Page 1

ZD620 and ZD420

Link-OS 4 inch Desktop Printers

User’s Guide

212485-003 Rev. A

Page 2

Copyright ZIH Corp. and/or its affiliates. All rights reserved. ZEBRA and the stylized Zebra head are

trademarks of ZIH Corp., registered in many jurisdictions worldwide. All other trademarks are the property

of their respective owners.

Information in this document is subject to change without notice. The software described in this document

is furnished under a license agreement or nondisclosure agreement. The software may be used or copied

only in accordance with the terms of those agreements.

For further information regarding legal and proprietary statements, please go to:

COPYRIGHTS:www.zebra.com/copyright

WARRANTY:www.zebra.com/warranty

END USER LICENSE AGREEMENT: www.zebra.com/eula

SOFTWARE:www.zebra.com/linkoslegal

Terms of Use

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation and its subsidiaries

(“Zebra Technologies”). It is intended solely for the information and use of parties operating and

maintaining the equipment described herein. Such proprietary information may not be used, reproduced,

or disclosed to any other parties for any other purpose without the express, written permission of Zebra

Technologies.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies. All specifications and designs are

subject to change without notice.

Liability Disclaimer

Zebra Technologies takes steps to ensure that its published Engineering specifications and manuals are

correct; however, errors do occur. Zebra Technologies reserves the right to correct any such errors and

disclaims liability resulting therefrom.

Limitation of Liability

In no event shall Zebra Technologies or anyone else involved in the creation, production, or delivery of the

accompanying product (including hardware and software) be liable for any damages whatsoever

(including, without limitation, consequential damages including loss of business profits, business

interruption, or loss of business information) arising out of the use of, the results of use of, or inability to

use such product, even if Zebra Technologies has been advised of the possibility of such damages. Some

jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

Publication Date

August 2018

2

Page 3

About

This guide is for integrators and operators of Zebra Link-OS ZD620 and ZD420 desktop printers. Use this

guide to install, change configuration, operate, and physically support these printers.

Other Online resources are available to support this printer include:

• “How To” videos

• ZD620 or ZD420 Desktop Printer Product page links for printer specifications

• Printer accessory, supplies, parts, and software links

• Various setup and configuration guides

• Programmer’s manuals,

• Printer Drivers (Windows, Apple, OPOS, etc.)

• Printer Firmware

• Printer Fonts

• Utilities

• Knowledge base and support contacts

• Printer warranty and repair links

Use these links to get to your Online printer support resources:

• ZD620 Thermal Transfer Printer — www.zebra.com/zd620t-info

• ZD620 Direct Thermal Printer — www.zebra.com/zd620d-info

• ZD420 Thermal Transfer Ribbon Cartridge Printer — www.zebra.com/zd420c-info

• ZD420 Thermal Transfer Printer — www.zebra.com/zd420t-info

• ZD420 Direct Thermal Printer — www.zebra.com/zd420d-info

3

Page 4

Other Valuable Printer Resources

Zebra has a large suite of free and fee based software, Apps (applications), and other technical resources

for your Zebra Link-OS printer.

These are just some of the extensive software and resource areas available Online:

• Label Design software

• Printer Management tools

• Virtual Devices for legacy languages normally associated with other printer brands

• Cloud based Enterprise printer management and printing

• XML and PDF format file printing

• Oracle and SAP support

• Zebra Savanna ™ Data Intelligence platform - turns raw data from devices (IoT) and sensors into

actionable intelligence for your business

• A suite of Link-OS Mobile Apps (applications for phones, tablets, etc.)

• Link-OS software development kit (SDK)

• Additional Operating Systems (OS) and Service platforms

About

See ZebraLink, Zebra Link-OS, and Zatar from this Online link: www.zebra.com/software

Zebra OneCare Printer Service and Support

For maximum productivity, we can help your business ensure its Zebra printers are Online and ready for

business. See the descriptions of the Zebra OneCare service and support options available for your

printers Online at this link: www.zebra.com/zebraonecare

Using This Document and Its Internally Attached Files

This document is best used with Adobe Reader or Adobe DC. This user’s guide includes attached User

Programming Example Files for sample printer operations.

Go to the Adobe Web site to load Adobe Reader (for free at the release time of this publication):

www.adobe.com

4

Page 5

Document Conventions

The following graphic icons are used throughout the documentation set. These icons and their associated

meanings are described below.

Caution • If the precaution is not heeded, the user could receive minor or moderate injury.

Eye Injury Caution • If the precaution is not taken, the user’s eyes could be damaged. EXAMPLE: Wear protective

eyewear when installing or removing E-rings, C-clips, snap rings, springs, and mounting buttons. These are under

tension and could fly off.

Electrical Shock Caution • If the precaution is not taken, the user could receive an electrical shock. EXAMPLE: Turn

off (O) the printer and disconnect it from the power source before performing the following procedure.

Hot Surface Caution • If the precaution is not taken, the user could be burned. EXAMPLE: The printhead may be hot

and could cause sever burns. Allow the printhead to cool.

About

Product Damage Caution • If the precaution is not taken, the product could be damaged. EXAMPLE: Unplugging the

computer without properly shutting it down may corrupt the data on your hard drive.

ESD Caution • If the precaution is not taken, the product electronics could be damaged by an electrostatic discharge.

EXAMPLE: Observe proper electrostatic safety precautions when handling static-sensitive components such as circuit

boards and printheads.

Important • The text here indicates information that is important for the user to know. EXAMPLE: Run the setup.exe

file for the product BEFORE connecting the product to your printer.

Note • The text here indicates information that is supplemental for the user to know and that is not required to complete

a task. EXAMPLE: Refer to zebra.com for complete information on product warranties.

5

Page 6

Contents

Terms of Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Proprietary Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Product Improvements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Liability Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Limitation of Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Publication Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

• About . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Other Valuable Printer Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Zebra OneCare Printer Service and Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Using This Document and Its Internally Attached Files . . . . . . . . . . . . . . . . . . . . . .4

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

• Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

• Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Link-OS 4 inch Desktop Thermal Printers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Common Desktop Link-OS Printer Features:. . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Link-OS 4 inch Desktop Printer Options: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Zebra Label Printing Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Modes of Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

What’s in the Box? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Unpack and Inspect the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

6

Page 7

Contents

• Printer Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Printer Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Inside the ZD620 Dual Capacity Ribbon Roll Printer . . . . . . . . . . . . . . . . . . . . . . .23

Inside the ZD620 and ZD420 Direct Thermal Printers . . . . . . . . . . . . . . . . . . . . . .25

Inside the ZD420 Ribbon Cartridge Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Label Dispenser Option (field installable) - All Models . . . . . . . . . . . . . . . . . . . . . .28

Cutter Option (field installable) - All Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Linerless Media Tear-Off Option (Direct Thermal Models Only) . . . . . . . . . . . . . .29

Linerless Cutter Option (Direct Thermal Models Only). . . . . . . . . . . . . . . . . . . . . .29

Identifying Platen Drive Rollers Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Printer Power Supply Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

ZD620 Locking Printer Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Zebra Print Touch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

• Install Hardware Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Field Installable printer Accessories and Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Printer Connectivity Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Accessing the Connectivity Module Slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Installing the Serial Port Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Installing the Internal Ethernet (LAN) Module . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Media Handling Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Removing the Standard Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Installing the Label Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Installing the Standard Media Cutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Installing the Linerless Media Cutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Installing the Linerless Media ‘Tear-Off’ Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Media Roll Core Size Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Print Resolution Upgrade Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Installing the Attached Power Supply Base Options . . . . . . . . . . . . . . . . . . . . . . .49

Installing the Attached Battery Base Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Installing the Battery into the Attached Power Base . . . . . . . . . . . . . . . . . . . . . . .52

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Standard Interface Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

LCD User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Meaning of the Indicator Light Patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Status - Typical Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Status - Printhead Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Status - Bluetooth Low Energy (BTLE) Option . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Status - Ethernet (LAN) Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Status - Wi-Fi (WLAN) Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Display Controls and Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Navigating through Menu Display Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Battery Indicators and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

7

Page 8

Contents

• Printer Configuration Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Adjust Printer Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

User Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

SETTINGS Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

DARKNESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

PRINT SPEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

MEDIA TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

PRINT METHOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

TEAR OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

PRINT WIDTH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

PRINT MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

LABEL TOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

LEFT POSITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

REPRINT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

LABEL LENGTH MAX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

TOOLS Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

PRINT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

IDLE DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

POWER UP ACTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

HEAD CLOSE ACTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

LOAD DEFAULTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

MEDIA/RIBBON CAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

DIAGNOSTIC MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

CONFIG INFO TO USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

ZBI ENABLED? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

RUN ZBI PROGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

STOP ZBI PROGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

PRINT USB FILE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

COPY USB FILE TO E: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

STORE E: FILE TO USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

PRINT STATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

PASSWORD PROTECT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

PRINT TEST FORMAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

8

Page 9

Contents

NETWORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

ACTIVE PRINT SERVER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

PRIMARY NETWORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

WIRED IP ADDRESS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

WIRED SUBNET MASK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

WIRED GATEWAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

WIRED IP PROTOCOL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

WIRED MAC ADDRESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

WLAN IP ADDRESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

WLAN SUBNET MASK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

WLAN GATEWAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

WLAN IP PROTOCOL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

WLAN MAC ADDRESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

ESSID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

CHANNEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

SIGNAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

IP PORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

IP ALTERNATE PORT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

RESET NETWORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

VISIBILITY AGENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

BATTERY Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

BATTERY STATUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

LANGUAGE Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

LANGUAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

COMMAND LANGUAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

COMMAND CHAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

CONTROL CHAR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

DELIMITER CHAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

ZPL MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

VIRTUAL DEVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

SENSOR TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

LABEL SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

TAKE LABEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

PORTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

BAUD RATE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

DATA BITS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

PARITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

HOST HANDSHAKE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

WML . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

9

Page 10

Contents

BLUETOOTH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

BLUETOOTH ADDRESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

DISCOVERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

CONNECTED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

BT SPEC VERSION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

MIN SECURITY MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

• Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Printer Setup Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Select a Location for the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Install Printer Options and Connectivity Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Attaching Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Getting Ready to Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Preparing and Handling Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Media Storage Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Loading Roll Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

Setting Media Sensing by Media type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

Instructions for media loading: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

Loading Thermal Transfer Roll Ribbon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

Loading Zebra Transfer Roll Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132

Loading the ZD420 Ribbon Cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

Run a SmartCal Media Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .143

SmartCal Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .143

Test Printing with the Configuration Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .144

Detecting a Media Out Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

Detecting a Ribbon Out Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

Connecting your Printer to a Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

Interface Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

Wi-Fi and Bluetooth Classic Wireless Connectivity Option . . . . . . . . . . . . . . . . . . . .151

• Setup for Windows® OS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Windows to Printer Communication Setup (Overview). . . . . . . . . . . . . . . . . . . . . . . .152

®

Pre-install Windows

Setting Up the Wi-Fi Print Server Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

Configure Using the ZebraNet Bridge’s Connectivity Wizard . . . . . . . . . . . . . . . . . . .154

Using a Configuration Script. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160

Bluetooth Option Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .162

Connecting to a Windows XP

Connecting to a Windows Vista® SP2 or Windows 7® Master Device. . . . . . . . .165

Connecting the Printer to a Windows 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .168

Connecting the Printer to a Windows 10 PC . . . . . . . . . . . . . . . . . . . . . . . . . . . .169

After Your Printer is Connected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .172

Printer Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

®

SP2 Master Device. . . . . . . . . . . . . . . . . . . . . . .164

10

Page 11

Contents

• Print Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Thermal Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .174

Determining Your Printer’s Configuration Settings. . . . . . . . . . . . . . . . . . . . . . . .174

Select a Print Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

Adjusting the Print Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

Darkness Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .176

Adjusting the Print Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .177

Replacing Supplies while Using the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . .177

Printing on Fan-Fold Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .178

Printing with Externally Mounted Roll Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .180

Externally Mounted Roll Media Considerations:. . . . . . . . . . . . . . . . . . . . . . . . . .180

Using the Label Dispenser Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .181

Using the Linerless Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

Linerless Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

Sending Files to the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

Ribbon Cartridge Programming Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

Printing with the Attached Battery Base and Battery Option . . . . . . . . . . . . . . . . . . .187

Printer Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .188

Identifying Fonts in Your Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .188

Localizing the Printer with Code Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .188

Asian fonts and Other Large Font Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

EPL Line Mode - Direct Thermal Printers only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

ZD620 and ZD420 Locking Printer Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

Zebra® ZKDU — Printer Accessory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .191

ZBI 2.0 ™ — Zebra Basic Interpreter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .191

Setting the Power Failure Recovery Mode Jumper . . . . . . . . . . . . . . . . . . . . . . . . . .192

• USB Host Port and Link-OS Usage Examples . . . . . . . . . . . . . . . . . . . . . 193

USB Host . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .193

Using USB Host for Firmware Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .194

USB Host and Printer Usage Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .195

Items Required for the USB Host Exercises . . . . . . . . . . . . . . . . . . . . . . . . . . . .195

Files for Completing the Exercises. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .195

Exercise 1: Copy Files to a USB Flash Drive and Perform USB Mirror . . . . . . . .198

Exercise 2: Print a Label Format from a USB Flash Drive . . . . . . . . . . . . . . . . . .200

Exercise 3: Copy Files to/from a USB Flash Drive. . . . . . . . . . . . . . . . . . . . . . . .201

Exercise 4: Enter Data for a Stored File with a USB Keyboard and Print a Label203

Using the USB Hosts Port and the NFC Capabilities . . . . . . . . . . . . . . . . . . . . . . . . .204

Exercise 5: Enter Data for a Stored File with a Smart Device and Print a Label .205

11

Page 12

Contents

• Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

Cleaning Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

Recommended Cleaning Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .208

Cleaning the Printhead. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .210

Media Path Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .213

Sensor Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .218

Platen Cleaning and Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .222

Replacing the Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .226

ZD620 and ZD420 Direct Thermal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .227

ZD620 and ZD420 Thermal Transfer Ribbon Roll . . . . . . . . . . . . . . . . . . . . . . . .231

ZD420 Thermal Transfer Ribbon Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . .236

Updating Printer Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .240

Other Printer Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .241

RTC Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .241

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .241

• Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Resolving Alerts and Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .242

Alert: Printhead Open. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .242

Alert: Media Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .243

Alert: Ribbon In (ZD420 Cartridge Printer only) . . . . . . . . . . . . . . . . . . . . . . . . . .245

Alert: Ribbon Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .246

Alert: Ribbon Low (ZD420 Cartridge Printer only) . . . . . . . . . . . . . . . . . . . . . . . .247

Alert: CUT ERROR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .247

Alert: PRINTHEAD OVER TEMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .248

Alert: PRINTHEAD SHUTDOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .248

Alert: PRINTHEAD UNDER TEMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .249

Alert: OUT OF MEMORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .250

Resolving Print Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .251

Issue: General Print Quality Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .251

Issue: No Print on the Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .252

Issue: Labels Are Distorted in Size or Print Area Start Position Varies . . . . . . . .253

Communication Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .254

Issue: Label Job Sent, No Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .254

Issue: Label Job Sent, Skips Labels or Prints Bad Content . . . . . . . . . . . . . . . . .254

Issue: Label Job Sent, Data Transfers, But No Print . . . . . . . . . . . . . . . . . . . . . .255

Miscellaneous Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .256

Issue: Settings are Lost or Ignored . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .256

Issue: Non-continuous labels act as Continuous labels. . . . . . . . . . . . . . . . . . . .257

Issue: Printer Locks-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .257

Issue: Erroneous Ribbon Cartridge Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .257

Issue: Battery has a Red Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .258

12

Page 13

Contents

• Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Printer Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .260

Power-On Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .260

SmartCal Media Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .260

Configuration Report (CANCEL Self Test) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .261

Printer Network (and Bluetooth) Configuration Report . . . . . . . . . . . . . . . . . . . . .262

Print Quality Report (FEED self test) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .263

Reset Printer Factory Defaults (PAUSE + FEED Self Test). . . . . . . . . . . . . . . . .266

Reset Network Factory Defaults (PAUSE + CANCEL Self Test) . . . . . . . . . . . . .266

Reset Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .267

Communication Diagnostics Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .268

Sensor Profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .269

Advanced Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .271

Manual Media Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .271

Manual Print Width Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .272

Manual Print Darkness Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .273

Factory Test Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .274

Universal Serial Bus (USB) Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .275

Serial Port Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .276

Connecting the Printer to a DTE Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .276

Connecting the Printer to a DCE Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .277

ZD620 / ZD420 Thermal Transfer Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .279

ZD620 / ZD420 Ribbon Cartridge Thermal Transfer Models . . . . . . . . . . . . . . . . . . .287

ZD620 / ZD420 Direct Thermal Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .295

• Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Types of Thermal Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .302

Determining Thermal Media Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .302

General Media and Print Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .303

• ZPL Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Managing the ZPL Printer Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .307

Configuration Setting to Command Cross-reference . . . . . . . . . . . . . . . . . . . . . . . . .309

Printer Memory Management and Related Status Reports . . . . . . . . . . . . . . . . . . . .312

ZPL Programming for Memory Management . . . . . . . . . . . . . . . . . . . . . . . . . . . .312

13

Page 14

Introduction

This section introduces the award winning Zebra® Link-OS 4-inch desktop thermal label printers, the

ZD620 and ZD420. It has an overview of the Link-OS printer’s features and options, and what ships with

your new printer.

This document covers the following ZD-series desktop printer models:

• ZD620 Thermal Transfer Printer — www.zebra.com/zd620t-info

• ZD620 Direct Thermal Printer — www.zebra.com/zd620d-info

• ZD420 Thermal Transfer Ribbon Cartridge Printer — www.zebra.com/zd420c-info

• ZD420 Thermal Transfer Printer — www.zebra.com/zd420t-info

• ZD420 Direct Thermal Printer — www.zebra.com/zd420d-info

Link-OS 4 inch Desktop Thermal Printers

The Zebra® Link-OS 4 inch Desktop printers are compact label printers with a wide range of features and

options.

• Direct Thermal and Thermal Transfer printer models available.

• Includes ZD420 Healthcare printer models with plastics that withstand common hospital cleaning

chemicals and include a medical grade power supply.

• ZD620 printers can support printing speeds* up to 203.4 mm/s per second (8 ips - inches per

second) for 203 dpi (dots per inch print density) printers and 152.4 mm/s (6 ips) for 300 dpi version

printers.

• ZD420 printers can support printing speeds* up to 152.4 mm/s per second (6 ips) for 203 dpi

printers and 101.6 mm/s (4 ips) for 300 dpi version printers.

• These printers support ZPL ™ and EPL Zebra printer programming languages and a wide variety of

other printer control languages via Link-OS Virtual Devices.

* — Maximum print speeds vary by model, print resolution, and the type of media in use.

14

Page 15

Introduction

Common Desktop Link-OS Printer Features:

• OpenAccess ™ design for simplified media loading.

• Color-coded “touch points” for operator controls and media guides.

• Enhanced user interface featuring three buttons and five status indicators.

• Easy, field installable media handling options.

• Media roll support:

• Outer Diameter (O.D.): Up to 127 mm (5 inch) and

• Inner Diameter (I.D.) roll cores:12.7 mm (0.5 inch), 25.4 mm (1 inch) and additional core sizes

with optional media core adapters.

• Movable Sensor provides compatibility with the widest range of media types:

• Compatible with full or partial width black mark media.

• Compatible with notched or slotted media.

• Multi-center position transmissivity sensor for use with label gap/web media.

• Universal Serial Bus (USB) Host Port that can be used for easy firmware updates.

• Universal Serial Bus (USB) 2.0 interface

• Modular Connectivity Slot for field installable 10/100 Ethernet (802.3 RJ-45) or

Serial (RS-232 DB-9) interface options.

• On–the–fly OpenType and TrueType font scaling and import, Unicode, resident scalable font (Swiss

721 Latin 1 font), and a selection of resident bitmap fonts.

• Backwards compatibility focused technology eases printer replacement:

• Drop in replacement of legacy Zebra desktop printers. The printer accepts both EPL and ZPL

programming languages.

• Supports Link-OS virtual devices to interpret non-Zebra printer programming languages.

• XML-Enabled printing—allows XML communications for barcode label printing, eliminating license

fees and print server hardware and lowering customization and programming costs.

• Zebra ™ Global Printing Solution – supports Microsoft Windows keyboard encoding (and ANSI),

Unicode UTF-8 and UTF 16 (Unicode Transformation Formats), XML, ASCII (7 and 8 bit used by

legacy programs and systems), basic single and double byte font encoding, JIS and Shift-JIS

(Japanese International Standards), Hexadecimal encoding, and custom character mapping (DAT

table creation, font linking, and character remapping).

• Factory installed network models support printer configuration via a setup utility running on mobile

devices.

• Use the printer’s optional Bluetooth Low Energy (LE) feature for short range communication to a

variety of mobile devices. Bluetooth LE works with Zebra mobile setup utility applications to

assist in printer setup, perform media calibration, and maximize print quality.

• Zebra’s Print Touch (Near Field Communication - NFC) ‘tap’ to pair devices, access printer

information, and access mobile applications.

• Zebra’s Link-OS - an open platform that connects operating systems for smart Zebra devices with

powerful software apps (applications), making the devices easy to integrate, manage and maintain

from any location.

• An On-board Real Time Clock (RTC).

• Printhead maintenance reporting enabled and customizable by the user.

• Easy tool-less replacement of printhead and platen (driver) ro

• A minimum of 64 MB of internal (E:\) printer memory for storing forms, fonts, and graphics.

ller.

15

Page 16

Introduction

Link-OS 4 inch Desktop Printer Options:

• A Color LCD User Interface for easy setup, print configuration, printing, and a range of Link-OS

features.

• Healthcare printer models:

• Healthcare wipe-able plastics for disinfecting and cleaning.

• IEC 60601-1 certified power supply.

• Factory Installed Wired and Wireless options:

• Bluetooth Low Energy (LE) wireless connectivity

• Wi-Fi (802.11ac – includes a/b/g/n), Bluetooth Classic 4.X (3.X compatible), and Bluetooth Low

Energy (LE) wireless connectivity.

• Factory installed Internal Ethernet Print Server (LAN, RJ-45 connector) — supports 10Base-T,

100Base-TX and fast Ethernet 10/100 auto-switching networks for wired connectivity. The

factory installed option includes Bluetooth Low Energy (LE) wireless connectivity.

• Thermal Transfer Printing - A choice of easy loading thermal transfer ribbon cartridge or dual

capacity ribbon roll (74 m and 300 m ribbons) models.

• ZD620 and select ZD420 printers have an factory installed, on-board Real Time Clock (RTC) in

printers that have Bluetooth Low Power (BTLE) or Wi-Fi with Classic Bluetooth configurations.

• Field installable connectivity modules:

• Internal Ethernet Print Server (LAN, RJ-45 connector) — supports 10Base-T, 100Base-TX and

fast Ethernet 10/100 auto-switching networks.

• Serial (RS-232 DB-9) Port

• Field installable media handling options:

• Label Dispenser (Peel-Off liner and present the label for the operator).

• General purpose media cutter.

• Linerless Label Tear-Off printing with a ‘Label Taken’ sensor.

• Linerless Label Cutter with a ‘Label Taken’ sensor.

• Media Core Adapter kit include adapters for media rolls with Outer Diameters (O.D.) up to 127 mm

(5 inches):

• 38.1 mm (1.5 inch) I.D. media cores.

• 50.8 mm (2.0 inch) I.D. media cores.

• 76.2 (3.0 inch) I.D. media cores.

• Attached Power Supply Base with internal power supply.

• Attached Battery Base with removable Battery.

• Attached Battery Base and Battery are sold separately.

• The battery provides a constant regulated 24 VDC until the battery shutdown for recharging to

maintain print quality. This keeps print from changing as the battery discharges with use.

• Includes a Shutdown Mode for shipping and storage.

• Includes battery charge and status indicators built into the battery.

• Field upgrade kit to change printer resolution is available. Change your printer from 203 dpi to 300

dpi - or - from 300 dpi to 203 dpi printing with these tool-less upgrade kits.

• Asian Language support with printer configuration options for the large Simplified and Traditional

Chinese, Japanese, or Korean character sets.

16

Page 17

Introduction

• Printers sold in China have the Simplified Chinese SimSun font pre-installed.

• Zebra® ZBI 2.0 ™ (Zebra BASIC Interpreter) programming language. ZBI allows you to create

custom printer operations that can automate processes, use peripherals (i.e. scanners, scales,

keyboards, Zebra® ZKDU ™ , etc.) all without being attached to a PC or network.

• Locking Media Cabinet for ZD620 Direct Thermal Healthcare printer models. This special

Healthcare model includes for additional security, Kensington ™ Slot for Kensington locking devices

to secure the printer.

17

Page 18

Zebra Label Printing Solution

The printer is just one of three (3) parts of a printing solution. To print; you need a printer (ZD620 or

ZD420), compatible media (thermal transfer ribbon cartridge or rolls, and thermal transfer media; or just

direct thermal media), and software (driver, applications or programming) to tell the printer what to do and

print. The printer can print without being connected to other devices or systems.

The media may be labels, tags, tickets, receipt paper, fan-fold stacks, tamper proof labels, etc.

Zebra assists you with label design and print with the free label and form design software:

ZebraDesigner ™ for Windows PC operating systems.

Zebra provides a complete suite of free Link-OS software applications and drivers to configure printer

settings, print labels and receipts, get printer status, import graphics and fonts, send programming

commands, update firmware, and download files.

The Zebra web site or your reseller will be able to help you identify media for your desired use case.

Modes of Printing

You can operate this printer in many different modes and media configurations:

Introduction

• Direct thermal printing (which uses heat sensitive media to print).

• Thermal transfer printing with easy to use thermal transfer ribbon cartridge or ribbon rolls (heat and

pressure transfers ink from the ribbon to media).

• Standard Tear-Off mode allows you to tear off each label/receipt or batch print a strip of labels and

tear them off after it is printed.

• Label Dispense Mode: If an optional dispenser is installed, the backing material can be peeled away

from the label as it is printed. After this label is removed, the next one is printed.

• Media Cutting: If an optional media cutter is installed, the printer can cut the label liner between

labels, receipt paper or tag stock.

• Linerless media printing with Cut or Tear-Off label options for easy pick and place label applications.

• Stand-alone: The printer can print without being directly connected to a computer.

• A printer with the color LCD display option can use menus to access and print a label

format/form.

• A Link-OS App connecting via Bluetooth (Wireless option).

• An auto running label format/form (programming based).

• A data input device connected to the printer’s USB Host port or serial port. This mode

accommodates data input devices, such as scanners, weigh scales, a Zebra Keyboard Display

Unit (ZKDU), etc.

• Shared network printing: Printers configured with Ethernet (LAN) and Wi-Fi interface options include

an internal print server.

18

Page 19

What’s in the Box?

Documentation and

Software

USB CablePrinter

Power Supply

Non-Zebra 300 Meter Ribbon Adapters

Printer Documentation

Included with Thermal Transfer Printer (uses ribbon rolls)

Empty Starter Ribbon Cores

After unpacking, make sure you have all parts shown below. Follow the procedures for inspecting the

printer to familiarize yourself with printer parts so you can follow the instructions in this book.

Introduction

Unpack and Inspect the Printer

When you receive the printer, immediately unpack it and inspect for shipping damage.

• Save all packing materials.

• Check all exterior surfaces for damage.

• Open the printer and inspect the media compartment for damage to components.

If you discover shipping damage upon inspection:

• Immediately notify the shipping company and file a damage report. Zebra Technologies Corporation

is not responsible for any damage to the printer incurred during shipment, and will not cover the

repair of this damage under its warranty policy.

• Keep all packaging material for shipping company inspection.

• Notify your authorized Zebra

See the Zebra Web site for ‘How To’ videos on packing and unpacking your printer. See About section for

links to one of these 5 basic Link-OS printer variations.

®

reseller.

19

Page 20

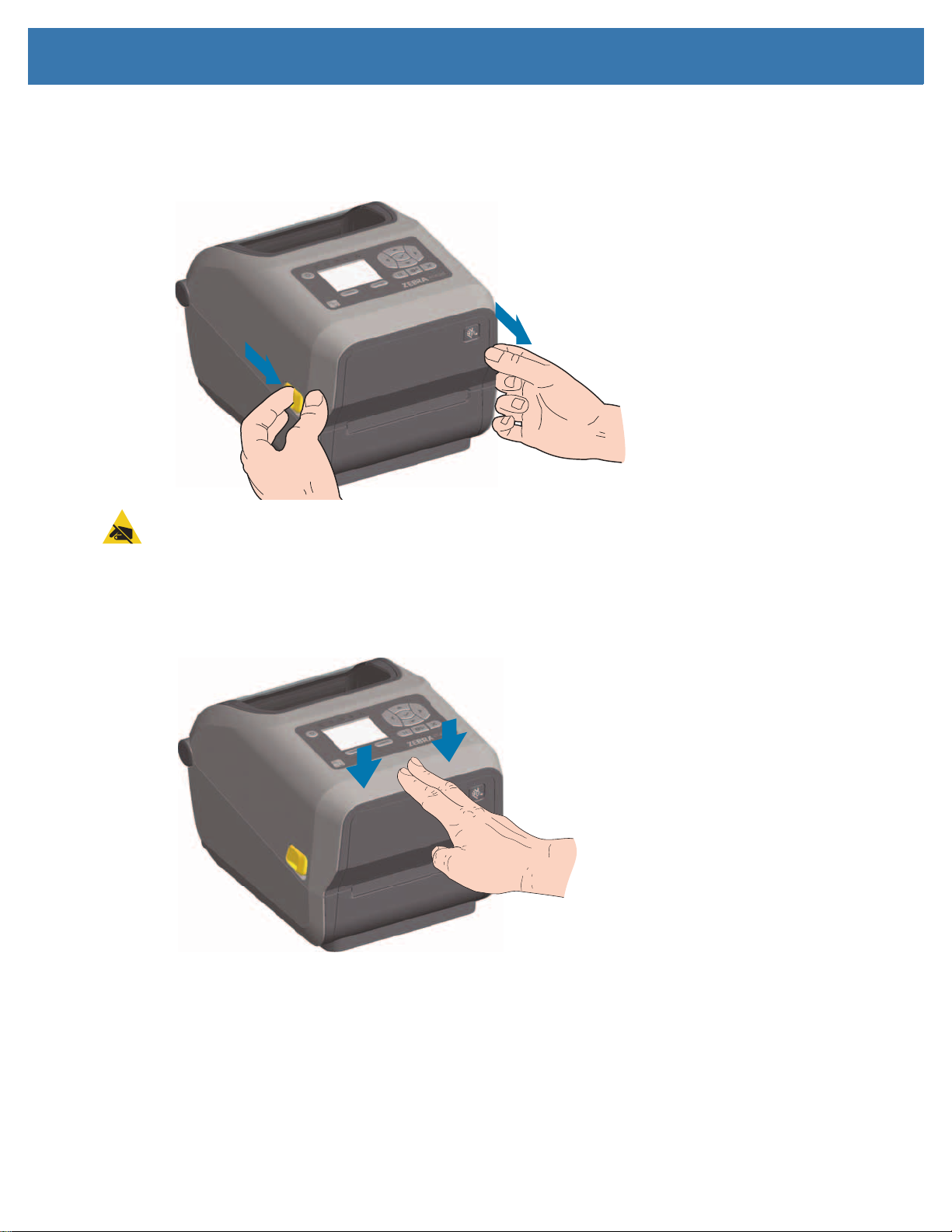

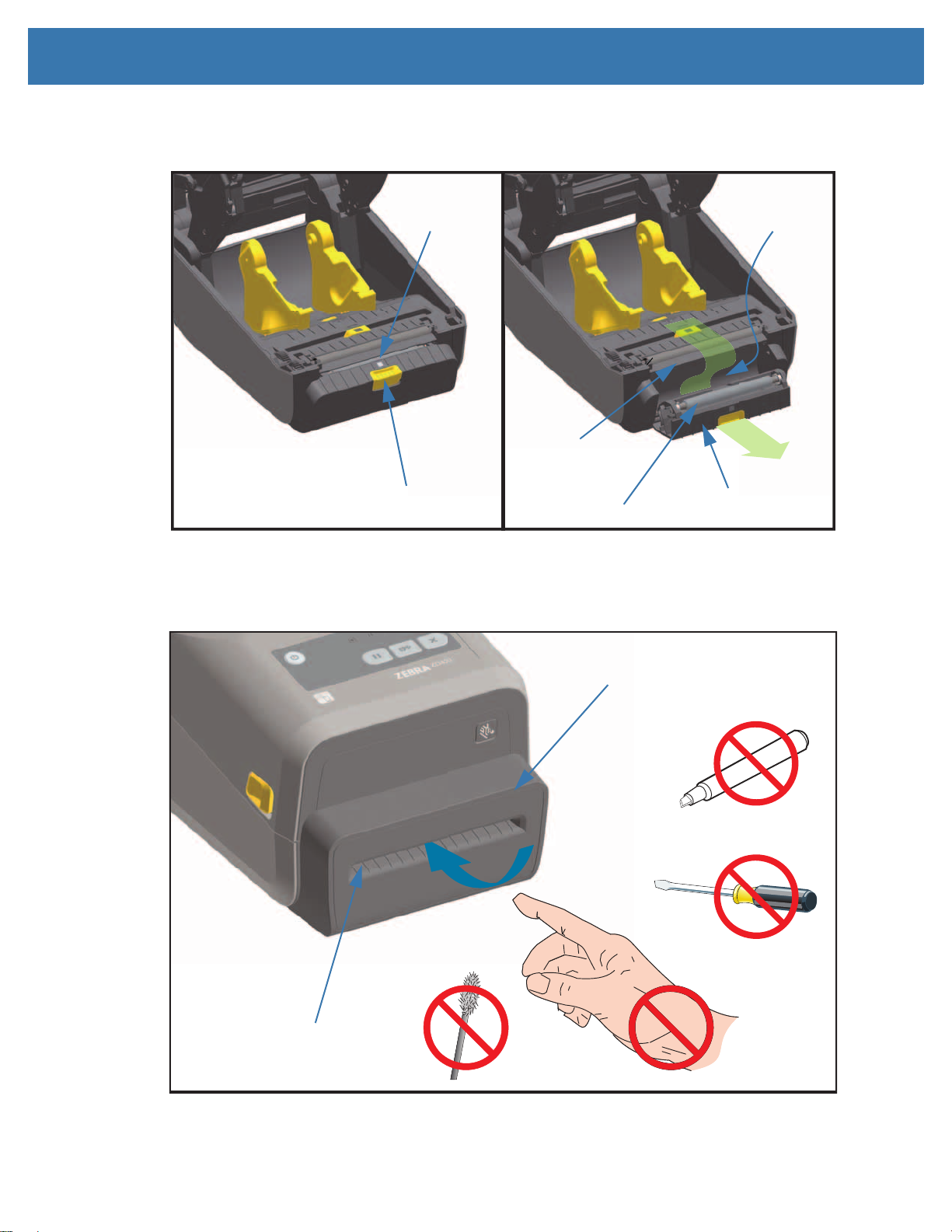

Open the Printer

To access the media compartment, pull the release latches towards you and lift the cover. Check the

media compartment for loose or damaged components.

Introduction

ESD Caution • The discharge of electrostatic energy that accumulates on the surface of the human body or other

surfaces can damage or destroy the printhead and other electronic components used in this device. You must observe

static-safe procedures when working with the printhead or the electronic components under the top cover.

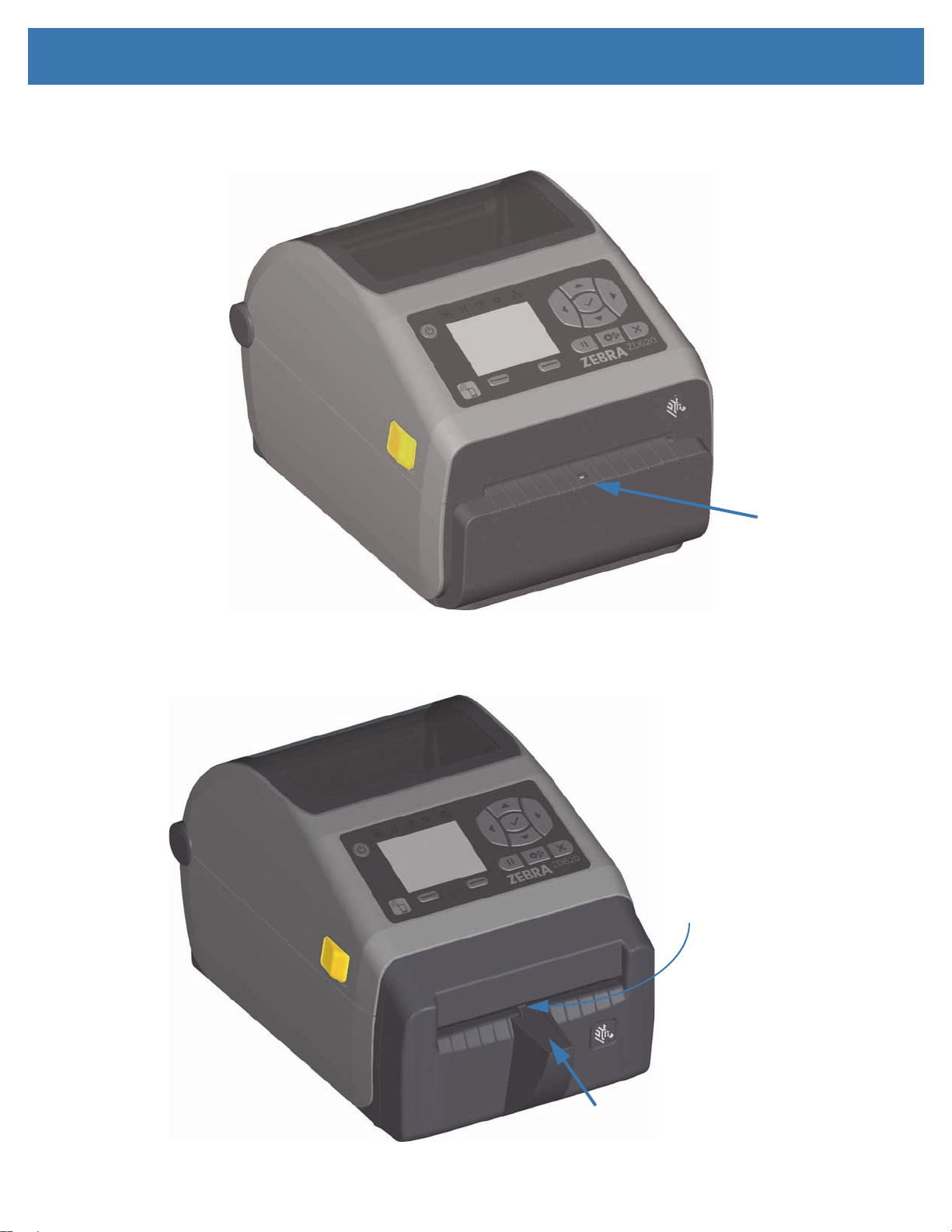

Closing the printer

Lower the top cover. Press down in the middle of the cover in front until the cover snaps closed.

20

Page 21

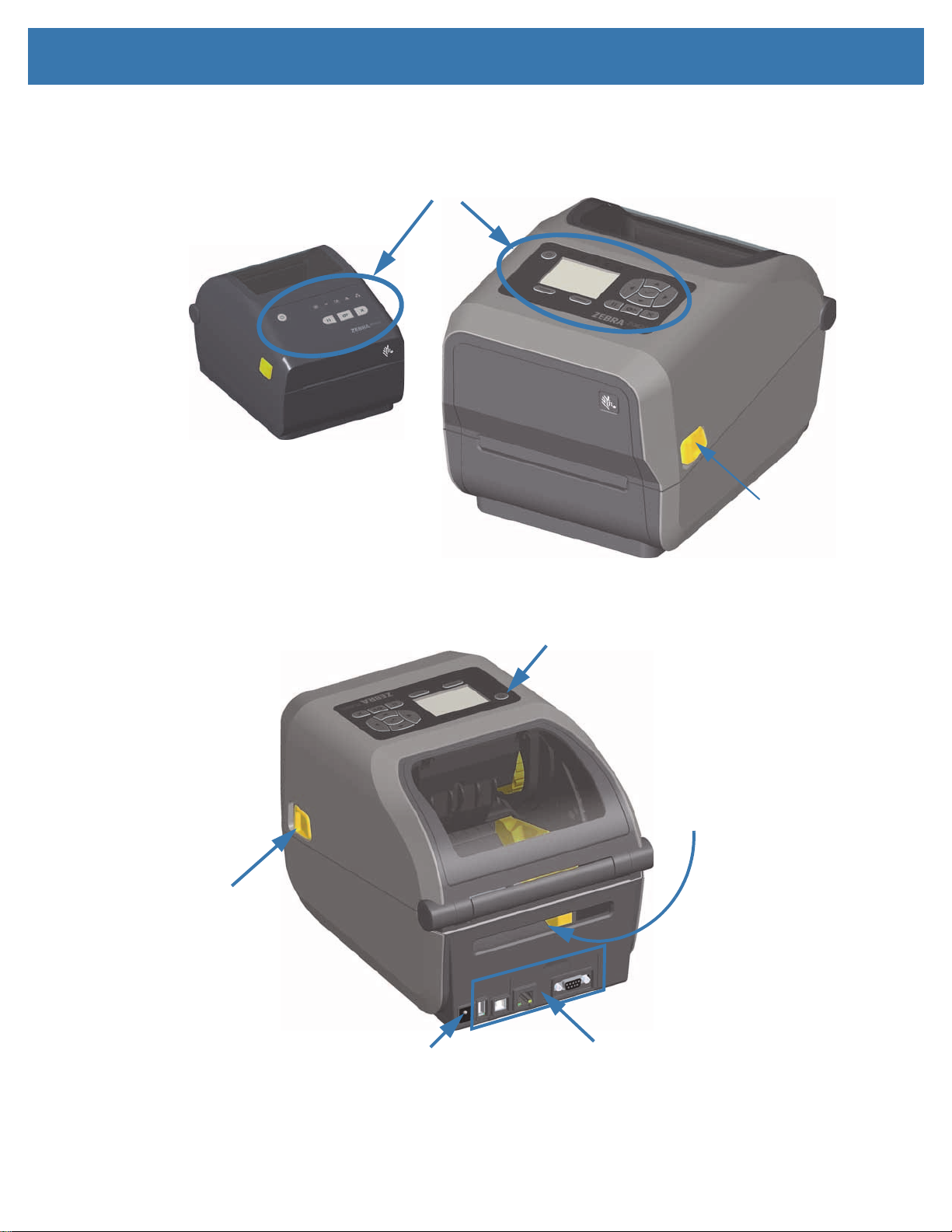

Printer Features

This section will help you identify features of these Zebra® Link-OS 4-inch desktop thermal label printers,

the ZD620 and ZD420. ‘How to’ videos on the Zebra Web site include a Printer Features video; as well as;

other printer setup and task specific videos. Links to these five (5) Link-OS 4-inch desktop printers are:

• ZD620 Thermal Transfer Printer — www.zebra.com/zd620t-info

• ZD620 Direct Thermal Printer — www.zebra.com/zd620d-info

• ZD420 Thermal Transfer Ribbon Cartridge Printer — www.zebra.com/zd420c-info

• ZD420 Thermal Transfer Printer — www.zebra.com/zd420t-info

• ZD420 Direct Thermal Printer — www.zebra.com/zd420d-info

21

Page 22

Printer Features

Interface and Connectivity Module

Slot Access

User Interface

Release

Latch

DC Power

Receptacle

Power Button

Release

Latch

Fan-Fold Media

Entry Slot

For more details on printer controls, see Controls and Indicators

Printer Features

22

Page 23

Printer Features

Movable Sensor

(Black Mark and Lower Web/Gap)

Media Guides

Head-Up Sensor

(inside)

Media Guide Stop

Adjustment

Platen (Drive) Roller

Roll Holders

Upper Web (Gap)

Array Sensor

(other side)

Ribbon Carriage

Printhead

Inside the ZD620 Dual Capacity Ribbon Roll Printer

23

Page 24

Printer Features

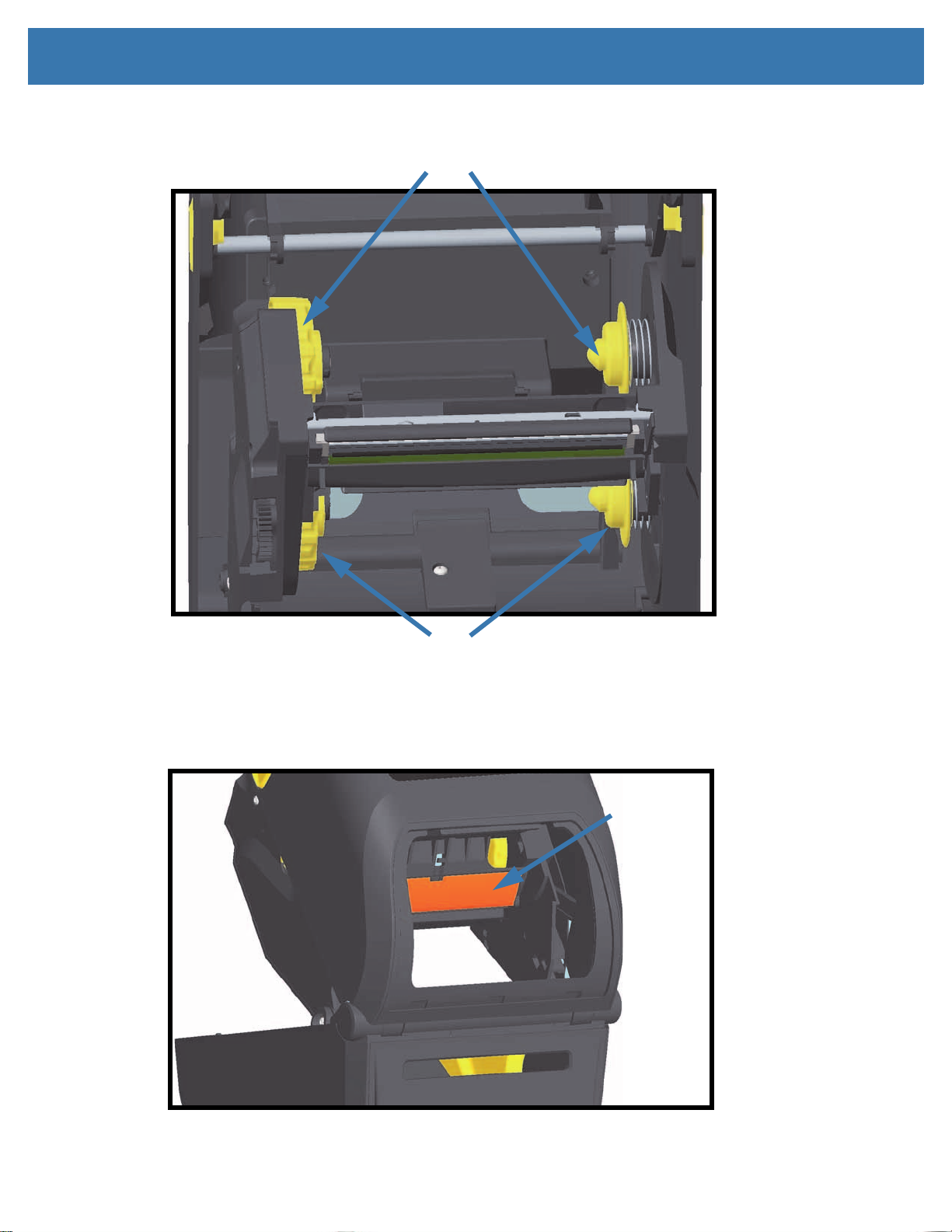

Take Up Spindles

Supply Spindles (full ribbon rolls)

Media Dancer

(ZD620 Only)

Dual Capacity Ribbon Chassis - Ribbon Roll Holders

Media Dancer - ZD620 Printer Models Only

The printer’s window is removed to show the Media Dancer (plate). The Media Dancer is re-colored to

make it easier to see. It is the same color as the dark gray parts adjacent to it.

24

Page 25

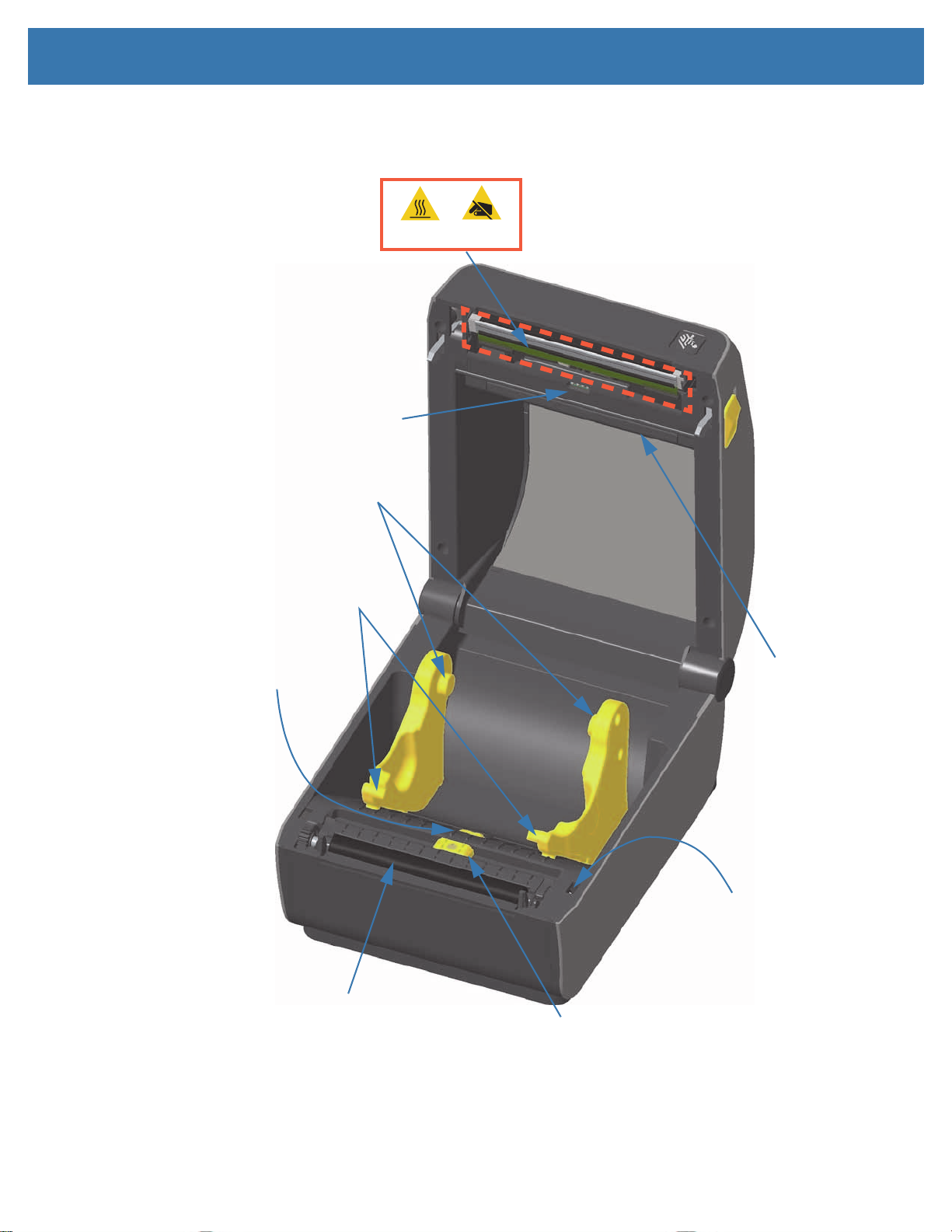

Printer Features

Movable Sensor

(Black Mark and Lower Web/Gap)

Media Guides

Head-Up Sensor

(inside)

Media Guide Stop

Adjustment

Platen (Drive) Roller

Roll Holders

Upper Web (Gap)

Array Sensor

Printhead

Media Dancer

(ZD620 Only)

Inside the ZD620 and ZD420 Direct Thermal Printers

25

Page 26

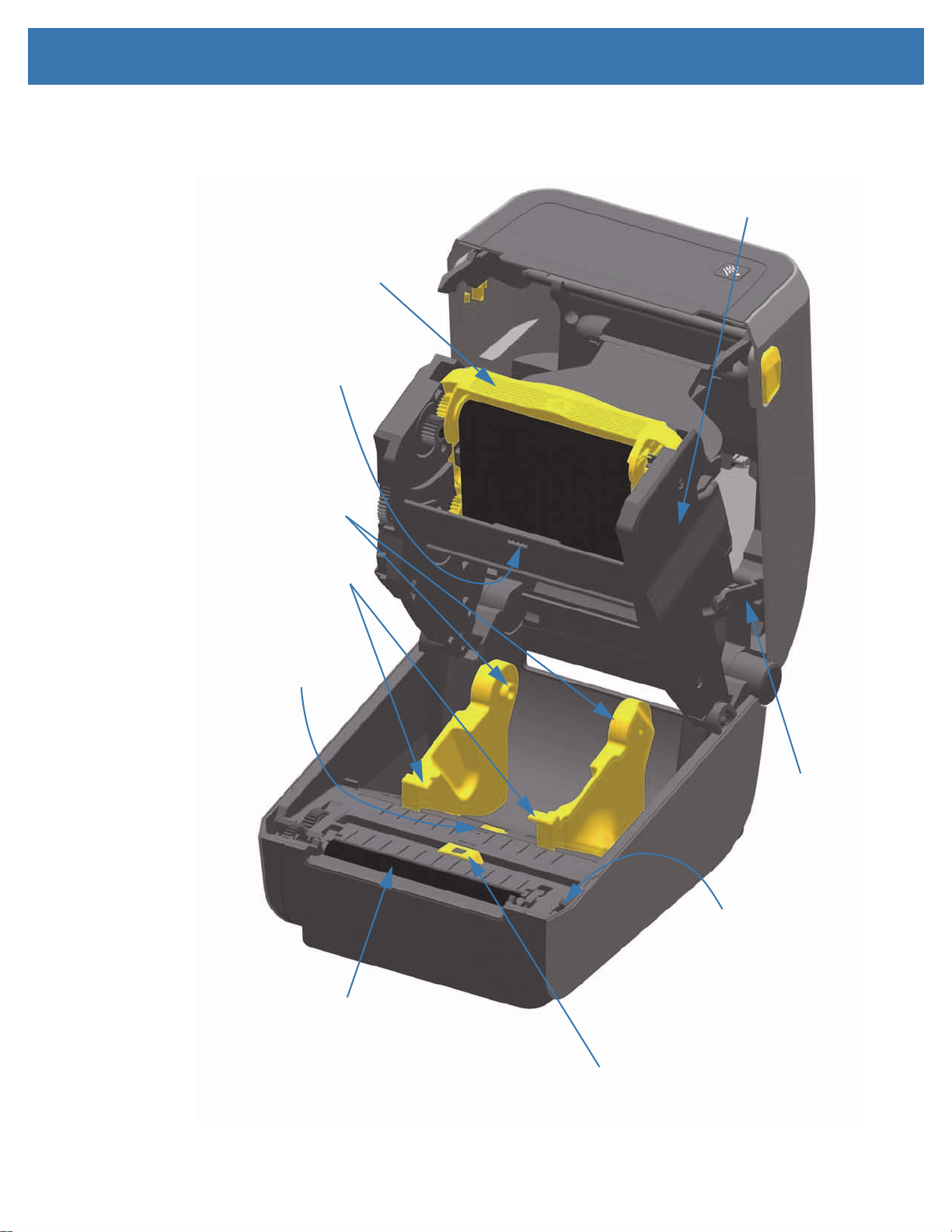

Printer Features

Movable Sensor

(Black Mark and Lower Web/Gap)

Media Guides

Head-Up Sensor

(inside)

Media Guide Stop

Adjustment

Platen (Drive) Roller

Roll Holders

Ribbon Cartridge

Shown Installed

(sold separately)

Upper Web (Gap)

Array Sensor

Release

Arms (2)

Ribbon Drive

Transport

Inside the ZD420 Ribbon Cartridge Printer

26

Page 27

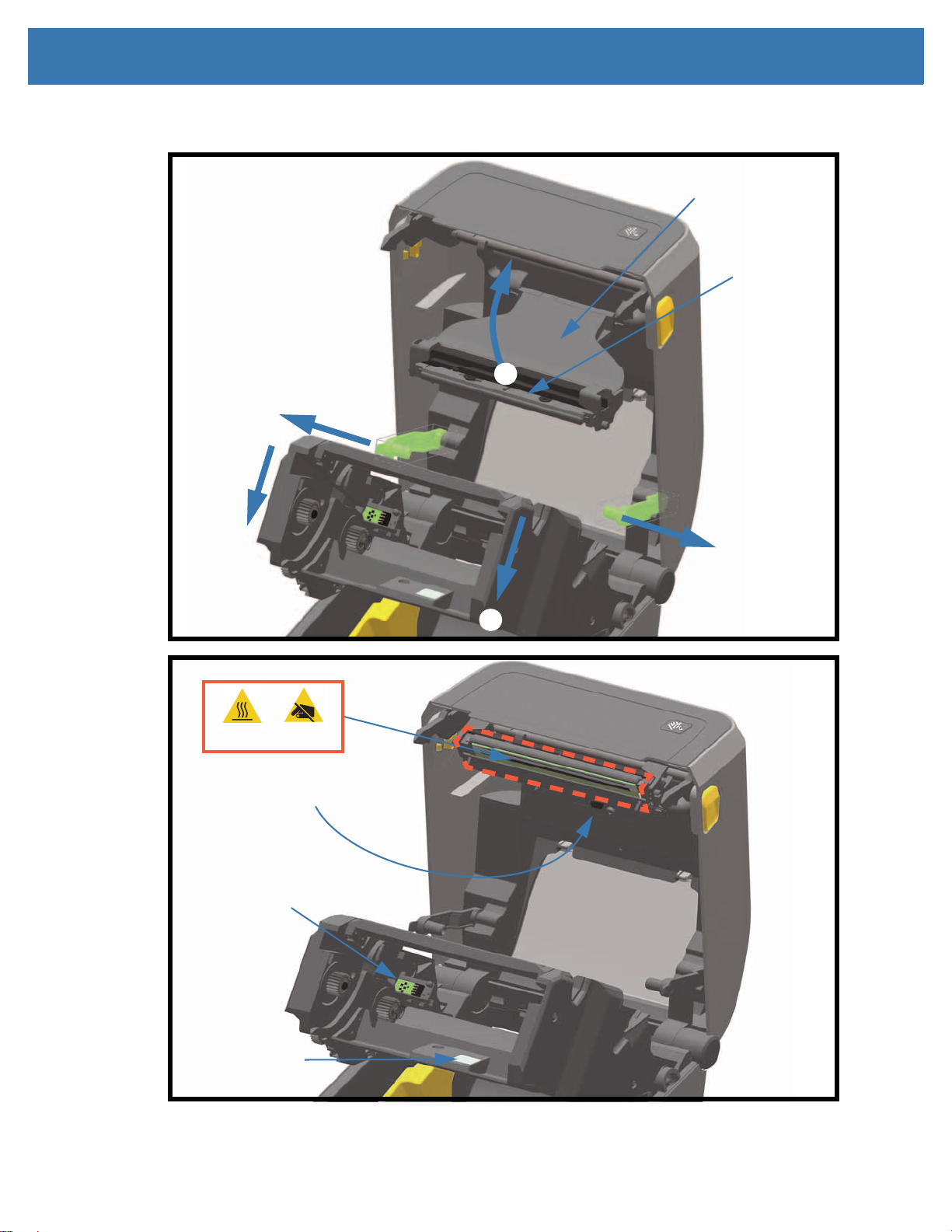

Printer Features

Backside of

Printhead

Printhead

Actuator Arm

PRINTHEAD ACCESS

1. Pull both release arms

out (green highlighted

black parts).

2. Ribbon drive transport

drops down.

3. Lift printhead actuator

arm up to access the

printhead

Printhead

Ribbon Cartridge

Authentication and Status

Interface

Ribbon Sensor

Ribbon Sensor’s

Reflector

Accessing the Printhead of the Ribbon Cartridge Printer

27

Page 28

Printer Features

Door Latch

Label Taken

Sensor

Label Peel Bar

Peel Roll

Dispenser Door

Label Liner

Exit Area

Media Exit Slot

Cutter Module

Label Dispenser Option (field installable) - All Models

Cutter Option (field installable) - All Models

28

Page 29

Printer Features

Label Taken

Sensor

Label Taken

Sensor

Cut Label Landing

Area

Linerless Media Tear-Off Option (Direct Thermal Models Only)

Linerless Cutter Option (Direct Thermal Models Only)

29

Page 30

Printer Features

203 dpi Standard Platen (black)

300 dpi Standard Platen (gray)

203 dpi Linerless Platen (reddish-brown)

300 dpi Linerless Platen (brown)

Identifying Platen Drive Rollers Types

The platen (drive) rollers are colored differently to identify the platen type and print resolution of your

printer (and the platen). Do not exchange platen types unless instructed to by an upgrade procedure or

Zebra technical support. The printer will not operate correctly and may cause a variety of problems

requiring maintenance.

30

Page 31

Printer Power Supply Options

Attached Power Supply

Base

ZD-Series printers offer field installable attached power options: an attached power supply base or a

battery power base. These options easily attach with screws and replace the power supply that was

included with your printer.

Attached Power Supply Base

Printer Features

31

Page 32

Printer Features

Battery Power

Base

Battery Status and

Charge Indicators

Printer with Battery Base Installed Battery

Power

Interface

Power Input Battery Control

Button

Battery Ready to Install Printer with Battery installed

Battery Latch

Attached Battery Base and Battery

ZD620

Important • The battery can be charged, checked, and configured for storage all without the printer. A printer power

supply or other approved Zebra power source is needed to charge your battery.

32

Page 33

ZD620 Locking Printer Features

Kensington Lock Slot

Cabinet Lock

This option is only available in a Healthcare printer models. It includes a lock and key access to the

printer’s media compartment and a Kensington Lock Slot on the back panel of the printer to secure the

printer. For more information on the Locking Printer option, see ZBI 2.0 ™ — Zebra Basic Interpreter.

Printer Features

33

Page 34

Zebra Print Touch

Print Touch Location

(Passive NFC)

The Zebra Print Touch ™ feature allows you to touch an Android ™ -based, Near Field Communication

(NFC)-enabled device such as a smart phone or tablet to the printer’s Print Touch logo to pair the device to

the printer. Print Touch is available on models with a factory installed networking (Wi-Fi, wired Ethernet,

Bluetooth, and Bluetooth Low Power). This capability allows you to use your device to provide information

for which you are prompted and then print a label using that information.

Important • Some mobile devices may not support NFC communication with the printer until you configure the

required NFC settings in your device. If you encounter difficulties, consult your service provider or your smart device

manufacturer for more information.

Printer Features

Data encoded into the tag includes:

• A URL for a Zebra QuickHelp style support web page

• The printer’s unique Bluetooth Low Energy MAC address

• The printer’s Bluetooth Classic MAC address (if present)

• The printer’s Wi-Fi (WLAN) MAC address (if present)

• The printer’s Ethernet (LAN) MAC address (if present)

• The printer SKU – ex. ZD42022-D01W01EZ

• The printer’s unique serial number

The NFC tag can be used to:

• Facilitate Bluetooth pairing with a compatible mobile device

• Launch an application

• Launch a mobile browser to a web page

34

Page 35

Install Hardware Options

This section assists you installing common printer connectivity modules and media handling options.

Important • To simplify and speed up the setup process, install all connectivity modules and media handling options

before setting up and using your printer for the first time.

Important • It is strongly recommended that you update your printer’s firmware after the printer has completed the

setup process. Many of these options have internal firmware that require an update to operate properly with the

printer’s Main Logic Board’s installed firmware version.

35

Page 36

Install Hardware Options

Field Installable printer Accessories and Options

Printer Connectivity Modules

The connectivity module’s access door must be removed prior to installing the following options —

Accessing the Connectivity Module Slot.

• ZD420 Serial Port — Installing the Serial Port Module

• RS-232 DB-9 connector with DTE/DTC auto-switching — Serial Port Interface

• ZD420 Internal Ethernet (LAN - wired) — Installing the Internal Ethernet (LAN) Module

• RJ-45 connector

• Fast Ethernet 10/100 auto-switching, 10Base-T, and 100Base-TX networks.

Media Handling Options

The printer’s standard bezel must be removed prior to installing the following options — Removing the

Standard Bezel.

• Label Dispenser (Peel-Off Liner and Present Label for Operator) - Installing the Label Dispenser

• General Purpose Media Cutter — Installing the Standard Media Cutter

• Linerless Media Cutter — Installing the Linerless Media ‘Tear-Off’ Bezel

• Linerless Media ‘Tear-Off’ Label Bezel — Installing the Linerless Media ‘Tear-Off’ Bezel

• Printer Resolution Upgrade Kits (203 dpi and 300 dpi) - Print Resolution Upgrade Kits

• Media Roll Adapters for 38.1 mm (1.5 inches), 50.8 mm (2.0 inches), or 76.2 mm (3.0 inches) I.D.

media cores - Media Roll Core Size Adapters

Power Base Options

The ZD-Series (ZD620 and ZD420) printers are supported with power base field upgrade kits for each the

direct thermal and thermal transfer versions of these printers.

• Attached Power Supply Base (power supply included) — Installing the Attached Power Supply

Base Options

• Battery Power Base (battery pack sold separately) — Installing the Attached Battery Base Options

• Battery Pack (battery poer base sold separately) — Installing the Battery into the Attached Power

Base

36

Page 37

Install Hardware Options

Printer Connectivity Modules

The connectivity modules can be easily installed without tools.

ESD Caution • The discharge of electrostatic energy that accumulates on the surface of the human body or other

surfaces can damage or destroy the printhead or electronic components used in this device. You must observe

static-safe procedures when working with the printhead or the electronic components.

Power Failure Recovery Mode Jumper (OFF by Default)

All of the Printer Connectivity Modules have a Power Failure Recovery jumper. It is set to the OFF position

by default. With the jumper set to ON, the printer will automatically Power ON when plugged into an active

(ON) AC power source (and not power off). See Standard Interface Controls - Power Button - Power

Failure Recovery Mode for power ON/OFF behaviors. See Setting the Power Failure Recovery Mode

Jumper for instructions on activating the mode.

Note • The Power Failure Recovery Mode is only available on printers with a Printer Connectivity Module installed in

your printer.

Accessing the Connectivity Module Slot

1. Disconnect the DC power plug from the rear of the printer.

2. Open the module access door by pushing down on the top of the door with your finger tip. This releases

the latch. Pull the door away and down to remove.

37

Page 38

Install Hardware Options

Serial Port (RS-232)

Installing the Serial Port Module

1. With the DC power plug and module’s access door removed, slide the serial port module into the

printer. Push the circuit card in slowly but firmly until the card is just past the inside lip of the access

door.

2. Align the bottom of the serial port’s door cover to the bottom lip of the module access opening. Swing

the door up and snap the cover closed.

Note • For best printer performance, update the printer’s firmware after installing options or immediately after the

printer’s initial setup. See Updating Printer Firmware.

38

Page 39

Install Hardware Options

Ethernet Port (RJ-45)

Installing the Internal Ethernet (LAN) Module

1. With the DC power plug and module’s access door removed, slide the Ethernet module into the printer.

Push the circuit card in slowly but firmly until the card is just past the inside lip of the access door.

2. Align the bottom of the Ethernet port’s door cover to the bottom lip of the module access opening.

Swing the door up and snap the cover closed.

Note • For best printer performance, update the printer’s firmware after installing options or immediately after the

printer’s initial setup. See Updating Printer Firmware.

39

Page 40

Install Hardware Options

Removing Printer Connectivity Modules

Connectivity modules can easily be removed for the purpose of reconfiguring a printer or repair. You

should not remove and replace connectivity modules as a general practice.

1. Remove the interface cable (Ethernet or Serial).

2. Remove the module access door. Push down on the top of the door with your finger tip. This releases

the latch. Pull the door away and down to remove.

3. Re-attach the interface cable to the connectivity module and secure the cable.

4. Gently pull on the interface cable that is secured to the connectivity module. Slowly pull the module out

of the printer.

5. Install a different connectivity module or re-install the connectivity module’s access door. Align it to the

bottom lip of the access opening and swing it up to snap and lock in place.

40

Page 41

Media Handling Options

ESD Caution • The discharge of electrostatic energy that accumulates on the surface of the human body or other

surfaces can damage or destroy the printhead or electronic components used in this device. You must observe

static-safe procedures when working with the printhead or the electronic components.

Removing the Standard Bezel

The standard bezel must be removed to mount your media handling option.

1. Disconnect the printer’s DC power input plug from the rear of the printer.

2. Turn the printer upside down. Remove the two (2) mounting screws with the supplied Torx wrench.

Save the screws.

3. Slide the bezel down the front about 12.5 mm (0.5 inch) and pull the loose bezel out.

Install Hardware Options

41

Page 42

Install Hardware Options

Installing the Label Dispenser

The standard bezel must be removed and DC input power disconnected before the Label Dispenser can

be installed. See Removing the Standard Bezel.

1. Place the label dispenser module and printer right side up with the top of the module 12.5 mm (0.5 inch)

below the bottom of the top cover. Center and push the module into the front of the printer and slide it

up until it stops.

2. Turn the printer upside down and attach the module to the printer with the two screws using the Torx

wrench.

Note • For best printer performance, update the printer’s firmware after installing options or immediately after the

printer’s initial setup. See Updating Printer Firmware.

42

Page 43

Install Hardware Options

Installing the Standard Media Cutter

The standard bezel must be removed and DC input power disconnected before the Label Dispenser can

be installed. See Removing the Standard Bezel.

Cut Warning • There are no operator serviceable parts in the cutter unit. Never remove the cutter cover (bezel). Never

attempt to insert objects or fingers in to the cutter mechanism.

Important• Using un-approved tools, cotton swabs, solvents, etc. all may damage or shorten the cutter’s usable life or

cause the cutter to bind.

1. Place the Cutter module and printer right side up with the top of the module even with the bottom of the

top cover. Center and push the module into the front of the printer and slide it up until it stops.

2. Turn the printer upside down and attach the module to the printer with the two screws using the Torx

wrench.

Note • For best printer performance, update the printer’s firmware after installing options or immediately after the

printer’s initial setup. See Updating Printer Firmware.

43

Page 44

Install Hardware Options

Installing the Linerless Media Cutter

The standard bezel must be removed and DC input power disconnected before the Linerless Media Cutter

Module can be installed. See Removing the Standard Bezel.

1. Open the printer and remove replace the standard platen roller with the Linerless platen roller. See

Platen Cleaning and Replacement for a replacement procedure. See Installing the Printhead

Resolution Upgrade Kits to help you identify platen rollers.

2. Place the Cutter module and printer right side up with the top of the module even with the bottom of the

top cover. Center and push the module into the front of the printer and slide it up until it stops.

3. Turn the printer upside down and attach the module to the printer with the two screws using the Torx

wrench.

Note • For best printer performance, update the printer’s firmware after installing options or immediately after the

printer’s initial setup. See Updating Printer Firmware.

44

Page 45

Install Hardware Options

Installing the Linerless Media ‘Tear-Off’ Bezel

The standard bezel must be removed and DC input power disconnected before the Linerless Tear-Off

Bezel module can be installed. See Removing the Standard Bezel.

1. Open the printer and remove replace the standard platen roller with the Linerless platen roller. See

Platen Cleaning and Replacement for a replacement procedure. See Installing the Printhead

Resolution Upgrade Kits to help you identify platen rollers.

2. Place the Tear-Off bezel module and printer right side up with the top of the module even with the

bottom of the top cover. Center and push the module into the front of the printer and slide it up until it

stops.

3. Turn the printer upside down and attach the module to the printer with the two screws using the Torx

wrench.

Note • For best printer performance, update the printer’s firmware after installing options or immediately after the

printer’s initial setup. See Updating Printer Firmware.

45

Page 46

Install Hardware Options

Media Roll Core Size Adapters

Adapter Kits

The media roll adapters kit includes three (3) pairs of media roll adapters. The kits are for the following

inner diameter (I.D.) media cores

• 38.1 mm (1.5 inches)

• 50.8 mm (2.0 inches)

• 76.2 (3.0 inches)

Adapter Usage

• The adapters are intended to be permanently installed in the printer.

• They may be changed to support other media roll sizes that require one of these adapter sizes.

• The adapters may wear out if they are changed too much.

• Removing the media adapters to print on standard roll cores may leave plastic pieces in the media

roll holders side areas that rub against the roll. Push those attached pieces back into the side of the

media roll holder.

:

Installing Media Roll Adapters

1. Place one screw in the top adapter mounting hole of both of the roll holders. Start turning the screws

clockwise using the Torx wrench until the tip of the screw is just protruding through the inside of the roll

holder. The screws are self-tapping.

2. Place the adapter on the inside of the roll holder. The large side of the adapter is on top. The smooth

side (no ribs) faces the middle of the printer.

3. Align the adapter’s top screw hole to the protruding screw tip and pinch it tightly to the roll holder body.

Tighten the screw until there is no gap between the adapter and roll holder. Do not tighten beyond this

point. Over tightening will strip the thread.

4. Insert a screw in the bottom adapter mounting hole. Pinch the adapter tightly to the roll holder while

tightening the screw. Tighten the screw until there is no gap between the adapter and roll holder. Do not

tighten beyond this point. Over tightening will strip the thread.

5. Repeat step 1-4 for the other adapter and roll holder.

46

Page 47

Install Hardware Options

Example of Label Roll

with 76.2 mm (3.0 inch)

Inner Core

mounted on Media Core

Adapters

47

Page 48

Install Hardware Options

Print Resolution Upgrade Kits

There are four (4) print resolution upgrade kits. The same procedure is used to change all the printhead

resolution upgrade kits. Both the printhead and platen (drive) rollers must be changed and are resolution

dependent. The printer automatically detects the change in printheads and the platen roller materials are

identified by color.

Standard Printing

• Change the printer from 203 dpi to 300 dpi printing.

• Change the printer from 300 dpi to 203 dpi printing.

Linerless Printing (for Direct Thermal ZD620 printers only)

• Change the printer from 203 dpi to 300 dpi printing.

• Change the printer from 300 dpi to 203 dpi printing.

Printheads used in the upgrade kits include a 203 or 300 marking to help you keep the unpackaged

upgrade printhead separate from the original printhead. The original printhead contains no marking

identifying its print resolution.

The platen (drive) rollers are colored differently to help you keep from accidentally using the old platen

roller. See Identifying Platen Drive Rollers Types

Installing the Printhead Resolution Upgrade Kits

1. Turn the printer off and disconnect the power.

2. Use the platen roller replacement procedure. See Platen Cleaning and Replacement

3. Use the printhead replacement procedure. See Replacing the Printhead

4. Re-attach power and turn the printer on. The printer will automatically detect the change in printhead

(but not the platen) when the printer verifies the printer’s configuration.

Important • For best results and the latest printer features and operation, download and install the latest printer

firmware. See Updating Printer Firmware.

48

Page 49

Install Hardware Options

Thermal Transfer Printers Direct Thermal Printers

Installing the Attached Power Supply Base Options

The power base is ready to attach to the printer. The base is installed using Torx T10 wrench (that you

supply) and the mounting screws provided with the upgrade kit. The direct thermal printer models attach to

the printer with three (3) screws and thermal transfer printer models use four (4) screws.

1. Remove any media rolls from the printer. Remove the original power supply cable from the back of the

printer.

2. Turn the printer over and align the power base to the bottom of the printer with the printer power plug

oriented toward the rear of the printer. The printer’s rubber feet align with recesses in the top of the

power base.

3. Use the screws provided to attach the power base to the printer. 3 screws for Direct Thermal printers. 4

screws for thermal Transfer printers. Tighten the screws using the Torx wrench supplied in the kit.

49

Page 50

Install Hardware Options

DC Input Power

Plug

DC Input Power

Plug

4. Insert the DC input power plug into the printer.

5. Re-connect the AC power cord to the printer power base.

50

Page 51

Install Hardware Options

Torx T10 Torx T10

Direct Thermal Printers Thermal Transfer Printers

Installing the Attached Battery Base Options

The battery base is ready to attach to the printer. The base is installed using a Torx T10 wrench and the