Page 1

USER MANUAL

DOCUMENT #626973-01REF

ProDSS

USER MANUAL

Page 2

This page left intentionally blank

i

Page 3

Contents

Introduction 3

Safety information 3

Precautionary symbols 3

Product components 3

Battery use and battery life 4

Charging the battery pack 5

Battery replacement 6

Connect the handheld to the cable assembly 8

ProDSS sensor installation/removal 9

Operation 13

Keypad and navigation 13

Startup 14

Navigation 14

Main display description 15

System menu 16

Sensor menu 22

Calibration menu 28

Files menu 29

Taking measurements 32

Calibration 33

Before calibration 33

Calibration setup (pH, ORP, ISE, conductivity, turbidity) 33

Conductivity 35

Barometer 36

Dissolved oxygen 37

pH/ORP 39

Depth 41

Turbidity 42

ISEs: Ammonium, Nitrate, & Chloride 44

Maintenance and storage 51

I

Page 4

ProDSS handheld instrument 52

Cable, bulkhead, and connectors 53

Sensor guard 53

Depth sensor maintenance and storage 54

Turbidity sensor 55

Conductivity/temperature sensor 56

Dissolved oxygen sensor 57

pH - pH/ORP sensors 61

ISE sensors 63

KorDSS software installation 67

Install the KorDSS software 68

ProDSS driver installation 69

KorDSS startup wizard 72

Accessories 73

Ordering 73

ProDSS handhelds 74

ProDSS cable assemblies (No sensors included) 74

ODO/OBOD sensor and cable assemblies - DO/Temp only 75

ProDSS smart sensors 75

Replacement sensor modules and ODO sensor caps 75

ProDSS accessories 76

Calibration standards 77

Safety and support 79

Rechargeable Lithium-Ion battery pack safety warnings and precautions 79

Service information 81

Technical support 81

Declaration of Conformity 82

Warranty 84

Appendix A - DO% calibration values 85

Appendix B - oxygen solubility table 87

II

Page 5

Introduction

Thank you for purchasing the YSI Professional Digital Sampling System (ProDSS).

ProDSS features include:

• Digital smart probes that are automatically recognized by the instrument when connected

• Waterproof (IP-67) case

• Long-life rechargeable lithium-ion battery pack

• Color display and backlit keypad

• User-selectable cable options

• USB connectivity

• Global Positioning System (GPS) (optional)

• Depth sensor (optional)

• Large memory with extensive site list capabilities

• Rugged enclosure with rubber over-molded case and miltary-spec (MS) connectors

Safety information

Please read this entire manual before unpacking, setting up or operating this equipment. Pay attention to all

precautionary statements. Failure to do so could result in serious injury to the operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired. Do not use or install this equipment in any

manner other than that specified in this manual.

NOTICE: The manufacturer is not responsible for any damages due to misapplication or misuse of this product

including, without limitation, direct, incidental and consequential damages, and disclaims such

damages to the full extent permitted under applicable law. The user is solely responsible to identify

critical application risks and install appropriate mechanisms to protect processes during a possible

equipment malfunction.

Precautionary symbols

NOTE: Information that requires special emphasis

NOTICE: Indicates a situation which, if not avoided, may cause damage to the instrument

CAUTION: Indicates a potentially hazardous situation that may result in minor or moderate injury

WARNING: Indicates a potentially or imminently hazardous situation which, if not avoided, could result in death

or serious injury

Product components

Carefully unpack the instrument and accessories and inspect for damage. If any parts or materials are damaged,

contact YSI Customer Service at 800-897-4151 (+1 937 767-7241) or the authorized YSI distributor from whom the

instrument was purchased.

3

Page 6

Introduction

Battery use and battery life

The ProDSS uses a rechargeable lithium-ion (Li-Ion) battery pack as a power source. The battery comes pre-installed in

the ProDSS and does not need to be replaced until the battery charge capacity is deemed unacceptable by the user.

The battery is shipped at ~50% full capacity and charging the battery is not required before first use.

Battery life depends on use, enabled parameters, LCD brightness, and GPS use. As with all lithium-ion batteries, battery

life will decline over time and use. This decay is typical and should be expected.

A new ProDSS battery is expected to last for the following durations (25 °C (77 °F), auto sampling, GPS on, keypad

backlight off):

• ProDSS instrument only - 48 hours

• ProDSS with fully loaded cable assembly and 25% (Default) LCD brightness - 20 hours

• ProDSS with fully loaded cable assembly and 100% LCD brightness - 14 hours

To increase battery life, enable manual sampling mode (Sampling on page 20). Manual sampling mode powers the

sensor/s on to take a measurement and then powers down to conserve battery life. Battery life may also depend on

the battery charging practices used. For maximum battery life, keep the battery 40% to 80% charged. Also, a larger

discharge (e.g. to 50%) is better than a small discharge (e.g. to 90%) between recharges.

4

Page 7

Introduction

Charging the battery pack

A USB cable is included with the ProDSS to charge the instrument battery pack and connect the instrument to a PC.

The instrument battery pack can be charged from the AC power adapter, directly from a computer USB connection or

from an external, portable USB battery pack (sold separately, see ProDSS accessories on page 76).

Plug the USB connector into the AC power adapter, computer USB connector or external USB battery pack, then plug

the micro USB connector into the ProDSS instrument (Figure 1).

NOTE: The ProDSS internal charge controller only allows the battery pack to be charged if the temperature is

between 0 and 45 °C (32 and 113 °F).

WARNING: Charge the battery pack in an open area away from flammable materials, liquids, and surfaces. Read

Rechargeable Lithium-Ion battery pack safety warnings and precautions on page 79.

The ProDSS will charge faster when plugged into an AC outlet for charging rather than a PC’s USB port. For the

instrument to recognize that it is using AC power, you must start charging the ProDSS while on. After the instrument

recognizes it is being charged, it can be turned off to finish charging.

When using the AC adapter, it takes approximately 14 hours to charge the ProDSS battery when the instrument is

turned off during the charge. The amount of time required to completely charge the battery pack when the ProDSS is

initially turned on during the charge is approximately 9 hours.

Figure 1 Connecting the ProDSS to AC power supply

5

Page 8

Introduction

Battery replacement

NOTE: The battery pack is pre-installed in the ProDSS instrument.

WARNING: Do not charge or handle a battery pack that is hot to the touch. Failure to follow the safety warnings

and precautions can result in personal injury and/or instrument damage not covered under

warranty. Read Rechargeable Lithium-Ion battery pack safety warnings and precautions on page

79.

1. Remove the battery pack cover by unscrewing (counter-clockwise) the four screws with a flat or Phillips head

screwdriver (Figure 2 on page 7).

NOTE: The retaining screws are captured into the battery pack cover and are not removable.

2. If replacing an existing battery pack, remove the Li-Ion battery pack and battery pack gasket/cradle. With two

fingers, grasp the battery pack connector and pull the connector straight up to disconnect and remove.

NOTE: Properly dispose of the old battery pack (Battery Disposal on page 80).

NOTE: A new gasket/cradle is included with a new battery pack to prevent water leaking into the instrument case.

When replacing the battery pack, use the new battery pack gasket/cradle supplied with the replacement

battery pack.

3. Inspect the replacement battery pack and battery pack gasket/cradle for damage. Contact YSI customer service

if the new battery pack and/or replacement gasket/cradle is damaged.

4. Correctly align and seat the battery pack gasket/cradle and battery pack into the instrument.

5. Align the battery pack connector wire terminals with the three instrument pins, then connect the battery pack to

the instrument.

NOTICE: Make sure that the three wire terminal connectors and three instrument pins are correctly aligned

before connecting the battery pack connector. Incorrect installation can damage the battery pack

connectors or instrument pins.

6. Install the battery pack cover, then tighten the cover screws. Make sure that the cover sealing surface is correctly

aligned and free of any contamination or damage.

NOTICE: Overtightening the cover screws can damage the battery cover.

6

Page 9

Introduction

1

2

3

5

4

6

Figure 2 Battery replacement

1 Battery pack cover 4 Instrument pin connectors

2 Battery pack 5 Battery pack gasket/cradle*

3 Battery pack connector 6 Battery pack gasket/cradle installed

*Color shown for reference

7

Page 10

Introduction

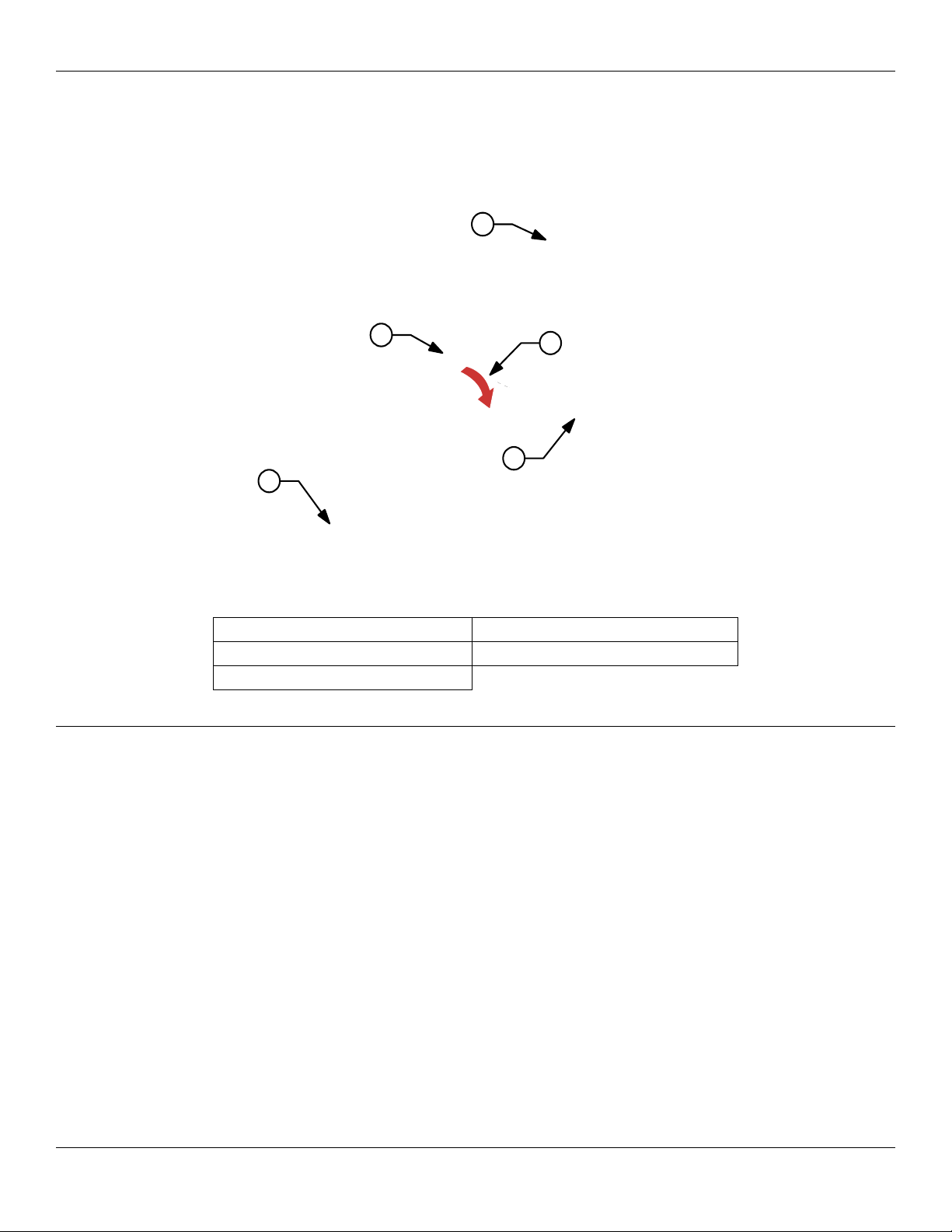

Connect the handheld to the cable assembly

The ProDSS cable connectors are keyed for positive mating and to prevent connector damage (Figure 3). The ProDSS

instrument retains its IP-67 rating when the cable is disconnected. However, the connectors are not wet-mateable and

should be clean and dry before connecting.

Align the keys on the cable assembly connector with the slots on the instrument connector. Push together firmly, then

twist the outer ring clockwise until it locks into place.

3

2

1

Figure 3 Keyed connectors

1 Handheld female

connector

2 Cable male connector

3 Keyed area of

connectors

8

Page 11

ProDSS sensor installation/removal

1

2

3

4

5

NOTICE: The ProDSS bulkhead and sensor connectors are not wet-mateable. Make sure that the sensor and

bulkhead connectors are clean and dry before sensor installation.

Introduction

Figure 4 Sensor installation

1 Sensor 4 Sensor retaining nut

2 Port plug 5 Sensor installation/removal tool

3 Bulkhead

Sensor installation

The ports on the ProDSS bulkhead are universal; therefore, you can install any sensor into any port. For highest

accuracy, always install a conductivity/temperature sensor to compensate all measurement data for temperature and

dissolved oxygen data for conductivity.

1. Remove and discard the dust plugs shipped with the instrument (Figure 5 on page 10).

2. Inspect the bulkhead port for contamination. If the port is wet, clean it with compressed air.

3. Apply a thin coat of Krytox o-ring lubricant to the sensor o-rings. Wipe off any excess o-ring grease with a lint-

free cloth.

4. Carefully align the sensor and bulkhead connectors by inserting the sensor into the port then gently rotating the

sensor until the connectors align. Once aligned, push the sensor toward the bulkhead until the sensor seats in

the port.

5. Carefully finger-tighten the retaining nut clockwise.

NOTICE: If any resistance is felt, loosen the retaining nut completely to prevent cross-threading. Incorrect

installation may cause damage to the sensor or bulkhead that is not covered by the warranty.

6. Use the sensor installation/removal tool to tighten the retaining nut clockwise until snug, about a 1/4 to 1/2

additional turn of the retaining nut.

NOTICE: Do not over-tighten the retaining nut. Over-tightening can cause damage to the sensor or bulkhead

not covered by the warranty.

9

Page 12

Introduction

1

2

Sensor removal

To remove a sensor, insert the sensor installation/removal tool into the retaining nut, then rotate the retaining nut

counterclockwise to loosen. After the retaining nut has been completely unscrewed from the bulkhead, pull the sensor

straight out of the port and place it on a clean surface.

NOTICE: Install a port plug if not reinstalling a sensor in the exposed port. Exposure to water can cause

damage or corrosion to the bulkhead connectors not covered by the warranty.

Port plugs

Figure 5 Port plugs

1 Shipping dust cover* 2 Port plug

*Color shown for reference

To protect the bulkhead connectors from damage, install a port plug into any port without an installed sensor. Port

plugs and a tube of o-ring lubricant are included in the maintenance kit that ships with all ProDSS cables. Refer to the

accessories section if an additional maintenance kit is needed (Ordering on page 73).

NOTICE: The shipping dust covers installed on the bulkhead when purchased (not sensor installation/removal

tool compatible) are not o-ring sealed and must be replaced with a port plug before field use.

NOTICE: Do not submerge the bulkhead without a sensor or port plug installed in all ports.

Installation

1. Apply a thin coat of Krytox o-ring lubricant to the o-rings on the plug port.

2. Remove any excess lubricant from the o-rings and port plug with a lint-free cloth.

3. Insert the port plug into the empty port and press until firmly seated.

4. Finger-tighten the port plug clockwise to install. If necessary, use the sensor installation tool to make sure that

the plug is fully seated into the port.

NOTICE: The o-rings will not be visible if a port plug is correctly installed.

NOTICE: Do not over-tighten the port plug. Over-tightening can cause damage to the port plug or bulkhead

not covered by the warranty.

10

Page 13

Introduction

1

2

3

4

5

Sensor guard and weight installation

1. Carefully slide the sensor guard over the bulkhead and attached sensors/port plugs. Push the sensor guard

toward the bulkhead until the sensor guard threads align with the bulkhead threads.

2. Carefully finger-tighten the sensor guard clockwise.

NOTICE: If any resistance is felt, loosen the sensor guard completely to prevent cross-threading. Incorrect

installation may cause damage to the sensor guard or bulkhead that is not covered by the warranty.

NOTICE: Do not submerge the bulkhead without a sensor or port plug installed in all ports.

Figure 6 Sensor guard and weight installation

1 Sensor guard 4 Depth sensor (if equipped)

2 Bulkhead 5 Weight

3 Bulkhead threads

11

Page 14

Introduction

Sensor guard weights

To help stabilize the sensors when profiling at deeper depths, a sensor guard weight is supplied with cables 10 meters

and longer. To attach the weight, carefully hand-tighten it clockwise on to the bottom of the sensor guard (Figure 6 on

page 11).

NOTICE: If any resistance is felt, loosen the sensor guard weight completely to prevent cross-threading.

Incorrect installation may cause damage to the sensor guard.

The bottom of the weight is threaded so that additional weights can be added if needed. See ProDSS accessories on

page 76.

NOTE: Do not have any weights installed on the sensor guard when calibrating using the calibration cup.

12

Page 15

Operation

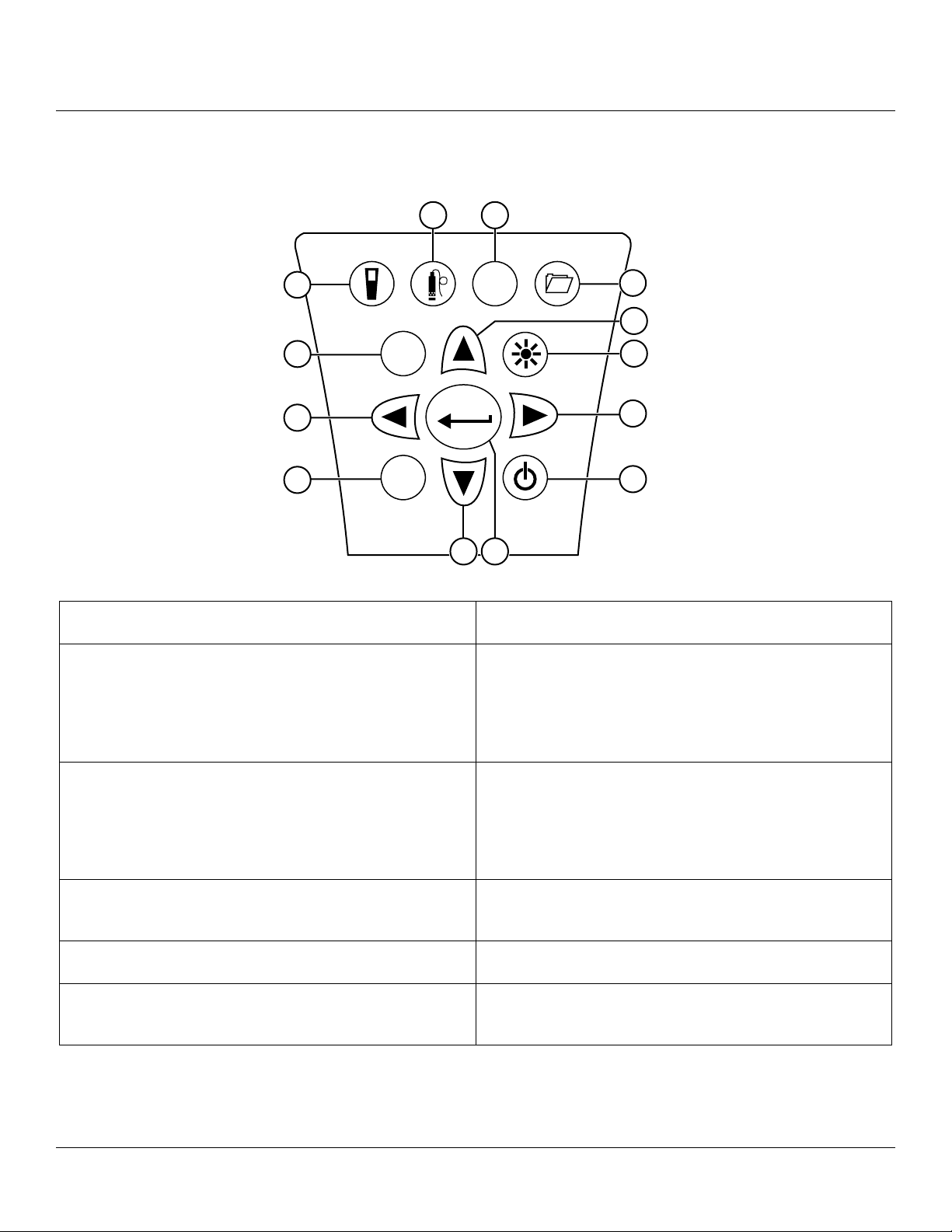

Keypad and navigation

1112

System Probe Calibration File

1

Cal

10

10

5

2

Esc

ENTER

3

4

?

9

8

7

5 6

Figure 7 Keypad description

1 System: Opens the system menu. Use to adjust

system settings

2 Exit/Escape key: Exits to the Run screen. When in

an alpha/numeric entry screen, returns to previous

menu

3 Left arrow key: Navigate left in an alpha/numeric

entry screen. Push to return to previous menu in all

screens except alpha/numeric entry. On the Run

screen, push to show graphical representations of

the displayed measurements. Push the right or left

arrow to return to the Run screen

4 Help: Shows context sensitive help 10 File: Opens the file menu. Use to view logged data

5 Up/down arrow keys: Scroll through menus or

enter numbers and letters

6 Enter key: Push to confirm selections. On the Run

screen, push to log a single data point or start

continuous data logging

7 ON/OFF: Turn on or turn off the instrument

8 Right arrow key: Navigate right in an alpha/

numeric entry screen. On the Run screen, push to

show graphical representations of the displayed

measurements. Push the right or left arrow to return

to the Run screen. In the View Data screen, push to

view additional parameters in the data set

9 Backlight: Turns the keypad backlight on or off for

use in low light conditions

and GLP files, backup data to a USB stick, and delete

data

11 Calibrate: Opens the calibration menu. Use to

calibrate all parameters except temperature

12 Probe: Opens the sensor menu. Use to setup

sensors, change the measurements shown on the

run screen, and turn on/off Auto Stable and GPS

13

Page 16

Operation

Esc

Esc

Esc

1

2

3

4

5

2

3

1

4

1

2

3

4

5

2

3

1

4

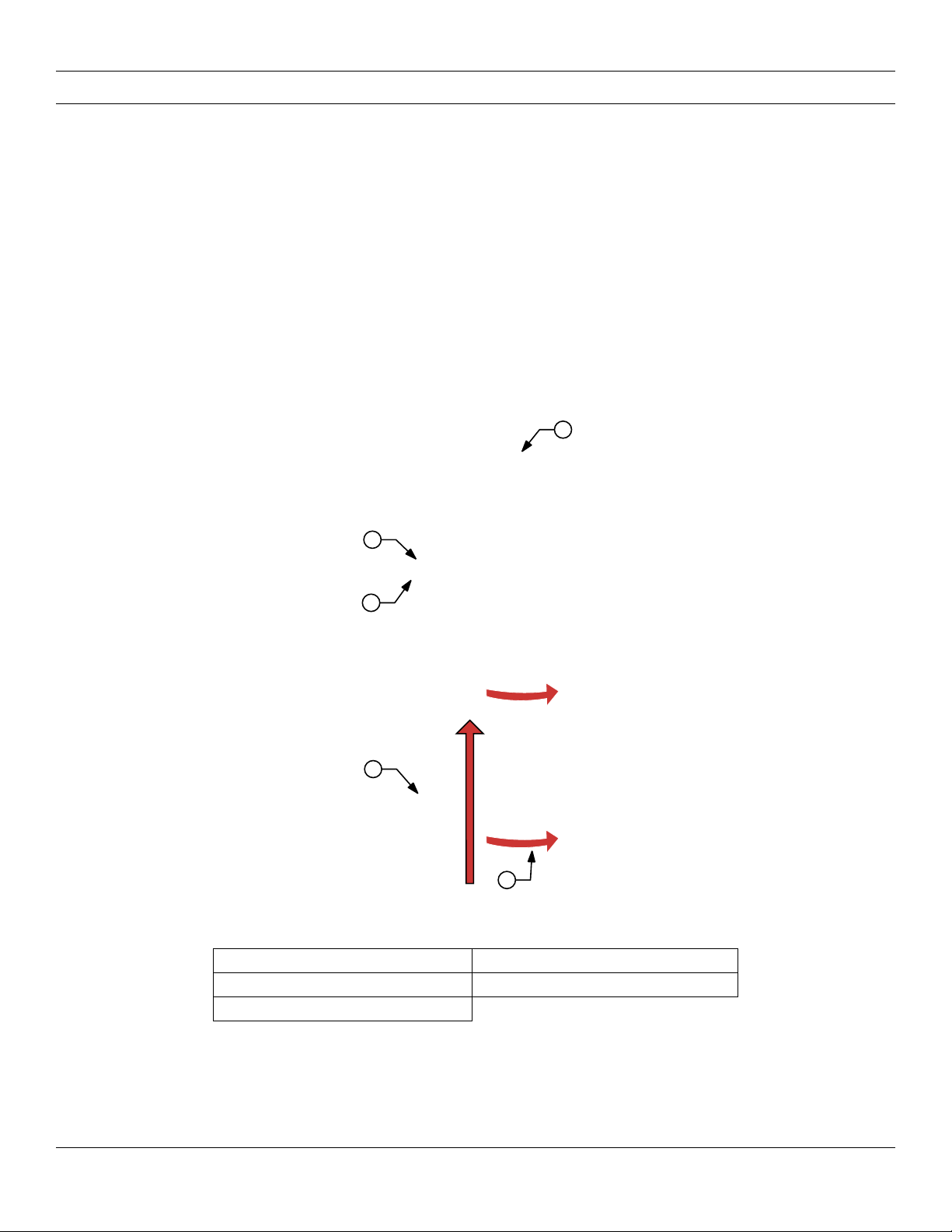

Startup

Push the key to turn on the handheld. If the handheld does not turn on, make sure that the battery pack is correctly

installed and charged. Push and hold the

key for 1.5 seconds to turn the handheld off.

Navigation

The ProDSS contains menus to change user-defined options, functions, and parameters. Use the arrow keys

(

and ) to highlight different options within menus and sub-menus, then push the

Push the key to return to the previous menu.

NOTE: When in an alpha/numeric screen, the

return to the previous menu.

Push the

key. Enabled functions appear as a circle with a dot

circle only or an empty box .

key to return to the Run screen. To enable or disable an option, highlight the option, then push the

key is for alpha/numeric navigation only. Push the

or a box with a check mark . Disabled functions appear as a

ENTER

key to select the option.

key to

ENTER

Alpha/numeric entry

When required, an alpha or alpha/numeric entry screen will be shown. When finished entering information, highlight

ENTER, then push the

NOTE: When in an alpha/numeric screen, the

return to the previous menu.

ENTER

key to save the entry (Figure 8).

key is for alpha/numeric navigation only. Push the

key to

Figure 8 Alpha/numeric and numeric entry screens

1 User entry field 4 Enter selection

2 Delete entire entry 5 Upper/lowercase

3 Backspace

14

Page 17

Operation

Main display description

The main display (Run screen) shows the current measurements as defined in the Sensor Display menu

(Sensor Display on page 25). If more measurements are selected than can be displayed on the Run screen, a scroll

bar will be shown. Use the and arrow keys to view the additional measurements (Figure 9).

The message area shows status messages, error messages, and information about selected functions.

4

3

5

6

2

7

1

8

10

9

Figure 9 Main display example

1 Log or sampling (update measurements) prompt on

Run screen (single or continuous)

2 Current screen/menu 7 USB/PC connection indicator

3 Date/Time 8 Scroll bar

4 GPS signal indicator 9 Message area

5 Battery charging indicator 10 Displayed measurements

6 Battery charge %

15

Page 18

Operation

System menu

Push the System key to view and adjust instrument settings. Highlight a sub-menu then push the

the sub-menu options (Figure 10).

Pre-defined or user-selected options are noted within brackets ([]). See Alpha/numeric entry on page 14.

Use the System menu to:

• Set the date and time (Date/Time on page 17)

• Change the user-defined Good Laboratory Practices (GLP) options

(GLP menu on page 17)

• Change the instrument language setting (Language on page 19)

• Change the radix point (Radix Point on page 19)

• Change logging options (Logging on page 19)

• Change sampling options (Sampling on page 20)

• Set the handheld auto-shutoff time (Auto-Shutoff on page 20)

• Set the backlight mode (Backlight on page 21)

• View the software version (Alpha/numeric entry on page 14)

• View the handheld serial number (Serial # on page 21)

• View and adjust the Unit ID (Unit ID on page 21)

• View the sensor specific information (Sensor info on page 22)

Figure 10 System menu

• Adjust the display brightness (Brightness on page 22)

ENTER

key to view

16

Page 19

Operation

Date/Time

→ Date/Time

For accurate logging and GLP data, correctly set the date and time

options (Figure 11). Select any of the following options to set the Date/

Figure 11 Date/Time

GLP menu

Detailed sensor calibration information is stored in the Good Laboratory Practice (GLP) file for later review.

One GLP file is used to store all calibration records. The instrument’s internal memory can save up to 400 individual

calibration records. After 400 records, the instrument will overwrite previously stored calibration records, starting with

the oldest.

Time in the ProDSS.

Date/Time options:

• Set YY/MM/DD, MM/DD/YY, DD/MM/YY or YY/DD/MM date format

• Set the correct date

• Select 12 or 24 hour time format

• Set the correct time

To prevent the permanent loss of GLP records, periodically download the GLP file to a computer using the KorDSS

software.

NOTE: GLP files uploaded to the PC will overwrite a previously downloaded GLP file if it has the same file name.

To prevent data loss, move or rename previously downloaded GLP files before downloading the GLP file.

GLP saved information

See Figure 12.

• Sensor calibrated

• Date/time stamp

• Sensor ID

• Sensor software version

• Calibration method (Conductivity and ODO calibrations)

• Calibration value

• Temperature

• User ID (optional)

• Probe ID (optional)

• User fields #1 and #2 (optional)

• Calibration status

Figure 12 GLP record example (single

point % DO calibration)

17

Page 20

Operation

GLP Options

→ GLP → Options

User ID, Probe ID, or User Field #1 or 2 can be user-defined for positive

GLP file identification of:

• The person calibrating the instrument.

• The sensor/cable serial number used during calibration (or other,

user-defined Probe ID).

• Other user-specific identification (User Field #1 and #2) (Figure 13).

Figure 13 GLP Options

Figure 14 Re-Cal Prompts

NOTE: User Field can be used to describe the condition of the

probe. For example, new sensor or new ODO cap.

Re-Cal Prompts

→ GLP → Options → Re-Cal Prompts

Re-Cal Prompts provide a reminder to recalibrate a probe in the

user-defined number of days (Figure 14).

The Re-Cal prompt will be displayed in the message area of the main

display when the set time has elapsed (Figure 9 on page 15).

Select the desired sensor Re-Cal prompt, then enter the desired number

of days before the Re-Cal prompt occurs.

Set the sensor value to zero (0) days (default) to turn off Re-Cal prompts.

NOTE: When enabled and the set amount of time since the last

calibration has passed, the Re-Cal prompt will be shown

when the instrument is turned on.

GLP Security

18

Figure 15 GLP Security

→ GLP → Security

The Calibration menu can be password protected to prevent accidental

or unauthorized sensor calibration (Figure 15).

1. From the GLP menu, select Security, then enter the default

password “ysi123”.

2. Select Set Password [] and change the default password.

3. Select the Protect Cal check box to password protect the

Calibration menu.

NOTE: Write down and keep the password in a safe place. Contact

YSI Technical Support if you lose the password (Technical

support on page 81).

Page 21

Figure 16 Language

Operation

Language

→ Language

The ProDSS is shipped with English enabled. If a different language

is desired and selected, the ProDSS will take approximately 10 to 20

seconds to enable the new language (during the first installation only).

Optional languages:

• French

• German

• Italian

• Japanese

• Norwegian

• Portuguese

• Simplified Chinese

• Spanish

• Traditional Chinese

Radix Point

Figure 17 Radix Point

Figure 18 Logging

→ Radix Point

The radix point can be changed to display a comma or a decimal in

numeric displays (e.g. 1.00 becomes 1,00 when Comma is selected)

(Figure 17).

Logging

→ Logging

The Logging menu allows user-defined site and Data ID lists to be added

to the logged data. Add a Site or Data ID, then select the applicable

check box to log data to that site and/or Data ID (Figure 18).

Continuous Mode ( Interval logging): Select the Continuous Mode check

box and enter the user-defined Log Interval (in HH:MM:SS hours:minutes:seconds) to log samples continuously at the specified

time interval. The Run screen will display Start Logging... when in

Continuous Mode.

One sample logging: Clear the Continuous Mode check box. The

Run screen will display Log One Sample. A sample will be logged each

time the

ENTER

key is pushed when in the Run screen.

19

Page 22

Operation

Esc

Sampling

→ Sampling

Figure 19 Sampling

Auto sampling mode continuously updates measurements on the display

(Figure 19).

Manual mode helps conserve battery power. The user-defined Sample

Period determines the measurement time limit.

When in Manual mode, the instrument will take measurements for the

duration of the Sample Period then “lock” or hold the readings on the

display (sample period default 50 seconds, user-defined between 15 to

60 seconds).

Once the measurements are locked, push the

data, or the

key and then the

ENTER

key to take a new measurement.

ENTER

key to log the held

Enter the desired Sample Period time.

NOTE: When both Continuous Logging Mode and Manual

Sampling mode are enabled, the ProDSS will power the

sensors on and take measurements for 15 seconds before

logging a data set.

Auto-Shutoff

→ Auto-Shutoff

Figure 20 Auto-Shutoff

To conserve battery power, auto-shutoff powers off the instrument after

a user-defined time period (in minutes) (Figure 20). Set to 0 (zero) to

disable Auto-Shutoff.

20

Page 23

Backlight

→ Backlight

Operation

Figure 21 Backlight

In Automatic mode, the instrument display will dim 60 seconds after the

last key was pushed. Once any key is pushed, the instrument display will

return to the user-defined brightness setting and the keypad backlight

will turn on. The screen will dim and the keypad backlight will turn off

after another 60 seconds of inactivity.

In manual mode, the instrument display remains at the user-defined

brightness until manually changed and the keypad backlight is turned on

and off by the Backlight key (Figure 21).

NOTE: In bright conditions, set the backlight to Manual mode.

Software (Sw) Version

→ Sw Version

Sw Version (System menu on page 16)

Sw Version shows the ProDSS software version number. The latest

instrument software version is available at ysi.com. Instrument software

can be updated through the KorDSS PC software program when

connected to the internet or if the firmware file has been transferred to

the PC. See the KorDSS help section for more information.

Serial #

→ Serial # (System menu on page 16)

Serial # shows the serial number of the ProDSS handheld instrument.

Note the serial number when contacting YSI support.

Unit ID

→ Unit ID (System menu on page 16)

Unit ID identifies the instrument in the KorDSS PC software program that

was included with the instrument.

Select Unit ID to change the default ID.

21

Page 24

Operation

Sensor info

→ Sensor info (System menu on page 16)

Sensor info shows measurement data, and hardware/software

information for each component of the system: instrument, sensor, and

bulkhead. Use the and arrow keys to scroll through the components.

Brightness

→ Brightness

The screen brightness can be adjusted to accommodate lighting

conditions and to conserve battery power (Figure 22).

Select Brightness then use the and arrow keys to adjust the screen

brightness.

NOTE: In bright conditions, set the screen brightness to 75% or

greater.

Figure 22 Display Brightness

Sensor menu

Use the Probe key to access the Sensor menu and change sensor settings (if applicable), enable the measurement

units displayed on the Run screen, set Auto Stable parameters, and if equipped, turn on/off GPS.

Push the

menu then push the

Pre-defined or user-selected sensor settings are noted within brackets

([]).

Figure 23 Probe (Sensor) menu

key to access the sensor menu (Figure 23). Highlight a sub-

ENTER

key to view sub-menu options.

22

Page 25

Operation

Sensor Setup

→ Setup

The Sensor Setup menu will show all sensors installed on the bulkhead

(Figure 24). If a sensor is installed on the bulkhead and is not listed on

the Sensor Setup menu (<None> displayed), check the sensor and cable

connections (ProDSS sensor installation/removal on page 9).

Figure 24 Sensor Setup

Figure 25 Setup ODO

Setup ODO

→ Setup → ODO

Local DO: Enable or disable localized DO% measurements. When

enabled, the calibration value is set to 100% regardless of altitude or

barometric pressure. When enabled, an L will be shown next to DO% on

the run screen. DO mg/L measurements are unaffected when Local DO is

enabled (Figure 25).

LDS: Last Digit Supression (LDS) rounds the DO value to the nearest

tenth, e.g. 8.27 mg/L becomes 8.3 mg/L.

Sensor Cap Coefficients: The sensor cap coefficients must be updated

after sensor cap replacement. Update the sensor cap coefficients using

the KorDSS software and the coefficient sheet provided with the new

sensor cap.

Setup Turbidity

Figure 26 TSS coefficients

→ Setup → Turbidity

TSS Coefficients: The Total Suspended Solids (TSS) coefficients are

calculated in KorDSS by entering turbidity and TSS correlation data.

Measure turbidity and take a grab sample for laboratory analysis of TSS

to obtain a value pair for the correlation. At least two and up to six value

pairs can be entered into KorDSS.

The TSS coefficients can be entered manually or updated through the

KorDSS software (Figure 26).

For highest accuracy, obtain 6 values pairs and calculate new coefficients

for each unique sampling site.

23

Page 26

Operation

Setup pH

→ Setup → pH

Figure 27 Setup pH

Figure 28 Setup Conductivity

Select USA auto-buffer recognition (4.01, 7.00, and 10.00) or NIST autobuffer recognition (4.01, 6.86, and 9.18) (Figure 27).

Setup Conductivity

→ Setup → Conductivity

Temp Ref (Temperature reference): Reference temperature used to

calculate temperature compensated specific conductance. All specific

conductance values are compensated to the Temp Ref temperature. The

default value is 25 °C (77 °C) (Figure 28). Enter a new value between

15.00 °C (59 °F) and 25.00 °C (77 °F).

%/°C (Percent per degree Celsius): Temperature coefficient used to

calculate temperature compensated specific conductance. The default is

1.91% based on KCl standards. Enter a new value between 0 and 4%.

TDS Constant: Multiplier used to calculate an estimated Total Dissolved

Solids (TDS) value from conductivity. The multiplier is used to convert

specific conductance in mS/cm to TDS in g/L. The default value is 0.65.

Enter a new value between 0 and 0.99.

This multiplier is highly dependent on the nature of the ionic species

present in the water sample. To be assured of moderate accuracy for

the conversion, you must determine a multiplier for the water at your

sampling site. Use the following procedure to determine the multiplier

for a specific sample:

24

1. Determine the specific conductance of a water sample from the

site.

2. Filter a portion of water from the site.

3. Carefully measure a volume of the filtered water. Completely

evaporate to yield a dry solid.

4. Accurately weight the remaining solid.

5. Divide the weight of the solid (in grams) by the volume of water

used (in liters) to yield the TDS value in g/L for the site.

6. Divide the TDS value in g/L by the specific conductance of the

water in mS/cm to yield the conversion multiplier.

NOTE: Make sure to use the correct units.

NOTE: If the nature of the ionic species at the site changes

between sampling studies, the TDS values will be in

error. TDS cannot be calculated accurately from specific

conductance unless the make-up of the chemical species in

the water remains constant.

Page 27

Setup Depth

→ Setup → Depth

For ProDSS bulkheads with the depth sensor:

Operation

Figure 29 Setup Depth

The ProDSS cable assemblies with a depth sensor in the bulkhead can

measure virtual vented depth (Figure 6 on page 11). The virtual vented

depth measurement allows for real time compensation for atmospheric

pressure using the instrument’s barometer.

Depth offset: Depth offset can be used if referencing water elevation

against a known datum. If a depth offset is entered (in meters), the output

value will shift by the value of the offset (Figure 29).

Altitude/Latitude: To compensate for atmospheric pressure based on

elevation and gravitational pull, enter the local altitude in meters relative

to sea level and latitude in degrees where the ProDSS is sampling.

Latitude effect: Varying latitudes cause a 200 mm change in depth from

equator to pole.

Altitude effect: Varying altitudes cause approximately 90 mm change

from sea level to 8000 m. A 100 m change causes 1.08 mm of change to

the readings.

Sensor Display

→ Display (Figure 30)

Figure 30 Sensor Display

The Sensor display menu determines the measurements that are shown

on the Run screen (Figure 3 Main display example on page 28). The Run

screen will only show measurements for sensors that are attached to the

cable bulkhead.

If more measurements are selected than can be displayed on one screen,

a scroll bar will be shown. Use the and keys to scroll through the

measurements.

25

Page 28

Operation

A

S

A

S

A

S

Figure 31 Auto Stable

Auto Stable

→ Auto Stable

Auto Stable indicates when a measurement is stable. Sensors with Auto

Stable enabled will have

screen.

will flash green when the measurement is stable.

Select a sensor to enable or disable Auto Stable. Set the stability

threshold parameters (Figure 31).

The Auto Stable stability threshold can be set by percent of measurement

or in the units of measurement selected in the Sensor Display menu.

Enter the stability value, then select Use Percent or Use Meas. Units

(Figure 32).

This threshold is used to compare the last reading with the previous. The

smaller the number entered in % or units, the longer it will take for the

instrument to reach the auto stable criteria.

flash beside the measurement on the Run

Figure 32 Auto Stable

stability threshold

Example: For temperature in °C, if unit threshold is set to 0.2 and the

temperature reading changes by more than 0.2 degrees,

will

continue to be red until the reading does not change by more

than 0.2 °C over the defined sample period and sample count.

Hold All Readings: After all sensors have reached their stability criteria,

the measurements will be held or ‘locked’ on the display. If disabled, the

sensor measurements will continue to change in real time.

Audio Enabled: An audio alert will sound when stability is reached.

Continuous Mode: The ProDSS will continuously check sensor values

against the stability criteria even after the sample period and sample

count have been met.

Log Samples: Logs the sample/s defined by the Sample Period to

memory.

Sample Period: Time interval between the sensor measurements

(sample) that are used to determine stability. Set the interval in seconds

(1 to 900).

Sample Count: Number of consecutive samples required for stability

(1 to 10).

Select Start Auto Stable to enable.

26

Page 29

Figure 33 Salinity

Operation

Salinity

→ Salinity (Figure 33)

Salinity is determined by calculations derived from the conductivity and

temperature sensors.

Because salinity is an important factor in determining dissolved oxygen,

YSI does not recommend calibrating or taking dissolved oxygen

measurements without the conductivity/temperature sensor installed in

the bulkhead.

GPS (optional)

→ GPS

Figure 34 GPS

GPS turns the ProDSS Global Positioning System On or Off. The

symbol is shown when a GPS signal is received (Figure 34).

When enabled, the GPS coordinates will be saved with the GLP file and

logged data.

27

Page 30

Operation

Calibration menu

Push the

sub-menu options.

Pre-defined or user-selected parameters are noted within brackets ([]). See Alpha/numeric entry on page 14.

Refer to the Calibration section for sensor specific calibration procedures (Calibration on page 33).

Cal

key to access the Calibration menu (Figure 35). Highlight a sub-menu then push the

NOTE: Attached sensors are listed according to the bulkhead port in which they are installed.

NOTE: User ID, Probe ID, and User Field #1 and #2 must be enabled in the GLP menu to appear in the Calibration

menu (GLP Options on page 18).

ENTER

key to view

1

2

3

4

5

6

7

Figure 35 Calibration menu

1 Sensors connected to bulkhead 5 User ID

2 Optional Depth sensor calibration 6 Probe ID

3 Barometer calibration 7 User Field #1

4 Restore Default Calibration - restores all

calibrations to factory default

28

Page 31

Files menu

Operation

Push the key to access the Files menu (Figure 36). Highlight a sub-menu then push the

menu options.

Use the Files menu to view, delete or backup logged data or the GLP file. Data can be filtered by a specific date and

time range and by user-created site and Data ID lists (Logging on page 29).

Data Memory (free) % shows the remaining memory available. Download

or delete data to free available internal memory.

Figure 36 Files menu

ENTER

key to view sub-

View Data Filter

→ View Data

Enter the desired filter criteria, then select Show Data or Graph Data to

view the tabular or graphical data. If necessary, use the and arrow

keys to scroll through the data (Figure 37 and Figure 38).

Site: View data from one site or all sites.

Figure 37 View Data Filter

Figure 38 View Filtered Log Data

Data ID: View data from one ID or all IDs.

Begin/End: View data within specific date and time ranges.

29

Page 32

Operation

Figure 39 View GLP

View GLP

→ View GLP

Select View GLP to show the stored sensor calibrations (Figure 39).

Use the arrow keys to scroll through the GLP file data.

Delete Data

→ Delete Data

Figure 40 Delete Data Filter

Enter the desired filter criteria, then select Delete Data to permanently

delete the data (Figure 40).

NOTE: If filter criteria are not selected, all logged data will be

permanently deleted.

Select Delete All Data to permanently delete all logged data from the

ProDSS.

30

Page 33

Figure 41 Backup Data

Operation

Backup Data

→ Backup Data

A USB female to micro USB male adapter is included to directly backup

files from the handheld to a standard USB storage device. The data is

exported as a CSV file.

Enter the desired filter criteria then connect the handheld to the USB

storage device using the supplied adapter. Select Backup Data to export

the data to an USB storage device (Figure 41 and Figure 42).

NOTE: The USB storage device must be formatted as FAT32, not

NTFS or exFAT. The handheld will only support FAT32.

Figure 42 Micro USB female connector

Figure 43 Delete GLP

Delete GLP

→ Delete GLP

To permanently delete the GLP file from the instrument, select Yes , then

push the

ENTER

key (Figure 43).

31

Page 34

Operation

Taking measurements

For the highest accuracy, calibrate the instrument before taking measurements (Calibration on page 33).

1. Create site and Data ID lists for logged data (if applicable) (Logging on page 19).

2. Set the logging method (single or interval) (Logging on page 19).

3. Set the Auto Stable parameters (if applicable) (Auto Stable on page 26).

4. Verify that the sensors and/or port plugs are correctly installed in all bulkhead ports ( on page 8).

5. Install the sensor guard (Figure 6 on page 11).

6. Insert the sensors into the sample.

NOTE: Make sure to submerge the sensors completely. If using a depth sensor, submerge to where the cable

assembly attaches to the bulkhead.

7. Move the bulkhead in the sample to release any air bubbles and to provide a fresh sample to the sensors.

8. Wait for the sensor/s to stabilize in the sample.

9. If logging, select Log One Sample or Start Logging (Logging on page 19).

32

Page 35

Calibration

ProDSS sensors (except temperature) require periodic calibration to maintain accurate measurements. Calibration

procedures follow the same basic steps with variations for specific parameters.

Before calibration

• Enter GLP user-defined data if applicable to user requirements (User ID, Probe ID, User Field #1/2)

(GLP menu on page 17).

• Setup sensor options, settings, and coefficients as applicable (Probe menu on page 37).

NOTICE: Install a gray port plug in all exposed ports. Exposure to water can cause damage or corrosion to the

bulkhead connectors not covered by the warranty.

Calibration setup (pH, ORP, ISE, conductivity, turbidity)

NOTE: Make sure the calibration cup, sensor guard, and all sensors are clean.

NOTE: If using the calibration cup, make sure to install the sensor guard before placing the sensors into the

calibration cup.

NOTE: The sensor guard and calibration cup should be used for the turbidity and DO calibration. All other

calibrations can be performed in other laboratory glassware.

NOTE: Make sure to use a clean probe guard during calibration to prevent contamination of the calibration

environment.

1. Install a clean, dry sensor and sensor guard (if used) onto the bulkhead (Figure 4 on page 9).

NOTICE: Install a gray port plug in any exposed port. All sensors must have either a sensor or port plug

installed.

2. Fill the calibration cup with a moderate amount of water and tighten the calibration cup onto the bulkhead. Use

the water to rinse the cup and the sensor to be calibrated. Discard the rinse.

3. Thoroughly rinse the calibration cup with a small amount of the calibration standard for the sensor to be

calibrated. Discard the standard.

4. Refill the calibration cup with fresh calibration standard to approximately the first line for pH, ORP, and turbidity

calibration. Fill to the second line for conductivity calibration (Figure 44 on page 34).

NOTE: Volumes will vary. Make sure that the temperature sensor and the sensor to be calibrated are submerged

in calibration solution, except when performing a DO% saturation calibration.

NOTE: Be careful to avoid cross-contamination with other standards.

NOTE: These rinsing recommendations are only suggested guidelines for highest data accuracy. Make sure to

follow your organization Standard Operating Procedures (SOPs) for instrument calibration and operation.

5. Immerse the sensor(s) in the standard and tighten the calibration cup onto the bulkhead.

6. Calibrate the sensor(s).

33

Page 36

Calibration

Alternately, pH, ORP, and conductivity calibrations can be completed in a beaker or other container using the same

basic procedure described above. Make sure that the temperature sensor and the sensor to be calibrated are

completely submerged. When submerging the conductivity sensor, make sure that the calibration solution covers the

vent hole on the side of the conductivity sensor and there is at least 25.4 mm (1 in) distance between the sides and

bottom of the calibration container and the conductivity probe.

Calibration cup installation

1. Make sure the calibration cup gasket is correctly seated (Figure 44). Loosely install the retaining nut on the

calibration cup.

2. Slide the calibration cup over the sensors and sensor guard.

3. Tighten the retaining nut.

4

3

2

1

Figure 44 Calibration cup standard volume

1 Fill line one (used for Turbidity, pH,

and ORP calibration solution)

2 Fill line two (used for conductivity

calibration solution)

3 Gasket

5

4 Retaining nut

5 Calibration cup installed

34

Page 37

Calibration

Cal

Conductivity

A conductivity/temperature sensor must be installed on the bulkhead for accurate temperature compensation and

measurements of all other parameters (Figure 4 on page 9). Temperature calibration is not available or required for

accurate temperature measurements.

The conductivity/temperature sensor can measure and calculate conductivity, specific conductance (temperature

compensated conductivity), salinity, non-linear function (nLF) conductivity, TDS, resistivity, and density. Calibration

is only available for specific conductance, conductivity, and salinity. Calibrating one of these options automatically

calibrates the other conductivity/temperature parameters listed above. For both ease of use and accuracy, YSI

recommends calibrating specific conductance.

Conductivity calibration

1. If necessary, clean the conductivity cell with the supplied soft

brush. See Conductivity/temperature sensor maintenance on

page 56.

2. Perform the Calibration setup (pH, ORP, ISE, conductivity, turbidity)

on page 33.

3. Place the correct amount of conductivity standard (225 mL if using

the calibration cup) into a clean and dry or pre-rinsed calibration

cup.

Figure 45 Calibrate specific

conductance

NOTE: Select the appropriate calibration standard for the

conductivity of the sampling environment. Standards

greater than 1 mS/cm (1000 μs/cm) are recommended for

the greatest stability. For fresh water applications, calibrate

to 1,000 or 10,000 uS. For salt water applications, calibrate

to 50,000 uS.

4. Carefully immerse the sensors into the solution. Make sure the

solution is above the vent holes on the side of the conductivity

sensor.

5. Gently rotate and/or move the sensor up and down to remove any

bubbles from the conductivity cell. Allow at least one minute for

temperature equilibration before proceeding.

6. Push the

Conductance.

NOTE: Calibrating any conductivity calibration option will

7. Select Calibration value then enter the calibration value of the

standard used. Note the measurement units the instrument is

reporting and calibrating and be sure to enter in the correct

calibration value for the units being used. For example, 10,000 uS

= 10 mS. Make sure that the units are correct and match the units

displayed on the handheld.

8. Observe the actual measurement readings for stability (white line

on graph shows no significant change for 40 seconds), then select

Accept Calibration (Figure 45). “Calibration successful!” will be

displayed in the message area.

key, select Conductivity, then select Specific

automatically calibrate the other options. Specific

conductance is recommended for both ease of use and

accuracy.

35

Page 38

Calibration

Cal

NOTE: If the data is not stabilized after 40 seconds, gently rotate the sensor or remove/reinstall the calibration

cup to make sure that no air bubbles are in the conductivity cell.

NOTE: If the actual measurement data is about 1/2 if the expected calibration value, the conductivity sensor is

not completely submerged. Add more calibration standard to the calibration cup.

NOTE: If you get calibration error messages, check for proper sensor immersion, verify the calibration solutions is

fresh, the correct value has been entered into the ProDSS, and/or try cleaning the sensor.

9. Rinse the bulkhead and sensors in clean water then dry.

Barometer

The barometer is factory calibrated and should rarely need to be recalibrated. The barometer is used for DO

calibration, %Local measurements, and for virtual depth measurements. Verify that the barometer is accurately reading

“true” barometric pressure and recalibrate as necessary.

Laboratory barometer readings are usually “true” (uncorrected) values of air pressure and can be used “as is” for

barometer calibration. Weather service readings are usually not “true”, i.e. they are corrected to sea level and cannot be

used until they are “uncorrected”. Use this approximate formula:

True BP in mmHg=[Corrected BP in mmHg] - [2.5* (Local altitude in ft. above sea level/100)]

Example:

Corrected BP = 759 mmHg

Local altitude above sea level = 978 ft

True BP = 759 mmHg - [2.5*(978ft/100)] = 734.55 mmHg

Barometer calibration

1. Push the

2. Select Calibration value then enter the correct “true” barometric

pressure.

NOTE: The measurement units during calibration are dictated by

• BP in mmHg=25.4 x BP inHg

• BP in mmHg=0.750062 x BP mb

• BP in mmHg=51.7149 x BP psi

• BP in mmHg=7.50062 x BP kPa

• BP in mmHg=760 x BP atm

key, then select Barometer.

what is enabled in the sensor setup menu. Be sure to enter

in the correct units.

3. Select Accept Calibration (Figure 46). “Calibration successful!”

will be displayed in the message area.

Figure 46 Calibrate Barometer

36

Page 39

Calibration

Cal

Dissolved oxygen

ODO calibration requires the current “true” barometric pressure. Make sure that the barometer is reading accurately

and recalibrate the barometer as necessary.

ODO% and ODO% local - water saturated air calibration

NOTE: This method calibrates the instrument’s DO% measurement

or DO% Local measurement if DO% local is enabled in the

sensor setup menu.

NOTE: Calibrating in DO% or DO% local automatically calibrates

the mg/L and ppm measurement. There is no reason

to calibrate both parameters. For both ease of use and

accuracy, we recommend that you calibrate DO% or DO%

Local and not mg/L.

1. Place a small amount of clean water (1/8 inch) into the calibration

cup.

2. Make sure there are no water droplets on the ODO sensor cap or

temperature sensor.

3. Attach the sensor guard to the bulkhead and carefully place

the guard/sensor into the calibration cup. Partially tighten the

calibration cup to the bulkhead.

Figure 47 Calibrate ODO %

NOTE: Do not fully tighten the calibration cup to the bulkhead.

Atmospheric venting is required for accurate calibration.

NOTE: Make sure the ODO and temperature sensors are not

immersed in water.

4. Turn the instrument on and wait approximately 5 to 15 minutes for

the air in the storage container to be completely saturated with

water.

5. Push the

the instrument’s DO% measurement or DO% Local measurement

if DO% Local is enabled in the sensor setup menu.

6. Observe the actual measurement readings for stability (white line

on graph shows no significant change for 40 seconds), then select

Accept Calibration (Figure 47). “Calibration successful!” will be

isplayed in the message area.

NOTE: If you see a calibration error message, verify the barometer

key, then select ODO. Select DO%. This will calibrate

reading and inspect the sensor cap. Clean and/or replace

the sensor cap as needed.

37

Page 40

Calibration

Cal

Cal

ODO mg/L calibration

1. Place the ODO and conductivity/temperature sensor into a water

sample that has been titrated by the Winkler method to determine

the dissolved oxygen concentration in mg/L.

Figure 48 Calibrate ODO mg/L

2. Push the

3. Select Calibration value.

4. Enter the dissolved oxygen concentration of the sample in mg/L.

5. Observe the actual measurement readings for stability (white line

on graph shows no significant change for 40 seconds), then select

Accept Calibration (Figure 48). “Calibration successful!” will be

displayed in the message area.

6. Rinse the bulkhead and sensors in clean water then dry.

key, then select ODO. Select DO mg/L.

ODO zero point calibration

1. Place the ODO and Conductivity/Temperature sensors in a

solution of zero DO.

Figure 49 Calibrate ODO zero point

NOTE: A zero DO solution can be made by dissolving

approximately 8-10 grams of sodium sulfite into 500 mL

of tap water. Mix the solution thoroughly. It may take the

solution 60 minutes to be oxygen-free.

2. Push the

3. Observe the actual measurement readings for stability (white line

on graph shows no significant change for 40 seconds), then select

Accept Calibration (Figure 49). “Calibration successful!” will be

displayed in the message area.

4. Thoroughly rinse the bulkhead and sensors in clean water then

dry.

5. Perform a ODO % water-saturated air calibration after performing

a zero point calibration.

key, then select ODO. Select Zero.

38

Page 41

pH/ORP

Cal

Calibration

pH calibration 1-point

NOTE: If performing a 1-point calibration, use buffer 7 (6.86) as

your calibration point for highest accuracy.

NOTE: Observe the pH mV readings during calibration to

understand the condition and response of the pH sensor.

In buffer 7, pH mVs should be between -50 and +50. In

buffer 4, the mVs should be a +165 to 185 away from the

pH 7 mV value or a 59 mV per decade slope. In buffer 10,

the mVs should be a -165 to -185 away from the pH 7 mV

value or a -59 mV per decade slope.

1. Perform the Calibration setup (pH, ORP, ISE, conductivity, turbidity)

on page 33.

2. Fill the calibration cup to the appropriate level (170 mL) with pH 7

buffer solution (or 6.86 if using NIST buffers).

3. Carefully immerse the probe end of the sensors into the buffer

solution.

Figure 50 Calibrate pH 1-point

4. Push the

NOTE: If using a pH/ORP sensor, select pH/ORP, then pH.

5. Allow at least one minute for temperature stabilization, then

select Calibration value.

6. Enter the pH buffer value that corresponds to the measured

temperature reading (example: the value of pH 7 buffer solution @

20 °C (68 °F) is 7.02 - this value can be found on the bottle of most

pH buffers).

7. Observe the actual measurement readings for stability (white line

on graph shows no significant change for 40 seconds), then select

Accept Calibration (Figure 50). “Ready for cal point 2” will be

displayed in the message area.

8. Select Finish Calibration for a 1-point calibration or continue on

to the 2-3 point calibration procedure (Calibration cup installation

on page 34).

key, then select pH or pH/ORP.

39

Page 42

Calibration

Cal

Figure 51 Calibrate pH 2- or 3-point

pH calibration 2- or 3-point

NOTE: If performing a 2- or 3-point calibration, one point should

be in buffer 7; however, the calibration points can be in any

order.

1. Perform steps 1-7 of the pH calibration 1-point procedure (pH

calibration 1-point on page 39).

2. Rinse the sensor 2-3 times with a small amount of pH 4 or pH 10

buffer solution.

3. Rinse, then fill the calibration cup to the appropriate level with

the buffer solution (approximately 170 mLs) that is the same value

(pH 4 or pH 10) used to rinse the sensor.

4. Carefully immerse the sensors into the solution.

5. Allow at least one minute for temperature stabilization, then

select Calibration value.

6. Enter the pH buffer value that corresponds to the buffer

temperature reading (value may be located on pH buffer bottle).

7. Observe the actual measurement readings for stability (white line

on graph shows no significant change for 40 seconds), then select

Accept Calibration (Figure 51). “Ready for cal point 3” will be

displayed in the message area.

8. Select Finish Calibration for a 2-point calibration or repeat the 2-

or 3-point calibration procedure with the third buffer solution.

ORP calibration

1. Obtain/prepare a standard with a known oxidation reduction

potential (ORP) value.

NOTE: YSI recommends Zobell solution.

2. Fill the solution to fill line 1 on the calibration cup (approximately

170 mLs).

3. Carefully immerse the sensors into the solution.

4. Push the

5. Allow the temperature of the standard to stabilize then select

Calibration value.

6. Enter the ORP calibration value that corresponds to the measured

temperature reading (example: the value of YSI Zobell @ 20 �C is

237.5)

7. Observe the actual measurement readings for stability (white line

on graph shows no significant change for 40 seconds), then select

Accept Calibration (Figure 52). “Calibration successful!” will be

Figure 52 Calibrate ORP

displayed in the message area.

key, then select pH/ORP, then ORP.

40

Page 43

Calibration

Cal

Depth

NOTE: This calibration option is available only if your bulkhead is equipped with a depth sensor. The depth

sensor is located where the cable connects to the bulkhead (Figure 59 on page 54).

For the calibration, make sure that the depth sensor is clean and in air, not immersed in any solution. For highest

accuracy, keep the bulkhead still and in one position while calibrating.

NOTE: Cables 10 m and longer are supplied with a weight that can be attached to the sensor guard for sampling

at water depths 10 m and greater.

Depth calibration

1. If applicable, enter the depth offset, altitude, and latitude (Figure

29 Setup Depth on page 25).

NOTE: Depth offset allows you to set the depth measurement

to something other than zero. If the depth offset is used,

the depth measurement will be adjusted by the offset

after calibration. Enter the altitude and latitude of your

sampling location to increase the accuracy of your depth

measurement.

2. Push the

3. Observe the actual measurement readings for stability (white line

on graph shows no significant change for 40 seconds), then select

Accept Calibration (Figure 53). “Calibration successful!” will be

displayed in the message area.

Figure 53 Calibrate Depth

key, then select Depth.

41

Page 44

Calibration

Turbidity

Before performing the calibration, review “Calibration setup (pH, ORP, ISE, conductivity, turbidity)” on page 33.

For proper calibration, you must use standards that have been prepared according to details in Standard Methods for

the Treatment of Water and Wastewater (Section 2130 B).

Acceptable standards include:

• AMCO-AEPA standards prepared specifically for the ProDSS turbidity sensor manufactured by YSI (YSI turbidity

standards)

• Formazin prepared according to Standard Methods, especially for calibration points greater than 1010

• Dilutions of 4000 FNU (NTU) formazin concentrate purchased from Hach

• Hach StablCal™ standards in various FNU (NTU) denominations

The use of standards other than those mentioned above will result in calibration errors and inaccurate field readings.

It is important to use the same type of standard for all calibration points. (i.e. do not mix formazine and AMCO-AEPA

standard for different points in a multi-point calibration).

Calibration limits

Because of the non-linear response of the turbidity sensor, calibration ranges may be limited. A 1-, 2- or 3-point

calibration can be completed using the following limits:

1-point 2-point 3-point

0-1 FNU (NTU) 5-200 FNU (NTU) 400-4200 FNU (NTU)

Calibration standards

The following standards are available for the ProDSS turbidity sensor:

608000 0 (all turbidity sensors); 1 gallon

607200 12.4 FNU (NTU) (ProDSS); 1 gallon

607300 124 FNU (NTU) (ProDSS); 1 gallon

607400 1010 FNU (NTU) (ProDSS); 1 gallon

42

Page 45

Calibration

Cal

Turbidity calibration 1-, 2- or 3-point

NOTE: The sensor guard must be installed for the turbidity sensor

calibration.

NOTE: When performing a turbidity calibration, the first point must

be zero.Select Calibration Value and enter 0.00.

1. Perform the Calibration setup (pH, ORP, ISE, conductivity, turbidity)

on page 33. Rinse the sensor 2-3 times with a small amount of 0

FNU (NTU) standard.

2. Fill the calibration cup to fill line one of the calibration cup

(approximately 170 mLs) with 0 FNU (NTU) standard (clear

deionized or distilled water is suitable). Immerse the sensors into

the water.

Figure 54 Calibrate turbidity

3. Push the

4. Select Calibration Value and enter 0.00.

5. Observe the data points readings for stability with the 0 FNU

(NTU) standard (white line on graph shows no significant change

for 40 seconds), then select Accept Calibration. “Ready for cal

point 2” will be displayed in the message area.

6. Select Finish Calibration to complete a 1-point calibration or

continue for the 2- or 3-point calibration.

7. Rinse the sensors, calibration cup, and sensor guard 2-3 times

with a small amount of standard #2. Discard the standard after

each rinse.

8. Fill the calibration cup to fill line 1 with standard #2. Immerse the

sensors in the second calibration standard.

9. Select Calibration Value and enter the value of the second

calibration standard.

10. Observe the actual measurement readings for stability (white line

on graph shows no significant change for 40 seconds), then select

Accept Calibration (Figure 54). “Ready for cal point 3” will be

displayed in the message area.

11. Select Finish Calibration to complete a 2-point calibration or

continue for the 3-point calibration.

12. Rinse the sensors, calibration cup, and sensor guard 2-3 times

with a small amount of standard #3. Discard the standard after

each rinse.

13. Fill the calibration cup to fill line 1 with standard #3. Immerse the

sensors in the third calibration standard.

14. Select Calibration Value and enter the value of the third

calibration standard.

15. Observe the data points readings for stability, then select Finish

Calibration. “Calibration successful!” will be displayed in the

message area.

16. Rinse the sensors in clean water then dry.

key, then select Turbidity.

43

Page 46

Calibration

ISEs: Ammonium, Nitrate, & Chloride

Before performing the calibration, review Calibration setup (pH, ORP, ISE, conductivity, turbidity) on page 33.

The ISE sensors can be calibrated to one, two or three points. A 2-point calibration without chilling a third calibration

solution is extremely accurate and is the preferred method. However, if there is a large temperature variation during

sampling, a chilled third calibration point is recommended.

Higher calibration accuracy can be obtained if the standards used have a least one order of magnitude difference

between them. For example, 1 mg/L and 10 mg/L or 10 mg/L and 100 mg/L.

mV information for the ISE calibration

Ammonium mV values

• NH4 1 mg/L = 0 mV +/- 20 mV (new sensor only)

• NH4 100 mg/L = 90 to 130 mV > 1 mg/L mV value

• The mV span between 1 mg/L and 100 mg/L values should be ≈ 90 to 130 mV. The slope should be 45 to 65 mV

per decade.

Nitrate mV values

• NO3 1 mg/L = 200 mV +/- 20 mV (new sensor only)

• NO3 100 mg/L = 90 to 130 mV < 1 mg/L mV value

• The mV span between 1 mg/L and 100 mg/L values should be ≈ 90 to 130 mV. The slope should be -45 to -65 mV

per decade.

Chlroide mV values

• Cl 10 mg/L = 225 mV +/- 20 mV (new sensor only)

• Cl 1,000 mg/L = 80 to 130 mV < 10 mg/L mV value

• The mV span between 10 mg/L and 1000 mg/L values should be ≈ 80 to 130 mV. The slope should be -40 to -65

mV per decade.

44

Page 47

Calibration

Cal

ISE calibration 3-point

1. Perform the Calibration setup (pH, ORP, ISE, conductivity, turbidity)

on page 33.

2. Fill the calibration cup to fill line one with standard #1

(approximately 170 mLs).

3. Push the

4. Carefully immerse the sensors into the standard solution.

5. Allow the temperature of the standard to stabilize, then select

Calibration value. Enter the calibration value that corresponds to

standard #1.

6. Observe the actual measurement readings for stability (white line

on graph shows no significant change for 40 seconds), then select

Accept Calibration (Figure 55). “Ready for cal point 2” will be

displayed in the message area.

7. Rinse the sensor 2-3 times with a small amount of standard #2.

8. Rinse, then fill the calibration cup to fill line one with

standard #2 (approximately 170 mLs).

Figure 55 Calibrate ISE

9. Carefully immerse the sensors into the solution.

10. Allow the temperature of the solution to stabilize then select

Calibration value. Enter the calibration value that corresponds to

standard #2.

11. Observe the actual measurement readings for stability (white line

on graph shows no significant change for 40 seconds), then select

Accept Calibration (Figure 55). “Ready for cal point 3” will be

displayed in the message area.

12. Rinse, then fill the calibration cup to fill line 1 with standard #3

(approximately 170 mLs).

key, then select the applicable ISE sensor.

NOTE: To calibrate with a chilled third standard, see Chilled third

calibration point on page 46.

13. Carefully immerse the sensor into the solution. Allow the

temperature of the solution to stabilize then select Calibration

value. Enter the calibration value that corresponds to standard #3.

14. Observe the actual measurement readings for stability (white line

on graph shows no significant change for 40 seconds), then select

Finish Calibration. “Calibration successful!” will be displayed in

the message area.

45

Page 48

Calibration

Chilled third calibration point

The 3-point calibration method assures maximum accuracy when the temperature of the media to be monitored

cannot be anticipated. If you must perform a chilled 3-point calibration, the following procedure requires one portion

of the high concentration calibration solution and two portions of the low concentration calibration solution.

The high concentration solution and one of the low concentration solutions should be at ambient temperature. The

other low concentration solution should be chilled to less than 10 °C (50 °F) to prior calibration point.

See ISE calibration 3-point on page 45.

1. When “Ready for cal point 3” is displayed in the message area during ISE calibration, place the proper amount

of chilled 1 mg/L standard (10 mg/L for the chloride) into a clean, dry or pre-rinsed calibration cup.

2. Carefully immerse the sensor into the solution. Allow for temperature equilibration. If necessary, select

Calibration value to manually enter the standard #3 value.

3. Once the readings are stable, select Accept Calibration. “Calibration successful!” will be displayed in the

message area.

46

Page 49

Calibration

Preparing chloride standards

The following recipes are provided for preparation of 10 and 1000 mg/L chloride reagents. Nitrate and Ammonium

standards can be purchased from YSI or other laboratory supply companies.

WARNING: Some of the chemicals required for these solutions could be hazardous under some conditions. It

is the responsibility of the user to obtain and study the MSDS for each chemical and to follow the

required instructions with regard to handling and disposal of these chemicals.

You will need:

• Solid sodium chloride or a certified 1000 mg/L chloride solution from a supplier

• Magnesium sulfate

• High-purity water

• A good quality analytical balance

• 1000 mL volumetric flask

• An accurate 10 mL measuring devices

• And 1000 mL glass or plastic storage vessels.

1000 mg/L Standard

1. Accurately weigh 1.655 grams of anhydrous sodium chloride and transfer into a 1000 mL volumetric flask.

2. Add 0.5 grams of anhydrous magnesium sulfate to the flask.

3. Add 500 mL of water to the flask, swirl to dissolve all of the reagents, then dilute to the volumetric mark with

water.

4. Mix well by repeated inversion, then transfer the 1000 mg/L standard to a storage bottle.

5. Rinse the flask extensively with water prior to its use in the preparation of the 10 mg/L standard. Alternatively,

simply add 0.5 grams of magnesium sulfate to a liter of a 1000 mg/L chloride standard from a certified supplier.

10 mg/L Standard

1. Accurately measure 10 mL of the above 1000 mg/L standard solution into a 1000 mL volumetric flask.

2. Add 0.5 grams of anhydrous magnesium sulfate to the flask.

3. Add 500 mL of water, swirl to dissolve the solid reagents, then dilute to the volumetric mark with water.

4. Mix well by repeated inversion, then transfer the 10 mg/L standard to a storage bottle.

47

Page 50

Calibration

Preparing nitrate standards

We recommend using YSI calibration solutions whenever possible. However, qualified users can save cost by following

these recipes for 1 and 100 mg/L nitrate standards. Other concentrations can be made by altering the amount of

potassium nitrate. All other concentrations should remain unchanged.

CAUTION: Some of these chemicals are hazardous and therefore, the standards should only be prepared by

qualified chemists in laboratories where proper safety precautions are possible. It is the responsibility

of the user to obtain and study the MSDS for each chemical and to follow the required instructions

with regard to handling and disposal of these materials.

You will need:

• Solid potassium nitrate or a certified 1000 mg/l NO3-N from a supplier

• Magnesium sulfate, high purity water

• A good quality analytical balance

• 1000 mL volumetric flask

• Accurate volumetric measuring devices for 100 mL, 10 mL and 1 mL of solution

• And 1000 mL glass or plastic storage vessels.

•

100 mg/L standard

1. Accurately weigh 0.7222 g of anhydrous potassium nitrate and transfer quantitatively into a 1000 mL volumetric

flask. Add 1.0 g of anhydrous magnesium sulfate to the flask.

2. Add approximately 500 mL of water to the flask. Swirl to dissolve all of the reagents, and then dilute to the

volumetric mark with distilled or deionized water.

3. Mix well by repeated inversion and then transfer the 100 mg/L standard to a storage bottle.

4. Rinse the flask extensively with water prior to its use in the preparation of the 1 mg/l standard. Alternatively, 100

mL of certified 1000 mg/L NO3-N standard can be used in place of the solid potassium nitrate.

1 mg/L standard

1. Accurately measure 10.0 mL of the above 100 mg/L standard solution into a 1000 mL volumetric flask. Add 1.0

g of anhydrous magnesium sulfate to the flask.

2. Add approximately 500 mL of distilled or deionized water. Swirl to dissolve the solid reagents, and then dilute

to the volumetric mark with water.

3. Mix well by repeated inversion and then transfer the 1 mg/L standard to a storage bottle.

NOTE: Recipes are given for 1 and 100 mg/L. Other concentrations can be made by altering the amount of

potassium nitrate. All other concentrations should remain unchanged.

48

Page 51

Calibration

Preparing ammonium standards

We recommend using YSI calibration solutions whenever possible. However, qualified users can save cost by following

these recipes for 1 and 100 mg/L standards. Other concentrations can be made by altering the amount of ammonium

chloride. All other ingredient concentrations should remain unchanged.

CAUTION: Some of these chemicals are hazardous and therefore, the standards should only be prepared by

qualified chemists in laboratories where proper safety precautions are possible. It is the responsibility

of the user to obtain and study the MSDS for each chemical and to follow the required instructions

with regard to handling and disposal of these materials.

You will need:

• Solid ammonium chloride or a certified 100 mg/L NH

• Lithium acetate dihydrate

• Concentrated hydrochloric acid

• High purity water

• A good quality analytical balance

• A 1000 mL volumetric flask

• Accurate volumetric measuring devices for 100 mL and 10 mL of solution

• And a 1000 mL glass or plastic storage vessels.

CAUTION: Hydrochloric acid is highly corrosive and toxic and should therefore be handled with extreme care

in a well-ventilated fume hood. The user could also add the equivalent amount of a less-hazardous,

more dilute sample of the acid if preferred.)

+

-N from a supplier

4

100 mg/L Standard

1. Accurately weigh 0.3817 g of ammonium chloride and transfer quantitatively into a 1000 mL volumetric flask.

Add 2.6 g of lithium acetate dihydrate to the flask.

2. Add approximately 500 mL of distilled or deionized water to the flask. Swirl to dissolve all of the reagents and

then dilute to the volumetric mark with distilled or deionized water.

3. Mix well by repeated inversion and then transfer the 100 mg/L standard to a storage bottle.

4. Add 3 drops of concentrated hydrochloric acid to the bottle, then seal and agitate to assure homogeneity.

Alternatively, 100 mL of certified 100 mg/L NH4+-N standard can be used in place of the solid ammonium

chloride.

1 mg/L Standard

1. Accurately measure 10.0 mL of the above 100 mg/L standard solution into a 1000 mL volumetric flask. Add 2.6