Page 1

USER MANUAL

Page 2

CONTENTS

Warranty ..............................................................................................................i

Introduction .......................................................................................................1

Getting Started ................................................................................................... 1

Initial Inspection .................................................................................1

Battery Installation ............................................................................. 1

Key Pad ................................................................................................2

Initial Setup ........................................................................................ 4

Main Display .......................................................................................6

Menu Layout ........................................................................................ 6

Alpha/Numeric Entry ......................................................................... 7

System ................................................................................................................8

Date/Time ............................................................................................ 8

Item #626279

Rev C

Drawing # A626279

March 2009

©2009 YSI Incorporated.

The YSI, ProODO, and ODO logos are registered

trademarks of YSI Incorporated.

Microsoft and Windows are registered trademarks of the Microsoft

Corporation in the United States and other countries.

Pentium is a registered trademark of Intel Corporation.

GLP ....................................................................................................... 8

Language ............................................................................................12

Radix Point ........................................................................................ 12

Logging ..............................................................................................13

Sampling Mode .................................................................................13

Auto Shutoff ...................................................................................... 14

Backlight ............................................................................................14

SW Version (Software Version) ....................................................... 14

Serial # ................................................................................................ 14

Unit ID ...............................................................................................14

Optical Dissolved Oxygen (ODO™) ...............................................................15

Page 3

ODO Probe Setup ............................................................................. 15

Dissolved Oxygen Readings .............................................................34

Calibration - Dissolved Oxygen ...................................................... 18

Barometer .........................................................................................................23

Display - Barometer ..........................................................................23

Calibration - Barometer ................................................................... 23

Temperature ...................................................................................................... 24

Taking Measurements ...................................................................................... 24

Files and Site Lists ............................................................................................ 25

File Memory ......................................................................................25

View Data ..........................................................................................25

Site List ............................................................................................... 26

Folder .................................................................................................27

Delete Data ........................................................................................27

Data Manager Desktop Software .................................................................... 27

Help ...................................................................................................35

Error/Status messages ...................................................................... 35

Restore Default Calibration Values ................................................36

Accessories / Part Numbers ............................................................................37

Declaration of Conformity ..............................................................................40

Recycling ........................................................................................................... 42

Contact Information ........................................................................................43

Ordering and Technical Support .....................................................43

Service Information ..........................................................................43

Appendix A-DO% Calibration Values ........................................................... 44

Appendix B-Oxygen Solubility Table ............................................................ 46

Using the Communications Saddle ................................................. 27

Manage Logged Data .......................................................................28

Real Time Data Collection ............................................................... 29

Configure Instruments ..................................................................... 29

Maintenance and Storage ................................................................................ 30

Updating Instrument and Probe Firmware .................................... 30

General Maintenance - Battery Compartment Gasket ................30

Sensor Maintenance - Dissolved Oxygen ....................................... 30

Sensor Storage ................................................................................... 34

Troubleshooting ...............................................................................................34

Page 4

THIS PAGE LEFT INTENTIONALLY BLANK

WAR R AN T Y

The YSI Professional ODO™ Instrument is warranted for three (3) years from date of

purchase by the end user against defects in materials and workmanship, exclusive of

batteries and any damage caused by defective batteries. ProODO™ field cable/probe

assemblies are warranted for two (2) years from date of purchase by the end user

against defects in material and workmanship. ProODO sensor caps are warranted

for one (1) year from date of purchase by the end user against defects in material

and workmanship. ProODO systems (instrument & cable/probe assemblies) are

warranted for 90 days from date of purchase by the end user against defects in

material and workmanship when purchased by rental agencies for rental purposes.

Within the warranty period, YSI will repair or replace, at its sole discretion, free of

charge, any product that YSI determines to be covered by this warranty.

To exercise this warranty, call your local YSI representative, or contact YSI Customer

Service in Yellow Springs, Ohio at +1 937 767-7241, 800-897-4151 or visit www.

YSI.com (Support tab) for a Product Return Form. Send the product and proof

of purchase, transportation prepaid, to the Authorized Service Center selected by

YSI. Repair or replacement will be made and the product returned, transportation

prepaid. Repaired or replaced products are warranted for the balance of the original

warranty period, or at least 90 days from date of repair or replacement.

LIMITATION OF WARRANTY

This Warranty does not apply to any YSI product damage or failure caused by:

Fai lure to install, operate or use the product in accordance w ith YSI’s written 1.

instructions;

Abuse or misuse of the product; 2.

Failure to maintain the product in accordance with YSI’s written instructions 3.

or standard industr y procedure;

Any improper repairs to the product; 4.

Use by you of defective or improper components or parts in servicing or 5.

repairing the product;

Modification of the product in any way not expressly authorized by YSI.6.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. YSI’S LIABILITY UNDER THIS WARRANTY

IS LIMITED TO REPAIR OR REPLACEMENT OF THE PRODUCT, AND THIS

SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY FOR ANY DEFECTIVE

PRODUCT COVERED BY THIS WARRANTY. IN NO EVENT SHALL YSI BE

LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES RESULTING FROM ANY DEFECTIVE PRODUCT COVERED BY

THIS WARRANTY.

i

Page 5

ii

1

THIS PAGE LEFT INTENTIONALLY BLANK

INTRODUCTION

Thank you for purchasing the YSI Professional Optical Dissolved Oxygen (Pro

ODO) instrument. The YSI ProODO™ measures dissolved oxygen in water using

lifetime luminescence technology and uses a digital signal to send information

between the instrument and probe. Key advantages of the new ProODO include

the elimination of sensor flow dependence and sensor warm-up time, greater

stability, the ability to zero the sensor for more accurate measurements at low

dissolved oxygen levels, and the elimination of frequent membrane/electrolyte

changes. The ProODO also features a waterproof (IP-67) case, a rugged MS-8

cable connector, backlit display and keypad, user-selectable cable lengths, USB

connectivity, large memory with extensive site list capabilities, and a rugged,

rubber over-molded case. For product specification information, please visit

www.ysi.com or contact Technical Support at 800-897-4151 (+1 937 767-7241).

Reading the entire manual before use is recommended for an overall

understanding of the instrument’s features.

GETTING STARTED

InItIal InspectIon

Carefully unpack the instrument and accessories and inspect for damage.

Compare received parts with items on the packing list. If any parts or materials

are damaged or missing, contact YSI Customer Service at 800-897-4151 (+1 937

767-7241) or the authorized YSI distributor from whom the instrument was

purchased.

Battery InstallatIon

The ProODO uses 2 alkaline C-cell batteries. Battery life depends on sampling

mode and usage. When used in Manual Sampling mode, under normal

conditions, battery life is approximately 80 hours at room temperature. The

use of Automatic Sampling mode may slightly reduce the battery life. See the

System section of this manual for more information on Sampling Modes.

Figure 1. ProODO with battery cover removed. Notice battery symbols indicating

polarities.

Page 6

2

3

To install or replace the batteries:

Turn the instrument over to view the battery cover on the back. 1.

Unscrew the four captive battery cover screws. 2.

Remove the battery cover and install the new batteries, ensuring correct 3.

polarity alignment on the instrument or the removed cover (Figure 1).

Replace the battery cover on the back of the instrument and tighten the four 4.

screws. Do NOT over-tighten.

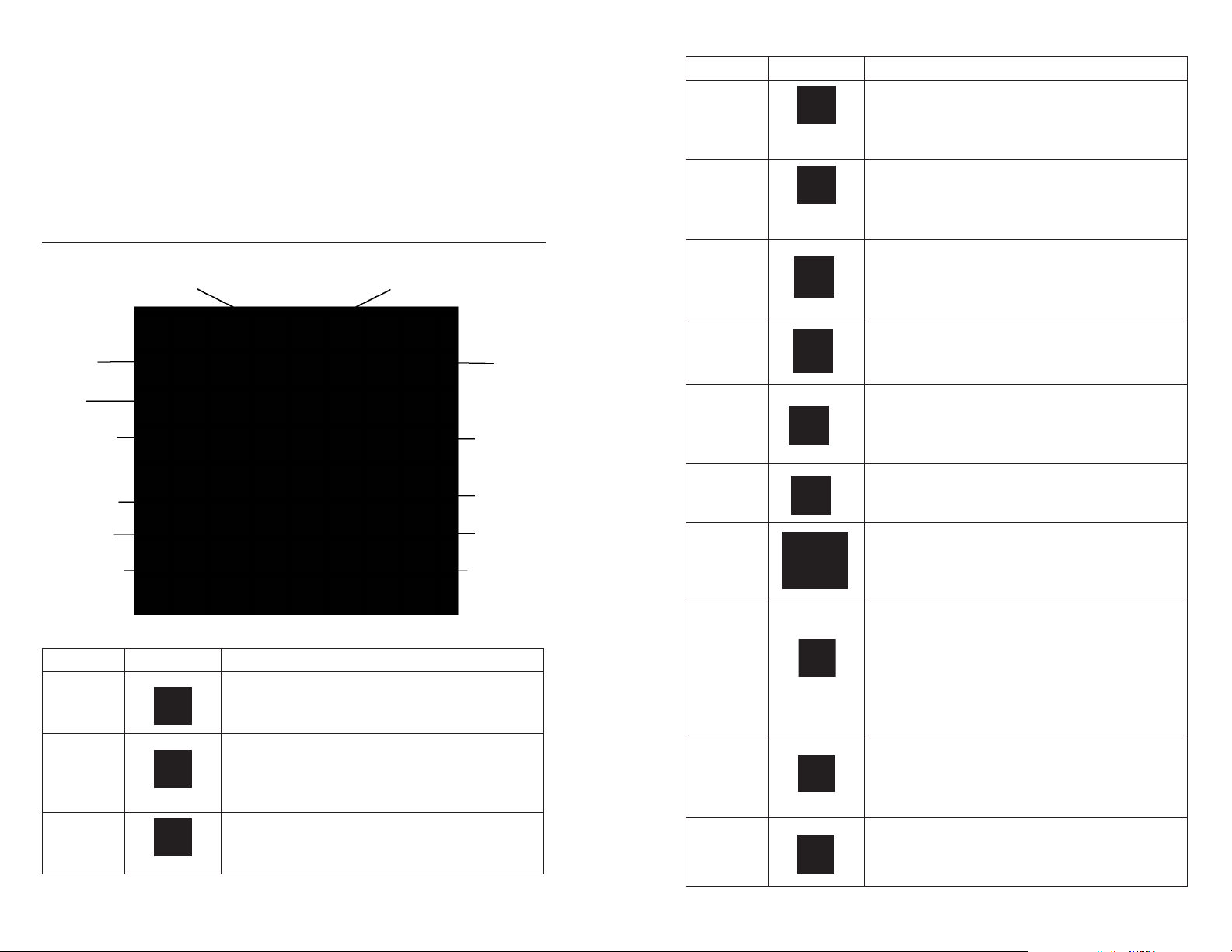

Key pad

1

2

System

3

Probe Calibration File

Number Key Description

4

File

Opens File Menu from any screen.

Use to view data and GLP files, set up

site and folder lists, and delete data.

5

Backlight

Press to turn the instrument backlight on and

off and to adjust the display contrast when

pressed with the left or right arrow key.

6 Right Arrow

Use to navigate right in alpha/numeric entry

screens. Can be pressed simultaneously with

Backlight button to increase display contrast.

7 Down Arrow

4

Use to navigate through menus and to navigate

down in alpha/numeric entry screens.

13

12

11

10

9

Figure 2

Number Key Description

1

System

Opens System Menu from any screen.

Use to adjust system settings.

2

Probe

Opens Probe Menu from any screen.

Use to setup DO probe, sensor

cap, and display units.

3

Calibrate

Opens Calibrate Menu from any screen.

Use to calibrate dissolved oxygen.

8 Power

Press and hold for 2 seconds to

5

tu rn t he in st rument on.

Press to turn off.

9 Help

6

7

10 Enter

Press to receive hints & tips during operation.

Press to confirm selections, including

8

alpha/numeric key selections.

11 Left Arrow

Use to navigate left in alpha/

numeric entry screens.

Press to return to previous menu in all

screens except alpha/numeric entry.

Can be pressed simultaneously with Backlight

button to decrease display contrast.

12 Exit/Escape

Exits back to Run Screen.

When in alpha/numeric entry screen,

escapes to previous menu.

13 Up Arrow

Use to navigate through menus and to

navigate up in alpha/numeric entry screens

Page 7

4

5

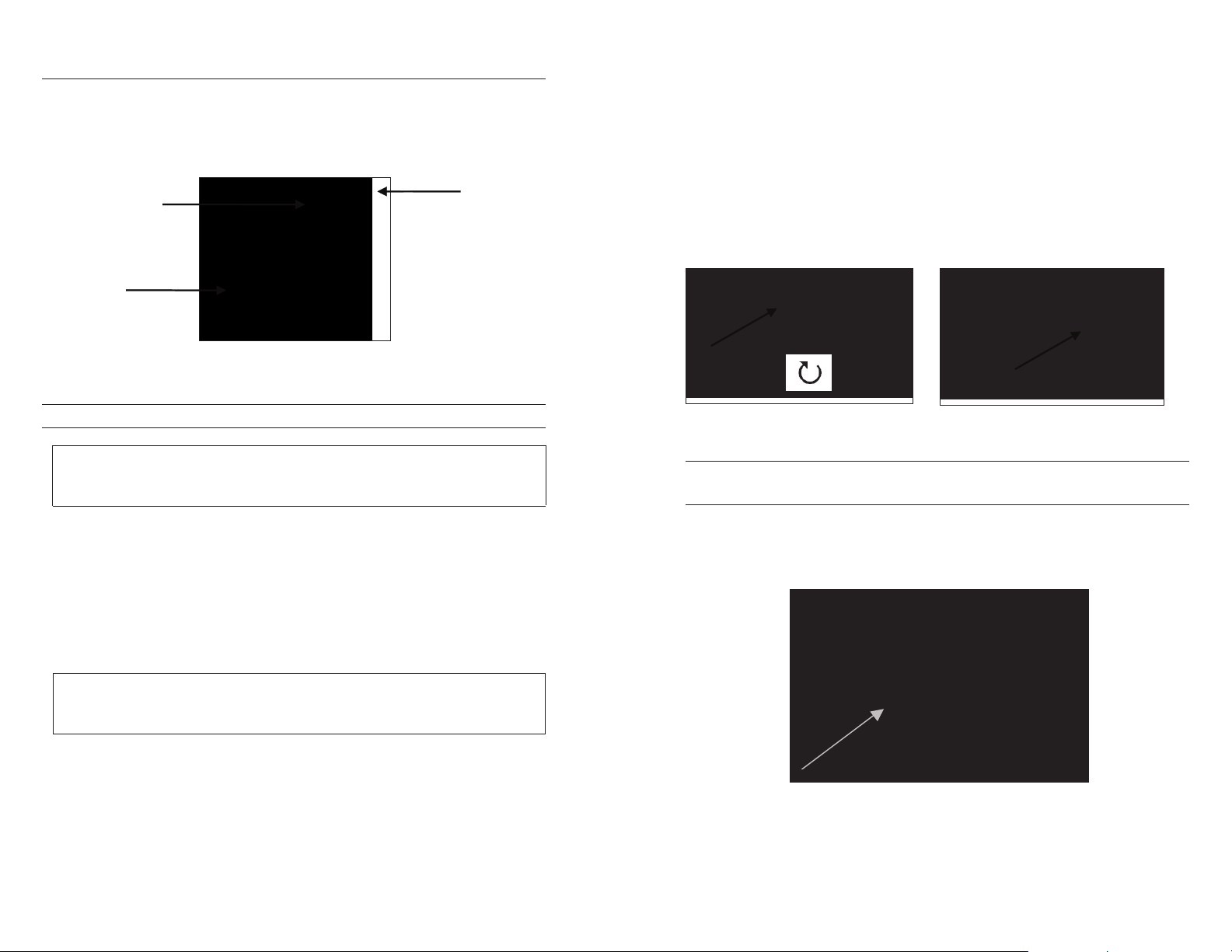

InItIal setup

Throughout the manual, the term “probe” refers to the end of the cable where

the sensor is located, the term “sensor” refers to the Optical Dissolved Oxygen

sensing portion of the cable/probe assembly, and the term “sensor cap” refers to

the removable sensing cap that is replaced about once per year (Figure 3).

Sensor

Probe

Figure 3

Sensor Cap

UNPACKING THE ODO PROBE

Each ProODO cable/probe assembly and replacement ODO

i

sensor cap includes an instruction sheet with important

information unique and specific to each individual sensing cap.

Reinstall the probe guard by sliding it carefully over the sensor and then 3.

threading it onto the cable/probe assembly with a clockwise rotation (Figure

4).

Locate the grey calibration/storage sleeve that was shipped with your probe/4.

cable assembly. Moisten the sponge in the grey calibration/storage with a

small amount of clean water.

Slide the calibration/storage sleeve over the probe guard to keep the probe 5.

in a moist atmosphere for storage or calibration (Figure 5). It is important

to always keep your sensor in a moist environment so the sensor cap does

not dry out. (See Care, Maintenance, and Storage for more information.)

Figure 4 Figure 5

CONNECTING THE PROBE/CABLE ASSEMBLY TO THE

INSTRUMENT

Remove the cable/probe assembly from the shipping container and locate

the instruction sheet included with your assembly. This instruction sheet is

important because it includes the calibration coefficients for your sensor cap.

After using this sheet for general probe setup, be sure to store it in a safe place in

case you need to reload these calibration coefficients in the unlikely event that

they are ever deleted from the probe.

Note - A new cable/probe assembly already has a

i

Preparing the probe for the first time:

Remove the metal probe guard from the probe by turning it 1.

counterclockwise.

Remove the red storage cap which contains a moist sponge from the end of 2.

the probe by pulling it straight off the sensor. Save this to use later for long

term storage.

sensor cap installed and the sensor cap coefficients

are preloaded into the probe at the factory.

To connect the cable, align the keys on the cable connector to the slots on the

instrument connector. Push together firmly, then twist the outer ring until it

locks into place (Figure 6). This MS-8 (Military Spec) connection is waterproof.

Figure 6. Note the keyed connector. The cable and instrument

connectors can only be mated once the keyed sections are properly

aligned. When disconnected, the cable connector and the

connector on the instrument maintain an IP-67 rating.

Page 8

6

7

MaIn dIsplay

Press and hold the Power key for two seconds to turn the instrument

on. The instrument will briefly display two splash screens then go directly

to the main run mode screen. The first time the instrument is powered

up, you will need to set the date and time. Follow the instructions under

the Setup | System | Date/Time section of this manual.

The display at the left shows the run mode

(main display) with temperature in °C,

barometric pressure in mmHg, DO in % and

mg/L as the reported parameters. The date,

time and battery level are indicated at the

bottom of the screen. The logging preference

of Log One Sample at a time is indicated at

the top of the screen.

alpha/nuMerIc entry

This screen also shows the message line

towards the bottom of the display above the

date and time. In this case, it doesn’t show

a message. However, messages will appear

frequently to indicate successful calibrations,

saved configuration changes, etc.

A USB symbol

the bottom of the display when connected

through USB with the communications saddle. The instrument will display full

battery power when it is receiving power through the USB connection.

Contrast – the contrast adjustment can be accomplished

by repeatedly pressing the backlight key and the

i

left or right arrow key at the same time.

will show up on

Menu layout

Press Esc at anytime in the menus to escape back to the Run screen. The

left arrow

except alpha/numeric entry screens. You must use Esc to get out of the alpha/

numeric screens if you want to exit before finishing or without saving changes.

Functions that are enabled appear as a circle with a dot . Disabled functions

appear as a circle only . In addition, some options appear as an empty box P

or a box with a check mark Q.

can be used to go back to the previous menu in all screens

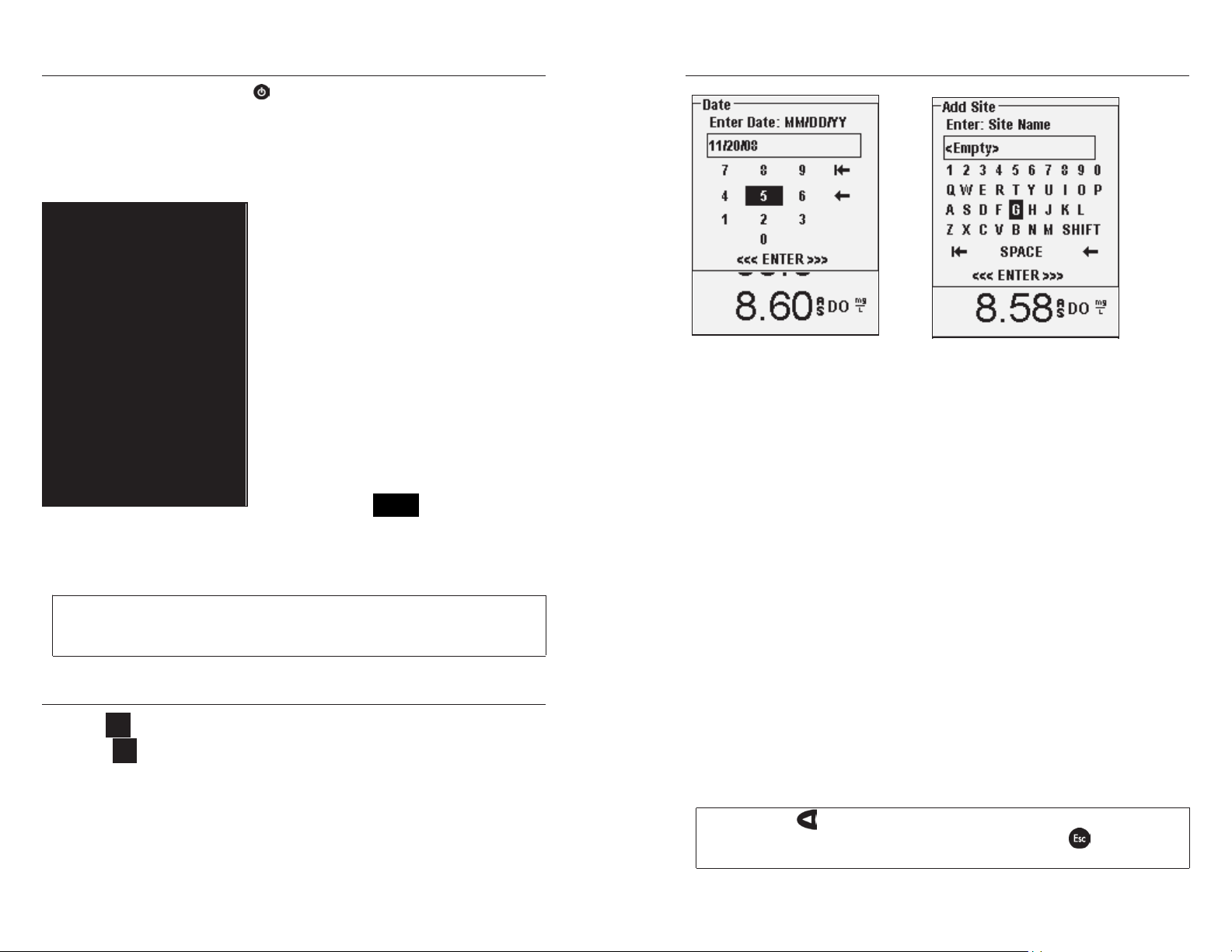

The numeric screens will display numbers only (shown above, left). Alpha/

numeric screens will display numbers across the top and letters along the

bottom rows (shown above, right). Letters appear as a common keyboard

arrangement.

When an alpha or numeric character is required, the display will show the alpha/

numeric entry screen. To select a character, highlight it by using the arrows to

move the highlight box over the desired selection. Then, press Enter on the

keypad to confirm the selection. After confirming the selection, it will appear

in the line at the top of the display.

For capital letters or lower case entry, highlight “SHIFT” and press Enter on the

keypad to change the characters from upper to lower case.

To delete the entire line of the current entry, highlight ) and press Enter on the

keypad. The ! symbol functions as a backspace key in the alpha/numeric entry

screens by deleting one character at a time. Use the “SPACE” function to add a

space between characters.

When you have finished entering the correct information (16 character max),

highlight <<<ENTER>>> at the bottom of the screen and press Enter on the

keypad to confirm.

The key cannot be used to escape to the previous menu from

i

an alpha/numeric entry screen. Instead, use the key to go

back to the previous menu when in alpha/numeric entry screens.

Page 9

8

9

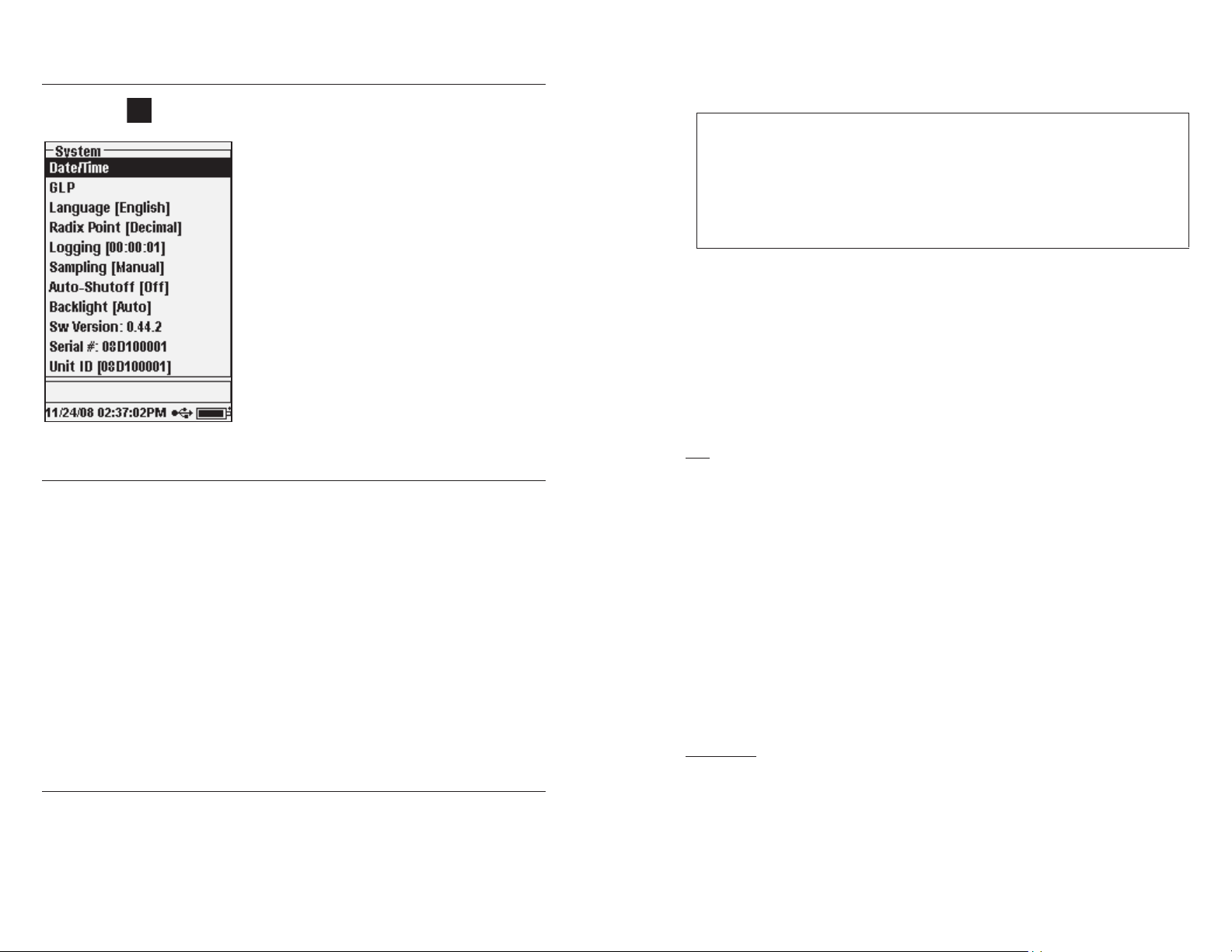

S Y S T E M

Press System to access any of the following menu items.

The System menu will allow you to access the

setup options of the instrument including;

Date/Time, GLP, Language, Radix Point,

Logging, Sampling, Auto Shutoff, Backlight,

Sw (Software) Ve rs i on , Serial #, and Unit ID.

Any item with [brackets] shows the current

setting inside the brackets. For instance, in the

example at the left, Radix Point is currently set

to [Decimal].

date/tIMe

Highlight Date/Time from the System menu. Press enter to select.

Date Format – Highlight and press enter to open a sub menu for selecting

the preferred date format: YY/MM/DD, MM/DD/YY, DD/MM/YY, or

YY/DD/MM.

Date – Highlight and press enter to use the numeric entry screen to set the

correct date.

Time Format – Highlight and press enter to open a submenu to select the

preferred time format from 12-hour or 24-hour.

Time – highlight and press enter to use the numeric entry screen to set the

correct time.

Glp

The GLP or ‘Good Laboratory Practice’ file saves detailed information

about calibrations. It also includes diagnostic information about the sensors.

Calibrations are logged into a file, the GLP, for later review as needed. A single

GLP file is utilized to store all calibration records and is capable of storing 500

records. Once the GLP file is full, the instrument will begin to overwrite the

oldest record with each new calibration record.

In order to keep all of your GLP records, periodically download

the GLP to Data Manager and export it to another program.

Otherwise, the instrument will overwrite the oldest record

i

Several calibration parameters are saved for each calibration including optional

ones that can be enabled by the user. Standard parameters include date/time

stamp, calibration method, and sensor information. Optional, user selectable

parameters include User ID, Probe ID, and User Fields 1 and 2.

In addition, there will be information specific to the Dissolved Oxygen or

Barometer calibration record. A Dissolved Oxygen calibration record will

contain the following calibration specific parameters:

DO

Sensor - Serial Number of the Sensor

Calibration Method - Zero, %, or mg/L

Cal Value

Sensor Value - Tangent of the angle between reference and signal LED, must be

within 0.2 of the default value in the sensor, typically between

-0.53 and -2.17

Salinity Mode - Always manual

Salinity Value - Value entered by the user

Barometer - Barometric Pressure during calibration

Temperature - Temperature during calibration

Calibrate Status - Calibrated

A Barometer calibration record will contain the following calibration specific

parameters:

Barometer

Barometer - Calibrate value in kPa

Calibrate Status - Calibrated

once the memory is full. Also, since Data Manager saves

GLP files under the Unit ID, you must periodically export

and rename the GLP file on your PC or it will be overwritten

each time you upload the GLP file from the instrument.

Page 10

10

11

An example of a GLP record

(Operation Performed is % DO Calibration)

*** Calibrate – DO ***

Date: 11/01/2008 MM/DD/YY

Time: 04:03:05 PM

User ID: Tech0001

Probe ID: SN: 08D

User Field #1 Cloudy

Sensor: 08F000015

Method: DO Air Calibrate

Cal Value: 100.0 %

Sensor Value: -0.591150

Salinity Mode: Manual

Salinity Value: 0.000000 SAL PSU

Barometer 767.09 mmHg

Temperature 19.2 °C

Calibrate Status: Calibrated

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

In the System menu, highlight GLP and press

enter to view and modify the GLP settings.

probe assembly from another, typically by serial number. Highlight Include

Probe ID and press enter to turn this function on and off. There will be a check

mark in the box when the function is enabled. Highlight Probe ID and press

enter to add, view, edit, or select a Probe ID. Probe ID may also be changed in

the Calibration menu during the calibration process. The character limit is 16

characters.

User Fields 1 and 2 are stored with the calibration record and may be used

to enter other parameters pertinent to the user, such as weather conditions,

elevation, etc. Highlight Include User Field 1 or Include User Field 2 and press

enter to turn this function on and off. Highlight User Field 1 or User Field 2

and press enter to add, view, edit, or select a User Field. The character limit is

16 characters. When enabled, a prompt for selecting a User Defined Field will

appear during the calibration process.

Re-Cal Prompt may be used to remind the user

to perform a calibration. To set a time interval,

highlight DO and press enter to access the

numeric entry screen. Enter a value in days and

press enter to confirm the reminder time. To

turn off the Re-cal prompt, set the reminder to

zero (0) days (this is the default).

Highlight Options and press enter to access

User ID, Probe ID, User Defined Fields, and

Re-Cal Prompt.

User ID may be used to identify the person

calibrating the instrument. Highlight User ID

and press enter to select or edit a User ID from

a list of previously entered IDs. Or, highlight

Add New and press enter to create a new User

ID using the alpha/numeric entry screen. The

User ID may also be changed in the Calibration

menu during the calibration process. The

selected User ID will be stored in the GLP file

with each calibration record. A User ID could

be a person’s initials or badge number. The

character limit is 16 characters.

Probe ID is stored with the calibration record

and may be used to distinguish one cable/

The Security section of the GLP menu is a password protected area. This area

includes options to set a new password and to lock access to the calibration

menu. When first viewing the security menu, you will be required to enter a

password. Use the “shift” on the alpha/numeric screen to switch to lower case

and enter “ysi123”. This is the default password.

Protect Cal can be enabled or disabled. When enabled, the user must know and

enter the instrument’s password to enter the calibration menu option. Highlight

Protect Cal and press enter to enable (Q) or disable (P) this feature.

Set Password allows a user to set the security password. Highlight Set Password

and press enter. Using the alpha/numeric entry screen, enter the new password.

The password can have up to 16 characters.

Contact YSI Technical Support at environmental@ysi.com or +1 937 767-7241 if

you forget or misplace your password.

Once a password is set, and the GLP security screen

i

exited, a password must be entered to make changes

under GLP security. Keep passwords in a safe place.

Page 11

12

13

lanGuaGe

loGGInG

radIx poInt

To change the instrument’s language setting,

highlight Language in the System menu and

press Enter. Highlight the desired language

and press enter to confirm. Languages include

English, Spanish, French, German, Italian,

Portuguese, and Norwegian.

Radix Point allows the user to select between

a comma or a decimal in numeric radix point

for displayed values. For example, 1.00 becomes

1,00 when Use Comma is selected. Highlight

Use Decimal or Use Comma and press enter to

make your selection.

From the System menu, highlight Logging and press enter to view or change

the logging options. Logging options include Use Site List, Use Folder List,

Continuous Mode, and Interval.

Use Site List and Use Folder List are optional

ways of filing or ‘tagging’ your logged data

points. If these settings are enabled, you will

be prompted to select a Site and/or Folder to

‘tag’ to logged data points. See the File and Site

Lists section of this manual for information on

creating Site and Folder Lists.

Check the box for Continuous Mode if you

want to log samples continuously at a specific

time interval. To set the length of time between

logged samples, highlight Interval and press

Enter. Enter the interval as HH:MM:SS. This

interval will display at the top of the screen

when you select the Start Logging option in

run mode. If operating the unit in Manual

mode, see next section, the continuous logging

interval must be set to 10 seconds or greater in order to log data.

To log one sample at a time, uncheck Continuous Mode.

saMplInG Mode

The Sampling mode can be set to Automatic or Manual. In Automatic mode,

which is the default mode, the readings are

constantly updated. In Manual mode, the

readings are held or ‘locked’ on the display

once they reach the stability of the Auto Stable

setting in the Probe menu. The user must then

press a key to either log the held data or update

the measurements. Selecting Manual mode may

increase the instrument’s battery life. Highlight

either Automatic or Manual and press enter to

make your selection. If continuously logging in

Manual mode, the logging interval must be set

to 10 seconds or greater.

Page 12

14

15

auto shutoff

OPTICAL DISSOLVED OXYGEN

Auto Shutoff powers the instrument off after a user specified time period.

Highlight Auto Shutoff and press enter. Using the numeric entry screen, enter

a value between 0 and 360 minutes. To disable auto shutoff, set the value to 0

(zero).

BacKlIGht

Backlight can be set to Automatic or Manual.

Automatic turns the backlight on when you

turn the instrument on and when you press any

key. Manual allows you to turn the backlight

on or off with the backlight key

Automatic mode, the instrument will turn the

backlight off after 60 seconds without any keys

being pressed. If a key is pressed during that

time, the instrument will “reset” the 60 second

time period. The lighted keypad will turn off

after approximately 20 seconds.

. When in

sW VersIon (softWare VersIon)

SW Version shows the instrument’s software version.

serIal #

Serial # shows the instrument’s serial number and allows you to match it with

the number engraved on the back of the instrument’s case. The Serial # is also

the default Unit ID.

unIt Id

Unit ID is used to identify instruments in the Data Manager software included

with your instrument. It is also used to identify GLP files, Site Lists, Configuration

Files, and Data files transferred from the instrument to the PC. The default Unit

ID is the Instrument’s serial number. To modify the Unit ID, highlight Unit ID,

press enter and use the alpha/numeric entry screen. The character limit is 16

characters.

ODO™

Each ProODO cable/probe assembly and replacement ODO

sensor cap includes an instruction sheet with important

information unique and specific to each individual sensing

i

See Initial Setup | Unpacking the ODO Probe for initial setup instructions.

i

odo proBe setup

Press Probe , Highlight DO, press enter.

In essence, even if the barometric pressure changes you wouldn’t notice the

difference with the DO% readings in air-saturated water or water-saturated air.

cap. This instruction sheet is important because it includes

the calibration coefficients for the sensor cap. After using this

sheet for general probe setup, be sure to store it in a safe place

in case you need to reload these calibration coefficients in the

unlikely event that they are ever deleted from the probe.

It is important to always keep your sensor in a moist

environment so the sensor cap does not dry out. (See

Maintenance and Storage for more information.)

Enabled allows you to enable or disable the DO

sensor. Highlight Enabled and press enter to

activate or deactivate dissolved oxygen.

The DO Setup menu also displays the ODO

p ro be’s SW Version and Serial #. This

information is programmed into the probe at

the factory and digitally sent to the instrument

when the cable is connected.

Local DO allows for localized DO%

measurements. This sets the calibration value

to 100% regardless of the altitude or barometric

pressure. Highlight Local DO and press enter

to enable or disable this function. Local DO

is a method for the ProODO to factor in the

barometric pressure on each DO measurement.

Page 13

16

17

Local DO is ideal for EU compliance. When Local DO is enabled, an L will

appear next to DO% on the run screen. DO mg/L readings are unaffected by the

selection of DO Local.

LDS (Last Digit Suppression) rounds the DO value to the nearest tenth; i.e. 8.27

mg/L becomes 8.3 mg/L. Highlight LDS and press enter to activate or deactivate

LDS. Some users may not want to read out to the hundredths place since the DO

mg/L accuracy spec is to the tenths place.

Sensor Cap allows you to view and enter information specific to the sensor

cap installed on the probe. Highlight Sensor Cap and press enter to view the

sensor cap’s Serial #, Temperature Coefficient, and Sensor Cap Coefficients.

This information is programmed into the sensor at the factory and sent to the

instrument when the cable is connected. Since the Temperature Coefficient is

programmed into the sensor at the factory, it should not be modified unless

instructed by YSI Technical Support.

The Sensor Cap Coefficients need to be updated when the sensor cap is replaced.

The sensor cap should be replaced about once per year. See the Dissolved

Oxygen Sensor Maintenance section of this manual or the instruction sheet

included with replacement sensor cap for instructions on updating the Sensor

Cap Coefficients. When updating the Coefficients, the sensor cap serial # will

be updated automatically based on your entries.

DISPLAY DISSOLVED OXYGEN

Press Probe , highlight Display and press enter. Highlight DO and press

enter. Note, you will not be able to display dissolved oxygen unless it is Enabled

in the DO Setup menu first, see previous section.

DO % will show DO readings in a percent scale from 0

to 500%.

DO mg/L will show DO readings in milligrams per liter

(equivalent to ppm) on a scale from 0 to 50 mg/L.

AUTO STABLE DISSOLVED OXYGEN

Press Probe , highlight Auto Stable and press enter. Highlight DO and press

enter.

Auto Stable indicates when a reading is stable.

Highlight Enabled and/or Audio Enabled

(instrument will beep when the stability is

achieved) and press enter to confirm. When

Auto Stable is enabled, AS will blink next to the

parameter until it is stable. Once the parameter

is stable, AS will stop blinking.

The Auto Stable Sensitivity can be decreased or

increased. Highlight Sensitivity and use the left and right arrow keys to slide

the bar. The more sensitive you make it (larger black bar) the harder it is to

achieve stability in a changing environment.

The Auto Stable system works by examining the previous 5 readings, computing

the percent change in the data and comparing that change against a % threshold

value. The % threshold value is determined by the Sensitivity bar setting. The

following chart can be used as a guide when setting the Sensitivity bar.

Sensitivity selected by User % Data Variance Threshold

100 - Most Sensitive, Sensitivity

bar is set to the far right

75 0.62525%

50 1.275%

25 1.8875%

0 - Least Sensitive, Sensitivity

bar is set to the far left

Example:

0.05%

2.5%

DO ppm will show DO readings in parts per million (equivalent to mg/L) on a

scale from 0 to 50 ppm.

All units can be displayed simultaneously on the screen. Highlight the desired

unit(s) and press enter to select. A check mark in the box next to the unit will

indicate that it is enabled.

The instrument obtained the following data:

Reading #1 95.5 DO%

Reading #2 95.7 DO%

Reading #3 95.8 DO%

Reading #4 96.1 DO%

Reading #5 95.3 DO%

Page 14

18

19

The instrument is programmed to determine the minimum and maximum

data value over the previous 5 samples, and to compute the percent difference

between those values. In this example, that gives a percent change of:

% Change = 100 * ((96.1 – 95.3 ) / 95.3)

% Change = 0.83%

In this example, if the Sensitivity Bar is set to the far right, the Auto Stable

requirement would not be met and AS would continue to blink. However,

if the sensitivity bar is set to the median threshold (1.275%), the Auto Stable

requirement would be met and AS would display steadily on the display.

barometric pressure. Refer to Appendix A for the DO% calibration values based

on barometric pressure.

The ProODO offers several options for calibrating dissolved oxygen. The

first and second methods calibrate the DO % saturation value to either water

saturated air or air saturated water. The third and fourth calibrates in mg/L

or ppm to a solution with a known DO concentration (usually determined by a

Winkler Titration). The fifth option is a zero calibration. If performing a zero

calibration, you must also perform a %, mg/L, or ppm calibration following the

zero calibration. For both ease of use and accuracy, YSI recommends performing

the following DO % water saturated air calibration:

If the Manual Sampling mode in the System menu is enabled, the Auto Stable

function will automatically be enabled and the sensitivity setting will be used to

determine when to hold the readings on the display. See Sampling Mode in the

System section of this manual for more information on the two Sampling mode

options.

SALINITY CORRECTION

The last feature in the Probe menu is the Salinity correction value for the mg/L

readings. Press Probe

numeric entry screen to enter the Salinity value of the water you will be testing

from 0 to 70 ppt.

The value entered here will be used when calculating mg/L from the temperature

and % saturation readings. As the salinity of water increases, its ability to dissolve

oxygen decreases. For example, fully oxygenated 20 °C water at sea level with

zero salinity will hold 9.092 mg/L of dissolved oxygen. If that same sample had

a salinity value of 9 ppt, then it would hold 8.621 mg/L of dissolved oxygen.

Therefore, to obtain accurate mg/L readings, it is important that you know the

salinity of the water you will be testing and input the value into the instrument.

The salinity of fresh water is typically 0-0.5 ppt and seawater is typically 35 ppt.

You will also have the opportunity to enter or modify the Salinity correction

value during DO calibration. Appendix B shows the oxygen solubility table.

, highlight Salinity, and press enter. Then, use the

calIBratIon - dIssolVed oxyGen

The ProODO sensor is an optical luminescent sensor which has greater stability

and is less susceptible to calibration drift than traditional electrochemistry

sensors. This increased stability means that the instrument may hold its

calibration for many months. However, for the highest data accuracy, YSI

recommends verifying the instrument’s calibration on a daily basis. To verify

the instrument’s calibration, place the sensor in its calibration environment

and check to see that the DO% is reading its calibration value based on the

It is not necessary to calibrate in both % and mg/L or ppm.

i

Calibrating in % will simultaneously calibrate

mg/L and ppm and vice versa.

CALIBRATING DO % IN WATER SATURATED AIR:

1POINT CALIBRATION

Moisten the sponge in the storage sleeve with a small amount of clean water.

The sponge should be clean since bacterial growth may consume oxygen and

interfere with the calibration. Make sure there are no water droplets on the

sensor cap and temperature sensor and then install the storage sleeve over the

probe. Make sure the DO and temperature sensors are not immersed in water.

The storage sleeve ensures venting to the atmosphere. Wait approximately 5

to 10 minutes for the storage container to become completely saturated and to

allow the temperature and dissolved oxygen sensors to stabilize.

Press Calibration

are enabled in the System GLP menu you will be

able to highlight these features and add, select,

edit, or delete an ID. When enabled these IDs

are stored with each calibration record in the

GLP file.

After selecting the Probe ID and/or User ID if

appropriate, highlight DO and press enter.

Highlight DO % and press enter to confirm.

The instrument will use the value from the

internal barometer during calibration and will

display this value in brackets at the top of the

. If Probe ID or User ID

Page 15

20

21

display. Highlight the barometer value and press

enter to adjust it if needed. If the barometer

reading is incorrect, it is recommended that

you calibrate your barometer. Note - the

barometer should be reading “true” barometric

pressure (see Barometer section for more

information on “true” barometric pressure).

If the value is acceptable, there is no need to

change it or perform a barometer calibration.

Wait for the temperature and DO% values

under “Actual Readings” to stabilize, then highlight Accept Calibration and

press enter to calibrate. If User Field 1 or 2 are enabled, you will be prompted to

select the fields and then press Cal

line at the bottom of the screen will display “Calibrating Channel...” followed by

“Calibration Successful”. Press Esc

to complete the calibration. The message

to cancel the calibration.

Wait for the temperature and DO% values under “Actual Readings” to stabilize,

then highlight Accept Calibration and press enter to calibrate. If User Field 1

or 2 are enabled, you will be prompted to select the fields and then press Cal

to complete the calibration. The message line at the bottom of the screen will

display “Calibrating Channel...” followed by “Calibration Successful”. Press Esc

to cancel the calibration.

CALIBRATING IN AIR SATURATION PERCENT DO %:

2POINT CALIBRATION WITH ZERO SOLUTION

Place the sensor in a solution of zero DO. Be sure to immerse both the ODO and

Temperature sensor into the water.

A zero DO solution can be made by dissolving approximately 8 - 10 grams of

sodium sulfite (Na2SO3) into 500 mL tap water or DI water. Mix the solution

thoroughly. It may take the solution 60 minutes to be oxygen-free.

CALIBRATING DO % IN AIR SATURATED WATER:

1POINT CALIBRATION

Continuously sparge water with air using an air stone or some type of aerator

until the water becomes completely saturated with air. For 500 ml of water at

room temperature, it may take 60 minutes or more for the water to become

completely saturated. Place the sensor in the air saturated water, be sure to

immerse both the ODO and Temperature sensor into the water, and wait for the

readings to stabilize (at least 2 minutes).

Press Calibration

menu you will be able to highlight these features and add, select, edit, or delete

an ID. When enabled these IDs are stored with each calibration record in the

GLP file.

After selecting the Probe ID and/or User ID if appropriate, highlight DO and

press enter. Highlight DO % and press enter to confirm.

The instrument will use the value from the internal barometer and will display

this value in brackets at the top of the display. Highlight the barometer value

and press enter to adjust it if needed. If the barometer reading is incorrect,

it is recommended that you calibrate your barometer. Note - the barometer

should be reading “true” barometric pressure (see Barometer section for more

information on “true” barometric pressure). If the value is acceptable, there is

no need to change it or perform a barometer calibration.

. If Probe ID or User ID are enabled in the System GLP

Press Calibration

menu you will be able to highlight these features and add, select, edit, or delete

an ID. When enabled these IDs are stored with each calibration record in the

GLP file.

After selecting the Probe ID and/or User ID if appropriate, highlight DO and

press enter. Highlight Zero and press enter. Wait for the temperature and

DO% values under “Actual Readings” to stabilize, then press enter to Accept

Calibration. If User Field 1 or 2 are enabled, you will be prompted to select the

fields and then press Cal

prompt for a follow-up second point calibration.

Highlight DO% for the second calibration point and press enter to continue with

the next point at full saturation. Rinse the sensor of any zero oxygen solution

using clean water. Follow the steps under either of the DO % Saturation methods

previously discussed to complete the second point.

. If Probe ID or User ID are enabled in the System GLP

to complete the calibration. The screen will then

CALIBRATING IN MG/L OR PPM AS A TITRATION:

1POINT CALIBRATION

Place the sensor into a water sample that has been titrated by the Winkler method

to determine DO concentration. Allow the sensor to stabilize.

Press Calibration

menu you will be able to highlight these features and add, select, edit, or delete

. If Probe ID or User ID are enabled in the System GLP

Page 16

22

23

an ID. When enabled these IDs are stored with each calibration record in the

GLP file.

BAROMETER

After selecting the Probe ID and/or User ID if appropriate, highlight DO and

press enter. Highlight DO mg/L or ppm and press enter.

Highlight Calibration value and press enter to

manually input the sample’s dissolved oxygen

value. Highlight Accept Calibration and press

enter once the temperature and Dissolved

Oxygen readings have stabilized. If User Field 1

or 2 are enabled, you will be prompted to select

the fields and then press Cal

calibration. After completing the calibration, the

message line will display “Calibration Successful”.

Press Esc

to cancel the calibration.

to complete the

CALIBRATING IN MG/L OR PPM AS A TITRATION:

2POINT CALIBRATION WITH ZERO SOLUTION

Place the sensor in a solution of zero DO. Be sure to immerse both the ODO and

Temperature sensor into the water.

A zero DO solution can be made by dissolving approximately 8 - 10 grams of

sodium sulfite (Na2SO3) into 500 mL tap water. Mix the solution thoroughly. It

may take the solution 60 minutes to be oxygen-free.

All ProODO instruments contain an internal barometer.

dIsplay - BaroMeter

Press Probe , highlight Display, and press enter. Highlight Barometer, press

enter. The measurement unit options are: mmHg, inHg, mBar, PSI, kPa, or Atm.

Only one unit can be displayed at a time. Select None if you do not want to

display a barometric pressure reading.

Whether or not you choose to display the barometer reading, the barometric

pressure will still be used for calibrating DO and for compensating for pressure

changes if Local DO is enabled.

calIBratIon - BaroMeter

The barometer in the instrument is calibrated at the factory. If the barometer

requires calibration, press Calibrate

the System GLP menu you will be able to highlight these features and add, select,

edit, or delete an ID. When enabled these IDs are stored with each calibration

record in the GLP file.

After selecting the Probe ID and/or User ID if appropriate, highlight barometer

and press enter.

Highlight the desired unit and press enter.

. If Probe ID or User ID are enabled in

Press Calibration

menu you will be able to highlight these features and add, select, edit, or delete

an ID. When enabled these IDs are stored with each calibration record in the

GLP file.

After selecting the Probe ID and/or User ID if appropriate, highlight DO and

press enter. Highlight Zero and press enter. Wait for the temperature and

DO% values under “Actual Readings” to stabilize, then press enter to Accept

Calibration. If User Field 1 or 2 are enabled, you will be prompted to select the

fields and then Press Cal

prompt for a follow-up second point calibration.

Highlight the desired calibration units (mg/L or ppm) and press enter to

continue with the next point in a known titrated value. Rinse the sensor of

any zero oxygen solution using clean water. Follow the steps under One Point

Calibration for mg/L or ppm for the second point.

. If Probe ID or User ID are enabled in the System GLP

to complete the calibration. The screen will then

Highlight Calibration Value and press enter to

manually enter the correct “true” barometric

pressure. Next, highlight Accept Calibration,

and press enter. If User Field 1 or 2 are enabled,

you will be prompted to select the fields and then

press Cal

completing the calibration, the message line will

display “Calibration Successful”. Press Esc

to cancel the calibration.

to complete the calibration. After

Page 17

24

25

Laboratory barometer readings are usually “true”

(uncorrected) values of air pressure and can be used “as is”

i

True BP = [Corrected BP] – [2.5 * (Local Altitude in ft. above sea level/100)]

for barometer calibration. Weather service readings are

usually not “true”, i.e., they are corrected to sea level, and

therefore cannot be used until they are “uncorrected”. An

approximate formula for this “uncorrection” is below:

TEMPERATURE

Once the Site and/or Folder name is selected, highlight 5. Log Now and press

Enter. The instrument will confirm that the data point was successfully

logged.

If you would like to log at a specific interval vs. logging one sample at a time

or vice versa, press System

Continuous Mode and adjust the time Interval if necessary. On the Run screen,

the option to log will change from Log One Sample to Start Logging based on the

time interval entered in the Logging Menu. Note – When utilizing the Manual

sampling mode, the Continuous Logging Interval must be set to 10 seconds or

greater.

, then highlight Logging and press Enter. Select

All probe/cable assemblies have built-in temperature. Temperature calibration

is not required nor is it available. To set the units, press Probe

Display. Highlight Temperature and press enter. Highlight the desired

temperature units of °F, °C, or K and press enter to confirm the selection. Only

one temperature unit may be displayed at a time. You may also choose to not

display temperature. If you choose not to display temperature, dissolved oxygen

readings will still be temperature compensated.

, and select

TAKING MEASUREMENTS

To take readings, insert the probe into the sample. Move the probe in the 1.

sample to release any air bubbles and to provide a fresh sample to the sensor

cap. This movement is only necessary when first inserting the probe into

the sample. Since the ProODO utilizes optical luminescent technology,

continuous sample movement or stirring is not required. The probe will

fit into a 300 mL BOD bottle for taking initial and final BOD readings. For

best results in a BOD bottle, a stirring device should be used to properly mix

the sample and to keep solids from settling at the bottom.

Allow the temperature readings to stabilize and wait approximately 25-35 2.

seconds for the DO readings to stabilize.

Log One Sample is already highlighted in Run mode. Press Enter to open 3.

a submenu. Highlight Sites or Folders and press Enter to select the site or

folder to log the sample to.

If necessary, use the keypad to create a new Site or Folder name. If Site List 4.

and Folder List are disabled in the System menu, you will not see these

options when logging a sample.

During a continuous log, the Start Logging dialog box on the Run screen will

change to Stop Logging. Press Enter to stop continuous logging.

Note - There is NO WARM-UP period associated with the ProODO sensor so

you may wish to turn off the ProODO instrument between readings to conserve

battery power.

FILES AND SITE LISTS

fIle MeMory

To view the file memory, press File .

The Data Memory shows a percentage

indicating the amount of memory available.

If the file memory is near 0%, files should be

downloaded to a PC and/or deleted to free up

memory.

VIeW data

Press File , highlight View Data, press enter.

Configuring your data view:

Site: will allow you to view data from one

particular site or all sites. Highlight Site, press

enter, and select the site you wish to view data

from or select All Sites to view data from all

sites.

Page 18

26

27

Folder: will allow you to view data from one particular folder or all folders.

Highlight Folder, press enter, and select the file you wish to view data from or

select All Folders to view data from all folders.

Begin and End will allow you to view data that was collected between two dates.

Highlight Begin and/or End, press enter, and use the numeric entry screen to

select the dates you wish to view.

folder

To modify the Folder List, press File , highlight Folder List, and press enter.

Enter new Folder names or edit existing folders with the alpha/numeric entry

screen.

delete data

sIte lIst

After making your selections in the Data Filter,

highlight Show Data and press enter. The data

will have date and time stamps. You will likely

have to scroll up and down and side to side

using the arrow keys to completely view the

data file.

To modify the Site List, press File , highlight

Site List, and press enter. Enter new site names

or edit existing sites with the alpha/numeric

entry screen. Site lists can also be created and

edited on your PC with Data Manager and then

downloaded to the instrument.

Press File , highlight Delete Data, and press enter. Enter the criteria for the

data you wish to delete in the Delete Data Filter, then highlight Delete Data and

press enter.

D A T A M A N A G E R DESKTOP SOFTWARE

Data Manager is provided with the purchase of a ProODO Instrument. Data

Manager is a powerful Windows® based software that will allow you to easily

manage logged data, set up instruments, and conduct real time studies.

Data Manager needs to be installed on a PC before use. Once the communications

saddle is connected to an instrument and the PC, the Data Manager software will

recognize the attached instruments. Data Manager will identify the connected

instruments by their Unit ID.

From the ‘home’ screen of Data Manager, you can select one of the following

functions: Retrieve Instrument Data, Real Time Instrument Data, Instrument

Configuration, or View Saved File/Data.

usInG the coMMunIcatIons saddle

WARNING: DO NOT connect the Communications Saddle to

your PC before installing Data Manager. The Communication

Saddle drivers MUST be installed prior to connecting it to your

PC. The drivers will install automatically during the Data

u

Manager installation. The first time the saddle is connected to

the PC, you may have to walk through a couple of installation

wizards. For detailed instruction, please refer to the Readme file

located on the CD that was included with your instrument.

Page 19

28

29

A PC will recognize the Communications Saddle (saddle) as a YSI water quality

instrument with or without the handheld installed in the saddle.

To connect to a ProODO, simply align the saddle to the oval section on top of

the instrument and push it down to snap it in place (Figure 7).

Figure 7. Locate the oval alignment groove at the top of the instrument

and inside the saddle. Insert the saddle into this oval groove. Press the

saddle towards the back of the instrument until it snaps into place.

Connect the USB cable to the top of the saddle and to a USB port on the PC.

Once Data Manager is launched, the program will recognize all saddles with

instruments connected to the PC.

The instrument will be powered through the saddle and USB connection when

connected to the PC.

ManaGe loGGed data

Data that has been logged to the ProODO can be uploaded to the PC via the

provided USB saddle. You can upload sensor data, GLP files, site lists, and

instrument configuration files individually or all at once. After connecting the

instrument to the PC via the USB saddle and cable and launching Data Manager,

click the Retrieve Instrument Data tab. Click on the Instrument’s Unit ID you

would like to retrieve data from, then select the files you would like to retrieve

and click Start.

Once the sensor data is uploaded to the PC, you can graph and view tabular data

by instrument Unit ID, date/time, site name, and/or folder name. This allows

you to configure the report according to your needs. You can select to view

all data from all instruments, or select a certain date/time range for only a few

specific instruments, there are multiple ways to view the data. Once the report

has been defined, you will be able to print the graph and/or export the table.

Data Manager takes information management one step further and allows

you to delete specific points instead of entire files. This allows you to clean up

data that is no longer needed or that may have been collected erroneously, for

example, when the sensor was out of the water. If you can not delete data due

to regulation and compliance purposes, Data Manager has the solution. While

viewing logged data or real time data, you have the ability to ‘tag’ individual data

points with comments.

In addition to sensor data, you will be able to view GLP files, site lists, and

configuration files that have been uploaded from the instrument. These can be

printed and exported as well.

real tIMe data collectIon

Data Manager allows you to view real time data on the PC.

After selecting your instrument, click the Real Time Instrument Data tab. Next,

input your sample interval, site/folder name, select the parameters you wish to

view and click OK. You must click Start on the next screen to begin your real

time study. Choose to hide the table or graph by unchecking the box next to

these options. Click Stop, then Edit Setup to change the Y-scale min/max of

the graph, to select different colors, or to name your graph. Add a comment

to a data point, by clicking in the comment field of the table next to the data

point. You may also Print the graph and Export the data for viewing in another

program.

confIGure InstruMents

Data Manager allows for easy and quick configuration of single or multiple

instruments. Once you have uploaded a site list or configuration file, you can edit

it as needed, save it, and download it to other instruments. You no longer need

to configure each instrument individually. By using the same configuration file

for all instruments, you can rest assured that all instruments will have identical

settings.

New site lists and configuration files can be created in Data Manager. These

lists and files can be downloaded to one or multiple instruments. Save time

by creating these files on your PC and downloading them to the instrument as

opposed to creating them on the instrument.

Minimum system requirements for Data Manager are a system with Windows®

2000 with SP4 (minimum) or Windows® XP with SP2 (minimum), 300 MHz or

higher Pentium®-compatible CPU, 128 MB of RAM or higher, 80 MB or more of

free hard-disk space, USB 2.0, and Microsoft® .NET.

Page 20

30

31

MAINTENANCE AND STORAGE

This section describes the proper procedures for care, maintenance and storage

of the ProODO. The goal is to maximize their lifetime and minimize down-time

associated with improper sensor usage.

updatInG InstruMent and proBe fIrMWare

SENSOR CAP REPLACEMENT

The Sensor Cap should be replaced about once per year but may last longer.

It should also be replaced if it is cracked or damaged (see Troubleshooting

section for instruction on how to inspect the cap for damage). The instruction

sheet shipped with the replacement ODO sensor cap includes the calibration

coefficients specific to your sensor cap.

The instrument and probe’s firmware can be updated via www.ysi.com. There

you will find the new firmware files and instructions on how to update the

instrument and/or probe. There is no need to send the instrument back to the

factory for upgrades.

General MaIntenance - Battery coMpartMent GasKet

The instrument utilizes a gasket as a seal to prevent water from entering the

battery compartment. If the gasket and sealing surfaces are not maintained

properly, it is possible that water can enter the battery compartment. This

could severely damage the battery terminals causing loss of battery power and

corrosion to the battery terminals. Therefore, when the battery compartment

lid is removed, the gasket that provides the seal should be carefully inspected for

contamination (e.g. debris, grit, etc.) and cleaned if necessary. If contamination

is evident, clean the gasket and nearby plastic parts with lens cleaning tissue or

equivalent lint-free cloth. Alcohol can be used to clean the plastic parts, but use

only water and mild detergent on the o-ring itself. Also, inspect the gasket for

nicks and imperfections.

i

Using alcohol on a gasket may cause a loss of

elasticity and may promote cracking.

sensor MaIntenance - dIssolVed oxyGen

i

The replacement ODO Sensor Cap is shipped in a humidified container and the

package should not be opened until immediately before sensor cap replacement.

Once the sensor cap has been installed on the ODO sensor as described below,

it is important to keep the sensor in a 100% humid environment. Therefore,

the ODO sensor should be stored either in the grey calibration/storage sleeve

with the sponge moistened or immersed in water, see Sensor Storage for more

information. If the sensor dries out, refer to the Rehydration procedure in this

manual.

Refer to Figure 8 below when following the instructions for replacing the cap.

IMPORTANT - Be sure to save the ODO Sensor Cap instruction

sheet in case you need to reload the calibration coefficients.

CLEANING THE SENSOR CAP

The Sensor Cap should be kept clean since some types of fouling may consume

oxygen which could affect the dissolved oxygen measurements. To clean the

Sensor Cap, gently wipe away any fouling with a lens cleaning tissue that has

been moistened with water. Do not use organic solvents to clean the Sensor Cap.

Using an organic solvent to clean the Sensor Cap may cause permanent damage

to the cap. For example, alcohol will dissolve the outer paint layer and other

organic solvents will likely dissolve the dye in the cap

Figure 8

Caution: Avoid touching the sensing end of the sensor

u

Remove the old sensor cap assembly from the sensor by grasping the probe 1.

body with one hand and then rotating the sensor cap counterclockwise until

it is completely free. Do not use any tools for this procedure.

cap during the following maintenance procedures.

Page 21

32

33

Inspect the o-ring on the probe for damage. If there is any indication of 2.

damage, carefully remove the o-ring and replace it with the new o-ring

included with the replacement sensor cap. Do not use any tools to remove

the o-ring.

Ensure that the o-ring installed on the probe is clean. If necessary, wipe 3.

clean with a lint free cloth or replace the o-ring as described in the previous

step.

Locate the o-ring lubricant included with the new sensor cap. Apply a thin 4.

coat of o-ring lubricant to the installed o-ring. After application, there

should be a thin coat of o-ring lubricant on the o-ring only. Remove any

excess o-ring lubricant from the o-ring and/or probe with a lens cleaning

tissue.

Remove the new sensor cap from its hydrated container and dry the inside 5.

cavity of the sensor cap with lens cleaning tissue. Make sure that the cavity

is completely dry before proceeding with the installation. Next, clean

the clear surface of the sensor on the end of the probe with lens cleaning

tissue.

Using clockwise motion, thread the new sensor cap onto the probe assembly 6.

until it is finger-tight. The o-ring should be compressed between the sensor

cap and probe. Do not over-tighten the sensor cap and do not use any tools

for the installation process.

After installing the new sensor cap, store the sensor in either water or in 7.

humidified air in the calibration sleeve.

Follow the procedures below for configuring the ProODO instrument for 8.

the new Sensor Cap.

Highlight each coefficient in turn (K1 4.

through KC) and use the numeric entry

screen to enter the corresponding new

coefficient from the Calibration Code

Label. Press Enter after each entry and

then proceed to the next K selection.

After all the new coefficients have been 5.

entered, highlight Update Sensor Cap

Coefficients and press the Enter.

A message will appear warning that you 6.

will be overwriting the current sensor cap coefficients and you should

confirm that you wish to carry out this action. Highlight Yes and press

enter to confirm the new coefficients.

After updating the Coefficients, the Serial # in the Sensor Cap menu will be

updated automatically based on your entries. The Temperature Coefficient

listed in the Sensor Cap menu is programmed into the sensor at the factory and

should not be modified unless instructed by YSI Technical Support.

If errors are made in entering the Sensor Cap Coefficients, the instrument will

block the update and an error message will appear on the display. If you see

this error message, re-enter the coefficients and check them carefully for correct

transcription from the Calibration Code Label prior to selecting Update Sensor

Cap Coefficients. If you continue to get an error message after several entry

attempts, contact YSI Technical Support for assistance.

CONFIGURING PROODO INSTRUMENT FOR NEW SENSOR CAP

After installing a new Sensor Cap, connect the probe/cable assembly to the

ProODO instrument and turn the instrument on. Locate the Calibration Code

Label at the top of the instruction sheet and note the six numbers which are

listed as K1 through K5 and KC. These six numbers contain the calibration

code for this particular sensor cap. Follow the instructions below to enter the

new calibration coefficients into your existing ODO instrument.

Press the 1. Probe

Highlight 2. Sensor Cap and press enter.

Highlight 3. Sensor Cap Coefficients and

press enter.

, highlight DO, and press enter.

After entering the new Sensor Cap coefficients, perform a 1-point DO

calibration.

REHYDRATING THE SENSOR CAP

The Sensor Cap must remain in a moist environment; see Sensor Storage for

storage recommendations. If you inadvertently leave your sensor exposed to

ambient air for a period of more than approximately 8 hours it may dry out. If

the sensor cap is allowed to dry out, it is likely to drift slightly at the beginning

of your next study unless it is rehydrated. If the cap dries out, you can rehydrate

it by soaking the probe tip with the sensor cap installed in warm tap water for 24

hours. After rehydration is complete, recalibrate and be sure to store the probe

in a moist environment.

Page 22

34

35

SENSOR MAINTENANCE TEMPERATURE

You must keep the temperature portion of the sensor free of build up. Other

than that, the sensor requires no maintenance. A soft bristle brush, like a tooth

brush can be used to scrub the temperature sensor if needed.

sensor storaGe

SHORTTERM STORAGE

When the ODO Sensor is not in use, it MUST BE STORED IN A MOIST

ENVIRONMENT, i.e., either in water or in water-saturated air. If the sensor

cap is allowed to dry out by exposure to ambient air, it is likely to drift slightly at

the beginning of your next study unless it is rehydrated.

For short-term storage (<30 days), moisten the sponge in the calibration/storage

sleeve with a small amount of clean water and place this over the probe with the

sensor cap installed. This will provide a 100% saturated air environment.

recalibrate. If you are still getting erroneous dissolved oxygen readings, try

replacing the sensor cap and then recalibrate. If the erroneous readings continue,

contact YSI Technical Support to help determine the next step.

INSPECTING THE SENSOR CAP FOR DAMAGE

Caution: Avoid touching the sensing end of the sensor

u

cap during the following maintenance procedures.

If readings seem to be in error or are jumpy, remove the sensor cap from the

sensor by grasping the probe body with one hand and then rotating the sensor

cap counterclockwise until it is completely free. Avoid using tools for the

removal of the cap if at all possible.

Inspect the sensor cap assembly for any cracks or damage. If damage has

occurred, contact YSI Customer Service to order a replacement sensor cap.

LONGTERM STORAGE

For long-term storage (>30 days), remove the batteries from the instrument.

Moisten the sponge in the red protective plastic cap that was provided with the

probe and place it over the sensor with the sensor cap installed. Inspect the

sponge every 30 days to make sure it is still moist. If you no longer have the red

protective cap, then moisten the sponge in the calibration/transport sleeve and

place this over the probe.

Alternatively, you can place the probe with sensor cap directly in a beaker or

other container of water, making sure that the water does not evaporate over

time.

Long-term Storage: -5 to 70°C (23 to 158°F)

TROUBLESHOOTING

dIssolVed oxyGen readInGs

Erroneous dissolved oxygen readings typically indicate a need to clean the sensor

cap, replace the sensor cap, and/or recalibrate the instrument. First, verify the

sensor is properly setup in the Probe menu. Next, clean the sensor cap following

the instructions in the Maintenance and Storage section of this manual and then

perform a calibration. If erroneous readings persist, follow the steps on the

next page to inspect the sensor cap for damage and then attempt to recalibrate

the instrument. If the problem continues, try to rehydrate the sensor cap then

Inspect the o-ring on the probe and the gasket at the top of the threads for

damage. If there is any indication of damage, carefully remove these parts and

contact YSI Technical Support to obtain a new o-ring and/or gasket. Avoid

using tools to remove the o-ring as damage to the sealing surfaces could result.

Before reinstalling the sensor cap, make sure that the cavity is completely dry

before proceeding with the installation. If water is found, dry the cavity with

lens cleaning tissue. Finally, clean the clear window on the end of the probe with

lens cleaning tissue.

After reinstalling the sensor cap, perform a calibration and then reevaluate the

quality of the dissolved oxygen readings. If problems persist, try rehydrating or

replacing the sensor cap.

help

During use of the ProODO instrument press Question from any screen to

view help messages directly on the display.

error/status MessaGes

If readings for a certain parameter are over range you will see a series of +++++

and if the readings are under range you will see a series of ----- plus the error

message along the bottom of the screen. If you see a series of ?????, that will

indicate that a certain parameter cannot be calculated. This could be due to a

Page 23

36

37

connection issue between the cable and instrument. The following are some of

the potential messages:

ACCESSORIES / PART NUMBERS

Message Description and Recommended Action

Probe Temp over range Temperature is over 100° C or reading

erroneously. Check cable connection and

ensure Temp sensor is clean.

Probe Temp under range Temperature is under -10° C or reading

erroneously. Check cable connection and

ensure Temp sensor is clean.

DO over range DO% saturation is over 550%. Check sensor

cap and recalibrate.

DO under range DO% saturation is under -5%. Check sensor

cap and recalibrate.

Barometer over range Barometric pressure is reading over 988

mmHg. Calibrate barometer.

Barometer under range Barometric pressure is reading under 375

mmHg. Calibrate barometer.

ODO Communications

Error

Clock Battery Low Internal battery for real time clock has low

Measurements Locked! Measurements are held in Manual Sampling

No communication between the instrument

and cable. Check cable connection.

voltage. Contact Technical Support.

mode. Select Update Measurements or Log

Held Data.

Part Number Description

626281 ProODO Instrument

626250-1, -4, -10, -20, -30,

-40, -50, -60, or -100

626320 Replacement Sensor Cap

605604 Communications saddle kit

1, 4, 10, 20, 30, 40, 50, 60, or

100-meter probe/cable assembly*

Illegal Value may appear during alpha/numeric entry on the message line. This

only appears if the values entered do not match the formatting. This will also

appear in the GLP security area if the password is incorrect.

restore default calIBratIon Values

Occasionally, the instrument may need to have the factory calibration default

values restored. In order to accomplish this press Calibrate

Restore Default Cal and press enter. Select the parameter you wish to restore,

either DO or Barometer, and press enter. After selecting barometer or DO, you

will be asked to confirm the operation. Highlight Yes and press enter.

, highlight

605515 Data Manager desktop software

603075 Carrying case, soft-sided

603076 and 603078 Extended length flow cell and single port

adapter. Both items are required for use with

a ProODO

Page 24

38

39

Part Number Description

603074 Carrying case, hard-sided

603069 Belt clip

Part Number Description

603062 Cable management kit

605978 Weight, sensor/cable, 4.9 oz.

063019 Weight, sensor/cable, 24 oz., 3”

063020 Weight, sensor/cable, 51 oz., 6”

603070 Shoulder strap

063517 Ultra clamp

063507 Tripod clamp

*All cables include a temperature and dissolved oxygen sensor. Special order

cables in 10 meter increments from 60 to 100 meters are available.

Page 25

40

41

DECLARATION OF CONFORMITY

The undersigned hereby declares on behalf of the named manufacturer under our

sole responsibility that the listed product conforms to the requirements for the listed

European Council Directive(s) and carries the CE mark accordingly.

Manufacturer:

Product Name: Professional ODO Water Quality Instrument

Model Numbers

Instrument/Accessory: ProODO (626281) / ProComm (605604)

Probe/Cable Assemblies: 626250

Conforms to the following:

Directives: EMC 2004/108/EC

Harmonized Standards: • EN61326-1:2006, Electrical equipment for

YSI Incorporated