Page 1

DS457 FIXED MOUNT

IMAGER

INTEGRATION GUIDE

Page 2

Page 3

DS457 FIXED MOUNT IMAGER

INTEGRATION GUIDE

72E-144361-05

Revision A

December 2017

Page 4

ii DS457 Fixed Mount Imager Integration Guide

No part of this publication may be reproduced or used in any form, or by any electrical or mechanical means, without permission in writing

from Zebra. This includes electronic or mechanical means, such as photocopying, recording, or information storage and retrieval systems.

The material in this manual is subject to change without notice.

The software is provided strictly on an “as is” basis. All software, including firmware, furnished to the user is on a licensed basis. Zebra

grants to the user a non-transferable and non-exclusive license to use each software or firmware program delivered hereunder (licensed

program). Except as noted below, such license may not be assigned, sublicensed, or otherwise transferred by the user without prior written

consent of Zebra. No right to copy a licensed program in whole or in part is granted, except as permitted under copyright law. The user

shall not modify, merge, or incorporate any form or portion of a licensed program with other program material, create a derivative work from

a licensed program, or use a licensed program in a network without written permission from Zebra. The user agrees to maintain Zebra’s

copyright notice on the licensed programs delivered hereunder, and to include the same on any authorized copies it makes, in whole or in

part. The user agrees not to decompile, disassemble, decode, or reverse engineer any licensed program delivered to the user or any

portion thereof.

Zebra reserves the right to make changes to any software or product to improve reliability, function, or design.

Zebra does not assume any product liability arising out of, or in connection with, the application or use of any product, circuit, or application

described herein.

No license is granted, either expressly or by implication, estoppel, or otherwise under any Zebra Technologies Corporation intellectual

property rights. An implied license only exists for equipment, circuits, and subsystems contained in Zebra products.

ZEBRA, ZEBRA TECHNOLOGIES and the Stylized Z logo are trademarks of ZIH Corp, registered in many jurisdictions worldwide. All

product names and numbers are Zebra trademarks. The Symbol logo is a registered trademark of Symbol Technologies, Inc., a Zebra

Technologies company.

This media, or Zebra Product, may include Zebra Software, Commercial Third Party Software, and Publicly Available Software.

The Zebra Software that may be included on this media, or included in the Zebra Product, is Copyright (c) by Zebra Technologies

Corporation, and its use is subject to the licenses, terms and conditions of the agreement in force between the purchaser of the Zebra

Product.

The Commercial Third Party Software that may be included on this media, or included in the Zebra Product, is subject to the licenses,

terms and conditions of the agreement in force between the purchaser of the Zebra Product and Zebra Technologies Corporation, unless a

separate Commercial Third Party Software License is included, in which case, your use of the Commercial Third Party Software will then

be governed by the separate Commercial Third Party License.

The Publicly Available Software that may be included on this media, or in the Zebra Product, is listed below. The use of the listed Publicly

Available Software is subject to the licenses, terms and conditions of the agreement in force between the purchaser of the Zebra Product

and Zebra Technologies Corporation, as well as, the terms and conditions of the license of each Publicly Available Software package.

Copies of the licenses for the listed Publicly Available Software, as well as, all attributions, acknowledgements, and software information

details, are included below. Zebra is required to reproduce the software licenses, acknowledgments and copyright notices as pro

the Authors and Owners, thus, all such information is provided in its native language form, without modification or translation.

The Publicly Available Software in the list below is limited to the Publicly Available Software included by Zebra. The Publicly Available

Software included by Commercial Third Party Software or Products, that is used in the Zebra Product, are disclosed in the Commerical

Third Party Licenses, or via the respective Commercial Third Party Publicly Available Software Legal Notices.

Publicly available software list:

Name: Regular Expression Evaluator

Version: 8.3

Description: Compiles and executes regular expressions

Software Site: http://www.freebsd.org/cgi/cvsweb.cgi/src/lib/libc/regex/

Source Code: No Source Distribution Obligations. Zebra will not provide nor distribute the Source Code for the

Regular Expression Evaluator.

License: BSD Style License

© 1992 Henry Spencer.

© 1992, 1993 The Regents of the University of California. All rights reserved.

This code is derived from software contributed to Berkeley by Henry Spencer of the University of Toronto. Redistribution and use in source

and binary forms, with or without modification, are permitted provided that the following conditions are met:

1. Redistributions of source code must retain the above copyright notice, this list of conditions and the following disclaimer.

2. Redistributions in binary form must reproduce the above copyright notice, this list of conditions and the following disclaimer in the

documentation and/or other materials provided with the distribution.

3. All advertising materials mentioning features or use of this software must display the following acknowledgement:

This product includes software developed by the University of California, Berkeley and its contributors.

vided by

Page 5

4. Neither the name of the University nor the names of its contributors may be used to endorse or promote products derived from this

software without specific prior written permission.

THIS SOFTWARE IS PROVIDED BY THE REGENTS AND CONTRIBUTORS ``AS IS'' AND ANY EXPRESS OR IMPLIED

WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE REGENTS OR CONTRIBUTORS BE LIABLE FOR ANY

DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO,

PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR PROFITS; OR BUSINESS INTERRUPTION)

HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT (INCLUDING

NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF THIS SOFTWARE, EVEN IF ADVISED OF THE

POSSIBILITY OF SUCH DAMAGE.

Warranty

For the complete Zebra hardware product warranty statement, go to:

http://www.zebra.com/warranty

iii

Page 6

iv DS457 Fixed Mount Imager Integration Guide

Revision History

Changes to the original guide are listed below:

Change Date Description

-01 Rev A 6/2011 Initial release

-02 Rev A 9/2012 Clarify that SSI is the default serial host; update URLs and service information,

update 123Scan2 chapter, update Driver’s License Setup chapter to remove server

based parsing algorithms and jurisdictional updates references

-03 Rev A 4/2014 - Added parameter attribute numbers.

- Added Presentation Performance Mode, Time Delay to Presentation Idle Mode,

Time Delay to Presentation Sleep Mode, and Power Up Light in Presentation

Mode.

- Removed Motion Enhancement in Presentation Mode parameter and

sub-parameters.

- Added Unique Bar Code Reporting.

- Added Multicode Mode Concatenation and Multicode Concatenation

Symbology.

- Moved Miscellaneous Parameters chapter content into User Preferences

chapter.

- Added Video Mode Format Selector.

- Added CUTE serial host.

- Added code types to serial host parameters table.

- For USB Device Type:

- Change HID Keyboard Emulation to USB Keyboard (HID).

- Change USB OPOS Hand-Held to IBM OPOS (IBM Hand-Held USB with

Full Scan Disable) and added related note.

- Added following parameters to USB chapter: Quick Keypad Emulation, USB

Ignore Beep Directive, USB Ignore Type Directive, USB Polling Interval,

Fast HID, IBM Specification Level.

- Added new OCR-B Variant options and OCR Inverse parameter.

- Added Code 128, Code 39, and I 2 of 5 Security Levels.

- Added Codabar Upper or Lower Case Start/Stop Character Transmission.

- Added GS1 DataBar Limited Security Level.

- Updated defaults for the following parameters: PDF Prioritization Timeout,

JPEG Size Value, Image File Meta Data, Image Edge Sharpening, I 2 of 5

Lengths, US Postnet, US Planet, UK Postal, Japan Postal, Australia Post,

Netherlands KIX Code, GS1 DataBar Limited, UPC Composite Mode, Decode

Mirror Images, Maxicode, Aztec Inverse

- Updated 123Scan2 chapter.

-04 Rev A 3/2015 Zebra Re-branding, add statement to temperature specification.

-05 Rev A 12/2017 Updated SSI Baud Rate bar code caption values

Changed

Changed IBM OPOS (IBM Hand-Held USB with Full Scan Disable) option to

OPOS (IBM Hand-held with Full Disable)

Changed GS1 DataBar-14 references to GS1 DataBar Omnidirectional

Updated 123Scan chapter

Removed Glossary

USB Keyboard HID to

USB HID Keyboard

Page 7

TABLE OF CONTENTS

About This Guide

Introduction ..................................................................................................................................... xv

Configurations................................................................................................................................. xv

Chapter Descriptions ...................................................................................................................... xv

Notational Conventions................................................................................................................... xvi

Related Documents ........................................................................................................................ xvii

Service Information......................................................................................................................... xviii

Chapter 1: Getting Started

Overview ........................................................................................................................................ 1-1

DS457 Features ....................................................................................................................... 1-2

Theory of Operation ....................................................................................................................... 1-2

DS457 Block Diagram Descriptions ......................................................................................... 1-3

DS457 Decoder/Interface Board .............................................................................................. 1-4

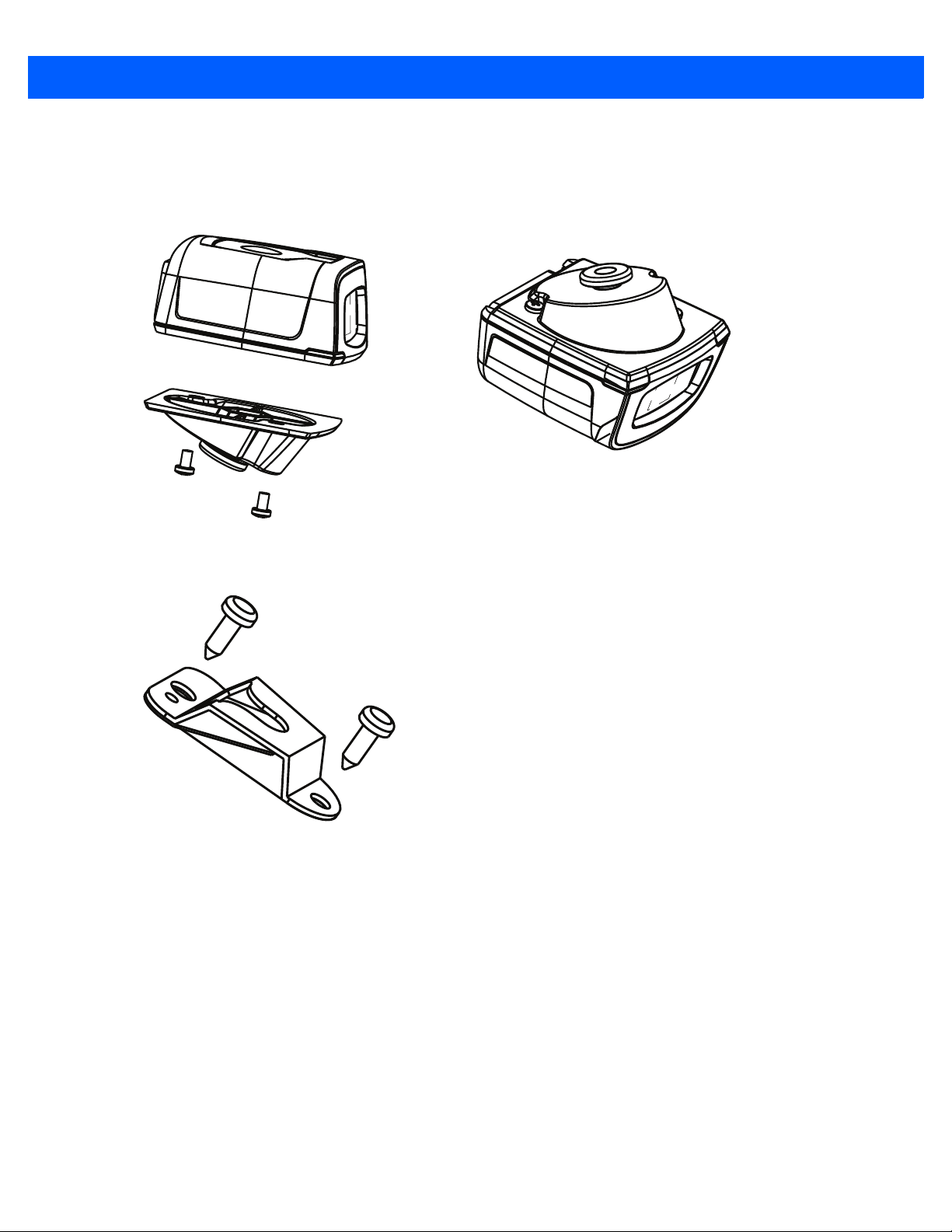

Chapter 2: Installation

Overview ........................................................................................................................................ 2-1

Unpacking ...................................................................................................................................... 2-1

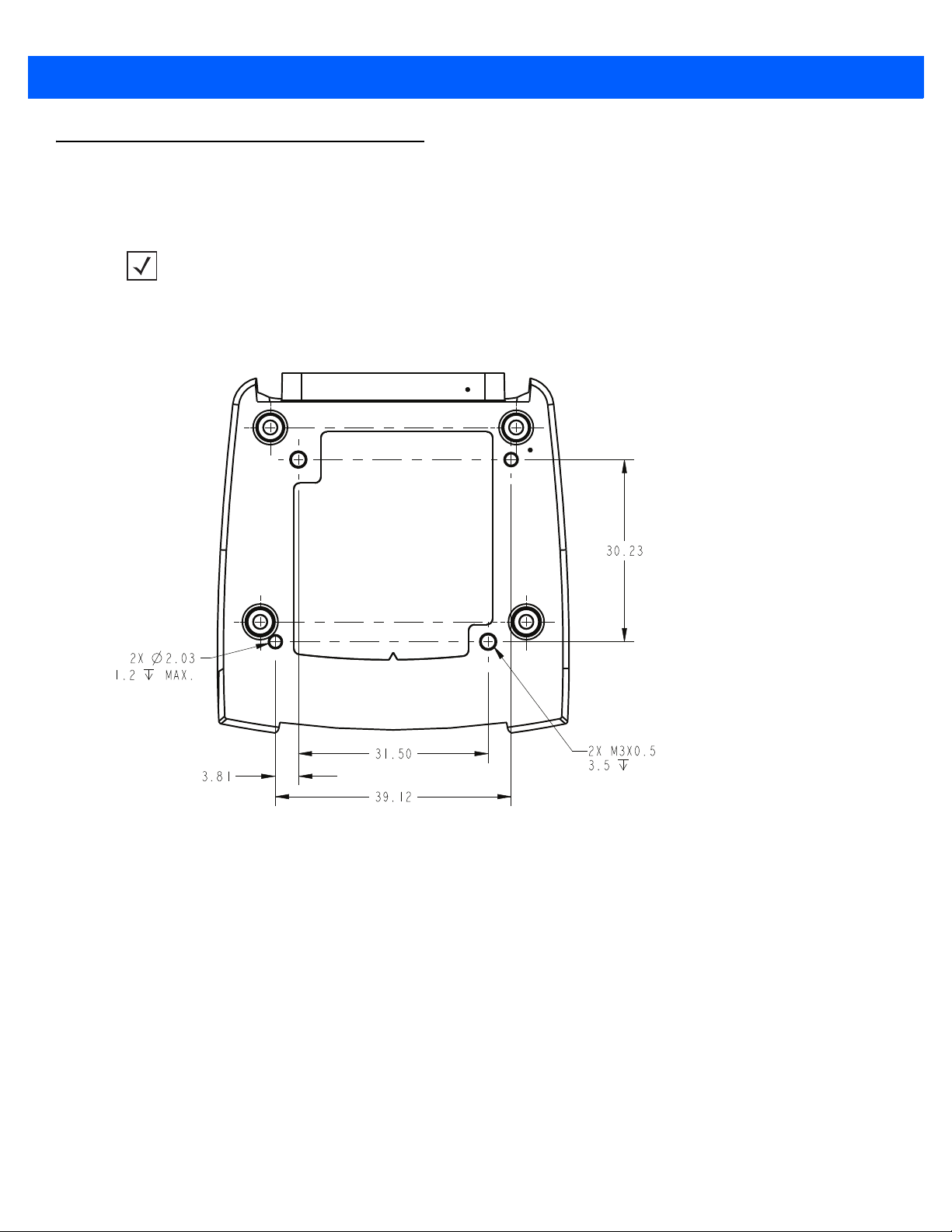

Mounting ........................................................................................................................................ 2-2

DS457 Mounting Dimensions .................................................................................................. 2-2

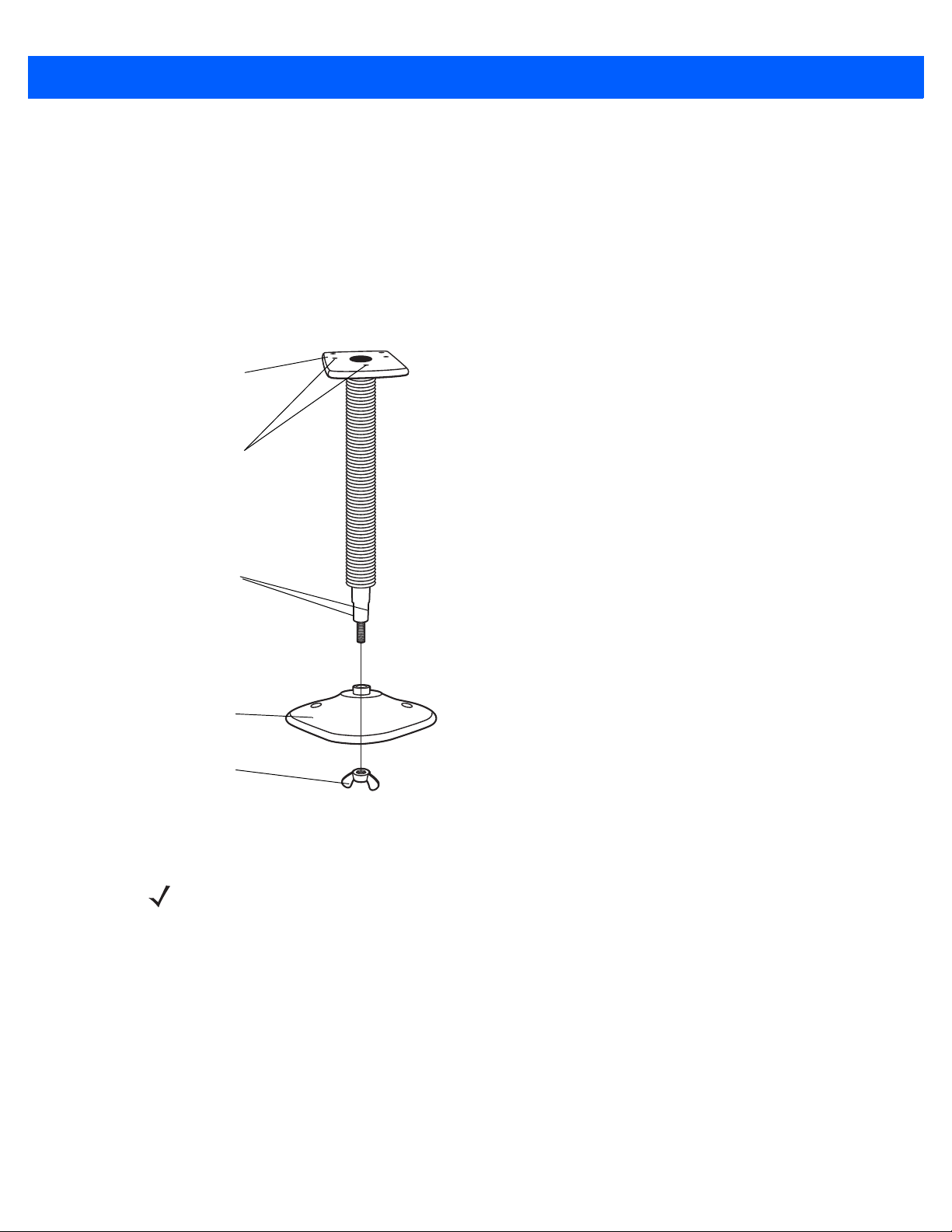

Mounting the Imager on the Gooseneck Stand ....................................................................... 2-3

Mounting the Imager on the POS Stand .................................................................................. 2-5

Mounting the Imager on the MS320X Conversion Mounting Bracket ...................................... 2-7

Connecting the DS457 ................................................................................................................... 2-8

USB Host Connection .............................................................................................................. 2-8

Serial Host Connection ............................................................................................................ 2-9

Trigger Jack Connector Pins .................................................................................................... 2-10

Location and Positioning ................................................................................................................ 2-10

Embedded Applications Requiring a Window ................................................................................ 2-11

Window Material ...................................................................................................................... 2-11

Window Coatings ..................................................................................................................... 2-12

Embedded Window Angle and Position ................................................................................... 2-13

Page 8

vi DS457 Fixed Mount Imager Integration Guide

Recommended Exit Window Information ....................................................................................... 2-15

Exit Window Notes ................................................................................................................... 2-15

Accessories ................................................................................................................................... 2-16

Simple Serial Interface Software Developer's Kit (SSI SDK) ................................................... 2-17

Zebra SNAPI Software Developer's Kit ................................................................................... 2-17

Chapter 3: Imaging

Overview ........................................................................................................................................ 3-1

Imaging System ............................................................................................................................. 3-1

Aiming Pattern ......................................................................................................................... 3-1

Aiming Error ............................................................................................................................. 3-1

Aiming Control ......................................................................................................................... 3-2

Illumination System .................................................................................................................. 3-2

Illumination Control .................................................................................................................. 3-2

Frame Rate Control ................................................................................................................. 3-2

Capturing Data ............................................................................................................................... 3-3

Beeper and Decode LED Indications ............................................................................................. 3-4

Supported Symbologies ................................................................................................................. 3-5

Operating Modes ........................................................................................................................... 3-5

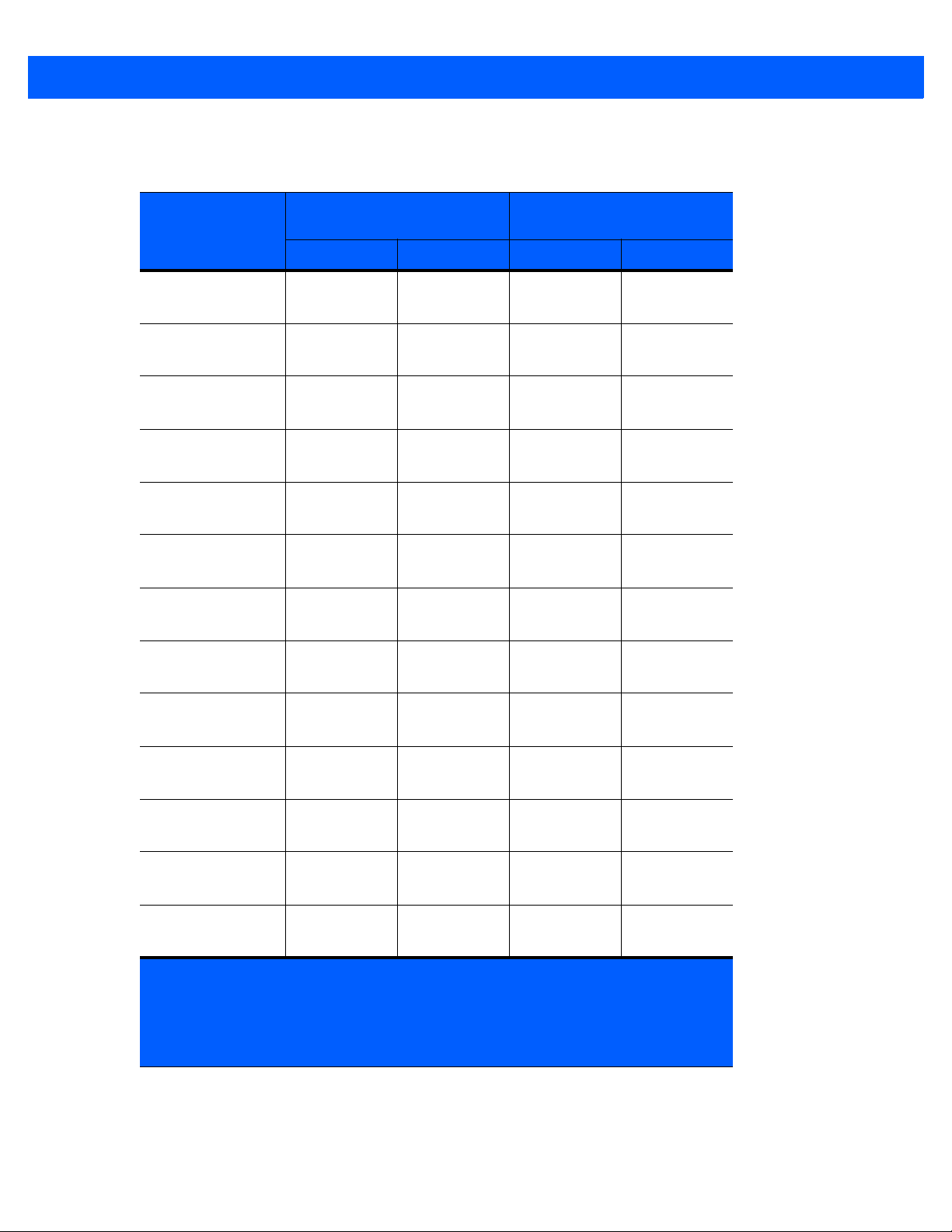

Chapter 4: Specifications

Electrical Interface ......................................................................................................................... 4-1

Dimension Drawings ...................................................................................................................... 4-2

DS457 Imager Technical Specifications ........................................................................................ 4-3

Skew, Pitch and Roll ................................................................................................................ 4-5

Decode Zones ............................................................................................................................... 4-6

DS457-SR/DL .......................................................................................................................... 4-6

DS457-HD/DP .......................................................................................................................... 4-9

Chapter 5: Maintenance & Troubleshooting

Overview ........................................................................................................................................ 5-1

Maintenance .................................................................................................................................. 5-1

Cleaning the Connector ........................................................................................................... 5-1

Troubleshooting ............................................................................................................................. 5-2

Chapter 6: User Preferences

Introduction .................................................................................................................................... 6-1

Host Selection .......................................................................................................................... 6-1

Phantom Scan Session ............................................................................................................ 6-1

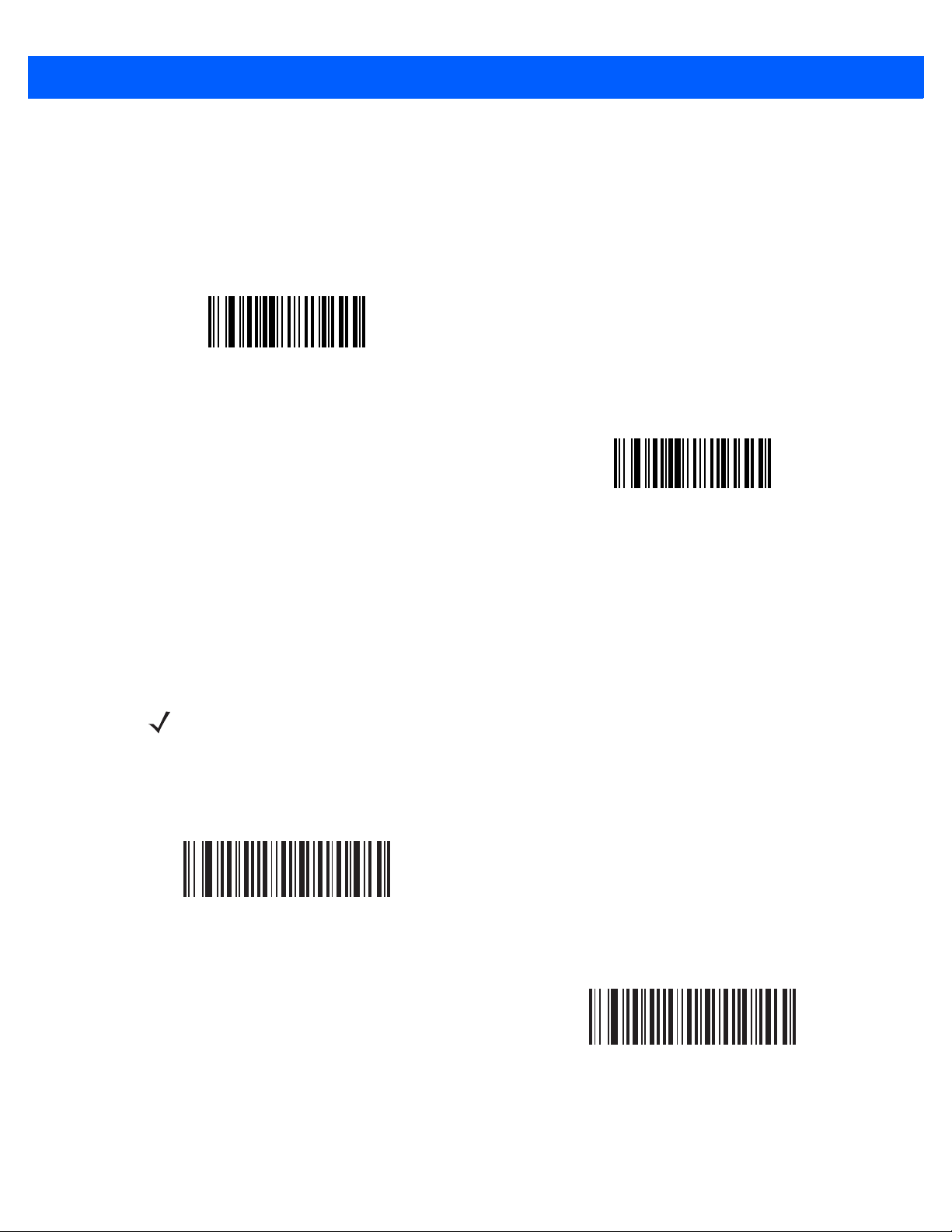

Changing Default Values ............................................................................................................... 6-2

Scanning Sequence Examples ...................................................................................................... 6-2

Errors While Scanning ................................................................................................................... 6-2

User Preferences Parameter Defaults ........................................................................................... 6-3

User Preferences ........................................................................................................................... 6-5

Set Default Parameter ............................................................................................................. 6-5

Parameter Scanning ................................................................................................................ 6-6

User Parameter Pass Through ................................................................................................ 6-7

Page 9

Table of Contents vii

Beep After Good Decode ......................................................................................................... 6-8

Beeper Tone ............................................................................................................................ 6-9

Beeper Volume ........................................................................................................................ 6-10

Suppress Power-up Beeps ...................................................................................................... 6-10

Trigger Mode ............................................................................................................................ 6-11

Presentation Performance Mode ............................................................................................. 6-12

Power Mode (RS-232 Hosts Only) ........................................................................................... 6-17

Time Delay to Low Power Mode .............................................................................................. 6-17

Picklist Mode ............................................................................................................................ 6-19

Decode Session Timeout ......................................................................................................... 6-19

Timeout Between Decodes, Same Symbol ............................................................................. 6-20

Continuous Bar Code Read ..................................................................................................... 6-20

Unique Bar Code Reporting ..................................................................................................... 6-21

Mirrored Image ......................................................................................................................... 6-21

Mobile Phone/Display Mode .................................................................................................... 6-22

Validate Concatenated Parameter Bar Codes ......................................................................... 6-22

PDF Prioritization ..................................................................................................................... 6-23

PDF Prioritization Timeout ....................................................................................................... 6-23

Multicode Mode ........................................................................................................................ 6-24

Multicode Expression ............................................................................................................... 6-25

Multicode Mode Concatenation ............................................................................................... 6-33

Multicode Concatenation Symbology ....................................................................................... 6-34

Multicode Troubleshooting ....................................................................................................... 6-35

Miscellaneous Parameters ............................................................................................................. 6-37

Transmit Code ID Character .................................................................................................... 6-37

Prefix/Suffix Values .................................................................................................................. 6-38

Scan Data Transmission Format ............................................................................................. 6-39

FN1 Substitution Values .......................................................................................................... 6-40

Transmit “No Read” Message .................................................................................................. 6-41

Report Version ......................................................................................................................... 6-41

Chapter 7: Imager Preferences

Introduction .................................................................................................................................... 7-1

Scanning Sequence Examples ...................................................................................................... 7-2

Errors While Scanning ................................................................................................................... 7-2

Imager Preferences Parameter Defaults ....................................................................................... 7-2

Imager Preferences ....................................................................................................................... 7-4

Operational Modes ................................................................................................................... 7-4

Decoding Autoexposure ........................................................................................................... 7-5

Decoding Illumination ............................................................................................................... 7-6

Decode Aiming Pattern ............................................................................................................ 7-6

Aim Brightness ......................................................................................................................... 7-7

Illumination Brightness ............................................................................................................. 7-7

Low Light Enhancement .......................................................................................................... 7-8

Power Up Light in Presentation Mode ..................................................................................... 7-8

Presentation Mode Field of View ............................................................................................. 7-9

Frame Rate .............................................................................................................................. 7-10

Image Capture Autoexposure .................................................................................................. 7-12

Image Capture Illumination ...................................................................................................... 7-12

Fixed Gain ................................................................................................................................ 7-13

Page 10

viii DS457 Fixed Mount Imager Integration Guide

Exposure Time ......................................................................................................................... 7-13

Snapshot Mode Timeout .......................................................................................................... 7-14

Snapshot Aiming Pattern ......................................................................................................... 7-14

Presentation Snapshot by Motion ............................................................................................ 7-15

Continuous Snapshot ............................................................................................................... 7-15

Image Cropping ....................................................................................................................... 7-16

Crop to Pixel Addresses .......................................................................................................... 7-17

Image Resolution ..................................................................................................................... 7-18

Image Brightness (Target White) ............................................................................................. 7-19

Image File Format Selector ...................................................................................................... 7-20

JPEG Image Options ............................................................................................................... 7-20

JPEG Quality and Size Value .................................................................................................. 7-21

Image File Meta Data ............................................................................................................... 7-22

Image Enhancement ................................................................................................................ 7-23

Image Edge Sharpening .......................................................................................................... 7-24

Image Contrast Enhancement ................................................................................................. 7-25

Image Rotation ......................................................................................................................... 7-26

Bits per Pixel ............................................................................................................................ 7-27

Signature Capture .................................................................................................................... 7-28

Signature Capture File Format Selector .................................................................................. 7-29

Signature Capture Bits per Pixel .............................................................................................. 7-30

Signature Capture Width .......................................................................................................... 7-30

Signature Capture Height ........................................................................................................ 7-31

Signature Capture JPEG Quality ............................................................................................. 7-31

Video Mode Format Selector ................................................................................................... 7-32

Video View Finder .................................................................................................................... 7-32

Target Video Frame Size ......................................................................................................... 7-33

Video View Finder Image Size ................................................................................................. 7-33

Video Resolution ...................................................................................................................... 7-34

Chapter 8: SSI Interface

Introduction .................................................................................................................................... 8-1

Communications ............................................................................................................................ 8-1

SSI Transactions ........................................................................................................................... 8-3

General Data Transactions ...................................................................................................... 8-3

Transfer of Decode Data .......................................................................................................... 8-4

Communication Summary ............................................................................................................. 8-5

RTS/CTS Lines ........................................................................................................................ 8-5

ACK/NAK Option ...................................................................................................................... 8-5

Number of Data Bits ................................................................................................................. 8-5

Serial Response Time-out ....................................................................................................... 8-5

Retries ...................................................................................................................................... 8-5

Baud Rate, Stop Bits, Parity, Response Time-out, ACK/NAK Handshake .............................. 8-6

Errors ....................................................................................................................................... 8-6

Things to Remember When Using SSI Communication ................................................................ 8-6

Using Time Delay to Low Power Mode with SSI ........................................................................... 8-7

Simple Serial Interface Default Parameters ................................................................................... 8-8

SSI Host Parameters ..................................................................................................................... 8-9

Select SSI Host ........................................................................................................................ 8-9

Baud Rate ................................................................................................................................ 8-10

Page 11

Table of Contents ix

Parity ........................................................................................................................................ 8-11

Check Parity ............................................................................................................................. 8-12

Software Handshaking ............................................................................................................. 8-12

Host RTS Line State ................................................................................................................ 8-13

Decode Data Packet Format .................................................................................................... 8-13

Host Serial Response Time-out ............................................................................................... 8-14

Host Character Time-out .......................................................................................................... 8-15

Multipacket Option ................................................................................................................... 8-16

Interpacket Delay ..................................................................................................................... 8-17

Event Reporting ............................................................................................................................. 8-18

Decode Event .......................................................................................................................... 8-18

Boot Up Event .......................................................................................................................... 8-19

Parameter Event ...................................................................................................................... 8-19

Chapter 9: Serial Interface

Introduction .................................................................................................................................... 9-1

Serial Parameter Defaults .............................................................................................................. 9-2

Serial Host Parameters .................................................................................................................. 9-3

Serial Host Types ..................................................................................................................... 9-5

Baud Rate ................................................................................................................................ 9-7

Parity ........................................................................................................................................ 9-9

Data Bits .................................................................................................................................. 9-9

Check Receive Errors .............................................................................................................. 9-10

Hardware Handshaking ........................................................................................................... 9-11

Software Handshaking ............................................................................................................. 9-13

Host Serial Response Time-out ............................................................................................... 9-15

RTS Line State ......................................................................................................................... 9-16

Beep on <BEL> ........................................................................................................................ 9-16

Intercharacter Delay ................................................................................................................. 9-17

Nixdorf Beep/LED Options ....................................................................................................... 9-18

Ignore Unknown Characters .................................................................................................... 9-18

ASCII Character Set for Serial Hosts ............................................................................................. 9-19

Chapter 10: USB Interface

Introduction .................................................................................................................................... 10-1

USB Parameter Defaults ................................................................................................................ 10-2

USB Host Parameters .................................................................................................................... 10-3

USB Device Type ..................................................................................................................... 10-3

Symbol Native API (SNAPI) Status Handshaking .................................................................... 10-5

USB Country Keyboard Types (Country Codes) ..................................................................... 10-6

USB Keystroke Delay .............................................................................................................. 10-8

USB CAPS Lock Override ....................................................................................................... 10-8

USB Ignore Unknown Characters ............................................................................................ 10-9

Emulate Keypad ....................................................................................................................... 10-9

Emulate Keypad with Leading Zero ......................................................................................... 10-10

Quick Keypad Emulation .......................................................................................................... 10-10

USB Keyboard FN1 Substitution .............................................................................................. 10-11

Function Key Mapping ............................................................................................................. 10-11

Simulated Caps Lock ............................................................................................................... 10-12

Page 12

x DS457 Fixed Mount Imager Integration Guide

Convert Case ........................................................................................................................... 10-13

USB Static CDC ....................................................................................................................... 10-13

USB Ignore Beep Directive ...................................................................................................... 10-14

USB Ignore Type Directive ...................................................................................................... 10-14

USB Polling Interval ................................................................................................................. 10-15

Fast HID Keyboard .................................................................................................................. 10-17

IBM Specification Level ............................................................................................................ 10-17

ASCII Character Set for USB ......................................................................................................... 10-18

Chapter 11: OCR Reading

Introduction .................................................................................................................................... 11-1

OCR Parameter Defaults ............................................................................................................... 11-2

OCR Parameters ........................................................................................................................... 11-3

Enable/Disable OCR-A ............................................................................................................ 11-3

OCR-A Variant ......................................................................................................................... 11-3

Enable/Disable OCR-B ............................................................................................................ 11-5

OCR-B Variant ......................................................................................................................... 11-6

Enable/Disable MICR E13B ..................................................................................................... 11-9

Enable/Disable US Currency Serial Number ........................................................................... 11-10

OCR Orientation ...................................................................................................................... 11-10

OCR Lines ............................................................................................................................... 11-12

OCR Minimum Characters ....................................................................................................... 11-13

OCR Maximum Characters ...................................................................................................... 11-13

OCR Security Level ................................................................................................................. 11-13

OCR Subset ............................................................................................................................. 11-14

OCR Quiet Zone ...................................................................................................................... 11-14

OCR Bright Illumination ........................................................................................................... 11-15

OCR Template ......................................................................................................................... 11-16

OCR Check Digit Modulus ....................................................................................................... 11-25

OCR Check Digit Multiplier ...................................................................................................... 11-26

OCR Check Digit Validation ..................................................................................................... 11-27

Inverse OCR ............................................................................................................................ 11-31

Chapter 12: Symbologies

Introduction .................................................................................................................................... 12-1

Scanning Sequence Examples ...................................................................................................... 12-2

Errors While Scanning ................................................................................................................... 12-2

Symbology Parameter Defaults ..................................................................................................... 12-2

Disable All Symbologies ................................................................................................................ 12-8

UPC/EAN ....................................................................................................................................... 12-9

Enable/Disable UPC-A ............................................................................................................. 12-9

Enable/Disable UPC-E ............................................................................................................. 12-9

Enable/Disable UPC-E1 ........................................................................................................... 12-10

Enable/Disable EAN-8/JAN-8 .................................................................................................. 12-10

Enable/Disable EAN-13/JAN-13 .............................................................................................. 12-11

Enable/Disable Bookland EAN ................................................................................................ 12-11

Decode UPC/EAN/JAN Supplementals ................................................................................... 12-12

User-Programmable Supplementals ........................................................................................ 12-15

UPC/EAN/JAN Supplemental Redundancy ............................................................................. 12-15

Page 13

Table of Contents xi

UPC/EAN/JAN Supplemental AIM ID Format .......................................................................... 12-16

Transmit UPC-A Check Digit ................................................................................................... 12-17

Transmit UPC-E Check Digit ................................................................................................... 12-17

Transmit UPC-E1 Check Digit ................................................................................................. 12-18

UPC-A Preamble ..................................................................................................................... 12-19

UPC-E Preamble ..................................................................................................................... 12-20

UPC-E1 Preamble ................................................................................................................... 12-21

Convert UPC-E to UPC-A ........................................................................................................ 12-22

Convert UPC-E1 to UPC-A ...................................................................................................... 12-22

EAN-8/JAN-8 Extend ............................................................................................................... 12-23

Bookland ISBN Format ............................................................................................................ 12-24

UCC Coupon Extended Code .................................................................................................. 12-25

Coupon Report ......................................................................................................................... 12-26

ISSN EAN ................................................................................................................................ 12-27

Code 128 ....................................................................................................................................... 12-28

Enable/Disable Code 128 ........................................................................................................ 12-28

Set Lengths for Code 128 ........................................................................................................ 12-28

Enable/Disable GS1-128 (formerly UCC/EAN-128) ................................................................. 12-30

Enable/Disable ISBT 128 ......................................................................................................... 12-30

ISBT Concatenation ................................................................................................................. 12-31

Check ISBT Table .................................................................................................................... 12-32

ISBT Concatenation Redundancy ............................................................................................ 12-32

Code 128 Security Level .......................................................................................................... 12-33

Code 39 ......................................................................................................................................... 12-34

Enable/Disable Code 39 .......................................................................................................... 12-34

Enable/Disable Trioptic Code 39 ............................................................................................. 12-34

Convert Code 39 to Code 32 ................................................................................................... 12-35

Code 32 Prefix ......................................................................................................................... 12-35

Set Lengths for Code 39 .......................................................................................................... 12-36

Code 39 Check Digit Verification ............................................................................................. 12-37

Transmit Code 39 Check Digit ................................................................................................. 12-38

Code 39 Full ASCII Conversion ............................................................................................... 12-38

Code 39 Buffering (Scan & Store) ........................................................................................... 12-39

Code 39 Security Level ............................................................................................................ 12-42

Code 93 ......................................................................................................................................... 12-43

Enable/Disable Code 93 .......................................................................................................... 12-43

Set Lengths for Code 93 .......................................................................................................... 12-43

Code 11 ......................................................................................................................................... 12-45

Code 11 ................................................................................................................................... 12-45

Set Lengths for Code 11 .......................................................................................................... 12-45

Code 11 Check Digit Verification ............................................................................................. 12-47

Transmit Code 11 Check Digits ............................................................................................... 12-48

Interleaved 2 of 5 (ITF) .................................................................................................................. 12-48

Enable/Disable Interleaved 2 of 5 ............................................................................................ 12-48

Set Lengths for Interleaved 2 of 5 ............................................................................................ 12-49

I 2 of 5 Check Digit Verification ................................................................................................ 12-50

Transmit I 2 of 5 Check Digit .................................................................................................... 12-51

Convert I 2 of 5 to EAN-13 ....................................................................................................... 12-51

I 2 of 5 Security Level .............................................................................................................. 12-52

Page 14

xii DS457 Fixed Mount Imager Integration Guide

Discrete 2 of 5 (DTF) ..................................................................................................................... 12-53

Enable/Disable Discrete 2 of 5 ................................................................................................. 12-53

Set Lengths for Discrete 2 of 5 ................................................................................................ 12-53

Codabar (NW - 7) .......................................................................................................................... 12-55

Enable/Disable Codabar .......................................................................................................... 12-55

Set Lengths for Codabar .......................................................................................................... 12-55

CLSI Editing ............................................................................................................................. 12-57

NOTIS Editing .......................................................................................................................... 12-57

Codabar Upper or Lower Case Start/Stop Characters Transmission ...................................... 12-58

MSI ................................................................................................................................................ 12-59

Enable/Disable MSI ................................................................................................................. 12-59

Set Lengths for MSI ................................................................................................................. 12-59

MSI Check Digits ..................................................................................................................... 12-61

Transmit MSI Check Digit(s) .................................................................................................... 12-62

MSI Check Digit Algorithm ....................................................................................................... 12-62

Chinese 2 of 5 ................................................................................................................................ 12-63

Enable/Disable Chinese 2 of 5 ................................................................................................. 12-63

Matrix 2 of 5 ................................................................................................................................... 12-63

Enable/Disable Matrix 2 of 5 .................................................................................................... 12-63

Set Lengths for Matrix 2 of 5 .................................................................................................... 12-64

Matrix 2 of 5 Check Digit .......................................................................................................... 12-65

Transmit Matrix 2 of 5 Check Digit ........................................................................................... 12-65

Korean 3 of 5 ................................................................................................................................. 12-66

Enable/Disable Korean 3 of 5 .................................................................................................. 12-66

Inverse 1D ..................................................................................................................................... 12-67

Postal Codes ................................................................................................................................. 12-68

US Postnet ............................................................................................................................... 12-68

US Planet ................................................................................................................................. 12-68

Transmit US Postal Check Digit ............................................................................................... 12-69

UK Postal ................................................................................................................................. 12-69

Transmit UK Postal Check Digit ............................................................................................... 12-70

Japan Postal ............................................................................................................................ 12-70

Australia Post ........................................................................................................................... 12-71

Australia Post Format .............................................................................................................. 12-72

Netherlands KIX Code ............................................................................................................ 12-73

USPS 4CB/One Code/Intelligent Mail ...................................................................................... 12-74

UPU FICS Postal ..................................................................................................................... 12-74

GS1 DataBar (formerly RSS, Reduced Space Symbology) .......................................................... 12-75

GS1 DataBar ............................................................................................................................ 12-75

GS1 DataBar Limited ............................................................................................................... 12-76

GS1 DataBar Limited Security Level ....................................................................................... 12-77

GS1 DataBar Expanded .......................................................................................................... 12-78

Convert GS1 DataBar to UPC/EAN ......................................................................................... 12-78

Composite ...................................................................................................................................... 12-79

Composite CC-C ...................................................................................................................... 12-79

Composite CC-A/B ................................................................................................................... 12-79

Composite TLC-39 ................................................................................................................... 12-80

UPC Composite Mode ............................................................................................................. 12-81

Composite Beep Mode ............................................................................................................ 12-82

GS1-128 Emulation Mode for UCC/EAN Composite Codes .................................................... 12-82

Page 15

Table of Contents xiii

2D Symbologies ............................................................................................................................. 12-83

Enable/Disable PDF417 ........................................................................................................... 12-83

Enable/Disable MicroPDF417 .................................................................................................. 12-83

Code 128 Emulation ................................................................................................................ 12-84

Data Matrix ............................................................................................................................... 12-85

Data Matrix Inverse .................................................................................................................. 12-86

Decode Mirror Images (Data Matrix Only) ............................................................................... 12-87

Maxicode .................................................................................................................................. 12-88

QR Code .................................................................................................................................. 12-88

QR Inverse ............................................................................................................................... 12-89

MicroQR ................................................................................................................................... 12-90

Aztec ........................................................................................................................................ 12-90

Aztec Inverse ........................................................................................................................... 12-91

Redundancy Level ......................................................................................................................... 12-92

Security Level ................................................................................................................................ 12-94

Intercharacter Gap Size ........................................................................................................... 12-95

Macro PDF Features ...................................................................................................................... 12-96

Macro PDF User Indications .................................................................................................... 12-96

Macro PDF Transmit / Decode Mode Symbols ........................................................................ 12-97

Transmit Macro PDF Control Header ...................................................................................... 12-98

Escape Characters .................................................................................................................. 12-98

Flush Macro Buffer ................................................................................................................... 12-99

Abort Macro PDF Entry ............................................................................................................ 12-99

Chapter 13: Driver’s License Set Up (DS457-DL)

Introduction .................................................................................................................................... 13-1

Driver’s License Parsing ................................................................................................................ 13-1

Parsing Driver’s License Data Fields (Embedded Driver's License Parsing) ................................. 13-2

Embedded Driver's License Parsing Criteria - Code Type ....................................................... 13-2

Driver’s License Parse Field Bar Codes .................................................................................. 13-3

AAMVA Parse Field Bar Codes ............................................................................................... 13-6

Parsing Rule Example ................................................................................................................... 13-16

Embedded Driver's License Parsing ADF Example ................................................................. 13-20

Field Update Procedure ................................................................................................................. 13-22

User Preferences ........................................................................................................................... 13-23

Set Default Parameter ............................................................................................................. 13-23

Send Keystroke (Control Characters and Keyboard Characters) ............................................ 13-23

Chapter 14: 123Scan

Introduction .................................................................................................................................... 14-1

Communication with 123Scan ....................................................................................................... 14-1

123Scan Requirements ................................................................................................................. 14-2

Scanner SDK, Other Software Tools, and Videos ......................................................................... 14-2

Chapter 15: Advanced Data Formatting

Introduction .................................................................................................................................... 15-1

Page 16

xiv DS457 Fixed Mount Imager Integration Guide

Appendix A: Standard Default Parameters

Default Parameters ........................................................................................................................ A-1

Reserved Parameters .................................................................................................................... A-13

Appendix B: Programming Reference

Code Identifiers .............................................................................................................................. B-1

AIM Code Identifiers ................................................................................................................ B-1

Appendix C: Sample Bar Codes

Code 39 ......................................................................................................................................... C-1

UPC/EAN ....................................................................................................................................... C-1

UPC-A, 100 % .......................................................................................................................... C-1

EAN-13, 100 % ........................................................................................................................ C-1

Code 128 ....................................................................................................................................... C-2

Interleaved 2 of 5 ........................................................................................................................... C-2

GS1 DataBar Omnidirectional ....................................................................................................... C-2

PDF417 .......................................................................................................................................... C-2

Data Matrix .................................................................................................................................... C-3

Maxicode ....................................................................................................................................... C-3

Appendix D: Numeric Bar Codes

Numeric Bar Codes ....................................................................................................................... D-1

Cancel ............................................................................................................................................ D-3

Appendix E: ASCII Character Set

Index

Page 17

ABOUT THIS GUIDE

Introduction

The DS457 Fixed Mount Imager Integration Guide provides general instructions for mounting, setting up, and

programming the DS457 fixed mount imager.

Configurations

The DS457 offers the following configurations:

•

DS457-SR - Standard range imager

•

DS457-HD - High density imager

•

DS457-DP - High density imager with Direct Part Marking (DPM) software

•

DS457-DL - Standard range imager, driver’s license parsing

Chapter Descriptions

Topics covered in this guide are as follows:

•

Chapter 1, Getting Started provides an overview of the DS457 imager, including applications and a theory of

operation.

•

Chapter 2, Installation provides mounting and connection information for the DS457, and lists accessories.

•

Chapter 3, Imaging provides information on the aiming and illumination system, and includes imaging tips

and a list of supported symbologies.

•

Chapter 4, Specifications provides technical specifications including electrical and mechanical information,

and provides decode ranges.

•

Chapter 5, Maintenance & Troubleshooting provides maintenance and troubleshooting tips.

•

Chapter 6, User Preferences provides programming bar codes for selecting user preference features.

•

Chapter 7, Imager Preferences provides programming bar codes for selecting imager preference features.

Page 18

xvi DS457 Fixed Mount Imager Integration Guide

•

Chapter 8, SSI Interface describes how to set up the decoder with a Simple Serial Interface (SSI) host.

Use SSI to program the decoder via bar code menu or SSI hosts commands.

•

Chapter 9, Serial Interface describes how to set up the decoder with a serial host. Use the serial interface

to connect the decoder to point-of-sale devices, host computers, or other devices with an available serial

port (e.g., com port).

•

Chapter 10, USB Interface describes how to set how to set up the decoder with a USB host. The decoder

connects directly to a USB host, or a powered USB hub, and is powered by it.

•

Chapter 11, OCR Reading describes how to set up the decoder for OCR programming.

•

Chapter 12, Symbologies describes all symbology features and provides the programming bar codes

necessary for selecting these features for the decoder.

•

Chapter 13, Driver’s License Set Up (DS457-DL) describes how to program the DS457-DL imager to

read and use the data contained in the 2D bar codes on US driver's licenses and AAMVA compliant ID

cards.

•

Chapter 14, 123Scan provides information on the PC-based software tool that enables rapid and easy

customized setup of scanners by Zebra.

•

Chapter 15, Advanced Data Formatting provides instructions for using ADF, a means of customizing data

before transmission to the host device.

•

Appendix A, Standard Default Parameters provides a table of all host and miscellaneous defaults.

•

Appendix B, Programming Reference provides a table of AIM code identifiers, ASCII character

conversions, and keyboard maps.

•

Appendix C, Sample Bar Codes includes sample bar codes of various code types.

•

Appendix D, Numeric Bar Codes includes the numeric bar codes to scan for parameters requiring

specific numeric values.

•

Appendix E, ASCII Character Set provides ASCII character value tables.

Notational Conventions

The following conventions are used in this document:

•

“Imager” refers to the DS457 imager

•

“Engine” or “imaging engine” refers to the SE4500 imaging engine.

•

Italics highlight chapters and sections in this and related documents

•

Bullets (•) indicate:

• action items

• lists of alternatives

• lists of required steps that are not necessarily sequential.

•

Sequential lists (e.g., those that describe step-by-step procedures) appear as numbered lists.

Page 19

About This Guide xvii

*Baud Rate 9600

(6)

Feature/Option

* Indicates default

Option value for programming

•

Throughout the programming bar code menus, asterisks (*) are used to denote default parameter

settings.

NOTE This symbol indicates something of special interest or importance to the reader. Failure to read the note

will not result in physical harm to the reader, equipment or data.

CAUTION This symbol indicates that if this information is ignored, the possibility of data or material damage may

occur.

WARNING! This symbol indicates that if this information is ignored the possibility that serious personal

Related Documents

•

DS457 Fixed Mount Imager Quick Reference Guide, p/n 72-144417-xx, provides information for setting

up the DS457.

•

Simple Serial Interface (SSI) Programmer Guide, p/n 72E-40451-xx, provides system requirements and

programming information about the Simple Serial Interface, which enables Zebra devices to

communicate with a serial host.

•

Symbol Native Application Programming Interface (SNAPI) Programmer Guide, p/n 72E-71370-xx,

describes the Symbol Native Application Programming Interface (SNAPI), a development library used to

implement USB communication between a Zebra scanner and a Windows 98/2000/XP host.

•

Advanced Data Formatting Programmer Guide, p/n 72E-69680-xx, provides bar codes and instructions

for advanced programming of Zebra scanners and imagers.

For the latest version of these guides and software, and all Zebra guides, go to: http://www.zebra.com/support.

injury may occur.

Page 20

xviii DS457 Fixed Mount Imager Integration Guide

Service Information

If you have a problem using the equipment, contact your facility's technical or systems support. If there is a

problem with the equipment, they will contact the Zebra Global Customer Support Center at:

http://www.zebra.com/support.

When contacting Zebra support, please have the following information available:

•

Serial number of the unit

•

Model number or product name

•

Software type and version number

Zebra responds to calls by e-mail, telephone or fax within the time limits set forth in service agreements.

If your problem cannot be solved by Zebra support, you may need to return your equipment for servicing and

will be given specific directions. Zebra is not responsible for any damages incurred during shipment if the

approved shipping container is not used. Shipping the units improperly can possibly void the warranty.

If you purchased your business product from a Zebra business partner, please contact that business partner

for support.

Page 21

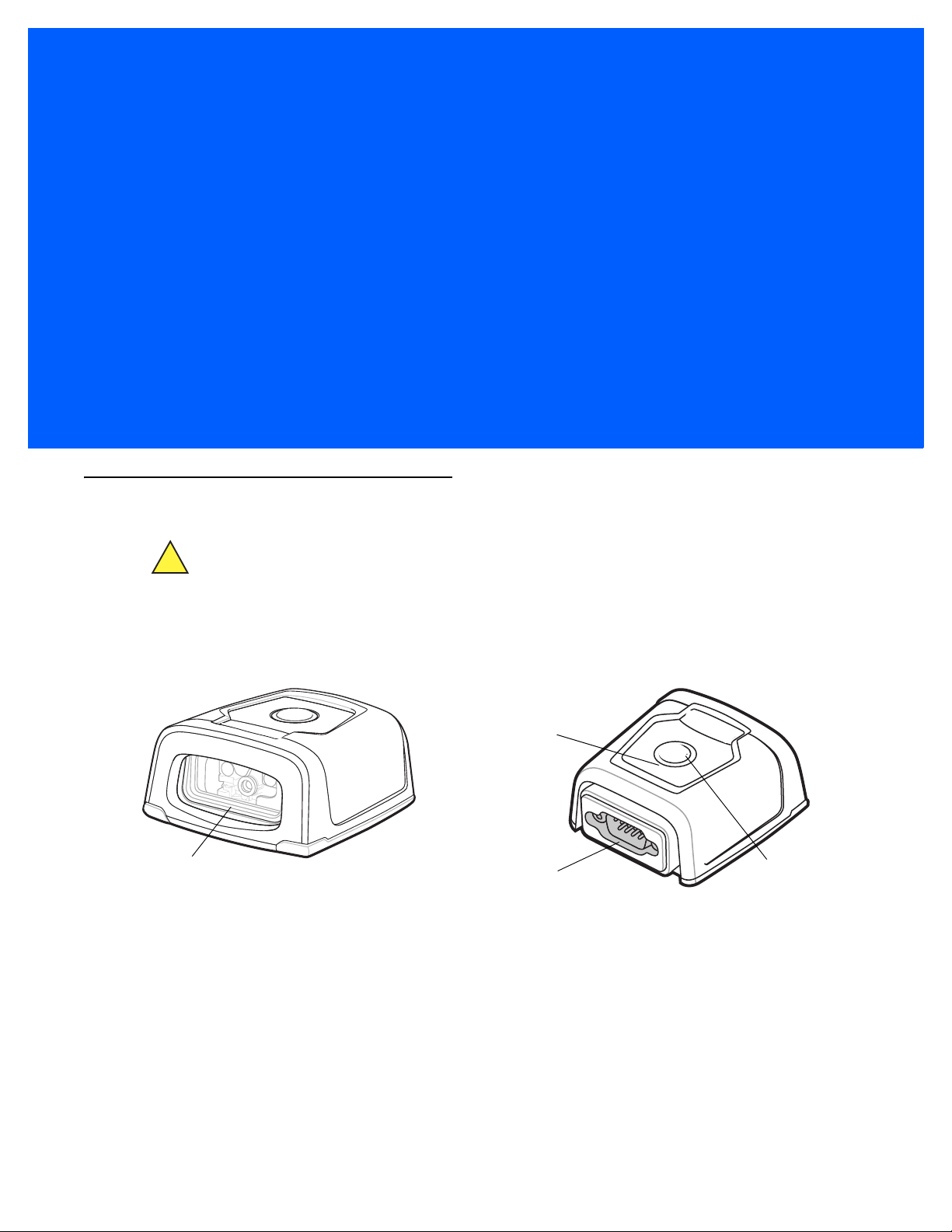

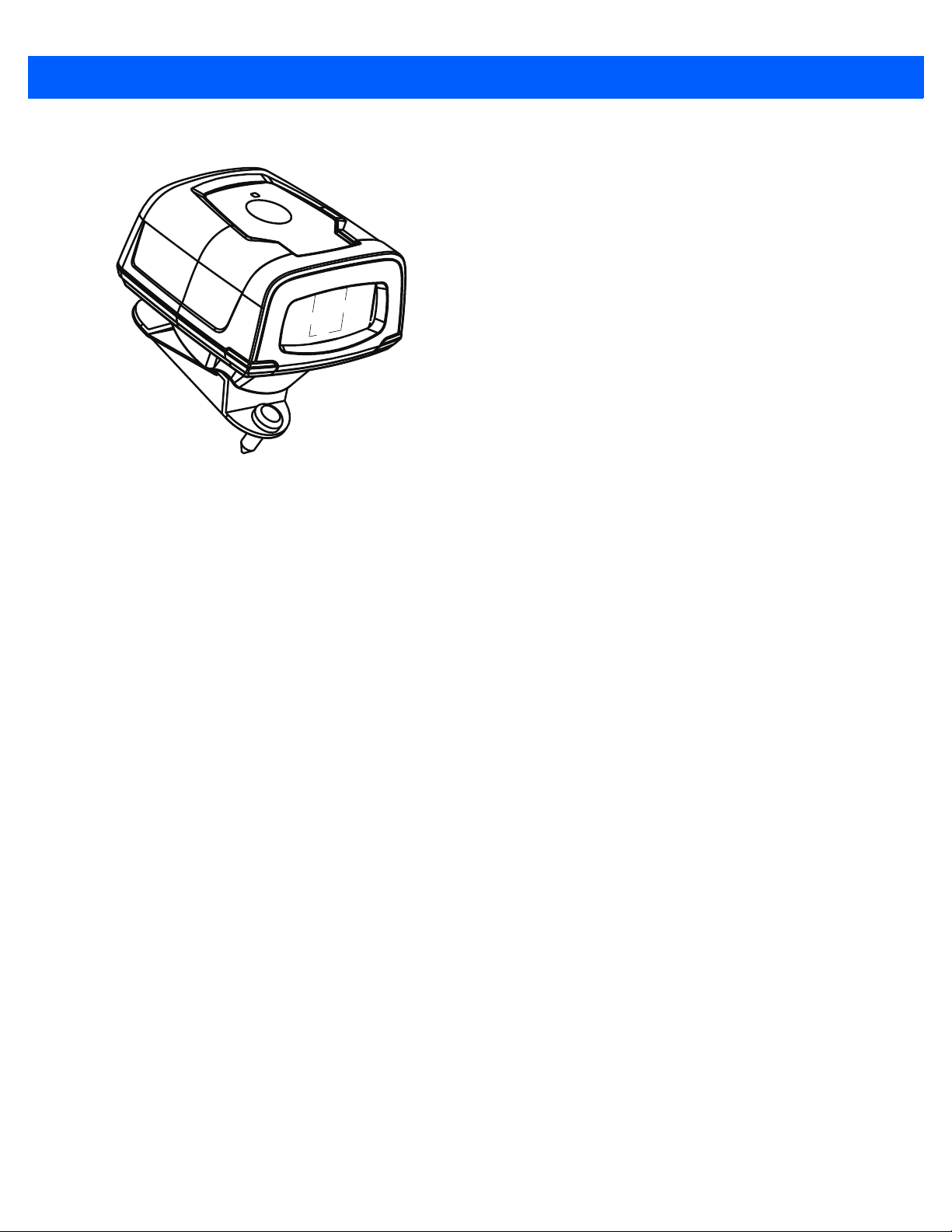

CHAPTER 1 GETTING STARTED

!

Indicator LED

Trigger Button

I/O Connector

Imager Window

Overview

CAUTION Use of controls, adjustments or procedures other than those specified here can result in

hazardous laser light exposure.

The DS457 fixed-mount imager is specifically designed for standalone applications and OEM applications. The

imager is extremely compact, provides easy and flexible integration into a host device, and offers

high-performance imaging on 1D and 2D bar codes. The DS457 is ideal for a wide variety of uses:

zero-footprint point-of-sale, kiosks, embedded diagnostic equipment, conveyor belts, and many more.

Figure 1-1

This integration guide includes programming parameters and describes the theory of operation, installation,

specifications, and configuration.

DS457 Fixed Mount Imager

Page 22

1 - 2 DS457 Fixed Mount Imager Integration Guide

DS457 Features

•

Quick and easy integration for OEM devices

•

Excellent imaging performance on all 1D and 2D bar codes

•

RS-232 (serial) or USB interface

•

Excellent motion tolerance

•

LEDs indicating power status and successful decodes

•

Trigger button for manual triggering

•

Small footprint optimal for "Zero Footprint" POS scanning applications

•

Direct Part Marking (DPM) support (DPM version only). Scan 2D symbols etched directly onto an item’s

surface (via laser etching and dot peening) for permanent identification.

•

Driver's license (DL) parsing (DL version only)

•

Easy programming and configuration

•

Integrated threaded mounting screw holes

•

Flexible mounting options

•

IP54 sealing

Theory of Operation

During image capture:

1. The image sensor array in the embedded SE4500 imaging engine captures an image of the bar code

through the engine’s optical lens. If necessary, the engine automatically adjusts illumination, exposure, and

other parameters to obtain the best quality image.

2. The imaging engine sends the image to the DS457 CPU.

3. The DS457 CPU processes the image to identify the target bar code(s), decodes them, and transmits the

decoded data to the host.

Set various parameters provided in this guide to adjust the performance of the DS457 to match the application

or desired usage profile.

Page 23

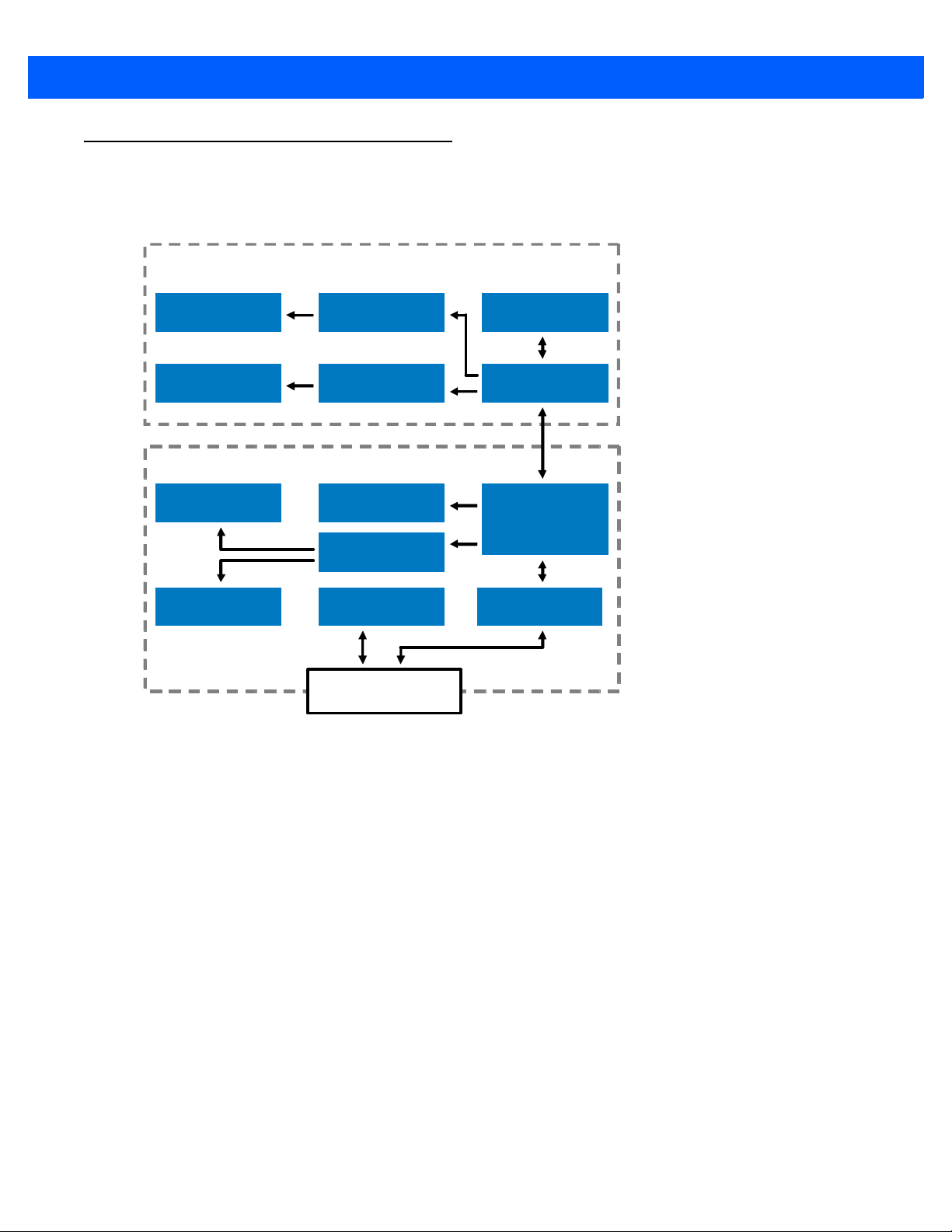

Block Diagram

LED Illumination

Driver

SE4500 Engine

Illumination LEDs

Laser Aimer Laser Aimer Driver Microprocessor

WVGA Sensor

Internal Beeper Internal Trigger

Interface CircuitryGreen/Red LEDs

PXA320

MIcrorprocessor,

RAM, and Flash

Power Regulation

Decoder/Interface

DB-9 Connector

User Interface

Drivers

The DS457 imager block diagram illustrates the functional relationship of the DS457 components. This section

also provides a description of each component in the block diagrams.

Getting Started 1 - 3

Figure 1-2

DS457 Block Diagram Descriptions