Page 1

ZPL & CPCL

PRINTER DRIVER

FOR OPOS

Application

Programmer’s Guide

P1014152-17EN

Page 2

ZEBRA and the stylized Zebra head are trademarks of Zebra Technologies Corporation, registered in

many jurisdictions worldwide. All other trademarks are the property of their respective owners.

© 2022 Zebra Technologies Corporation and/or its affiliates. All rights reserved.

Information in this document is subject to change without notice. The software described in this document

is furnished under a license agreement or nondisclosure agreement. The software may be used or copied

only in accordance with the terms of those agreements.

For further information regarding legal and proprietary statements, please go to:

SOFTWARE:http://www.zebra.com/linkoslegal

COPYRIGHTS:http://www.zebra.com/copyright

WARRANTY:http://www.zebra.com/warranty

END USER LICENSE AGREEMENT: http://www.zebra.com/eula

Terms of Use

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation and its subsidiaries

(“Zebra Technologies”). It is intended solely for the information and use of parties operating and

maintaining the equipment described herein. Such proprietary information may not be used, reproduced,

or disclosed to any other parties for any other purpose without the express, written permission of Zebra

Technologies.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies. All specifications and designs are

subject to change without notice.

Liability Disclaimer

Zebra Technologies takes steps to ensure that its published Engineering specifications and manuals are

correct; however, errors do occur. Zebra Technologies reserves the right to correct any such errors and

disclaims liability resulting therefrom.

Limitation of Liability

In no event shall Zebra Technologies or anyone else involved in the creation, production, or delivery of the

accompanying product (including hardware and software) be liable for any damages whatsoever

(including, without limitation, consequential damages including loss of business profits, business

interruption, or loss of business information) arising out of the use of, the results of use of, or inability to

use such product, even if Zebra Technologies has been advised of the possibility of such damages. Some

jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

Publication Date

April 28, 2022

2

Page 3

About This Document

Who Should Use This Document

The manual is targeted to an application developer who requires access to POS-specific peripheral

devices.

OPOS Web Sites

Refer to the following web sites for Open Point of Service (OPOS) information:

• Reference implementation — Common Control Objects: http://monroecs.com/opos.htm

How This Document Is Organized

The Application Programmer’s Guide is set up as follows:

• OPOS Information on page 7

• Supported Bar Codes and Fonts on page 9

• Supported Specifications and Printers on page 14

• Common Properties, Methods, and Events on page 16

• Driver Installation on page 28

• Device Manager on page 34

• Test Application on page 62

• ZPL Fonts and Bar Codes on page 70

3

Page 4

Contents

About This Document ........................................................................................................................ 6

Who Should Use This Document..................................................................................... 6

OPOS Web Sites ............................................................................................................. 6

How This Document Is Organized ................................................................................... 6

OPOS Information............................................................................................................................... 7

OLE for Retail POS Controls............................................................................................ 7

How an Application Uses an OPOS Control .................................................................... 7

Summary......................................................................................................................... 8

Supported Bar Codes and Fonts....................................................................................................... 9

Supported Bar Codes....................................................................................................... 9

Supported ZPL Fonts..................................................................................................... 10

Font D..................................................................................................................... 10

Example Command.......................................................................................... 10

Printed Image................................................................................................... 11

Font F ..................................................................................................................... 11

Example Command.......................................................................................... 11

Printed Image................................................................................................... 11

Font A ..................................................................................................................... 11

Example Command.......................................................................................... 11

Printed Image................................................................................................... 11

Supported CPCL Fonts.................................................................................................. 12

Font for Typeface 0 ................................................................................................ 12

Example Command.......................................................................................... 12

Printed Image................................................................................................... 12

Font for Typeface 1 ................................................................................................ 12

Example Command.......................................................................................... 12

Printed Image................................................................................................... 12

Font for Typeface 2 ................................................................................................ 13

Example Command.......................................................................................... 13

4

Page 5

Contents

Printed Image................................................................................................... 13

Supported Specifications and Printers .......................................................................................... 14

Specifications Supported ............................................................................................... 14

Supported Operating Systems....................................................................................... 14

Supported Printers ........................................................................................................ 15

Common Properties, Methods, and Events ................................................................................... 16

Summary of Common Properties................................................................................... 16

Summary of Common Methods ..................................................................................... 17

Summary of Common Events ........................................................................................ 17

Summary of Specific Properties..................................................................................... 18

Summary of Specific Methods ...................................................................................... 22

Summary of Events........................................................................................................ 23

Data Characters and Escape Sequences...................................................................... 23

In-line Barcode Printing.................................................................................................. 25

Driver Installation ............................................................................................................................. 28

OPOS Driver Installation................................................................................................ 28

OPOS Driver Silent Installation..................................................................................... 32

Add Printer Via Command Line .............................................................................. 32

Device Manager ................................................................................................................................ 34

Using the Device Manager............................................................................................. 34

Connecting Using Bluetooth........................................................................................... 36

Connecting Using an IP Address .................................................................................. 37

Connecting Using a Parallel Cable ............................................................................... 38

Connecting Using a Parallel Cable for 64-Bit Machines......................................... 39

Connecting Using a Serial Cable .................................................................................. 42

Connecting Using a USB Cable.................................................................................... 43

Configuration Settings.................................................................................................... 44

Adding a Printer...................................................................................................... 44

Adding a KR403 Kiosk Printer ................................................................................ 45

Output Logging ....................................................................................................... 47

Additional Font Handling............................................................................................... 48

Adding a New Font in Device Manager .................................................................. 48

Assigning Multiple Fonts......................................................................................... 51

Deleting a Font ....................................................................................................... 51

Selecting and Using a Font with Chinese Characters ............................................ 51

5

Page 6

Contents

Setting the Printer Font Information ................................................................. 51

Testing the New Font ....................................................................................... 54

Programming Tips For Using Additional ZPL Fonts....................................................... 55

Use of OPOS Character Properties ............................................................................... 56

KR403 Specific User Interface....................................................................................... 57

Kiosk Printer Settings ............................................................................................. 57

Kiosk Properties ..................................................................................................... 58

New Page:........................................................................................................ 58

Current Page:................................................................................................... 58

Kiosk Values: ................................................................................................... 58

Details for Variable Continuous Mode vs. Continuous Mode ................................. 59

Continuous Mode ............................................................................................. 59

Variable Continuous Mode 2............................................................................ 60

Implementation................................................................................................. 61

Test Application................................................................................................................................ 62

Preparing Windows and Printer for Unicode Printing..................................................... 62

Zebra OPOS Test Application........................................................................................ 63

Printing Unicode with the Test Application.................................................................... 69

ZPL Fonts and Bar Codes................................................................................................................ 70

Standard Printer Fonts................................................................................................... 70

Proportional and Fixed Spacing..................................................................................... 71

Scalable Versus Bitmapped Fonts................................................................................. 72

Scalable Fonts........................................................................................................ 72

Bitmapped Fonts .................................................................................................... 73

Magnification Factor......................................................................................... 73

Changing Bitmapped Font Size ....................................................................... 73

Font Matrices ................................................................................................................. 74

Bar Codes ..................................................................................................................... 77

Basic Format for Bar Codes ................................................................................... 78

Bar Code Field Instructions .................................................................................... 78

Bar Code Command Groups .................................................................................. 80

6

Page 7

OPOS Information

OLE for Retail POS Controls

The goal of this document is to provide an overview and programming guide for the Zebra ZPL & CPCL

Printer Driver for OPOS driver implementation.

How an Application Uses an OPOS Control

The first action the application must take on the Control is to call its Open method. The parameter for this

method selects a device name to associate with the Control. The Open method performs the following

steps:

• Establishes a link to the device name that, in our case, is the Windows

• Initializes the properties OpenResult, Claimed, DeviceEnabled, DataEventEnabled, FreezeEvents,

AutoDisable, DataCount, and BinaryConversion, as well as descriptions and version number of the

OPOS Control layers. Additional class-specific properties may also be initialized.

Several applications may have an OPOS Control open at the same time. Therefore, after the device is

opened, the application will need to call the ClaimDevice method to gain exclusive access to the device.

The device must be claimed before the Control allows access to its methods and properties. Claiming the

device ensures that other applications do not interfere with the use of the device. The application may call

the ReleaseDevice method when the device can be shared by other applications—for instance, at the end

of a transaction.

®

printer driver name.

Before using the device, the application must set the DeviceEnabled property to TRUE. This value brings

the device to an operational state, while FALSE disables the device.

After the application has finished using the device, the DeviceEnabled property should be set to FALSE,

then the ReleaseDevice method, and finally the Close method should be called to release the device and

associated resources. Before exiting, an application should close all open OPOS Controls.

7

Page 8

Summary

OPOS Information

In summary, the application follows this general sequence:

• Open method: Call to link the Control Object to the Service Object.

• ClaimDevice method: Call to gain exclusive access to the device. Required for exclusive-use devices;

optional for some sharable devices.

• DeviceEnabled property: Set to TRUE to make the device operational.

• Use the device.

• DeviceEnabled property: Set to FALSE to disable the device.

• ReleaseDevice method: Call to release exclusive access to the device.

• Close method: Call to release the Service Object from the Control Object.

8

Page 9

Supported Bar Codes and Fonts

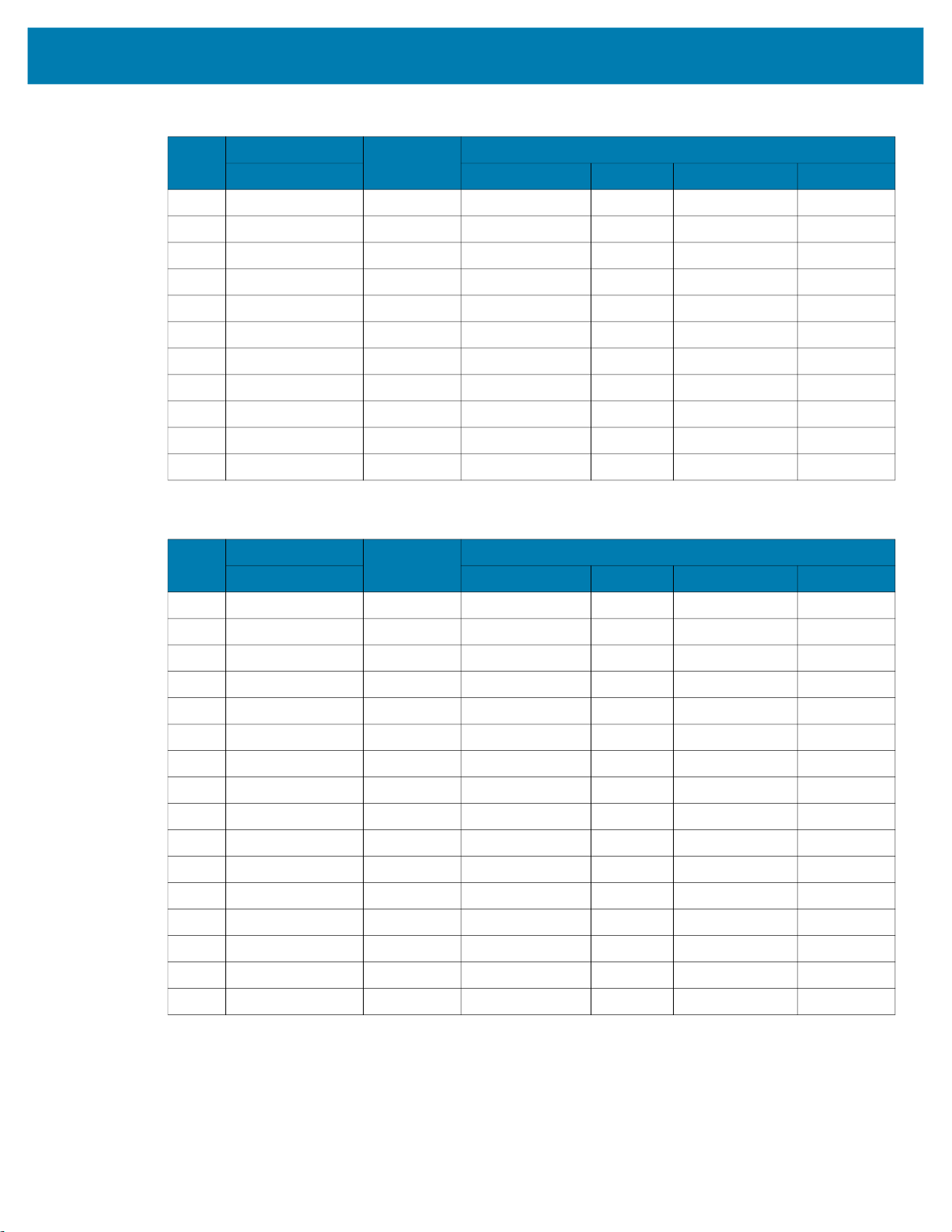

Supported Bar Codes

Barcode Symbology Supported in ZPL Supported in CPCL

Codabar Yes Yes

Code 128 Yes Yes

* Code 128 Parsed Yes Yes

Code 39 Yes Yes

Code 93 Yes Yes

† DataMatrix

* EAN 128 Yes Yes

* EAN 13s

* EAN 8S

EANJan 13 Yes Yes

EANJan 8 Yes Yes

ltf Yes Yes

* Maxicode Yes Yes

* PDF417 Yes Yes

† QRCode

* GS1DataBar Yes Yes

* GS1DataBarExpanded Yes Yes

TF Yes No

UPC-A Yes Yes

* UPC-AS

NOTES:

*Identifies those Barcodes that have no center and right alignments, and the driver will return E_ILLEGAL when used

with PTR_BC_CENTER or PTR_BC_RIGHT.

1) Supports the UPCA with a 5-digit extension for the CPCL firmware.

2) Supports the UPCE with a 5-digit extension for the CPCL firmware.

3) Supports the EAN-x with a 5-digit extension for the CPCL firmware.

† Properties for 2D barcodes:

4) DataMatrix barcode parameters should be in the following range:

Width: 1; Height : <= 30 (depending on width of printer); Alignment: left, center, or right; Text Position: above, below, or

none

5) QRCode parameters should be in the following range:

Width: 1 < 10; Height: 2 <= 10; Alignment: left, center, or right; Text Position: Below

4

3

3

5

1

Yes No

Yes Yes

Yes Yes

Yes No

Yes Yes

9

Page 10

Supported Bar Codes and Fonts

Barcode Symbology Supported in ZPL Supported in CPCL

UPC-D No No

UPC-D2 No No

UPC-D3 No No

UPC-D4 No No

UPC-D5 No No

* OCR-A Yes Yes

OCR-B No No

UPC-E Yes Yes

* UPC-ES

NOTES:

*Identifies those Barcodes that have no center and right alignments, and the driver will return E_ILLEGAL when used

with PTR_BC_CENTER or PTR_BC_RIGHT.

1) Supports the UPCA with a 5-digit extension for the CPCL firmware.

2) Supports the UPCE with a 5-digit extension for the CPCL firmware.

3) Supports the EAN-x with a 5-digit extension for the CPCL firmware.

2

Yes Yes

† Properties for 2D barcodes:

4) DataMatrix barcode parameters should be in the following range:

Width: 1; Height : <= 30 (depending on width of printer); Alignment: left, center, or right; Text Position: above, below, or

none

5) QRCode parameters should be in the following range:

Width: 1 < 10; Height: 2 <= 10; Alignment: left, center, or right; Text Position: Below

Supported ZPL Fonts

Font Typeface

(Value for # in

ESC|#fT)

0 D 18 x 10 24 2 12

1 F 26 x 13 30 3 16

2 A 9 x 5 12 1 6

Font D

Font D will be the default font. If nothing is specified in the print command, this font will be used. The

spacing between lines shall be 24 dots. Counting the inter-character gap of 2 dots the characters are 12

dots wide. In calculating the number of characters that can be placed on an 832 dot line, the result is 69

characters.

Example Command

PrintNormal "123456789ABCDEFGHIJKLMNOPQRSTUVWXYZ6789012345678901234567890123456789"

PrintNormal "0987654321abcdefghijklmnopqrstuvwxyz65432109876543210987654321098765432"

PrintNormal "123456789012345678901234567890123456789012345678901234567890123456789"

PrintNormal "098765432109876543210987654321098765432109876543210987654321098765432"

Font Name

Font Size

(h x w)

Line

Height

Inter-Character

Gap (dots)

Total Width

(dots)

10

Page 11

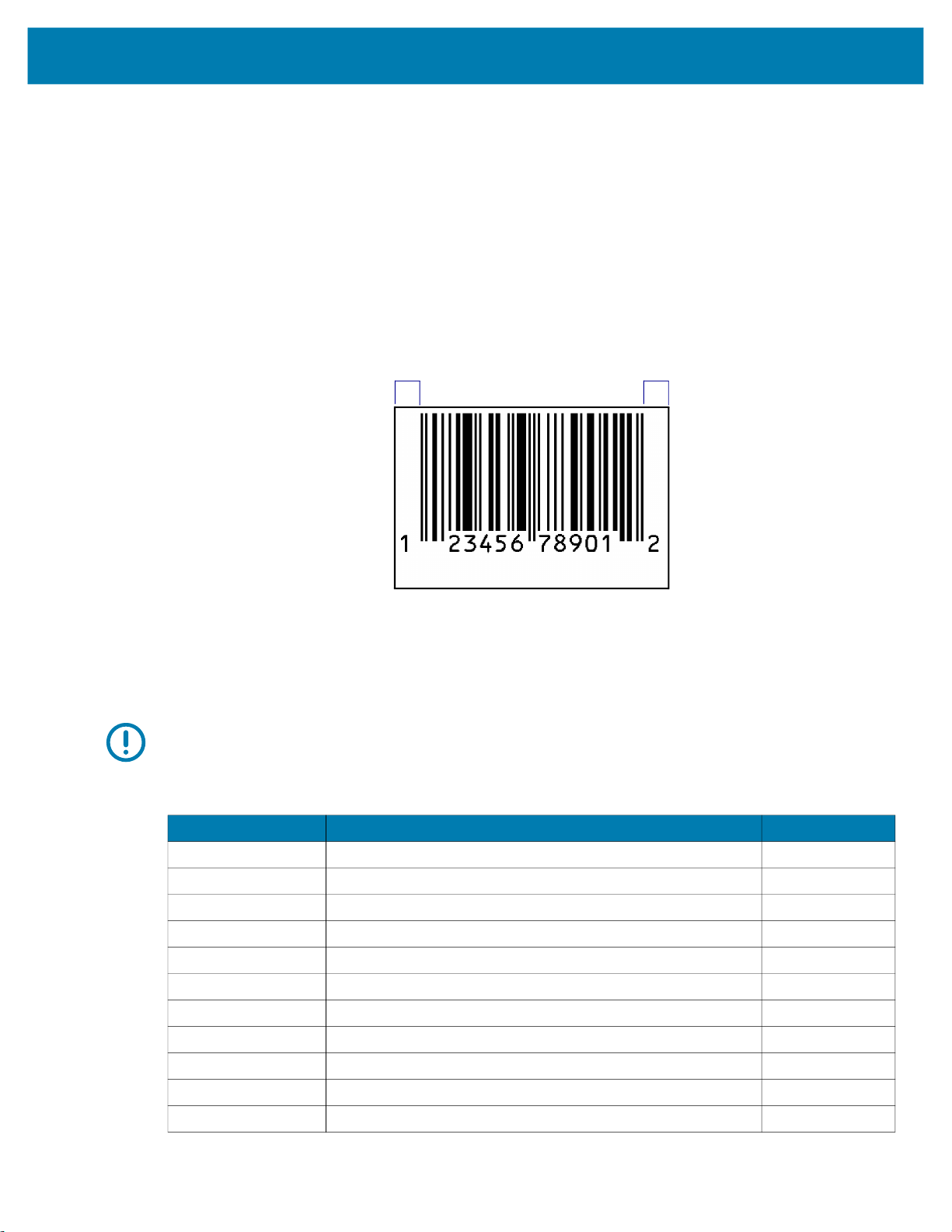

Printed Image

Font F

The spacing between lines shall be 28 dots. Counting the inter-character gap of 3 dots, the characters are

16 dots wide. In calculating the number of characters that can be placed on an 832 dot line, the result is 52

characters.

Example Command

PrintNormal "ESC|1fT1234567890123456789012345678901234567890123456789012"

PrintNormal "ESC|1fT0987654321098765432109876543210987654321098765432109"

PrintNormal "ESC|1fT1234567890123456789012345678901234567890123456789012"

PrintNormal "ESC|1fT0987654321098765432109876543210987654321098765432109"

Supported Bar Codes and Fonts

Printed Image

Font A

The spacing between lines shall be 12 dots. Counting the inter-character gap of 1 dots, the characters are

6 dots wide. In calculating the number of characters that can be placed on an 832 dot line, the result is 138

characters.

Example Command

PrintNormal "ESC|2fT123456789012345678901234567890123456789012345678901234567890123456789"

PrintNormal "ESC|2fT 098765432109876543210987654321098765432109876543210987654321098765432"

PrintNormal "ESC|2fT123456789012345678901234567890123456789012345678901234567890123456789"

PrintNormal "ESC|2fT 098765432109876543210987654321098765432109876543210987654321098765432"

Printed Image

11

Page 12

Supported CPCL Fonts

Supported Bar Codes and Fonts

Font Typeface

(Value for # in

ESC|#fT)

0 7 0 (24 x 12) 24 12

1 0 3 (18 x 16) 18 16

2 Mono1* 0 (24 x 12) 24 12

Note: You must install the Mono1 font. If you do not install this font, you will not receive a printout.

Font for Typeface 0

The Font for typeface 0 will be CPCL font 7. If nothing is specified in the print command this font will be

used. The spacing between lines shall be 24 dots. Counting the inter-character gap of 2 dots, the

characters are 10 dots wide. In calculating the number of characters that can be placed on an 832 dot line,

the result is 69 characters.

Example Command

PrintNormal "0987654321abcdefghijklmnopqrstuvwxyz6543210987654321098765432109876"

PrintNormal "1234567890123456789012345678901234567890123456789012345678901234567"

PrintNormal "0987654321098765432109876543210987654321098765432109876543210987654"

Font Name

Font Size

(h x w)

Line Height Total Width (dots)

Printed Image

Font for Typeface 1

The spacing between lines shall be 28 dots. Counting the inter-character gap of 2 dots, the characters are

14 dots wide. In calculating the number of characters that can be placed on an 832 dot line, the result is 52

characters.

Example Command

PrintNormal "ESC|1fT1234567890123456789012345678901234567890123456789012"

PrintNormal "ESC|1fT0987654321098765432109876543210987654321098765432109"

PrintNormal "ESC|1fT1234567890123456789012345678901234567890123456789012"

PrintNormal "ESC|1fT0987654321098765432109876543210987654321098765432109"

Printed Image

12

Page 13

Font for Typeface 2

The Font for Typeface 2 will be Mono1. The spacing between lines shall be 24 dots. The character width

shall be 12 dots. This amounts to approximately 43 charters on a 3 inch printhead depending on the actual

print width in dots.

Example Command

PrintNormal "ESC|2fT1234567890123456789012345678901234567890123456789012"

PrintNormal "ESC|2fT0987654321098765432109876543210987654321098765432109"

PrintNormal "ESC|2fT1234567890123456789012345678901234567890123456789012"

PrintNormal "ESC|2fT0987654321098765432109876543210987654321098765432109"

Printed Image

Supported Bar Codes and Fonts

13

Page 14

Supported Specifications and Printers

Specifications Supported

• UPOS specification supported: v1.14

• ActiveX supported

• The Common Control Objects (CCO) must be installed from http://monroecs.com/opos.htm for

ActiveX to work.

• .NET framework supported: v4.8

• Use of Microsoft POS for .NET v1.14

Supported Operating Systems

• Windows 10 (32 bit and 64 bit)

• Windows 11

14

Page 15

Supported Specifications and Printers

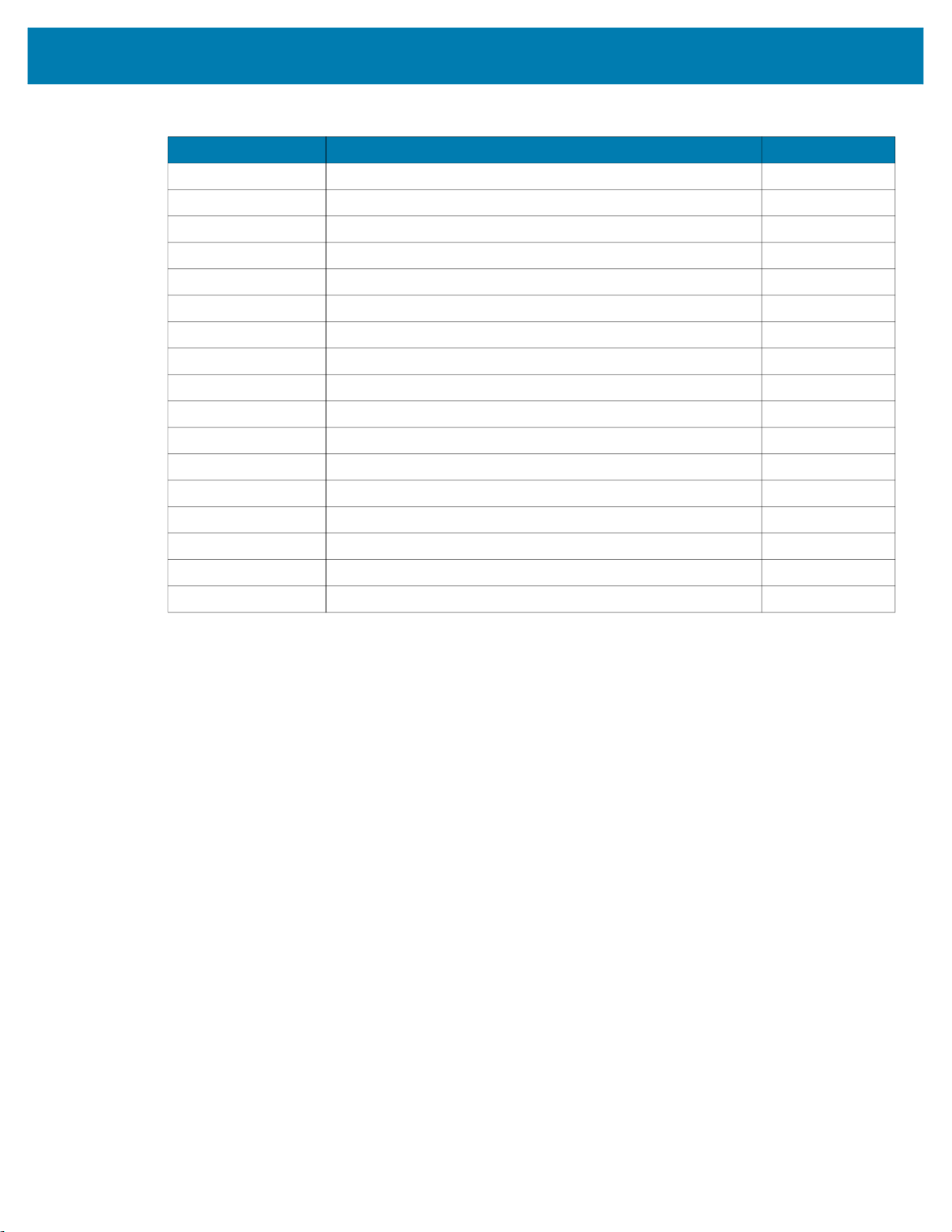

Supported Printers

Table 1 Supported Printer Models (Alphabetical Order)

#’s -QL RW-ZQ ZQ-ZT

105SL (203 dpi, 300 dpi)

110PAX4 (203 dpi, 300 dpi)

110XiIIIPlus (203 dpi, 300 dpi, 600 dpi)

140XiIIIPlus

170PAX4 (203 dpi, 300 dpi)

170XiIIIPlus (203 dpi, 300 dpi)

220XiIIIPlus (203 dpi, 300 dpi)

EZ320

GC420d (ZPL)

GC420t (ZPL)

GK420d

GK420t

GK888d

GK888t

GT800 (203 dpi, 300 dpi, ZPL)

GX420d

GX420s

GX420t

GX430t

iMZ220 (ZPL/CPCL)

iMZ320 (ZPL/CPCL)

KR403

LP 2824 Plus (ZPL)

LP 2824-Z

LP 2844-Z

MZ 220

MZ 320

QL 220 Plus

QL 320 Plus

QL 420 Plus

QLn220 (ZPL/CPCL)

QLn320 (ZPL/CPCL)

QLn420 (ZPL/CPCL)

RW 220

RW 420

S4M (203 dpi, 300 dpi)

TLP 2824 Plus (ZPL)

TLP 2824-Z (203 dpi)

TLP 2844-Z (203 dpi)

TLP 3844-Z (300 dpi)

ZD220 (ZPL)

ZD230 (ZPL)

ZD410 (203 dpi, 300 dpi, ZPL)

ZD411 (203 dpi, 300 dpi, ZPL)

ZD420 (203 dpi, 300 dpi, ZPL)

ZD421 (203 dpi, 300 dpi, ZPL)

ZD500 (203 dpi, 300 dpi, ZPL)

ZD500R (203 dpi, 300 dpi, ZPL)

ZD611 (203 dpi, 300 dpi, ZPL)

ZD611R (203 dpi, 300 dpi, ZPL)

ZD620 (203 dpi, 300 dpi, ZPL)

ZD621 (203 dpi, 300 dpi, ZPL)

ZD621R (203 dpi, 300 dpi, ZPL)

ZD888 (ZPL)

ZE500-4 (203 dpi, 300 dpi, ZPL)

ZE500-6 (203 dpi, 300 dpi, ZPL)

ZE500R-4 (203 dpi, 300 dpi, ZPL)

ZM400 (203 dpi, 300 dpi, 600 dpi)

ZM600 (203 dpi, 300 dpi)

ZQ112 (CPCL)

ZQ120 (CPCL)

ZQ210 (CPCL)

ZQ220 (CPCL)

ZQ310 (ZPL/CPCL)

ZQ320 (ZPL/CPCL)

ZQ510 (ZPL/CPCL)

ZQ511 (ZPL,CPCL)

ZQ511R (ZPL)

ZQ520 (ZPL/CPCL)

ZQ521 (ZPL,CPCL)

ZQ521R (ZPL)

ZQ610 (ZPL/CPCL)

ZQ620 (ZPL/CPCL)

ZQ630 (CPCL, ZPL)

ZQ630R (ZPL)

ZR118 (CPCL)

ZR138 (CPCL)

ZR318(ZPL/CPCL)

ZR328 (ZPL/CPCL)

ZR338 (ZPL/CPCL)

ZR628 (ZPL/CPCL)

ZR638 (ZPL/CPCL)

ZR658 (ZPL/CPCL)

ZR668 (ZPL/CPCL)

ZT210 (203 dpi, 300 dpi, ZPL)

ZT220 (203 dpi, 300 dpi, ZPL)

ZT230 (203 dpi, 300 dpi, ZPL

ZT410 (203 dpi, 300 dpi, 600 dpi, ZPL)

ZT410R (203 dpi, 300 dpi, 600 dpi, ZPL)

ZT411 (203 dpi, 300 dpi, 600 dpi, ZPL)

ZT411R (203 dpi, 300 dpi, 600 dpi, ZPL)

ZT420 (203 dpi, 300 dpi, ZPL)

ZT420R (203 dpi, 300 dpi, ZPL)

ZT421 (203 dpi, 300 dpi, ZPL)

ZT421R (203 dpi, 300 dpi, ZPL

ZT510 (203 dpi, 300 dpi, ZPL)

ZT610 (203 dpi, 300 dpi, 600 dpi, ZPL)

ZT610R (203 dpi, 300 dpi, 600 dpi, ZPL)

ZT620 (203 dpi, 300 dpi, ZPL)

ZT620R (203 dpi, ZPL)

15

Page 16

Common Properties, Methods, and Events

This section provides the common and specific commands for properties, methods, and events.

Summary of Common Properties

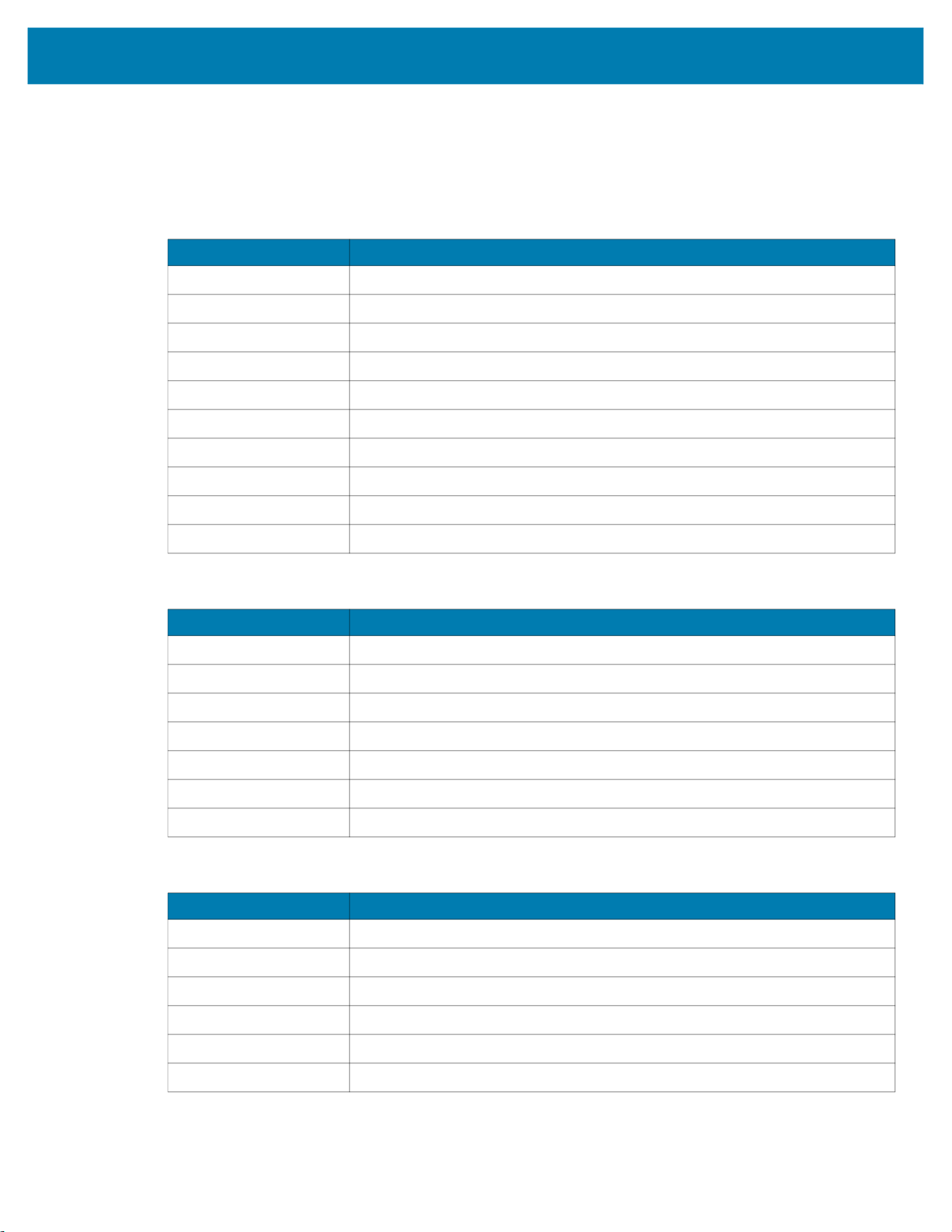

Name Type/Access

AutoDisable Boolean /R/W No No

CapCompareFirmwareVersion Boolean /R No No

BinaryConversion Long R/W No No

CapPower Reporting Long /R Yes Yes

CapStatisticsReporting Boolean /R Yes No

CapUpdateFirmware Boolean /R No No

CapUpdateStatistics Boolean /R No No

CheckHealthTest String /R Yes Yes

Claimed Boolean /R Yes Yes

DataCount Long /R No No

DataEventEnabled Boolean /R/W No No

DeviceEnabled Boolean /R/W Yes Yes

FreezeEvents Boolean /R/W Yes Yes

OpenResult Long /R Yes Yes

OutputID Long /R Yes Yes

PowerNotify Long /R/W Yes Yes

PowerState Long /R Yes Yes

ResultCode Long /R Yes Yes

ResultCodeExtended Long /R Yes Yes

State Long /R Yes Yes

ControlObjectDescription String /R Yes Yes

ControlObjectVersion Long /R Yes Yes

Service ObjectDescription String /R Yes Yes

Supported for Zebra

ZPL Printer

Supported for Zebra

CPCL Printer

16

Page 17

Common Properties, Methods, and Events

Name Type/Access

ServiceObjectVersion Long /R Yes Yes

DeviceDescription String /R Yes Yes

DeviceName String /R Yes Yes

Summary of Common Methods

Name

Open Yes* Yes*

Close Yes Yes

Claim Yes* Yes*

ReleaseDevice Yes Yes

CheckHealth Yes Yes

ClearInput No No

ClearInputProperties No No

ClearOutput Yes Yes

DirectIO Yes Yes

CompareFirmwareVersion No No

ResetStatistics No No

RetrieveStatistics No No

UpdateFirmware No No

UpdateStatistics No No

*Note: The status check has been moved from the Open to the Claim function, which also implies that the driver will always open

even if the printer has an error or is not there.

Supported for Zebra

ZPL Printer

Supported for Zebra

ZPL Printer

Supported for Zebra

CPCL Printer

Supported for Zebra

CPCL Printer

Summary of Common Events

Name

DataEvent No No

DirectIOEvent Yes Yes

ErrorEvent Yes Yes

OutputCompleteEvent Yes Yes

StatusUpdateEvent Yes Yes

17

Supported for Zebra

ZPL Printer

Supported for Zebra

CPCL Printer

Page 18

Common Properties, Methods, and Events

Summary of Specific Properties

Name Type/Access

CapConcurrentJrnRec Boolean /R No No

CapConcurrentJrnSlp Boolean /R No No

CapConcurrentRecSlp Boolean /R No No

CapCoverSensor Boolean /R Yes Yes

CapTransaction Boolean /R Yes Yes

CapConcurrentPageMode Boolean /R No No

CapMapCharacterSet Boolean /R No No

CapJrnPresent Boolean /R Yes Yes

CapJrn2Color Boolean /R Yes Yes

CapJrnBold Boolean /R Yes Yes

CapJrnCartridgeSensor Long /R Yes Yes

CapJrnColor Long /R Yes Yes

CapJrnDhigh Boolean /R Yes Yes

CapJrnDwide Boolean /R Yes Yes

CapJrnDwideDhigh Boolean /R Yes Yes

CapJrnEmptySensor Boolean /R Yes Yes

CapJrnItalic Boolean /R No No

CapJrnNearEndSensor Boolean /R No No

CapJrnUnderline Boolean /R No No

CapRecPresent Boolean /R Yes Yes

CapRec2Color Boolean /R Yes Yes

CapRecBarCode Boolean /R Yes Yes

CapRecBitmap Boolean /R Yes Yes

CapRecBold Boolean /R Yes Yes

CapRecCartridgeSensor Long /R Yes Yes

CapRecColor Long /R Yes Yes

CapRecDhigh Boolean /R Yes Yes

CapRecDwide Boolean /R Yes Yes

CapRecDhighDwide Boolean /R Yes Yes

CapRecEmptySensor Boolean /R Yes Yes

CapRecItalic Boolean /R No No

CapRecLeft90 Boolean /R Yes Yes

CapRecMarkFeed Long /R Yes Yes

CapRecNearEndSensor Boolean /R No No

CapRecPapercut Boolean /R Yes Yes

CapRecRight90 Boolean /R Yes Yes

CapRecRotate180 Boolean /R Yes Yes

Supported for

Zebra ZPL Printer

Supported for

Zebra CPCL

Printer

18

Page 19

Common Properties, Methods, and Events

Name Type/Access

CapRecStamp Boolean /R No No

CapRecUnderline Boolean /R No No

CapRecPageMode Boolean /R Yes Yes

CapRecRuledLine Int32 No No

CapSlpPageMode Boolean /R No No

CapSlpRuledLIne Int32 No No

CapSlpPresent Boolean /R No No

CapSlpFullslip Boolean /R No No

CapSlp2Color Boolean /R No No

CapSlpBarCode Boolean /R No No

CapSlpBitmap Boolean /R No No

CapSlpBold Boolean /R No No

CapSlpBothSidesPrint Boolean /R No No

CapSlpCartridgeSensor Long /R No No

CapSlpColor Long /R No No

CapSlpDhigh Boolean /R No No

CapSlpDwide Boolean /R No No

CapSlpDhighDwide Boolean /R No No

CapSlpEmptySensor Boolean /R No No

CapSlpItalic Boolean /R No No

CapSlpLeft90 Boolean /R No No

CapSlpNearEndSensor Boolean /R No No

CapSlpRight90 Boolean /R No No

CapSlpRotate180 Boolean /R No No

CapSlpUnderline Boolean /R No No

AsyncMode Boolean /R/W Yes Yes

CartridgeNotify Long /R/W Yes Yes

CharacterSet Long /R/W Yes Yes

CharacterSetList String /R Yes Yes

CoverOpen Boolean /R No No

ErrorLevel Long /R Yes Yes

ErrorStation Long /R Yes Yes

ErrorString String /R Yes Yes

FontTypefaceList String /R Yes Yes

FlagWhenIdle Boolean /R/W No No

MapCharacterSet Boolean /R/W No No

MapMode*

See the NOTE Regarding MapMode:

on page 21.

Long /R/W Yes Yes

Supported for

Zebra ZPL Printer

Supported for

Zebra CPCL

Printer

19

Page 20

Common Properties, Methods, and Events

Name Type/Access

PageModeArea String /R/W Yes Yes

PageModeDescriptor Int32 R/W Yes Yes

PageModeHorizontalPosition Int32 R/W Yes Yes

PageModePrintArea String /R/W Yes Yes

PageModePrintDirection Int32 R/W Yes Yes

PageModeStation Int32 R/W Yes Yes

PageModeVerticalPosition Int32 R/W Yes Yes

RotateSpecial Long /R/W Yes Yes

JrnLineChars Long /R/W Yes Yes

JrnLineCharsList String /R Yes Yes

JrnLineHeight Long /R/W Yes Yes

JrnLineSpacing Long /R/W Yes Yes

JrnLineWidth Long /R Yes Yes

JrnLetterQuality Boolean /R/W Yes Yes

JrnEmpty Boolean /R Yes Yes

JrnNearEnd Boolean /R Yes Yes

JrnCartridgeState Long /R Yes Yes

JrnCurrentCartridge Long /R/W Yes Yes

RecLineChars Long /R/W Yes Yes

RecLineCharsList String /R Yes Yes

RecLineHeight Long /R/W Yes Yes

RecLineSpacing Long /R/W Yes Yes

RecLineWidth Long /R Yes Yes

RecLetterQuality Boolean /R/W Yes Yes

RecEmpty Boolean /R No No

RecNearEnd Boolean /R No No

RecSidewaysMaxLines Long /R Yes Yes

RecSidewaysMaxChars Long /R Yes Yes

RecLinesToPaperCut Long /R Yes Yes

RecBarCodeRotationList String /R Yes Yes

RecBitmapRotationList String /R No No

RecCartridgeState Long /R Yes Yes

RecCurrentCartridge Long /R/W Yes Yes

SlpLineChars Long /R/W No No

SlpLineCharsList String /R No No

SlpLineHeight Long /R/W No No

SlpLineSpacing Long /R/W No No

SlpLineWidth Long /R No No

SlpLetterQuality Boolean /R/W No No

Supported for

Zebra ZPL Printer

Supported for

Zebra CPCL

Printer

20

Page 21

Common Properties, Methods, and Events

Name Type/Access

SlpEmpty Boolean /R No No

SlpNearEnd Boolean /R No No

SlpSidewaysMaxLines Long /R No No

SlpSidewaysMaxChars Long /R No No

SlpMaxLines Long /R No No

SlpLinesNearEndToEnd Long /R No No

SlpBarCodeRotationList String /R No No

SlpBitmapRotationList String /R No No

SlpPrintSide Long /R No No

SlpCartridgeState Long /R No No

SlpCurrentCartridge Long /R/W No No

NOTE Regarding MapMode:

In the Zebra SO, MapMode applies only to RecLineCharsList settings.

Supported for

Zebra ZPL Printer

Supported for

Zebra CPCL

Printer

The following properties may get changed:

• RecLineChars, RecLineHeight, RecLineSpacing

• RecLineWidth, RecSidewaysMaxChars, RecSidewaysMaxLines

• RecLinesToPaperCut

The following properties are not changed:

• PageModeArea property

• PageModePrintArea property

• PageModeHorizontalPosition

• PageModeVerticalPosition

Barcode printing: printBarcode

• Due to the nature of the printer barcodes and how they are generated and printed Zebra allows only

specific DOT values for barcode width and height as outlined in the barcode notes.

Bitmap printing: printBitmap

• The width of the bitmap is ignored and therefore not converted.

21

Page 22

Common Properties, Methods, and Events

Summary of Specific Methods

Name

Supported for:

Zebra ZPL

Printer

Zebra CPCL

Printer

Name

Zebra ZPL

Supported for:

Printer

Zebra CPCL

Printer

PrintNormal Yes Yes RotatePrint Yes Yes

PrintTwoNormal No No PrintBarcode *‡ Yes Yes

PrintImmediate Yes Yes PrintBitmap

#

Yes Yes

PrintMemoryBitmap Yes Yes TransactionPrint Yes Yes

BeginInsertion No No ValidateData Yes Yes

EndInsertion No No SetBitmap Yes Yes

BeginRemoval No No SetLogo Yes Yes

ClearPrintArea Yes Yes ChangePrintSide No No

EndRemoval No No MarkFeed Yes Yes

CutPaper Yes Yes PageModePrint Yes Yes

DrawRuledLine No No

* NOTE: The provided OPOS constant for Data Matrix and QR code will not work with the PrintBarCode function. You must replace the provided OPOS

constant BarCodeSymbology.QRCode with the custom OPOS constant BarCodeSymbology.Other and BarCodeSymbology.DataMatrix with

(BarCodeSymbology.Other + 1). Additionally, to use the QR barcode, the driver uses the ^HB command, which is not supported on the KR403 printer.

You need custom firmware for this feature.

‡ NOTE: The effect of the PrintBarCode width parameter depends on the Barcode symbology being used.

# NOTE: The width parameter of the printBitmap method will be ignored as only the width of the actual bitmap will be taken into consideration.

Therefore the Map Mode parameter will not have any effect on this function.

For the following barcodes, the width parameter,

supplied in the PrintBarcode method, controls the

barcode module width in dots, and must be a value

between 1 and 10.

• Code 39, Code 128, Code 128 parsed

• Ean8s, Ean13s

• EanJan8, EanJan13

• ITF (Code 2 of 5)

For the following barcodes, the width parameter,

supplied in the PrintBarcode method, has no effect

and the barcodes print with fixed ZPL values

according to the description below:

• Code 93 has a fixed width as defined by the ZPL

command ^BY4.

• QR Code has a fixed width as defined by the

ZPL command ^BY2.

• Data Matrix has a fixed width as defined by the

ZPL command ^BY2.

• TF has a fixed width as defined by the ZPL

command ^BY4.

• UPCD1 to UPCD5 have a fixed width as defined

by the ZPL command ^BY2.

• UPCE has a fixed width as defined by the ZPL

command ^BY4.

For the following barcodes, the barcode

module width is calculated using the width

parameter supplied in the PrintBarcode

method.

• Codabar

• Ean128

• MaxiCode

• PDF417

• GS1 Data Bar and GS1 Data Bar

Expanded

• UPCA, UPCAs

• UPCEs

22

Page 23

Summary of Events

Common Properties, Methods, and Events

Name May Use After

DataEvent Not Supported No No

DirectIOEvent Open, Claim & Enable Yes Yes

ErrorEvent Open, Claim & Enable Yes Yes

OutputCompleteEvent Open, Claim & Enable Yes Yes

StatusUpdateEvent Open, Claim & Enable Yes Yes

Data Characters and Escape Sequences

The default character set of all POS printers is assumed to support at least the ASCII characters 0x20

through 0x7F, which include spaces, digits, uppercase, lowercase, and some special characters. If the

printer does not support lowercase characters, then the Service may translate them to uppercase.

Every escape sequence begins with the escape character, whose value is 27 decimal, followed by a

vertical bar (‘|’). This is followed by zero or more digits and/or lowercase alphabetic characters. The

escape sequence is terminated by an uppercase alphabetic character.

If a sequence does not begin with ESC "|", or it begins with ESC "|" but is not a valid UnifiedPOS escape

sequence, the Service will make a reasonable effort to pass it through to the printer. However, not all such

sequences can be distinguished from printable data, so unexpected results may occur.

The application can use the ESC|#E escape sequence to ensure more reliable handling of the amount of

data to be passed through to the printer. Use of this escape sequence will make an application

non-portable. The application may, however, maintain portability by performing Embedded Data Escape

sequence calls within conditional code. This code may be based upon the value of the

DeviceServiceDescription, the PhysicalDeviceDescription, or the PhysicalDeviceName property.

Supported for

Zebra ZPL

Printer

Supported for

Zebra CPCL

Printer

NOTE: This command sequence definition and the corresponding definition in the Point Card Reader

Writer Chapter, are the only known deviations from preserving the interchangeability of devices defined in

this specification. If an application finds it necessary to utilize this command sequence, please inform the

UnifiedPOS Committee with the details of its usage, so that a possible standard/generic Application

Interface may be incorporated into a future release of the UnifiedPOS Standard. In order to preserve

peripheral independence and interoperability at the Application level, it is the Committee’s position that this

command sequence should be used only as a “last resort”.

To determine if escape sequences or data can be performed on a printer station, the application can call

the validateData method. (For some escape sequences, corresponding capability properties can also be

used.)

The following escape sequences are recognized. If an escape sequence specifies an operation that is not

supported by the printer station, then it is ignored.

Commands, outlined in Table 2, perform the indicated action.

23

Page 24

Common Properties, Methods, and Events

Table 2 Commands

Name Data Remarks ZPL Printer CPCL Printer

a

Paper cut ESC |#P Cuts receipt paper. The character '#' is replaced by an

Yes

ASCII decimal string telling the percentage cut

desired. If '#' is omitted, then a full cut is performed.

For example: The C string "\x1B|75P" requests a 75%

partial cut.

a

Feed and

Paper cut

ESC |#fP Cuts receipt paper, after feeding the paper by the

RecLinesToPaperCut lines. The character '#' is

Yes

defined by the "Paper cut" escape sequence.

Feed, Paper

cut, and Stamp

ESC |#sP Cuts and stamps receipt paper, after feeding the

paper by the RecLinesToPaperCut lines. The

No No

character '#' is defined by the "Paper cut" escape

sequence.

Fire stamp ESC |sL Fires the stamp solenoid, which usually contains a

No No

graphical store emblem.

Print bitmap ESC |#B Prints the pre-stored bitmap. The character '#' is

Yes Yes

replaced by the bitmap number. See setBitmap

method.

Print top logo ESC |tL Prints the pre-stored top logo. Yes Yes

Print bottom

ESC |bL Prints the pre-stored bottom logo. Yes Yes

logo

Feed lines ESC |#lF Feed the paper forward by lines. The character '#' is

Yes Yes

replaced by an ASCII decimal string telling the

number of lines to be fed. If '#' is omitted, then one line

is fed.

Feed units ESC |#uF Feed the paper forward by mapping mode units. The

Yes Yes

character '#' is replaced by an ASCII decimal string

telling the number of units to be fed. If '#' is omitted,

then one unit

Feed reverse ESC |#rF Feed the paper backward. The character '#' is

No No

replaced by an ASCII decimal string telling the

number of lines to be fed. If '#' is omitted, then one line

is fed.

Pass through

embedded data

ESC |#E Send the following # characters of data through to the

hardware without modifying it. The character '#' is

Yes Yes

replaced by an ASCII decimal string telling the

number of bytes following the escape sequence that

should be passed through as-is to the hardware.

Print in-line

barcode

ESC |#R Prints the defined barcode in-line. The character '#' is

the number of characters following the R to use in the

Yes Yes

definition of the characteristics of the barcode to be

printed. See details below.

Note: The QR and Data Matrix codes can be

configured with the Microsoft defined constants.

Notes:

a. All printers will perform only a full cut. The Kiosk printer KR403 is the only exception. You need to configure the partial cut in the Device Manager and

use the Escape command to activate the partial cut in your data stream.

Yes

Yes

a

a

24

Page 25

Common Properties, Methods, and Events

In-line Barcode Printing

The application can use the ESC|#R escape sequence to print barcodes in-line with other print commands.

The character '#' is the number of characters following the R to use in the definition of the characteristics of

the barcode to be printed.

In the data following the R, other lower case letters and numbers are used to identify different values. The

same value definitions as defined for the printBarCode method headers and definitions are used for the

various barcode values. Converting to string the values from the definitions are consistent.

The attribute symbols are defined as follows:

s symbology h height w width a alignment

t human readable text position

d start of data

e end of sequence

The attributes must appear in the order specified in the above list.

Using a basic UPCA, center aligned, with bottom text, 200 dots height and ~400 dots wide, the command

is as follows:

ESC|33Rs101h200w400a-2t-13d123456789012e

Commands associated with Print Mode characteristics (see Table 3) are remembered until explicitly

changed.

Table 3 Print Mode Commands

Name Data Remarks ZPL Printer CPCL Printer

Font typeface

selection

Commands associated with Print Line characters (see Table 4) are reset at the end of each print method,

by an explicit reset (where applicable), or by a “Normal” sequence.

ESC |#fT Selects a new typeface for the

following data. Values for the

character '#' are:

0 = Default typeface.

= Select first typeface from the

1

FontTypefaceList property.

= Select second typeface from the

2

FontTypefaceList property.

And so on.

Yes Yes

25

Page 26

Common Properties, Methods, and Events

Table 4 Print Line Commands

Name Data Remarks ZPL Printer CPCL Printer

Bold ESC |(!)bC Prints in bold or double-strike. If '!' is specified then bold

is disabled.

Underline ESC |#uC Prints with underline. The character '#' is replaced by

an ASCII decimal string telling the thickness of the

underline in printer dot units. If '#' is omitted, then a

printer-specific default thickness is used.

Italic ESC |(!)iC Prints in italics. If '!' is specified then italic is disabled. No No

Alternate color

(Custom)

ESC |#rC Prints using an alternate custom color. The character '#'

is replaced by an ASCII decimal string indicating the

desired color. The value of the decimal string is equal to

the value of the cartridge constant used in the printer

device properties. If '#' is omitted, then the secondary

color (Custom Color 1) is selected. Custom Color 1 is

usually red.

Reverse video ESC

|(!)rvC

Prints in a reverse video format. If '!' is specified then

reverse video is disabled.

Shading ESC |#sC Prints in a shaded manner. The character '#' is

replaced by an ASCII decimal string telling the

percentage shading desired. If '#' is omitted, then a

printer-specific default level of shading is used.

Single high

ESC |1C Prints normal size. Yes Yes

and wide

Double wide ESC |2C Prints double-wide characters. Yes Yes

Double high ESC |3C Prints double-high characters. Yes Yes

Double high

ESC |4C Prints double-high/double-wide characters. Yes Yes

and wide

Scale

horizontally

RGB Color ESC |#fC Prints in

ESC |#hC Prints with the width scaled '#' times the normal size,

where '#' is replaced by an ASCII decimal string.

# color. The character '#' is replaced by an ASCII

decimal string indicating the additive amount of RGB to

produce the desired color. There are 3 digits each of Red,

Green, and Blue elements. Valid values range from "000"

to "255". (E.g., "255255000" represents yellow). Color

Matching to the subtractive percentage of CMY (Cyan,

Magenta and Yellow color components) to produce the

desired color matching specified by RGB is up to the

Service. If '#' is omitted, then the primary color is used.

Bitmap printing is not affected.

SubScript ESC

|(!)tbC

SuperScript ESC

|(!)tpC

†

Note: The justification (or alignment) associated with these ESC commands are only supported when using internal or downloaded TTF monospaced

fonts for both, ZPL and CPCL printers. Justification is not supported when using proportional fonts.

Prints SubScript characters. If '!' is specified then

SubScript is disabled.

Prints SuperScript characters. If '!' is specified then

SuperScript is disabled.

Yes Yes

No No

No No

No No

Yes Yes

No No

No No

No No

26

Page 27

Common Properties, Methods, and Events

Name Data Remarks ZPL Printer CPCL Printer

†

Center ESC |cA Aligns following text in the center. Yes Yes

†

Right justify ESC |rA Aligns following text at the right. Yes Yes

†

Left justify ESC |lA Aligns following text at the left. Yes Yes

Normal ESC |N Restores printer characteristics to normal condition. Yes Yes

†

Note: The justification (or alignment) associated with these ESC commands are only supported when using internal or downloaded TTF monospaced

fonts for both, ZPL and CPCL printers. Justification is not supported when using proportional fonts.

27

Page 28

Driver Installation

This section provides the steps to install the OPOS printer driver.

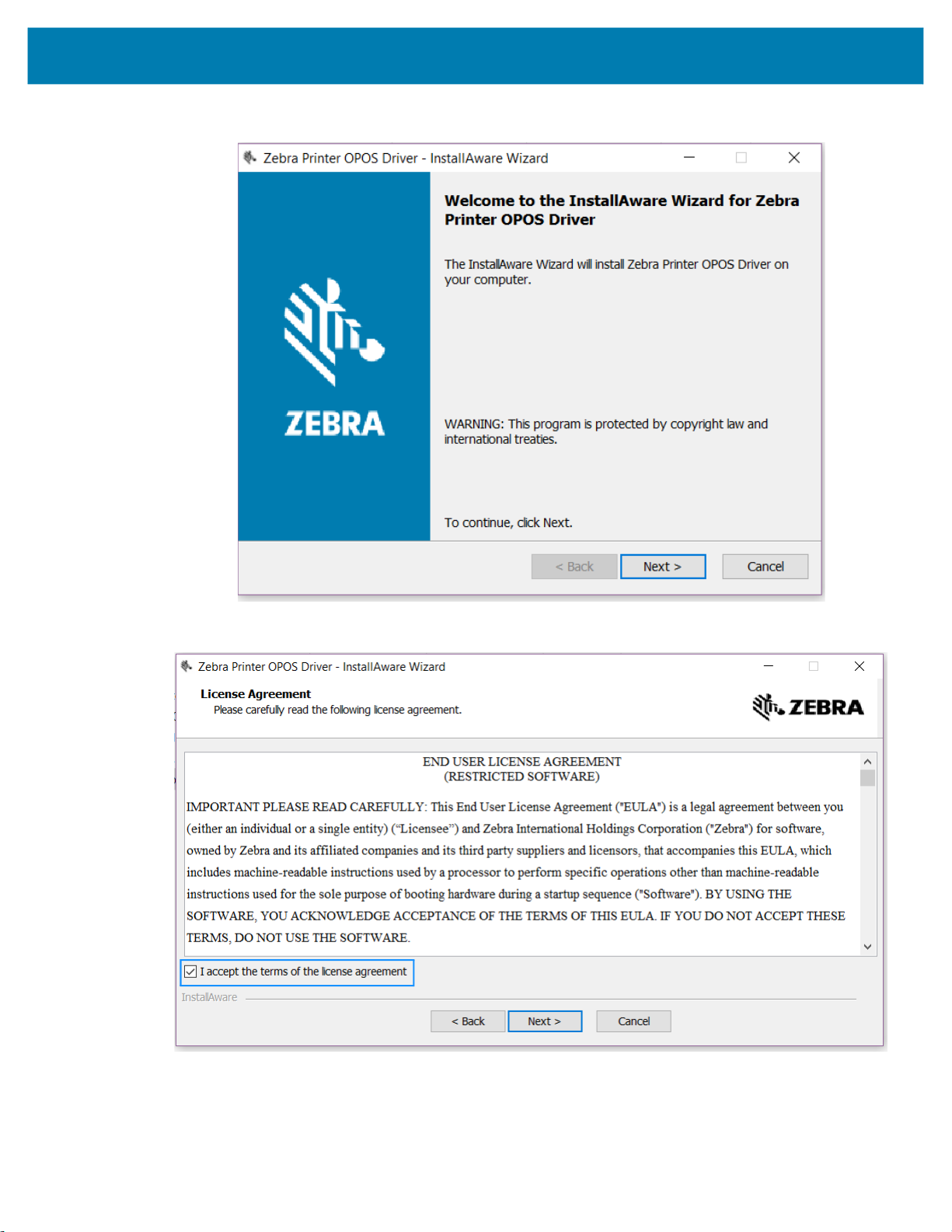

OPOS Driver Installation

To start the installation, perform the following steps.

1. Open the installation file

(where X reflects the version of this driver and changes with each new version.)

The User Account Control dialog box opens.

2. Click Yes to install the driver.

zebra-printer-opos-driver-installer-X_XX_X_XX.exe.

The Welcome to the InstallAware Wizard opens.

28

Page 29

3. Click Next to continue.

Driver Installation

The License Agreement dialog box opens.

4. Select the I accept the terms of the license agreement checkbox.

29

Page 30

Driver Installation

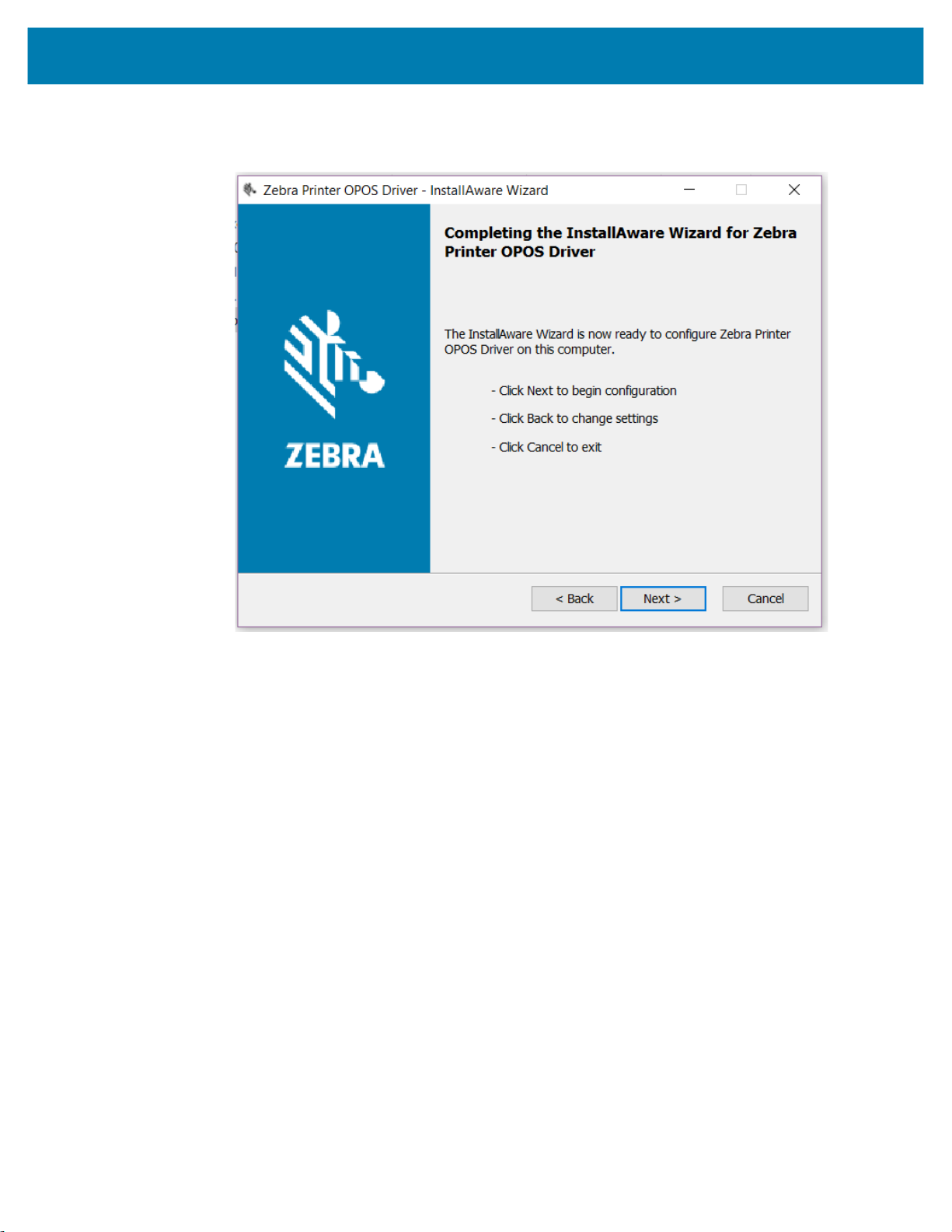

5. Click Next to accept the license agreement.

The Completing the InstallAware Wizard dialog box opens.

30

Page 31

Driver Installation

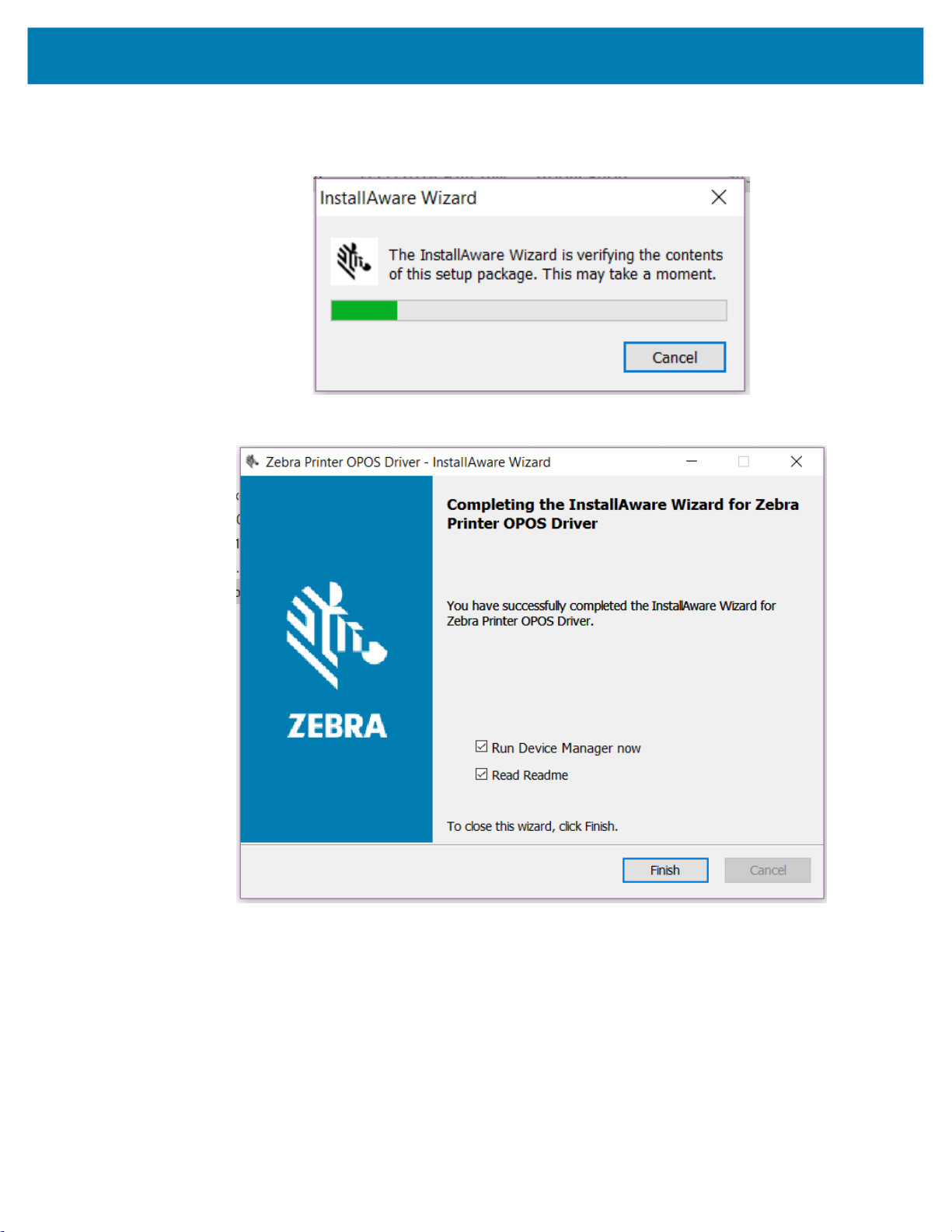

6. Click Next to confirm and begin the installation.

The InstallAware Wizard dialog box opens.

The Installation Complete dialog box opens.

7. Select the Read Readme checkbox, if desired, and the file will open in an Internet Explorer browser.

8. Click Finish.

9. To configure your printer for use with the OPOS driver, use the Device Manager. See Device Manager

on page 34 for more information on configuration.

31

Page 32

Driver Installation

OPOS Driver Silent Installation

To silently install the OPOS driver, you must start the executable with the /s command line parameter.

zebra-printer-opos-driver-installer-X_XX_X_XX.exe /s

This will preinstall the driver, the test application, and Device Manager, but will not install any printers. To

install a printer, you must use the Device Manager or have the Zebra Custom Application Group (CAG)

create a special driver.

Add Printer Via Command Line

To add a printer via command line you can also use the POSDM tool found in the C:\Program Files

(x86)\Microsoft Point Of Service directory.

To properly add a Zebra printer you must add all properties that the Device Manager configures when a

printer is getting added.

The following is a sample batch file to install a printer via POSDM: (Note: all the properties must be

adjusted to the printer properties that should be installed.)

@echo on

rem batch adding a new Zebra OPOS printer via Ethernet or WiFi

rem %~1=port

rem %2=printer name

rem %3=printer family

rem all properties like labellength, pagewidth, darkness, printspeed, etc. should be

established before and added to the batch

If "%~1"=="" goto usage

If "%~2"=="" goto usage

If "%~3"=="" goto usage

posdm adddevice %~1 /type:PosPrinter /soname:ZPLSO

posdm addname %~2 /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty PortType IP/WiFi /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty PortName %~1 /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty ModelName "%~3" /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty DNSName "" /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty interface ETHERNET /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty portNumber 9100 /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty ItemList "" /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty units Mm /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty labellength 0 /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty pagewidth 832 /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty darkness 30 /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty pollingInterval 60 /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty printspeed 5 /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty orientation Off /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty mirrorimage Off /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty isCutterEquipped No /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty EnableAuditLog On /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty operationmode Rewind /type:PosPrinter /soname:ZPLSO /path:%~1

32

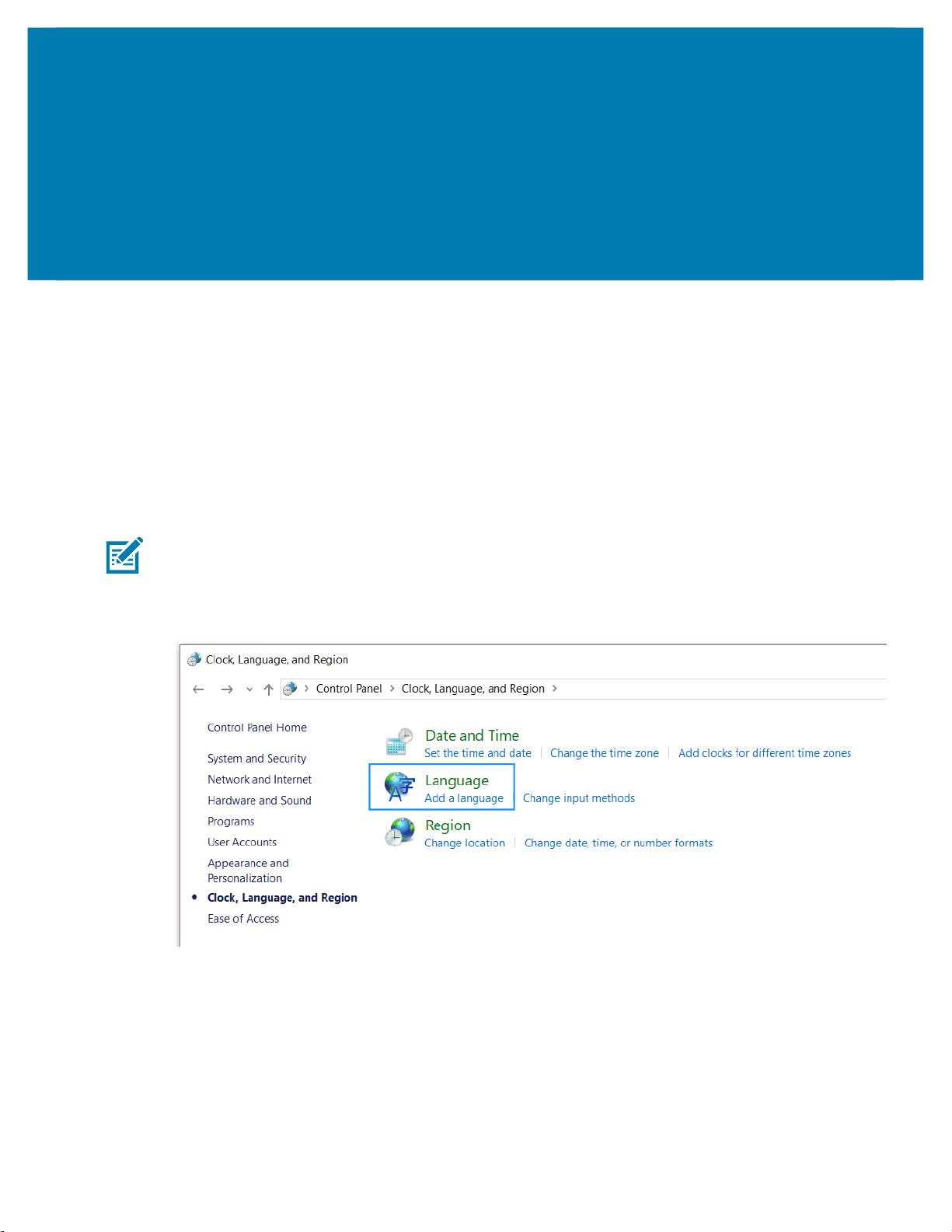

Page 33

Driver Installation

posdm addproperty lHomeLeft 0 /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty lHomeTop 0 /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty mediatype Direct /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty trackingmode Continuous /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty DPI 203 /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty RecLinesToPaperCut 4 /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty defaultfontsize 28 /type:PosPrinter /soname:ZPLSO /path:%~1

posdm addproperty defaultfont 0 /type:PosPrinter /soname:ZPLSO /path:%~1

goto end

:usage

echo batch adding a new Zebra OPOS printer via Ethernet or WiFi

echo First parameter=port

echo Second parameter=printer name

echo Third parameter=printer family

echo all properties like labellength, pagewidth, darkness, printspeed, etc.

echo should be established before and added to the batch

:end

33

Page 34

Device Manager

This section provides information about the Device Manager and its uses.

Using the Device Manager

Use the Zebra OPOS Device Manager to add a printer. First, make a cable or wireless connection to a

supported printer with one of the following:

• Bluetooth

• IP/WiFi

• Parallel

• Serial

• USB

To connect to a supported printer, perform the following steps:

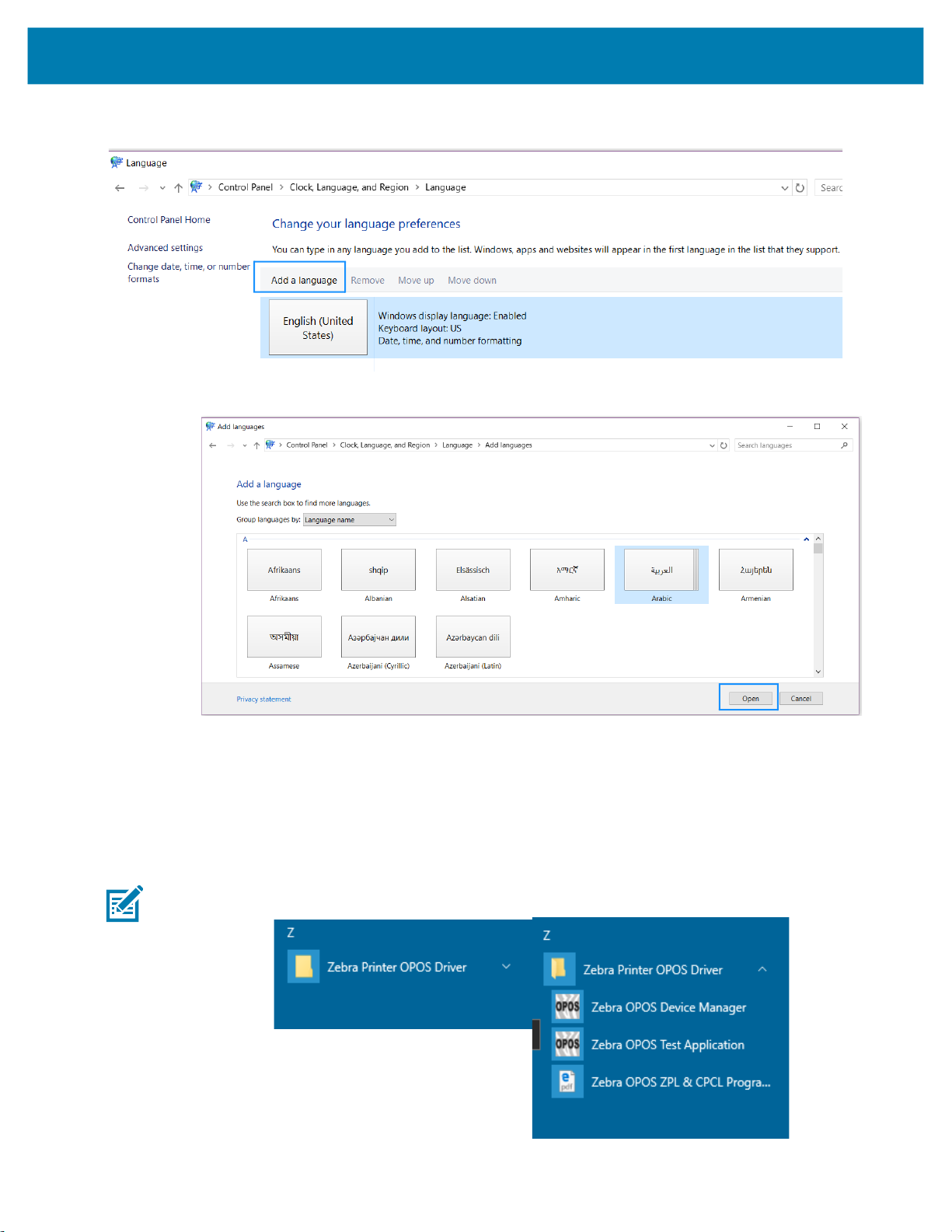

1. To run the Device Manager from the Start button on the PC, go to Start > Zebra Printer OPOS Driver >

Zebra OPOS Device Manager.

NOTE: In Windows 10 and Windows 11, you may need to run this application with Administrator rights.

34

Page 35

Device Manager

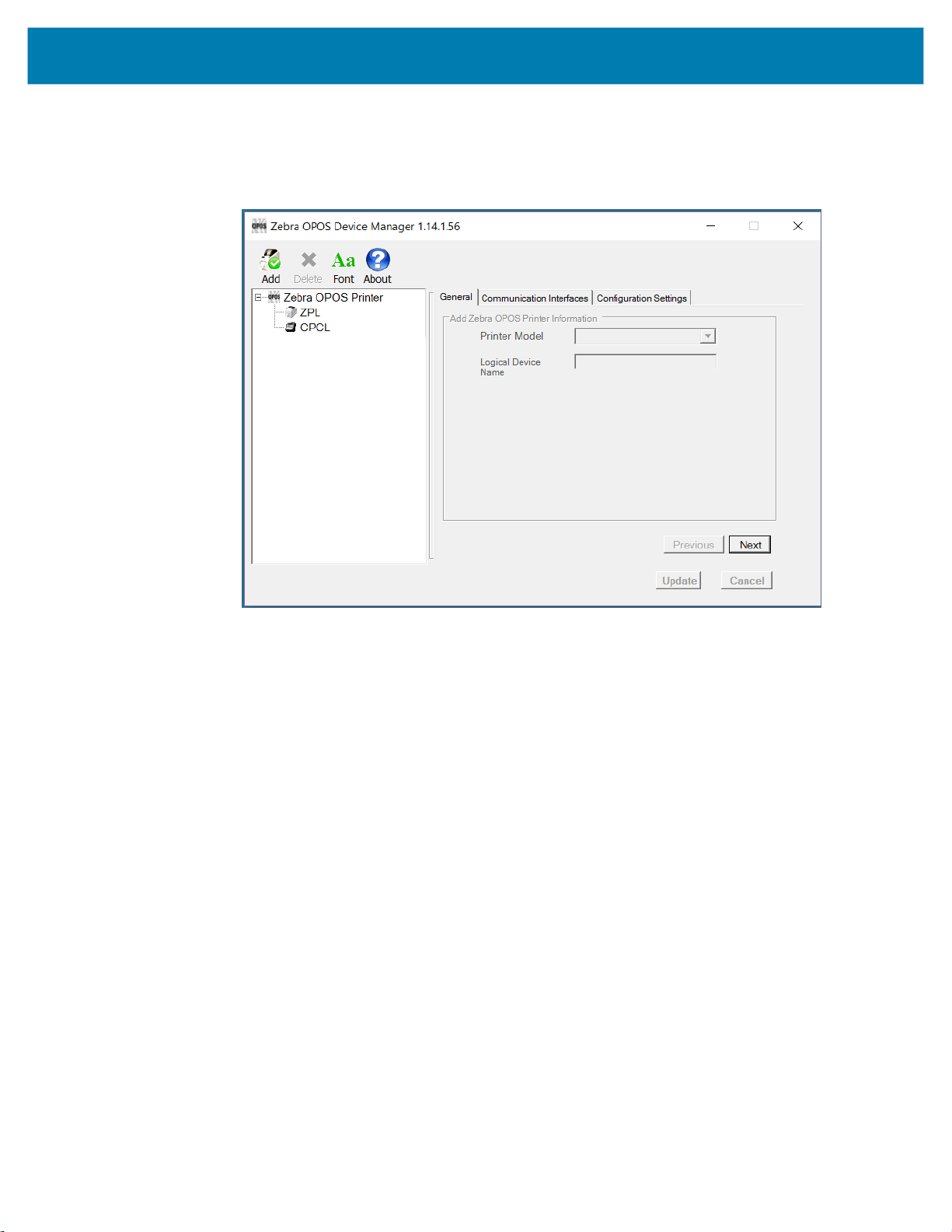

2. When the program displays, click the Add icon. The General tab is used to add a printer by selecting

the printer model using the drop-down menu.

A logical device name for the printer must be defined, as this name will be used by the OPOS

application.

3. Once these steps are complete click Next.

The Communication Interfaces dialog displays.

4. On this screen, select the port type from the drop-down menu.

5. Choose the interface to which the printer is connected.

35

Page 36

Device Manager

6. Click Search and the printer model should populate the area under Available Printer(s).

Connecting Using Bluetooth

With Bluetooth as a Port Type, make a serial cable connection, and define the Bluetooth Configuration

parameters to match the Bluetooth device.

Once this is complete, click Next.

36

Page 37

Device Manager

Connecting Using an IP Address

With IP/WiFi as a Port Type, manually enter the IP Address of the device or click Search. A search for

devices that have the same subnet as the PC running the Device Manager will start and then populate the

drop-down menu.

Once this is complete, click Next.

37

Page 38

Device Manager

Connecting Using a Parallel Cable

A parallel cable can be used to connect to the printer. Configure Port Type to Parallel.

NOTE: When connecting on a Windows 10 x64 or higher operating system, you may discover problems

with Plug and Play caused by the system settings. See Connecting Using a Parallel Cable for 64-Bit

Machines on page 39.

Parallel cable configuration

Once this is complete, click Next.

38

Page 39

Device Manager

Connecting Using a Parallel Cable for 64-Bit Machines

1. Open the Device Manager for your computer.

39

Page 40

2. Open Printer Port Properties.

Device Manager

40

Page 41

3. Select the Port Settings tab.

Device Manager

4. Select the Enable legacy Plug and Play detection checkbox.

5. Click OK to save the setting and reboot the computer.

This setting change enables the parallel port Plug and Play function and the Device Manager to find

your parallel printer.

41

Page 42

Device Manager

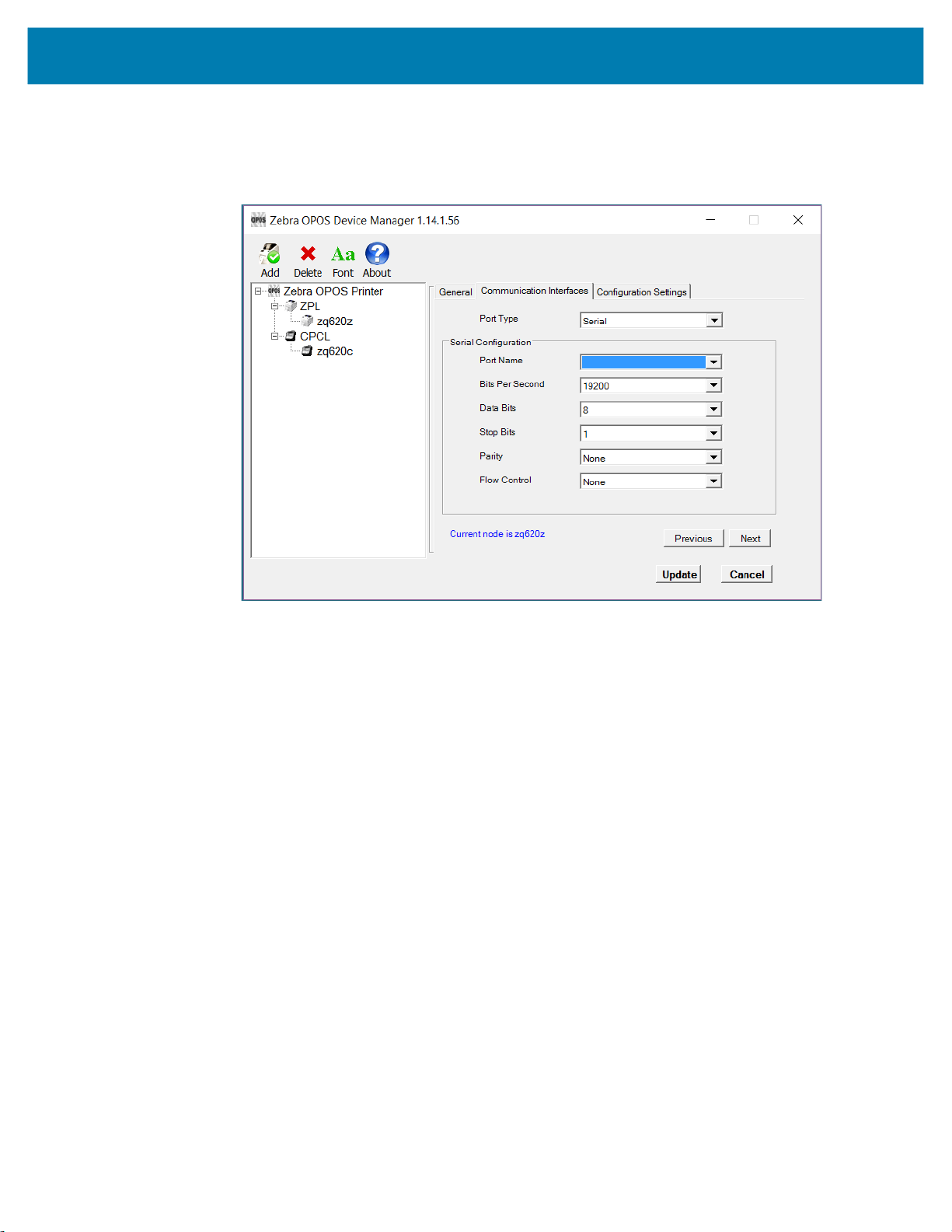

Connecting Using a Serial Cable

A serial cable can be used to connect to the printer. Configure Port Type to Serial, then configure Port

Name, Bits Per Second, Data Bits, Stop Bits, Parity and Flow Control to match the settings on the printer.

Once this is complete, click Next.

42

Page 43

Device Manager

Connecting Using a USB Cable

1. When using a USB cable, make the cable connection first.

2. Then, click Search.

This will populate the Available Printer(s) area with found printers.

3. Click on the printer.

4. Click Next.

The Configurations Settings tab displays.

43

Page 44

Configuration Settings

Adding a Printer

1. On the Configurations Settings tab, select the settings that will be used for the printer.

Device Manager

2. Once complete, click Update.

3. A message appears asking if you are sure you want to add the printer, click Yes.

The printer is added under the CPCL directory.

44

Page 45

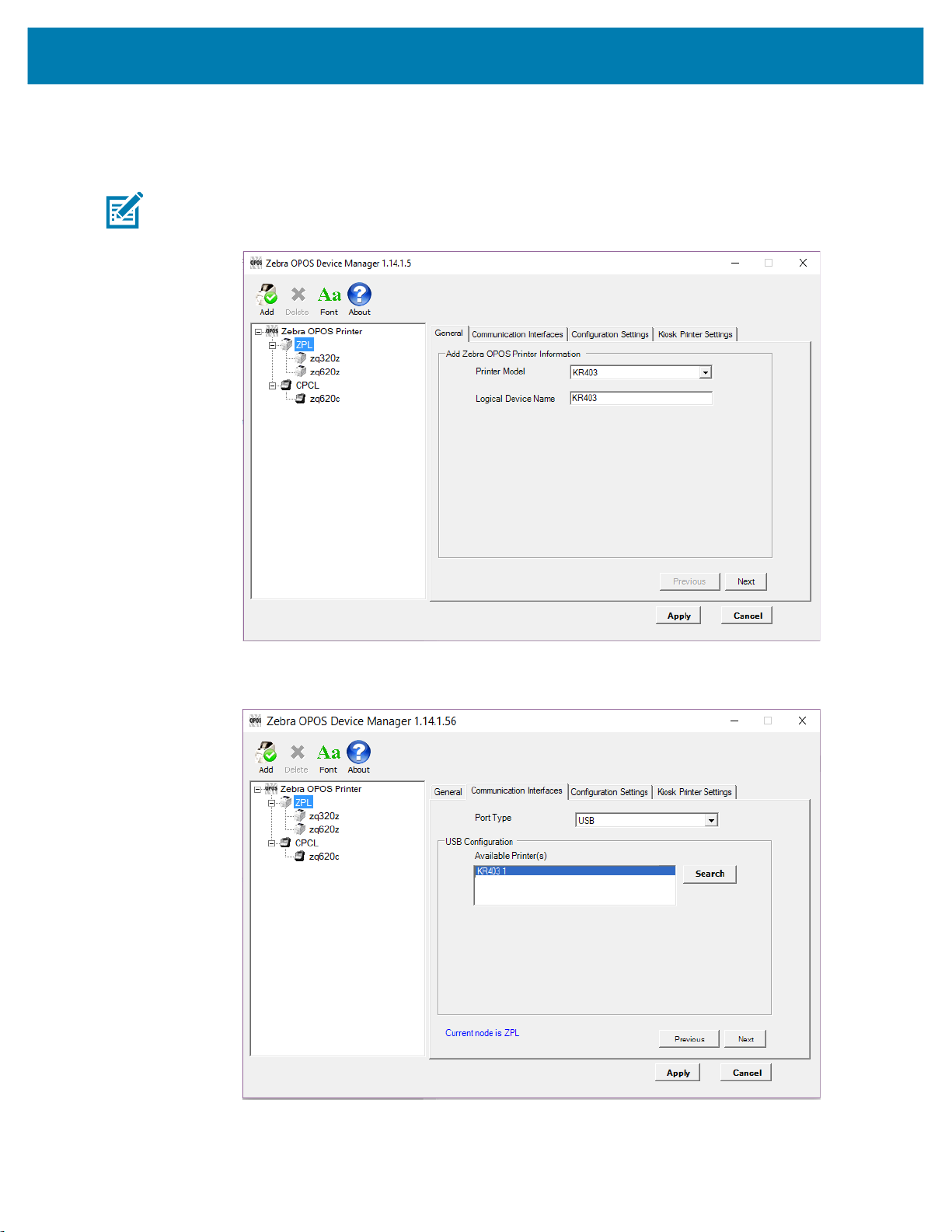

Adding a KR403 Kiosk Printer

1. Open the Device Manager application, select ZPL under Zebra OPOS Printer. Click Add.

NOTE: In Windows 10 and Windows 11, you may need to run this application with Administrator rights.

2. Select KR403 from the Printer Model drop-down menu and type in the logical device name.

Device Manager

3. Click Next.

4. In the Communication Interfaces tab, select the Port Type and then click Next.

45

Page 46

Device Manager

5. In the Configuration Settings tab, select the settings such as Media Type, Tracking Mode, etc. Check

the Enable Audit Log box to enable event logging.

6. Click Next and configure the Kiosk Printer Settings.

For a detailed explanation of the Kiosk Printer Settings, see Kiosk Printer Settings on page 57.

7. Click Apply.

8. Click Yes to add the printer.

The KR403 should now be listed in the Device Manager.

46

Page 47

Output Logging

The Driver can log its printer command output for troubleshooting purposes. By default, this option is not

turned on to keep the logs from consuming disk space. In the event that the Output Logs are needed, the

feature can be activated from within the Device Manager.

To turn on Output Logging, perform the following:

1. Run the Device Manager and select the printer to be monitored.

NOTE: In Windows 10 and Windows 11, you may need to run this application with Administrator rights.

2. Click on the Configuration Settings tab and check Enable Audit Log.

Device Manager

The logs can be found at C:\ProgramData\Zebra Technologies\OPOS\LOGS.

There are two logs:

• ZebraPOS_Audit.txt - contains a running log of the OPOS commands used and the resulting driver

output.

• ZebraPOS_Status_Audit.txt - contains a running log of when status queries were sent.

To turn off the logging, perform the following:

1. Uncheck the Enable Audit Log box in the Device Manager.

NOTE: If logging is turned off or on while a printer is in the "Claimed" state, the setting change will not take

effect until the printer has been "Released".

47

Page 48

Device Manager

Additional Font Handling

In order to provide customers with the ability to add fonts to the printer and then use those in the OPOS

driver, the Device Manager UI has the following functionality.

NOTES:

• Zebra offers a pre-converted font for use with ZPL-based printers. This is a monospaced font called

“Mono1”.

• Zebra also offers a pre-converted font for use with CPCL-based printers. This is a monospaced font

called “Mono1”. As a convenience, “Mono1” is predefined as an Additional Font for the CPCL printer

models.

Fonts are included in the installation at C:\Program Files (x86)\Zebra Technologies\ZebraOPOS\FONTS.

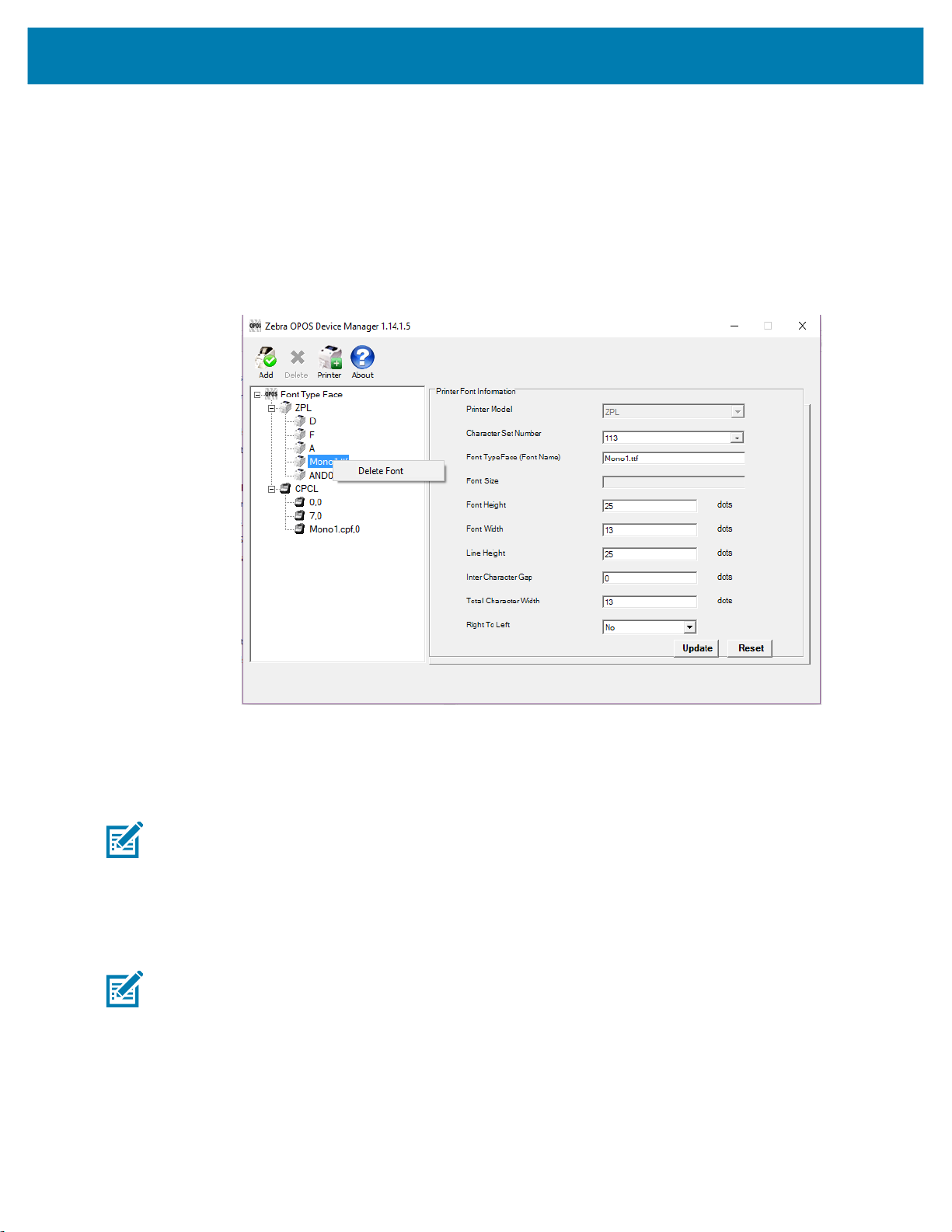

Adding a New Font in Device Manager

The following example demonstrates how to add the “Mono1” font to a ZPL printer.

1. Open the Device Manager Application and click the Font button.

NOTE: In Windows 10 and Windows 11, you may need to run this application with Administrator rights.

1. Right-click ZPL and click Add Font.

Fonts D, F and A will be listed under ZPL.

48

Page 49

Device Manager

2. Select the Character Set Number drop-down menu, verify selectable character sets (100, 101, 102,

103, 104, 105, 106, 107, 108, 109, 110, 113, 128, 129, 130) and select the character sets by clicking

the corresponding boxes.

3. Enter Font Name, Font Height, and Width (in dots). If adding the “Mono1” font, use the name

“Mono1”, height 25, and width 13.

4. Enter Line Height, Inter Character Gap (in dots), Total Character Width, and select Yes or No to

identify if your Font supports “Right to Left”.

NOTE: For the Mono1 font the following parameter values should be added:

For CPCL:

• Font Name = Mono1.cpf

• Font Size = 0

• Font Height = 25

• Font Width = 13

• Line Height = 25

• Inter Character Gap = 0

• Total Character Width = 13

For ZPL:

• Select Character Set Number 1252

• Font Name = Mono1.ttf

• Font Height = 25

• Font Width = 13

• Line Height = 25

• Inter Character Gap = 0

• Total Character Width = 13

49

Page 50

Device Manager

5. Click Save to save the Font.

(The user will be presented with a dialog box to confirm the adding of the font.)

6. The new font should now be listed.

NOTE: When using One Shot ESC commands, the index entry for the font will be assigned by the Device

Manager to the next available font slot.

0, 1, 2 are built-in ZPL fonts and any new font will be assigned a following number.

50

Page 51

Assigning Multiple Fonts

1. To assign multiple fonts, repeat the steps in Adding a New Font in Device Manager on page 48 for

every font you want to add.

Deleting a Font

1. To delete a font from the list, simply right-click the Font you wish to delete and select Delete Font.

(The user will be presented with a dialog box to confirm the deletion of the font.)

Device Manager

Selecting and Using a Font with Chinese Characters

The Andale Mono WT S font has a character set for Simplified Chinese and is available from Zebra for

purchase. Using this font with the OPOS driver allows you to print Chinese characters.

NOTE: Other Andale Mono fonts are available for purchase from Zebra for printing Traditional Chinese,

Japanese, and Korean languages.

Setting the Printer Font Information

1. Open Device Manager and select Font button.

2. See Figure 1. In the Printer Model dialog box, select ZPL.

NOTE: This font can only be used with a ZPL printer.

51

Page 52

Figure 1 Setting the Printer Model

Device Manager

1. See Figure 2. Enter the Character Set Number for the selected font.

For the Andale font, select all numbers up to Code 128.

Figure 2 Setting the Character Set Numbers

2. See Figure 3. Add the name and all other parameters for the font.

Enter the font name exactly as it appears on the printer as this representation will be used to select the

font.

52

Page 53

Figure 3 Setting the Font Name

Device Manager

3. See Figure 4. Click Save and click Yes to add the font typeface.

Figure 4 Saving the Font Information

53

Page 54

Device Manager

4. See Figure 5. You have now added the Andale font to your OPOS driver which is available within the

OPOS application using the ESC|#fT command.

In this example, the printer now has three default fonts and one OEM font, and the OEM font target

number would be 3(ESC|3fT).

Figure 5 Confirming the New Font Type

Testing the New Font

1. See Figure 6. Open the test application to try out the new font.

2. Open, Claim and Enable the printer and enter ESC|3fT in the Print Data box.

Figure 6 Setting the Print Data

54

Page 55

Device Manager

3. See Figure 7. Press Print Normal once, and then change the CharacterSet number to 128

Click OK in the confirmation dialog.

Figure 7 Updating the Character Set Property

Now you can add Chinese text behind the ESC command in the Print Data box and print to the printer.

Programming Tips For Using Additional ZPL Fonts

In order to print in other languages, it is necessary to load a new font Swiss721 into the printer and control

it within the OPOS driver. See Adding a New Font in Device Manager on page 48 for more specific

information.

An OPOS application developer has to select the proper font encoding by selecting the new codepage as

described in the font definition.

In order to enable locale setting, we can check the currently selected language support in the OS and

select the OPOS CharacterSet value according to the following selection:

Zebra ^CI Values

0 = Single Byte Encoding - U.S.A. 1 Character Set 100

1 = Single Byte Encoding - U.S.A. 2 Character Set 101

2 = Single Byte Encoding - U.K. Character Set 102

3 = Single Byte Encoding - Holland Character Set 103

4 = Single Byte Encoding - Denmark/Norway Character Set 104

5 = Single Byte Encoding - Sweden/Finland Character Set 105

6 = Single Byte Encoding - Germany Character Set 106

7 = Single Byte Encoding - France 1 Character Set 107

8 = Single Byte Encoding - France 2 Character Set 108

CharacterSet

OPOS

Value

55

Page 56

Device Manager

OPOS

Zebra ^CI Values

9 = Single Byte Encoding - Italy Character Set 109

10 = Single Byte Encoding - Spain 110

13 = Zebra Code Page 850 113 (default)

27 = Code page 1252 1252

28 = Unicode (UTF-8 encoding) - Unicode Character Set 128

29 = Unicode (UTF-16 Big-Endian encoding) - Unicode

Character Set

30 = Unicode (UTF-16 Little-Endian encoding) - Unicode

Character Set

NOTE: If printing with a new font and character set shall occur, perform the steps in the next procedure

shown on page 56.

If using Swiss721 font (with font index 3), perform the steps below.

1. Send the ESC|3fT. With the first use, the CharacterSetNumber value (128,129,130) (assigned to the

Swiss721 font) will be appended to the default CharacterSetList property

(100,101,102,103,104,105,106,107,108,109,110,113).

CharacterSet

Value

129

130

This will throw an exception as “Selected Font doesn't support character set”. You will need to add the

appropriate character set number within 128,129,130.

2. Assign the CharacterSetNumber within the CharacterSetNumber value (128,129,130) selected for

Swiss721.

Now, the Service Object will change the CharacterSetNumber to the specified number and use it for

future printing.

NOTE: Using a proportional font may cause unexpected results. Due to the nature of proportional fonts,

the driver cannot calculate the exact text position for all text, and text wrapping may not work as expected.

The benefit this font has is that you can use international character sets with multiple languages. In

general, the use of monospaced fonts such as the Mono1 font is preferred.

Use of OPOS Character Properties

The CharacterSetList property will display all of the ASCII numeric set numbers associated with the

currently loaded fonts. The default is:

“100,101,102,103,104,105,106,107,108,109,110,113”.

If a new font is added, the new character set values will be added to the CharacterSetList so an

application can choose the new values for the respective fonts.

The CharacterSet property will initialize with 113 on “open”.

The CapMapCharacterSet property will be initialized with FALSE on “open”.

NOTE: The above setting has the effect that the MapCharacterSet property will also always show FALSE

regardless of what the user sets it to. If MapCharacterSet is set to TRUE, an error E_ILLEGAL will be

thrown.

56

Page 57

The CapCharacterSet property will initialize with DISP_CCS_ASCII on “open”. This property will change

with a different selection of the CharacterSet property.

CapCharacterSet CharacterSet

DISP_CCS_ASCII 100-110, 113

DISP_CCS_UNICODE 128,129,130

NOTE: Error handling - If a specific character set value is selected with the CharacterSet property and a

font is selected that cannot support the character set, an error E_ILLEGAL will be thrown.

NOTE: OPOS Properties - The driver does not support font mapping. The application is responsible for

this task. CapMapCharacterSet is always FALSE, which will also cause MapCharacterSet to always be

FALSE. If MapCharacterSet is set to TRUE, an error E_ILLEGAL will be thrown.

KR403 Specific User Interface

Kiosk Printer Settings

The Kiosk Printer Settings tab will appear only after adding KR403 as a Printer Model under the General

tab. The following information will assist configuring Kiosk properties.

Device Manager

57

Page 58

Kiosk Properties

New Page:

There are three settings which you may select when a new page is printed:

• Eject Upon New Page

• Retract Upon New Page

• Do Nothing

These settings instruct the printer to change the presenter function mode.

Eject Upon New Page – Ejects the current page while the new page is printed.

Retract Upon New Page – Retracts current page while the new page is printed.

Do Nothing – The current page still remains in the printer neither ejects nor retracts.

Current Page:

Retract upon Timeout – If a label is not taken, you can define a timeout value when expired will retract

the current page. Retract timeout can be defined from 0 – 300 seconds.

Device Manager

Clear Presenter – Will eject the current page before printing a new page.

Kiosk Values:

Uncut Amount – When a partial cut is made by the printer, the media left uncut can be defined from 10 to

60mm.

Cut Margin – This setting determines the margin between the cutter and the printhead. It is defined from

2 to 9mm. The default is 9mm.

Presenter Loop Length – Determines the length of the presenter loop. It is defined from 3 to 1023mm.

The default gives a loop of approximately 400mm.

With this feature, we build a loop with the imaged receipt and keep the printout in the printer to prevent the

kiosk user from taking the receipt while it is still being imaged. When the full receipt is imaged, we cut the

receipt and present a portion of the receipt to the user for them to take. This reduces jamming and print

image distortion of the receipt.

Present Length – Determines the amount of media to eject the page through the presenter module.

When the customer takes the receipt, the printer detects a movement and issues the rest of the receipt at

300 mm/s to help ensure receipt is removed undamaged. Value range from 0 to 255mm.

Kiosk Wall Compensation – By default, the printer will eject the paper 50 mm during a present cycle.

The kiosk wall compensation setting allows the user to increase the distance that media is ejected during a

present cycle. The additional distance can range from 0 to 255 mm.

58

Page 59

Device Manager

Details for Variable Continuous Mode vs. Continuous Mode

The KR403 printer supports two continuous modes. The “variable continuous mode” is different from the

“continuous mode”. Variable continuous mode allows the printer to print pages without length limitation.

NOTE: The minimum presenter length of 70 mm always applies.

• Variable continuous mode will print on continuous paper without page boundaries until a cut command

is issued.

• Continuous mode requires a defined page length and will print a page that adheres to that set page

length.

Continuous Mode

• You have a set label width

• You have a set label height (minimum length is 70 mm)

• You have a Label Home (left and top)

You print content that is not filling the page and you receive a cut command.The printer shall feed to the

end of the page and cut there.

59

Page 60

Variable Continuous Mode 1

• You have a set label width

• You have a minimum label height of 70 mm

• You have a Label Home (left and top)

You print content that is not filling the page and you receive a cut command.The printer shall feed to the

end of the page and cut there.

Device Manager

In this example, the minimum label length is not exceeded and is not different from Continuous mode.

Variable Continuous Mode 2

• You have a set label width

• You have a minimum label height of 70 mm

• You have a Label Home (left and top)

You print content that is exceeding the minimum page and you receive a cut command.

shall not feed to the end of the page and cut right after the last print.

The printer

In this example, only the minimum page length is honored and after the minimum length is exceeded the

printer can cut at any location after the last print statement.

60

Page 61

Implementation

To begin printing in variable continuous mode, we need to issue PrintNormal statements until the minimum

page length is exceeded and the cut command is received.

This means we have to establish a hybrid. Using page mode and continuous mode, you will set up a