Zebra MS4717 Integration Manual

MS4717

Fixed Mount Imager

Integration Guide

Draft V1.0

MN-003432-01

Copyright

© 2019 ZIH Corp. and/or its affiliates. All rights reserved. ZEBRA and the stylized Zebra head are trademarks of

ZIH Corp., registered in many jurisdictions worldwide. All other trademarks are the property of their respective

owners.

COPYRIGHTS & TRADEMARKS: For complete copyright and trademark information, go to www.zebra.com/

copyright.

WARRANTY: For complete warranty information, go to www.zebra.com/warranty.

END USER LICENSE AGREEMENT: For complete EULA information, go to www.zebra.com/eula.

Terms of Use

• Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation and its subsidiaries

(“Zebra Technologies”). It is intended solely for the information and use of parties operating and

maintaining the equipment described herein. Such proprietary information may not be used, reproduced,

or disclosed to any other parties for any other purpose without the express, written permission of Zebra

Technologies.

• Product Improvements

Continuous improvement of products is a policy of Zebra Technologies. All specifications and designs are

subject to change without notice.

• Liability Disclaimer

Zebra Technologies takes steps to ensure that its published Engineering specifications and manuals are

correct; however, errors do occur. Zebra Technologies reserves the right to correct any such errors and

disclaims liability resulting therefrom.

• Limitation of Liability

In no event shall Zebra Technologies or anyone else involved in the creation, production, or delivery of the

accompanying product (including hardware and software) be liable for any damages whatsoever

(including, without limitation, consequential damages including loss of business profits, business

interruption, or loss of business information) arising out of the use of, the results of use of, or inability to

use such product, even if Zebra Technologies has been advised of the possibility of such damages. Some

jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

Revision History

Changes to the original guide are listed below:

Change Date Description

Initial Draft 1/2019 Draft Version 1.0

2

Table of Contents

Copyright ........................................................................................................................................... 2

Terms of Use .................................................................................................................................... 2

Revision History ................................................................................................................................ 2

About This Guide

Introduction ........................................................................................................................................ i

Chapter Descriptions ......................................................................................................................... i

Notational Conventions ..................................................................................................................... ii

Related Documents .......................................................................................................................... ii

Service Information ........................................................................................................................... ii

Getting Started

Introduction ....................................................................................................................................... 3

MS4717 Features ........................................................................................................................ 4

Theory of Operation .......................................................................................................................... 4

MS4717 Block Diagram Descriptions .......................................................................................... 5

MS4717 Decoder/Interface Board ............................................................................................... 5

Power Management .............................................................................................................. 5

123Scan

Introduction ....................................................................................................................................... 6

123Scan ............................................................................................................................................ 6

Communication with 123Scan ..................................................................................................... 7

123Scan Requirements ............................................................................................................... 7

123Scan Information ................................................................................................................... 7

Scanner SDK, Other Software Tools, and Videos ...................................................................... 8

Advanced Data Formatting (ADF) ..................................................................................................... 8

Introduction ....................................................................................................................................... 9

Mounting ........................................................................................................................................... 9

MS4717 Mounting Dimensions ................................................................................................... 9

Connecting the MS4717 ................................................................................................................. 12

USB Host Connection ............................................................................................................... 12

Accessories ..................................................................................................................................... 13

Location and Positioning ................................................................................................................. 13

Window Material ........................................................................................................................ 14

Cell Cast Acrylic (ASTM: PMMA) .............................................................................................. 14

Cell Cast ADC (ASTM: ADC) .................................................................................................... 14

Chemically Tempered Glass ..................................................................................................... 14

Commercially Available Coatings ................................................................................................... 15

Anti-Reflection Coatings ......................................

Polysiloxane Coating ................................................................................................................. 15

A Word About Coatings ............................................................................................................. 15

Embedded Window Angle and Position .................................................................................... 16

Optical Path .................................................................................................................................... 17

Recommended Exit Window Information ........................................................................................ 18

Exit Window Notes .................................................................................................................... 18

Zebra SNAPI Software Developer's Kit ........................................................................................... 19

...................................................................... 15

3

Table of Contents

Scanning

Introduction ..................................................................................................................................... 20

Imaging System .............................................................................................................................. 20

Aiming System .......................................................................................................................... 20

Aiming with MS4717 ................................................................................................................. 20

Aiming Error .............................................................................................................................. 20

Aiming Control ........................................................................................................................... 20

Illumination System ................................................................................................................... 21

Illumination Control ................................................................................................................... 21

Frame Rate Control ................................................................................................................... 21

Supported Symbologies .................................................................................................................. 21

Operating Modes ............................................................................................................................ 22

Specifications

MS4717 Technical Specifications .................................................................................................. 23

Skew, Pitch and Roll ................................................................................................................. 25

Decode Zones ................................................................................................................................. 26

Maintenance and Troubleshooting

Overview ......................................................................................................................................... 27

Maintenance ................................................................................................................................... 27

Troubleshooting .............................................................................................................................. 27

User Preferences

Introduction ..................................................................................................................................... 29

Scanning Sequence Examples ....................................................................................................... 30

Errors While Scanning .................................................................................................................... 30

User Preferences Parameter Defaults ............................................................................................ 30

User Preferences ............................................................................................................................ 32

Default Parameters ................................................................................................................... 32

Parameter Barcode Scanning ................................................................................................... 33

Beep After Good Decode .......................................................................................................... 33

Direct Decode Indicator ............................................................................................................. 34

Beeper Volume ......................................................................................................................... 35

Beeper Tone ............................................................................................................................. 36

Beeper Duration ........................................................................................................................ 37

Suppress Power Up Beeps ....................................................................................................... 37

Low Power Mode ...................................................................................................................... 38

Hands-free Decode Aiming Pattern .......................................................................................... 41

Picklist Mode ................................................................................................................

Continuous Barcode Read ........................................................................................................ 43

Unique Barcode Reporting ........................................................................................................ 43

Decode Session Timeout .......................................................................................................... 44

Hands-free Decode Session Timeout ....................................................................................... 44

Timeout Between Decodes, Same Symbol ............................................................................... 45

Decode Mirror Images (Data Matrix Only) ................................................................................ 46

Mobile Phone/Display Mode ..................................................................................................... 47

PDF Prioritization ...................................................................................................................... 48

............. 42

4

Table of Contents

PDF Prioritization Timeout ........................................................................................................ 49

Presentation Mode Field of View .............................................................................................. 49

Decoding Illumination ................................................................................................................ 50

Add an Enter Key ...................................................................................................................... 50

Transmit Code ID Character ..................................................................................................... 51

Prefix/Suffix Values ................................................................................................................... 52

Scan Data Transmission Format ............................................................................................... 53

FN1 Substitution Values ............................................................................................................ 54

Transmit “No Read” Message ................................................................................................... 55

Unsolicited Heartbeat Interval ................................................................................................... 56

Dump Scanner Parameters ....................................................................................................... 57

Imager Preferences

Introduction ..................................................................................................................................... 58

Scanning Sequence Examples ....................................................................................................... 59

Errors While Scanning .................................................................................................................... 59

Imaging Preferences Parameter Defaults ....................................................................................... 59

Imaging Preferences ....................................................................................................................... 61

Operational Modes .................................................................................................................... 61

Decode Mode ...................................................................................................................... 61

Snapshot Mode ................................................................................................................... 61

Image Capture Illumination ....................................................................................................... 62

Image Capture Autoexposure ................................................................................................... 62

Fixed Exposure ......................................................................................................................... 63

Fixed Gain ................................................................................................................................. 63

Gain/Exposure Priority for Snapshot Mode ............................................................................... 64

Snapshot Mode Timeout ........................................................................................................... 65

Snapshot Aiming Pattern .......................................................................................................... 66

Silence Operational Mode Changes ......................................................................................... 66

Image Cropping ......................................................................................................................... 67

Crop to Pixel Addresses ............................................................................................................ 68

Image Size (Number of Pixels) ................................................................................................. 69

Image Brightness (Target White) .............................................................................................. 70

JPEG Image Options ................................................................................................................ 70

JPEG Target File Size ............................................................................................................... 71

JPEG Quality and Size Value ................................................................................................... 71

Image Enhancement ................................................................................................................. 72

Image File Format Selector ....................................................................................................... 73

Image Rotation .......................................................................................................................... 74

Bits Per Pixel ............................................................................................................................. 75

USB Interface

Introduction ..................................................................................................................................... 76

Connecting a USB Interface ........................................................................................................... 76

USB Parameter Defaults ................................................................................................................. 78

USB Host Parameter ...................................................................................................................... 79

USB Device Type ...................................................................................................................... 79

Symbol Native API (SNAPI) Status Handshaking ..................................................................... 81

USB Keystroke Delay ................................................................................................................ 82

5

Table of Contents

USB CAPS Lock Override ......................................................................................................... 82

USB Ignore Unknown Characters ............................................................................................. 83

USB Convert Unknown to Code 39 ........................................................................................... 83

Emulate Keypad ........................................................................................................................ 84

Emulate Keypad with Leading Zero .......................................................................................... 84

Quick Keypad Emulation ........................................................................................................... 85

USB Keyboard FN 1 Substitution .............................................................................................. 85

Function Key Mapping .............................................................................................................. 86

Simulated Caps Lock ................................................................................................................ 86

Convert Case ............................................................................................................................ 87

USB Static CDC ........................................................................................................................ 87

Optional USB Parameters ............................................................................................................... 88

Ignore Beep ............................................................................................................................... 88

Ignore Barcode Configuration ................................................................................................... 88

USB Polling Interval .................................................................................................................. 89

USB Fast HID ............................................................................................................................ 91

IBM Specification Version ......................................................................................................... 91

ASCII Character Set for USB .......................................................................................................... 91

Symbologies

Introduction ..................................................................................................................................... 92

Scanning Sequence Examples ....................................................................................................... 92

Errors While Scanning .................................................................................................................... 92

Symbology Parameter Defaults ...................................................................................................... 93

Enable/Disable All Code Types ...................................................................................................... 98

UPC/EAN ........................................................................................................................................ 99

Enable/Disable UPC-A .............................................................................................................. 99

Enable/Disable UPC-E .............................................................................................................. 99

Enable/Disable UPC-E1 .......................................................................................................... 100

Enable/Disable EAN-8/JAN-8 ................................................................................................. 100

Enable/Disable EAN-13/JAN-13 ............................................................................................. 101

Enable/Disable Bookland EAN ................................................................................................ 101

Decode UPC/EAN/JAN Supplementals .................................................................................. 102

User-Programmable Supplementals ....................................................................................... 105

UPC/EAN/JAN Supplemental Redundancy ............................................................................ 105

UPC/EAN/JAN Supplemental AIM ID Format ......................................................................... 106

UPC Reduced Quiet Zone ...................................................................................................... 107

Transmit UPC-A Check Digit ................................................................................................... 107

Transmit UPC-E Check Digit ................................................................................................... 108

Transmit UPC-E1 Check Digit ................................................................................................. 108

UPC-A Preamble ..................................................................................................................... 109

UPC-E Preamble ..................................................................................................................... 110

UPC-E1 Preamble ................................................................................................................... 111

Convert UPC-E to UPC-A ....................................................................................................... 112

Convert UPC-E1 to UPC-A ..................................................................................................... 112

EAN-8/JAN-8 Extend .............................................................................................................. 113

Bookland ISBN Format ........................................................................................................... 113

UCC Coupon Extended Code ................................................................................................. 114

Coupon Report ........................................................................................................................ 115

ISSN EAN ............................................................................................................................... 115

6

Table of Contents

Code 128 ...................................................................................................................................... 116

Enable/Disable Code 128 ....................................................................................................... 116

Set Lengths for Code 128 ....................................................................................................... 117

Enable/Disable GS1-128 (formerly UCC/EAN-128) ................................................................ 118

Enable/Disable ISBT 128 ........................................................................................................ 118

ISBT Concatenation ................................................................................................................ 119

Check ISBT Table ................................................................................................................... 120

ISBT Concatenation Redundancy ........................................................................................... 120

Code 128 Security Level ......................................................................................................... 121

Code 128 Reduced Quiet Zone .............................................................................................. 122

Ignore Code 128 <FNC4> ....................................................................................................... 122

Code 39 ........................................................................................................................................ 123

Enable/Disable Code 39 ......................................................................................................... 123

Enable/Disable Trioptic Code 39 ............................................................................................. 123

Convert Code 39 to Code 32 .................................................................................................. 124

Code 32 Prefix ........................................................................................................................ 124

Set Lengths for Code 39 ......................................................................................................... 125

Code 39 Check Digit Verification ............................................................................................ 127

Transmit Code 39 Check Digit ................................................................................................ 127

Code 39 Full ASCII Conversion .............................................................................................. 128

Code 39 Security Level ........................................................................................................... 129

Code 39 Reduced Quiet Zone ................................................................................................ 130

Code 93 ........................................................................................................................................ 130

Enable/Disable Code 93 ......................................................................................................... 130

Set Lengths for Code 93 ......................................................................................................... 131

Code 11 ........................................................................................................................................ 132

Code 11 ................................................................................................................................... 132

Set Lengths for Code 11 ......................................................................................................... 133

Code 11 Check Digit Verification ............................................................................................ 134

Transmit Code 11 Check Digits .............................................................................................. 135

Interleaved 2 of 5 (ITF) ................................................................................................................. 135

Enable/Disable Interleaved 2 of 5 ........................................................................................... 135

Set Lengths for Interleaved 2 of 5 ........................................................................................... 136

I 2 of 5 Check Digit Verification ............................................................................................... 137

Transmit I 2 of 5 Check Digit ................................................................................................

Convert I 2 of 5 to EAN-13 ...................................................................................................... 138

I 2 of 5 Security Level .............................................................................................................. 139

I 2 of 5 Reduced Quiet Zone ................................................................................................... 140

Discrete 2 of 5 (DTF) .................................................................................................................... 140

Enable/Disable Discrete 2 of 5 ................................................................................................ 140

Set Lengths for Discrete 2 of 5 ................................................................................................ 141

Codabar (NW - 7) .......................................................................................................................... 142

Enable/Disable Codabar ......................................................................................................... 142

Set Lengths for Codabar ......................................................................................................... 143

CLSI Editing ............................................................................................................................ 144

NOTIS Editing ......................................................................................................................... 144

Codabar Upper or Lower Case Start/Stop Characters Detection ........................................... 145

MSI ................................................................................................................................................ 145

Enable/Disable MSI ................................................................................................................. 145

Set Lengths for MSI ................................................................................................................ 146

MSI Check Digits ..................................................................................................................... 147

... 138

7

Table of Contents

Transmit MSI Check Digit(s) ................................................................................................... 147

MSI Check Digit Algorithm ...................................................................................................... 148

Chinese 2 of 5 ............................................................................................................................... 148

Enable/Disable Chinese 2 of 5 ................................................................................................ 148

Matrix 2 of 5 .................................................................................................................................. 149

Enable/Disable Matrix 2 of 5 ................................................................................................... 149

Set Lengths for Matrix 2 of 5 ................................................................................................... 150

Matrix 2 of 5 Check Digit ......................................................................................................... 151

Transmit Matrix 2 of 5 Check Digit .......................................................................................... 151

Korean 3 of 5 ................................................................................................................................ 152

Enable/Disable Korean 3 of 5 ................................................................................................. 152

Inverse 1D ..................................................................................................................................... 153

GS1 DataBar ................................................................................................................................. 154

GS1 DataBar-14 ...................................................................................................................... 154

GS1 DataBar Limited .............................................................................................................. 154

GS1 DataBar Expanded .......................................................................................................... 155

Convert GS1 DataBar to UPC/EAN ........................................................................................ 155

GS1 DataBar Limited Security Level ....................................................................................... 156

Composite ..................................................................................................................................... 157

Composite CC-C ..................................................................................................................... 157

Composite CC-A/B .................................................................................................................. 157

Composite TLC-39 .................................................................................................................. 158

UPC Composite Mode ............................................................................................................ 158

Composite Beep Mode ............................................................................................................ 159

GS1-128 Emulation Mode for UCC/EAN Composite Codes ................................................... 159

2D Symbologies ............................................................................................................................ 160

Enable/Disable PDF417 .......................................................................................................... 160

Enable/Disable MicroPDF417 ................................................................................................. 160

Code 128 Emulation ................................................................................................................ 161

Data Matrix .............................................................................................................................. 162

GS1 Data Matrix ...................................................................................................................... 162

Data Matrix Inverse ................................................................................................................. 163

Maxicode ................................................................................................................................. 163

QR Code ................................................................................................................................. 164

GS1 QR .......................................................................................................................

MicroQR .................................................................................................................................. 165

Aztec ....................................................................................................................................... 165

Aztec Inverse .......................................................................................................................... 166

Han Xin ................................................................................................................................... 167

Han Xin Inverse ....................................................................................................................... 167

Postal Codes ................................................................................................................................. 168

US Postnet .............................................................................................................................. 168

US Planet ................................................................................................................................ 168

Transmit US Postal Check Digit .............................................................................................. 169

UK Postal ................................................................................................................................ 169

Transmit UK Postal Check Digit .............................................................................................. 170

Japan Postal ........................................................................................................................... 170

Australia Post .......................................................................................................................... 171

Australia Post Format .............................................................................................................. 172

Netherlands KIX Code ........................................................................................................... 173

USPS 4CB/One Code/Intelligent Mail ..................................................................................... 173

............ 164

8

Table of Contents

UPU FICS Postal .................................................................................................................... 174

Mailmark .................................................................................................................................. 174

Symbology-Specific Security Levels ............................................................................................. 175

Redundancy Level .................................................................................................................. 175

Redundancy Level 1 ......................................................................................................... 175

Redundancy Level 2 ......................................................................................................... 175

Redundancy Level 3 ......................................................................................................... 175

Redundancy Level 4 ......................................................................................................... 176

Security Level .......................................................................................................................... 177

1D Quiet Zone Level ............................................................................................................... 178

Intercharacter Gap Size .......................................................................................................... 179

Report Version .............................................................................................................................. 179

Macro PDF Features ..................................................................................................................... 180

Flush Macro Buffer .................................................................................................................. 180

Abort Macro PDF Entry ........................................................................................................... 180

Appendix A: Standard Default Parameters

Appendix B: Country Codes

Introduction ................................................................................................................................... B-1

USB and Country Keyboard Types (Country Codes) ................................................................... B-2

Appendix C: Country Code Pages

Introduction ................................................................................................................................... C-1

Country Code Page Defaults ........................................................................................................ C-1

Country Code Page Bar Codes .................................................................................................... C-5

Appendix D: CJK Decode Control

Introduction ................................................................................................................................... D-1

CJK Control Parameters ............................................................................................................... D-2

Unicode Output Control ........................................................................................................... D-2

CJK Output Method to Windows Host ..................................................................................... D-3

Non-CJK UTF Bar Code Output .............................................................................................. D-5

Unicode/CJK Decode Setup with Windows Host .......................................................................... D-7

Setting Up the Windows Registry Table for Unicode Universal Output .................................. D-7

Adding CJK IME on Windows ................................................................................................. D-7

Selecting the Simplified Chinese Input Method on the Host ................................................... D-8

Selecting the Traditional Chinese Input Method on the Host .................................................. D-9

Appendix E: Programming Reference

Symbol Code Identifiers ................................................................................................................ E-1

AIM Code Identifiers ..................................................................................................................... E-3

9

Table of Contents

Appendix F: Sample Bar Codes

Code 39 ......................................................................................................................................... F-1

UPC/EAN ....................................................................................................................................... F-1

UPC-A, 100% ........................................................................................................................... F-1

EAN-13, 100% ......................................................................................................................... F-2

Code 128 ....................................................................................................................................... F-2

Interleaved 2 of 5 ........................................................................................................................... F-2

GS1 DataBar-14 ............................................................................................................................ F-3

PDF417 .......................................................................................................................................... F-3

Data Matrix ..................................................................................................................................... F-3

Maxicode ........................................................................................................................................ F-4

QR Code ........................................................................................................................................ F-4

US Postnet ..................................................................................................................................... F-4

UK Postal ....................................................................................................................................... F-4

Appendix G: Alphanumeric Bar Codes

Alphanumeric Bar Codes .............................................................................................................. G-1

Appendix H: Numeric Bar Codes

Numeric Bar Codes ....................................................................................................................... H-1

Cancel ........................................................................................................................................... H-2

Appendix I: ASCII Character Sets

Appendix J: Communication Protocol Functionality

Functionality Supported via Communication (Cable) Interface ...................................................... J-1

Appendix K: Non-Parameter Attributes

Introduction ................................................................................................................................... K-1

Attributes ....................................................................................................................................... K-1

Model Number ......................................................................................................................... K-1

Serial Number ......................................................................................................................... K-1

Date of Manufacture ................................................................................................................ K-2

Date of First Programming ...................................................................................................... K-2

Configuration Filename ........................................................................................................... K-2

Beeper/LED ............................................................................................................................. K-3

Parameter Defaults ................................................................................................................. K-4

Beep on Next Bootup .............................................................................................................. K-4

Reboot ..................................................................................................................................... K-4

Host Trigger Session ............................................................................................................... K-4

Firmware Version .................................................................................................................... K-5

Scankit Version ....................................................................................................................... K-5

ImageKit Version ..................................................................................................................... K-5

10

About This Guide

Introduction

The MS4717 Fixed Mount Imager Integration Guide provides general instructions for mounting, setting up, and

programming.

NOTE: Screens and windows pictured in this guide are samples and may differ from actual screens.

Chapter Descriptions

Topics covered in this guide are as follows:

• Getting Started provides general information about the MS4717, including its features and theory of

operation.

• 123Scan describes the Zebra software tools available for customizing imager operation.

• Installation provides information on mounting and installing the fixed mount engine.

• Scanning provides information on aiming, illumination, data capture, beeper and decode LED feedback,

supported symbologies, and operating modes.

• Specifications provides specification details and decode ranges.

• Maintenance and Troubleshooting provides information on maintenance and troubleshooting.

• User Preferences describes each user preference feature and provides the programming barcodes

necessary for selecting these features.

• Imager Preferences describes scanner preference features and provides the programming barcodes for

selecting these features.

• USB Interface provides instructions for programming the imager to interface with a USB host.

• Symbologies describes symbology features and provides the programming barcodes for selecting these

features.

i

Notational Conventions

The following conventions are used in this document:

• “Imager” refers to the MS4717 fixed mount imager.

• Bullets (•) indicate:

• Action items

• Lists of alternatives

• Lists of required steps that are not necessarily sequential.

• Sequential lists (e.g., those that describe step-by-step procedures) appear as numbered lists.

Related Documents

The following documents provide more information about the imager.

• MS4717 Fixed Mount Imager Quick Reference Guide (p/n MN-003368-xx).

About This Guide

For the latest version of these guides and software, visit: www.zebra.com/support

Service Information

If you have a problem using the equipment, contact your facility's technical or systems support. If there is a

problem with the equipment, they will contact the Zebra Global Customer Support Center at:

www.zebra.com/support

When contacting Zebra support, please have the following information available:

• Serial number of the unit

• Model number or product name

• Software type and version number.

Zebra responds to calls by e-mail, telephone or fax within the time limits set forth in support agreements.

If your problem cannot be solved by Zebra support, you may need to return your equipment for servicing and will

be given specific directions. Zebra is not responsible for any damages incurred during shipment if the approved

shipping container is not used. Shipping the units improperly can possibly void the warranty. If you purchased your

business product from a Zebra business partner, contact that business partner for support.

.

.

ii

Getting Started

Imager Window

Indicator LED

Beeper

Introduction

The MS4717 fixed mount imager is specifically designed to be mounted into various enclosures such as the

food ordering kiosk in the quick-serve restaurant, to the ticketing kiosk at the airport or amusement park. The

imager provides an easy and flexible integration into most USB host devices and offers high performance

scanning on both 1D and 2D barcodes.

This integration guide includes programming parameters and describes the theory of operation, installation,

specifications, and configuration.

Figure 1 MS4717 Fixed Mount Imager

MS4717 Features

• Quick and easy integration for OEM devices

• Excellent imaging performance on all 1D and 2D barcodes

• USB interface

• LEDs indicating power status and successful decodes

• Easy programming and configuration

• Flexible mounting options

Theory of Operation

During image capture:

1. The image sensor array in the embedded imaging engine captures an image of the barcode through the

engine’s optical lens. If necessary, the engine automatically adjusts illumination, exposure, and other

parameters to obtain the best quality image.

2. The imaging engine sends the image to the MS4717 CPU.

3. The MS4717 CPU processes the image to identify the target barcode(s), decodes them, and transmits the

decoded data to the host.

Getting Started

Set various parameters provided in this guide to adjust the performance of the MS4717 to match the application or

desired usage profile.

4

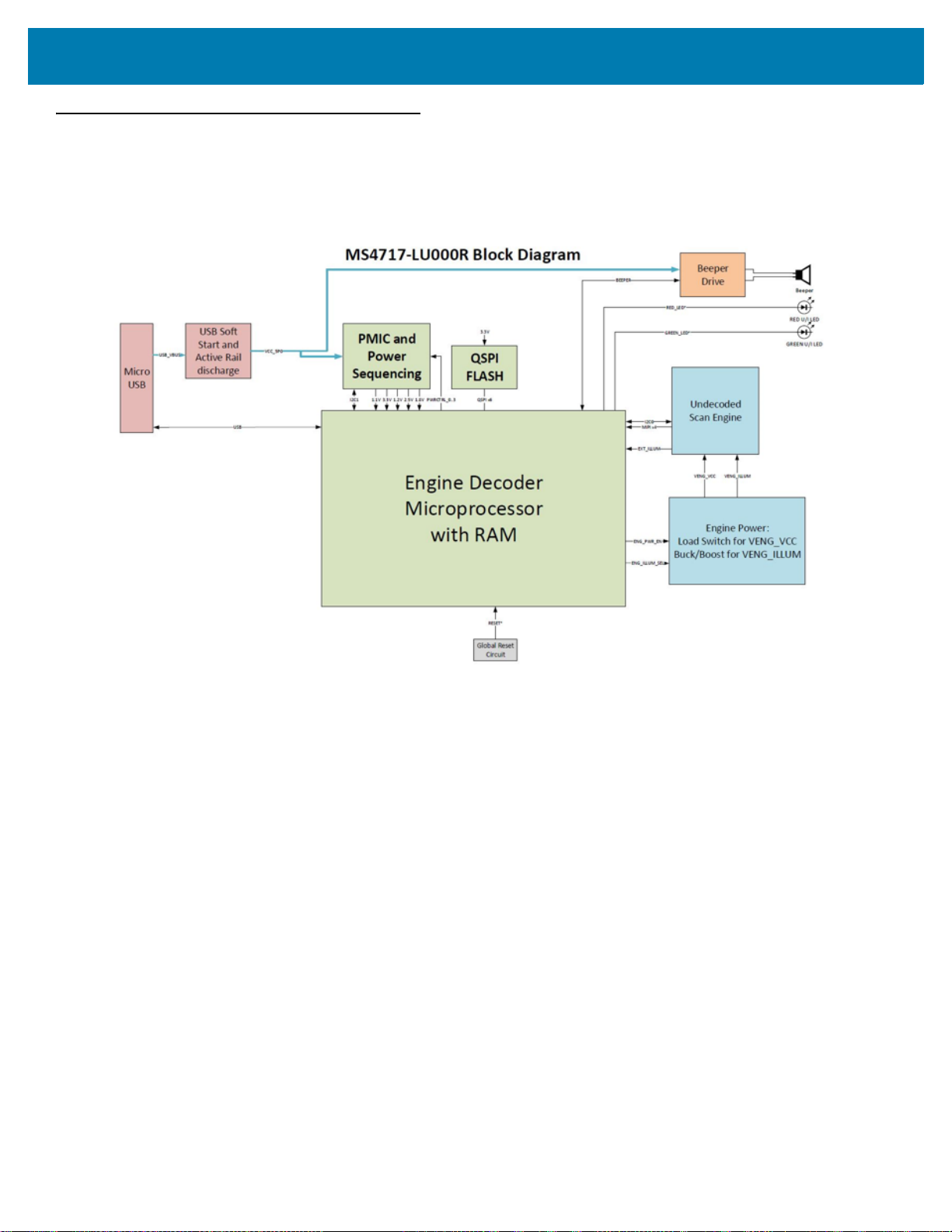

Block Diagram

The MS4717 scanner block diagram illustrates the functional relationship of the MS4717 components. This section

also provides a description of each component in the block diagrams.

Figure 2 MS4717 Block Diagram

Getting Started

MS4717 Block Diagram Descriptions

Scan Engine - The imaging engine captures 8-bit gray scale WVGA images at up to 30 fps, which are sent

uncompressed to a companion board for processing. The engine uses a red LED for intuitive aiming and features

LED illumination.

Decoder Interface - The decoder board is a companion decoder module for the imaging engine, which controls the

engine, receives images, decodes 1D and 2D symbologies, and performs various image processing tasks. The

board controls red and green LEDs for visual feedback, and supports SNAPI (Symbol Native API) as well as USB

HID Keyboard through a micro USB connector. The micro USB connector provides an outlet for the various interface

signals used between the MS4717 and the host.

MS4717 Decoder/Interface Board

Power Management

• USB Host Interface - The MS4717 automatically manages its power usage, including USB suspend

mode. Additionally, when drawing power from the USB bus, the MS4717 does not exceed the USB limit of

500 mA.

5

123Scan

Introduction

This chapter briefly describes the Zebra software tools available for customizing scanner operation.

123Scan

123Scan is a software tool that simplifies scanner setup and more.

Intuitive enough for first time users, the 123Scan wizard guides users through a streamlined setup process.

Settings are saved in a configuration file that can be printed as a single programming barcode for scanning,

emailed to a smart phone for scanning from its screen, or downloaded to the scanner using a USB cable.

Through 123Scan a user can:

• Configure a scanner using a wizard.

• Program the following scanner settings.

• Beeper tone / volume settings.

• Enable / disable symbologies.

• Communication settings.

• Modify data before transmission to a host using Advanced Data Formatting (ADF).

• Load parameter settings to a scanner via the following.

• Barcode scanning.

• Scan a paper barcode.

• Scan a barcode from a PC screen.

• Scan a barcode from a smart phone screen.

• Download over a USB cable.

• Load settings to one scanner.

• Stage up to 10 scanners simultaneously (Powered USB Hub recommended with 0.5 amp / port).

• Validate scanner setup.

• View scanned data within the utility's Data view screen.

• Capture an image and save to a PC within the utility's Data view screen.

• Review settings using the Parameter Report.

• Clone settings from an already deployed scanner from the Start screen.

• Upgrade scanner firmware.

• Load settings to one scanner.

• Stage up to 10 scanners simultaneously (Powered USB Hub recommended with 0.5 amp / port).

123Scan

• View statistics such as:

• Asset tracking information.

• Time and usage information.

• Barcodes scanned by symbology.

• Battery diagnostics (select scanners).

• Generate the following reports.

• Barcode Report - Programming barcode, included parameter settings, and supported scanner models.

• Parameter Report - Parameters programmed within a configuration file.

• Inventory Report - Scanner asset tracking information.

• Validation Report - Scanned data from the Data view.

• Statistics Report - All statistics retrieved from the scanner.

For more information go to: http://www.zebra.com/123Scan.

Communication with 123Scan

Use a USB cable to connect the scanner to a Windows host computer running 123Scan.

123Scan Requirements

• Host computer running Windows XP, 7, 8, and 10

• Scanner

• USB cable.

123Scan Information

For more information on123Scan, go to: http://www.zebra.com/123Scan

For a 1 minute tour of 123Scan, go to: http://www.zebra.com/ScannerHowToVideos

To see a list of all of our software tools, go to: http://www.zebra.com/scannersoftware

7

123Scan

Scanner SDK, Other Software Tools, and Videos

Tackle all your scanner programming needs with our diversified set of software tools. Whether you need to simply

stage a device, or develop a fully featured application with image and data capture as well as asset management,

these tools help you every step of the way.

To download any of the following free tools, go to: http://www.zebra.com/scannersoftware.

• 123Scan configuration utility

• SDKs

• Scanner SDK for Windows

• Scanner SDK for Linux

• Scanner SDK for Android

• Scanner SDK for iOS

• Drivers

• OPOS driver

• JPOS driver

• USB CDC driver

• TWAIN driver

• Scanner Management Service (SMS) for Remote Management

• Windows

• Linux

• Mobile Apps

• Scanner Control App

•Android

•iOS

• Zebra AppGallery

• Scan-To-Connect Utility

•Android

• Windows

• How-To-Videos

Advanced Data Formatting (ADF)

Advanced Data Formatting (ADF) allows customizing data before transmission to the host device. Use ADF to edit

scanned data to suit the host application's requirements. With ADF you scan one barcode per trigger pull. ADF is

programmed using 123Scan.

For a video on Creating an Advanced Data Formatting (ADF) Rule using 123Scan, go to:

http://www.zebra.com/ScannerHowToVideos.

For additional information, refer to the Advanced Data Formatting Programmer Guide.

8

Installation

Introduction

This chapter provides information on mounting and installing the imager.

Mounting

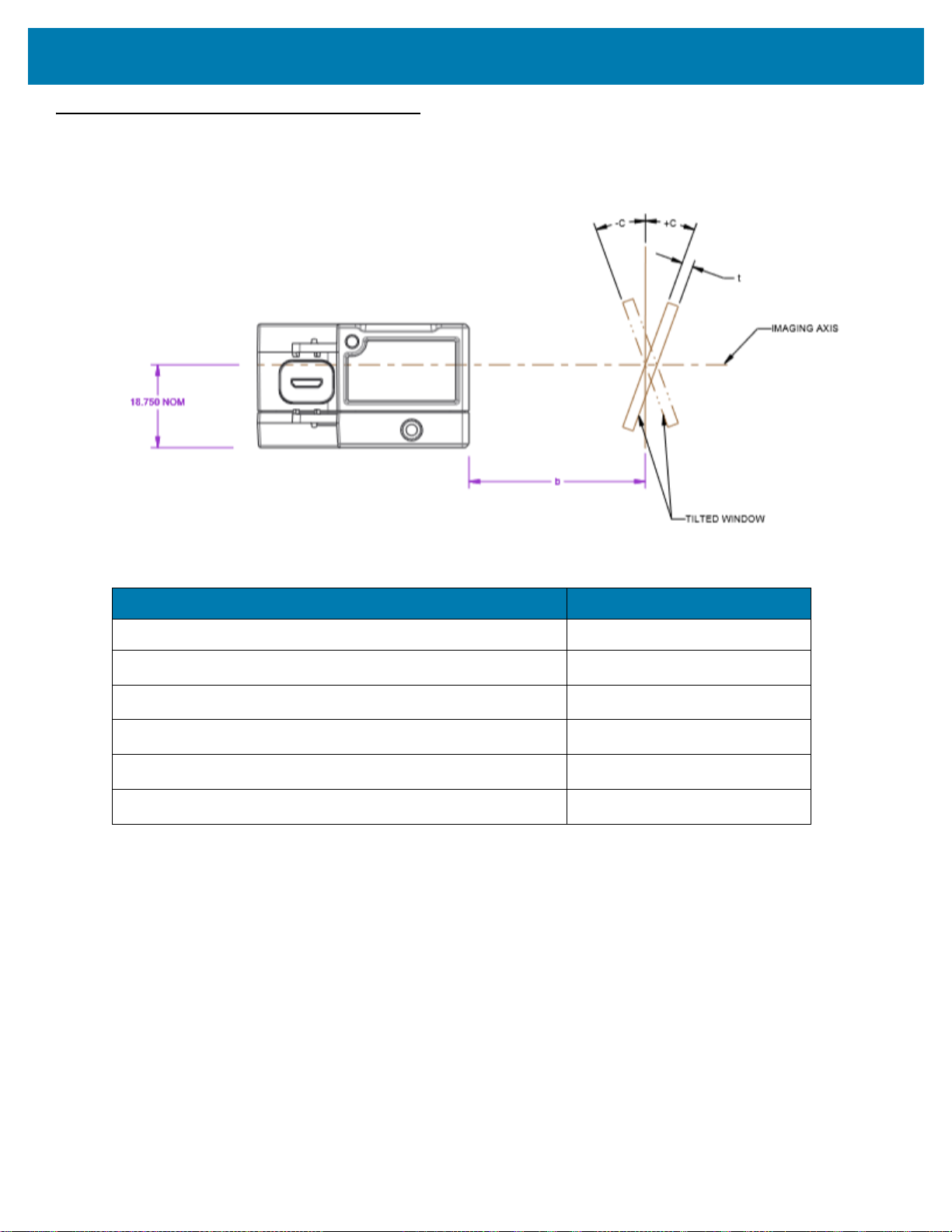

The following figures provide the mounting dimensions.

NOTE: Do not use screws that penetrate more than 5 mm into the bottom mousing of the MS4717

since this is the maximum depth of the useful thread.

MS4717 Mounting Dimensions

Figure 3 Mounting Dimensions (Left Side View)

Installation

Figure 4 MS4717 Mounting Dimensions (Overhead View)

Figure 5 MS4717 Mounting Dimensions (Right Side View)

10

Figure 6 MS4717 Mounting Dimensions

Installation

11

Connecting the MS4717

USB Cable

Clip Ramp

Cable Retention Clip

USB Host Connection

1. Unpack the imager.

2. Remove cable retention clip by lightly pinching the sides of the cable retention clip and sliding away from the

device.

3. Plug USB cable into the device.

4. Place cable retention clip over the USB cable and attach to the MS4717 by pinching the sides of the clip

slightly, using the arrows on the clip (pointing towards device) as a guide until secure.

5. Plug the USB series A into the appropriate port on the host.

6. Check all connections to ensure they are secure.

7. The green power LED illuminates upon connecting and powering on host.

Figure 7 USB Connection

Installation

NOTE: It is recommended that a Zebra USB cable is used for installation (p/n = 25-124330-01R). If

other USB cables used must be compatible with current USB.org requirements.

Please refer to USB.org connectors and compliance documentation for more information

found here:

https://www.usb.org/document-library/usb-type-c-connectors-and-cable-assemblies-complian

ce-document-v12

12

Accessories

Zebra offers additional accessories for the MS4717 through Solution Builder (ordering guide), it is recommended

that this tool is used to order any accessories.

NOTE: To ensure that the USB cable will fit properly with the cable retention clip, it is recommended

that the connector shell size does not exceed 11.5 mm (w) and 8.7 mm (thickness). The width

cannot exceed 12.5 w and 10.5 thickness. The cable connector shell length cannot exceed 17

mm.

Location and Positioning

The location and positioning guidelines do not consider unique application characteristics. Zebra recommends that

an opto-mechanical engineer perform an opto-mechanical analysis prior to integration.

NOTE: Integrate the imager in an environment that is not more extreme than the product’s

specification, where the imager will not exceed its temperature range. For instance, do not

mount the scanner onto or next to a large heat source. When placing the imager with another

device, ensure there is proper convection or venting for heat. Follow these suggestions to

ensure product longevity, warranty, and overall satisfaction with the scanner.

Installation

Embedded Applications Requiring a Window

Use the following guidelines for applications that require a window in front of the MS4717.

NOTE: Zebra does not recommend placing an exit window in front of the MS4717; however, the following

information is provided for applications that require such a window.

13

Installation

Window Material

Many window materials that look clear can contain stresses and distortions that reduce performance. For this

reason, use only cell-cast plastics or optical glass (with or without an anti reflection coating, depending on the

application). Following are descriptions of three popular window materials: PMMA, ADC (CR-39

chemically tempered glass. Table 3-1 outlines the suggested window properties.

Table 3-1 Suggested Window Properties

Property Description

Thickness Typically 0.03 - 0.06 in. (0.7 - 1.5 mm)

Wavefront Distortion (transmission) 0.2 wavelengths peak-to-valley maximum and 0.04 l maximum rms over

any 0.08 in. diameter within the clear aperture

Clear Aperture To extend to within 0.04 in. of the edges all around

Surface Quality 60-20 scratch/dig

When using plastic materials pay extra attention to the wave front distortion recommendation specified above.

Plastic materials are not recommended for tilted windows since surface scratches cause image artifacts. Colored

windows are not recommended if motion detection mode is required since it reduces engine sensitivity to the

moving target.

TM

), and

Cell Cast Acrylic (ASTM: PMMA)

Cell Cast Acrylic, or Poly-methyl Methacrylic (PMMA) is fabricated by casting acrylic between two precision sheets

of glass. This material has very good optical quality, reasonably good impact resistance and low initial cost, but is

relatively soft and susceptible to attack by chemicals, mechanical stresses, and UV light. Therefore polysiloxane

coating is strongly recommended. Acrylic can be laser cut into odd shapes and ultrasonically welded.

Cell Cast ADC (ASTM: ADC)

Also known as CR-39TM, Allyl Diglycol Carbonate (ADC) is a thermal-setting plastic produced by cell-casting. Most

plastic eyeglasses sold today are uncoated, cell-cast CR-39. This material has excellent chemical and

environmental resistance, and reasonably good impact resistance. It also has quite good surface hardness, and

therefore does not have to be hard-coated, but may be coated for severe environments. This material cannot be

ultrasonically welded.

Chemically Tempered Glass

Glass is a hard material that provides excellent scratch and abrasion resistance. However, unannealed glass is

brittle. Increasing flexibility strength with minimal optical distortion requires chemical tempering. Glass cannot be

ultrasonically welded and is difficult to cut into odd shapes.

14

Installation

Commercially Available Coatings

Anti-Reflection Coatings

Anti-reflection coatings can be used for stray light control or to achieve maximum working range, and can be

applied to the inside and/or outside of the window to reduce the amount of light reflected off the window back into

the engine. However, they are expensive and have very poor abrasion and scratch resistance.

Polysiloxane Coating

Polysiloxane type coatings are applied to plastic surfaces to improve the surface resistance to both scratch and

abrasion. To apply, dip and air dry in an oven with filtered hot air.

To gauge a window's durability, use ASTM standard D1044, Standard Test Method for Resistance of Transparent

Plastics to Surface Abrasion (the Taber Test), which quantifies abrasion resistance as a percent increase in haze

after a specified number of cycles and load. Lower values of the increase in haze correspond to better abrasion

and scratch resistance. See Table 3-2.

Table 3-2 Taber Test Results on Common Exit Window Materials

Sample

Chemically Tempered Glass 1.20% 1.50% Best

PMMA with Polysiloxane Hardcoat 3% 10%

ADC 5% 30%

PMMA 30% Worst

* All measurements use a 100 gram load and CS-10F Abraser.

Haze 100

cycles

Haze 500

cycles

Abrasion

Resistance

A Word About Coatings

If using an anti-reflective (AR) coating, the specifications in Table 3-3 apply. Polysiloxane coating is not required.

Recess the exit window to minimize scratches and digs.

Table 3-3 AR Coatings Specifications

Specification Description

Material Both tempered glass and plastic (e.g., CR-39 or hard coated acrylic) exit

windows can be AR coated. AR coated glass is easier and more durable

because of a better adhesion property on the glass structure. In addition, it can

be more cost effective to put an AR coating on the glass substrate rather than

on the plastic.

AR Coating Specification

• Single side AR-coating: 92% minimum transmittance within spectrum

range from 420 nm to 730 nm.

• Double side AR-coating: 97% minimum transmittance within spectrum

range from 420 nm to 730 nm.

• For parallel windows, see Figure 9 on page 18.

15

Installation

Embedded Window Angle and Position

If you are placing a window between the MS4717 and the target, observe the following guidelines:

• Window Clear Opening - Make the clear opening of the window large enough so that the entire imager

clear aperture passes through the window. Cutting off any part of the clear aperture can degrade decode

range performance. Ensure that window placement relative to the MS4717 accounts for tolerances on all

parts involved in that assembly.

• Window Angle - Minimum window tilt is indicated in Table 4. Further tilting the window is acceptable and

decreases the possibility of a secondary reflection from that window degrading the scanner's performance.

• Minimum Window Distance - (TBD)

• Optical Working Range - Adding a window can reduce the working range of the scanner since there is a

signal loss when passing through window material. To minimize this reduction, use a special coating

described in A Word About Coatings on page 15. To understand the difference, test the scanner in the

desired orientation and see if the difference affects scanner performance.

16

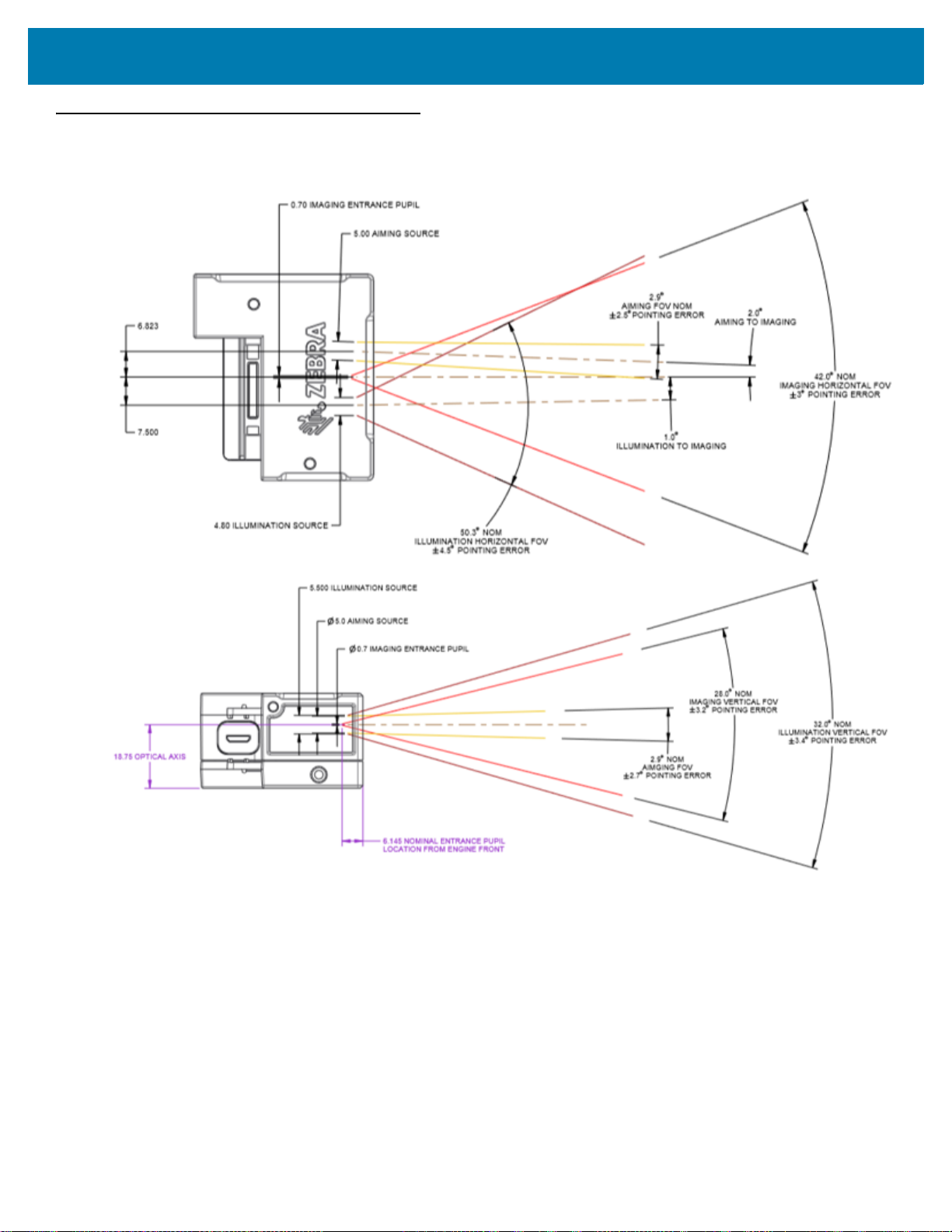

Optical Path

Notes:

1. Imaging axis pointing tolerance vs. datums ABC:

± 3º horizontal; ± 3.2º vertical

2. Clipping the scanner clear aperture is not permitted.

3. Dimensions are in mm.

Figure 8 MS4717 Optical Path and Exit Window

Installation

17

Installation

Recommended Exit Window Information

Figure 9 Exit Window Distance Information

Table 4 Recommended Exit Window Information - Tilted Window

External Window Specification Minimum Window Angle

Non-coated, minimum window positive tilt (+c) TBD

Non-coated, minimum window negative tilt (-c)

AR coated, one side, minimum window positive tilt (+c)

AR coated, one side, minimum window negative tilt (-c)

AR coated, two sides, minimum window positive tilt (+c)

AR coated, two sides, minimum window negative tilt (-c)

Exit Window Notes

• Integration tolerances are not included.

• Ensure the window size is large enough to cover the engine clear aperture plus mounting tolerances of the

window relative to the engine.

TBD

TBD

TBD

TBD

TBD

18

Installation

Zebra SNAPI Software Developer's Kit

The Symbol Native Application Programming Interface Software Development Kit (SNAPI SDK) facilitates

communicate with SNAPI-based Zebra scanners over USB, providing the following features:

• Barcode capture and decode

• Image and video capture

• Electronic scanner configuration and software update

• Reference sample application in Microsoft Visual C#

To download the SDK, go to: www.zebra.com/support.

®

.NET.

19

Scanning

Introduction

This chapter provides information on aiming, illumination, data capture, beeper and decode LED feedback,

supported symbologies, and operating modes.

Imaging System

Aiming System

A 610 nm LED is used to generate a circular aiming pattern which indicates the center of the imager’s field of

view.

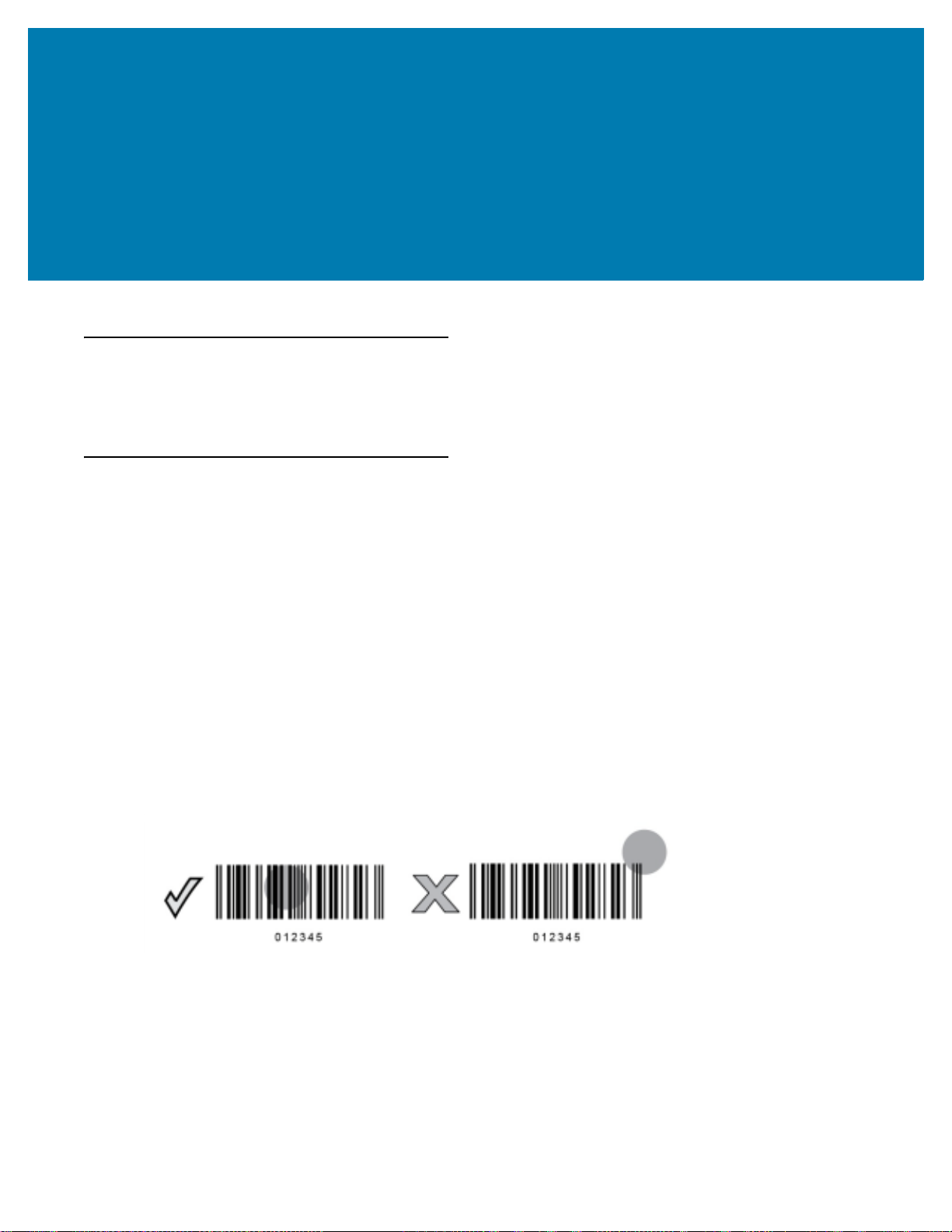

Aiming with MS4717

When scanning, the device projects an orange LED dot, which allows positioning the barcode within its field of

view. If necessary, the imager turns on its red LEDs to illuminate the target barcode.

To scan a barcode, center the symbol and ensure the entire symbol is within the rectangular area formed by

the illumination LEDs. The imager can also read a barcode presented within the aiming dot not centered. The

figure below illustrates proper LED placement to produce a successful decode.

Figure 10 MS4717 Aiming Pattern

Aiming Error

The aiming pattern is rotated by 2º relative to the imaging axis in the horizontal plane to minimize parallax

between the aiming axis and the imaging axis at 190.45 mm (7.5 in.) from the front of the MS4717.

Aiming Control

The MS4717 can capture images with both the aiming subsystem turned on during exposure (the image of the

aiming pattern is visible in the digital image) or off. If the aiming system is turned off during exposure,

brightness of the aiming pattern decreases as exposure increases.

Loading...

Loading...