P1003640-004 Rev. A

Zebra® TTP 2100

Kiosk Ticket Printer

Technical Manual

© 2012 ZIH Corp. The copyrights in this manual and the software and/or firmware in the printer described

therein are owned by ZIH Corp. and Zebra’s licensors. Unauthorized reproduction of this manual or the software

and/or firmware in the printer may result in imprisonment of up to one year and fines of up to $10,000

(17 U.S.C.506). Copyright violators may be subject to civil liability.

This product may contain ZPL®, ZPL II®, and ZebraLink™ programs; Element Energy Equalizer™ Circuit; E3™;

and Monotype Imaging fonts. Software © ZIH Corp. All rights reserved worldwide.

ZebraLink, Element Energy Equalizer, E3 and all product names and numbers are trademarks, and Zebra, the Zebra

head graphic, ZPL and ZPL II are registered trademarks of ZIH Corp. All rights reserved worldwide.

All other brand names, product names, or trademarks belong to their respective holders. For additional trademark

information, please see “Trademarks” on the product CD.

Proprietary Statement This manual contains proprietary information of Zebra Technologies Corporation and its

subsidiaries (“Zebra Technologies”). It is intended solely for the information and use of parties operating and

maintaining the equipment described herein. Such proprietary information may not be used, reproduced, or disclosed

to any other parties for any other purpose without the express, written permission of Zebra Technologies Corporation.

Product Improvements Continuous improvement of products is a policy of Zebra Technologies Corporation.

All specifications and designs are subject to change without notice.

Liability Disclaimer Zebra Technologies Corporation takes steps to ensure that its published Engineering

specifications and manuals are correct; however, errors do occur. Zebra Technologies Corporation reserves the right

to correct any such errors and disclaims liability resulting therefrom.

Limitation of Liability In no event shall Zebra Technologies Corporation or anyone else involved in the creation,

production, or delivery of the accompanying product (including hardware and software) be liable for any damages

whatsoever (including, without limitation, consequential damages including loss of business profits, business

interruption, or loss of business information) arising out of the use of, the results of use of, or inability to use such

product, even if Zebra Technologies Corporation has been advised of the possibility of such damages. Some

jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation

or exclusion may not apply to you.

Contents

1 • Introduction .................................................... 7

About this Manual ....................................................... 7

2 • Product Presentation ............................................ 9

TTP 2100 Series ........................................................ 9

Presenter ............................................................. 12

Eject Mode ......................................................... 12

Hold Mode ......................................................... 12

Controls .............................................................. 13

Feed Button ....................................................... 13

Power Indicator ..................................................... 14

Status Indicator ..................................................... 14

3 • Installation .................................................... 15

Installing a Paper Guide .................................................. 15

Top of Form (TOF) Sensor ................................................ 19

Selecting Fork (Transmissive) or Reflex (Black Mark) TOF Sensor .............. 19

Calibrating the TOF Sensor ............................................ 20

Positioning the TOF Sensor ............................................ 20

Installation Considerations ................................................ 21

Orientation ......................................................... 22

Quick-Fit Hubs ...................................................... 23

Design Your Own Mounting ............................................ 24

Electrostatic Discharges and Earth Currents ............................... 25

Ambient Light ....................................................... 25

Installing a Paper-low Sensor (Optional) ..................................... 26

Connecting to the Computer .............................................. 27

TTP 2110 .......................................................... 28

TTP 2130 .......................................................... 28

09/18/2014 TTP 2100™ Technical Manual P1003640-004

Contents

4

Connecting the Power ................................................... 29

Making a Self-Test Printout ............................................... 31

Customizing the Self-Test Printout ...................................... 33

Installing a Printer Driver ................................................. 33

4 • Operation ..................................................... 35

Loading Fanfold Ticket Stock .............................................. 36

Installing a Paper Roll ................................................... 37

Clearing Paper Jams .................................................... 39

5 • Programming .................................................. 41

Programming Overview .................................................. 42

How the Commands are Described ......................................... 43

Summary of Control Codes and Escape Sequences ........................... 45

Software Command Syntax ............................................... 48

Black Mark (Top-of-Form) Commands .................................... 48

Text Commands ..................................................... 49

Barcode Commands ................................................. 56

Graphics Commands ................................................. 62

Print Commands .................................................... 65

Cut and Present Commands ........................................... 67

System Related Commands ........................................... 70

Status Reporting Commands .......................................... 74

Font Loading .......................................................... 85

File Format ......................................................... 85

Character Bitmap Data ............................................... 86

Logotypes ............................................................ 87

Loading ........................................................... 87

File Format ......................................................... 87

Printing ............................................................ 88

Erasing ............................................................ 88

Status Reporting ....................................................... 89

6 • Default Parameter Settings ....................................... 91

Parameter Settings ..................................................... 91

How the Parameters are Described ......................................... 92

Default Value ....................................................... 92

Examples .......................................................... 92

Summary of Parameter Settings ........................................... 92

Serial Interface Set-up ................................................... 94

Print Setup ............................................................ 95

Fixed Document Mode ............................................... 100

P1003640-004 TTP 2100™ Technical Manual 09/18/2014

Contents

7 • Page Setup ................................................... 109

Printable Area ........................................................ 109

Aligning Preprint and Thermal Print ........................................ 110

Simple Calibration Process ........................................... 112

FF (Form Feed) ....................................................... 113

Black Mark Sensing from within Windows ................................... 113

8 • Interface ..................................................... 115

Printer Interface ....................................................... 115

Serial: TTP 2110 ...................................................... 115

Setup Options ..................................................... 116

USB: TTP 2130 ....................................................... 117

9 • Maintenance ................................................. 119

Fault Finding / Troubleshooting ........................................... 119

Cleaning the Printhead ................................................. 121

Cleaning the Presenter and Platen Rollers .................................. 121

Firmware ............................................................ 121

Loading .......................................................... 122

Firmware Identification ............................................... 126

5

10 • Specifications ...............................................127

Ticket Specifications ................................................... 128

TOF Detection ........................................................ 129

Features .......................................................... 129

Print Module .......................................................... 129

Ticket Separation ...................................................... 129

Presenter ............................................................ 130

Electronics ........................................................... 130

Firmware ............................................................ 130

Text Mode ............................................................ 131

Miscellaneous ........................................................ 131

Basic Character Set .................................................... 131

Part Number List ...................................................... 133

Printers .......................................................... 133

Accessories ....................................................... 133

Dimensions .......................................................... 134

Printer ........................................................... 134

Media Holder ...................................................... 135

Power Supply ...................................................... 136

Output Tray ........................................................ 136

09/18/2014 TTP 2100™ Technical Manual P1003640-004

Contents

6

A•₼⦌ 5R+6 㧟㠨⭿㢝

(China RoHS Material Declaration) .................. 137

Index ........................................................... 139

P1003640-004 TTP 2100™ Technical Manual 09/18/2014

1

Introduction

Contents

About this Manual ....................................................... 7

Contacts ............................................................... 8

About this Manual

This manual is updated from time to time when printer functions and features are added or

amended. You can find the latest edition on our website at

functions not found in this manual edition, please contact

the Zebra partner from which you purchased the printer.

www.zebra.com. If you require

Technical Support for your region or

09/18/2014 TTP 2100™ Technical Manual P1003640-004

Introduction

8

About this Manual

P1003640-004 TTP 2100™ Technical Manual 09/18/2014

2

Product Presentation

Contents

TTP 2100 Series ........................................................ 9

Presenter ............................................................. 12

Controls .............................................................. 13

TTP 2100 Series

The TTP 2100 series of ticket printers are available both for Kiosk integration and Desktop

use. These printers are Common Use Self-Service (CUSS) capable.

These ticket printers print on most ticket media from 50 mm to 82.5 mm wide using direct

thermal printing. The ticket media can be up to 0.25 mm thick, fanfold, roll, or single cut

handfed.

09/18/2014 TTP 2100™ Technical Manual P1003640-004

Product Presentation

10

TTP 2100 Series

The printers have an integrated guillotine cutter, straight presenter, and control board. The

print speed is up to 150 mm/s and the eject speed 300 mm/s to ensure high throughput.

The cut can be synchronized with:

• Gaps between tickets, or punched holes

• Black marks on the non thermal side of the ticket stock

• Ticket corner radius

• Label gaps (for adhesive labels on backing/liner)

You can also print fixed-length or variable-length tickets without synchronization. The

presenter can be set to eject the ticket into a tray or hold it by the back edge until the customer

takes it. The top can easily be opened to give the operator access to the paper path and

printhead for maintenance purposes.

P1003640-004 TTP 2100™ Technical Manual 09/18/2014

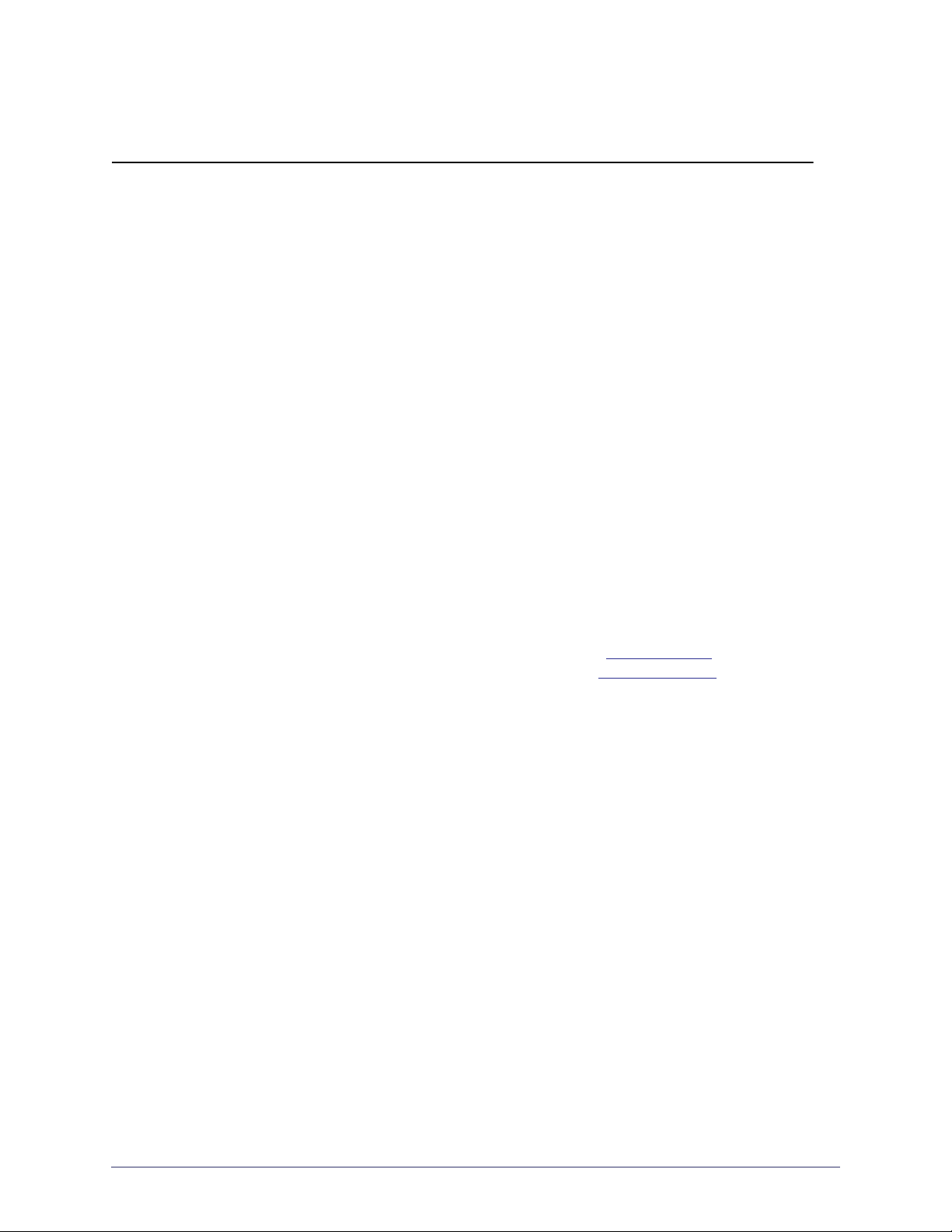

Figure 1 • Principle of Operation

Product Presentation

TTP 2100 Series

9

11

5

4

3

2

1

Control panel on both sides

1

Cutter

2

Tickets fall (into tray)

3

Ticket sensor (taken/fallen)

4

Straight presenter

5

Ticket load sensor

6

Printhead

7

Upper media sensor (IR light source), adjustable sideways

8

Top release lever

9

Paper entry

10

Lower media sensor (IR light receiver), adjustable sideways

11

Control board

12

6

7

8

10

11

12

The upper media sensor is an IR light source that illuminates the media. The lower media

sensor is an IR light receiver. These sensors must work together to sense media gaps or out-ofmedia conditions.

The printer is available with two different control boards; the TTP 2110 with serial interface

and the TTP 2130 with USB interface.

A printer driver for Microsoft Windows™ is available, and the TTP 2130 interface is

compatible with the Plug and Play standard.

09/18/2014 TTP 2100™ Technical Manual P1003640-004

Product Presentation

12

Presenter

Presenter

Eject Mode

Hold Mode

The KPL control command language makes it easy to print directly from the ticket software

without using a driver. This is especially useful for the serial interface version with its limited

data transfer rate.

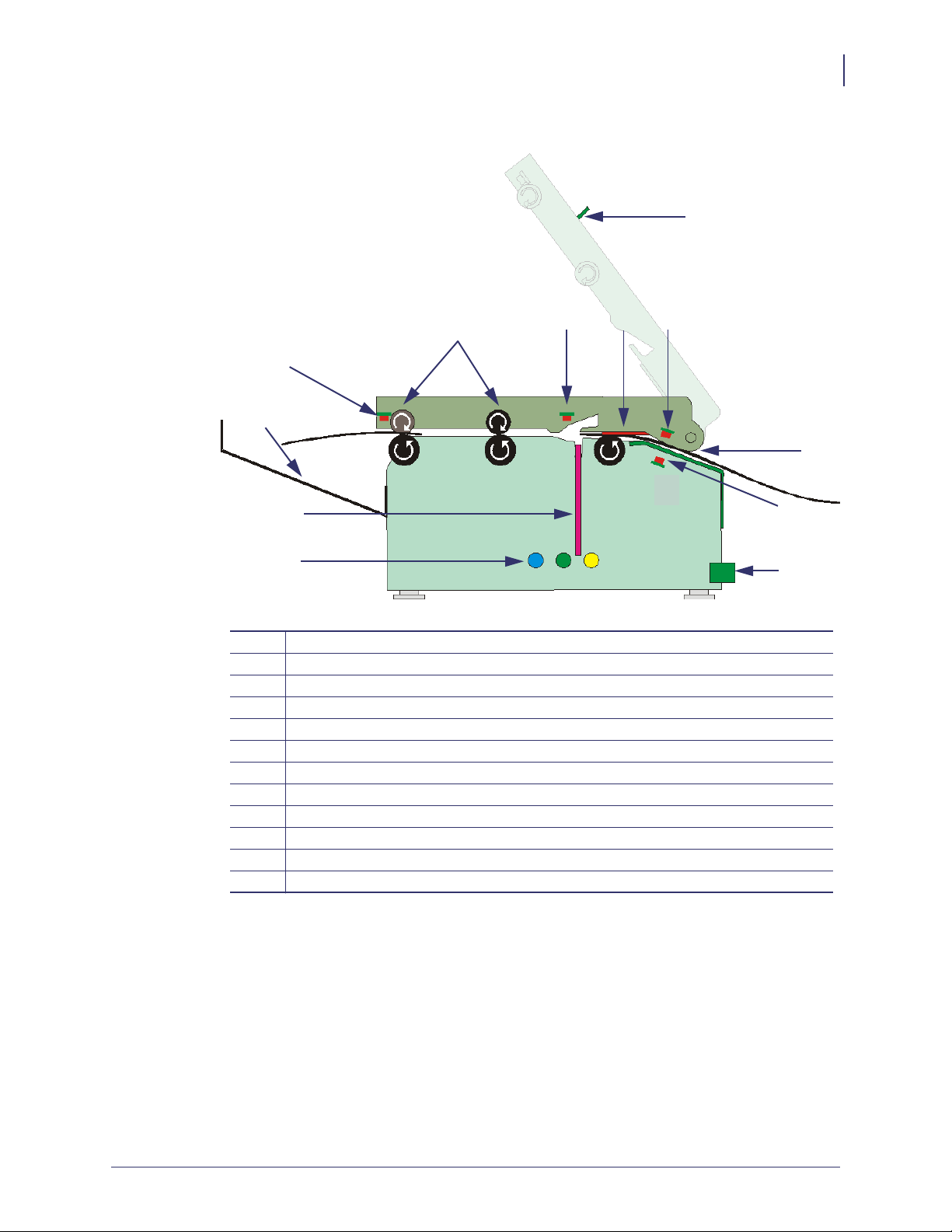

The TTP 2100 does not loop the media. The presenter carries the media through the printer for

presentation to the user.

The ticket is ejected after being cut. The printer is designed so that the ticket always drops

down. A sensor is located at the exit of the presenter to ensure that the printer can verify that

the ticket drops down. To enable this functionality, in the Properties dialog, click the Device

Settings tab, and under Presenter Settings set the Clear presenter value to Ye s .

When presented, only the very end of the printout is held by the printer so the customer can

easily take the printout no matter how long or short it is. If a customer is printing more than

one ticket, the printer can detect when the first is taken and automatically print the next and

hold that ticket until taken, continuing this process until all tickets have been printed.

Figure 2 • The Presenter

Print and drop

Print and take

P1003640-004 TTP 2100™ Technical Manual 09/18/2014

Controls

Cover lock

Feed Button

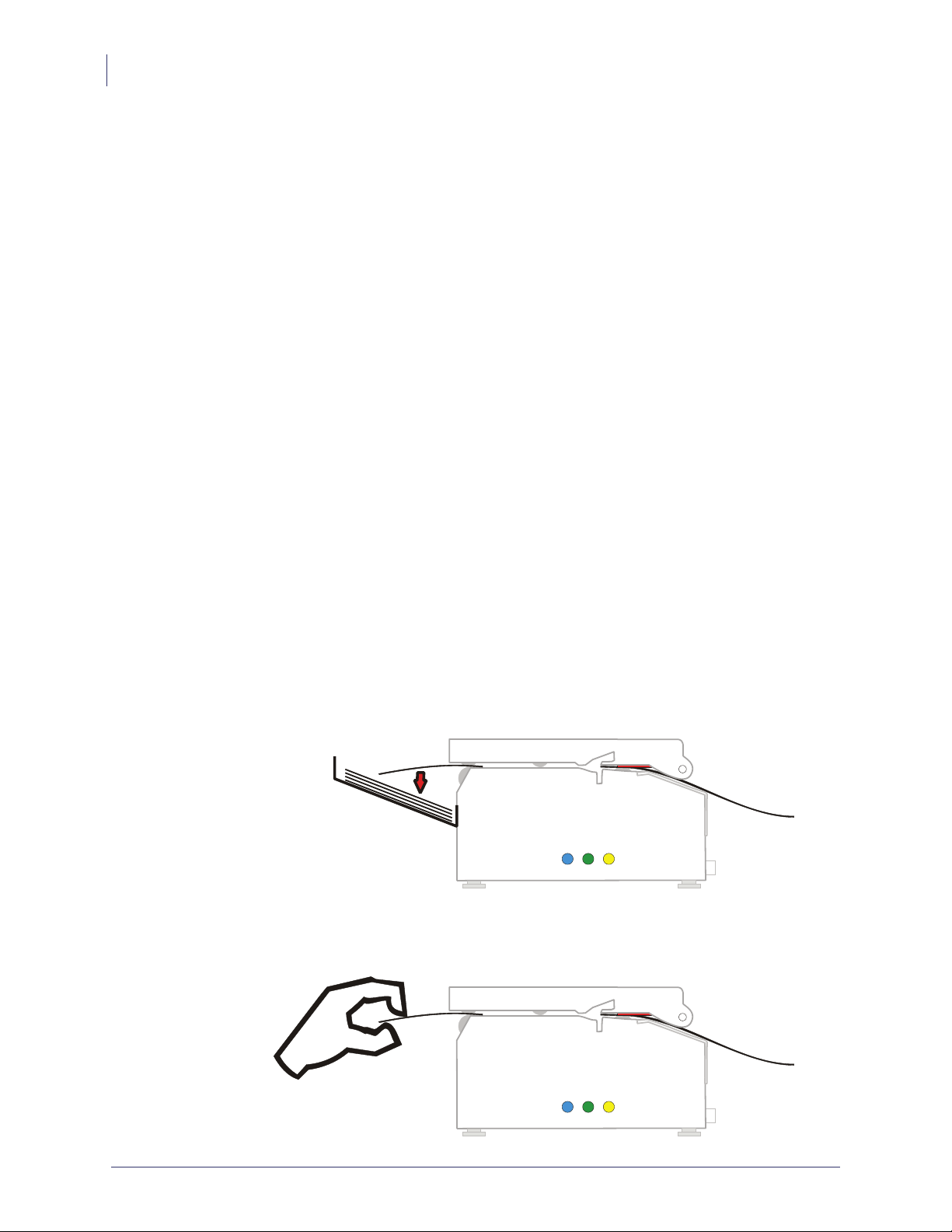

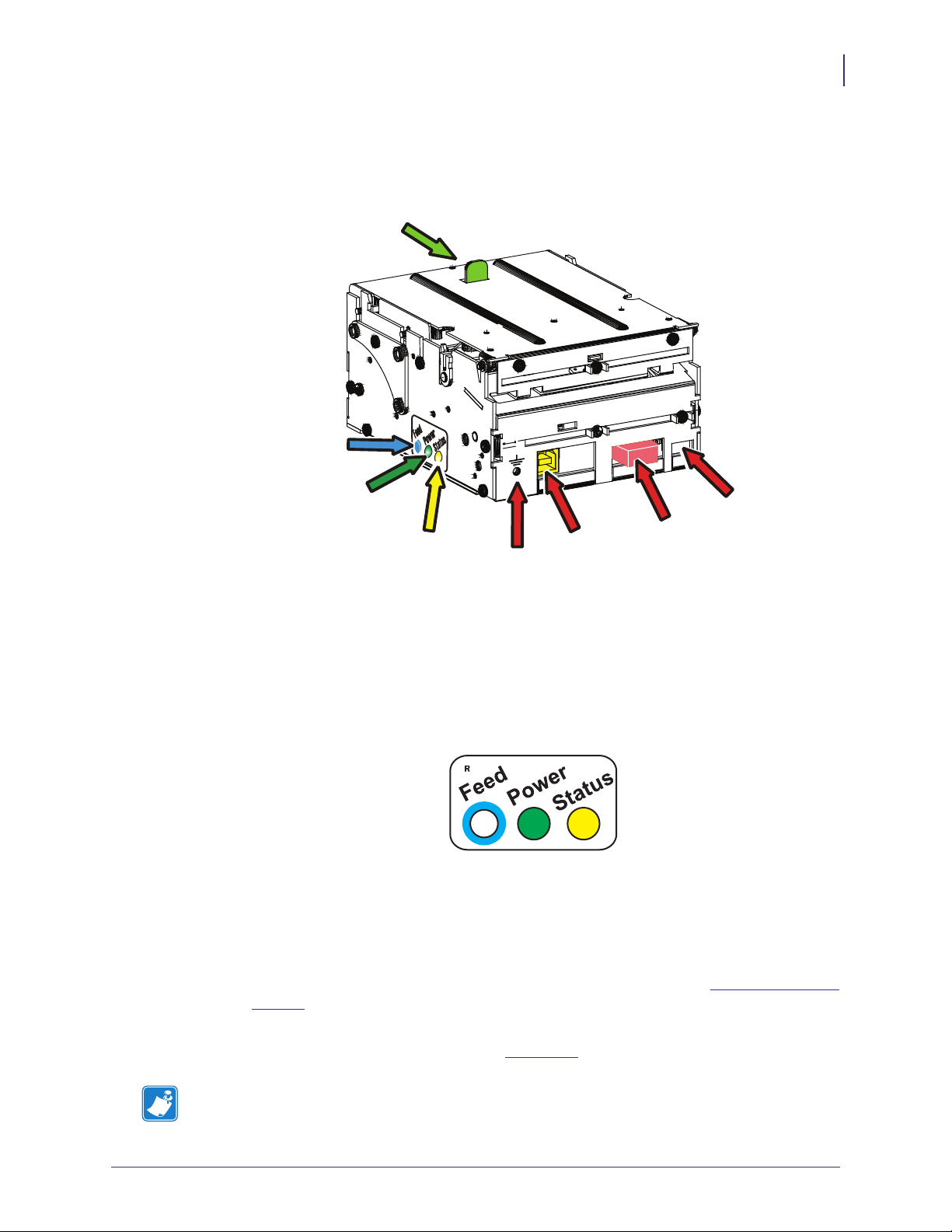

Figure 3 • Rear View

Product Presentation

Controls

13

The buttons and indicators are duplicated on both sides of the printer so that they are easily

accessible regardless of how the printer is installed.

Feed Button

The Blue Feed button has several functions:

• Press and release will feed, cut, and present a complete page.

• Any data in the print buffer will be printed.

If the buffer is empty the page will be blank.

In black mark mode, the page will be synchronized with the black mark.

Power Indicator

Status Indicator

Earth

Screw

Interface

Connector

Paper low

Connector

Power

Connector

• Press and hold Feed for three seconds to print a self-test printout (See

Making a Self-Test

Printout).

• With no paper in the printer, hold the Feed button pressed while closing the printhead to

enter TOF mark calibration mode (see

Note • If the printer has firmware version 3.82 or lower, press and hold the Feed button

Print Setup).

while turning on the printer to print a self-test printout.

09/18/2014 TTP 2100™ Technical Manual P1003640-004

Product Presentation

14

Controls

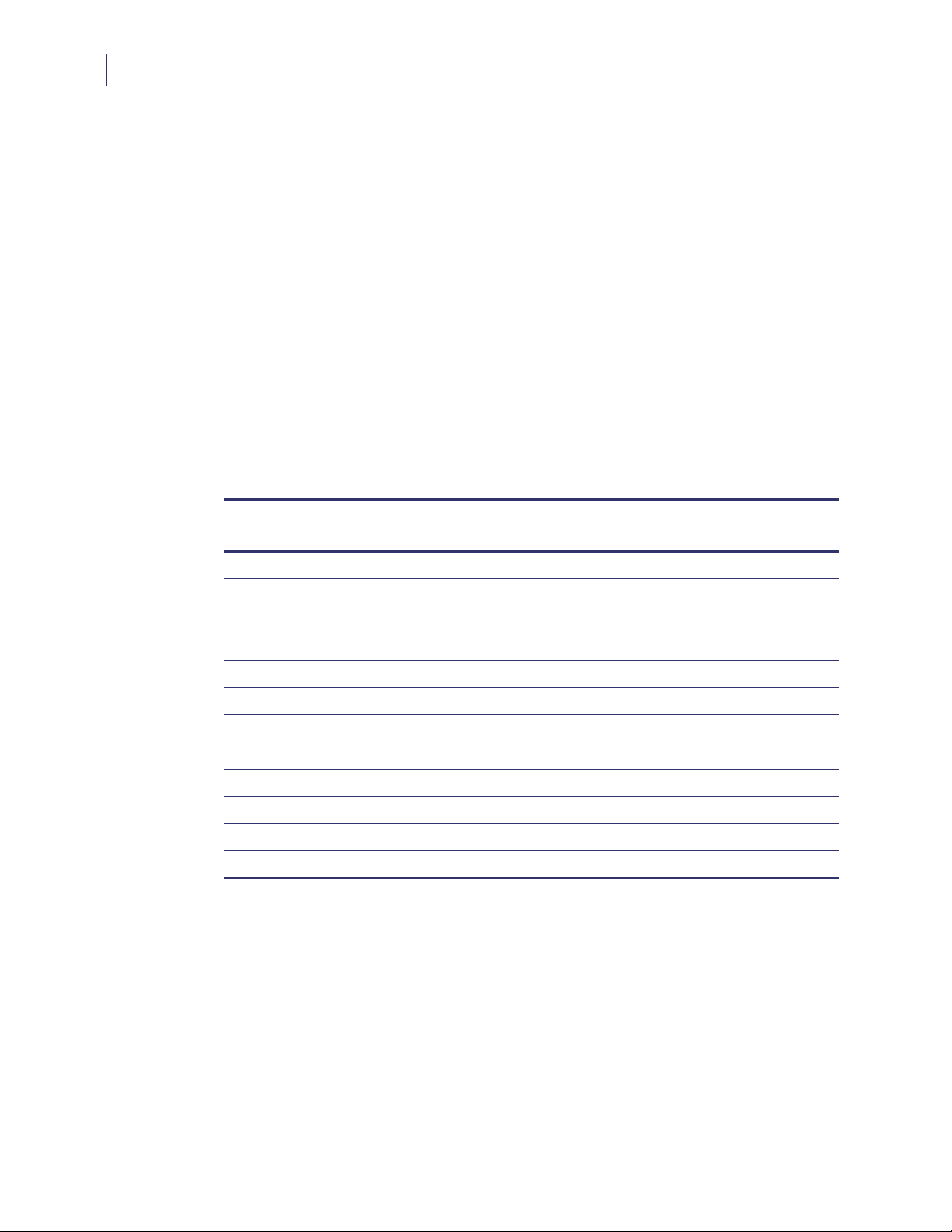

Power Indicator

Status Indicator

● When the green power indicator is illuminated, a 24V supply is connected to the printer.

● The status indicator has several functions:

• ON constantly — the printer is operational

• Flash, flash, pause, flash, flash — is the warning-code for paper low.

The warning-code is reset automatically when the condition causing it is removed.

This behavior is disabled by default but can be enabled by setting parameter 52

(Warning Level) to 1.

• Flashes rapidly — indicates error. Hold down the Feed button and the number of flashes

will reflect the status-code.

Table 1 • Status Indicator Flash Codes

Number of

Flashes

1 Presenter jam, paper cannot be ejected

2 Cutter cannot return to home position

3 Out of paper

4 Printhead lifted

5 Paper did not reach presenter sensor in time

6 Temp error, printhead is above 60

7 Paper jam during present

10 TOF mark not found (on media load)

11 TOF mark calibration error

Fast flashes Checksum error at firmware loading

Steady light Wrong firmware type

Constantly off Waiting for paper in TOF mark calibration mode

Status codes are reset:

Description

°C

• When the conditions causing them are removed.

• When the printer is power cycled (turned off and then on).

• For all paper jam conditions, after the jam is cleared, lifting and lowering the printhead.

P1003640-004 TTP 2100™ Technical Manual 09/18/2014

3

Installation

Contents

Installing a Paper Guide .................................................. 15

Top of Form (TOF) Sensor ................................................ 19

Installation Considerations ................................................ 21

Installing a Paper-low Sensor (Optional) ..................................... 26

Connecting to the Computer .............................................. 27

Connecting the Power ................................................... 29

Making a Self-Test Printout ............................................... 31

Installing a Printer Driver ................................................. 33

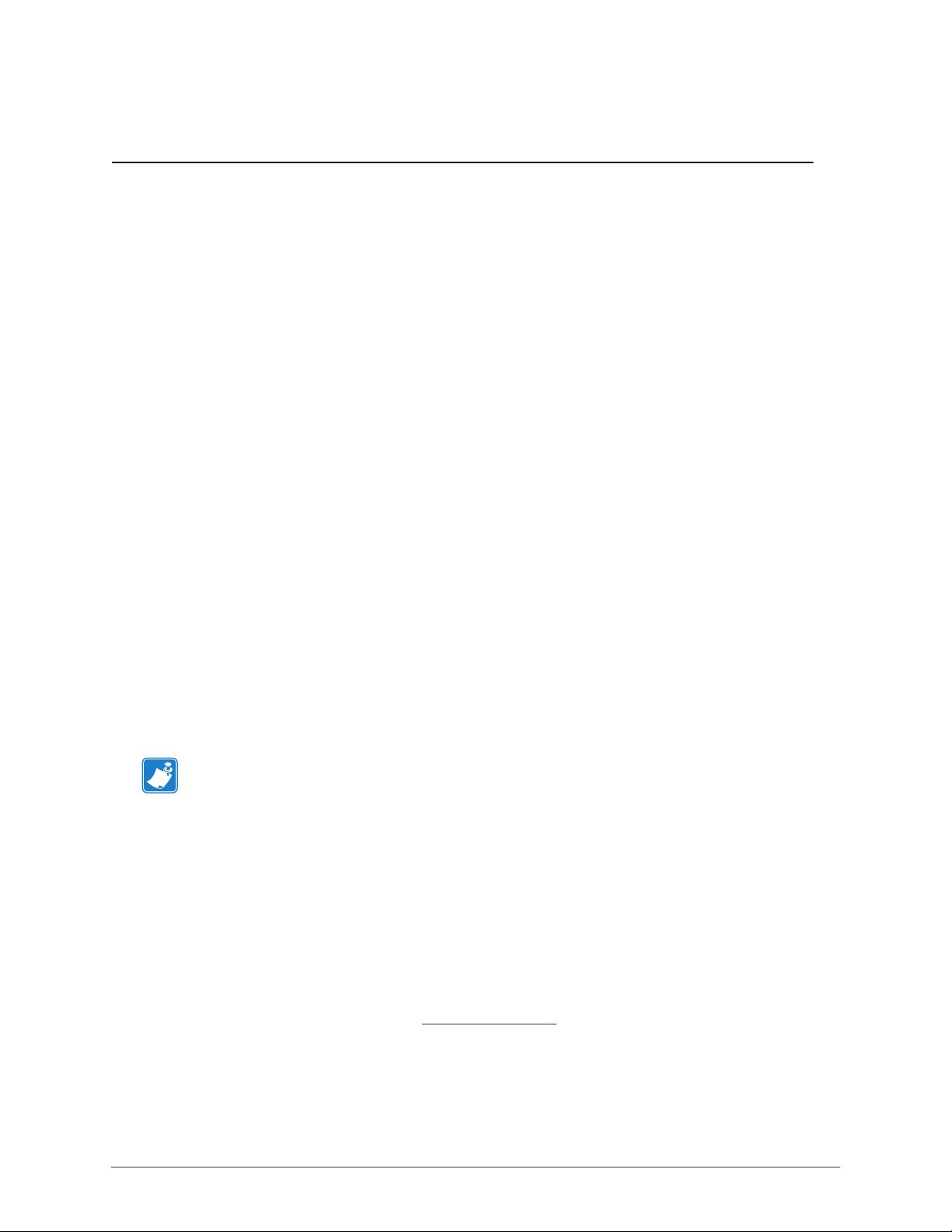

Installing a Paper Guide

Caution • Before proceeding, always disconnect the printer from power to avoid the

guide installation short circuiting the electronics in the printer. If the printer is installed in

a Kiosk, then all Kiosk power should be turned off to prevent the screw or media guide

bracket from accidentally falling into powered up Kiosk components (e.g., the screw or

bracket may fall and bounce into the Kiosk components mounted adjacent to or

mounted below the printer).

TTP 2100 printers are delivered without the paper guide fitted. TTP 2100 paper guides are

available in widths ranging from 51 mm to 82.5 mm. A dual paper guide is available with a

54 mm and 82.5 mm paper path.

1. Push the green printhead open lever backwards.

2. Lift up the printhead. See Clearing Paper Jams.

3. Insert the T-shaped tabs of the paper guide into the “T”-holes, press the rear of the guide

down, and using your fingers or a 5 mm wrench tighten the knurled nut.

4. Close the printhead.

09/18/2014 TTP 2100™ Technical Manual P1003640-004

Installation

16

Installing a Paper Guide

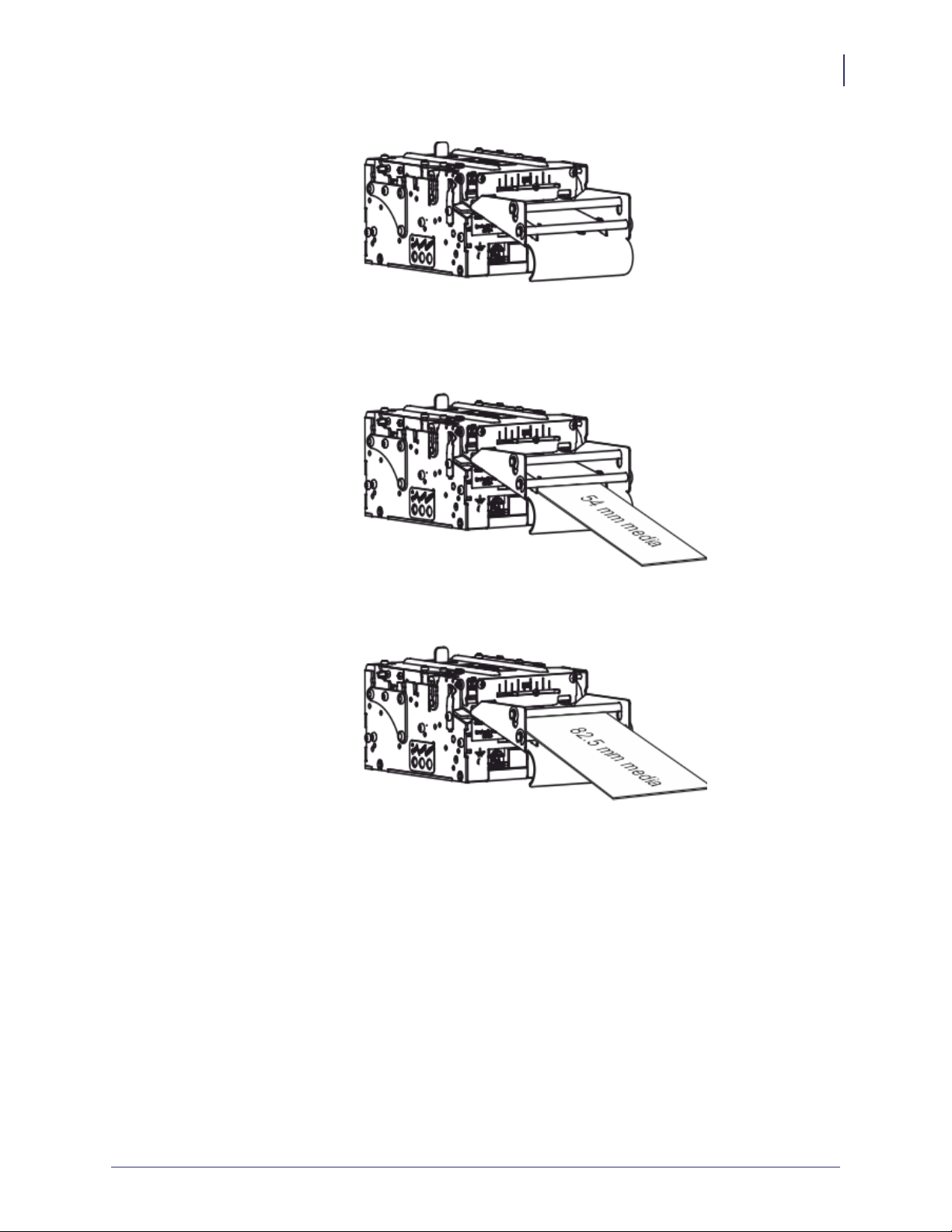

Figure 4 • Fitting the TTP 2100 Paper Guide

When a guide is fitted, make an auto calibration (see Calibrating the TOF Sensor

on page 20) with the ticket media that you are going to use in the printer. Most ticket

media auto calibrate perfectly, and the printer is ready to use.

P1003640-004 TTP 2100™ Technical Manual 09/18/2014

Figure 5 • TTP 2100 Dual Paper Guide

Installation

Installing a Paper Guide

17

If you use the TTP 2100 Dual Paper Guide 01990-400 on your printer, you must calibrate

twice (once in the wide paper path and once in the narrow paper path). The printer chooses

the appropriate set of parameters based on which paper path contains ticket stock.

If auto calibration fails on your media, set up paper width parameter n48, and sensor

selected parameter n63 to reflect your media. Then redo the auto calibration.

09/18/2014 TTP 2100™ Technical Manual P1003640-004

Installation

18

Installing a Paper Guide

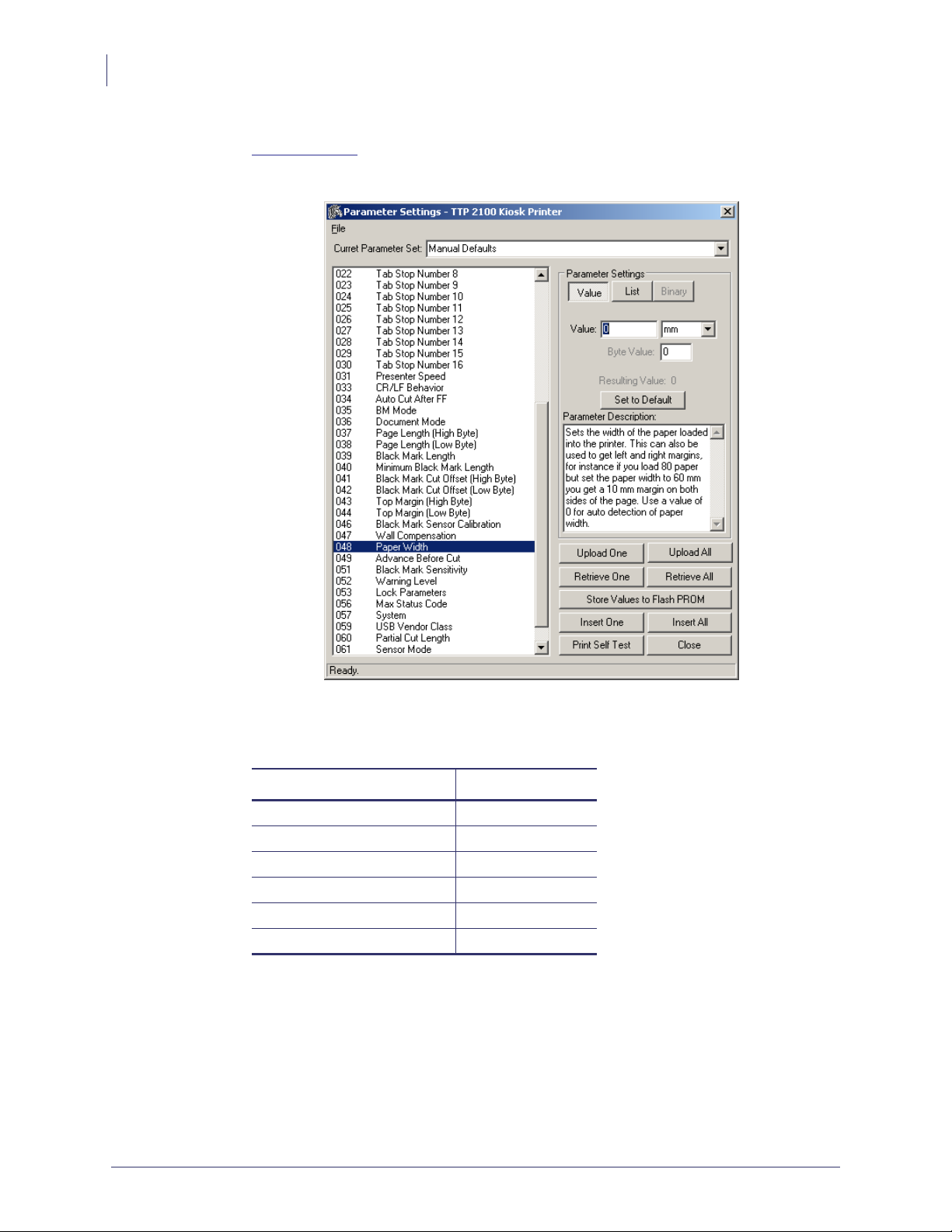

5. Start the utility program Zebra Toolbox. This application is available from

www.zebra.com.

6. On the Tools menu, click Parameter Settings.

7. Select 048 Paper Width, click Value, and enter the value in millimeters of the desired

print width.

Paper Width Setting

82.5 mm n48=80

80 mm n48=72

76 mm n48=70

60 mm n48=54

54 mm n48=50

51 mm n48=46

8. Click Upload One.

P1003640-004 TTP 2100™ Technical Manual 09/18/2014

Installation

Top of Form (TOF) Sensor

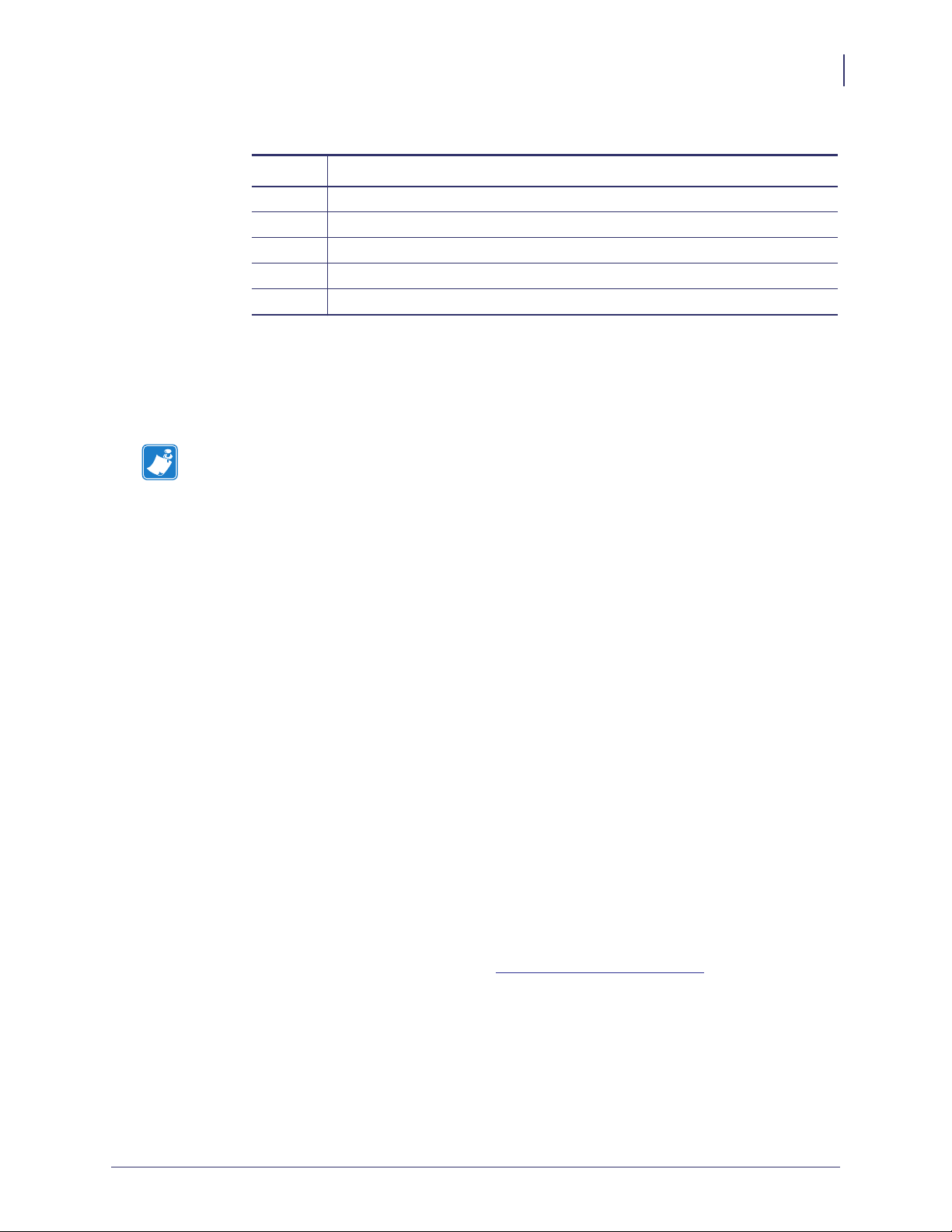

9. Select 063 BM Sensor and enter the desired value. Recommended values are:

Value When Used

0 Auto selects between 1, 2, 3, and 4 based on width of media loaded

1 (edge sensor) for ATB tickets without hole in the perforation

2 (center sensor) for ISO tickets, most other ticket types, and adhesive labels

3 17.5 mm from center sensor

4 12.5 mm from center sensor (for baggage tags according to IATA 740)

10. Click Upload One.

11. Click Store Values to Flash PROM.

12. Wait for the printer to buzz as a confirmation that the new value is stored.

Note • It is recommended that you run the auto calibration routine when the printer is

taken out of the box and whenever you change the media. Running auto calibration after

a head open event is recommended but is only necessary to insure proper first ticket

registration.

19

Top of Form (TOF) Sensor

The TTP 2100 has a flexible top of form detection system. When delivered the printer is

configured with fork (transmissive) sensor to detect holes/gaps between tickets. The

holes/gaps should be in the paper center, 12.5 mm to the right of the center (Bag tags

according to IATA resolution 740), 17.5 mm to the right of the center, or at the edge of

82.5 mm wide tickets (Boarding cards).

If the Top Of Form (TOF) mark is at a suitable position, an auto calibration routine configures

everything for you.

You can force the printer to use a specific sensor. If you switch to reflex sensor for black mark

detection by setting up the parameters in the printer to enable the use of non-standard sensor

positions, you can physically move the sensor to other positions.

Selecting Fork (Transmissive) or Reflex (Black Mark) TOF Sensor

The TTP 2100 can use a fork (transmissive) sensor that looks for holes between tickets, or a

reflex (black mark) sensor that looks for black marks on the back of the ticket stock. Sensor

mode is selected with parameter n61, see

Summary of Parameter Settings.

09/18/2014 TTP 2100™ Technical Manual P1003640-004

Installation

20

Top of Form (TOF) Sensor

Calibrating the TOF Sensor

1. Open the printhead.

2. Remove the ticket stock.

3. Press and hold the Feed button, and then close the printhead (keeping the button pressed

the entire time).

4. Release the button.

The Status LED should be off.

5. Load ticket stock (slide it into the paper guide and let the printer auto load the paper).

Note • To ensure good calibration conditions, lightly press the ticket stock towards the

bottom of the input guide during calibration.

The printer will forward the paper until it finds two TOF marks and then stop and save all

TOF-mark parameters.

6. Open the printhead and remove the ticket stock.

7. Close the printhead and feed the tickets in through the paper guide again.

The printer is ready for use.

Repeat this procedure if the calibration fails or if the printer is used with tickets that differ

from the original specification.

Note • If you use the Dual guide 01990-400 on your printer, you must calibrate twice (once

in the wide paper path and once in the narrow). The printer will choose the appropriate set of

parameters based on which paper path contains ticket stock.

Positioning the TOF Sensor

Note • Moving the sensor and IR source require customized paper guides with holes for the

new sensor position. Please contact Zebra Development Services (CAG) if your application

requires a non-standard sensor position.

The sensor board containing the lower media sensor sits on a bracket that can slide left and

right in a groove (see Figure 32, Sensor Positioning, on page 110). This bracket is located

below the ticket entry. The IR light source (upper media sensor) sits on a similar bracket above

the ticket entry. When delivered, the bracket is positioned to the far right. In this position

Sensor 1 is at the right side ready to detect the corner radius of Boarding cards, Sensor 2 is at

the center of the page, and Sensor 4 is 12.5 mm to the right of the center at the position

determined for baggage tags in IATA resolution 740. To configure the printer for other papers

that do not fall into any of the three categories, complete the following steps:

1. Loosen the screw holding the sensor 1 ½ turns.

2. Press the screw in with the screwdriver and carefully slide it to the new position making

sure the cables to the sensor do not obstruct the movement.

P1003640-004 TTP 2100™ Technical Manual 09/18/2014

3. Tighten the screw.

4. Move the IR light source (upper media sensor) to the same position, directly above the

sensor.

Installation Considerations

The TTP 2100 Kiosk printer is for embedded applications and should be installed in an

enclosure such as a self-service Kiosk.

Installation

Installation Considerations

a3

21

Upper sensor

adjuster

Lower sensor

adjuster

Caution • NEVER use screws that go into the printer more than 4 mm! Longer screws will

destroy the electronics inside.

The TTP 2100 Desktop printer is a stand alone printer in a housing. The housings can be

stacked so two or more printers can reside on top of each other to save space.

09/18/2014 TTP 2100™ Technical Manual P1003640-004

Installation

22

Installation Considerations

Orientation

The TTP 2100 printer can be installed horizontally or vertically. Horizontal is the most

common use but vertical with the ticket presenting upwards can be used if you want the ticket

to come up from the desk surface. Vertical with the ticket presented downwards can be used if

you want to stack many tickets before picking them up.

Figure 6 • Printer Installation Orientation Options

P1003640-004 TTP 2100™ Technical Manual 09/18/2014

Quick-Fit Hubs

The printers attach to the Kiosk in two ways:

• Using two screws

• Using slides with leaf spring retainers and the quick-fit hubs

Ticket exit

Figure7•Front, Bottom View

Push down

Installation

Installation Considerations

Quick-fit hubs

23

Optional

quick-fit

hubs

Keyholes

Lock spring

Push

forward

Fitted

09/18/2014 TTP 2100™ Technical Manual P1003640-004

Installation

24

Installation Considerations

Design Your Own Mounting

The illustration below gives an example of a printer-mounting shelf. See Dimensions, and the

3D solid models and outline drawings for CAD that are available on

www.zebra.com.

Figure 8 • Example of a Simple Shelf for Fastening a Standard Printer Using

Quick-Fit Hubs and a Leaf Spring Retainer (Order No. 01473-000)

m

m

5

.

1

Leaf spring

01473-000

Inner corner of bend

134 mm

110 m m

90.8 m m

10 mm

∅12 mm

Center

10 mm

Min. 100 mm

∅6.5 mm

+ 10 mm

Paper width

8 mm

44 mm

10 mm

Add material for corner radius

Additional space is required for paper loading and paper jam removal, Consider mounting the

printer on a movable platform so that the printer can be maintained outside the printer

enclosure.

We recommend that you make the output slot 97 mm wide. This way you will be able to use

all paper widths that the TTP 2100 series of printers can handle.

P1003640-004 TTP 2100™ Technical Manual 09/18/2014

Caution • NEVER use screws that go into the printer more than 4 mm! This will destroy the

electronics inside.

Electrostatic Discharges and Earth Currents

Preventing ESD and earth currents from affecting the printer operation requires proper

connection of the printer chassis to protective earth through a mounting platform or through a

separate earth conductor. A threaded hole for an M4 earth screw is provided on the back of the

printer. Use an M4 x 10 screw and two lock washers when fastening the ground cable.

Figure 9 • Location of Earth Grounding Screw

Installation

Installation Considerations

25

Earth

Screw

Note • An optional antistatic brush can be fitted to the front of the printer if required.

Ambient Light

There is an optical sensor at the paper exit at the front of the printer.

To ensure proper printer operation, design the Kiosk so that it prevents direct sunlight or light

from indoor lamps from reaching the sensor through the paper exit.

09/18/2014 TTP 2100™ Technical Manual P1003640-004

Installation

26

Installing a Paper-low Sensor (Optional)

Installing a Paper-low Sensor (Optional)

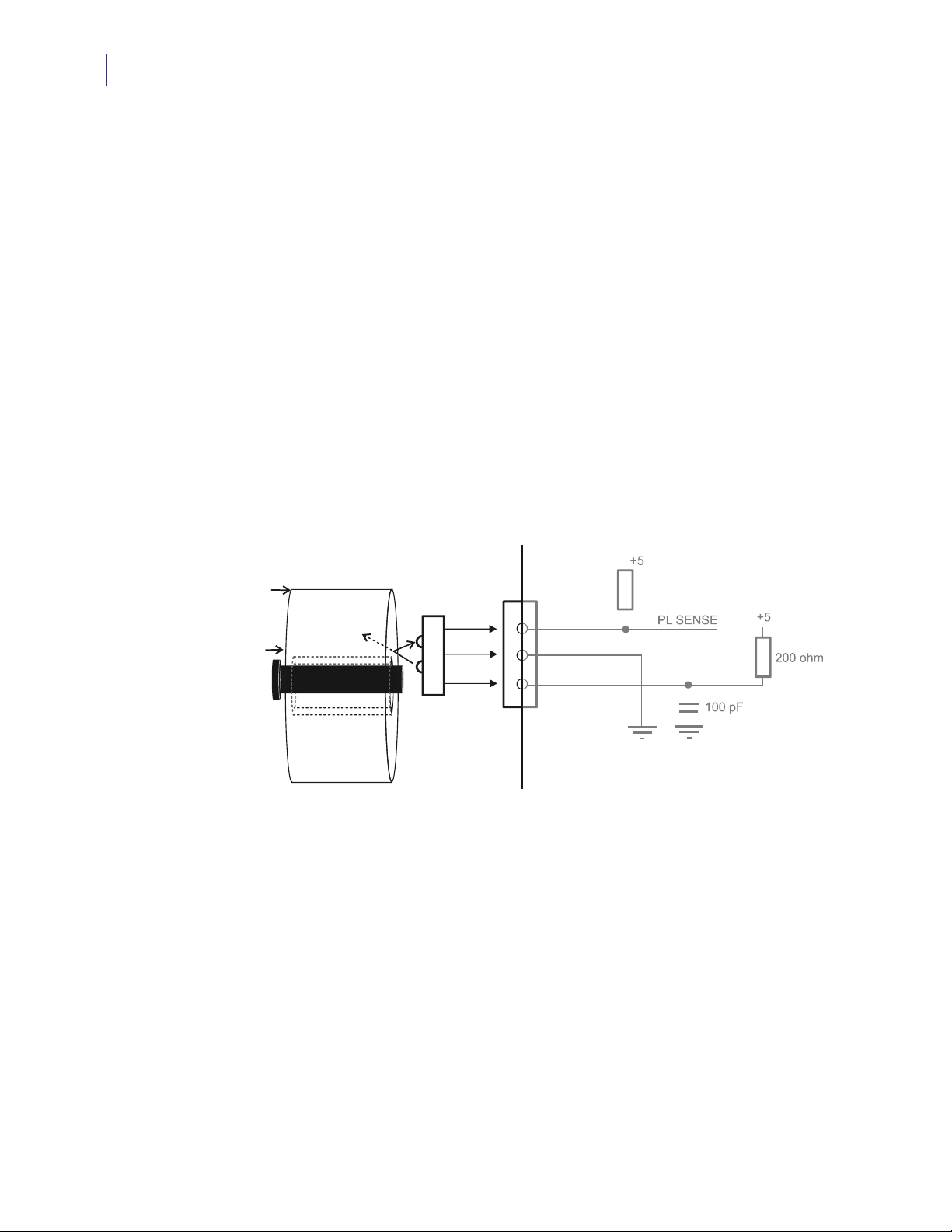

A paper-low sensor alerts the system that the media stock level is running low. The paper-low

sensor works with paper rolls and fanfold media.The purpose of this sensor is to get an early

alert so that you can replace the ticket stock in time in remotely located Kiosks.

The paper-low sensor operates by reflecting a light against the side of a media roll to detect it.

When the media is low, no light is reflected.

The printer automatically reads the paper-low sensor to check media status every time a

printout is cut. After three successive readings show that no paper is present at the sensor, the

status is set to paper low which alerts the system that the media needs to be replaced. Three

successive readings are required to prevent false paper low readings if the side of the media

roll is not clean. When a new roll of media is installed, the printer reads the sensor when the

printout is cut and the paper-low status is changed to paper present or paper not low.

Roll holders supplied by Zebra can be equipped with paper-low sensors. Attach the sensor and

connect the cable to the paper low connector at the back of the printer.

Paper roll

New

Near

end

Figure 10 • Paper-low Sensor Connection

Roll holder shaft

Paper-low

sensor

J10

+5

3

2

1

PL SENSE

Gray = Connection

inside printe r

+5

200 ohm

100 pF

SW97081F

P1003640-004 TTP 2100™ Technical Manual 09/18/2014

Installation

Connecting to the Computer

27

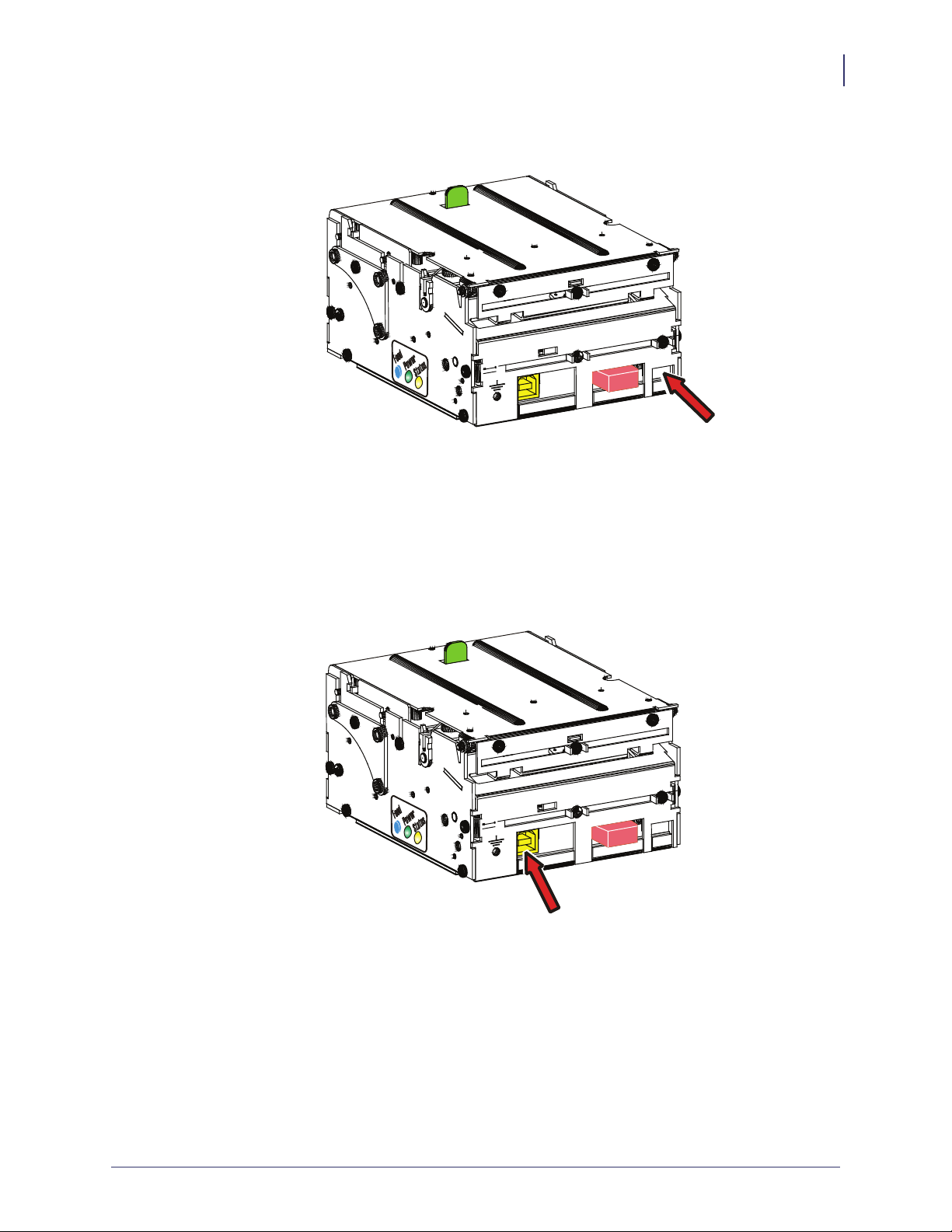

Figure 11 • Location of Paper-low Connector

Paper Low

Connector

Connecting to the Computer

Figure 12 • Location of Interface Connector

Interface

Connector

09/18/2014 TTP 2100™ Technical Manual P1003640-004

Installation

28

Connecting to the Computer

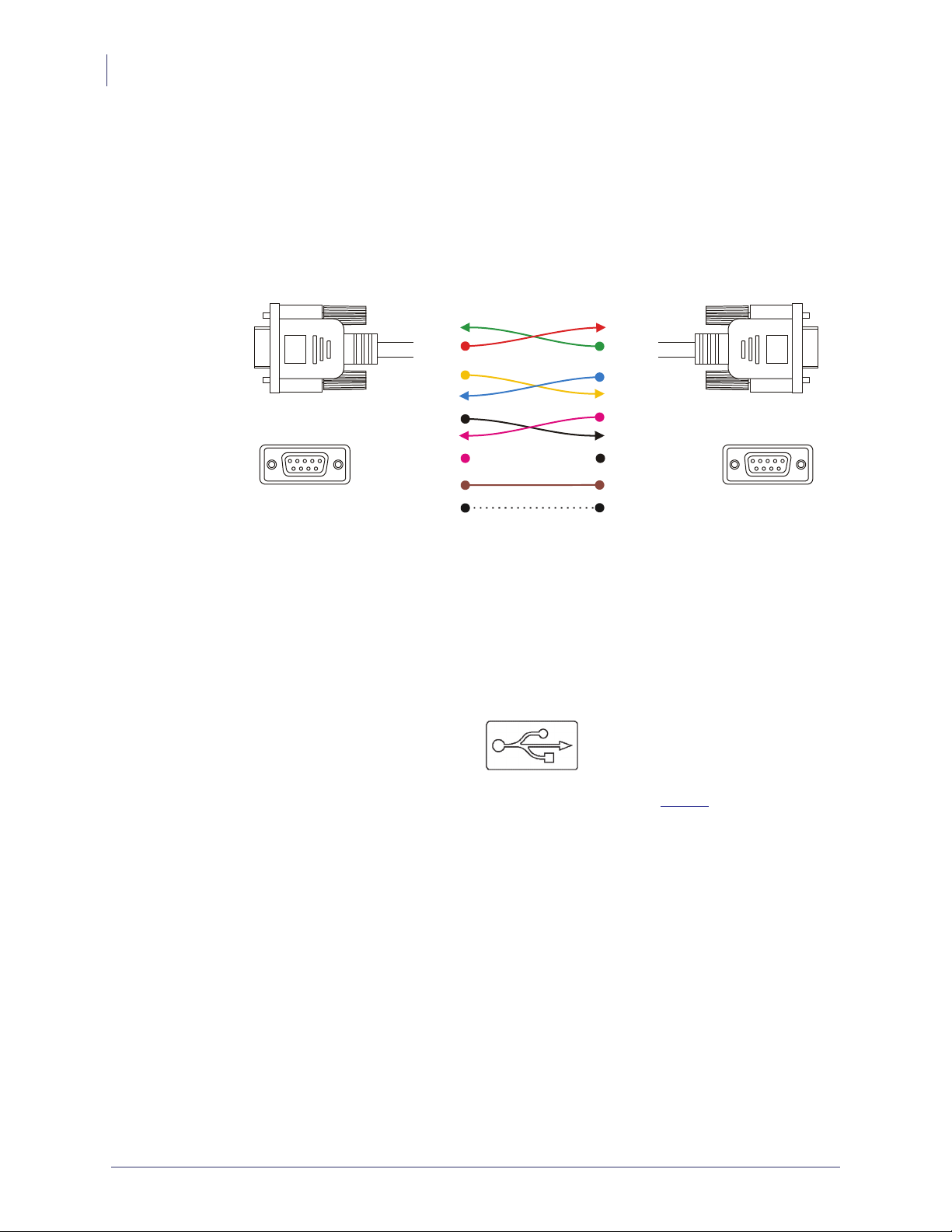

TTP 2110

Connect a Zebra serial cable (part No. 10825-000) between the printer and the computer to be

used. We strongly recommend using the Zebra cable because many incompatible cables are

available, which may cause communication problems.

Figure 13 • Serial Interface Cable 10825-000.

2RxDRxD2

3TxDTxD3

4DTRDTR4

PC

594837261

Female

Serial Cable 10825-000

6DSRDS R6

7RTSRTS7

8CTSCTS8

1DCDDCD1

5GNDGND5

9RIRI9

Printer

594837261

Female

TTP 2130

Dotted leads are not connected in the printer. To be able to connect the cable in any direction,

make symmetrical cables.

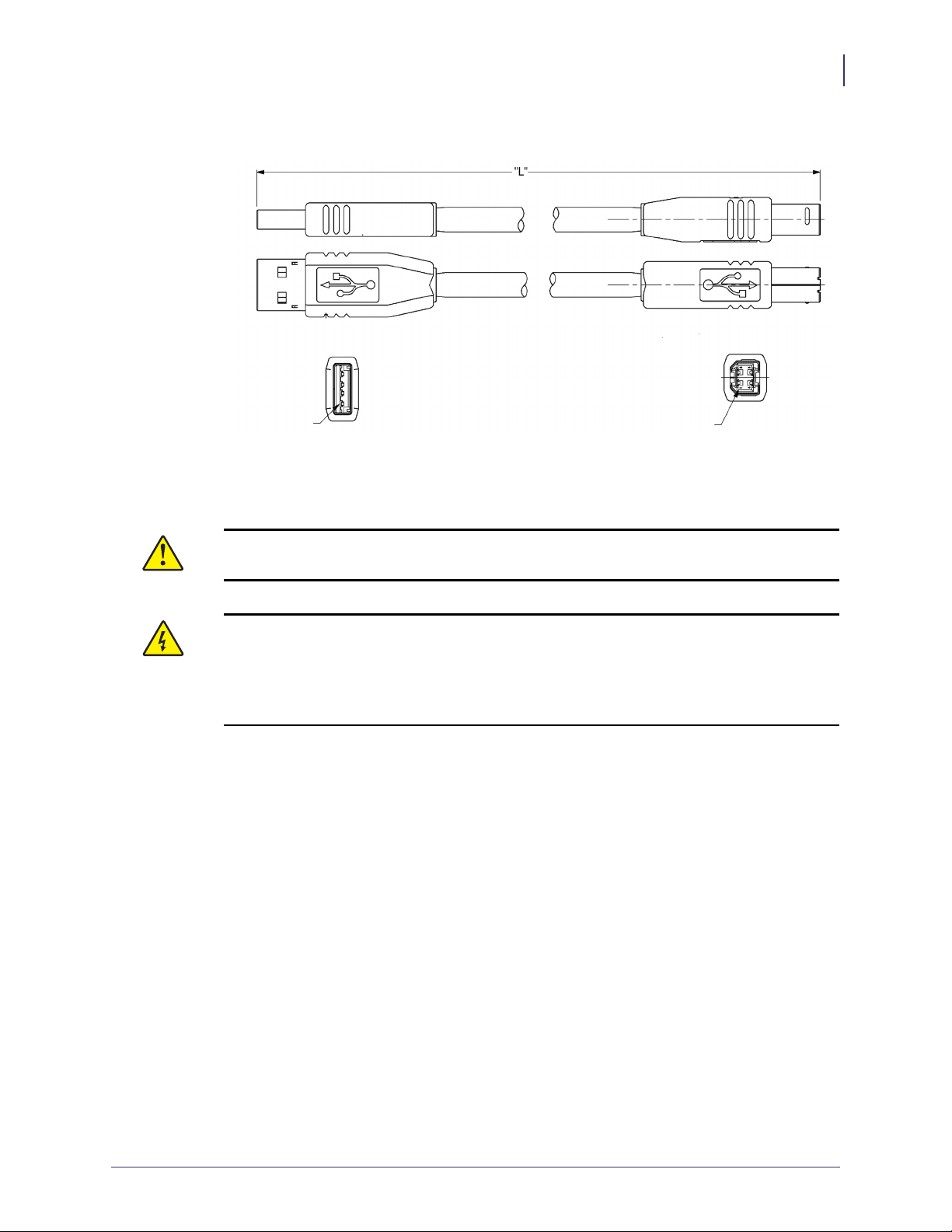

Connect the printer to the USB port of the computer or the USB hub to be used. USB

connectors can be recognized by the following symbol:

.

The connector on the printer is a 4-pin USB type B connector. See Table 4 for pin assignment.

A suitable cable is available from Zebra, part number 105850-028.

P1003640-004 TTP 2100™ Technical Manual 09/18/2014

Figure 14 • USB Cable with Type A and Type B Connectors

PC Printer

Position 1 Position 1

Connecting the Power

Installation

Connecting the Power

29

Caution • Using a non-Zebra power supply may cause excessive EMC interferences and

void the EMC certifications of the printer.

Caution • To avoid electrical shock and printer damage, wiring of a non-Zebra power

supply should only be done by qualified service personnel. Use ONLY a power supply

which meets the following minimum requirements:

• 24 VDC ±5%

• 70W (2.92A)

09/18/2014 TTP 2100™ Technical Manual P1003640-004

Installation

30

Connecting the Power

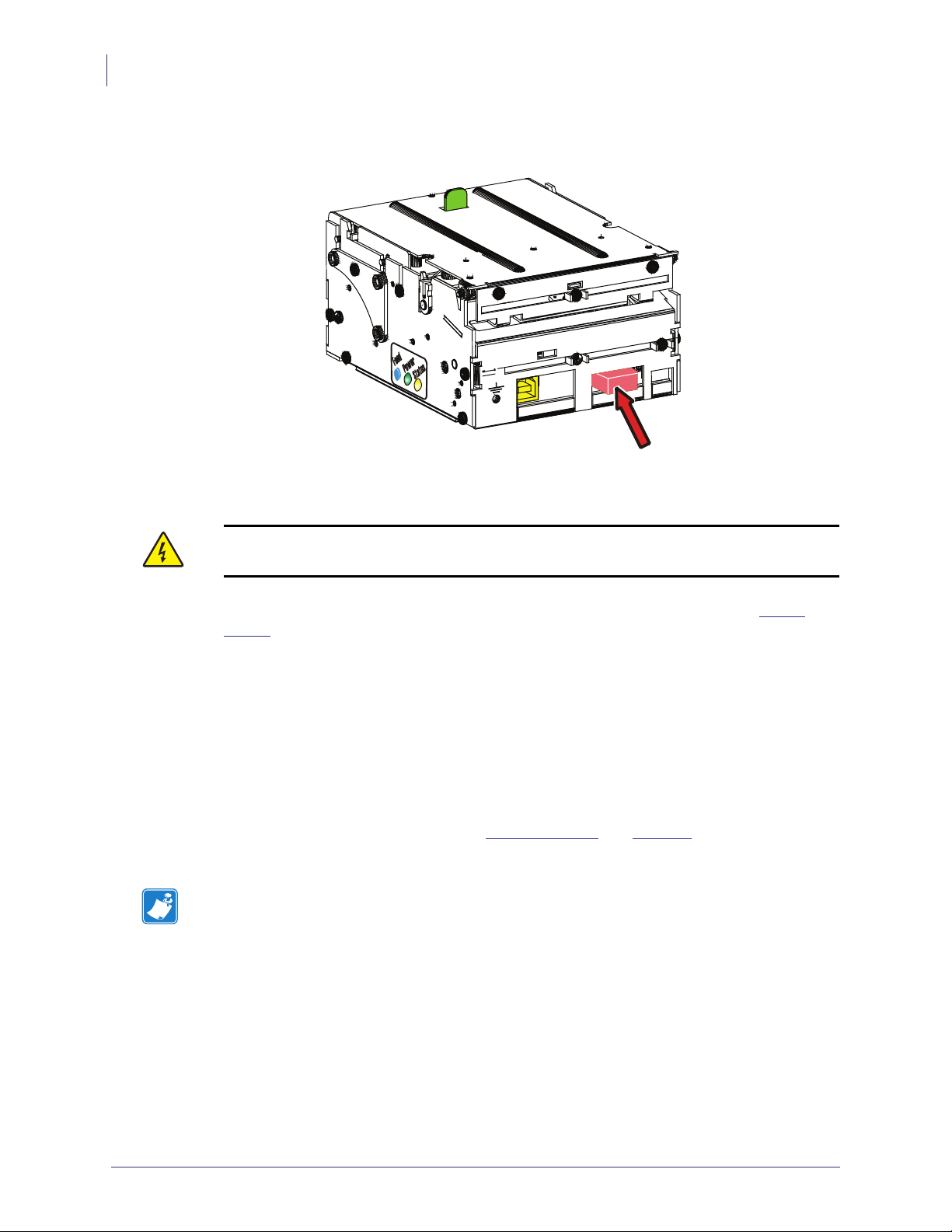

Figure 15 • Location of Power Connector

Power

Connector

Caution • On power supplies with line voltage selector, make sure it is set to your local line

voltage.

Using the appropriate Zebra power supply for TTP 2100 Desktop, or Embedded (

Power

Supply):

1. Connect the cable from the power supply to the power connector on the back of the

printer.

2. Connect the power cable to the line outlet.

3. Turn ON the power.

In Kiosk applications you may draw power from a common PSU in the Kiosk if the

characteristics are suitable. In such a case, cables that fit the connector on the back of the

TTP 2100 are available from Zebra (see

Part Number List on page 133). If you make cables of

your own, connect the voltages according to the following illustration.

Note • Protective ground and minus output should not be interconnected in the power supply.

A 600 mm power cable is available from Zebra. Use this if you have a common power supply

for the entire Kiosk and power the printer from there. Use the connector shown below if you

want to make cables of other lengths. At the printer end of the cable, use a TE Connectivity

Mate-N-Lok connector housing and two contact-sockets.

P1003640-004 TTP 2100™ Technical Manual 09/18/2014

Loading...

Loading...