Page 1

TLP2746

Mid-Range

Thermal Printers

Service Manual

980023-005 Rev.B

©2001 Zebra Technologies Corporation

Page 2

ii 980023-005 Rev.B

Page 3

CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

REQUIRED TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

REPLACING PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Exterior Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Print Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Power & Main PCBA Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Set AC Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

AC Power Module & Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Main PCBA Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

IC Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Main Cable Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

DC Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Main PCBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Print Head Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Label Guide & Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Label Sensor PCBAs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Head-up Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Label Taken Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Peel Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Label Guide Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Ribbon Pulley (60 tooth) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Ribbon Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Rewind Drive Pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Platen Belt (120 tooth) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Platen Clutch & 42 Tooth Pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Ribbon Collar & Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Ribbon Tubes & Shaft Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Rewind Tube & Shaft Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Platen Bearing & Replacement Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Lower Print Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Print Head Carriage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Cutter Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Securing the Main Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Printer Configuration Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

DC Power Verification & Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Platen Belt and Motor Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Tube Tension Verify & Adjust. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Ribbon Path Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Packaging for Shipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

CLEANING AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . 71

980023-005 Rev.B iii

Page 4

FOREWORD

This manual provides maintenance, diagnosis, service and repair information for the TLP2746

printer models manufactured by Zebra Technologies Corporation, Camarillo, California.

TECHNICAL SUPPORT

If for any reason you require product technical support, please contact the Distributor where you first

purchased your equipment. If they cannot help you or at their direction, contact Zebra Repair

Administration.

RETURN MATERIALS AUTHORIZATION

Before returning any equipment to Zebra for in warranty or out of warranty repair, contact Repair

Administration for a Return Materials Authorization (RMA) number. Repack the equipment in the

original packing material and mark the RMA number clearly on the outside. Ship the equipment,

freight prepaid, to the address listed below:

Zebra Repair Administration, USA

1001 Flynn Road

Camarillo, CA 93012

Phone: +1 (805) 579-1800

FAX: +1 (805) 579-1808

Label Printers: Card Printers:

Zebra International, Europe Zebra International, Europe

Zebra House, The Valley Centre Zone Indutrielle, Rue d'Amsterdam

Gordon Road, High Wycombe 44370 Varades, France

Buckinghamshire HP13 6EQ, United Kingdom Phone: +33 (0) 240 097 070

Phone: +44 (0) 1494 472872 FAX: +33 (0) 240 834 745

FAX: +44 (0) 1494 450103

COPYRIGHT NOTICE

This document contains information proprietary to Zebra Technologies Corporation. This document

and the information contained within is copyrighted by Zebra Technologies Corporation and may

not be duplicated in full or in part by any person without written approval from Zebra. While every

effort has been made to keep the information contained within current and accurate as of the date of

publication, no guarantee is given or implied that the document is error-free or that it is accurate

with regard to any specification. Zebra reserves the right to make changes, for the purpose of

product improvement, at any time.

TRADEMARKS

TLP2746 is service mark and Zebra Technologies is a trademark of Zebra Technologies

Corporation. Windows and MS-DOS are registered trademarks of Microsoft Corp. All other marks

are trademarks or registered trademarks of their respective holders.

OPERATOR CAUTIONS AND WARNINGS

These pages describe general safety and maintenance procedures that an operator must follow.

They are referenced throughout the service manual. The manual may include other warnings and

cautions not displayed here.

iv 980023-005 Rev.B

Page 5

Warning - Shock Hazard

The printer should never be operated in a location where it can get wet.

Personal injury could result.

Warnung - Stromschlaggefahr - Der Drucker sollte nie an feuchten

Standorten in Betrieb genommen werden. Es besteht erhöhte Verletzungs

und Unfallgefahr.

Warning - Static Discharge

The discharge of electrostatic energy that accumulates on the surface of

the human body or other surfaces can damage or destroy the print head or

electronic components used in this device. DO NOT TOUCH the print

head or the electronic components under the print head assembly.

Caution - Printer Setup & Handling

1)When installing or modifying the printer setup or configuration,

ALWAYS TURN POWER OFF Before

A) Connecting any cables.

B) Performing any cleaning or maintenance operations.

C) Moving the printer.

:

2) Damage to the printer interface connector, accessories or enclosure

may result from placing the printer on it’s front bezel or backside during

unpacking or handling.

980023-005 v

Page 6

Media Cautions & Tips

1) Always use high quality Zebra approved labels and tags. Zebra approved

supplies can be ordered from your Zebra dealer. For the name of a dealer

in your area, call Zebra Customer Service at one of the numbers listed on

the back page of this manual.

2) If poor quality, adhesive backed labels are used, that DO NOT lay flat on

the backing liner, the exposed edges may stick to the label guides and

rollers inside the printer, causing the label to peel off from the liner and

jam the printer.

3) DO NOT use non-Zebra transfer ribbon. Permanent damage to the print

head may result if a non-Zebra ribbon is used. Non-Zebra ribbons maybe

wound incorrectly for the printer or contain chemicals that may damage

the print head.

4) IMPORTANT - If a transfer ribbon is installed incorrectly by the

operator, damage to the print head may result.

5) DO NOT use a ribbon when printing with direct thermal media.

Media Reload Tip

If you should run out of labels or ribbon while printing, DO NOT turn the

power switch OFF (0) while reloading or data loss may occur. The printer

will automatically resume printing when a new label or ribbon roll is

loaded.

Print Mode Control

The printer is reconfigured for direct thermal (or thermal transfer) printing

with the “O” command. See the EPL2 programmer's manual for details.

Print Quality Tip

Print density (darkness) is affected by the heat energy (density setting)

applied and by the print speed. Changing both Print Speed and Density

may be required to achieve the desired results.

vi 980023-005

Page 7

INTRODUCTION

This service manual is intended for the field service engineer or technician. It's scope covers routine

maintenance, troubleshooting and repair procedures for the printer.

Follow the parts replacement procedures as closely as possible. If you are unsure of any procedure,

please contact your service representative or call the Zebra Technologies technical support group at

(805) 579-1800. See our web site at www.zebra.com

options: printer drivers, software, firmware, FAQ's, contacts, supplies, etc..

Zebra Technologies stocks all Zebra replacement parts for the printer. Be sure your facility stocks

sufficient parts so that scheduled maintenance can take place in a timely manner.

Unpacking the Printer

Printers are carton shipped and wrapped inside a protective bag. Keep all packing materials in case

you need to reship the printer later or store the printer for any length of time.

Preparing a Static-Safe Work Area

Prepare a static-safe work area before opening the printer for repair. The area must include a

properly grounded conductive cushioned mat to hold the printer and a conductive wrist strap for the

technician. ESD protective devices are available from most electronic supply stores or by contacting

3M corporation at (800) 328-1368.

for a complete list of international support

Environmental and Shock Protection

Extreme temperature and humidity fluctuations or mishandling can damage the printer and power

supply. Allow 30 minutes or more before opening the printer's plastic bag. This time allows the

printer to stabilize temperature especially after storage in a cool, dry location and then placement in

a warmer, more humid location. Warm, humid air condenses on the cool components of the printer

and this condensation may damage the components.

Move the printer carefully. While the printer has sturdy construction, mechanical

damage can certainly result from falls or rough handling.

980023-005 Rev.A 1

Page 8

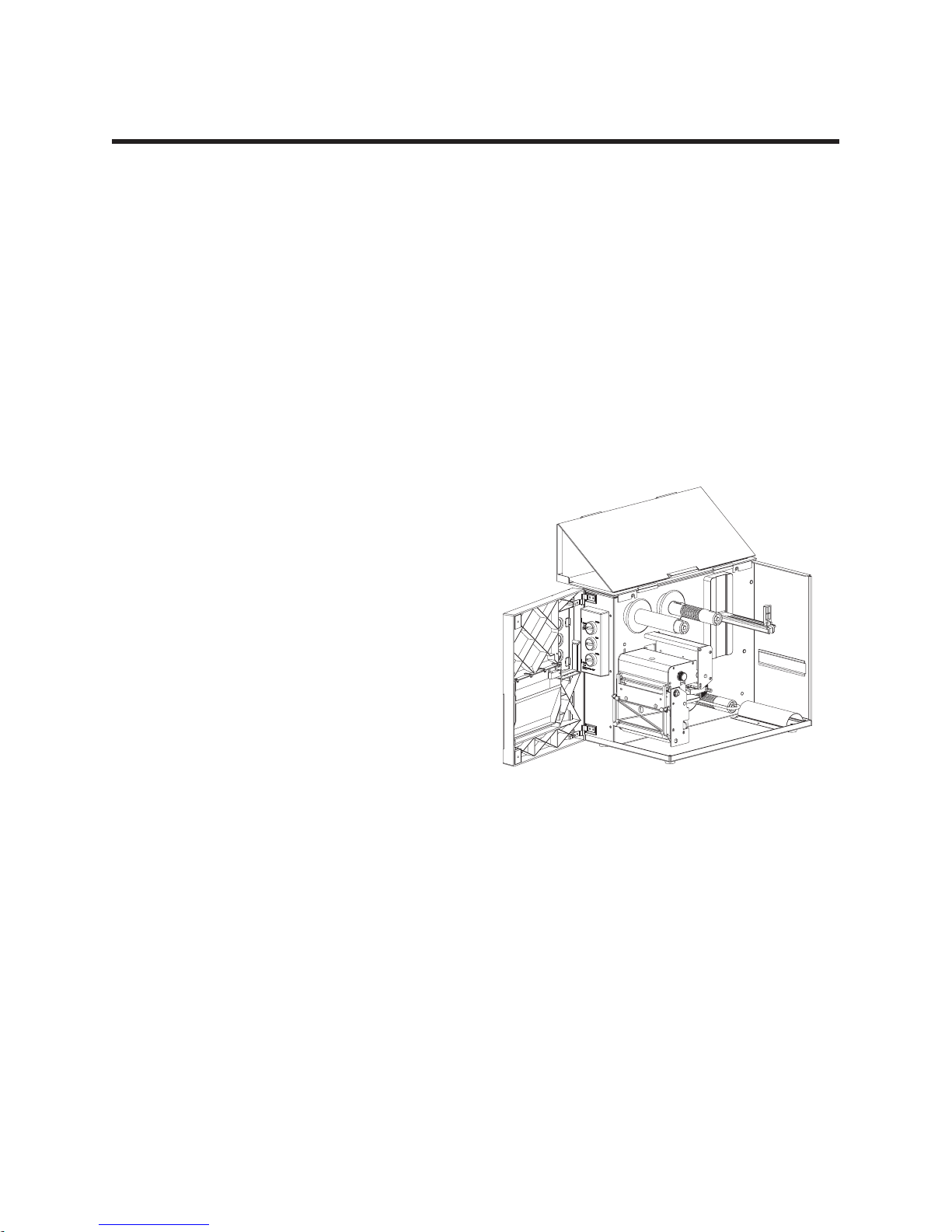

Models

Many of the earlier model Zebra printers are similar in appearance to the Zebra TLP2746 thermal

printer. The printer features that identify the TLP2746 printer from similar Zebra printers are:

Printer Color - Light Grey

•

Flash Programmed Printer Memory - No Memory Cartridge (see the rear panel of printer)

•

Carbon Fiber (Black) 1 inch (inner diameter) Media Roll Holder

•

Label Dispense (Peel) and Batch Mode Switch (see the rear panel of printer)

•

A High Tension Label Dispense (Peel) Mechanism

•

Head-Up Sensor (small sensor slot in the center panel)

•

300 Watt Power Supply

•

Expanded Language Support (14 MS DOS™ and 7 Windows™ code pages)

•

Industry Standard Bar Code including PDF417 and Maxicode two dimensional bar codes

•

Memory Expansion up to 1 MByte (Flash) and 512 SRAM (Image Buffer)

•

Optional Asian Language Support - Today, including Japanese, Chinese and Korean

•

Optional Cutter

•

Optional Real Time Clock (RTC) with a ten year battery life

•

TLP2746

Printers with thermal transfer printing have ribbon

tubes above the print head mechanism and can

print in Direct Thermal or Thermal Transfer print

modes.

See service procedure 980023-150 to help you identify installed printer features and modes.

2 980023-005 Rev.A

Page 9

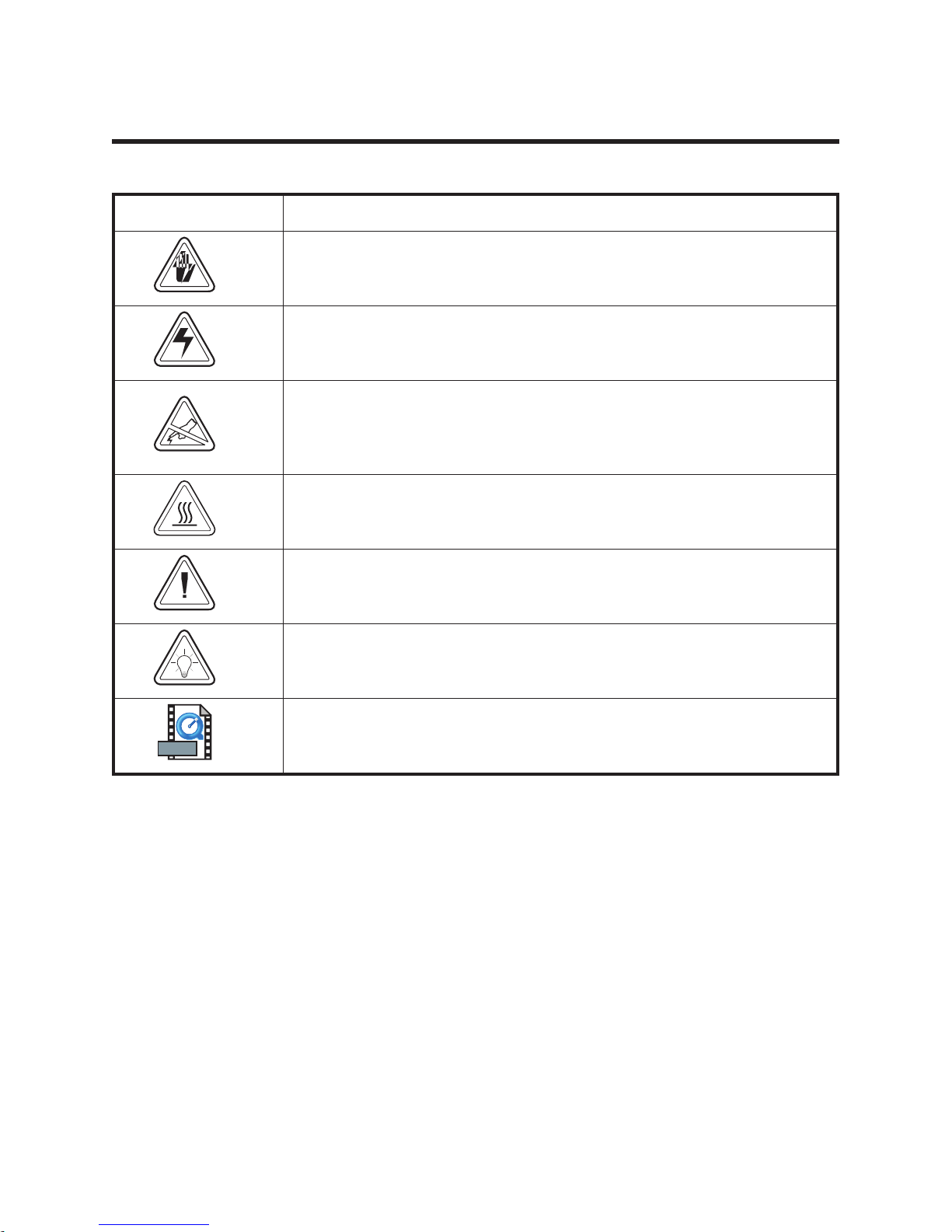

Conventions

This manual uses the following notations to call attention to important information.

ICON / SYMBOL MEANING

WARNING - critical safety information.

CAUTION - problem avoidance messages.

STATIC SENSITIVE - follow procedures that protect against the discharge

of electrostatic energy that accumulates on the surface of the human body

or other objects as this discharge can damage or destroy the print head

and other electronic components.

HEAT - The print head becomes hot while printing. Protect against

personal injury. DO NOT touch the print head. Use only the cleaning

pen to perform maintenance.

MOVIE

NOTE - important instructions and reminders.

HINT - helpful information.

Quicktime Movie - Click on this Icon in the electronic version of this

manual for an instruction video.

980023-005 Rev.A 3

Page 10

4 980023-005 Rev.A

Page 11

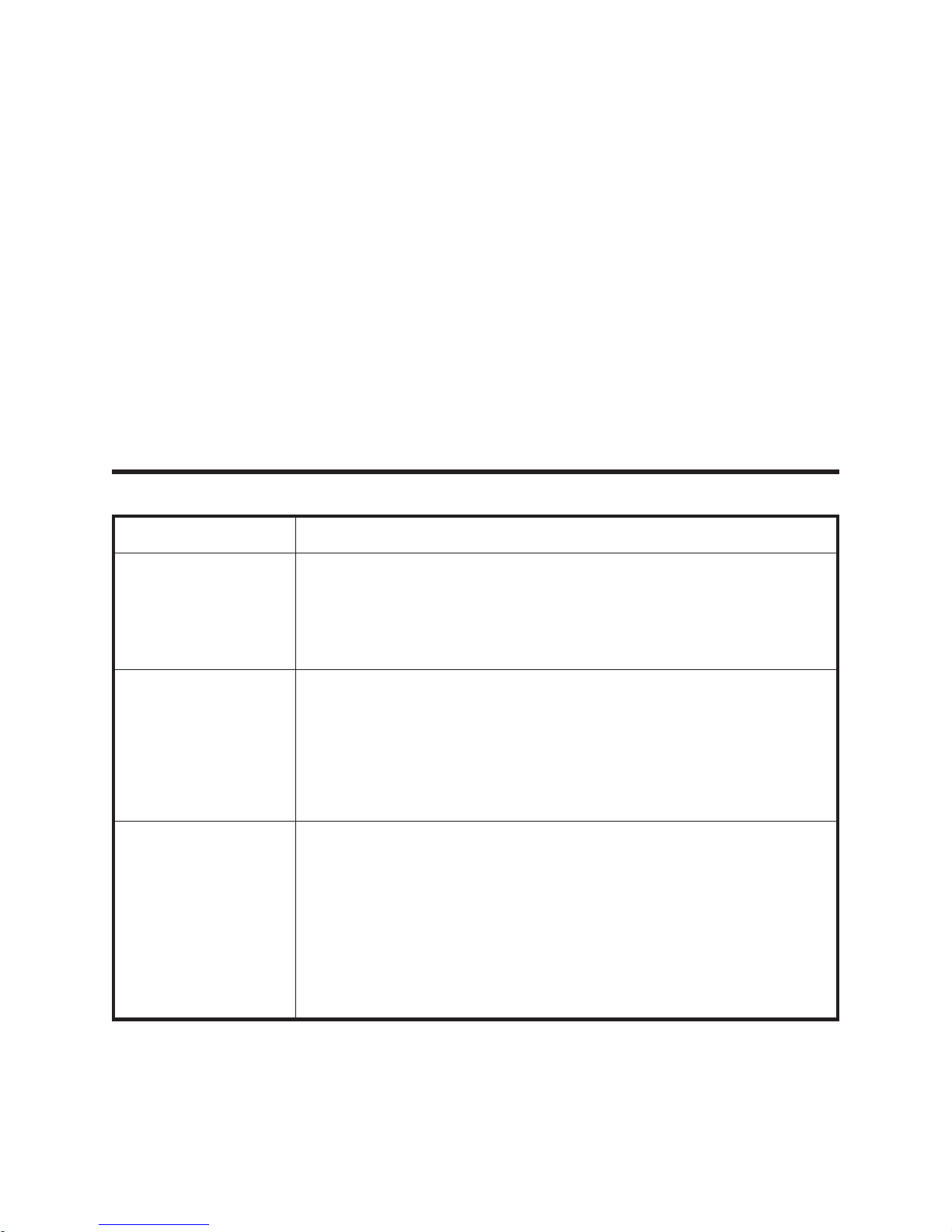

TROUBLESHOOTING GUIDE

PROBLEMS SOLUTIONS

With the STATUS

indicator light GREEN,

the printer appears to

be working, but nothing

is printed.

Status indicators do

not light when power

switch is on (I)

Printer appears to be

working with the

indicator light

GREEN, but nothing

is printed.

1. Verify the labels are the correct type.

2. Check the roll and verify that the print surface faces up for printing.

3. Check the transfer ribbon is correctly routed and has the ink side out

for thermal transfer printing, only.

1. Check power connections from the printer to the outlet.

2. Remove power supply and check fuse. If blown, replace the power

supply.

3. Verify power supply voltage settings, AC input voltage (110VAC or

220VAC), and DC voltage (980023-152).

4. Printer works, but no indicator light. Replace the control panel.

1. Check the connections between the printer and the cable as well as

the cable and the computer.

2. Verify the labels are the correct type.

3. Check the roll and verify that the print surface faces up for direct

thermal printing.

4. Check the transfer ribbon is correctly routed and has the ink side

down.

5. Check print head wire bundle connections at main PCBA.

980023-005 Rev.A 5

Page 12

PROBLEMS SOLUTIONS

1. Wipe the print head with the cleaning pen.

2. Adjust print speed/darkness in software or with programming.

Printing is uniformly

faded or poor quality.

3. Check the roll and verify that the media print surface is facing up.

4. Verify the correct combination thermal transfer ribbon and media are

in use.

Printing has streaks,

white (non printing)

lines, uneven printing

(a side or sides), or

faded print areas.

Printing stops and the

STATUS indicator

lights RED.

1. Wipe the print head with the cleaning pen.

2. Use the "SAVE-A-PRINTHEAD" cleaning film (P/N 44902)

contamination build-up.

3. The head may be worn out and needs to be replaced.

4. Static damage from touching the head has blown out pixels or the

electronic logic circuitry in the print head assembly. Replace the head

or secondarily the main board.

5. The main board has failed components.

6. The print head cable is loose or damaged.

1. Possible problem sensing labels with transmissive (gap) sensor.

Perform AutoSense adjustment. Align the transmissive (gap) sensor

position, see the user’ manual.

2. Possible problem with label media.

a) Gap between the bottom of a label and the top of the next label

should be at least 1/16" (1.6mm).

b) For tags, see Tag Media Sensing, page .

c) Use only Zebra approved labels and tags.

3. Possible label jam.

4. Check that the media is correctly routed.

5. Possible software/programming problem.

a) Check the printer memory configuration.

b) Refer to the EPL2 Programming manual for the correct data

syntax.

6. Transmissive sensor is dirty. Clean the media path.

Printer is in dump

mode but nothing

1. File does not contain a form feed code that will advance sheet. Press

prints after sending

file.

ASCII characters print

1. Printer may be in dump mode. Press the Feed button to reset to

in place of expected

label art and bar

2. Check serial port configuration using the Y command. See the EPL2

codes.

6 980023-005 Rev.A

the Feed button to print data in the printer’s buffer.

normal operation.

programmer’s manual.

Page 13

PROBLEMS SOLUTIONS

1. Align the transmissive (gap) sensor near the narrowest gap between

labels.

2. Perform the AutoSense adjustment.

Printing stops and

status indicator lights

red

3. Check that gap between labels is at least 1/16 inch (1.6mm)

4. For tags, see the discussion of Tag Media Sensing.

5. Check for media jam.

6. Check media is correctly routed.

7. Check printer memory configuration and correct data syntax.

8. Transmissive (gap) is dirty. Clean media path.

1. Check for out-of-media condition or missing labels in the middle of a

roll.

2. Check for out-of-ribbon condition or damage or previous use of

ribbon in middle of roll.

Status indicator

remains red.

3. Check the ribbon and label stock or correctly routed

4. If using direct thermal printing, check that programmed mode or

printer driver is set for direct thermal printing. See the programmer’s

book for details.

5. Transmissive (gap) sensor may be dirty. Clean media path.

6. Check the printer carriage is closed and latched.

Rubbing noise when

pressing Feed button.

Cutter makes

incomplete cuts or

cuts in the wrong spot.

1. Media is not loaded and the platen is rubbing against the print head.

Insert media (and load ribbon if necessary) between carriage and

platen.

1. Printer is set for dispense/peel mode. Move switch to batch position.

2. Form length is set wrong. Change length through printer driver or

programming language. See the EPL2 programming manual.

The printer firmware is updated by way of the parallel port.

1. Use the download utility to send firmware to the printer.

Printer firmware must

be updated.

2. Optionally, you can download from the c:\ prompt by typing

copy/b filename lpt1: from the directory holding the update file.

The printer's light should start flashing green-orange, and then every few

seconds will flash red a couple of seconds. Once the update is done, the

light goes dark then comes on green.

Print Head Life

The print head has a limited life and is considered a consumable item. The media rubs across the

print head print elements and wears away the surface. This process is affected by many factors

relating to the media material, operational settings and environment. To maximize your print head

life, use the "SAVE-A-PRINTHEAD" cleaning film (P/N 44902) contamination build-up after every

roll.

980023-005 Rev.A 7

Page 14

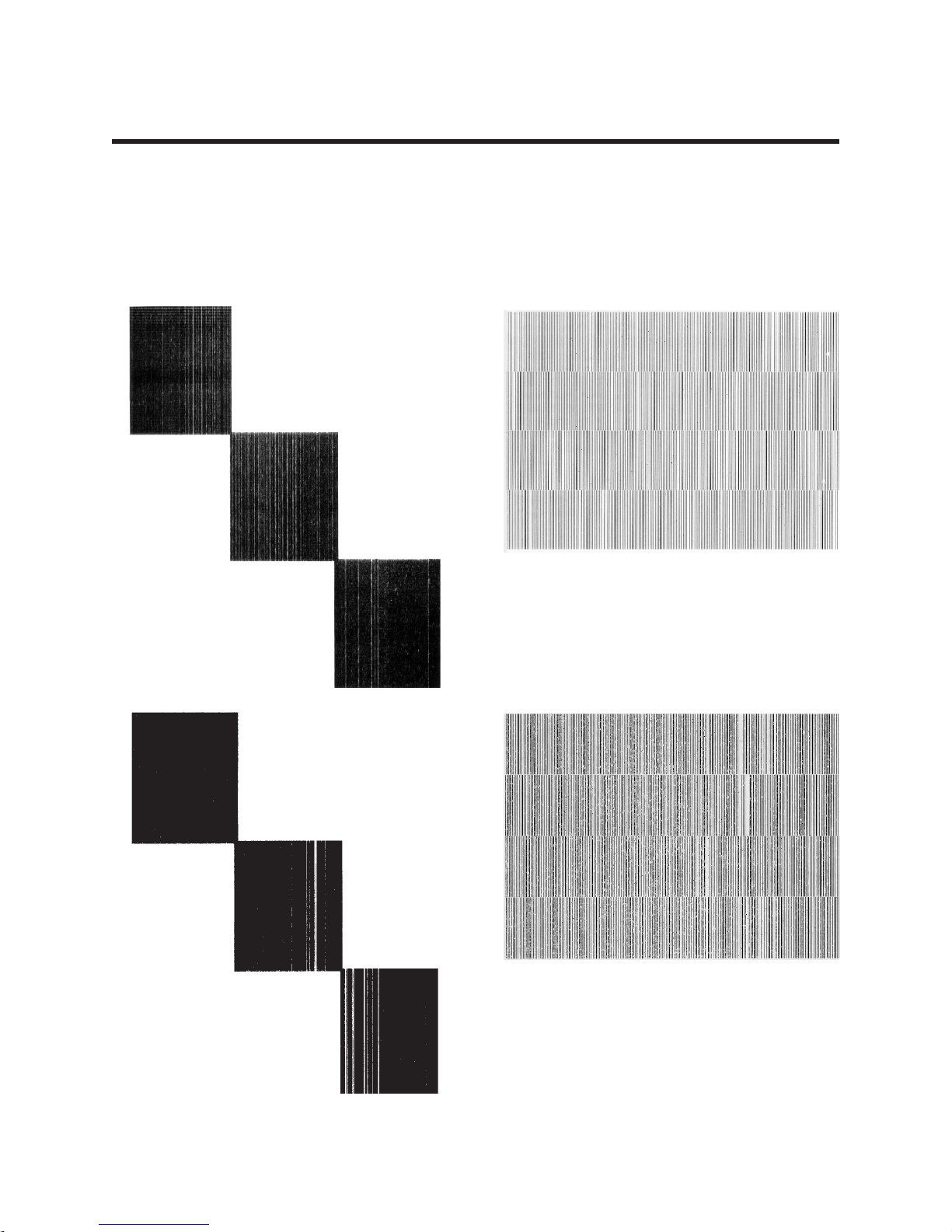

Identifying Print Head Problems

The print head wears with printer use. If the print quality does not improve after cleaning, the print

head may require replacement. Printing with worn damaged print elements may create unreadable

bar codes. Print head damage can be caused by improper cleaning (unapproved fluids or

implements), electro static discharge (ESD), and touching the print head (contaminates, ESD and

body oil acids). The following are examples of print head wear or damage.

Weak or Damaged Print Elements

(Full-On Print Pattern)

Weak or Damaged Print Elements or Print Logic

(Rotating Print Element Pattern)

8 980023-005 Rev.A

Page 15

REQUIRED TOOLS

Make use of the following tools while performing replacement procedures:

Torque wrench with 1/4" hex receptacle)

•

Phillips driver #1 (tip for 1/4" hex receptacle)

•

Phillips driver #2 (tip for 1/4" hex receptacle)

•

•

Allen key socket tip drivers (tip for 1/4" hex receptacle);

sizes: 1/16", 5/64", 3/32", 1/8", 4mm

•

Nut driver, sizes: 7mm, 8mm, 1/4"

•

Flat Blade screwdriver (small)

•

needle-nose pliers

•

pliers for E-ring retainers (12R)

•

pliers for axial retainers

•

pliers for integrated chips

•

tweezers

•

Clutch torque bit (and torque gauge are spare 105902-060)

•

.005" shim

•

Loctite 222 thread locker or equivalent

980023-005 Rev.A 9

Page 16

10 980023-005 Rev.A

Page 17

REPLACING PARTS

To access some parts, you need to dissemble other parts; therefore, other procedures must be

followed before and after performing a particular replacement.

MOVIE

980023-005 Rev.A 11

Page 18

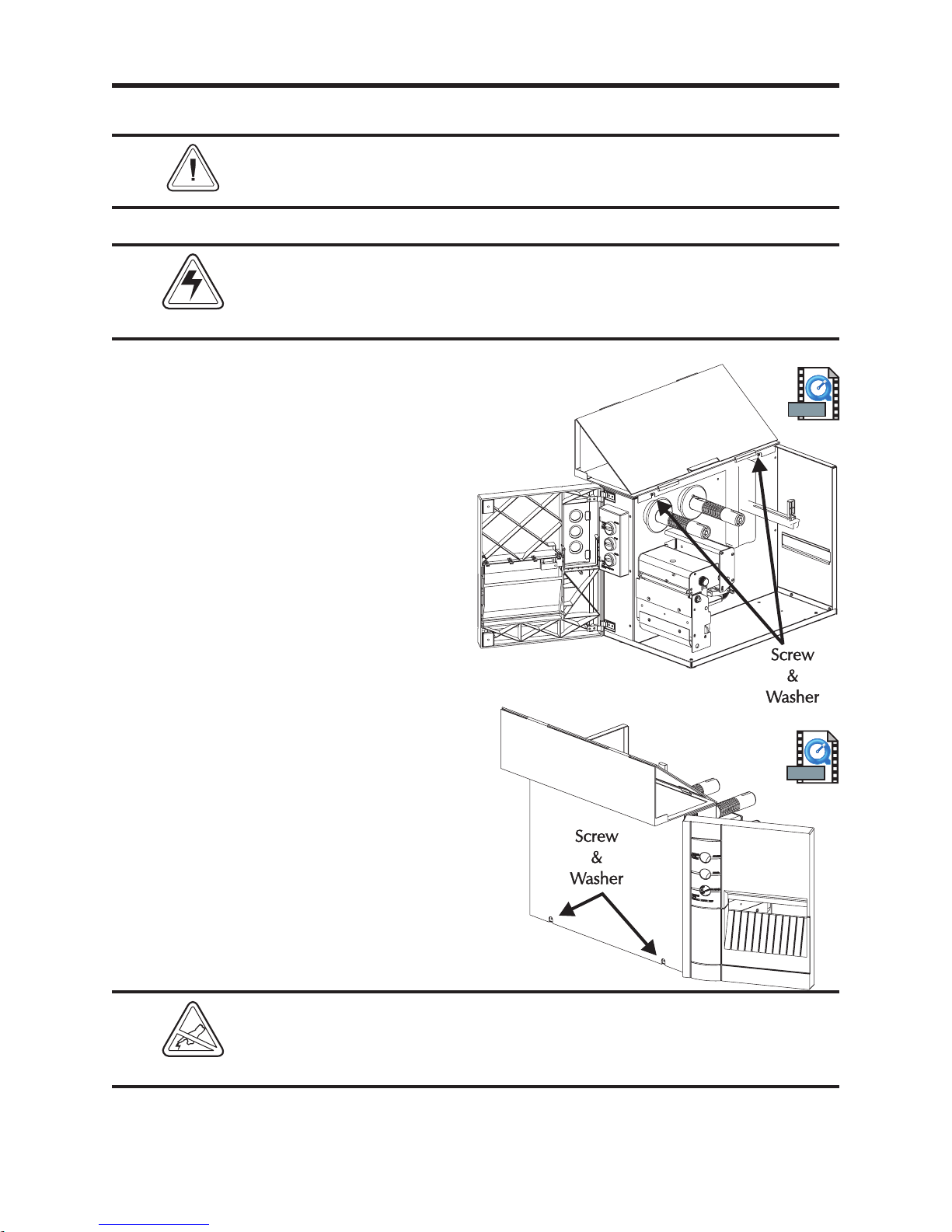

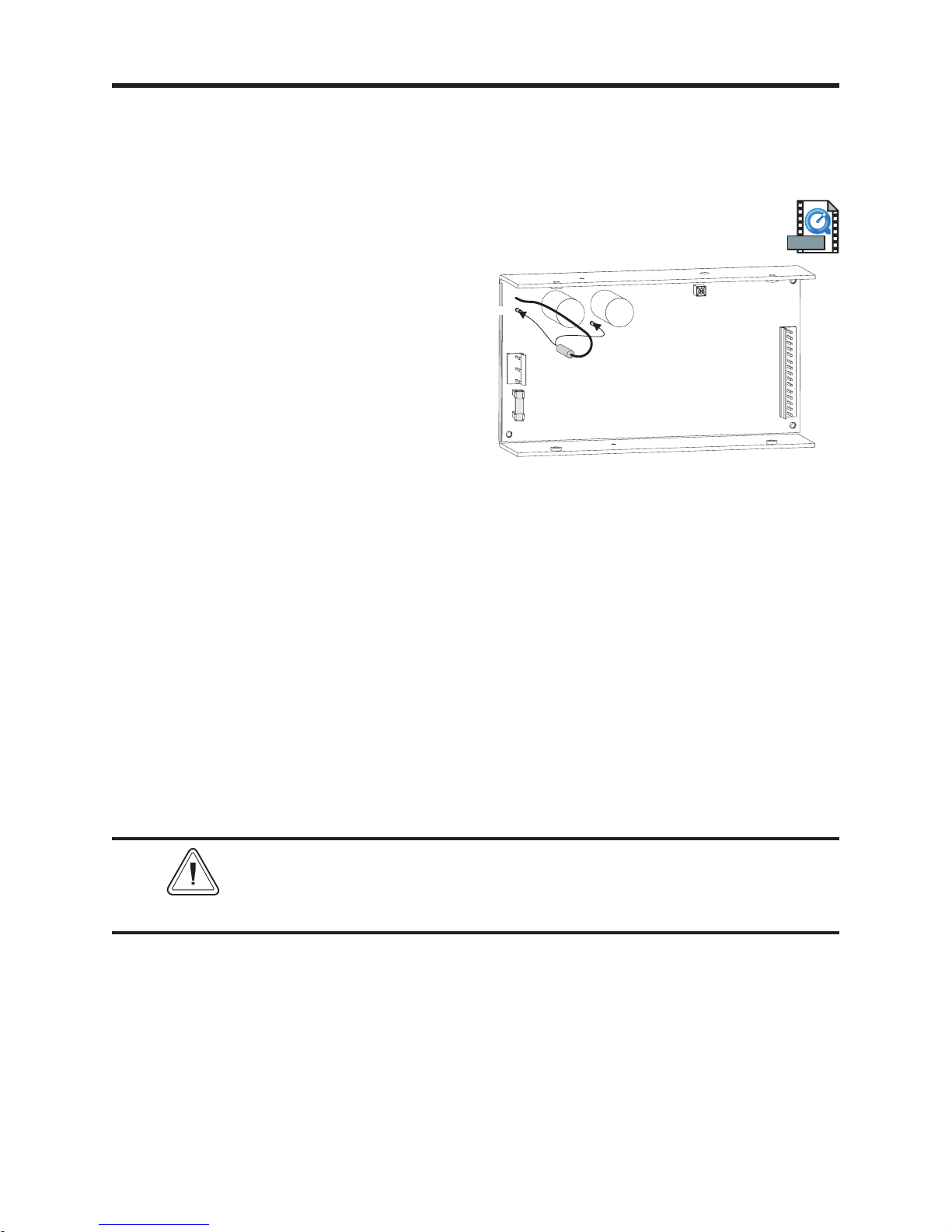

Exterior Cover

Preparations

The printer's exterior cover needs to be removed to perform most of

the disassembly and replacement procedures for the printer.

NOTE

Before starting the procedure, open the printer, then remove media and any ribbon from the printer.

Shock Hazard

Always turn off the printer before performing any maintenance or

repair operations. Wait for the indicator light to be dark, then unplug

the power cord.

Tools:

#2 Philips screw driver

Removal

1. Remove the two (2) upper screws and two

(2) lower screws shown. Lift the cover off.

Installation

1. Place the cover in position. Secure the cover

with the two (2) upper screws (and washers)

and the two (2) lower screws (and washers)

shown

MOVIE

MOVIE

Protect against static discharge when handling the printer with the

cover removed. Your work area must be static-safe and should

include a properly grounded conductive cushioned mat to hold the

printer and a conductive wrist strap for yourself.

12 980023-101 Rev.B

Page 19

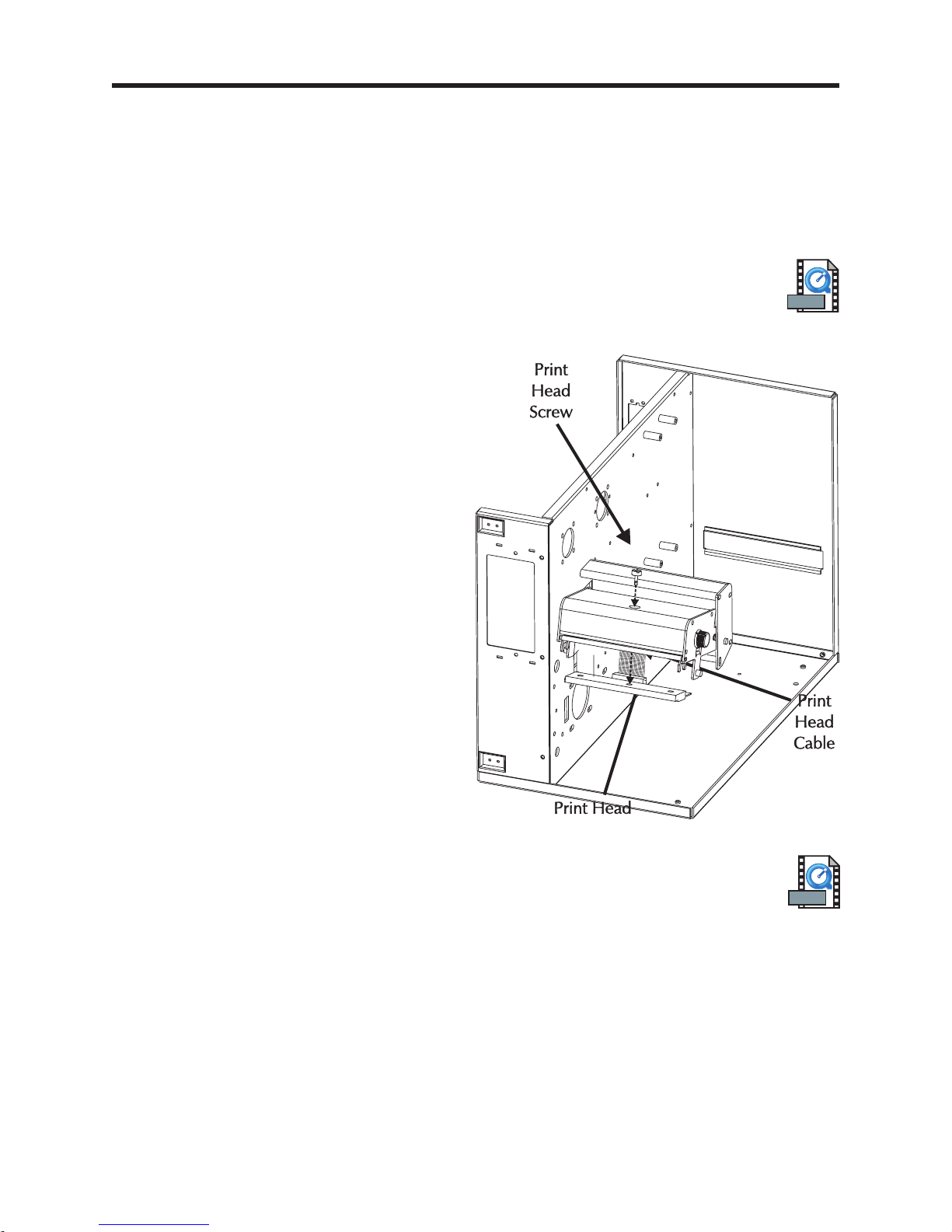

Print Head

Preparations

Before starting the procedure, open the printer, then remove media and any ribbon from the printer.

Tools:

Flat blade screw driver

Removal

1. Open the print head assembly.

2. Lower the print head by loosening the

mounting screw accessed through a hole in

the top of the print head assembly.

3. Detach the print head (ribbon) cable.

Installation

1. Connect the replacement print head. Pin 1

on the print head and cable is toward the

center panel of the printer.

2. Align the print head with the two bracket

alignment pins.

3. Secure print head to print head bracket by

tightening the print head bracket screw.

Tighten the screw to 4.7 ±1 in. lb.

MOVIE

4. Close and open the print head and recheck

that the print head cable still secure and

connected to the print head.

5. Clean the print head after completing

installation.

980023-102 Rev.B 13

MOVIE

Page 20

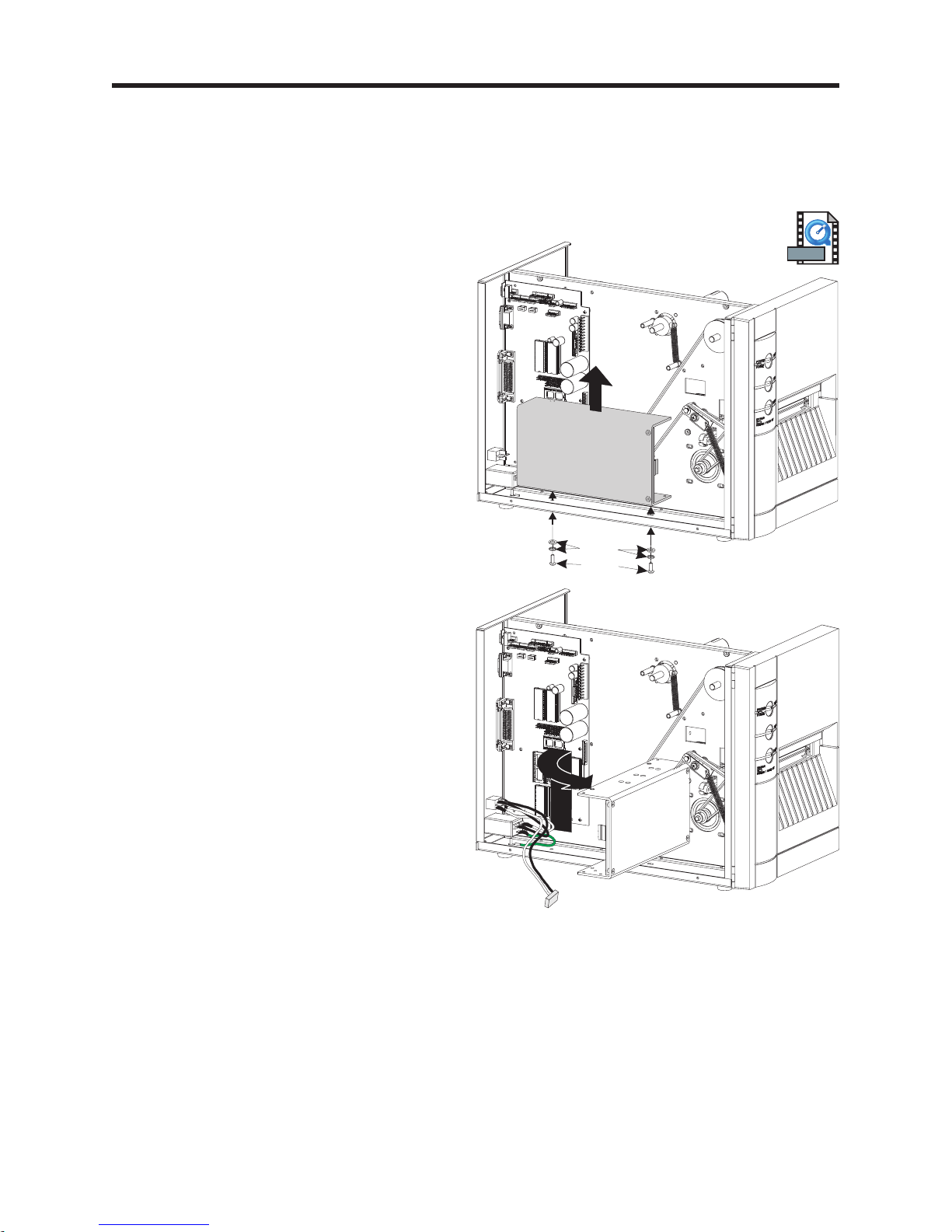

Power & Main PCBA Access

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

Tools:

#2 Philips screw driver

1. For easier access to the power supply and

Main PCBA, remove the two (2) screws

securing it to the bottom of the printer

chassis.

With the printer on it's right side, hold the

power supply while removing the two (2)

screws (and washers) that secure it to

bottom panel.

2. Disconnect the AC input power connector

plug from the power supply. This allows

easier access to the power supply without

disassembling the cabling and cable ties.

3. Swing the power supply out to gain access

to the voltage setting jumper.

MOVIE

WASHERS

SCREWS

Set the power supply down gently on the

printer base to keep the supply from

swinging into the Main PCBA and

damaging components.

Caution - The connectors or the cable's tie

down may come loose or inadvertently

disconnected if special care is not taken.

14 980023-103 Rev.B

Page 21

Set AC Voltage

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

The power supply must be detached from the bottom panel for access. (980023-103)

Set Voltage

1. Move the voltage selection jumper wire to

the appropriate voltage pin. Verify the

correct voltage is marked next to the

jumpers pin.

Re-assemble Printer

2. Remount the power supply using the screws

and washers. Keep the power supply from

swinging into the Main PCBA and

damaging components.

3. Verify that the cables and ties have not

become loose or damaged. Verify that the

cable tie points have not moved, allowing

the cables to touch belts or gears.

230VAC

AC

Input

110VAC

MOVIE

1

DC

Supply

Voltage

to PCBA

4. Re-attach the exterior cover.

Fuse Warning

If the power supply's fuse has blown, the power supply most likely has

NOTE

a critical component failure. Most cases require power supply

replacement.

980023-104 Rev.B 15

Page 22

Power Supply

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

The AC input power voltage (jumper) should be set prior to installing the power supply.

(980023-104)

Some power supplies come with DC power cables and may also require changing. (980023-113)

Tools:

#2 Philips screw driver

Removal

1. Cut the tie-wrap securing the cables to the

top of the power supply. Caution - Do not

cut the cables!

2. With the printer on it's right side, hold the

power supply while removing the two (2)

screws (and washers) that secure it to

bottom panel. Set the power supply down

gently on the printer base to keep the supply

from swinging into the Main PCBA and

damaging components.

3. With printer upright, tilt the power supply

outward to rest on it's side.

4. Disconnect the two (2) cables and remove

the power supply.

Installation

1. Verify the power supply voltage setting.

Reconfigure the power setting as necessary.

MOVIE

Cut

2. Set the replacement power supply in

position. Reconnect power cables.

3. Remount the power supply the screws and

washers.

5. Attach a new cable tie to the anchor on the

power supply (top front outside corner).

Loop a new cable tie through the cable

anchor and re-attach the cable bundle to

the power supply chassis.

16 980023-105 Rev.B

WASHERS

SCREWS

Page 23

AC Power Module & Switch

Preparations

The exterior cover must be removed prior to proceeding. (Procedure 980023-101)

The power supply must be unscrewed from the printer's bottom plate. (Procedure 980023-103)

Power Switch Removal

1. Push the retaining tabs into the side of the

power switch or AC power filter module

and slide the switch out of the back panel.

Power Switch Installation

1. Disconnect the old switch's wires, one at a

time, and reconnect them to the new switch

in the same position. Note the switch's

orientation, 1 (one) to the outside and 0

(zero) towards the center panel.

MOVIE

2. Push the new switch into the back panel

until flush with the back panel. Wiggle it

from the inside to very that it has locked in

place.

AC Module Removal

1. Push the retaining tabs into the side of the

AC power filter module and slide the

module out of the back panel.

AC Module Installation

1. Disconnect the old module's wires, one at a

time, and reconnect them to the new switch

in the same position. Note the module's

orientation, ground towards the bottom

plate.

2. Push the new module into the back panel

until flush with the back panel. Wiggle it

from the inside to very that it has locked in

place.

980023-106 Rev.B 17

Page 24

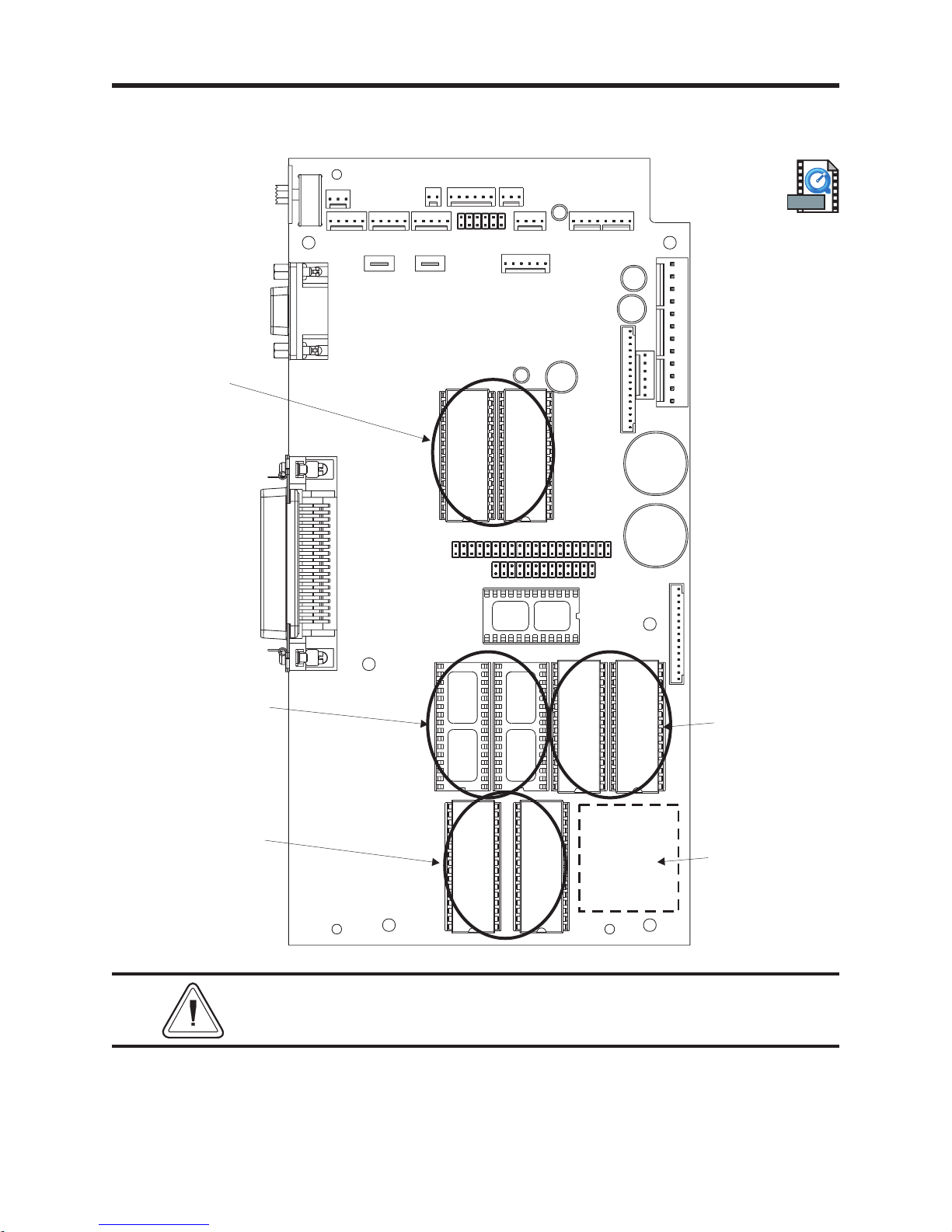

Main PCBA Configuration

The following diagrams the printer's physical location for the memory and real time clock (RTC)

chips.

Print Engine

Firmware

MOVIE

Extended Image

Printer SRAM

(in Spare PCBA's also)

Image Engine

Firmware

U14

U31

U24

U13

U2

U18

U25

U26

U34

&

U33

U27

Standard Image

Printer SRAM

(Spare PCBA's also)

Asian Language

Flash Firmware

(in Spare PCBA's also)

To identify the printer's Main PCBA configuration without opening

the printer, use the printer's AutoSense procedure.

18 980023-109 Rev.B

Page 25

IC Installation

Preparations

The exterior cover must be removed prior to proceeding. (Procedure 980023-101)

The power supply must be unscrewed from the printer's bottom plate. (Procedure 980023-103)

Tools:

IC Chip Removal Tool

Replacing the Integrated Circuit Chips

To replace a chip, use the following procedure:

1. Use I.C. chip pliers to pull the chip out of its socket on the main PCBA.

2. Carefully align each chip and insert it into the main PCBA. Check that all pins are in their

holes.

IE Flash 1MB Upgrade

Replace the image engine flash chips at

locations U25 and U24.

IE Flash stores pre-designed elements

(fonts, forms and graphics) that go into a

print job plus some operation code for the

printer.

Print Engine Upgrade

MOVIE

Replace the print engine flash chips at

locations U13 and U14.

IE Flash stores pre-designed elements

(fonts, forms and graphics) that go into a

print job plus some operation code for the

printer.

980023-110 Rev.B 19

Page 26

SRAM 512KB Upgrade

You add two RAM chips into empty sockets,

U18 and U31.

SRAM provides image buffer for the printer.

A larger SRAM capacity allows for larger

and longer images.

Real Time Clock Option

Add the real time clock option chip into the

socket at location U2.

The real time clock option stores the time of

day and date. The chip's battery has a life

of up to ten years.

MOVIE

See the EPL2 Programmer's Manual

for information about setting the real time

clock, and formatting the layout of the date

and time.

Re-assembling the Printer

1. Reattach the power supply.

2. Reconnect the AC power input plug.

3. Reattach the printer cover.

4. Attach the power cord and interface cable.

20 980023-110 Rev.B

Page 27

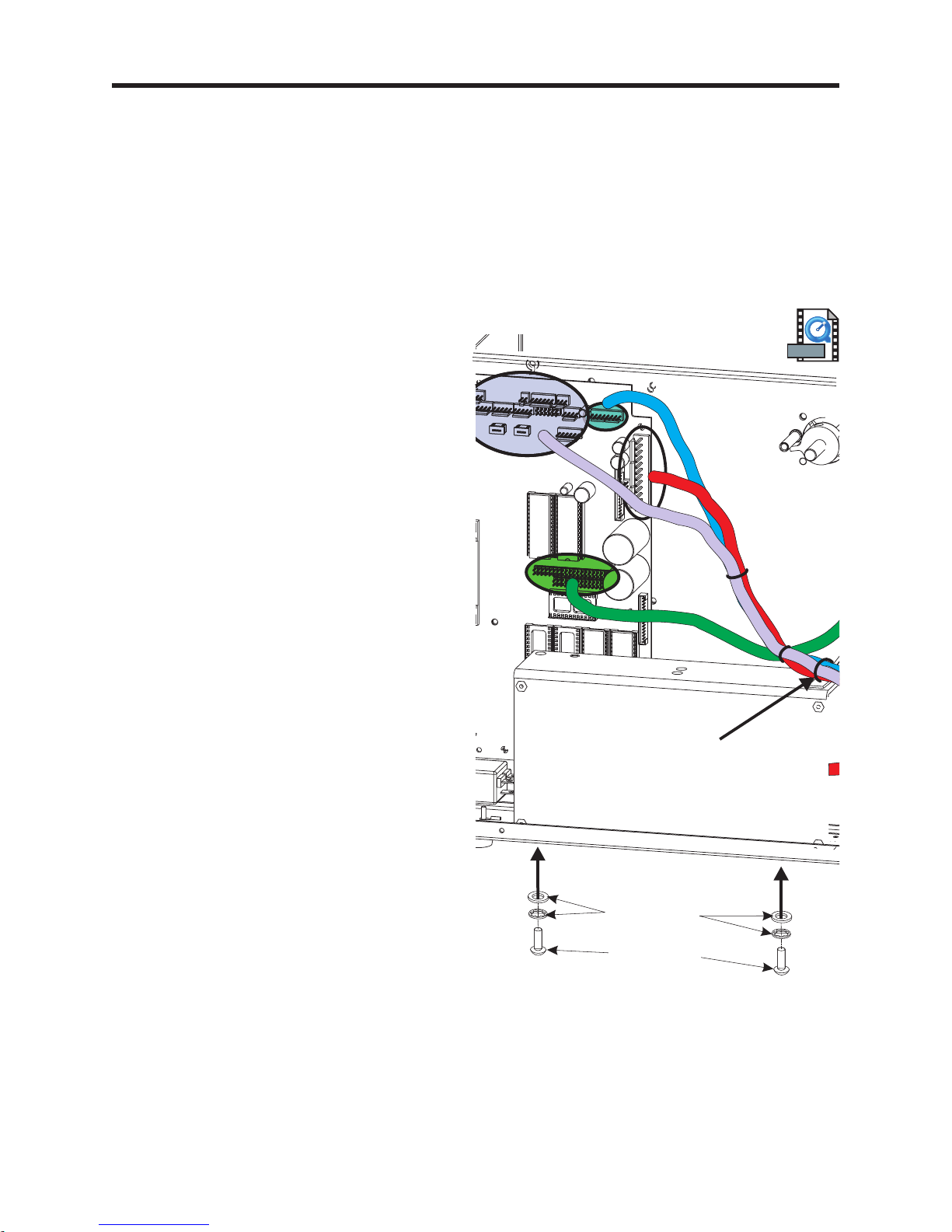

Main Cable Harness

The following diagrams the physical location of the printer's primary cable groups and cable tie

points.

Controls and

Sensors

Motor

DC Power

Print Head Cable Ties Cable Tie

980023-112 Rev.B 21

and

Anchor

Page 28

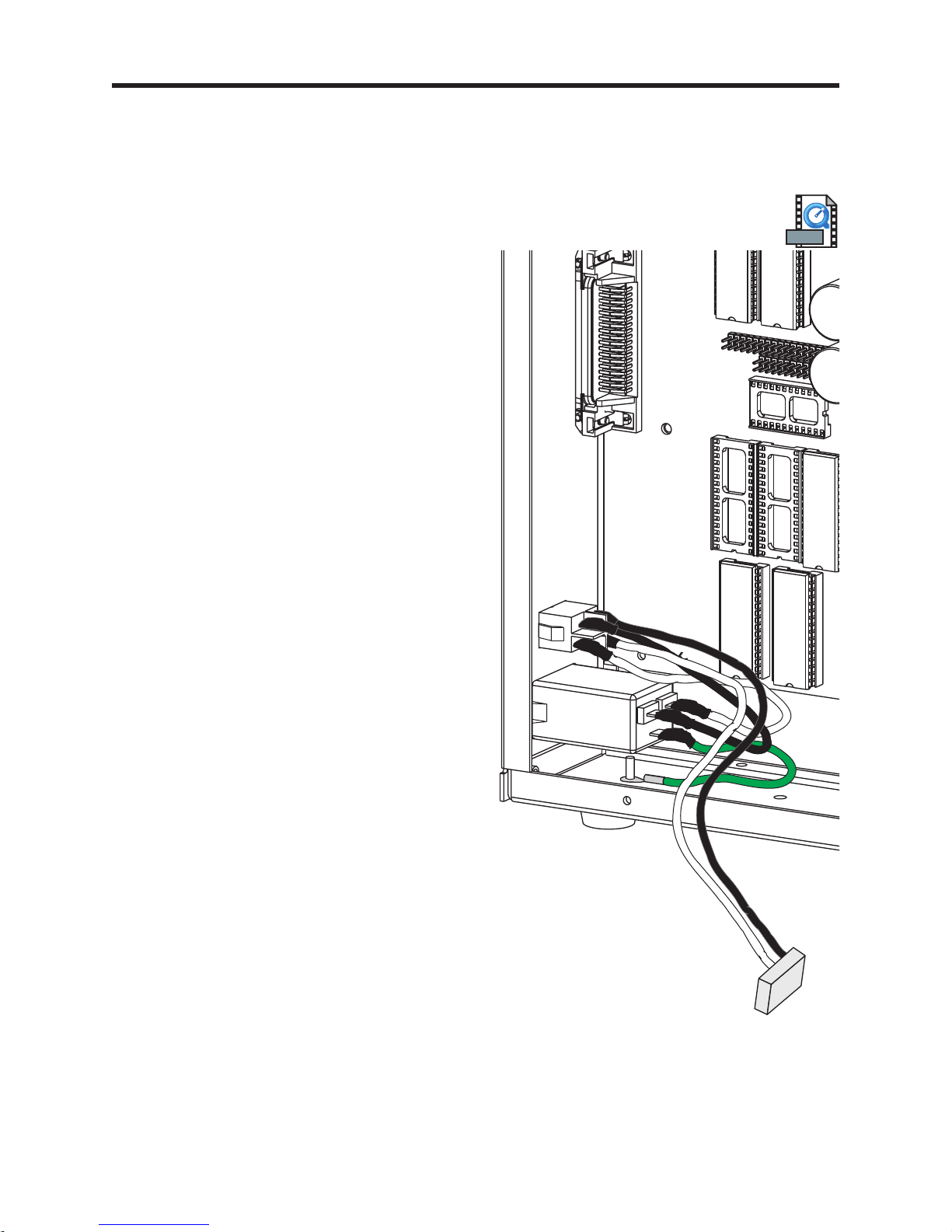

DC Power Cable

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

Note the main cable harness routing and cable tie positions. (980023-112)

Removal

1. Cut the three (3) tie-wraps securing the

main cable harness. Caution - Do not cut

the cables!

MOVIEMOVIE

2. Disconnect the power cable (JP6) from

main PCBA.

3. Disconnect the power cable from the power

supply.

Installation

1. Connect the power cable (JP6) to the main

PCBA.

2. Connect the power cable to the power

supply.

3. Re-tie the main PCBA harness. Use the

"Securing the Harness" procedure.

DC Power

JP6

22 980023-113 Rev.B

Page 29

Main PCBA

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

The power supply must be loosened from the printer's bottom plate. (Procedure 980023-103)

Tools:

#1 Philips screw driver

Removal

1. Disconnect the cables from the main PCBA.

2. Disconnect the motor, DC power, and the

print head cables from the main PCBA.

3. Remove the two (2) mounting screws

holding the main PCBA to the center panel.

4. With the sensor and control cables still

attached to the main PCBA, gently lift the

main PCBA off the stand-offs.

5. Set the old main PCBA gently aside, next to

the power supply. Have care not to

disconnect the sensor and control cables.

Installation

1. Mount the main PCBA on the stand-offs.

2. Secure the main PCBA to the center panel

with the two (2) mounting screws.

MOVIE

Screws

3. Swing the old main PCBA next to with both

board sensor and control connectors and

cables accessible.

4. From right to left and one at a time,

disconnect the sensor and control cables

from the old board to the new main PCBA.

5. Remount the power supply the screws and

washers. Reconnect the AC power plug to

the power supply.

6. Connect the motor, DC power, and the

print head cables to the new main PCBA.

7. Re-install the case.

980023-115 Rev.B 23

Page 30

Print Head Cable

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

Removal

1. Cut the center tie-wrap securing the main

cable harness. Caution - Do not cut the

cables!

2. Disconnect the print head cable (JP21) from

main PCBA.

MOVIE

24 980023-116 Rev.B

Pin 1 of JP21

Print Head

Connector

Page 31

3. Open the print head assembly.

4. Lower the print head by loosening the

mounting screw accessed through a hole in

the top of the print head assembly.

5. Detach the print head (ribbon) cable. Set

the loose print head on a clean, soft and

static safe surface (mat).

6. Pull the cable out through the center panel.

7. Remove the cable's spiral wrap.

Installation

1. Place the spiral wrap on the new cable.

2. Connect the cable to the JP21 on the main

PCBA. Note pin 1 on the connector and

cable. Slide the spiral wrap 2" from the print

head end of the cable.

3. Route the cable through the center panel.

Lower the print head for easier access.

4. Connect the print head. Pin 1 on the print

head and cable is toward the center panel.

5. Align the print head with the two bracket

alignment pins.

6. Secure print head to print head bracket by

tightening the print head bracket screw.

Tighten the screw to 4.7 ±1 in. lb.

7. Close and open the print head and recheck

that the print head cable still secure and

connected to the print head. Verify that 1/4

is inside and 3/4 of the spiral wrap is outside

of the center panel. This protects the cable

from rubbing on the belt and print head

carriage.

8. Re-tie the main PCBA harness. Use the

"Securing the Harness" procedure.

MOVIE

9. Clean the print head after completing

installation.

980023-116 Rev.B 25

Page 32

Label Guide & Sensor

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

Note the main cable harness routing and cable tie positions. (980023-112)

The Label Guide & Sensor assembly is mounted below the print head assembly. The sensor slide

and cables pass through the center panel of the printer chassis and plug into the main PCBA.

Tools:

#2 Philips screw driver

Removal

1. Cut the three (3) tie-wraps securing the

main cable harness. Caution - Do not cut

the cables!

2. Disconnect the label guide and sensor

cables (JP27, JP28, JP4 and JP5) from

main PCBA.

3. From the user’s access area (right side of

printer), open the print head with the print

head's release latch.

Adjust the sensor slide to the outside

position, away from the center panel of the

printer chassis.

4. Remove the pan head screw securing the

label guide and sensor assembly to center

panel of the printer chassis (user access

side).

JP27

JP5

JP4

JP28

MOVIE

26 980023-117 Rev.B

Screw

Release Latch

Page 33

5. Slide the label guide and sensor assembly

toward the front of the printer, (approx. 1/4"

parallel to the center panel) and pull the

assembly out away from the center panel

when it clears the panel.

Pull the sensor cables out through the center

panel.

980023-117 Rev.B 27

Page 34

Installation

1. Slide the sensor guide's four (4) cables

through the sensor slide’s hole.

2. Insert and hook the label guide’s tab onto

the center panel’s cut-out.

3. Secure the label guide and sensor assembly

to the center panel with the pan head screw.

4. Close the print head.

Hook guide to center panel

5. Re-connect the cables (JP27, JP28, JP4 and

JP5) to the Main PCBA. The five (5)

conductor cable exiting the bottom of the

sensor slide gets connected to JP5.

5 conductor - JP4

(middle set)

6. Re-tie the main PCBA harness. Use the

"Securing the Harness" procedure.

3 conductor - JP27

2 conductor - JP28

5 conductor - JP5

(bottom set)

28 980023-117 Rev.B

Page 35

Label Sensor PCBAs

Preparations

The exterior cover must be removed prior to proceeding. (Procedure 980023-101)

Note the main cable harness routing and cable tie positions. (980023-112)

Remove the Label Sensor and Guide Assembly from the printer. (980023-117)

Tools:

#2 Philips screw driver

Removal

1. Slide the sensor adjustment slide into the

sensor housing.

MOVIE

2. Remove the three (3) screws attaching the

lower housing to the upper.

3. Gently rock the lower housing while slowly

pulling lower housing and slide parallel to

the upper housing.

980023-118 Rev.B 29

Page 36

4. Completely slide the lower and upper

housings from the slide.

5. Remove the adhesive securing the cables at

the end of the slide. Caution - Do not

damage the slide or good cables or

good PCBAs.

6. Slide the appropriate cable out of the cable

clips. Note how the cables are attached and

routed.

7. While holding the slide to keep it from

spreading apart, gently pull the appropriate

PCBA from the slide.

Installation

Gap Receiver / Ribbon Out PCBA

Cable Clips

Cable Clips

Gap Emitter / Black Mark PCBA

1. Press the new PCBA onto the slide with the

components and cables facing up.

2. Route the cables flat against the slides

without twists and under the cable clips.

Cable Routed

Under Clips

30 980023-118 Rev.B

Page 37

3. Add adhesive (hot melt glue or RTV) to the

end of the slide to secure the cables to the

slide. Remove excess adhesive immediately.

let the adhesive set before continuing.

4. Slide the sensor adjustment slide half way

into the lower housing.

5. Insert the cables into the slide access in the

upper housing.

6. Finish sliding the two housings together.

Gently rock the lower housing while slowly

pushing the lower housing into the upper

housing.

7. Re-attach the lower housing to the upper

with the three (3) screws.

8. Install the label guide and sensor assembly

using the "Label Guide & Sensor"

procedure.

980023-118 Rev.B 31

Page 38

Control Panel

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

Note the main cable harness routing and cable tie positions. (980023-112)

Tools:

#1 Philips screw driver

Removal

1. Cut the three (3) tie-wraps securing the

main cable harness. Caution - Do not cut

the cables!

2. Disconnect the control panel cables (JP35)

from main PCBA.

3. Cut the tie wrap holding the three (3)

ribbon cables to the back of the control

panel's PCBA. Caution - Do not cut the

cables!

JP35

MOVIE

4. Remove the two (2) screws retaining the

control panel assembly.

5. Open the front door and pull the control

panel assembly straight out the front panel

of the printer.

32 980023-119 Rev.B

Cut Cable Tie

Screws

Page 39

Installation

1. Insert the control panel cable into the

control panel's access hole.

2. Slide the control panel's four (4) guide posts

into the front panel.

3. Attach the control panel assembly to the

inside of the front panel with the two (2)

retaining screws. Tighten to

4.7±1inch-pounds of torque.

4. Place the adhesive backed tie anchor on the

back of the control panel PCBA, as shown.

5. Group the three cables (control panel,

head-up, and label taken sensor) into a

harness bundle and lock the them to the

anchor with a cable tie.

MOVIE

Control

Panel

Cable

Verify the head-up sensor cable is not

twisted and easily clears the ribbon drive

belt.

6. Connect the control panel cable to the main

PCBA at header JP35.

7. Re-tie the main PCBA harness. Use the

"Securing the Harness" procedure.

Place Tie

Anchor & Tie

Cables

980023-119 Rev.B 33

Page 40

Head-up Sensor

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

Note the main cable harness routing and cable tie positions. (980023-112)

Removal

1. Cut the three (3) tie-wraps securing the

main cable harness. Caution - Do not cut

the cables!

2. Disconnect the head-up cable (JP14) from

main PCBA.

3. Cut the tie wrap holding the three (3)

ribbon cables to the back of the control

panel's PCBA. Caution - Do not cut the

cables!

JP14

MOVIE

4. Pull the head-up sensor PCBA stand-offs.

34 980023-121 Rev.B

Cut Cable Tie

Head-Up

Sensor

PCBA

Page 41

Installation

1. Insert the head-up sensor PCBA onto the

stand-offs with the cable facing out and

toward the front of the printer.

2. Group the three cables (head-up, control

panel, and label taken sensor) into a

harness bundle and lock the them to the

anchor with a cable tie.

Verify the head-up sensor cable is not

twisted and easily clears the ribbon drive

belt.

3. Connect the control panel cable to the main

PCBA at header JP14.

4. Re-tie the main PCBA harness. Use the

"Securing the Harness" procedure.

Place Tie

Anchor & Tie

Cables

980023-121 Rev.B 35

Page 42

Label Taken Sensor

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

Note the main cable harness routing and cable tie positions. (980023-112)

Tools:

#1 Philips screw driver

Removal

1. Cut the three (3) tie-wraps securing the

main cable harness. Caution - Do not cut

the cables!

2. Disconnect the label taken cable (JP26)

from main PCBA.

3. Cut the tie wrap holding the three (3)

ribbon cables to the back of the control

panel's PCBA. Caution - Do not cut the

cables!

4. Open the printer's front door.

JP26

MOVIE

4. Remove the three (3) screws holding the

cable cover. Note the cable routing for

installation.

5. Pull the sensor's cable out through the side

of the control panel housing. The control

panel retaining screws can be loosened to

allow the plug to pass through easier.

6. Pull the label taken sensor out of the

shroud. Gently pull the shroud to get the

PCBA past the snap locks to remove.

36 980023-123 Rev.B

Label Taken

Sensor

Cut Cable Tie

Cable Cover

Page 43

Installation

Stand-off Columns

1. Insert the label taken sensor PCBA into the

shroud. Orient the LED block out and the

cable towards the inside. The PCBA will

snap in place.

2. Insert the sensor's connector plug through

the hole in the side of the control panel

housing. Tighten control panel screws.

3. Route the cable with the label taken sensor

gate down. The cable goes through a notch

in the adjacent wall and then between the

stand-offs and flat against the wall in the

wire trap. The cable exits the wire trap

between the stand-off and wall nearest the

control panel.

4. Remount the cable cover with the three (3)

screws.

Notch

5. With the front door opened wide, group the

three cables (label taken sensor, control

panel, and head-up) into a harness bundle

and lock them to the anchor with a cable

tie.

Verify the head-up sensor cable is not

twisted and easily clears the ribbon drive

belt.

6. Open and close the door to verify that the

wires are not pinching or binding and the

door closes properly. Pull any excess cable

through the anchored tie.

7. Connect the control panel cable to the main

PCBA at header JP26.

8. Re-tie the main PCBA harness. Use the

"Securing the Harness" procedure.

Place Tie

Anchor & Tie

Cables

980023-123 Rev.B 37

Page 44

Door

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

Note the main cable harness routing and cable tie positions. (980023-112)

Tools:

#1 Philips screw driver

Removal

1. Cut the three (3) tie-wraps securing the

main cable harness. Caution - Do not cut

the cables!

2. Disconnect the label taken cable (JP26)

from main PCBA.

3. Cut the tie wrap holding the three (3)

ribbon cables to the back of the control

panel's PCBA. Caution - Do not cut the

cables!

4. Open the printer's front door.

JP26

MOVIE

4. Pull the label taken sensor's cable out

through the side of the control panel

housing. The control panel retaining screws

can be loosened to allow the plug to pass

through easier.

5. Remove the four (4) screws retaining the

door hinges to the front panel of the printer.

(See following illustration).

38 980023-124 Rev.B

Cut Cable Tie

Label Taken

Sensor Cable

Page 45

Installation

1. Mount the new door to the front panel with

the four (4) retaining screws.

2. Insert the sensor's connector plug through

the hole in the side of the control panel

housing. Tighten control panel screws.

MOVIE

3. With the front door opened wide, group the

three cables (label taken sensor, control

panel, and head-up) into a harness bundle

and lock the them to the anchor with a

cable tie.

Verify the head-up sensor cable is not

twisted and easily clears the ribbon drive

belt.

4. Open and close the door to verify that the

wires are not pinching or binding and the

door closes properly. Pull any excess cable

through the anchored tie.

5. Connect the control panel cable to the main

PCBA at header JP26.

6. Re-tie the main PCBA harness. Use the

"Securing the Harness" procedure.

Place Tie

Anchor & Tie

Cables

980023-124 Rev.B 39

Page 46

Peel Mechanism

Tools:

#1 Philips screw driver

Removal

1. Remove the two (2) screws holding the peeler mechanism to the lower print mechanism. The

peeler spacer plate will also become loose.

Note - Earlier model printers have a peel bar instead of the peel mechanism and can be

upgraded.

Installation

1. Place the peeler spacer plate against the lower print mechanism with the cutout facing down.

Align the plate up with the mounting two (2) holes.

2. Place the peel mechanism against the spacer plate and insert the two (2) flat head screws.

Tighten the screws to 4.7 inch-pounds torque.

3. Verify the label rewind tube torque setting is set to 17 ±1 inch-pounds.

Note - Earlier printer models with a peel bar instead of the peel mechanism require a label

rewind tube torque setting of 26±2 inch-pounds. Upgrading early model printers require that

the peeler mechanism be adjusted to operate properly.

MOVIE

40 980023-105 Rev.B

Page 47

Label Guide Tab

Tools:

Pliers and a scribe

Removal

1. Push the tab stop pin out of the guide tab's

slide on the label guide and sensor

assembly.

2. Rotate the guide tab down and slide the tab

off the slide.

Tab Stop Pin

Guide Tab

MOVIE

Installation

1. Slide the guide tab on the slide.

2. Insert the tab stop pin until it is flush with

the bottom.

3. Pull the guide tab to the outside of the slide

and verify the guide tab can rotate up.

R

O

T

O

M

R

E

P

P

E

T

S

980023-126 Rev.B 41

Page 48

Motor

C

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

Tools:

TORX tool with #T25 tip or 4mm allen head

Removal

1. Remove the four (4) M5x14 socket head mounting screws securing the motor to the center

panel. (Use Torx tip #T25 or 4mm allen head socket - 1/4 inch hex shank for use with torque

gauge).

2. With the motor loose, disconnect the motor cable from the motor's connector.

Reference - Do Not Disconnect Pulley

CENTER PANEL

PULLEY

STEPPING

MOTOR

0.070 inch

Gap

Pulley

TORX OR SOCKET

HEAD SCREWS

MOVIE

LOCK WASHER

FLAT WASHER

HEX NUT

Installation

1. Attach the motor to the motor cable's connector.

2. Insert new motor, but leave the mounting screws loose.

3. Re-install the belt around the 42-tooth pulley on the platen and the motor pulley.

4. Tighten the belt by sliding the motor toward the rear panel. Secure the motor in place. Refer to

Adjusting Belt Tension for setting the recommended belt tension.

42 980023-129 Rev.B

MOTOR

CABLE

TO

MAIN P

B

CABLE

CONNECTOR

Page 49

Ribbon Pulley (60 tooth)

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

Tools:

11/32 Allen driver

Removal

1. Loosen the ribbon belt by rotating the belt

tensioner idler counter-clockwise. Lift the

ribbon belt off the ribbon pulley.

2. Rotate ribbon pulley to view set screw from

the top of the center panel. Loosen set

screw.

3. Remove ribbon pulley from shaft.

REWIND

PULLEY

PLATEN

PULLEY CLUTCH

ASSEMBLY

LOCATION OF

POWER SUPPLY

MOVIE

RIBBON

PULLEY

(60-TOOTH)

RIBBON

DRIVE BELT

(324-TOOTH)

MOVIE

BELT

TENSION

IDELER

Installation

1. Slide a nylon washer and then the ribbon

pulley onto the tube shaft. The pulley's set

screw faces the center panel.

2. Hold ribbon take-up tube against shaft

support housing and center panel. Use a

.005 inch shim to space pulley from shaft

support housing. Tighten set screw to 11

inch-pounds torque. Use a thread lock

(Loctite) on the set screw.

3. Place the belt on rewind pulley behind the

power supply.

4. Place the belt over the belt tension idler and

around the outside gear of the pulley clutch.

Rotate the tensioner counter-clockwise to

provide slack. Pull the belt over the ribbon

pulley. Release the tensioner.

MOVIE

980023-131 Rev.B 43

Page 50

Ribbon Drive Belt

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

Removal

1. Cut the center tie-wrap securing the main

cable harness. Caution - Do not cut the

cables!

2. Disconnect the print head cable (JP21) from

main PCBA.

MOVIE

3. Loosen the belt by rotating the belt

tensioner idler counter-clockwise. Lift the

ribbon belt off the ribbon pulley and out.

Installation

1. Slide belt into position with the print head

ribbon cable passing through the belt.

2. Place the belt on rewind pulley behind the

power supply.

3. Place the ribbon belt over the belt tension

idler and around the outside gear of the

pulley clutch assembly. Rotate the tensioner

counter-clockwise to provide slack. Pull the

belt over the ribbon pulley. Release the

tensioner.

Pin 1

Print Head

JP21

RIBBON

PULLEY

RIBBON

BELT

(324-TOOTH)

PLATEN

PULLEY CLUTCH

ASSEMBLY

BELT

TENSION

IDELER

4. Reconnect the print head cable to the main

PCBA .

5. Re-tie the main PCBA harness. Use the

"Securing the Harness" procedure.

44 980023-132 Rev.B

REWIND

PULLEY

LOCATION OF

POWER SUPPLY

MOVIE

Page 51

Rewind Drive Pulley

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

The power supply must be loosened from the printer's bottom plate. (Procedure 980023-103)

Tools:

11/32 Allen driver

RIBBON

PULLEY

MOVIE

Removal

1. Loosen the ribbon belt by rotating the belt

tensioner idler counter-clockwise. Lift the

ribbon belt off the ribbon pulley.

2. Rotate rewind pulley to view set screw from

the top of the center panel. Loosen set

screw.

3. Remove rewind pulley from the shaft.

Installation

1. Slide a nylon washer and then the ribbon

pulley onto the tube shaft. The pulley's set

screw faces the center panel.

REWIND

PULLEY

RIBBON

BELT

(324-TOOTH)

PLATEN

PULLEY CLUTCH

ASSEMBLY

BELT

TENSION

IDELER

LOCATION OF

POWER SUPPLY

MOVIE

2. Hold rewind tube against shaft support

housing and center panel. Use a .005 inch

shim to space the rewind pulley from shaft

support housing. Tighten set screw to 11

inch-pounds torque. Use a thread lock

(Loctite) on the set screw.

3. Place the ribbon belt around the rewind

pulley, over the belt tension idler and

around the outside gear of the pulley clutch

assembly. Rotate the tensioner

counter-clockwise to provide slack. Pull the

belt over the ribbon pulley. Release the

tensioner.

980023-133 Rev.B 45

Page 52

Platen Belt (120 tooth)

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

Tools:

TORX tool with #T25 tip or 4mm allen head

Removal

1. Loosen the ribbon belt by rotating the belt

tensioner counter clockwise. Lift the ribbon

belt off the ribbon and clutch pulleys. Do

not disconnect the print head cable.

2. Loosen the four (4) M5x14 socket head

mounting screws securing the motor to the

center panel. Manually walk the platen belt

off the pulley.

MOVIE

RIBBON

PULLEY

BELT

TENSION

IDELER

PLATEN

PULLEY CLUTCH

ASSEMBLY

Installation

1. Slide platen belt on the motor gear and then

onto the 42 tooth pulley inside of the pulley

clutch.

2. Place the belt on rewind pulley (behind the

power supply).

3. Place the ribbon belt around the belt tension

idler and lower pulley. Rotate the tensioner

counter-clockwise to provide slack. Pull the

belt over the ribbon pulley. Release the

tensioner.

4. Tighten the platen belt by sliding the motor

toward the rear panel. Secure the motor in

place. Refer to Adjusting Belt Tension for

setting the recommended belt tension.

REWIND

PULLEY

PLATEN

BELT

(120-TOOTH)

LOCATION OF

POWER SUPPLY

46 980023-136 Rev.B

Page 53

Platen Clutch & 42 Tooth Pulley

H

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

Tools:

TORX tool with #T25 tip or 4mm allen head

Pliers for E-ring retainers (12R)

11/32 Allen driver

Removal

1. Loosen the ribbon belt by rotating the belt

tensioner counter clockwise. Lift the ribbon

belt off the ribbon pulley.

2. Loosen the four (4) M5x14 socket head

mounting screws securing the motor to the

center panel. Manually walk the platen belt

off the pulley.

3. Remove the E-ring from the end of the

clutch on the platen shaft.

4. Rotate pulley clutch to view set screw.

Loosen set screw. Remove the 42 tooth

pulley from shaft.

REWIND

PULLEY

MOVIE

RIBBON

PULLEY

BELT

TENSION

IDELER

PLATEN

PULLEY CLUTC

ASSEMBLY

PLATEN

BELT

(120-TOOTH)

LOCATION OF

POWER SUPPLY

PLATEN

SHAFT

SHIM

PULLEY

CLUTCH

E-RING

42 TOOTH

PULLEY

SET SCREWS

980023-137 Rev.B 47

Page 54

Installation

1. Slide the small nylon washer and then the

42 tooth pulley on platen shaft. The brass

platen sleeve and flange bearing should still

be on the shaft and through the center

panel.

2. Use a .005 inch shim to space the 42 tooth

pulley from nylon washer (and against the

flange bearing). Tighten the two (2) set

screws to 11 inch-pounds torque. Use a

thread lock (Loctite) on the set screws.

3. Slide platen belt on the motor gear and then

onto the 42 tooth pulley.

4. Slide the large nylon washer, the clutch

pulley and a small nylon washer onto the

platen shaft.

5. Lock the clutch and washers onto the platen

shaft by snapping the E-ring into the grove

on the end of the platen shaft.

PLATEN SLEEVE

FLANGE-TYPE BEARING

42-TOOTH PULLEY

32-TOOTH

CLUCH PULLEY

GRIP RING

NYLON WASHERS

6. Place the ribbon belt around the pulley

clutch, the belt tension idler and rewind

pulley. Rotate the tensioner

counter-clockwise to provide slack. Pull the

belt over the ribbon pulley. Release the

tensioner.

7. Tighten the platen belt by sliding the motor

toward the rear panel. Secure the motor in

place. Refer to Adjusting Belt Tension for

setting the recommended belt tension.

48 980023-137 Rev.B

Page 55

Ribbon Collar & Spring

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

Tools:

Pliers for E-ring retainers (12R)

11/32 Allen driver

Removal

1. Loosen supply ribbon tube's collar set screw.

2. Slide the collar off the tube shaft and spring

off the post.

Installation

MOVIE

1. Slide the nylon washer and then the collar

onto the tube shaft.

2. Slide the end of the collar's spring on the

post below the collar.

3. Rotate the shaft of the supply ribbon tube

has the set screw and slot facing up. The set

screw needs to face up to allow access to

adjust tube tension.

4. Hold the ribbon tube against the center

panel. Use a .005 inch shim to space the

collar from the shaft support housing.

Tighten set screw to 11 inch-pounds torque.

Use a thread lock (Loctite) on the set screw.

980023-138 Rev.B 49

Page 56

Ribbon Tubes & Shaft Support

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

Take-Up Ribbon Tube Or Shaft Support Housing - The ribbon belt and pulley must be

removed from the tube shaft prior to preceding. (980023-132)

Supply Ribbon Tube Or Shaft Support Housing - The ribbon belt and pulley must be

removed from the tube shaft prior to preceding. (980023-132)

Take-Up

Ribbon

Tubes

MOVIE

Supply

MOVIE

Tools:

#2 Philips screwdriver

Removal

1. With the collar or pulley removed, slide the ribbon tube out of the shaft support housing.

2. Shaft Support Housing only - Remove the two (2) mounting screws securing the shaft support

housing to the center panel.

Installation

1. Place the nylon washer on the shaft and push it against the tube assembly.

If both the tube and shaft housing are replaced - Lightly lube the shaft with silicon

grease while leaving the last 3/4 of an inch clear of grease.

2. Shaft Support Housing only - Insert the housing into the center panel. Rotate the housing to

align the two (2) molded posts. Attach the housing to the center panel with two (2) screws.

3. Slide the tube assembly into the shaft support housing and re-install the collar (supply) or

ribbon belt and pulley (take-up).

50 980023-148 Rev.B

Page 57

Rewind Tube & Shaft Support

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

The power supply must be loosened from the printer's bottom plate. (980023-103)

The ribbon belt and pulley must be removed from the tube shaft prior to preceding. (980023-132)

MOVIE

Tools:

#2 Philips screwdriver

11/32 Allen driver

Removal

1. With the power supply rotated out of the

way, loosen the two (2) screws retaining

the label rewind tube assembly (shaft

support housing) to the center panel. Do not

remove the screws.

2. Slide the rewind belt off the rewind pulley

by rotating the pulley. Use your hands, only.

3. Pulley Only - Rotate rewind pulley to view

set screw from the top of the center panel.

Loosen set screw. Slide the pulley off.

Installation

1. Pulley only - Slide rewind pulley on shaft.

Use a .005 inch shim to space pulley from

shaft support housing.

2. Tighten set screw to 11 inch-pounds torque.

Use a thread lock (Loctite) on the set screw.

3. Pulley & Belt - Slide the rewind belt into

pulley clutch and then the rewind pulley.

Rotate the rewind pulley while pressing the

belt on by hand.

4. Tighten the two (2) screws retaining the

label rewind tube assembly to 11

inch-pounds torque.

980023-140 Rev.B 51

Page 58

Platen Bearing & Replacement Kit

S

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

The platen belt, clutch pulley and 42 tooth pulley must be removed prior to proceeding.

(980023-137)

Tools:

Pliers for E-ring retainers (12R)

11/32 Allen driver

Removal

MOVIE

1. Remove the E-ring from the end of the platen shaft on the outside of the lower print

mechanism.

2. Remove nylon washers and flange bearings.

3. Slide the platen right (from front) and remove the brass platen sleeve and then left and remove

the other sleeve from the other side of the center panel.

4. With platen pushed into the center panel, lift the other side up and out of the lower print

mechanism.

PLATEN SLEEVE

PLATEN SHAFT

PLATEN SLEEVE

GRIP RING

PLATEN

FLANGE-TYPE BEARING

42-TOOTH PULLEY

32-TOOTH

CLUCH PULLEY

GRIP RING

NYLON WASHER

NYLON WASHER

FLANGE-TYPE

BEARING

REAR PANEL

52 980023-143 Rev.B

Page 59

Installation

1. Slide the long shaft end of the platen roller into the printer's center panel.

MOVIE

2. With the platen roller's shaft perpendicular to the center panel, slide the short end of the platen

shaft into the lower print mechanism's side bracket.

3. Place, in sequence, the following on the outside platen shaft: a platen sleeve, flange bearing

(flange outside), and a nylon washer. Lock the them on the shaft with the E-ring.

4. From inside the center panel, pull the platen shaft tight against the lower print mechanism's

side plate. Verify the bearing is through the side plate and resting on the flange of the bearing.

5. Place, in sequence, the following on the inside platen shaft: a platen sleeve, flange bearing

(flange outside), and a nylon washer.

6. The platen kits parts will be secured when the 42 tooth platen pulley is mounted. See the

980023-137 procedure to complete installation.

980023-143 Rev.B 53

Page 60

Lower Print Mechanism

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

The peel mechanism must be removed prior to proceeding. (980023-125)

Tools:

#1 & #2 Philips Screw drivers

11/32 Allen driver

Removal

MOVIE

1. Remove the peel mechanism from the lower print mechanism.

2. Remove the E-ring from the end of the platen shaft on the outside of the lower print

mechanism. Remove the nylon washer and flange bearing.

3. Remove the two (2) screws securing the (curved) label rewind plate from the lower mechanism.

4. Remove the three screws securing the side plate to the lower print mechanism. Slide the plate

off the platen shaft and latch assembly. Note the washer on the outside of the latch pivot shaft.

54 980023-144 Rev.B

Page 61

5. Remove the lower print mechanisms extrusion bracket that the peel mechanism and label

rewind plate were mounted to.

6. Slide the latch assembly out of the assembly's shaft pivot in the center panel and the spring off

the post.

Latch Assembly

Post

Spring

Washers

Installation

1. Loosely attach the extrusion to the center panel with a single screw in the bottom screw hole.

Let the extrusion swing down to the outside of the printer.

2. Slide a metal washer on each end, two (2) total, of the latch assembly's shaft. Insert the latch

assembly's shaft into the center panel.

2. Hook the spring to the post on the center panel and the latch assembly's prong.

3. Swing the extrusion up and attach it to the center panel with the other two screws to finish

mounting the extrusion. Be careful, do not knock the latch assembly out of the center panel.

Tighten the all three (3) screws to 11 inch-pounds torque.

4. Place the side plate on the latch assembly and attach the plate to the extrusion with three (3)

screws and washers. Tighten the three (3) screws to 11 inch-pounds torque.

5. Place, in sequence, the following on the outside platen shaft: a platen sleeve, flange bearing

(flange outside), and a nylon washer. Lock the them on the shaft with the E-ring.

6. Attach the (curved) label rewind plate with the two (2) flat head screws to the lower print

mechanism. Tighten the screws to 4.7 inch-pounds torque.

7. Attach the peel mechanism onto the lower print mechanism with two (2) flat head screws and

washers. Tighten the screws to 4.7 inch-pounds torque.

980023-144 Rev.B 55

Page 62

Print Head Carriage

S

Preparations

Before starting the procedure, open the printer, then remove media and any ribbon from the printer.

The exterior cover must be removed prior to proceeding. (980023-101)

Remove the print head and set it on a clean, soft and static safe surface (mat). (980023-102)

Tools:

#2 Philips & a flat blade screwdrivers

Removal

MOVIE

1. Remove the bottom left print head side plate screw. Pull the ribbon adjustment rod out.

2. Open the print head and unhook the print head carriage spring from the other side of the

center panel. Push down on the spring while holding the print head up to release the spring.

3. Remove the three (3) remaining screws retaining the print head side plate to the center panel

of the printer. Lift the print head carriage out. Note the carriage pivot and cable routing.

CENTER

PANEL

PRINTHEAD

CARRIAGE

Print Head Spring on Inside of Center

Panel

ASSEMBLY

PRINTHEAD

SIDE PLATE

ACCESS HOLE

PRINT HEAD

RIBBON

CABLE

PRINTHEAD

56 980023-146 Rev.B

WASHERS

SCREW

LOCK WASHERS

RIBBON

ADJUSTMENT ROD

Page 63

Installation

1. Slide the print head cable through the print head carriage assembly.

2. Place the print head carriage's pivot shaft into the pivot hole in the center panel.

2. Place the print head side plate on the carriage print head pivot hole on the opposite side.

Loosely secure the carriage and side plate to the extrusion bracket with three (3) screws and

washers.

3. Push the side plate to match the upper print mechanism's extrusion profile (rear and top).

Tighten the three (3) screws to 15.8 inch-pounds of torque.

4. Reposition the print head spring to the carriage. Lift the print head carriage up and push the

spring arm down and then into the carriage to engage.

5. Insert the ribbon adjustment rod in the "D" slot in the center panel. Attach the rod to the side

plate with a screw and washer and loosely tighten.

6. Adjust ribbon adjustment shaft to be in the center of slot on the side plate. Tighten the screw to

15.8 inch-pounds of torque.

7. Re-attach the print head.

8. Verify the print head's cable does not extend into the ribbon path.

9. With media and ribbon, adjust to remove ribbon wrinkle. See the Ribbon Adjustment

procedure for details.

Print Head

Cable

Check for cable routing interference with ribbon path

Ribbon

980023-146 Rev.B 57

Page 64

Cutter Cable

Preparations

The exterior cover must be removed prior to proceeding. (980023-101)

Note the main cable harness routing and cable tie positions. (980023-112)

Removal

1. Cut the three (3) tie-wraps securing the

main cable harness. Caution - Do not cut

the cables!

2. Disconnect the cutter cable (JP15) from

main PCBA if the cutter cable is being

replaced.

3. Remove the spiral wrap from the motor

(and cutter) cable for re-use. If the cable is

being replaced, disconnect the cable from

the cutter assembly under the print

mechanism.

Installation

1. Connect the cutter cable (JP15) to the main

PCBA.

2. Insert the cutter through the center panel

next toth e motor cable.

3. Re-tie the main PCBA harness.

2746 Cutter

JP15

MOVIE

4. Add the spiral wrap to the cutter and motor

cable.

4. Spiral wrap should extend as far from the

center panel as the tension idler spring in

TLP2746 printer.

5. Use the "Securing the Harness" procedure to

dress the wiring to clear moving parts and

provide service loops.

58 980023-147 Rev.B

Spring

Spiral

Wrap

Page 65

See the user's manual or cutter mounting

instruction to mount and use the cutter.

Cutter Cable

Exits Here

980023-147 Rev.B 59

Cable

Ties

Cutter &

Motor Cables

Page 66

Securing the Main Harness

The printer was designed to meet or exceed all regulatory agency (CE, FCC, UL, CSA, etc.) safety

and electro-magnetic requirements. The positioning and anchoring of the cables and connectors are

critical to meet these requirements.

The following diagrams the physical location of the printer's primary cable groups and cable tie

points.

Controls and

Sensors

Motor

DC Power

MOVIE

Print Head Cable Ties Cable Tie

Verify all cables are connected prior to proceeding.

Verify the Main PCBA is pressed into the center panel's circuit board standoffs. They

may have come loose when pulling on cables and connectors.

60 980023-149 Rev.B

and

Anchor

Page 67

Cable Clearance Check Procedure

The printer cables and connectors must not interfere (touch) with any

moving components (belts, gears or springs).

Placement of cable tie points, tie anchors, and cable tension and slack areas are outline in the

following steps.:

Control Panel Tie Point

1. Pull the control panel cable until minimum

1/8" service loop (slack) is present.

2. Open the front door to maximum range.

Pull the label taken sensor cable until

minimum 1/8" service loop (slack) is present

in front.

3. Very the head-up sensor cable is not twisted

and easily clears the ribbon drive belt.

4. Secure the cable tie.

Power Supply Cable Tie Point

1. Loosely connect the DC power cable,

control panel cable tie group, label sensor,

and motor cables with a cable tie through

the anchor on top of the power supply.

2. Push the label sensor slide the maximum

distance into the user side of the printer.

Pull the sensor cables through the power

supply anchor tie towards the main PCBA,

taught but not strained. Tighten the tie.

3. Pull the control panel cable through the

power supply anchor tie towards the main

PCBA, taught but not strained.

4. Push the plastic spiral wrap towards the

motor. While holding the spiral wrapped

motor cable portion parallel to the printer

base and equal distant between the platen

belt and belt tension spring, pull the motor

cable towards the main PCBA.

5. Pull the DC power cable until no more than

2 inches and no less than 1 inch of service

loop away from the front side of the power

supply.

980023-149 Rev.B 61

Cable Tie

Page 68

Print head Tie Point

1. Tie the print head cable to the main harness

1 1/2 inches up from the power supply

cable tie. Do not tie wrap the plastic spiral

wrap. Push the spiral wrap through the hole

in the center panel 1/2 inch.

The print head cable should be center

between the ribbon belt.

Prin Head

Cable

Cable Tie

Power Supply Cable Tie Point

1. Loosely connect by hand the DC power

cable, control panel cable tie group, label

sensor, and motor cables into a cable

bundle 1 to 2 inches from the DC power

connector on the main board. Fold the

excess cable form the sensors and controls

into the bundle.

2. Tie the bundle with a cable tie

approximately 1 1/2 inches from the DC

power connector on the main board. Finish

tightening the tie wrap.

3. Verify there is approximately 1/8 inch

service loop on all the cable going into the

main PCBA.

Final Check

1. Verify the printer cables and connectors are

not interfering (touch) with any moving

components (belts, gears or springs).

DC Power

Comnnector

2. Verify all ties are snug.

3. Cut excess cable tie tails off. Do not cut the

cables!

62 980023-149 Rev.B

Cable Bundle

& Tie Point

Print Head