 pi x ( ) =

24 pi x ( ) =

30 pi x ( ) =

5 pi x ( ) =

pi

pi

pi

pi

pi

pi

pi

6”

chapeau de

toiture circ.

6” circ. à

rect. de

3-1/4" x 10"

6” circ. à

rect. de

3-1/4" x 10",

coude à 90º

7” or 10”

circ.,

coude à 90º

7” or 10”

circ.,

coude à 45º

7” or 10”

embout

mural

circ./registre

7” or 10”

circ., chapeau

de toiture

30 pi x ( ) =

1 pi x ( ) =

16 pi x ( ) =

15 pi x ( ) =

9 pi x ( ) =

30 pi x ( ) =

30 pi x ( ) =

pi

pi

pi

pi

pi

pi

pi

3-1/ 4” x 10”

coude à 90º

rect. à circ.

de 6"

6” circ.,

coude à 90º

6” circ.,

coude à 45º

20 pi x ( ) =

15 pi x ( ) =

9 pi x ( ) =

Sous-total - colonne 1=

pi

pi

pi

pi

Longueur maximale du conduit d’aération :

Pour un mouvement d’air convenable, la longueur totale d’un conduit

d’aération rectangulaire de 3 1/4" x 10", ou circulaire de 6" ou 7" de diamètre,

ne devrait pas compter plus que l’équivalent de 100 pieds.

5

7” circ. à

rect. de

3-1/4" x 10"

7” circ. à

rect. de

3-1/4" x 10",

coude à 90º

8 pi x ( ) =

23 pi x ( ) =

Sous-total - colonne 2 =

Sous-total - colonne 1 =

Total du conduit =

pi

pi

pi

pi

pi

Installation – Feuille de calcul pour le conduit d’aération

Page 32

24” min.

32” max.

www.zephyronline.com

Il est important d’installer la hotte à la hauteur

de montage adéquate. Les hottes installées

trop basses pourraient être endommagées par

la chaleur en plus de présenter des risques

d’incendie plus élevés tandis que les hottes

installées trop hautes seront diffi ciles à atteindre

et verront leur effi cacité et leur rendement réduits.

Si elles sont disponibles, consultez les exigences

de hauteur d’espace libre requise par le fabricant

de la cuisinière ainsi que la hauteur recommandée

de montage de la hotte au-dessus de la surface

de cuisson. Informez-vous toujours des normes et

des réglementations locales en vigueur pour toute

différence par rapport aux normes du fabricant.

36”

CONDUIT D’AÉRATION

Un conduit circulaire de 6” doit être utilisé pour

assurer une circulation d’air maximale.

N’utilisez que des conduits en métal rigide. Les

conduits souples pourraient réduire la circulation

d’air jusqu’à 50 %.

Utilisez la feuille de calcul pour obtenir la longueur

totale du conduit.

Lorsqu’il possible de le faire, diminuez

Installation – Espace libre et hauteur de montage

TOUJOURS le nombre de pièces et de

changements de direction. Si un long tronçon de

conduit est nécessaire, augmentez le diamètre du

conduit de 6” à 7” ou 8”.

Si des changements de direction ou des

adaptateurs sont nécessaires, installez-les le

plus loin possible de l’ouverture et le plus éloigné

possible l’un de l’autre.

La hauteur de montage de la surface de la

cuisinière au bas de la hotte ne devrait pas être

inférieure à 24” et supérieure à 32”.

ENDOMMAGEMENT LORS DE LA LIVRAISON/

INSTALLATION :

• Veuillez vous assurer que toutes les pièces

de l’appareil ne sont pas endommagées avant

l’installation.

• Si l’appareil est endommagé durant la livraison,

retournez l’appareil à l’endroit où vous l’avez

acheté pour réparation ou remplacement.

• Si l’appareil est endommagé par le client, la

réparation ou le remplacement est à la charge du

client.

• Si l’appareil est endommagé par l’installateur

(si autre que le client), le client et l’installateur

doivent en venir à une entente pour la réparation

ou le remplacement.

6

Page 33

AVERTISSEMENT DE RISQUE D’INCENDIE

N’évacuez ou ne terminez JAMAIS l’échappement du conduit dans les espaces entre les murs, les vides

sanitaires, le plafond, le grenier, ou le garage. Tous les échappements doivent être dirigés à l’extérieur de la

maison, à moins que l’option de reprise d’air ne soit utilisée.

N’utilisez que des conduits en métal pour cloison simple.

Fixez toutes les pièces du conduit avec des vis à tôle et isolez tous les joints avec du ruban adhésif en toile ou

du ruban réfl ecteur certifi é.

Exemples d’options pour le conduit d’aération

Installation – Options pour le conduit d’aération

7

Page 34

www.zephyronline.com

LC

Installation – Spécifi cations de la hotte

8

Page 35

9/16”

1-

7”

19-7/8”

C/L

Fig.1

7 3/4”

9-

7/8”

Fig.2

1. Calculez et marquez la ligne centrale sur le mur et sur le bas de l’armoire avec un crayon.

2. Si le bas de l’armoire est enfoncé, vous devrez installer des blocs de bois pour aligner correctement le bas de l’armoire avec

la hotte. Les blocs de bois devraient arriver à ras du bas de l’armoire.

3. Respectez les dimensions de la Fig.1 et coupez le bas de l’armoire pour créer une ouverture permettant l’installation de

l’armoire. Si vous avez une armoire sans cadre, calculez la distance de 1-9/16” (mentionné à la Fig.1) à partir de l’avant

de la porte de l’armoire. Ainsi, le rebord avant de la hotte arrivera à égalité avec les portes de l’armoire lorsqu’elles seront

fermées. Voir Fig.2.

9

INSTALLATION – Préparation de l’armoire

Page 36

www.zephyronline.com

1) Préparez le câblage électrique et le conduit dans l’armoire. Les emplacements de la boîte de connexion et l’ouverture de

refoulement de ventilateur sont indiqués à la page 8.

Fig.3 Fig.4

2) Dévissez les (10) vis du panneau avant et laissez le

panneau de côté, Fig.3. Vous aurez maintenant accès à

l’intérieur de la hotte.

3) Ouvrez les portes de l’armoire. Soulevez la hotte et

faites-la glisser dans l’ouverture située au bas de l’armoire,

Fig.4. Assurez-vous que l’ouverture correspond aux

dimensions indiquées à la page 9, Fig.1.

Installation – Installation de la hotte

Fig.5 Fig.6

4) Des attaches à ressort sont situées sur les côtés

gauche et droit du boîtier de la hotte. Elles tiendront

temporairement la hotte en place, Fig.5.

2

1

5) Fixez les supports supérieurs aux côtés gauche et droit

du boîtier de la hotte à l’aide de (2) vis 3/16 x 3/8” par

support, Fig.6. Assurez-vous que les (2) trous à vis pour

les écrous imperdables pointent vers le bas. Note : Compte

tenu de l’espace de travail restreint pour les armoires des

hottes de 30”, vous devrez utiliser un tournevis à angle droit

ou un tournevis cruciforme de 2”.

10

Page 37

Fig.7 Fig.8

6) Placez les supports d’installation inférieurs sous les

supports d’installation supérieurs situés sur les côtés

gauche et droit du boîtier de la hotte, Fig.7. Note : La partie

plus large des supports d’installation inférieurs devrait se

trouver au bas de la hotte.

2

1

1

7) À partir de l’intérieur de la hotte, fi xez (1) vis M4x8 dans

chaque support d’installation inférieur. La position de ces

vis est ajustable et s’adapte à différentes épaisseurs de

dessous d’armoire, Fig.8. Ne serrez pas complètement les

vis pour l’instant.

Fig.9 Fig.10

8) Installez (2) vis 3/16x1” dans les écrous imperdables

de chaque support d’installation supérieur. Serrez les vis

pour ajuster la hauteur de la hotte jusqu’à ce qu’il n’y ait

plus d’espace entre le bas de l’armoire et le rebord avant

de la hotte, Fig.9. Une fois que la hotte est en place, serrez

complètement les vis des supports d’installation inférieurs

de l’étape 7, Fig.8-1.

B

A

9) Un panneau de remplissage est inclus pour composer

avec les différentes profondeurs d’armoire. Deux vis de

serrage sont situées à l’intérieur de la hotte sur les côtés

gauche et droit à l’arrière de la hotte, Fig.10A. Tournez

chaque vis de serrages dans le sens des aiguilles d’une

montre pour pousser le panneau de remplissage vers le

mur, Fig.10B. Serrez les vis de serrage jusqu’à ce que le

panneau de remplissage touche au mur et qu’il soit bien

fi xé en place. Consultez les spécifi cations de la page 8

pour les profondeurs d’armoire possible.

11

Installation – Installation de la hotte

Page 38

Fig.11 Fig.12A

10) Placez le conduit circulaire de 6” par-dessus le collier

du ventilateur et fi xez le tout avec du ruban à conduit en

aluminium. Si vous utilisez la hotte en mode de reprise

d’air, allez à la page 13.

Installez le câblage électrique. Note : Un raccord de câble

(non inclus) pourrait également être exigé par les normes

et réglementations locales. Informez-vous des exigences

et des normes locales. Achetez et installez le connecteur

approprié si nécessaire.

www.zephyronline.com

A

11) Secure (2) 1 “vis à bois (A) dans les trous de vis sur les

côtés gauche et droit de l’ouverture du fi ltre. Ainsi, pourra

le corps de la hotte à la base du cabinet et de prévenir le

capot de se déplacer après installation.

Assurez-vous qu’aucun matériel d’emballage ne se trouve

à l’intérieur de la hotte. Allumez la hotte, assurez-vous qu’il

n’y a pas de fuites où il y a du ruban à conduit et assurez-

Installation – Installation de la hotte

vous du bon fonctionnement de toutes les fonctions.

Fig.12B

12) Remettez le panneau avant sur la hotte et fi xez-le en

place à l’aide des (10) vis que vous aviez préalablement

enlevées à l’étape 2.

12

Page 39

La confi guration de reprise sans conduit a été conçue pour les applications où il est impossible d’installer un conduit

d’aération. Lorsque transformée, la hotte fonctionne comme une hotte de reprise d’air plutôt que comme un système

d’évacuation d’air. Les vapeurs et fumées de cuisson sont aspirées et fi ltrées par un ensemble optionnel de fi ltres à charbon.

L’air est ensuite purifi é et redirigé à l’intérieur de la maison.

Nous recommandons de TOUJOURS évacuer l’air à l’extérieur de la maison en utilisant le conduit en place ou, s’il y a

possibilité, en installant un nouveau conduit. La hotte est plus effi cace lorsqu’utilisée comme système d’évacuation d’air. Vous

ne devriez recourir à la confi guration de reprise d’air que lorsqu’il est impossible d’installer un conduit d’aération.

Lorsque la confi guration de reprise d’air est choisie, un fi ltre à charbon doit être installé sur le fi ltre à tamis décoratif.

Commandez-les en vous référant au numéro de pièce ci-dessous. Le fi ltre à tamis décoratif est conçu pour capturer les

résidus de cuisson et le fi ltre à charbon optionnel aide à la purifi cation des vapeurs et fumées de la cuisson lors de la reprise

d’air.

ENSEMBLE DE REPRISE D’AIR (REQUIS SI AUCUN CONDUIT N’EST UTILISÉ)

L’ensemble comprend un fi ltre à charbon et un défl ecteur d’air.

Modèle de hotte Numéro de pièce Filtres par paquet

ZGE (tous les modèles) ZRC-00GE 1

1. Procurez-vous l’ensemble de reprise d’air en utilisant le numéro de pièce ci-dessus

2. Retirez le fi ltre à tamis décoratif de la hotte et placez le fi ltre à charbon au-dessus du fi ltre

à tamis. Fixez le fi ltre à charbon au fi ltre à tamis en utilisant les supports à câble fournis, tel

qu’illustré sur la Fig. 13.

3. Réinstallez le fi ltre à tamis décoratif.

4. Pour que la reprise d’air se fasse convenablement, un évent de reprise d’air doit être installé

pour permettre à l’air recyclé d’être relâché dans la cuisine, Fig. 14. Un conduit doit être

installé du ventilateur à l’évent. L’évent de reprise d’air peut être placé sur le dessus de

l’armoire, ou dans le plafond ou vide sanitaire.

5. Allumez l’indicateur de changement du fi ltre sur le tableau de commande (voir page 15).

6. Le fi ltre à charbon doit être remplacé après 120 heures d’utilisation (ou approximativement

tous les 3-4 mois à raison de 1 heure d’utilisation quotidienne). Le microprocesseur peut

être réglé pour calculer le temps d’utilisation et vous indiquerquand changer le fi ltre, toutes

les 120 heures d’utilisation.

Installation - Reprise d’air sans conduit

Remplacement du fi ltre à charbon

Modèle de hotte Numéro de pièce Quantité à commander

ZGE (Tous les modèles) Z0F-C0GE 1

FIG.14

13

FIG.13

Page 40

www.zephyronline.com

Commandes - Commandes à effl eurement

14

Page 41

15

Commandes – Indicateur de changement des fi ltres à charbon

Page 42

www.zephyronline.com

COMMANDES – Indicateur de nettoyage des fi ltres à tamis métalliques

16

Page 43

Mise en garde de la Commission fédérale des communications: Dans le but d’assurer une conformité

continue, toute modifi cation apportée sans l’approbation expresse du parti responsable de la conformité pourrait annuler

l’autorisation de l’utilisateur de faire fonctionner cet appareil. Cet appareil respecte l’article 15 des réglementations FCC.

Le fonctionnement doit respecter les deux réglementations suivantes : (1) cet appareil ne doit pas causer de brouillage

nuisible et (2) cet appareil doit pouvoir recevoir tout type d’interférence, dont des interférences qui pourraient causer un

fonctionnement involontaire.

La commande à distance est vendue séparément comme accessoire en option. Achetez la pièce Zephyr

portant le numéro 14000005

Cette commande à distance peut fonctionner dans un environnement humide, mais pas lorsque laissée sur une surface

trempée

SYNCHRONISATION: Pour créer un lien unique entre votre hotte de cuisiniére et de controle à distance s’il vous

plait suivre les êtapes ci-dessous:

1. Avec hotte appuyez et maintenez les “lumiéres” sur la hotte jusqu’à ce que la lettre “F” apparait sur l’êcran.

2. Appuyez sur le “lumiéres” sur la télécommande, les lumiéres sur le capot se mettra en marche. La synchronisation est terminée.

FONCTIONS DE CONTROLE A DISTANCE:

La commande à distance radioélectrique est munie d’un aimant pour un entreposage facile. la commande peut être placé sur n’importe quelle

surface magnétique, comme un réfrigérateur ou le support à commande zephyr. la distance maximale de l’appareil à laquelle la commande

fonctionne est de 15 pieds.

Commandes – Commande à distance radioélectrique

ENTRETIEN DE LA COMMANDE À DISTANCE:

Nettoyez la commande à distance avec des détergents non abrasifs.

Suivez les instructions ci-dessous pour remplacer la pile.

Enlevez le couvercle du compartiment à pile (A) à l’aide d’un tournevis plat pour

avoir accès à la pile.

+

A

-

Enlevez la pile et remplacez-la avec une pile de type A23 12V. L’extrémité négative

devrait faire face au ressort à l’intérieur de la commande à distance.

Remettez le couvercle du compartiment en place et recyclez la vieille pile.

17

Page 44

www.zephyronline.com

ENTRETIEN DES SURFACES

Nettoyez régulièrement les surfaces de la hotte avec de l’eau savonneuse chaude et un chiffon de coton

propre. N’utilisez pas de détergent abrasif ou corrosif, de laines d’acier ou de tampons à récurer; ils

égratigneront et endommageront les surfaces.

Pour les taches plus tenaces, utilisez du produit dégraissant liquide.

Après le nettoyage, vous pouvez polir les surfaces avec des produits de polissage à acier inoxydable non

abrasifs pour redonner de l’éclat et du lustre aux surfaces. Frottez toujours doucement, avec un chiffon de

coton propre, et dans le sens du grain.

N’utilisez pas de produits à blanchir au chlore ou d’agents nettoyants « orange ».

Filtres à tamis décoratifs

Le fi ltre à tamis installé par le fabricant a pour fonction de fi ltrer les résidus et la graisse de cuisson. Il ne

nécessite aucun remplacement sur une base régulière, mais doit être gardé propre.

Le fi ltre devrait être nettoyé chaque 30 heures d’utilisation ou une fois par mois.

Enlevez-le et nettoyez-le à la main ou au lave-vaisselle avec de l’eau tiède. Vaporisez avec du détergent pour

graisse et laissez tremper pour éliminer la saleté accumulée.

Séchez le fi ltre et réinstallez-le avant d’utiliser la hotte.

Remplacement du fi ltre à tamis

Si le fi ltre s’use en raison de son âge ou d’une usage

prolongé, remplacez-le avec la pièce portant le numéro

suivant :

Modèle de hotte: No de pièce Quantité à

commander

Tous les modèles ZGE 50200036 1

Pour enlever le fi ltre à tamis décoratif

Entretien – Nettoyage des fi ltres et de la hotte

1.Poussez sur les poignées à ressort

2.Tirez sur la poignée du fi ltre vers le bas pour enlever le

fi ltre

1

2

18

Page 45

Remplacement des ampoules

Attention : Les ampoules deviennent extrêmement chaudes lorsqu’allumées.

Veuillez NE PAS les toucher avant de les avoir éteintes et laissées refroidir. Le contact avec les

ampoules chaudes pourrait causer de sérieuses brûlures.

Assurez-vous que l’alimentation électrique est coupée et que les ampoules ne sont pas chaudes.

Enlevez les ampoules en les dévissant dans le sens contraire des aiguilles d’une montre. Note : les ampoules

ne se dévissent pas; après une rotation de 60 degrés, elles s’arrêtent et tombent de la douille.

Lorsqu’il est diffi cile de retirer les ampoules après un usage prolongé, fi xez une ventouse équivalant

approximativement au diamètre de l’ampoule ou utilisez des gants en latex et tournez.

Les ampoules de remplacement sont disponibles dans les magasins spécialisés en éclairage. Procurez-vous

des ampoules halogènes GU-10 50W (MR16).

Consultez la page 22 du présent guide pour obtenir les numéros de pièces Zephyr.

Entretien – Lumières

19

Page 46

www.zephyronline.com

Entretien – Schéma de câblage

20

Page 47

PROCÉDURES DE DÉPANNAGE POUR LA HOTTE GENOVA

Problème Cause Solution

Après

l’installation,

l’appareil ne

fonctionne pas.

Les lumières

fonctionnent,

mais le moteur

ne tourne pas.

L’appareil vibre. 1. Le ventilateur n’est pas bien fi xé en place. 1. Serrez solidement les vis du ventilateur en

Le moteur

fonctionne, mais

pas les lumières.

La hotte ne

fonctionne pas

bien.

Le fi ltre en métal

vibre.

La commande

à distance

radioélectrique

ne fonctionne

pas

1. Le bloc d’alimentation n’est pas allumé 1. Assurez-vous que l’alimentation du disjoncteur

et de l’appareil est allumée

2. La ligne électrique et le raccord de câble ne sont

pas correctement branchés

3. Les fi ls électriques du tableau de contrôle et de

commande sont débranchés

4. Les câbles du tableau de commande ne sont

pas assez serrés.

5. Tableau de contrôle/commande défectueux 5. Remplacez le tableau de contrôle/commande

1. Le moteur est défectueux, possiblement bloqué 1. Remplacez le moteur.

2. Le système de protection thermale détecte que

le moteur est trop chaud pour fonctionner et

l’éteint.

3. Le condensateur est endommagé. 3. Remplacez le condensateur

4. Le câble du ventilateur n’est pas branché 4. Assurez-vous que le câble du ventilateur est

2. La roue du ventilateur est endommagée. 2. Remplacez le ventilateur.

3. La hotte n’est pas bien fi xée en place. 3. Vérifi ez l’installation de la hotte.

1. L’ampoule halogène est défectueuse. 1. Remplacez l’ampoule halogène.

2. L’ampoule est desserrée. 2. Serrez l’ampoule.

3. 3.Les câbles du tableau de commande ne sont

pas assez serrés.

1. La hotte est possiblement installée trop haut par

rapport à la cuisinière.

2. Du vent provenant d’une fenêtre ou d’une porte

ouverte avoisinante nuit à la ventilation.

3. L’ouverture du conduit ou le conduit lui-même

est bloqué.

4. L’ouverture du conduit est contre le vent. 4. Ajustez l’orientation de l’ouverture du conduit.

5. Mauvaises dimensions de conduit d’aération. 5. Remplacez le conduit par un conduit adéquat.

1. Le fi ltre en métal est desserré. 1. Remplacez le fi ltre en métal.

2. L’attache à ressort ne fonctionne pas

convenablement.

1. La pile est morte 1. Remplacez-la pile à l’aide d’une pile A23 12v.

2. Mauvaise communication avec la hotte. 2. La commande à distance doit se trouver à

3. La commande à distance a perdu la

communication avec la hotte.

2. Vérifi ez que le branchement de l’appareil a été

fait correctement.

3. Assurez-vous que les fi ls électriques entre les

tableaux de contrôle et de commande sont

branchés convenablement

4. Assurez-vous que les câbles du tableau de

commande sont branchés convenablement.

2. Le moteur fonctionnera normalement lorsque

le système de protection thermale aura refroidi

branché dans le connecteur Molex

place.

3. Assurez-vous que les câbles du tableau de

commande sont branchés convenablement.

1. Ajustez la distance entre la surface de la

cuisinière et la base de la hotte entre 24” et

32”.

2. Fermez toutes les portes et fenêtres pour

éliminer les courants d’air.

3. Enlevez tout ce qui bloque l’ouverture ou le

conduit d’aération.

2. Ajustez la poignée jusqu’à ce que l’attache à

ressort fonctionne.

moins de 15 pi de la hotte.

3. Réinitialisez la hotte et la commande à

distance en coupant le courant du disjoncteur

pendant 5 minutes. Placez la commande à

distance sur le comptoir près de la hotte et

remettez le disjoncteur sous tension.

DÉPANNAGE

21

Page 48

www.zephyronline.com

DESCRIPTION NO DE PIÈCE

Pièces de remplacement

Ampoule GU10 50W (chaque) Z0B-0020S

Filtre à tamis décoratif 50200036

Accessoires optionnels

Ensemble de reprise d’air ZRC-00GE

Filtres à charbon de remplacement (chaque) Z0F-C0GE

Commande à distance radioélectrique 14000005

Pour commander des pièces, visitez-nous en ligne au www.zephyronline.com ou

communiquez avec nous par téléphone au 1-888-880-8368

Listes des pièces et des accessoires

22

Page 49

AGRAFEZ VOTRE REÇU ICI

Une preuve de la date d’achat originale

Garantie limitée

POUR OBTENIR DU SERVICE SOUS GARANTIE OU POUR TOUTE QUESTION LIÉE À L’ENTRETIEN,

veuillez communiquer avec nous au 1-888-880-8368

Zephyr Corporation (désigné aux présentes sous le nom de « nous ») garantit au premier acheteur (désigné aux présentes sous le nom de « vous » ou « votre ») de produits Zephyr (les « Produits ») que lesdits produits sont exempts de

défauts de fabrication ou de main-d’œuvre selon les conditions suivantes :

Garantie de trois ans sur les pièces : Garantie de trois ans à partir de la date d’achat originale du Produit. Nous

fournirons sans frais les Produits ou les pièces de remplacement qui comportaient des défauts de fabrication. Nous

pourrions choisir, à notre seule discrétion, de réparer ou de remplacer des pièces avant de prendre la décision de remplacer le Produit.

Garantie limitée d’un an sur la main-d’œuvre : Garantie d’un an à partir de la date d’achat originale du Produit. Nous

couvrirons sans frais les frais de main-d’œuvre afférents à la réparation du Produit ou des pièces de remplacement qui

comportaient des défauts de fabrication. Un an après la date d’achat originale, vous serez responsable de tous les frais

de main-d’œuvre associés à la présente garantie.

Exclusions de la garantie : Cette garantie ne couvre que la réparation ou le remplacement, à notre gré, de pièces ou

de Produits défectueux et ne couvre aucun autre coût afférent aux Produits, dont, sans s’y limiter, les frais liés : (a) à

l’entretien normal des Produits et au remplacement des pièces consommables, comme les ampoules, les filtres métalliques, les filtres à charbon et les fusibles; (b) à tout Produit ou pièce ayant été endommagé durant le transport ou étant

le résultat d’un mauvais usage, d’une négligence, d’un accident, d’une installation incorrecte ou ne respectant pas les

notices d’installation recommandées, d’un entretien ou d’une réparation inapproprié (dont ne nous sommes pas responsables); (c) à une utilisation commerciale ou ne correspondant pas à l’utilisation pour laquelle les Produits sont conçus;

(d) à l’usure naturelle du fini, à l’usure due à un entretien inadéquat, à l’utilisation de produits nettoyants corrosifs ou

abrasifs, de tampons nettoyeurs et de produits de nettoyage pour le four; (e) aux éclats, entailles ou fissures résultant

d’un abus ou d’une mauvaise utilisation du Produit; (f) aux déplacement d’un technicien de service à votre domicile pour

vous montrer comment utiliser les Produits; (g) aux dommages causés par un accident, un incendie, une inondation ou

un cas fortuit. Si vous vous trouvez à l’extérieur du territoire que nous desservons, des frais supplémentaires pourraient

s’appliquer pour la livraison des produits à nos points de service désignés pour une réparation sous garantie ou vous

pourriez avoir à débourser les frais de déplacement du technicien à votre domicile pour que le Produit soit réparé, enlevé

ou réinstallé. Un an après la date d’achat originale du Produit, vous êtes également responsable de tous les frais de

main-d’œuvre associés à la présente garantie.

est nécessaire pour obtenir du service

lorsque le produit est sous garantie

Restrictions de la garantie. NOTRE OBLIGATION DE RÉPARER OU DE REMPLACER, À NOTRE GRÉ, LE PRODUIT

CONSTITUE VOTRE SEUL ET UNIQUE RECOURS SOUS LA PRÉSENTE GARANTIE. NOUS NE NOUS PORTONS

PAS RESPONSABLES POUR TOUT DOMMAGE INDIRECT, ACCESSOIRE OU PARTICULIER RÉSULTANT OU AYANT

UN LIEN AVEC L’UTILISATION OU LE RENDEMENT DES PRODUITS. LES GARANTIES EXPRESSES DE LA SECTION PRÉCÉDENTE SONT EXCLUSIVES ET TIENNENT LIEU DE TOUTE AUTRE GARANTIE EXPRESSE. PAR LES

PRÉSENTES, NOUS REJETONS ET EXCLUONS TOUTE AUTRE GARANTIE EXPRESSE POUR LES PRODUITS ET

TOUTES LES GARANTIES TACITES PRÉVUES PAR LA LOI, DONT CELLES RELATIVES À LA QUALITÉ

MARCHANDE OU À L'ADÉQUATION DU PRODUIT POUR UNE UTILISATION PARTICULIÈRE. Certains États ou