Page 1

Okeanito

CO K-E36SX

CO K-E42SX

CO K-E48SX

www.zephyronline.com

Use, Care, and Installation Guide

Model number:

Serial number:

Date of Purchase:

Sales Dealer:

©

MAY07.0101

Zephyr Corpo ration.

Page 2

www.zephyronline.com

Page 3

SAFETY NOTICE ..............................................

LIST OF MATERIALS .......................................

INSTALLATION

Ducting Calculation Sheet ...............................

Mounting Height and Clearance .....................

Ducting ..................................................................

Specifications .......................................................

Internal Blower ....................................................

Preparing Hood for External Blower ..............

Mounting the Hood ............................................

FEATURES & CONTROLS

Controls Overview ..............................................

MAINTENANCE

Cleaning .................................................................

Lights .......................................................................

2

3

4

5

6

7

8 - 9

10 - 11

12 - 14

15 - 16

17

18

Ta ble of C o nte nts

TROUBLE SHOOTING ......................................

LIST OF ACCESSORIES/PARTS .......................

19

20

1

Page 4

READ AND SAVE THESE INSTRUCTIONS

www.zephyronline.com

WARNING

TO REDUCETH E RIS K O F F IR E O R E LE C TR IC SHOC K, DO N OT USE THIS FAN W ITH ANY S O LID-S TATE

SPE E D CONTROLDEVICE.

WARNING

TO RE DUCE TH E R IS K O F F IR E, E LE CTR IC SH O C K, O R INJU RY TO P ER SONS, O B S E RVE TH E FO LLO W ING:

a. Use this unit only in the manner intended by the manufacturer, If you have questions, contact the manufacturer.

b. Before servicing or cleaning unit, switch power o at service panel and lock the service disconnecting means to prevent power from being

switched on accidentally.

When the service disconnecting means cannot be locked, securely fasten a prominentwarning device, such as tag, to the service panel.

CAUTION

For General Ventilating Use Only. Do not Use to Exhaust Hazardous or Explosive Materials and Vapors.

Take care when using cleaning agents or detergents.Suitable for use in household cooking area.

WARNING

DUCE

TO RE

a. Never leave surface units unattended at high settings. Boilovers cause smoking and greasy spillovers that may ignite. Heat oils slowly on low

or medium settings.

b. Always turn hood ON when cooking at high heat or when cooking ambeing food (i.e. Crepes Suzette, Cherries Jubilee, Peppercorn

Beef Flambe)

c. Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or lter.

Important safety Notice

d. Use proper pan size. Always use cookware appropriate for the size of the surface element.

TH E R IS K O F A RA NG E TO P GR EAS E FIR E:

WARNING

TO RE DU CE THE R IS K O F INJURY TO P ERSON S IN THE EV E NT O F A RA NG E TO P G R EAS E FIR E, O B S ERVE THE FO LLO W ING :

a. SM OTHER FLA MES with a close-tting lid, cookie sheet, or metal tray, then turn o the burner. B E C ARE F UL TO P REV E NT BUR NS.

If the ames do not go out immediately,E VACUATE AND C ALL T H E F IR E DE PARTME NT.

b. N EVE R PIC K UP A FLAMI NG PAN - You may be burned.

c. DO NOT USE WATE R, including wet dishcloths or towels - a violent steam explosion will result.

d. Use an extinguisher ON LY if:

1. You know you have a class AB C extinguisher, and you already know how to operate it.

2. The re is small and contained in the area where it started.

3. The re departmentis being called.

4. You can ght the re with your back to an exit.

5. Based on “Kitchen Fire Sa fety Tips” published by NF PA.

WARNING

TO R EDUC E TH E R IS K O F FIRE, E LEC TR IC SHOCK OR INJURY TO PER SONS, OB S E RVE TH E FO LLOW ING :

a. Installation Work and Electrical Wiring Must be Done by Qualied P erson (s) In Accordance with all Applicable Codes and Standards,

IncludingFire-Rated Construction.

b. Sucient air is needed for proper combustion and exhausting of gases through the ue (chimney) of fuel burning equipmentto prevent back

drafting. Follow the heating equipmentmanufacturer’s guideline and safety standards such as those published by the National Fire Protection

Association (N FPA), and the American S ociety for Heating, Refrigeration, and Air ConditioningEngineers (ASHR AE) and the local code authorities.

c. When cutting or drillinginto wall or ceiling, do not damage electrical wiring and other hiddenutilities.

d. Ducted fans must always vent to the outdoors.

WARNING

TO REDUCETH E R IS K O F FI R E, US E O NLY ME TAL DUC TW O RK.

CAUTION

To reduce risk of re and to properly exhaust air, be sure to duct air outside - Do not vent exhaust air into spaces within walls or ceilings or into

attics, crawl spaces or garages.

CAUTION

To Reduce the Risk of Fire and Electric Shock, Install This Range Hood Only with Remote Blower Models C B E-1000 Rated

Maximum6.2 amp, 120 Vac 6 0Hz or Integral Blowers Manufactured by Zephyr Ventilation, Models C B I-6 00.

2

Page 5

MODEL: COK-ExxS

1 - Hood

1 - Bae Filter (2 on 48” model)

2 - 50W 120V Halogen Light Bulbs GU-10

2 - 40W 120V Appliance Bulbs

1 - Utensil Rail

2 - Telescopic Duct Covers

1 - Ceiling Mounting Bracket (pre attached to duct cover)

1 - Wall Mounting Bracket

1-HARDWAREPACKET

7 - 2” Wood Screws

7 - Anchors

7 - 1/2” Washers

4 - 1/2” Screws 5x15mm

4 - 10mm Washers

1 - SMALL HARDWARE PACKET

1 - T ool

3 - Short Set Screws (4 on 48” Model)

1 - HARDWARE PACKET, EXTERNAL BLOWER KIT

1 - 8” Collar

1 - External Blower Wiring Box with Wires

10 - 1/2” Self Tapping Screws

10 - 4mm Internal Diameter Washers

List of Materials

NO DUCTING IS PROVIDED

EXTERNAL AND INTERNAL BLOWER SOLD SEPARATELY

Make sure to remove the protective lm o of the hood before installation in order to make removal of the lm

easier. Be careful not to scratch the stainless steel while installing.

3

Page 6

www.zephyronline.com

Duct pieces

31/4”x10”

Rect.,

straight

7” Round,

straight

7” Round,

straight

31/4”x10”

0

Rect. 90

elbow

31/4”x10”

0

Rect. 45

elbow

31/4”x10”

0

Rect. 90

at elbow

31/4”x10”

Rect.

wall cap

with damper

Equivalent number

length x used =

1 Ft. x ( ) =

1 Ft. x ( ) =

1 Ft. x ( ) =

15 Ft. x ( ) =

9 Ft. x ( ) =

24 Ft. x ( ) =

30 Ft. x ( ) =

To t a l

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Duct pieces

6” Round

wall cap

with damper

6” Round,

roof cap

6” round to

31/4”x10”

rect.

transition

6” round to

3 1/4” x 10”

rect.

transition

0

elbow

90

7” Round,

900elbow

7” Round,

450elbow

7” Round

wall cap

with damper

Equivalent number

length x used =

30 Ft. x ( ) =

30 Ft. x ( ) =

1 Ft. x ( ) =

16 Ft. x ( ) =

15 Ft. x ( ) =

9 Ft. x ( ) =

30 Ft. x ( ) =

To t a l

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

31/4”x10”

Rect. to

6” round

transition

31/4”x10”

Rect. to

6” round

transition

0

elbow

90

5 Ft. x ( ) =

15 Ft. x ( ) =

Installation - Ductwork Calculation S heet

6” Round,

0

90

elbow

6” Round,

0

elbow

45

Maximum Duct Length:

the total duct length ofa31/4”x10”rectangular, 6” or 7”

diameter round ductshould not exceed 100 equivalent feet.

15 Ft. x ( ) =

9 Ft. x ( ) =

Subtotal column 1 =

For satisfactory air movement,

Ft.

Ft.

Ft.

Ft.

Ft.

7” Round,

roof cap

7” round to

31/4”x10”

rect.

transition

7” round to

3 1/4” x 10”

rect.

transition

900elbow

30 Ft. x ( ) =

8 Ft. x ( ) =

15 Ft. x ( ) =

Subtotal column 2 =

Subtotal column 1 =

Total ductwork =

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

4

Page 7

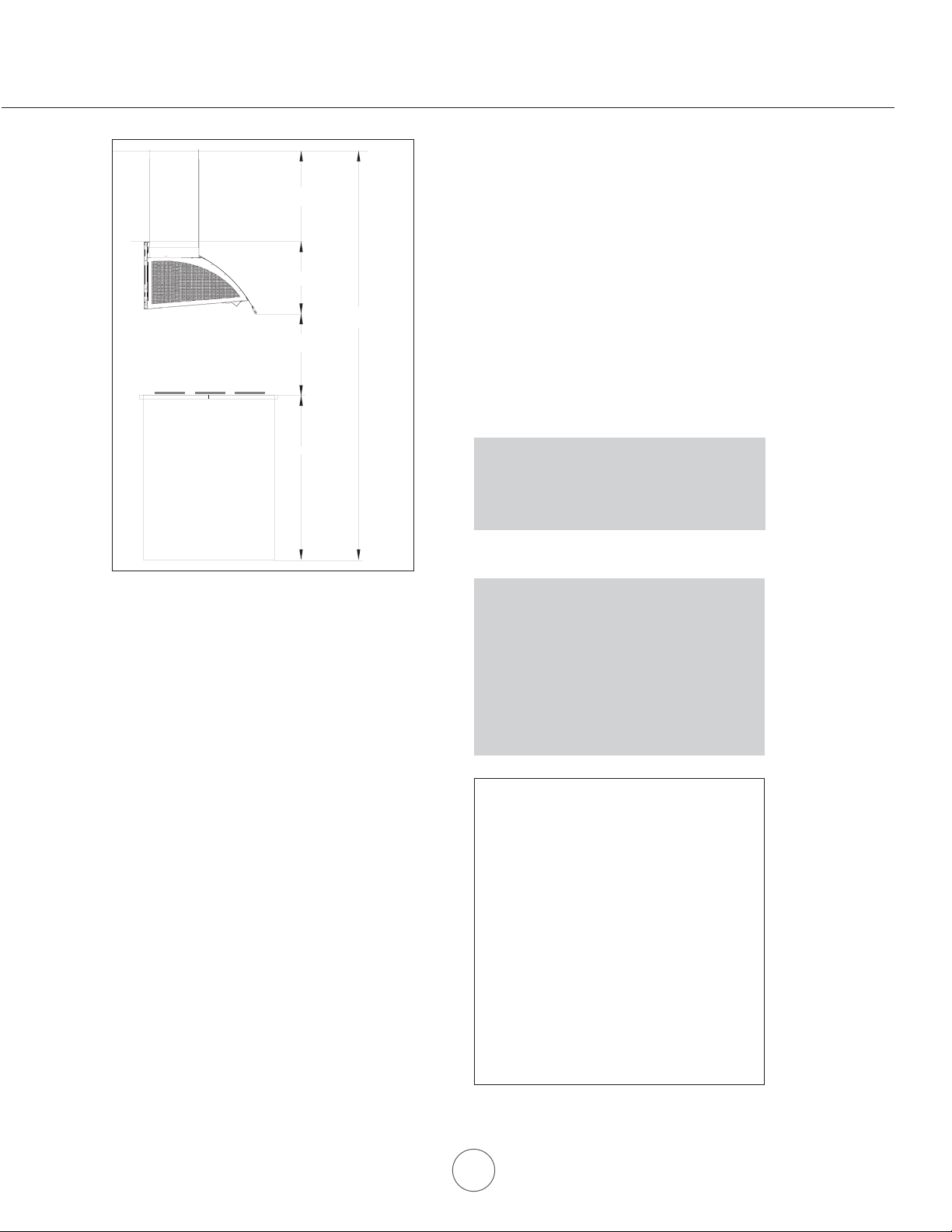

”

Minimum mount height between range top to hood bottom should be no less than 28".

Min 32"-Max 52"

14 1/2"

Min 96"-Max 124

Min 28"-Max 36"

36"

DUC T IN G

A minimum of 6” round or 3-1/4 x 10"

rectangular duct work must be used to maintain

maximum air ow eciency with the 600 cfm

internal blower. A minimum of 10"to 8” round

used with the 1000 cfm external blower.

Always use rigid type metal duct work only.

Flexible ducts could restrict air ow by up

to 50%.

Use calculation worksheet to compute total

duct work.

must be

Maximum mount height should be no higher than 36".

It is important to install the hood at the proper mounting

height. Hoods mounted too low could result in heat

damage and re hazard; while hoods mounted too high

will be hard to reach and will loose its performance and

eciency.

If available, also refer to range manufacturer's height

clearance requirements and recommended hood

mounting height above range. Always check your local

codes for any differences.

*Minimum ceiling height of 96”. Hood

mounted at 28” above cooking surface.

** Maximum ceiling height of 124". Hood

mounted at 36" above cooking surface.

Minimum Duct Size:

Round - 6” minimum at 600 cfm

Round - 10" to 8” minimum at 1000 cfm

Rect angular - 3 1/4” x 10” minimum only if

using internal blower at 600 cfm. Using

rectangular ductwork will require a transition

adapter (not provided, but readily available at

most hardware stores).

DAMAGE-SHIPMENT / INSTALLATION:

• Please fully inspect unit for damage

before installation.

Installation - Mounting Height & Clearance

ALWAYS, when possible, reduce the number

or transitions and turns. If a reducer is used,

install a long reducer instead of a pancake

reducer. Reduce duct size as far away from

opening as possible.

If turns or transitions are required:

Install as far away from opening and as far

apart, between 2, as possible.

• If the unit is damaged in shipment , return

the unit to the store in which it was bought

for repair or replacement.

If the unit is damaged by the customer ,

•

repair or replacement is the responsibility

of the customer.

• If the unit is damaged by the installer (if

other than the customer), repair of replace

ment must be made by arrangement

between customer and installer.

5

Page 8

www.zephyronline.com

WARNING FIRE HAZARD

NEVER exhaust air or terminate duct work into spaces between walls, crawl spaces, ceiling, attics, or garages. All exhaust must

be ducted to the outside.

Use single wall rigid Metal ductwork only.

Fasten all connections with sheet metal screws and tape all joints w/ certified Silver Tape or DuctTape.

Some Ducting Options:

Roof Pitch w/

Flashing & Cap

Installation - Ducting

side wall

cap with

gravity

damper

External

Blower

External

Blower

Soffit or crawl space

Soffit or crawl space

6

Page 9

19 3/4”

19 3/4”

10”

16 5/8”

13 3/8”

RIHPEZYBNGISEDGNEHCOGOL

95°

11 7/8”

14 1/2”

36”, 42”, 48”

22 5/8”

5" - 36 "

8" - 42"

31/2"-48"

6"

Installation - Specifications

15”

4/1

”

R

14

O

”8/37

”61/5

R

“1

8/

”

4

1

1

/

23

”

8 5/16”

9 3/16”

1

5

/

3

2

”

7

Page 10

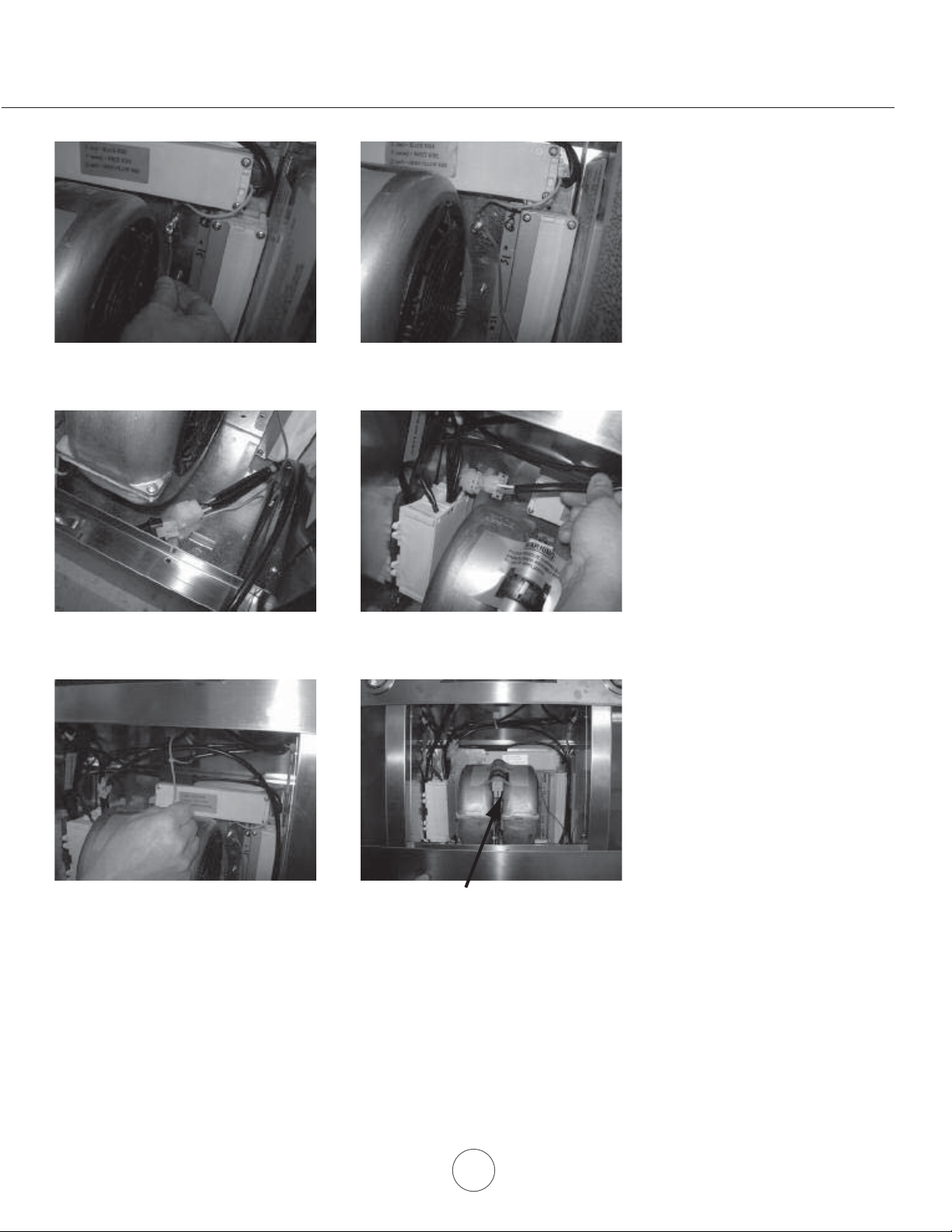

www.zephyronline.com

ATTENTION

The following are intructions for installing internal blower model CBI-600. For instructions on preparing for external

blower model CBE-1000 please turn to page “10”. Before installing, verify that motor spins freely.

The internal blower kit consists of the blower

and capacitor box with wiring.

Installation - Internal Blower

2. Att ach blower to ange as shown using

the provided 1/2” 5x15mm screws with

washers.

1. Position blower as shown.

3. P osition capacitor box as shown.

4. Secure capacitor bo x to hood using the

provided 1/2” self tapping screws.

8

Page 11

5. Remove existing grounding screw and

attach grounding wire from capacitor box.

7. Attach short capacitor connector to blower

connector.

6. Re-attach grounding screw to nish

installation of capacitor box. Refer to Fig-A on

previous page.

Installation - Internal Blower

8. Att ach long capacitor connector to control

board connector.

9. Use plastic tie to hold wiring together. 10. Remove wood block

Final view of internal blower install.

Continue to page “12” for hood installation instructions.

9

Page 12

www.zephyronline.com

ATTENTION

The following are intructions on preparing your hood for installation with external blower model CBE-1000.

For instructions on installing internal blower model CBI-600 please turn to page “8”.

NOTE: Please refer to the CBE-1000 manual for external blower mounting instructions.

The external blower kit consists of an 8”

collar, and external blower wiring box. The

external blower is purchased separately.

2. Remove internal ange from hood. 3. Position 8” collar as shown.

1. Remove screws from internal ange.

Installation - Preparing E xternal B lower

4. Att ach 8” collar to hood as shown using

provided 1/2” self t apping screws.

5. Attach external blower wiring box to top of

hood using provided 1/2” self t apping

screws.

10

Page 13

6. Position cover onto external blower

wiring box.

7. Secure cover to box with provided screw.

8. Attach connector from external blower

wiring box to control board box connector

inside hood.

10. Final view of external blower preparation

9. Attach grounding wire from external blower

wiring box to grounding screw of the junction

box. Refer on Fig-A in diagram below .

Installation - Preparing E xternal B lower

Continue to page “12” for hood installation instructions.

For external blower installation please refer to the manual

included with the external blower.

11

Page 14

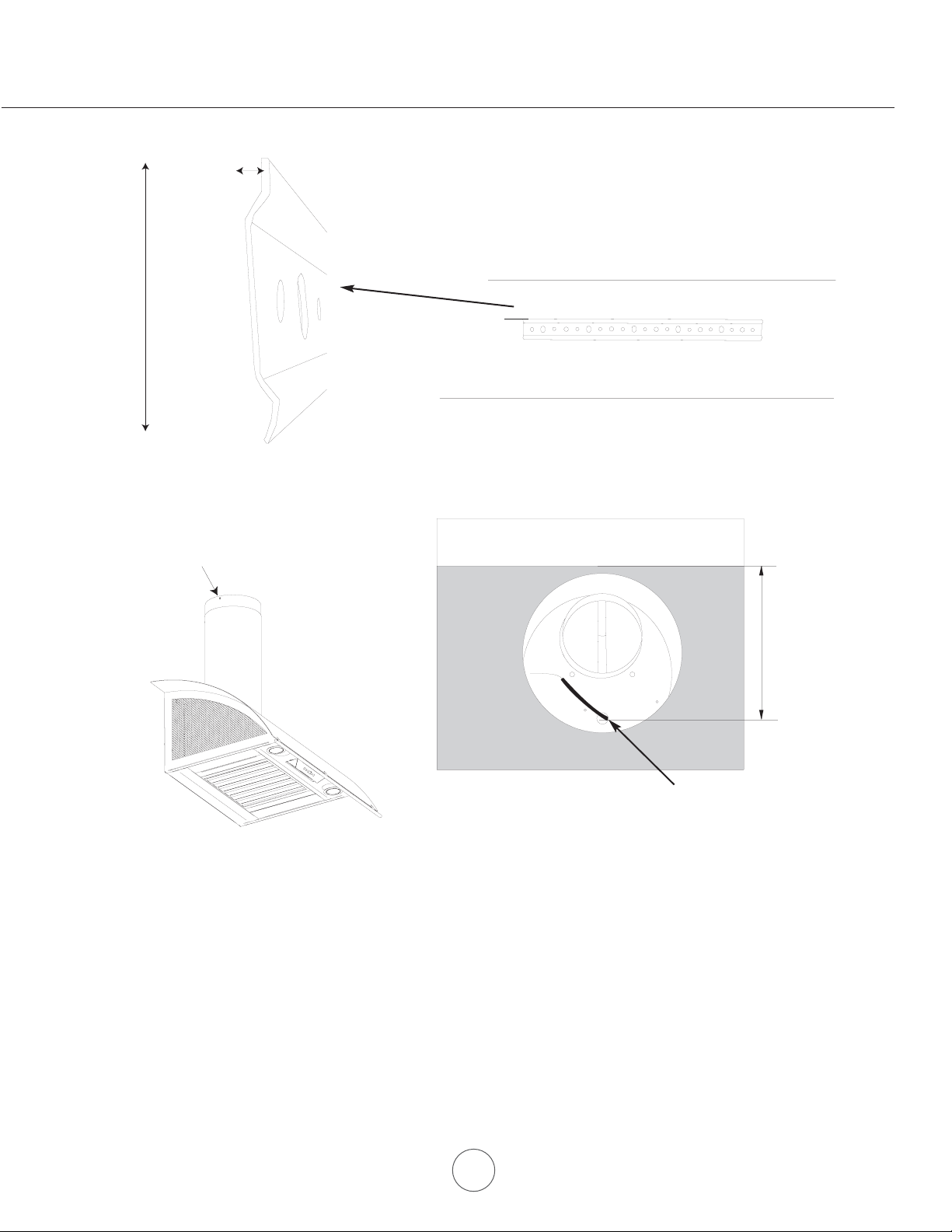

Duct Cover

Ceiling Bracket

B

www.zephyronline.com

C/L

Duct Cover

Ceiling Bracket

-noitallatsnI dooHgniraperP

C

A

1. Measure from cooking surface to hood bottom, level and mark line A.

2. Plum and mark center line.

3. Mark mounting height, line B (14 1/2” from line A). This is the top of the hood.

21”

C/L

14 1/2”

7 1/2”

min 28”

max 36”

C/L

Attach screws to

ceiling bracket

4. Measure up, 7 1/2” from line A and mark mounting spread from C/L Line C. (21”)

5. Follow center line up to the ceiling, measure and mark 6” from the wall.

on the center line. This is where the

6. Place duct cover ceiling bracket onto ceiling and mark the (2) holes where screws will be attached. If attaching

bracket to drywall only, drill and insert provided anchors into the marked holes. Cut out inside diameter of the

ceiling bracket to fit the 6” or 8” round duct work. Attach bracket to ceiling with (2) screws provided.

7. Prepare duct work and electrical.

All Electrical work must be performed by a qualified electrician or person with similiar

GNINRAW-LACIRTCELE

technical know and background.

For personal safety, remore house fuse or open circuit beaker before beginning installation.

Do not use extension cords or adapter plug with this appliance.

Follow National Electrical Codes or prevailing local codes and ordinances.

Electrical Supply:

This appliance requires a 120V 60Hz electrical supply, and connected to an individual, properly grounded branch

circuit, protected by a 15 or 20 ampere cicuit breaker or time delay fuse. Wiring must be 2 wire with ground.

Please refer to Electrical Diagram labeled on product.

center of the duct cover ceiling bracket will mount.

Make sure the spot you mark is still

12

Page 15

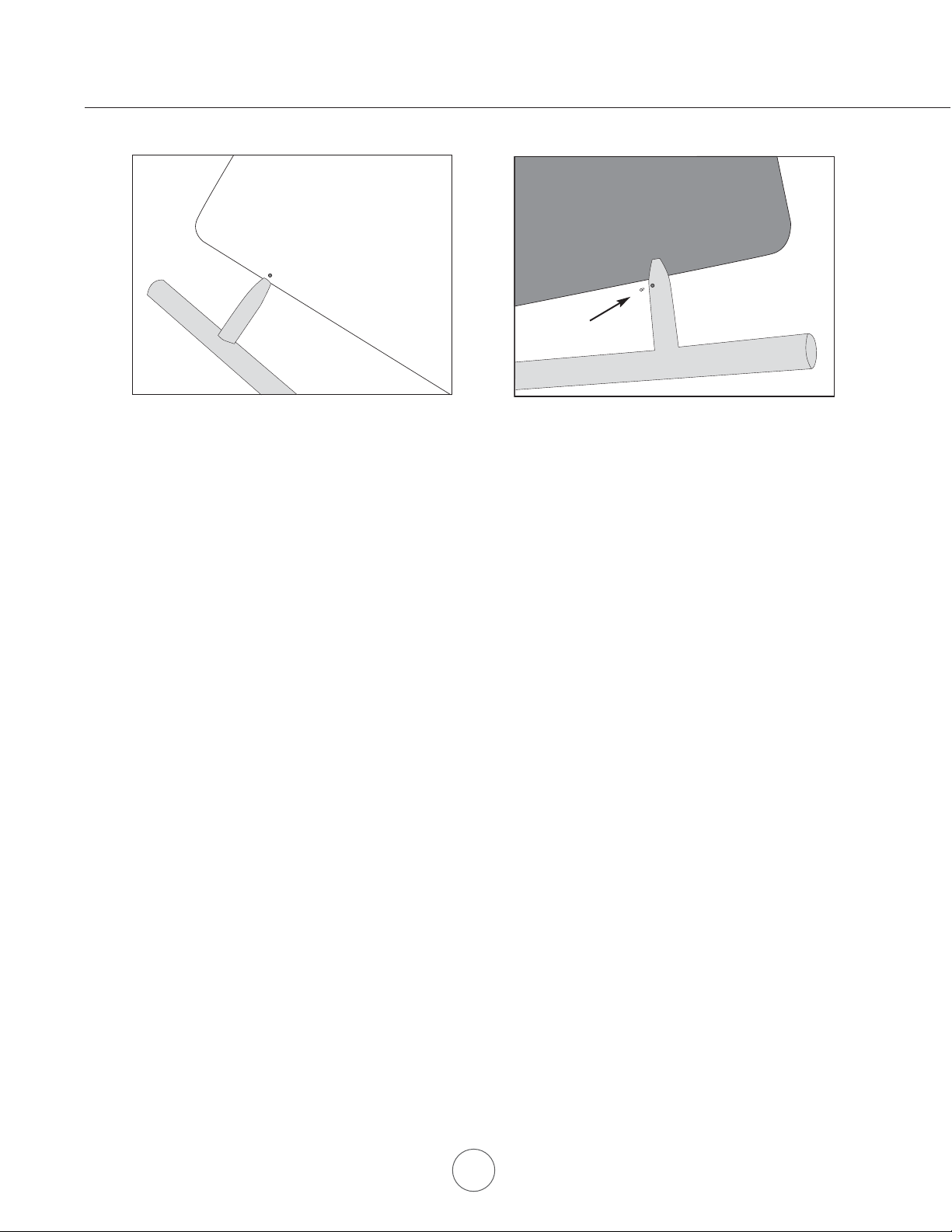

Top

gap between

bracket and

wall

Bottom

Attach screws to both

sides of the duct covers

and secure to ceiling bracket.

B

C

A

10”

Electrical

1. Place wall brac

sure bracket is attached to wall as shown in the diagram. The top of the wall bracket should have a gap between

it and the wall. The bottomshould be ush against the wall. Use (3) 2” wood screws to attach bracket to wall. Use

anchors if not mountingto studs.

2. Lift hood onto wall bracket, there is a lip on the back of the hood which will rest on the wall bracket. Secure in

place by *screwing (2) screws with washers throughhood into the wall. There are two holes at the bottom inside

the hood in which to do this.

3. Place telescopic duct covers on top of hood and extend top duct cover to the ceiling bracket. Attach duct cover to

ceiling bracket with the providedscrews.

4. Run duct work down to top of motor. Attach electrical wiring from ceiling to wiringon top of motor housing. (slide

duct cover up towards ceiling to gain access to the motor housing)

ket on line C. Position top of wall bracket so it is even with the 21” mounting spread. Make

Installation - Mounting Hood

* Note: If installing onto drywall only with no wall studs present, attach E Z anchors (not provided) into the wall.

Please see page 15 for external blower installation instructions.

13

Page 16

www.zephyronline.com

Set

screw

kcaBtnorF

1. Attach utensil rail to hood canopy. A small hole has been pre-drilled into the canopy to provide a starting point

to attach the rst utensil rail post. After the rst post is lined up with the hole, gently slide the rest of the rail onto

the canopy. (note: be careful not to scratch the stainless steel when performing this step, this is why there is a

starter hole).

2. A ttach a short set screw into eac h post in order to hold utensil rail onto canopy.

Installation - Attaching Utensil Rail

14

Page 17

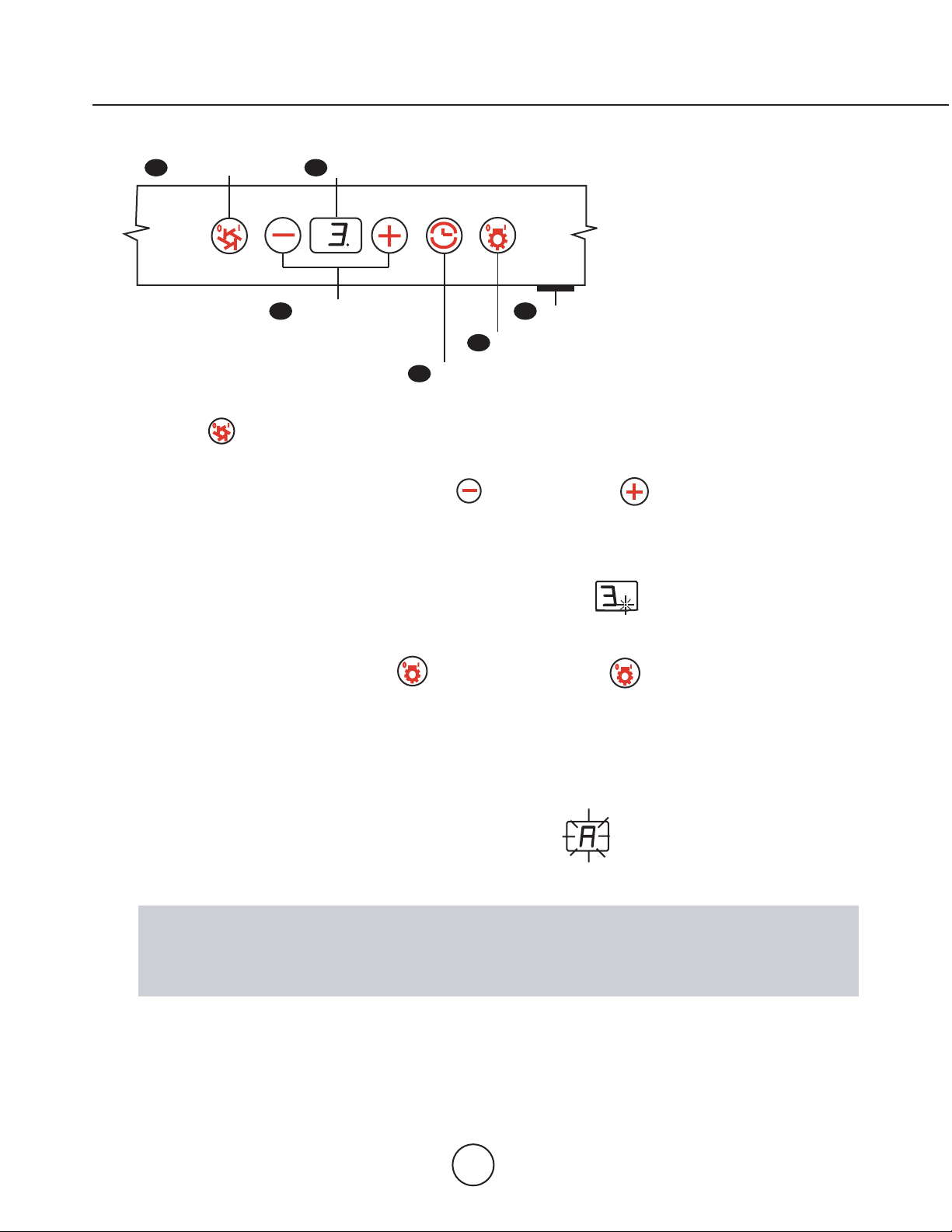

o

d

,

p

.

www.zephyronline.com

1

Blower On/Off

5

Display

2

Adjust 3 Speed Levels

(Speed level, Delay O Indicator, Filter Clean/Change)

6

Mood Light On/Off

4

Lights On/Off/Hold to Dim

3

15 Min Delay Off

1. Blower On/Off

By pressing , the blower is switched On and Off.

2. Speed Selection

The 3 speed levels are selected by pressing to decrease and to increase speed level.

The display indicates level selected.

3. Delay Off

This is used for programmed shut down of blower and lights 15 minutes after the function is activated.

Press once, a dot flashes in the lower right hand side of display indicating the function is on.

The hood will completely shut down in 15 minutes.

4. Lights On/Off/Dim

Switch lights On and Off by pressing once. T

im lights

ress again

5. Advance Display Functions

6. Mood Light On/Off

This switch turns the mood lights On and Off. Press IN to turn on, press again to turn OFF.

Filters Clean Reminder (Metal):

After every 30 hours of use, the display will start flashing an reminding you to clean the baffle

filters from residue and possible clogs.

Features & Controls - Touch Controls & Features

The standard Baffle Filters are required to be cleaned frequently and as recommended in order to maintain

blower efficiency. If improperly maintained, residue from cooking will sift through filters and cause damage to

hood blowers and other sensitive components; and possibly clog duct work and create a fire hazard.

15

Page 18

Filter Clean Reminder (Standard Bae Filters tted):

A set of bae lters are tted by the factory. These Bae Filters are intended to lter out residue from cooking. They

need not be replaced on a regular basis but are required to be kept clean. The Filter Clean Reminder function in

the microprocessor will automatically indicate by a ashing when the metal lters need to be cleaned after

every 30 hrs. of use. Filters can be cleaned by hand with non-abrasive soap or in a dishwasher.

Filter Clean Reminder:

When ashes on display, the bae

lters installed are required to be cleaned.

This will occur after every 30 hours of use.

Re-setting Function:

Reset the Filter Clean Reminder timer when

lters are cleaned and re-installed (with

hood o). Press and hold for approx.

5 seconds, the display will appear; hold for

approximately 5 seconds until on display disappears . The Filter Clean

Reminder function is now re-set and a new

30 hours elapse cycle is initiated.

Clean Filters

To Reset

hold 5 secs.

display <A> flashes

display from <C> to < >

16

Features & Controls - B affle Filters Change Indicator

Page 19

S

:

Clean

y

withhot

s

y

waterand

clean

cotto

ot

corrosive

orabrasive

t

,

orstee

l

ds

c

s

t

cand

d

.

er

so

.

A

fte

g,

youmay

e

sta

ess

stee

/

c

d

out

the

sta

ess

uster

and

g

ean

cotto

,

and

withthe

g

.

o

t

c

g

chlo

ea

cnot

s.

aeilters

he

f

y

are

d

to

lteroutresidue

and

g

y

eednot

d

on

a

s

are

d

to

.

lters

should

cleaned

afte

3

0rs

of

se.se

th

on

th

ls

tod

e

when

e

cl

e

lter

g

towards

u

and

e

and

clean

d

o

e

.

S

y

d

etosoak

d.

s

and

Should

lters

wear

out

due

to

age

and

www.zephyronline.co

m

”

urface

eriodicall

/scouringa

woo

Forheavi

rcleanin

rain. Alwaysscrubightlywithcl

D

B

eMetalFilterstted

n

t

require

i

u

contro

mov

pullingdown (Fig. 1).

aintenance

oap

cra

il

liquiddegreaser

n-abrasiv

anyroduc

replace

e

eptclean

eFilterCleaneminder function

etermin

slidin

ontainin

t

actor

reasefrom cooking.The

egular

revery

lters requir

rinel

i

yo

amagesurface

inl

ncloth

ntende

e

eaning.

ncloth.n

l polish

leaners,toolishan

“orange”cleaner

2 3/4

rain

detergen

inl

l

l

andles

mov

pra

egreasingdetergentandeav

eavilysoile

rylter

eplacingaeFilte

use, contact Zephyr to purchase replacements.

y

n

rindishwash

e-installbefore usingood.

s

Fig. 1)

Page 20

Replacing Light Bulbs:

CAUTION: Light bulbs become extremely hot when turned on. DO NOT touch bulbs until switched o

and cooled. Touching hot bulbs may cause serious burns.

Make sure all power is turned o and bulbs are not hot.

Remove bulb by pressing both ends of the metal retaining clip together, the light socket will now protudefrom the hood

allowingyou to remove the bulb.(B e careful when releasing retain clip as it is under pressure to hold it in place)

Replacement halogen bulbs are available at most stores which sell light bulbs. Purchase type GU-10, 120 V, 50 W.

Press together

to release clip

HalogenBulb

To replace mood lightingbulb, remove bae lter from hood. Lift up the metal plate which is inside the hood on the left

and right sides. It is held on with two philipshead screws. Unscrew mood lightingbulb counter-clockwise and replace

with a standard 4 0W, 125V-1 3 0V medium base bulb.

Maintenance - Lights

MetalPlate

MoodLightingBulb

18

Page 21

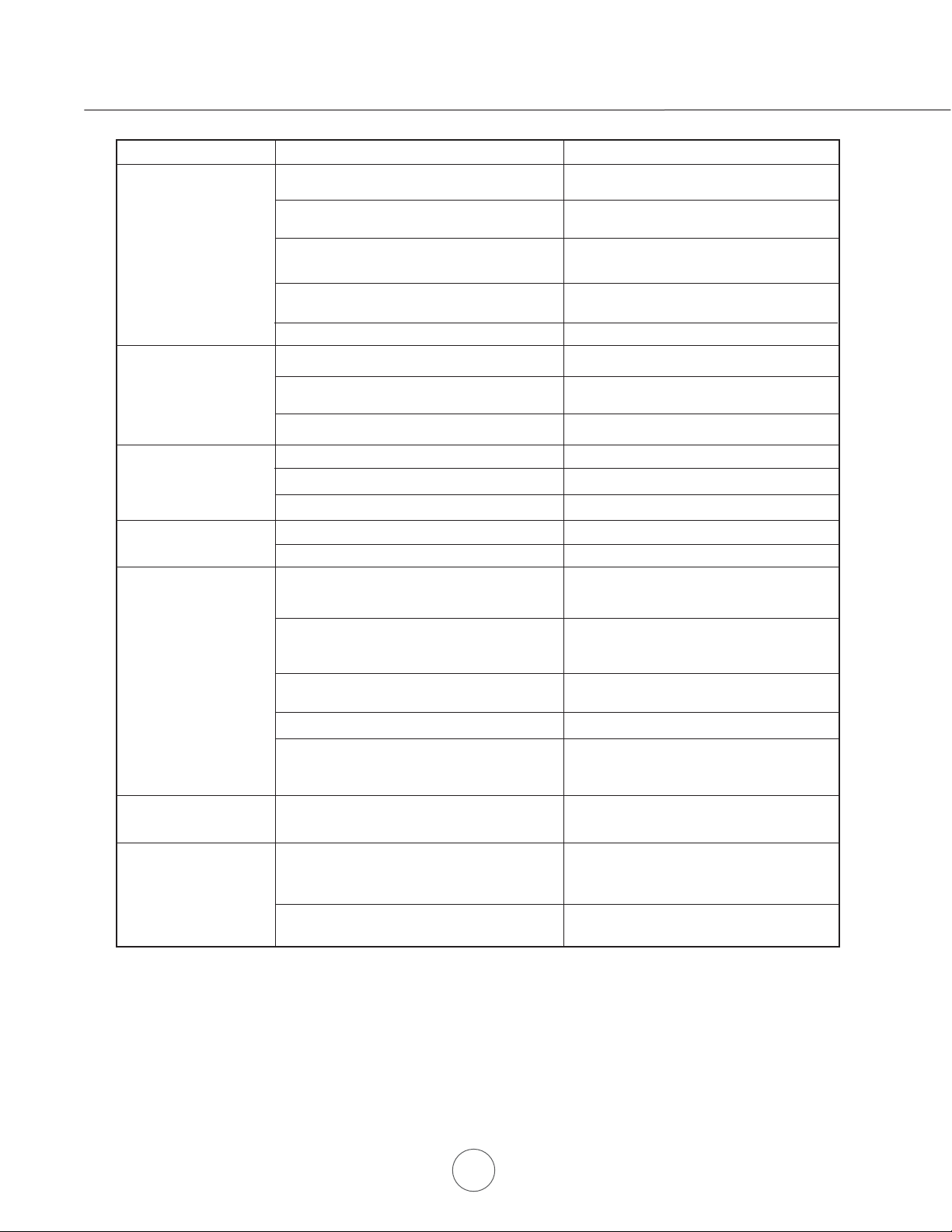

After installation, the unit

doesn’t work?

1. The power source is not turned ON.

2. The power line and the cable locking connector is

not connecting properly.

www.zephyronline.com

odottahWesuaCeussI

1. Make sure the circuit breaker and the unit’s

power is ON.

2. Check the power connection with the unit is

connected properly.

Light works, but motor is

not turning.

Trouble S hooting

The unit is vibrating.

The motor is working,

but the lights are not.

The hood is not venting

out properly.

3. The switch board and control board wirings

are disconnected.

4. On the switch board, Black/White wire of White

wire is disconnected.

5. The switch board or control board is defective.

1. The motor is defective, possible seized.

2. The thermally protected system detects if the motor

is too hot to operate and shuts the motor down.

3. Damaged capacitor.

1. The motor is not secure in place.

2. Damaged blower wheel/makes noise.

3. The hood is not secured in place.

1. Defective halogen bulb.

2. The light bulb is loose.

1. T he hood might be hanging too high from the

cook top.

2. The wind from the opened windows or opened

doors in the surrounding area are a ecting the

ventilation of the hood.

3. Blocking in the duct opening or ductwork.

4. The direction of duct opening is against the wind.

3. Make sure the wirings between the switch

board and control board are connected properly.

4. Make sure the Black/White wire or White wire

connects properly.

5. Change the switch board or control board.

1. Change the motor.

2. T he motor will function properly after the

thermally protected system cool down.

3. Change the capacitor.

1. Tighten the motor in place.

2. Change the motor.

3. Check the installation of the hood.

1. Change the halogen bulb.

2. Tighten the light bulb.

1. Adjust the distance between the cook top

and the bottom of the hood within 24” and

32” range.

2. Close all the windows and doors to eliminate the

outside wind ow.

3. Remove all the blocking from the duct work or

duct opening.

4. Adjust the duct opening direction.

Filter is vibrating.

After hood has been

installed for a period of

time, it stopped working.

5. Using the wrong size of ducting.

1. Bae lter is loose.

1. Control board needs to be reset.

1. Defective control board.

5. Change the ducting to at least 6” or higher

for the internal blower and 8” or higher for the

external blower.

1. Remove lter and reinstall it or change the

bae lter.

1. Turn circuit breaker which controls the hood o

for at least 15 minutes.

Turn it back on and this should x the problem.

1. Replace control b oard.

19

Page 22

Part Description Part#

Halogen Bulb G U-10, 120V, 50W Z0B-0020

Incadescent Bulb T29 127V 40 W Z0B-0003

Accessory Description Part#

Internal Blower, 600 cfm CBI-600

External Blower, 1000 cfm CBE-1000

Duct Cover Extension Kit Z1C-00OK

www.zephyronline.com

List of Parts and Accessories

20

Page 23

www.zephyronline.com

TO OBTAIN SERVICE UNDER WARRANTY

or any Service Related Questions, please call:

1-888-880-8368

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warranty.

Warranty

TO OBTAIN SERVICE UNDER WARRANTY: You must present proof of original purchase date.

Please keep a copy of your dated proof of purchase (sales slip) in order to obtain service under warranty.

One Year Service Repair Warranty:

For one year from date of original purchase, we will provide free of charge, service labor to repair any failed parts or

components due to manufacturing defects.

Two Years Parts Warranty:

For two years from date of original purchase, we will provide free of charge, nonconsumable replacement parts or

components that failed due to manufacturing defects. Consumable parts not covered by this warranty include: Light Bulbs,

Metal and Charcoal Filters.

Who is Covered:

This warranty is extended to the original purchaser for products purchased for ordinary home use in the 48 mainland states,

Hawaii and Washington D.C. In Canada and Alaska, this warranty is Limited. There might be costs associated with

shipping the products to our designated service locations or you might need to pay service technician's travel costs, to have

the appliance repaired in-home.

This Warranty will be Voided when:

Product damaged through negligence, misuse, abuse, accident. Improper installation and failure to follow installation instructions. When product is used commercially or other than its intended purpose. Damaged because of improper connection with

equipment of other manufacturers. Repaired or modified by anyone other than Zephyr's Authorized Agents.

What is Not Covered:

Consumable parts such as light bulbs, filters, and fuses. Services outside of service area and the labor cost incurred in

connection with the removal, shipping and reinstallation cost, nor does it cover any other contingent expenses. The natural

wear of finish, and wear due to improper maintenance, use of corrosive and abrasive cleaning products, pads, and oven

cleaner products. Chips, dents or cracks due to abuse, misuse, freight damage, or improper installation. Service trips to your

home to teach you how to use the product. Damage of product caused by accident, fire, floods or act of God.

This warranty is valid in the United States and Canada. It is non-transferable and applies only to the original purchaser and

does not extend to subsequent owners of this product. Any applicable implied waranties, including the warranty of

merchantability, are limited in duration to a period of express warranty as provided herein beginning with the date of original

purchase at retail

Have your product proof of purchase with date ready for warranty issues.

Or write to:

and, no warranties, whether express or implied, shall apply to this product thereafter.

Zephyr Corporation

Service and Warranty Department

395 Mendell Street

San Francisco, CA 94124

JAN07.0101

Loading...

Loading...