Page 1

Operating manual

pH combination electrodes Order number

SensoLyt

®

SEA

109 115Y

SensoLyt

®

SEA-HP

109 118Y

SensoLyt

®

ECA

109 117Y

SensoLyt

®

DWA

109 119Y

ORP combination electrodes Order number

SensoLyt

®

PtA

109 125Y

®

SensoLyt

combination electrodes

ba76005e01 01/2012

Page 2

Fields of application SensoLyt® combination electrodes

Fields of application

Electrode Application area

pH combination elec-

®

trode SensoLyt

SEA

pH combination electrode

®

SensoLyt

SEA-HP

pH combination electrode SensoLyt

®

ECA

pH combination elec-

®

trode SensoLyt

DWA

ORP combination elec-

®

trode SensoLyt

PtA

Assembly

Measurements in moderately or heavily l oaded

waste water and in emulsions, suspensions

and media that contain protein and sulfide.

Measurements in moderately or heavily l oaded

waste water and in emulsions, suspensions

and media that contain protein and sulfide.

To be used under increased pressure and t emperature conditio ns.

Measurements in municipal and normally

charged waste water.

Measurements in drinking water.

Measurements in waste water, emulsions, suspensions and media that contain protein and

sulphide.

Note

Prior to installing the electrode in an armature, lubricate the two O rings of the

armature with the grease provided.

Calibrating, measuring

Note

See operating manual of the meter.

Note

Take off the watering cap when you want to calibrate or measure.

2

ba76005e01 01/2012

Page 3

SensoLyt® combination electrodes Cleaning

Cleaning

Contamination Cleaning

Gross contamination at the

junction

Carefully brush off contamination under

running water using a soft toothbrush

Membrane contamination Splash the electrode with water, then blot it

dry using a moist paper towel (do not rub).

Fat, oil, protein-containing

coatings and similar substanc-

Remove with household washing-up

liquid

es

Conversion to standard hydrogen electrode

®

(SensoLyt

UH = U

with: U

Meas

H

U

Meas

U

Ref

PtA only)

+ U

Ref

= ORP, referring to the standard hydrogen electrode

= Measured ORP

= Voltage of the reference system compared to the st andard

hydrogen electrode

U

depends on the reference system and temperature and is given in the

Ref

following table (see also DIN 38404-6 for the system, Ag/AgCl/

saturated KCl):

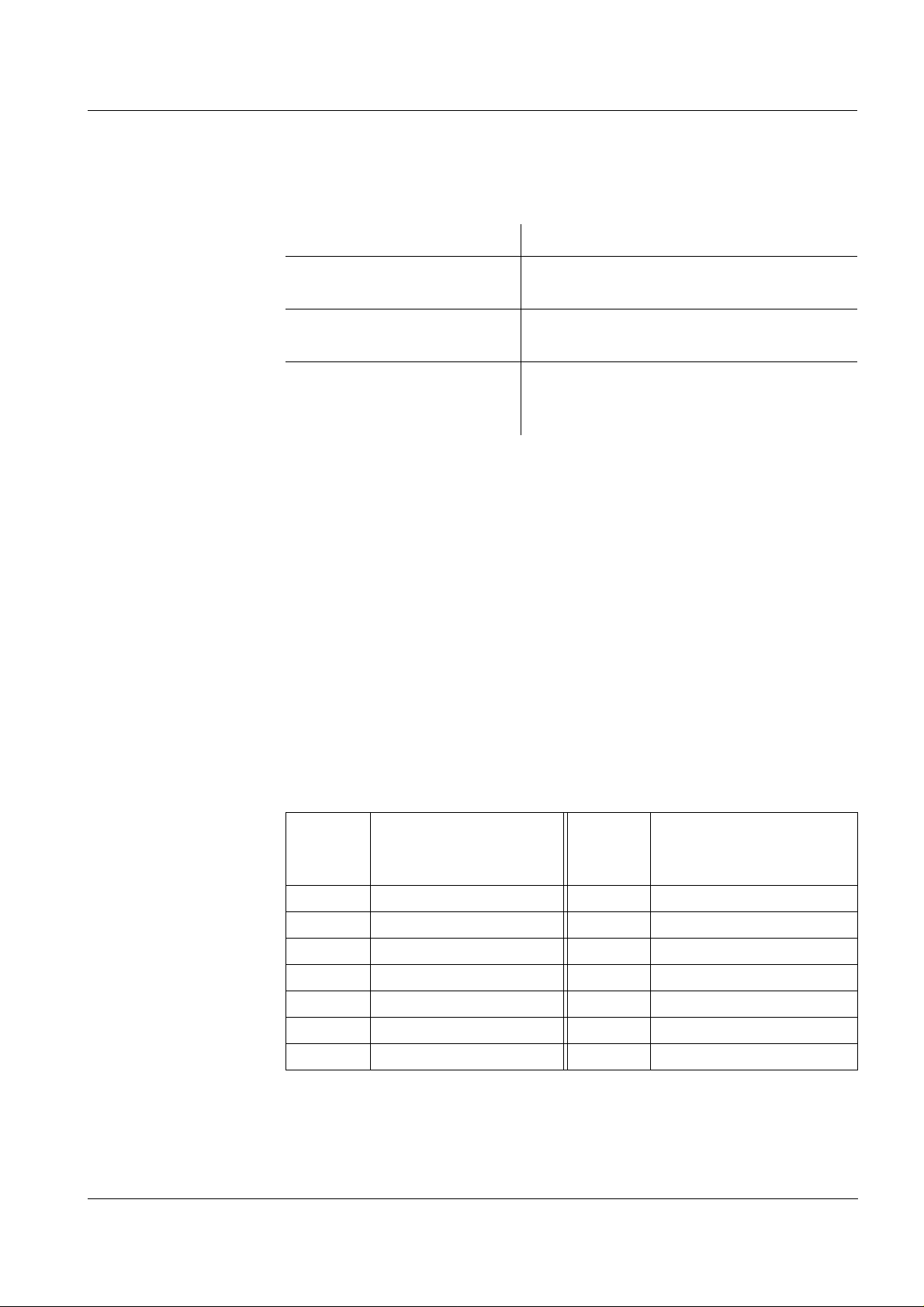

T (°C) U

SensoLyt

tion electrodes

[mV] T (°C) U

Ref

®

combina-

SensoLyt® combina-

[mV]

Ref

tion electrodes

0 +221 35 +187

5 +216 40 +181

10 +212 45 +176

15 +207 50 +171

20 +202 55 +165

25 +197 60 +160

30 +192

ba76005e01 01/2012

3

Page 4

Maintenance / regeneration (SensoLyt® PtA only) SensoLyt® combination electrodes

1000

800

600

400

200

20481012146

0

pH value

U

H

in mV

oxidizing pretreatment

reducing pretreatment

Maintenance / regeneration

®

(SensoLyt

PtA only)

First-time

activation during

installation and as

required

Activation during

very long set-up

times

For first-time activation, use the activating powder provided with the SORT/

RH reagent set. Use a paper towel to gather a small amount of activating

powder. Using moderate pressure, press the activati ng powder against the

moist (but not dripping) platinum elect rode from two opposi te sides and turn

the electrode to and fro several times. Activation happens mainly due to

abrasion. Then remove the adherent remains of activating powder under

running water with a soft brush (e.g. toothbrush).

When changing from oxidizing to reducing test sol utions and vice versa this

can result in set-up times that can take signifi cantly more than an hour. In this

case pretreatment (activ ation) of the plat inum surface can shor ten the set-up

time. The type of pretreatment (reduci ng or oxidizing) is based on the pH value and the ORP voltage (U

) of the test soluti on where the l atter must be es-

H

timated for the first measurement.

The type of pretreatment can then be det ermined using the following diagram

where U

refers to the normal hydrogen electrode:

H

4

Oxidizing pretreatment

Reducing pretreatment

Immerse the platinum electrode for two to three

days in a sulfuric Clorina solution. Clorina powder

for producing the solution is included in the SORT/

RH reagent set.

The junction must not be immersed in the Clo-

Note:

rina solution (see figure below)!

When the electrode is ready for the test immerse it

in the Zobell ORP buffer solution and wai t for a st able measured value.

ba76005e01 01/2012

Page 5

SensoLyt® combination electrodes Accessories

Maximum depth of immersion

for cleaning solution

Note

The platinum electrode (1) should be completely covered duri ng the pretreatment but the electrode must not be immersed in the solution up to the refer ence system with the hole junction (2) (see followi ng figure).

Note

Detailed information on activating platinum electrodes, such as how to produce the Clorina solution, is gi ven in th e WT W appli cati on report ent itl ed R

GENERATING ORP ELECTRODES. The application report is included in the

E-

SORT/RH reagent set.

General

accessories

Buffer solutions

for SensoLyt

pH electrodes

Accessories for

SensoLyt

®

PtA

Accessories

Description Model Order no.

Reference electrolyte solution 250 ml

to fill the water in g cap

(KCl 3 mol/L, Ag

+

free)

Description Model Order no.

®

pH 4 (box of 6 pints) 3821 003821

pH 7 (box of 6 pints) 3822 003822

pH 10 (box of 6 pints) 3823 003823

pH assorted (2 pints ea of 4, 7, and 10) 3824 603824

Description Model Order no.

Reagent set for regenerating ORP platinum electrodes, comprising

10 g activation powder and 30 g Clorina

powder

KCl-250 109 705Y

SORT/RH 109 730Y

ba76005e01 01/2012

Zobell ORP buffer solution (125 ml) 3682 061320

5

Page 6

Technical data SensoLyt® combination electrodes

Technical data

pH measuring

range

ORP measuring

range

Pressure range at

temperature

(armored

electrodes only)

Measuring

electrode

SensoLyt® SEA

SensoLyt

SensoLyt

SensoLyt

SensoLyt

®

ECA

®

SEA-HP pH 4 ... 12

®

DWA pH 0 ... 14

®

PtA -2000 ... 2000 mV

pH 2 ... 12

(pH application range pH 4 ... 12)

SensoLyt

SensoLyt

SensoLyt

SensoLyt

®

SEA

®

ECA

®

DWA

®

PtA

Temperature

Allowed overpressure

0 °C (32 °F) 1000 kPa (10 bar)

20 °C (68 °F) 1000 kPa (10 bar)

30 °C (86 °F) 500 kPa (5 bar)

40 °C (104 °F) 300 kPa (3 bar)

60 °C (140 °F) 100 kPa (1 bar)

SensoLyt

All SensoLyt

®

SEA-HP 0-60 °C (32-140 °F) 1000 kPa (10 bar)

®

combination electrodes meet the requi rements of article 3 (3)

of the directive 97/23/EC ("Pressure equipment directive").

SensoLyt

®

PtA Platinum ring

Reference

electrolyte,

junction

Shunt conduction

element

Connection Plug-in system (S7)

Minimum

immersion depth

All except for

SensoLyt

SensoLyt

SensoLyt

SensoLyt

SensoLyt

SensoLyt

®

PtA

®

SEA

®

SEA-HP

®

PtA

®

ECA Gel electrolyte; 1-hole junction

®

DWA Modified gel electrolyte;

Ag/AgCl

25 mm

Glass

Gel polymer solid electrolyte;

2-hole junction

ceramic junction

6

ba76005e01 01/2012

Page 7

SensoLyt® combination electrodes Technical data

77

83

120 23,5

Ø12

Ø20

Ø18,8

Ø16

Ø24

Dimensions

Weight approx. 65 g

Materials Shaft Glass

Armoring SensoLyt

®

SEA-HP: POM

All other types: PVC-U

Connection head PPS-GF40

O-rings FPM (Viton)

Watering cap PE

Storage With watering cap, filled with KCl 3 mol/L, Ag

Disposal Residual waste

+

free

ba76005e01 01/2012

7

Page 8

1725 Brannum Lane

Yellow Springs, Ohio 45387 USA

+1 937-767-7241

800-765-4974 (US)

FAX (937) 767-1058

Email: environmental@ysi.com

Internet: www.ysi.com

Loading...

Loading...