Page 1

TTP 7000 Kiosk Printer

Technical Manual

Publ. No.: 01536-000, Ed. F

Page 2

Acknowledgments

Adobe and Acrobat are trademarks of Adobe Systems

Incorporated

Windows and Windows NT are trademarks of Microsoft

Corporation

This is a publication of Swecoin AB

Box 322, SE-192 30 Sollentuna, Sweden

Phone +46 8 623 45 60

Fax +46 8 594 709 89

E-mail techsupport@swecoin.se

sales@swecoin.se

Web site http://www.swecoin.se

© Swecoin AB 1998, 2001, 2003

All rights reserved. Reproduction in whole or in parts is

prohibited without written consent of the copyright owner. We

have taken great care to ensure that the information in this

manual is correct and complete. However, if you discover any

errors or omissions, or if you wish to make suggestions for

improvements, you are welcome to send your comments to

us. Swecoin AB disclaims any liability resulting from the use

of this information and reserves the right to make changes

without notice.

Edition F, August 2003

Printed in Sweden

2 TTP 7000 Kiosk Printer – Technical Manual 0308

Page 3

CONTENTS

1 Introduction ...................................................................................................................5

1.1 About this manual............................................................................................5

1.2 Updating ..........................................................................................................5

2 Product presentation....................................................................................................6

2.1 Indicators.........................................................................................................7

2.2 Feed-forward (FF) button ................................................................................7

3 Installation .....................................................................................................................8

3.1 Installation considerations...............................................................................8

3.2 Connecting to the computer ............................................................................9

3.3 Connecting the power ...................................................................................11

3.4 Making a test printout ....................................................................................11

3.5 Installing a printer driver ................................................................................12

3.6 Paper level sensors.......................................................................................12

4 Operation .....................................................................................................................14

4.1 Installing a paper roll .....................................................................................14

4.2 Clearing paper jams ......................................................................................16

4.3 Self-test printout ............................................................................................17

5 Programming ..............................................................................................................18

5.1 Summary of control codes & escape sequences..........................................19

5.2 Software command syntax............................................................................21

5.3 Font loading...................................................................................................43

5.4 Logotypes......................................................................................................45

5.5 Status reporting .............................................................................................46

5.6 Default parameter setting..............................................................................47

5.7 Windows WIN32 API calls.............................................................................50

6 Aligning preprint and thermal print ..........................................................................52

6.1 Commands used with the black-mark ...........................................................53

6.2 Black-mark sensing from within "Windows" ..................................................54

7 Interface .......................................................................................................................55

7.1 Parallel...........................................................................................................55

7.2 USB ...............................................................................................................61

7.3 Serial (option) ................................................................................................61

8 Maintenance ................................................................................................................62

8.1 Fault finding...................................................................................................62

0308 TTP 7000 Kiosk Printer – Technical Manual 3

Page 4

8.2 Cleaning the printhead ..................................................................................63

8.3 Removing the printhead ................................................................................63

8.4 Installing the printhead ..................................................................................63

8.5 Printer disassembly .......................................................................................64

8.6 Replacement parts ........................................................................................66

8.7 Firmware........................................................................................................67

9 Specifications .............................................................................................................70

9.1 Print data .......................................................................................................70

9.2 Text modes (non-Windows applications) ......................................................70

9.3 Basic character set........................................................................................71

9.4 Paper handling ..............................................................................................73

9.5 Printer dimensions.........................................................................................74

9.6 Environmental conditions ..............................................................................74

9.7 Miscellaneous................................................................................................75

9.8 Paper specification ........................................................................................75

9.9 Ordering numbers .........................................................................................77

REGISTER NOW!

If you wish to stay informed of product changes, manual updates etc., you are

welcome to subscribe to our bulletin service.

To register as a subscriber, either visit our web site http://www.swecoin.se to fill in

your subscription request, or send an e-mail to bulletins@swecoin.se.

Enter the text Subscribe bulletins as the subject. Do not enter any text in the message

area.

Registration date (for your own records):

REVISION HISTORY

Edition D, major changes

Status reporting for ESC ENQ 2 corrected

Status indicator LED-blink signals added

Retract and retain option added

Edition E, major changes

Added emphasis on fixed page length for landscape mode.

New commands added, (ESC L n) (EM)

Edition F, major changes

Added features up to firmware version 2.30

4 TTP 7000 Kiosk Printer – Technical Manual 0308

Page 5

1 INTRODUCTION

1.1 About this manual

This manual contains the information required to install the printer and to run it from a

host computer such as a PC.

Chapter 5 gives the applicable control codes and escape sequences supported by the

printer processor firmware.

Other chapters of the manual contain information about the printer error codes,

communications parameters, test print functions, specifications, replacement parts, etc.

1.2 Updating

This manual will be updated as, from time to time, printer functions and features may be

added or amended. You will always find the latest edition on our web site

(http://www.swecoin.se). You can order printed copies of the current manual by e-mail,

fax, or phone.

If you require functions not found in the manual edition at your disposal, you are welcome

to consult one of our representatives for information.

0308 TTP 7000 Kiosk Printer – Technical Manual 5

Page 6

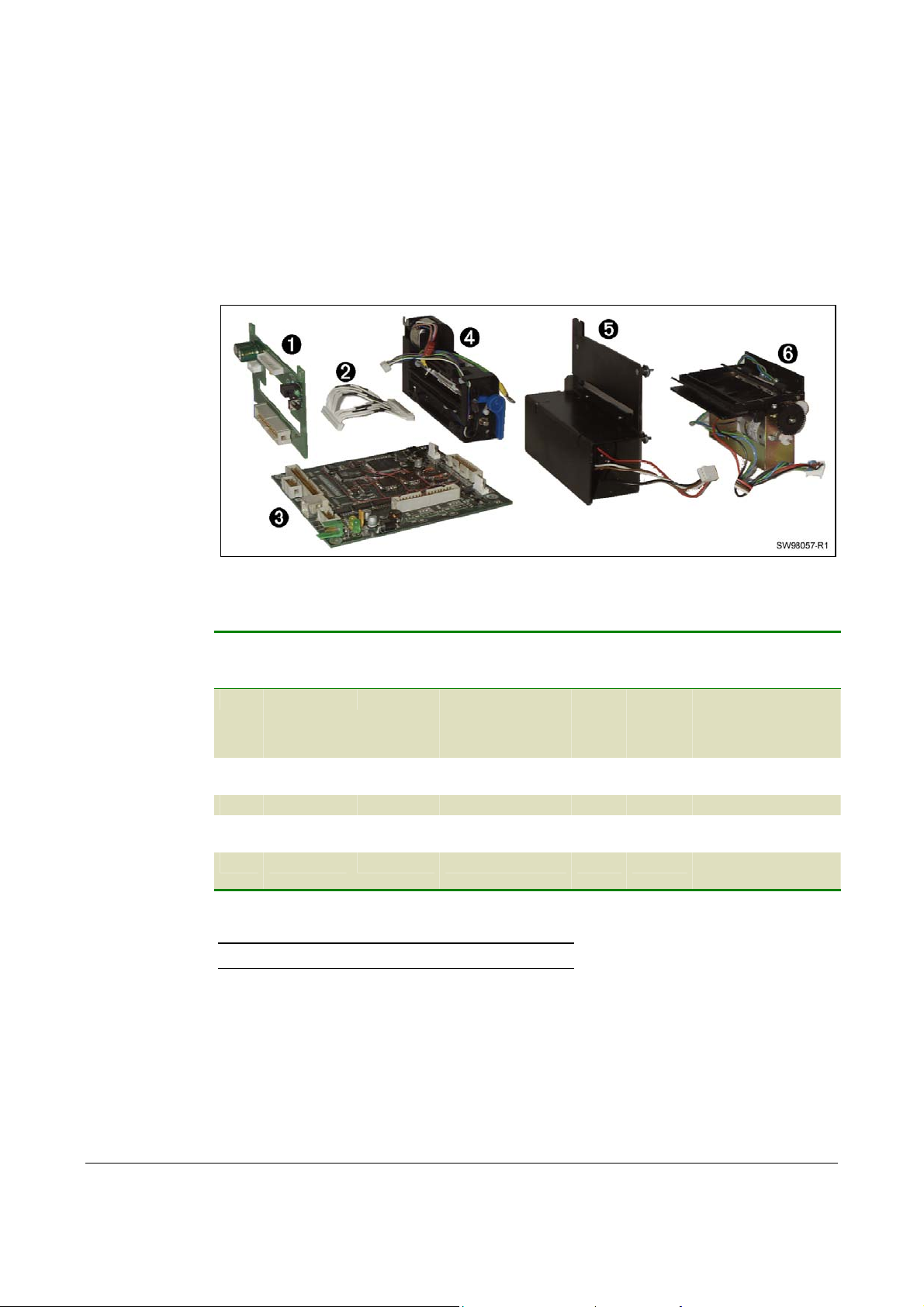

2 PRODUCT PRESENTATION

Status indicator

Feed-forward button

Paper entry

Control board

Figure 1. Printer exterior, side view

Print mechanism

flip-back handle

Paper release lever

Printhead lifted

Paper released

Normal operation

Paper exit shutter

FRONT

SW98049

The TTP 7000 is a kiosk printer using direct thermal printing. The print speed is up to

75 mm per second.

The printer has an integrated control board that communicates with the host computer

through an IEEE-1284 bi-directional parallel port, an USB port, or an optional serial port.

Printer drivers for most versions of Microsoft Windows™ are available, and the printer is

compatible with the Plug and Play standard. It is also possible to address the printer

directly from the kiosk software without using Windows.

The loop generating presenter mechanism handles documents of various lengths. It holds

the receipt until printed, then cuts and presents the complete receipt to the customer. A

retract and retain option can retract uncollected receipts into a wastebasket inside the

kiosk.

A flip-up print module gives the operator access to the paper path, and printhead, for

maintenance purposes.

Paper entry

Serial adapter (option)

Indicators for 24 and 5V

Roll holder paper level sensors

J1

IEEE-1284C

J10

Figure 2. Printer exterior, rear view

USB

J13

Power

J8

SW98051

6 TTP 7000 Kiosk Printer – Technical Manual 0308

Page 7

2.1 Indicators

2.1.1 Status indicator

The yellow status indicator (see Figure 1) has several functions:

••

ON constantly — the printer is operational

Blinks, pauses, blinks — indicates non-severe error. The number of blinks reflects

the error code:

1 Presenter jam

2 Cutter stuck

3 No paper at head

4 Head up

5 Paper-feed error

6 Temp error

Flashes rapidly — indicates severe error. The printer must be reset to be operable

again. Hold down the feed-forward button and the number of blinks will reflect the

error code.

2.1.2 Control board indicators

The control board has two power indicators behind the power connector.

Green indicator constantly ON: 24 V present

••

Red indicator constantly ON: 5 V OK (generated on control board)

••

2.2 Feed-forward (FF) button

When you insert the paper through the paper entry the printer will feed it forward, cut and

eject a receipt, then switch to on-line mode. Use the feed-forward button if you want to

advance the paper forward further.

To feed paper:

1. Press and hold the button, paper-feed starts.

2. Release the button to stop paper feed.

You can also use the feed-forward button to print a self-test receipt. See page 17.

0308 TTP 7000 Kiosk Printer – Technical Manual 7

Page 8

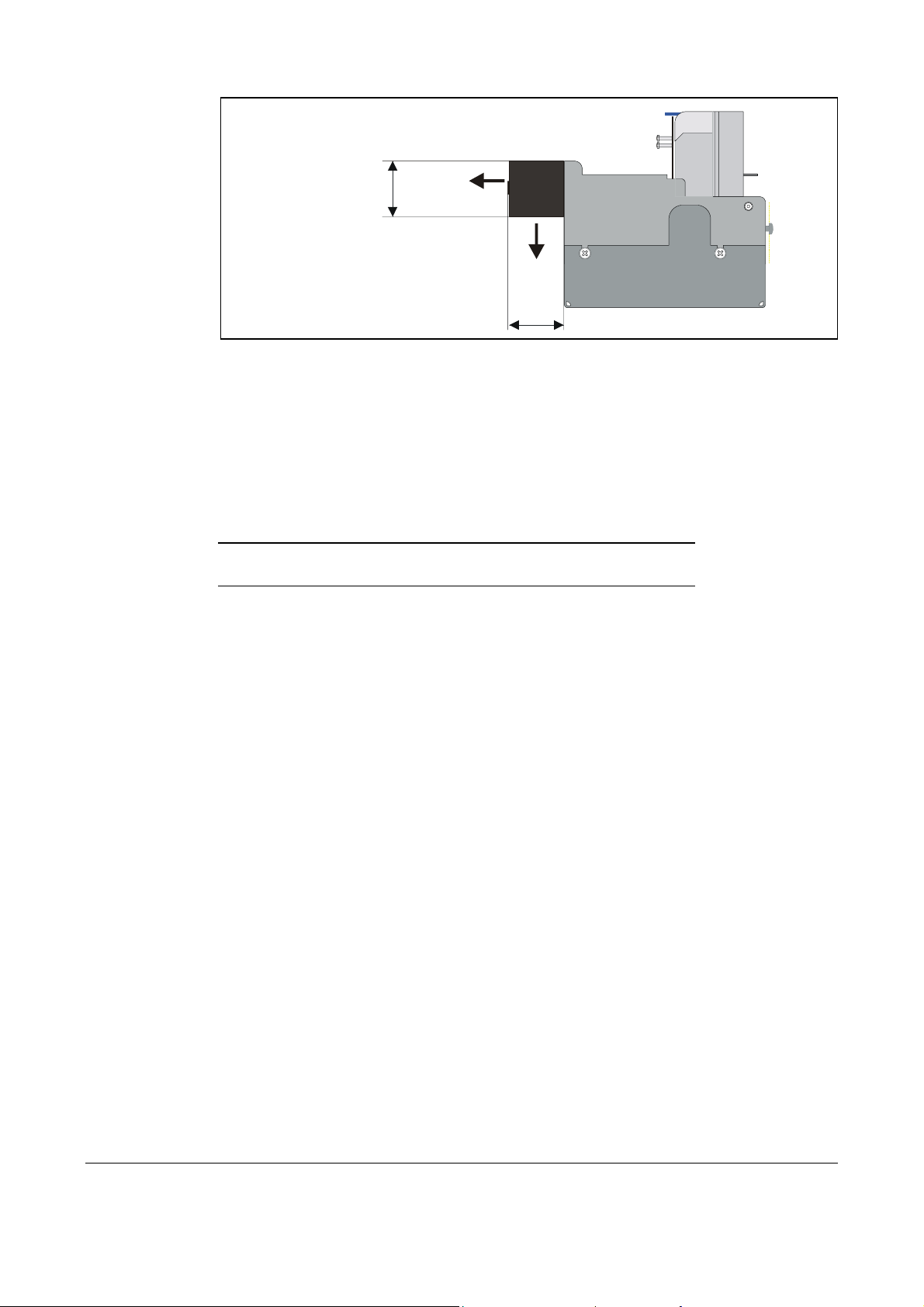

3 INSTALLATION

3.1 Installation considerations

The TTP 7000 printer should be installed in some kind of enclosure such as a self-service

kiosk. The illustration below gives an example of a printer-mounting shelf. See also

"Printer dimensions" on page 74.

5

.

1

19.0

26.0

76.0

Top v i e w

84.5 (116.5)

128.5 (160.5)

4.2 (4x)

81

91

All measurements are in mm. Measurements in parenthesis are for TTP 7000/112.

Figure 3. Example of a simple shelf for fastening a standard printer

16.0

86.0

148.8

12.0

104.0

SW98056

Additional space is required for paper replenishment and paper jam removal. Consider

mounting the printer on a movable platform so that the printer can be maintained outside

the printer enclosure.

8 TTP 7000 Kiosk Printer – Technical Manual 0308

Page 9

3.1.1 Electrostatic discharges, and earth currents

Preventing ESD and earth currents from affecting the printer operation requires proper

connection of the printer chassis to protective earth through a mounting platform or

through a separate earth conductor.

3.1.2 Ambient light

There is an optical sensor just inside the paper exit at the front of the printer.

To ensure proper printer operation, design the printer enclosure so that it prevents direct

sunlight or light from indoor lamps from reaching the sensor through the paper exit.

3.2 Connecting to the computer

3.2.1 Using the parallel interface

Connect the printer to the parallel port of the computer to be used.

Connector J10 is an IEEE-1284 type C, 36-pole mini Centronics, with clip latches. See

Table 10 for pin assignment of J10.

Use only certified cables marked IEEE-1284. See page 77 for Swecoin ordering number.

You can also use commercially available cables such as AMP 158393-3.

Figure 4. IEEE-1284 cable with type A and type C connectors

0308 TTP 7000 Kiosk Printer – Technical Manual 9

Page 10

3.2.2 Using the USB interface1

Connect J13 of the printer to the USB port of the computer or the USB hub to be used.

USB connectors are recognized by the following symbol:

.

Connector J13 is a 4-pin USB type B connector. See Table 14 for pin assignment.

A suitable cable is available from Swecoin, see page 77 for ordering number. You can

also use commercially available cables such as AMP 621775-4.

Figure 5. USB cable with type A and type B connectors

3.2.3 Using a serial adapter

1. Loosen the control board module, see Control board, Removal on page 65.

2. Connect the serial adapter to J4 on the control board.

3. Fasten the control board module, see Control board, replacement on page 65.

4. Fasten the serial adapter with the two screws on the right hand side of the printer.

Connect a Swecoin serial cable, ordering No. 01659-000, between the printer and the

computer to be used. We strongly recommend using the Swecoin cable because many

incompatible cables are available.

SW98066

Figure 6. Fitting a serial adapter to the printer.

1

The USB interface was implemented in hardware revision B. You can see the hardware revision on the self-test printout.

10 TTP 7000 Kiosk Printer – Technical Manual 0308

Page 11

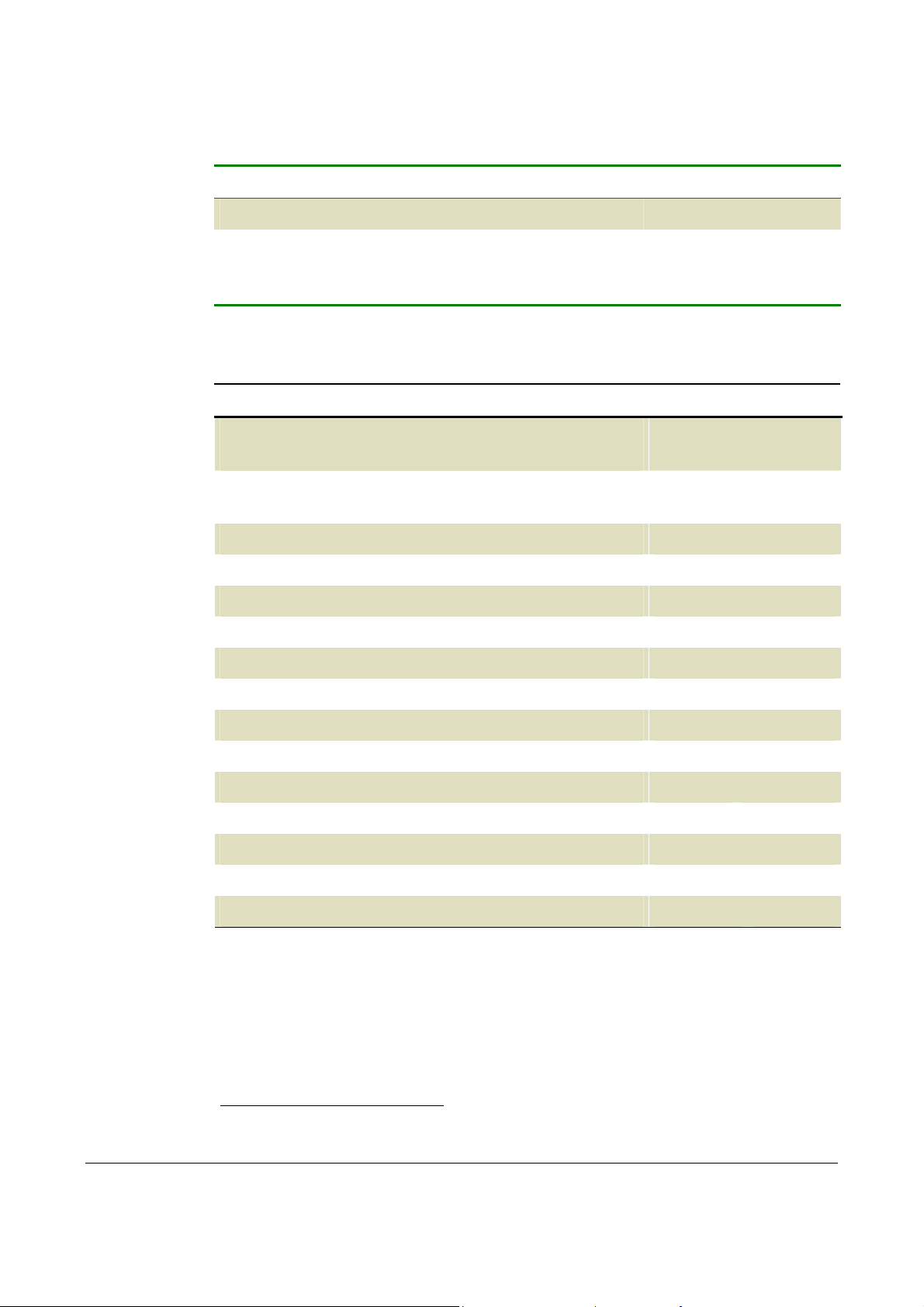

3.3 Connecting the power

Using the Swecoin power supply (see page 77 for ordering number):

1. Make sure the line voltage selector on the power supply is set to your local line

voltage.

2. Connect the cable from the power supply to J8.

3. Connect the power cable to the line outlet.

4. Turn ON the power supply.

If you use another type of power supply unit, connect the voltages according to the

following table. At the printer end of the cable, use an AMP Mate-N-Lok connector

housing and two contact-sockets:

Pin Function

1 +24 Vdc

2 GND

AMP No. 350777-1 AMP No. 350689-1

Table 1. Power connection

80 mm paper width 112 mm paper width

Idle 150 mA 150 mA

Standard text printing 2.5 A average 3.5 A average

All black printing 8.5 A 11 A

Table 2. Current consumption

3.4 Making a test printout

You can make a self-test printout if you want to verify that the printer operates correctly.

See " Self-test printout" on page 17.

0308 TTP 7000 Kiosk Printer – Technical Manual 11

Page 12

3.5 Installing a printer driver

Printer drivers for most versions of Microsoft Windows™, Macintosh and Linux are

available on the Swecoin web site http://www.swecoin.se, or on diskette from Swecoin.

See page 2 for address, and page 77 for ordering number. Please follow the installation

instructions that accompany the drivers.

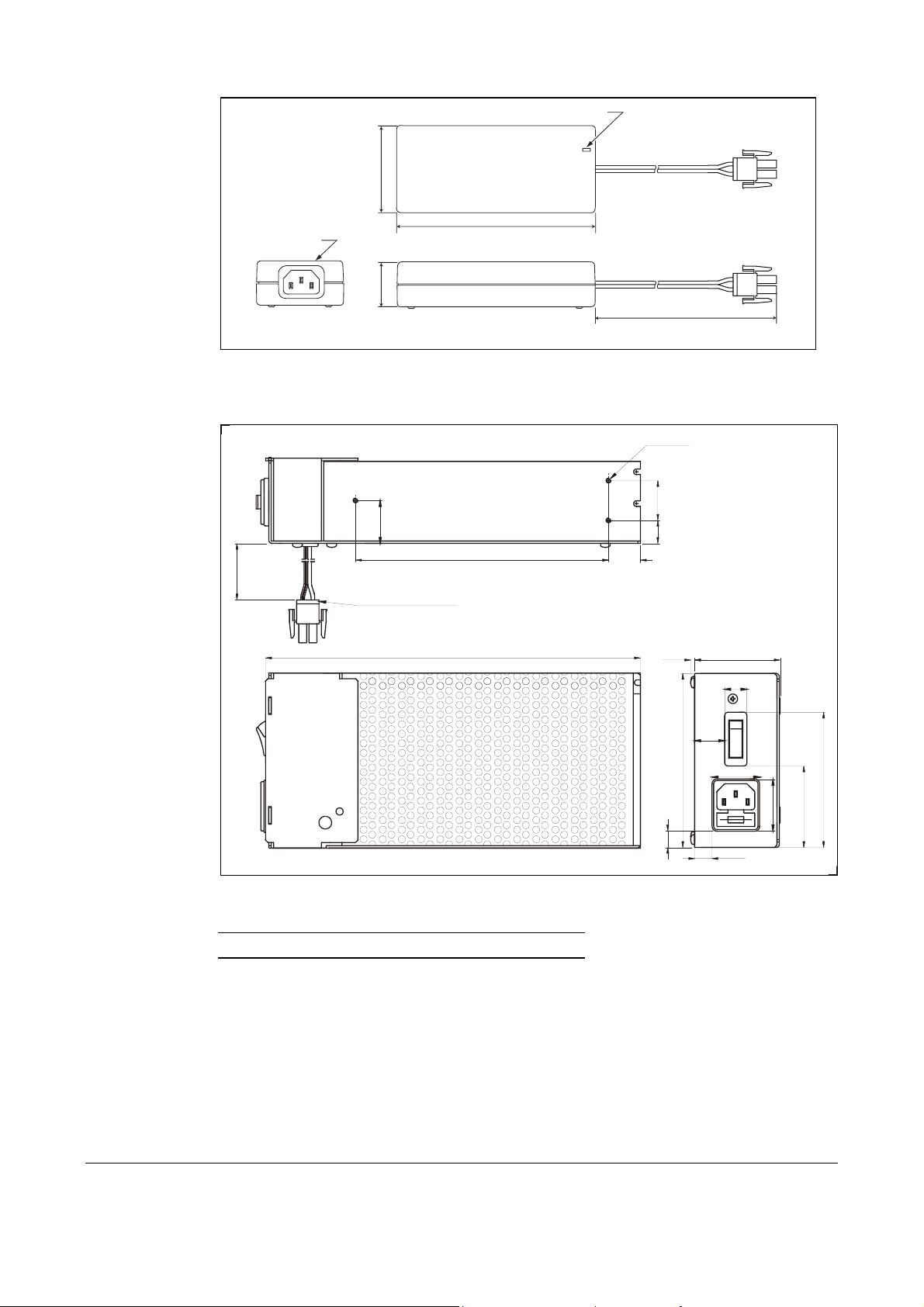

3.6 Paper level sensors

The printer has inputs for one paper-near-end sensor, and one weekend sensor.

Optical weekend sensor.

Lock screw

Adjustment range equals

approximately 30 to 150 m

of paper

SENSOR

+5V

OUT

GND

Optical paper-near-end

sensor. Activated when a

couple of meters of paper

SENSOR

+5V

OUT

GND

20-60 mm

remains.

25.7

SW98052

Figure 7. Sensors on 200 mm roll holder

The paper-near-end sensor alerts the system when a couple of meters of paper remain

on the roll. The purpose of this sensor is to get an early alert so that you can replace the

paper roll in time in remotely located kiosks.

The weekend sensor should alert when the remaining paper does not last over a

weekend. A reason to use this sensor is that it is more expensive to get a serviceman out

in a weekend or holiday, than it is to replace the roll before it is totally empty.

The Swecoin 110 mm and 150 mm paper roll holders are equipped with paper-near-end

sensors, while the 200 mm roll holders have both paper-near-end and weekend sensors.

When installing the Swecoin roll holder just connect the cable from the roll holder to

connector J1 at the back of the printer. See Figure 2 on page 6.

If you use custom designed roll holders, connect the sensors according to Figure 8

12 TTP 7000 Kiosk Printer – Technical Manual 0308

Page 13

+5 V

Near

end

Roll holder shaft

Ω

Weekend sensor

Sharp GP2S40

Sharp GP2S40

1

2

3

4

5

6

J1

200

Gray

Blue

Green

Red

Black

Green

Paper-nearend sensor

2

4

1

6

3

5

Figure 8. Paper-near-end sensor connection

Ω

47 k

Ω

Ω

47 k

200

WE SENSE

PL SENSE

8

0

0

-

0

3

0

3

4

x

e

l

o

M

x

e

0

l

0

o

6

M

0

-

5

2

0

3

4

SW97081D

0308 TTP 7000 Kiosk Printer – Technical Manual 13

Page 14

4 OPERATION

4.1 Installing a paper roll

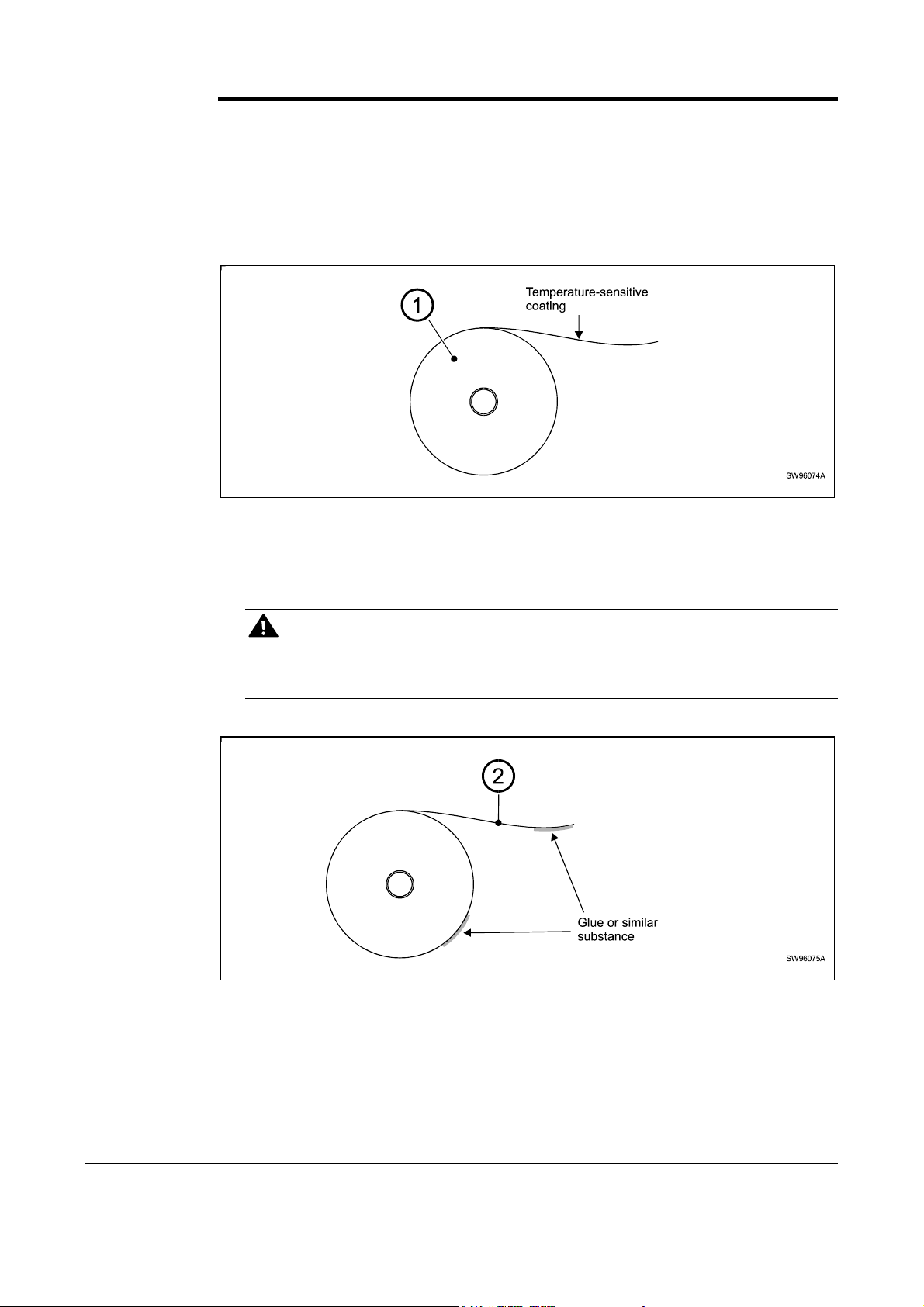

1. Turn the new paper roll as shown. The paper should be inserted into the printer with

the temperature-sensitive side up.

Figure 9. Turn the paper roll so that the paper leaves the roll from the top

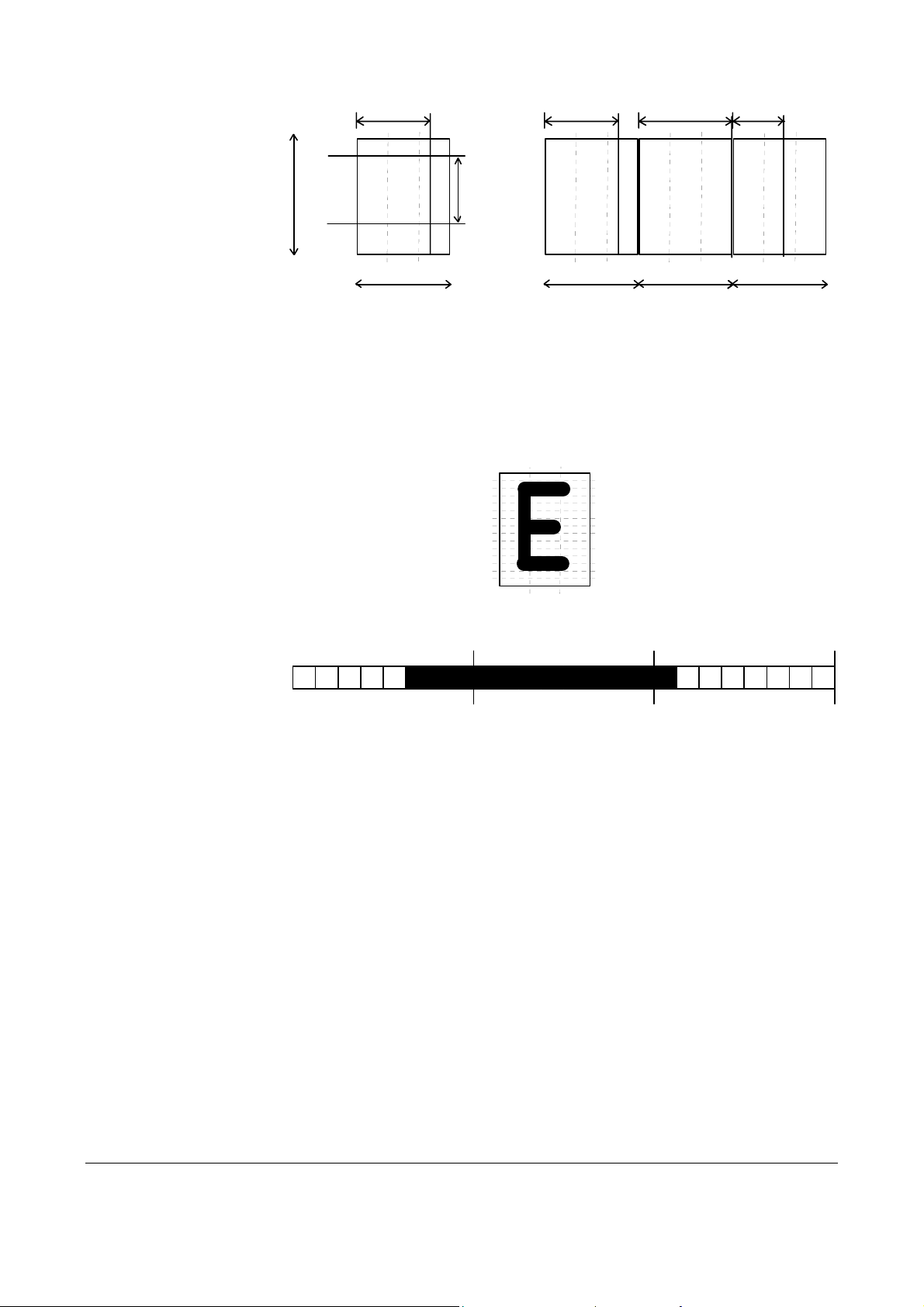

2. Tear off a full turn of the paper (approximately 0.5 m) from the new paper roll.

CAUTION!

This is important since the outer end of the paper is usually fixed to the roll with some

type of glue or self-adhesive substance that might otherwise cause paper jam or even

printhead damage.

Figure 10. Tear off 0.5 m from the new paper roll

3. Make sure the printer is turned ON.

14 TTP 7000 Kiosk Printer – Technical Manual 0308

Page 15

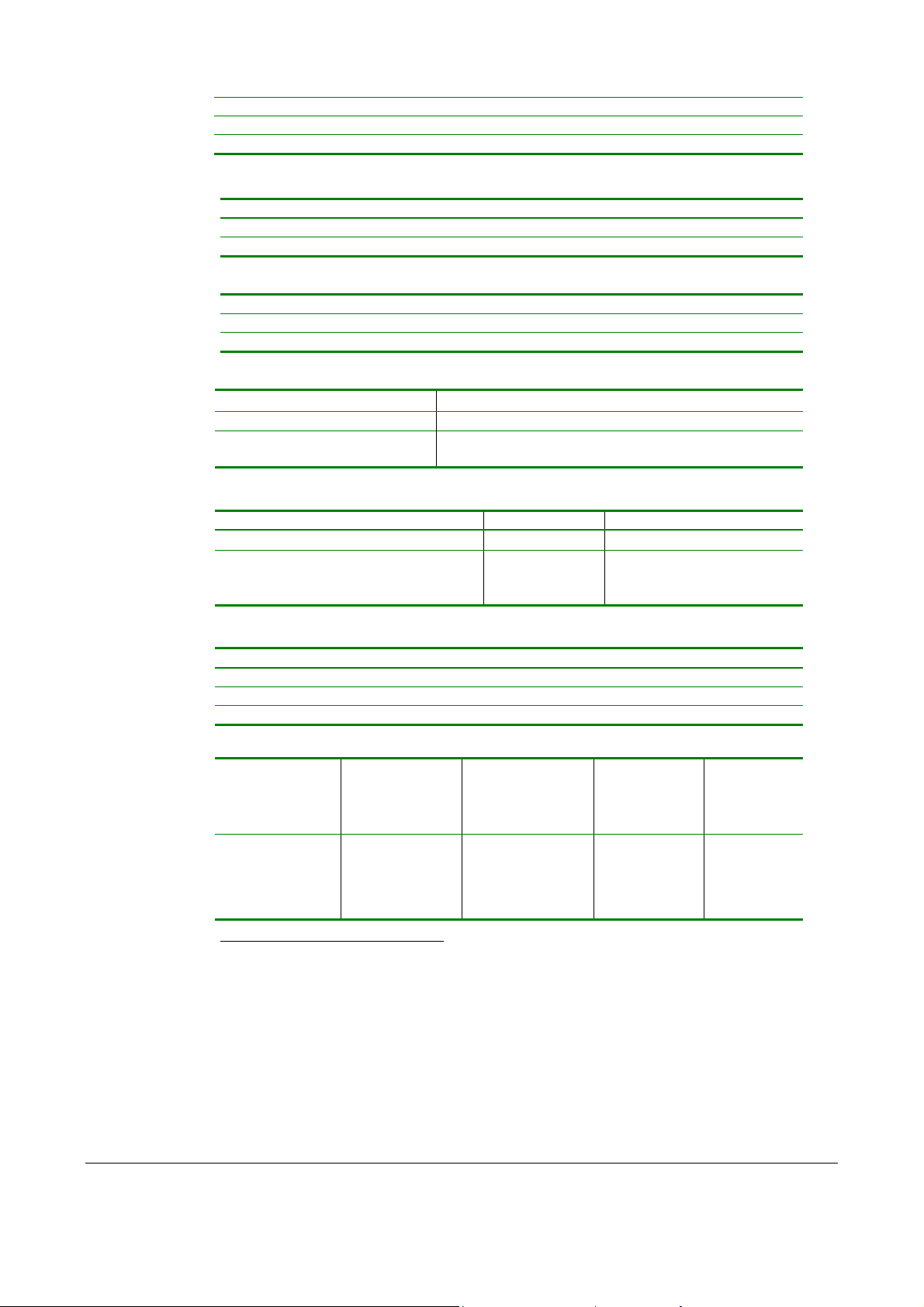

4. Cut the paper in a suitable angle:

90

(Front Surface) (Front Surface)

To

70

Figure 11. Suitable paper edge for auto load

NOTE 1! — The paper sensor is at the same side as the blue paper release lever (where

the arrow points in Figure 12). If the paper is cut in a direction opposite to that as shown

in the figure above, the sensor will not detect the paper.

5. Insert the paper through the paper entry opening at the back of the printer. The

printer will now feed, cut and eject a receipt, and then automatically go on-line. 1

NOTE 2! — In high temperature and high humidity, the paper may lose its stiffness

resulting in paper jam at automatic paper loading. In such cases, load paper manually.

Figure 12. Insert the new paper

1

TTP 7000/112 was designed for manual paper loading. A modification of the control board is required for auto loading. Such

modification was introduced mid 2003. Auto loading was improved in firmware version 2.37 (see version history).

0308 TTP 7000 Kiosk Printer – Technical Manual 15

Page 16

4.2 Clearing paper jams

Should a paper jam occur, follow the procedure below:

1. Tear off the paper close to the paper roll and flip back the print module.

Figure 13. Flip open the print module

2. Lift the printhead by pushing the paper release lever upwards.

3. Remove any paper trash by gently pulling the paper up and out of the print module.

CAUTION! — Never

pull paper backwards through the print mechanism.

This may destroy the print module

Figure 14. Remove paper trash

16 TTP 7000 Kiosk Printer – Technical Manual 0309

Page 17

4.3 Self-test printout

1. Switch OFF the power.

2. Hold the feed-forward button depressed while powering ON the printer. Keep the

button depressed for at least 5 seconds.

This produces a printout showing the firmware program version and date, control board

revision number and serial number, name of loaded fonts and logotypes, parameter

settings, and the set printhead burn.

3. Each successive press of the button will produce a test printout.

4. Switch the printer OFF and ON again to exit self-test mode.

0308 TTP 7000 Kiosk Printer – Technical Manual 17

Page 18

5 PROGRAMMING

There are two completely different ways of setting up the receipt: Text oriented and driver

oriented style.

Text oriented

The receipt can be seen as the page of a simple word processor. You send text and

graphics to the printer, which prints the information in the same sequence as the data is

received. Design features are limited to the font stored in the flash PROM of the printer.

Text and logotypes can also be printed landscape orientation.

There are two text cursors, one for portrait, and one for landscape. The start positions of

the cursors are the upper left corner for the portrait cursor, and the upper left corner for

the landscape cursor, see Figure 15. You can switch between these cursors at any time,

the cursor will retain its last position on the ticket.

Driver oriented

When a Windows driver is used, you can use any Windows program to design the ticket

with text, graphics, bar codes or whatever you want to print and in any orientation you

want.

The Windows driver issues all the necessary commands. Only the cut-and-present and

black-mark commands need to be specified by the programmer.

Tex t r ec ei p t

Tex t

text

text

text text text text

text text text text

text text text text text text text text text text

text text text

text text text text text text text text text text

Text text text text text text text text text text

Driver (Windows) receipt

1 234567 890128

Text text

text text

text text

text text

text text

Text text text text text text text text text text

Bar codes can be added.

Text can be printed in

any orientation, font,

and size.

Lines can be added.

Graphics can be rotated,

color images converted

to gray scale, etc.

Sw98073

Figure 15. Ticket styles

18 TTP 7000 Kiosk Printer – Technical Manual 0308

Page 19

5.1 Summary of control codes & escape sequences

Command Hex Decimal Function Page

BS 08 008 Backspace

CAN 18 024 Cancel

CR 0D 013 Carriage return

EM 19 025 Enforced clear presenter

ENQ 05 005 Clear presenter

ESC ACK n 1B 06 n 027 006 Set acknowledge marker

ESC ! n 1B 21 n 027 033 Select font

ESC & 1 1B 26 01 027 038 001 Load logotype into flash PROM

ESC & 4 1B 26 04 027 038 004 Store current parameter values

in flash PROM

ESC & C 1B 26 43 027 038 067 Erase all fonts

ESC & D 1B 26 44 027 038 068 Erase fonts 4—7

ESC & L 1B 26 4C 027 038 076 Erase all logotypes

ESC & P n v 1B 26 50 n v 027 038 080 n v Set parameter values

ESC & NUL 1B 26 00 027 038 000 Load font

ESC ? 1B 3F 027 063 Reset (full)

26

36

27

34

34

42

29

36

36

37

37

36

37

36

36

ESC @ 1B 40 027 064 Reset (initialize)

ESC 3 n 1B 33 n 027 051 Line spacing

ESC b 0 x1 x2 y1 y2

ESC B n 1B 42 n 027 066 n Bold ON/OFF

ESC c n 1B 63 n 027 099 n Variable page length ON/OFF

ESC C n1 n2 1B 43 n1n2 027 067 n1 n2 Page length

ESC d n 1B 64 n 027 100 n Make n line feeds

ESC ENQ 01 1B 05 01 027 005 001 Status enquiry, general

ESC ENQ 02 1B 05 02 027 005 002 Paper-near-end enquiry

ESC ENQ 04 1B 05 04 027 005 004 Fonts and logotype enquiry

ESC ENQ 06 1B 05 06 027 005 006 Status report

ESC ENQ 07 1B 05 07 027 005 007 Firmware version enquiry

ESC ENQ 09 1B 05 09 027 005 009 Serial number enquiry

ESC ENQ 10 1B 05 0A 027 005 010 Control board revision enquiry

ESC ENQ 99 1B 05 63 027 005 099 Request device ID

ESC ENQ P 1B 05 50 027 005 080 Parameter setting data enquiry

1B 62 n… 027 098 n… Print bitmap at XY position

36

27

31

25

22

21

27

38

39

39

40

40

41

41

41

41

ESC f n 1B 66 n 027 102 n Presenter loop ON/OFF/length

0308 TTP 7000 Kiosk Printer – Technical Manual 19

35

Page 20

Command Hex Decimal Function Page

ESC F n1..nx NUL 1B 46 n1...nx 00 027 070 n...nx 000 Set horizontal tabs

ESC FF n 1B 0C n 027 012 n Eject (run presenter)

ESC g n1 n2 n3 n4 n5 1B 67 n1...n5 027 103 n1...n5 Print logotype at specified X, Y

ESC h n 1B 68 n 027 104 n Set multiple-height print

ESC i n 1B 69 n 027 105 n Italics ON/OFF

ESC J n 1B 4A n 027 074 n Paper advance

ESC j n 1B 6A n 027 106 n Paper reverse

ESC L n 1B 4C n 027 76 n Print logotype at current position

ESC M n1 n2 1B 4D n1n2 027 077 n1 n2 Black mark definition

ESC N n 1B 4E n 027 078 n Text alignment

ESC NUL 1B 00 027 000 Load firmware

ESC o n 1B 6F 027 111 Text and logotype orientation

ESC p 1B 70 027 112 Print

ESC q n 1B 71 n 027 113 n Print contrast adjustment

ESC RS 1B 1E 027 030 Cut only, no eject

28

34

32

29

25

32

32

33

23

24

37

24

32

33

34

ESC s n 1B 73 n 027 115 n Send dot line

ESC S n1 n2 1B 53 n1 n2 027 083 n1 n2 Send graphics data

ESC T n 1B 54 n 027 084 n Reversed text ON/OFF

ESC u n 1B 75 n 027 117 n Underline ON/OFF

ESC w n 1B 77 n 027 119 n Set multiple-width print

ESC V n 1B 56 n 027 086 n Print speed adjustment

ESC X n1 n2 1B 58 n1 n2 027 088 n1 n2 Sense black-mark position

ESC x n1 n2 1B 78 n1 n2 027 120 n1 n2 Set internal black-mark counter

ESC Z 1B 5A 027 090 Go to next top of form

FF 0C 012 Form feed

HT 09 009 Horizontal tabulation

LF 0A 010 Linefeed

RS 1E 030 Cut and eject paper

Table 3. Control codes & escape sequences in alphabetical order

31

31

29

29

29

32

23

23

23

28

28

27

34

NOTE! – In all responses from the printer the most

significant byte (MSB) is transmitted first.

20 TTP 7000 Kiosk Printer – Technical Manual 0308

Page 21

5.2 Software command syntax

The commands in this section are grouped after what they do, and these groups are

sorted in a theoretical usage sequence. It starts with commands for specifying the printed

page — through text-and-graphics commands — to cut-and-present commands. System

and status commands are presented at the end.

5.2.1 Page setup commands

ESC C n1 n2

1B 43 n1 n2 hex

027 067 n1 n2 decimal

NOTE! — Use this command only when you want a fixed page

length. Shorter tickets will automatically be extended, while longer

tickets will be divided into several tickets of the desired length.

Set fixed page length

Top margin (Distance between cut and print line, 17 mm)

Page length

(minimum 75 mm)

Page width =

applicable print

window width

TEXT

Text text

Paper transport

direction

TEXT

Text text

SW97063-R2

Figure 16. Definition of page size

Sets the fixed page length expressed as a number of 0.125-mm pixel line-feeds. Form

feed is effected with the FF command.

NOTE! — Do not use fixed page length less than 75 mm (n1 = 2, n2 = 88)

• The ESC C n1 n2 setting applies unless superseded by command ESC c n that

enables the variable page length.

• Fixed page length settings, shorter than the minimum page length as defined by

default parameter settings, will automatically be adjusted to the default value.

NOTE! — To enable fixed page length you must also use ESC c 0,

see next page

0308 TTP 7000 Kiosk Printer – Technical Manual 21

Page 22

Example:

Length Command n1 n2 Length Command n1 n2

ESC c n

1B 63 n hex

027 099 n decimal

n = 0 OFF. Automatic form feed if the printed page length exceeds the

75 mm ESC C <002> <088>

80 mm ESC C <002> <128>

85 mm ESC C <002> <168>

90 mm ESC C <002> <208>

95 mm ESC C <002> <248>

100 mm ESC C <003> <032>

105 mm ESC C <003> <072>

110 mm ESC C <003> <112>

115 mm ESC C <003> <152>

120 mm ESC C <003> <192>

125 mm ESC C <003> <232>

130 mm ESC C <004> <016>

135 mm ESC C <004> <056>

140 mm ESC C <004> <096>

145 mm ESC C <004> <136>

150 mm ESC C <004> <176>

Table 4. Example of page length commands

Variable page length ON /OFF

length set by

ESC C n1 n2.

155 mm ESC C <004> <216>

160 mm ESC C <005> <000>

165 mm ESC C <005> <040>

170 mm ESC C <005> <080>

175 mm ESC C <005> <120>

180 mm ESC C <005> <160>

185 mm ESC C <005> <200>

190 mm ESC C <005> <240>

195 mm ESC C <006> <024>

200 mm ESC C <006> <064>

205 mm ESC C <006> <104>

210 mm ESC C <006> <144>

215 mm ESC C <006> <184>

220 mm ESC C <006> <224>

225 mm ESC C <007> <008>

230 mm ESC C <007> <048>

n = 1 ON. Selects continuous print mode (no auto FF). See also “Default

parameter settings”.

22 TTP 7000 Kiosk Printer – Technical Manual 0308

Page 23

5.2.2 Black-mark (top-of-form) commands

See also Aligning preprint and thermal print on page 52.

ESC M n1 n2

1B 4D n1 n2 hex

027 077 n1 n2 decimal

This command specifies maximum (n1) and minimum (n2) length (in transport direction)

of the black mark printed on the reverse side of the paper. The black-mark identifies the

top of the next form (document). The length of the mark is expressed in pixel lines of

0.125-mm height.

Active transition is from ”black” to ”white” (trailing edge of black-mark)

n1 Maximum valid value is 160 pixel lines (20.0 mm). Marks longer than this

n2 Minimum valid value is 15 pixel lines (1.9 mm). Marks shorter than this value

ESC X n1 n2

1B 58 n1 n2 hex

027 088 n1 n2 decimal

Looks for a black mark within the distance (paper transport) specified by n1n2, starting at

the current position.

n1n2 Specifies the distance to be searched for black-mark. n1 is the higher-order

Black mark size

value is interpreted as paper out. Default value = 80 pixel lines (10.0 mm)

is interpreted as dirt. Default value = 24 pixel lines (3.0 mm)

Locate black mark

and n2 the lower-order byte. The distance is to be expressed as a number of

0.125-mm steps.

The printer adds an error code in the status report (error, top of form, byte 1,

bit 3) if no black-mark is found within the specified distance.

ESC x n1 n2

1B 78 n1 n2 hex

027 120 n1 n2 decimal

ESC Z

1B 5A hex

027 090 decimal

Delay cut after black mark detection

n1n2 Sets the number of 0.125-mm steps to feed between the black mark

detection and the cut. n1 is the higher-order and n2 the lower-order byte.

At completed printout, an

ESC Z command effects paper feed until a black mark is

detected, that is, when black-to-white transition is detected at the trailing edge of the

black mark. The paper feed then continues the number of steps specified by n1n2, at

which point the correct cut-position is assumed.

Go to next black mark

Executes the number of pixel line feeds as defined by command ESC x n1 n2 minus

such pixel line feeds that have been effected after detection of black-mark.

NOTE! — If the black-mark has not passed the paper-out/blackmark sensor when the ESC Z is received, additional paper feed

(maximum 128 mm) takes place until a black-mark is detected.

0308 TTP 7000 Kiosk Printer – Technical Manual 23

Page 24

5.2.3 Text commands

Text received by the printer is printed with the currently selected font and font attributes.

Text exceeding the page width is wrapped with the line spacing selected.

ESC o n

1B 6F n hex

027 111 n decimal

Changes the orientation of text and logotypes.

n = 0 Gives portrait orientation

n = 1 Gives landscape orientation

Portrait and landscape can be mixes on the same receipt. There are two cursors, one for

portrait and one for landscape. The cursor always starts at the top left corner of the

document. Looking at the paper when it exits the printer, the portrait cursor is at the top

left corner of the receipt, moving to the right as text is typed, while the landscape cursor is

at the top right corner, moving downwards.

NOTE! — Landscape only works if fixed page length is used. Start a

page by specifying page length for example <ESC>C<003><032>,

then turn off auto page length with <ESC>c<000>

NOTE! — ESC o <001> and ESC o <000> must be on separate lines

(separated by a linefeed <LF>).

ESC N n

1B 4E n hex

027 078 n decimal

Changes the alignment of text and logotypes.

Text and logotype orientation

Text alignment

ESC N 0= Left ESC N 1 = Center ESC N 2 = Right

ESC ! n

1B 21 n hex

027 033 n decimal

This command selects one of eight fonts. The font design depends on which fonts have

been loaded

1

into the printer. Make a test printout to see which fonts are available in your

printer.

ESC ! 0 selects normal font (font 0) ESC ! 4 selects font 4

ESC ! 1 selects font 1 ESC ! 5 selects font 5

ESC ! 2

ESC ! 3 selects font 3 ESC ! 7 selects font 7

selects font 2 ESC ! 6 selects font 6

Lines, too long to be printed in the selected font, are automatically wrapped around.

Different fonts can be used on the same line.

1

For font loading, see " " on page 36 System related commands

Select font

Table 5. Font selection commands

24 TTP 7000 Kiosk Printer – Technical Manual 0308

Page 25

Selection of an erased or for any other reason non-existent font, will set bit 4 of byte 1 in

the status enquiry response to ”1". See “Parameter setting data enquiry” on page 41.

NOTE! — If more than 256 characters are sent to the printer before an LF,

the first part of the buffer contents is printed-out automatically. The text is

formatted according to the already received formatting commands.

ESC B n

1B 42 n hex

027 66 n decimal

ESC i n

1B 69 n Hex

027 105 n decimal

ESC T n

1B 54 n hex

027 084 n decimal

ESC u n

1B 75 n hex

027 117 n decimal

Bold Normal Bold

n = 0 Turns OFF bold (Normal)

n = 1 Turns ON bold

Bold is designed for normal character width and shows less and less as the width

increases.

Italics Normal Italics

n = 0 Turns OFF Italics (Normal)

n = 1 Turns ON Italics

Reversed print ON/OFF

Selects normal or reversed print.

n = 0 Gives normal print, black on white

n = 1 Gives reversed print, white on black

Single words, characters, or complete text lines can be reversed.

Underline

n = 0 Turns OFF underline

n = 1 Turns ON a 1 pixel wide underline

n = 2 Turns ON a 2 pixel wide underline, etc. up to n=7.

Single words, characters, or complete text lines can be underlined.

0308 TTP 7000 Kiosk Printer – Technical Manual 25

Page 26

ESC h n

1B 68 n hex

027 104 n decimal

Applicable n values are 000 — 015.

n = 1 Increases the character height to 2 times the basic character height.

n = 2 Increases the character height to 3 times the basic character height etc.

n = 0 Resets the character height to the basic character height.

In combination with variable character width (

depending on the font to which the command has been applied.

Different fonts and heights can be mixed on the same print line.

ESC w n

1B 77 n hex

027 119 n decimal

Applicable n values are 000 — 007.

n = 1 Increases the character width to 2 times the basic character width.

n = 2 Increases the character width to 3 times the basic character width etc.

n = 0 Resets the character width to the basic character width.

In combination with variable character height (

depending on the font to which the command has been applied.

Set multiple-height print

ESC w n), give highly legible characters

Set multiple-width print

ESC h n), give highly legible characters

Different fonts and widths can be mixed on the same print line.

ESC t n1 n2 n3 n4 n5 data

1B 74 n1 n2 n3 n4 n5 data hex

027 116 n1 n2 n3 n4 n5 data decimal

Prints a text string at the specified X-Y position. The string will use the formatting set by

font, reversed, width, height, bold and underline commands.

n1n2 Two byte definition of the X print position (in pixels).

n3n4 Two byte definition of the Y print position (in pixels).

n5 The number of characters in the string.

data The text string. The length must be exactly the number of characters specified by

n5, otherwise the printer will stop, waiting for more characters.

After the string has been printed, the cursor will return to the position it had before the

string command was issued.

NOTE! — The Y print-position only works if fixed page length is used.

Start a page by specifying page length for example

<ESC>C<003><032>, then turn off auto page length with <ESC>c<000>

BS

05 hex

005 decimal

Moves the print-position one step to the left. Backspace can be used to combine

characters. For instance to print a Ø, send text commands O BS / to the printer, and the

slash will overprint the O.

Print text string

Back Space

Only one backspace can be used at a time. Excessive backspaces will be ignored.

26 TTP 7000 Kiosk Printer – Technical Manual 0308

Page 27

CAN

18 hex

024 decimal

CR

0D hex

013 decimal

LF

0A hex

010 decimal

Cancel

Cancels print data on the same line as the command itself. ESC commands, issued on

the same line as the CAN command, are not cancelled.

Carriage Return

Carriage return is ignored by default.

By changing the default settings, you can:

• Interpret is as

• Interpret

(see command

CR. This returns print position to beginning of line without line feed.

CR as CR/LF. This inserts line space as specified by the line spacing setting

ESC 3 n on page 27), and returns the print position to beginning of

the line.

See “Carriage return and line feed behavior ” on page 48.

Linefeed

Linefeed is interpreted as CR/LF by default. This inserts line spaces as specified by the

line spacing setting (see command

beginning of the line.

ESC 3 n on page 27), and returns the print position to

By changing the default settings, you can:

• Interpret

• Ignore

See “Carriage return and line feed behavior ” on page 48.

ESC d n

1B 64 n hex

027 100 n decimal

Executes the number of linefeeds as defined by variable n. The length of each line feed is

determined by.

• the default value for selected font (see command

• the line setting effected by command ESC 3 n, (n = ”0” gives no line feed)

The print position is returned to the beginning of the line. Any text on the line is lost. To

avoid loosing text, send an LF before sending ESC d n.

ESC 3 n

1B 33 n hex

027 051 n decimal

This command is used to increase the line spacing. The entered value n is the absolute

line spacing expressed as a number of pixel lines (0.125-mm increment). To increase the

line spacing to 5 mm, for example, enter value n = 40 (5 / 0.125 = 40).

LF as Linefeed. This inserts line space as specified by the line spacing

setting (see command

ESC 3 n on page 27), without returning the print position to

the beginning of the line.

LF.

Execute n linefeeds

ESC 3 n on page 27) or

Set line spacing

The command is ignored if “n” is less than the default line spacing of the selected font.

The default line spacing is directly related to the size of the selected font.

0308 TTP 7000 Kiosk Printer – Technical Manual 27

Page 28

Examples: 10 cpi 30 pixels = 3.75 mm 15 cpi 20 pixels = 2.5 mm

12 cpi 24 pixels = 3.0 mm 17 cpi 18 pixels = 2.25 mm

Double-height text on a line will double the line spacing for the entire line.

FF

0C hex

012 decimal

HT

09 hex

009 decimal

Form Feed

Prints data from the input buffer and feeds the paper to the top of the next page.

• In fixed document length (FORM-mode) this command prints data in the input buffer

and feeds the paper to the top of next page.

• In variable document length mode this command acts as

• In black-mark mode, the printer interprets incoming

CR/LF.

FF commands as ESC X 08 00

If Autocut at FF is set to 1 (in start-up parameter setting ESC & P n34), FF effect both

form-feed, cut, and eject.

NOTE! — Use

ESC C n1 n2 to define page length.

Horizontal Tabulation

Shifts the current print position to the next Tab position.

Set tab positions with the ESC F n1....nx command on page 28.

ESC F n1 ... nx NUL

1B 46 n1 ... nx 00 hex

027 70 n1 ... nx 000 decimal

This command defines the desired horizontal tab positions. Variables n1...nx represent

each tab position. Up to 16 tab positions are allowed. Minimum allowed value is “1”.

Tab position 255 sets a tab stop on the last position of the line. Use this if you want

underline or reversed text to extend across the full paper width.

Note that the tab positions are always expressed in number of 2.5-mm steps.

n = 1 Means 2.5 mm from the left-hand edge of the print window.

EXAMPLE

Send→ ESC F 005 010 015 020 025 000

Sets tab stops at 12.5, 25, 37.5, 50, and 62.5 mm.

NOTE! — Do not use value n = 0. The values must

be sorted from low to high numbers.

Set horizontal tabs

28 TTP 7000 Kiosk Printer – Technical Manual 0308

Page 29

5.2.4 Barcode commands1

ESC BC n

1B 42 43 n hex

027 067 068 n decimal

Clears the bar code field reserved by command ESC BS.

n Specifies which bar code field to clear. The range is 0 to 15. The fields may be

cleared in any order.

ESC BS n1 ... nx NUL

1B 42 53 n1 ... n11 00 hex

027 66 83 n1 ... n11 000 decimal

Bar codes can only be printed in portrait mode unless fixed page length is selected.

The command reserves an information field as a bar code field. The command also

identifies the type, number of digits, and the configuration of bars to be placed in the bar

code field.

n1 Specifies the bar code field No. (0—15). Bar code fields may be specified in any

order.

n2n3 Sets the X coordinate of the bar code field origin (n2 is the higher-order and n3

the lower-order byte).

n2 and n3 must be 1-byte hexadecimal or decimal numbers. The values must not

place the bar code outside the total pixel count that can be handled by the printer.

n4n5 Specifies the Y coordinate of the bar code field position, (n4 is the high, and n5

the lower-order byte).

Barcode Clear

Barcode field Specify

n4 and n5 must be 1-byte hexadecimal or decimal numbers.

n6 Specifies the number of bar code digits, but is ignored by the printer.

n7n8 Specifies the height of the bars.

n9 Specifies the type of bar code. The following types are supported.

n10 Specifies the thickness of the narrow bar 0=1 pixel, 1=2 pixel, and so on.

n11 Specifies the wide-bar-to-narrow-bar ratio. Only used in Code 39 and 2-of-5

ESC BW n1 nx

1B 42 57 n1 nx hex

027 066 087 n1 nx decimal

Writes data to the bar code field reserved by the ESC BS command.

1

Introduced in firmware version 2.31

n9 = 0 EAN 8 or 13 (auto detect). The printer calculates the necessary check

digit.

n9 = 1 UPC

b9 = 2 2/5 Interleaved (even number of characters must be sent)

n9 = 3 ISBN

n9 = 6 Code39

interleaved where different ratios are allowed.

Barcode Write

0308 TTP 7000 Kiosk Printer – Technical Manual 29

Page 30

n1 Specifies the field No. Range 0 to 15. Fields can be specified in any order

but other values than 0 to 15 are ignored.

n2 . . . nx Specifies bar code data bytes.

To create a bar code add-on, insert a space character and then the data for

the add-on.

NUL must be placed at the end of the bar code data.

Any invalid bar code character terminates the command.

5.2.5 Example:

<ESC>BS<h00><h00><h78><h00><h00><h0C><h00><h50><h00><h02><h00>«»

<ESC>BW<h00>733104000099<h00>«»

<RS>«»

Will print one barcode with height = 10 mm and moved 15 mm to the right

30 TTP 7000 Kiosk Printer – Technical Manual 0308

Page 31

5.2.6 Graphics commands

ESC S n1 n2 data

1B 53 n1 n2 data hex

027 083 n1 n2 data decimal

Sends bit image graphics data to the printer.

n1 and n2 High and low order byte. Determine the number of dot lines.

<data> If less data than specified is received, the printer may enter a wait state,

ESC s n

1B 73 n hex

027 115 n decimal

Sends one line of dot data. This command is used to build images, one dot line at a time.

n Determines the number of bytes.

<data> 1–72 bytes of data for 80 mm printer, 1–104 bytes for 112 mm printer

Send graphics data

expecting further data. The printer may handle subsequent character

code, or non-bit-image data, as bit-image data. The host computer must

therefore supply 72 x (n1n2) data bytes for the 80 mm printer, and

104 x (n1n2) data bytes for the 112 mm printer, that is, 72 alternatively

104 bytes per line times the number of dot lines to be printed.

Send dot line

• If less than 72 or 104 bytes are sent, the printer will fill the rest of the

dot line with spaces.

• If more than 72 or 104 bytes are received, the rest of the bytes are

ESC b n1 x1 x2 y1 y2 data

1B 62 n1 x1 x2 y1 y2 data hex

027 98 n1 x1 x2 y1 y2 data decimal

Prints a black & white Windows bitmap at the specified X-Y position. The bitmap must be

a complete Windows bitmap (BMP-file) where the data starts with BM.

n1 Always 0

x1x2 Two byte definition of the X print position (in pixels).

y1y2 Two byte definition of the Y print position (in pixels).

data Bitmap data.

After the bitmap has been printed, the cursor will return to the X-position that it had before

the bitmap command was issued.

Selecting horizontal mode (with ESC o 0) prints the image in portrait orientation, while

selecting the vertical mode (with ESC o 1) prints the image in landscape orientation.

NOTE! — The Y print-position and horizontal/vertical orientation only

works if fixed page length is used.

Start a page by specifying page length for example

<ESC>C<003><032>, then turn off auto page length with <ESC>c<000>

discarded.

Print bitmap image

0308 TTP 7000 Kiosk Printer – Technical Manual 31

Page 32

5.2.7 Print commands

ESC p

1B 70 hex

027 112 decimal

This command makes the printer print the contents of the line buffer.

Text is converted from text to pixel lines and stored in the line buffer when an LF is

received. If the line buffer is empty when ESC p is received, nothing is printed.

Text to be printed <LF><esc>p prints "Text to be printed" on the paper.

Printout is effected automatically at:

Cut (

Clear presenter (

Run presenter (

Print buffer full When print data for approximately 0.75 m receipt length has been

ESC J n

1B 4A n hex

027 074 n decimal

The value n represents the number of dot lines (0.125 mm) the paper is to be transported

forwards. Maximum value for n = 255, equal to approximately 32 mm.

Print

RS and ESC RS)

ENQ)

ESC FF n)

received (0.5 m for TTP 7000/112)

Paper advance

ESC j n

1B 6A n hex

027 106 n decimal

The value n represents the number of dot lines (0.125 mm) the paper is to be transported

backwards. Maximum value for n = 255, equal to approximately 32 mm.

ESC V n

1B 56 n hex

027 086 n decimal

n specifies the printing speed. The main reason to decrease the print speed

NOTE! — Some settings result in printer chassis resonance

causing excessive noise and deteriorated print quality.

mm/s

Paper reverse

Print speed adjustment

is to enhance print quality, and to reduce the peak current consumption.

n = 17 is default value (maximum speed)

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

n

13 21 27 32 37 41 45 48 52 55 57 60 63 66 68 71 73

Table 6. Print speed settings

75

32 TTP 7000 Kiosk Printer – Technical Manual 0308

Page 33

ESC q n

1B 71 n hex

027 113 n decimal

n = 0–15

This command adjusts the burn time to obtain the optimal print contrast with the paper

quality in use.

Each step n represents a pulse width adjustment of 5%. The actual burn time depends

on ambient temperature and heat built up in the head.

Example:

ESC q 0: 75% pulse width

ESC q 5: 100% pulse width (default)

ESC q 15: 150% pulse width

At power ON, the contrast is set to the value stored as default parameter. See page 47.

ESC L n

1B 4C n Hex

027 076 n Decimal

Prints a customized logotype1 stored in the flash PROM at the position of the cursor. The

bottom line of the logotype is positioned at the baseline of the text on the line. If the

logotype is higher than the text, the line spacing is increased.

Print contrast adjustment

Print logotype at current cursor position

See also Logotypes on page 45.

n One-byte logotype identification No. (0—15)

ESC g n1 ... N

1B 67 n1 ... N5 hex

027 103 n1 ... N5 decimal

5

Prints a customized logotype1 stored in the flash PROM. See also Logotypes on page 45.

n1 One-byte logotype identification No. (0—15)

n2n3 Two-byte definition of desired print position in X-direction (expressed in

n4n5 Two-byte definition of desired print position in Y-direction expressed in pixels

Print logotype at specified X–Y

pixels) measured from left-hand edge of the page (see page 21 regarding

definition of ”page”). X-direction is perpendicular to the paper transport

direction.

from top of the page.

These bytes must always be inserted but they are ignored in variable-

page-length mode where logotypes are always printed at the current Yposition.

1

For logotype loading, see " " on page 36 System related commands

0308 TTP 7000 Kiosk Printer – Technical Manual 33

Page 34

5.2.8 Cut and present commands

RS

1E hex

030 decimal

Effects a paper cut-off and a default-length eject through the presenter module.

If the receipt length is too short, paper-feed is added until the 75-mm minimum receipt

length is reached, before execution of the Cut command.

ESC RS

1B 1E hex

027 030 decimal

Effects paper cut-off only.

Eject can be effected with the

If the receipt length is too short, paper-feed is added until the 75-mm minimum receipt

length is reached, before execution of the Cut command.

ESC FF n

1B 0C n hex

027 012 n decimal

ESC FF ejects the document through the presenter module. Variable n represents the

number of eject-steps.

One step is approximately 2 mm

The maximum number of steps is 255

Normally, this command is placed after a cut command (

receipt to the customer. Set the number of eject steps so that a small part of the receipt is

retained in the presenter module, avoiding that the receipt drops to the floor.

Cut and eject receipt (record separate)

Cut only, no eject

ESC FF n command (see page 34).

Eject (run presenter)

ESC RS) to partially eject the

ENQ

05 hex

005 decimal

EM

19 Hex

025 Decimal

Another use of the command is to eject a part of a long document without preceding cut.

The reason to do this is to limit the size of the loop build-up in the presenter.

NOTE! – The loop is limited to the value set by

ESC f n to avoid paper

jam. The default setting of n=18, gives a loop of just above 0.5 m. When

this length has been looped, the printer presents that part of the receipt.

Then, without cutting the paper, it continues to print the rest of the

receipt.

Clear presenter

Clears the paper path in the presenter, for example, to eject a document not removed

during the previous print/cut/eject operation.

Enforced Clear Presenter

Same function as ENQ but overrides the Retract and Retain parameter (p45) with another

presenter behavior. The function of n can be 0 or 100 (se the description of parameter

45). The command will clear the presenter immediately (with printing synchronization).

34 TTP 7000 Kiosk Printer – Technical Manual 0308

Page 35

ESC f n

1B 66 n hex

027 102 n decimal

Presenter loop ON/OFF/max length

n = 0 Presenter sensor is ignored. The paper is fed straight through the presenter.

range 0 and 3 to 255. n = the loop length limit in 3.2 cm steps.

If the receipt length exceeds the max loop limit, it is partially ejected before the

printer continues.

n = 18 Default setting which gives a loop of just above 0.5 m.

Can be turned ON/OFF at any time during an operation.

0308 TTP 7000 Kiosk Printer – Technical Manual 35

Page 36

5.2.9 System related commands

ESC ?

1B 3F hex

027 063 decimal

ESC @

1B 40 hex

027 064 decimal

ESC & 1

1B 26 01 hex

027 038 001 decimal

ESC & L

1B 26 4C hex

027 038 076 decimal

Reset (full)

Restarts the printer with a complete reset.

Reset (initialize)

Terminates the processing and initializes the control board. The control board is reset to

default-values (same as after power ON). Do not use this command as part of a print data

command string.

Load logotype

Stores a logotype bitmap in the flash PROM. The logotype is printed with the ESC g

command, see page 32. Also see Logotypes on page 45.

Erase all logotypes

Erases all logotypes stored in the flash PROM.

NOTE! — This command is only executed if all these conditions are met:

• At least one logotype has been loaded

• Status inquiry response byte 1, bit 5, ”Power has been OFF” is set to ”1”

• No

ESC & 4

1B 26 04 hex

027 038 004 decimal

Stores all parameter values, currently in use in the printer, as permanent default

parameter values in the flash PROM. This takes approximately 15 seconds. The printer

then resets automatically and activates the presenter motor temporarily.

See also

ESC & NUL

1B 26 00 hex

027 038 000 decimal

This command is used to load a font to the printer flash PROM. The font is placed in the

first free address position in the order of load sequence.

A Swecoin font-file consists of a header containing data describing the font as well as

data for each individual character in the font.

ESC ENQ 6 command has been received

Store current parameter values in flash PROM

ESC & P (Set temporary default parameters) on page 37.

Load font

1

1

When parallel cable is connected, both printer and host computer must have

been off to set this bit. This is because the interface powers the RAM in the

printer.

36 TTP 7000 Kiosk Printer – Technical Manual 0308

Page 37

Fonts can be designed with the font editor and loaded or deleted with the software

available for free on the Swecoin web site. The font loading and deleting commands

described here should only be used if you do not work in the Windows environment.

For complete specification of the font format, see Font loading on page 43.

NOTE! 256 Kbytes are available for font storage. A maximum of 8 fonts can be

addressed. Exceeding any of these limits will cause this command to fail.

ESC & C

1B 26 43 hex

027 038 067 decimal

Erases all fonts stored in the flash PROM.

NOTE! — This command is only executed if all these conditions are met:

• At least one font has been loaded

• Status inquiry response byte 1, bit 5, ”Power has been OFF” is set to ”1”

• No

ESC & D

1B 26 44 hex

027 038 068 decimal

Erases fonts number 4–7. Fonts 0–3 are not affected by this command.

The operation is complete when the printer resets automatically and activates the

presenter motor temporarily. Takes approximately 15 seconds.

ESC & P n v

1B 26 50 n v hex

027 038 080 n v decimal

A number of bytes in the flash PROM hold various parameter values called default

parameters. One or several of them can be overridden temporarily with this command.

Erase all fonts

ESC ENQ 6 command has been received

Erase fonts 4–7

Set temporary default parameters

n Parameter number

v Parameter value.

See Default parameter setting on page 47.

The permanently stored parameters will be used again after a printer-reset command or

at power ON.

The temporary values can, however, be stored in the flash PROM as permanent values

with command

ESC & 4.

ESC NUL

1B 00 hex

027 000 decimal

Load firmware

This command should only be used when loading new firmware into the printer. See also

Firmware on page 67.

0308 TTP 7000 Kiosk Printer – Technical Manual 37

Page 38

5.2.10 Status reporting commands

See also Status reporting on page 41.

NOTE! – The status commands are immediate, that is they are executed exactly when

they are received. This means they pass the print queue in the printer and may be

executed before other commands.

ESC ENQ 1

1B 05 01 hex

027 005 001 decimal

A status enquiry results in response ACK (06 decimal) if all sensors are clear, but NAK (15

decimal) + code if one or more sensors report fault condition.

Status enquiry

Error code Meaning

ACK OK (printer is operable)

NAK 01 Paper left in presenter module. Attempt to clear the paper path failed.1

NAK 02 Cutter not in home position

NAK 03 Out of paper

NAK 04 Printhead lifted

NAK 05 Paper-feed error. No paper detected in presenter although 10 cm has been

printed. Paper might be wound around the platen or, in some way, has been

forced above the presenter module.

NAK 06 Temperature error. The printhead temperature has exceeded the 80 °C

maximum limit.

Table 7. Error codes

NOTE! — Errors 2, 5, and 6 are terminal faults that require you to reset

the printer before it will be operable again. The printer automatically

recovers from the other error conditions as soon as the error is corrected.

A status enquiry command can only return one status code at a time. If there are two or

more simultaneous errors, each error condition should be cleared and the status enquiry

repeated in order to get a complete report of all status codes.

The host computer cannot be certain that all error conditions have been cleared until an

ACK is received.

The possible error conditions are reported in the above order.

1

The printer will answer ACK even if paper is present in the presenter unless you send a clear presenter command first, and

that command fails. To get an immediate sensor status reply, use ESC ENQ 6 instead and look at bit 3 in the second byte.

38 TTP 7000 Kiosk Printer – Technical Manual 0308

Page 39

ESC ENQ 2

1B 05 02 hex

027 005 002 decimal

This command requests a paper-near-end sensor (paper low) status from the printer in a

1-byte format.

Value = (01H) indicates ”No paper”

Value = (00H) indicates ”Paper present” at the sensor position

NOTE! – The status of the sensor is sampled every time the receipt is cut. If three

succeeding samples show "no paper", the status reply changes to 00. This is to

prevent false alarm if the side of the paper roll is not clean. If you want the

momentary status of the sensor, use

ESC ENQ 4

1B 05 04 hex

027 005 004 decimal

Requests multiple bytes of information regarding loaded fonts and logotypes.

EXAMPLE (↵ = CR LF)

Send→ ESC ENQ 004

Read←

0:9632 Courier 13↵

1:12612 Ariel 12

2: ↵

3: ↵

4: ↵

5: ↵

6: ↵

7:

Free font memory:246122↵

00: ↵

01: ↵

02: ↵

03:14 110 Recycle↵

04:

05:103 65 Warning

06:

07: ↵

08:

09: ↵

10:

11: ↵

12:

13:

14: ↵

15: ↵

16:

Free logotype memory:189512↵

↵

↵

↵

↵

↵

↵

↵

↵

↵

↵

Paper-near-end enquiry

ESC ENQ 6 and extract the paper-near-end bit.

Font and logotype enquiry

The response begins with 8 lines of

font data containing font numbers,

font sizes in bytes, font names, and

font height in pixels.

Remaining font memory in bytes.

16 lines of logotype data containing

logotype number, with and height of

the logotype in pixels, and logotype

name.

Remaining logotype memory in bytes

0308 TTP 7000 Kiosk Printer – Technical Manual 39

Page 40

ESC ENQ 6

1B 05 06 hex

027 005 006 decimal

Results in a 2-byte response, reflecting the status of each sensor. This command is

intended as a go/no go indication. When everything is OK, this status report returns 0.

NOTE! – If no weekend sensor is installed, 64 is returned when everything is OK. If

no weekend or paper-near-end sensors are installed, 64+2=66 is returned when OK.

Status report

First byte, bit No.: Second byte, bit No.:

7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0

Weekend sensor

Head lifted

Cutter not home

FF button pressed

Paper at presenter

-

-

-

Print data exists**

Pending error code*

Power has been OFF***

Error Black Mark

Software error****

Table 8. Sensor status

Retract unit fitted

Out of paper

Paper-near-end*****

* This bit indicates that an error code is available. Use ESC ENQ 1 to fetch it.

** This bit tells you that there are data in the printer that have not yet been printed. There

*** When parallel cable is connected, both printer and host computer must have

**** Trying to select non existing font or other error

***** This paper-near-end bit differs from the ESC ENQ 2 response, see page 39.

Bits 3 to 5 in the first byte are reset when they are read.

ESC ENQ 7

1B 05 07 hex

027 005 007 decimal

Results in a 2-byte response representing the version of the installed firmware.

The first byte represents major versions, and the second byte minor versions.

EXAMPLE

are two possible reasons for that:

1. The last command received by the printer was not a command that triggers a printout.

2. The printer is printing

been off to set this bit. This is because the interface powers the RAM in the

printer.

Firmware version enquiry

Send→ ESC ENQ 007

Read←

<001><020>

That is, a response with the value <001><020> indicates version 1.20.

40 TTP 7000 Kiosk Printer – Technical Manual 0308

Page 41

ESC ENQ 9

1B 05 09 hex

027 005 009 decimal

Results in a 6-byte response representing the serial number.

EXAMPLE

Send→ ESC ENQ 009

Read←

00h 00h 02h 2Bh C6h 28h (hex), or 000 000 002 043 198 040 (dec)

ESC ENQ 10

1B 05 10 hex

027 005 010 decimal

Results in a 1-byte response representing the control board revision. A minus sign

indicates that no revision has been made, while A indicates the first revision, and so on.

EXAMPLE

Send→ ESC ENQ 010

Read←

n Where n can be ‘A’ (ASCII) or41h (hex) or 065 (dec)

ESC ENQ c

1B 05 63 hex

027 005 099 decimal

Results in a string containing the device ID in the Windows Plug and Play string format.

The two first bytes represent the string length.

Serial number enquiry

Control board revision enquiry

Request device ID

EXAMPLE

Send→ ESC ENQ 099

Read←

000 106 This indicates that the string is 104 characters (plus two characters indicating

Read← ”MANUFACTURER:Swecoin AB;COMMAND SET:None;MODEL:TTP7000;CLASS:PRINTER;

DESCRIPTION:Ticket Printer TTP7000;”

NOTE! – The read string above is just an example.

Read out the actual string from your printer.

ESC ENQ P n

1B 05 50 n hex

027 005 080 n decimal

This command requests information about the setting of parameter n, that is, the

parameter value stored in flash PROM or any parameter value temporarily set by other

ESC commands. Parameter names (n) are listed on page 48.

the string length)

Parameter setting data enquiry

0308 TTP 7000 Kiosk Printer – Technical Manual 41

Page 42

ESC ACK n

1B 06 n hex

027 006 n decimal

n = One-byte marker. Range 0 to 255

The "acknowledge marker" n is placed in the command queue and when the execution of

commands reaches the marker it is sent back to the host computer. This is an addition to

the status commands that pass the queue and are answered immediately when received.

EXAMPLE:

"Print data" <ESC><ACK><001>"Cut & Eject" <ESC><ACK><002>

The printer will send

has been performed.

NOTE! — Acknowledge marker cannot be used for events that write to the flash PROM,

for instance font loading. This is because the writing procedure erases the buffer,

including the markers, and uses all RAM in the printer.

Set acknowledge marker1

<001> when <print data> has executed and <002> when the ejecting

1

Added in firmware version 2.29b

42 TTP 7000 Kiosk Printer – Technical Manual 0308

Page 43

5.3 Font loading

The printer can store 8 fonts in its flash PROM. 256 kB are available for font storage. The

font size is fixed1, so you must load one font file for each character size you require. The

fonts are given font numbers when they are loaded into the printer. The first font is

assigned number 0 and the next font 1 etc. up to font 7. The font number parameter

number14 of the default parameter setting will be used when no font selection command

has been received (see page 47).

You cannot erase a single font, but must erase font 4-7 with command

ESC & D, or all

eight fonts with ESC & C, then reload the fonts you wanted to keep.

Windows software for font generation and management is available on the Swecoin web

site. If you need to load fonts in a non-Windows environment, use the

ESC & NUL

command.

The time required for processing the font data that is loaded is typically 15–20 seconds

per font, excluding transfer time. During this time, any data sent to the printer will be lost.

NOTE! — The font processing is ends with a reset. The presenter motor runs

momentarily to indicate that the printer is ready to be used.

CAUTION! — Loading to the flash PROM will erase the RAM completely since the RAM

is used during the loading process. Any print data residing in RAM will thus be lost.

5.3.1 File format

A font consists of a header describing the font, then data for every character in the font.

The header has to be downloaded even if the font consists of a single character only.

Below is a description of the font header.

1 byte Reserved Should always be 0 (zero)

1 byte Reserved Should always be 0 (zero)

1 byte Char. width (X) The number of bytes required for the width of one character,

usually 2 or 3. Range 1 to 8.

1 byte Character pitch The maximum width of one character in the set. This value is

used for tab position calculation. Range 1 to 255.

1 byte Char. height (Y) The maximum height of one character matrix measured in

pixels. This is also the minimum line spacing for this

character set.

27 byte Font name String of characters used to identify the character set.

This will be printed on status receipts. (E.g. Swiss 10 cpi.)

Char_matrix table: 256 records, each containing 3 bytes.

3 byte Char_width (pixels) + Char_Ystart(pixels) + Char_Yheight(pixels)

Char_bitmap data: Bitmap data for all characters that are to be defined.

1

Multiple height, and width commands can be used on all fonts.

0308 TTP 7000 Kiosk Printer – Technical Manual 43

Page 44

Char_width

Char_Ystart

Char_width

Char_width

Char_width

Char_sizeY

Baseline

Character bitmap data:

A character is made up of a bitmap the size of which is:

Char. width (X) * Char. Height (Y) bytes.

MSB LSB MSB LSB

A

Char_sizeX

Col 0 Col 1

Char_Yheight

A

Char_pitch

COLUMN

012

0

4

ROW

W

Char_pitch

Col 2

MSB LSB

g

Char_pitch

Row 1

=03H =FFH =80H

The bitmap data consists of bitmap patterns for each character in a character set for

which the parameter Char_width in the Char_matrix table is set to a value between 1 and

24. A character that has its Char_width set to zero, is not included in the bitmap data.

The bitmap for one character is then defined according to the following table:

(COL 0, ROW Ystart) , (COL 1, ROW Ystart) , (COL 2, ROW Ystart)

(COL 0, ROW Ystart+1) , (COL 1, ROW Ystart+1) , (COL 2, Ystart+1)

.

.

.

(COL 0, ROW Ystart+Yheight), (COL 1, ROW Ystart+Yheight ), (COL 2, ROW

Ystart+Yheight)

In this example, each row consists of 3 columns equal to 3 bytes.

In order to minimize the required storage space, only rows between Ystart and

Ystart+Yheight are included in the character bitmap.

44 TTP 7000 Kiosk Printer – Technical Manual 0308

Page 45

5.4 Logotypes

Up to 16 logotypes can be stored in the flash PROM of the printer. The logotypes can be

positioned and printed out with commands

The exact number of logotypes and their sizes is determined by the total amount of

memory used for fonts, logotypes and loaded firmware. Make a test printout to see how

much memory is available.

5.4.1 Loading

Windows software that convert black and white BMP bitmap files to logotypes and load

them into the printer is available on the Swecoin web site. If you need to load logotypes in

a non-Windows environment, use the

The time required by the printer to process logotype data, excluding transfer time from the

PC, is typically 15 to 20 seconds, per logotype. During this time, any data sent to the

printer will be lost.

5.4.2 File format

ESC g or ESC L.

ESC & 1 command.

A header containing information about the logotype number, size and logotype name

shall define each loaded logotype. Immediately after the header follows the actual bitmap

of the logotype.

ESC & 01H <Header><Bitmap>

Header:

Byte 0 Logotype number used to identify the logotype when printing.

Byte 1 X size measured in bytes.

Byte 2 Y size measured in pixels.

Byte 3—15 A logotype name that will be printed on test printouts.

Bitmap:

The bitmap must have exactly (X size * Y size) number of bytes. 1=black, 0=white dot.

Bit No. 7 in byte 0 represents the top left corner of the logotype.

X size

7

Byte 0

0

Y size

0308 TTP 7000 Kiosk Printer – Technical Manual 45

Page 46

5.4.3 Printing

To print a logotype you can use two commands,

current cursor position, just like any character.

ESC L n1, prints the logotype at the

ESC g n1 n2n3 n4n5 prints the logotype

at a specified X-Y position.

n1 One byte logotype number, (0—15)

n2n3 Two byte X position measured in pixels from the left hand edge of the print

window.

n4n5 Two byte Y position in pixels from top of the page.

These bytes must always be inserted but they are ignored in variable-pagelength mode where logotypes are always printed at the current Y-position.

5.4.4 Erasing

All logotypes are erased with the

ESC & L command.

CAUTION! — Loading to the flash PROM will erase the RAM completely since the RAM

is used during the loading process. Any print data residing in RAM will thus be lost.

5.5 Status reporting

The printer is equipped with a number of sensors that report the printer status and various

error conditions such as out-of-paper, previous printout not removed, etc.

A good practice in unattended printer applications is to check for errors and paper

availability before printing.

1. Send a Status Report Query (

ESC ENQ 6, page 40) and check that the answer is "No

errors"

2. If an error is indicated, read out the error message with Status Request (

ESC ENQ 1,

page 38), and take appropriate actions. Repeat this step until no more error code is

available. If weekend sensor signals “level passed” check again after next document

is printed. If the sensor still signals “level passed” after three successive print/check

cycles, report the condition to the systems supervisor so that he can schedule a

service visit to the printer. This three cycle check is to ensure that dirt on the side of

the roll does not cause the alarm.

3. Send a paper-near-end query (

ESC ENQ 2, page 39) to see if the sensor reports low

paper level.

4. If paper-near-end is indicated, report the condition to the systems supervisor so that

he can schedule a service visit to the printer.

5. Print the receipt.

46 TTP 7000 Kiosk Printer – Technical Manual 0308

Page 47

5.6 Default parameter setting

Some of the printer settings can be stored in the flash PROM so that they will be used

also after power OFF. When the printer is set up the way you like it to be, you send

<ESC>&<004>, and the following settings will be stored.

1 Baud

2 Data bits

3 Parity

4 Flow control

5 Disable parallel port signaling

7 Burn time

8 Max print speed

9 Loop ON/OFF

10 Printhead pulse control