Page 1

RFID

Programming Guide 3

for Link-OS RFID printers

P1062165-05EN

Page 2

ZEBRA and the stylized Zebra head are trademarks of Zebra Technologies Corporation, registered in

many jurisdictions worldwide. All other trademarks are the property of their respective owners.

© 2020 Zebra Technologies Corporation and/or its affiliates. All rights reserved.

Information in this document is subject to change without notice. The software described in this document

is furnished under a license agreement or nondisclosure agreement. The software may be used or copied

only in accordance with the terms of those agreements.

For further information regarding legal and proprietary statements, please go to:

SOFTWARE:www.zebra.com/linkoslegal

COPYRIGHTS:www.zebra.com/copyright

WARRANTY:www.zebra.com/warranty

END USER LICENSE AGREEMENT: www.zebra.com/eula

Terms of Use

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation and its subsidiaries

(“Zebra Technologies”). It is intended solely for the information and use of parties operating and

maintaining the equipment described herein. Such proprietary information may not be used, reproduced,

or disclosed to any other parties for any other purpose without the express, written permission of Zebra

Technologies.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies. All specifications and designs are

subject to change without notice.

Liability Disclaimer

Zebra Technologies takes steps to ensure that its published Engineering specifications and manuals are

correct; however, errors do occur. Zebra Technologies reserves the right to correct any such errors and

disclaims liability resulting therefrom.

Limitation of Liability

In no event shall Zebra Technologies or anyone else involved in the creation, production, or delivery of the

accompanying product (including hardware and software) be liable for any damages whatsoever

(including, without limitation, consequential damages including loss of business profits, business

interruption, or loss of business information) arising out of the use of, the results of use of, or inability to

use such product, even if Zebra Technologies has been advised of the possibility of such damages. Some

jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

Publication Date

June 25, 2020

2

Page 3

Contents

Introduction to RFID.............................................................................................................................. 6

RFID Overview................................................................................................................. 6

Electronic Product Code (EPC)....................................................................................... 7

EPC Fields................................................................................................................ 7

EPC Structure in RFID Labels.................................................................................. 7

EPC Class 1, Generation 2 (Gen 2)................................................................................. 7

Data and Tag Security.............................................................................................. 7

Gen 2 Memory Map.................................................................................................. 8

Using RFID Features ............................................................................................................................ 9

Performing Firmware Updates ......................................................................................... 9

RFID Label Selection .................................................................................................... 10

Considering RFID Transponder Characteristics..................................................... 10

Accounting for Transponder Inlay Position............................................................. 10

Testing RFID Labels............................................................................................... 10

Maximizing RFID Potential......................................

Avoiding Radio Frequency Interference ................................................................. 12

Storing or Handling RFID Labels Correctly ............................................................ 12

Using the Correct RFID Settings.................................................................................... 12

Setting the RFID Values Using Tag Calibration ..................................................... 13

Setting the RFID Values Manually.......................................................................... 13

Restoring the Printer’s Default Programming Position ........................................... 13

Locking RFID Tags ....................................................................................................... 14

....................................................... 12

RFID Printer Configuration ................................................................................................................. 15

Creating Basic RFID Label Formats ................................................................................................... 20

Create and Send an RFID Label Format ....................................................................... 20

Sample RFID Label Formats......................................................................................... 21

3

Page 4

Contents

RFID Label Format 1—Encode a Gen 2 Tag in Hexadecimal................................ 21

RFID Label Format 2—Encode a Gen 2 Tag in ASCII ........................................... 22

RFID Label Format 3—Read Data from Tag and Print Data on Label ................... 23

RFID Label Format 4—Encode Tag, Read Tag, and Print Data on Label ............. 24

RFID Label Format 5—Encode Tag, Read Tag, and Return Results to Host ........ 26

Troubleshooting .................................................................................................................................. 28

RFID Problems............................................................................................................... 28

RFID Error Codes and Messages .................................................................................. 31

ZPL Commands for RFID ................................................................................................................... 34

^HL or ~HL.....................................................................................................................35

Return RFID Data Log to Host ............................................................................... 35

^HR ................................................................................................................................ 37

Calibrate RFID Tag Position................................................................................... 37

^HV ................................................................................................................................ 43

Host Verification ..................................................................................................... 43

^RB ................................................................................................................................ 44

Define EPC Data Structure..................................................................................... 44

^RF................................................................................................................................. 46

Read or Write RFID Format.................................................................................... 46

^RL................................................................................................................................. 50

Lock/Unlock RFID Tag Memory ............................................................................. 50

^RLM – Lock/Unlock the Specified Memory Bank .................................................. 50

^RLB – Permanently Lock Specified Memory Sections.......................................... 51

~RO................................................................................................................................ 52

Reset Advanced Counters...................................................................................... 52

^RR ................................................................................................................................ 53

Enable Adaptive Antenna Selection ....................................................................... 53

^RS ................................................................................................................................ 54

Set Up RFID Parameters........................................................................................ 54

^RU ................................................................................................................................ 57

Read Unique RFID Chip Serialization .................................................................... 57

^RW ............................................................................................................................... 59

Set RF Power Levels for Read and Write............................................................... 59

SGD Commands for RFID .................................................................................................................. 61

device.applicator.rfid_void.............................................................................................. 62

odometer.rfid.valid_resettable ........................................................................................ 63

odometer.rfid.void_resettable......................................................................................... 64

4

Page 5

Contents

rfid.adaptive_antenna..................................................................................................... 65

rfid.antenna_sweep........................................................................................................ 66

rfid.country_code............................................................................................................ 67

rfid.enable ...................................................................................................................... 68

rfid.error.response.......................................................................................................... 69

rfid.hop_table_version .................................................................................................... 70

rfid.log.clear.................................................................................................................... 71

rfid.log.enabled...............................................................................................................72

rfid.log.entries................................................................................................................. 73

rfid.position.program ...................................................................................................... 74

rfid.reader_1.antenna_port............................................................................................ 75

rfid.reader_1.firmware_version....................................................................................... 77

rfid.reader_1.hardware_version...................................................................................... 78

rfid.reader_1.model ........................................................................................................ 79

rfid.reader_1.power.read................................................................................................ 80

rfid.reader_1.power.write................................................................................................ 81

rfid.recipe_version ......................................................................................................... 82

rfid.region_code.............................................................................................................. 83

rfid.tag.calibrate.............................................................................................................. 84

rfid.tag.data .................................................................................................................... 85

rfid.tag.read.content ....................................................................................................... 86

rfid.tag.read.execute ...................................................................................................... 87

rfid.tag.read.result_line1................................................................................................. 88

rfid.tag.read.result_line1_alternate ................................................................................. 89

rfid.tag.read.result_line2................................................................................................. 90

rfid.tag.read.result_line2_alternate ................................................................................. 91

rfid.tag.test.content......................................................................................................... 92

rfid.tag.test.execute........................................................................................................ 93

rfid.tag.test.result_line1 .................................................................................................. 94

rfid.tag.test.result_line2 .................................................................................................. 95

5

Page 6

Introduction to RFID

This section describes the basic concepts of Radio Frequency Identification (RFID) and how RFID works

with your printer.

RFID Overview

An RFID printer encodes (writes) information on ultra-thin HF or UHF RFID transponders that are

embedded in “smart” labels, tickets, and tags. The printer encodes the information; verifies proper

encoding; and prints bar codes, graphics, and/or text on the label’s surface.

The RFID transponder is sometimes called the RFID tag or an inlay. The transponder is usually made of

an antenna that is bonded to an integrated circuit (IC) chip. The IC chip contains the RF circuit, coders,

decoders, and memory. If you hold an RFID label up to the light, you can see the transponder’s antenna,

and you can feel a bump in the label where the IC chip is located.

Encoding and printing of an RFID label usually are completed on the first try, but some failures may occur.

If you experience consistent failures, it may signal a problem with the RFID tags, with your label formats, or

with the transponder placement.

6

Page 7

Introduction to RFIDIntroduction to RFID

Electronic Product Code (EPC)

EPC is a product-numbering standard administered by GS1 that can be used to identify a variety of items

by using RFID technology. The 96-bit EPC code links to an online database, providing a secure way of

sharing product-specific information along the supply chain.

NOTE: The information in this section is provided for your convenience only and is subject to change. Go

to http://gs1.org/epcglobal for the latest EPC information.

EPC Fields

As with bar codes, EPC is divided into numbers that identify the manufacturer and product type. However,

EPC contains the following additional information:

• Header—identifies the length, type, structure, version, and generation of EPC

• Manager Number—identifies the company or company entity

• Object Class—similar to a stock keeping unit (SKU)

• Serial Number—the specific instance of the Object Class being tagged

Additional fields may be used as part of the EPC code to encode and decode information from different

numbering systems into human-readable form. For more information about EPC specifications, refer to the

EPC Global web site.

EPC Structure in RFID Labels

In the printer, you can subdivide transponder data into unique fields. You can customize these fields to

create “smart” labels that meet your needs or that meet the standards necessary in EPC programming.

The

^RB ZPL command (see ^RB on page 44 for) is used to define EPC structure. EPC field data can be

delimited with any of the following characters:

, ~ ! @ # $ % ^ & * | . < > / \ : ;

EPC Class 1, Generation 2 (Gen 2)

Gen 2 tags typically have a 96-bit EPC identifier and can support large data structures. The size of user

memory available (if any) varies by the model and manufacturer of the tag.

Data and Tag Security

Tag Passwords You can set optional 32-bit passwords that allow you to access tag data, to lock tag data,

or to permanently disable (kill) a tag. If desired, use the ZPL command ^RF on page 46 to set the

passwords and ^RL on page 50 to specify the type of lock.

Data Locking Options Tag memory can be safeguarded with flexible locking options using ^RL on

page 50. For example, you can lock a tag’s memory to prevent it from being encoded accidentally and later

unlock it for writing. A permanent locking feature prevents rewriting of tag data.

7

Page 8

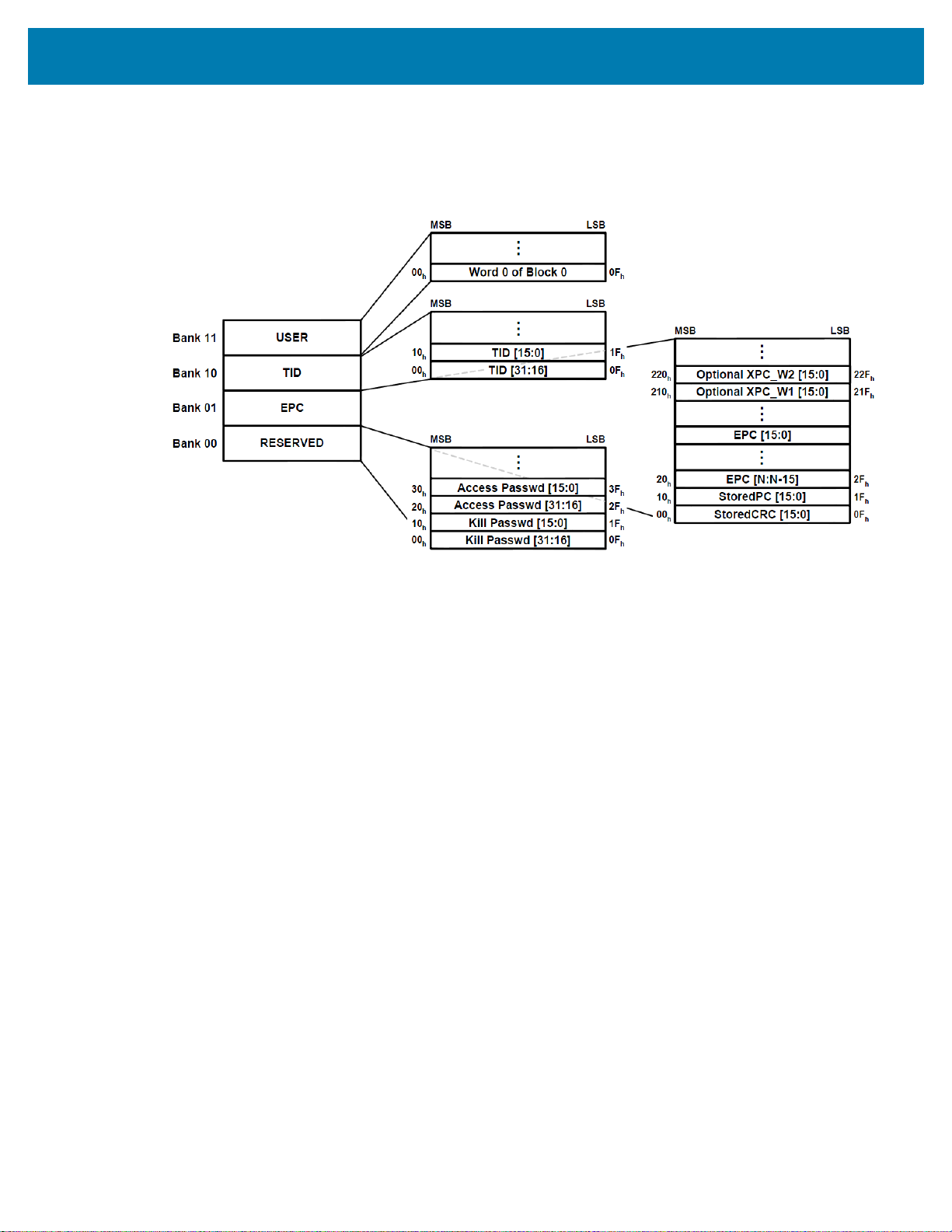

Gen 2 Memory Map

Figure 1 shows how information is stored on a Gen 2 tag.

Figure 1 Gen 2 Memory Map

Introduction to RFIDIntroduction to RFID

8

Page 9

Using RFID Features

This section guides you through some ideas to consider and some tasks that you may need to perform

before you begin using RFID labels. When you have completed this section, you will be ready to program

your RFID label formats.

Performing Firmware Updates

Zebra may update printer firmware periodically to add new functionality or to fix any known issues with

older firmware. At any time, you may download the most recent firmware for your RFID printer. For the

firmware files and the downloading instructions, go to http://www.zebra.com/firmware.

IMPORTANT: Download only the firmware designed for your printer. Downloading inappropriate firmware

may disable your printer or some or all of the RFID functionality. Before downloading new firmware, print a

printer configuration label and verify that the new printer firmware version is appropriate for your printer.

9

Page 10

Using RFID Features

RFID Label Selection

To select RFID labels for your printer, consider the RFID transponder (commonly called the RFID tag) and

where the transponder is placed in the label. Run tests to determine if the RFID labels that you selected

work as you expected before you purchase a large quantity of them. This section provides a brief overview

of things that you should take into account. Additional RFID media considerations specific to your printer

may be found at http://www.zebra.com/transponders/.

IMPORTANT: To use Silverline RFID media, you must use a ZT410 printter with the Silverline Printing

Solution or a ZT411 with the On-metal Tagging Solution. Other RFID printers may not handle this media

correctly.

Considering RFID Transponder Characteristics

Before you purchase Gen 2 RFID labels, determine which RFID transponder (tag) to use. Many RFID

transponders look similar, but they behave differently. For different transponders, the following

characteristics vary:

• the amount of programmable memory (which corresponds to the amount of data that can be encoded in

it)

• the way that data is segmented

• custom commands that can be used (such as block lock)

Select the transponder that best suits your needs.

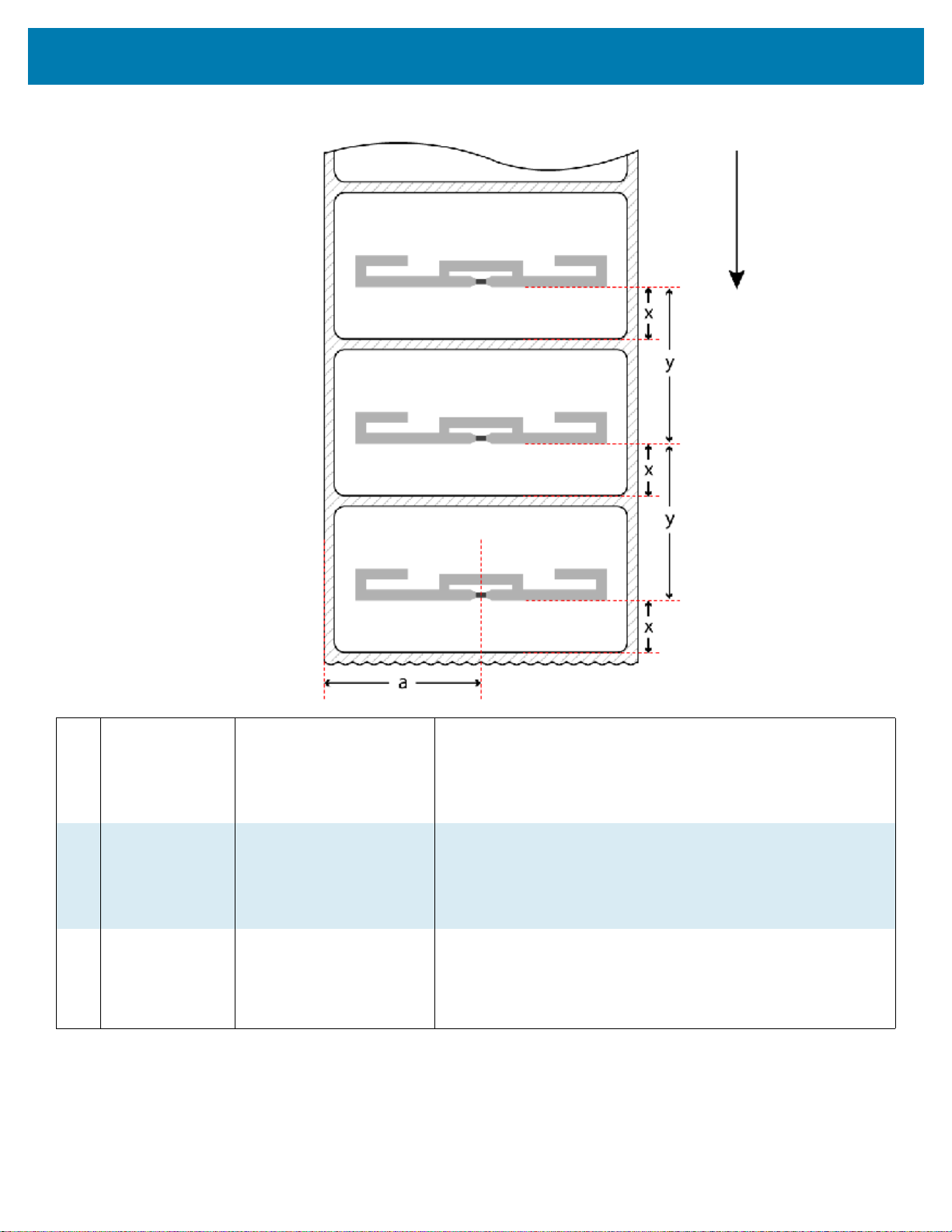

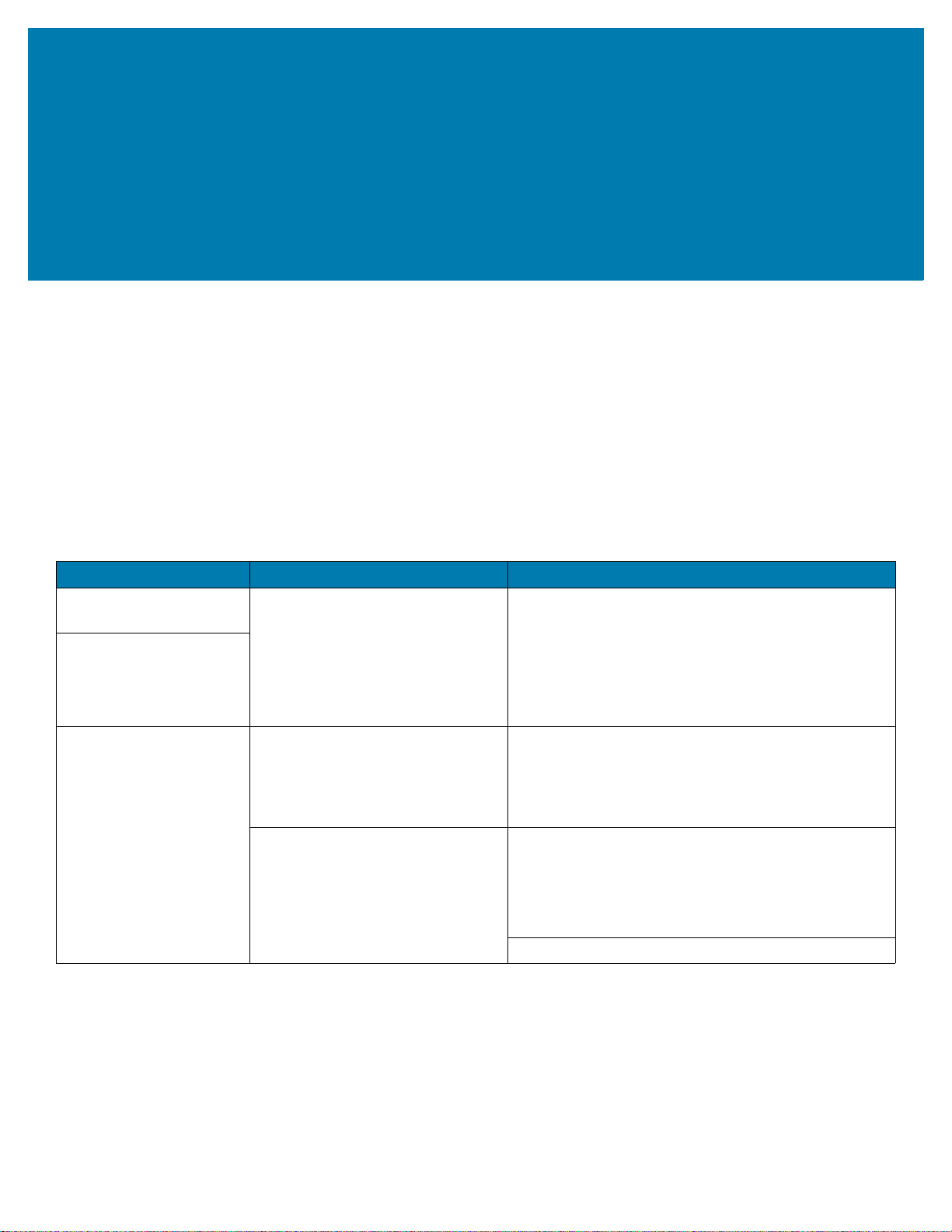

Accounting for Transponder Inlay Position

Communication between the RFID label and the printer is established when the RFID label’s transponder

lines up with the printer’s RFID antenna or active antenna element. The optimal tag programming position

varies with the transponder size, its configuration, and the type of chip used. Figure 2 on page 11 shows

the physical specifications that should be taken into account for each transponder when deciding where to

place the transponder on a label.

For center-justified printers, the RFID inlay should always be centered horizontally in the label.

IMPORTANT: Print quality may be affected by printing directly over the transponder. In particular, there is

an area on each label immediately around the location of the IC chip where the printer may print with low

quality. Design your printed label around the location of the chip in the type of approved RFID label that

you select.

Testing RFID Labels

Before you purchase a large quantity of Gen 2 RFID labels, test a small batch to make sure that they

function as you need them to. You may need to adjust the transponder location or change transponders if

the RFID labels do not work in your application.

10

Page 11

Using RFID Features

feed direction

Figure 2 Transponder Placement Guidelines

a

Inlay Center Left inner edge to

transponder (inlay) center.

Viewed from face stock

side, feed direction down.

x

Inlay Position Label Start to transponder

antenna leading edge.

y

Inlay Pitch Distance from the leading

edge of one transponder

antenna to the next.

RF coupling with the transponder can change horizontally across

the width of the label. This dimension is relative to the center of

the transponder antenna, which is not always the same as the

chip location.

This measurement is typically defined with a ±3 mm tolerance.

The Inlay Position ensures proper RF encoding with the

transponder in the current label. This dimension is relative to the

leading edge of the transponder antenna and is the optimal

distance from the print line to the antenna during encoding.

This measurement is typically defined with a ±3 mm tolerance.

If transponders are spaced too closely together, coupling to

multiple transponders can sometimes occur. This dimension

defines the minimum pitch required to ensure coupling only with

the transponder in the current label. The minimum pitch for

printers supported by this manual is 16 mm (0.63 in.)

11

Page 12

Using RFID Features

Maximizing RFID Potential

After an RFID label is encoded, how well it functions depends where the label is placed on an item, the

contents of the item (such as metals or liquids), the location of the RFID readers, and how the label is

stored.

Avoiding Radio Frequency Interference

Radio Frequency (RF) interference can be caused by many sources. This interference can affect RFID

performance by limiting the range of the RFID tags or preventing reading/writing to the tags.

• Metal reflects radio frequency signals and is a leading source of RF interference. Foil or metal-based

media should only be used for RFID applications if the tags are designed to work correctly with that

type of media.

• Water and other liquids can absorb RF signals. Some media adhesives and label materials can be

unexpected sources of liquids that cause performance problems.

• Other RF equipment can cause interference if the equipment is positioned too close together. Allow

sufficient physical space between the RFID printer and other RF products that share the same

bandwidth (such as antennas, readers, wireless LANs, or other RFID printer/encoders).

Storing or Handling RFID Labels Correctly

Store RFID labels at temperatures ranging from 60 to 203 °F (15.5 to 95 °C) in environmentally stable

conditions.

Limit RFID label exposure to electrostatic discharge (ESD). Low-humidity environments may require the

use of antistatic mats, straps, or clothing to help counter ESD.

Using the Correct RFID Settings

You can perform two types of calibration on an RFID printer. Media calibration sets the printer for the

media criteria, such as label length and interlabel gap. RFID tag calibration sets the printer for RFID

criteria, such as the optimal programming position.

For best results, run tag calibration each time you change RFID media to allow the printer to select the

best programming position and other RFID settings for you. If tag calibration does not produce the desired

results, you can adjust the values manually.

NOTE: In the ZD500R printer with firmware version V74.19.6Z, any time that a new label length is

measured, the programming position returns to the default value. This can happen in the following

situations:

• any calibration methods that measure length

•

^SS parameter for Label Pitch Length

With all other printers and firmware versions supported by this manual, the program position is persistent.

12

Page 13

Using RFID Features

Setting the RFID Values Using Tag Calibration

Before running tag calibration, calibrate your printer for the media being used, close the printhead, and

feed at least one label to make sure that tag calibration will begin from the correct position. For more

information on media calibration, refer to the User Guide for your printer.

Perform tag calibration using one of the following ways:

• using the

• using the

host computer.

• using the

page 100).

During the tag calibration procedure, the printer feeds an RFID label 1 mm at a time while taking readings

(via READ TAG and WRITE TAG commands) to profile the location of the RFID transponders in the media.

This process ensures that only the current tag will be encoded, not the tag before or after it. Based on the

results, the printer selects optimal values for the following items for the media being used:

• the programming position

• the read/write power levels

• the antenna element (for printers with more than one antenna element)

These values are saved to nonvolatile memory (the value is saved even if the power is turned off) and are

used for all subsequent labels unless a label format specifies a different value.

If the tag cannot be read during the RFID tag calibration process, RFID calibration fails, and the printer

defaults are used. Try running the RFID tag calibration again with another RFID label.

RFID CALIBRATE user menu option (see RFID Tag Calibration (RFID Calibrate) on page 16)

^HR ZPL command (see ^HR on page 50). This command also returns a results table to the

"run" option in the rfid.tag.calibrate SGD command (see rfid.tag.calibrate on

Setting the RFID Values Manually

You can manually change the RFID settings in several ways. See Adjust the Printer’s RFID Settings on

page 22 for more information.

Restoring the Printer’s Default Programming Position

To restore the printer’s default programming position at any time, use the "restore" option in the

rfid.tag.calibrate SGD command (see rfid.tag.calibrate on page 100).

13

Page 14

Locking RFID Tags

If an RFID tag supports locking, you can lock/unlock or permanently lock (permalock)/permanently unlock

memory banks or blocks/sectors of the tag’s memory.

To perform a lock/unlock command or a permalock command, the access password used for the lock

command must match the access password that is stored on the tag. The default access password that is

stored on tags is 00000000. This value must be changed to something other than zero to perform

lock/unlock functions; however, it can remain zero for permalock functions.

If the access password on a tag needs to be changed, use the following command:

^RFW,H,P^FD<access password>^FS

If the correct password is already encoded on your tag, you do not need to write the password to the tag as

part of the label format, thereby adding to the programming time. Instead, you may simply specify the

password as part of the format using the following command, which saves the time of writing it to the tag:

^RFS,H,P^FD<access password>^FS

For more information, see ^RF on page 58 and ^RL on page 62.

Using RFID Features

14

Page 15

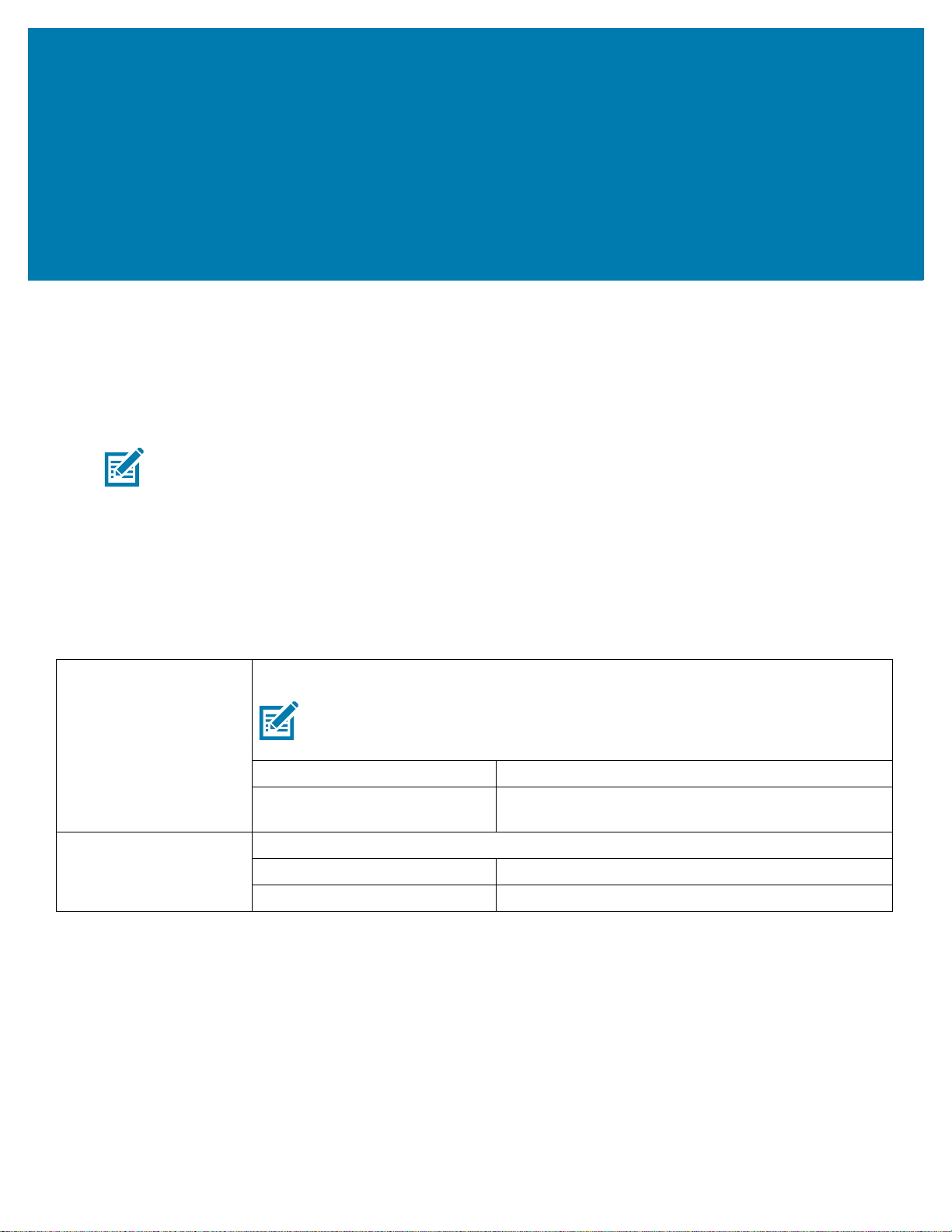

RFID Printer Configuration

This section presents the printer RFID settings that you can change and identifies the ways for changing

them. These ways include the following:

• Through the printer’s display (if the printer has one)

NOTE: The settings shown here may not be in the same order in which you see them on your printer.

•ZPL and Set/Get/Do (SGD) commands

• The printer’s user menus

• The printer’s web pages when the printer has an active wired or wireless print server connection (See

the ZebraNet Wired and Wireless Print Servers User Guide for more information about accessing the

web pages. A copy is available at http://www.zebra.com/manuals.)

Table 1 RFID Settings

RFID Country Code Select the RFID country code (if applicable).

NOTE: A prompt for the country code appears only on some printers the first time

that they are powered up, depending on the world region to which the printers were

shipped. Specify the appropriate country to access the printer’s RFID features.

SGD command used: rfid.country_code on page 67

Printer web page: View and Modify Printer Settings > RFID Setup > RFID

COUNTRY CODE

RFID Status Display the status of the RFID subsystem of the printer.

Related ZPL command(s): ^HL or ~HL on page 35

SGD command used: rfid.error.response on page 69

15

Page 16

Table 1 RFID Settings (Continued)

RFID Printer Configuration

RFID Tag Calibration

(RFID Calibrate)

Initiate tag calibration for RFID media. (Not the same as media and ribbon calibration.)

During the process, the printer moves the media, calibrates the RFID tag position, and

determines the optimal settings for the RFID media being used. These settings include the

programming position, the antenna element to use, and the read/write power level to use.

IMPORTANT: Before running this command, load the printer with RFID media,

calibrate your printer, close the printhead, and feed at least one label to make sure

that tag calibration will begin from the correct position.

Leave all transponders before and after the tag that is being calibrated. This allows

the printer to determine RFID settings which do not encode the adjacent tag. Allow a

portion of media to extend out the front of the printer to allow for backfeed during the

tag calibration procedure.

Related ZPL command(s): ^HR on page 37

SGD command used: rfid.tag.calibrate on page 84

Read RFID Data Read and return the specified tag data from the RFID tag located over the RFID antenna.

No printer movement occurs while tag data is being read. The printhead can be open or

closed.

Accepted values: •

epc = reads the EPC data based on the EPC size

specified in the RFID tag’s protocol bits, up to 160

bits

•

tid information = reads the first 32 bits of the TID

(Tag ID)

•

password status = reads the tag’s access and kill

passwords

•

protocol bits = reads the protocol bits from the

EPC memory banks and converts that value to the

EPC size

•

memory bank sizes = reads the EPC, TID, and user

memory banks sizes

•

up = sets the command to the previous test

•

down = sets the command to the next test

Related ZPL command(s): ^RF on page 46

SGD command used: rfid.tag.read.content on page 86 and

rfid.tag.read.execute on page 87

16

Page 17

RFID Printer Configuration

Table 1 RFID Settings (Continued)

RFID Test During the RFID test, the printer attempts to read and write to a transponder. No printer

movement occurs with this test.

Accepted values: •

SGD command used: rfid.tag.test.content on page 92 and

quick = performs a read EPC test and a write EPC

test (using random data)

•

read = performs a read EPC test

•

write = performs a write EPC test (using random

data)

•

up = sets the command to the previous test

•

down = sets the command to the next test

rfid.tag.test.execute on page 93

RFID Programming

Position

If the desired programming position (read/write position) is not achieved through RFID tag

calibration, a value may be specified. See Using the Correct RFID Settings on page 12 for

more information.

Accepted values:

F0 to Fxxx (where xxx is the label length in millimeters

or 999, whichever is less)—The printer feeds the label

forward for the specified distance and then begins

programming.

B0 to B30—The printer backfeeds the label for the

specified distance and then begins programming. To

account for the backfeed, allow empty media liner to

extend out of the front of the printer when using a

backward programming position.

NOTE: Backward program positions of

B1 to B30

may not yield the best results with some media.

If a backward programming position does not

yield the desired results, consider redesigning

your label format so that the printer uses a

forward program position of

F0 to Fxxx.

Related ZPL command(s): ^RS on page 54

SGD command used: rfid.position.program on page 74

Printer web page: View and Modify Printer Settings > RFID Setup >

PROGRAM POSITION

17

Page 18

RFID Printer Configuration

Table 1 RFID Settings (Continued)

RFID Antenna Element If the desired antenna is not achieved through RFID tag calibration, a value may be

specified.

NOTE: This applies only to ZT400 and ZT600 series RFID printers, which have

multiple antenna elements. Other printers, which only have one antenna element,

always use an antenna element value of

Accepted values: A1, A2, A3, A4

B1, B2, B3, B4

C1, C2, C3, C4

D1, D2, D3, D4

E1, E2, E3, E4

Related ZPL command(s): ^RW on page 59

SGD command used: rfid.reader_1.antenna_port on page 75

Printer web page: View and Modify Printer Settings > RFID Setup > RFID

ANTENNA

RFID Adaptive Antenna NOTES:

A1.

• This applies only to ZT400 and ZT600 series RFID printers, which have multiple

antenna elements.

• The label length must be 2 in. (51 mm) or longer.

• Activating this feature may slow throughput on damaged or weak RFID tags.

This command enables or disables adaptive antenna selection.If the printer cannot find

RFID tags with the antenna element specified, the printer may try neighboring antenna

elements. If the printer is unsuccessful communicating with the RFID tag after trying the

neighboring antenna elements, the printer voids the label.

Accepted values: •

none = The printer uses only the current antenna

element selection.

•

neighbors = The printer attempts to read the tag

using the antenna elements to the left/right and

above/below the current antenna. The antenna

element that is successful is used for all subsequent

RFID commands until the next unsuccessful

attempt.

Related ZPL command(s): ^RR on page 53

SGD command used: rfid.adaptive_antenna on page 65

Printer web page: View and Modify Printer Settings > RFID Setup >

ADAPTIVE ANTENNA

18

Page 19

RFID Printer Configuration

Table 1 RFID Settings (Continued)

RFID Antenna Sweep NOTE: This feature applies to ZT400 and ZT600 printers. The label must be 2 in.

(51 mm) or longer, and the label format must have a programming position of F0.

This feature enables/disables the antenna sweep feature. If the RFID media loaded in the

printer is known to be in range of an antenna at the F0 programming position, you can avoid

RFID calibration by using the RFID antenna sweep feature. With this feature enabled, when

the first RFID format is sent after a printer powerup or printhead close, the printer scans

through the antennas to find the optimal antenna element.

Accepted values:

Related ZPL command(s): rfid.antenna_sweep on page 66

RFID Read Power If the desired read power is not achieved through RFID tag calibration, a value may be

specified.

Accepted values: 0 to 30

Related ZPL command(s): ^RW on page 59

SGD command used: rfid.reader_1.power.read on page 80

Printer web page: View and Modify Printer Settings > RFID Setup > RFID

RFID Write Power If the desired write power is not achieved through RFID tag calibration, a value may be

specified.

Accepted values: 0 to 30

Related ZPL command(s): ^RW on page 59

on, off

READ PWR

SGD command used: rfid.reader_1.power.write on page 81

Printer web page: View and Modify Printer Settings > RFID Setup > RFID

WRITE PWR

RFID Valid Counter Resets the RFID valid label counter to zero.

Related ZPL command(s): ~RO on page 52

SGD command used: odometer.rfid.valid_resettable on page 63

RFID Void Counter Resets the RFID void label counter to zero.

Related ZPL command(s): ~RO on page 52

SGD command used: odometer.rfid.void_resettable on page 64

19

Page 20

Creating Basic RFID Label Formats

Use the ZPL samples in this section as a base for programming your own RFID label formats.

For specific information about individual ZPL commands, see ZPL Commands for RFID on page 34.

Create and Send an RFID Label Format

The following pages contain sample RFID label formats that you can modify to create your own RFID label

formats.

To create an RFID label based on a sample label, complete these steps:

1. Using any word processor or text editor that is capable of creating ASCII-only files (for example, use

Microsoft

sample.

2. Save the file to your computer.

When naming the file, use

file

3. Set up the printer, and turn the power On (I).

4. Copy the file to the printer. One way to do this is by using the Zebra Setup Utilities (to download go to

http://www.zebra.com/us/en/products-services/software/manage-software/zebra-setup-utility.html).

5. Compare your label results with those shown in the sample. If your results are not the same as those

shown, confirm that the file you created is identical to the format shown, and then repeat the printing

procedure.

6. Check the RFID data on your label.

a. Open the printhead, and place the label above the antenna in the printer.

b. Use one of the methods given in Read RFID Data on page 16 to view the transponder data.

c. Compare your RFID data with that shown in the sample. If your data does not look like what is

7. When you are certain that the file you created is correct, substitute your data in the label format where

necessary.

®

Word and save as a .txt file), type in the label format exactly as shown in the desired

.zpl as the extension for the file (for example, you may choose to name a

format1.zpl).

shown, confirm that the file you created is identical to the format shown, and then resend the label

format to the printer.

20

Page 21

Creating Basic RFID Label FormatsCreating Basic RFID Label Formats

Simple write example

▼

READ RFID DATA

EPC

▲

11223344556677889900

1122

READ

Sample RFID Label Formats

Use the formats in this section to assist you in creating your own RFID label formats.

RFID Label Format 1—Encode a Gen 2 Tag in Hexadecimal

Line

Number

1

2

^XA

^FO50,50

^A0N,65

^FDSimple write example

^FS

3

^RFW,H

^FD112233445566778899001122

^FS

4

Resulting Label

^XZ

Type This ZPL Code Function of ZPL Code

Indicates start of label format.

Prints “Simple write example” on the label

at location 50,50.

W,H = write hex

Encodes the 12 bytes of data (96 bits) to

the tag. The data written is:

112233445566778899001122

Indicates end of label format.

Programmed to Transponder

112233445566778899001122

Sample Control Panel Display

21

Page 22

Creating Basic RFID Label FormatsCreating Basic RFID Label Formats

Simple write example

▼

READ RFID DATA

EPC

▲

30302072666964206461

7461

READ

RFID Label Format 2—Encode a Gen 2 Tag in ASCII

This label format is different in what shows on the control panel. The control panel always displays RFID

data in hexadecimal.

Line

Number

1

2

^XA

^FO50,50

^A0N,65

^FDSimple write example

^FS

3

^RFW,A

^FD00 rfid data

^FS

4

Resulting Label

^XZ

Type This ZPL Code Function of ZPL Code

Indicates start of label format.

Prints “Simple write example” on the label at

location 50,50.

W,A = write ASCII

Encodes 00 rfid data to the tag in hexadecimal

format, which is 12 bytes of data (96 bits). The

data written is:

303020726669642064617461

Indicates end of label format.

Programmed to Transponder

303020726669642064617461

Sample Control Panel Display

22

Page 23

Creating Basic RFID Label FormatsCreating Basic RFID Label Formats

112233445566778899001122

▼

READ RFID DATA

EPC

▲

11223344556677889900

1122

READ

RFID Label Format 3—Read Data from Tag and Print Data on Label

This example assumes that the tag created using RFID Label Format 1—Encode a Gen 2 Tag in

Hexadecimal on page 21 is being read.

Line

Number

1

2

^XA

^FO50,50

Type This ZPL Code Function of ZPL Code

^A0N,40

^FN0

^FS

3

^FN0

^RFR,H

^FS

4

Read from Transponder

^XZ

112233445566778899001122

Resulting Label

Indicates start of label format.

^FN0 is a placeholder field variable for the tag data

that will be read in the following line. When the

label prints, the data read from the tag will be

printed at location 50,50.

R,H = read hexadecimal

The read results are put into field variable 0 (

At this point, the printer substitutes previous

instances of

from this field. If necessary, the data read from the

tag will be padded with zeroes to the maximum bit

size.

Indicates end of label format.

^FN0 in the label format with the data

^FN0).

Sample Control Panel Display

23

Page 24

Creating Basic RFID Label FormatsCreating Basic RFID Label Formats

0data

RFID Label Format 4—Encode Tag, Read Tag, and Print Data on Label

Line

Number

1

2

^XA

^FO60,60

Type This ZPL Code Function of ZPL Code

^A0N,40

^FN7

^FS

3

^RFW,A

^FD0data

^FS

4

^FN7

^RFR,A

^FS

5

Programmed to Transponder

^XZ

Indicates start of label format.

When the label prints, the data read from the tag at

field variable 7 (

60,60.

W,A = write ASCII

Encodes 0data into the block in hexadecimal

format, padded with 8 bytes of zeroes to make the

data 12 bytes. The data written is:

306461746100000000000000

R,A = read ASCII

Reads the tag data into field variable 7 (

After this occurs, any fields in this label format that

^FN7 will be replaced with this read data.

have

Because ASCII format was specified, the

hexadecimal value is converted back to ASCII

format before being printed on the label.

Indicates end of label format.

^FN7) will be printed at location

^FN7).

306461746100000000000000

Read from Transponder

306461746100000000000000

Resulting Label

24

Page 25

Creating Basic RFID Label FormatsCreating Basic RFID Label Formats

▼

READ RFID DATA

EPC

▲

30646174610000000000

0000

READ

Sample Control Panel Display

25

Page 26

Creating Basic RFID Label FormatsCreating Basic RFID Label Formats

010203040500000000000000

RFID Label Format 5—Encode Tag, Read Tag, and Return Results to Host

Line

Number

1

2

3

4

5

6

Type This ZPL Code Function of ZPL Code

^XA

^FO50,50

^A0N,65

^FN3

^FS

^RFW,H

^FD0102030405

^FS

^FN3

^RFR,H

^FS

^HV3

^XZ

Indicates start of label format.

When the label prints, the data read from the tag at

field variable 3 (

50,50.

W,H = write hex

Encodes 12 bytes of data (96 bits) to the tag with

7 bytes of zeroes as padding. The data written is:

010203040500000000000000

R,H = read hexadecimal

Reads the tag data into field variable 3 (

After this occurs, any fields in this label format that

^FN3 will be replaced with this read data.

have

Returns the value in ^FN3 to the host computer.

Data is sent over whichever communication

channel is established with the host (such as

parallel, serial, USB, Ethernet). In this example,

010203040500000000000000 would be returned to

the host.

Indicates end of label format.

^FN3) will be printed at location

^FN3).

Programmed to Transponder

010203040500000000000000

Read from Transponder

010203040500000000000000

Resulting Label

26

Page 27

Creating Basic RFID Label FormatsCreating Basic RFID Label Formats

▼

READ RFID DATA

EPC

▲

01020304050000000000

0000

READ

Sample Control Panel Display

Sent to Host Computer

010203040500000000000000

27

Page 28

Troubleshooting

This section provides information about RFID operational errors that you might need to troubleshoot. For

other types of problems, consult the User Guide for your printer.

RFID Problems

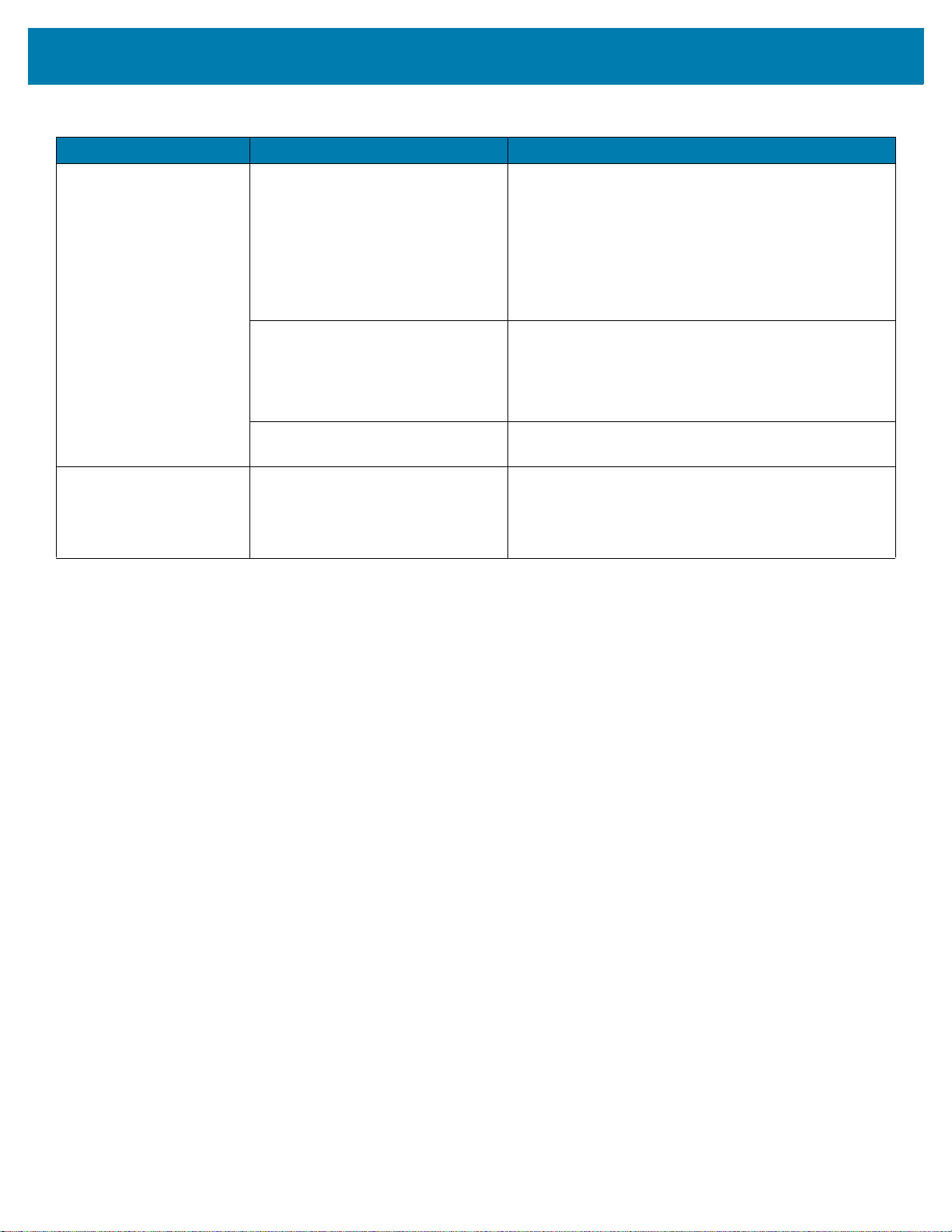

Table 2 identifies problems that may occur with RFID printers, the possible causes, and the recommended

solutions.

Table 2 RFID Problems

Problem Possible Cause Recommended Solution

The printer encodes the

wrong tag.

The printed data does not

match the encoded data.

RFID tag calibration fails. Some RFID inlays are more

The printer is not calibrated for the

media being used.

sensitive than others. The RFID

inlay being calibrated may be more

or less sensitive than others on the

same roll of media.

On ZQ511, ZQ521, and ZQ630

printers, the RFID inlays are placed

too close together.

1. Perform media calibration. Refer to the User Guide

for your printer for media calibration instructions.

2. Perform RFID tag calibration. (See Setting the

RFID Values Using Tag Calibration on page 13.)

3. If necessary, adjust the RFID settings manually.

(See RFID Printer Configuration on page 15.)

Perform RFID tag calibration again. (See Setting the

RFID Values Using Tag Calibration on page 13.)

1. Manually set the program position and read/write

power levels. (See RFID Printer Configuration on

page 15.)

2. Verify that the tags are being programmed with the

correct information.

Change the spacing of the RFID inlays.

28

Page 29

Table 2 RFID Problems (Continued)

Problem Possible Cause Recommended Solution

Low yields. Too many

RFID tags per roll are

voided.

Some RFID inlays are more

sensitive than others and may

require special printer settings.

TroubleshootingTroubleshooting

1. Perform RFID tag calibration. (See Setting the

RFID Values Using Tag Calibration on page 13.)

2. If necessary, adjust the RFID settings manually.

(See RFID Printer Configuration on page 15.)

3. If the problem persists, consider using a different

tag type. Contact an authorized Zebra RFID

reseller for more information.

The printer stops at the

RFID inlay.

Radio frequency (RF) interference

from another RF source.

The printer is using outdated

printer firmware.

The printer calibrated the label

length only to the RFID inlay

instead of to the interlabel gap.

Do one or more of the following as necessary:

• Move the printer away from fixed RFID readers.

• Make sure that the media door is closed at all

times during RFID programming.

Go to www.zebra.com/firmware for updated firmware.

1. Perform media calibration. Refer to the User Guide

for your printer for media calibration instructions.

2. Perform RFID tag calibration. (See Setting the

RFID Values Using Tag Calibration on page 13.)

29

Page 30

Table 2 RFID Problems (Continued)

Problem Possible Cause Recommended Solution

The RFID-enabled printer

voids every label.

The printer is not calibrated for the

media being used.

TroubleshootingTroubleshooting

1. Perform media calibration. Refer to the User Guide

for your printer for media calibration instructions.

2. Perform RFID tag calibration. (See Setting the

RFID Values Using Tag Calibration on page 13.)

3. If necessary, adjust the RFID settings manually.

(See RFID Printer Configuration on page 15.)

You are using an incorrect value for

the programming position or

another RFID setting.

You are sending RFID ZPL or SGD

commands that are incorrect.

The settings are incorrect in your

label designer software.

Radio frequency (RF) interference

from another RF source.

The printer is unable to

communicate with the RFID

reader/encoding module.

1. Perform RFID tag calibration. (See Setting the

RFID Values Using Tag Calibration on page 13.)

2. If necessary, adjust the RFID settings manually.

(See RFID Printer Configuration on page 15.)

1. Check your label formats. See ZPL Commands for

RFID on page 34 or SGD Commands for RFID on

page 61.

2. For sample label formats, see Sample RFID Label

Formats on page 21.

The software settings override the printer settings.

Make sure that the software and printer settings

match.

Do one or more of the following as necessary:

• Move the printer away from fixed RFID readers or

other RF sources.

• Make sure that the media door is closed at all

times during RFID programming.

1. Turn off (O) the printer.

2. Wait 10 seconds.

3. Turn on (I) the printer.

The DATA light flashes

indefinitely after you

attempt to download

printer firmware.

The download was not successful.

For best results, cycle power on the

printer before downloading any

firmware.

30

4. If the problem persists, you may have a bad

encoding module or a loose connection between

the encoding module and the printer. Contact

Technical Support or an authorized Zebra RFID

service technician for assistance.

1. Turn off (O) the printer.

2. Wait 10 seconds.

3. Turn on (I) the printer.

4. Attempt to download the firmware again.

5.

If the problem persists, contact Technical Support.

Page 31

Table 2 RFID Problems (Continued)

Problem Possible Cause Recommended Solution

RFID parameters do not

appear in Setup mode,

and RFID information

does not appear on the

printer configuration

label.

The printer does not void

RFID labels that are not

programmed correctly.

An incorrect version of firmware

was loaded on the printer.

The printer is unable to

communicate with the RFID

subsystem.

TroubleshootingTroubleshooting

1. Go to www.zebra.com/firmware

2. Download the correct printer firmware, if

necessary.

3. If the problem persists, contact Technical Support.

1. Turn off (O) the printer.

2. Wait 10 seconds.

3. Turn on (I) the printer.

4. If the problem persists, you may have a bad RFID

reader or a loose connection between the RFID

reader and the printer. Contact Technical Support

or an authorized service technician for assistance.

.

RFID is disabled. The SGD

command

"off".

rfid.enable is set to

1. Change

page 68.)

2. Restart your printer for changes to take effect.

rfid.enable to "on". (See rfid.enable on

RFID Error Codes and Messages

In the event of an RFID error, the printer does the following:

• displays an RFID error or status message on the second line of the

display

• returns RFID error codes to the RFID data log (see ^HL or ~HL on page 35 for more information about

the RFID data log)

Table 3 lists the error codes. Numbers that appear in the format “

individually.

Table 3 RFID Error Codes

Error Code

XXXXXXXX READER ERR XXXXXXXX

00000000 RFID OK The RFID operation completed successfully.

00001239 ENCODER ERROR An error occurred in the RFID encoder module firmware.

RFID Error or

Status Message

Description/Action Required

XXXXXXXX is 8 hex characters returned from the reader.

This error can indicate a read/write error with your RFID tag, or it could

indicate an internal problem with the RFID reader. If the problem persists,

contact Technical Support.

RFID STATUS control panel

READER ERR xxxxxxxx” are not listed

00001240 BAD RFID DATA The data that was attempted to be written to a tag is not valid.

00001241 RFID TEST ERROR An error occurred during an RFID test.

00001242 COUNTRY CODE ERROR The value of the country code that was sent to the RFID reader is not valid,

or the value was not specified. See RFID Country Code on page 15 for

more information.

00001244 NO READER PRESENT The printer does not detect an RFID reader.

02000100 DATA AMOUNT ERROR The wrong amount of data was specified in an RFID reader command.

31

Page 32

Table 3 RFID Error Codes (Continued)

TroubleshootingTroubleshooting

Error Code

02000101 INVALID OPCODE The command sent to the RFID reader module was invalid.

02000102 UNKNOWN OPCODE The command sent to the RFID reader module is not known by the module

02000103 RFID PWR TOO HIGH An attempt was made to set the power of the RFID reader to a value that is

02000104 INVALID FREQUENCY The frequency selected in an RFID command to reader module is not valid.

02000105 INVALID PARAMETER A parameter of an RFID command for the reader module is not valid.

02000106 RFID PWR TOO LOW An attempt was made to set the power of the RFID reader to a value that is

02000109 INVALID COMMAND The command sent to the RFID reader module was invalid.

02000200 BAD IMAGE CRC The RFID reader firmware had a bad validation checksum.

02000201 READER FW ERROR An error occurred in the RFID reader module.

02000300 RFID FLASH ERROR An error occurred while attempting to write firmware to the RFID reader

02000301

02000302

02000303

02000304

02000305

02000306

02000400 NO TAG FOUND The reader attempted to locate an RFID tag and was unable to do so.

RFID Error or

Status Message

Description/Action Required

firmware.

too large.

too small.

module.

02000401 PROTOCOL UNDEFINED The RFID reader was not properly told the type of RFID tag.

02000402 INVALID PROTOCOL The type of RFID tag that the RFID reader was told to expect is not valid.

02000403 LOCK ERROR An error occurred while attempting to change the lock bits on the tag.

02000404 NO DATA READ An attempt to read data from a tag could not find any data.

02000405 AFE NOT ON The reader module does not have the AFE on.

02000406 WRITE FAILED The tag write failed.

02000407 NOT IMPLEMENTED The RFID reader command that was sent to the reader is not implemented

in this version of reader firmware.

02000408 INVALID WRITE DATA The data that was attempted to be written to a tag is not valid.

02000409 INVALID ADDRESS The memory address for data to be written to a tag is not valid.

02000410 PROTOCOL BAD EPC The protocol definition is inconsistent with the size of the EPC data area.

02000411 PROT BAD NUM DATA The protocol definition is inconsistent with the amount of data sent.

02000420 GEN2 PROTOCOL ERR An error was made in the specification of a Generation 2 tag protocol.

02000423 GEN2 MEMORY BAD PC An error was made in the specification of a Generation 2 tag protocol control

bit.

02000424 GEN2 MEMORY LOCKED The Generation 2 tag memory area is locked.

02000430 GEN2 UNKNOWN ERROR An unknown error was made with a Generation 2 tag.

02000500 TRANSMITTER ON The RFID radio transmitter is on.

32

Page 33

Table 3 RFID Error Codes (Continued)

TroubleshootingTroubleshooting

Error Code

02000503 NO ANTENNA FOUND The RFID reader module found that no antenna was connected.

02000504 RFID TOO HOT The RFID reader module is too hot.

02000505 HIGH RETURN LOSS The amount of energy being reflected by the antenna connection is higher

02000507 BAD ANTENNA CFG An attempt was made to set the reader module to an invalid antenna

02000600 NOT ENOUGH TAGS The RFID module memory contained data from fewer tags than was

02000601 TAG ID BUFFER FULL The RFID module memory is full.

02000602 REPEATED TAG ID An attempt was made to write data to the RFID module memory with an ID

02000603 TOO MANY TAG IDS The RFID reader was asked to read more tags into module memory than

02000604 BLOCKED RESPONSE The RFID module response is blocked.

02001001 RDR COMM TIMEOUT An attempt to communicate with the reader module took too much time.

02001238 PRINTER ERROR The printer caused an error.

02001242 COUNTRY CODE ERROR The RFID country code is not selected.

0200010A INVALID BAUD RATE An attempt was made to set the serial communication baud rate of the RFID

0200010B INVALID REGION An attempt was made to set the region of the RFID reader to a value that is

0200010C BAD LICENSE KEY The RFID reader firmware's license key does not match the RFID reader

RFID Error or

Status Message

Description/Action Required

than acceptable.

configuration.

requested by printer firmware.

that is already present in the memory.

the module could hold.

reader to a value that is not valid.

not valid.

firmware.

0200040A GENERAL TAG ERROR Miscellaneous error while attempting to read or write to a tag.

0200040B DATA TOO LARGE Too much data was attempted to be written to a tag.

0200040F PROT BIT DCDNG BAD Protocol bit decoding failure.

0200042B GEN2 LOW POWER The Generation 2 tag is set to low power mode.

0200042F GEN2 ERROR An unspecified error was made with a Generation 2 tag.

02007F00 SYS UNKNOWN ERROR A firmware routine in the RFID reader module firmware returned an

unknown error.

02007F01 TM ASSERT FAILED An unexpected internal error has occurred in the RFID reader module

firmware.

33

Page 34

ZPL Commands for RFID

This section contains the ZPL II commands for RFID-specific applications.

34

Page 35

^HL or ~HL

Return RFID Data Log to Host

Description: The printer can log RFID data and store it in the printer’s RAM. These commands request

that the RFID data log be returned to the host computer. The

while the

The firmware version determines the way that these commands function:

^HL command is processed after all of the previous formats (^XA ... ^XZ) have been processed.

ZPL Commands for RFID

~HL command is processed immediately,

• In firmware X.20.16Z and later, for security, logging is disabled by default. The

current data log and restarts data recording. The

log. The RFID host logs can be enabled or disabled by the "rfid.log.enabled" SGD command (see

rfid.log.entries on page 73).

• In firmware X.20.15Z and earlier, logging is enabled by default. Both commands clear the current data

log and restart data recording.

Format:

In the log, RFID data displays in this format:

[date&time][RFID operation],[program position],[antenna element],

[read or write power], [RFID status],[data]

where

•

•

^HL or ~HL

[date&time]*

a time stamp for the log entry

* With some older versions of firmware, this parameter does not display.

[RFID operation]

B = a ^RLB command was issued (see ^RLB – Permanently Lock Specified Memory Sections on

page 51)

E = log file reset

L = lock

M = a ^RLM command was issued (see ^RLM – Lock/Unlock the Specified Memory Bank on page 50)

R = read

W = write

~HL command does not automatically clear the data

^HL command clears the

•

[program position],[antenna element],[read or write power]*

Additional information about the program position, the antenna, and the read or write power follows the

RFID operation.

Such as:

R,F1,D3,27,00000000,DATA

where

F1 = the program position, D3 = the antenna, and 27 is the write power.

* With some older versions of firmware, these parameters do not display.

• [RFID status]

######## = an RFID error code (see RFID Error Codes and Messages on page 43)

FFFFFFFF (or limited to length FFFF for some printers) = indicates that the log file was reset

•

[data]

the data read or written

Comments:

• Data is shown in the format specified by the

^RFW command (ASCII, Hex, or EPC).

35

Page 36

ZPL Commands for RFID

• If the RFID data log exceeds the maximum size, the following occurs:

• In firmware X.20.16Z and later, when the data log reaches 1500K, one or more older entries are

deleted to make room for the newest entry.

• In firmware X.20.15Z and earlier, when the data log reaches 64K, the RFID data log is cleared

automatically, and data recording restarts. When this happens, the following appears in the log:

E,FFFFFFFF,Logfile automatically reset

• In firmware X.20.15Z and earlier, If the printer loses power, the log is lost. If the log results are

important to you, retrieve the information frequently.

36

Page 37

^HR

Calibrate RFID Tag Position

Description: Use this command to initiate tag calibration for RFID media. During the tag calibration

process (which can take up to 5 minutes on some printers, depending on the type of RFID inlay and the

label size) the printer moves the media, reads the tag’s TID to determine chip type, calibrates the RFID tag

position, and determines the optimal settings for the RFID media being used. Depending on the printer,

these settings include the programming position, the antenna element to use, and the read/write power

level to use.

ZPL Commands for RFID

Results of the

rfid.tag.calibrate SGD command performs the same calibration but does not create a results table. To

restore the printer’s default programming position at any time, use the

rfid.tag.calibrate SGD command (see rfid.tag.calibrate on page 84).

Before running this command, load the printer with RFID media, calibrate your printer, close the printhead,

and feed at least one label to make sure that tag calibration will begin from the correct position. For more

information on media calibration, refer to the User Guide for your printer.

IMPORTANT: Leave all transponders before and after the tag that is being calibrated. This allows the

printer to determine RFID settings which do not encode the adjacent tag. Allow a portion of media to

extend out the front of the printer to allow for backfeed during the tag calibration procedure.

Format:

a = start string This parameter specifies the user text to appear before the results table.

b = end string This parameter specifies the user text to appear after the results table.

^HR tag calibration are returned to the host computer. The "run" option in the

"restore" option in the

^HRa,b,c,d,e

Parameters Details

Values: any string less than 65 characters

Default: start

Values: any string less than 65 characters

Default: end

37

Page 38

ZPL Commands for RFID

Parameters Details

c = start position This parameter specifies the start position of the calibration range. All

numeric values are in millimeters. Forward or backward designations

assume that the label's initial position is with the leading edge at the print

line.

Values:

•Forward:

F0 to Fxxx (where xxx is the label length in millimeters or 999,

whichever is less)

The printer feeds the label forward for the specified distance and then

begins tag calibration.

• Backward:

B0 to B30

The printer backfeeds the label for the specified distance and then

begins tag calibration. To account for the backfeed, allow empty media

liner to extend out of the front of the printer when using a backward

programming position. For printers that do not use backfeed during

RFID calibration, the media is moved forward until it is in the same

relative position for the following label.

Default:

• For ZT400 Series and ZT600 Series printers with RFID option:

• For all other supported printers:

d = end position This parameter specifies the end position of the calibration range (last

B20

B30

program position to check). All numeric values are in millimeters. Forward

or backward designations assume that the label's initial position is with the

leading edge at the print line.

Values:

•Forward:

F0 to Fxxx (where xxx is the label length in millimeters or 999,

whichever is less)

The printer performs tag calibration until it reaches the specified end

position and then ends the process.

• Backward:

B0 to B30

The printer performs tag calibration until it reaches the specified end

position and then ends the process. Valid only with a backward start

position that is greater than the end position.

• Automatic:

A

The printer automatically ends the tag calibration process after

successfully reading and encoding a consecutive range of 5 mm on the

label. The printer also ensures that no other tags can be programmed at

the programming position with the calibration-determined power levels.

Default:

A

38

Page 39

Parameters Details

e = antenna and

read/write power level

detection

ZPL Commands for RFID

This parameter specifies whether to select the antenna and read/write

power levels automatically or manually.

NOTE: The ZD500R, ZQ511/ZQ521, and ZQ630 printers have only

one antenna, so this parameter applies only to the read/write power

level settings.

Values:

•

A = Automatic. The printer automatically scans through the antennas

and read/write power during calibration.

•

M = Manual. The printer uses the current antenna and read/write power

level settings.

Default:

A

39

Page 40

ZPL Commands for RFID

Example: When the ^HR command is sent to the printer, the printer performs tag calibration and returns a

results table such as the following:

start

position=B14 MM,A1,18,25

tid information=E200.3414:Alien

leading edge

Tag 1 ,Tag 2 ,Tag 3 ,Tag 4 ,Tag 5 ,Tag 1 ,Tag 2 ,Tag 3 ,Tag 4 ,Tag 5 ,

EPC,7109 ,BA29 ,6FD0 ,58AE ,9CDE ,7109 ,BA29 ,6FD0 ,58AE ,9CDE ,

B30,A1,12,18,A1,29, ,A1, , ,A1, , ,A1, , ,B1, , ,B1,17,24,B1, , ,B1, , ,B1, , ,

B29,A1,13,18,A1,25, ,A1, , ,A1, , ,A1, , ,B1, , ,B1,14,19,B1, , ,B1, , ,B1, , ,

B28,A1,15,20,A1,23,29,A1, , ,A1, , ,A1, , ,B1, , ,B1,09,15,B1, , ,B1, , ,B1, , ,

B27,A1,17,22,A1,23,29,A1, , ,A1, , ,A1, , ,B1, , ,B1,08,14,B1, , ,B1, , ,B1, , ,

B26,A1,19,25,A1, , ,A1, , ,A1, , ,A1, , ,B1, , ,B1,09,15,B1,28, ,B1, , ,B1, , ,

B25,A1,22,28,A1,22,27,A1, , ,A1, , ,A1, , ,B1, , ,B1,11,18,B1,26, ,B1, , ,B1, , ,

B24,A1,26, ,A1,13,19,A1, , ,A1, , ,A1, , ,B1, , ,B1,15,21,B1,27, ,B1, , ,B1, , ,

B23,A1, , ,A1,08,14,A1, , ,A1, , ,A1, , ,B1, , ,B1,18,24,B1, , ,B1, , ,B1, , ,

B22,A1, , ,A1,05,11,A1, , ,A1, , ,A1, , ,B1, , ,B1,21,28,B1,19,24,B1, , ,B1, , ,

B21,A1, , ,A1,05,11,A1, , ,A1, , ,A1, , ,B1, , ,B1,25, ,B1,11,17,B1, , ,B1, , ,

B20,A1, , ,A1,06,12,A1, , ,A1, , ,A1, , ,B1, , ,B1,30, ,B1,07,13,B1, , ,B1, , ,

B19,A1, , ,A1,08,15,A1, , ,A1, , ,A1, , ,B1, , ,B1, , ,B1,05,11,B1, , ,B1, , ,

B18,A1, , ,A1,15,22,A1, , ,A1, , ,A1, , ,B1, , ,B1, , ,B1,05,10,B1, , ,B1, , ,

B17,A1, , ,A1,22,28,A1, , ,A1, , ,A1, , ,B1, , ,B1, , ,B1,05,11,B1, , ,B1, , ,

B16,A1, , ,A1,16,23,A1, , ,A1, , ,A1, , ,B1, , ,B1, , ,B1,07,13,B1, , ,B1, , ,

B15,A1, , ,A1,13,19,A1, , ,A1, , ,A1, , ,B1, , ,B1, , ,B1,13,20,B1, , ,B1, , ,

B14,A1, , ,A1,12,19,A1, , ,A1, , ,A1, , ,B1, , ,B1, , ,B1,18,23,B1, , ,B1, , ,<---****A1

B13,A1, , ,A1,14,20,A1,24,30,A1, , ,A1, , ,B1, , ,B1, , ,B1,10,16,B1, , ,B1, , ,

B12,A1, , ,A1,15,22,A1,22,29,A1, , ,A1, , ,B1, , ,B1, , ,B1,08,14,B1, , ,B1, , ,

B11,A1, , ,A1,18,25,A1,26, ,A1, , ,A1, , ,B1, , ,B1, , ,B1,08,14,B1, , ,B1, , ,

B10,A1, , ,A1,21,27,A1,26, ,A1, , ,A1, , ,B1, , ,B1, , ,B1,11,17,B1,26, ,B1, , ,

B09,A1, , ,A1,24, ,A1,15,21,A1, , ,A1, , ,B1, , ,B1, , ,B1,14,20,B1,25, ,B1, , ,

B08,A1, , ,A1,28, ,A1,09,15,A1, , ,A1, , ,B1, , ,B1, , ,B1,17,23,B1, , ,B1, , ,

B07,A1, , ,A1, , ,A1,06,11,A1, , ,A1, , ,B1, , ,B1, , ,B1,20,26,B1,27,30,B1, , ,

B06,A1, , ,A1, , ,A1,05,11,A1, , ,A1, , ,B1, , ,B1, , ,B1,24,30,B1,16,19,B1, , ,

B05,A1, , ,A1, , ,A1,05,11,A1, , ,A1, , ,B1, , ,B1, , ,B1,28, ,B1,10,14,B1, , ,

B04,A1, , ,A1, , ,A1,08,14,A1, , ,A1, , ,B1, , ,B1, , ,B1, , ,B1,07,11,B1, , ,

B03,A1, , ,A1, , ,A1,12,18,A1, , ,A1, , ,B1, , ,B1, , ,B1, , ,B1,06,11,B1, , ,

B02,A1, , ,A1, , ,A1,20,26,A1, , ,A1, , ,B1, , ,B1, , ,B1, , ,B1,06,10,B1, , ,

B01,A1, , ,A1, , ,A1,18,24,A1, , ,A1, , ,B1, , ,B1, , ,B1, , ,B1,09,13,B1, , ,

F00,A1, , ,A1, , ,A1,14,21,A1, , ,A1, , ,B1, , ,B1, , ,B1, , ,B1,12,17,B1, , ,

F01,A1, , ,A1, , ,A1,13,19,A1, , ,A1, , ,B1, , ,B1, , ,B1, , ,B1,20,25,B1, , ,

F02,A1, , ,A1, , ,A1,13,19,A1,27, ,A1, , ,B1, , ,B1, , ,B1, , ,B1,16,20,B1, , ,

F03,A1, , ,A1, , ,A1,14,21,A1,26,29,A1, , ,B1, , ,B1, , ,B1, , ,B1,11,16,B1, , ,

F04,A1, , ,A1, , ,A1,17,24,A1,27, ,A1, , ,B1, , ,B1, , ,B1, , ,B1,11,15,B1, , ,

F05,A1, , ,A1, , ,A1,19,26,A1, , ,A1, , ,B1, , ,B1, , ,B1, , ,B1,12,16,B1,25, ,

F06,A1, , ,A1, , ,A1,22,29,A1,23,26,A1, , ,B1, , ,B1, , ,B1, , ,B1,15,18,B1,23,28,

F07,A1, , ,A1, , ,A1,26, ,A1,15,19,A1, , ,B1, , ,B1, , ,B1, , ,B1,17,22,B1,23,29,

F08,A1, , ,A1, , ,A1, , ,A1,10,14,A1, , ,B1, , ,B1, , ,B1, , ,B1,20,25,B1, , ,

F09,A1, , ,A1, , ,A1, , ,A1,08,12,A1, , ,B1, , ,B1, , ,B1, , ,B1,24,28,B1,21,26,

F10,A1, , ,A1, , ,A1, , ,A1,08,11,A1, , ,B1, , ,B1, , ,B1, , ,B1,27, ,B1,13,18,

trailing edge

end

In the results table, the tags visible to the antenna elements are numbered, and the EPC number that is

unique to each tag is displayed.

40

Page 41

ZPL Commands for RFID

Each line in the results table gives a row number followed by readings associated with RFID tags that are

visible at that row. Multiple values on a line indicate that multiple tags were visible. The order of the RFID

tags is arbitrary.

[Row],[Antenna Element],[Min Read Power],[Min Write Power], [Antenna Element],[Min Read Power],[Min Write Power] ...

where

• Row = the position from the leading edge of the label where calibration occurred

• Antenna Element = the antenna used

• Minimum Read Power = calibration results (

• Minimum Write Power = calibration results (

The read and write power values are left empty (such as

In the sample results table for this example, at position

0 – 30) for a tag visible from that row

0 – 30) for the same tag

A1,,,) when no tag is found.

B25 (25 mm behind the print line), two RFID tags

are visible to the printer at antenna A1. Tag 1 (EPC 7109) can be read at power level 22 and written to at

power level 28. Tag 2 (EPC BA29) can be read at power level 22 and written to at power level 27. At that

position, Tags 2 and 3 are visible to antenna B1 while Tag 1 is not.

Tag 1 ,Tag 2 ,Tag 3 ,Tag 4 ,Tag 5 ,Tag 1 ,Tag 2 ,Tag 3 ,Tag 4 ,Tag 5 ,

EPC,7109 ,BA29 ,6FD0 ,58AE ,9CDE ,7109 ,BA29 ,6FD0 ,58AE ,9CDE ,

...

B25,A1,22,28,A1,22,27,A1, , ,A1, , ,A1, , ,B1, , ,B1,11,18,B1,26, ,B1, , ,B1, , ,

B24,A1,26, ,A1,13,19,A1, , ,A1, , ,A1, , ,B1, , ,B1,15,21,B1,27, ,B1, , ,B1, , ,

B23,A1, , ,A1,08,14,A1, , ,A1, , ,A1, , ,B1, , ,B1,18,24,B1, , ,B1, , ,B1, , ,

B22,A1, , ,A1,05,11,A1, , ,A1, , ,A1, , ,B1, , ,B1,21,28,B1,19,24,B1, , ,B1, , ,

B21,A1, , ,A1,05,11,A1, , ,A1, , ,A1, , ,B1, , ,B1,25, ,B1,11,17,B1, , ,B1, , ,

...

At position B23, only Tag 2 is visible to antenna A1. Tag 1 is no longer visible.

Tag 1 ,Tag 2 ,Tag 3 ,Tag 4 ,Tag 5 ,Tag 1 ,Tag 2 ,Tag 3 ,Tag 4 ,Tag 5 ,

EPC,7109 ,BA29 ,6FD0 ,58AE ,9CDE ,7109 ,BA29 ,6FD0 ,58AE ,9CDE ,

...

B25,A1,22,28,A1,22,27,A1, , ,A1, , ,A1, , ,B1, , ,B1,11,18,B1,26, ,B1, , ,B1, , ,

B24,A1,26, ,A1,13,19,A1, , ,A1, , ,A1, , ,B1, , ,B1,15,21,B1,27, ,B1, , ,B1, , ,

B23,A1, , ,A1,08,14,A1, , ,A1, , ,A1, , ,B1, , ,B1,18,24,B1, , ,B1, , ,B1, , ,

B22,A1, , ,A1,05,11,A1, , ,A1, , ,A1, , ,B1, , ,B1,21,28,B1,19,24,B1, , ,B1, , ,

B21,A1, , ,A1,05,11,A1, , ,A1, , ,A1, , ,B1, , ,B1,25, ,B1,11,17,B1, , ,B1, , ,

...

At position B13, Tag 3 (EPC 6FD0) becomes visible to antenna A1 and can be read with at power level 24

and written to at power level 30.

Tag 1 ,Tag 2 ,Tag 3 ,Tag 4 ,Tag 5 ,Tag 1 ,Tag 2 ,Tag 3 ,Tag 4 ,Tag 5 ,

EPC,7109 ,BA29 ,6FD0 ,58AE ,9CDE ,7109 ,BA29 ,6FD0 ,58AE ,9CDE ,

...

B16,A1, , ,A1,16,23,A1, , ,A1, , ,A1, , ,B1, , ,B1, , ,B1,07,13,B1, , ,B1, , ,

B15,A1, , ,A1,13,19,A1, , ,A1, , ,A1, , ,B1, , ,B1, , ,B1,13,20,B1, , ,B1, , ,

B14,A1, , ,A1,12,19,A1, , ,A1, , ,A1, , ,B1, , ,B1, , ,B1,18,23,B1, , ,B1, , ,<---****A1

B13,A1, , ,A1,14,20,A1,24,30,A1, , ,A1, , ,B1, , ,B1, , ,B1,10,16,B1, , ,B1, , ,

...

41

Page 42

ZPL Commands for RFID

The arrow (<---****) in the table indicates that a valid program position and power levels were found

during calibration. The program position is identified at the top of the table as

14 millimeters). The optimal antenna element at that position is A1. The optimal read power is 18, and the

optimal write power is 25.

start

position=B14 MM,A1,18,25

tid information=E200.3414:Alien

leading edge

...

B14,A1, , ,A1,12,19,A1, , ,A1, , ,A1, , ,B1, , ,B1, , ,B1,18,23,B1, , ,B1, , ,<---****A1

...

position=B14 MM (backfeed

42

Page 43

^HV

Host Verification

Use this command to return data from specified fields, along with an optional ASCII header, to the host

computer. You can use this command with any field that has been assigned a number with the

commands.

ZPL Commands for RFID

^FN and ^RF

Format:

#= field number specified

with another command

n = number of bytes to be

returned

h = header to be returned

with the data

t = termination This field is Field Hex (^FH) capable.

a = command applies to When ^PQ is greater than 1 or if a void label occurs, send one response for

^HV#,n,h,t,a

Parameters Details

The value assigned to this parameter should be the same as the one used

in another command.

Values:

Default: 0

Values:

Default: 64

Delimiter characters terminate the string. This field is Field Hex (^FH)

capable.

Values:

Default: no header

Values: 0 to 3072 characters

a label format or one for every label printed.