Page 1

RS507/RS507X

Hands-Free Imager

Product Reference Guide

72E-120802-06

Page 2

Copyright

© 2020 ZIH Corp. and/or its affiliates. All rights reserved. ZEBRA and the stylized Zebra head are trademarks of

ZIH Corp., registered in many jurisdictions worldwide. All other trademarks are the property of their respective

owners.

COPYRIGHTS & TRADEMARKS: For complete copyright and trademark information, go to www.zebra.com/

copyright.

WARRANTY: For complete warranty information, go to www.zebra.com/warranty.

END USER LICENSE AGREEMENT: For complete EULA information, go to www.zebra.com/eula.

Terms of Use

• Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation and its subsidiaries

(“Zebra Technologies”). It is intended solely for the information and use of parties operating and

maintaining the equipment described herein. Such proprietary information may not be used, reproduced,

or disclosed to any other parties for any other purpose without the express, written permission of Zebra

Technologies.

• Product Improvements

Continuous improvement of products is a policy of Zebra Technologies. All specifications and designs are

subject to change without notice.

• Liability Disclaimer

Zebra Technologies takes steps to ensure that its published Engineering specifications and manuals are

correct; however, errors do occur. Zebra Technologies reserves the right to correct any such errors and

disclaims liability resulting therefrom.

• Limitation of Liability

In no event shall Zebra Technologies or anyone else involved in the creation, production, or delivery of the

accompanying product (including hardware and software) be liable for any damages whatsoever

(including, without limitation, consequential damages including loss of business profits, business

interruption, or loss of business information) arising out of the use of, the results of use of, or inability to

use such product, even if Zebra Technologies has been advised of the possibility of such damages. Some

jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

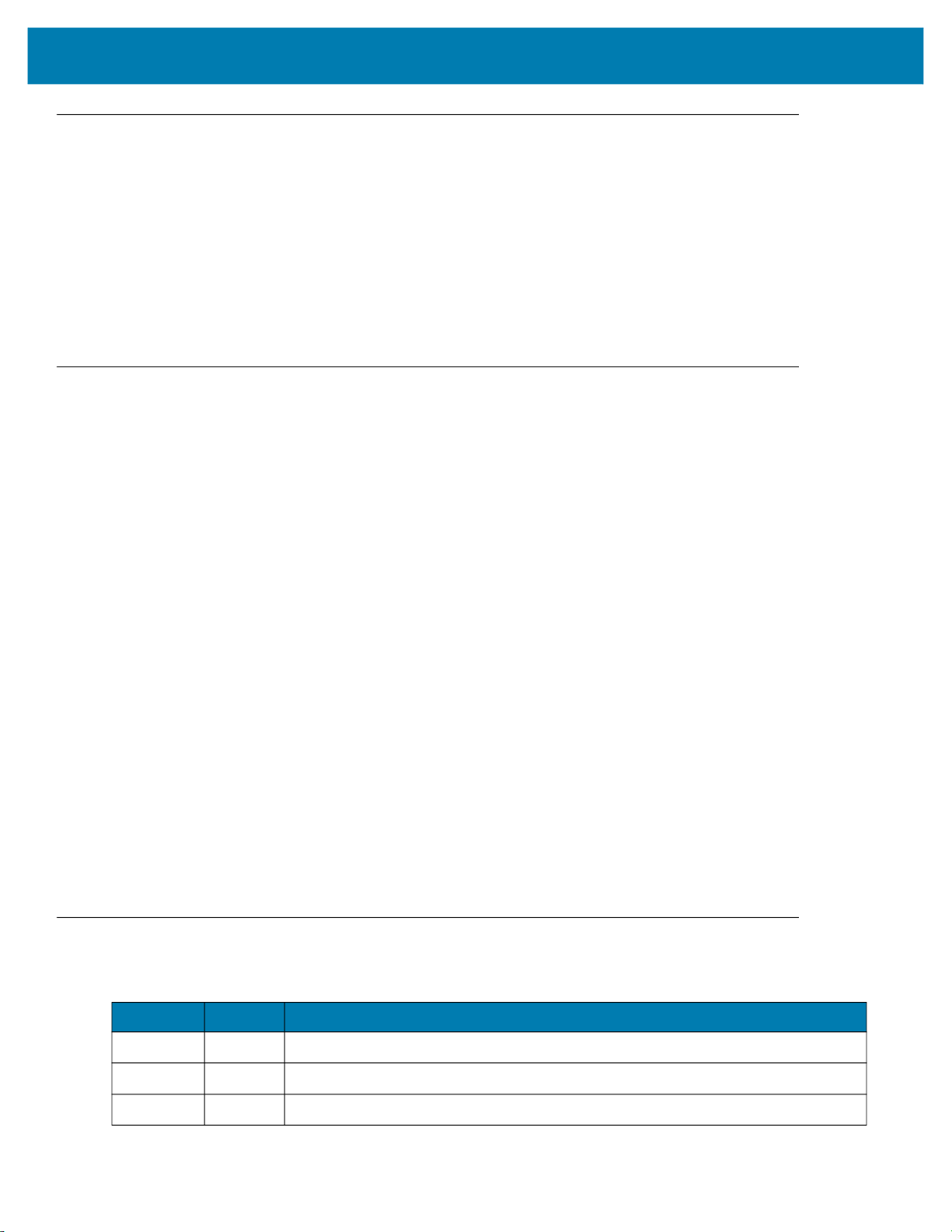

Revision History

Changes to the original guide are listed below:

Change Date Description

-06 Rev A 12/2020 Replaced master/slave references with central/peripheral

-05 Rev A 5/2018 Add Image Capture mode and HID Features for Apple iOS (HID only)

-04 Rev A 11/2017 Add model number RS507X

2

Page 3

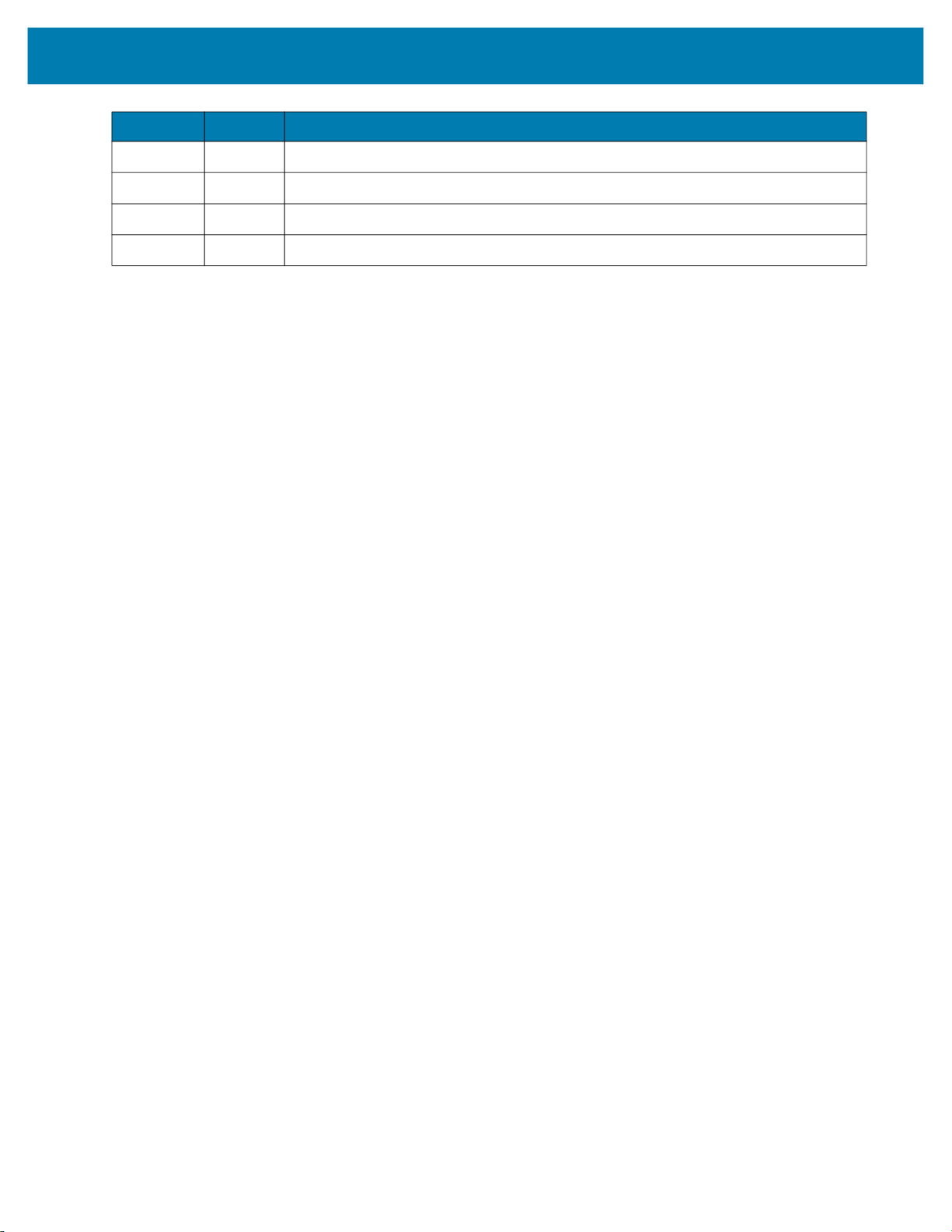

Change Date Description

-03 Rev A 4/2017 Correct LED indicator indications in Table 2.

-02 Rev A 3/2015 Zebra rebranding

-01 Rev B 10/2011 Add Chapter 7

-01 Rev A 10/2009 Release

3

Page 4

Table of Contents

Copyright ........................................................................................................................................... 2

Terms of Use .................................................................................................................................... 2

Revision History ................................................................................................................................ 2

About This Guide

Introduction ..................................................................................................................................... 12

Documentation Set ......................................................................................................................... 12

Model Configurations ...................................................................................................................... 12

Chapter Descriptions ...................................................................................................................... 13

Notational Conventions ................................................................................................................... 13

Related Documents ........................................................................................................................ 14

Service Information ......................................................................................................................... 14

Provide Documentation Feedback .................................................................................................. 14

Getting Started

Introduction ..................................................................................................................................... 15

RS507 Hands-Free Imager Features .............................................................................................. 15

Unpacking ....................................................................................................................................... 16

Cordless Configuration Features .................................................................................................... 17

Corded Configuration Features ....................................................................................................... 18

Trigger Swivel Assembly - Change Trigger Position ................................................................. 19

Getting Started - Cordless Configuration ........................................................................................ 20

Charge the Battery .................................................................................................................... 20

Install the Battery ...................................................................................................................... 20

Remove the Battery .................................................................................................................. 20

Wearing the Imager ................................................................................................................... 20

Getting Started - Corded Configuration .......................................................................................... 21

Connect the Corded Adapter .................................................................................................... 21

Remove the Corded Adapter .................................................................................................... 22

Connect to a WT4XXX Wearable Terminal ............................................................................... 22

Wearing the Imager ................................................................................................................... 23

Status Indications ............................................................................................................................ 23

Imager Standby Mode ..................................................................................................................... 25

Bluetooth Connection ...................................................................................................................... 25

Establish Bluetooth Connection ................................................................................................ 25

Restore Lost Bluetooth Connection .......................................................................................... 27

4

Page 5

Table of Contents

Remove Bluetooth Connection ................................................................................................. 27

Pairing Bar Code Format .......................................................................................................... 28

Scan ................................................................................................................................................ 28

Scan Triggering Modes ............................................................................................................. 28

Aiming the Imager ..................................................................................................................... 29

Customize the Imager ..................................................................................................................... 30

Changing from Triggered to Triggerless Configuration ............................................................. 30

Changing Triggerless to Triggered Configuration ..................................................................... 30

Resetting the Imager ....................................................................................................................... 31

Warm Boot ................................................................................................................................ 31

Cold Boot .................................................................................................................................. 31

Clean Boot ................................................................................................................................ 31

SAC5070 8-Bay Battery Charger

Introduction ..................................................................................................................................... 32

Unpacking the Charger ................................................................................................................... 32

Parts of the Charger ........................................................................................................................ 33

Installation ....................................................................................................................................... 34

Tabletop / Shelf Set Up ............................................................................................................. 34

Wall Mount ................................................................................................................................ 34

Inserting the Imager Battery in the Charger .................................................................................... 35

Charge the Battery .................................................................................................................... 36

Battery Age Test ............................................................................................................................. 36

Charge Status LED ................................................................................................................... 37

Troubleshooting & Maintenance

Introduction ..................................................................................................................................... 38

Troubleshooting .............................................................................................................................. 38

Imager ....................................................................................................................................... 38

Charger ..................................................................................................................................... 39

Maintenance ................................................................................................................................... 40

Maintaining the Imager ................................................................................................................... 40

Comfort Pad Replacement ........................................................................................................ 40

Trigger Swivel Assembly Replacement ..................................................................................... 41

Triggerless Strap Holder Replacement ..................................................................................... 42

Finger Strap Replacement (Trigger Swivel Assembly) ............................................................. 43

Finger Strap Replacement (Triggerless Strap Holder) .............................................................. 44

Strap Buckle Replacement ........................................................................................................ 45

Field Replaceable Parts ............................................................................................................ 45

Cleaning the Imager .................................................................................................................. 46

Maintaining the Charger .................................................................................................................. 47

Operating conditions for the Charger ........................................................................................ 47

Handling the Charger ................................................................................................................ 47

Cleaning the Charger ................................................................................................................ 47

RS507 Update and Configuration

Introduction ..................................................................................................................................... 48

Configuring the Imager ................................................................................................................... 48

5

Page 6

Table of Contents

Introduction ............................................................................................................................... 48

Control Panel Application .......................................................................................................... 49

RSMSample Application ........................................................................................................... 50

Imager Attributes ....................................................................................................................... 53

Imager Motion and Proximity Configuration .............................................................................. 57

.................................................................................................................................................. 61

Real Time Logger ........................................................................................................................... 61

Imager Firmware Update ................................................................................................................ 62

Required Equipment ................................................................................................................. 62

Updating the RS507 Firmware .................................................................................................. 62

Miscellaneous Imager Options

Introduction ..................................................................................................................................... 66

Scanning Sequence Examples ....................................................................................................... 66

Errors While Scanning .................................................................................................................... 67

User Preferences/Miscellaneous Options Parameter Defaults ....................................................... 67

User Preferences ............................................................................................................................ 68

Set Default Parameter ............................................................................................................... 68

Parameter Bar Code Scanning ................................................................................................. 69

Beep After Good Decode .......................................................................................................... 69

Beeper Tone ............................................................................................................................. 70

Beeper Volume ......................................................................................................................... 71

Imager Activity Modes ............................................................................................................... 72

Picklist Mode ............................................................................................................................. 73

Fuzzy 1D Processing ................................................................................................................ 74

Decoding Illumination ................................................................................................................ 75

Low Battery Indication Cycle ..................................................................................................... 75

Bluetooth Disconnection Alert Control ...................................................................................... 76

Miscellaneous Scanner Parameters ............................................................................................... 78

Transmit Code ID Character ..................................................................................................... 78

Prefix/Suffix Values ................................................................................................................... 79

Scan Data Transmission Format ............................................................................................... 80

Scan Data Transmission Format (continued) ............................................................................ 82

FN1 Substitution Values ............................................................................................................ 82

Transmit “No Read” Message ................................................................................................... 83

Symbologies

Introduction ..................................................................................................................................... 84

Scanning Sequence Examples ....................................................................................................... 84

Errors While Scanning .................................................................................................................... 85

Symbology Parameter Defaults ...................................................................................................... 85

UPC/EAN ........................................................................................................................................ 90

Enable/Disable UPC-A .............................................................................................................. 90

Enable/Disable UPC-E .............................................................................................................. 90

Enable/Disable UPC-E1 ............................................................................................................ 90

Enable/Disable EAN-8/JAN-8 ................................................................................................... 91

Enable/Disable EAN-13/JAN-13 ............................................................................................... 92

Enable/Disable Bookland EAN .................................................................................................. 92

Decode UPC/EAN/JAN Supplementals .................................................................................... 93

6

Page 7

Table of Contents

User-Programmable Supplementals ......................................................................................... 96

UPC/EAN/JAN Supplemental Redundancy .............................................................................. 96

UPC/EAN/JAN Supplemental AIM ID Format ........................................................................... 97

Transmit UPC-A Check Digit ..................................................................................................... 97

Transmit UPC-E Check Digit ..................................................................................................... 98

Transmit UPC-E1 Check Digit ................................................................................................... 98

UPC-A Preamble ....................................................................................................................... 98

UPC-E Preamble ....................................................................................................................... 99

UPC-E1 Preamble ................................................................................................................... 100

Convert UPC-E to UPC-A ....................................................................................................... 101

Convert UPC-E1 to UPC-A ..................................................................................................... 102

EAN-8/JAN-8 Extend .............................................................................................................. 103

Bookland ISBN Format ........................................................................................................... 104

UCC Coupon Extended Code ................................................................................................. 105

ISSN EAN ............................................................................................................................... 105

Code 128 ...................................................................................................................................... 106

Enable/Disable Code 128 ....................................................................................................... 106

Set Lengths for Code 128 ....................................................................................................... 106

Enable/Disable GS1-128 (formerly UCC/EAN-128) ................................................................ 107

Enable/Disable ISBT 128 ........................................................................................................ 108

ISBT Concatenation ................................................................................................................ 109

Check ISBT Table ................................................................................................................... 110

ISBT Concatenation Redundancy ........................................................................................... 110

Code 39 ........................................................................................................................................ 111

Enable/Disable Code 39 ......................................................................................................... 111

Enable/Disable Trioptic Code 39 ............................................................................................. 111

Convert Code 39 to Code 32 .................................................................................................. 112

Code 32 Prefix ........................................................................................................................ 112

Set Lengths for Code 39 ......................................................................................................... 113

Code 39 Check Digit Verification ............................................................................................ 114

Transmit Code 39 Check Digit ................................................................................................ 114

Code 39 Full ASCII Conversion .............................................................................................. 115

Code 39 Buffering - Scan & Store ........................................................................................... 115

Code 39 Buffering - Scan & Store (continued) ........................................................................ 116

Code 93 ........................................................................................................................................ 118

Enable/Disable Code 93 ......................................................................................................... 118

Set Lengths for Code 93 ......................................................................................................... 118

Set Lengths for Code 93 (continued) ...................................................................................... 119

Code 11 ................................................................................................................................... 120

Code 11 ................................................................................................................................... 120

Set Lengths for Code 11 ......................................................................................................... 120

Code 11 Check Digit Verification ............................................................................................ 121

Transmit Code 11 Check Digits .............................................................................................. 123

Interleaved 2 of 5 (ITF) ................................................................................................................. 123

Enable/Disable Interleaved 2 of 5 ........................................................................................... 123

Set Lengths for Interleaved 2 of 5 ........................................................................................... 124

Set Lengths for Interleaved 2 of 5 (continued) ........................................................................ 125

I 2 of 5 Check Digit Verification ............................................................................................... 126

Transmit I 2 of 5 Check Digit ................................................................................................... 126

Convert I 2 of 5 to EAN-13 ...................................................................................................... 127

Discrete 2 of 5 (DTF) .................................................................................................................... 127

7

Page 8

Table of Contents

Enable/Disable Discrete 2 of 5 ................................................................................................ 127

Set Lengths for Discrete 2 of 5 ................................................................................................ 128

Set Lengths for Discrete 2 of 5 (continued) ............................................................................. 129

Codabar (NW - 7) .................................................................................................................... 130

Enable/Disable Codabar ......................................................................................................... 130

Set Lengths for Codabar ......................................................................................................... 130

Set Lengths for Codabar (continued) ...................................................................................... 131

CLSI Editing ............................................................................................................................ 131

NOTIS Editing ......................................................................................................................... 132

MSI ................................................................................................................................................ 133

Enable/Disable MSI ................................................................................................................. 133

Set Lengths for MSI ................................................................................................................ 133

Set Lengths for MSI (continued) ............................................................................................. 134

MSI Check Digits ..................................................................................................................... 134

Transmit MSI Check Digit(s) ................................................................................................... 135

MSI Check Digit Algorithm ...................................................................................................... 136

Chinese 2 of 5 ............................................................................................................................... 136

Enable/Disable Chinese 2 of 5 ................................................................................................ 136

Matrix 2 of 5 .................................................................................................................................. 137

Enable/Disable Matrix 2 of 5 ................................................................................................... 137

Set Lengths for Matrix 2 of 5 ................................................................................................... 138

Matrix 2 of 5 Redundancy ....................................................................................................... 139

Matrix 2 of 5 Check Digit ......................................................................................................... 139

Transmit Matrix 2 of 5 Check Digit .......................................................................................... 140

Inverse 1D ..................................................................................................................................... 140

Postal Codes ................................................................................................................................. 141

US Postnet .............................................................................................................................. 141

US Planet ................................................................................................................................ 141

Transmit US Postal Check Digit .............................................................................................. 142

UK Postal ................................................................................................................................ 142

Transmit UK Postal Check Digit .............................................................................................. 143

Japan Postal ........................................................................................................................... 143

Australian Postal ..................................................................................................................... 144

Netherlands KIX Code ........................................................................................................... 144

USPS 4CB/One Code/Intelligent Mail ..................................................................................... 145

UPU FICS Postal .................................................................................................................... 145

Mailmark ....................................................................................................................................... 145

GS1 DataBar ................................................................................................................................. 145

GS1 DataBar-14 ...................................................................................................................... 146

GS1 DataBar Limited .............................................................................................................. 146

GS1 DataBar Expanded .......................................................................................................... 147

Convert GS1 DataBar to UPC/EAN ........................................................................................ 147

Composite ..................................................................................................................................... 148

Composite CC-C ..................................................................................................................... 148

Composite CC-A/B .................................................................................................................. 148

Composite TLC-39 .................................................................................................................. 149

UPC Composite Mode ............................................................................................................ 149

Composite Beep Mode ............................................................................................................ 150

GS1-128 Emulation Mode for UCC/EAN Composite Codes ................................................... 150

2D Symbologies ............................................................................................................................ 151

Enable/Disable PDF417 .......................................................................................................... 151

8

Page 9

Table of Contents

Enable/Disable MicroPDF417 ................................................................................................. 151

Code 128 Emulation ................................................................................................................ 151

Data Matrix .............................................................................................................................. 153

Data Matrix Inverse ................................................................................................................. 153

Maxicode ................................................................................................................................. 154

QR Code ................................................................................................................................. 154

QR Inverse .............................................................................................................................. 155

MicroQR .................................................................................................................................. 155

Aztec ....................................................................................................................................... 156

Aztec Inverse .......................................................................................................................... 156

Redundancy Level ........................................................................................................................ 157

Redundancy Level 1 ............................................................................................................... 157

Redundancy Level 2 ............................................................................................................... 157

Redundancy Level 3 ............................................................................................................... 157

Redundancy Level 4 ............................................................................................................... 158

Security Level ............................................................................................................................... 158

Intercharacter Gap Size .......................................................................................................... 159

Report Version .............................................................................................................................. 160

Macro PDF Features ..................................................................................................................... 161

Flush Macro Buffer .................................................................................................................. 161

Abort Macro PDF Entry ........................................................................................................... 161

Bluetooth Connection Using HID and SPP Profiles

Introduction ................................................................................................................................... 162

RS507 to Computer Bluetooth Connection Modes ....................................................................... 162

RS507 Important hardware features ............................................................................................. 163

Refreshing Boot Choices .............................................................................................................. 163

HID (Human Interface Device) Mode ....................................................................................................... 164

How to change to HID mode ................................................................................................... 164

How to format the scanned data ............................................................................................. 165

How to pair and connect with a computer running Windows 7 SP1 ............................................. 165

How to pair and connect with a computer running Windows XP SP3 and Bluetooth 2.1 ........ 167

How to pair and connect with other devices ............................................................................ 171

Reconnecting .......................................................................................................................... 171

How to demonstrate HID connection with a computer ............................................................ 171

Country keyboard type change ............................................................................................... 172

Connecting multiple RS507 into single device ........................................................................ 173

Using random PIN code .......................................................................................................... 173

How to return to SSI (SCAN) mode ........................................................................................ 177

Serial Port Profile (SPP) Mode ..................................................................................................... 178

How to change to SPP mode .............................................................................................................. 17

w to format the scanned data the data ............................................................................... 179

Ho

How to pair and connect with a computer running Windows 7 SP1 ........................................ 179

How to pair and connect with a computer running Windows XP SP3 ..................................... 185

SPP connection with RS507 as a Peripheral .......................................................................... 189

How to pair and connect with other devices ............................................................................ 192

Reconnecting .......................................................................................................................... 193

How to demonstrate SPP connection with a computer ........................................................... 193

Connecting multiple RS507 into single device ........................................................................ 194

Special characters ................................................................................................................... 195

8

9

Page 10

Table of Contents

How to return to SSI (SCAN) mode ........................................................................................ 195

Switching between SSI (SCAN), HID and SPP ....................................................................... 195

Firmware upgrade ......................................................................................................................... 198

Upgrading using a computer and the PC Tool application ...................................................... 198

Retrieving the RS507 log file ........................................................................................................ 202

Bluetooth Bar Codes ................................................................................................................................... 206

Bluetooth Authentication Control ............................................................................................. 206

Bluetooth Automatic Reconnection Control ............................................................................ 207

Bell Indication Control ............................................................................................................. 209

Bluetooth Profile Control ......................................................................................................... 214

Bluetooth Pairing Control ........................................................................................................ 215

Bluetooth Security Level Control ............................................................................................. 215

Batch Mode ............................................................................................................................. 216

Unique Identifier ...................................................................................................................... 218

Force Bluetooth Role Switch (SPP only) ................................................................................. 218

Image Capture (SPP only) ...................................................................................................... 219

HID Features for Apple iOS (HID Only) .................................................................................. 219

123Scan and Software Tools

Introduction ................................................................................................................................... 220

123Scan ........................................................................................................................................ 220

Communication with 123Scan ................................................................................................. 220

123Scan Requirements ........................................................................................................... 221

123Scan Information ............................................................................................................... 221

Advanced Data Formatting (ADF) ................................................................................................. 221

Specifications

Technical Specifications ............................................................................................................... 222

Imager ..................................................................................................................................... 222

8 Slot Battery Charger ............................................................................................................. 225

Standard Default Parameters

Standard Default Parameters Table ............................................................................................. 226

Programming Reference

Symbol Code Identifiers ................................................................................................................ 231

AIM Code Identifiers ..................................................................................................................... 232

Sample Bar Codes

Code 39 ........................................................................................................................................ 237

UPC/EAN ...................................................................................................................................... 237

UPC-A, 100% .......................................................................................................................... 237

EAN-13, 100% ........................................................................................................................ 238

Code 128 ...................................................................................................................................... 238

Interleaved 2 of 5 .......................................................................................................................... 238

GS1 DataBar-14 ........................................................................................................................... 238

10

Page 11

Table of Contents

PDF417 ......................................................................................................................................... 239

Data Matrix .................................................................................................................................... 239

Maxicode ....................................................................................................................................... 239

QR Code ....................................................................................................................................... 240

US Postnet .................................................................................................................................... 240

UK Postal ...................................................................................................................................... 240

Numeric Bar Codes

Numeric Bar Codes ....................................................................................................................... 241

Cancel ........................................................................................................................................... 242

Index

11

Page 12

About This Guide

Introduction

This Product Reference Guide provides additional information that is not covered by the Quick Reference Guide

and is helpful for application developers and customers alike.

The Product Reference Guide provides information on operating the Imager for the first time, using the Imager,

resetting and capturing data.

The guide also covers issues such as charging and testing the Imager battery, troubleshooting, maintenance, firmware

update and configuration of the Imager. Sample bar codes are provided for configuring and testing the Imager.

This guide applies to Model Numbers RS507 and RS507X.

Documentation Set

The documentation set for the RS507 is divided into guides that provide information for specific user needs.

• RS507/RS507X Hands-Free Imager Quick Start Guide - describes how to use the Imager.

• SAC5070 8-Bay Battery Charger Quick Reference Guide - describes how to use the Imager charger.

• EMDK Help File - provides API information for writing applications.

• Advanced Data Formatting Programmer Guide - describes how to customize data before transmission

to the host device.

Model Configurations

This guide covers the following model configurations:

• RS507-IM2xxxxSTWR -Triggered RS507 with standard battery

• RS507-IM2xxxxSNWR - Triggerless RS507 with standard battery

• RS507-IM2xxxxENWR -Triggerless RS507 with extended battery

• RS507-IM2xxxxCTWR - Corded and Triggered RS507

• RS507X-IM2xxxxSTWR -Triggered RS507 with standard battery

• RS507X-IM2xxxxSNWR - Triggerless RS507 with standard battery

• RS507X-IM2xxxxENWR -Triggerless RS507 with extended battery

• RS507X-IM2xxxxCTWR - Corded and Triggered RS507

For shipping configuration of each model option, refer to Unpacking on page 16.

12

Page 13

Chapter Descriptions

Topics covered in this guide are as follows:

• Getting Started provides information on getting the Imager up and running for the first time, basic

instructions for using the Imager and instructions for resetting the Imager and capturing data.

• SAC5070 8-Bay Battery Charger provides information on charging and testing the Imager battery.

• Troubleshooting & Maintenance provides troubleshooting, cleaning, part replacement and technical

specifications for the Imager.

• RS507 Update and Configuration provides instructions for firmware update and configuration of the Imager

operation.

• Miscellaneous Imager Options provides information on programming the Imager to perform various

functions, or activating different features.

• Symbologies

• Bluetooth Connection Using HID and SPP Profiles describes the Bluetooth connection modes of the

RS507 to a personal computer and non-Zebra terminals.

• Specifications provides Imager and charger technical specifications.

• Standard Default Parameters provides a sample of bar codes used for configuring the Imager.

• Programming Reference provides symbol code characters.

• Sample Bar Codes provides sample bar codes for Imager testing.

• Numeric Bar Codes provides a sample of numeric bar codes.

details symbology features and provides programming bar codes for selecting these features.

About This Guide

Notational Conventions

The following conventions are used in this document:

• “RS507” refers to the Zebra RS507/RS507X Hands-Free Imager.

• “Imager” refers to the Zebra RS507/RS507X Hands-Free Imager.

• “Terminal” refers to the Wearable Terminal WT4XXX or any mobile computer connected to the Imager.

• “Charger” refers to the SAC5070 8-Bay Battery Charger of the RS507/RS507X.

• Bold text is used to highlight the following:

• Dialog box, window and screen names

• Drop-down list and list box names

• Check box and radio button names

• Icons on a screen

• Key names on a keypad

• Button names on a screen.

• Bullets (•) indicate:

• Action items

• Lists of alternatives

• Lists of required steps that are not necessarily sequential.

• Sequential lists (e.g., those that describe step-by-step procedures) appear as numb lists.

13

Page 14

Related Documents

• RS507/RS507X Hands-Free Imager Quick Start Guide, p/n 72-115987-01-xx

• SAC5070 8-Bay Battery Charger Quick Reference Guide, p/n 72-115989-01-xx

• WT4090 Quick Start Guide p/n 72-86717-02-xx

• WT41N0 Quick Start Guide p/n 72-157178-xx as well as other supported terminals'

For the latest version of this guide and all guides, go to: www.zebra.com/support.

Service Information

If you have a problem with your equipment, contact Zebra Support for your region. Contact information is available

at:

www.zebra.com/support.

When contacting Support, please have the following information available:

• Serial number of the unit

• Model number or product name

• Software type and version number

About This Guide

The following information should be available when reporting a problem:

• Customer name

• Application used

• Configuration (corded/cordless, trigger/triggerless, standard or extended battery)

• RS507 or Cradle version number

• RS507 CAB file version and OEM version

• Use the PC Tool application to retrieve and E-mail the RS507 log to the support representative

• Occurrence (always, once out of 10 attempts, etc…)

• Suggested steps to reproduce the problem

Zebra responds to calls by E-mail, telephone or fax within the time limits set forth in support agreements.

If your problem cannot be solved by Zebra Support, you may need to return your equipment for servicing and will

be given specific directions. Zebra is not responsible for any damages incurred during shipment if the approved

shipping container is not used. Shipping the units improperly can possibly void the warranty.

If you purchased your business product from a Zebra business partner, contact that business partner for support.

Provide Documentation Feedback

If you have comments, questions, or suggestions about this guide, send an email to EVM-Techdocs@zebra.com.

14

Page 15

Getting Started

Introduction

This chapter describes the features of the RS507 Hands-Free Imager and explains how to install and charge the

battery, capture data and reset the Imager.

RS507 Hands-Free Imager Features

The RS507 Hands-Free Imager (also referred to as the Imager) is a wearable bar code scan solution for both 1D

and 2D bar code symbologies. The Imager is also compatible with a wide range of mobile computers

communicating over Bluetooth.

The Imager is designed for a wide range of applications from management of products in a warehouse, to

processing deliveries at a courier facility to processing prescription drugs at the pharmaceutical distribution center.

The Imager uses camera-based scanning technology, designed to offer flexible hands-free operation with

ergonomic comfort for right or left hand users.

15

Page 16

Unpacking

Carefully remove all protective material from around the equipment and save the shipping container for later

storage and shipping.

After opening the shipping box, inspect the contents. You should have received the following:

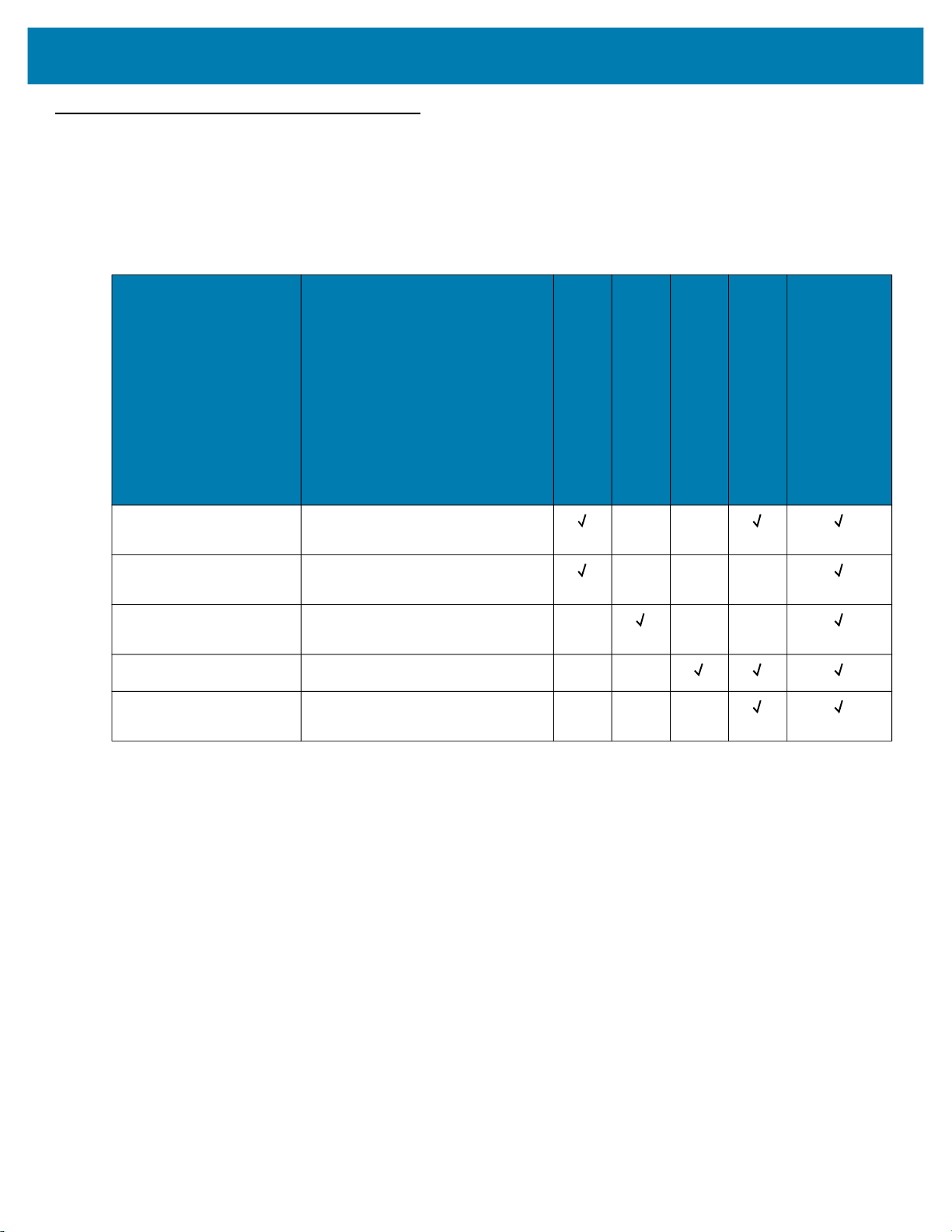

Table 1 RS507 Shipping Configuration Model Options

IM = SR focus

DL = DL focus

blank = RS507 (legacy)

x = RS507X (new)

Model

yy:

z:

Getting Started

Description

Standard Battery

Extended Battery

Trigger

Corded Adapter

or

Regulatory Guide

Quick Reference Guide

RS507z-yy2xxxxSTWR Cordless, triggered RS507 with

standard battery

RS507z-yy2xxxxSNWR Cordless, triggerless RS507 with

standard battery

RS507z-yy2xxxxENWR Cordless, triggerless RS507 with

extended battery.

RS507z-yy2xxxxCTWR Corded and triggered RS507

RS507z-yy2xxxx0TWR Cordless, triggered RS507 with no

battery

- Standard Range (SR): The SR focusing is used to maximize the far reading distance and is the standard offering

on all mobile computing products using same imager. The SR focusing is not specified to read 5 mil code 128 or

6.6 mil Databar and is thus inadequate for applications that have these somewhat higher density reading

requirements. This is the default configuration and the configuration of choice where the far reading range is more

important than the ability to read high density symbols.

- Driver License (DL): The DL focusing is optimized for reading all drivers license and is also specified to read

higher density codes such as 5 mil code 128 and Databar and 5 Mil PDF417. As a result it has a slightly reduced

range on EAN/UPC codes (typically 12" on photographic quality symbol). This is the preferred configuration where

the ability to read these higher density codes is more important than range on medium or low density codes (10 mil

and above). DL is recommended in electronics, pharmacy or when handling small items.

Inspect the equipment for damage. If you are missing any equipment or if you find any damaged equipment,

contact the Zebra Support immediately. See Service Information on page 14 for contact information.

16

Page 17

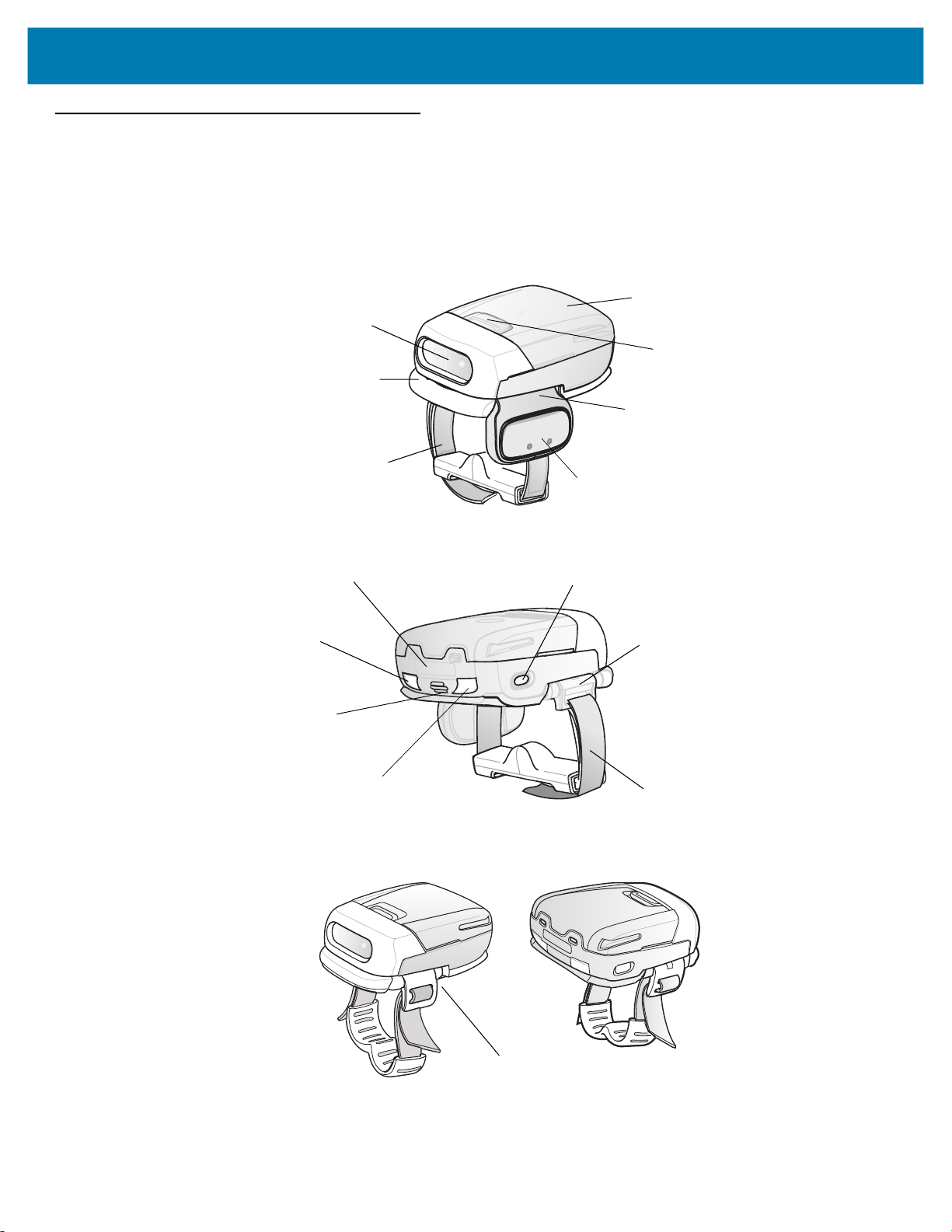

Getting Started

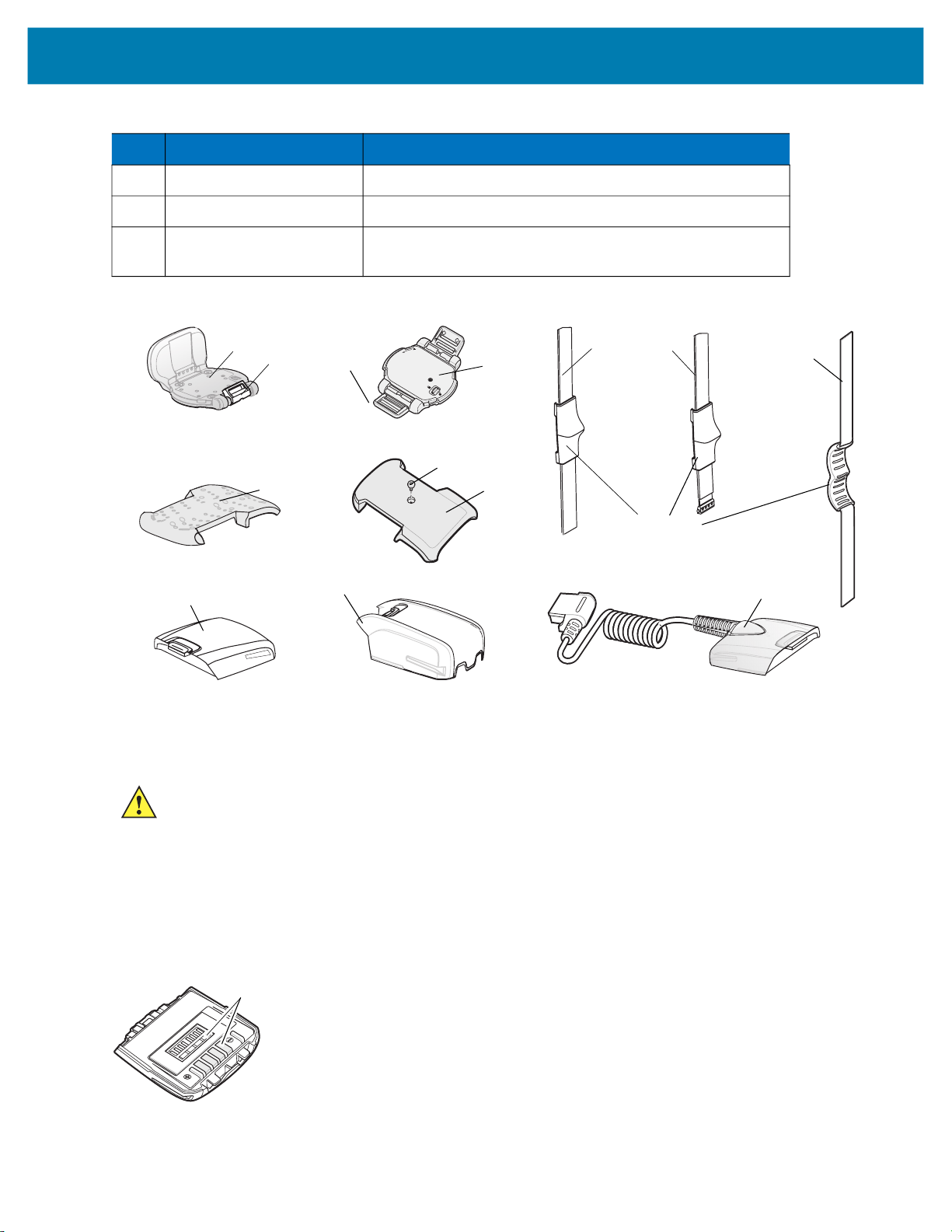

Cordless Configuration Features

Figure 1 RS507 Cordless Configuration Features

Triggered Configuration

Imager Window

Comfort Pad

Finger Strap

Battery

Battery Release Latch

Trigger Swivel Assembly

Scan Trigger

Asset Control Label

Left Scan LED

Beeper

Right Scan LED

Restore Key

Strap Buckle

Finger Strap

Triggerless Configuration

Triggerless Strap Holder

17

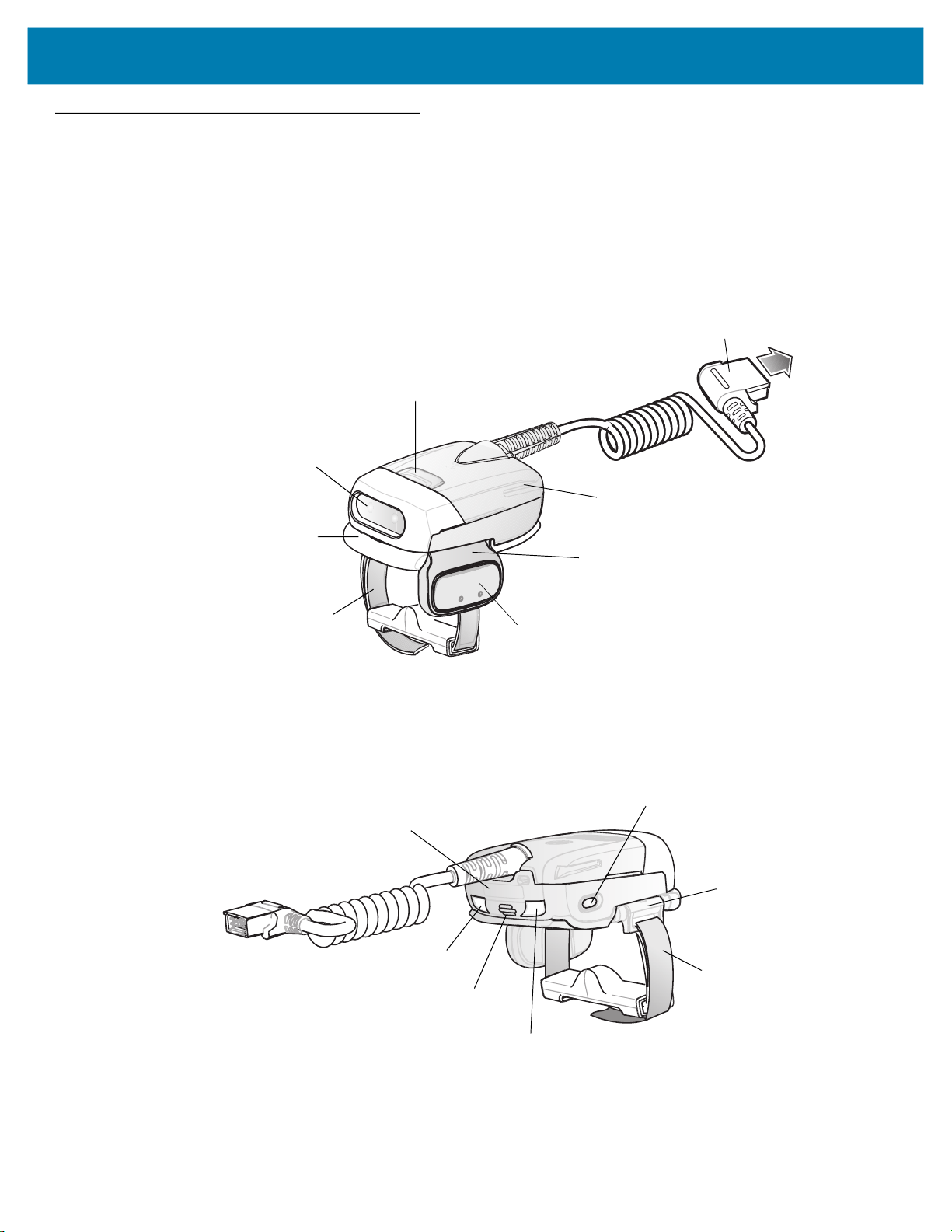

Page 18

Corded Configuration Features

Figure 2 RS507 Corded Configuration Features

Release Latch

Imager Window

Getting Started

Interface Cable Connector to WT4XXX

Corded Adapter

Comfort Pad

Finger Strap

Asset Control Label

Left Scan LED

Trigger Swivel Assembly

Scan Trigger

Restore Key

Strap Buckle

Finger Strap

Beeper

Right Scan LED

18

Page 19

Getting Started

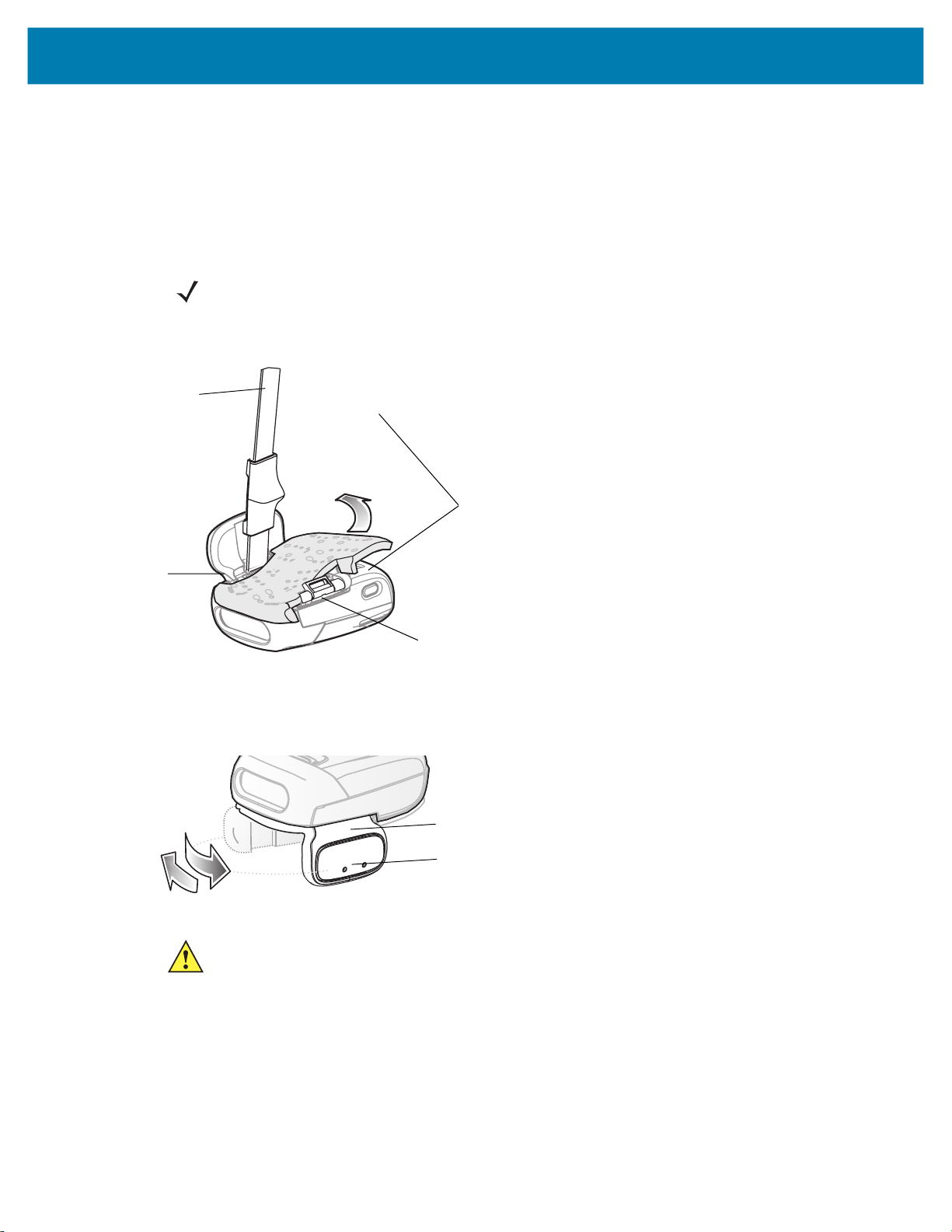

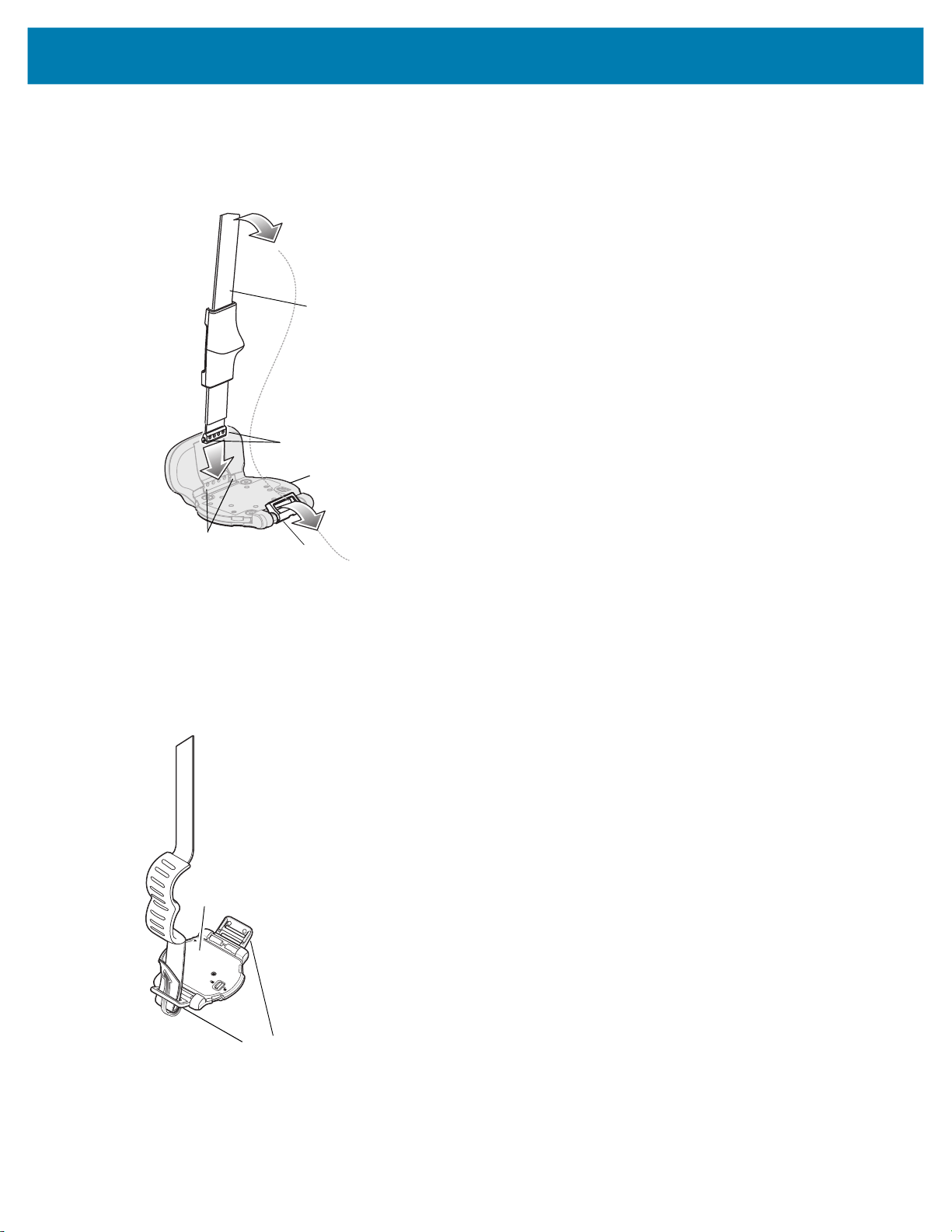

Trigger Swivel Assembly - Change Trigger Position

The Imager is worn on the index and middle fingers, and triggered with the thumb. The Trigger Swivel Assembly of

the Imager rotates to provide left-hand or right-hand use.

To change the position of the Trigger:

1. From the bottom of Imager, hold and pull the Comfort Pad off the Imager.

NOTE: When removing the Comfort Pad off the Imager, It is not necessary to remove the Finger Strap

from the Trigger Swivel Assembly.

Figure 3 Change Trigger Position - Release Finger Strap from Buckle and Remove Comfort Pad

Finger Strap

Comfort Pad

Trigger

Swivel

Assembly

Strap Buckle

2. Determine whether the Imager is used on the right or left hand and rotate the Trigger Swivel Assembly.

Figure 4 Change Trigger Swivel Assembly Position

Trigger Swivel Assembly

Scan Trigger

CAUTION:The Trigger Swivel Assembly only rotates 180° around the front of the scan assembly. Do not

rotate the Trigger Swivel Assembly past the designed stops.

3. Rotate the Trigger Swivel Assembly so that the Scan Trigger is positioned next to the thumb when the Imager

is placed on the index and middle fingers.

4. Position the Comfort Pad onto the Imager.

5. Press the Comfort Pad onto the Imager. When properly installed, the Comfort Pad locks into place.

6. Insert the Finger Strap into the Strap Buckle.

19

Page 20

Getting Started

Getting Started - Cordless Configuration

Charge the Battery

Before using the Imager, charge the battery. The SAC5070 8-Bay Battery Charger supports both standard and

extended capacity batteries.

To charge the Imager battery, refer to the SAC5070 8-Bay Battery Charger Quick Reference Guide, p/n

72-115989-01 available at: www.zebra.com/support and search for 'SAC5070'.

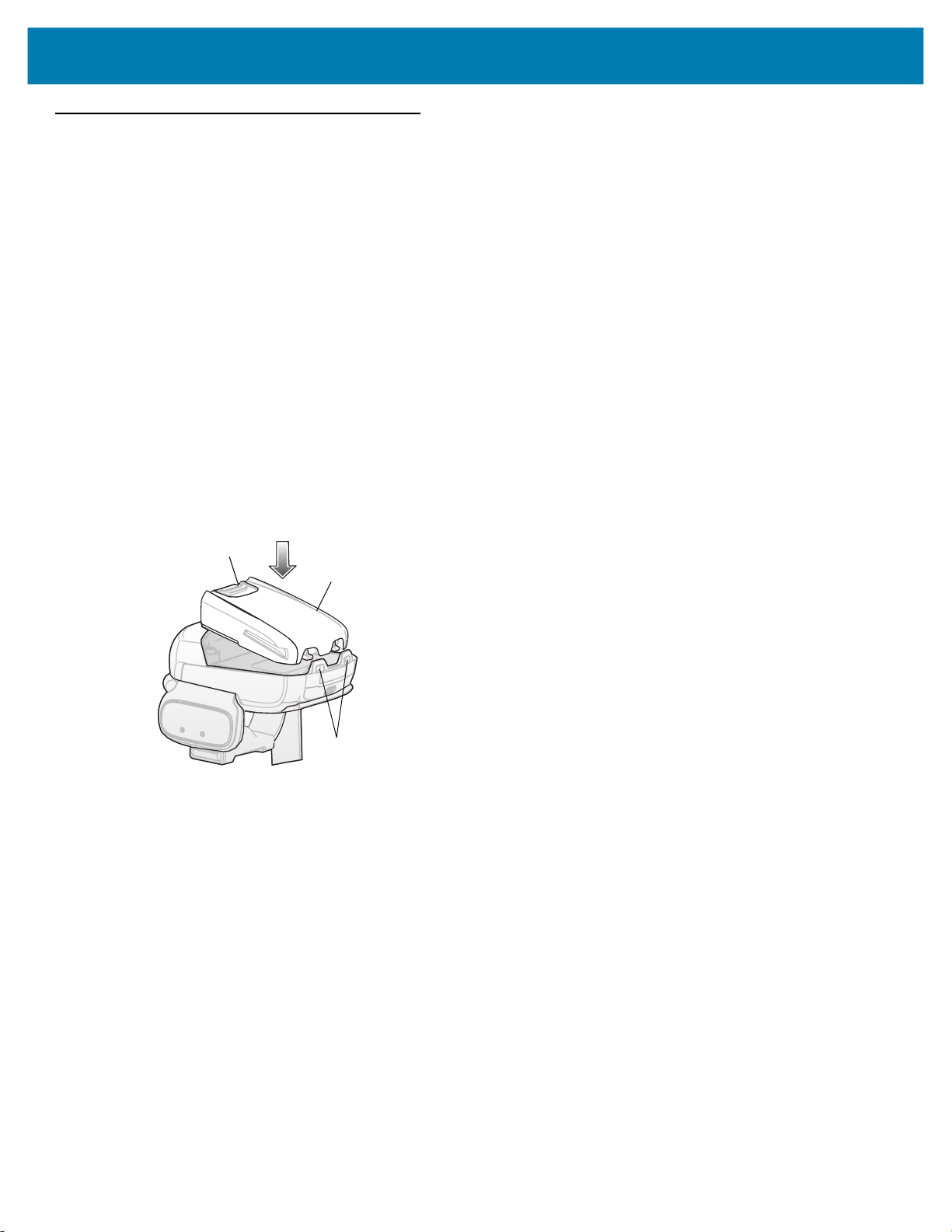

Install the Battery

1. Align the battery on top of the Imager.

2. Push the battery all the way into the Locking Slots of the Imager.

3. Firmly press the battery into the Imager until a “click” is heard ensuring the Battery Release Latch is fully

engaged with the Imager.

Figure 5 Install the Battery

Battery Release Latch

Battery

Locking Slots

Remove the Battery

1. Hold the Imager in one hand.

2. Press the Battery Release Latch.

3. Pull up the battery to release it from the Locking Slots of the Imager.

Wearing the Imager

1. Slide the Imager onto the index and middle fingers with the Scan Trigger next to the thumb.

20

Page 21

Getting Started

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

aaaaaaaaaaaaaaa

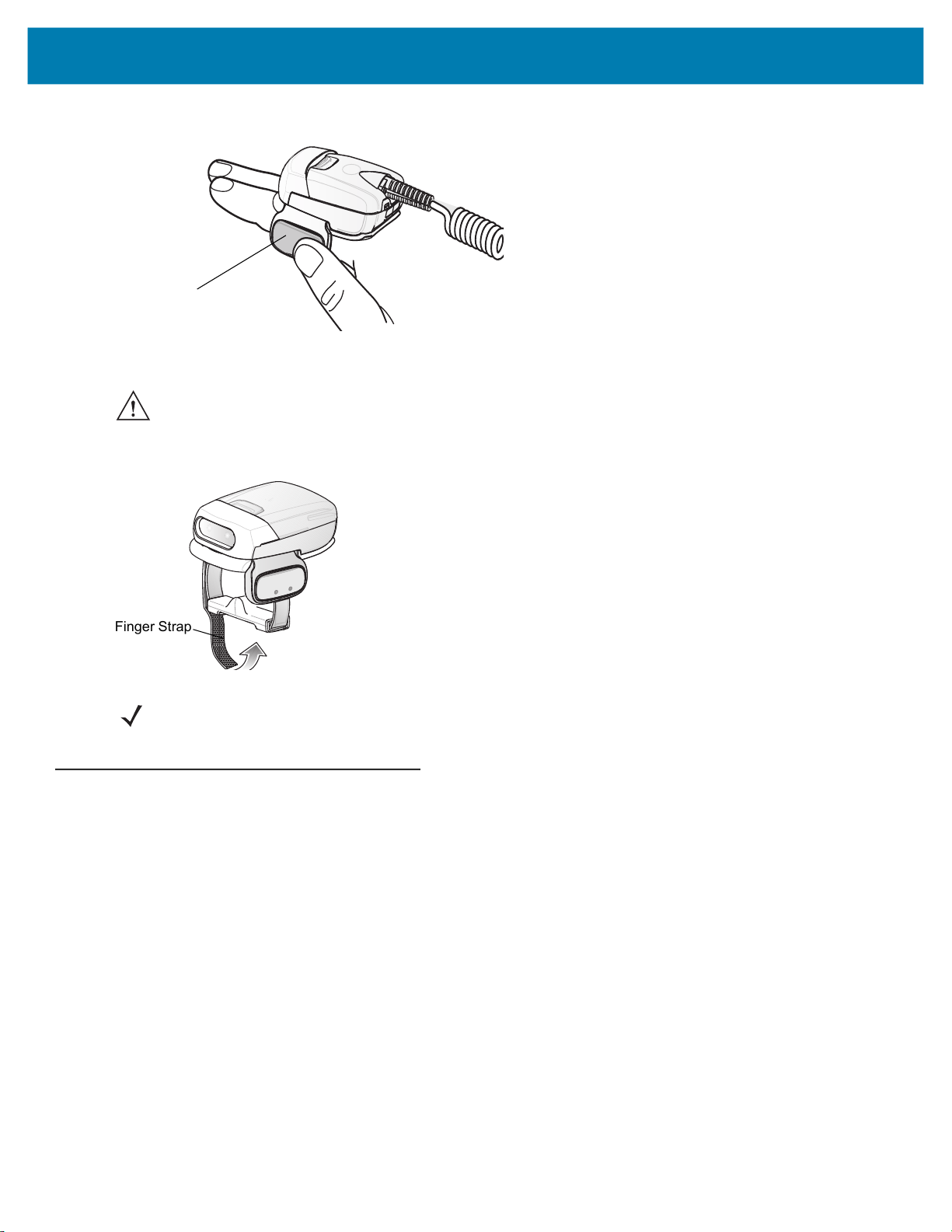

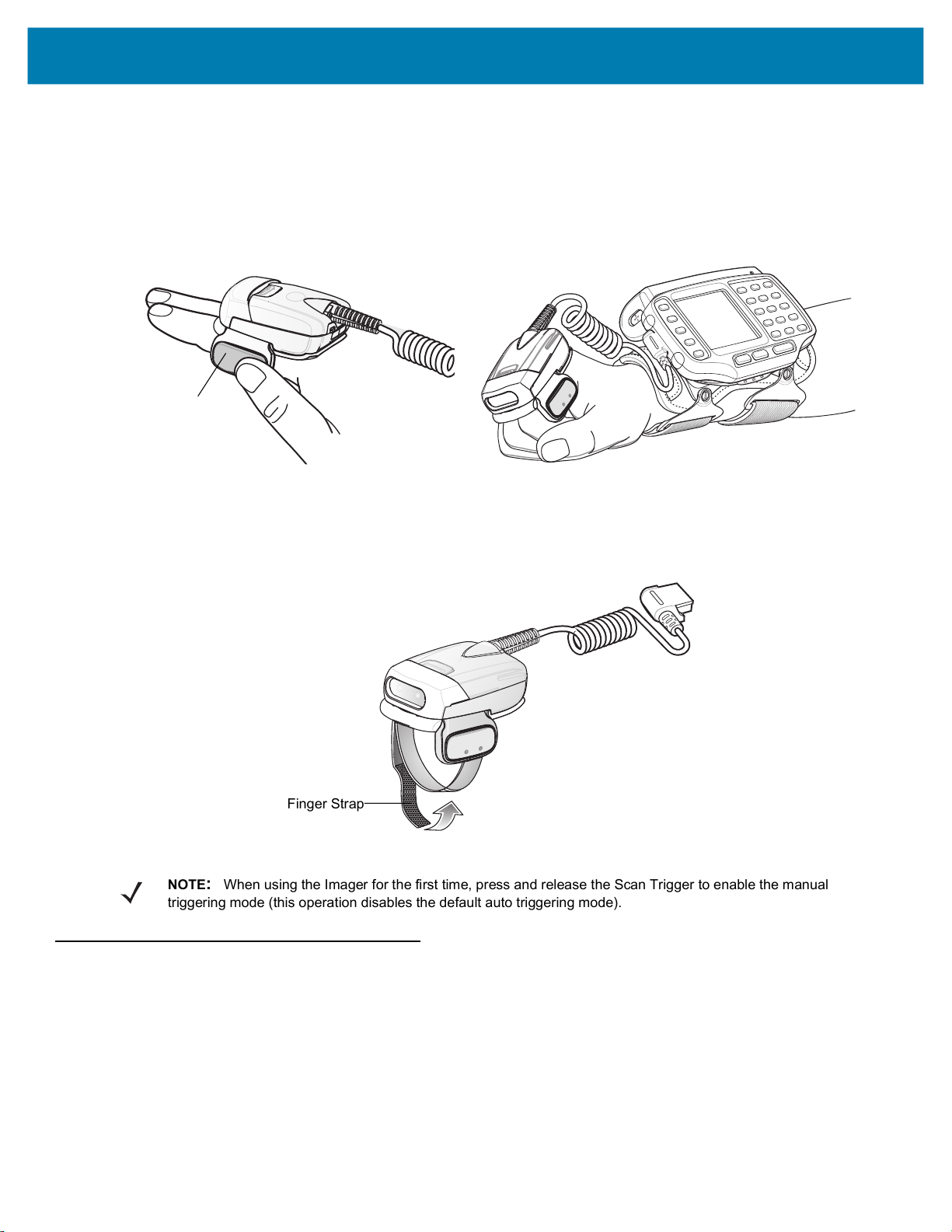

Figure 6 Wearing the Imager - Corded Configuration

Scan Trigger

2. Tighten the Finger Strap until it is snug, but not too tight.

CAUTION:To prevent user discomfort, wear the imager snug against the base of the index and middle finger. Do

not over tighten.

Figure 7 Wearing the Imager - Cordless Configuration

Finger Strap

NOTE: When using the Imager for the first time, press and release the Scan Trigger to enable the manual

triggering mode (this operation disables the default auto triggering mode).

Getting Started - Corded Configuration

In order to start using the Imager you must install the Corded Adapter.

Connect the Corded Adapter

To connect the Corded Adapter:

1. Align the Corded Adapter on top of the Imager.

2. Support the bottom side of the Imager and push the Corded Adapter all the way into the Locking Slots of the

Imager.

3. Firmly press the Corded Adapter into the Imager until a click is heard ensuring the Adapter Release Latch is

fully engaged with the Imager.

21

Page 22

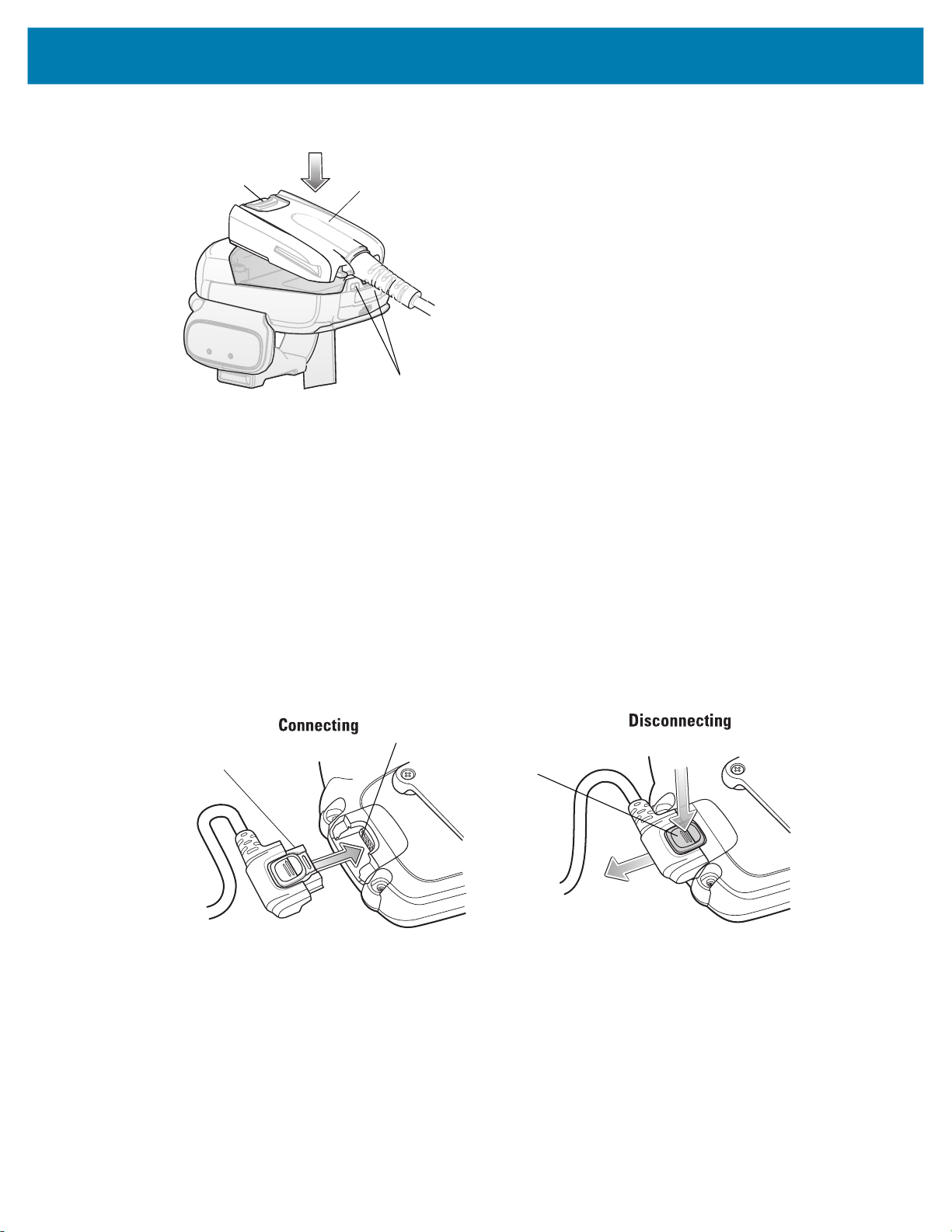

Figure 8 Connect Corded Adapter

Getting Started

Adapter Release Latch

Corded Adapter

Locking Slots

Remove the Corded Adapter

To remove the Corded Adapter:

1. Hold the Imager in one hand.

2. Press the Adapter Release Latch.

3. Pull up the Corded Adapter to release it from the Locking Slots of the Imager.

Connect to a WT4XXX Wearable Terminal

The Imager connects to the Wearable Terminal and mounts on the fingers.

Figure 9 Connecting and Disconnecting to a Wearable Terminal

WT4XXX Interface Connector

Interface Cable Connector

Disconnect

Button

2

1

To connect the Imager to the terminal:

1. On the terminal, remove the cover from the WT4XXX Interface Connector.

2. Connect the Interface Cable Connector of the Imager to the WT4XXX Interface Connector.

To disconnect the Imager from the terminal:

1. Press the Disconnect Button on the Interface Cable Connector.

2. Pull the Interface Cable Connector out of the WT4XXX Interface Connector.

22

Page 23

Getting Started

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

4t×Q

Wearing the Imager

To wear the Imager:

1. Slide the Imager onto the index and middle fingers with the Scan Trigger next to the thumb (see Figure 10).

Figure 10 Wear the Imager - Corded Adapter

Scan Trigger

2. Tighten the Finger Strap.

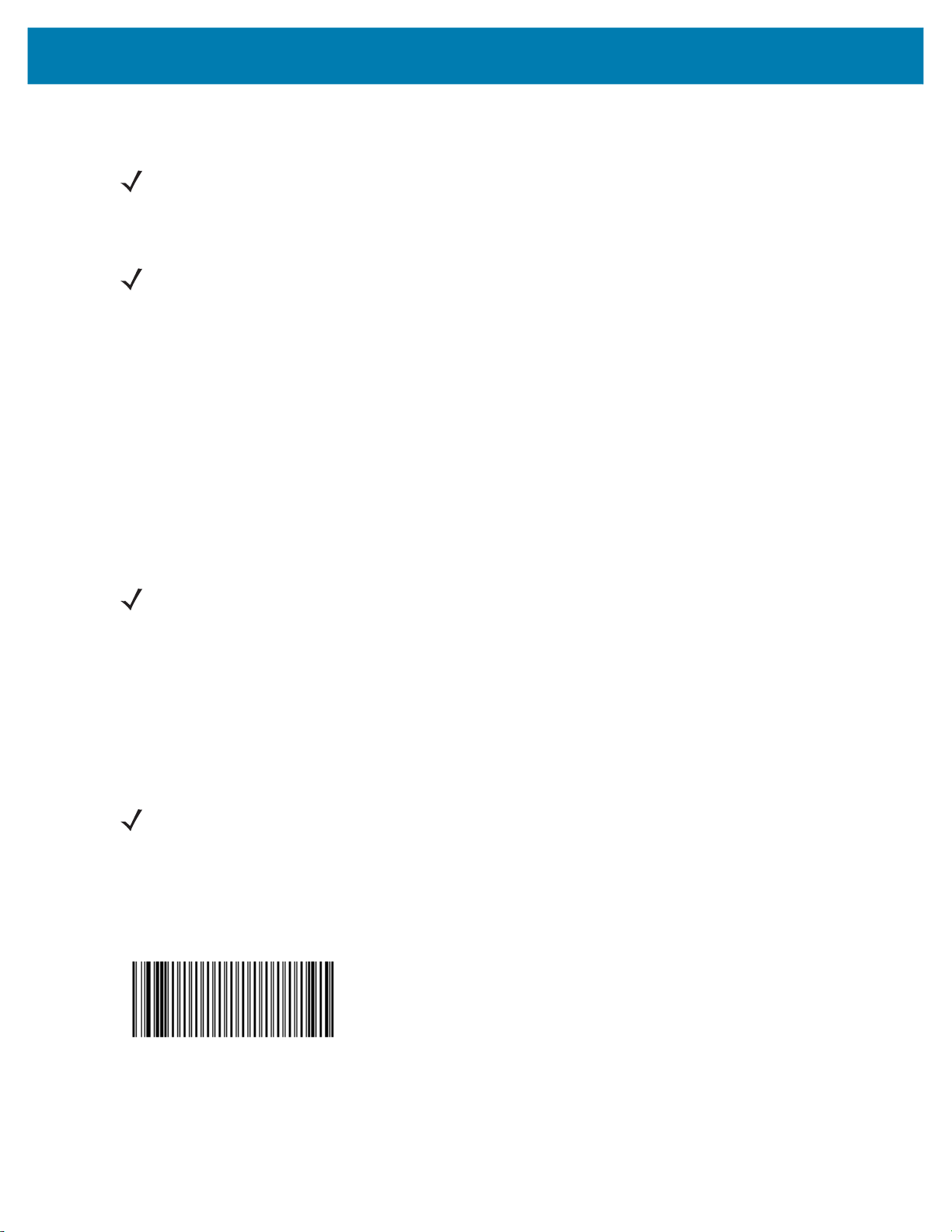

Figure 11 Wear the Corded Adapter Imager - Finger Strap

NOTE: When using the Imager for the first time, press and release the Scan Trigger to enable the manual

triggering mode (this operation disables the default auto triggering mode).

Status Indications

Finger Strap

The Imager has two Scan LEDs that provide identical indications. The Imager is also equipped with a beeper that

issues different beep sequences and patterns to indicate status.

23

Page 24

Getting Started

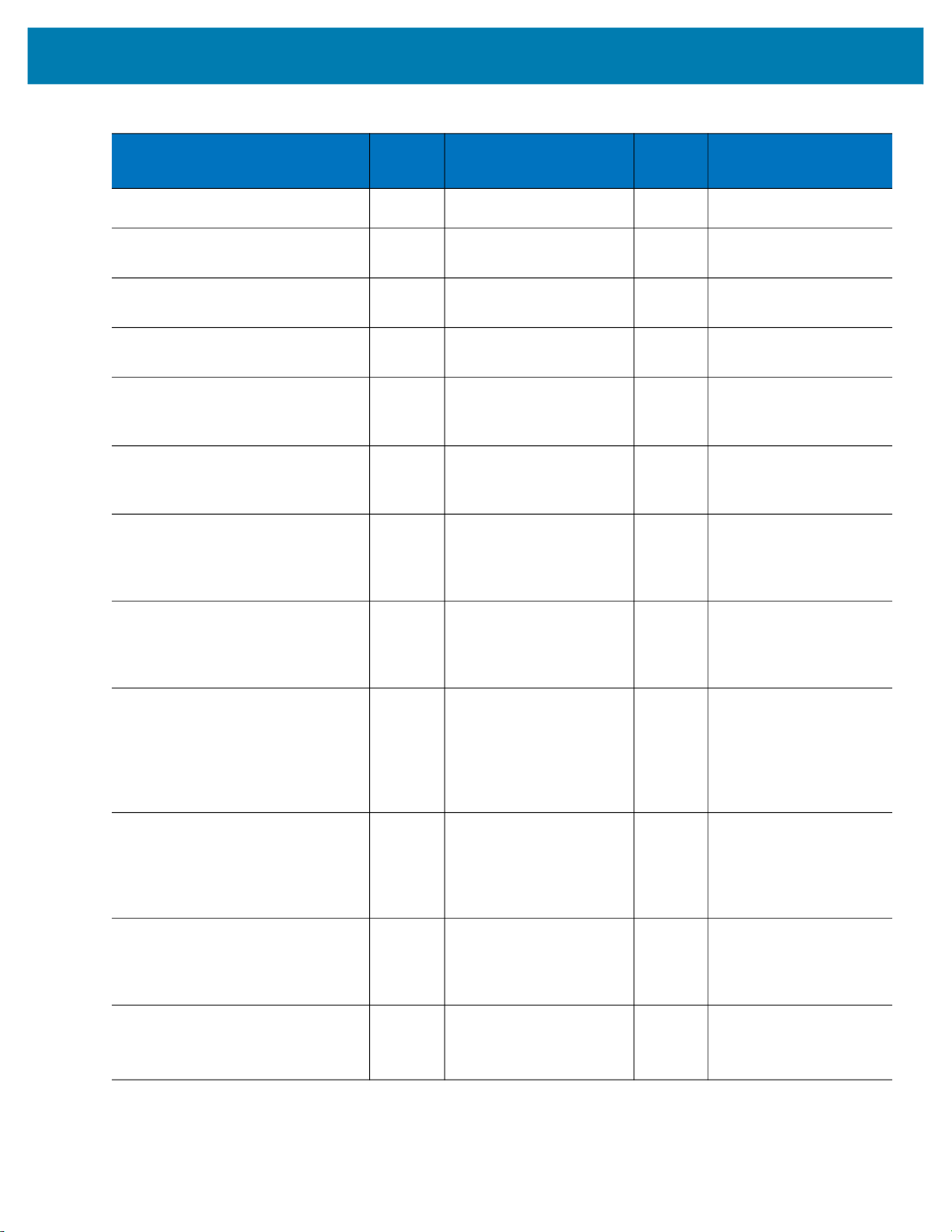

Table 2 defines the LED and beep sequences indications that occur during normal operation and bar code

scanning.

Table 2 Status Indications

No. LED Beep Indication Description

1. None High/low Bluetooth communication is disconnected

.

due to:

• host device is powered off.

• host device Bluetooth is off.

• Bluetooth un-pair bar code

scanned by the RS507.

• Bluetooth Disconnect bar code

scanned by the RS507.

• RS507 is out of Bluetooth range

with the host device.

2. Short green flashes None Attempting to connect over Bluetooth.

3. None Low/high Imager is connected over Bluetooth.

4. None High/low/high/low Properly decoded scan of Bluetooth

pairing bar code.

5. None Long low/ long high/ Bluetooth connection attempt failed.

If there is no acknowledgment from the

host device.

Example: Bluetooth on the host device is

off.

6. None Long low/ long high/ Long low/

long high/

7. One green flash High Proper scanning indication.

8. None 4 long beeps No Bluetooth communication after

9. Red flash 2 short beeps every 15 seconds Low battery.

10. Long red flash

followed by a green

flash

High/low High/low Clean Boot was performed successfully.

Bluetooth connection attempt is rejected.

When the RS507 tries to connect to the

host and the host rejects the connection.

Example: There is already a successful

Bluetooth connection in the host device

and it unable to create a new connection.

re-connection failure.

NOTE: When the Imager is connected by corded configuration, only “Proper scanning indication” and “Clean

Boot was perform successfully” status events are indicated.

24

Page 25

Imager Standby Mode

To save battery power, the Imager goes into Standby when not active.

The Image resumes functionality when:

• Bluetooth data is received from the mobile computer (in cordless configuration)

• Scan trigger is pressed

• Restore key is pressed

• Motion is detected (in cordless configuration)

• Incoming data from mobile computer is sensed (in corded configuration).

Bluetooth Connection

Establish Bluetooth Connection

To establish Bluetooth connection with a mobile computer:

Getting Started

1. Ensure that the Imager is within a range of 10 meters (30 feet) from the mobile computer.

2. Install the battery in the Imager.

3. Launch the Bluetooth Device (BD) address application (see Figure 12) from the mobile computer. Most BD

Address applications display a pairing bar code image on the screen of the mobile computer.

NOTE: To find the BD address application tap the Start button and select Programs > Display_BD_Address or Start

> Programs > BT Information and then tap the Generate Local BD Address Barcode button to display the BD

address bar code.

25

Page 26

Getting Started

Figure 12 Icon of Bluetooth Device (BD) Address Application

Bluetooth Device (BD) address icon

on WT4XXXApplication screen

Bluetooth Device (BD) address icon

on MC909X Demo screen

Bluetooth pairing application for

WT6000

4. Scan the pairing bar code on the mobile computer screen (see Figure 13) or a provided pairing label. When

Bluetooth Device (BD) address icon on

Windows Mobile Programs screen

BTUI pairing application for WT41N0

scanning, the Imager emits one string of high/low/high/low beeps.

NOTE: To create printed pairing bar code label, refer to Pairing Bar Code Format on page 28.

Figure 13 Pairing Bar Code Example as Shown on the Mobile Computer Screen

26

Page 27

Getting Started

5. The Scan LED starts flashing green indicating that the Imager is attempting to establish connection with a

mobile computer.

NOTE: If the Imager default PIN code is required for establishing connection, enter the following code: "12345".

You may also need to set the authentication and encryption to Enabled.

6. When connection is established, the Scan LED turns off and the Imager emits one string of low/high beeps.

The Imager is connected and ready for scanning.

NOTE: When replacing the Imager battery, the Imager memory retains the pairing information of the last paired

mobile computer.

Restore Lost Bluetooth Connection

The Imager maintains Bluetooth communication with a mobile computer within a range of 10 meters (30 feet).

When the Imager fails to establish connection or connection is lost during operation, the Imager emits one string of

high/low beeps.

To reestablish the Bluetooth connection with a mobile computer:

1. Ensure that the Imager is within a range of 10 meters (30 feet) from the mobile computer.

2. Ensure that the mobile computer is on and “awake” (not in Suspend mode).

3. The Imager automatically attempts reconnecting to the mobile computer for 30 seconds (Scan LED flashes

green). If automatic re-connection fails, verify that the Imager is within Bluetooth range and briefly press the

Restore Key on the Imager to reconnect.

NOTE: You can also reconnect by scanning a pairing bar code from the mobile computer screen or provided

label. When scanning, the Imager emits one string of high/low/high/low beeps.

4. The Scan LED starts flashing green indicating that the Imager is attempting to establish connection with a

mobile computer. The Scan LED turns off and the Imager emits one string of low/high beeps indicating that the

Imager is connected and ready for scanning.

Remove Bluetooth Connection

Remove Bluetooth connection to allow the Imager to connect to another mobile computer or to enable the a mobile

computer to accept the connection from another Imager.

NOTE: Removing Bluetooth connection is only required if the Imager is configured to auto-connect upon

power-up (permanent pairing is enabled) and has to be paired with a different mobile computer.

To remove Bluetooth connection:

1. Scan an un-pairing bar code for disconnecting the Imager from the mobile computer.

Figure 14 Un-pairing Bar Code

2. The Imager emits one string of high/low beeps indicating that Bluetooth communication with the mobile

computer is disconnected.

27

Page 28

Getting Started

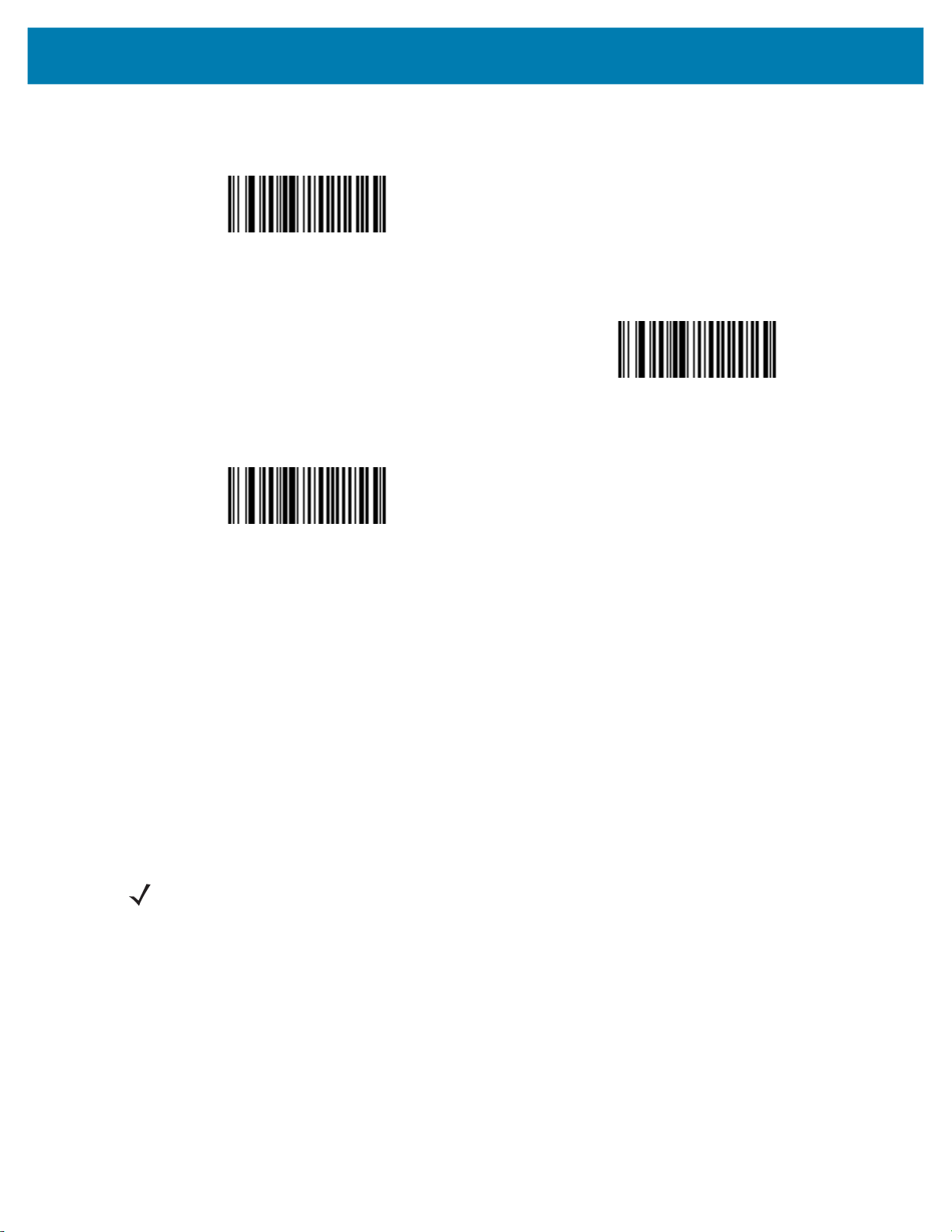

Pairing Bar Code Format

In order to pair the Imager with a mobile computer over Bluetooth, a pairing bar code must be created. You can use

the Display_BD_Address application on the mobile computer, or create and print a pairing bar code label. To

create a pairing bar code label, the Bluetooth address of the mobile computer should be available (refer to the

mobile computer user guide).

Pairing bar codes are Code 128, Data Matrix or Aztec symbologies formatted as follows:

<Fnc3>Bxxxxxxxxxxxx

Where xxxxxxxxxxxx represents the 12-character Bluetooth address.

Pairing Bar Code Example

If the mobile computer to which the Imager connects has a Bluetooth address of 11:22:33:44:55:66, then the

pairing bar code is:

Figure 15 Creating a Pairing Bluetooth Bar Code

Paring Bar Code Content: <Fnc 3> ‘B’ + Bluetooth Address

Scan

The Imager uses digital camera technology to take an image of a bar code and software decoding algorithms are

executed to extract the bar code data from the image.

Scan Triggering Modes

Manual Triggering (Triggered models only)

1. Launch a scanning software application on the mobile computer.

2. Position the Imager approximately 22.8 cm (9 inches) from a bar code and press the Scan Trigger. Position the

cross hair laser beam to cover the bar code. The Imager takes a digital picture (image) of the bar code and

stores it in memory for decoding.

NOTE: After battery is inserted or a corded adaptor is connected (on both sides), the first trigger press disables the

auto triggering mode.

3. One green flash of the LEDs is given and a high beep sounds to indicate that the bar code was properly

decoded.

NOTE: In some configurations proper decoding of a bar code is indicated by the software application running on

the mobile computer.

Auto-triggering (Triggerless models only)

The Imager is provided with auto-triggering capability. In auto-triggering mode, both motion and proximity sensors

are used to trigger the Imager when the user intends to scan a bar code.

28

Page 29

Getting Started

With auto-triggering activated, the Imager automatically scans when motion stops and a bar code is placed within

the depth of field of the Imager. The Imager scans the bar code and turns off to conserve power.

To scan a bar code in auto-triggering mode:

1. Position the Imager approximately 22.8 cm (9 inches) from a bar code.

2. Aim at the bar code.

3. The Imager takes a picture (image) of the bar code and stores it in memory for decoding.

4. One green flash of the Scan LEDs and a high beep indicates that a bar code was properly decoded.

NOTE: In some applications, proper detection of a bar code is indicated by a software application running on

the mobile computer.

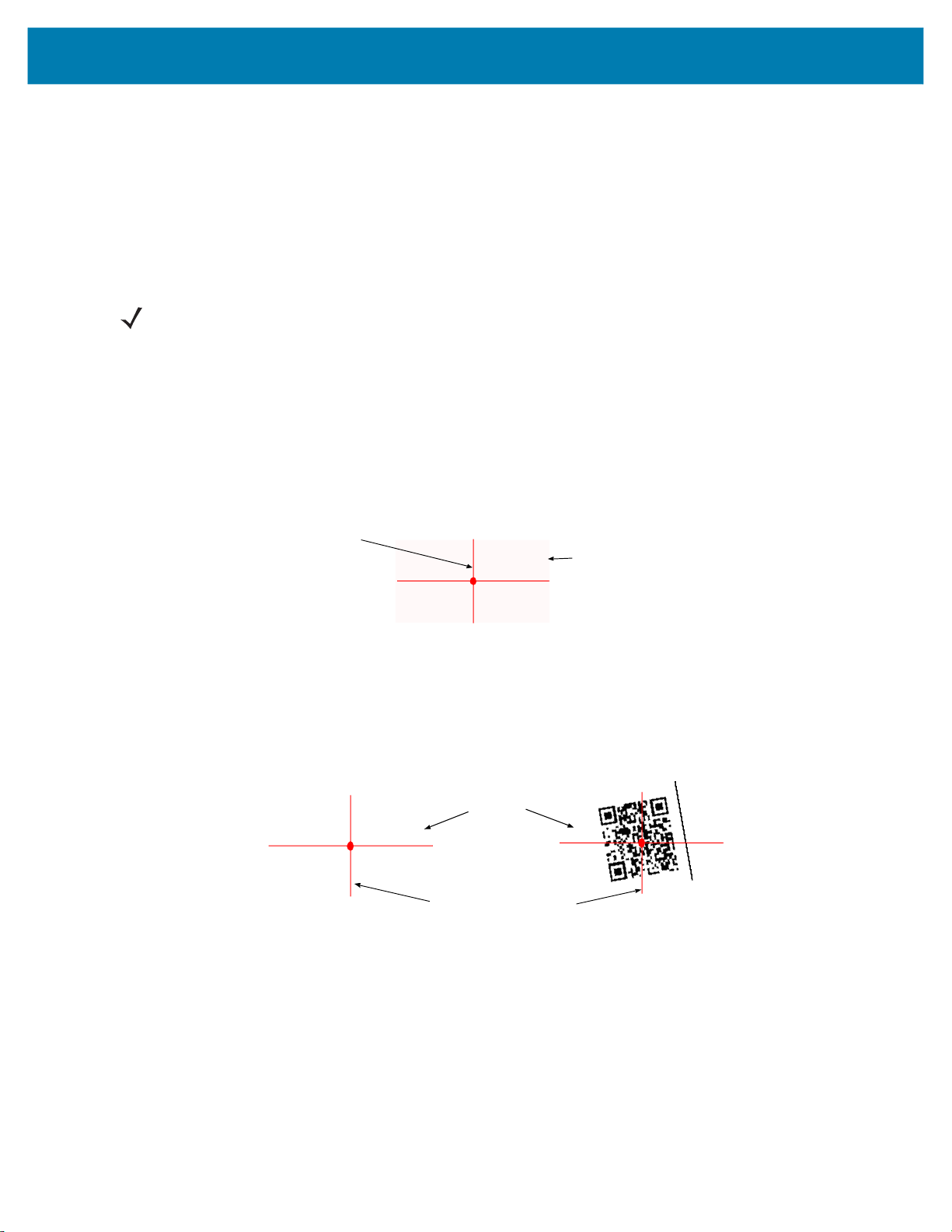

Aiming the Imager

The aiming pattern of the Imager is a cross hair laser beam with bright center dot (see Figure 16). The virtual

rectangle made by the cross hair reflects the field of view of the Imager. The aiming pattern is used to position the

bar code within the field of view.

Figure 16 Cross Hair Laser Beam

Cross hair laser beam

Virtual rectangle made by the cross hair laser beam

Enter the symbol in any orientation within the virtual rectangle made by the cross hair laser beam, making use of its

omnidirectional reading capability within the entire field of view.

Figure 17 Symbol Scan Orientation

1D Bar Code

Symbol

2D Bar Code

@1234@

Aiming pattern Pattern

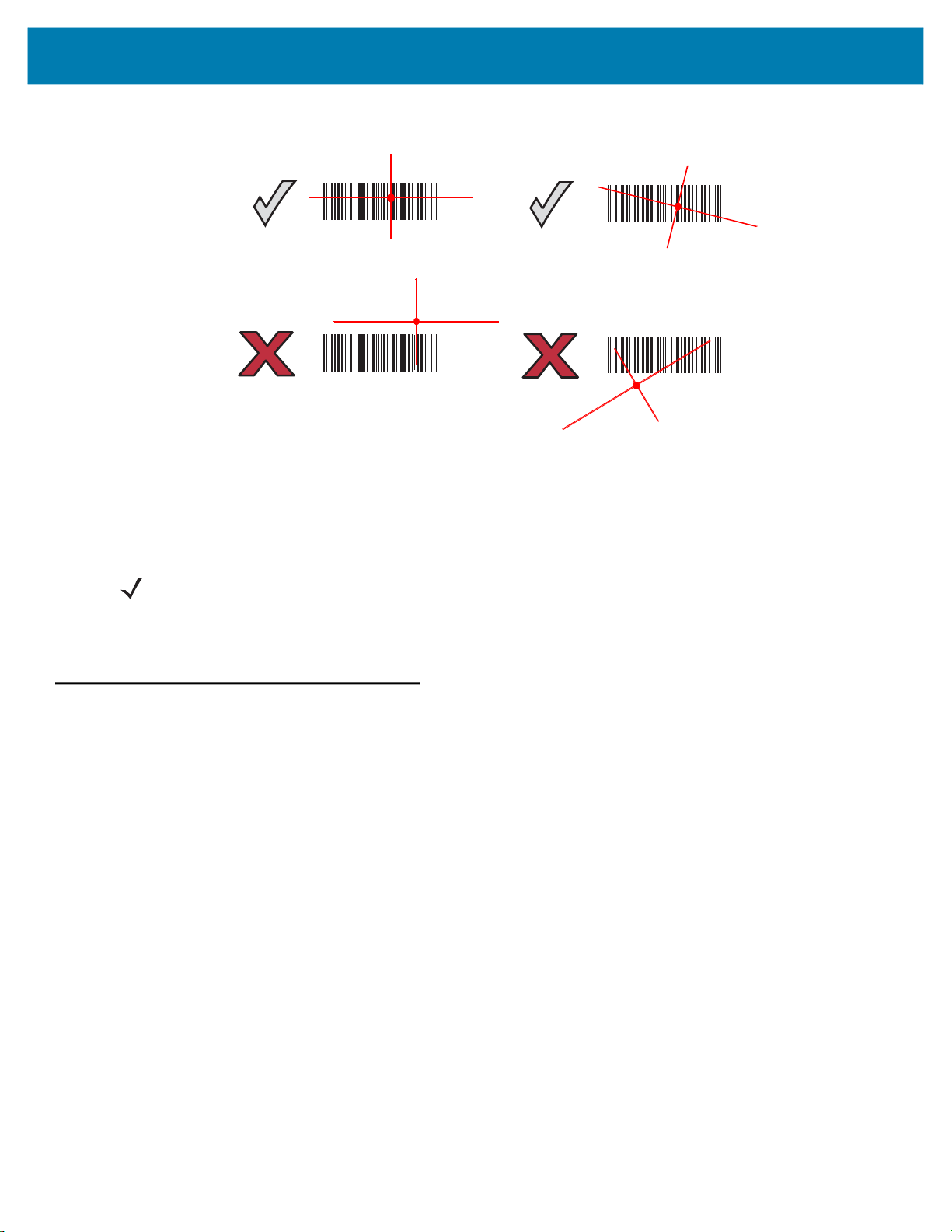

The Imager can also read a bar code presented within the aiming pattern but not centered (see the top bar codes

on Figure 18). The bar codes marked with X in Figure 18, however, show bar code aiming that may result in no

decode.

When using the application on your mobile computer in “Pick List” mode, the Bright Center Dot can be positioned

anywhere on the symbol (see Figure 16).The top examples in Figure 18 show acceptable aiming options, while the

bottom examples can not be decoded.

29

Page 30

Getting Started

012345

012345

012345

012345

Figure 18 Acceptable Aiming Options

The aiming pattern is smaller when the Imager is closer to the symbol and larger when it is farther from the symbol.

Scan symbols with smaller bars or elements (mil size) closer to the Imager and those with larger bars or elements

(mil size) farther from the Imager.

1. Hold the Imager between two and eleven inches from the bar code (depending on the bar code density).

NOTE: When a symbol is under transparent plastic or on a mobile computer screen, it is recommended to use a

tilt (pitch) or skew scan angle to minimize reflection.

2. Press the Scan trigger. The aiming pattern illuminates red indicating that the laser is on. One green flash of the

Scan LED and a high beep indicates that a bar code was properly decoded.

Customize the Imager

Changing from Triggered to Triggerless Configuration

To change from Triggered to Triggerless configuration:

1. Remove the Comfort Pad (see Comfort Pad Replacement on page 40).

2. Remove the Trigger Swivel Assembly (see Trigger Swivel Assembly Replacement on page 41).

3. Install the Triggerless Strap Holder (see Triggerless Strap Holder Replacement on page 42).

4. Install the Comfort Pad (see Comfort Pad Replacement on page 40).

5. Perform a cold boot (see Cold Boot on page 31).

Changing Triggerless to Triggered Configuration

To change from Triggerless to Triggered configuration:

1. Remove the Comfort Pad (see Comfort Pad Replacement on page 40).

2. Remove the Triggerless Strap Holder (see Triggerless Strap Holder Replacement on page 42).

3. Install the Trigger Swivel Assembly (see Trigger Swivel Assembly Replacement on page 41).

4. Install the Comfort Pad (see Comfort Pad Replacement on page 40).

5. Perform a cold boot (see Cold Boot on page 31).

30

Page 31

6. Press and release the Scan Trigger to enable the manual triggering mode (this operation disables the default

Triggerless mode).

Resetting the Imager

If the Imager stops responding to input, reset it. There are three reset functions, warm boot, cold boot and clean

boot. Perform a warm boot first. If the Imager still does not respond, perform a cold boot. Perform clean boot to

restore the Imager to its factory default configuration.

Warm Boot

To perform warm boot, press and hold the Restore Key for more than six seconds.

Cold Boot

Cold boot restores the Imager’s operation by resetting its software. To perform cold boot, remove and re-insert the

battery into the Imager. When using a corded Imager model with WT4XXX, remove and reconnect the interface

cable that connects between the Imager and the WT4XXX.

Getting Started

Clean Boot

Clean Boot restores the Imager to its factory default configuration.

To perform clean boot:

1. Remove battery or disconnect the Corded Adapter.

2. Press and hold the Restore Key.

3. Insert the battery or Corded Adapter into the Imager.

4. Continue to press and hold the Restore Key for about five seconds until a chirp is heard and the Scan LEDs

flash green. The Imager is now in its factory default configuration.

NOTE: The factory default configuration is set in the factory or the service center. These parameters are unique

for each Imager and cannot be changed. The Factory default configuration includes: Imager serial number,

Bluetooth Device (BD) address, model number, production date and proximity calibration.

31

Page 32

SAC5070 8-Bay Battery Charger

Introduction

The SAC5070 8-Bay Battery Charger is an accessory for the RS507/RS507X Hands-free Imager and provides a