Page 1

CLP100

Bar Code Reader

OPERATING INSTRUCTIONS

Page 2

Software Versions

Operating Instructions

CLP100 Bar Code Reader

Software Versions

Device/Software/Tool Function Version

CLP100 Firmware from V 1.10

CLP Setup Configuration software from V 1.10

CLP Setup Help Online help (HTML) from V 1.10

Copyright

Copyright © 2007 - 2008

SICK AG Waldkirch

Auto Ident, Reute Plant

Nimburger Strasse 11

79276 Reute

Germany

Trademarks

Windows 95/98

TM

er

are trademarks or registered trademarks of the Microsoft Corporation in the USA and

TM

, Windows NT4.0TM, Windows 2000TM, Windows XPTM and Internet Explor-

other countries.

TM

Adobe

ReaderTM is a trademark of Adobe Systems Incorporated.

Latest Manual Version

For the latest version of this manual (PDF), see www.sick.com.

2 © SICK AG · Division Auto Ident · Germany · All rights reserved 8008912/R289/2008-11-28

Page 3

Operating Instructions

CLP100 Bar Code Reader

Contents

Contents

1 Notes on this document ............................................................................................. 6

1.1 Function.................................................................................................................... 6

1.2 Target audience ....................................................................................................... 6

1.3 Information content .................................................................................................6

1.4 Symbols used ........................................................................................................... 7

2 Safety information ...................................................................................................... 8

2.1 Authorized users ...................................................................................................... 8

2.2 Intended use ............................................................................................................ 8

2.3 General safety instructions ..................................................................................... 9

2.4 Quick- Stop and Quick-Restart ................................................................................9

2.5 Environmental information....................................................................................10

3 Product description...................................................................................................11

3.1 Design.....................................................................................................................11

3.2 Product features and functions (overview) ..........................................................14

3.3 Working method of the device ..............................................................................15

3.4 Display and operating elements ...........................................................................15

4 Installation ................................................................................................................. 17

4.1 Installation sequence ............................................................................................17

4.2 Preparations for installation..................................................................................17

4.3 Installation site......................................................................................................18

4.4 Installation and adjustment of the device ...........................................................21

4.5 Installing the reading-pulse sensor ......................................................................22

4.6 Disassembling the device .....................................................................................22

5 Electrical installation ................................................................................................23

5.1 Overview of installation sequences ......................................................................23

5.2 Planning the electrical installation .......................................................................23

5.3 Electrical connections and cables ........................................................................24

5.4 Carry out the electrical installation.......................................................................25

6 Startup and configuration........................................................................................29

6.1 Overview ot the startup procedure .......................................................................29

6.2 Quick-Start..............................................................................................................29

6.3 Operating modes and output of the read result ..................................................30

6.4 Configuration..........................................................................................................30

6.5 Default setting........................................................................................................35

6.6 Switching off the CLP100......................................................................................36

7 Maintenance .............................................................................................................. 37

7.1 Maintennance during operation ...........................................................................37

7.2 Cleaning the CLP100.............................................................................................37

7.3 Replacing a CLP100 ..............................................................................................38

7.4 Disposal..................................................................................................................39

8 Troubleshooting.........................................................................................................40

8.1 Possible errors and faults .....................................................................................40

8.2 Troubleshooting table............................................................................................41

8.3 SICK support ..........................................................................................................42

9 Technical data ........................................................................................................... 43

9.1 Data sheet CLP100 bar code reader....................................................................43

9.2 Reading field diagram ...........................................................................................44

9.3 Dimensional drawings ...........................................................................................45

10 Appendix.....................................................................................................................46

10.1 Appendix overview .................................................................................................46

10.2 Installation and handling of the CLP Setup software..........................................46

10.3 Calculation of the number of scans......................................................................51

10.4 Calculation of the code length of a bar code.......................................................52

10.5 Command language for CLP100 bar code reader...............................................53

10.6 EC Declaration of Conformity................................................................................56

8008912/R289/2008-11-28 © SICK AG · Division Auto Ident · Germany · All rights reserved 3

Page 4

Figures and tables

Abbreviations used

CLP Code Leser Parallel (Code Reader Parallel)

CCD Charge Coupled Device

PLC Progammable Logic Controller

HTML Hyper Text Markup Language

LED Light Emitting Diode

Tables

Table 1-1: Target group of the document........................................................................... 6

Table 2-1: Required qualifications for starting up the CLP100 ........................................ 8

Table 3-1: CLP100 delivery ...............................................................................................13

Table 3-2: Variants of the CLP100....................................................................................13

Table 3-3: Overview of the product features and functions............................................14

Table 3-4: Meaning of the LEDs........................................................................................16

Table 4-1: Permissible angle occurring between the scan line and the bar code bars 19

Table 5-1: Pin assignment of the D Sub plug...................................................................24

Table 5-2: Assignment of the wire colors of the open cable end ...................................24

Table 5-3: Maximum cable length between the CLP100 and the host computer.........25

Table 5-4: Communication parameters of the host interface (default setting) .............26

Table 5-5: Characteristic data of the "Sensor" switching input ......................................27

Table 5-6: Characteristic data of the "Result" switching output .....................................28

Table 6-1: Default setting of the parameters of the CLP100 .........................................35

Table 8-1: Troubleshooting table ......................................................................................41

Table 9-1: Technical specification of the CLP100...........................................................43

Table 10-1: Default settings of CLP Setup .........................................................................48

Table 10-2: Functions of the CLP Setup configuration software (overview) ....................50

Table 10-3: Auxiliary table for calculating the code length of a bar code ........................52

Table 10-4: Command language for CLP bar code readers ..............................................53

Operating Instructions

CLP100 Bar Code Reader

Figures

Fig. 3-1: Design of the CLP100 with front end reading window .....................................12

Fig. 3-2: Design of the CLP100 with side reading window .............................................12

Fig. 3-3: Function of the CLP100......................................................................................15

Fig. 4-1: Position of the threaded holes

Fig. 4-2: Reading distance to the object ..........................................................................18

Fig. 4-3: 90° angle between the scan line and the bar code bars................................19

Fig. 4-4: Reading angle occurring between the scan line and the bar code bars.........19

Fig. 4-5: Angle between the emitted light and the bar code (tilted to the

perpendicular) .....................................................................................................20

Fig. 4-6: Adjustment of the CLP100 in order to avoid reflections;

a: With front end reading window, b: With side reading window.....................21

Fig. 4-7: Installation site for the reading-pulse sensor and the reflector

(b smaller than a)................................................................................................22

Fig. 5-1: Wiring the host interface (RS 232) ....................................................................26

Fig. 5-2: Wiring the terminal interface (RS 232 TTL).......................................................27

Fig. 5-3: Wiring of the "Sensor" switching input...............................................................27

Fig. 5-4: Wiring of the "Result" switching output (NPN) ..................................................28

Fig. 6-1: Bar code sample (code 39, 0.35 mm (13.8 mil)), printing ratio 2:1)..............29

Fig. 6-2: Configuration with CLP Setup and storage of the parameter set....................30

Fig. 6-3: Terminal emulator with input of a command string .........................................32

Fig. 6-4: Terminal emulator with reading results of the CLP100 in diagnosis mode.... 34

Fig. 7-1: Cleaning the reading window .............................................................................38

Fig. 9-1: Reading field diagram.........................................................................................44

Fig. 9-2: Dimensions of the CLP100 with front end reading window.............................45

!at CLP100 ....................................................18

4 © SICK AG · Division Auto Ident · Germany · All rights reserved 8008912/R289/2008-11-28

Page 5

Operating Instructions

CLP100 Bar Code Reader

Figures and tables

Fig. 9-3: Dimensions of the CLP100 with side reading window .................................... 45

Fig. 10-1: User interface of the CLP Setup software......................................................... 49

Fig. 10-2: Calculation example: Number of scans for ladder positioning of

the bar code bars ............................................................................................... 51

Fig. 10-3: Copy of the EC Declaration of of conformity, page 1 (scaled down in size) ... 56

8008912/R289/2008-11-28 © SICK AG · Division Auto Ident · Germany · All rights reserved 5

Page 6

Chapter 1 Operating Instructions

Notes on this document

CLP100 Bar Code Reader

1 Notes on this document

1.1 Function

This document provides instructions for technical staff on the installation and operation of

the CCD bar code reader CLP100 in the following versions:

• front end or side reading window

• connection via cable with 9-pin D Sub plug or cable with open end

A summary of all device versions is given in Table 3-2, Page 13.

The document contains information on

• Installation and electrical installation

• Startup and configuration

• Maintenance

• Troubleshooting

• Replacing the CLP100 bar code reader

All actions are described step-by-step.

Important The CLP100 bar code reader will all simply be called "CLP100" below.

1.2 Target audience

This document is intended for persons who are responsible for the following activities:

Tasks Target group

Installation, electrical installation, maintenance and replacement

Startup and configuration Qualified staff, e.g. technicians and engineers

Table 1-1: Target group of the document

Qualified staff, e.g. electricians and service technicians

1.3 Information content

This document contains all the information required for the installation, electrical installation and startup of the CLP100 with the default setting at the installation location.

Configuration of the CLP100 for the application-specific reading conditions is carried out

using the CLP Setup configuration software. The CLP Setup configuration software contains

an online help system to facilitate configuration. Installation and use of the software are described in the appendix.

Further information on the construction of the bar code reader as well as the bar code technology can be obtained from SICK AG, Auto Ident Division.

On the Internet at www.sick.com.

6 © SICK AG · Division Auto Ident · Germany · All rights reserved 8008912/R289/2008-11-28

Page 7

Operating Instructions Chapter 1

CLP100 Bar Code Reader

Notes on this document

1.4 Symbols used

To gain easier access, some information in this document is emphasised as follows:

NOTICE

Notice!

Indicates a potential risk of damage or impair on the functionality of the CLP100.

WARNING

Warning notice!

A warning noctice indicates real or potential danger. This should protect you against accidents.

The safety symbol next to the warning notice indicates why there is a risk of accident. e.g.

due to electricity. The warning levels (CAUTION, WARNING, DANGER) indicate the seriousness of the risk.

¾ Carefully read and follow the warning notices.

Reference Italic script denotes a reference to further information.

Important This important note informs you about specific features.

Recommendation A "Recommendation" provides information on how to carry out an action optimally.

TIP A "TIP" explains the setting possibilities in the CLP Setup configuration software.

T

HIS FONT characterizes a term used in the user interface of the CLP Setup configuration soft-

ware (for example, menu item, tab card).

¾ There is a procedure which needs to be carried out. This symbol indicates operational in-

structions which only contain one operational step or operational steps in warning notices

which do not have to be followed in any particular order.

Operational instructions comprising several steps are denoted using consecutive numbers.

8008912/R289/2008-11-28 © SICK AG · Division Auto Ident · Germany · All rights reserved 7

Page 8

Chapter 2 Operating Instructions

Safety information

CLP100 Bar Code Reader

2 Safety information

This chapter deals with your safety and operator safety in the operational area.

¾ Read this chapter carefully before using the CLP100.

2.1 Authorized users

The CLP100 must be installed and operated by qualified personnel in order to ensure that

it functions correctly and safely.

NOTICE

Repairs to the CLP100 should only be carried out by qualified and authorised SICK AG

service staff.

The following qualifications are required for the various activities:

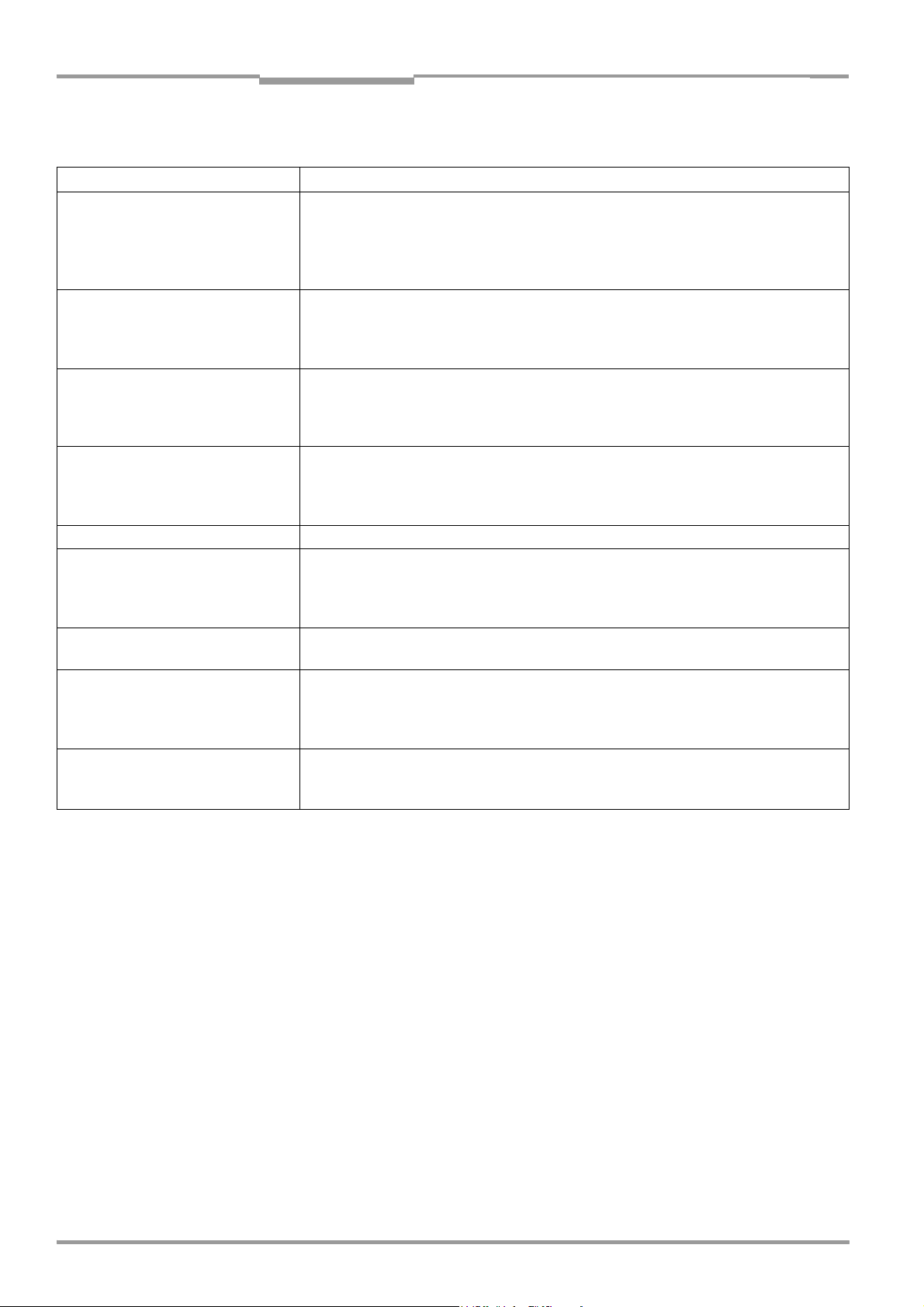

Tasks Qualifications

Installation, maintenance – General technical training

– Knowledge of the standard guidelines relating to safety in the work-

place

Electrical installation,

replacement

Startup, configuration – Basis knowledge of the Windows

Operation of the devices in

each operational area

– Practical electrical training

– Knowledge of the common electrical safety guidelines

– Knowledge regarding the operation of the devices in the relevant ap-

plication (for example, packaging machines, clinical automatic analyzer, access control)

TM

operating system

– Basis knowledge of working with an HTML browser (e.g. Internet

ExplorerTM) for using the online help

– Basic knowledge of data transfer

– Basic knowledge of bar code technology

– Knowledge regarding the operation and handling of the devices in

the relevant application (for example, packaging machines, clinical

automatic analyzer, access control)

– Knowledge of the hardware and software environment of the rele-

vant application

Table 2-1: Required qualifications for starting up the CLP100

2.2 Intended use

The CLP100 is used for the automatic detection and decoding of bar codes. It is installed

as a reading station and reads, for example, bar codes on objects of a clinical automatic

analyser. The CLP100 transmits the decoded bar code information via its host interface to

a host computer for further processing.

NOTICE

Claims under the warranty rendered void!

Any warranty claims against SICK AG shall be deemed invalid in the case changes to the

CLP100, such as opening the housing, this includes modifications during installation and

electrical installation or changes to the SICK software.

¾ Only operated the CLP100 in the permitted ambient air temperature range (see

Chapter 9 Technical data, Page 43).

8 © SICK AG · Division Auto Ident · Germany · All rights reserved 8008912/R289/2008-11-28

Page 9

Operating Instructions Chapter 2

CLP100 Bar Code Reader

Safety information

2.3 General safety instructions

¾ Read the general safety instructions thoroughly and observe them strictly at all activi-

ties at the bar code reader. This also applies to the warnings before the handling instructions in the individual chapters of this document.

2.3.1 LED illumination

CAUTION

LED radiation!

The illumination of the CLP100 operates with LEDs of LED class 1. Under normal and sensible conditions, the accessible radiation of the LEDs is not hazardous.

The entire area of the reading window acts as a LED outlet aperture.

Caution – use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

¾ Never look directly into the illumination.

¾ Do not open the housing.

(Opening the housing does not deactivate the LEDs by the reading pulse.)

¾ Always observe the latest valid version of laser protection regulations.

Important The illumination LEDs operate at a wavelength of λ = 630 nm (visible red light).

The product is classified in LED class 1 in accordance with EN/IEC 60825-1.

Maintenance is not required to ensure compliance with LED class 1.

2.3.2 Electrical installation

NOTICE

• Electrical installation should only be carried out by qualified staff.

• Connect or disconnect current linkages only under de-energised conditions.

• Wire cross sections and their correct protection have to be selected and implemented

according to valid engineering standards.

• Observe the current safety regulations when working on eletrical systems.

2.4 Quick- Stop and Quick-Restart

The CLP100 can be switched on or off using the user’s main switch.

2.4.1 Switching off the CLP100

¾ Switch off the supply voltage or remove the 9-pin D Sub plug.

At the most the last read result is lost.

2.4.2 Switching on the CLP100 again

¾ Switch on the supply voltage or reconnect the 9-pin D Sub plug.

The CLP100 resumes operation with the last parameter set saved.

8008912/R289/2008-11-28 © SICK AG · Division Auto Ident · Germany · All rights reserved 9

Page 10

Chapter 2 Operating Instructions

Safety information

CLP100 Bar Code Reader

2.5 Environmental information

The CLP100 is designed so that it harms the environment as little as possible. It does not

contain or emit any substances harmful to the environment and is not a source of faults for,

for example, coating wetting in paint shops.

The maximum power consumption of the CLP100 amounts to 2 W.

2.5.1 Disposal after final removal from service

At p resent S ICK AG do es n ot take b a ck devi ces which ha v e becom e un usable or i rrepara ble.

¾ Dispose of unusable or irreparable devices in accordance with the respective state reg-

ulations on waste disposal in a manner compatible with the environment.

The CLP100 design allows it to be separated into recyclable secondary raw materials (housing) and hazardous waste (electronic scrap). See Chapter 7.4, Page 39.

10 © SICK AG · Division Auto Ident · Germany · All rights reserved 8008912/R289/2008-11-28

Page 11

Operating Instructions Chapter 3

CLP100 Bar Code Reader

Product description

3 Product description

This chapter describes the design, the features and the functions of the CLP100.

¾ For installation, electrical installation and startup assistance as well as for the applica-

tion-specific configuration of the CLP100 using the CLP Setup configuration software,

please read this chapter prior to carrying out any of the tasks.

3.1 Design

The CLP100 consists of an optical system with CCD line and an electronic unit with integrated decoder. All components are loctated in an industry-compatible housing (enclosure rating IP 40). The light exits and enters via a reading window in the housing.

For an adaptation to on-site space conditions two housings are available: a housing with

front reading window and a housing with side reading window. Via the integrated angle attachment, the reflected light enters through the side reading window at an angle of 90°,

referred to the centre-line of the housing.

Two LEDs on the rear of the CLP100 indicate the status depending on the operating mode.

Depending on the type, the CLP100 is electrically connected by a shielded cable with a

D-Sub plug or with an open end.

8008912/R289/2008-11-28 © SICK AG · Division Auto Ident · Germany · All rights reserved 11

Page 12

Chapter 3 Operating Instructions

Product description

CLP100 Bar Code Reader

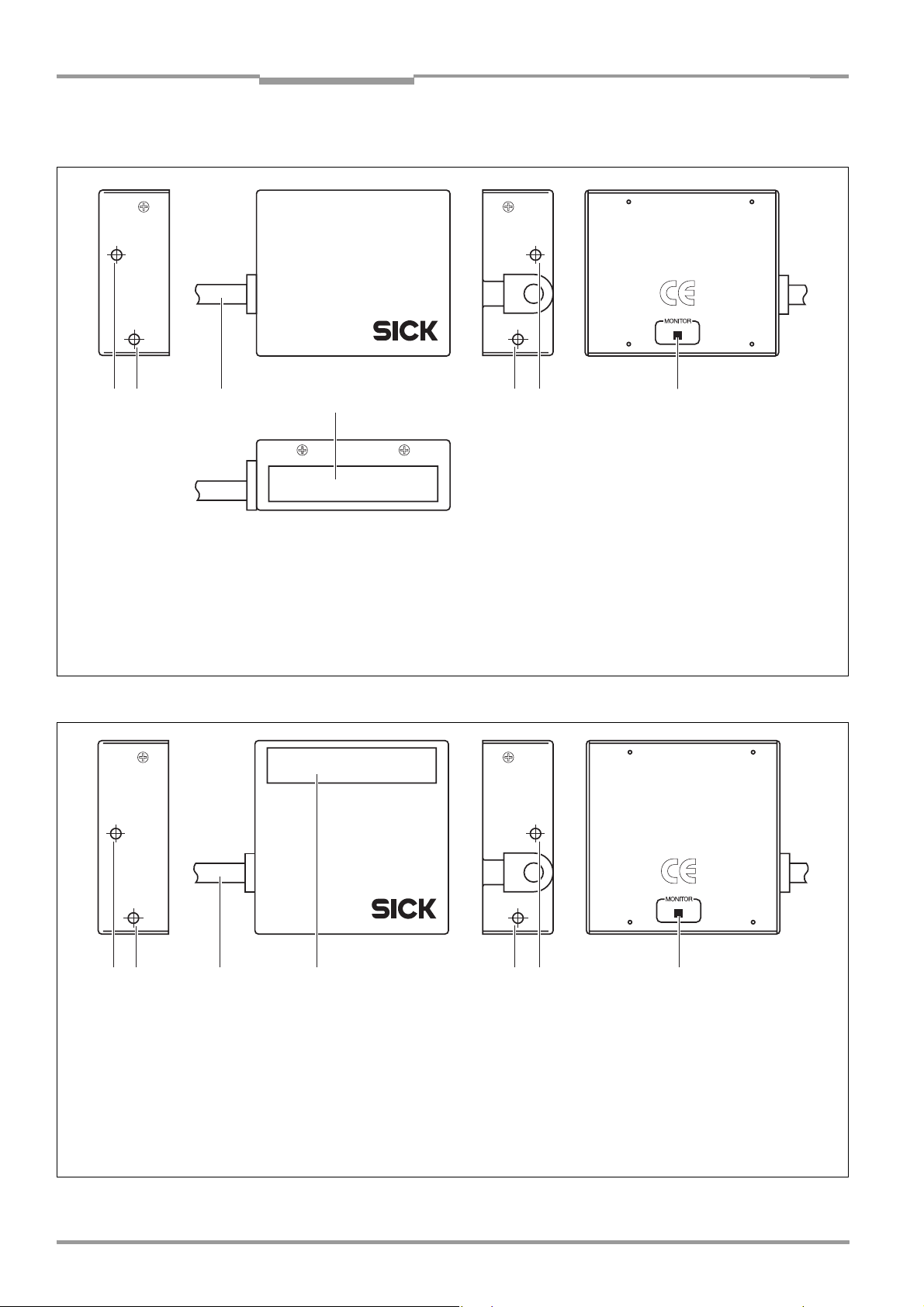

3.1.1 View of device

!! " § !!

Legend:

! Threaded hole M3, 2.5 mm deep

" Connection cable

§ Reading window

$ LED (status display)

Fig. 3-1: Design of the CLP100 with front end reading window

$

!! " § !! $

Legend:

! Threaded hole M3, 2.5 mm deep

" Connection cable

§ Reading window

$ LED (status display)

Fig. 3-2: Design of the CLP100 with side reading window

12 © SICK AG · Division Auto Ident · Germany · All rights reserved 8008912/R289/2008-11-28

Page 13

Operating Instructions Chapter 3

CLP100 Bar Code Reader

Product description

3.1.2 Scope of delivery

Delivery of the CLP100 includes the following components:

No. Component Comment

1 CLP100 bar code reader Type depends on version, see Table 3-2

1 Notes on device with electrical connection dia-

gram and quick start as primary information

1 CD-ROM "Manuals & Software Bar Code Scan-

ners"

CLP100 Operating Instructions in printed

form, in German and/or English

Table 3-1: CLP100 delivery

Included in the device packing of the

CLP100

Included in the device packing of the

CLP100

Optional, depending on the number of

issues explicitly ordered upon purchase

3.1.3 Contents of the CD-ROM (no. 2029112)

• CLP Setup: Configuration software for standard PC (Windows

TM

) with integrated

online help system CLP Setup Help (HTML files)

• CLP100 operating instructions: PDF version in German and English as well as further

publications of other SICK devices (connection modules, bar code scanners)

• Adobe Reader: Freely available PC software for displaying PDF files

Important All current versions of publications and programs on the CD-ROM can also be downloaded

at www.sick.com.

3.1.4 Variants

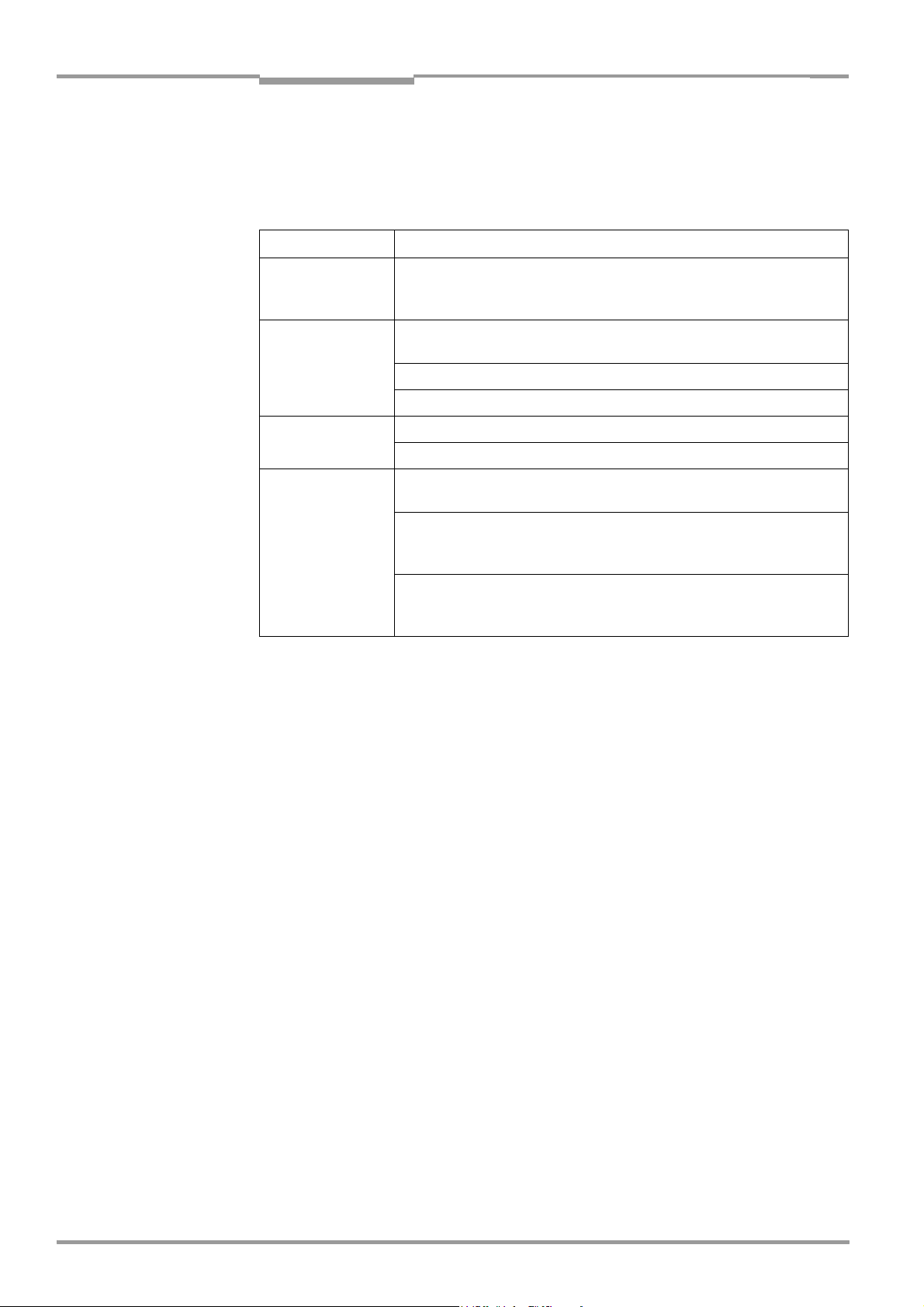

At present the CLP100 is available in the following variants:

Device Order no. Reading window Connection

CLP100-0010 1018331 Front 9-pin D-Sub plug

CLP100-2010 1018332 Side 9-pin D-Sub plug

CLP100-0110 1018333 Front Open cable end

CLP100-2110 1018334 Side Open cable end

Table 3-2: Variants of the CLP100

3.1.5 System requirements

The following are required to start-up and operate the CLP100:

• A supply power pack with a stabilised output voltage of 5 V DC ± 5 % in accordance with

IEC 60364-4-41 (functional extra-low voltage) and at least 2 W power output

• In the case of external reading pulsing via the "Sensor" switching input: A suitable sen-

sor for signaling an object with bar code, for example, a photoelectric reflex switch

• A PC as followed:

– Min. 80486, 66 MHz, 16 MB RAM, CD drive, a serial port (COM x), mouse

(recommended), colour screen (resolution min. 800 x 600 pixel)

– Operating system Windows 95

Windows XP

TM

.

TM

/98TM, Windows NTTM, Windows 2000TM or

– Free space available on the hard disk: approx. 6.5 MB

• An RS 232 data connection cable (null modem, TxD and RxD transposed)

• In order to install the CLP Setup configuration software and to use the CLP Setup Help

online help system an HTML browser, for example, Internet Explorer

TM

.

8008912/R289/2008-11-28 © SICK AG · Division Auto Ident · Germany · All rights reserved 13

Page 14

Chapter 3 Operating Instructions

Product description

CLP100 Bar Code Reader

3.2 Product features and functions (overview)

Feature Characteristic

High-performance bar code reader • Optical system with CCD line and integrated LED illumination

• Fixed focus

• Front reading window or side reading window

• Resolution 0.15 to 1.0 mm (5.9 mil to 39.5 mil), reading range (DOF) see Fig. 9-1, Page 44

• Scanning/decoding frequency 500 Hz

Safety and user-friendly features • Robust, compact metal housing, CE certification

• LED class 1

• Automatic self-test on startup

• Low power consumption

Easy configuration • Configuration (online/offline) via CLP Setup configuration software with integrated help

system

• Configuration alternatively with simple command strings, also for use with special devices

• Two status LEDs

Operating modes • Reading mode

• Diagnostic mode

• Adjusting mode

• Online test mode

Reading pulse • External reading pulse, via switching input(s) or serial data interface (command)

Bar code evaluation • All standard bar code types

• Max. 10 codes per reading pulse

• Code length max. 32 digits (depends on number of codes per reading pulse)

• Code comparison (one matchcode)

Data communication • Host interface: variable output format for reading result

• Auxiliary interface (auxiliary data interface): same output format as on host interface

Electrical interfaces • Host interface (RS 232), variable data transfer rate and protocol

• Auxiliary interface (RS 232 TTL), same data transfer rate and protocol as on host interface

• One digital switching input for external reading pulse

• One digital switching output for signaling the reading status

Connection technology (design) • Data and switching interfaces as well as power supply:

– Cable with 9-pin D Sub plug or

– Cable with open end

Table 3-3: Overview of the product features and functions

14 © SICK AG · Division Auto Ident · Germany · All rights reserved 8008912/R289/2008-11-28

Page 15

Operating Instructions Chapter 3

CLP100 Bar Code Reader

Product description

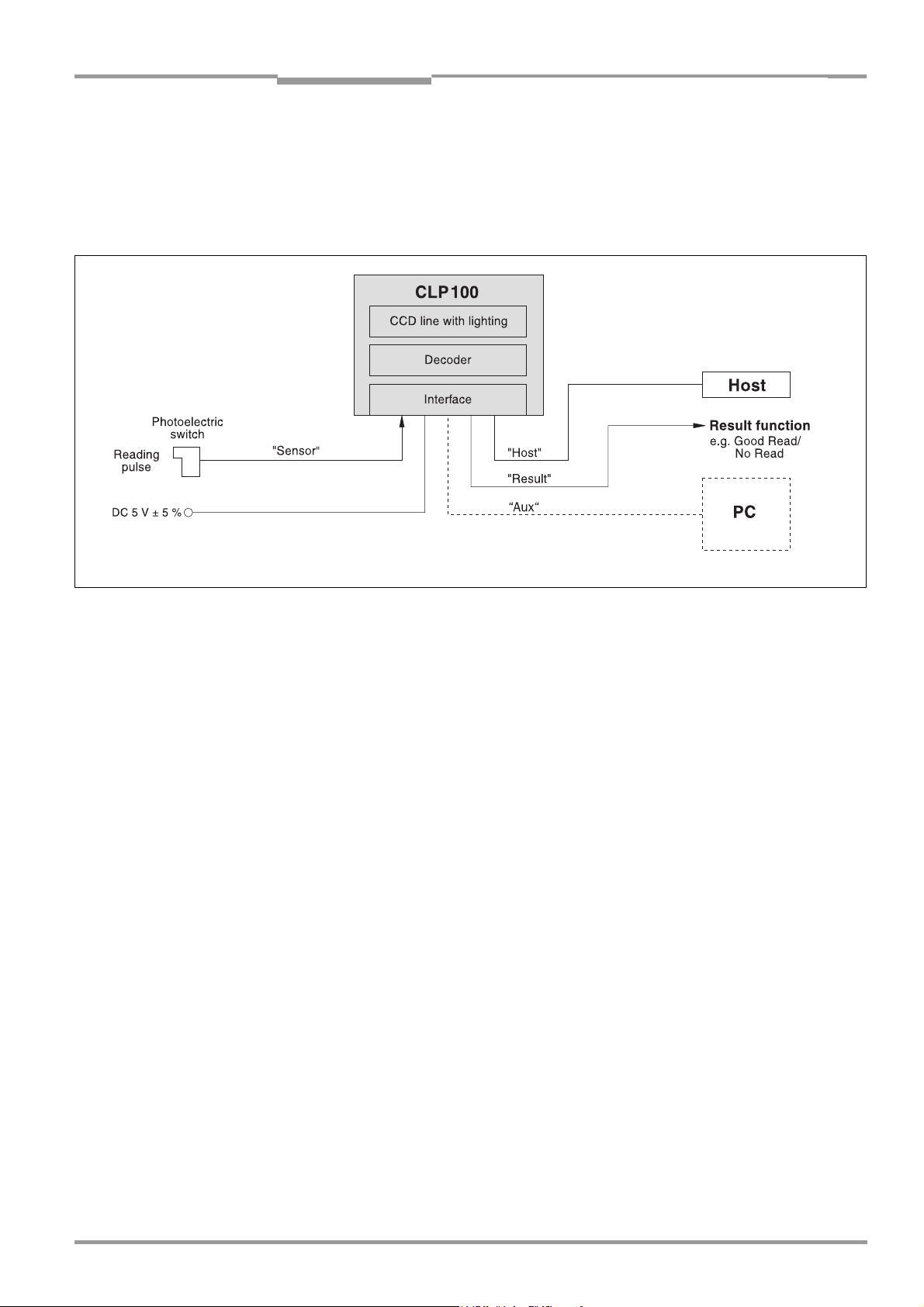

3.3 Working method of the device

The CCD bar code reader CLP100 detects bar codes in an illuminated scan field (scan line)

and decodes the bar codes. The CLP100 transmits this data via the serial host interface to

a host/PC for further processing. Refer to Fig. 3-3 for an overview of the functionality of the

CLP100.

Fig. 3-3: Function of the CLP100

--- Cable if required

The CLP100 derives useful data for diagnostics from the reading processes. The quality of

the reading data can be checked in the diagnosis mode.

The CLP100 requires suitable pulsing (triggering) in order to start a reading process when

there is an object in the reading area. This results in a time window for the reading process

being opened in the CLP100. Triggering is carried out either with an external sensor or with

a command string via the host interface. Both options are active in the default setting.

The switching input ("Sensor" input) informs the CLP100 when it must start a reading process. The switching output ("Result" output) can have result functions assigned to them and

triggers external devices such as, for example, a PLC input.

3.4 Display and operating elements

The CLP100 is operated or configured via the host interface by using the CLP Setup

PC software or with command strings. The CLP100 is adapted to various applications by

means of parameterization. The CLP Setup software is used, for example, to carry out the

following settings:

• Configuration of the code types to be read

• Read, evaluation and output properties

• Communication parameters of the host interface

• Structure of the data output strings of the host interface

• Function of the auxiliary interface (terminal interface)

Chapter 10.2, Page 46 describes the installation and handling of the CLP Setup software.

The procedure for configuring the CLP100 with the software is explained in Chapter 6.4,

Page 30.

8008912/R289/2008-11-28 © SICK AG · Division Auto Ident · Germany · All rights reserved 15

Page 16

Chapter 3 Operating Instructions

Product description

CLP100 Bar Code Reader

An LED status display ("Monitor") with two LEDs (red and green) on the rear of the CLP100

indicates the current operating state of the device. The meaning of the display for the respective operating mode is shown in Table 3-4. The display can be parameterized differently in some operating modes. The table lists all the possible meanings.

:

Operating mode Display Function

Start Green/red • Light up during the switching on phase if the self-test is suc-

cessful

• Extinguish when changing to the read standby state

Reading mode Green/red • Light up when the signal for reading is given, until the begin-

ning of the next reading cycle

Green • Lights up after successful reading ("Good Read")

Red • Extinguishes after successful reading ("Good Read")

Adjusting mode Green • Extinguishes after unsuccessful reading ("No Read")

Red • Lights up after unsuccessful reading ("No Read")

Matchcode operation Green/red • Extinguish, when there was no signal for reading and there is

no read result

Red • Lights up at "No Read" or "Read & No Match"

Green • Lights up at "Read & Match"

Table 3-4: Meaning of the LEDs

or in accordance with the parameterization

• Lights up at "No Read" or "Read & Match"

or in accordance with the parameterization

• Lights up at "Read & No Match"

16 © SICK AG · Division Auto Ident · Germany · All rights reserved 8008912/R289/2008-11-28

Page 17

Operating Instructions Chapter 4

CLP100 Bar Code Reader

Installation

4 Installation

This chapter describes the installation sequences for the CLP100.

4.1 Installation sequence

The typical installation sequences are listed below:

• Select the installation site for the CLP100

• Connect the power supply

• Align the CLP100 to the bar code

• Install the CLP100

• Adjust the CLP100

• Install the external sensor for the reading pulse

NOTICE

Claims under the warranty rendered void!

Do not open the housing of the CLP100. If the device is opened, the SICK AG warranty shall

not apply.

4.2 Preparations for installation

The following general requirements should be observed for installation:

• Typical space requirement: application-specific and type-dependent (reading range,

orientation of reading window)

• Unobstructed view of the objects for the CLP100

• Stable installation holder with sufficient load capacity and dimensions suited to the

CLP100 (see Chapter 9.3 Dimensional drawings, Page 45)

• Shock absorbent and vibration free attachment

The following tools and resources are required for installation:

• 2 screws M3 for fixing the CLP100 to the installation site,

Screw length depends on the wall thickness of the base.

Screws may not be screwed more than 2.5 mm (0.1 in) into the CLP100

• Tool

• Measuring tape

• Angulometer

4.2.1 Laying out the components to be installed ready

• CLP100 bar code reader

4.2.2 Threaded holes

The CLP100 is fastened by means of two threaded holes (M3) to the top or bottom of the

device (Fig. 4-1, Page 18). The complete housing dimensions are shown in Chapter 9.3 Di-

mensional drawings, Page 45.

8008912/R289/2008-11-28 © SICK AG · Division Auto Ident · Germany · All rights reserved 17

Page 18

Chapter 4 Operating Instructions

Installation

CLP100 Bar Code Reader

!! !!

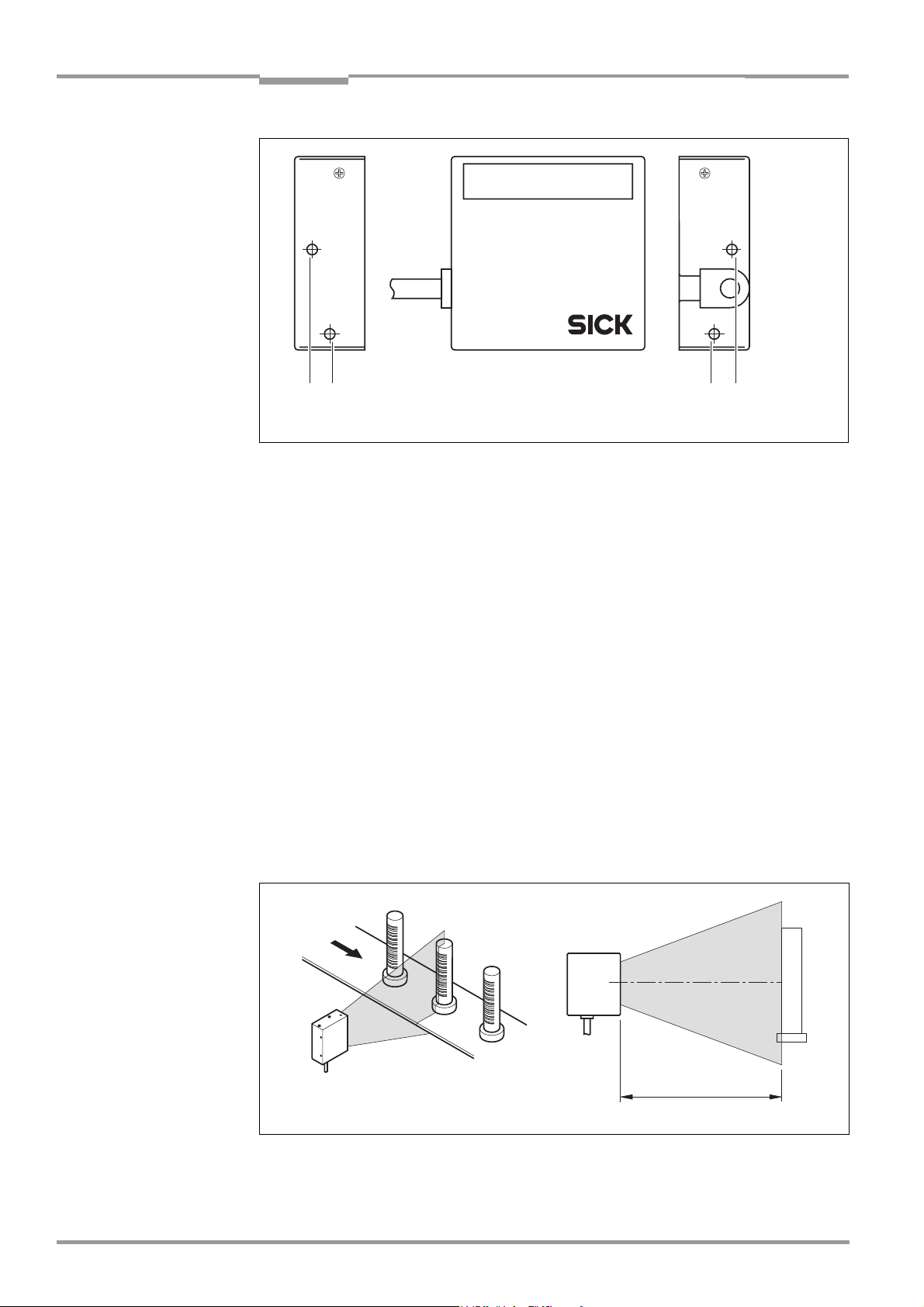

Fig. 4-1: Position of the threaded holes !at CLP100

4.3 Installation site

The following aspects are relevant for the selection of the installation location:

• Reading distance to the code/field of view dimensions

• Angle alignment of the CLP100

• Avoiding surface reflections

When selecting the installation site take the distance between the CLP100 and the host.

4.3.1 Distance between the CLP100 and the host

The maximum distance between the CLP100 and the host when extension cables are used

amounts to 12 m (39.37 ft) (host interface RS 232).

4.3.2 Distance between the CLP100 and the bar code/field of view dimensions

The distance a between the reading window of the CLP100 and the bar code must amount

to 20 to 70 mm (0.79 to 2.76 in) depending on the width of the bar code (see Fig. 4-2).

Chapter 9.2 Reading field diagram, Page 44 shows the width of the reading area of the

CLP100 in relation to the reading distance for various resolutions (module widths).

a

Fig. 4-2: Reading distance to the object

18 © SICK AG · Division Auto Ident · Germany · All rights reserved 8008912/R289/2008-11-28

Page 19

Operating Instructions Chapter 4

CLP100 Bar Code Reader

Installation

Angle alignment of the CLP100

The angle between the scan line and bar code is selected, so that a good reading is possible. The optimum alignment of the CLP100 is reached at an angle of 90° between the scan

line and the bar code bars (see Fig. 4-3). Possible reading angles which can arise between

the scan line and the bar code bars must be taken into consideration (see Fig. 4-4 and

Table 4-1).

Fig. 4-3: 90° angle between the scan line and the bar code bars

Fig. 4-4: Reading angle occurring between the scan line and the bar code bars

Angle Limit

Tilt α 0° ± 2°

Pitch β 0° ± 5°

Skew γ 10° ± 5°

Table 4-1: Permissible angle occurring between the scan line and the bar code bars

8008912/R289/2008-11-28 © SICK AG · Division Auto Ident · Germany · All rights reserved 19

Page 20

Chapter 4 Operating Instructions

Installation

CLP100 Bar Code Reader

Important If the light of the scan line falls exactly vertically on the surface of the bar code, disturbing

reflections can occur when the reflected light is received. In order to avoid this effect the

CLP100 must be installed so that the emitted light is tilted relative to the perpendicular (see

Fig. 4-5).

Front end reading window Side reading window

10°

10°

Bar code

Bar code

15

Reading

Distance

Reading

Distance

Fig. 4-5: Angle between the emitted light and the bar code (tilted to the perpendicular)

8

20 © SICK AG · Division Auto Ident · Germany · All rights reserved 8008912/R289/2008-11-28

Page 21

Operating Instructions Chapter 4

CLP100 Bar Code Reader

Installation

4.4 Installation and adjustment of the device

4.4.1 Installing the CLP100

1. Align the CLP100 so that the angle between the scan line and the bar code bars

amounts to 90°. Take any possible reading angle occurring into consideration (see

Fig. 4-4, Page 19).

2. In order to avoid disturbing reflections align the CLP100 so that the emitted light im-

pacts on the bar code at an angle of 100° (see Fig. 4-5, Page 20 and Fig. 4-6).

NOTICE

Damage to the device!

The screws may not be screwed more than 2.5 mm (0.1 in) into the CLP100. Longer screws

may damage the device.

¾ Use screws with a suitable length.

3. Screw the screws through the base to which the CLP100 is fastened into the threaded

hole.

4. Tighten the screws slightly.

5. Adjust the CLP100 as described below.

ab

100°

Fig. 4-6: Adjustment of the CLP100 in order to avoid reflections;

a: With front end reading window, b: With side reading window

4.4.2 Adjusting the CLP100

The adjusting operating mode supports the adjustment of the CLP100. In this operating

mode the green LED extinguishes if the reading process fails ("No Read"). If the green LED

does not light up, the CLP100 cannot read the bar code. If the green LED flickers, the

CLP100 can only read the bar code badly. If the green LED shows steady light, the CLP100

is aligned optimally. The scanning frequency in adjusting mode amounts to 500 Hz.

1. Connect the CLP100 to the supply voltage and switch on the supply voltage.

2. Connect the CLP100 to the PC.

3. Start the CLP Setup configuration software (see Chapter 10.2, Page 46).

4. In the CLP Setup select the D

5. Click in the O

6. Click in the LED

7. Carry out the download to the CLP100 (see Chapter 6.4.1, Page 31).

PERATING MODE field and select ADJUSTING MODE.

DISPLAY field and select NO READ/GOOD READ.

EVICE CONFIGURATION tab card.

100°

8008912/R289/2008-11-28 © SICK AG · Division Auto Ident · Germany · All rights reserved 21

Page 22

Chapter 4 Operating Instructions

Installation

CLP100 Bar Code Reader

8. Guide objects with bar codes realistically into the reading area of the CLP100. Ensure

that the permitted reading angle is not exceeded.

9. Start the reading pulse: Cover the optical path of the sensor or make connection (see

Chapter 4.5, Page 22).

10. Align the CLP100 so that the green LED lights up steadily as far as possible (reading

result "Good Read").

11. Tighten the screws.

The CLP100 is aligned optimally to the bar code.

4.5 Installing the reading-pulse sensor

If the CLP100 is triggered via an external sensor, the sensor and a reflector have to be installed near the CLP100. Fig. 4-7 shows an example of the installation site of the sensor.

a

b

Fig. 4-7: Installation site for the reading-pulse sensor and the reflector (b smaller than a)

1. Install the reading-pulse sensor at the installation site.

2. Connect the reading-pulse sensor to the CLP100 (see Chapter 5.4.4, Page 27).

3. Call up the CLP Setup and check the read result with the terminal emulator (see

Chapter 6.4, Page 30).

4. Check whether the reading process of the CLP100 is synchronized with the incoming

objects.

4.6 Disassembling the device

1. Switch off the supply voltage.

2. Disconnect the cable connection.

3. Screw off the CLP100.

4. Dispose of the CLP100 ecologically friendly (see Chapter 7.4, Page 39)

22 © SICK AG · Division Auto Ident · Germany · All rights reserved 8008912/R289/2008-11-28

Page 23

Operating Instructions Chapter 5

CLP100 Bar Code Reader

Electrical installation

5 Electrical installation

5.1 Overview of installation sequences

Important Electrical installation should only be carried out by qualified staff.

The following list provides an overview of a typical installation sequence:

• Connecting the supply voltage

• Wiring the host interface (Connecting the PC)

• Wiring the "Sensor" switching input

• Wiring the "Result" switching output

Once electrical installation has been completed, the CLP100 is started up and configured

(see Chapter 6 Startup and configuration, Page 29).

5.2 Planning the electrical installation

The following general requirements should be observed for the electrical installation:

• Supply voltage 5 V DC

IEC 60364-4-41). The power supply unit must output a continuous output of 2 W and

be provided by the customer using e.g. a supply power pack.

• With external reading pulsing: Suitable reading pulse sensor (start/stop), e.g. photo-

electric reflex switch, for registering an object in the field of view

• Host computer with RS RS 232 data interface for further processing the reading data

± 5 % (functional extra-low voltage in accordance with

The following toots and resources are required for electrical installation:

• Tool

• Digital measuring device (current/voltage measurement)

8008912/R289/2008-11-28 © SICK AG · Division Auto Ident · Germany · All rights reserved 23

Page 24

Chapter 5 Operating Instructions

Electrical installation

CLP100 Bar Code Reader

5.3 Electrical connections and cables

The electrical connection of the CLP100 is carried out either via a 9-pin D-Sub cable plug or

the open cable end. The cable length is 0.9 m (2.95 ft).

5.3.1 Pin assignment of the connection plug or wire colors of the cable end

5

1

6

9

Pin Signal

1 Sensor

2 RxD (Host)

3 TxD (Host)

4 Result "GO/NG"

5 GND

6 Not assigned

7 RxD (Terminal), TTL

8 TxD (Terminal), TTL

9 +5 V

Table 5-1: Pin assignment of the D Sub plug

Wire color Signal

Pink Sensor

Brown RxD (Host)

Gray TxD (Host)

White Result "GO/NG"

Black GND

Yellow RxD (Terminal), TTL

Orange TxD (Terminal), TTL

Red +5 V

Blue RTS

Green CTS

Table 5-2: Assignment of the wire colors of the open cable end

24 © SICK AG · Division Auto Ident · Germany · All rights reserved 8008912/R289/2008-11-28

Page 25

Operating Instructions Chapter 5

CLP100 Bar Code Reader

Electrical installation

5.4 Carry out the electrical installation

NOTICE

Claims under the warranty rendered void!

Do not open the housing of the CLP100. If the device is opened, the SICK AG warranty shall

not apply.

• Connect or disconnect current linkages only under de-energised conditions.

• Wire cross sections and their correct protection have to be selected and implemented

according to valid engineering standards.

• For data connection use only shielded data cables (twisted pair).

• In order to avoid interferences, do not install data cable parallel to the power- supply

and motor cables over long distances (for example in cable ducts).

• Lay all cables so th a t t h ere is no poss i b i lity of people trip p i n g over them and s o t hat they

are protected against damage.

5.4.1 Supply voltage

For operation the CLP100 requires a supply voltage of 5 V DC

± 5 % in accordance with

IEC 60364-4-41 (functional extra-low voltage). The functional extra-low voltage can be generated by a power supply unit using a safety transformer . The power supply unit must output a continuous output of 2 W.

Important The output circuit of the power supply unit must be electrically insulated from the input

circuit. This is usually created by means of a safety transformer in accordance with

IEC 742.

To ensure that the incoming supply cables are protected against short-circuits/overloads,

the wire cross-sections must be dimensioned and protected in accordance with valid standards.

Connecting the supply voltage:

¾ Connect the supply voltage to Pin 5 and Pin 9 of the 9-pin D Sub plug (see Table 5-1,

Page 24) respectively to the wires of the open cable end (see Table 5-2, Page 24).

5.4.2 Wiring the host interface (Connecting the PC)

The CLP100 is operated and configured with the CLP Setup software. For this purpose it

must be connected temporarily to the PC via the host interface.

The host interface of the CLP100 is an RS 232 interface.

For the pin assignment refer to Table 5-1, Page 24 or Table 5-2, Page 24. Table 5-3 shows

the recommended maximum cable length as a function of the data transmission rate.

.

Interface type Transmission rate Max. distance to the host

RS 232 Up to 19,200 Bd 12 m (39.37 ft)

Table 5-3: Maximum cable length between the CLP100 and the host computer

When the PC is connected, the communications parameters are set as described in

Chapter 6.4.1 Transferring the parameter set between the CLP Setup and CLP100,

Page 31.

8008912/R289/2008-11-28 © SICK AG · Division Auto Ident · Germany · All rights reserved 25

Page 26

Chapter 5 Operating Instructions

Electrical installation

CLP100 Bar Code Reader

Fig. 5-1 shows the wiring of the host interface.

*) 9-pin internal D-Sub plug to PC

Fig. 5-1: Wiring the host interface (RS 232)

NOTICE

Damage to the interface module in the CLP100!

Electronic components can be damaged if the host interface is wired incorrectly.

¾ Wire the host interface correctly in accordance with Fig. 5-1.

¾ Check the wiring before switching on the CLP100.

¾ Connect the host interface of the CLP100 EMC-compatibly to the host by means of

shielded cables. Observe the maximum cable lengths (see Table 5-3, Page 25).

Recommendation ¾ Connect the shielding at one end.

1. Switch off the PC and the supply voltage of the CLP100.

2. Connect the desired port "COM x" of the PC to the CLP100. To this purpose use an

RS-232 data connection cable (null modem, RxD and TxD transposed).

3. Switch on the PC and the supply voltage of the CLP100.

4. Set the communication parameters of the PC (see Chapter 10.2.3, Page 48).

In the default setting the CLP100 communicates via the RS 232 interface with the host

using the values listed in Table 5-4.

Parameter Host interface value Aux interface value

Data transmission rate 9,600 Bd 9,600 Bd

Data bit 8 8

Parity None None

Stop bit 1 1

Protocol SICK:

Sending start characters: STX

Sending stop characters: ETX

Repeat request: None

Timeout: 50 ms

SICK:

Sending start characters: STX

Sending stop characters: ETX

Repeat request: None

Timeout: 50 ms

Table 5-4: Communication parameters of the host interface (default setting)

26 © SICK AG · Division Auto Ident · Germany · All rights reserved 8008912/R289/2008-11-28

Page 27

Operating Instructions Chapter 5

CLP100 Bar Code Reader

Electrical installation

5.4.3 Wiring the auxiliary (terminal) interface

As an alternative the PC may be connected to the Aux interface which operates parallel to

the host interface with the same communication parameter values. The Aux interface can

be use e.g. to monitor the data traffic on the host interface.

Fig. 5-2 shows the wiring of the Aux interface.

Important The terminal interface is a TTL level interface.

73 *

82 *

55 *

*) 9-pin internal D-Sub plug to PC

Fig. 5-2: Wiring the Aux interface (RS 232 TTL)

5.4.4 Wiring the "Sensor" switching input

If a reading process is to be triggered via an external sensor, connect the sensor to the "Sensor" switching input. This triggering type is selected as the default setting of the CLP100.

Fig. 5-3 shows the wiring of the "Sensor" switching input. Table 5-5 lists the characteristic

data of this switching input.

Fig. 5-3: Wiring of the "Sensor" switching input

¾ Connect the sensor as shown in Fig. 5-3.

Switching behaviour Connecting GND to the input starts the read port of the CLP100 (low)

Properties Not electrically separated

Electrical values Low (Reading gate active):

0 V ≤ V

≤ 0.8 V

S

I ≤ 1.5 V µA

Table 5-5: Characteristic data of the "Sensor" switching input

High (Reading gate inactive):

2.4 V ≤ VS ≤ 5 V

I ≤ 1.5 V µA

TIP The D

EVICE CONFIGURATION tab card of the CLP Setup software can be used to modify the

response time of the "Sensor" input (debouncing).

8008912/R289/2008-11-28 © SICK AG · Division Auto Ident · Germany · All rights reserved 27

Page 28

Chapter 5 Operating Instructions

Electrical installation

CLP100 Bar Code Reader

5.4.5 Wiring the "Result" switching output

The switching output can have various result functions assigned to it. If the corresponding

event occurs during a reading process, the switching output becomes live for the selected

pulse duration. Fig. 5-4 shows the wiring of the "Result" switching output. Table 5-6 lists the

characteristic data of the switching output.

Fig. 5-4: Wiring of the "Result" switching output (NPN)

¾ Wire the switching output as described in Figure 5-4.

Switching behaviour NPN switching against GND

Properties Not electrically separated

Electrical values V

Table 5-6: Characteristic data of the "Result" switching output

= 5 V ≤ V ≤ 30 V

out

I

= ≤ 50 mA

out

Recommendation ¾ In order to check the switching functions wire the switching output to a load and meas-

ure the voltage with a high-voltage digital voltmeter. This avoids the display of incorrect

voltage values and switching states.

TIP The D

EVICE CONFIGURATION tab card of the CLP Setup software can be used to modify the func-

tion assignment, the pulse duration and the output instant of the signal.

28 © SICK AG · Division Auto Ident · Germany · All rights reserved 8008912/R289/2008-11-28

Page 29

Operating Instructions Chapter 6

CLP100 Bar Code Reader

Startup and configuration

6 Startup and configuration

Startup, adjustment, configuration and diagnosis are carried out via the CLP Setup configuration software. In normal reading operation the CLP100 operates fully automated.

6.1 Overview ot the startup procedure

• Startup of the CLP100 with the default setting set by factory (Quick-Start).

• Installing the CLP Setup software (Chapter 10.2, Page 46).

• Connecting the PC to the CLP100 (Chapter 5.4.2, Page 25).

• In order for optimising the functionality of the CLP100, adjusting the CLP100 and con-

figuring the CLP100 for the application.

• Checking correct functioning of CLP100 in automatic reading operation.

6.2 Quick-Start

1. Carry out the electrical installation in accordance with Chapter 5, Page 23. A PC does

not have to be connected if the CLP100 is operated with the default setting.

2. Switch on the supply voltage.

The LEDs of the CLP100 light up and are extinguished after the self-test has been completed successfully.

3. Present the bar code sample from Fig. 6-1 to the CLP100 at a distance of approx.

35 mm.

4. Start the reading pulse: Cover the optical path of the sensor (close the switch).

Both LEDs on the rear light up.

5. End the reading pulse: Unmask the optical path of the sensor (open the switch).

If the reading has been successful, the red LED is extinguished, the green LED lights up.

The CLP100 is ready to operate with the default setting of our works.

The CLP100 can be switched off without the configuration data being lost, since no changes

were carried out to the parameter set.

0123412345

Fig. 6-1: Bar code sample (code 39, 0.35 mm (13.8 mil)), printing ratio 2:1)

The default setting shows Table 6-1, Page 35.

8008912/R289/2008-11-28 © SICK AG · Division Auto Ident · Germany · All rights reserved 29

Page 30

Chapter 6 Operating Instructions

Startup and configuration

CLP100 Bar Code Reader

6.3 Operating modes and output of the read result

When configuring the CLP100, it is possible to choose between the following operating

modes:

• Reading mode

• Diagnostic mode

• Adjusting mode

• On-line test mode

In reading mode the CLP100 detects the presented bar codes and emits the read result at

the end of the reading pulse parallel via the host and aux interface.

In diagnosis mode the quality of the bar code readings is judged. These are brought statistically into the read field of the CLP100 (no transport movement). The output is emitted via

the host and aux interface. For details on the diagnosis mode refer to Chapter 6.4.8,

Page 33.

In adjusting mode the CLP100 is adjusted to the bar code (see Chapter 4.4.2, Page 21).

In the on-line test mode the CLP100 emits the read result only via the aux interface and not

via the host interface.

When outputting the read result, it is possible to choose between the normal reading function and the code comparison function (matchcode). The matchcode function allows the

comparison of the read bar codes with a code which is entered at the CLP100. It is possible

to select between complete or partial matching of the codes.

6.4 Configuration

The CLP Setup configuration software or command strings optimise the CLP100 to reading

conditions on site. Starting point for this is the factory default setting which can be adjusted

to optimise the CLP100. The CLP Setup configuration software is used to create an application-specific parameter set which can be loaded permanently into the CLP100 and saved/

archived as a configuration file (slp file) on the PC.

CLP100

Parameter set in the

main memory

Permanently saved

parameter set

Factory default setting

Download

Upload

RAM

PROM

ROM

PC with CLP Setup

configuration software

Opened configuration file

with current parameter set

(after upload)

RAM

Saved configuration file

(*.slp) with archived parameter set

Data base

(hard drive)

Fig. 6-2: Configuration with CLP Setup and storage of the parameter set

To this purpose a PC has to be connected and the CLP Setup has to be installed.

30 © SICK AG · Division Auto Ident · Germany · All rights reserved 8008912/R289/2008-11-28

Page 31

Operating Instructions Chapter 6

CLP100 Bar Code Reader

Startup and configuration

6.4.1 Transferring the parameter set between the CLP Setup and CLP100

In order to edit the current parameter set of the CLP100 it must first be copied from the

CLP100 to the CLP Setup. This process is designated as uploading.

Changes to the parameter set carried out in the CLP Setup are not effective until they have

been transferred to the CLP100. CLP Setup always copies the complete parameter set. Saving the parameters to the CLP100 is designated as downloading.

Uploading the parameter set from the CLP100

¾ Click on in the CLP Setup toolbar.

CLP Setup copies the parameter set last saved in the CLP100 from the CLP100 into its

database and displays its values in the tab cards.

If the CLP Setup software does not recognize the loaded parameters during uploading, a

warning is emited. Unknown parameters can be edited in the terminal emulator under observance of the conventions for command strings. These parameters are also taken into

consideration when the parameter set is saved.

Downloading the parameter set to the CLP100

¾ Click on in the CLP Setup toolbar.

The new parameter set is saved in the CLP100.

Saving the parameter set in the CLP Setup

1. Select the S

AVE AS menu item in the FILE menu bar in order to save the modified param-

eter set as the new configuration file in the CLP Setup or to overwrite an existing file.

The S

AVE CLP FILE dialog box is opened.

2. Enter the path and file name in the dialog box (extension of the file name: "*.slp") and

click on OK.

The new parameter set is saved in the CLP Setup.

6.4.2 Parameterize the CLP100 with command strings

The CLP100 can be parameterized for example by means of the terminal emulator by entering command strings. Parameters which are unknown to the CLP Setup can also be used.

The command language of the CLP100 accesses the command interpreter of the device directly. Fig. 6-3, Page 32 shows a view of the terminal emulator. A0 is entered as an example

in the framed text field for entering commands. This input is repeated in the large output

window. For a full description of the command language refer to Table 10-4, Page 53.

1. Click on in the CLP Setup toolbar.

The terminal emulator window opens.

2. Enter the command in the framed text field and press the Return key.

The command is transmitted to the CLP100.

Important The CLP100 does not transmit an answer, but reacts immediately to the command.

8008912/R289/2008-11-28 © SICK AG · Division Auto Ident · Germany · All rights reserved 31

Page 32

Chapter 6 Operating Instructions

Startup and configuration

CLP100 Bar Code Reader

Fig. 6-3: Terminal emulator with input of a command string

6.4.3 Selecting reading mode

After being switched on the CLP100 carries out a self-test and then changes over to the

reading mode (default setting). Reading mode can be selected as follows if the CLP100 is

in another operating mode:

1. In the CLP Setup select the D

2. Click in the O

PERATING MODE field and select READING MODE.

3. Carry out the download to CLP100.

The CLP100 is in reading mode.

6.4.4 Adjusting the reading pulse

In the CLP100 default setting the reading pulse (trigger) is supplied by an external sensor.

Debouncing of the sensor and the type of reading pulse end (through a time window or a

sensor signal) can be set by means of the CLP Setup software.

1. In the CLP Setup select the D

2. Select the settings in the R

3. Carry out the download to CLP100.

6.4.5 Triggering the reading pulse

EVICE CONFIGURATION tab card.

EVICE CONFIGURATION tab card.

EADING PULSE or READING PULSE END field.

In its default setting the CLP100 receives the reading pulse (trigger) via an external sensor

or a command string (software trigger). For test purposes, the reading pulse can also be triggered directly via the terminal emulator.

1. Click on in the CLP Setup toolbar.

The terminal emulator window opens. The CLP100 is in reading mode.

32 © SICK AG · Division Auto Ident · Germany · All rights reserved 8008912/R289/2008-11-28

Page 33

Operating Instructions Chapter 6

CLP100 Bar Code Reader

Startup and configuration

2. Click on START READING.

3. Present the bar code.

4. Click on S

TOP READING.

The CLP100 outputs the read result in the window of the terminal emulator.

6.4.6 Setting the structure of the read result

In its default setting the CLP100 sends the data contents of the bar code to the host as the

read result. In the default setting this data string is STX-/ETX-framed.

The structure of the data string can be selected by means of the H

CONFIGURATION tab cards.

1. In the CLP Setup select the R

2. Click in the S

3. Select the H

4. Click in the S

END PREFIX list box and select a prefix from the list (A-Z, 1-0).

OST INTERFACE tab card.

EPARATOR list field and select a separator.

EADING CONFIGURATION tab card.

OST INTERFACE and READING

5. Carry out the download to CLP100.

The CLP100 operates with the new settings.

6.4.7 Setting the matchcode function

The matchcode function allows the comparison of the read bar codes with a code which is

entered manually at the CLP100 or trained in automatically (matchcode).

1. In the CLP Setup select the D

2. Click in the A

CTIVE box in the COMPARE CODE field.

3. Enter the code which is to be used for comparison in the M

4. If only a part of the code has to agree, enter the partial code in the P

OF THE MATCHCODE text field, and complete the field with question marks or @ characters.

5. Selection the function of the switching output in the S

SON field.

EVICE CONFIGURATION tab card.

ATCHCODE text field.

ARTIAL COMPARISON

WITCHING OUTPUT AT CODE COMPARI-

6. Carry out the download to CLP100.

The CLP100 outputs a result either at agreement of the read codes with the matchcode

or at non-agreement.

6.4.8 Setting the diagnosis mode

In diagnosis mode the quality of the bar code readings is judged. These are brought statistically into the read field of the CLP100 (no transport movement). The CLP100 carries out

100 readings after the reading pulse and evaluates them.

The data string in the diagnosis mode is STX-/ETX-framed. The data string contains the bar

code information (data) at the first place, followed by a slash and a three-digit identifier. The

data string is followed by the combination of slash and identifier repeated thrice (a total of

four identifiers separated by slashes):

<STX>Data/www/xxx/yyy/zzz<ETX>.

The maximum value of an identifier is 100. If the value is lower (one- or two-digit number),

the leading blanks will be filled with spaces. If the D

ISPLAY CONTROL CODE function is activated,

a space is displayed as <SPC>. The identifiers mean:

www = Number of successful readings ("Good reads")

xxx = Number of successful decoding processes (with misinterpretations)

8008912/R289/2008-11-28 © SICK AG · Division Auto Ident · Germany · All rights reserved 33

Page 34

Chapter 6 Operating Instructions

Startup and configuration

CLP100 Bar Code Reader

yyy = Number of successful indentifications of a start or stop character (depending on

the scan direction)

zzz = Number of readings carried out (the CLP100 carries out 100 readings each in the

diagnosis mode)

Error-free reading and decoding of a bar code would thus have the following form:

<STX>Data/100/100/100/100<ETX>.

A reading with some failed decodings has, for example, the following form:

<STX>Data/<SPC>67/<SPC>67/100/100<ETX>.

If the CLP100 has only recognized the start character, it transfers a question mark instead

of the data string:

<STX>?/<SPC><SPC>0/<SPC><SPC>0/100/100<ETX>.

Fig. 6-4 shows further examples of reading results in the diagnosis mode:

Fig. 6-4: Terminal emulator with reading results of the CLP100 in diagnosis mode

The diagnosis mode can be selected directly in the terminal emulation window or set via the

tab cards:

¾ If the terminal emulator window is active: Click in the D

IAGNOSTIC MODE box and present

the bar code.

The reading process is started automatically. The CLP100 scans the bar code once per

second.

- or -

1. If the terminal emulator window is not active: In the CLP Setup select the D

URATION tab card.

2. Click in the O

PERATING MODE field and select DIAGNOSTIC MODE.

EVICE CONFIG-

3. Carry out the download to CLP100.

The CLP100 is in diagnosis mode.

34 © SICK AG · Division Auto Ident · Germany · All rights reserved 8008912/R289/2008-11-28

Page 35

Operating Instructions Chapter 6

CLP100 Bar Code Reader

Startup and configuration

4. Click on in the CLP Setup toolbar.

The terminal emulator window opens.

5. Click on S

TART READING.

6. Present the bar code.

The CLP100 outputs the read result in the window of the terminal emulator.

7. In order to return to reading mode proceed as described in Chapter 6.4.3, Page 32.

6.5 Default setting

Table 6-1 shows an overview of the default setting of our works for the CLP100. The para-

meters in the default setting are selected so that the CLP100 can be used directly for many

applications in this configuration. With the default setting no PC is required for starting up.

Parameter Default setting

Active code type Code 39

Code length Free

Multiple reading 2

Number of codes 1

Reading direction Both

Send start/stop characters Not active

Check digit None

Reading pulse generation Active low (unchangable)

Switching output Not active

Host interface RS 232 (unchangable)

Protocol Start characters STX, Stop characters ETX

Data transmission rate 9,600 Bd

Data format 8 data bits, no parity, 1 stop bit

Output instant Immediately

No Read message BR

Table 6-1: Default setting of the parameters of the CLP100

If the CLP100 is connected to a PC, the current parameters can be changed by using the

CLP Setup software. The parameter set of the default setting is saved in the CLP Setup and

in the CLP100 and can be re-activated at any time.

The complete default setting can be viewed by using the CLP Setup software and printed

out, if required:

1. In order to save the current settings: Select the S

AVE AS menu item in the FILE menu bar

and enter the file name.

2. Click on in the toolbar.

The default setting is loaded and is displayed in the tab cards.

3. Click on in the toolbar.

The F

ILE PRINT dialog box is opened.

4. Enter the comment for the header of the output and click on OK.

The dialog box for the print settings is opened.

5. Enter the settings for printing and click on OK.

CLP Setup prints out the default settings.

8008912/R289/2008-11-28 © SICK AG · Division Auto Ident · Germany · All rights reserved 35

Page 36

Chapter 6 Operating Instructions

Startup and configuration

CLP100 Bar Code Reader

6.6 Switching off the CLP100

1. If the parameter set was changed, download the parameter set to the CLP100 and save

the parameter set as a configuration file in the CLP Setup.

2. Switch off the supply voltage.

The last parameter set saved in the CLP100 remains valid.

36 © SICK AG · Division Auto Ident · Germany · All rights reserved 8008912/R289/2008-11-28

Page 37

Operating Instructions Chapter 7

CLP100 Bar Code Reader

Maintenance

7 Maintenance

7.1 Maintennance during operation

The CLP100 operates maintenance free. No maintenance is required to keep this product

in compliance with LED class 1.

NOTICE

Claims under the warranty rendered void!

Do not open the housing of the CLP100. If the device is opened, the SICK AG warranty shall

not apply.

7.2 Cleaning the CLP100

Recommendation In order to make use of the full optical reading capacity of the CLP100, the reading window

should be checked regulary (e.g. weekly) for soiling. This is especially recommended when

operating the device in harsh conditions (dust, abraison, humidity).

CAUTION

LED radiation!

The illumination of the CLP100 operates with LEDs of LED class 1. Under normal and sensible conditions, the accessible radiation of the LEDs is not hazardous.

The entire area of the reading window acts as a LED outlet aperture.

Caution – use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

¾ Never look directly into the illumination.

¾ Do not open the housing.

(Opening the housing does not deactivate the LEDs by the reading pulse.)

¾ Always observe the latest valid version of laser protection regulations.

7.2.1 Cleaning the reading window

NOTICE

Damage to the reading window!

The CLP100 reading window is made of glass.

Scratches and streaks on the reading window impair the reading performance.

¾ Use a mild detergent without scouring agents.

¾ Avoid cloths or sponges which scratch.

¾ Clean the reading window carefully.

Important Electrostatic charges cause dust particles to stick to the reading window. This effect can be

combated by using anit-static SICK synthetic cleaner (no. 5600006) in combination with a

SICK lens cloth (no. 4003353).

8008912/R289/2008-11-28 © SICK AG · Division Auto Ident · Germany · All rights reserved 37

Page 38

Chapter 7 Operating Instructions

Maintenance

CLP100 Bar Code Reader

Cleaning the reading window:

¾ Use a clean, soft brush to free the reading window.

¾ If necessary, additionally clean the reading window with a clean, damp, lint-free cloth

and a mild, anti-static window cleaning fluid.

a

Fig. 7-1: Cleaning the reading window

If the reading window is scratched or damaged (cracked, broken), it must be replaced.

Please contact the SICK Service.

7.2.2 Cleaning the housing

¾ If necessary, also clean the LEDs on the back side of the housing.

7.2.3 Cleaning further optical effective surfaces

If an external reading pulse generator with a sensor (e.g. photoelectric reflex switch) is used,

make sure to clean the relevant optical surfaces regulary (e.g. weekly). Contamination on

these surfaces can cause switching errors.

¾ In oder to prevent incorrect switching behaviour, remove soiling from the optical effec-

tive surfaces of the external sensor.

b

7.3 Replacing a CLP100

An incorrect or damaged CLP100 has to be removed and replaced with either a new or an

repaired CLP100.

NOTICE

Repairs to the CLP100 should only be carried out by qualified and authorised SICK AG

service staff.

7.3.1 Removing the CLP100

1. Switch off the power supply to the CLP100.

2. Remove the cable plug of the CLP100 respectively remove the wires when using the

variant with open cable end.

3. Mark the situation and alignment of the CLP100 on the holder or environment.

4. Remove the CLP100 from the holder.

38 © SICK AG · Division Auto Ident · Germany · All rights reserved 8008912/R289/2008-11-28

Page 39

Operating Instructions Chapter 7

CLP100 Bar Code Reader

Maintenance

7.3.2 Replacing the CLP100

1. Align and install the new or repaired CLP100.

To do so, observe any marks made previously on the holder or environment (see also

Chapter 4.4 Installation and adjustment of the device, Page 21).

2. Reconnect the cable plug of the CLP100 respectively reconnect the wires when using

the variant with open cable end.

3. Switch on the power supply to the CLP100.

The CLP100 starts with the factory default settings.

4. Establish communication to the CLP100 using the CLP Setup configuration software.

5. Transfer the configuration of the replaced device stored on the PC via download to the

new CLP100 (see Chapter 6.4.1 Transferring the parameter set between the

CLP Setup and CLP100, Page 31). The configuration can only be transferred between

identical device types.

6. Check the behaviour of the CLP100 in the reading process.

7.4 Disposal

After removal from service dispose of unusable or irreparable devices in a manner which is

not harmful to the environment. Observe the respective state regulations on waste disposal.

At present, SICK AG does not take back devices which have become unusable or irreparable.

1. Remove the CLP100 housing.

2. Remove the electronic modules and connection cable.

3. Recycle the housing.

4. Dispose of electronic modules and connection cable as hazardous waste.

8008912/R289/2008-11-28 © SICK AG · Division Auto Ident · Germany · All rights reserved 39

Page 40

Chapter 8 Operating Instructions

Troubleshooting

CLP100 Bar Code Reader

8 Troubleshooting

This chapter describes how errors at the CLP100 can be recognised and eliminated.

NOTICE

Claims under the warranty rendered void!

Do not open the housing of the CLP100. If the device is opened, the SICK AG warranty shall

not apply.

8.1 Possible errors and faults

8.1.1 Installation faults

• CLP100 aligned unfavorably to the bar code (for example, reflections).

• Reading-pulse sensor positioned incorrectly

8.1.2 Faults during the electrical installation

• Interfaces of the CLP100 wired incorrectly

8.1.3 Parameterization errors

• Functions not adapted to the local conditions, for example, communication parameters

of the host interface set incorrectly

8.1.4 Faults during operation

• Device fault (hardware/software)

40 © SICK AG · Division Auto Ident · Germany · All rights reserved 8008912/R289/2008-11-28

Page 41

Operating Instructions Chapter 8

T

CLP100 Bar Code Reader

roubleshooting

8.2 Troubleshooting table

Aids during troubleshooting:

• These operating instructions

• Multimeter for measuring voltage and current

Fault Possible cause Check Remedy

1. When the supply voltage is

applied to the CLP100:

The LEDs do not light up

(LEDs must light up for

three seconds after

voltage is applied if the

self-test is successful)

2. CLP100 cannot be started

via the external sensor,

Scan field of the CLP100

(red light) is not displayed

or

LEDs do not light up after

an executed signal for

reading

3. Green LED does not light

up after the end of the

reading pulse (reading not

successful)

Tab l e 8-1: Troublesh o oting t a ble

1.1 CLP100 without supply

voltage

1.2 CLP100 has diagnosed a

device fault during the

self-test

2.1 External sensor connected

incorrectly

2.2 Photoelectric switch not

aligned to the reflector or

Optical path covered (light

scanner or inductive

sensor is not dampened)

2.3 CLP100 does not receive

command string for

pulsing via the host

interface

3.1 No bar code in the reading

area during the reading

process

3.2 Scan field does not

contact the bar code

3.3 Reading distance