Page 1

EPL2

Programmer’s

Manual

Programming for Page Mode

Printing

Manual No. 980352-001 Rev. A

©2001 Zebra Technologies Corporation

Page 2

FOREWORD

This manual provides programming information for printers featuring Zebra’s EPL2 Pro

gramming and command language, which are manufactured by Zebra Technologies Corpora

tion, Camarillo, California.

COPYRIGHT NOTICE

This documentcontains information proprietary to Zebra Technologies Corporation. This docu

ment and the information contained within is copyrighted by Zebra Technologies Corporation

and may not be duplicated in full or in part by any person without written approval from Zebra.

While every effort has been made to keep the information contained within current and accurate

as of the date of publication, no guarantee is given or implied that the document is error-free or

thatitisaccuratewith regardtoany specification.Zebrareserves therightto makechanges,for the

purpose of product improvement, at any time.

TRADEMARKS

-

-

-

Zebra and EPL2 are trademarks of Zebra Technologies Corporation. All other marks are trademarks or registered trademarks of their respective holders.

REVISION HISTORY

Rev.A - Thismanual version coincides with Zebraprinters with EPL2 firmware version4.04and

is available from Zebra in electronic form.

See the Zebra web site for information on Zebra Technologies printers at: www.zebra.com

ii

980352-001 Rev.A

Page 3

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . 1-1

Command Conventions . . . . . . . . . . . . . . . . 1-2

Basic Command Syntax . . . . . . . . . . . . . . . . 1-3

Command Editor. . . . . . . . . . . . . . . . . . . . 1-3

Placing Elements in the Print Image . . . . . . . . . . 1-4

Text (Fonts) . . . . . . . . . . . . . . . . . . . . . . 1-5

Bar Codes . . . . . . . . . . . . . . . . . . . . . . . 1-7

Programming Sequences Affect Graphic Results . . . . 1-8

Printer Configuration . . . . . . . . . . . . . . . . . 2-1

Printer AutoSense Feature . . . . . . . . . . . . . . . 2-1

Determining Printer Firmware Version . . . . . . . . . 2-2

Programming Mode Configuration . . . . . . . . . . . 2-3

Media Detection . . . . . . . . . . . . . . . . . . . . 2-4

Command Reference . . . . . . . . . . . . . . . . . 3-1

A

Command - ASCII Text . . . . . . . . . . . . . . . . . . . 3-4

Asian Character Font Sets . . . . . . . . . . . . . . . 3-8

AUTOFR

B Command - Bar Code . . . . . . . . . . . . . . . . . . . 3-11

b Command - 2D Bar Code - MaxiCode Specific Options . . 3-16

b Command - 2D Bar Code - PDF417 Specific Options . . . 3-20

C Command - Counter . . . . . . . . . . . . . . . . . . . . 3-27

C Command - Cut Immediate . . . . . . . . . . . . . . . . 3-29

D Command - Density . . . . . . . . . . . . . . . . . . . . 3-30

dump Command - Enable Dump Mode . . . . . . . . . . . 3-31

eR Command - User Defined Error/Status Character . . . . 3-32

EI Command - Print Soft Font Information . . . . . . . . . . 3-33

EK Command - Delete Soft Font . . . . . . . . . . . . . . . 3-34

ES Command - Store Soft Font . . . . . . . . . . . . . . . . 3-35

f Command - Cut Position . . . . . . . . . . . . . . . . . . 3-40

FE Command - End Form Store . . . . . . . . . . . . . . 3-41

FI Command - Print Form Information . . . . . . . . . . . . 3-42

FK Command - Delete Form . . . . . . . . . . . . . . . . . 3-43

FR Command - Retrieve Form . . . . . . . . . . . . . . . . 3-44

FS Command - Store Form . . . . . . . . . . . . . . . . . . 3-45

GG Command - Print Graphics . . . . . . . . . . . . . . . 3-47

GI Command - Print Graphics Information . . . . . . . . . . 3-48

GK Command - Delete Graphics . . . . . . . . . . . . . . . 3-49

GM Command - Store Graphics . . . . . . . . . . . . . . . 3-50

GW Command - Direct Graphic Write . . . . . . . . . . . . 3-52

Command - Automatic Form Printing . . . . . . . 3-9

980352-001 Rev.A

iii

Page 4

I Command - Character Set Selection . . . . . . . . . . . . . 3-53

JB Command - Disable Top Of Form Backup . . . . . . . . . . 3-55

JF Command - Enable Top Of Form Backup . . . . . . . . . . 3-56

LE Command - Line Draw Exclusive . . . . . . . . . . . . . . . 3-57

LO Command - Line Draw Black . . . . . . . . . . . . . . . . 3-58

LS Command - Line Draw Diagonal . . . . . . . . . . . . . . . 3-59

LW Command - Line Draw White . . . . . . . . . . . . . . . . 3-60

M Command - Memory Allocation . . . . . . . . . . . . . . . 3-61

N Command - Clear Image Buffer. . . . . . . . . . . . . . . . 3-62

o Command - Cancel Software Options . . . . . . . . . . . . 3-63

oB Command - Cancel Auto Bar Code Optimization . . . . . . 3-64

oE Command - Line Mode Font Substitution . . . . . . . . . . 3-65

oH Command - Macro PDF Offset . . . . . . . . . . . . . . . 3-66

oM Command - Disable Initial Esc Sequence Feed . . . . . . . 3-68

oR Command - Character Substitution (Euro) . . . . . . . . . . 3-69

oW Command - Customize Bar Code Parameters . . . . . . . 3-71

O Command - Hardware Options . . . . . . . . . . . . . . . . 3-73

OEPL1 Command - Set Line Mode . . . . . . . . . . . . . . . 3-75

P Command - Print . . . . . . . . . . . . . . . . . . . . . . . 3-76

PA Command - Print Automatic . . . . . . . . . . . . . . . . . 3-77

q Command - Set Label Width . . . . . . . . . . . . . . . . . 3-78

Q Command - Set Form Length . . . . . . . . . . . . . . . . 3-80

r Command - Set Double Buffer Mode . . . . . . . . . . . . . 3-84

R Command - Set Reference Point . . . . . . . . . . . . . . . 3-85

S Command - Speed Select . . . . . . . . . . . . . . . . . . . 3-86

TD Command - Define Date Layout . . . . . . . . . . . . . . . 3-87

TS Command - Set Real Time Clock . . . . . . . . . . . . . . 3-88

TT Command - Define Time Layout . . . . . . . . . . . . . . 3-89

U Command - Print Configuration (General) . . . . . . . . . . 3-90

UA Command - Enable Clear Label Counter Mode . . . . . . . 3-91

UB Command - Reset Label Counter Mode . . . . . . . . . . . 3-92

UE Command - External Font Information Inquiry . . . . . . . 3-93

UF Command - Form Information Inquiry . . . . . . . . . . . . 3-94

UG Command - Graphics Information Inquiry . . . . . . . . . 3-95

UI Command - Host Prompts/Codepage Inquiry . . . . . . . . 3-96

UM Command - Codepage & Memory Inquiry . . . . . . . . . 3-97

UN Command - Disable Error Reporting . . . . . . . . . . . . 3-98

UP Command - Codepage & Memory Inquiry/Print . . . . . . . 3-99

UQ Command - Configuration Inquiry . . . . . . . . . . . . 3-100

US Command - Enable Error Reporting . . . . . . . . . . . . 3-101

V Command - Define Variable . . . . . . . . . . . . . . . . 3-103

W Command - Windows Mode . . . . . . . . . . . . . . . . 3-105

iv

980352-001 Rev.A

Page 5

xa Command - AutoSense . . . . . . . . . . . . . . . . . 3-106

X Command - Box Draw . . . . . . . . . . . . . . . . . . 3-107

Y Command - Serial Port Setup . . . . . . . . . . . . . . . 3-108

Z Command - Print Direction . . . . . . . . . . . . . . . . 3-109

? Command - Download Variables . . . . . . . . . . . . . 3-110

^@ Command - Reset Printer . . . . . . . . . . . . . . . 3-111

^ee Command - Error Report - Immediate . . . . . . . . 3-112

Appendix A - Character References . . . . . . . . . . A-1

Resident Fonts 1-5 . . . . . . . . . . . . . . . . . . . A-1

Default Character Map Code Page - 437. . . . . . . . A-2

Dump Mode Character Map . . . . . . . . . . . . . . A-3

Appendix B - Cash Drawer Kicker Option . . . . . . . B-1

Cash Drawer Cable Wiring. . . . . . . . . . . . . . . B-2

<Esc>p

Command - Generate Pulse CDK . . . . . . . . . . B-3

<Esc>u Command - CDK Status . . . . . . . . . . . . . . . B-4

980352-001 Rev.A

v

Page 6

vi

980352-001 Rev.A

Page 7

Introduction

This section contains information about the ba

sic features, command syntax and terminology

oftheEPL2ProgrammingLanguageforZebra's

desktop printers with flash memory architecture. These printers incorporate common programmingcodesetsandarchitecturalfeatures.

The primary operating mode for the printer is

EPL2, a page description language. It is designed to assemble all the elements of the label

prior to printing to speed the printing process.

EPL2 is an ideal language foryourlabeling and

bar code requirements. The EPL2 is versatile

and is capable of printing a wide range media

and bar codes.

Some printer models also include a legacy

printer compatibility mode, Line Mode. Line

Mode supports our early model EPL program

ming language - ELP1. A separate manual is

provided for Line Mode printing

(p/n 980326-001). See the printer's Software

and Documentation CD with the specific

model'sProgrammer' Manualbuttonselector or

visit our web site at: www.zebra.com

-

-

980352-001 Rev.A

1-1

Page 8

Command

Conventions

The manual uses the following typographic

conventions to describe commands.

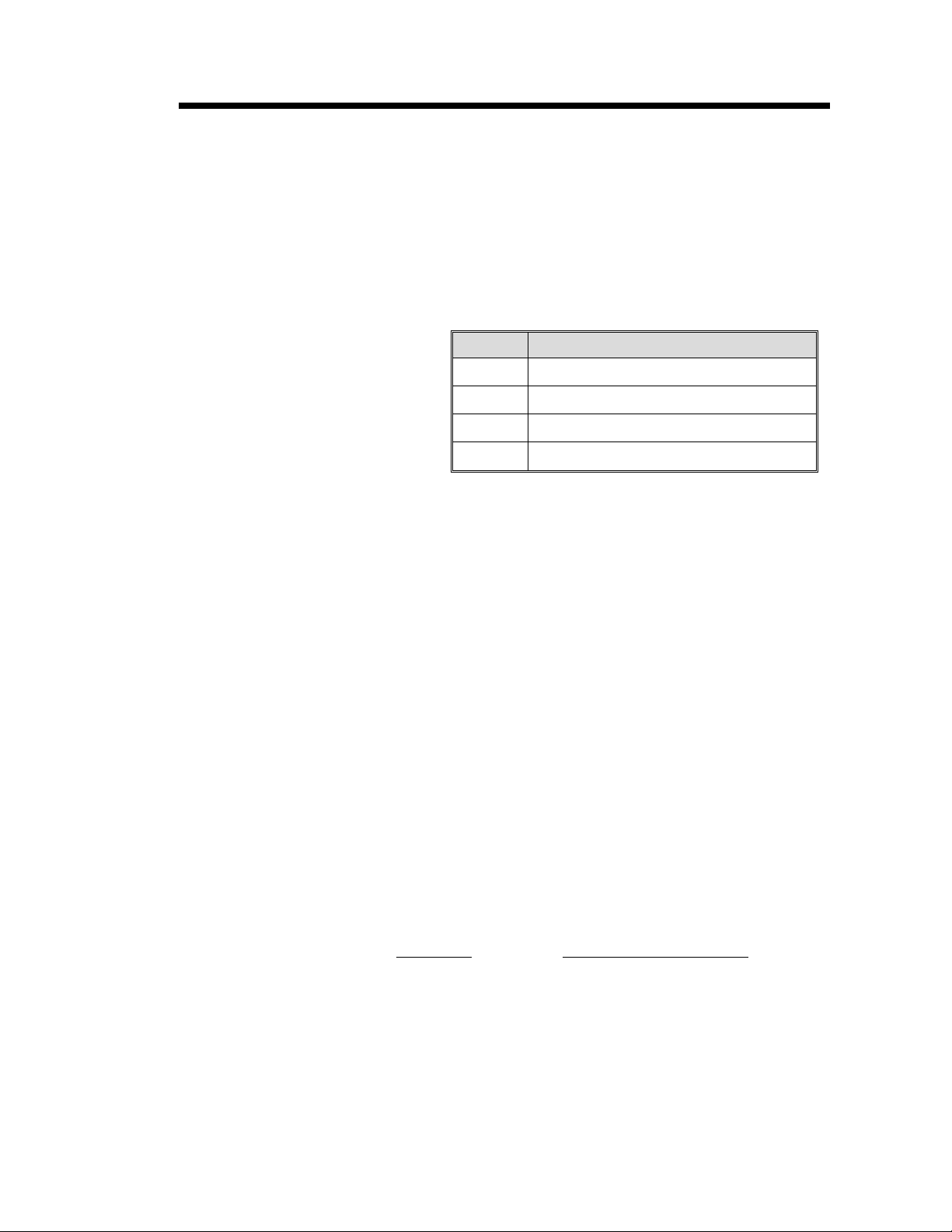

Example Description

A Commands (Case Sensitive)

p

1,p2,p3

, p2, p3]

[p

1

{Choice 1|Choice 2}

This text should be→

on one line

↵ Line feed character.

“NAME”

“DATA”

Required parameters

Optional parameters

Indicates a mandatory choice be

tween two or more items. You

must include one of the items un

less all of the items are also en

closed in square brackets.

The line-continuation character

(→) indicates that code is contin

ued from one line to the next and

should be typed all on one line.

The name of a form or graphic in

double quote marks.

The text or bar code data in double quote marks.

The (\) character designates that

the character following is a literal

and will encode into the data

field. Refer to the following examples:

-

-

-

-

“PROMPT”

To Print

”\"

“Company” \"Company\"

\\\

\code\ \\code\\

An ASCII text field that will be

transmitted to the host (via the se

rial interface) each time this com

mand is executed.

Enter into Data Field

-

-

Attention!!

All commands and alpha character command

parameters are case sensitive!

1-2

980352-001 Rev.A

Page 9

Basic Command

Syntax

Each command consists of one or two ASCII

(case sensitive) alpha characters to identify the

specific command desired. Some commands

require one or more additional parameters to

supply the printer with sufficient information to

complete the command. Refer to Figure 1- for

the basic command syntax.

Figure 1-1

Command Name

Basic Command

Syntax

Command Parameters Command

WRITE TEXT

Ap,p,p,p,p,p,p,"DATA "

1234567

Specific

Data

↵

Each command line must be terminated with a

Line Feed (LF) character (Dec. 10). Most PC

based systems send CR/LF when the Enter key

is pressed. The Carriage Return (CR) character

is ignored by the printer and cannot be used in

place of LF.

Command Editor One method to createcommandfilesis through

anASCIIbased text editor.IntheDOSenvironment, MS-DOS EDIT or BRIEF are good

choices. To execute the file, use the editor’s

print command or from the DOS prompt, use

the COPY command to send the file directly to

theprinter. Anexampleof the use of the COPY

command is:

980352-001 Rev.A

COPY “FILENAME.EXT” LPT1↵

or

COPY “FILENAME.EXT” COM1↵

For more information on the use of the COPY

command, refer to your DOS software manual.

Configure the COM port to match the printer’s

serial port setting (typically set to defaults). See

the Y command in section 2 for details.

1-3

Page 10

Placing Elements in

°

the Print Image

Sample Format

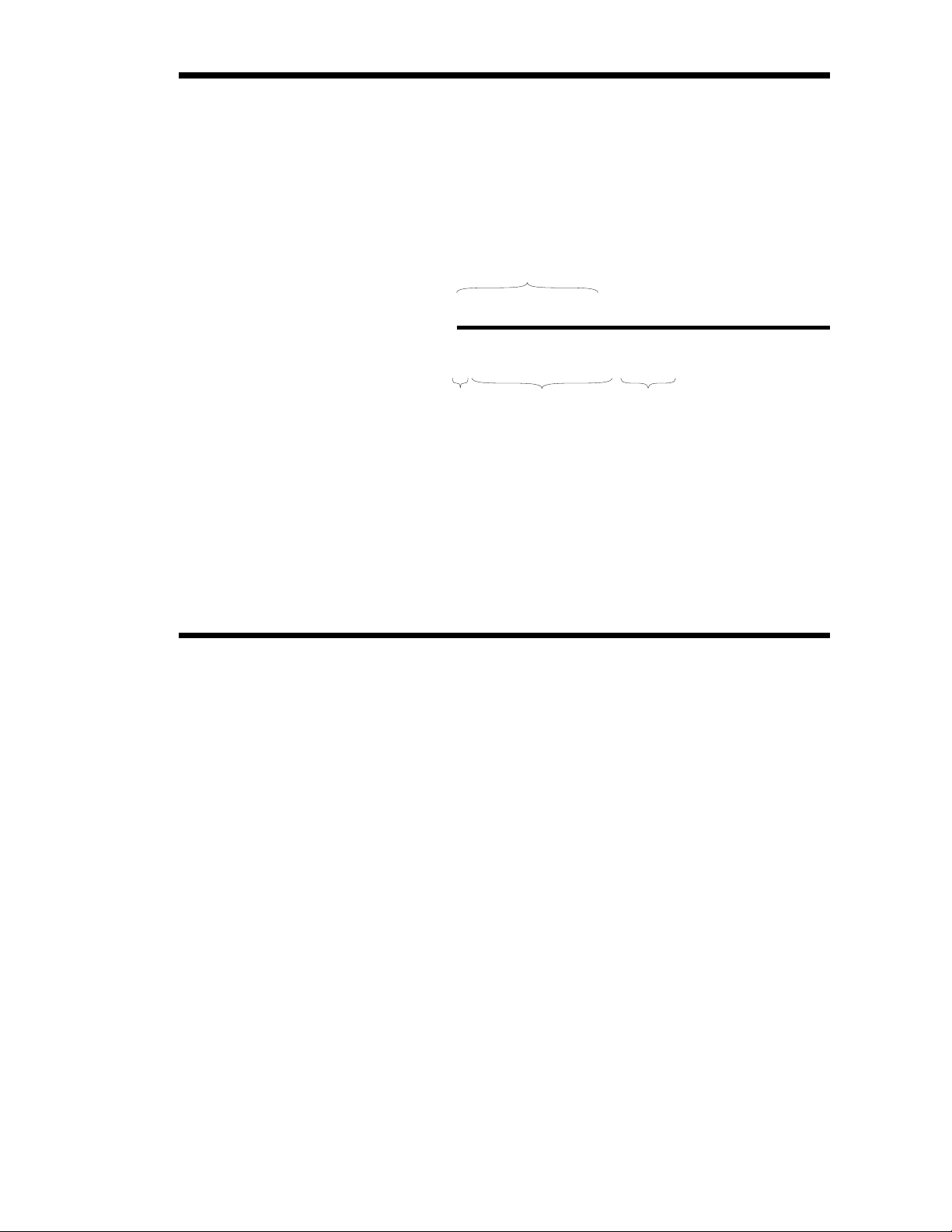

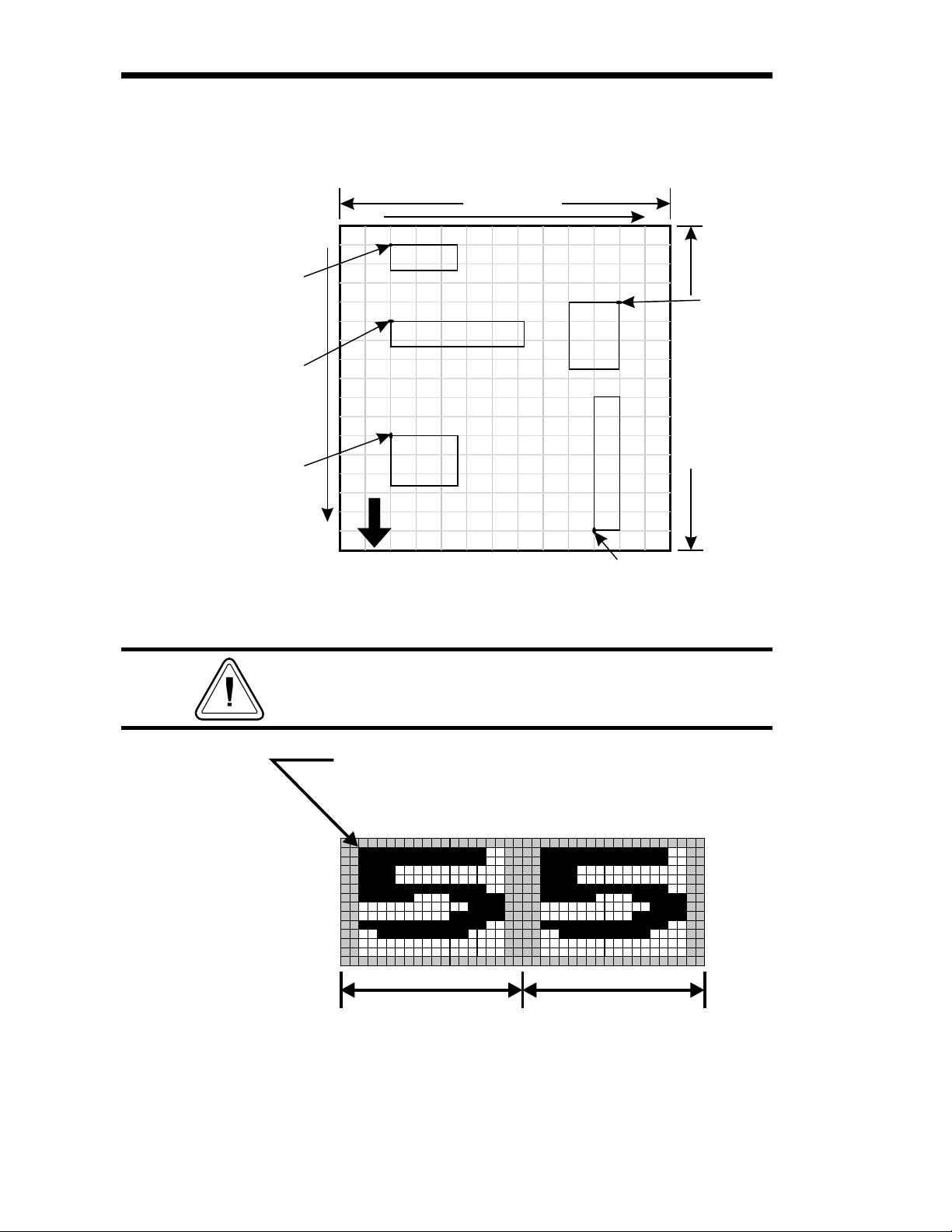

Image elements are located in the image print

buffer on a X-Y grid expressed in dots. The X

value represents thewidth and the Y value rep

resents the height of the grid.

The point of origin (the starting point) for a

non-rotated object is the upper left corner. As

anobjectrotates, the point oforiginrotateswith

the object.

These image buffer properties are depicted

graphically in the following illustration.

-

Point of

Origin for

Text Object

Point of

Origin for

BarCode Object

"q" dots

Te x t

Te x t

"Q"

dots

y axis

x axis

(0,0)

Te x t

Direction Of Feed

The minimum non printingmargin on all edges

ofthelabel is 1mm.Printingcloserthan 1mm to

the top or bottom edge of the label may cause

theprinter toadvanceunwantedlabelsor cause

the printer to go into error condition.

Point of

Origin for

Text Object

Rotated 90°

Point of

Origin for

Text Object

Rotated 270

1-4

980352-001 Rev.A

Page 11

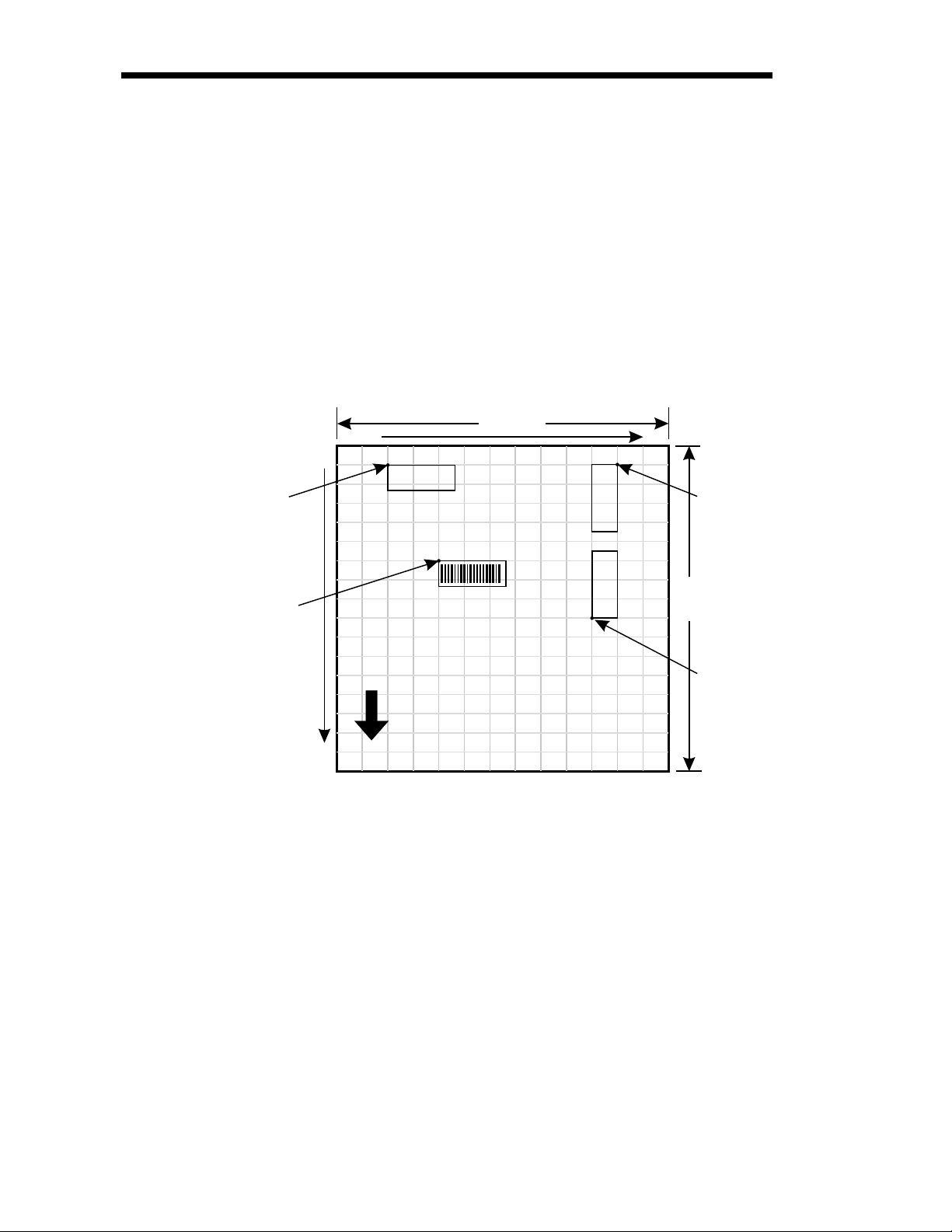

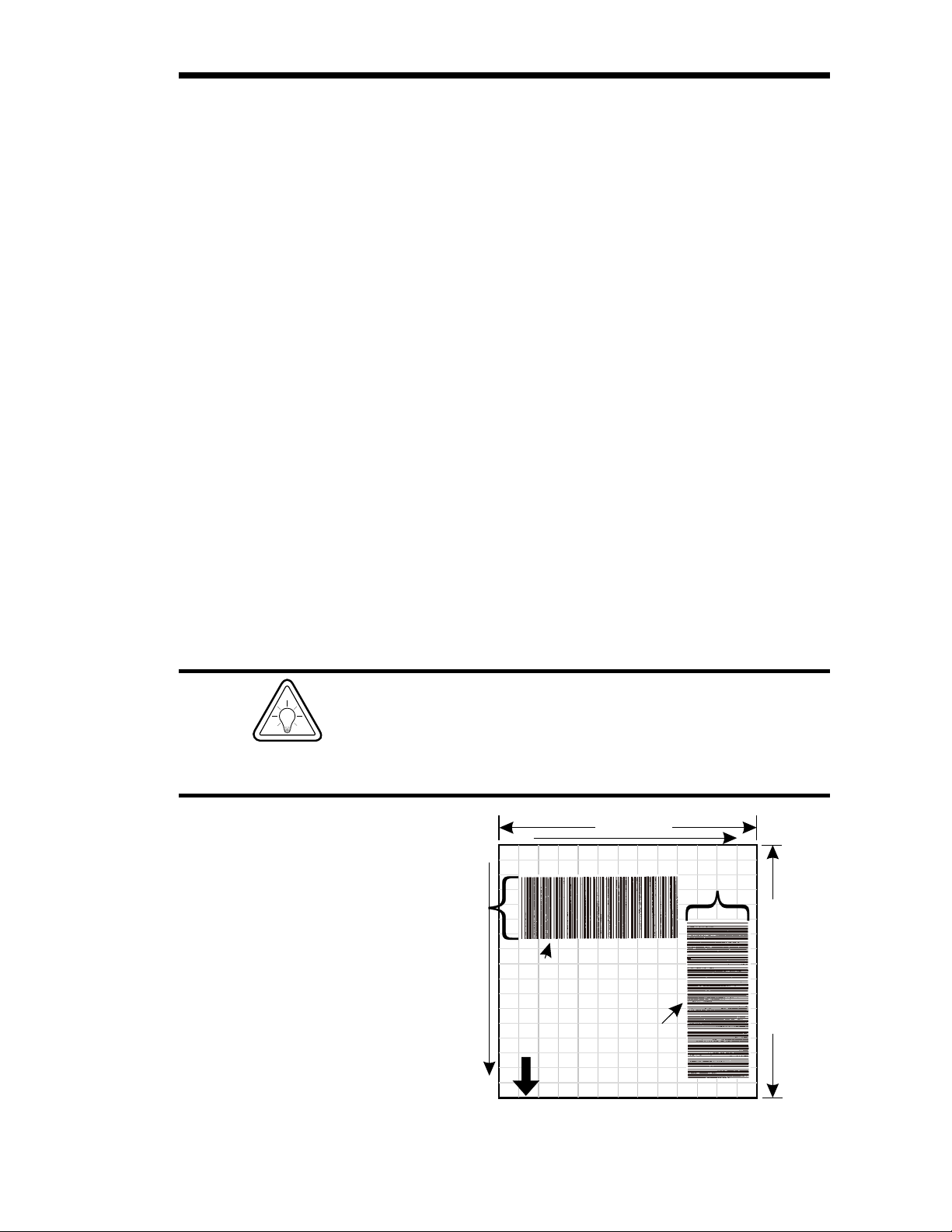

Text (Fonts) The standard EPL2 printer has five (1-5) resi

(

)

dent mono-spaced dot fonts. Fonts A-Z and a-z

(upper and lower case alpha characters) are re

served for downloading soft fonts.

First Character of Text String Reference Point

12

D

o

t

s

-

-

8 Dots

Character Width

Total Character Width

Inter-character Space

actuallywhite dots

Control text height (in horizontal dots) and

width (in vertical dots) with the horizontal and

vertical multipliers. The textis oriented first and

then the A command’s font multipliers are ap

plied.

-

980352-001 Rev.A

1-5

Page 12

Thetext is placedintothe image buffer.Seethe

following example.

Point of

Origin for

Text Object

Point of

Origin for

Text Object

Point of

Origin for

Text Object

y axis

x axis

(0,0)

Horizontal Dots

Text

2x Horizontal Multiplier

Text - No Size Multipliers

Text

2x Vertical Multiplier

Text

Direction Of Feed

Text

Text

Point of Origin

for Text Object

Rotated 270°

Point of

Origin for

Text Object

V

e

Rotated 90°

r

t

i

c

a

l

D

o

t

s

The reference point of the first character in a text

stringisnotaffectedbythefont sizemultipliervalues.

First Character of Text

String Reference Point

2times 2times

1-6

980352-001 Rev.A

Page 13

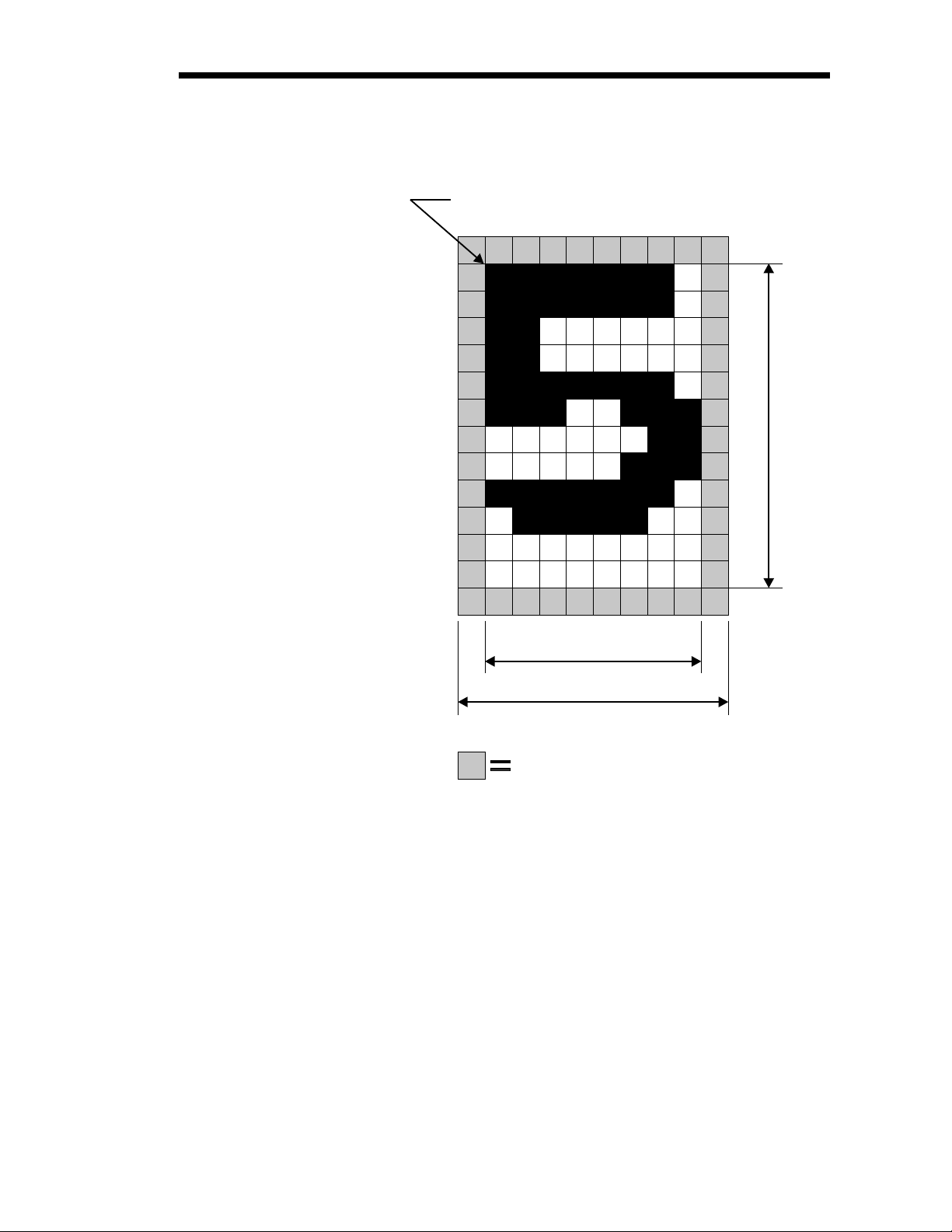

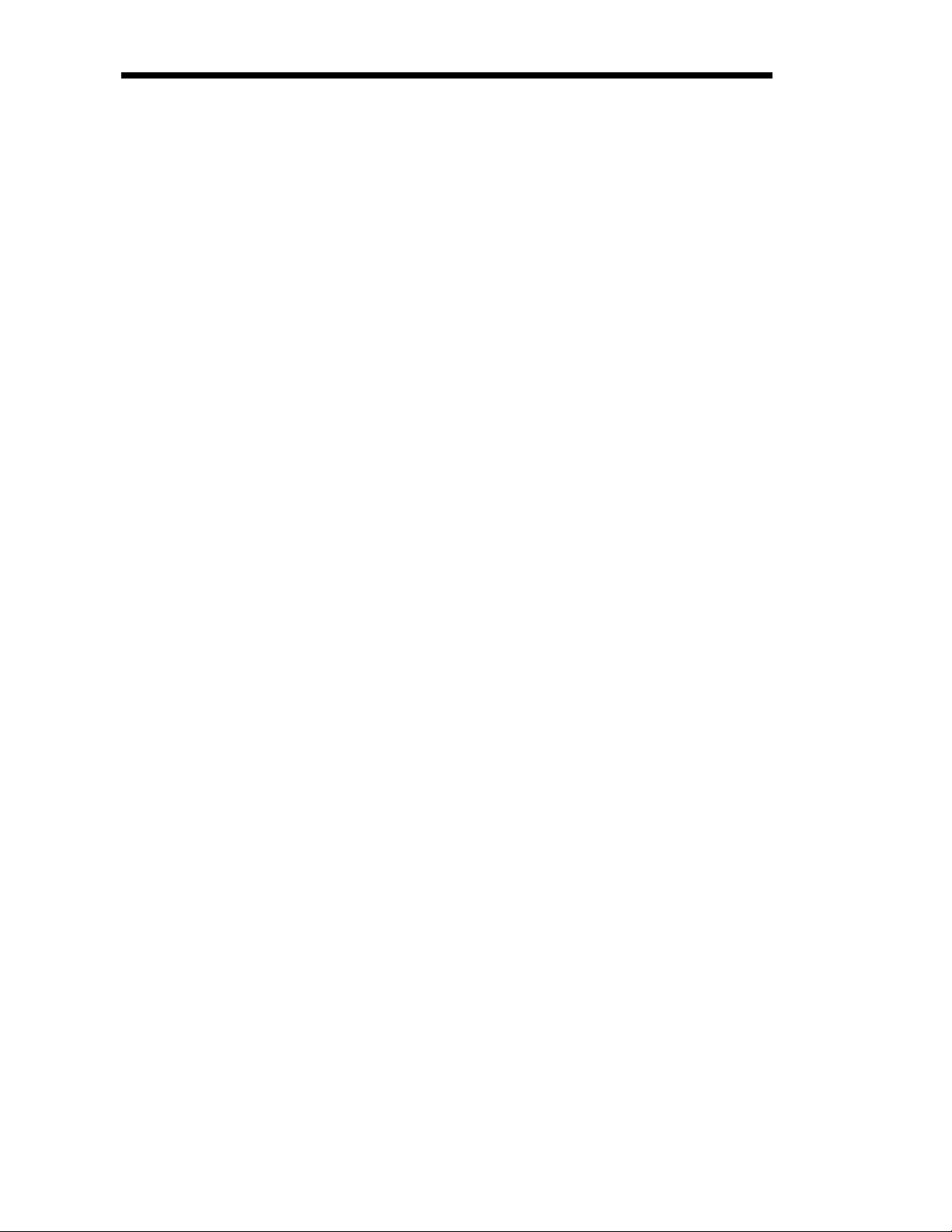

Bar Codes All bar codes supported by the EPL2 language

have associated industry specifications that the

programmershouldbe aware of and adhere to.

The programmer needs to consider bar code

features and requirements when choosing and

using a bar code for different applications.

Some of the features and requirements that

need consideration are listed below:

Data used by the application are per the bar

❏

code specification (numbers only, alphanu

meric, alphanumeric and special characters,

etc.).

Minimum and maximum number of charac

❏

ters allowed or required per bar code.

❏Density or magnification of a given bar code

type.

❏White area required around bar codes (the

“Quiet Zone”).

-

-

❏The bar code must print within the image

buffer (printable area of the label).

Bar Code Orientation Tip

To help ensure that generated bar codes are readable by the widest variety of bar code readers, print

bar codes in the “Picket Fence” orientation versus

the “Ladder” orientation.

Horizontal Dots

Ladder

Orientation

Height of

Bar Code

V

e

r

t

i

c

a

l

D

o

t

s

Height of

Bar Code

y axis

x axis

(0,0)

Picket Fence

Orientation

Direction Of Feed

980352-001 Rev.A

1-7

Page 14

Programming

Sequences Affect

Graphic Results

Graphic elements can interact andthe resultant

image can be affected by other commands.

Structure command sequences to reduce the

chancesofunexpectedprintresults.Theprinter

will process lines, text, boxes and most bar

codes in command sequence. The printer then

processes the printer control processes, coun

ters, variable data, Postnet, and then graphics

last.

-

1-8

980352-001 Rev.A

Page 15

Printer Configuration

This section covers the interpret your printer's

configuration setup and setting basic modes.

Printer AutoSense

Feature

Use the printer's AutoSense feature to determineyourprinter'sconfigurationandoperating

mode. The primary functions that AutoSense

provides are:

❏AdjustmentoftheMediaSensorintheprinter

to the media in use.

❏

Programming Mode - Page (EPL2) or Line

(EPL1emulation) Mode.Note- LineModeis

not available for all printer models.

❏

The printer' serial interface settings.

❏

Reports the printer's configuration status in

cluding printer options.

-

980352-001 Rev.A

2-1

Page 16

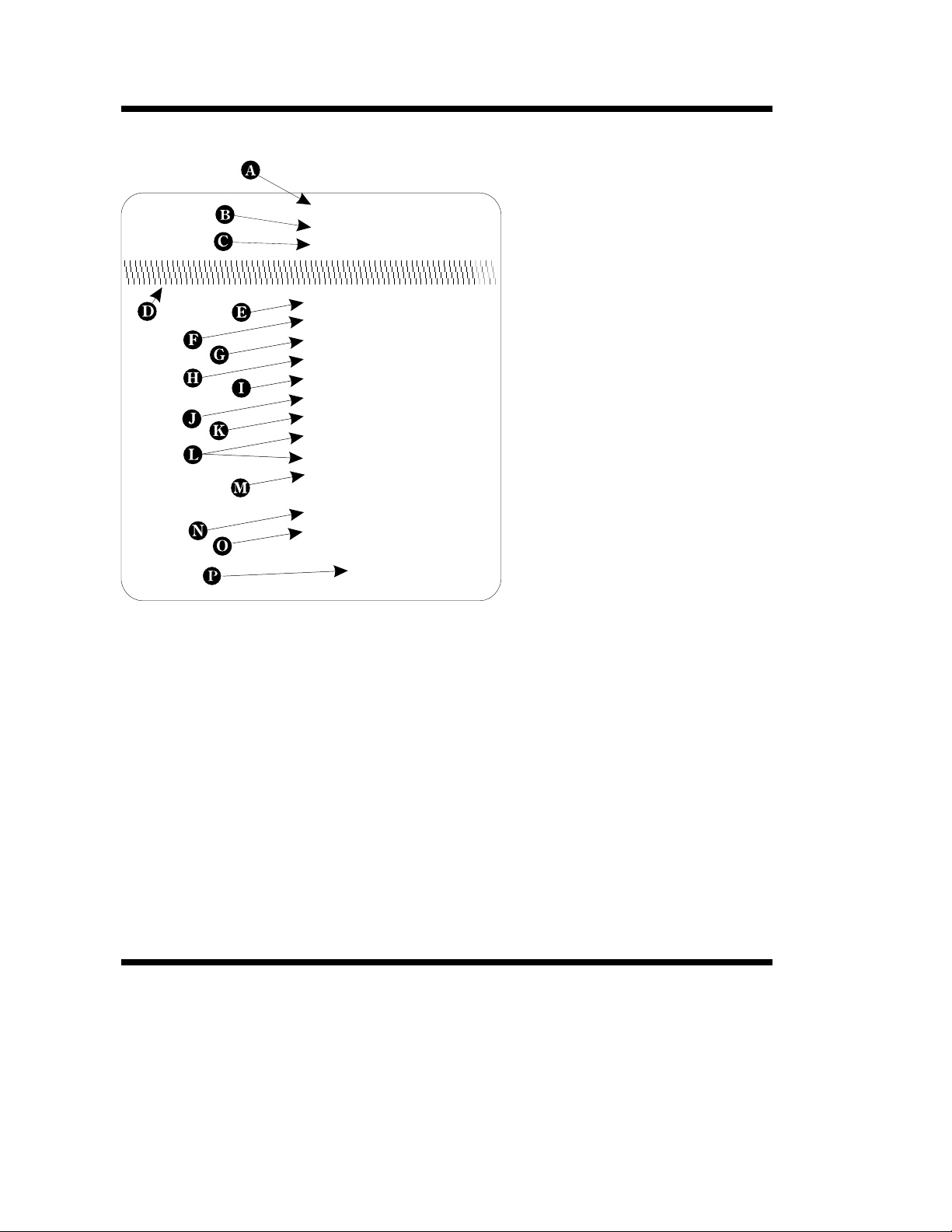

Explanation of the Status Printout

4M03351F 16 V3.18

Serial por t:96,N,8,1

Page Mode 200dpi

Image buffer size:0507K

Fmem:000.0K,061.4K avl

Gmem:000K,045K avl

Emem:024K,045K avl

I8,0,001 rY

S4 D00 R128,000 ZT UN

q832 Q1022,029

Option:D,P,C,S

oEw,x,y,z

16 23 31

Date: 10-05-94

Time:01:00:00

Dump Mode Print Sample

A

. Printer I.D.code number and firmware

version number.

B

. Serial port configuration.

C.

Programming Mode

Print head resolution

USB is printed here ifinstalled

D.

Print head test pattern.

E

. A mountof memory availablefor the

Image buffer.

F

.

Amount of memory used and memory

available for

G

.

Amount of memory used and memory

available for

H

.

Amount of memory used and memory

available for Soft fonts.

I

. Currently selected CharacterSet ( )

and Image Buffer mode setting ( ).

= Double Buffering Enabled

rY

= Double Buffering Disabled

rN

J

. Curr entlyselectedPrint Speed ( ),

Heat Density ( ), Reference Point( ),

Print Orientation ( ) and Error Status

().

U

K

. Currently selected Form Width ( ) and

Length( ).

L

. Current Hardware and Software

Option status .

M

. Curr entAutoSense Through (Gap)

Sensor values. The three numbers

represent;

1. Backing Transparent point

2. Set point

3. Label Transpar entpoint.

N

. Current time set in Real Time Clock.

This value will only be displayed if

your printer is equippedwith the Real

Time Clock feature.

O

. Current date set in Real Time Clock.

This value will only be displayed if

your printer is equippedwith the Real

Time Clock feature.

Formstorage.

Graphics storage.

r

S

DR

Z

q

Q

I

Determining Printer

Firmware Version

2-2

The printer version numbers are a code used to

document product function and the feature

support level of the printer. The latest firmware

version and updates can be obtained from our

web site.

980352-001 Rev.A

Page 17

Programming Mode

Configuration

Flash based printers are, by default, configured

for Page (EPL2) mode operations. The opera

tor must convert the printer to Line Mode prior

tothe initialuseof LineMode.Thisis doneviaa

hardwareselectprocedurewiththeFeedbutton

during printer power-up. See the OEPL1 com

mand (page 3-75) for details on switching be

tween line and page modes via programming.

-

-

-

Manually Setting

Line Mode

As of January 2001, the following printers sup

port Line Mode (EPL1 emulation):

2443

·

2722

·

2824

·

2844

·

The Line Mode (and Page Mode) configuration setting is retained after reset has been issued or power

has been cycled.

TheLineModecapableprinterutilizes the Feed

button during printer power-up to toggle between the printer personality modes, Line and

Page (EPL2).

1. With printer power off, press and hold the

Feed button while turning the printer on, then

release the button when the LED starts blinking

red.

-

980352-001 Rev.A

2.When theindicatorLED startsflashinggreen,

immediately press and hold Feed button.

3. Release the Feed buttonwhen the LED turns

a steady Amber (orange).

4. Verify printer personality with Dump Mode

printout:. Line Mode or Page Mode (EPL2).

5. Press the Feed button to exit the Dump

Mode.

2-3

Page 18

Media Detection Media detection in EPL2 printers is a combina

tionofprogrammingandprintermediasensing.

TheQ (SetForm Length) and O (Option) com

mands program the media detection method.

The user must configure the printer for the me

dia type and the (programmed)form or label in

use.

Theprintercandetectthebeginningandendof

the printable areaon the media by one of three

methods: Gap, Notch (hole), or Black line. The

Gap method detects the difference in optical

density of a label on a liner from the liner only

with the Transmissive (Gap) sensor. The Notch

methodusestheTransmissivesensortodetecta

hole in the media (gap-less labels or tag stock).

The Black line method uses the Reflective sen

sor to detect a preprinted black line on the media back (for gap-less labels or tag stock).

Printing on continuous media requires programming to control media positioning.

-

-

-

-

EPL2 printers also support a “Label Dispense”

modeasaprinterconfigurationoption(formost

models). The printers use a “Label Taken”sensor to detect the removal of a label.

One or more of these sensors may require user

adjustment or configuration for proper operation. All EPL2 printers have an AutoSense fea

ture to optimize label and label gap detection by

the transmissive (gap) sensor. See the printer’s

user’s manual for printer specific sensor adjust

ment control.

-

-

2-4

980352-001 Rev.A

Page 19

Command Reference

This section contains a complete listing of all

commands in alphabetical order.

980352-001 Rev.A

3-1

Page 20

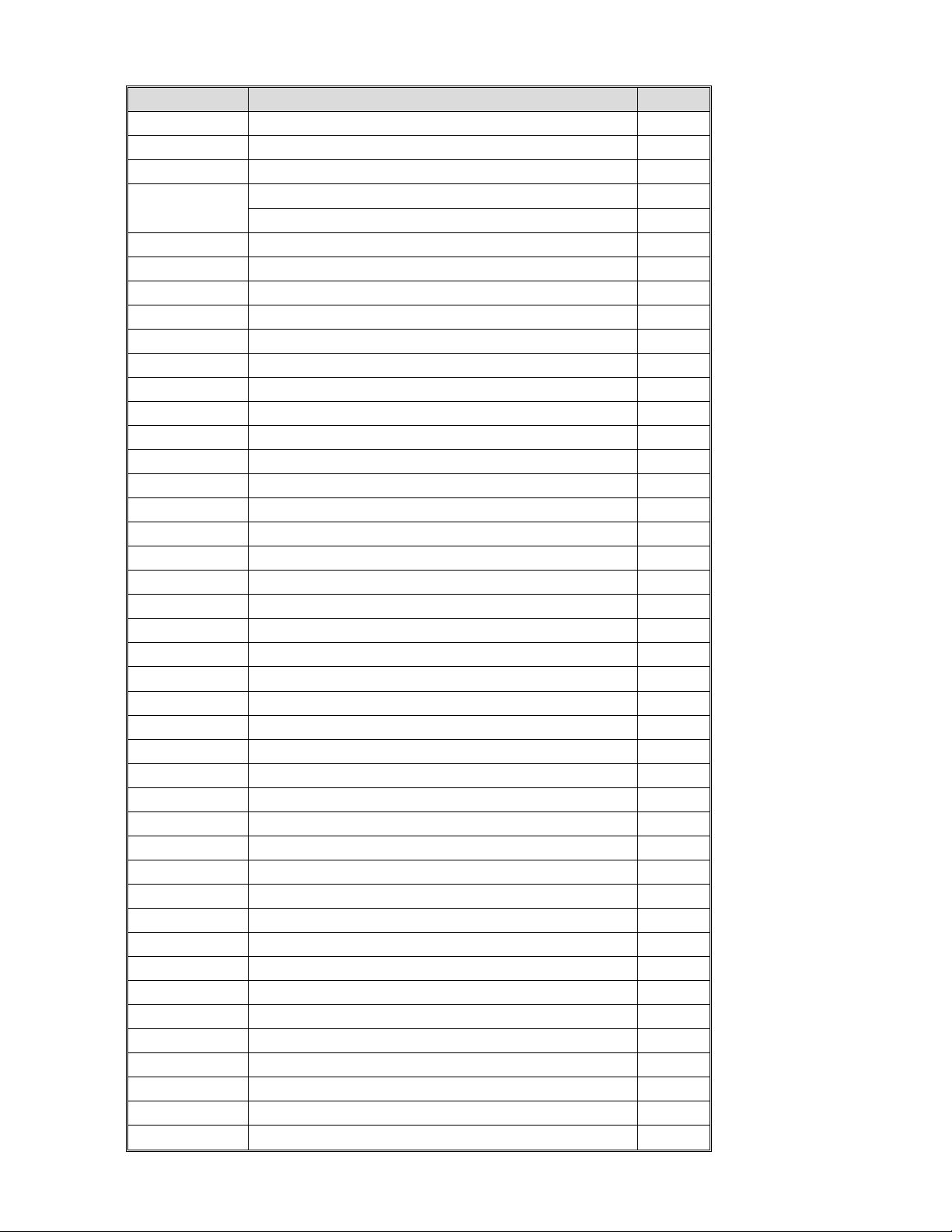

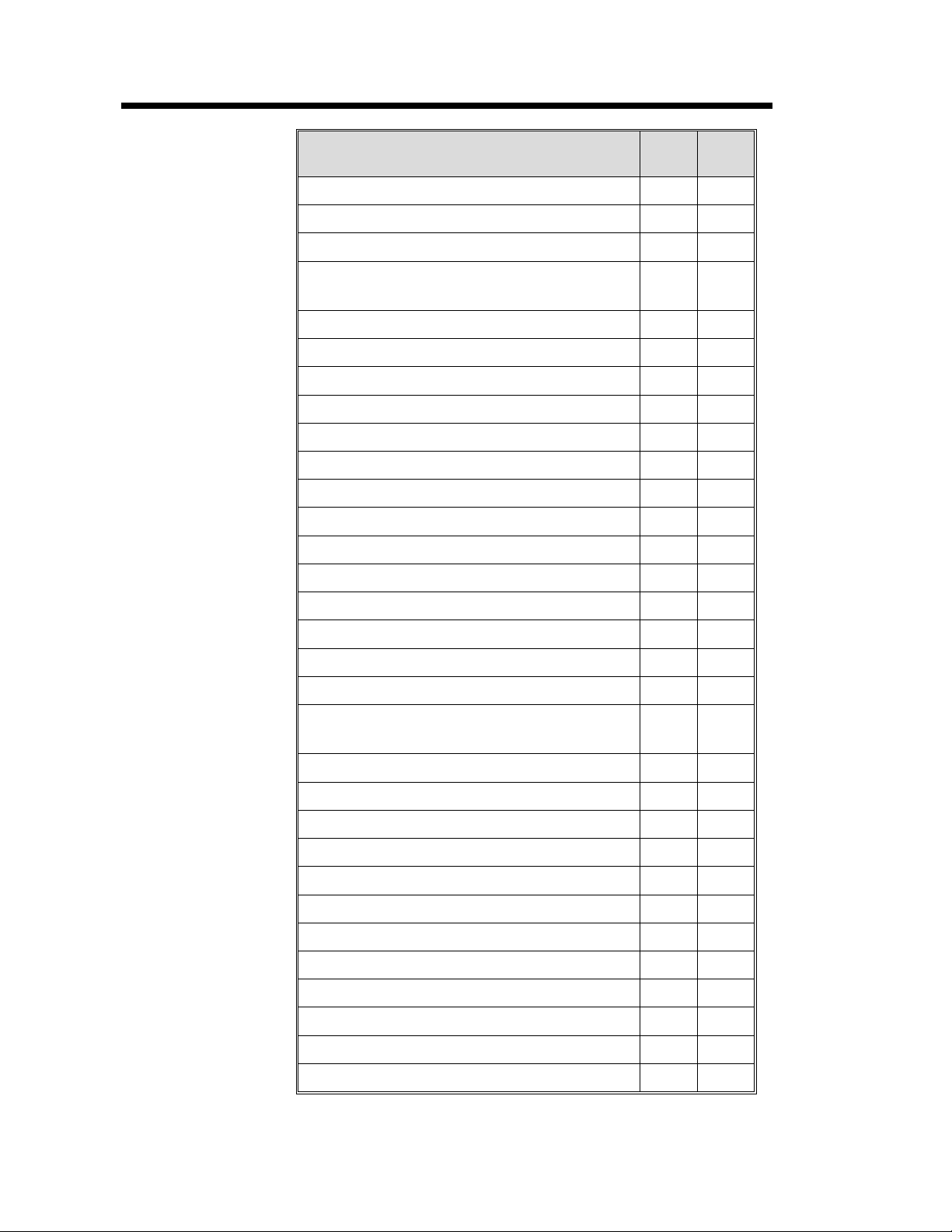

Command Description Page

A ASCII Text 3-4

AUTOFR Automatic Form Printing 3-9

B Bar Code 3-11

b

C Counter 3-27

C Cut Immediate 3-29

D Density 3-30

EI Print Soft Font Info. 3-33

EK Delete Soft Font 3-34

eR User Definable Error Response 3-32

ES Store Soft Font 3-35

f Cut/Peel Position 3-40

FE End Form Store 3-41

FI Print Form Info. 3-42

FK Delete Form 3-43

FR Retrieve Form 3-44

FS Store Form 3-45

GG Retrieve Graphics 3-47

GI Print Graphics Info. 3-48

GK Delete Graphic 3-49

GM Store Graphic 3-50

GW Direct Graphic Write 3-52

I Character Set Selection 3-53

JB Disable Top Of Form Backup 3-55

JF Enable Top Of Form Backup 3-56

LE Line Draw Exclusive 3-57

LO Line Draw Black 3-58

LS Line Draw Diagonal 3-59

LW Line Draw White 3-60

M Memory Allocation 3-61

N Clear Image Buffer 3-62

o Cancel Customized Settings 3-63

oB Cancel Customize Bar Code 3-64

oE Line Mode Font Substitution 3-65

oH Macro PDF Offset 3-66

oM Disable Initial Esc Sequence Feed 3-68

oR Character Substitution (Euro) 3-69

oW Customize Bar Code Parameters 3-71

O Options Select 3-73

OEPL1 Set Line Mode 3-75

P Print 3-76

PA Print Automatic 3-77

MaxiCode 3-16

PDF417 3-20

3-2

980352-001 Rev.A

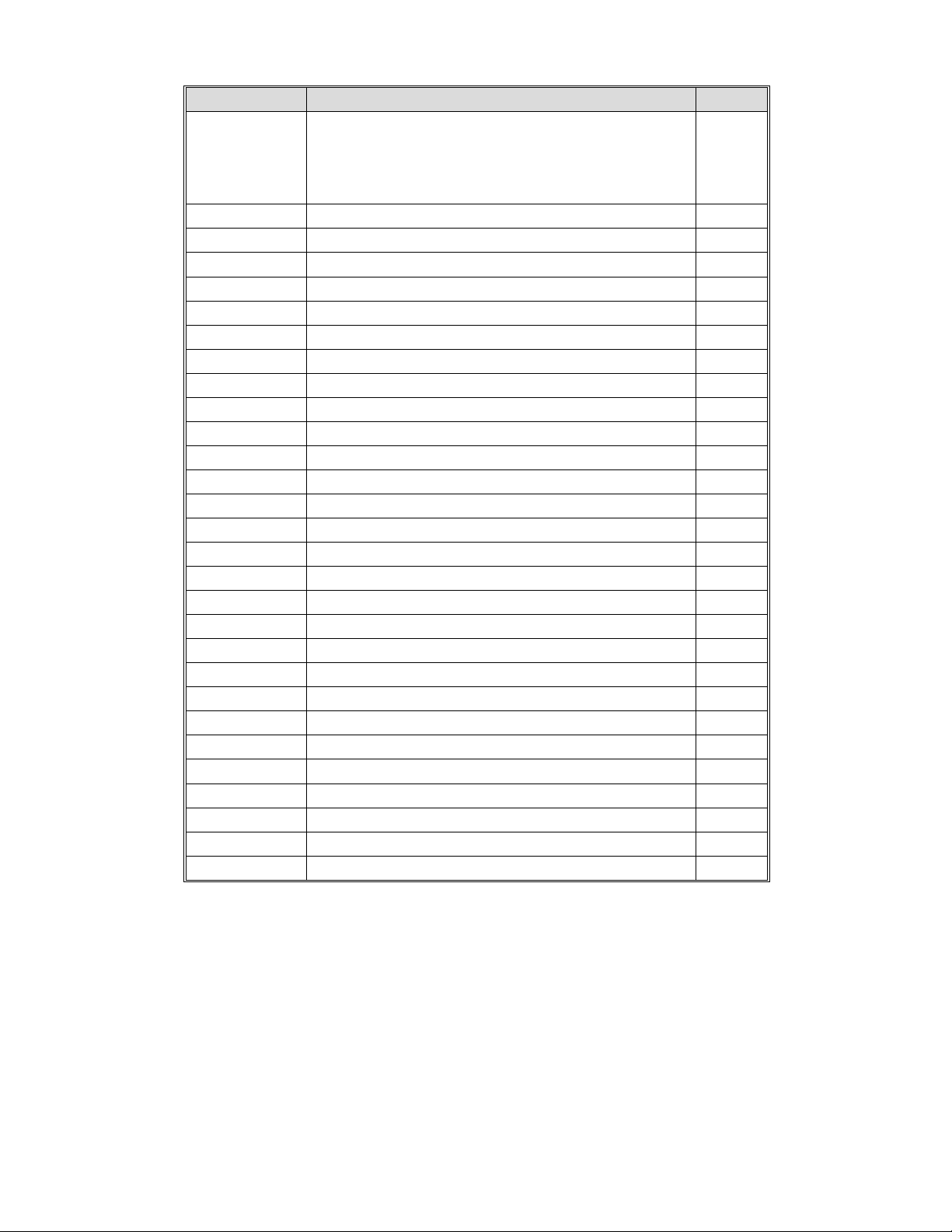

Page 21

Command Description Page

Set Form Length

Q

q Set Form Width 3-78

r Set Double Buffer Mode 3-84

R Set Reference Point 3-85

S Speed Select 3-86

TD Define Date Layout (& Print Date) 3-87

TS Set Real Time Clock 3-88

TT Define Time Layout (& Print Time) 3-89

U Print Configuration 3-90

UA Enable Clear Label Counter Mode 3-91

UB Reset Label Counter Mode 3-92

UE External Font Information Inquiry 3-93

UF Form Information Inquiry 3-94

UG Graphic Information Inquiry 3-95

UI Host Prompts/Codepage Inquiry 3-96

UM Codepage & Memory Inquiry 3-97

UN Disable Error Reporting 3-98

UP Codepage & Memory Inquiry/Print 3-99

UQ Configuration Inquiry 3-100

US Enable Error Reporting 3-101

V Define Variable 3-103

W Windows Mode 3-105

xa Sense Media 3-106

X Box Draw 3-107

Y Serial Port Setup 3-108

Z Print Direction 3-109

? Download Variables 3-110

^@ Reset Printer 3-111

^ee Status Report - Immediate 3-112

Transmissive (Gap) Sensor

Black Line Sensor

Continuous Stock

3-80

980352-001 Rev.A

3-3

Page 22

A Command - ASCII Text

Description Prints an ASCII text string.

Syntax Ap

Parameters p

p

p

p4= Font selection

1,p2,p3,p4,p5,p6,p7

= Horizontal start position (X) in dots.

1

=Vertical start position (Y) in dots.

2

= Rotation

3

Value Description

0

1

2

3

Value

1

2

No rotation

90 degrees

180 degrees

270 degrees

203 dpi 300 dpi

20.3 cpi, 6 pts,

(8 x 12 dots)

16.9 cpi, 7 pts,

(10 x 16 dots)

,"DATA"

Description

25 cpi, 4 pts,

(12 x 20 dots)

18.75 cpi, 6 pts,

(16 x 28 dots)

14.5 cpi, 10 pts,

3

(12 x 20 dots)

12.7 cpi, 12 pts,

4

(14 x 24 dots)

5.6 cpi, 24 pts,

5

(32 x 48 dots)

A - Z

Fonts 1 - 5 are fixed pitch.

Reserved for

Soft Fonts

15 cpi, 8 pts,

(20 x 36 dots)

12.5 cpi, 10 pts,

(24 x 44 dots)

6.25 cpi, 21 pts,

(48 x 80 dots)

Reserved for

Soft Fonts

p5= Horizontal multiplier, expands the text

horizontally. Values: 1, 2, 3, 4, 5, 6, & 8.

= Vertical multiplier, expands the text ver

p

6

tically. Values: 1, 2, 3, 4, 5, 6, 7, 8, & 9.

=N for normal or R for reverse image

p

7

“DATA” = Represents a fixed data field.

-

3-4

980352-001 Rev.A

Page 23

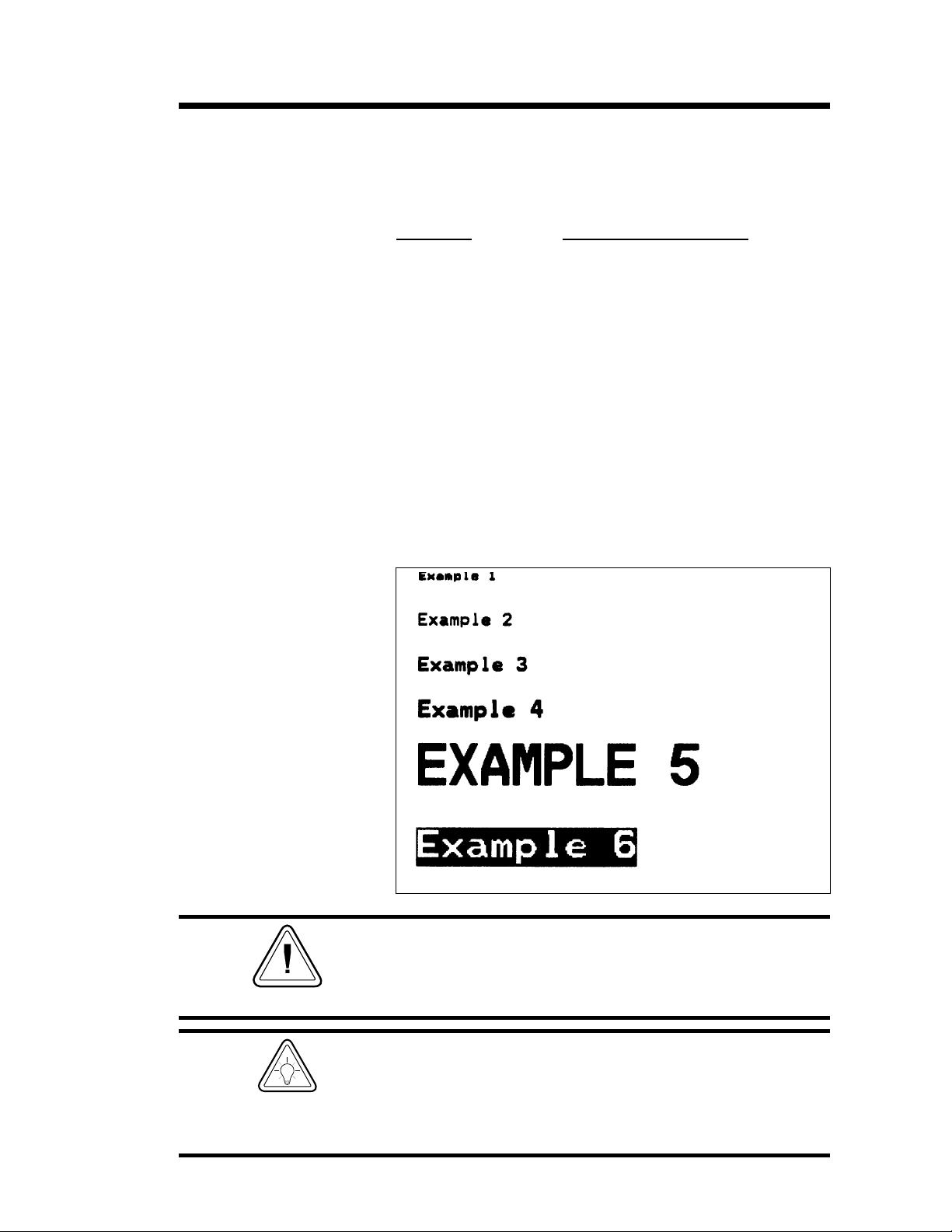

A Command - ASCII Text

Examples:

Will Produce:

The backslash (\) character designates the fol

lowing character is aliteral and will encodeinto

thedatafield.Refertothefollowingexamples:

To Print

Enter into data field

“ \”

“Company” \”Company\”

\ \\

\code\ \\code\\

¿

N¿

A50,0,0,1,1,1,N,"Example 1"¿

A50,50,0,2,1,1,N,"Example 2"¿

A50,100,0,3,1,1,N,"Example 3"¿

A50,150,0,4,1,1,N,"Example 4"¿

A50,200,0,5,1,1,N,"EXAMPLE 5"¿

A50,300,0,3,2,2,R,"Example 6"¿

P1¿

-

HINT

980352-001 Rev.A

As shown in example 5 above, font 5 only supports

upper case characters. Refer to Appendix A for a

complete listing of available fonts and character sets

supported.

Use the LE command to create reverse print text in

stead of the “R”intheA command parameter p

This is the recommend method because it provides

the best size, position and centering of the black line

(rectangle) bordering the reversed text.

7

3-5

.

Page 24

A Command - ASCII Text

Variable Data and

Counter Functions

Example:

Data with the RTC

Time & Date

Functions

The “Data” field can be replaced by or com

bined with the following commands:

Vnn= Prints the contents of variable “nn” at

this position where nn is a 2 digit num

ber from 00 to 99. See the V command,

page

Cn= Prints the contents of counter “n” at this

position where n is a one digit number

from 0 to 9. See the C command, page .

A50,0,0,1,1,1,N,"DATA"¿ : Writes Text

A50,50,0,2,1,1,N,V01¿: Writes contents of variable 01

A50,100,0,3,1,1,N,C1¿: Writes contents of counter 1

A50,100,0,3,1,1,N,C1+2¿ : Writes contents of counter 1 plus 2

The “Data” field can be replaced by or combined with the following variables:

TT = Prints the current time at this position in

the predefined format. See the TT command for format selection. This variable

is available only if the printer Time &

Date option is installed.

-

Examples:

TD=Prints the current date at this position in

the predefined format. See the TD command for format selection. This variable

is available only if the printer Time &

Date option is installed.

A50,150,0,4,1,1,N,TT↵ : Writes current time

A50,200,0,5,1,1,N,TD↵ : Writes current date

or a combination of several options:

A50,300,0,3,2,2,R,"Deluxe"V01C2"Combo"TDV01TT↵

:Writes the text “Deluxe” followed by the contents of variable 01 fol

lowed by the contents of counter 2 followed by the text “Combo” fol

lowed by the current date followed by the contents of variable 01

followed by the current time.

-

-

3-6

980352-001 Rev.A

Page 25

A Command - ASCII TEXT

Simple Expressions

in Data Fields

Syntax Ap

Parameters For the p

Anadvancedfunctionof the A command allows

addition and subtraction to be performed on

constant and variable values in flash printers.

1,p2,p3,p4,p5,p6,p7

- p7and “DATA” parameters -

1

,"DATA"[p8p9p10…]

See first page of A command, page 3-4.

= Required. Must be a variable data field

p

8

number, e.g. V00, V01 etc.

= Required. Operator, + or –

p

9

= Required. Variable data field number

p

10

or constant value.

Valid Number Ranges:

Constant = 0 to 2147483647

Variable = 0 to 2147483647

Result = -2147483648 to 2147483647

❏The Expression must start with a variable

field.

❏Thecharacter field length defined for the first

variable in the expression will be used to for

mat the result. If the result is of a greater

length than the defined character length,

then the result field will contain ‘X’s.

❏

A syntax error will be generated during form

store if the constant value is too large.

❏

Ifanerror occurs during theevaluationofthe

expression, the resultant field will be filled

with ‘X’s.

-

980352-001 Rev.A

3-7

Page 26

A Command - Simple Expressions in Data Fields

Example:

¿

FK"1"¿

FK"1"¿

FS"1"¿

V00,10,N,"Enter current mileage"¿

A100,100,0,4,1,1,N,"Current mileage is “V00" miles.”¿

A100,200,0,4,1,1,N,"Change oil at “V00+3000" miles.”¿

FE¿

¿

FK"2"¿

FK"2"¿

FS"2"¿

V00,10,N,"Enter current mileage."¿

V01,10,N,"Enter interval mileage."¿

A100,100,0,4,1,1,N,"Current mileage is “V00" miles.”¿

A100,200,0,4,1,1,N,"Mileage interval is “V01" miles.”¿

A100,200,0,4,1,1,N,"Change oil at “V00+V01" miles.”¿

FE¿

¿

FK"3"¿

FK"3"¿

FS"3"¿

V00,10,N,"Enter value 1."¿

V01,10,N,"Enter value 2."¿

V02,10,N,"Enter value 3."¿

A100,200,0,4,1,1,N,"Answer: “V01+123+V00-10-V02¿

FE¿

Asian Character Font

Sets

3-8

The flash based printers support three Asian

languagesets. Asian language support is an op

tional feature and requires a special version of

the printer (PCBA) to support the large Asian

character sets.

The Asian character maps and special features

of the A command that support the character

sets can be found on our Internet site or from

CD ROM. Click on the code page reference (in

the electronic manual version) to display the

Addendum and its code pages.

Chinese Addendum - P/N 980095-061

Japanese Addendum - P/N 980095-071

Korean Addendum - P/N 980095-081

980352-001 Rev.A

-

Page 27

AUTOFR Command - Automatic Form Printing

Description This special form process allows you to detach

the printer from the computer and print in a

standalone mode. The EPL2 printer reserves

the form name AUTOFR to allow the printer to

automaticallystarta form whentheprinteris in

itialized power-up. This feature can be used in

many ways:.

Feed a single label in peel mode and print

·

multiple labels set to the number of labels on

the roll.

Have a form with a variable and enter the

·

variable with a scanner, terminal, weight

scale, circuit analyzer or any other device ca

pable of sending ASCII character data.

Using AUTOFR Download a form to the printer with the name

AUTOFR.

-

-

Example:

¿ :Line Feed to initialize the printer

FK"AUTOFR"¿ :Form Kill (delete any existingAUTOFR)

FS"AUTOFR"¿ :Form Save (save file from here to FE at

: the bottom)

V00,8,L,""¿ :Variable field definition

Q254,20¿ :Label height followed by gap width

S2¿ :Speed (2ips)

D7¿ :Density setting

ZB¿ :Print direction (ZTflips it 180 degrees)

A340,20,0,4,1,2,N,"QUANTITY"¿

:Fixed text line

B265,75,0,3,2,4,101,B,V00¿ :Bar code definition

PA1¿ :Print1 labelAutomatically *

FE¿ :FormEnd (Line Feed)

* - If using the CAL TOOLS, CAL WIN, etc. programs to gener

ate label files (files with .ejf extensions), then the PA command

must be added manually by editing the .ejf file.

-

980352-001 Rev.A

3-9

Page 28

AUTOFR - Automatic Form Printing Feature

AUTOFR treats any incoming data as a variable in

tended for printing. This means if you send the

printer a memory partition command, the label will

print, if you send a delete command - the label will

print! So, while you are testing AUTOFR it isbest to

use another name for the form. Once you are satis

fied with the form, rename it AUTOFR before you

download it.Thereis no need to specify a file exten

sion.

Isolating Data From

the Input Device

Place the printer in the diagnostic dump mode

andsendfromyourdatainput device. All charac

tersthedevicesendswillbeprintedonthelabel.

If nothing prints, nothing is arriving - check

·

pin-outs and serial settings.

Disabling AUTOFR Senda XOFF data character (13 hex. or ASCII

19) oraNUL(00hex.orASCII0)totheprinter.

Theformmaynowbedeletedfromtheprinter.

-

-

-

-

Removing AUTOFR The programmer must send a Delete Form - FK

command to the printer after disabling

AUTOFR.

Example:

FK"AUTOFR"¿

FK"AUTOFR"¿

3-10

980352-001 Rev.A

Page 29

B Command - Bar Code

Description Usethiscommandtoprintstandardbarcodes.

Syntax Bp

Parameters p

p

p

p4= Bar Code selection (see Table 2-1 on

p

p

1,p2,p3,p4,p5,p6,p7,p8

=Horizontal start position (X) in dots

1

= Vertical start position (Y) in dots.

2

= Rotation

3

Value Description

0

1

2

3

No rotation

90 degrees

180 degrees

270 degrees

,"DATA"

next page).

=Narrow bar width in dots. (see Table

5

2-1 on next page).

=Wide bar width in dots.

6

Acceptable values are 2-30.

=Bar code height in dots.

p

7

=Print human readable code.

p

8

Values: B=yes or N=no.

“DATA” = Represents a fixed data field. The

data in this field must comply with the selected

bar code’s specified format.

The backslash (\) character designates the fol

lowing character is aliteral and will encodeinto

thedatafield.Refertothefollowingexamples:

To Print

Enter into data field

“ \”

“Company” \”Company\”

\ \\

\code\ \\code\\

-

980352-001 Rev.A

3-11

Page 30

B Command - Bar Code

Bar Codes

Description

Code 39 std. or extended

Code 39 with check digit

Code 93

Code 128 UCC

Serial Shipping Container Code

Code 128 auto A, B, C modes

Code 128 mode A

Code 128 mode B

Code 128 mode C

Codabar

EAN8

EAN8 2 digit add-on

EAN8 5 digit add-on

EAN13

EAN13 2 digit add-on

P

4

Value

E80 2-4

E82 2-4

E85 2-4

E30 2-4

E32 2-4

Value

3 1-10

3C 1-10

9 1-10

0 1-10

1 1-10

1A 1-10

1B 1-10

1C 1-10

K 1-10

P

5

EAN13 5 digit add-on

German Post Code

Interleaved 2 of 5

Interleaved 2 of 5 with mod 10 check digit

Interleaved 2 of 5 with human readable

check digit

Postnet 5, 9, 11 & 13 digit

Japanese Postnet

UCC/EAN 128*

UPC A

UPC A 2 digit add-on

UPC A 5 digit add-on

UPC E

UPC E 2 digit add-on

UPC E 5 digit add-on

UPC Interleaved 2 of 5

Plessey (MSI-1) with mod. 10 check digit

E35 2-4

2G 3-4

2 1-10

2C 1-10

2D 1-10

P—

J—

1E 1-10

UA0 2-4

UA2 2-4

UA5 2-4

UE0 2-4

UE2 2-4

UE5 2-4

2U 1-10

L—

3-12

MSI-3 with mod. 10 check digit

* - Use ASCII 06 to delimit variable length fields.

M—

980352-001 Rev.A

Page 31

B Command - Bar Code

Example:

Will Produce:

¿

N¿

B10,10,0,3,3,7,200,B,"998152-001"¿

P1¿

Bar Codes with

Variables & Counters

Examples:

The data field can be replaced by or combined

with the following commands:

Vnn =Prints the contents of variable “nn” at

this position. Range of nn = 00 to 99.

Cn =Prints the contents of counter “n” at this

position. Range of n = 0 to 9

See Appendix C for additional Data parame

ters for printers with the RTC (real time clock)

option installed.

B50,0,0,3,1,2,50,B,"DATA"¿ : Writes bar code

B50,50,0,3,1,2,50,N,V01¿ : Writes contents of variable 01 as bar

: code

B50,50,0,3,1,2,50,N,C1¿ : Writes contents of counter 1 asbar

:code

B50,50,0,3,1,2,50,N,C1+2¿ : Writes contents of counter 1 plus2 as

:barcode

or a combination of several options:

B50,300,0,3,1,2,50,B,"Deluxe"V01C2"Combo"V01¿

:Writes the text “Deluxe” followed by the contents of variable 01 fol

lowed by the contents of counter 2 followed by the text “Combo” fol

lowed by the contents of variable 01 all as a code 39 bar code.

-

-

-

980352-001 Rev.A

3-13

Page 32

B Command - Bar Code

Data with the RTC

Time & Date

Functions

Code 128 Bar Code

Function Characters

The “Data” field can be replaced by or com

bined with the following variables:

TT = Prints the current time at this position in

the predefined format. See the TT com

mand for format selection. This variable

is available only if the printer Time &

Date option is installed.

TD =Prints the current date at this position in

the predefined format. See the TD command

for format selection. This variable is available

only if the printer Time & Date option is in

stalled.

Some bar code formats will not support date names

or the date or time delimiters used by the printer to

separate

The printer supports code 128 function control

characters (FCN#). Multiple FCN#s, TTs, TDs

and “DATA” strings can be concatenated, allowing themtobe insertedanywherewithin the

symbol.

-

-

FCN2, FCN3 and FCN4 are illegal in code

128 mode C (p

= 1C) and will result in a syn-

4

tax error.

Please refer to the Code 128 standard for a de

scription of function characters FNC1 through

FNC3.

“Standard” Code 128 can encode all 128 stan

dard ASCII characters (0-127). Function char

acter FCN4 provides a means of also encoding

extended ASCII characters (128-255). It directs

the reader to add 128 to the value of each af

fected character before transmitting it.

Two consecutive FCN4s toggle between stan

dardandextendedASCIImodeforall succeed

ingdatacharacters(until the end of the symbol,

oruntilanotherpairofsisencountered).This is

referred to as latching into extended ASCII

mode or latching into standard ASCII mode.

-

-

-

-

-

-

3-14

980352-001 Rev.A

Page 33

B Command - Bar Code

Code 128 Bar Code

Function Characters

(continued)

A single FCN4 toggles between standard and

extended ASCII mode for only a single follow

ing data character. This is referred to as shifting

into extended ASCII mode or shiftinginto stan

dard ASCII mode.

BothcodesetsA and B are needed to represent

the entire extended ASCII character set, just as

both sets are needed to represent the standard

ASCII character set.

FCN4s can be inserted manually, if necessary

or desired, by following the syntax described

above. The printer will, however, insert them

automatically if extended ASCII characters are

encountered in the DATA. It will do so in the

most efficient manner possible:

·

If up to 4 contiguous extended ASCII charactersareencountered,it willshiftintoextended

ASCII mode by inserting a single FCN4 before each one;

-

-

· If5or more contiguousextended ASCII char-

acters are encountered, it will latch into extended ASCII mode by inserting two FCN4s

before them.

·

While latched into extended ASCII mode, it

will apply the same rules if standard ASCII

characters are encountered.

Thus, the preferred way to encode extended

ASCIIcharacters is tosimplyembed them inthe

DATA and let the printer manage the encoding

task. For best results, the code set should also

not be specified (i.e., p4 = 1). FCN4 s should

be manually insertedonly in systems where ex

tended ASCII characters cannot be transmitted

to the printer.

it is illegal to mix automatic and manual modes

within thedata for a single symbol; i.e.,anextended

ASCIIcharacterencounteredinthedataafter an will

beconsidered asyntaxerror. Likewise,an FCN4 af

ter an extended ASCII character will also be consid

ered a syntax error.

-

-

-

980352-001 Rev.A

3-15

Page 34

b Command - 2D Bar Code - MaxiCode Specific Options

Description Use this command to generate MaxiCode bar

code symbols with a single command. The

printer will automatically interpret and encode

data into MaxiCode symbols for data modes 2,

3,4,and6.Uptoeightsymbolscanbelinked.

Syntax bp

Parameters p

p

p

p

1. If p4(Mx) is not used, the printer willusethe

following rules to automatically format the

“DATA” parameter. If the postal code (third

parameter, PC) in the “DATA” is:

1,p2,p3

=Horizontal start position (X) in dots

1

=Vertical start position (Y) in dots

2

=M - Must be "M" for MaxiCode

3

=Mode Selection

4

·

All numeric characters, the printer will auto

matically select Mode 2.

,[p4,][p5,]“DATA”

Value Description

Not Used Automatic Selection Mode 2 or 3

M2 Mode 2

M3 Mode 3

m4 Mode 4

m6 Mode 6

-

3-16

·

Alpha only or alpha-numeric character com

binations will set the printer to Mode 3.

·

Not used, the printer automatically selects

Mode 3.

2.Ifp4valueis“M2or M3”,the printerwilluse

the following rules toformat the “Data” param

eter:

·

In Mode 2 - If a non-numeric character is en

tered in the Postal Code “Data” parameter

field,thentheMaxiCodebarcodewill notprint.

·

In Mode 3 – If the Postal Code “Data” field

exceed 6 characters, then the additional char

acterswillbetruncatedfromthebar codefield.

980352-001 Rev.A

-

-

-

-

Page 35

b Command - 2D Bar Code - MaxiCode Specific Options

p5= x,y

Associated MaxiCode symbol numbering

where:

x = Symbol Number of

y = Total Number of Associated Sym

bols

Default: Not used

Range: 1-8 for both x or y

-

”DATA”=

Mode dependent data is bounded by quotation

marks. Maximum of 2 KBytes of data.

cl = Class Code (3 digits required)

co = Country Code (3 digits required)

pc = Postal Code

lpm = Low priority message (data)

Mode Dependent Data Format

Mode Data Format

2 & 3 “cl,co,pc,lpm”

4 & 6 “lpm”

Mode 2 = Numeric Characters

Mode 3 = International Characters

(up to 6 characters)

Mode 2 = 5 or 9 characters

(All Numeric, including USA

Postal ZIP 5 or 9 char.)

For less than 9 characters, the

printer will pad the field with 0’s.

Mode 3 (International)= Any

alphanumeric character

(up to 6 characters)

ASCII printable characters (up to

84 characters per symbol), any

256 character map.

980352-001 Rev.A

Theprogrammershould rely onthesymbology's

specification to insure format compliance and

proper implementation. See the AIM web site

for specifications at:

http://www.aimi.org/

3-17

Page 36

b Command - 2D Bar Code - MaxiCode Specific Options

Example:

Will Produce:

N¿

b20,20,M,"300,840,93065,1692,This isMaxiCode, but not MaxiCode

formatted data"¿

P1¿

3-18

980352-001 Rev.A

Page 37

Using AIM Specified

MaxiCode Data

Formatting

The EPL printer can use and automatically de

codetheAIMITS(InternationalTechnical Stan

dards) MaxiCode data format. The printer

detects the message/start header ([)>R

separator (G

(R

SEOT

) data control strings.

), and the end of messagemarker

S

), field

S

The hexadecimal (ASCII) data control strings

are in the following table. See the EPL2 dump

mode character map in Appendix A.

Control String Hexadecimal Code

Message/Start Header

[ ) > R

Field Separator

G

S 1D

End Of Message Marker

RSE

S 5B 29 3E 1E

OT 1E 04

-

-

Syntax bp1,p2,M,p4“[AIM MaxiCode Data]”

Example

b20,400,M,m2”001,840,93065,1692,[)>R

01GS98XXXZZFDAAFGSSHIPGS309GSGS1/1GS10G

NGSGSCAMARILLOGSCAGSRSEOT!!!!!!!!!!!!!!!!!!!!!!!”

¿

Notes:

1) This programming example represents actual data used to

format a single AIM compliant MaxiCode symbol as pro

grammed by a major international and domestic shipping com

pany.

2) The shipper has explicitly set the MaxiCode symbol for Mode

2. This can be omitted by the programmer and the printer will

auto-select the mode per the rules on page 3-16.

3) The shipper has used the "!" character to pad the symbol's

data. A scanner reads back all the "Data" within the quotation

marks, including the "!" characters following the End Of Mes

sage Marker (E

OT

).

S

S

-

-

-

980352-001 Rev.A

4) All of the data fields in the Low Priority Message are not

used in the example. Some are left empty with the field delim

iting G

character used as a format field holder.

S

3-19

-

Page 38

b Command - 2D Bar Code - PDF417 Specific Options

Description Use thiscommandto print PDF 417 and Macro

PDF bar code symbols. The printer will auto

matically change from PDF417 to Macro PDF

barcode mode if the data senttothe printer ex

ceeds the maximum amount supported by the

PDF417 symbol. The oH command is used to

place the addition Macro PDF symbols needed

for the continuation data.

-

-

Theprinterwillautomaticallyoptimizethesym

bol for readability of data (and use the mini

mum number of symbols when using Macro

PDF). The symbol's geometry is adjusted (typi

callyreducing thesizeofthe symbol)perthe de

finedparameters.Theprinterwilluse thelargest

module size (bar width and height) and minimize the number of rows and columns.

Syntax bp

1,p2,p3,p4,p5

[,p

][,p12][,p13][,p14][,p15],”DATA”

11

[,p6][,p7][,p8][,p9][,p10]

Parameters The printer will automatically generate the

PDF417barcodeusingthefollowingparameters.

= Horizontal start position (X) in dots

p

1

= Vertical start position (Y) in dots

p

2

-

-

-

-

3-20

= P - Must be "P" for PDF 417 bar codes

p

3

(www) =maximum print width in dots

p

4

(hhh) = maximum print height in dots

p

5

Theprogrammershould rely onthesymbology's

specification to insure format compliance and

proper implementation. See the AIM web site

for specifications at:

http://www.aimi.org/

980352-001 Rev.A

Page 39

b Command - 2D Bar Code - PDF417 Specific Options

The following parameters may be omitted and de

fault values will automatically be inserted. Each pa

rameter value (data string)mustbe proceeded by its

associated command prefix character.

p6(s) = sets error correction level

Error Correction codewords per symbol

Values: s1 - s8

If level is not specified, a level will automati

cally be assigned as per the following table:

EC level EC Codewords Auto Select Level

02 —

1 4 0-31

2 8 32-63

3 16 64-127

4 32 128-255

5 64 256-511

6 128 512-928

7 256 —

8 512 —

-

-

-

p7(c) = selects data compression method

Values: 0 or 1, default is 0

c0 = Auto-encoding

c1 = Binary mode

Data Type Compression (Byte by Byte)

Text 2 Characters per codeword

Numeric 2.93 Characters per codeword

Binary 1.2 Bytes per codeword

p8(pxxx,yyy,mm) = print human readable

This parameter is a non-standard implemen

tor of the PDF417 and is only

recommended for troubleshooting purposes.

Additional variables:

p ="p" - parameter identifier

xxx = horizontal start location

yyy = vertical start location

mm = maximum characters per line

-

980352-001 Rev.A

3-21

Page 40

b Command - 2D Bar Code - PDF417 Specific Options

p9(f) = Bar code origin point

Values: 0 or 1, Default is 1

f1- Center of bar code as defined by the

automatically adjusted

width and height. Parameters p

values are maximum values only.

p

5

f0- Upper left corner of bar code.

(x) - module width (in dots)

p

10

Values: 2 - 9 (i.e. x2-x9)

Default: Auto selects 6 (dots). Tests data

with maximum size limit set by p

and then the other optional parame

p

5

ters. The printer automatically reduces

the module width in one dot increments

until the data fits within the symbols

maximum dimensions (and other applied parameters) or until 3 dots has

failed, then reports an error.

symbol size, i.e.

4

and

and

4

-

p

(y) - set bar height (in dots)

11

Range: 4 - 99 (i.e. y4-y99)

Default: 4 times module width (p

(r) - maximum row count

p

12

Maximum limit for the number of rows to

be used for auto selecting symbol features.

(l) - maximum column count

p

13

Maximum limit for the number of col

umns to be used for auto selecting sym

bol features.

(t) - truncated flag - legal values are:

p

14

0 = not truncated, 1= truncated

See the PDF 417 specification for details.

(o) - rotation

p

15

Values: 0= 0º, 1= 90º, 2= 180º, 3= 270º

Settings of 90° & 270° will cause the sym

bols maximum height (p

) and width (p5)

4

values to transpose when automatically cal

culating and generating the symbol, i.e. the

height would affect column dimensions

and width would affect row dimensions.

10

)

-

-

-

-

3-22

980352-001 Rev.A

Page 41

b Command - 2D Bar Code - PDF417 Specific Options

"DATA" = ASCII data or Binary data bytes

Represents a fixed data field.

PDF417: General

Information

The backslash (\) character designates the fol

lowing character is aliteral and will encodeinto

thedatafield.Refertothefollowingexamples:

To Print

Enter into data field

“ \”

“Company” \”Company\”

\ \\

\code\ \\code\\

¿ \¿

A PDF417 symbol is organized into minimum

of 3 to a maximum of 90 rows and a minimum

of 5 to a maximum of 34 columns of

codewords.

Eachcodewordis17moduleswide.Thereare4

bars and 4 spaces per codeword.

Multiply the module width (in dots, p

)by17

10

to get the codeword width.

Multiplethemodule height (in dots, p

)bythe

11

number of rows to get the symbol height.

-

Four of the codewords in each row are start,

stop and two row indicators. The remaining

codewords are referred to as the data region

and contain symbol overhead and compacted

data.

There can be no more than 928 codewords in

the data region. All combinations of rows

and columns are notlegal;90rowstimes 30

columns would produce a data region of 2700

codewords which exceeds the 928 codeword

maximum per symbol. See the following table

(on the next page) that shows the maximum

number of rows and the resulting number of

codewords in the data region for each column

count.

980352-001 Rev.A

3-23

Page 42

b Command - 2D Bar Code - PDF417 Specific Options

PDF417

Symbol Geometry

Columns Maximum Rows Codewords

59090

6 90 180

7 90 270

8 90 360

9 90 450

10 90 540

11 90 630

12 90 720

13 90 810

14 90 900

15 84 924

16 77 924

17 71 923

18 66 924

19 61 915

20 58 928

21 54 918

22 51 918

23 48 912

24 46 920

25 44 924

26 42 924

27 40 920

28 38 912

29 37 925

30 35 910

31 34 918

32 33 924

33 32 928

3-24

34 30 900

980352-001 Rev.A

Page 43

b Command - 2D Bar Code - PDF417 Specific Options

Automatic PDF 417

Bar Code Generation

The printer automaticallytests and changes the

PDF 417 bar code geometry to maximize the

readabilityofthebarcodeforagivenmaximum

height and width, specified by p

and p5.

4

Theprinterteststhe PDF 417 parameters inthis

order for a given data string (error correction

and compression included):

1. Module width p

2. Symbol width p

3. Symbol column maximum p

4. Module height p

5. Symbol height p

6. Symbol row maximum p

(for codeword width)

10

4

13

11

5

12

The printer will start with the maximum value

(default or explicit) for these parameters. The

printer reduces these values to get the module

width and height to maximize readability.

980352-001 Rev.A

3-25

Page 44

b Command - 2D Bar Code - PDF417 Specific Options

Example:

Will Produce:

N¿

b80,100,P,700,600,x2,y7,l100,r100,f0,s5," \ ¿

Fourscore and seven years ago our fathers brought forth on this conti

nent a new nation, conceived in liberty and dedicated to the proposi

tion that all men are created equal. Now we are engaged in a great

civil war, testing whether that nation or any nation so conceived and

so dedicated can long endure.

"¿

¿

b80,200,P,400,300,p40,440,20,f1,x3,y10,r60,l5,"ABCDEFGHIJK12345

67890abcdefghijk"¿

P¿

-

-

3-26

Thesecond symbol hasbeenset to printhuman

readable data with the p

parameter

8

(p40,440,20) and is not part of the PDF417

symbol.

980352-001 Rev.A

Page 45

C Command - Counter

Description The counter (C) command defines one of 10

automatic counters used in consecutive num

bering applications (i.e. serial numbers). Coun

ters must be defined after variables.

For Numeric Serialization Only. The counter

function does not support Alpha or Alpha-Numeric

Serialization.

Syntax Cp1, p2, p3, p4, “[-]PROMPT”

-

-

Parameters p

KDU Prompt

Options

=Counter number. Range: 0 to 9

1

=Maximum number of digits for the counter.

p

2

Range: 1 to 29

=Field Justification.

p

3

L = Left R = Right

C = Center N = No Justification

=Step Value. + or - sign followed by a

p

4

single digit of 1-9. Using a step value of

+0 allows the counter to be used as an

additional variable data field.

“PROMPT”= An ASCII text field that will be

transmitted to the KDU or host (via the

serial interface) each time the command

is executed. Typically used to request the

operator to enter a starting counter value.

[-] = Having the first character of the prompt

a single minus sign will cause the

prompt to display only once after form

retrieval.

980352-001 Rev.A

3-27

Page 46

C Command - Counter

TheCcommand isusedinformsthatrequirese

quentialnumbering. Wheninitializingcounters,

they must be defined in order (e.g. C0 first, C1

second...).

Field justification (p

) affects the printing of

3

counter data. When L, R or C are selected, the

counter field is the width of p

justify within the counter (p

lected p

. The N parameter will print the mini

3

value. Data will

2

) field per the se

2

mum number of characters. See programming

example 13 in Appendix H.

Toprintthe contentsofthecounter, the counter

numberis referenced inthe“DATA” field ofthe

A (ASCII text) or B (Bar Code) commands.

If the starting valueofa counter is “1", then no leadingzeropaddingwillbe added.If thestartingvalue is

“01”, then the counter will be padded, up to the

maximum number of digits (p

), with zeros.

2

-

-

-

Example:

Saving and

Protecting

Consecutive

Numbers in

Nonvolatile Memory

Single Digit

Summation with

Counters

C0,10,L,+1,"-Enter Serial Number:"¿

Thisfeature isusefulwhenthe counterfieldrepresentsaserialnumber(orotherstypesofnumbers) that should never be repeated. This

feature allows for automaticretrieval and incre

menting (or decrementing) of the previous

counter value used every time a form is re

trieved (and printed).

By placing one minus sign as the first character

ofthe prompt,theprompt willappearonlyonce

after the form is retrieved, thereby protecting

the integrity of the data.

Add or subtract a single digit from the recalled

countervaluein a form. If formrecalledcounter

C0 had a value of 3, then processing C0+1

wouldyieldavalueof4andC0-2wouldyielda

value of 1.

-

-

3-28

980352-001 Rev.A

Page 47

C Command - Cut Immediate

Description: This command allows the printer to initiate an

immediatemediacut without a form printoper

ation. The printer must have the cutter option

installed.

The C command – Cut Immediate can not

❏

be used inside of a form.

TheinitialcharacterC in a command string is

❏

used for both the Cut Immediate (C) and

Counter Conmmand function (Cp

can only be used within a form. The Cut Im

mediate Command (C) can not be used in a

form.

❏TheCcommand – CutImmediatecan not be

used with the KDU.

) which

1

-

-

Syntax: C

Parameters: None

Example:

C¿

Only cut label liner (backing) or tag stock. Label ad

hesive willbuilt up on the cutter bladeand cause the

cutter to operate poorly or jam if the labels are cut

along with the label liner.

UsetheCcommand-CutImmediate 5timeswithout

medialoaded, toperforma selfcleaning ofthe cutter

blade.

-

980352-001 Rev.A

3-29

Page 48

D Command - Density

Description Use this command to select the print density.

Syntax Dp

1

Parameters p1=Density setting. Acceptable values are:

Model Acceptable Values1Default Value

2722 0 - 15 7

2742 0 - 15 7

3742 0 - 15 7

2443 (Orion) 0 - 15 10

2824 0 - 15 7

2844 0 - 15 10

Hx-146 0 - 15 7

2746 0 - 15 7

2684 (Strata) 0 - 15 7

Note 1: 0 is the lightest print and 15 is the darkest.

The density command controls the amount of

heatproducedbytheprinthead.Moreheatwill

produce a darker image. Too much heat can

cause the printed image to distort.

Example:

The density and speed commands can dramatically

affectprintquality.Changesin thespeedsettingtypically require a change to the print density.

D5¿ : selects density 5

3-30

980352-001 Rev.A

Page 49

dump Command - Enable Dump Mode

Description This command allows the advanced program

mer to force a user diagnostic “data dump”

mode. Sending the dump command to the

printer allows the programmer to compare ac

tualdatasenttoprinterwiththehostprogram.

Send data to the printer after the dump com

mandhasbeenissuedtoevaluateprogramand

printer control data. The printer will process all

data bytes into ASCII character data , range

0-255 decimal (00-FF hexadecimal).

Press the printer’s Feed button until “Out of

Dump” is printed or power cycle the printer to

terminate the dump mode.

Syntax dump

Parameters None

Usethe“DumpMode”charactermap inAppendixA

of the EPL2 programmer’s manual to interpret the

dump mode data (characters printed on the labels)

back into ASCII data.

-

-

-

Example:

Graphicsdatadumpmaybe largeandrequire multiple labels to print.

Set the image buffer width with the q command to

match the media width prior to issuing the dump

command.

Press the Feed button to view dump data that ex

ceedsasingle label’sprintarea. Repeattoviewmore

dump data.

Pressing the Feed button after the dump data is fin

ished printing will cause the printer to exit the dump

mode.

dump¿

-

-

980352-001 Rev.A

3-31

Page 50

eR Command - User Defined Error/Status Character

Description: This command allows the advanced program

mer to specify the printer's error/status report

character for error reporting via the RS-232 se

rial interface.

Syntax: eRp

1,p2

Parameters: p1= Any single ASCII character

Range: 0-255 decimal (00-FF hexadeci

mal)

= Error/Status Response Mode

p

2

p

Mode Descriptions

2

Standard (default):

0

XON (17 dec. / 11 hex.) on Recovery

XOFF (19 dec. / 13 hex.) on Error

Character Only:

1

Reports the selected error/status character

followed by a Carriage Return and Line Feed.

-

-

-

Character & Error/Status Code:

Reports the selected error/status character, er-

2

ror/status code (see page 3-112 for codes),

and then by a Carriage Return and Line Feed.

Example: For Mode 2 Error and Status Reporting:

eR$,2¿ : Sets Error Character to "$" and

: Sets Error Mode to "2".

: User operates and prints with printer.

: User opens print head.

$11¿ : Reports Print Head Open

: User closes print head

$00¿ : Reports No Error

: Printer Ready for next command.

: (Status report for Print Head Closed)

3-32

980352-001 Rev.A

Page 51

EI Command - Print Soft Font Information

Description This command will cause the printer to print a

list of all soft fonts that are stored in memory.

Syntax

Example:

Will Produce:

EI¿

Soft fonts can be downloaded to and deleted from

the printer from the Soft Font Downloader Utility,

CAL Tools or CAL3.

EI¿ :prints soft font list

980352-001 Rev.A

3-33

Page 52

EK Command - Delete Soft Font

Description This command is used to delete soft fonts from

memory.

Soft fonts can be downloaded to and deleted from

the printer from the Soft Font Downloader Utility,

CAL Tools or CAL3.

Syntax EK {“FONTNAME”|"*"}

Parameters “FONTNAME” = By entering the name of a

font, that font will be deleted from mem

ory.

“*” = By including an “*” (wild card), ALL

fonts will be deleted from memory.

-

Example:

EK"A"¿ :deletes font “A”

EK"*"¿ :deletes all fonts

3-34

980352-001 Rev.A

Page 53

ES Command - Store Soft Font

Description This command is used to download and store

soft fonts in memory.

Soft fonts can be downloaded to and deleted from

the printer from the Soft Font Downloader Utility,

CAL Tools or CAL3.

Syntax ES"FONTNAME"p1p2p3a1b1c1“DATA1”a

2b2c2

Parameters “FONTNAME” = One letter font name

“DATA2” ... anbncn“DATAn”

Range: a-z, Lower Case

Lower Case named fonts minimize soft font

·

memory usage to only store fonts down

loaded and have 256 character limit.

The following use hexadecimal

coding for parameter values.

-

p

: Number of characters to be downloaded

1

Range: 00 - FF hex. (0-255 decimal)

for 1 to 256 fonts per soft font set.

: Character Rotation

p

2

·

00 hex. = 0 and 180 degrees

·

01 hex. = 90 and 270 degrees (clockwise)

·

02 hex. = Both 0 and 180 degree rotation

pairandthe90and270degree rotationpair

p3: Font Height

Range: 00 to FF hex.

Measured in dots and expressed as a

hexadecimal number, i.e. 1B hex. = 27

dots

Font height includes accentors and dis

senters of characters and need to fit in

the character cell

·

203 dpi printers =

256 dots = 1.26 inches = 32.03 mm

-

980352-001 Rev.A

·

300 dpi printers = 00 to FF hex.

256 dots = 0.85 inches = 21.67 mm

3-35

Page 54

ES Command - Store Soft Font

a1:(1st) Download Character (map position)

Range: 00 to FF hex.

:(1st) Spacing To Next Print Character

b

1

Downloaded character’s next printed

character position in dots, i.e. Character

tracking - the space between characters.

Must be greater than or equal to the

character width, see parameter c

in a decimal number converted to a

hexadecimal number.

Range: 00 to FF hex.

:(1st) Downloaded Character’s Width

c

1

Dots in a decimal number converted to

a hexadecimal number.

Range: 00 to FF hex.

. Dots

1

“DATA

” : (1st) Character Bitmap

1

× c1= bit map data (in bytes)

p

3

Data is received in bytes, on a line by line

basis. The font character’s 0,0 cell map

position is in the top left corner of the map

as viewed in the 0 degree rotation. See

the examples on the following pages.

:(2nd) Download Character (map position)

a

2

:(2nd) Spacing To Next Print Character

b

2

:(2nd) Downloaded Character’s Width

c

2

“DATA

Repeat for each character until the last char

acter in the set is downloaded.

” : (2nd) Character Bitmap

2

× c2bytes = bit map data

p

3

an: (Last) Download Character (map position)

: (Last) Spacing To Next Print Character

b

n

-

3-36

: (Last) Downloaded Character’s Width

c

n

“DATA

” : Character Bitmap

n

× cnbytes = bit map data

p

3

980352-001 Rev.A

Page 55

ES Command - Store Soft Font

For fonts with the rotation parameter set

for “both” (p

Repeat the individual font character download

for each 90° rotated character from the start of

the character set until the last rotated character

in the set is downloaded.

= 02 hex.):

2

Example of

Measuring Soft Font

Size

a

1-90°b1-90°c1-90°

a

2-90°b2-90°c2-90°

a

3-90°b3-90°c3-90°

a

n-90°

b

n-90°

: (Last) Download Character

: (Last) Spacing To Next Print Charac

ter

c

n-90°

“DATA

: (Last) Downloaded Character’s Width

n-90°

” : Character Bitmap

p

The number of individual character

maps downloaded will be double the

characters in the font set (p

Reference Point

10 Dots

“DATA

“DATA

“DATA

× cnbytes = bit map data

3

1-90°

2-90°

3-90°

”

”

”

).

1

-

980352-001 Rev.A

12

D

o

t

s

8Dots

Parameter Dots Data Entered as Hexadecimal

p

3

b

c 8 08 hex.

12 0C hex.

10 0A hex.

Inter-character Space

(actually white dots)

3-37

Page 56

ES Command - Store Soft Font

Soft Fonts

Programming Code

Example

00000000

00000010

00000020

00000030

00000040

00000050

00000060

00000070

00000080

00000090

000000A0

000000B0

0D 0A 45 4B 22 61 22 0D 0A 45 53 22 61 22 03 00

CR & LF

1A 41 17 03 00 7C 00 00 7C 00 00 7C 00 00 EE 00

p3a1b1c

00 EE 00 01 EF 00 01 C7 00 01 C7 00 03 83 80 03

83 80 07 83 C0 07 01 C0 07 01 C0 0E 00 E0 0F FF

E0 0F FF E0 1F FF F0 1C 00 70 3C 00 78 38 00 38

38 00 38 70 00 1C 70 00 1C F0 00 1E E0 00 0E 00

00 00 42 17 03 1F FF 00 1F FF C0 1F FF E0 1C 01

a2b2c

E0 1C 00 F0 1C 00 70 1C 00 70 1C 00 70 1C 00 E0

1C 01 E0 1F FF C0 1F FF C0 1F FF E0 1C 00 F0 1C

00 70 1C 00 38 1C 00 38 1C 00 38 1C 00 38 1C 00

38 1C 00 70 1C 00 F0 1F FF E0 1F FF C0 1F FF 00

00 00 00 43 19 03 00 7F 00 01 FF C0 03 FF E0 07

The typical soft font download command

strings to the printer. The following example

was generated with the CAL3 software.

..EK"a"..ES"a"..

CR & LF

1

2

p1p

2

.A...|..|..|....

................

................

.........p<.x8.8

8.8p..p.........

..B.............

......p..p..p...

................

.p..8..8..8..8..

8..p............

...C............

000000C0

000000D0

000000E0

000000F0

00000100

a3b3c

C1 F0 0F 00 78 1E 00 38 1C 00 3C 1C 00 18 3C 00

00 38 00 00 38 00 00 38 00 00 38 00 00 38 00 00

38 00 00 38 00 00 1C 00 0C 1C 00 0E 1C 00 1C 0E

00 3C 0F 00 7C 07 C0 F8 03 FF F0 01 FF E0 00 7F

80 00 00 00 0D 0A

3

CR & LF

....x..8..<...<.

.8..8..8..8..8..

8..8............

.<..|...........

......

3-38

980352-001 Rev.A

Page 57

ES Command - Store Soft Font

Font Bitmap Data

Format

The black and white bitmap that represents the

fontmustbeconvertedintoASCIIhexadecimal

code. The 0° font format has dot converted to

data bytes reading from left to right and the last

byte in a line is padded with zeros to complete

the line and data byte.

The 0° and 90° font data is then sent to the

printer in line order.

980352-001 Rev.A

3-39

Page 58

f Command - Cut Position

Description Use this command on an individual printer to

provide precision cut placement.

·

·

Compensate sensor to cutter position differ

ences on a printer by printer basis.

Fine-tune cut position to compensate for dif

ferences in media.

-

-

Syntax fp

1

Parameters p1=Cut position index measured in dots.

Acceptable values: 070 to 130. The de

fault value is 100.

When using the label liner cutter option, the

printer will advance each printed label to the

appropriate programmed offset cut position,

between

labels, before cutting. Due to media

differences, the printer may not accurately

position the labels before cutting, causing the

cutter to cut the label instead of the liner.

The printer’s cutter is not designed to cut labels. Labels have adhesive that may interfere with the

proper operation of the cutter.

Only cut label liner and tag stock anddo not exceed

the specified media density and thickness of the

cutter.

-

3-40

Ifthecut position causes the label justprintedto

be cut, increase the cut position index value

(>100). If the cut position causes the label fol

lowing the one just printed to be cut, decrease

the cut position index value (<100).

980352-001 Rev.A

-

Page 59

FE Command - End Form Store

Description This command is used to end a form store se

quence.

Syntax FE

Example:

FS"FORMNAME"↵

...

FE↵

The form store sequence is started with the FS

command.

-

980352-001 Rev.A

3-41

Page 60

FI Command - Print Form Information

Description This command will cause the printer to print a

list of all forms stored in memory.

Syntax FI

Example:

Will Produce:

FI¿ :prints forms list

3-42

980352-001 Rev.A

Page 61

FK Command - Delete Form

Description This command is used to delete forms from

memory.

Syntax FK [ "FORMNAME" | "*" ]

Parameters “FORMNAME” = By entering the name of a

form, that form will be deleted from

memory.

Thenamemaybeupto8 characterslong.

·

Form names stored by the printer are case

·

sensitive and willbestoredexactly as entered

on the FS command line; i.e. “FORM1”,

“form1” and “FoRm1” are three different

formswhenstored intotheprinter orwhenre

trieved by the user.

Deleting a single form requires the

·

FK”FORMNAME” be issued twice for each

form to be deleted. Some label generation

programs re-issue forms (form delete and

store) every time a label is printed which reduces flash memory life.

-

Example:

“*” = By including an “*” (wild card), ALL

forms will be deleted from memory. The

FK”*” does not need to be issued twice

to delete all forms.