Page 1

UNIVERSAL SCAN

ENGINE DEVELOPER’S

INSTALLATION GUIDE

Page 2

Page 3

UNIVERSAL SCAN ENGINE DEVELOPER’S KIT

INSTALLATION GUIDE

72E-59636-05

Rev. A

May 2015

Page 4

ii UNIVERSAL SCAN ENGINE DEVELOPER’S KIT INSTALLATION GUIDE

No part of this publication may be reproduced or used in any form, or by any electrical or mechanical means,

without permission in writing from Zebra. This includes electronic or mechanical means, such as photocopying,

recording, or information storage and retrieval systems. The material in this manual is subject to change

without notice.

The software is provided strictly on an “as is” basis. All software, including firmware, furnished to the user is on

a licensed basis. Zebra grants to the user a non-transferable and non-exclusive license to use each software

or firmware program delivered hereunder (licensed program). Except as noted below, such license may not be

assigned, sublicensed, or otherwise transferred by the user without prior written consent of Zebra. No right to

copy a licensed program in whole or in part is granted, except as permitted under copyright law. The user shall

not modify, merge, or incorporate any form or portion of a licensed program with other program material, create

a derivative work from a licensed program, or use a licensed program in a network without written permission

from Zebra. The user agrees to maintain Zebra’s copyright notice on the licensed programs delivered

hereunder, and to include the same on any authorized copies it makes, in whole or in part. The user agrees not

to decompile, disassemble, decode, or reverse engineer any licensed program delivered to the user or any

portion thereof.

Zebra reserves the right to make changes to any software or product to improve reliability, function, or design.

Zebra does not assume any product liability arising out of, or in connection with, the application or use of any

product, circuit, or application described herein.

No license is granted, either expressly or by implication, estoppel, or otherwise under any Zebra Technologies

Corporation, intellectual property rights. An implied license only exists for equipment, circuits, and subsystems

contained in Zebra products.

Warranty

For the complete Zebra hardware product warranty statement, go to:

http://www.zebra.com/warranty

.

Page 5

Revision History

Changes to the original guide are listed below:

Change Date Description

-01 Rev A 7/2011 New Motorola Solutions branding; updated engines: removed end-of-life engines;

-05 Rev A 5/2015 Zebra Re-branding

iii

added new engines and relevant data; updated drawings.

Page 6

iv UNIVERSAL SCAN ENGINE DEVELOPER’S KIT INSTALLATION GUIDE

Page 7

TABLE OF CONTENTS

Warranty ......................................................................................................................................... ii

Revision History.............................................................................................................................. iii

About This Guide

Introduction ..................................................................................................................................... vii

Chapter Descriptions ...................................................................................................................... vii

Notational Conventions................................................................................................................... viii

Related Documents ........................................................................................................................ viii

Service Information......................................................................................................................... ix

Chapter 1: GETTING STARTED

Introduction .................................................................................................................................... 1-1

Unpacking ...................................................................................................................................... 1-1

UDK Contents ................................................................................................................................ 1-2

Mounting Considerations ............................................................................................................... 1-3

SE655, SE955, SE965, SE1524 .............................................................................................. 1-3

SE3300/PL3307, SE4500/PL4507, SE6700/PL6707 .............................................................. 1-3

Simple Serial Interface ................................................................................................................... 1-3

Symbol Native Application Programming Interface (SNAPI) ......................................................... 1-4

Development Board ....................................................................................................................... 1-4

Quick Installation ...................................................................................................................... 1-4

Chapter 2: ELECTRICAL CONSIDERATIONS

Introduction .................................................................................................................................... 2-1

Board Functional Descriptions ....................................................................................................... 2-1

Power Configuration - Block 1 ....................................................................................................... 2-2

USB Power Selection - Block 2 (Imager Engine Systems) ............................................................ 2-4

Host Communication Configuration - Block 3 (Imager Engine Systems) ....................................... 2-5

Signal Breakout - Block 4 ............................................................................................................... 2-6

External Illumination Interface - Block 5 (Imager Engine Systems) ............................................... 2-7

Download Button - Block 6 ............................................................................................................. 2-7

Page 8

vi UNIVERSAL SCAN ENGINE DEVELOPER’S KIT INSTALLATION GUIDE

RS-232 Circuitry - Block 7 ............................................................................................................. 2-8

User Interface Circuitry - Block 8 ................................................................................................... 2-8

Engine Mounting Holes - Block 9 ................................................................................................... 2-9

Appendix A: REFERENCE SCHEMATIC

UDK Reference Schematic ............................................................................................................ A-1

Index

Glossary

Page 9

ABOUT THIS GUIDE

Introduction

The Universal Scan Engine Developer’s Kit Installation Guide provides general instructions for installing and

configuring the Universal Development board.

For the latest Simple Serial Interface (SSI) Software Developer’s Kit (SDK) and Symbol Native API (SNAPI) SDK,

visit: http://www.zebra.com/support/product/DKSE-2000.html

Chapter Descriptions

This guide includes the following topics:

•

Chapter 1, GETTING STARTED provides an overview of the Universal Scan Engine Developers Kit,

including descriptions of SSI and SNAPI, engine mounting considerations, and general installation

instructions.

•

Chapter 2, ELECTRICAL CONSIDERATIONS describes the components of the development board.

.

•

Appendix A, REFERENCE SCHEMATIC provides schematic drawings of the development board kit.

Page 10

viii UNIVERSAL SCAN ENGINE DEVELOPER’S KIT INSTALLATION GUIDE

Notational Conventions

This document uses the following conventions:

•

Italics are used to highlight chapters and sections in this and related documents

•

bullets (•) indicate:

• Action items

• Lists of alternatives

• Lists of required steps that are not necessarily sequential

•

Sequential lists (e.g., those that describe step-by-step procedures) appear as numbered lists.

NOTE This symbol indicates something of special interest or importance to the reader. Failure to read the note

will not result in physical harm to the reader, equipment or data.

CAUTION This symbol indicates that if this information is ignored, the possibility of data or material damage may

WARNING! This symbol indicates that if this information is ignored the possibility that serious personal

Related Documents

•

Simple Serial Interface (SSI) SDK

•

Simple Serial Interface (SSI) Software Developer’s Kit Programmer Guide, p/n 72E-59860-xx

•

Symbol Native API (SNAPI) SDK

•

Symbol Native Application Programming Interface (SNAPI) Programmer Guide, p/n 72E-71370-xx

For the latest version of software and guides, visit: http://www.zebra.com/support/product/DKSE-2000.html

occur.

injury may occur.

.

Page 11

Service Information

If you have a problem with your equipment, contact Zebra Support for your region. Contact information is

available at: http://www.zebra.com/support.

When contacting Mobility, please have the following information available:

•

Serial number of the unit

•

Model number or product name

•

Software type and version number.

Zebra responds to calls by E-mail, telephone or fax within the time limits set forth in support agreements.

If your problem cannot be solved by Zebra Support, you may need to return your equipment for servicing and

will be given specific directions. Zebra is not responsible for any damages incurred during shipment if the

approved shipping container is not used. Shipping the units improperly can possibly void the warranty.

If you purchased your business product from a Zebra business partner, contact that business partner for

support.

About This Guide ix

Page 12

xUNIVERSAL SCAN ENGINE DEVELOPER’S KIT INSTALLATION GUIDE

Page 13

CHAPTER 1 GETTING STARTED

Introduction

The Universal Scan Engine Developer’s Kit (UDK), p/n DKSE-2000-000R, provides the software and hardware

tools needed to design and test an embedded scan engine application before integration into a host device.

This guide explains how to install and configure the scan engine. The SSI Software Developer’s Kit

Programmer Guide (p/n 72E-59860-xx) explains how to use the Simple Serial Interface (SSI) UDK. This UDK

is a complete package that enables users to benefit from Zebra's SSI protocol used in all of our decoded and

imager engine offerings: SE6700/PL6707, SE3300/PL3307, SE4500/PL4507, and SE655, and laser-based

engines such as the SE955, SE965, SE1223 and SE1524.

Imager engine systems also support the SNAPI protocol over USB. The kit consists of a developer's board,

interface cables, and 5 V universal power supply. Use the link below to download the latest versions of the SSI

Software Developer’s Kit and SNAPI Software Developer’s Kit.

The UDK offers many user-friendly features and allows developers to use one development platform to work

with all Zebra's decoded engines, so the development board can be re-used for all decoded engine integration

projects.

Unpacking

Remove the material from its packing and inspect for damage. If the material was damaged in transit, contact

Zebra Support. See Service Information on page ix for information. KEEP THE PACKING. It is the approved

shipping container; use this to return the equipment for servicing.

NOTE Visit: http://www.zebra.com/support/product/DKSE-2000.html for the latest documentation and

downloads.

Page 14

1 - 2 UNIVERSAL SCAN ENGINE DEVELOPER’S KIT INSTALLATION GUIDE

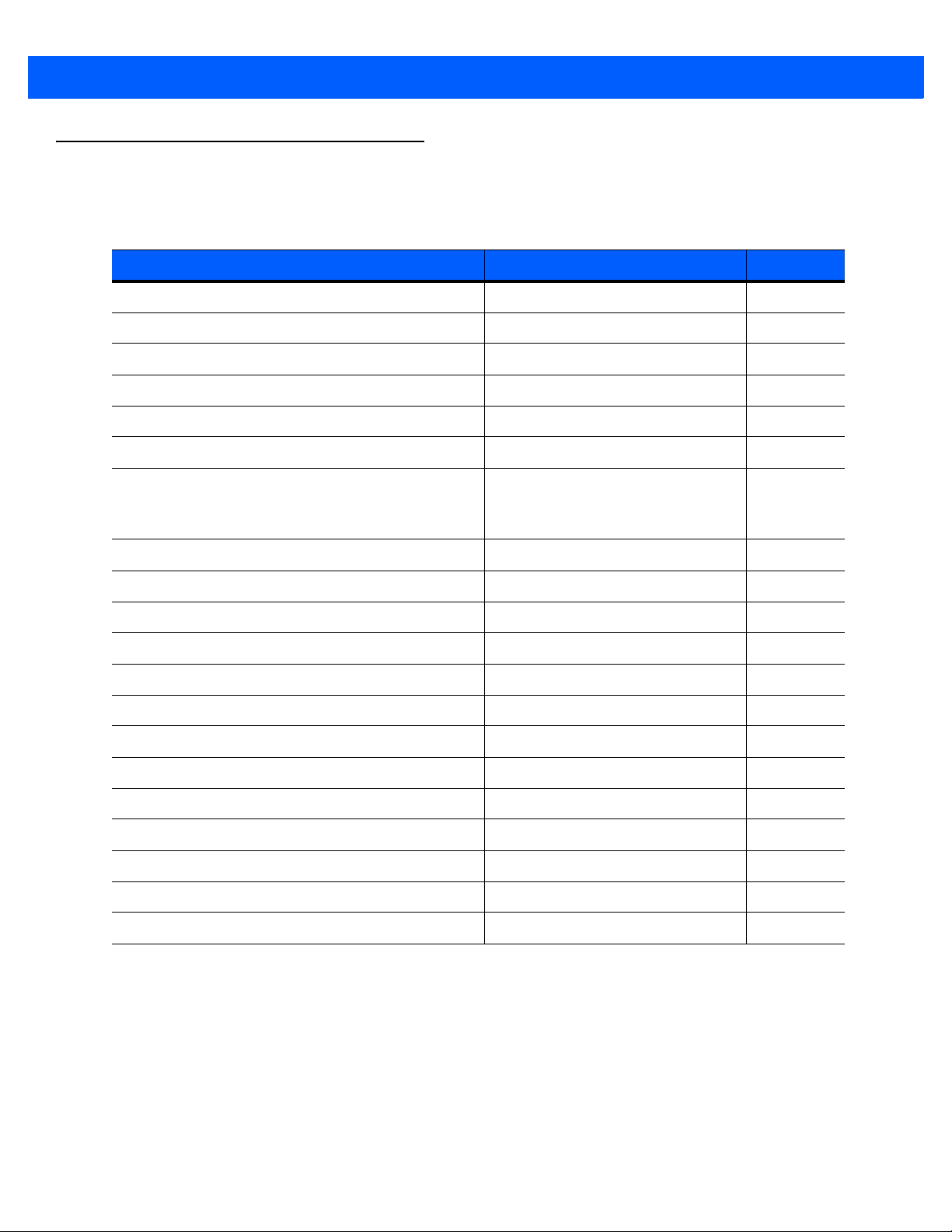

UDK Contents

Tab l e 1- 1 lists the material included in the UDK box.

Tab l e 1- 1

RS-232 Cable Assembly 50-16000-410 1

5.2VDC Power Supply 50-14000-058R 1

UDK Decoded Circuit Board 60-151670-01 1

Berg Header Jumpers 50-02100-1105 40

12 Pin Fanout Flex for SE955, SE965, SE1524 15-81378-01 1

12 Pin 10 in. Flex for SE935, SE965, SE1524 50-16000-134R 1

30 Pin Flex for PL3307/4507//6707 to Host 50-16000-623

SE655 Flex 15-141354-01 1

SE4500 21 Flex 15-113896-01 1

SE655 10 Pin Fanout 15-10414-01 1

Screw: #0 - 48 x 0.19 50-12809-068B 6

Screw: #2 - 32 x 0.19 50-12809-001 4

DKSE-2000-000R Contents

Item Part Number Quantity

Note:

White Flex; part number does

not appear on Flex.

1

Screw: M2 - 0.4mm x 4mm L 50-12854-0040L 4

Screw: M1.6 - 0.35mm x 6mm L 50-12800-1190 6

Screw: M1.6 - 0.35mm x 4mm L 50-12800-944 4

Nut: M1.6 50-12800-1191 6

Spacers for PL Decoder Boards 50-12800-1304 6

Standoffs 50-01400-408 4

DKSE2000 China RoHS Insert 72-96027-0336 1

DKSE2000 Download Information 72-152004-01 1

Page 15

Mounting Considerations

SE655, SE955, SE965, SE1524

1. Install the engine to the corresponding holes of the UDK board as indicated in Tab le “ 1” / M TG H OL ES

shown on the UDK board. Mount using the screws provided in the kit.

2. Install one end of the appropriate flex into the engine; install the other end of the flex into J4 on the UDK

board.

SE3300/PL3307, SE4500/PL4507, SE6700/PL6707

1. Install the engine to the corresponding holes of the UDK board as indicated in Tab le “ 1” / M TG H OL ES

shown on the UDK board. Mount using the screws provided in the kit.

2. Install the “PL” decoder board to the four holes in the middle of the UDK board labeled "A" using screws,

spacer/washer and nuts provided in the kit.

3. Install two flexes as follows. First, install one end of the “SE” engine flex into the smaller connector on the

decoder board and the other end into the engine. Next, install one end of the decoder board host flex into

J23 on the UDK board and the other end into the larger connector on the “PL” decoder board.

GETTING STARTED 1 - 3

NOTE SE6700/PL6707: Install the dark shielded flex into the SE6700 camera connector with the flex pins

positioned towards the center of the SE6700 (i.e., mate the metal area of the flex with the metal pins of the

connector). Mate the other end of the flex with the PL6707 camera connector (the connector located on

the side of the board with few components present (i.e., the connector on the side opposite the

microprocessor). Ensure the latches on both sides are pressed in securely.

Install the white host flex to connector J23 on the UDK board and other end to the PL6707 host connector.

The PL6707 connector is on the same side as the microprocessor. Ensure the metal connection on the

flex aligns with the metal connection connectors - the connector latch must be lifted to enable the flex to

slide in. When the flex is in place, press down securely to latch the flex.

The heat sink on the bottom of the SE6700 fits into the cut out area of the UDK board.

Simple Serial Interface

The Simple Serial Interface (SSI) provides a cost effective, highly integrated, flexible protocol for designing bar

code scanning applications and Auto-ID markets using Zebra’s broad range of engines. SSI provides a

communications link between Zebra's decoded engines and a serial host.

For the latest SSI SDK, visit: http://www.zebra.com/support/product/DKSE-2000.html

.

Page 16

1 - 4 UNIVERSAL SCAN ENGINE DEVELOPER’S KIT INSTALLATION GUIDE

Symbol Native Application Programming Interface (SNAPI)

The Symbol Native Application Programming Interface (SNAPI) is a development library used to implement

USB communication between a Zebra decoder and a Windows 98/2000/XP host. SNAPI is a

transaction-based protocol that enables communication with SNAPI devices over USB. The SNAPI DLL

implements:

•

USB HID communications

•

SNAPI USB imaging driver communications

•

SNAPI message building

•

SNAPI protocol handling for a communications link between Zebra scanners and a Windows host.

For the lastest SNAPI SDK, visit: http://www.zebra.com/support/product/DKSE-2000.html

Development Board

The UDK PCB accommodates multiple scope probes, debug aids, and provides a large work area for

developers. The board also has many ground and VCC posts so users can easily probe and simulate logic

levels on scanner lines.

Since the board supports all decoded engines, instructions for configuring the board to an engine is

silk-screened on the board.

NOTE Not all connectors provided on the board are used with every engine.

Quick Installation

The following installation procedure is typical for most development applications, and does not address all

board features. For detailed debugging and testing, see the appropriate sections of this guide.

1. Install the four white PCB standoffs (included in the kit) by snapping them into the corresponding holes in

the corners of the UDK board.

2. Mount the engine on the development board. See UDK Contents on page 1-2 and Mounting

Considerations on page 1-3 for assistance.

3. Determine the voltage requirements for the engine. See Table “1” in Figure 1-1 on page 1-5, which is

silk-screened on the board, or see Tab le 2 -1 o n pa ge 2 -3 .

.

CAUTION Be sure to set the voltage on the board to the proper voltage for the engine. Applying incorrect voltage

can destroy the engine.

4. Configure the power supply on the board to the correct output voltage determined in Step 3 by setting the

jumpers on header J29 as specified in Power Configuration - Block 1 on page 2-2.

5. Add a jumper to the appropriate header that connects the board voltage to the engine. See Ta ble 2- 1 o n

page 2-3.

6. If using the SE4400/PL4407, SE4500/PL4507, or SE6700/PL6707, configure the System Configuration

Bits to reflect the proper communication bus to the host. See Host Communication Configuration - Block 3

(Imager Engine Systems) on page 2-5.

7. Install the 13 Break Out Header jumpers on headers J17, J18, J14, and J21. See Signal Breakout - Block

4 on page 2-6.

8. Connect the interface cable between the development board and the host system.

9. Connect the DC power cord between the power supply and connector J1 on the development board.

Page 17

10. Connect the AC cord between the power supply and an AC outlet.

PL330

PL450

PL670

S

/

/

/

C

E

D

B

G

/E

G

B

B

F

F

955

965

1524

GETTING STARTED 1 - 5

E655

SE3300/PL3307

SE4500/PL4507

SE6700/PL6707

SE1524

3.3V

3.3V

3.3V

3.3V

E/A

C/A

G/A

B

SE965

3.3V

D

SE955-3V

SE955-5V

3.3V

5V

D

D

7

7

7

SE655 3.3V

F

D

Figure 1-1

Universal Development Board Assembly

Page 18

1 - 6 UNIVERSAL SCAN ENGINE DEVELOPER’S KIT INSTALLATION GUIDE

Page 19

CHAPTER 2 ELECTRICAL

CONSIDERATIONS

Introduction

The UDK is a universal development board for all Zebra data capture engines. The board supports the

decoded imaging solutions SE6700/PL6707, SE3300/PL3307, SE4500/PL4507, and SE655, and laser-based

engines such as the SE955, SE965, SE1223 and SE1524. The board includes a detailed silk screen to assist

in installation and use of the engines during development. The following section describes each part of the

board.

Board Functional Descriptions

The following sections detail the specific components on the board. Figure 1-1 on page 1-5 indicates each

component or group of components on the assembly in outlined areas, by block number.

Page 20

2 - 2 UNIVERSAL SCAN ENGINE DEVELOPER’S KIT INSTALLATION GUIDE

Power Configuration - Block 1

Block one (1) represents board power configuration and selection. Since the UDK board supports many

decoded engines, configure the power supplied to the engine to the voltage specified in Table 1, which is

silk-screened on the PCB. To set engine power, populate jumpers on J29 according to the figures

silk-screened on the PCB in the section labeled Board Power Selection. The electrical schematic and jumper

configurations are shown in Figure 2-1 and Figure 2-2. For the selected voltage, attach a jumper to J29 where

a rectangle is drawn.

Figure 2-1

Figure 2-2

In addition to configuring the voltage to the engine, populate a jumper to supply power to the particular engine

being used. Populate the jumper on the appropriate power enable header according to Ta ble 2 -1 . As an

alternative to the jumper, place an ammeter across this power enable header to measure the current draw of

the engine.

Electrical Schematic

NOTE For the SE4500/PL4507, choose 3.3V settings on J29.

Jumper Configurations for Power

Page 21

ELECTRICAL CONSIDERATIONS 2 - 3

An external power supply connected to J1 supplies the power, regardless of whether the USB connection is

used. If no power supply is connected to J1, all power is supplied to the UDK board and scan engine through

the USB connection. Ensure the power switch located near the power jack (J1) is in the ON position to enable

power to the UDK board and scan engine. The red LED adjacent to J1 indicates that the UDK board is

powered, and is on even if the appropriate power enable header does not have the necessary jumper.

Tab l e 2- 1

SE3300/PL3307

SE4500/PL4507

SE6700/PL6707

SE655 J4 J3

SE955 J4 J3

SE965 J4 J3

SE1524 J4 J3

* Special instructions to power PL33/45 from 5V and 3.3V, and 5V only:

** Configure board power (J29) for 5V, install J12 (1-2) to enable SE6700 illumination.

Power Enable Headers

Engine Connector Power Enable Header

J23 J13 *

J23 J13

J23 J13 **

- 5V only - Remove J29 and J13; set J12 to the 5V position (jump pins 1 and 2).

- 5V and 3.3V - Jump J12 pins 1 and 2; Jump J29 pins 4-6; install J13

Page 22

2 - 4 UNIVERSAL SCAN ENGINE DEVELOPER’S KIT INSTALLATION GUIDE

Optional 3.3 V Input

for PL4407and PL6707

USB

USB Power Selection - Block 2 (Imager Engine Systems)

NOTE Not all Zebra engines support the USB interface.

The jumper pad in Figure 2-3 provides three power options (indicated on the silk screen) for the PL4407,

PL4507, and PL6707.

USB subsystem:

•

Supply the USB system with +5 V from the DC power jack (J1). To do this (based on the silk screen),

install the jumper on J12 pins 1-2.

•

Supply the USB system with +5 V from the USB bus via connector J25. To do this (based on the silk

screen), install the jumper on J12 pins 3-4. DO NOT install the power supply in J1; the power switch (S4)

still controls the power to the board.

•

For the PL4407 and PL6707 only: Supply the USB system with +3.3 V. To do this (based on the silk

screen), install the jumper on J12 pins 7-8, then drive 3.3 V in terminal T5 located next to J12. Ensure the

external supply is also referenced to the board ground which can be located on J10 or any of the four

black test posts (T1, T2, T3, and T7).

Figure 2-3

Jumper Configurations for USB Power

Page 23

ELECTRICAL CONSIDERATIONS 2 - 5

Host Communication Configuration - Block 3 (Imager Engine Systems)

The jumper pad in Figure 2-4 sets the system configuration bits, which determine the type of communication

between the PL4407/PL6707 and a host. Based on the silk screen the following jumper configurations set the

desired communication method:

Tab l e 2- 2

Communication Type Jumper Settings for J7

RS-232 Install jumper on pins 1-2 and 3-4

USB Install jumper on pins 1-2

HSSI Install jumper on pins 3-4

Jumper Settings for Host Communication

NOTE For PL4507 configuration, refer to the Symbol PL4507 Decoder Integration Guide, p/n 72E-116649-xx.

Installing a jumper represents a value of 0; omitting a jumper represents a value of 1.

Pins 1 - 2 correspond to HOST_SYS_CFG1; pins 3 - 4 correspond to HOST_SYS_CFG0.

Figure 2-4

Jumper Configurations for Host Communication

Page 24

2 - 6 UNIVERSAL SCAN ENGINE DEVELOPER’S KIT INSTALLATION GUIDE

Signal Breakout - Block 4

Block four (4) contains multiple jumper pads including J9, J19, J26, J27, J11, J17, J18, J14, and J21 shown in

Figure 2-5. These jumpers provide test points for probing all logic signals to and from the engine. This block

also functions as a break-out pad so jumpers can be removed and the signal between the engine and the host

can be isolated and driven externally by another source.

Figure 2-5

The break out pads are the dual row headers J17, J18, J14, and J21 from left to right as they appear on the

board and in Figure 2-5. The signals mapped to these headers are silk screened between these headers and

the single row headers J9, J27, J26, J19, and J20. The single row headers are test points for probing, and are

connected directly to the engine signals that propagate from J23/J4/J8. Install the jumpers on the dual row

headers to connect these signals to the rest of the board including the board connectors, LEDs, and beeper.

Remove the jumpers on the dual row headers to break this connection and access either node of the signal.

Signal Breakout Jumpers

Page 25

ELECTRICAL CONSIDERATIONS 2 - 7

External Illumination Interface - Block 5 (Imager Engine Systems)

If necessary, add an external illumination system which is controlled and powered from the UDK through

connector J22, according to Ta b le 2-3 . Use header J28 to select either 3.0 V/3.3 V or 5 V to power the external

illumination system, according to the jumper setting shown in Figure 2-6. When using the 3.0 V/3.3 V setting,

the jumper settings on the Board Power Selection header J29 determine the illumination voltage.

Tab l e 2- 3

External Illumination System

External Illumination Power J22-1

Ext_Illum_Cntl J22-2

Ground J22-3

Figure 2-6

External Illumination System Signals

Signal

Illumination System Jumper Settings

Download Button - Block 6

Connector pin

S3, shown in Figure 2-7 controls the state of the download signal, J23 pin 30 and J4 pin 12. To place the device

in download mode, press this button during a power cycle until the device beeps. In download mode, the

device's bootloader communicates over the RS-232 connection through J6,

Figure 2-7

Download Button

Page 26

2 - 8 UNIVERSAL SCAN ENGINE DEVELOPER’S KIT INSTALLATION GUIDE

RS-232 Circuitry - Block 7

The circuitry in block seven (7) shown in Figure 2-8 is composed of the RS-232 DB-9 connector (J6), a 1 Mbps

RS-232 transceiver (U1), and four LEDs that provide visual status of the RTS, CTS, TXD, and RXD signals

between the host and the engine.

Figure 2-8

RS-232 Subsystem Circuitry

User Interface Circuitry - Block 8

Block eight (8) contains the Trigger button, Aim/Wake button, Decode LED and Power Down LED. Ta bl e 2 -4

details each of these components.

Tab l e 2- 4

Trigger Button (S2) This button controls the polarity of the trigger signal, J23 pin 19 and J4 pin 1, to the

Aim/Wake Button (S1) This dual-purpose button drives the AIM/WAKE* signal J23 pin 20 and J4 pin 2, to the

Power Down LED This LED is tied to the PWRDWN* signal, J23 pin 23 and J4 pin 5. The engine

Block Eight Components

Component Description

engine. When pressed it forces a trigger into the engine, starting a decode session. It

also wakes the engine from low power mode.

engine.

When the engine is in low power mode, the button drives the wake signal into the engine

to force it into normal power mode.

If the engine is in normal power mode, the button drives the aim signal which turns on

the aiming pattern when the engine is in the correct mode. Refer to the PL4407

Integration Guide for more details.

illuminates this to indicate it is low power mode.

Decode LED This LED is tied to the DLED* signal, J23 pin 19 and J4 pin 3. The engine illuminates

this to indicate a good decode.

Page 27

Engine Mounting Holes - Block 9

Block nine (9) contains the mounting holes for all supported data capture engines. Refer to the silk screen on

the board for mounting hole instructions.

ELECTRICAL CONSIDERATIONS 2 - 9

Page 28

2 - 10 UNIVERSAL SCAN ENGINE DEVELOPER’S KIT INSTALLATION GUIDE

Page 29

APPENDIX A REFERENCE SCHEMATIC

LP3855

U20

TO263-5

C51

47UF

+

1.47K

R241

10.0UF

C25

VCC_5

VCC_3

0

R10

1K

R17

2200PF

C3

221

R1

-

S2HDR

J29

- J29

- J29

- J29

- J29

- J29

VCC

VCC_3VCC_5

4

5

3V/3.3V

VCC

FOR 3V

INSTALL

FOR 3VFOR 3V

4

5V

5V CONFIGURATION

3.3V CONFIGURATION

6

2

1

3

3V CONFIGURATION

BOARD POWER SELECTION

5V

5

3V/3.3V

6

3

1

2

VCC

5V

65

43

1

INSTALL

2

VCC

3V/3.3V

3V/3.3V POWER SUPPLY

INSTALL

SD

VOUT

VIN

FB

GND MTH

6

4

2

5

3

1

42

1

MTH3

5

X7R

1210

10V

20%

1%

0805

1%

10V

S2

S1

S3

FLASH DOWNLOAD SECTION

PRESS AND HOLD BUTTON WHILE RECYCLING POWER

SILK SCREEN: AIM/WK*

SILK SCREEN: TRIG*

SILK SCREEN:

4

3

2

1

4

3

2

1

4

3

2

1

DNLD_ADP*

I152

AIM_ADP*

I160

I158

TRIG_ADP*

UDK Reference Schematic

Figure A-1

UDK Reference Schematic

Page 30

A - 2 UNIVERSAL SCAN ENGINE DEVELOPER’S KIT INSTALLATION GUIDE

LCX244

OE

Y

Y

Y

Y

A

A

A

A

3

2

1

0

3

2

1

0

LCX244

OE

Y

Y

Y

Y

A

A

A

A

3

2

1

0

3

2

1

0

R16

47.5K

R13

47.5K

R12

47.5K

VCC

VCC

R15

47.5K

C13

0.1UF

R14

47.5K

R11

47.5K

R19

31.6

47K

2.2K

Q1

CR11

BPR1

QMX-05ST

+

-

VCC

VCC

49.9

R5

CR1

CR2

49.9

R7

49.9

R9

CR6

CR7

49.9

R8

49.9

R3

49.9

R2

CR9

VCC

USER INTERFACE SECTION

CTS_LED*

RXD_LED

TXD_LED

VCC=VCC

CTS_ADP*

1

2

3

4

2

3

5

7

9

19

17

15

13

11

U4

12

14

16

18

1

8

6

4

2

U4

CA

CA

CR8

C

A

C

A

C

A

CA

VCC=VCC

I49

GREEN

RTS_ADP*

TXD_ADP

PWRDWN_ADP

RTS_LED*

RXD_ADP

DEC_LED*

PWRDN_LED

DLED_ADP*

BPR_ADP*

Figure A-2

UDK Reference Schematic (continued)

Page 31

REFERENCE SCHEMATIC A - 3

RZIF20_SMD

J4 J4

-

J4

-

J4

-

J4

-

J4

-

J4

J4 J4

J4

J4

J4

-

-

RZIF20SMD-MOL

J23

- J23

-

J23

- J23

-

J23

-

J23

-

J23

-

J23

-

J23

-

J23

-

J23

-

J23

-

J23

-

J23

-

J23

-

J23

-

J23

-

J23

-

J23

-

J23

-

J23

-

J23

-

J23

-

J23

-

J23

-

J23

-

J23

- J23

-

J23

- J23

10K

R25

10K

R24

RZIFP6-JAE

J8 J8

J8 J8

J8

J8

J8

J8

J8

J8

J8

-

0 R20

0

R21

SCAN ENGINE INTERFACE

(SE X22X/824)

(PL4407)

CSE 600 DECODED

12 PIN DECODED

SCAN ENGINE INTERFACE

CONNECTORS

ENGINE/DECODER INTERFACE

HOST CONNECTOR

USB_OUT+

USB_OUT-

HSSI0_RXFS

HSSI0_RXCLK

HSSI0_TXCLK

TRIG*

BPR*

VCC_JUMP3

USB_VCC_IN

PWRDWN

VCC_JUMP2

DLED*

RXD

RTS*

CTS*

TXD

PWRDWN

TRIG*

AIM*

DLED*

RXD

TXD

RTS*

CTS*

DLED*

BPR*

PWRDWN

TRIG*

AIM*

TXD

CTS*

RXD

EXT_ILLUM_CNTL2

SYS_CONFIG1

DNLD*

BPR*

DNLD*

VCC_JUMP1

HSSI0_TXFS

RTS*

HSSI0_TXDAT

HSSI0_RXDAT

USB_VCC_REG

VCC_JUMP1

AIM*

SYS_CONFIG0

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

1

2

3

4

5

6

7

8

9

10

11

Figure A-3

UDK Reference Schematic (continued)

Page 32

A - 4 UNIVERSAL SCAN ENGINE DEVELOPER’S KIT INSTALLATION GUIDE

TESTLOOP

T4

VCC_5

VCC_3_3

VCC_3

TESTLOOP

T5

TESTLOOP

T6

TESTLOOP

T2

TESTLOOP

T7

TESTLOOP

T3

TESTLOOP

T1

S1HDR

J9J9

J9

J9

J9

J9

J9

J9

J9

J9

J9

J9

J9

J9

-

S2HDR

J18J18

-

J18

-

J18

-

J18

-

J18

-

J18

J18

J18

J18

J18

J18

-

J14-

J14

-

J14

-

J14

-

J14

J14

-

S2HDR

J14-

J14

-

J14

-

J14

-

J14

-

J14

-

J11

S1HDR

- J11 -

VCC VCC

S2HDR

J17J17

-

J17

-

J17

-

J17

J17

J17

J17

J17

-

J17-

S2HDR

J7 J7

-

J7

J7

-

J10

S1HDR

- J10 -

S2HDR

J21J21

-

J21

J21

-

J20

S1HDR

J20 -

J19

S1HDR

J19 J26 J26 J27 J27 -

SYSTEM CONFIGURATION

VCC/GND PROBES

(RED - VCC_5)

(BLACK - GND)

(BLACK - GND)

(RED - VCC_3.3)

(RED - VCC_3V)

(BLACK - GND)

(BLACK - GND)

SIGNAL BREAK OUT CONNECTOR

TEST POINTS

JUMPER PAD

2

4

TXD_ADP

DNLD_ADP*

SYS_CONFIG1

TRIG*

AIM*

DLED*

BPR*

PWRDWN

RTS*

CTS*

TXD

RXD

DNLD*

TXD

EXT_ILLUM_CNTL2_ADP

HSSI0_TXCLK

CTS_ADP*

USB_OUT_ADPUSB_OUT_ADP+

HSSI0_TXFS

USB_OUT-

RXD_ADP

HSSI0_TXDAT_ADP

RTS*

EXT_ILLUM_CNTL2

USB_OUT+

HSSI0_TXDAT

HSSI0_RXDAT

DNLD*

RXD

HSSI0_TXCLK_ADP

BPR*

DLED*

PWRDWN

SYS_CONFIG1

SYS_CONFIG0

AIM_ADP*

RTS_ADP*

HSSI0_RXCLK

AIM*

TRIG*

HSSI0_RXFS

USB_OUTUSB_OUT+

HSSI0_TXFS

HSSI0_RXDAT

HSSI0_TXDAT

TRIG_ADP*

BPR_ADP*

CTS*

HSSI0_RXFS

PWRDWN_ADP

HSSI0_RXCLK_ADP

DLED_ADP*

HSSI0_RXFS_ADP

HSSI0_RXDAT_ADP

HSSI0_TXFS_ADP

EXT_ILLUM_CNTL2

SYS_CONFIG0

HSSI0_TXCLK

HSSI0_RXCLK

1

1

1

1

1

1

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1

3

5

7

9

11

2

4

6

8

10

12

2

12

10

8

4

6

1

9

7

5

3

11

12

1

3

5

7

2

4

6

8

109

1

3

12

132

4

1

2

1

2

1

2

1

2

Figure A-4

UDK Reference Schematic (continued)

Page 33

REFERENCE SCHEMATIC A - 5

-J25

-J25

-J25

-J25

J24

S2HDR

J24 J24 J24 J24 J24 J24 J24 -

VCC_3

-J25

-J25

-J22

S1HDR

-J22

-J22

U1

SN65C3232DW

VCC

0.047UF

C5

0.047UFC90.047UF

C14

0.1UF

C6

0.1UF

C2

J6

R_DSUB

-

J6 -

J6 -

J6 -

J6 -

J6 -

J6 -

J6 -

J6 -

SI3441BDV

Q10

R69

100K

C47

0.1UF

10K

R22

-

J28

S1HDR

-J28

-J28

VCC_3 VCC_5

0

R86

HSSI CONNECTOR

DO NOT INSTALL

SOFT START

TO LIMIT IN RUSH

FOR USB OPERATION

RS-232 XCVR

AND CONNECTOR

CONNECTOR

USB "B"

INTERFACE CONNECTORS

EXT. ILLUM

CONNECTOR

GND

VCC

C2-

DIN1

RIN1

DIN2

C1+

C1C2+

RIN2

DOUT1

ROUT1

DOUT2

ROUT2

V+

V-

USB_5V

HSSI0_TXFS_ADP

HSSI0_RXCLK_ADP

EXT_ILLUM_CNTL2_ADP

RXD_IN

CTS_ADP*

RTS_OUT

SOIC16-TI

RXD_ADP

CTS_IN

TXD_ADP

HSSI0_TXCLK_ADP

CTS_IN

TXD_OUT

RXD_IN

RTS_ADP*

USB_OUT_ADP+

HSSI0_TXDAT_ADP

HSSI0_RXFS_ADP

1206

USB_PWR_IN

USB_OUT_ADP-

HSSI0_RXDAT_ADP

1

4

5

6

1

2

3

4

5

6

7

8

2

3

1

2

3

1

10

11

1213

14

15 16

2

3

4

5

6

7

89

1

2

3

4

5

6

7

8

9

1256

3

4

1

2

3

Figure A-5

UDK Reference Schematic (continued)

Page 34

A - 6 UNIVERSAL SCAN ENGINE DEVELOPER’S KIT INSTALLATION GUIDE

330

R4

VCC_5

J1

0.1UF

C7

S4

C8

10UF

+

60.4

R6

J12 -

J13

S1HDR

-

C16

0.1UF

J13 -

0.1UF

C4

VCC_3_3

VCC_5

J12 -

J12 -

J12 -

J12 -

J12 -

J12 -

J12 -

J5

S1HDR

-

VCC

J5 -

J3

S1HDR

- J3 -

0.1UF

C15

PL4407

SE-X22X/824

POWER JACK

CSE-600

5V POWER SUPPLY

+5V POWER

VCC TO ENGINES

VCC_JUMP3

BRD_PWR

USB_5V

5%

25V

USB_5V

VCC_JUMP1

5%

VCC_JUMP2

USB_VCC_IN

16V

USB_VCC_REG

CR4

AC

A

B

C

C

NC

NO

4

12

2

8

6

1

3

5

7

12

12

20%

Figure A-6

UDK Reference Schematic (continued)

Page 35

INDEX

A

assembly drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

B

board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

assembly drawing . . . . . . . . . . . . . . . . . . . . . . . . 1-5

component descriptions . . . . . . . . . . . . . . . . . . . 2-1

download button . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

external illumination interface . . . . . . . . . . . . . . . 2-7

host communication . . . . . . . . . . . . . . . . . . . . . . 2-5

mounting holes . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

power configuration . . . . . . . . . . . . . . . . . . . . . . 2-2

RS232 circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

signal breakout . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

USB power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

user interface circuitry . . . . . . . . . . . . . . . . . . . . 2-8

C

circuit board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

contents of UDK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

conventions

notational . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

D

development board . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

assembly drawing . . . . . . . . . . . . . . . . . . . . . . . . 1-5

component descriptions . . . . . . . . . . . . . . . . . . . 2-1

download button . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

external illumination interface . . . . . . . . . . . . . . . 2-7

host communication . . . . . . . . . . . . . . . . . . . . . . 2-5

mounting holes . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

power configuration . . . . . . . . . . . . . . . . . . . . . . 2-2

RS232 circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

signal breakout . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

USB power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

user interface circuitry . . . . . . . . . . . . . . . . . . . . . 2-8

download button . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

E

electrical schematic . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

external illumination interface . . . . . . . . . . . . . . . . . . 2-7

jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

H

host communication

configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

I

information, service . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

J

jumper configurations

external illumination interface . . . . . . . . . . . . . . . 2-7

host communication . . . . . . . . . . . . . . . . . . . . . . 2-5

power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

signal breakout . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

USB power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

M

mechanical parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

mounting

board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

considerations for engines . . . . . . . . . . . . . . . . . 1-3

holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Page 36

Index - 2 UNIVERSAL SCAN ENGINE DEVELOPER’S KIT INSTALLATION GUIDE

SE1524 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

SE3300/PL3307 . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

SE4500/PL4507 . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

SE655 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

SE6700/PL6707 . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

SE955 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

SE965 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

N

notational conventions . . . . . . . . . . . . . . . . . . . . . . . . . viii

P

power configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

power enable headers . . . . . . . . . . . . . . . . . . . . 2-3

R

reference schematic . . . . . . . . . . . . . . . . . . . . . . . . . A-1

RS232 circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

S

U

USB

jumper configurations . . . . . . . . . . . . . . . . . . . . . . 2-4

power selection . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

user interface circuitry . . . . . . . . . . . . . . . . . . . . . . . . 2-8

schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

SE1524

mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

SE3300/PL3307

mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

SE4500/PL4507

mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

SE655

mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

SE6700/PL6707

mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

SE955

mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

SE965

mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

service information . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

signal breakout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Simple Serial Interface

guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

SNAPI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

SSI

guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Symbol Native Application Programming Interface . . 1-4

Page 37

GLOSSARY

A

Aperture. The opening in an optical system defined by a lens or baffle that establishes the field of view.

API. An interface by means of which one software component communicates with or controls another. Usually used to

refer to services provided by one software component to another, usually via software interrupts or function calls

Application Programming Interface. See API.

ASCII. American Standard Code for Information Interchange. A 7 bit-plus-parity code representing 128 letters,

numerals, punctuation marks and control characters. It is a standard data transmission code in the U.S.

Autodiscrimination. The ability of an interface controller to determine the code type of a scanned bar code. After this

determination is made, the information content is decoded.

B

Bar. The dark element in a printed bar code symbol.

Bar Code. A pattern of variable-width bars and spaces which represents numeric or alphanumeric data in

machine-readable form. The general format of a bar code symbol consists of a leading margin, start character, data

or message character, check character (if any), stop character, and trailing margin. Within this framework, each

recognizable symbology uses its own unique format. See Symbology.

Bar Code Density. The number of characters represented per unit of measurement (e.g., characters per inch).

Bar Height. The dimension of a bar measured perpendicular to the bar width.

Bar Width. Thickness of a bar measured from the edge closest to the symbol start character to the trailing edge of the

same bar.

BIOS. Basic Input Output System. A collection of ROM-based code with a standard API used to interface with standard

PC hardware.

Page 38

Glossary - 2 UNIVERSAL SCAN ENGINE DEVELOPER’S KIT INSTALLATION GUIDE

Bit. Binary digit. One bit is the basic unit of binary information. Generally, eight consecutive bits compose one byte of

data. The pattern of 0 and 1 values within the byte determines its meaning.

Bits per Second (bps). Bits transmitted or received.

Boot or Boot-up. The process a computer goes through when it starts. During boot-up, the computer can run

self-diagnostic tests and configure hardware and software.

BOOTP. A protocol for remote booting of diskless devices. Assigns an IP address to a machine and may specify a boot

file. The client sends a bootp request as a broadcast to the bootp server port (67) and the bootp server responds

using the bootp client port (68). The bootp server must have a table of all devices, associated MAC addresses and

IP addresses.

bps. See Bits Per Second.

Byte. On an addressable boundary, eight adjacent binary digits (0 and 1) combined in a pattern to represent a specific

character or numeric value. Bits are numbered from the right, 0 through 7, with bit 0 the low-order bit. One byte in

memory is used to store one ASCII character.

C

CDRH. Center for Devices and Radiological Health. A federal agency responsible for regulating laser product safety.

This agency specifies various laser operation classes based on power output during operation.

CDRH Class 1. This is the lowest power CDRH laser classification. This class is considered intrinsically safe, even if all

laser output were directed into the eye's pupil. There are no special operating procedures for this class.

CDRH Class 2. No additional software mechanisms are needed to conform to this limit. Laser operation in this class

poses no danger for unintentional direct human exposure.

Character. A pattern of bars and spaces which either directly represents data or indicates a control function, such as a

number, letter, punctuation mark, or communications control contained in a message.

Character Set. Those characters available for encoding in a particular bar code symbology.

Check Digit. A digit used to verify a correct symbol decode. The scanner inserts the decoded data into an arithmetic

formula and checks that the resulting number matches the encoded check digit. Check digits are required for UPC

but are optional for other symbologies. Using check digits decreases the chance of substitution errors when a

symbol is decoded.

Codabar. A discrete self-checking code with a character set consisting of digits 0 to 9 and six additional characters: ( -

$ : / , +).

Code 128. A high density symbology which allows the controller to encode all 128 ASCII characters without adding extra

symbol elements.

Code 3 of 9 (Code 39). A versatile and widely used alphanumeric bar code symbology with a set of 43 character types,

including all uppercase letters, numerals from 0 to 9 and 7 special characters (- . / + % $ and space). The code name

is derived from the fact that 3 of 9 elements representing a character are wide, while the remaining 6 are narrow.

Code 93. An industrial symbology compatible with Code 39 but offering a full character ASCII set and a higher coding

density than Code 39.

Page 39

Glossary - 3

Code Length. Number of data characters in a bar code between the start and stop characters, not including those

characters.

Cold Boot. A cold boot restarts the mobile computer and erases all user stored records and entries.

COM port. Communication port; ports are identified by number, e.g., COM1, COM2.

Continuous Code. A bar code or symbol in which all spaces within the symbol are parts of characters. There are no

intercharacter gaps in a continuous code. The absence of gaps allows for greater information density.

Cradle. A cradle is used for charging the terminal battery and for communicating with a host computer, and provides a

storage place for the terminal when not in use.

D

Dead Zone. An area within a scanner's field of view, in which specular reflection may prevent a successful decode.

Decode. To recognize a bar code symbology (e.g., UPC/EAN) and then analyze the content of the specific bar code

scanned.

Decode Algorithm. A decoding scheme that converts pulse widths into data representation of the letters or numbers

encoded within a bar code symbol.

Decryption. Decryption is the decoding and unscrambling of received encrypted data. Also see, Encryption and Key.

Depth of Field. The range between minimum and maximum distances at which a scanner can read a symbol with a

certain minimum element width.

Discrete 2 of 5. A binary bar code symbology representing each character by a group of five bars, two of which are

wide. The location of wide bars in the group determines which character is encoded; spaces are insignificant. Only

numeric characters (0 to 9) and START/STOP characters may be encoded.

Discrete Code. A bar code or symbol in which the spaces between characters (intercharacter gaps) are not part of the

code.

DRAM. Dynamic random access memory.

E

EAN. European Article Number. This European/International version of the UPC provides its own coding format and

symbology standards. Element dimensions are specified metrically. EAN is used primarily in retail.

Element. Generic term for a bar or space.

Encoded Area. Total linear dimension occupied by all characters of a code pattern, including start/stop characters and

data.

ENQ (RS-232). ENQ software handshaking is also supported for the data sent to the host.

ESD. Electro-Static Discharge

Page 40

Glossary - 4 UNIVERSAL SCAN ENGINE DEVELOPER’S KIT INSTALLATION GUIDE

F

Flash Disk. An additional megabyte of non-volatile memory for storing application and configuration files.

Flash Memory. Flash memory is responsible for storing the system firmware and is non-volatile. If the system power is

interrupted the data is not be lost.

FTP. See File Transfer Protocol.

H

Hard Reset. See Cold Boot.

Host Computer. A computer that serves other terminals in a network, providing such services as computation,

database access, supervisory programs and network control.

Hz. Hertz; A unit of frequency equal to one cycle per second.

I

IDE. Intelligent drive electronics. Refers to the solid-state hard drive type.

IEC. International Electrotechnical Commission. This international agency regulates laser safety by specifying various

laser operation classes based on power output during operation.

IEC60825-1 Class 1. This is the lowest power IEC laser classification. Conformity is ensured through a software

restriction of 120 seconds of laser operation within any 1000 second window and an automatic laser shutdown if the

scanner's oscillating mirror fails.

IEEE Address. See MAC Address.

Input/Output Ports. I/ O port s are pr i mari l y dedi cated t o pas s ing i n forma tion into or out of the terminal’s memory. Series

9000 mobile computers include Serial and USB ports.

Intercharacter Gap. The space between two adjacent bar code characters in a discrete code.

Interleaved 2 of 5. A binary bar code symbology representing character pairs in groups of five bars and five

interleaved spaces. Interleaving provides for greater information density. The location of wide elements

(bar/spaces) within each group determines which characters are encoded. This continuous code type uses no

intercharacter spaces. Only numeric (0 to 9) and START /STOP characters may be encoded.

Interleaved Bar Code. A bar code in which characters are paired together, using bars to represent the first character

and the intervening spaces to represent the second.

Interleaved 2 of 5. A binary bar code symbology representing character pairs in groups of five bars and five interleaved

spaces. Interleaving provides for greater information density. The location of wide elements (bar/spaces) within

each group determines which characters are encoded. This continuous code type uses no intercharacter spaces.

Only numeric (0 to 9) and START/STOP characters may be encoded.

Page 41

Glossary - 5

I/O Ports. interface The connection between two devices, defined by common physical characteristics, signal

characteristics, and signal meanings. Types of interfaces include RS-232 and PCMCIA.

IOCTL. Input/Output Control.

IP Address. (Internet Protocol address) The address of a computer attached to an IP network. Every client and server

station must have a unique IP address. A 32-bit address used by a computer on a IP network. Client workstations

have either a permanent address or one that is dynamically assig n e d to them each ses s i on. IP ad d r e sses are w r i t ten

as four sets of numbers separated by periods; for example, 204.171.64.2.

IPX/SPX. Internet Package Exchange/Sequential Packet Exchange. A communications protocol for Novell. IPX is

Novell’s Layer 3 protocol, similar to XNS and IP, and used in NetWare networks. SPX i s N o vell's vers ion of the Xerox

SPP protocol.

IS-95. Interim Standard 95. The EIA/TIA standard that governs the operation of CDMA cellular service. Versions include

IS-95A and IS-95B. See CDMA.

K

Key. A key is the specific code used by the algorithm to encrypt or decrypt the data. Also see, Encryption and

Decrypting.

L

LASER. Light Amplification by Stimulated Emission of Radiation.The laser is an intense light source. Light from a laser

is all the same frequency, unlike the output of an incandescent bulb. Laser light is typically coherent and has a high

energy density.

Laser Diode. A gallium-arsenide semiconductor type of laser connected to a power source to generate a laser beam.

This laser type is a compact source of coherent light.

Laser Scanner. A type of bar code reader that uses a beam of laser light.

LCD. See Liquid Crystal Display.

LED Indicator. A semiconductor diode (LED - Light Emitting Diode) used as an indicator, often in digital displays. The

semiconductor uses applied voltage to produce light of a certain frequency determined by the semiconductor's

particular chemical composition.

Light Emitting Diode. See LED.

Liquid Crystal Display (LCD). A display that uses liquid crystal sealed between two glass plates. The crystals are

excited by precise electrical charges, causing them to reflect light outside according to their bias. They use little

electricity and react relatively quickly. They require external light to reflect their information to the user.

Page 42

Glossary - 6 UNIVERSAL SCAN ENGINE DEVELOPER’S KIT INSTALLATION GUIDE

M

MIL. 1 1 mil = 1 thousandth of an inch.

Misread (Misdecode). A condition which occurs when the data output of a reader or interface controller does not agree

with the data encoded within a bar code symbol.

N

Nominal. The exact (or ideal) intended value for a specified parameter. Tolerances are specified as positive and

negative deviations from this value.

Nominal Size. Standard size for a bar code symbol. Most UPC/EAN codes are used over a range of magnifications

(e.g., from 0.80 to 2.00 of nominal).

NVM. Non-Volatile Memory.

O

ODI. See Open Data-Link Interface.

Open Data-Link Interface (ODI). Novell’s driver specification for an interface between network hardware and

higher-level protocols. It supports multiple protocols on a single NIC (Network Interface Controller). It is capable of

understanding and translating any network information or request sent by any other ODI-compatible protocol into

something a NetWare client can understand and process.

Open System Authentication. Open System authentication is a null authentication algorithm.

P

PAN . Personal area network. Using Bluetooth wireless technology, PANs enable devices to communicate wirelessly.

Generally, a wireless PAN consists of a dynamic group of less than 255 devices that communicate within about a

33-foot range. Only devices within this limited area typically participate in the network.

Parameter. A variable that can have different values assigned to it.

PC Card. A plug-in expansion card for laptop computers and other devices, also called a PCMCIA card. PC Cards are

85.6mm long x 54 mm wide, and have a 68 pin connector. There are several different kinds:

• Type I; 3.3 mm high; use - RAM or Flash RAM

•Type II; 5 mm high; use - modems, LAN adaptors

•Type III; 10.5 high; use - Hard Disks

PCMCIA. Personal Computer Memory Card Interface Association. See PC Card.

Page 43

Glossary - 7

Percent Decode. The average probability that a single scan of a bar code would result in a successful decode. In a

well-designed bar code scanning system, that probability should approach near 100%.

PING. (Packet Internet Groper) An Internet utility used to determine whether a particular IP address is online. It is used

to test and debug a network by sending out a packet and waiting for a response.

Presentation Mode. Typically used when the digital scanner sits on a countertop or is mounted on a wall, in this mode,

the digital scanner operates in continuous (constant-on) mode, where it automatically decodes a bar code presented

in its field of view.

Print Contrast Signal (PCS). Measurement of the contrast (brightness difference) between the bars and spaces of a

symbol. A minimum PCS value is needed for a bar code symbol to be scannable. PCS = (RL - RD) / RL, where RL

is the reflectance factor of the background and RD the reflectance factor of the dark bars.

Programming Mode. The state in which a scanner is configured for parameter values. See Scanning Mode.

Q

Quiet Zone. A clear space, containing no dark marks, which precedes the start character of a bar code symbol and

follows the stop character.

QWERTY. A standard keyboard commonly used on North American and some European PC keyboards. “QWERTY”

refers to the arrangement of keys on the left side of the third row of keys.

R

RAM. Random Access Memory. Data in RAM can be accessed in random order, and quickly written and read.

Reflectance. Amount of light returned from an illuminated surface.

Resolution. The narrowest element dimension which is distinguished by a particular reading device or printed with a

particular device or method.

RF. Radio Frequency.

ROM. Read-Only Memory. Data stored in ROM cannot be changed or removed.

Router. A device that connects networks and supports the required protocols for packet filtering. Routers are typically

used to extend the range of cabling and to organize the topology of a network into subnets. See Subnet.

RS-232. An Electronic Industries Association (EIA) standard that defines the connector, connector pins, and signals

used to transfer data serially from one device to another.

Page 44

Glossary - 8 UNIVERSAL SCAN ENGINE DEVELOPER’S KIT INSTALLATION GUIDE

S

Scan Area. Area intended to contain a symbol.

Scanner. An electronic device used to scan bar code symbols and produce a digitized pattern that corresponds to the

bars and spaces of the symbol. Its three main components are: 1) Light source (laser or photoelectric cell) illuminates a bar code,; 2) Photodetector - registers the difference in reflected light (more light reflected from

spaces); 3) Signal conditioning circuit - transforms optical detector output into a digitized bar pattern.

Scanning Mode. The scanner is energized, programmed and ready to read a bar code.

Scanning Sequence. A method of programming or configuring parameters for a bar code reading system by scanning

bar code menus.

SDK. Software Development Kit

Self-Checking Code. A symbology that uses a checking algorithm to detect encoding errors within the characters of a

bar code symbol.

Shared Key. Shared Key authentication is an algorithm where both the AP and the MU share an authentication key.

SHIP. Symbol Host Interface Program.

SID. System Identification code. An identifier issued by the FCC for each market. It is also broadcast by the cellular

carriers to allow cellular devices to distinguish between the home and roaming service.

Soft Reset. See Warm Boot.

Space. The lighter element of a bar code formed by the background between bars.

Specular Reflection. The mirror-like direct reflection of light from a surface, which can cause difficulty decoding a bar

code.

Standard Trigger Mode. The digital scanner uses this mode when lifted off the counter or removed from the wall mount.

In this mode, aim the digital scanner at a bar code and pull the trigger to decode.

Start/Stop Character. A pattern of bars and spaces that provides the scanner with start and stop reading instructions

and scanning direction. The start and stop characters are normally to the left and right margins of a horizontal code.

STEP. Symbol Terminal Enabler Program.

Subnet. A subset of nodes on a network that are serviced by the same router. See Router.

Subnet Mask. A 32-bit number used to separate the network and host sections of an IP address. A custom subnet mask

subdivides an IP network into smaller subsections. The mask is a binary pattern that is matched up with the IP

address to turn part of the host ID address field into a field for subnets. Default is often 255.255.255.0.

Substrate. A foundation material on which a substance or image is placed.

SVTP. Symbol Virtual Terminal Program.

Symbol. A scannable unit that encodes data within the conventions of a certain symbology, usually including start/stop

characters, quiet zones, data characters and check characters.

Page 45

Glossary - 9

Symbol Aspect Ratio. The ratio of symbol height to symbol width.

Symbol Height. The distance between the outside edges of the quiet zones of the first row and the last row.

Symbol Length. Length of symbol measured from the beginning of the quiet zone (margin) adjacent to the start

character to the end of the quiet zone (margin) adjacent to a stop character.

Symbology. The structural rules and conventions for representing data within a particular bar code type (e.g. UPC/EAN,

Code 39, PDF417, etc.).

T

TCP/IP. (Transmission Control Protocol/Internet Protocol) A communications protocol used to internetwork dissimilar

systems. This standard is the protocol of the Internet and has become the global standard for communications. TCP

provides transport functions, which ensures that the total amount of bytes sent is received correctly at the other end.

UDP is an alternate transport that does not guarantee delivery. It is widely used for real-time voice and video

transmissions where erroneous packets are not retransmitted. IP provides the routing mechanism. TCP/IP is a

routable protocol, which means that all messages contain not only the address of the destination station, but the

address of a destination network. This allows TCP/IP messages to be sent to multiple networks within an

organization or around the world, hence its use in the worldwide Internet. Every client and server in a TCP/IP

network requires an IP address, which is either permanently assigned or dynamically assigned at startup.

Telnet. A terminal emulation protocol commonly used on the Internet and TCP/IP-based networks. It allows a user at a

terminal or computer to log onto a remote device and run a program.

Terminal Emulation. A “terminal emulation” emulates a character-based mainframe session on a remote

non-mainframe terminal, including all display features, commands and function keys. The VC5000 Series supports

Terminal Emulations in 3270, 5250 and VT220.

Terminate and Stay Resident (TSR). A program under DOS that ends its foreground execution to remain resident in

memory to service hardware/software interrupts, providing background operation. It remains in memory and may

provide services on behalf of other DOS programs.

TFTP. (Trivial File Transfer Protocol) A version of the TCP/IP FTP (File Transfer Protocol) protocol that has no directory

or password capability. It is the protocol used for upgrading firmware, downloading software and remote booting of

diskless devices.

Tolerance. Allowable deviation from the nominal bar or space width.

Transmission Control Protocol/Internet Protocol. See TCP/IP.

Trivial File Transfer Protocol. See TFTP.

TSR. See Terminate and Stay Resident.

U

UDP. User Datagram Protocol. A protocol within the IP protocol suite that is used in place of TCP when a reliable

delivery is not required. For example, UDP is used for real-time audio and video traffic where lost packets are simply

Page 46

Glossary - 10 UNIVERSAL SCAN ENGINE DEVELOPER’S KIT INSTALLATION GUIDE

ignored, because there is no time to retransmit. If UDP is used and a reliable delivery is required, packet sequence

checking and error notification must be written into the applications.

UPC. Universal Product Code. A relatively complex numeric symbology. Each character consists of two bars and two

spaces, each of which is any of four widths. The standard symbology for retail food packages in the United States.

V

Visible Laser Diode (VLD). A solid state device which produces visible laser light.

W

Warm Boot. A warm boot restarts the mobile computer by closing all running programs. All data that is not saved to

flash memory is lost.

Page 47

Page 48

Zebra Technologies Corporation

Lincolnshire, IL U.S.A.

http://www.zebra.com

Zebra and the stylized Zebra head are trademarks of ZIH Corp., registered in many jurisdictions

worldwide. All other trademarks are the property of their respective owners.

©2015 ZIH Corp and/or its affiliates. All rights reserved.

72E-59636-05 Revision A - May 2015

Loading...

Loading...