Page 1

TR 220

Thermal Printer

User’s Manual

User’s Manual No. 980402-001 Rev.A

©2002 ZIH Corp.

Page 2

COPYRIGHT NOTICE

This document contains information proprietary to Zebra Technologies Corporation. This docu

ment and the information contained within is copyrighted by Zebra Technologies Corporation and

may not be duplicated in full or in part by any person without written approvalfromZebraTechnol

ogies Corporation . Whileeveryefforthasbeenmadetokeeptheinformation contained withincur

rent and accurate as of the date ofpublication, no guarantee isgiven or implied thatthe document

is error-free or that it is accurate with regard to any specification. Zebra Technologies Corporation

reserves the right to make changes, for the purpose of product improvement, at any time.

TRADEMARKS

TR 220 is aservice markand Zebraand Zebra Technologiesare trademarksof ZebraTechnologies

Corporation .

SPT 1700, SPT 1800, PDT 2700 and PDT 2800 are trademarks of Symbol Technologies, Inc.

All other marks are trademarks or registered trademarks of their respective holders.

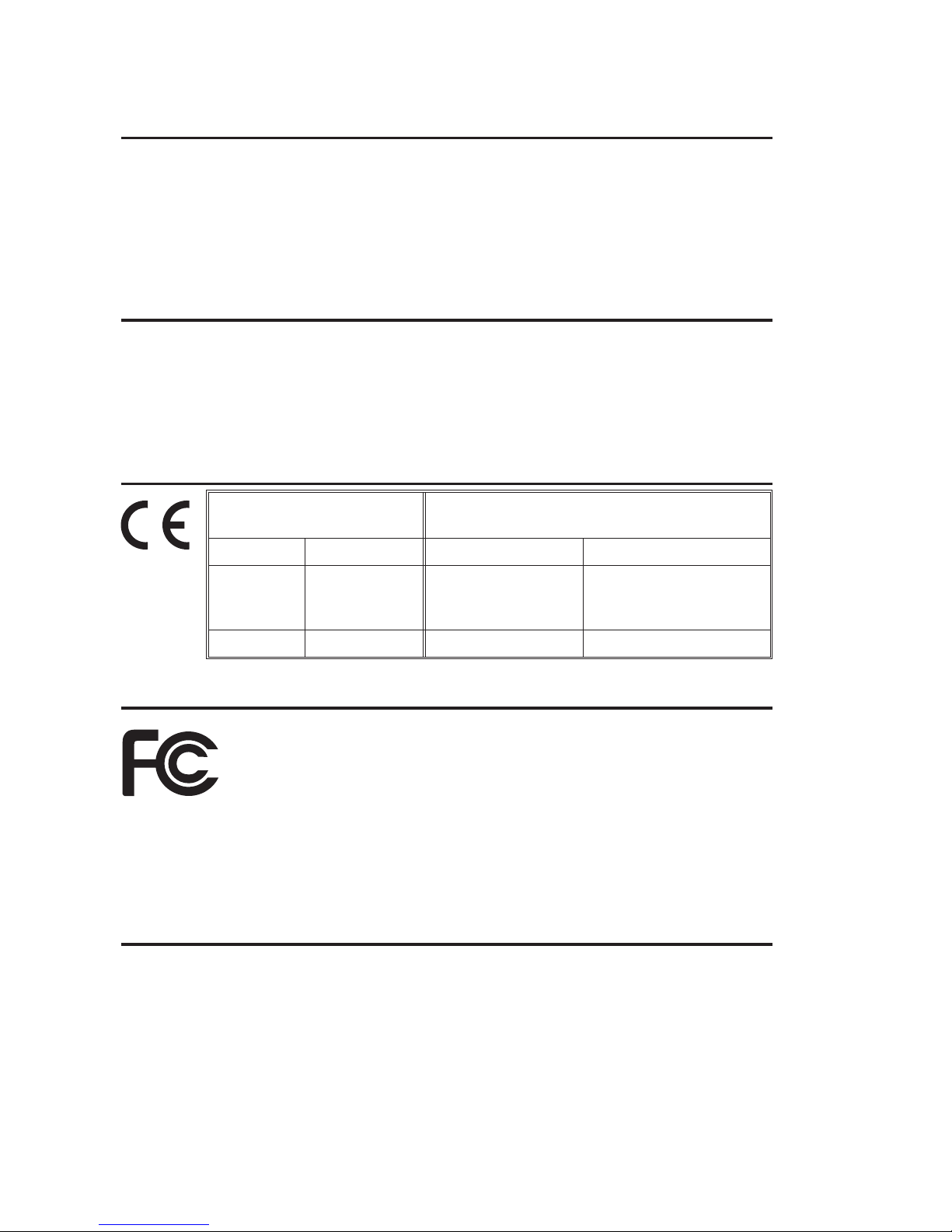

TR 220 Thermal Printer

European Council

Directive

89/336/EEC EMC Directive EN55022-B, 1998 RF Emissions control

92/31/EE EMC Directive EN55024, 1998

Compliance to Standards

Immunity to

Electromagnetic

Disturbances

-

-

-

73/23/EEC CB Schema EN60950 IEC950 Product Safety

FCC - Declaration Of Conformity:

Model: TR 220 conforms to the following specification:

FCC Part 15, Subpart B, Section 15.107(a) and Section

15.109(a) Class B digital device

Supplemental Information:

This device complies withPart 15 ofthe FCC Rules.Operation is subjectto the followingTwo Con

ditions: (1) This device may not cause harmful interference , and (2) this device must accept any

interference received, including interference that may cause undesired operation.

Industry Canada Notice:

This device complies with Industry Canada ICS-003 class B requirements.

Cet equipement est conforme a l’ICS-003 classe B de la norm Industrielle Canadian

-

ii 980402-001 Rev.A

Page 3

Contents

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . Chapter 1

Getting to Know Your Printer. . . . . . . . . . . . . . . . . . . . . . . 2

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Charge the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Loading Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

AutoSense: Media Sensing without the Terminal . . . . . . . . . . . . 10

Mating the Terminal to the Printer. . . . . . . . . . . . . . . . . . . . 11

AutoSense: Media Sensing with the Terminal Installed . . . . . . . . . 12

Terminal Configuration Information. . . . . . . . . . . . . . . . . . . 13

Dump Mode Printer Status Label . . . . . . . . . . . . . . . . . . . . 16

Operator Maintenance . . . . . . . . . . . . . . . . . . . . Chapter 2

Maintaining Your Printer . . . . . . . . . . . . . . . . . . . . . . . . 17

Media, Cleaning and Handling . . . . . . . . . . . . . . . . . . . . . 18

Print Care Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cleaning the Print Head. . . . . . . . . . . . . . . . . . . . . . . . . 19

Cleaning the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Cleaning the Platen Roller. . . . . . . . . . . . . . . . . . . . . . . . 21

Universal Battery Charger Accessory . . . . . . . . . . . . . Chapter 3

Using the UBC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Charging the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . 25

UBC Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Serial Interface Communication Configuration . . . . . . . . . . . . . 31

Symbol Terminal Serial Interface . . . . . . . . . . . . . . . . . . . . 31

TR 220 Command Reference . . . . . . . . . . . . . . . . Chapter 5

General Printer Configuration Information . . . . . . . . . . . . . . . 36

980402-001 Rev.A iii

Page 4

General Cautions and Warnings

This page describes general safety and maintenance warnings and cautions for the printer and

are referenced throughout the manual.

Warning - Static Discharge

The discharge of electrostatic energy that accumulates on the

surface of the human body or other surfaces can damage or

destroy the print head or electronic components used in this

device. DO NOT TOUCH the print head or the electronic

components under the print head assembly.

Media Warning

Always use high quality approved labels and tags. If adhesive

backed labels are used that DO NOT lay flat on the backing

liner, the exposed edgesmay stick to inside theprinter, causing

the label to peel off from the liner and jam the printer.

Media Reload Hint

If you should run out of labels while printing, DO NOT turn the

terminal power OFF or remove the printer’s battery while

reloading or data loss may occur. The printer will automatically

resume printing when a new label is loaded.

iv 980402-001 Rev.A

Page 5

Battery Handling and Usage Warnings

Misusing the battery may cause the battery to get hot, explode,

or ignite and cause serious injury. Be sure to follow the safety

rules listed below:

Do not place the battery in fire or heat the battery.

Do not disassemble or modify the battery. The battery

contains safety and protection devices which, if damaged,

may cause the battery to generate heat, explode or ignite.

Do not connect the positive terminal and the negative

terminal of the battery to each other with any metal object

(such as wire).

Do not solder directly onto the battery.

Do not pierce the battery with nails, strike the battery with a

hammer, step on the battery, or otherwise subject it to strong

impacts or shocks.

Do not expose the battery to water or salt water, or allow the

battery to get wet.

Do not place the battery on or near fires, stoves, or other

high-temperature locations. Do not place the battery in

direct sunshine, or use or store the battery inside cars in hot

weather. Doing so may cause the battery to generate heat,

explode, or ignite. Using the battery in this manner may also

result in a loss of performance and a shortened life

expectancy.

When the battery is worn out, insulate the terminals with

adhesive tape or similar materials before disposal.

Immediately discontinue use of the battery if, while using,

charging, or storing the battery, the battery emits an unusual

smell, feels hot, changes color, changes shape, or appears

abnormal in any other way.

In the event thatthe battery leaks and thefluid gets intoone’s

eye, do not rub the eye. Rinse well with water and

immediately seek medical care. If left untreated the battery

fluid could cause damage to the eye.

980402-001 Rev.A

v

Page 6

vi 980402-001 Rev.A

Page 7

1

Operation

The Zebra TR 220 is a 2-inch wide direct thermal mobile printer that is designed to mate with

a variety of Symbol® Portable Data Terminals,

including Symbol models SPT 1700, SPT

1800, PDT 2700 and PDT 2800. The printer’s

rugged design features include a tough

polycarbonate plastic body and shock absorbing rubber bumpers to permit the unit to withstand a 3-foot drop.

The TR 220 direct thermal printer can address

printing requirements for labels, receipts, and

tags. The printer accepts a maximum media

width of 2.25 inches and prints in an industry

standard 203 dpi (dots per inch) print

resolution. Media sensing capability includes

gap, black mark and notch.

980402-001 Rev.A 1

The printer has a light lithium ion battery that

allows printing of 2500 inches at 25% black

coverage of media on a single charge.

The printer utilizes the Zebra EPL2 program

ming language to communicate and process la

bels and forms.

-

-

Page 8

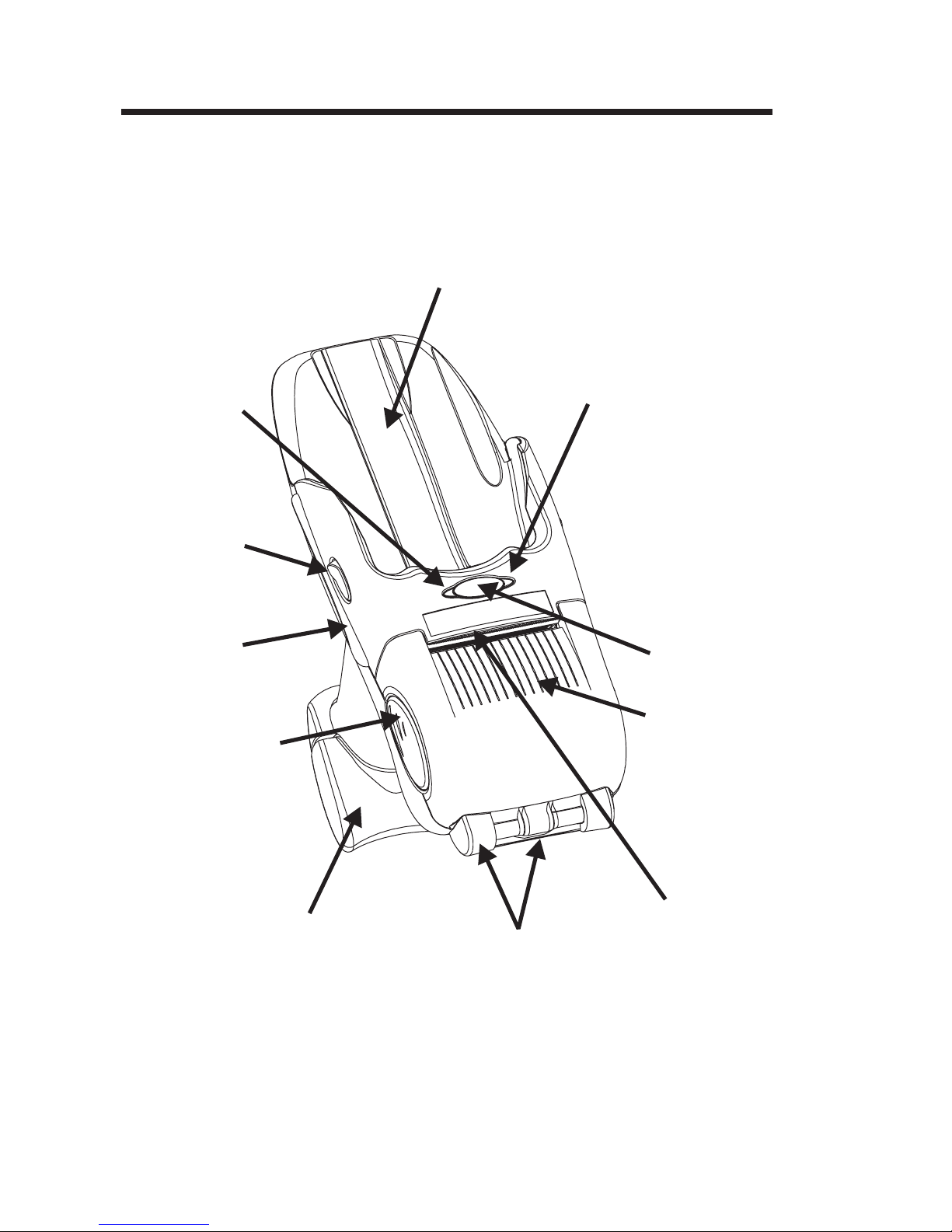

Getting to Know

Your Printer

Terminal

Cradle

Printer Status

Indicator

Terminal

Latch

Release

Bumper

Media Door

Release

Battery Status

Indicator

Feed Button

Media Door

Battery Installed

in Handle

2 980402-001 Rev.A

Rear Bumper

and Hinge

Media

Tear-Off

Strip

Page 9

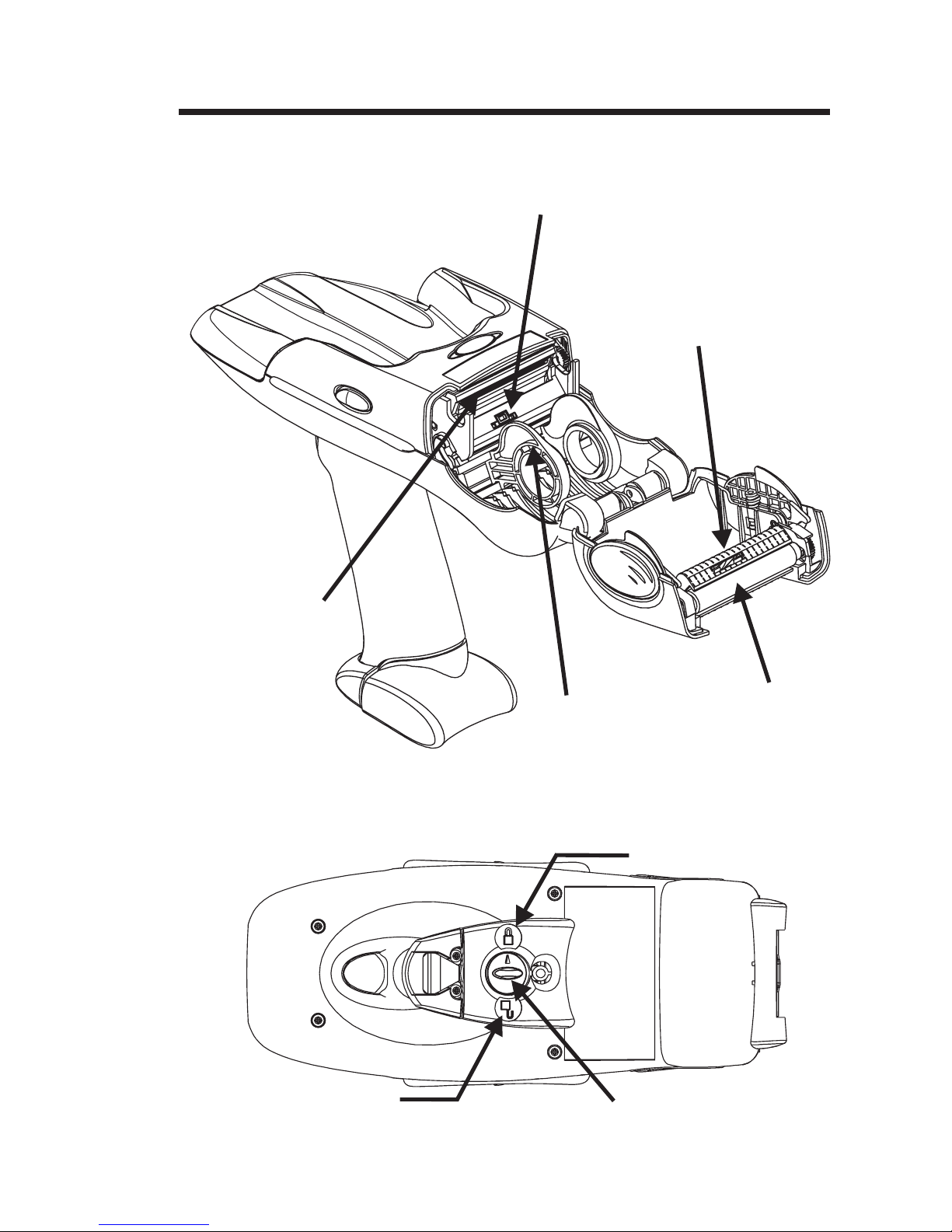

Getting to Know

Your Printer

(continued)

Media Sensor

(Transmissive “Gap” Transmitter)

Media Sensor

(Transmissive “Gap” Receiver and

Reflective “Black line”

Receiver and Transmitter)

Print Head

Media

Holders

Bottom View

Platen

Roller

Locked

Unlocked

980402-001 Rev.A 3

Battery

Latch

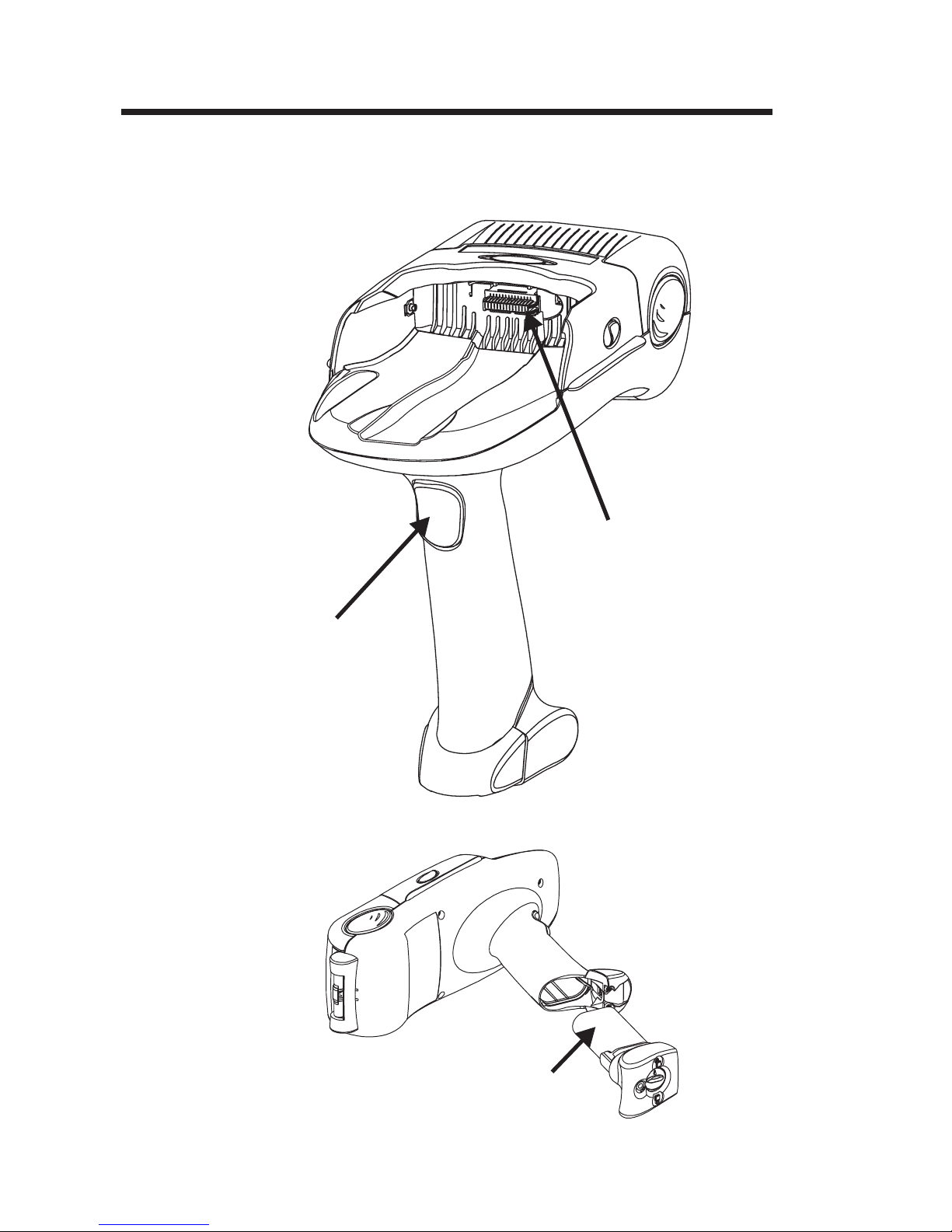

Page 10

Getting to Know

Your Printer

(continued)

Serial Port

Scan Trigger

Bottom View

4 980402-001 Rev.A

Lithium Ion Battery

Page 11

Getting Started Before you can use the TR 220 printer, do the

following:

Charge and Install the Battery

•

Load the Printer with Media

•

Initialize the Media

•

Mate the Printer and Terminal

•

Charge the Battery Before the printer can be used the first time, the

lithium-ion battery must be charged and in

stalled into the printer.

The printer’s battery can be charged using the

Universal Battery Charger (UBC) which is an

optional printer accessory, see page 23.

For instructions on using the UBC to charge

your battery, see the Quick Reference Guide

which comes with the UBC. Follow these same

procedures to recharge the battery when the

printer’s battery level is low.

-

The printer’s battery (Reorder number

p/n 105312-001) must be exclusively used as

the power source for the TR 220 printer and

should not be used for any other purpose.

980402-001 Rev.A 5

Page 12

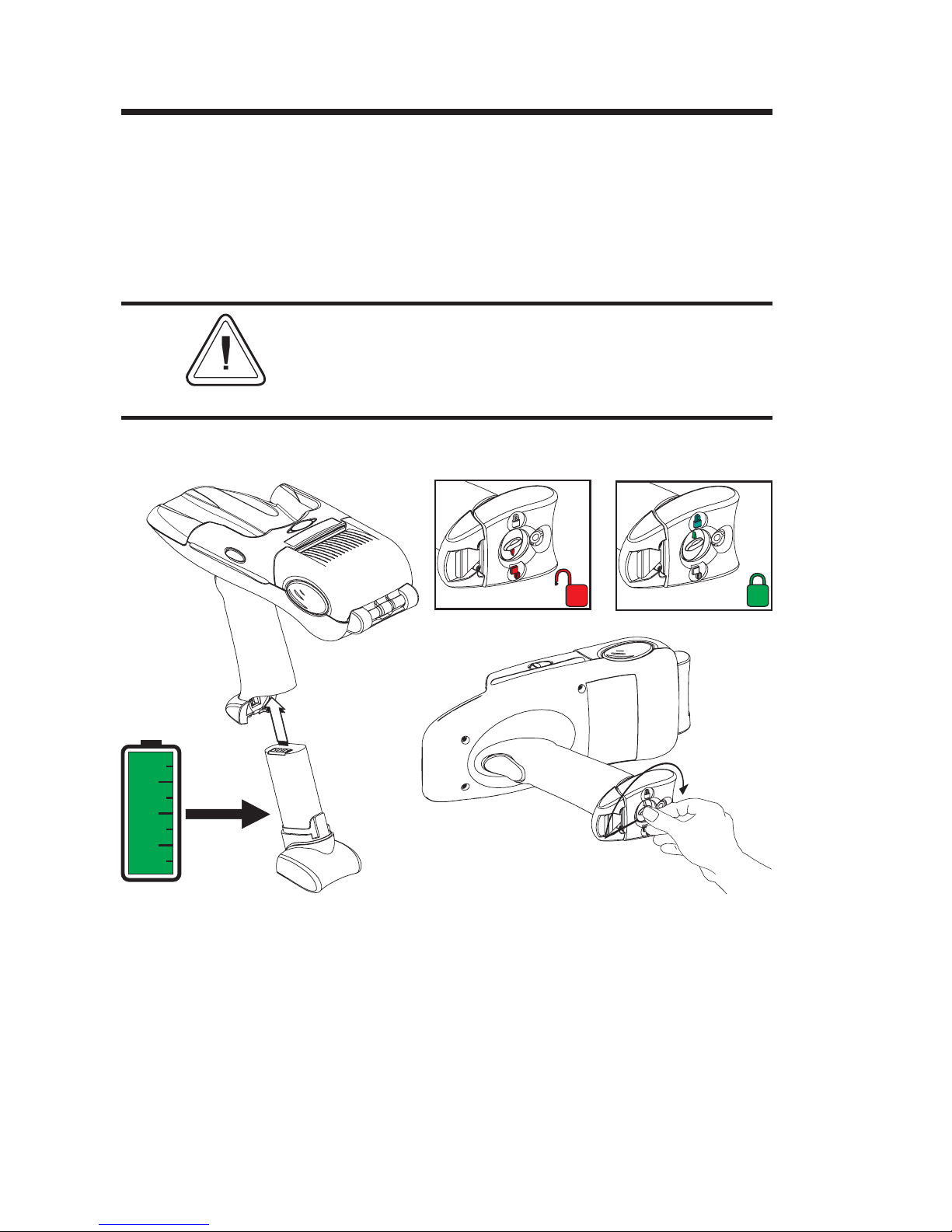

Installing the

Battery

Step 1 Remove the fully charged battery from the

To install the battery in the TR 220 printer:

charger. Leave the battery latch in the unlocked

position to install into the printer.

Do not force the battery. The battery and printer

are uniquely shaped (keyed) to avoid inserting

the battery incorrectly or mixing batteries with

similar products.

100%

0%

Un-latched

Latched

Lock

Battery

Step 2 Slide the battery into the empty printer handle.

Step 3 Rotate the battery latch while holding the bat

tery in the printer’s handle to secure the battery.

The point the arrow on the latch’s locking knob

to the closed lock symbol.

-

6

980402-001 Rev.A

Page 13

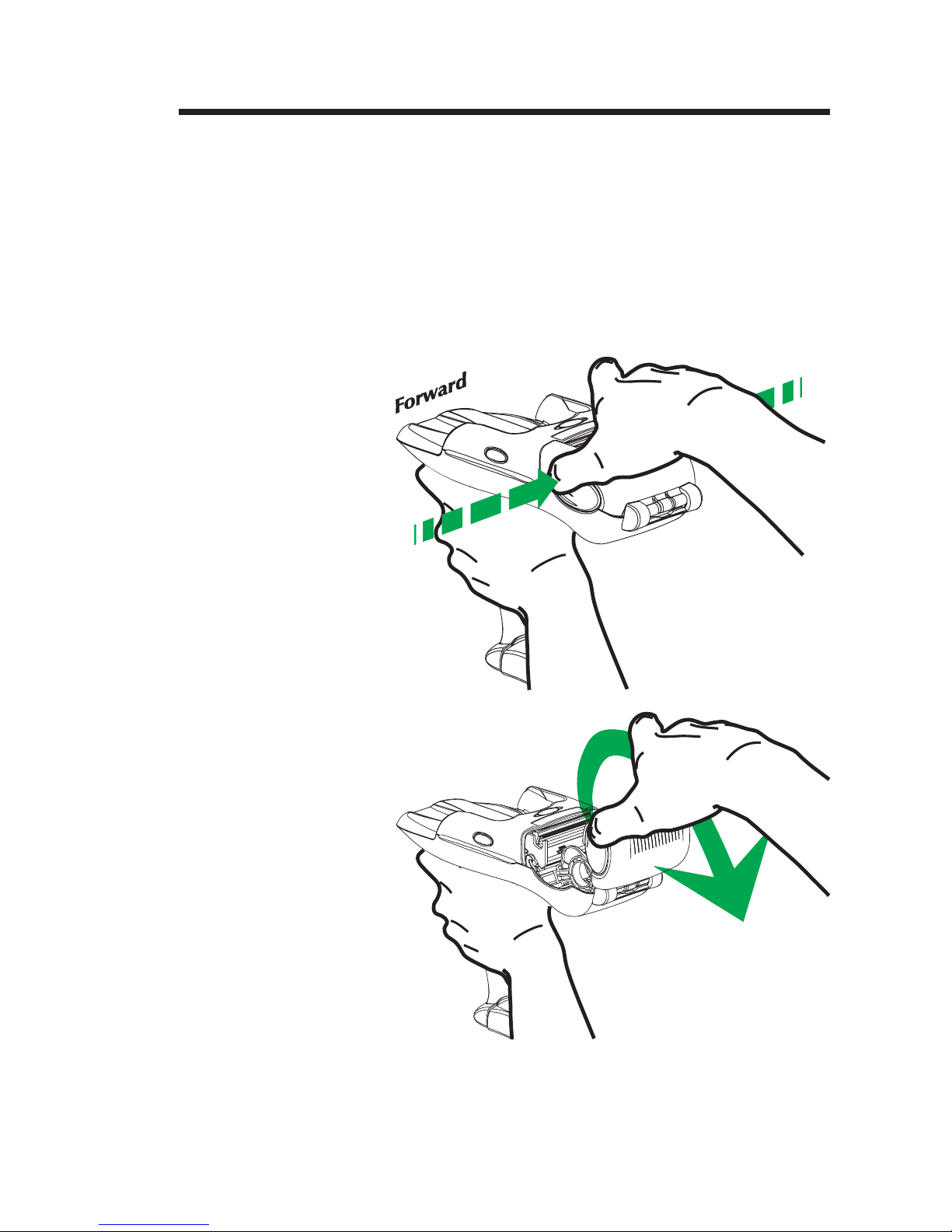

Loading Media To load media into the printer:

Step 1 To open the media door, simultaneously press

the front (forward) portion of the media door

release buttons, located on the right and left

sides.

Lift the door open.

980402-001 Rev.A 7

Page 14

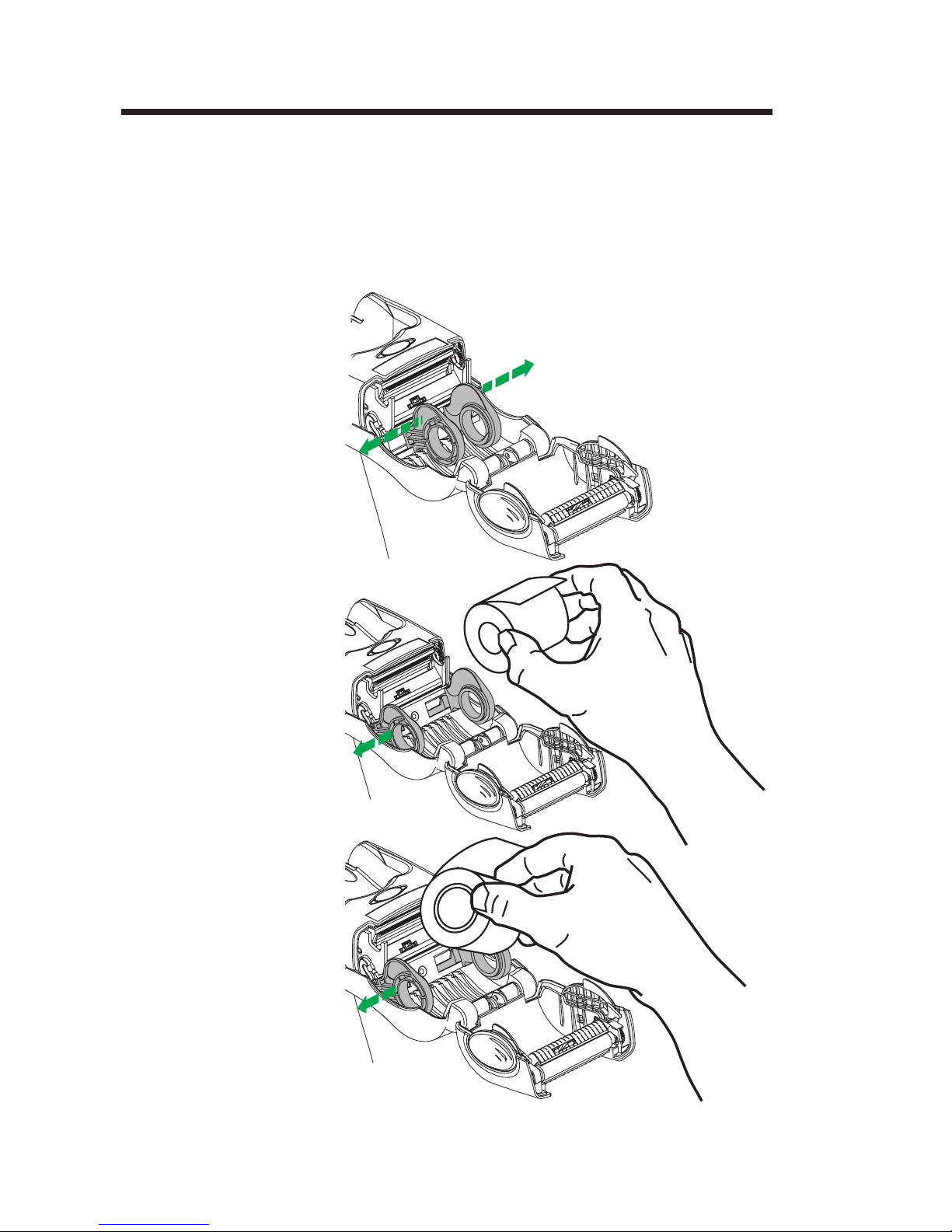

Loading Media

Step 3

Open the media guides. Insert the media roll.

The media roll holders are linked. Both sides

open when one side is pushed open.

Place the media to unwind in the clockwise di

rection when viewed from the left side of the

printer.

-

8

980402-001 Rev.A

Page 15

Loading Media

Step 4

Center the roll between the holders and release

the roll holders. Gently wiggle and pull on the

roll to guarantee the roll has seated and is cen

tered on the roll holders. The roll should not

bind and be able to rotate freely.

-

Step 5 Close and lock the cover. Tear off the excess

media.

Remove the first few inches of media to

eliminate contamination that collects from

handling, storage and adhesive. Contaminates

can transfer from the media to the print head,

reducing print head life or performance.

980402-001 Rev.A 9

Page 16

AutoSense:

Media Sensing

without the

Terminal

Step 1 Remove the terminal from the printer.

Step 2 Load media into the printer.

Step 3 Press and hold the Scan Trigger.

Step 4 Press and hold the Feed Button down for 2

Prior to printing, the media sensing levels

and the label’s length and gap distances be

tween labels must be set to print properly.

The user initiates the TR 220’s AutoSense

feature to set and store these parameters in

the printer.

Use the following procedure to run the

printer’s AutoSense routine.

seconds and release. The Printer Status Indicator should begin blinking green.

-

Step 5 The indicator will stop blinking and then go

solid green. When the media begins to feed

(advance), release the Scan Trigger.

Step 6 The printer will advance 3-4 labels (or ap-

proximately 12 inches) while performing the

adjustment. When the adjustment is complete, a status summary label will be printed

and the printer will be placed in Diagnostic

Dump mode.

Step 7 Press the Feed Button once to exit “Dump

Mode”.

The printer will remain on for 5 minutes in

Stand-by Mode and then automatically turn

off if there is no printer activity.

See “AutoSense: Media Sensing with the

Terminal Installed” on page 12 to detect and

configure the printer for new media while us

ing the terminal and printer.

-

10

980402-001 Rev.A

Page 17

Mating the

Terminal to the

Printer

1 Secure the strap.

2 Turn the terminals power off.

3 Slide the terminal into the printer until it latches

The terminal can be inserted into and mate

with the printer. The printer connects to the ter

minal via a unique serial connector (port) and a

patented latching mechanism.

The terminal’s hand strap maybe installed or

removed. The strap should be closed and se

cured to itself to avoid interference with the

scanner, binding or catching on other objects.

To mate the terminal to the printer:

in place. Both latches typically will make an audible click when the terminal is engaging properly with the printer.

-

-

980402-001 Rev.A 11

Verify that the terminal is secured properly,

gently pull the terminal outward and wiggle it.

Page 18

AutoSense:

Media Sensing

with the Terminal

Installed

Step 1 Load media into the printer.

Prior to printing, the media sensing levels and

the label’s length and gap distances between la

bels must be set to print properly. The user initi

ates the TR 220’s AutoSense feature to set and

store these parameters in the printer.

Use the following procedure to run the printer’s

AutoSense routine.

-

-

Step 2 To turn on the printer, activate (select) an appli

cation previously loaded in the terminal that is

designed to use the TR220 printer. The printer

status indicator should be on and green, if the

printer is ready to operate.

The software application in the terminal must

activate the printer via a serial port signal

(5volts) for the printer to operate. Contact your

system integrator or administrator to identify

the proper software, application, and terminal

combination to operate the printer.

Step 3 Turn the terminal off.

Step 4 Press and hold the Feed button down turn the

terminal on. Release the Feed button after the

printer status indicator is blinking green.

Step 5 The indicator will stop blinking and then go

solid green. The printer will advance 3-4 labels

(or approximately 12 inches) while performing

the adjustment. When the adjustment is com

plete, a status summary label will be printed

and the printer will be placed in Diagnostic

Dump mode.

-

-

Step 6 Press the Feed Button once to exit “Dump

12

Mode”.

The printer is ready to print.

980402-001 Rev.A

Page 19

Terminal

Configuration

Information

In order to successfully use the TR220, the 5V

output signal must be activated, and a printing

library needs to be installed. The printing li

brary, printer manual, printcap file and sample

printing code are included in the Symbol SDK.

Symbol software tools are available online at:

http://devzone.symbol.com

External 5V Signal The terminals each require particular software

drivers that enable Palm and Windows CE ap

plications to control the activation of the exter

nal 5V signal. However, these drivers are not

readily found on all terminals nor do they all

work the same way. The steps required by each

terminal to allow for the control of the external

5V signal are given below.

SPT 1700 The power driver (powerdrv35r.prc) and trigger

scan mgr (1700_trigger_scanmgr.prc) must be installed through a Hot-Sync operation followed by

a soft reset. Once installed, the application developer then initializes the serial communication

port with the "srmOpen" function and "upwr" port

parameter to activate the external 5V signal.

-

-

-

SPT 1800 The power driver for the SPT 1800 is pre-installed

and does not require any other software installa

tion. By initializing the serial communication port

with the "srmOpen" function and "upwr" port pa

rameter, the external 5V signal is activated.

PPT 2700 and

2800

Printer Command

Language

980402-001 Rev.A 13

The driver is pre-installed on the PPT 2700 and

PPT 2800 terminals. By selecting “Com7” as

the active serial communication port, the exter

nal 5V signal is automatically activated.

For SPT 1700 and SPT 1800 terminals, you

must use EPL2 Page Mode commands via the

"ptwriteprinter" command. Refer to the Symbol

Software Development Kit for more informa

tion. For PPT 2700 and 2800 terminals, refer to

the PPT 2700 and PPT 2800 WinCE SDK.

-

-

-

-

Page 20

The Feed Button, Scan Trigger and Status Indicators

Printer State Media Feed Button Printer Response

Terminal mated

with Power Off

Terminal mated

with Power On

Terminal mated

with Power On,

door latched,

ready, not printing

Terminal mated

with Power On,

door latched,

ready, not printing

Terminal mated

with Power On,

door latched,

ready, not printing

N/A

N/A

Labels or Tags

Loaded

Labels or Tags

Loaded

Continuous Media

Loaded

Tap or Hold No Action

Wakes up printer from

Standby Mode.

Tap and Release

Tap

(If in Standby

mode, tap and

release to wake

up printer)

Press and Hold

(If in Standby

mode, tap and

release to wake

up printer)

Press and Hold

Standby Mode is initi

ated by eight seconds

of printer inactivity.

Form Feed: the printer

advances to the top of

the next label or tag.

Continuous Form Feed:

the printer advances

media continuously until the button is released, then continues

to the top of the next

label or tag.

The printer advances

media continuously

while the button is

pressed. Upon release,

the printer will advance

one form length (set by

programming com

mand).

-

-

Terminal mated

with Power On,

door latched

No terminal, door

latched, ready, not

printing

Terminal mated

door latched,

ready, not printing

Media Loaded

Media Loaded

14 980402-001 Rev.A

Media Out

(If in Standby

mode, tap and

release to wake

up printer)

Press and Hold

Uses the Feed button and Scan Trigger

to initiate the AutoSense Routine for de

tecting the media without the terminal,

see page 10 for details.

Uses the Feed button and the terminal to

initiate the AutoSense Routine for detect

ing the media with the terminal installed,

see page 12 for details.

Motor will turn equiva

lent of 15mm media

motion, printer will de

tect no media condition

and then motor will

stop.

-

-

-

-

Page 21

Status

Indicator

Battery

Indicator

Condition Printer Operational State

Dark Dark Off

Terminal Power Off or is not mated.

The printer’s battery is missing or not

connected.

Ready

Green N/A

or

Printing

Red N/A Media Out

Error - Syntax

(Data)

Orange N/A

Error - Media

Detection

Terminal Power ON, printer opera

tion normal.

Note: If a print job is in process and

the terminal power goes off or the

terminal is disconnected after passing

the print job to the printer, the printer

status indicator will remain green and

the print job will finish. The status in

dicator will then go dark (off) after

completion of this print job.

Terminal Power On. Printer is not

printing. No media is detected.

Terminal Power ON, printer is not

printing, Error condition detected.

1) If the error report status is commanded to be “off’ via software, the

status indicator will only indicate motor or print head over temperature errors.

2) If error reporting status is enabled

by the US command, then all pro

gramming syntax and media detec

-

tion errors will result in an

Orange-constant status indicator con

dition.

-

-

N/A

N/A

Blinking

Orange

Orange

Constant

980402-001 Rev.A 15

Low Battery

Warning

Battery

Replacement

or

Recharge

required

Indicates battery remaining charge

power level is less than 40% initial

full charge.

Printer will operate normally while

this warning is displayed.

Indicates battery remaining charge

power level is less than 20% of full

charge and requires recharging. The

printer will finish printing jobs in

progress, but will not start new print

jobs until the battery charge level is

greater than 20%.

Page 22

Dump Mode

Printer Status

Label

Uq311 V3.18

Serial port:96,N,8,1

Image buffer size:114K

Fmem:000.0K,061.4K avl

Gmem:000K,069K avl

Emem:000K,069K avl

I8,0,001 rN

Battery: 60%

|**|**|**|--|--|

D10 R000,000 ZT UN

q384 Q817,025

Option:

16 23 31

now in DUMP

Dump Mode Print Sample

The operator can use the Dump Mode Status

printout to check the battery charge status, print

quality, verify printer to terminal serial interface

settings (printer and terminal must match) and

the firmware version number. The rest of the in

formation on the printout is for program devel

opment and debug.

. Printer I.D. code number and firmware

A

version number.

. Serial port configuration.

B

. Print head test pattern.

C

.Amountofmemoryavailableforthe

D

Image buffer.

. Amount of memory used and memory

E

available for Form storage.

. Amount of memory used and memory

F

available for Graphics storage.

. Amount of memory used and memory

G

available for Soft fonts.

. Currently selected Character Set ( ) and

H

Image Buffer mode setting

rN

( = Double Buffering Disabled)

. Battery Status

I

. Currently selected Heat Density ( ),

J

Reference Point ( ), Print Orientation ( )

and Error Status ( ).

. Currently selected Form Width (q) and

K

Length ( ).

. Current Hardware and Software

L

Option status - (Not Supported)

. Current AutoSense Through (Gap)

M

Sensor values. The three numbers

represent;

1. Backing Transparent point

2. Set point

3. Label Transparent point.

. Current Dump Mode Status

N

Q

RZ

U

I

D

-

-

16

980402-001 Rev.A

Page 23

2

Operator Maintenance

This section provides information on operator

maintenance procedures for your printer.

Maintaining Your

Printer

The printer requires regularmaintenance to optimize printing and extend the serviceable life of

your printer. Zebra Technologies uses only

high quality components and materials in its

printers. The printers are manufactured and

tested under a strict quality management program. Although only minimal routine maintenance is required, following these simple

maintenance guidelines will ensure longer life

with quality printing performance.

The printer’s design allows for cleaning of

printer’s media path. The operator can safely

clean the print head, platen roller and areas ad

jacent to the media path surfaces by following

the simple procedures and guidelines on the

following pages.

-

980402-001 Rev.A 17

Page 24

Media, Cleaning

and Handling

The printer requires periodic cleaning to maxi

mize the print quality and print head life. The

main factors that contribute to reduced head

life (and platen life) are:

Touching the print head! Static electricity

can discharge and damage the print head. The

body’s oils and acids also damage the print

head.

Cleaning - For optimum performance, clean

the print head regularly after every 3-5 rolls of

media.

Abrasion - Over time, the movement of media

across the print head will wear through the protective ceramic coating, exposing and eventually damaging the print elements (dots).

-

Use of proper media - Use only approved

media. Non-approved media may contain

chemicals that can destroy or dramatically reduce the print head’s life.

Temperature - Print head density (heat) setting. Set the density to the lowest possible setting that prints a good image.

Using Zebra Technologies approved media also

helps ensure that your printer will have a longer

life with quality printing performance.

See www.zipzebra.com

for your on-line

thermal label and ribbon media source.

ZipZebra has bar code label and ribbon supplies

for Zebra and Eltron label printers, and thermal

printer ribbons and labels for other popular

thermal label printing systems.

18

980402-001 Rev.A

Page 25

Print Care

Guidelines

Remove the outer layer of media from the la

•

bel roll before loading media. Tape or adhe

sive that holds the loose end and the outside

length of media becomes contaminated

when handled or stored. When you remove

this part of the media, you remove poten

tially contaminating oils, dust, and adhe

sives.

Clean the print head every 3-5 label rolls.

•

Clean the platen (drive) roller to remove con

•

taminates. Note - Paper or label liner parti

cles do not normally affect print operation.

-

-

-

-

-

-

Cleaning the Print

Head

1 Open the media door and remove the media.

2 Gently rub the cleaning pen across the upper

As you use your printer, the print head may become contaminated resulting in poor print

quality. Every 3-5 rolls of media the print head

should be cleaned with a cleaning pen.

black and colored areas of the print head. Allow

the print head to dry for 1 minute before loading media.

980402-001 Rev.A 19

Do Not Clean the Print Head with sharp ob

jects! Only used approved cleaning materials.

-

Page 26

Cleaning the

Printer

Cleaning the outside of the printer is not gener

ally recommended except in cases where the

contaminates may migrate to the media or the

platen roller (both contact the print head).

-

Linerless media printers need additional clean

ing to avoid adhesive buildup on the ribs in the

media path near the platen roller.

Always Remove The Battery And

Terminal Before Cleaning the Platen

Roller or General Printer Cleaning.

Do Not Clean The Battery.

Do Not Clean the Printer’s Serial Port

Connector.

The exterior surfaces and the media path surfaces (except the print head) can be cleaned

with a lint free, clean, damp cloth very lightly

moistened with medical grade alcohol. Medical

grade alcohol (95% pure or better) may be

used to help remove any adhesive or label material buildup.

-

20

Avoid cleaning the media sensors. Remove ac

cumulated dust with a dry swab from the sen

sors by gently wiping them off. If adhesives or

other contaminates get on the sensor, then an

alcohol moistened swab may be used. Clean

several times to remove any film that may be

left from the initial cleaning or sensors may not

function properly. Using too much alcohol can

allow it to get between the electronic compo

nents and will require a much longer drying

time before the printer will function properly.

980402-001 Rev.A

-

-

-

Page 27

Cleaning the

Platen Roller

The standard platen (drive) roller normally

does not require cleaning. Paper and liner dust

can accumulate without effecting print opera

tions. Contaminates on the platen roller can

damage the print head or cause the media to

slip when printing. Adhesive, dirt, general dust,

oils and other contaminates should be cleaned

immediately off the platen.

The non-stick platen roller on Linerless media

printers requires frequent cleaning to keep ad

hesive buildup from occurring and transferring

to the print head and the media path.

The platen can be cleaned with a fiber free

swab (such as a Texpad swab) or a lint free,

clean, damp cloth very lightly moistened with

medical grade alcohol (95% pure or better). Do

Not Use the Cleaning Pen!

-

-

1 Open the media door and remove the media.

2 Clean the platen surface with the alcohol moist-

ened swab. Rotate the platen while swabbing.

Repeat this process two to three times with a

new swab to remove residual contaminates.

Adhesives and oils, for example, may be

thinned by the initial cleaning but not com

pletely removed.

-

980402-001 Rev.A 21

Allow the printer to dry for 1 minute before

loading labels.

Page 28

22 980402-001 Rev.A

Page 29

Power

Cord

3

Universal Battery Charger Accessory

The Universal Battery Charger (UBC) is not included with the printer and is sold as an accessory. The UBC is designed specifically for use

with TR 220 printer. It provides the proper voltage and currents to safely charge your printer’s

lithium-ion battery. The UBC accessory contains the following:

980402-001 Rev.A 23

Power

Supply

UBC

The Universal Battery Charger (UBC) is the

only approved, safe method to charge your

battery. Using other methods to charge your

printer’s battery may damage the battery or in

the worst cases cause a fire or explosion.

See the Battery Warnings on page v

Page 30

Using the UBC The single unit UBC configuration setup is out

lined below.

1 Plug the DC Power cable into the UBC.

2 Plug the AC Power cord into the power supply.

The power supply has a standard modular AC

plug design to accommodate multiple

grounded power cord variations. The power

supply is capable of utilizing a wide range of in

put voltages from 100 to 240 VAC.

Plug the other end of the AC Power cord into a

properly grounded AC power receptacle.

3 The UBC’s Power indicator will light green.

-

-

12

24

3

980402-001 Rev.A

Page 31

Charging the

Battery

1 Set the battery’s lock to the unlocked position

2 Insert the battery and while pushing down on

3 The UBC’s Charge indicator will flash for a few

4 The Ready indicator will go green when charg-

The printer’s battery is keyed and designed to

only install into it’s UBC. This is to protect the

battery and operator from improper charging.

and insert it into the UBC.

the battery, turn the battery’s lock to the locked

position.

seconds while the battery and charger are

initializing and then go solid yellow while

charging.

ing has completed.

980402-001 Rev.A 25

Page 32

UBC Status

Indicators

POWER - Solid Green when the UBC has

power connected and is ready to charge.

READY - Solid Green when the battery is

ready to use.

CHARGING / FAULT - Solid Yellow when

the battery is charging.

CHARGING / FAULT - Flashing Yellow

when the battey has been rejected due to bat

tery failure (short, dead cell, etc.).

-

26

980402-001 Rev.A

Page 33

Appendix A - Troubleshooting

Problem Solution or Reason

Sleep Test - Press the Feed Button

until the Printer Status Indicator blinks

green and release the trigger and button.

This is normal operation. If the

indicators are:

1. Both Dark - The battery needs to be

Printer Status Unknown

Terminal Not Mated

Status indicators are:

Printer - DARK

Battery - DARK

installed, charged or is defective.

2. Both Dark - Printer failure.

3. Battery Status - Orange or Blinking

Orange - Battery Low, needs charge.

3. Printer Status other than blinking green Remove and re-insert the battery to

reset the printer. Repeat Sleep Test.

Function Test and Status Report Run the AutoSense: Media Sensing

without the Terminal procedure (see

page 10) to verify printer operation. The

Dump Mode printout includes battery

charge status.

Terminal Mated and ON

Terminal application

software is active - Status

Unknown

The status indicators are:

Printer - DARK

Battery - DARK

Terminal Mated and ON

The status indicators are:

Printer - GREEN

Battery -N/A

Sleep Test - Printer only

Press the Feed Button and verify printer

status is blinking green. If the indicators

are:

1. Both DARK - The battery needs to be

installed, charged or is defective.

2. Both DARK - Remove the terminal and

verify printer operational readiness with

the Sleep Test and Function Test above.

3. Printer Status - Blinking GREEN Printer is not activated via software.

Install or activate a printer aware

application on the terminal.

Printer operating normally.

1. Printer Ready - Printer aware software is

active.

2. Printer is receiving data through

interface.

980402-001 Rev.A 27

Page 34

Problem Solution or Reason

Terminal Mated and ON

The status indicators are:

Print - Blinking GREEN

Battery - N/A

Print command(s) sent

1. Printer is in a functional diagnostic or

test mode.

2. With the Feed button depressed - printer

is in Sleep test, AutoSense and other

diagnostics modes.

3. Error condition - Reset printer by

removing and re-installing the battery.

The status indicators are:

Print - ORANGE

Battery - N/A

Printing stops and STATUS

indicator lights ORANGE or

RED.

AutoSense - Media Change

The status indicators are:

Print - ORANGE

Battery - N/A

1. Printer has a syntax or command error.

Check program and resend print job.

1. Perform AutoSense gap sensor

adjustment on page 12.

2. Possible problem with label stock. Use

only approved labels and tags.

3. Possible label jam.

4. Terminal - Application may have set

insufficient memory for label size or is

caused by other programming issues.

Contact your system integrator or

administrator to identify the

configuration for proper printing.

Integrator - Check the printer’s

memory configuration. Refer to the

EPL2 Programming manual.

1. Media type has changed from labels

or black line media to continuous

media. Prints “no gap detected” or

“no black line detected”.

Terminal - change to an application

that supports the media or insert the

correct media for the application.

Contact your system integrator or

administrator to identify the proper

software media combination. Note - The

media setting is programmed into the

printer via printer commands embedded

into the print job.

28 980402-001 Rev.A

Page 35

Problem Solution or Reason

The status indicators are:

Print - Blinking ORANGE

with momentary GREEN

Battery - N/A

1. Firmware download in process.

Terminal Mated and ON

Media Loaded and a

Print Command or Feed has

been issued to printer

The status indicators are:

Print - RED

Battery - N/A

Terminal Mated and ON

The status indicators are:

Print - GREEN

Battery - N/A

Terminal Mated and ON

Media Loaded

Will not print or FEED labels

The status indicators are:

Print - GREEN

1. Media is out. Reload with new media.

2. Sensor has contaminates on it or label

jam. Check media path.

3. Clean platen roller. Platen roller may be

contaminated causing media to slip.

4. Verify that the media cover is closed

properly.

5. Power-up failure. Reset the printer by

removing and replacing the battery

1. Printer ready to receive flash

programming during firmware

download.

1. Verify that the terminal is mated

correctly to the printer.

2. Check that the media roll is loaded with

the direct thermal side facing up. Ensure

top cover is locked closed.

3. Clean platen roller. Platen roller may be

contaminated causing media to slip.

4. Terminal - Application software

sending the print job may have print

density (darkness) set to low. Contact

your system integrator or administrator

to identify the proper software media

and density setting combination for

proper printing. Note - The media

setting is programmed into the printer

via printer commands embedded into

the print job.

980402-001 Rev.A 29

Page 36

Problem Solution or Reason

Printing is faded or poor

quality.

Printer appears to be

working (media is being fed

out), but nothing is printed.

The status indicators are:

Print - GREEN

1. Clean the print head with cleaning pen.

2. Terminal - Adjust print darkness within

software. Application software sending

the print job may have print density

(darkness) set to low. Note - The media

setting is programmed into the printer

via printer commands embedded into

the print job.

3. Check the media and verify that print

surface is facing up.

1. Verify the roll is loaded with the direct

thermal side facing up.

2. Verify that the media is the correct type.

Use approved direct thermal media

only. Thermal transfer or regular paper

will not print.

3. Clean the print head with cleaning pen.

4. Terminal - Application software

sending the print job may have print

density (darkness) set to low. Contact

your system integrator or administrator

to identify the proper software media

and density setting combination for

proper printing. Note - The media

setting is programmed into the printer

via printer commands embedded into

the print job.

Prints only partial label or

skips a label.

30 980402-001 Rev.A

1. Perform AutoSense gap sensor

adjustment on page 12.

2. Label caught on print head. Clean print

head.

3. Top cover is not properly latched.

4. Terminal - Possible software problem.

Contact your system integrator or

administrator to identify the

configuration for proper printing.

Integrator - Check the printer’s

memory configuration. Refer to the

EPL2 Programming manual.

Page 37

Serial Interface

Communication

Configuration

The printer’s serial port is configured with the

Y command for the printer. The printer sup

ports interface data rates from 1200 to 38,400

baud. See the EPL2 programmer's manual for

details.

The printer’s serial port default configuration is:

9600 baud

8 bit data

1 stop bit

No parity

The printer and the terminal communication

speeds and settings must match. Check the

printer’s settings with the AutoSense routine’s

“Dump Mode” status printout.

-

Symbol Terminal

Serial Interface

Pin # Signal

1 5.0V input

2 DSR

3 RxD

4 RTS

5 TxD

6 CTS

7I1

8I2

9 DTR

10 XGND

11 PGND

The figure below displays the connections

needed to communicate with the printer via the

printer’s custom serial interface. The printer’s

connector is a SMK p/n CSS5014-0314R.

Description

5.0V applied by terminal, used to turn printer on.

Not Used

Data Receive

Ready to Send (Hardware flow control)

Data Transmit

Clear to Send (Hardware flow control)

Interrupt 1 used by terminal application to initiate

scanning. (Terminal side is “high” activate)

Not Used

Not Used

Digital Ground (Connected to PCB ground)

Power Ground (Connected to PCB ground)

12 8V input

13 Thermistor

14 Thermistor

980402-001 Rev.A 31

Reserved

Connected to PCB ground

Connected to Analog input of microprocessor (used

to monitor stepper motor operating temperature)

Page 38

32 980402-001 Rev.A

Page 39

Appendix B

TR 220 Command Reference

This section outlines the mobile printer EPL2

commands supported by the TR 220 printer. It

is intended as a quick reference for EPL2 page

mode programmers. The EPL Page Mode

Programmer’s manual is available in electronic

form on the user’ documentation CD or on the

Internet at www.zebra.com

.

980402-001 Rev.A 33

Page 40

Command Summary for the TR220 Mobile Printer

The EPL2 command and description are noted in the left columns,

while the unique TR220 operation appears in the right column.

Command

A ASCII Text

AUTOFR Automatic Form Printing

B Bar Code

b MaxiCode

C Counter

C Cut Immediate

D Density

EI Print Soft Font Info.

EK Delete Soft Font

eR User Definable Error Response

ES Store Soft Font

f Cut/Peel Position

FE End Form Store

FI Print Form Info.

FK Delete Form

FR Retrieve Form

FS Store Form

GG Retrieve Graphics

GI Print Graphics Info.

GK Delete Graphic

GM Store Graphic

GW Direct Graphic Write

I Character Set Selection

JB Disable Top Of Form Backup

JF Enable Top Of Form Backup

LE Line Draw Exclusive

LO Line Draw Black

LS Line Draw Diagonal

LW Line Draw White

M Memory Allocation

N Clear Image Buffer

o Cancel Customized Settings

oB Cancel Customize Bar Code

oE Line Mode Font Substitution

oH Macro PDF Offset

oM Disable Initial Esc Sequence Feed

oR Character Substitution (Euro)

Description

PDF417

TR220 Unique Operation

Not Supported

Not Supported

Not Supported

Not Supported

Not Supported

Not Supported

34

980402-001 Rev.A

Page 41

Command Summary for the TR220 Mobile Printer

Command

Description

oW Customize Bar Code Parameters

O Options Select

OEPL1 Set Line Mode

P Print

PA Print Automatic

Set Form Length

Q

Transmissive (Gap) Sensor

Black Line Sensor

Continuous Stock

q Set Form Width

R Set Reference Point

r Set Double Buffer Mode

S Speed Select

TD Define Date Layout (& Print Date)

TS Set Real Time Clock

TT Define Time Layout (& Print Time)

U Print Configuration

UA Enable Clear Label Counter Mode

UB Reset Label Counter Mode

UE External Font Information Inquiry

UF Form Information Inquiry

UG Graphic Information Inquiry

UI Host Prompts/Codepage Inquiry

UM Codepage & Memory Inquiry

UN Disable Error Reporting

UP Codepage & Memory Inquiry/Print

UQ Configuration Inquiry

US Enable Error Reporting

U% Host Prompt/Battery Inquiry

U%

Host Prompt/Motor Temperature

Inquiry

V Define Variable

W Windows Mode

xa Sense Media

X Box Draw

Y Serial Port Setup

Z Print Direction

? Download Variables

^@ Reset Printer

^ee Status Report - Immediate

TR220 Unique Operation

Not Supported

Not Supported

Single Buffer Only

Auto Selects Speed

Not Supported

Not Supported

Not Supported

Status LED Enable

Mobile Printers Only

Mobile Printers Only

Not Supported

Not Supported

980402-001 Rev.A 35

Page 42

General Printer

Configuration

Information

The TR 220 mobile printer has features that re

quire special consideration when program

ming. The EPL2 command support has been

modified to maximize battery charge utilization

and ignore unusable features. Some of the

features and commands that need special con

sideration when developing applications in

clude the following:

The TR 220 printer operates in Single Buffer

•

Mode only.

Single buffering increases the maximum

•

image buffer size to 2235 dots long (22

inches/ 558.8mm) with the maximum print

width of 384 dots (1.89 inches/ 48 mm).

• Speed (S) is automatically adjusted to maxi-

mize battery life. It can not be set by programming.

-

-

-

-

• Density (D) has a default value of 10. The

programmer should set this value to the lowest level that produces ausable label to maximize battery life.

• The use of large, highly dot dense images

(solid black) is not recommended. This will

reduce battery charge utilization. The printer

is rated to print at 25% density (3mm solid

black bar across the print width alternated

with a 9mm non-printing bar or an equiva

lent density pattern).

•

Long multiple label or high density print jobs

may cause the printer to temporarily delay

printing operations while the motor or print

head cool to safe operation temperatures.

•

The Enable Error Reporting (US) command

enables the command syntax error reporting

via the orange printer status indicator.

-

36

980402-001 Rev.A

Page 43

U% Host Prompts/Motor Temperature

Description EPL2 Mobile Printers Only (TR 220) - This

command will cause the printer to send to the

host the motor temperature status through the

mobile printer’s serial port.

Syntax

U%

The printer will send motor temperature in 2ºC

increments to the host via the serial port. The

printer uses the data format of NNdeg C,

where NN equals the motor temperature.

Range Reported (

U%

Degrees Celsius): 24≤NN<60

EPL2 Mobile printers suspend printing

operations, including printer to host

communication, until the motor returns to safe

operating temperatures.

The mobile printer will stop printing are 60ºC or

higher.

Example:

980402-001 Rev.A 37

The printer will resume printing at 50ºC.

U%¿ : Command sent to printer

: Printer responds with motor temperature

: 24 deg C

Page 44

U$ Host Prompts/Battery Status

Description EPL2 Mobile Printers Only (TR 220) - This

command will cause the printer to send to the

host the battery charge status.

Syntax

U$

The printer will send information about battery

charge status in increments of 10 percent. The

printer uses the data format of VccNNN%,

where NNN represents the battery’s charge

level.

EPL2 Mobile printers suspend all new printing

operations, including printer to host

communication, until the battery charge level is

greater than 20%.

Print jobs or forms (single label or batch

operations) will continue processing until

finished.

The mobile printer will accept new commands

and print after the battery charge is greater than

20%.

Example:

38 980402-001 Rev.A

U$¿ : Command sent to printer

: Printer responds with

: Vcc90%

Page 45

US Enable Error Reporting

Description Use this command to enable the printer’s status

reporting feature.

Serial Port - If an error occurs, the printer will

send a NACK(0x15), followed by the error

number, to the computer. If no errors occur, the

printer will echo ACK(0x6) after each P com

mand.

If paper or ribbon empty occurs, the printer will

send, through the serial port, a”-07” and

“Pnnn” where nnn is the number of labels re

maining to print.

Mobile Printers Only (TR220) - Enables

command error reporting via printer’s status indicator, as well as, the serial port.

-

-

Syntax

US[p1]

The printer’s default setting is off.

Parameters p

If no errors occur, the printer will echo

ACK(0x6) after each label that is successfully

printed.

= 1 Optional Parameter

1

980402-001 Rev.A 39

Page 46

US Command - Enable Error Reporting

Code Error/Status Description

No Error

00

Syntax Error

01

Object Exceeded Label Border

02

Bar Code Data Length Error

03

(e.g.: EAN-13 is a 12 or 13 digit only)

Insufficient Memory to Store Data

04

Memory Configuration Error

05

RS-232 Interface Error

06

Paper

07

Duplicate Name: Form, Graphic or Soft Font

08

Name Not Found: Form, Graphic or Soft Font

09

Not in Data Entry Mode

10

Pause Mode or Paused in Peel mode

12

Mobile Printers: Print head too hot

13

Mobile Printers: Motor too hot

14

Mobile Printers: Battery low warning (≥ 40%)

15

Mobile Printers: Battery low limit (≥ 20%)

16

Does not fit in area specified

50

Data length to long

51

PDF-417 coded data to large to fit in bar code

93

40 980402-001 Rev.A

Loading...

Loading...