Page 1

and

User Guide

Page 2

© Copyright 2003 ZIH Corp.

This copyrighted guide and the label printers described herein are owned by

Zebra Technologies Corporation. All rights are reserved. Unauthorized

reproduction of the guide or the software in the label printer may result in

imprisonment of up to one year and fines of up to $10,000 (17 U.S.C.506).

Copyright violators may be subject to civil liability.

IBM® is a registered tradement of IBM Corporation and TrueType® is a

registered trademark of Apple Computer, Inc.

Zebra®, Stripe®, ZPL®, and ZPL II® are registered trademarks of Zebra

Technologies Corporation.

All other brand names, product names, or trademarks belong to their respective

holders.

Z4Mplus and Z6Mplus User Guide:

Customer order number 13163L

Manufacturer part number 13163LB

Page 3

Your Feedback Is Important

Your feedback helps us improve our documents to better serve you!

Please take a few minutes to evaluate your experience using this document.

Product and Personal Information

1. What printer are you using? ____________________________

2. What document are you using? ___________________________

3. Have you ever worked with our product before? Yes No

If Yes, how many ___years? ___months?

4. What is your education level?______________

Document Usability

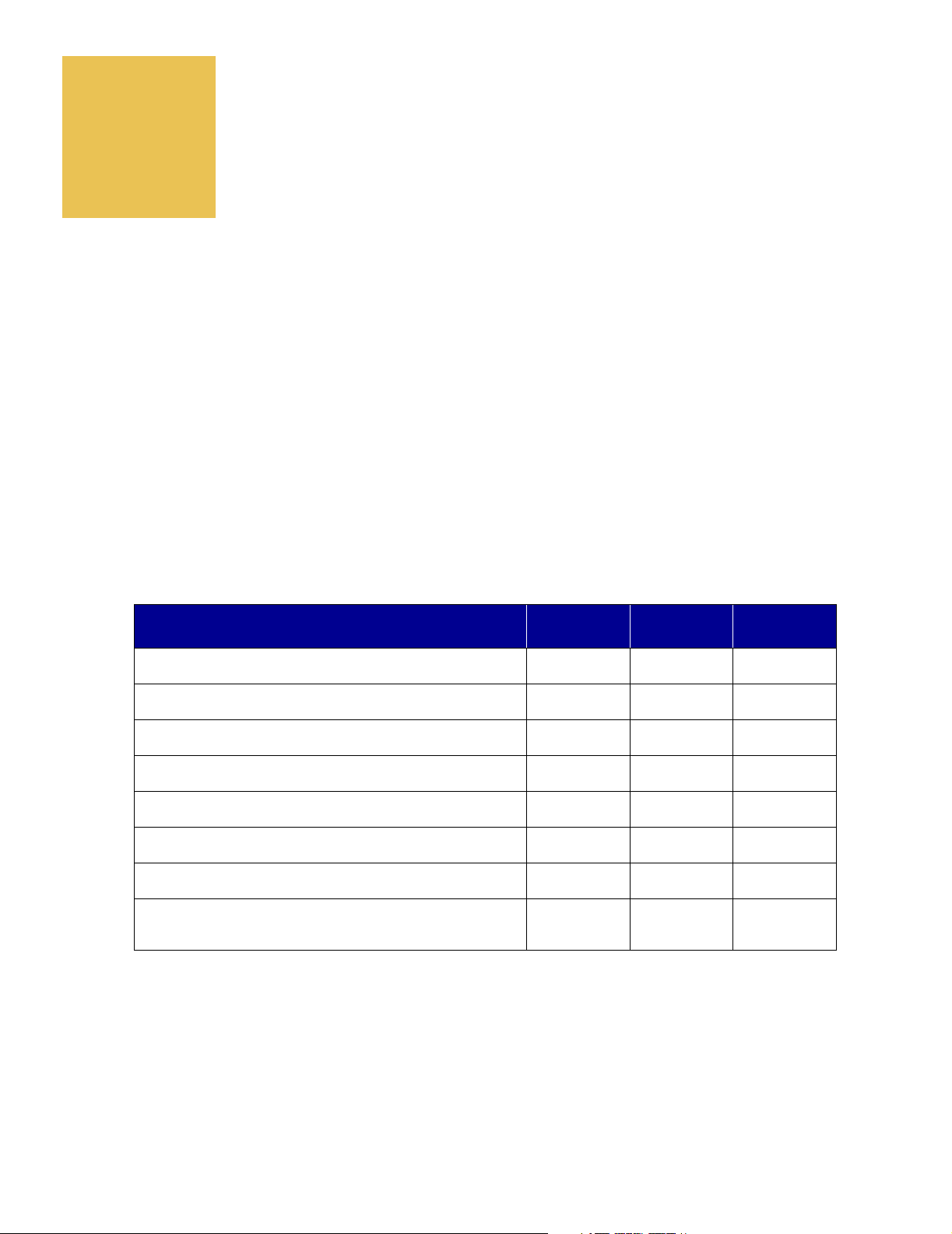

Check the rating that applies to your experience using this document:

Content Excellent Good Poor

The information I needed was available.

The information I needed was easy to find.

The information and directions were clear.

The illustrations were helpful.

The document was arranged logically.

The Table of Contents and Index were helpful.

The Glossary was helpful.

The level of information was appropriate for my

technical expertise.

Additional Comments

Write any additional comments on the lines provided on the next page.

Z4Mplus and Z6Mplus User Guide iii

Page 4

Feedback Form

Comments • _______________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

Thank you for taking the time to provide us with feedback.

!

! Fax: 1.847.821.1795 Attention: TechPubs — CTC

!!

!!!! E-mail: techpubs@zebra.com

iv Z4Mplus and Z6Mplus User Guide

Page 5

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation and

its subsidiaries (“Zebra Technologies”). It is intended solely for the information and

use of parties operating and maintaining the equipment described herein. Such

propriety information may not be used, reproduced, or disclosed to any other parties

for any other purpose without the expressed written permission of Zebra Technologies

Corporation.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies Corporation.

All specifications and designs are subject to change without notice.

Z4Mplus and Z6Mplus User Guide v

Page 6

FCC Compliance Statement

Note: This equipment has been tested and found to comply with the limits for a Class

B Digital Device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a residential environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the product

manuals, may cause harmful interference to radio communications.

In order to ensure compliance, this printer must be used with Shielded Communication

Cables.

“The user is cautioned that any changes or modifications not expressly approved by

Zebra Technologies Corporation could void the user’s authority to operate the

equipment.”

Canadian DOC Compliance Statement

This Class B digital apparatus complies with Canadian ICES-003.

Liability Disclaimer

Zebra Technologies Corporation takes steps to assure that its published Engineering

specifications and manuals are correct; however, errors do occur. Zebra Technologies

Corporation reserves the right to correct any such errors and disclaims liability

resulting therefrom.

Limitation of Liability

In no event shall Zebra Technologies Corporation or anyone else involved in the

creation, production or delivery of the accompanying product (including hardware and

software) be liable for any damages whatsoever (including, without limitation,

consequential damages including loss of business profits, business interruption or loss

of business information) arising out of the use of or the results of use of or inability to

use such product, even if Zebra Technologies Corporation been advised of the

possibility of such damages. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not

apply to you.

vi Z4Mplus and Z6Mplus User Guide

Page 7

Copyrights

The copyrights in this manual and the label printer described therein are owned by

Zebra Technologies Corporation. All rights are reserved. Unauthorized reproduction

of this manual or the software in the label printer may result in imprisonment of up to

one year and fines of up to $10,000 (17 U.S.C.506). Copyright violators may be

subject to civil liability.

All trademarks and registered trademarks are property of their respective owners.

Copyright 2003 ZIH Corp. All rights reserved.

Z4Mplus and Z6Mplus User Guide vii

Page 8

viii Z4Mplus and Z6Mplus User Guide

Page 9

DECLARATION OF CONFORMITY

I have determined that the Zebra printers identified as the

Z4Mplus/Z6Mplus-Series

manufactured by:

Zebra Technologies Corporation

333 Corporate Woods Parkway

Vernon Hills, Illinois 60061-3109 U.S.A.

Have been shown to comply with the applicable technical standards of the FCC

For Home, Office, Commercial, and industrial use

If no unauthorized change is made in the equipment,

and if the equipment is properly maintained and operated.

Z4Mplus and Z6Mplus User Guide ix

Page 10

x Z4Mplus and Z6Mplus User Guide

Page 11

Warranty Information

Effective November 1, 2001

All Zebra Technologies Corporation products are sold with warranties. Following is

some general information:

Printer Products

Printers. All printers (excluding printheads) are warranted against defect in material or

workmanship for twelve (12) months from the purchase date.

Proof of purchase or shipment date is required to validate the warranty period. The

warranty becomes void if the equipment is modified, improperly installed or used,

damaged by accident or neglect, or if any parts are improperly installed or replaced by

the user.

Note: Products returned must be packaged in the original or comparable packing and

shipping container. In the event equipment is not so packaged, or if shipping damage is

evident, it will not be accepted for service under warranty. Surface transportation

charges for return to customers in the continental United States is paid by Zebra.

Otherwise, Zebra pays CPT (carriage paid to) nearest airport; customer pays customs,

duties, taxes, and freight from airport to destination. If Zebra determines that the

Z4Mplus and Z6Mplus User Guide xi

Page 12

Printer Products

product returned for warranty service or replacement is not defective as herein

defined, the customer will pay all handling and transportation costs.

Printheads. Since printhead wear is part of normal operation, the original printhead is

covered by a limited warranty as indicated below. Warranty period begins on purchase

date.

Printhead Warranty Period

Bar code label printer printheads 6 months

Card printer printheads 12 months

To qualify for this warranty, the printhead must be returned to the factory or to an

authorized service center. Customers are not required to purchase Zebra supplies

(media and/or ribbons) for warranty qualification. However, if it is determined that the

use of other manufacturer supplies has caused any defect in the printhead for which a

warranty claim is made, the user is responsible for Zebra’s labor and material charges

required to repair the defect. The warranty becomes void if the printhead is physically

worn or damaged; also if it is determined that failure to follow the preventive

maintenance schedule listed in the User’s Guide has caused defect in the thermal

printhead for which a warranty claim is made.

Software. Software is warranted to be free of defects in material and workmanship for

30 days from the date of purchase. In the event of notification within the warranty

period of defects, Zebra will replace the defective diskette or documentation.

Batteries. Mobile printer batteries are warranted to be free of defects in material and

workmanship for 90 days from date of purchase. In the event of notification within the

warranty period, Zebra will replace the defective battery provided there has not been

damage resulting from user abuse.

. All parts, maintenance kits, options kits, and accessories are warranted to be free

Parts

of defects in material and workmanship for 90 days (except where otherwise noted)

from date of purchase. This warranty becomes void if the item is modified, improperly

installed or used, or damaged by accident or neglect.

xii Z4Mplus and Z6Mplus User Guide

Page 13

Printer Products

Supplies Products

Supplies are warranted to be free from defect in material and workmanship for a

period of six (6) months for media and twelve (12) months for ribbon from the date of

shipment by Zebra. This is provided the user has complied with storage guidelines,

handling, and usage of the supplies in Zebra printers.

Zebra’s sole obligation under these warranties is to furnish parts and labor for the

repair or possible replacement of products found to be defective in material or

workmanship during the warranty period. Zebra may in its discretion issue a credit for

any such defective products in such amount as it deems reasonable.

Warranty Exclusions & Conditions Statement

The warranties provided above are the only warranties applicable. No other

warranties, expressed or implied, are given. Zebra does not make any IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE in connection with its sale of products or services. While Zebra’s desire is

to be responsive to specific needs and questions, Zebra does not assume responsibility

for any specific application to which any products are applied including, but not

limited to, compatibility with other equipment. All statements, technical information

or recommendations relating to Zebra products are based upon tests believed to be

reliable yet do not constitute a guaranty or warranty.

Zebra’s maximum liability for warranty claims is limited to the invoice price of the

product claimed defective. Zebra does not assume responsibility for delays or

replacement or repair of products. Zebra shall not under any circumstances whatsoever

be liable to any party for loss of profits, lost data, diminution of good will, or any other

special or consequential damages whatsoever with respect to any claim made under

agreement with Zebra. Specifically for software, Zebra is not liable for any incidental

or consequential damages caused by abuse or misapplication of the software or by its

use in violation of the U.S. copyright law or international treaty.

No salesperson, representative, or agent of Zebra is authorized to make any guaranty,

warranty, or representation that contradicts the foregoing. Any waiver, alteration,

addition or modification to the foregoing warranties must be in writing and signed by

an executive officer of Zebra to be valid.

Z4Mplus and Z6Mplus User Guide xiii

Page 14

Printer Software and Firmware License Agreement

Zebra Link License Agreement

Printer Software and Firmware License

Agreement

YOU SHOULD CAREFULLY READ THE FOLLOWING TERMS AND

CONDITIONS OF THIS ZEBRA TECHNOLOGIES CORPORATION PRINTER

SOFTWARE AND FIRMWARE LICENSE AGREEMENT (“PSFLA”) BEFORE

USING THE PRINTER WHICH IS ENCLOSED OR OTHERWISE ASSOCIATED

WITH THIS AGREEMENT. IF YOU DO NOT AGREE WITH THESE TERMS

AND CONDITIONS, DO NOT OPERATE THE PRINTER AND PLEASE

PROMPTLY RETURN THE PRINTER, ENCLOSURES AND ALL PACKAGING

FOR A FULL REFUND.

Zebra Technologies Corporation (“ZEBRA”) hereby grants you a non-exclusive, nontransferable license to use the SOFTWARE and FIRMWARE embedded in the printer

and the accompanying documentation according to the following terms:

1. The printer enclosed with or otherwise associated with this Agreement has or

includes certain SOFTWARE and FIRMWARE therein which is protected by

copyright laws and international copyright treaties, as well as other intellectual

property laws and treaties. The SOFTWARE and FIRMWARE is licensed, not

sold. Such SOFTWARE and/or FIRMWARE may include, but is not limited to,

SOFTWARE and/or FIRMWARE that is licensed under one or more of the

following trademarks: ZPL (Zebra Programming Language), Zebralink, Web

View, Web Alert, ZBI (Zebra Basic Interpreter), BAR-ONE, ZTools, Utilities,

ZebraNet View for IP, ZebraNet Alert, PC Management Program, ZebraNet View

for Networks and ZebraNet Connect.

2. GRANT OF LICENSE. This License grants you the following rights:

• SOFTWARE and FIRMWARE. You may use, access, display, run, or

otherwise interact with (“RUN”) the SOFTWARE and FIRMWARE in

connection with operating the printer which is enclosed with or otherwise

associated with this PSFLA (“PRINTER”). The primary user of the PRINTER

may make a second copy for his or her exclusive use on a portable computer/

printer.

xiv Z4Mplus and Z6Mplus User Guide

Page 15

Printer Software and Firmware License Agreement

• Storage/Network Use. You may also store or install a copy of the SOFTWARE

and FIRMWARE on a storage device, such as a network server, used only to

RUN the SOFTWARE and FIRMWARE on your other PRINTERS over an

internal network; however, you must acquire and dedicate a license for each

separate PRINTER on which the SOFTWARE and FIRMWARE is RUN from

the storage device. A license for the SOFTWARE and FIRMWARE may not

be shared or used concurrently on different PRINTERS.

• Reservation of Rights. All rights not expressly granted are reserved by

ZEBRA.

• Accessing Services Using the SOFTWARE and FIRMWARE. Your use of any

service accessible using the SOFTWARE and FIRMWARE is not covered by

this PSFLA and may be governed by separate terms of use, conditions or

notices.

3. RESTRICTIONS.

• You must maintain all copyright notices on all copies of the SOFTWARE and

FIRMWARE.

• Limitations on modification. You may not modify, adapt, translate, or create

derivative works based on this SOFTWARE OR FIRMWARE or the

accompanying documentation.

• Limitations of Reverse Engineering, Decompilation and Disassembly. You

may not reverse engineer, decompile, or disassemble the SOFTWARE or the

FIRMWARE, except and only to the extent that such activity is permitted by

applicable law notwithstanding this limitation.

• Rental. You may not rent or lease or lend the SOFTWARE or FIRMWARE.

• Support Services. ZEBRA may provide you with support services related to

the SOFTWARE and/or FIRMWARE (“SUPPORT SERVICES”), in its

discretion. Use of SUPPORT SERVICES, if any, is governed by the ZEBRA

policies and programs described in the user manual, in “online”

documentation, and/or other ZEBRA provided materials. Any supplemental

SOFTWARE or FIRMWARE code provided to you as a part of SUPPORT

SERVICES shall be considered part of the SOFTWARE and/or FIRMWARE

and is subject to the terms of this PSFLA. With respect to technical

information you provide to ZEBRA as part of the SUPPORT SERVICES,

ZEBRA may use such information for its business purposes, including for

product support and development. ZEBRA will not utilize such technical

information in a form that personally identifies you except to the extent

necessary to provide you with support.

Z4Mplus and Z6Mplus User Guide xv

Page 16

Printer Software and Firmware License Agreement

• Replacement, Modification and Upgrade of the SOFTWARE and/or

FIRMWARE. ZEBRA reserves the right to replace, modify or upgrade the

SOFTWARE and/or FIRMWARE at any time by offering you a replacement

or modified version of the SOFTWARE and/or FIRMWARE or such upgrade

and to charge for such replacement, modification or upgrade. Any such

replacement or modified SOFTWARE and/or FIRMWARE code or upgrade to

the SOFTWARE and/or FIRMWARE offered to you by ZEBRA shall be

considered part of the SOFTWARE and/or FIRMWARE and subject to the

terms of this PSFLA (unless this PSFLA is superseded by a further PSFLA

accompanying such replacement or modified version of or upgrade to the

SOFTWARE and/or FIRMWARE). In the event that ZEBRA offers a

replacement or modified version of or any upgrade to the SOFTWARE and/or

FIRMWARE, (a) your continued use of the SOFTWARE and/or FIRMWARE

is conditioned on your acceptance of such replacement or modified version of

or upgrade to the SOFTWARE and/or FIRMWARE and any accompanying

superseding PSFLA and (b) in the case of the replacement or modified

SOFTWARE and/or FIRMWARE, your use of all prior versions of the

SOFTWARE and/or FIRMWARE is terminated.

4. TERMINATION. Without prejudice to any other rights, ZEBRA may terminate

this PSFLA if you fail to comply with the terms and conditions of this PSFLA.

ZEBRA may terminate this PSFLA by offering you a superseding PSFLA for the

SOFTWARE and/or FIRMWARE or any replacement or modified version of or

upgrade to the SOFTWARE and/or FIRMWARE and conditioning your continued

use of the SOFTWARE and/or FIRMWARE or such replacement, modified or

upgraded version on your acceptance of such superseding PSFLA. In addition,

ZEBRA may terminate this PSFLA by notifying you that your continued use of the

SOFTWARE and/or FIRMWARE is prohibited. In the event that ZEBRA

terminates this PSFLA, you must immediately stop using the SOFTWARE and/or

FIRMWARE and destroy all copies of the SOFTWARE and/or FIRMWARE and

all of its component parts.

5. COPYRIGHT. All title and copyrights in and to the SOFTWARE and

FIRMWARE, the accompanying printed materials, and any copies of the

SOFTWARE and FIRMWARE, are owned by ZEBRA or its suppliers. All title

and intellectual property rights in and to the content which may be accessed

through use of the SOFTWARE and/or FIRMWARE is the property of the

respective content owner and may be protected by applicable copyright or other

intellectual property laws and treaties. This PSFLA grants you no rights to use

such content. If this SOFTWARE and/or FIRMWARE contains documentation

which is provided only in electronic form, you may print one copy of such

electronic documentation. You may not copy the printed materials accompanying

the SOFTWARE and/or FIRMWARE.

xvi Z4Mplus and Z6Mplus User Guide

Page 17

Printer Software and Firmware License Agreement

6. U.S. GOVERNMENT RESTRICTED RIGHTS. All SOFTWARE and/or

FIRMWARE provided to the U.S. Government pursuant to solicitations issued on

or after December 1, 1995 is provided with the commercial rights and restrictions

described elsewhere herein. All SOFTWARE and/or FIRMWARE provided to the

U.S. Government pursuant to solicitations issued prior to December 1, 1995 is

provided with RESTRICTED RIGHTS as provided for in FAR, 48 CFR 52.227-14

(JUNE 1987) or DFAR, 48 CFR 252.227-7013 (OCT 1988), as applicable.

7. EXPORT RESTRICTIONS. You agree that you will not export or re-export the

SOFTWARE and/or FIRMWARE, any part thereof, or any process or service that

is the direct product of the SOFTWARE and/or FIRMWARE (the foregoing

collectively referred to as the “RESTRICTED COMPONENTS”), to any country,

person or entity subject to U.S. export restrictions. You specifically agree not to

export or re-export any of the RESTRICTED COMPONENTS (i) to any country

to which the U.S. has embargoed or restricted the export of goods or services,

which currently include, but are not necessarily limited to Cuba, Iran, Iraq, Libya,

North Korea, Sudan and Syria, or to any national of any such country, wherever

located, who intends to transmit or transport the RESTRICTED COMPONENTS

back to such country; (ii) to any person or entity who you know or have reason to

know will utilize the RESTRICTED COMPONENTS in the design, development

or production of nuclear, chemical or biological weapons; or (iii) to any person or

entity who has been prohibited from participating in U.S. export transactions by

any federal agency of the U.S. government. You warrant and represent that neither

the U.S. Commerce Department, Bureau of Export Administration nor any other

U.S. federal agency has suspended, revoked or denied your export privileges.

8. DISCLAIMER OF WARRANTIES. ZEBRA AND ITS SUPPLIERS PROVIDE

THE SOFTWARE AND/OR FIRMWARE “AS IS” AND WITH ALL FAULTS,

AND HEREBY DISCLAIM ALL OTHER WARRANTIES AND CONDITIONS,

EITHER EXPRESS, IMPLIED OR STATUTORY, INCLUDING BUT NOT

LIMITED TO ANY (IF ANY) IMPLIED WARRANTIES OR CONDITIONS OF

MERCHANTABILITY, OF FITNESS FOR A PARTICULAR PURPOSE, OF

LACK OF VIRUSES, AND OF LACK OF NEGLIGENCE OR LACK OF

WORKMANLIKE EFFORT. ALSO, THERE IS NO WARRANTY OR

CONDITION OF TITLE, OF QUIET ENJOYMENT, OR OF

NONINFRINGEMENT. THE ENTIRE RISK ARISING OUT OF THE USE OR

PERFORMANCE OF THE SOFTWARE AND FIRMWARE IS WITH YOU.

ZEBRA DOES NOT WARRANT THAT THE OPERATION OF THE

SOFTWARE OR FIRMWARE WILL BE UNINTERRUPTED OR ERROR

FREE.

Z4Mplus and Z6Mplus User Guide xvii

Page 18

Printer Software and Firmware License Agreement

9. EXCLUSION OF ALL DAMAGES. TO THE MAXIMUM EXTENT

PERMITTED BY APPLICABLE LAW, IN NO EVENT SHALL ZEBRA OR ITS

SUPPLIERS BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL,

DIRECT, INDIRECT, SPECIAL, PUNITIVE, OR OTHER DAMAGES

WHATSOEVER (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR

ANY INJURY TO PERSON OR PROPERTY, DAMAGES FOR LOSS OF

PROFITS, BUSINESS INTERRUPTION, LOSS OF BUSINESS

INFORMATION, FOR LOSS OF PRIVACY FOR FAILURE TO MEET ANY

DUTY INCLUDING OF GOOD FAITH OR OF REASONABLE CARE, FOR

NEGLIGENCE, AND FOR ANY PECUNIARY OR OTHER LOSS

WHATSOEVER) ARISING OUT OF OR IN ANY WAY RELATED TO THE

USE OF OR INABILITY TO USE THE SOFTWARE OR FIRMWARE,

WHETHER BASED ON CONTRACT, TORT, NEGLIGENCE, STRICT

LIABILITY OR OTHERWISE, EVEN IF ZEBRA OR ANY SUPPLIER HAS

BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. THIS

EXCLUSION OF DAMAGES SHALL BE EFFECTIVE EVEN IF ANY

REMEDY FAILS OF ITS ESSENTIAL PURPOSE.

10.LIMITATIONS AND RELEASE OF LIABILITY.

• To the extent that the SOFTWARE and/or FIRMWARE covered by this

PSFLA includes emulation libraries, emulation libraries are offered “as is”.

ZEBRA does not provide any warranty associated with the emulation

libraries.

• The emulation library does not work 100% correctly or cover 100% of the

functionality of the printer language being emulated. Modifications may be

required for each target application. If such modification is necessary, prior to

making any such modification, you are required to contact ZEBRA to obtain

express written consent to make such modification.

• If the emulation library is sold separately by an authorized party other than

ZEBRA (“RESELLER”—A party other than ZEBRA which is authorized by

ZEBRA to distribute the SOFTWARE and/or FIRMWARE with its

application so long as the SOFTWARE and/or FIRMWARE is used with a

ZEBRA printer) or is sold bundled with a printer to an end-user by a

RESELLER, and if claims are made by the RESELLER that the emulation

library performs as a 100% emulation solution, ZEBRA is not responsible if

the emulation library does not work as advertised by the RESELLER.

Furthermore, ZEBRA is not liable for any damages directly or indirectly

relating to such emulation library which is sold separately by the RESELLER

or which is sold bundled with a printer to an end-user by the RESELLER.

xviii Z4Mplus and Z6Mplus User Guide

Page 19

Printer Software and Firmware License Agreement

• The SOFTWARE and FIRMWARE was provided to you at no additional

charge and ZEBRA has included in this PSFLA terms that disclaim all

warranties and liability for the SOFTWARE and FIRMWARE. To the full

extent allowed by law, YOU HEREBY RELEASE ZEBRA AND ITS

SUPPLIERS FROM ANY AND ALL LIABILITY ARISING FROM OR

RELATED TO ALL CLAIMS CONCERNING THE SOFTWARE AND/OR

FIRMWARE OR ITS USE. If you do not wish to accept the SOFTWARE OR

FIRMWARE under the terms of this PSFLA, do not use the PRINTER

enclosed with or otherwise associated with this PSFLA.

11. GOVERNING LAW. If you acquired the SOFTWARE and/or FIRMWARE in the

United States of America, the laws of the State of Illinois, U.S.A. will apply to this

contract. If you acquired this SOFTWARE and/or FIRMWARE outside of the

United States of America, then local law may apply. If any provision of this

PSFLA is held invalid, the remainder of this PSFLA shall continue in full force

and effect.

12.QUESTIONS. Should you have any questions, or if you desire to contact ZEBRA

for any reason, please contact the ZEBRA subsidiary serving your country, or

write:

Zebra Technologies Corporation

333 Corporate Woods Parkway

Vernon Hills, IL 60061

Z4Mplus and Z6Mplus User Guide xix

Page 20

Printer Software and Firmware License Agreement

xx Z4Mplus and Z6Mplus User Guide

Page 21

Table of Contents

1 • Proprietary Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Product Improvements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

FCC Compliance Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Canadian DOC Compliance Statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Liability Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

Limitation of Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Copyrights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

DECLARATION OF CONFORMITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Printer Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Printer Software and Firmware License Agreement. . . . . . . . . . . . . . . . . . . . . . xiv

2 • Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvii

Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxviii

Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxviii

About this Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxix

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxx

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxxii

Z4Mplus and Z6Mplus User Guide xxi

Page 22

Table of Contents

3 • Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Inspect the printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Report Damage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Z4Mplus and Z6Mplus Printer Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Printer Side View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 • Printer Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Ribbon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Types of Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Print Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Load Media and Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Load the Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Load the Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Auto Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Printhead Pressure Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Rewind Media Alignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Configuration Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Print a Configuration Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Troubleshoot Printing Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Basic Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Basic Configuration Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Position the Label Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Reflective Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Configure the Software or Printer Driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5 • Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

System Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

xxii Z4Mplus and Z6Mplus User Guide

Page 23

Table of Contents

6 • Printer Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Printer Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Load Roll Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Tear-Off Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Cutter Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Peel-Off Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Liner Take-Up Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Rewind . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Load Fanfold Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Load the Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Remove the Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7 • Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Enter Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Change Password-Protected Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Leave the Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Configuration and Calibration Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8 • Routine Care and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . 87

Cleaning Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Clean the Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Clean the Interior. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Clean the Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Clean the Rewind Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Clean the Peel-Off Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Clean the Cutter Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

9 • Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

LCD Error Conditions and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Error Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Print Quality Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Communication Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Z4Mplus and Z6Mplus User Guide xxiii

Page 24

Table of Contents

Printer Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Power-On Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Additional Printer Self Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Cancel Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Pause Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Feed Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Communications Diagnostics Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

10 • Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Printing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Media Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Ribbon Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Zebra Programming Language (ZPL II) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Bar codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

AC Power Cord. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Power Line Cord Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Appendix A • DB-9 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Printer Interface Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Serial Data Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Appendix B • Parallel Data Port . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Parallel Data Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Parallel Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Parallel Port Interconnections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Appendix C • • Memory Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Memory Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

PCMCIA Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Appendix D • • Extend Printhead Life . . . . . . . . . . . . . . . . . . . . . 141

Extend the Life of Your Printhead with Save-a-Printhead Cleaning Film . . . . . 142

Recommended for all Zebra printers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Use Save-a-Printhead Cleaning Film . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

How to Order Cleaning Film Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

xxiv Z4Mplus and Z6Mplus User Guide

Page 25

Preface

The Preface discusses the topics and illustrates standards that are used throughout this

guide.

Contents

Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

Support . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

About this Document . . . . . . . . . . . . . . . . . . xxvii

Document Conventions. . . . . . . . . . . . . . . xxviii

Related Documents. . . . . . . . . . . . . . . . . . . . xxx

Z4Mplus and Z6Mplus User Guide xxv

Page 26

Preface

Contacts

Contacts

You can contact Zebra Technologies Corporation, USA at any of the following:

Visit us at: www.zebra.com

Our Mailing Address:

Zebra Technologies Corporation

333 Corporate Woods Parkway

Vernon Hills, Illinois 60061.3109 U.S.A

Telephone: +1 847.634.6700

Facsimile: +1 847.913.8766

Zebra Technologies Europe Limited

Zebra House

The Valley Centre, Gordon Road

High Wycombe

Buckinghamshire HP13 6EQ, UK

Telephone: +44 (0)1494 472872

Facsimile: +44 (0)1494 450103

Support

You can contact Zebra support at any of the following:

Caution • The Web address is case-sensitive. The SS must be all caps.

Web address: www.zebra.com/SS/service_support.htm

US Phone Number: +1 847.913.2259

UK/International Phone Number: +44 (0) 1494 768289

xxvi Z4Mplus and Z6Mplus User Guide

Page 27

About this Document

The User Guide contains these chapters:

Title Content Description

Introduction Provides a high level overview of the

Printer Setup Provides instructions for loading media

Communication Describes communications options and

Printer Basics Discusses detailed functions of controls

Preface

About this Document

Z4Mplus and Z6Mplus printer.

and ribbon.

their connections.

and lights.

Configuration Discusses detailed configuration settings.

Routine Care and Adjustments Discusses printer cleaning and minor

adjustments.

Troubleshooting Discusses errors and warnings, print

quality, and printer diagnostics.

Specifications Lists all printer specifications.

DB-9 Connectors Serial data connectors.

Parallel Data Port Parallel port connections.

Memory Cards Memory card installations.

Extend Printhead Life How to extend the life of the printhead.

Z4Mplus and Z6Mplus User Guide xxvii

Page 28

Preface

Document Conventions

Document Conventions

The following conventions are used throughout this document to convey certain

information:

About this Chapter: This section lists and describes each main section of the chapter,

including the initial page number of that section. These sections primarily serve as

hyperlink components for the Adobe Acrobat.pdf version of this guide.

Alternate Color: (on-line only) Cross-references contain hot links to other sections in

this guide. If you are viewing this guide on-line in.pdf format, you can click the

cross-reference (royal blue text) to jump directly to its location.

Command Line Examples: All command line examples appear in Courier font.

For example, you would type the following to get to the Post-Install scripts in the

bin directory: Ztools

Files and Directories: All file names and directories appear in Courier New font.

For example, the Zebra<version number>.tar file and the /root directory.

Caution, Important, Note, and Example: These topics are defined in the following

example:

Caution • Advises you that failure to take or avoid a specific action could result in

physical harm to you or the hardware.

Caution • Advises you that failure to take or avoid a specified action could result

in loss of data or hardware damage.

Important • Provides information that is essential to the completion of a task.

Note • Indicates neutral or positive information that emphasizes or supplements

important points of the main text.

Example • Provides an example, often a scenario, to better clarify a section of text.

xxviii Z4Mplus and Z6Mplus User Guide

Page 29

Preface

Document Conventions

Illustration Call-out Instructions: Illustration call-out instructions are used when an

illustration contains either information about a dialog box, step(s) to accomplish, or

numbers in a table.

10

12

11

2

1

3

4

5

6

7

PAUSE

8

9

Z4Mplus and Z6Mplus User Guide xxix

Page 30

Preface

Related Documents

Related Documents

In addition to the Z4Mplus and Z6Mplus User Guide, the following documents might

be helpful references:

• The ZPL II Programming Guide Volume I and Volume II (Zebra part number

45540L) details how to create the perfect label format for your application. The

guide explains how the optional ZBI™ extends the power of ZPL II by allowing

custom programs to be written that operate within the printer, directly interfacing

with bar code scanners, keyboard display devices, etc. The guide also contains

information about the enhanced operating system features of your printer. There

are three ways to obtain this guide: on the accessory CD-ROM (supplied with the

printer), on our web site (www.zebra.com), or by ordering printed manuals from

your distributor.

• The PrintServer II User and Reference Guide (Zebra part number 45537L)

explains how you can quickly set up your printer on an IP network and experience

ZebraLink, our revolutionary real-time connectivity and control solution for Zebra

printers (optional ZebraNet PrintServer II required).

• The Z4Mplus and Z6Mplus Maintenance Manual (Zebra part number 13358L)

contains the information you need to maintain your printer.

xxx Z4Mplus and Z6Mplus User Guide

Page 31

CHAPTER 1

Introduction

This chapter provides a high level overview of the Z4Mplus and Z6Mplus Printer.

Contents

Inspect the printer . . . . . . . . . . . . . . . . . . . . . . . 2

Report Damage . . . . . . . . . . . . . . . . . . . . . . . 2

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Z4Mplus and Z6Mplus Printer Overview . . . . . . 3

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Printer Side View . . . . . . . . . . . . . . . . . . . . . . 5

Z4Mplus and Z6Mplus User Guide 1

Page 32

Introduction

Inspect the printer

Inspect the printer

• Check all exterior surfaces.

• Raise the media access door and inspect the media compartment.

• Save the carton and all packing material in case the printer needs to be shipped.

Contact your authorized Zebra reseller for instructions.

• Depending on how your printer was ordered, a power cord may or may not be

included. If one is not included, or if the one included is not suitable for your

requirements, see AC Power Cord on page 122.

Caution • For personnel and equipment safety, always use a three-prong plug with

an earth-ground connection to the AC power source.

Report Damage

If you discover shipping damage:

.

Important • Zebra Technologies Corporation is not responsible for any damage

incurred during the shipment of the equipment and will not repair this damage under

warranty

Storage

If you are not placing the printer into operation immediately, repackage it using the

original packing materials. The printer may be stored under the following conditions:

• Immediately notify the shipping company and file a damage report.

• Keep the carton and all packing material for inspection.

• Notify your local Zebra reseller.

• Temperature: –40°F to 140°F (–40°C to 60°C)

• Relative humidity: 5% to 85%, non-condensing

2 Z4Mplus and Z6Mplus User Guide

Page 33

Z4Mplus and Z6Mplus Printer Overview

Z4Mplus and Z6Mplus Printer Overview

The following information is a general overview of the Z4Mplus and Z6Mplus

printers operational controls and location of major components needed in the loading

of media and ribbon.

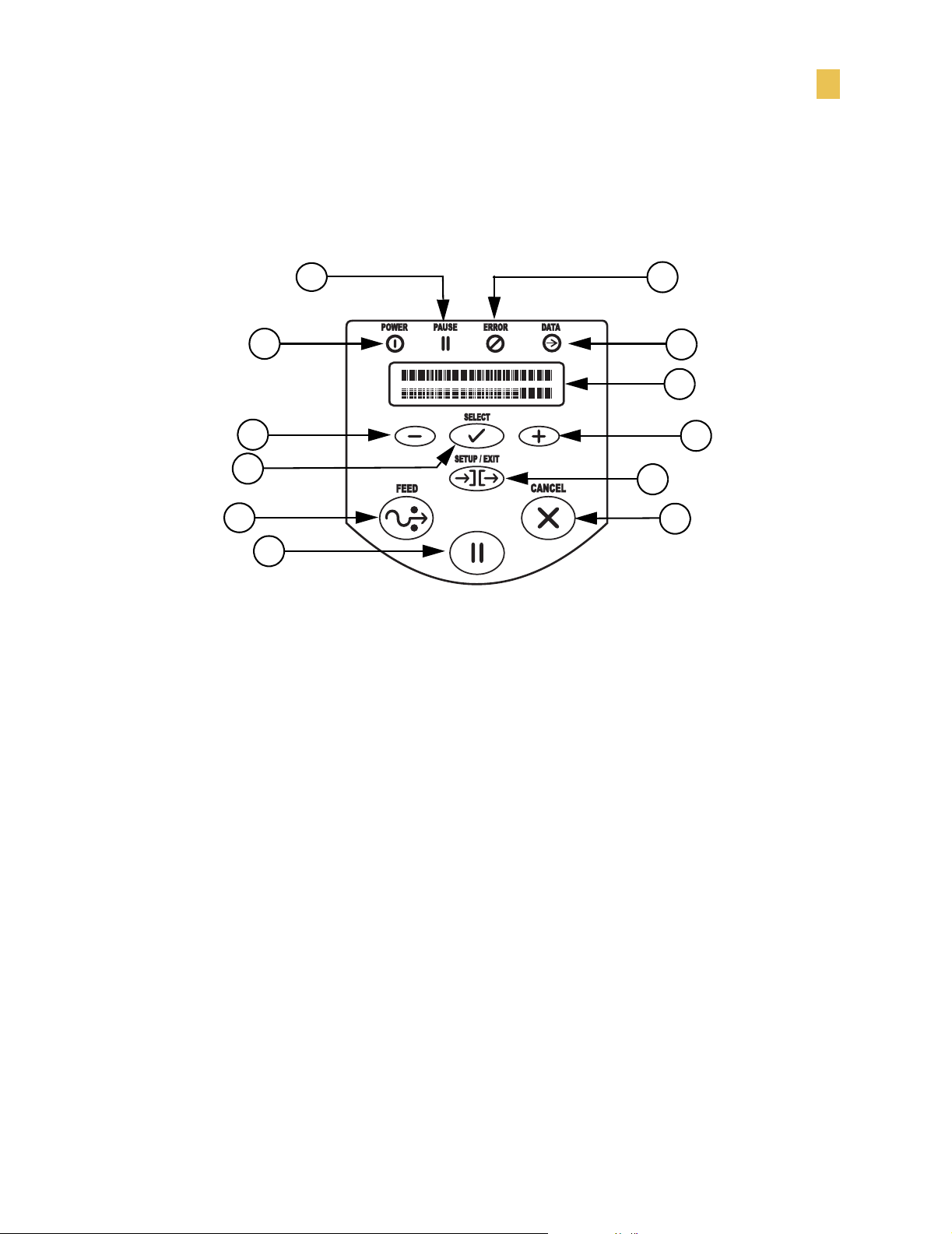

Front Panel

The front panel keys and lights are shown below.

Introduction

10

12

11

2

1

3

4

5

6

7

PAUSE

8

9

Front Panel Controls and Lights

Z4Mplus and Z6Mplus User Guide 3

Page 34

Introduction

Z4Mplus and Z6Mplus Printer Overview

Number Description

2

3

4

5

6

7

8

9

10

11

12

1

Power LED

Pause LED

Error LED

Data LED

LCD

PLUS (+) Key

SETUP/EXIT Key

CANCEL Key

PAUSE Key

FEED Key

SELECT Key

MINUS (–) Key

4 Z4Mplus and Z6Mplus User Guide

Page 35

Printer Side View

The illustration below is a simplified view of your printer. Depending on installed

options, your printer may look slightly different.

Introduction

Z4Mplus and Z6Mplus Printer Overview

2

1

5

6

7

Number Description

1

2

3

4

Printhead Assembly

Transmissive Sensor

Label Supply Guide

Label Supply Hanger

3

4

5

6

7

Z4Mplus and Z6Mplus User Guide 5

Dancer

Label Guide

Printhead Open Lever

Page 36

Introduction

Z4Mplus and Z6Mplus Printer Overview

6 Z4Mplus and Z6Mplus User Guide

Page 37

CHAPTER 2

Printer Setup

This chapter provides instructions for loading labels and ribbon.

Contents

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . 8

Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Types of Media . . . . . . . . . . . . . . . . . . . . . . 10

Print Mode . . . . . . . . . . . . . . . . . . . . . . . . . 12

Load Media and Ribbon . . . . . . . . . . . . . . . . . 13

Load the Media . . . . . . . . . . . . . . . . . . . . . . 13

Load the Ribbon . . . . . . . . . . . . . . . . . . . . . . . 14

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Auto Calibration . . . . . . . . . . . . . . . . . . . . . . 15

Printhead Pressure Adjustment . . . . . . . . . . . 16

Rewind Media Alignment . . . . . . . . . . . . . . . . 18

Configuration Label . . . . . . . . . . . . . . . . . . . . . 19

Print a Configuration Label . . . . . . . . . . . . . 19

Troubleshoot Printing Problems . . . . . . . . . . . 21

Basic Configuration . . . . . . . . . . . . . . . . . . . . . 22

Basic Configuration Process . . . . . . . . . . . . 23

Position the Label Sensor . . . . . . . . . . . . . . . . 26

Reflective Sensor . . . . . . . . . . . . . . . . . . . . 26

Configure the Software or Printer Driver . . . 28

Z4Mplus and Z6Mplus User Guide 7

Page 38

Printer Setup

Before You Begin

Before You Begin

Media

The Z4Mplus and Z6Mplus are capable of using various types of media. These include

continuous roll and fanfold media as labels or card stock with optional perforations

and registration holes.

Refer to Printer Basics on page 33 for a detailed description of loading label media

and ribbon.

Roll Media Fanfold Media

8 Z4Mplus and Z6Mplus User Guide

Page 39

Ribbon

Printer Setup

Before You Begin

Ribbon is a thin film carrying wax or wax resin that is transferred to the media during

the thermal transfer process. Direct thermal media does not require the use of a ribbon,

but printhead life may be shortened because of the abrasion of direct contact with the

media.

Printhead life may be reduced by the abrasion from exposed paper fibers when using

perforated media. Refer to Printer Basics on page 33 for a detailed description of

loading label media and ribbon.

Caution • The ribbon must be as wide or wider than the media being used. If the

ribbon is narrower than the media, areas of the printhead are unprotected and subject

to premature wear.

Note • When printing in direct thermal mode, ribbon is not used and should not be

loaded into the printer.

Z4Mplus and Z6Mplus User Guide 9

Page 40

Printer Setup

Before You Begin

Types of Media

The following is a description of the various types of media approved for use in the

Z4Mplus and Z6Mplus printers.

Non-Continuous Web Media

Non-continuous web media (shown below) refers to individual labels separated by a

gap, notch, or hole. When you look at the media, you can tell where one label ends and

the next one begins. The illustration below shows samples of all three. The

noncontinuous with gaps, is individual labels on a continuous liner.

1

2

3

3

Number Description

1

2

3

Hole

Notch

Label Gap

10 Z4Mplus and Z6Mplus User Guide

Page 41

Printer Setup

Before You Begin

Non-Continuous Black Mark Labels

Non-continuous black mark labels have black marks printed on the back of the liner

indicating the start and end of each label (shown below).

1

1

Number Description

1

Black Mark

Continuous Media

Continuous media (shown below) is one uninterrupted roll of material without gaps,

holes, notches, or black marks that allows the image to be printed anywhere on the

label.

Z4Mplus and Z6Mplus User Guide 11

Page 42

Printer Setup

Before You Begin

Print Mode

Print modes are displayed on the LCD on the front panel of the printer. Print modes

should match the media and printer options chosen. Print mode choices are listed in

the table below.

Mode Printer Option Action

Tear-Off Mode

(Default setting)

Use for most

applications.

Peel-Off Mode Use only if printer has

the peel option.

Cutter Mode Use only if printer has a

cutter option.

Rewind Mode Use only if printer has

the rewind option.

Each label or strip of

labels can be torn off

after printing.

Liner material is peeled

away from the label as it

is printed. After the

printed label is removed

the next label prints.

Printer automatically

cuts the label after it is

printed.

The media and/or liner

are rewound onto a core

as they are printed.

12 Z4Mplus and Z6Mplus User Guide

Page 43

Load Media and Ribbon

Load the Media

One method of media loading is shown in the illustration below. For more detailed

instructions, as well as information about how to load the different types of media and

the various printing modes, see Printer Basics on page 33.

Printer Setup

Load Media and Ribbon

2

1

5

7

6

Number Description

1

2

3

4

Printhead Assembly

Transmissive Sensor

Media Supply Guide

Media Supply Hanger

3

4

5

6

7

Z4Mplus and Z6Mplus User Guide 13

Dancer

Media Guide

Printhead Open Lever

Page 44

Printer Setup

Load the Ribbon

Load the Ribbon

If the media is thermal transfer material, you must load a ribbon to print labels. See the

illustration below. If the media is direct thermal material, do not load a ribbon.

2

1

3

4

5

Number Description

1

2

3

4

5

Strip Plate

Printhead Assembly

Ribbon Take-Up Spindle

Ribbon Supply Spindle

Printhead Open Lever

14 Z4Mplus and Z6Mplus User Guide

Page 45

Calibration

Auto Calibration

The Z4Mplus and Z6Mplus automatically calibrate on power up. During auto

calibration, the printer determines the label length and sensor settings.

Auto calibration occurs when the printer is turned on and each time the printer

recovers from an error condition. To clear an error, open and close the printhead

assembly and then press PAUSE. The printer begins auto calibration when all errors

have been cleared.

The results of the auto calibration are stored in the printer's memory and are retained

even if printer power is removed. These parameters remain in effect until the next

calibration is performed.

Printer Setup

Calibration

,

Note • If the front panel setting for MEDIA POWER UP or HEAD CLOSE are set

to LENGTH, NO MOTION, or FEED, the printer starts printing without auto

calibrating.

Z4Mplus and Z6Mplus User Guide 15

Page 46

Printer Setup

Printhead Pressure Adjustment

Printhead Pressure Adjustment

Refer to the illustration below.

This adjustment may be necessary if printing is too light on one side or if thick media

is used.

Pressure Adjustment Dials

R

The pressure adjustment dials for the Z4Mplus each have four possible settings

designated by blocks of increasing size embossed on the print mechanism. The

smallest block (fully counterclockwise) is considered position 1 and the largest block

(fully clockwise) is considered position 4. The same is true for the Z6Mplus, except it

has 7 positions.

L

16 Z4Mplus and Z6Mplus User Guide

Page 47

Printer Setup

Printhead Pressure Adjustment

Set Printhead Pressure

Use the tables below, depending upon which printer you have, to select the initial dial

settings for your media.

Z4Mplus

Media Width Left Dial Right Dial

1 in. (25.4 mm) 3 1

2 in. (51 mm) 4 1

3 in. (76 mm) 3 2

3.5 in. and up (89 mm and up) 3 3

Z6Mplus

Media Width Left Dial Right Dial

2 in. (50 mm) 6 1

3 in. (75 mm) 6 2

4 in. (100 mm) 7 3

5 in. (125 mm) 7 4

5.5 in. and up (140 mm and up) 6 6

Some media types require higher pressure to print well. For these media, increase both

dials one position. If the media tends to shift to the left while printing, increase the

right dial setting one position or decrease the left dial setting one position. If the media

tends to shift to the right while printing, increase the left dial setting one position or

decrease the right dial setting one position.

Z4Mplus and Z6Mplus User Guide 17

Page 48

Printer Setup

Rewind Media Alignment

Rewind Media Alignment

The instructions below apply if the printer has a rewind option. Refer to the

illustration below.

Note • The liner should be installed flush against the backplate of the take-up

spindle to prevent the media/backing from winding too loosely.

Do the adjustments in the order given. Do only what is needed to solve the problem.

1. Turn the adjustment dial clockwise to align the media toward the mainframe.

2. Turn the dial counter clockwise to align the media away from the mainframe.

4

3

Number Description

1

2

3

4

Rewind Spindle Backplate

Rewind Spindle

Adjustment Dial

Printhead Assembly

1

2

18 Z4Mplus and Z6Mplus User Guide

Page 49

Configuration Label

Print a configuration label to test the printer setup. Do this when the printer is first

installed, or when the printer cannot properly detect the top of the label.

Print a Configuration Label

1. Turn the printer Off (O).

2. Press and hold CANCEL while turning the printer On (l). See the Front Panel

illustration on page 3.

3. Release CANCEL after the DATA light turns off (approximately five seconds).

A configuration label prints showing the printer’s currently stored parameters (similar

to the labels shown on the next page).

Printer Setup

Configuration Label

• If you encounter any problems while you are configuring the printer or printing a

test label, see Troubleshoot Printing Problems on page 21. If the test label printed

correctly, go to Communication on page 29.

Z4Mplus and Z6Mplus User Guide 19

Page 50

Printer Setup

Configuration Label

Z6Mplus - 300dpi

4

Z4Mplus - 200dpi

4

20 Z4Mplus and Z6Mplus User Guide

Page 51

Troubleshoot Printing Problems

Troubleshoot Printing Problems

If the configuration label did not print, or if the labels are aligned properly, review the

items below in the order shown. Do only as many steps as needed to solve the printing

problem.

• Review Types of Media on page 10.

• Review Load the Media on page 13.

• Configure the printer according to the directions given in Basic Configuration on

page 22.

• Check the position of the media sensor and move if necessary. Follow the

directions in Position the Label Sensor on page 26.

Printer Setup

Z4Mplus and Z6Mplus User Guide 21

Page 52

Printer Setup

Basic Configuration

Basic Configuration

If your labels are not printing correctly, the configuration may need to be changed

because the printer defaults may not reflect the options you need. Media, ribbon,

darkness, print mode, media type, sensor type, and print method all affect the way the

printer is configured. Refer to Configuration on page 58 for more detailed

information.

Review the Front Panel illustration on page 3 to familiarize yourself with the controls.

The table below shows the LCD display settings you will need and what they mean.

LCD Display Meaning

PRINTER READY Ready to print labels or to configure the printer.

All printer self-tests have been performed

successfully.

DARKNESS The larger the number, the darker the print.

The range is 0 to 30, with a default setting of 10.

PRINT SPEED The print speed is given in inches per second. The

larger the number, the faster the label prints.

TEAR OFF Establishes the position of the media over the

tear-off bar after printing.

PRINT MODE Tear-Off (default setting), Peel-Off, Cutter,

Rewind.

MEDIA TYPE Non-continuous (default setting), Continuous

SENSOR TYPE Web (default setting), Mark

SENSOR SELECT Auto Select (default setting), Reflective,

Transmissive

PRINT METHOD Thermal transfer (default setting using a ribbon),

Direct thermal (no ribbon)

22 Z4Mplus and Z6Mplus User Guide

Page 53

Basic Configuration Process

See the instructions below to perform basic a configuration:

1. Enter the configuration mode by pressing SETUP/EXIT.

DARKNESS displays.

2. If there is no print darkness problem, press PLUS (+) to move to the next option,

Print Speed.

If the labels moved forward, but the print is light or there is no print, increase the

darkness.

If the print is too dark, or the ribbon sticks to the media, decrease the darkness.

3. Press SELECT.

4. Press PLUS (+) to increase the darkness or MINUS (–) to decrease the darkness.

5. Press SELECT to accept the change.

Printer Setup

Basic Configuration

6. Press PLUS (+) to move to the next option.

PRINT SPEED displays.

7. If the image is crisp, press PLUS (+) to move to the next option, Tear-Off.

If the print is dark enough, but the image is not crisp, slow down the print speed.

Print speed is given in inches per second (ips).

8. Press SELECT.

9. Press PLUS (+) to increase the speed or MINUS (–) to decrease the speed.

10.Press SELECT to accept the changes.

11. Press PLUS (+) to move to the next option.

TEAR OFF displays.

The Tear Off position defines the position of the label on the tear-off bar. When

working with non-continuous labels, the inter-label gap should be on the tear bar.

If the label gap is lining up on the tear bar, or if you are using continuous material,

press PLUS (+) to move to the next option, Print Mode.

12.If the position of the label needs to be adjusted, press SELECT.

13.Press PLUS (+) to move the label forward or MINUS (–) to move the label back.

14.Press SELECT to accept the changes.

Z4Mplus and Z6Mplus User Guide 23

Page 54

Printer Setup

Basic Configuration

15.Press PLUS (+) to move to the next option.

PRINT MODE displays.

When the wrong Print Mode is selected, the top of the label is not found by the

printer. Some examples of common problems are gaps between noncontinuous

labels not lining up on the tear bar, or continuous media not being cut at the right

interval.

If the labels line up correctly on the tear bar, press PLUS (+) to go to the next step,

Media Type.

If the labels are not lined up correctly, review the media and the printer options, then

adjust accordingly, continue with Step 16.

16.Press SELECT.

17.Press PLUS (+) or MINUS (–) to scroll through the setting options. Stop at the

setting that matches your printer options (Tear-Off, Peel-Off, Cutter, or Rewind)

18.Press SELECT to accept the change.

19.Press PLUS (+) to move to the next option,

MEDIA TYPE displays.

Types of Media on page 10 showed examples of non-continuous and continuous

media.

If your media matches the Media Type, press PLUS (+) to go to the next step,

Sensor Type.

If your label media does not match the Media Type, follow the steps below.

20.Press SELECT.

21.Press PLUS (+) or MINUS (–) to scroll through the setting options. Stop at the

setting that matches your printer options (Continuous or Noncontinuous).

22.Press SELECT to accept the change.

23.Press PLUS (+) to move to the next option.

SENSOR TYPE displays.

Web sensor is used with most labels, unless the label liner has black marks on the

back.

If your liner does not have black marks, press PLUS (+) to go to the next step,

Sensor Select.

24 Z4Mplus and Z6Mplus User Guide

Page 55

Printer Setup

Basic Configuration

If the label liner has black marks, continue with Step 24.

24.Press SELECT.

25.Press PLUS (+) or MINUS (–) to scroll through the setting options. Stop at the

setting that matches your printer options (Web or Mark).

26.Press SELECT to accept the change.

27.Press PLUS (+) to move to the next option.

SENSOR SELECT displays.

Auto Select is the default setting. Do not make any changes.

28.Press PLUS (+) to move to the next option.

PRINT METHOD displays.

• Use Thermal Transfer if you are using ribbon with your label material.

• Use Direct Thermal if you are not using ribbon. Direct thermal label media

has ink embedded in the label material that is brought out by the heat of the

printhead.

If the Print Method setting matches your media and ribbon choices, press

SETUP/EXIT to leave the front panel menu,

SAVE CHANGES PERMANENT displays.

29.Press SETUP/EXIT again.

30.SAVING PERMANENT displays. One or more labels may feed out, depending on

your setting choices.

The LCD displays PRINTER READY.

If the Print Method setting does not match your media and ribbon choices, follow the

steps below.

31.Press SELECT.

32.Press PLUS (+) or MINUS (–) to scroll through the setting options. Stop at the

setting that matches your printer options (Thermal Transfer or Direct Thermal).

33.Press SELECT to accept the change.

34.Press SETUP/EXIT to leave the front panel menu.

SAVE CHANGES PERMANENT displays.

35.Press SETUP/EXIT again.

SAVING PERMANENT displays. One or more labels may feed out, depending on

your settings. The LCD displays PRINTER READY.

Z4Mplus and Z6Mplus User Guide 25

Page 56

Printer Setup

Position the Label Sensor

Position the Label Sensor

There are two media sensors in this printer: reflective and transmissive.

Reflective Sensor

The reflective sensor detects the start-of-label indicator (the notch, hole, black mark,

or gap between die-cut labels).

The reflective sensor must be positioned:

• directly under the notch, hole, or black mark

• anywhere along the width of the media if there is a gap between labels

The glow of the red light through the media may help you accurately position the

reflective sensor.

Note • If you are using continuous media, position the reflective sensor anywhere

under the media to detect an out-of-paper condition. The reflective sensor is

compatible with most types of media. If you have difficulties with calibration, use the

transmissive sensor. See Transmissive Sensor on page 28.

Adjust the Reflective Sensor

Refer to the illustration on the next page.

See the instructions below to adjust the reflective sensor:

1. Open the printhead assembly by pressing the printhead open lever.

Caution • Ensure printhead is fully open and engaged in the up position. Failure to

latch in the up position could result in the printhead falling on your hand during the

procedure.

2. Locate the reflective sensor positioning lever.

3. Move the reflective sensor positioning lever across the width of the media until the

reflective sensor aligns with the gap or notch. The glow of the red light assists in

the proper placement of the reflective sensor.

26 Z4Mplus and Z6Mplus User Guide

Page 57

4. Close the printhead assembly.

Printer Setup

Position the Label Sensor

1

2

4

Number Description

1

2

3

4

Printhead Assembly

Reflective Sensor

Adjustment Lever

Printhead Open Lever

3

Z4Mplus and Z6Mplus User Guide 27

Page 58

Printer Setup

Position the Label Sensor

Transmissive Sensor

The standard transmissive sensor is in a fixed position and enabled from the front

panel. For more detailed information, see SENSOR SELECT on page 64.

Standard Transmissive Sensor

Adjustable Transmissive Sensor

(Optional)

Configure the Software or Printer Driver

Many printer settings may also be controlled by your printer’s driver or label

preparation software. See the driver or software documentation for more information.

28 Z4Mplus and Z6Mplus User Guide

Page 59

CHAPTER 3

Communication

This chapter describes communications options and their connections.

Contents

System Considerations . . . . . . . . . . . . . . . . . . 30

Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Cable Requirements . . . . . . . . . . . . . . . . . . 32

Z4Mplus and Z6Mplus User Guide 29

Page 60

Communication

System Considerations

System Considerations

Interfaces

Standard interfaces: the RS-232 DB-9 serial data port, and IEEE 1284 compliant

bi-directional parallel port.

Note • For further information on serial and parallel, pin-out, and technical

information, see Appendices A and B, starting on page 123.

Optional interfaces:

• Socket Card for PCMCIA cards

Note • For further information on PCMCIA cards, see Appendix C, starting on

page 135

Optional PrintServers:

• ZebraNet PrintServer II (external)

• PS II Internal PrintServer (factory installed only)

Which enables the printer to be connected to 10Base-T Ethernet networks.

Note • For further information on PrintServer II, see the PrintServer II User and

Reference Guide (Zebra part number 45537L).

Standard Interfaces

The standard serial and parallel interfaces ar discussed in this section.

Serial Port Communicating using a serial data port (see illustration on next page)

requires choosing the baud rate, number of data bits, stop bits, parity, and handshake

(default settings are 9600 baud, 8 data bits, 1 stop bit, no parity, and XON/XOFF).

Parity only applies to data transmitted by the printer since the parity of received data is

ignored. See Serial Data Communications on page 124 to configure the

30 Z4Mplus and Z6Mplus User Guide

Page 61

Communication

System Considerations

communication parameters. The values selected must be the same as those used by the

host equipment connected to the printer.

Printer

9

9

Computer

Male

25

9

Null modem adaptor

(if using a standard

modem cable)

50 ft. (15 mm) maximum

Parallel Port Communicating using the parallel port (see the parallel illustration

below), does not require special settings. The serial settings do not affect the parallel

port. Refer to Parallel Data Port on page 131 for further information.

Z4Mplus and Z6Mplus User Guide 31

Page 62

Communication

System Considerations

36-pin

male

Cable Requirements

Printer

Computer

PC

25-pin

female

10 ft. (3 mm) maximum

25-pin

male

Note • Zebra printers comply with FCC Rules and Regulations, Part 15 for Class B

equipment using fully shielded data cables. Use of unshielded cables may increase

radiation above the Class B limits.

Data cables must be fully shielded and fitted with metal or metalized connector shells.

Shielded cables and connectors are required to prevent radiation and reception of

electrical noise.

To minimize electrical noise pickup in the cable:

• Keep data cables as short as possible.

• Do not bundle the data cables tightly with the power cords.

• Do not tie the data cables to power wire conduits.

Note • RS-422 and RS-485 applications should use twisted shielded pairs as

recommended in the Appendix of the TIA/EIA-485 Specification.

32 Z4Mplus and Z6Mplus User Guide

Page 63

CHAPTER 4

Printer Basics

This chapter provides instructions for loading media and ribbon.

Contents

Printer Overview . . . . . . . . . . . . . . . . . . . . . . . 34

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . 34

Load Roll Media . . . . . . . . . . . . . . . . . . . . . . . 38

Tea r - O ff M o d e . . . . . . . . . . . . . . . . . . . . . . . 38

Cutter Mode. . . . . . . . . . . . . . . . . . . . . . . . . 40

Peel-Off Mode . . . . . . . . . . . . . . . . . . . . . . . 42

Liner Take-Up Mode . . . . . . . . . . . . . . . . . . 44

Rewind . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Load Fanfold Media. . . . . . . . . . . . . . . . . . . . . 54

Load the Ribbon . . . . . . . . . . . . . . . . . . . . . . . 56

Remove the Ribbon. . . . . . . . . . . . . . . . . . . 58

Z4Mplus and Z6Mplus User Guide 33

Page 64

Printer Basics

Printer Overview

Printer Overview

This printer overview provides you the basics of printer controls and media loading.

Front Panel

The front panel display shows the printer’s operating status and allows you to change

settings as needed to work with your media and label formats.

The front panel keys and lights are shown below.

10

12

11