VC80

M1M7M2M8M3M9M4

M10M5M11M6M12

Vehicle-Mount Computer

User Guide

VC80

USER GUIDE

MN002384A01

Rev. A

January 2016

ii VC80 User Guide

Revision History

Changes to the original guide are listed below:

Change Date Description

Rev A 01/2016 Initial release.

TABLE OF CONTENTS

Revision History ................................................................................................................................. ii

About This Guide

Introduction ....................................................................................................................................... vii

Configurations ........................................................................................................................................viii

Chapter Descriptions .............................................................................................................................. ix

Notational Conventions..................................................................................................................... ix

Related Documents and Software ........................................................................................................... x

Service Information ............................................................................................................................ x

Chapter 1: Getting Started

Introduction .................................................................................................................................... 1-1

Unpacking ...................................................................................................................................... 1-1

Removing the Protective Film from the Display ....................................................................... 1-1

Safety ............................................................................................................................................. 1-2

Initial Operation Safety Considerations .................................................................................... 1-2

Power Supply/Cable Safety ..................................................................................................... 1-2

External Devices Safety ........................................................................................................... 1-2

VC80 Vehicle-Mount Computer Features ...................................................................................... 1-3

Front Keys and LED Indicators ...................................................................................................... 1-5

Front Keys ................................................................................................................................ 1-5

LED Indicators .......................................................................................................................... 1-6

Configuring GPS ............................................................................................................................ 1-6

Connecting External Devices ......................................................................................................... 1-7

Powering Up the VC80 .................................................................................................................. 1-7

Powering Down the VC80 .............................................................................................................. 1-7

Setting Up WLAN ........................................................................................................................... 1-8

Connecting WLAN .................................................................................................................... 1-8

Setting Up a New Connection or Network ................................................................................ 1-9

Broadcom Help ...................................................................................................................... 1-10

iv VC80 User Guide

Chapter 2: Installation

Introduction .................................................................................................................................... 2-1

Overview ........................................................................................................................................ 2-1

Mounting Instructions ..................................................................................................................... 2-1

Heater Status ................................................................................................................................. 2-1

Installing the VC80 ......................................................................................................................... 2-2

Electrical Installation ................................................................................................................ 2-2

Wiring Guidelines ............................................................................................................... 2-3

Wiring Vehicle Power to the VC80 ........................................................................................... 2-4

Positioning the VC80 in the Vehicle ......................................................................................... 2-5

Overview of the Assembly Steps ............................................................................................. 2-5

Cable Dust Cover ..................................................................................................................... 2-5

Strain Relief .............................................................................................................................. 2-5

Installing the VC80 on a Forklift ............................................................................................... 2-6

Forklift Battery Replacement Conditions ........................................................................................ 2-7

Starting from Cold Soak ................................................................................................................. 2-7

Installing the Power Pre-Regulator ................................................................................................ 2-8

Non-Vehicle Installations ............................................................................................................... 2-8

Power On/Off with Ignition ............................................................................................................. 2-9

Screen Blanking Wiring ................................................................................................................ 2-10

Connecting Switch for Screen Blanking ................................................................................. 2-10

Chapter 3: Software

Introduction .................................................................................................................................... 3-1

Microsoft Windows Setup and Configuration ................................................................................. 3-1

Folder Structure ....................................................................................................................... 3-1

VC80 Software Components ......................................................................................................... 3-2

VC80 Without Operating System ................................................................................................... 3-2

Connecting to Terminal Emulation ................................................................................................. 3-3

TekTerm ................................................................................................................................... 3-3

Bar Code Scanners and Settings ................................................................................................... 3-4

Serial Scanners ........................................................................................................................ 3-4

USB Scanners .......................................................................................................................... 3-6

Bluetooth Scanners .................................................................................................................. 3-6

Pairing Bluetooth Scanners Using Bar Codes ................................................................... 3-6

Settings .......................................................................................................................................... 3-9

Quick Setup ..................................................................................................................

Touch Panel Calibration ................................................................................................... 3-11

Manage VC Configuration ................................................................................................ 3-16

Bezel Keyboard ...................................................................................................................... 3-17

Haptic Feedback .................................................................................................................... 3-18

Heater Status ......................................................................................................................... 3-19

Power ..................................................................................................................................... 3-20

Push To Talk .......................................................................................................................... 3-21

Screen Blanking ..................................................................................................................... 3-22

System Info ............................................................................................................................ 3-23

TekWedge .............................................................................................................................. 3-24

UPS Battery Status ................................................................................................................ 3-27

Data Logging .......................................................................................................................... 3-28

.......... 3-10

Table of Contents v

My-T-Soft ..................................................................................................................................... 3-29

Windows Management Instrumentation ....................................................................................... 3-31

GPS ............................................................................................................................................. 3-31

Satellite Level ......................................................................................................................... 3-32

Location Coordinates ............................................................................................................. 3-32

U-Center Software ................................................................................................................. 3-32

Chapter 4: Maintenance and Troubleshooting

Introduction .................................................................................................................................... 4-1

Cleaning ........................................................................................................................................ 4-1

Housing Cleaning ..................................................................................................................... 4-1

Touchscreen Cleaning ............................................................................................................. 4-1

Touchscreen .................................................................................................................................. 4-2

Troubleshooting ............................................................................................................................. 4-3

Chapter 5: Accessories and Mounting

Introduction .................................................................................................................................... 5-1

Accessories .................................................................................................................................... 5-1

External Bar Code Scanners ......................................................................................................... 5-5

VC80 Antenna Options .................................................................................................................. 5-6

VC80 Mounting Accessories .......................................................................................................... 5-7

MT43XX RAM Mount ............................................................................................................... 5-8

Optional Mounts ....................................................................................................................... 5-9

Plate Bases for MT35XX Mounts ....................................................................................... 5-9

MT4200 Quick Release Mount ............................................................................................... 5-10

Assembling MT4200 ........................................................................................................ 5-10

Attaching MT4200 to VC80 .............................................................................................. 5-11

MT4210 Adaptor Bracket ....................................................................................................... 5-12

Chapter 6: Scancode Map

Introduction .................................................................................................................................... 6-1

Integrated Keypad .......................................................................................................................... 6-2

Appendix A: Specifications

Introduction ................................................................................................................................... A-1

Technical Specifications ............................................................................................................... A-2

VC80 Drill Hole Dimensions .......................................................................................................... A-5

vi VC80 User Guide

ABOUT THIS GUIDE

Introduction

This guide provides instructions for setting up, operating, configuring, and maintaining the VC80 vehicle-mount

computer.

NOTE Screens and windows pictured in this guide are samples and can differ from actual screens.

WARNING! Before transporting, assembling, and starting the computer, please read this manual

carefully and follow all the safety guidelines and requirements.

viii VC80 User Guide

Configurations

The VC80 offers different configurations to suit various work requirements. Some of the configuration options

include:

•

Intel E3825 Dual Core, 1.33 GHz, 1 MB Cache, 2 GB RAM

•

Intel E3845 Quad Core, 1.91 GHz, 2 MB Cache, 4 GB RAM

•

SSD (32 GB or 64 GB)

•

Sunlight Readable Display

•

Internal Antenna

•

External Antenna

•

Freezer Condensing

•

Windows Embedded Standard 7

•

Windows 7 Professional for Embedded Systems

•

Basic I/O

•

CanBus

•

Ethernet

NOTE For detailed configuration and part number information, contact your Zebra representative.

About This Guide ix

Chapter Descriptions

Topics covered in this guide are as follows:

•

Chapter 1, Getting Started, provides information on safety guidelines and initial VC80 setup.

•

Chapter 2, Installation, provides instructions on installing the VC80.

•

Chapter 3, Software, explains how to configure the VC80.

•

Chapter 4, Maintenance and Troubleshooting, includes instructions on cleaning the VC80 and provides

troubleshooting solutions for potential problems during device operations.

•

Chapter 5, Accessories and Mounting, describes the accessories and mounting options available for the

VC80.

•

Chapter 6, Scancode Map, provides information on the integrated scancode maps for the VC80.

•

Appendix A, Specifications, summarizes the device’s intended operating environment and technical

specifications.

Notational Conventions

The following conventions are used in this document:

•

Italics are used to highlight the following:

• Chapters and sections in this guide

• Related documents.

•

Bold text is used to highlight the following:

• Dialog box, window and screen names

• Drop-down list and list box names

• Check box and radio button names

• Icons on a screen

• Key names on a keypad

• Button names on a screen.

•

Bullets (•) indicate:

• Action items

• Lists of alternatives

• Lists of required steps that are not necessarily sequential.

•

Sequential lists (e.g., those that describe step-by-step procedures) appear as numbered lists.

x VC80 User Guide

Related Documents and Software

The following document provides more information about the VC80 vehicle-mount computer.

•

VC80 Quick Reference Guide, p/n MN002383Axx - includes VC80 setup information and regulatory

information.

For the latest version of this guide and all guides, go to: http://www.zebra.com/support

Service Information

If you have a problem with your equipment, contact Zebra Customer Support for your region. Contact information is

available at: http://www.zebra.com/support

When contacting support, please have the following information available:

•

Serial number of the unit

•

Model number or product name

•

Software type and version number.

Zebra responds to calls by email, telephone or fax within the time limits set forth in support agreements.

If your problem cannot be solved by Zebra Customer Support, you may need to return your equipment for servicing

and will be given specific directions. Zebra is not responsible for any damages incurred during shipment if the

approved shipping container is not used. Shipping the units improperly can possibly void the warranty.

If you purchased your Zebra business product from a Zebra business partner, contact that business partner for

support.

.

.

CHAPTER 1 GETTING STARTED

Introduction

The VC80 is a rugged, vehicle mounted computer running Microsoft Windows Embedded Standard 7 and Windows

Professional for Embedded Systems operating systems. Wireless communications are supported over a 802.11

WLAN network. The Bluetooth module supports Bluetooth printers and scanners. The VC80 can be used with or

without an external keyboard. There are six programmable macro keys on the front bezel and when used with the

Blue modifier key, provides six additional programmable keys.

The VC80 is intended for use in commercial and industrial applications with a focus on real time wireless data

transactions with options suiting materials handling applications in warehouses, manufacturing facilities, ports,

yards, and freezers.

Unpacking

WARNING

NOTE

Carefully remove all protective material from the device and save the shipping container for later storage and

shipping.

Inspect the equipment for damage. If any equipment is missing or damaged, contact the Zebra Support Center

immediately. See Service Information on page x for contact information.

!

Before operating the unit for the first time, carefully read Safety on page 1-2.

Configure the computer before fastening it to machines or vehicles.

Removing the Protective Film from the Display

The front display of the VC80 is protected during transport by a transparent film. This film should remain on the

front display during assembly to avoid damage to the front display surface. Only remove the film once all of the

assembly work has been completed.

1 - 2 VC80 User Guide

Safety

In order to prevent injury and damage, observe the following safety guidelines prior to assembly and

commissioning. The VC80 is a multifunction terminal for stationary and mobile use in commercial environments

such as, warehouses, manufacturing, yard/ports, and freezers. Different or extraordinary usage is not permitted.

For resulting damage, the user/operator of the VC80 is solely responsible. This also applies to any changes that

you make to the device. Compliance with the safety guidelines is particularly important for the proper use of this

device. The manufacturer assumes no liability for any and all damages that can be attributed to non-compliance

with these guidelines.

Initial Operation Safety Considerations

•

Installation/Initial Operation - Perform VC80 installation in accordance with Chapter 2, Installation.

Specifically, pay special attention to the various electrical potentials of the vehicle. Some vehicles have a

chassis that is connected to one of the battery supply lines (DC+ or DC-), while most electrically-driven forklift

vehicles have floating chassis, connected to neither DC+ or DC-. See Wiring Vehicle Power to the VC80 on

page 2-4 for required wiring of vehicle power and fusing for the VC80.

•

Risk of injury during transit or installation - The unit can fall during transit or installation and cause injury.

Always ensure that there are two persons available when installing or removing the device.

•

Ensure that no persons are injured in case the mounting bracket breaks - The VC80 may not be

installed in such a way that persons can be injured during a breaking of the mounting bracket (e.g. fatigue

break). If the device is mounted in a place where people can be injured if the bracket breaks, apply

appropriate safety measures (e.g. install a security cable in addition to the device bracket).

Power Supply/Cable Safety

The main power cord shall comply with the national safety regulations of the country where the equipment is to be

used.

•

Operation in an emergency - In case of an emergency (such as damage to the power cable or housing, or

ingress of liquid or other foreign bodies), disconnect the device immediately from the power supply. Contact

technical support staff at once.

•

Protection of the power supplies - If, after replacement, the fuse fed by the internal power supply blows,

send the device for servicing immediately.

•

Danger of electrocution when cleaning/servicing the device - In order to avoid electrocution, always

disconnect the VC80 from the power supply before cleaning or servicing the device.

•

Do not exceed maximum voltage when charging the vehicle battery - While charging the vehicle battery,

disconnect the VC80 from the battery or ensure that the maximum allowed input voltage of the VC80 is not

exceeded.

•

Do not switch on devices with damaged cables or plugs - Do not use the VC80 if a cable or plug is

damaged. Replace damage parts immediately.

•

Do not connect or disconnect cables during storms - Cables must never be connected or disconnected

during an electrical storm.

External Devices Safety

The use of additional wiring and other peripheral devices, which are not recommended or sold by the manufacturer, can result in fire, electrocution or personal injury.

•

If a power supply is used, only use the power supply recommended by the manufacturer.

•

Before connecting or disconnecting peripheral devices (exception: USB devices), disconnect the VC80 from

the power supply to avoid serious damage to both the VC80 and the connected devices.

Getting Started 1 - 3

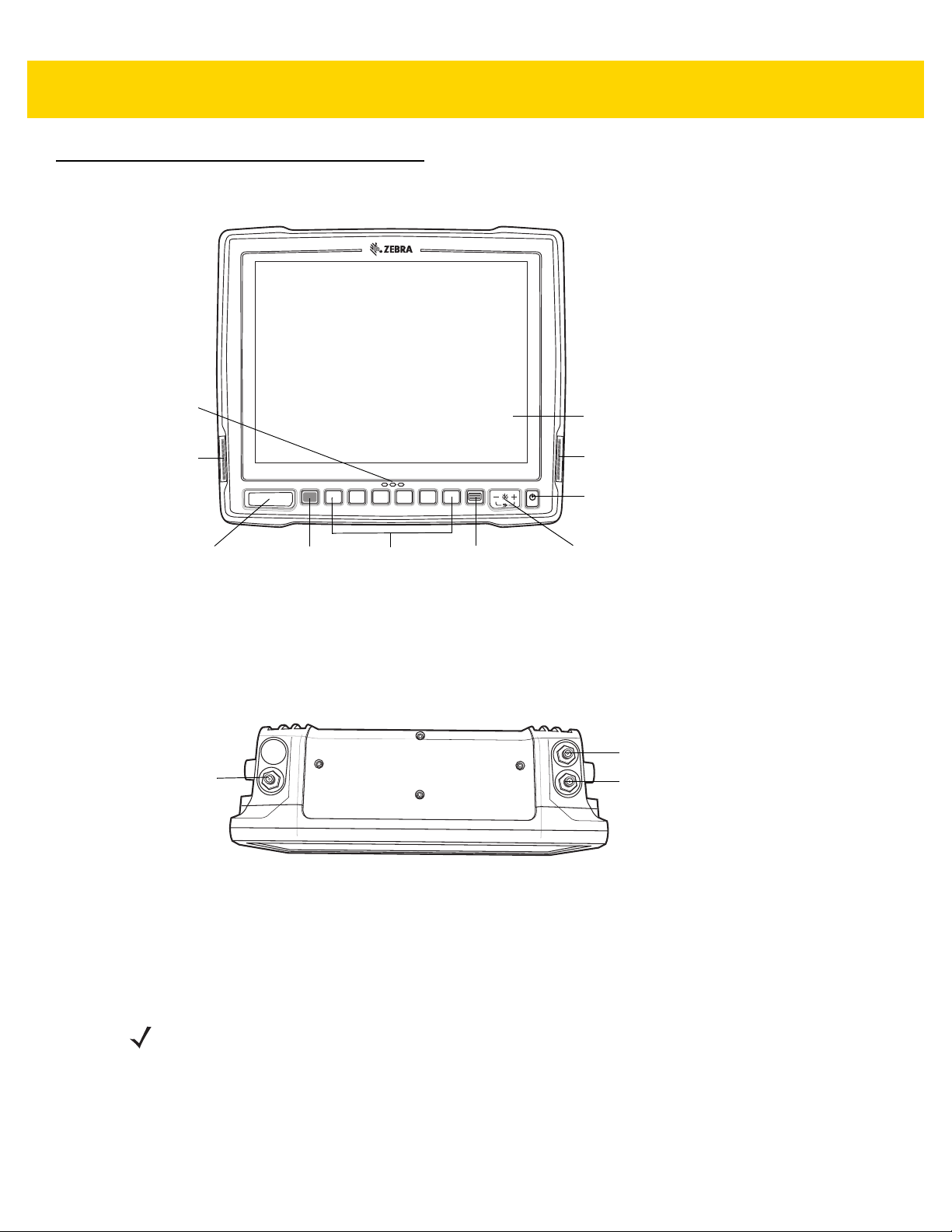

M1M7M2M8M3M9M4

M10M5M11M6M12

Speaker

On Screen

Keyboard

Speaker Vol ume/

Display Brightness

Power

Button

Pairing

Bar Code

Unpairing

Bar Code

Programmable

Macro Keys

(6 + 6)

Blue

Modifier

Key

LEDs

(three)

Resistive

Touch Screen

802.11 a/b/g/n/ac Radio External Antenna Connectors

ANT 1

ANT 2

ANT 3

ANT 1 - Reverse Polarity SMA Jack (WLAN) / External Main WiFi Antenna

ANT 2 - Reverse Polarity SMA Jack (WLAN + BT) / External WiFi Diversity or MIMO Antenna

ANT 3 - SMA Jack (GPS)

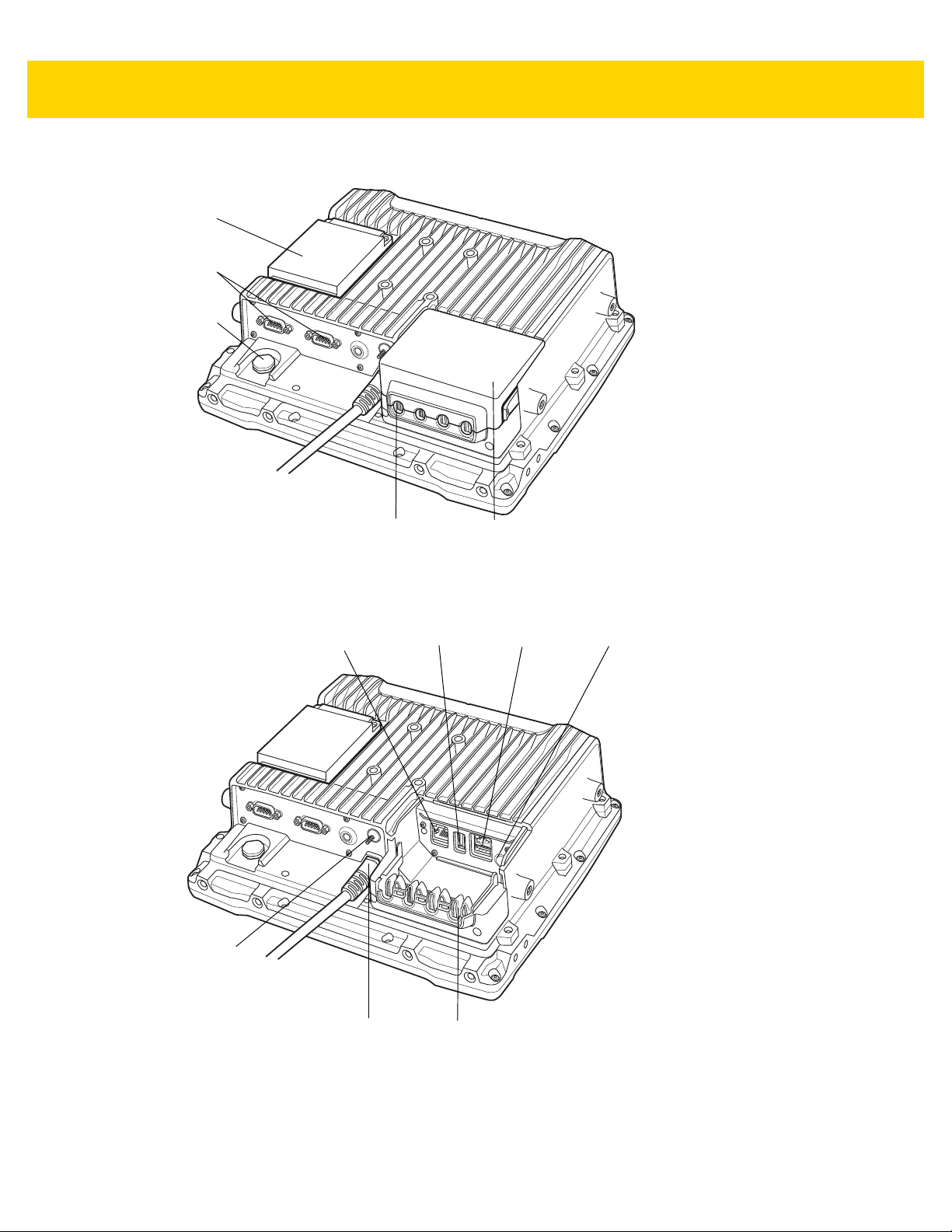

VC80 Vehicle-Mount Computer Features

Figure 1-1 VC80 Front View

Figure 1-2 VC80 Top View

NOTE

Antenna options are dependent on the VC80 configuration. Some configurations only have internal

antennas while other configurations have two or more external antenna connectors. WiFi antennas are

not shipped with the VC80 and must be ordered as a separate accessory.

1 - 4 VC80 User Guide

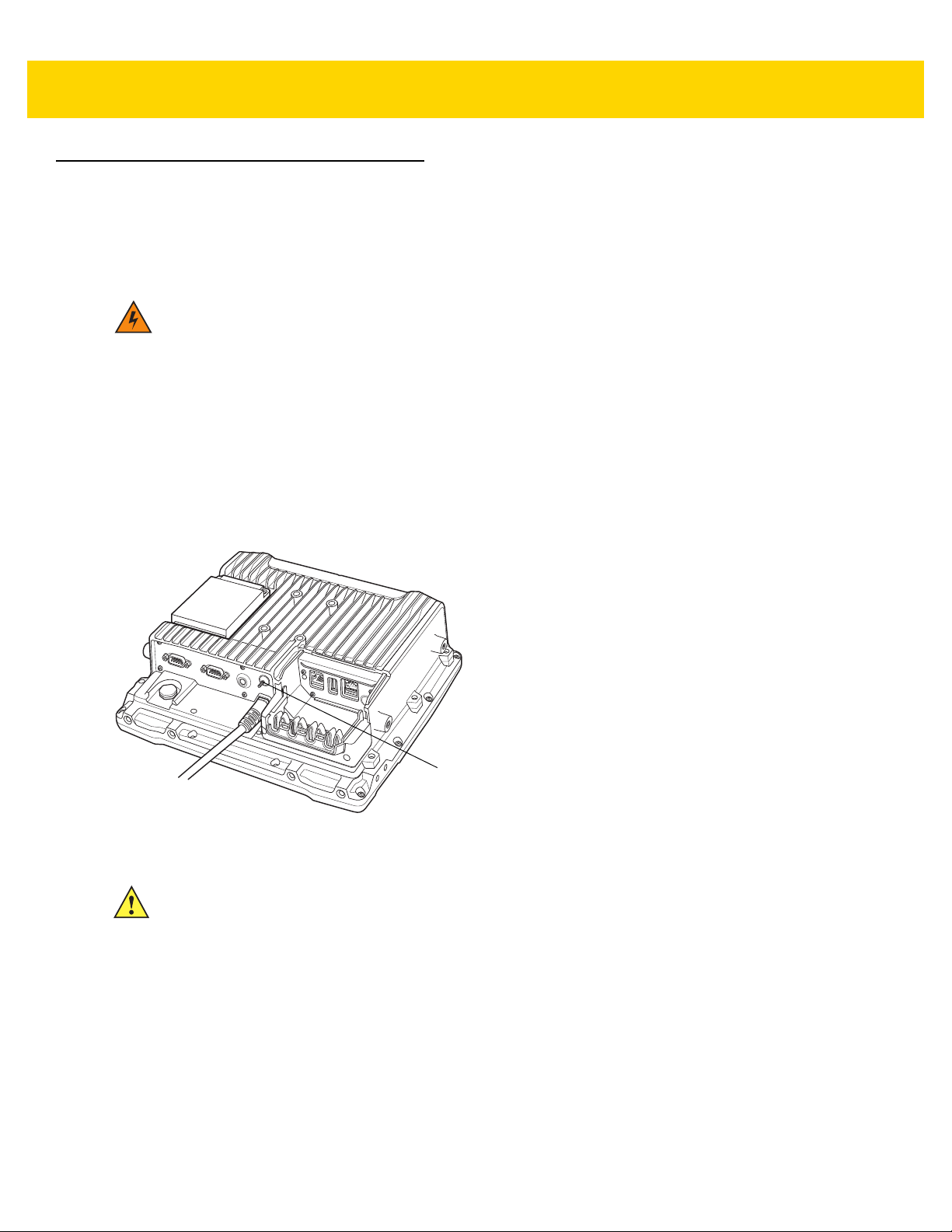

Dust

Cover

RS-232

(two)

UPS

Battery

Strain Relief

(four)

Vent

Ethernet or

CAN Bus

(optional)

Standard

USB

Powered

USB

Speaker/

Mic

Strain

Relief

Power

Ground

Lug

Figure 1-3 VC80 Back View with Dust Cover

Figure 1-4 VC80 Back View without Dust Cover

Getting Started 1 - 5

Front Keys and LED Indicators

The VC80 has the following front bezel keys and LEDs:

Front Keys

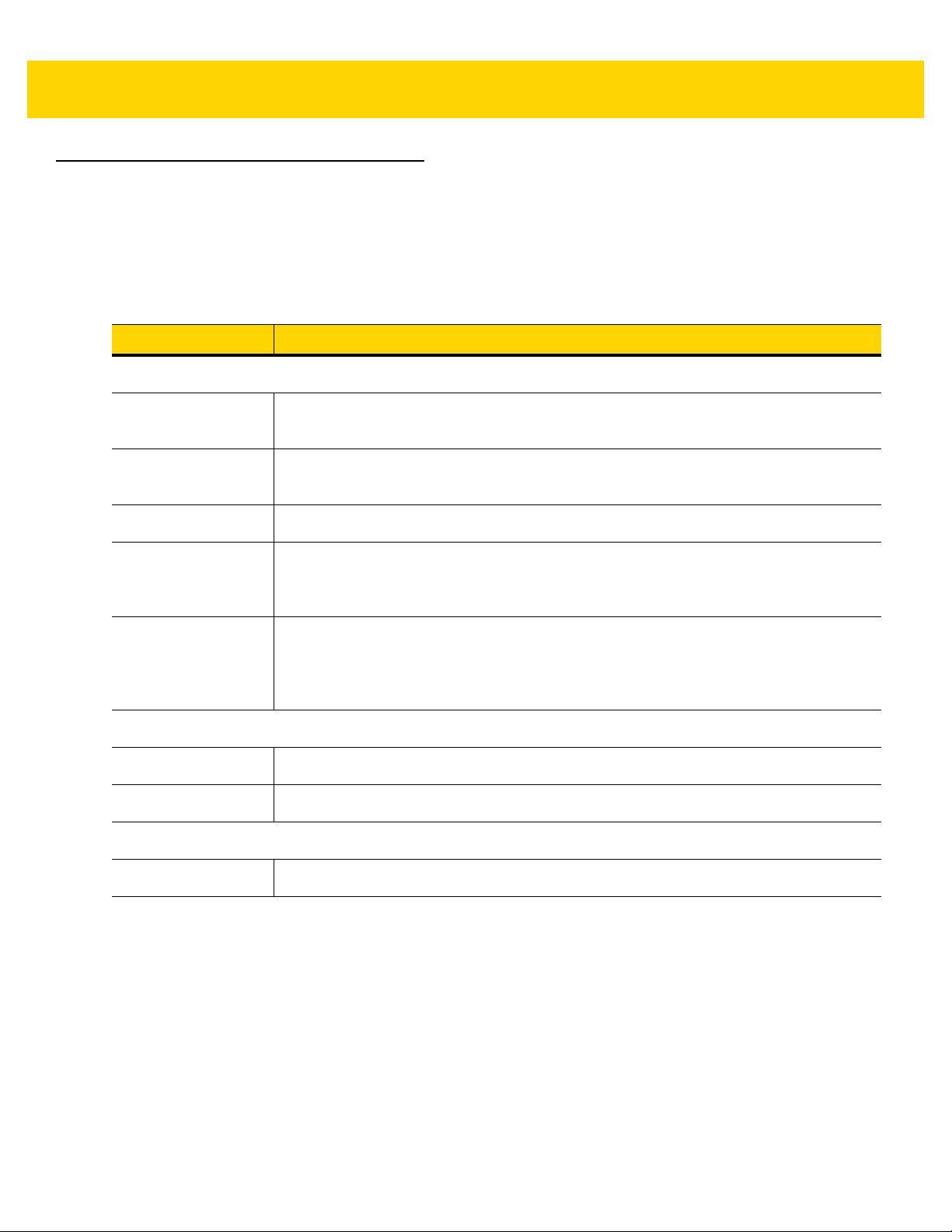

Table 1-1 VC80 Front Keys

Front Function

Power Keys

On/Off Button Powers the VC80 On or Off. To reset the device, press and hold the On/Off button for

at least seven seconds until the green LED changes to amber.

Speaker/Display Speaker volume and display brightness adjustment button. Use the (-) sign to

decrease volume/brightness and use the (+) to increase the volume/brightness.

Keyboard Display on screen keyboard.

Blue Modifier Key Modifies programmable macro keys allowing for an additional six programmable keys.

Press the Blue Modifier key twice to lock the key on and to unlock, press the key once

again.

Macro Keys

Programmable

Bar Codes

Pairing Bar Code Pair peripheral Bluetooth scanners to the VC80.

Unpairing Bar Code Unpair peripheral Bluetooth scanners to the VC80.

Speaker

Front Speaker Located on front bezel.

Six programmable macro keys. When used with the Blue modifier key, six additional

programmable keys are provided. Keys may be mapped in the Control Panel by

assigning scancodes (see Chapter 6, Scancode Map) or macro mapping with

My-T-Soft.

1 - 6 VC80 User Guide

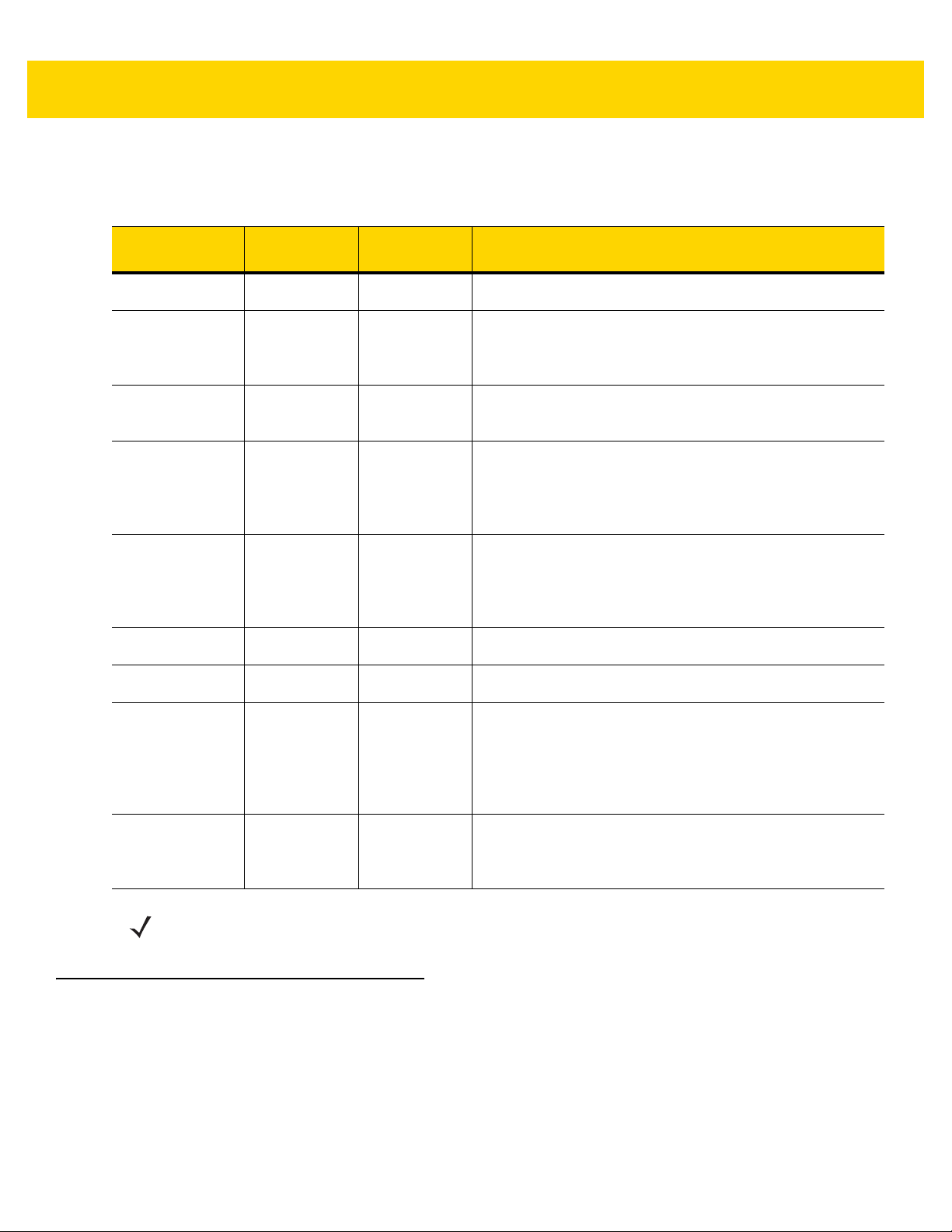

LED Indicators

Table 1-2 VC80 LED Indicators

Green/Amber

LED

Off Off Off No external power and the VC80 is not running on UPS.

Amber On Off Off External power is available but the VC80 is not turned On

Green On Off External power is available and the VC80 is turned ON.

Green Flashing

(50% Duty

Cycle On at

500ms Period)

Green Flashing

(25% Duty

Cycle On at

4000ms Period)

Green On Off Off Bezel keyboard keys: M1, M2, M3, M4, M5, M6

Green On Off On Bezel keyboard keys: M7, M8, M9, M10, M11, M12

Red LED Blue LED Description

(in shutdown or hibernate mode). The VC80 is ready to

be turned on and is currently charging the UPS battery.

The UPS battery is charging.

External power is removed. The VC80 is running on UPS

battery power.

Off Off The VC80 is in sleep mode.

Off On Off Warm up condition. The average of radio card and audio

NOTE

For fields in the above table without LED information, the LED can be On or Off dependent on user

actions and ambient temperature.

Configuring GPS

For VC80 configurations with GPS, see GPS on page 3-31 for information on setting up and configuring the GPS

with U-Center.

Flashing Red

(50% Duty

Cycle On at

500ms

Period)

Temperature related warning or error event in the

system. Average of radio card and audio codec temperature readings is either <-35° C or > +65° C. No action is

required if the OS is running. If the OS is in Sleep or

Hibernate state, then the EC should switch the VC80 Off.

codec temperature readings is between -35° C and 0° C.

The OS is not running. The Power Button is disabled.

Getting Started 1 - 7

Connecting External Devices

Disconnect the VC80 from the power supply before:

• Connecting or disconnecting external devices (e.g., scanner, keyboard).

• Connected to network.

CAUTION

Turn on external peripheral devices with power supplies at the same time or after turning on the VC80.

Ensure that the VC80 is adequately protected from power leakage caused by an external device.

Powering Up the VC80

Power up the VC80 after connecting all of the devices.

To power up the VC80, connect to an appropriate power supply and press the Power button (see Figure 1-1) or the

ignition signal.

CAUTION

Make sure there is a suitable disconnecting device such as a power switch or circuit breaker in the

power supply circuit. See Installing the VC80 on page 2-2 for more information.

Powering Down the VC80

Always shut down the VC80 as follows:

1. Select Start.

2. Select Shut Down.

1 - 8 VC80 User Guide

Setting Up WLAN

Connecting WLAN

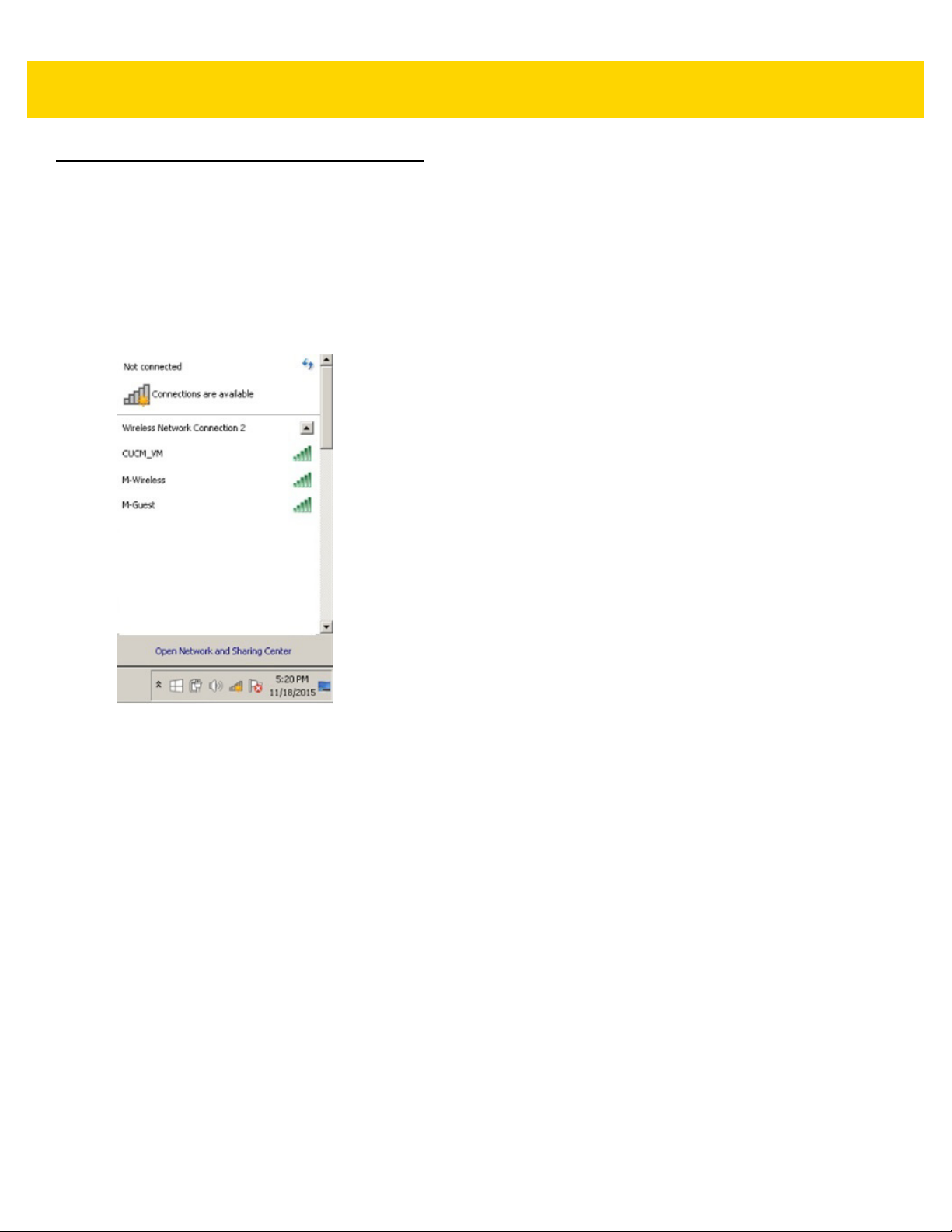

To connect to the WLAN:

1. Click on the WiFi icon in the system tray to display available WLAN networks.

2. Click on the desired network and select Connect.

Figure 1-5 WLAN Connection

Getting Started 1 - 9

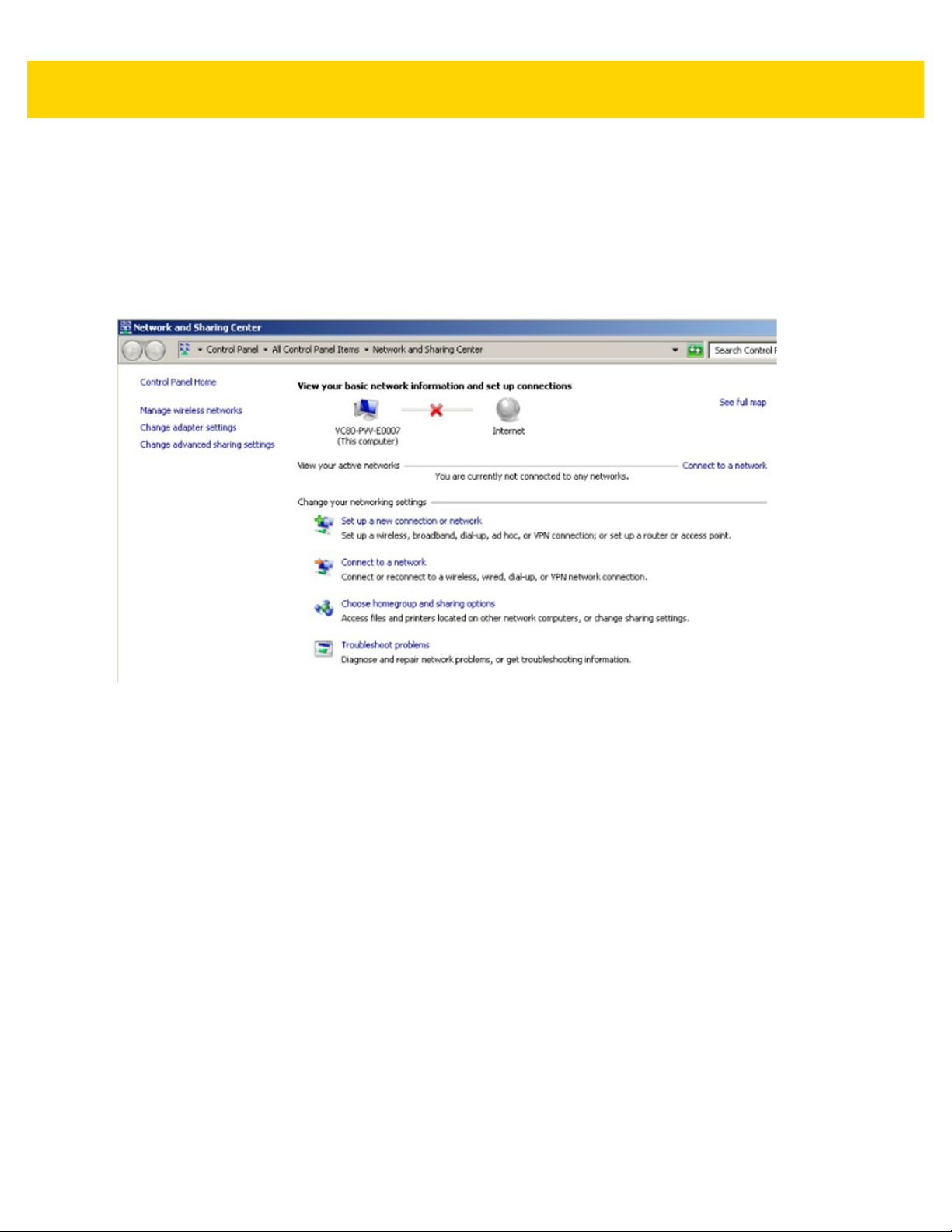

Setting Up a New Connection or Network

To set up a new connection or network:

1. Click on the WiFi icon in the system tray.

2. Select Open Network and Sharing Center (see Figure 1-5).

3. Select Set Up a New Connection or Network.

Figure 1-6 Setup New Connection or Network

4. Choose a connection option.

5. Follow the prompts to complete setup.

1 - 10 VC80 User Guide

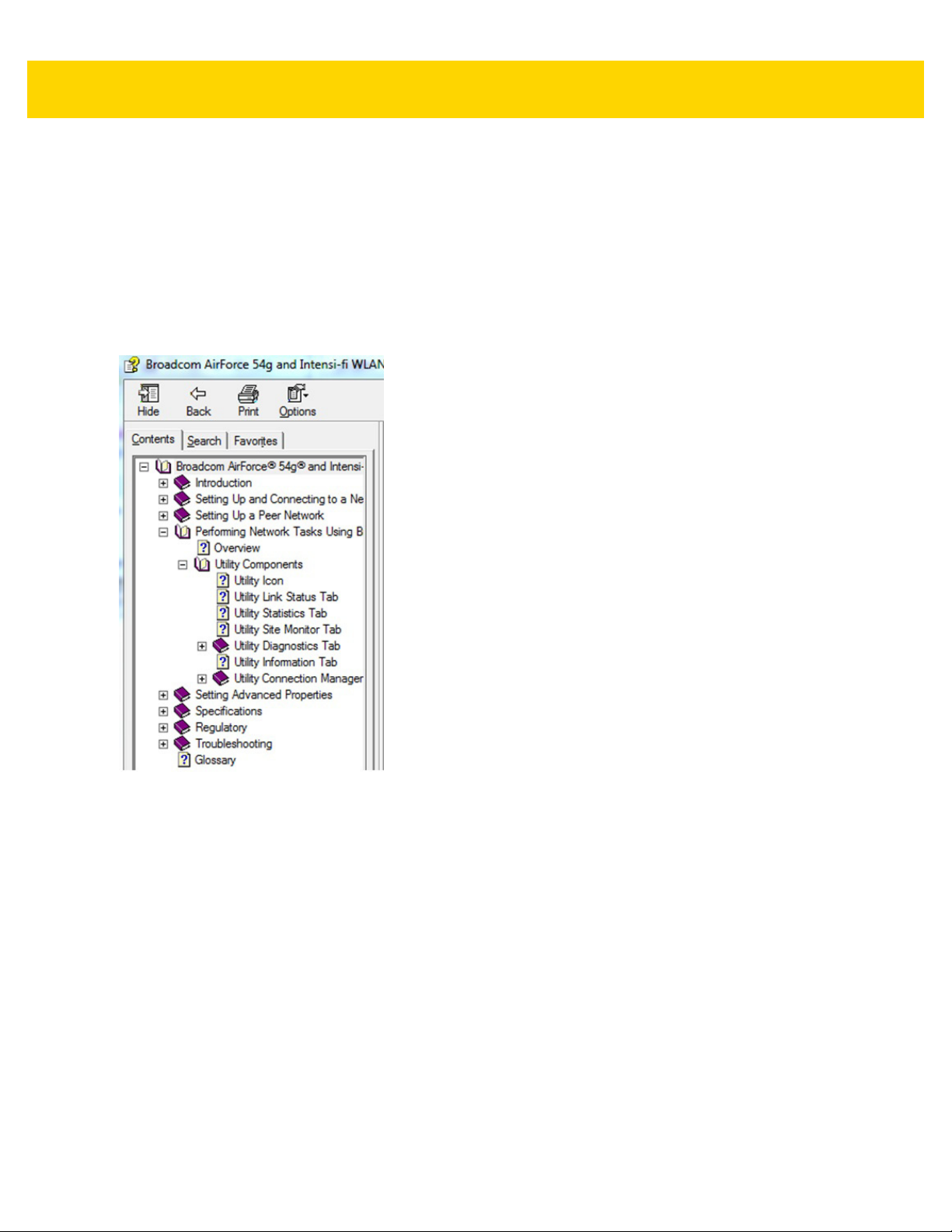

Broadcom Help

The Broadcom Help utility assists with managing the WiFi connection or network.

To access Broadcom Help:

1. Go to Start > Control Panel > Broadcom Utility.

2. Select the Help tab on the top tool bar.

3. Select the desired topics for assistance.

Figure 1-7 Broadcom Help

CHAPTER 2 INSTALLATION

Introduction

This chapter provides instructions on installing the VC80.

Overview

The VC80 can be installed in a variety of ways:

• Position the VC80 horizontally on a desk or mounted on a vehicle console.

• Wall mount the VC80 using the optional wall mount (see VC80 Mounting Accessories on page 5-7).

• Overhead mount on a lift truck cage using mounting hardware.

Depending on the vibration resistance and pivoting demands, mounting brackets, clamp foots or RAM mount

elements can also be used to attach the device. Contact your Zebra sales office to find out more about the range of

available installation options.

WARNING

!

The unit could fall during transit or installation/mounting and cause injury. Always

ensure that there are two people available when installing or removing the device.

Mounting Instructions

Follow and retain the mounting instructions included with assembly kit when installing the VC80. See Safety on

page 1-2 for safety instructions.

Heater Status

The VC80 offers a unique heater system that enables continuous operations in freezer environments. See Heater

Status on page 3-19 for information about the heater settings.

2 - 2 VC80 User Guide

Ground Lug

Installing the VC80

Electrical Installation

There are various electrical potentials when installing the unit on a vehicle such as a forklift.

Most electrically driven forklift vehicles have floating chassis connected to

neither DC+ or DC-. However, electrical faults can cause the battery + or - to be

connected to the chassis via low resistance paths. All connected peripherals

must be completely isolated.

The VC80 accepts DC power sources with a minimum of 10VDC nominal and

48VDC nominal. A Power Pre-regulator is required for voltages above 48VDC

nominal.

Applying a voltage above 48VDC nominal without the pre-regulator or reversing

polarity may result in permanent damage to the VC80 and voids the product

warranty.

Figure 2-1 VC80 Ground Lug

CAUTION

Attach the VC80 connecting cable as close to the battery as possible. Connecting the VC80

to large electrical loads, such as converters for the forklift motor may result in random

restarts, malfunctions and/or irreparable damage to the device.

To connect devices fed by other power sources to the VC80, such as printers, power up the

peripheral devices at the same time or after the VC80 to avoid start-up problems,

malfunctions or irreparable damage to the device.

Installation 2 - 3

Wiring Guidelines

The metal chassis of the VC80 is equipped with a ground lug (located on the underside adjacent to the power

cable) to provide additional ground to the vehicle. It is strongly recommended that a grounding strap is used to

connect the ground stud on the vehicle-mount to a solid, reliable contact point on the main portion of the vehicle

chassis. It must not be connected to battery negative or terminal block.

As with other vehicle cables, carefully consider the routing of the ground strap to ensure it does not pose a hazard

to the operator or the safe operation of the vehicle. If necessary, secure the ground strap with cable ties or some

other mechanical means to prevent loops or loose lengths of wire from catching on stationary items when the

vehicle is in motion.

Before installing the cables between the mount and other devices, consider the following:

• Ensure that drilling holes do not damage the vehicle or its wiring.

• Protect cable runs from pinching, overheating and physical damage.

• Use grommets to protect cables that pass through metal.

• Use plastic straps and tie-downs to secure cables and connectors in their desired location, away from areas

where they may get snagged or pulled.

• Keep cables away from heat sources, grease, battery acid and other potential hazards.

• Keep cables away from control pedals and other moving parts that may damage the cables or interfere with the

operation of the vehicle.

IMPORTANT

Make sure the cables run inside the roll cage of the vehicle.

If the VC80 is installed in an environment where earth ground is present such as a vehicle

with metal wheels running on a metal track, or is powered by the AC/DC adaptor in a

permanent installation, the ground lug must be connected to the ground structure.

2 - 4 VC80 User Guide

Wiring Vehicle Power to the VC80

WARNING Applying voltage above the input voltage rating or reversing polarity may result

in permanent damage to the VC80 and void the product warranty.

An extension power cable is used to wire the VC80 to the truck battery (order cable separately, see Accessories on

page 5-1). Wire this cable to a filtered, fused (15A max) accessory supply on the vehicle. Follow the installation

instructions supplied with the extension cable.

Additional wiring (minimum 14 gauge), connectors or disconnects used should be rated for at least 300 VDC, 15A.

When connecting the extension power cable:

•

If a power extension cable with ignition sense is used, ensure that the ignition sense wires (18AWG wires in

red and black leads) and the power wires (14AWG in red and black leads) are reliably secured away from

each other, or are separated with reliably secured certified insulation. Minimum 2.8 mm distance, or 0.4mm

distance through insulation is required for the separation.

•

The red lead of the 14AWG power cables attach to the vehicles battery positive terminal. The 14AWG black

lead connects to the vehicle’s battery negative terminal. This should be connected to a proper terminal block

and not to the vehicle body. An optional grounding strap wire (sourced separately) may be connected to the

ground lug of the VC80 terminal connector bay and to the vehicle chassis.

•

You may have the option to connect power before or after the key switch. Though the VC80 is equipped with

a UPS, a proper shut down is recommended using the windows shut down procedure. If it is wired after the

key switch, the operator must shut down the VC80 using the Windows shut down procedure before turning

off the vehicle. If it is wired before the key switch, then to avoid excessive drain on the vehicle battery, either

the operator should shut it down when the vehicle is to be left off for an extended period, or the ignition cable

shut down wire should be connected and the VC80 configured to shut down automatically.

•

An appropriate fuse type must be used with the power extension cable according to the installation

instructions. For main power cable, use 3AB, 15A, 250V, slow blow fuse. For ignition sense input, use 3AB,

0.3A, 250V, slow blow fuse.

NOTE

The VC80 supports the ignition sense feature that detects when the ignition switch or key

switch is On or Off to allow automatic computer start up or shut down (with delay as needed).

When wiring the ignition sense wires (18AWG in red and black), the red 18AWG wire is

connected to a positive DC voltage source switched on by the ignition. The black 18AWG wire

is connected to ground reference of this switched ignition source.

Installation 2 - 5

Positioning the VC80 in the Vehicle

When positioning the VC80 on the vehicle:

•

The driver's field of view must be kept free.

•

Plan for sufficient space if a keyboard and scanner are installed with the VC80.

•

No part of the VC80 system may project beyond the vehicle.

Overview of the Assembly Steps

Before fastening the VC80 to the vehicle:

•

Configure shut down automation.

•

Prepare the forklift such as ignition connection and correct voltage.

•

It is recommended to fasten the bracket to the vehicle and then install the VC80 to the bracket.

Cable Dust Cover

For the dust cover location, see VC80 Back View with Dust Cover on page 1-4.

CAUTION

CAUTION

Turn on external peripheral devices with their own power supply at the same time or after the VC80. If

this is not possible, ensure that the VC80 is adequately protected from power leakage caused by an

external device.

For safety reasons, install the supplied cable cover for the external ports prior to using the VC80.

Strain Relief

After the VC80 and bracket are fastened, prepare the strain relief as follows:

1. Install the cables loosely on the strain relief rail (see Figure 1-4 on page 1-4).

2. As far as possible, route cables leading to or away from the unit next to one another without crossing.

3. Fasten the cables into the strain relief rail precisely at the positions at which the cable openings in the cable

cover are located.

2 - 6 VC80 User Guide

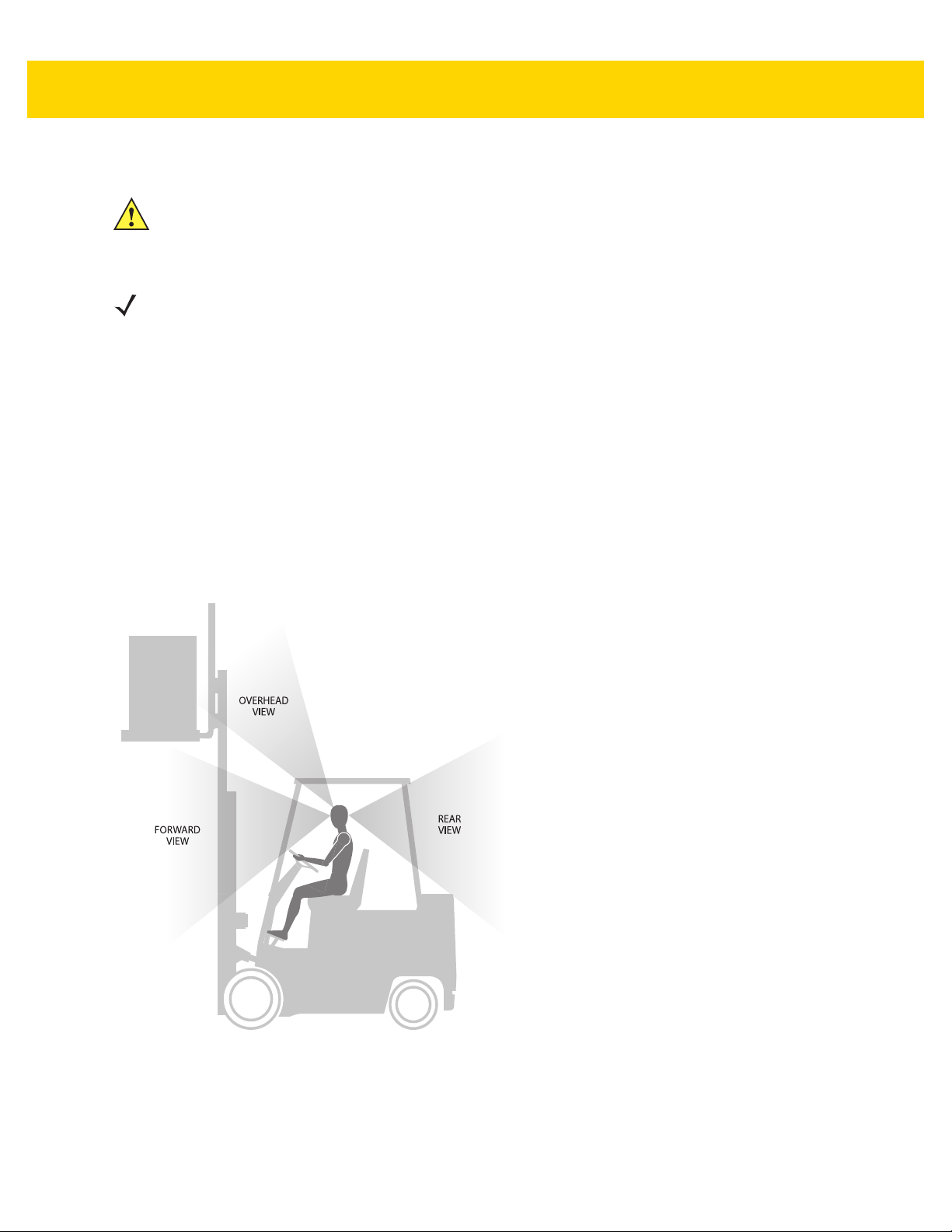

View Obstruction Considerations

Installing the VC80 on a Forklift

CAUTION

NOTE

If installing peripherals, allow enough space when selecting a mounting location.

1. Attach the desired mount to the VC80. Refer to the VC80 User Guide at www.zebra.com/support for detailed

Tighten peripherals with thumbscrews by hand only. Do not use tools for tightening thumbscrews.

mounting options and instructions.

2. Attach the mounted VC80 to the vehicle and position in a location that does not obstruct the operator’s view.

3. If using an external antenna, connect antenna in a vertical position to the VC80.

4. Connect peripherals to the VC80. Place the cables in the strain relief brackets inside the dust cover and replace

the dust cover (see Figure 1-3 on page 1-4).

5. Connect the VC80 to the vehicle DC supply.

6. Press the Power button to turn the device On or Off (see Figure 1-1 on page 1-3).

Figure 2-2 View Obstruction Considerations

Installation 2 - 7

Forklift Battery Replacement Conditions

The VC80 maintains normal function of applications and connections during and after forklift battery replacement.

Replace the forklift battery at any point during a shift and/or while the VC80 is fully running.

The forklift battery may be replaced under following condition: VMC external temperature range: -30° C to +50° C.

During forklift battery replacement (VMC is running on UPS battery), both Windows and the VC80 are monitoring

remaining UPS battery capacity. The default Low Battery notification threshold is set to 20% for all Windows Power

plans. The Critical Battery threshold is set to 10%. If UPS battery is discharged below 10%, the VC80 automatically

shuts down.

An additional notification message can be enabled in the VC80 with a threshold set to the configured Low Battery

level plus an additional 10%. If enabled, this message appears to the User when the UPS battery is discharged to

30% (20% + 10%) level.

Starting from Cold Soak

The VC80 does not startup from a saturated cold soak when internal VC80 temperature (critical components and

UPS battery) is below -30° C or UPS battery has less than 10% capacity. The red LED warning indicator may

display.

The VC80 can to start up from a saturated cold soak at -30° C (or above) internal VC80 temperature when a valid

external DC power source is present.

The VC80 design minimizes wait time from -30° C cold soak to load the OS and have internal heaters to assist

system warm up.

From a -30° C cold soak condition, the VC80 battery heater may be activated to warm the UPS battery to an

acceptable charging temperature if charging is needed. The conditions and time to heat the battery are managed

by the system. The OS load time and VC80 ready for use time is independent of warming the battery.

2 - 8 VC80 User Guide

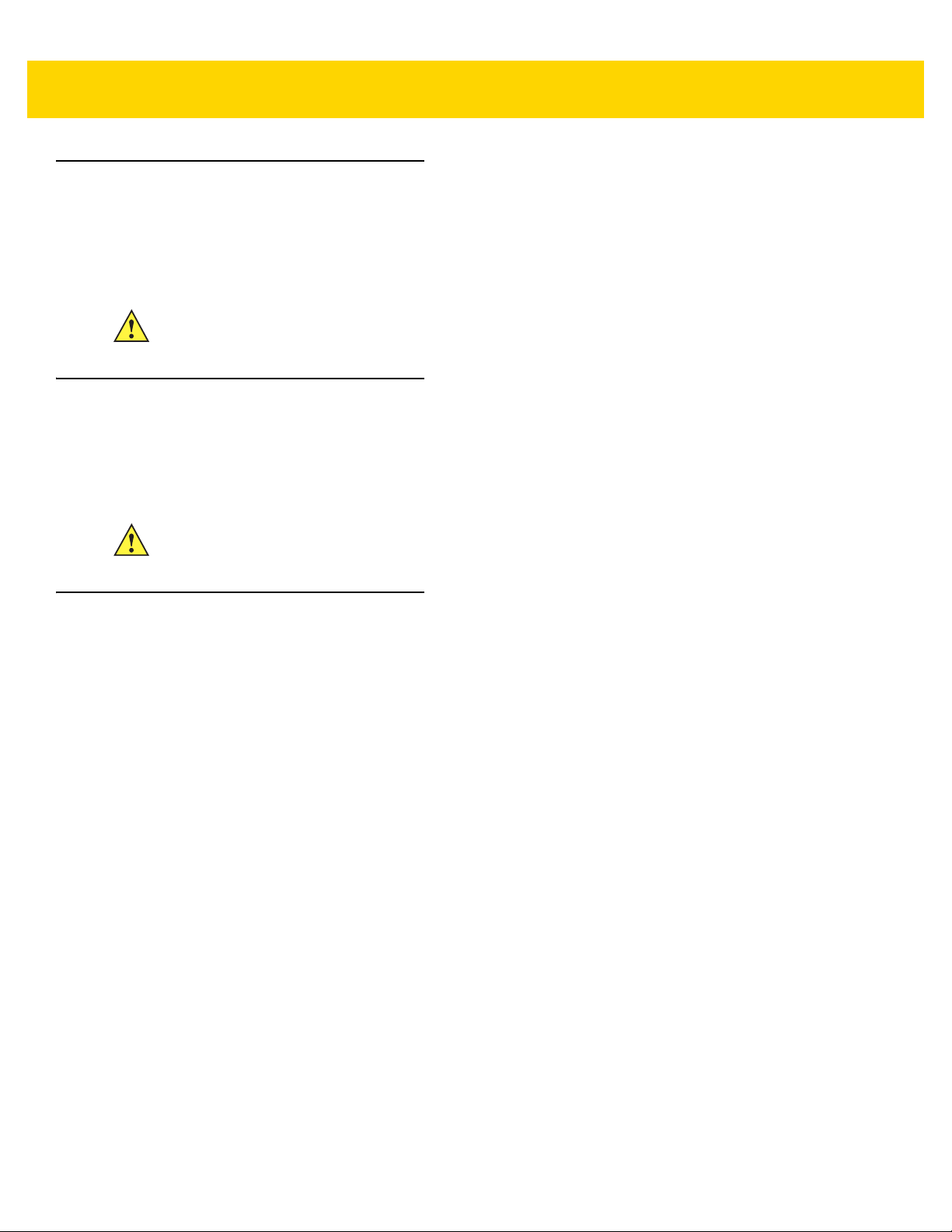

Without Power Pre-regulator

For vehicles with DC power 48V or less

With Power Pre-regulator

For vehicles with DC power greater than 48V

M1M7M2M8M3M9M4

M10M5M11M6M12

Power Extension

without Ignition Sense (p/n CA1210)

Power Extension

without Ignition Sense

(p/n CA1210)

Power Extension

with Ignition Sense

(p/n CA1220)

Power Extension

for Pre-regulator with

Ignition Sense

(p/n CA1230)

Installing the Power Pre-Regulator

IMPORTANT

The Zebra power extension cable positive lead is red and the negative lead is black.

It is recommended that all connections be secured with electrical tape or heat shrink to

prevent contaminants from degrading the connection.

To install the power pre-regulator:

1. Attach the pre-regulator cable male connector to the Zebra power extension cable which is installed on the

vehicle.

2. Connect the pre-regulator cable female connector either directly to the VC80 power cable, or to the power

extension cable. See Figure 2-3.

M1M7M2M8M3M9M4

M10M5M11M6M12

Figure 2-3 Connections To Vehicle DC Supply

Non-Vehicle Installations

Using AC power, the VC80 Vehicle-Mount Computer can be mounted at fixed locations adjacent to cross-dock

doors, manufacturing stations, or in offices.

Use the 100/240 VAC Power Supply (p/n PS000145A01) to power the computer from an AC source.

IMPORTANT

The AC/DC power supply is only intended for use at room temperature condition such as

an office environment.

Installation 2 - 9

Power On/Off with Ignition

The VC80 is equipped with an ignition sense feature which puts the terminal into suspend/shutdown when the

vehicle ignition is turned off and can power on the terminal when the ignition is switched on. To use this feature, a

power extension cable with ignition sense wires must be used and installed properly on the vehicle.

The cable in Figure 2-4 is the power extension cable (p/n CA1220) with two wires used to connect to vehicle ignition. The red and black leads of the two 18AWG wires that connect to the key switch of the ignition and ground,

respectively. Once the wires are connected, the VC80 may switch on or off depending on the state of the vehicle

ignition key. See Power on page 3-20 to select power settings.

IMPORTANT

When connecting to an ignition switch using the power extension cable with ignition sense

wires, ensure that the wires of different polarities are reliably secured away from each

other, or are separated with reliably secured certified insulation. A minimum distance of

2.8mm (or 0.4mm distance through insulation) is required for the separation.

The thinner wires (18 AWG) are used for Ignition Sense wires while the thicker wires

(14AWG) are used for Vehicle Power and Ground. Identify them carefully and

Do Not confuse them.

An appropriate fuse type must be used with the power extension cable according to the

installation instructions. For the main power cable, use 3AB, 15A, 250V, slow blow fuse.

For ignition sense input, use 3AB, 0.3A, 250V, slow blow fuse.

Figure 2-4 Power Extension Cable Kit with Optional Ignition Sense Wires (p/n CA1220)

2 - 10 VC80 User Guide

Screen Blanking Wiring

Connecting Switch for Screen Blanking

To use Screen Blanking, connect one of the two DB9 serial ports (using CA1300 Screen Blanking cable) on the

VC80 to a switch. Activate this switch electrically (e.g. motion sensor, GPS) or mechanically (e.g. pedal switch)

when the vehicle is in motion.

Figure 2-5 Connecting the Switch to the DB9 Cable

IMPORTANT

The screen blanking feature makes use of either one of the DB-9 ports to monitor electrical relay closure. When

enabled, the CTS/RTS pins of the DB9 port are continuously monitored by the screen blanking application. See

Figure 2-6 for pin configuration.

When the vehicle is in motion, the switch closes the circuit, allowing data packets to be sent or received through the

RTS and CTS pins. The computer detects that the circuit is closed and turns off the screen.

When the vehicle is not in motion, the switch opens the circuit, preventing data packets from being sent or

received. The computer detects that the circuit is open and turns on the screen.

For customers migrating to the VC80 from a 8515, 8525, 8535 vehicle mount computer or

a 753x hand-held computer cradle:

If the screen blanking feature was used previously, ensure that you are no longer feeding

the screen blanking signals to the VC80 main DC power cable. Rewire the screen

blanking inputs to the VC80 DB-9 serial port through the DB-9 screen blanking cable. In

previous generations of vehicle-mount computers, the screen blanking signals were fed in

to the terminal through 2 of the 4 wires in the CPC connector of the DC power cable. This

no longer applies for the VC80.

Figure 2-6 Screen Blanking DB9 Pin Configuration

CHAPTER 3 SOFTWARE

Introduction

This chapter provides software information and instruction for the VC80.

Microsoft Windows Setup and Configuration

After the system files are processed, Microsoft Windows loads. Standard Windows configuration options apply to

the VC80. Configuration options are located in the System Tray or the Control Panel. For example, use the System

Tray to adjust the time, date or volume level and the Control Panel to add, delete or modify software.

Folder Structure

Microsoft Windows is installed in the \Windows folder. For information on the folder structure, refer to the

commercially available Microsoft Windows OS Reference Guide.

3 - 2 VC80 User Guide

VC80 Software Components

The VC80 contains the following software components:

•

BIOS

•

Embedded Controller firmware

•

Microsoft Operating System (Windows 7 Standard or Professional).

•

VC Control Panel

The following Windows OS features are unique to the VC80 (dependent on configuration):

•

Touch driver

•

WLAN/Bluetooth driver

•

Ethernet driver

•

GPS

•

Zebra printer tools and drivers.

The Embedded Controller manages communication with the following VC80 unique features:

•

Heaters

•

Battery state

•

Data logging.

VC80 Without Operating System

The VC80 can be ordered with no operating system. This configuration requires the following:

•

Windows 7 installation media

•

A valid product licensing key.

When prompted for driver locations during installation and setup, direct the device wizard to the USB drive.

•

For Windows 7 drivers, go to: www.zebra.com/support.

Software 3 - 3

Connecting to Terminal Emulation

The VC80 supports terminal emulators such as TekTerm. For connection to a host, have the following information

available:

•

Alias name or IP host address

•

Port number of the host system

•

Emulation.

To connect to a host:

1. Ensure the mobile client network settings are correctly configured.

2. Ensure the VC80 is connected to the network if connecting via WLAN.

3. Launch the terminal emulation application.

TekTerm

TekTerm is a powerful terminal emulation software application with the ability to interface with multiple Bluetooth

and serial scanners. TekTerm is pre-licensed and pre-installed on the VC80.

It is recommended to check the latest TekTerm version released for the VC80. For more information regarding

TekTerm, go to: www.zebra.com/support.

3 - 4 VC80 User Guide

Bar Code Scanners and Settings

The VC80 supports the following types of bar code scanners:

•

Tethered scanner connected to COM1 or COM2.

•

Tethered scanner connected to a USB host port

•

Wireless scanner connected via Bluetooth.

Serial Scanners

To configure serial scanners:

1. Open the VC Control Panel and select Power.

2. Enable the power to the port.

Figure 3-1 Enable Power for Serial Scanners

Software 3 - 5

3. Select TekWedge and select Enable TekWedge to support serial scanners.

4. Select Config Ports.

Figure 3-2 Enable TekWedge for Serial Scanners

5. Select the new COM port and select Enable Port.

Figure 3-3 Enable Port for Serial Scanner

6. Select OK.

3 - 6 VC80 User Guide

USB Scanners

The Windows OS loads a USB driver for USB scanners. USB scanners are not controlled or managed by

TekWedge therefore, post processing such as translation rules can not be used with USB scanners. 123Scan

be used to create rules and download to the scanner.

To configure USB scanners, connect the scanner to the VC80 USB port and follow the scanner setup instructions.

For Zebra scanner guides, go to: www.zebra.com/support.

Bluetooth Scanners

See Quick Setup on page 3-10 for information on connecting Bluetooth scanners. Always use TekWedge on page

3-24 to configure Bluetooth parameters.

Pairing Bluetooth Scanners Using Bar Codes

NOTE

If the Bluetooth scanner connection to the VC80 is lost, it is recommended to first scan the Unpair bar code

and then scan the Pair bar code.

To pair Bluetooth scanners using bar codes:

1. Select Bluetooth >Open Settings to access Bluetooth settings.

2

can

Figure 3-4 Open Settings

Software 3 - 7

2. In the Options tab, select check boxes under Discovery and Connections.

Figure 3-5 Bluetooth Discovery and Connections

3. In the COM Ports tab, select Add.

4. Select the radio button Incoming (device initiates the connection).

5. Select OK.

Figure 3-6 Add Incoming Bluetooth Devices

3 - 8 VC80 User Guide

6. Open the VC Control Panel and select TekWedge.

7. Enable TekWedge.

8. Select Config Ports.

Figure 3-7 Enable TekWedge

9. Select the new COM port and select Enable Port.

Figure 3-8 Enable COM Port for Bluetooth Device

10. Select OK.

11. Scan the bar code to pair the scanner (the scanner must be configured for SPP mode).

Software 3 - 9

Settings

Select Start Menu > Admin Tools > VC Control Panel to configure the following VC80 settings:

•

Quick Setup

•

Bezel Keypad

•

Haptics Feedback

•

Heater Status

•

Power

•

Push to Talk

•

Screen Blanking

•

System Info

•

TekWedge

•

UPS Battery

•

Data Logging

Figure 3-9 VC80 Settings

3 - 10 VC80 User Guide

Quick Setup

Select Start Menu > VC Control Panel > Quick Setup to configure the following quick setup options.

Links to Microsoft or third party utilities:

•

Touch Panel Calibration - Calibrate the touch panel.

•

WLAN Configuration - Configure WLAN.

•

Network Configuration - Configure network parameters such as, Static IP address and DHCP.

•

On-Screen Keyboard Configuration - My-T-Soft Keyboard configuration.

VC80 control panel:

•

Manage VC Configuration - Load or save configuration files.

Figure 3-10 Quick Setup Settings

Software 3 - 11

Touch Panel Calibration

Hardware

Associates the pointer device with the monitor/desktop area that is controlled by the device and shows the

hardware port information.

NOTE

Select Help for detailed information on the Touch Panel Calibration options.

• Handling Whole Desktop - Whole indicates the primary monitor.

• Connected to USB Port - Displays the port connected to the device.

• Add a New Device - Option to add a device. Only non USB devices are manually added. USB devices

are automatically added.

• Remove this Device - Option to remove a device. Only non USB or inactive USB are manually

removed.

Figure 3-11 Hardware Settings

3 - 12 VC80 User Guide

Click Mode

• Interactive Touch - Shows the current click mode emulation for a single touch. The setting is only

active if the driver is responsible for the pointer handling via the standard mouse interface into the OS.

• Extended Touch - Vista and above, UPDD can deliver touch co-ordinate data to the Windows OS via

three interfaces: mouse class, HID class, Win8TI API interface.

• Visual Notification - Indicates if visual feedback is shown during Interactive Touch right click

countdown.

• Interactive Switch Delay - Select the delay pace.

• Sound Options - Configure touch sound options.

• System Mouse Settings - Adjust the mouse pointer settings defined within the OS.

• Test Icons - Test Right Click and Double Click. A tick is shown if the click test is successful.

Figure 3-12 Click Mode Settings

Software 3 - 13

Properties

• Name - Associates a name to the device. By default the name is the drivers controller device name.

• Low Pass Filter - Applies a filter to produce a smoother drawing. The speed of drawing is affected, the

higher the value used.

• Liftoff Time - Specifies the time interval required to register a stylus lift after the last touch packet is

received. Lift off time is defined in units of 10ms.

• Stabilization - Causes small movements to be ignored.

• Averaging - Applies a filter to produce smoother drawings. Filtering can improve drawing without

affecting the drawing speed.

• Mode - In a multi pointer device environment, this setting indicates the priority given to the device. With

the Interlock option, the device can only be used if no other device is in use. The Admin option allows

any device currently in used to be forced into a pen up state and the device is given immediate priority.

• Release Time - Defines the interlock release times.

• Use Lift-off Packet - Only shown if a pen up data packet is generated by the device on stylus lift off.

• Anchor Mouse - If the device generates a pen up data packet on stylus lift, the mouse cursor returns

to its original position after using the pointer device.

• Enabled - Indicates if the device is enabled. This is an option to free up resources without uninstalling

the driver.

• Advanced - Includes advanced features such as, Edge Acceleration, Ignore Touches Outside

Calibrated Area, Support for New Events, and Portrait Rotation.

Figure 3-13 Properties Settings

3 - 14 VC80 User Guide

Calibration

• Style - Invoke Calibration styles manually, from an application, a toolbar, or a command line interface.

• Add a New Style - Add a new calibration style.

• Number of Points - The number of calibration points determines the calibration pattern used. It is

highly recommended that four or more points are used for greater flexibility.

• Margin % - The percentage margin from the edge of the visual display area from which to draw the

calibration points.

• Timeout (secs) - Specifies the number of seconds to wait for a calibration touch before canceling the

calibration procedure.

• Use Eeprom Storage - Store calibration data in the controllers Eeprom.

• Confirm After Calibration - Select to use new calibration data.

• Sound Options - Calibration sound options.

• Calibrate - Invoke calibration procedure for the current device. When calibrating for the first time in a

multi-monitor environment, calibrating the devices also sets up desktop/touch device relationships.

Figure 3-14 Calibration Settings

Software 3 - 15

Status

• Controller Type - The actual controller type in use irrespective of the name given to it in the UPDD

console.

• State - Indicates if the device is enabled at the UPDD level.

• Macro Result - Shows if a controller is initialized by the driver.

• Replay Initialization Macro - Reinitializes the controller. The macro, if defined, is sent to the controller.

• Reset Error Counts - Reset the sync error count. Only enabled if error count > 0.

• Reload Driver Settings - Reload the driver.

• Show Test Screen - Invoke the test utility.

• Show Test Grid - Invoke the test utility with drawing grid.

• Dump Settings - Dump driver settings to a file. The file is useful for support purposes but can also be

used in subsequent installs to define the initial settings.

Figure 3-15 Status Settings

3 - 16 VC80 User Guide

Manage VC Configuration

• Import - Load VC configuration from file.

•Export - Export VC configuration to file.

• Restore Default - Sets all parameters to factory default.

Figure 3-16 Manage VC Configuration

Software 3 - 17

Bezel Keyboard

•

My-T-Soft Macro Mapping - Allows remapping and/or assigning various custom functions to the Bezel

buttons.

•

Assign Bezel Key Scancodes - Map bezel keys one of the following ways:

• Bezel Key - Assign bezel key using the drop-down menu.

• Assign Scancodes - Assign scancode function from drop-down menu. To change scancodes to assign

unique functions/characters, see Chapter 6, Scancode Map.

•

Blue Key

• One-Shot -Activates the Blue key function on the first key press and remains activated until any key is

pressed again.

•Lock - Activates the Blue key function on the first key press and remains activated until the Blue key is

pressed again.

• One-Shot/Lock - Activates the Blue key function on the first key press. The second Blue key press locks

the Blue key function. The third Blue key press deactivates the function.

Figure 3-17 Bezel Keyboard Settings

3 - 18 VC80 User Guide

Haptic Feedback

•

Haptics Feedback

• Enable/disable Haptics Feedback.

• Select Full Screen or My-T-Soft Only.

•

Parameters

• Select the haptics waveform type: Long Double Sharp Click Waveform or Strong Click Waveform.

• Select the haptics waveform level.

Figure 3-18 Haptics Feedback Settings

Software 3 - 19

Heater Status

The VC80 heater ensures optimum performance in freezers. The heater benefits include:

• Touch screen heater clears condensation on the display.

• Port heater prevents condensation on contacts.

• Audio Codec, UPS Battery and WLAN/BT radio require heaters to operate below freezing temperatures.

• The user interface displays current temperatures.

Heater Status settings:

•

Current Temperature - Displays internal and external temperatures.

•

Display Temperature - Select desired temperature scale.

•

Temperature Status

• Green LED - Heater is enabled.

• Red LED - Heater is disabled.

• Start Test - Verifies heater operation when temperature increases.

Figure 3-19 Heater Status Settings

3 - 20 VC80 User Guide

Power

NOTE

Ignition detect requires a CA1220 power extension cable.

•

Interface Power Configuration - Enable/disable power for serial and USB ports.

NOTE

To configure a serial scanner, turn on the power to the port and in TekWedge settings, enable

the port and TekWedge (see

•

Vehicle Ignition Detection

• Start VC when vehicle ignition changes from OFF to ON state.

• Shut down VC when vehicle ignition changes from ON to OFF state.

• Enter desired minutes to delay in the Delay field.

TekWedge on page 3-24

).

Figure 3-20 Power Settings

Software 3 - 21

Push To Talk

•

Connection Status - Displays the current connection status.

•

PTT Handset Scan Code - Scan code for bezel key setting.

•

Speaker - Enable the Bezel Speaker or PTT Handset Speaker.

Figure 3-21 Push To Talk Settings

3 - 22 VC80 User Guide

Screen Blanking

The optional Screen Blanking setting turns the screen off when the vehicle is moving and back on when the vehicle

is stopped.

NOTE

To use Screen Blanking, first connect one of the two DB9 serial ports on the VC80 to a user-supplied

switch or relay. See Connecting Switch for Screen Blanking on page 2-10.

•

Screen Blanking - Enable/disable screen blanking feature.

•

Delay

• Blanking the VC Screen - Screen blanking duration in seconds.

• Re-Enabling the VC Screen - Re-enable screen duration in seconds.

•

Blank Screen Based On

• Com Port 1 or Com Port 2.

• Blank screen when port pins are connected - Select blank screen option. De-select to disconnect the

blank screen option.

Figure 3-22 Screen Blanking Screen

Software 3 - 23

System Info

The System Info screen provides information about the system such as the Serial Number, OS Details, and SKU

Detail. The system information is required for technical support inquiries.

To export the system information to a text file:

1. Select Save.

2. Select a location to save the file to.

3. Name the file in the File Name field.

4. Select a file type from the Save As Type drop-down menu.

Figure 3-23 System Information

3 - 24 VC80 User Guide

TekWedge

TekWedge provides the ability to interface with Serial and Bluetooth scanners.

NOTE

To configure a serial scanner, turn on the power to the port (see

TekWedge settings, enable the port and TekWedge.

•

TekWedge to support serial scanners - Enable/disable TekWedge support for serial and Bluetooth

scanners.

•

Properties

• Enable Good Scan Beep - VC80 beeps when data is received from the scanner.

• Code Page - Select code page from drop-down menu.

•

Data Transmission - Select one type of data transmission.

• Copy/Paste (Application supports Ctrl-V) - Copy/Paste is efficient for large amounts of scanned data.

• Keyboard Wedge.

•

Ports and Translation Rules

Power on page 3-20

) and in

Figure 3-24 TekWedge Settings

Software 3 - 25

• Config Ports - Select the COM Port from the ports window and adjust the port settings such as Baud

Rate, Data Bits, Parity, Flow Control, Stop Bits, and Timeout as desired.

• Set to Default - Sets the default for the selected COM port.

• Clear Unavailable Ports - Clears unavailable ports such as ports that are no longer active.

Figure 3-25 Config Ports

NOTE

For large bar codes, adjust the Timeout duration. The longer the timeout, the slower the scans.

3 - 26 VC80 User Guide

• Config Translation Rules - Allows you to define up to 10 cases, each consisting of up to 10 rules in

sequential order. Only one case is applied to a bar code and a case is applied if all rules specified in the

case are successful. If a rule within a case fails, the entire case fails.

• Case Rules -The case rules are defined as follows:

•No Rule

• Verify Barcode Size — Verifies the barcode size. Assign this rule first, before creating subsequent

rules.

• Match at Index — Matches the match string at a specified index.

• Add Barcode Prefix/Suffix — Adds a global prefix or suffix.

• Search and Replace — Replaces all instances of the match string.

• Match and Replace at Index — Matches the match string at a specified index and replaces/changes

it.

• Replace at Index — Replaces/changes unspecified data in a given range.

Translation information about the status of each case/rule is displayed in the scan log file. This is useful to

determine why a rule is failing.

Select a Case/Rule to modify and then select the Scan Type drop-down menu to apply a rule.

Figure 3-26 Translation Rules

Software 3 - 27

UPS Battery Status

•

Information - Displays the current battery information such as the Serial Number, Manufacture Date, and

Remaining Battery Life.

•

Notification - Enable/disable Low Battery Notifications and enter a Threshold percentage for low battery

life warnings.

Figure 3-27 UPS Battery Settings

3 - 28 VC80 User Guide

Data Logging

Data Logging logs information about VC80 custom features.

•

Log Information Level

•Source - Select a source from the drop-down menu such as Heaters, Haptics, UPS Battery.

• Content - Select a priority level from the drop-down menu such a Critical, Major, Minor.

• Disable All Logging - Removes logging VC80 custom feature information.

•

Log File Management - Select a Log File Location, quantity of log files in the Create up to field, and disk

size (default is 2 MB) in the Total Size On Disk field.

Figure 3-28 Data Logging Settings

NOTE

Application crash dump files are captured and stored in a restricted folder permitted for

Administrators only (C:\VC\Logs or C:\Windows\MiniDmp).

Software 3 - 29

My-T-Soft

My-T-Soft offers a database of existing keyboard layouts for screen keyboard customization and key mapping.

Each VC80 has access to a Zebra account on the Build a Board website for keyboard layouts. Unique custom

keyboard layouts may be acquired for additional license fee(s).

To access My-T-Soft, go to: www.build-a-board.com.

Figure 3-29 My-T-Soft Screen Keyboard Layout Examples

3 - 30 VC80 User Guide

All VC80s are My-T-Soft licensed through a common account which is only available from the VC80.

To access My-T-Soft:

1. Select Start > Select My-T-Soft > Licensing Information.

Figure 3-30 My-T-Soft License Information

2. The UAC window displays. Select Yes.

3. In the IMG License Manager menu, select Go to My Build-A-Board.com Account.

Figure 3-31 IMG License Manager

4. The Zebra account web page displays. Download existing keyboards or create your own and save in the Zebra

account.

NOTE

To create a private collection of keyboards, you must acquire your own account.

Software 3 - 31

COM Port Connection

Windows Management Instrumentation

Windows Management Instrumentation (WMI) is a free component of the Microsoft Windows® operating system

that provides a scalable system management infrastructure. Using a free provider plug-in from Zebra, WMI

enables local and network remote management of scanner(s). System administrators can leverage WMI to query

and set information on desktop systems, applications, networks, components, and accessories, such as a scanner.

For more WMI information, go to:

•

https://msdn.microsoft.com/en-us/library/aa384642(v=vs.85).aspx

•

http://www.zebra.com/support

GPS

U-Center is used to set up GPS on the VC80.

To set up the GPS:

1. Ensure that the antenna is properly installed on the GPS port (see Figure 1-2 on page 1-3).

2. Open U-Center by selecting Start > Program Files > U-Center.

3. Ensure that the receiver is connected. See Figure 1-2 on page 1-3. After approximately thirty seconds, some of

signals bars turn to green. This signifies that the GPS has obtained 3D lock.

Figure 3-32 U-Center Connection

3 - 32 VC80 User Guide

Satellite Level

To view the Satellite Level, select View > Docking Windows > Satellite Level.

Location Coordinates

To view Location Coordinates, select View > Docking Windows > Data.

Figure 3-33 Location Coordinates

U-Center Software

•

For detailed U-Center information, refer to the U-Center User Guide at:

https://www.u-blox.com/sites/default/files/u-center_UserGuide_%28UBX-13005250%29.pdf

•

Other applications/software such as Visual GPS can be used to collect location data by communicating with

the GPS receiver.

CHAPTER 4 MAINTENANCE AND

TROUBLESHOOTING

Introduction

This chapter includes instructions on cleaning the device and provides troubleshooting solutions for potential

problems during device operations.

WARNING Danger due to electric shock when cleaning and maintaining the device. To avoid

electric shock, turn the VC80 off and disconnect it from the power supply before

cleaning or maintaining it.

Cleaning

CAUTION

Do not use compressed air, a high-pressure cleaner or vacuum cleaner, as this can damage

the surface. Using a high-pressure cleaner poses the additional risk of water entering the

device and damaging the electronics or display.

Housing Cleaning

Clean the fully assembled VC80 vehicle mount computer housing using only a mild detergent on a lightly dampened soft cloth.

Touchscreen Cleaning

•

Use neutral detergent or isopropyl alcohol on a clean soft cloth to clean the panel surface. Do not use any

kind of chemical solvent, acidic or alkali solution.

4 - 2 VC80 User Guide

Touchscreen

The VC80 is equipped with a resistive touchscreen.

CAUTION

Operation of the resistive touchscreen is recommended with:

• Clean, dry fingers.

• Clean, dry, soft gloves.

• Suitable touch stylus (plastic or wood, rounded tip).

- Keep the touchscreen clean (see Touchscreen Cleaning on page 4-1).

- Do not apply adhesives to the surface.

- Avoid high voltage and/or static charge.

- Do not use ball point pens, writing utensils, tools, or sharp objects.

- Touch the panel with your finger or stylus only to ensure normal operation.

- Operate in a stable environment. Abrupt variation of temperature and humidity may cause malfunction.

- Avoid applying excessive activation force or sudden impact on the touchscreen surface.

Maintenance and Troubleshooting 4 - 3

Troubleshooting

Table 4-1 Troubleshooting

Symptom Possible Cause Solution

The vehicle

computer does

not power on or

shuts off

suddenly.

Cannot see

characters on

display.

The power cable ignition

sense wire (yellow) is not

connected properly.

Power cable not

connected properly or

unplugged.

If the vehicle computer is

powered by a vehicle

battery, the vehicle

battery is depleted.

Vehicle computer not

powered on (Power LED

is Off).

Screen is too bright/dark. Adjust the brightness; see

Display not adjusted

properly.

The vehicle computer is

in low power mode

(Power LED is on).

Verify that the power cable is connected properly. See

Vehicle Power to the VC80 on page 2-4

Connect power cable to power cable portion underside of

vehicle computer. Turn the main power switch on.

Replace or charge the vehicle battery.

Press the Power button on.

Select

Display

display.

Press the Power button to turn on the vehicle computer.

in the Control Panel settings and adjust the

.

Figure 1-1 on page 1-3

Wiring

.

The touchscreen

is not working.

Display not properly

calibrated.

Replacement screen

protector was not applied

correctly.

Recalibrate the screen through the Touch Panel Calibration

utility (see

continues, contact Zebra support. See

page ii-x

Replace or re-apply screen protector.

Touch Panel Calibration on page 3-11

.

Service Information on

). If problem

4 - 4 VC80 User Guide

Table 4-1 Troubleshooting

Symptom Possible Cause Solution

The optional

serial scanner

does not

operate.

No sound is

heard when you

tap the

touchscreen or

press a key.

Scanner is not properly

connected to the vehicle

computer.

TekWedge application is

not enabled or set to the

correct COM Port.

External power is not

connected.

Volume is turned down. Adjust the volume in the Control Panel.

Application currently

running disabled the

sound.

Faulty speaker. Contact Zebra support at www.zebra.com/support.

The optional external

speaker cable is

connected without the

speaker.

Connect the scanner to the COM1 port. Ensure the proper COM

port is selected in the TekWedge application, see

page 3-24

Product Reference Guide.

Ensure that the TekWedge application is enabled and set to the

correct port. See

Verify external power connection.

Configure the application to enable the sound.

Connect the external speaker or disconnect the cable.

. If the problem continues, refer to the scanner

TekWedge on page 3-24

.

TekWedge on

Missing pixels on

the display.

COM1 or COM2

port is not

working.

No keys are

working on the

optional or

built-in keyboard.

Power is not enabled on

the COM port.

Faulty LCD. Contact Zebra support. See www.zebra.com/support.

Another application, or

SerialWedge is using the

port.

The optional keyboard is

not properly connected to

the vehicle computer.

The application does not

require keyboard input.

Vehicle computer is not

responding.

Ensure the power is applied to the COM port by the VC80.

Stop the application using the port or change the TekWedge

COM Port Settings.

Check the cable connections between the keyboard and the

vehicle computer.

Configure the application to use the keyboard.

Warm boot the vehicle computer.

Maintenance and Troubleshooting 4 - 5

Table 4-1 Troubleshooting

Symptom Possible Cause Solution

The vehicle

computer

cannot find any

Bluetooth

devices nearby.

When installed

on some electric

forklifts, the

scanner range is

shorter then it is

when installed

on other forklifts.

Too far from other

Bluetooth devices.

The Bluetooth device(s)

nearby are not turned

on.

The Bluetooth device(s)

are not in discoverable

mode.

Electro-magnetic

interference caused by

the forklift.

Move closer to the other Bluetooth device(s).

Turn on the Bluetooth device(s).

Set the Bluetooth device(s) to discoverable mode. If needed,

refer to the device’s user documentation for help.

Consult forklift vendor about reducing the interference by